Yaskawa F7 Drives Catalog

Catalog CA.F7.01

F7 Drives for Industrial Automation

Date: 5/1/09

Table of Contents

F7 Drive (F7)

Description ................................................................... 3

Standard Drives ................................................................... 4

Dynamic Braking Options ................................................................... 6

Ring Kit Options ................................................................... 10

End Cap Kit Options ................................................................... 11

Reactor Options ................................................................... 12

Control Options ................................................................... 15

Communications Options ................................................................... 17

Dimensions and Data ................................................................... 18

Page

F7/Configured Package (F7C)

Description ................................................................... 19

Configured Drives and Options ................................................................... 24

Heatsink Filter Kit Options ................................................................... 26

Dimensions and Data ................................................................... 27

Software, Drawings, Manuals ................................................................... 28

Technical Training ................................................................... 29

Terms and Conditions ................................................................... 30

Options Matrix ................................................................... 32

Page 1

Data subject to change without notice

CA.F7.01, 5/1/09

Yaskawa Electric America

This price book may describe trademarked equipment, which is the property of other companies. These

trademarks are the property of the registered owner companies and may include the following:

TM

DeviceNet

Profibus

Modbus

LonWorks

Modbus

, trademark of ODVA.

®

, trademark of PROFIBUS International

®

, trademark of Schneider Automation, Inc.

®

, trademark of Echelon Corporation

®

TCP/IP, trademark of Schneider Automation, Inc.

EtherNet/IP™, trademark of ODVA

Other Documents and Manuals are available to support special use or installation of this product. These

documents may be provided with the product or upon request. Contact Yaskawa Electric America, Inc. or visit

www.yaskawa.com, as required. Documents may include the following:

TM.F7.01... Drive User Manual included on CD ROM with product

TM.F7.02... Programming... Drive Programming Manual included on CD ROM with product

TM.F7.11... Parameter Access... Manual included on CD ROM with product

TM.AFD.12... ProfibusDP... Manual included on CD ROM with product

TM.AFD.13... DeviceNet... Manual included on CD ROM with product

TM.AFD.17... Modbus Plus... Manual included on CD ROM with product

TM.AFD.20... LonWorks... Manual included on CD ROM with product

TM.AFD.26... EtherNet/IP... Included on CD ROM with product

DriveWizard... Software and Manual...Included on CD ROM with product

Options Instructions... Included on CD ROM with product

REVISIONS

Change Page

Changed revision date all pages

Updated Remote Operator Kit information 16

Changed revision date all pages

Updated text and table information 4, 5, 8, 10, 11, 15, 16, 17, 20, 21, 23, 24, 25

Added trademarks 2

Updated training class info 29

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

Page 2

Description

1/2 - 500HP

This AC drive is the Industrial Workhorse that can handle every conventional application found within the

typical industrial plant from simple variable torque pumping to sophisticated networked material handling.

This drive is designed for tough industrial environments. It is rugged and reliable, with an MTBF of 28 years.

A variety of enclosure options provide the right environmental protection. The dual ratings, Normal and

Heavy duty, enable the most economical match of overload capacity for the application. Providing the right fit

to power requirements is also easy with 208 to 230/240 and 480 volt ratings, built-in bus choke above 30 HP,

provisions for 12-pulse rectification above 30 HP, common bus capability and regeneration options. Patented

high slip braking can eliminate the need for dynamic braking resistors for high inertia loads. Other features

include motor auto-tuning and a wide range of configurable options, such as breakers and fuses.

To provide the optimum control method, the F7 can operate in conventional V/f, V/f with encoder feedback,

open loop vector, or closed loop vector mode. Drive performance can be further enhanced for a specific

application with optional drive software.

The F7 supports the industry’s open architecture, open connectivity demands with network communications

choices such as DeviceNet, Profibus-DP, and others. Drive coordination with other equipment is simplified with

inputs and outputs for digital pulse train, 4 to 20ma, -10 to +10V, and an assortment of programmable contacts.

F7

Performance Features

• Ratings: 0.5 to 150HP, 208 to 230/240 VAC

0.75 to 500HP, 480 VAC

• Overload capacity:

• 150% for 1 min heavy duty, 110% for

1 min normal duty, 200% peak

• Starting torque, heavy duty:

150% at 0.5 Hz (open loop), at 0.3 Hz

(closed loop)

• Starting torque, normal duty:

120% at 1.5 Hz (V/f)

• Output frequency: 0.01 to 300Hz for heavy

duty, 400Hz for normal duty

• Controlled speed range:

40:1 (V/f), 50:1 (V/f with PG), 200:1 (open

loop), 1000:1 (closed loop)

• Speed regulation:

2-3% (V/f), 0.5-1% (V/f with PG), 0.2%

(open loop), 0.01% (closed loop)

• Speed/frequency resolution: 0.01% with

digital reference, 0.1% with analog reference

• Electronic reversing

• Adjustable accel/decel: 0.1 to 6000 sec

• Stall prevention

• Drive efficiency: 96 to 98%

• Displacement power factor: 0.98

• Power loss ride-thru: 2 sec

• Inertial ride-thru

• Selectable auto restart after momentary

power loss

• Programmable auto restart

(0 to 10 attempts) on re-settable fault

• Critical frequency rejection: 3 selectable,

adjustable bands

Protective Features

• DC bus CHARGE indicator

• Optically-Isolated controls

• Phase-to-phase / phase-to-neutral short

circuit protection

• Ground fault protection

• Electronic motor overload (UL, cUL, NEC)

• Current and torque limit

• Over-torque / under-torque detection

• Fault circuit: over-current, over-voltage,

and over-temperature

• Input/output phase loss

Service Conditions

• Ambient service temperatures:

-10 to 40°C (104°F) NEMA-1, to 45°C

(113°F) protected chassis

• Humidity: non-condensing 95%

• Altitude: to 3300 feet (1000 meter)

• Service Factor: 1.0

• Input voltage: +10% / -15%, 200 to

240VAC, 380 to 480VAC

• Enclosure: NEMA 1 or protected chassis

(other options)

• Input frequency: 50/60Hz ± 5%

• 3-phase, 3-wire phase insensitive

• Vibration: 1G (10 to 20Hz), 0.2G, (20 to

50Hz)

Design Features

• LCD keypad display, 5 lines x 16 characters, backlit, 7 languages, copy function

• Multi-speed settings: 17 available

• Setpoint (PID) trim control

• Signal follower: bias and gain

• Up / down / hold reference (digital M.O.P.)

• Timer function; on/off delay

• 32-bit microprocessor logic

• Easy access, quick start parameter groups

• Non-volatile memory/program retention

• Flash memory for update and custom

applications

• 24VDC control logic

• DC injection braking, adjustable level

• Dynamic braking (25HP and below)

• Ramp to stop or coast to stop

• High-slip braking

• Dual motor parameter sets

• Synchronized start into rotating motor

• Motor auto-tuning, static and dynamic

• Common bus capability

• DC link choke: 30 to 150HP at 240VAC, 30

to 500HP at 480VAC

• Twelve-pulse rectification with optional

input transformer: 30 to 150HP at 240V, 30

to 500HP at 480V

• Terminal strip, quick disconnect

• Split cover for ease of wiring

• Plug-in heat sink fan

Inputs and Outputs

• Analog input: -10 to +10VDC (20K ohms)

or 4 to 20 mA (250 ohm)

• Analog output: -10 to +10VDC or 4-20mA

proportional to output parameters

• Digital pulse train input/output (32KHz

max)

• Digital Inputs: 8 multi-function

• Programmable outputs: Three form A

• Fault contacts: one form C

• RS-485/422 communication terminals

Additional Features for V/f

• Torque boost: full range, auto

• V/f ratio: 15 preset, one adjustable

• Slip compensation

Standards & Reliability

• UL 508C (Power Conversion)

• CSA 22.2 No. 14-95

(Industrial Control Equipment)

• UL, cUL listed; CE marked

• UL 1995 (Plenum)

• EN 50178 (LVD)

• EN 61800-3 (w/ External Filter)

• IEC 529, 146

• FCC CFR 47 Part 15 Subpart B

(w/ External Filter)

Options

• Remote display/keypad

• Various feedback cards

• DriveWizard™ software (upload / download)

• DeviceNet, Profibus-DP, others

• Custom drive software

• Input breaker, disconnect, fuses

• 115 VAC interface

• DB resistors and modules

• Input/output reactors

• EMC-compliant filters

• DC link choke (25HP and below)

• Isolation transformer

• Line regeneration (RC5 or DC5)

• Dynamic braking (25HP and above)

• Twelve-pulse transformer

Page 3

Data subject to change without notice

CA.F7.01, 5/1/09

Yaskawa Electric America

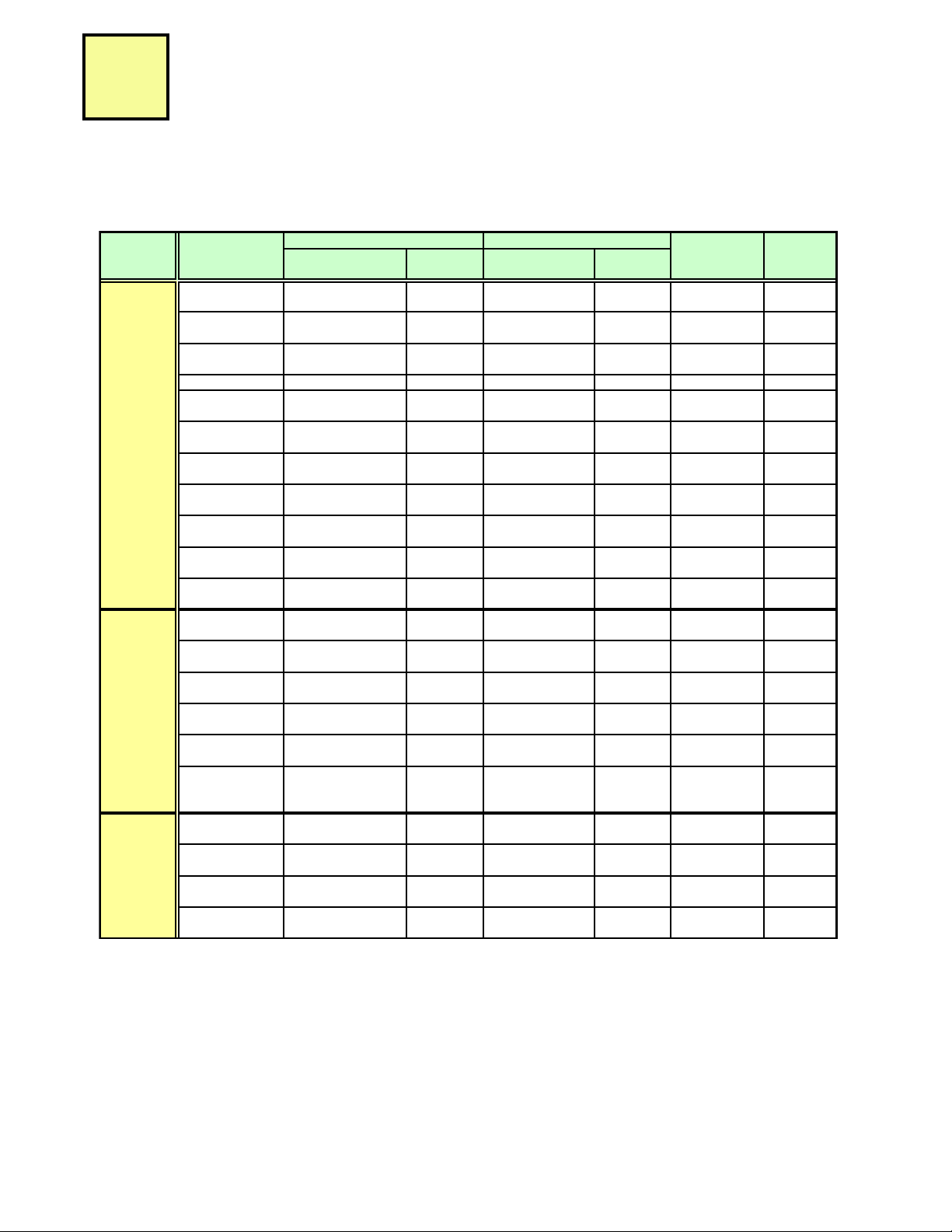

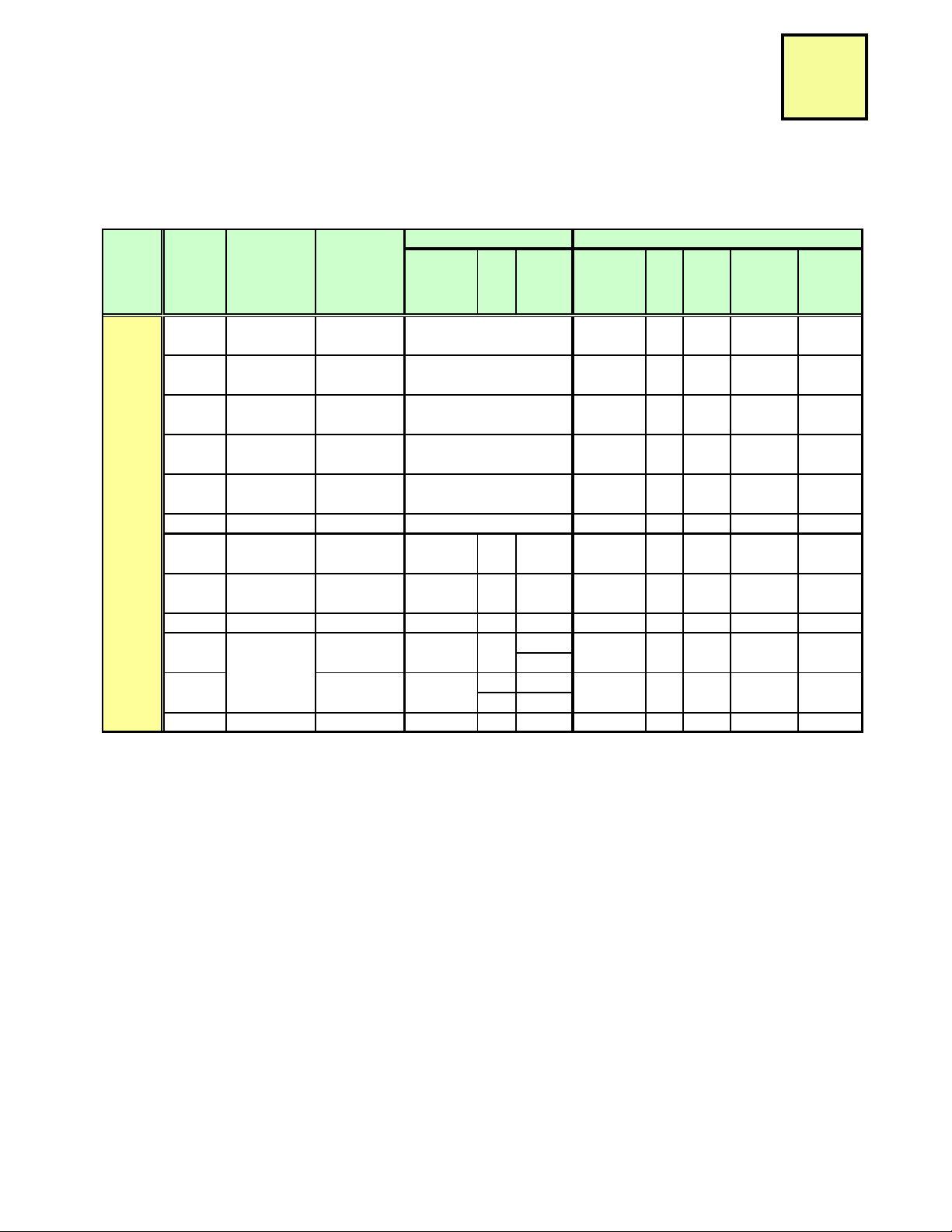

F7

Rated Output

Current (Amps)

(3)

Rated Output

Current (Amps)

(3)

1/2

3/4

4.6 1 4.2 3/4

7.8 2 7.0 1

10.8 3 9.6 2

16.8 5 15.2 3

23.0 N/A 23.0 5 NEMA 1

7.5 7.5

10 10

46.2 15 45.0 N/A

59.4 20 58.0 15

74.8 25 71.4 20

88 30 85 25

30

40

162 50 145 50

192 60 180 60

215 75 215 75

312 100 283 100

1/2 1/2

3/4 3/4

4.6 1 4.2 1

7.8 2 7.0 2

10.8 3 9.6 3

16.8 5 15.2 5

23.0 7.5 23.0 7.5

31.0 10 31.0 10

46.2 15 45.0 15

59.4 20 58.0 20

74.8 25 71.4 25

88 30 85 30

115 40 115 40

50

60

192 75 180 60

215 N/A 215 75

100

125

360 150 346 125

415 N/A

150

NEMA 1

NEMA 1

Protected

Chassis

Protected

Chassis

Chassis

NEMA 1

NEMA 1

50

100

NEMA 1

NEMA 1

230V

Protected

Chassis

Protected

Chassis

Protected

Chassis

Chassis

20370

20750

162

312

145

208V

240V

20P41

3.6 3.2

31.0 31.0

283

NEMA 1

20301

115 40 115 NEMA 1

Drive List

Price $

20P41

3.6 3.2 1/2 NEMA 1

Rated Input

Voltage

Drive Model

Number

CIMR-F7U

Normal Duty

(2)

NEMA 1

NEMA 1

NEMA 1

NEMA 1

Heavy Duty

(2, 4)

Standard

Enclosure

27P51

Standard Drives

F7 Drives - 1/2-500HP, 208-230/240 and 480V, 3-phase

Nominal HP

(1)

input, NEMA 1 or protected chassis enclosure

Nominal HP

20P71

21P51

22P21

23P71

25P51

20111

20151

20181

20221

20370

20450

20550

20750

20900

21100

20P71

21P51

22P21

23P71

25P51

27P51

20111

20151

20181

20221

20301

20450

20550

360 125 346 125

415 150

360

(4)

Protected

150

20900

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Normal Duty overload current rating is 110% of rated output current for 60 seconds; Heavy Duty overload current rating is 150% of rated

output current for 60 seconds

(3) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(4) O.L. 138% for 60 seconds

21100

360

(4)

Protected

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

Page 4

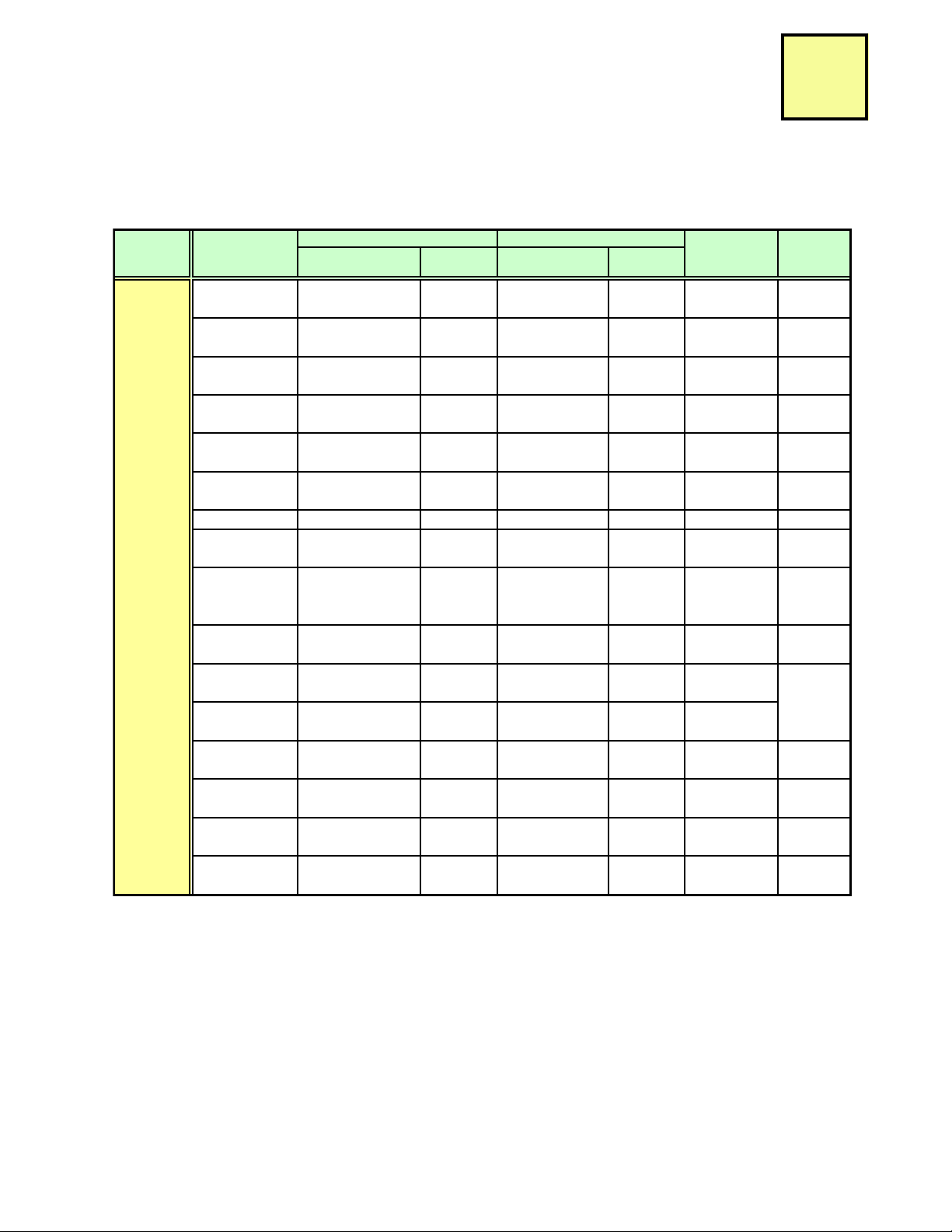

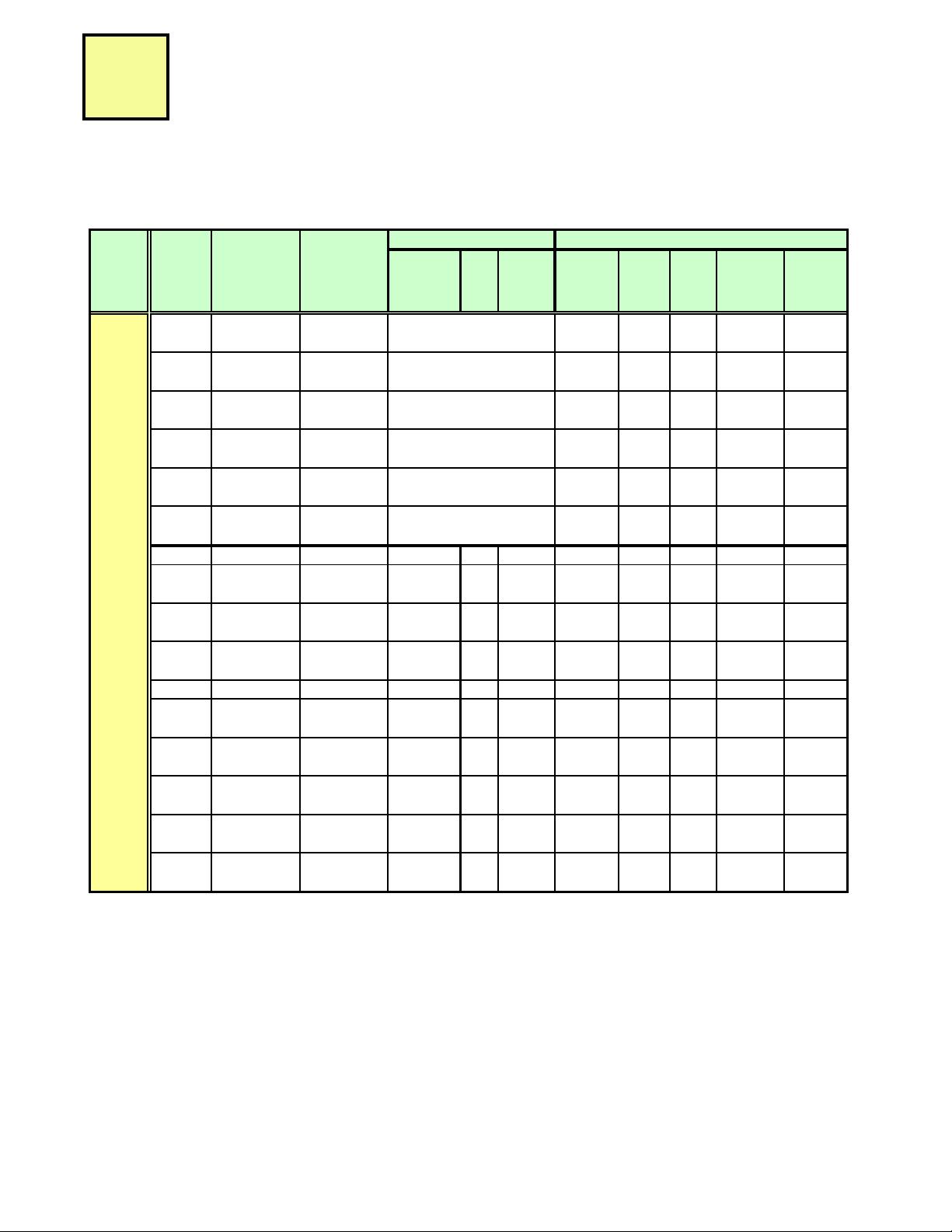

F7 Drives (Continued)

(Amps)

(3)

(Amps)

(3)

1/2 1/2

3/4 3/4

40P71 2.1 1 2.1 1

41P51 3.7 2 3.7 2

42P21 5.3 3 5.3 3

43P71 7.6 5 7.6 5

45P51 12.5

7.5

12.5

7.5

47P51 17.0 10 17.0 10

15

15

20

15

40151 34.0

25

31.0

20

40181 40.0

30

39.0

25

40221 50.4 N/A 45.0 30

NEMA 1

40

50

40371 77 60 75 50

40451 96 75 91 60

40551 125 100 112 75

125

150

41100 240 200 216 N/A

41320 260 N/A 260 200

300

350

400

450

400

500

350

Protected

Chassis

180

NEMA 1

NEMA 1

NEMA 1

NEMA 1

NEMA 1

Protected

Chassis

Protected

Chassis

675

40900

304

125

150

250

370

506

(5)

590

(5)

150

Voltage

Number

CIMR-F7U

500

43000

27.0

156

180

304

414

515

67.2

41600

41850

42200

480V

40111

40750

40301

Heavy Duty

Standard

Enclosure

Drive List

Price $

40P41

1.8 1.8 NEMA 1

Normal Duty

24.0

40

100

250

300

60.0

NEMA 1

Protected

Chassis

Protected

Chassis

Protected

Chassis

Protected

Chassis

NEMA 1

Standard Drives

F7

Rated Input

(1) For single-phase input applications, consult Yaskawa Drives Applications Engineering for proper sizing

(2) Normal Duty overload current rating is 110% of rated output current for 60 seconds; Heavy Duty overload current rating is 150% of rated

output current for 60 seconds

(3) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(5) O.L. 150% for 45 seconds

Drive Model

Rated Output

Current

(2)

Nominal HP

Page 5

Rated Output

Current

(2, 5)

Nominal HP

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

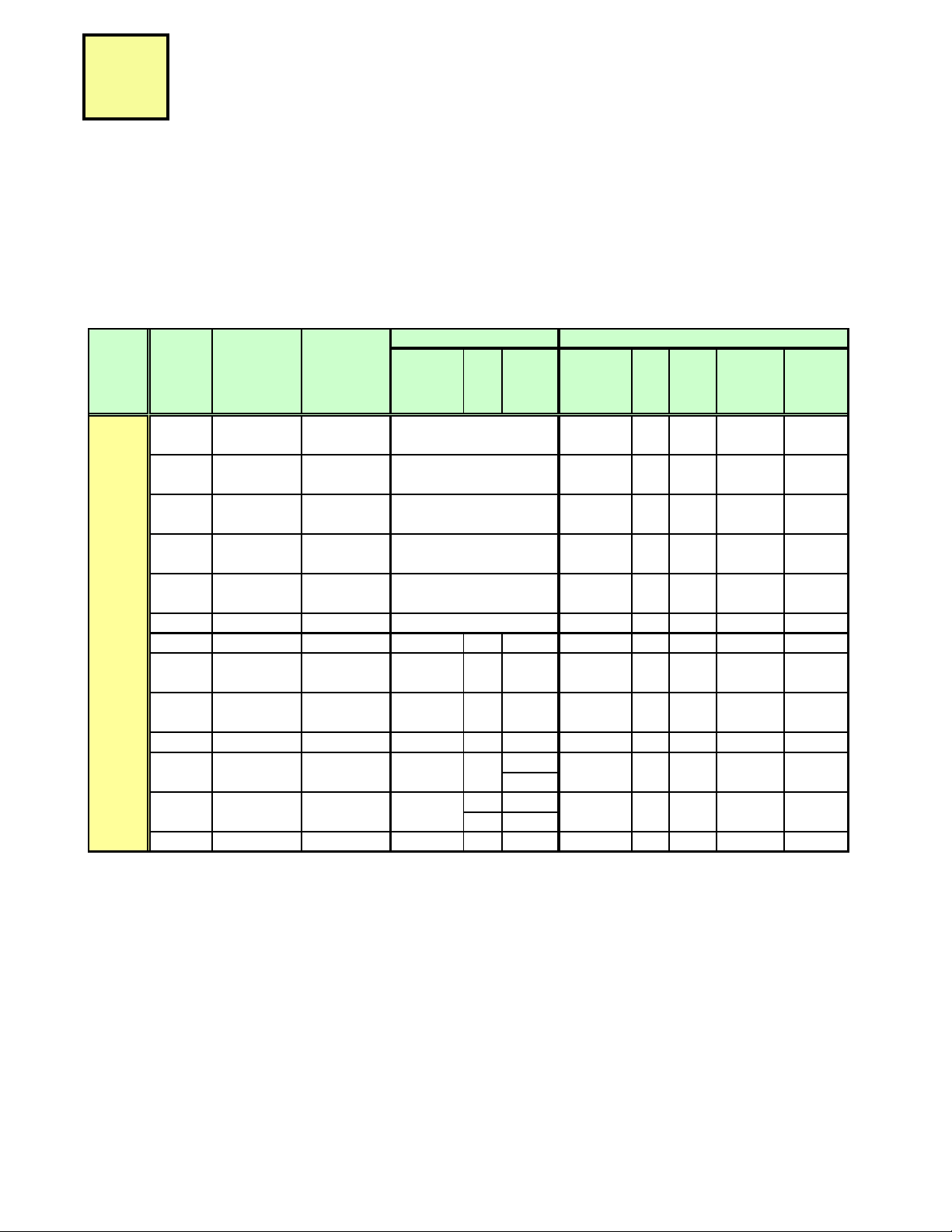

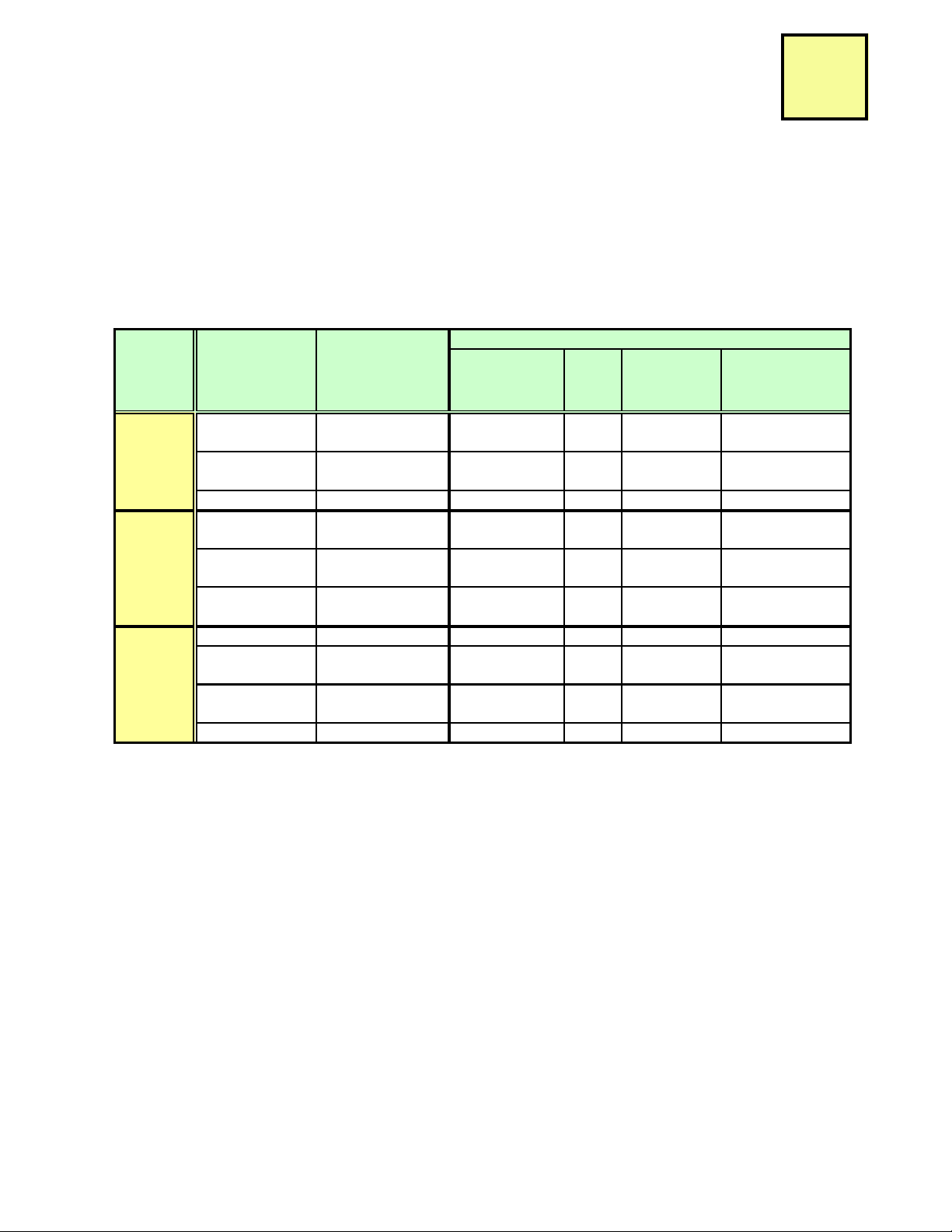

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Config-

uration

(2)

Total List

Price $

(5)

1/2 20P41

034

1

Single

(3)

3/4 20P71

022

1

Single

(3)

1 20P71 21P51

022

1

Single

(3)

2 21P51 22P21

023

1

Single

(3)

3 22P21 23P71

024

1

Single

(3)

5 23P71 25P51

025

1

Single

(3)

7.5

026

1

Single

(3)

10

027

1

Single

(3)

15 20111 20151

140

1

Single

(4)

20 20151 20181

136

1

Single

(4)

25 20181 ---

136

1

Single

(4)

25 --- 20221

2022B

2

135

1Single

30 20221 20301

135

1 Dual

40 20301 20301

129

1 Dual

50 20370 20370

60 20450 20450

75 20550 20550

2110B

1

096

1

Single

Single

Single

1

Single

2

Dual

150 21100 21100

2110B

2

097

1

Dual

1Single

100

125

20750

20900

Resistor(s)

20900

1

each

100

1

each

2110B

1

each

1

096 & 128

096 & 129

2

2022B

Included

Included

Rated

Input

Voltage

Normal Duty

Drive Model

Number

CIMR-F7U

208V

2110B &

2022B

2110B &

2022B

27P51

20750

Nominal

HP

(1)

Heavy Duty

Drive Model

Number

CIMR-F7U

Transistor Module(s)

Included20P41

Included

Included27P51

Included

F7

Dynamic Braking, 10% Duty Cycle - Used to assist the drive to periodically decelerate a load without overvoltage

trips. Ten percent dynamic braking is not typically used for "hold-back" type applications, such as unwinders, elevators, hoists,

or downhill conveyors. Dynamic braking consists of at least one transistor and at least one resistor, and are sized for rated

motor horsepower. The braking transistor may be included in the standard drive; this is indicated in the tables below. The

resistors are sized for a 10% duty cycle (10 seconds maximum on-time of every 100 seconds), and will provide approximately

150% braking torque. Refer to the dynamic braking instruction sheet for more details; consult Yaskawa for information on

higher duty cycles.

10% Duty

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

(2) Single = 1 resistor per package

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

Page 6

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Config-

uration

(2)

Total List

Price $

(5)

1/2 20P41

034

1

Single

(3)

3/4 20P71

022

1

Single

(3)

1 20P71 21P51

022

1

Single

(3)

2 21P51 21P51

023

1

Single

(3)

3 22P21 22P21

024

1

Single

(3)

5 23P71 25P51

025

1

Single

(3)

7.5 25P51 25P51

026

1

Single

(3)

10 27P51 27P51

027

1

Single

(3)

15 20111 20111

140

1

Single

(4)

20 20151 20151

136

1

Single

(4)

25 20181 20181

136

1

Single

(4)

30 20221 20221

135

1 Dual

40 20301 20301

129

1 Dual

50 20370

60 20450

75 20450 20550

2110B

1

096

1

Single

Single

Single

1

Single

2

Dual

150 20900 21100

2110B

2

097

1

Dual

Included

Included

2110B &

2022B

Included

2022B

2110B

2110B &

2022B

2

1

1

each

1

each

1

100

Rated

Input

Voltage

Normal Duty

Drive Model

Number

CIMR-F7U

230/

240V

125

Included

Included

Included

Nominal

HP

(1)

Heavy Duty

Drive Model

Number

CIMR-F7U

Transistor Module(s) Resistor(s)

100

20P41

20370

20750

20750

Single

20900

096 & 128

096 & 129

1

each

Dynamic Braking, 10% Duty Cycle (continued for 230/240V)

10% Duty

F7

Three-Phase Alternating Current Motors

(2) Single = 1 resistor per package

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

Page 7

Data subject to change without notice

Yaskawa Electric America

CA.F7.01, 5/1/09

Dynamic Braking Options

Part

Number

CDBR-

Qty

List

Price

(ea.) $

Part

Number

URS000

Qty

List

Price $

Config-

uration

(2)

Price $

(5)

1/2

3/4

1 40P71 40P71 032 1

Single

(3)

2 41P51 41P51 033 1

Single

(3)

3 42P21 42P21 034 1

Single

(3)

5 43P71 43P71 035 1

Single

(3)

7.5 45P51 45P51 036 1

Single

(3)

10 47P51 47P51 037 1

Single

(3)

15 40111 038 1

Single

(3)

20 40151 040 1

Single

(3)

25 40151 40181 040 1

Single

(3)

30 40181 --- 154 1

Single

(3)

30 --- 40221 4045B 1 150 1 Single

40 40301 4045B 1 142 1 Single

50 40371 4045B 2 151 1 Dual

60 40371 40451 151 1 Dual

75 40451 40551 143 1 Dual

100 40551 40750

125 40750 40900

150 40900 40900 4220B 1 165 1 Single

1 Single

1 Single

1 Single

2 Dual

300 41850 41850

350 41850 42200

Dual

Single

450 42200 43000

500 43000 43000

Included

Included

Included

Included

Included

Included

40P41

Rated

Input

Voltage

Normal Duty

Drive Model

Number

CIMR-F7U

480V

200

Nominal

HP

(1)

Heavy Duty

Drive Model

Number

CIMR-F7U

Transistor Module(s) Resistor(s)

250

400

40111

40301

41100

42200

41600

40P41

41600

43000

4045B

4220B

4220B &

4045B

4220B &

4045B

4220B

4220B

41320

4220B

2

2

3

3

1

165 & 143

166

120 & 165

167

1

1

1

1 each

1 each

032

165 & 142

1

1

119

Single

(3)

Single

Dual

Triple

F7

Dynamic Braking, 10% Duty Cycle (continued for 480V)

10% Duty

Total List

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

(2) Single = 1 resistor per package

(3) This resistor package provides 120% braking torque

(4) This resistor package provides 100% braking torque

(5) Total List Price includes all resistors and transistor modules to provide the Dynamic Braking function

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

Three-Phase Alternating Current Motors

Dual = 2 resistors per package (requires 2 DB transistor modules, as indicated in table above)

Triple = 3 resistors per package (requires 3 DB transistor modules, as indicated in table above)

Page 8

Dynamic Braking Options

Part Number Qty List Price $ Braking Torque

20P41 1/2 R7505 220

20P71 1 R7505

125

21P51 2 R7504

125

22P21 3 R7503

120

23P71 5 R7510

1 100

1/2

3/4

20P71 1 R7505

125

21P51 2 R7504

125

22P21 3 R7503

120

23P71 5 R7510

100

40P41

3/4

R7508 1 230

1

2

41P51 3 R7507

125

42P21 3 R7506

115

43P71 5 R7505

1 110

Rated Input

Voltage

Drive Model

Number

CIMR-F7U

Resistor

R7505

1

Nominal HP

(1)

208V

240V

1

220

40P71

R7508

1 130

1

1

480V

20P41

1

1

3% Duty

Dynamic Braking, 3% Duty Cycle - Used to assist the drive to periodically decelerate a load without overvoltage

trips. Three percent dynamic braking is not applicable for "hold-back" type applications, such as unwinders, elevators, hoists,

or downhill conveyors. Dynamic braking consists of at least one transistor and at least one resistor, and are sized for rated

motor horsepower. The braking transistor is included in the standard drive for these resistors. The resistors are sized for a 3%

duty cycle (3 seconds maximum on-time of every 100 seconds), and will provide at least 100% braking torque. Refer to the

dynamic braking instruction sheet for more details; consult Yaskawa for information on higher duty cycles. These resistors

can be mounted directly to the heatsink on the back of the drive.

F7

(1) Horsepower rating is based on standard NEMA B 4-pole motor design as represented in NEC table 430.150 Full-Load Current,

Three-Phase Alternating Current Motors

Page 9

Data subject to change without notice

CA.F7.01, 5/1/09

Yaskawa Electric America

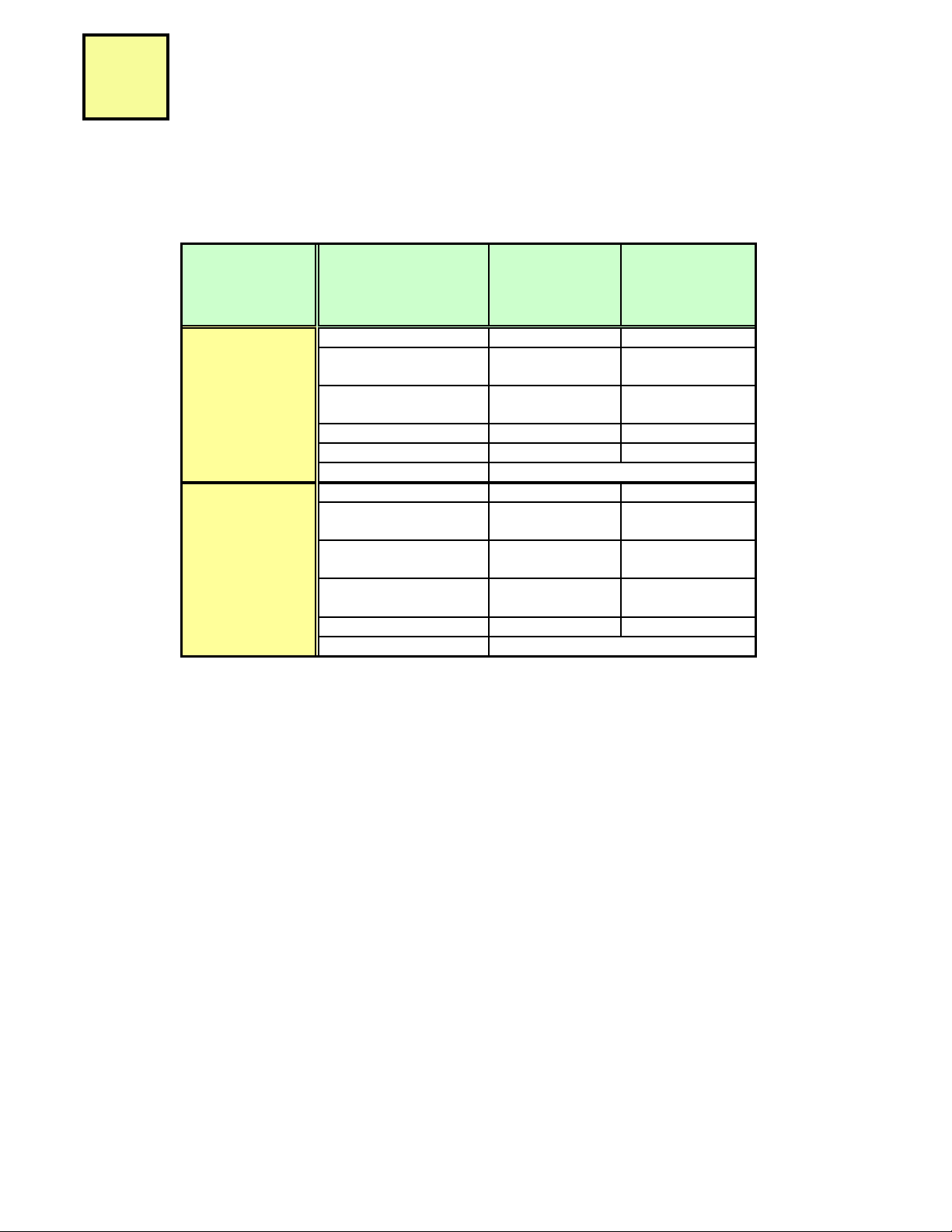

Ring Kit Options

20P41 thru 25P51 D

27P51

20111

20151

20181

20221 F

20301 E

20370 thru 21100

40P41 thru 45P51 D

47P51

40111

40151

40181

40221

40301

40371 thru 40551 A

40750 thru 43000

208-230/240V

480V

C

B

C

B

E

Not Available

Not Available

Rated Input Voltage

Drive Model Number

CIMR-F7U

Kit Model No.

UDA00417-

Kit List Price $

F7

Ring Kit - These kits allow installation of the drive into a customer's enclosure with the heatsink mounted out the back to

reduce overall enclosure size. Each kit includes all of the necessary components, including hardware and instructions.

CA.F7.01, 5/1/09

Data subject to change without notice

Yaskawa Electric America

Page 10

Loading...

Loading...