Page 1

F7 Drive

User Manual

Model: CIMR-F7U Document Number: TM.F7.01

Page 2

Page 3

Warnings and Cautions

This Section provides warnings and cautions pertinent to this product, that if not

heeded, may result in personal injury, fatality, or equipment damage. Yaskawa is

not responsible for consequences of ignoring these instructions.

WARNING

YASKAWA manufactures component parts that can be used in a wide variety of industrial applications. The selection and

application of YASKAWA products remain the responsibility of the equipment designer or end user. YASKAWA accepts no

responsibility for the way its products are incorporated into the final system design. Under no circumstances should any

YASKAWA product be incorporated into any product or design as the exclusive or sole safety control. Without exception, all

controls should be designed to detect faults dynamically and fail safely under all circumstances. All products designed to

incorporate a component part manufactured by YASKAWA must be supplied to the end user with appropriate warnings and

instructions as to that part’s safe use and operation. Any warnings provided by YASKAWA must be promptly provided to the

end user. YASKAWA offers an express warranty only as to the quality of its products in conforming to standards and

specifications published in the YASKAWA manual. NO OTHER WARRANTY, EXPRESS OR IMPLIED, IS OFFERED.

YASKAWA assumes no liability for any personal injury, property damage, losses, or claims arising from misapplication of its

products.

WARNING

• Read and understand this manual before installing, operating, or servicing this Drive. All warnings, cautions, and

instructions must be followed. All activity must be performed by qualified personnel. The Drive must be installed according

to this manual and local codes.

• Do not connect or disconnect wiring while the po we r is on. Do not remov e covers or tou ch ci rcuit boar ds while the po w er is

on. Do not remove or ins ert the digital operator while power is on.

• Before servicing, disconnect all power to the equipment. The internal capacitor remains charged even after the power supply

is turned off. The char g e indicator LED will extin guis h when the DC bus voltag e is below 50Vdc. To prevent electric shock,

wait at least five minutes after all indicators are OFF and measure DC bus voltage level to confirm safe level.

• Do not perform a withstand voltage test on any part of the unit. This equipment uses sensitive devices and may be damaged

by high voltage.

WARNING

• The Drive is suitable for circuits capable of delivering not more than 100,000 RMS symmetrical Amperes, 240Vac

maximum (200V Class) and 480Vac maximum (400V Class). Install adequate branch circuit short circuit protection per

applicable codes. Failure to do so m ay result in equipment damage and/or personal injury. Refer to Appendix E for further

details.

• Do not connect unapproved LC or RC interference suppression filters, capacitors, or overvoltage protection devices to the

output of the Drive. These devices may generate peak currents that exceed Drive specifications.

i

Page 4

• To avoid unnecessary fault displays caused by contactors or output switch es placed between Drive and motor, auxiliary

contacts must be properly integrated into the control logic circuit.

• YASKAWA is not responsible for any modification of the product made by th e user; doing so will void the warranty. This

product must not be modified.

• Verify that the rated voltage of the Drive matches the voltage of the incoming power supply before applying power.

• To meet CE directives, proper line filters and proper installation are required.

• Some drawin gs in this manual may be shown with protective cover s or shields removed, to describe details . These must be

replaced before operation.

• Observe electrostatic discharge procedures when handling circuit boards to prevent ESD da mage.

• The equipment may start unexpectedly upon application of power. Clear all personnel from the Drive, motor, and machine

area before applying power. Secure covers, couplings, shaft keys, and machine loads before energizing the Drive.

• Please do not connect or operate any equipment with visible damage or missing p arts. The ope rating company is responsible

for any injuries or equipment damage resulting from failure to heed the warnings in this manual.

Intended Use

Drives are intended for installation in electrical systems or machinery.

The Drives are designed and manufactured in accordance with applicable UL and cUL standards, and CE directives.

For use in the European Union, the installation in machinery and systems must conform to the following product standards of

the Low Voltage Directive:

EN 50178: 1997-10, Electronic Equipment for Use in Power Installa tions

EN 60201-1: 1997-12Machine Safety and Equipping with Electrical Devices

Part 1: General Requirements (IEC 60204-1:1997)

EN 61010: 1997-11 Safety Requirements for Information Technology Equipment

(IEC 950:1991 + A1:1992 + A2:1993 + A3:1995 + A4:1996, modified)

The F7 series Drives comply with the provisions of the Low Voltage Directive 73/23/EEC as amended by 93/68/EEC. These

Drives conform to the following standard: EN 50178: 1997-10.

Your supplier or Yaskawa representative must be contacted when using leakage current circuit b reaker in conjunction with frequency inverters.

In certain systems it may be necessary to use additional monitoring and safety devices in compliance with the relevant safety

and accident prevention regulations. The frequency inverter hardware must not be modified.

ii

Page 5

Introduction

This section describes the applicability of the manual.

This manual is applicable t o F7 Drives defi ned by mode l numbe rs of CIMR -F7UFFFF. This manual reflects the Software

Version 3020.

The F7 Drive is a Pulse Width Modulated Drive for AC 3-Phase inductio n mo tors. This type of Drive is also known as an

Adjustable Frequency Drive, Variable Frequency Drive, AC Drive, AFD, ASD, VFD, VSD, and Inverter. In this manual, the

F7 Drive will be referred to as the “Drive”.

The LCD keypad/operator is equipped with local/remote functions, copy feature, 7 language choices, and 5 lines of display

with 16 characters per line. User parameter settings can be recovered at any time via “user initialization” when enabled.

Optional Drive Wizard software allows upload/download, as well as graphing and monitoring of Drive parameters from a PC

for ease of Drive management.

This manual may describe trademarked equipment, which is the property of other companies, who are the registered owners.

Other Documents and Manuals are available to support special use or installation of this product. These documents may be

provided with the product or upon request. Contact Yaskawa Electric America, Inc. as required. Documents may include the

following:

TM.F7.02.Programming…Manual included on CD ROM with product

TM.F7.01.…Manual included on CD ROM with product

DriveWizard...Software and Manual…Included on CD ROM with product

Option Instructions… Included on CD ROM with product

This manual is subject to change as product improvements occur. The latest version of the manual can be obtained from the

Yaskawa website: www.dr ives. com. The date shown on the rear cover is changed when revisions are made. The latest version

of Drive software is also shown.

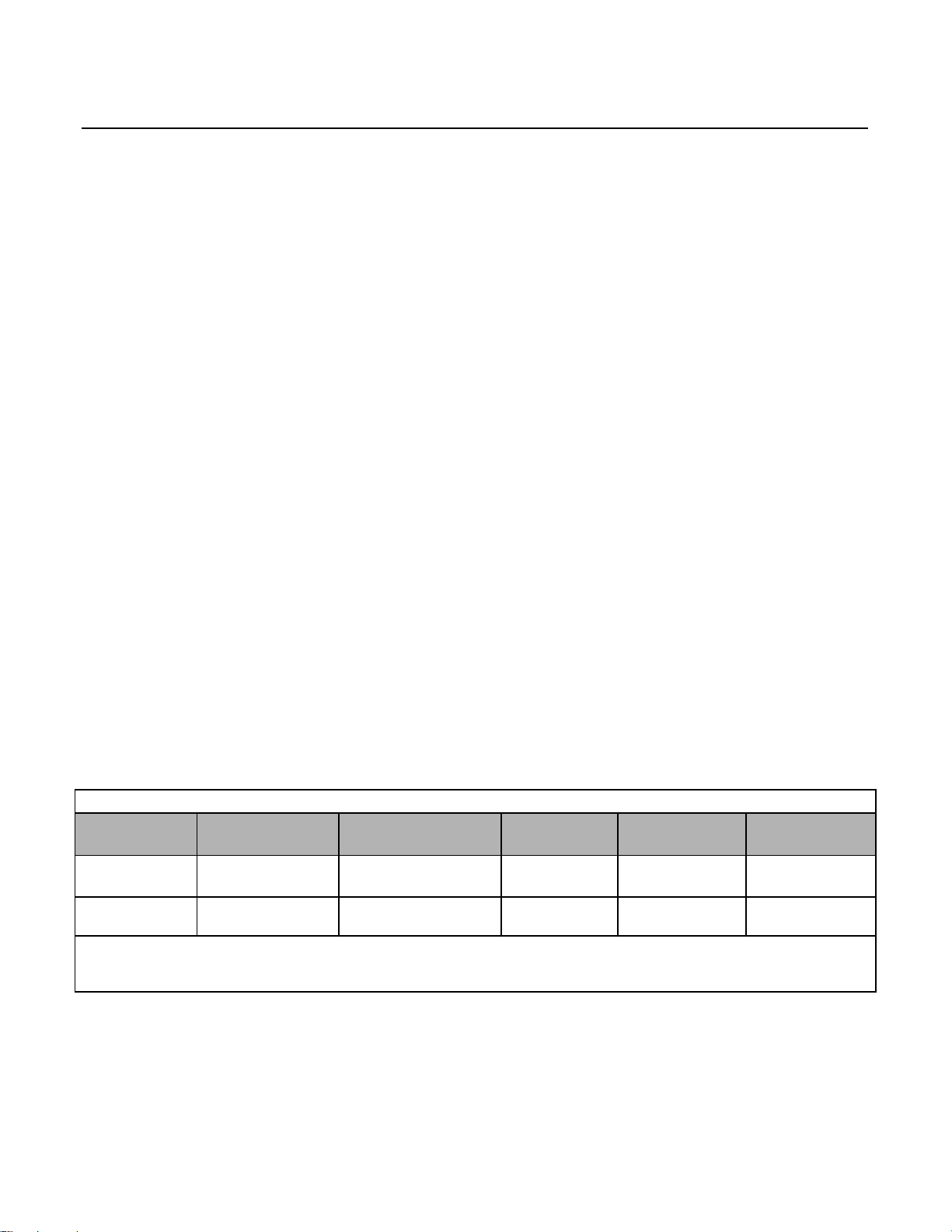

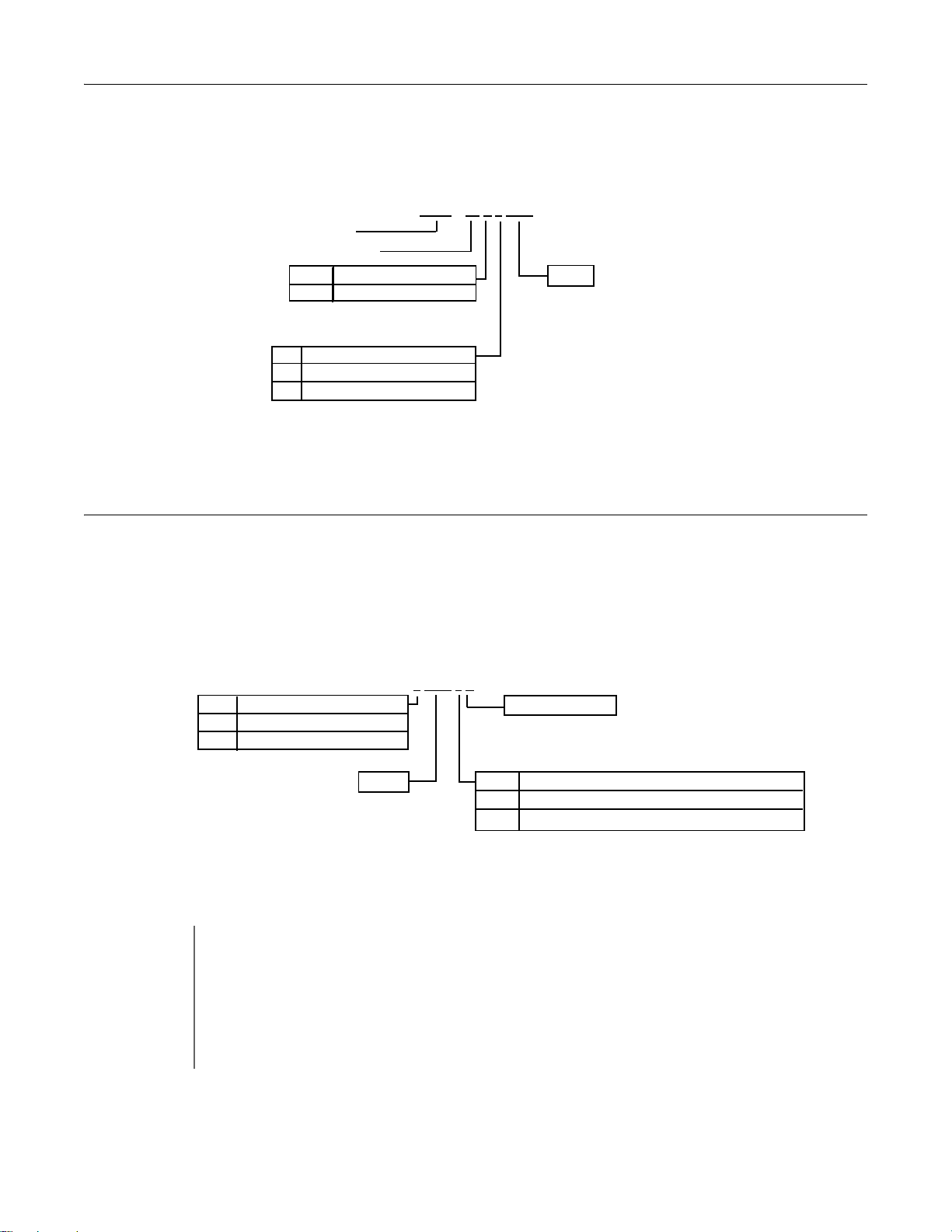

The Drive’s capacity is categorized based on two types of load characteristics: Heavy Duty and Normal Duty. See Table i.1

below for the differences between Heavy Duty and Normal Duty.

Table i.1 Drive Duty Selection

Parameter

C6-01

0: Heavy Duty

(default)

2: Normal Duty

* See Drive Specifications

** Software version VSF103021 and higher allows the carrier frequency to b e in creased while in HD (C6-01=0). The continuous current

and overload are automatically reduced to the levels indicated in Table 5.1.

This manual references the various Drive capacities according to its model number CIMR-F7U

Rated Output

Current

Standard rating

(varies by model*)

Extended rating

(varies by model*)

Overload

Capacity

150% for 1 min. 150%

Approx. 110% for 1 min.

(varies by mode l*)

Current Limit

120%

Carrier

Frequency

Low

(2kHz**)

High

(varies by model*)

FFFF. See Drive

Maximum Output

Frequency

300Hz

400Hz

Output Specifications Table i.2 and Table i.3 on the following pages for rated capacities and Drive specifications.

iii

Page 6

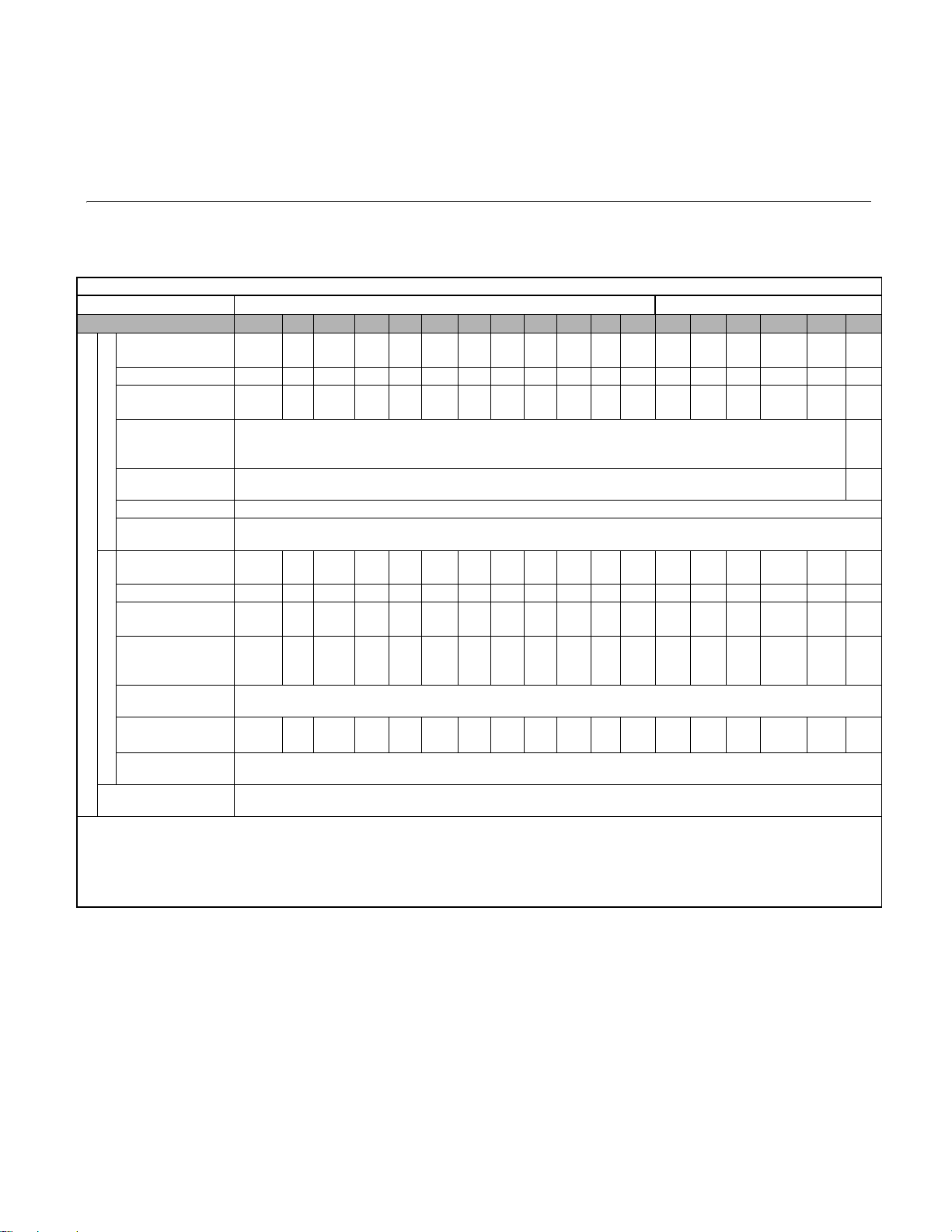

Drive Output Specifications

Output ratings

*1

*1

The standard Drive specifications are listed in the following tables.

208-240Vac

Table i.2 208-240Vac Drive Specifications

208-240Vac 208-230Vac

Model Number CIMR-F7U

Rated output

capacity

(kVA)

Horsepower

*2

Rated output

current

(A)

Overload capacity

(% of rated output

current for 60 sec.)

Heavy Duty

Current limit (% of

rated outpu t cu rrent)

Carrier frequency

Maximum output

frequency

Rated output

(kVA)

capacity

Horsepower

*2

Rated output

current

(A)

Overload capacity

(% of rated output

current for 60 sec.)

Current limit (% of

Normal Duty

rated outpu t cu rrent)

Carrier frequency

*5

(kHz)

Maximum output

frequency

Maximum output voltage

*1 The difference between Heavy Duty ratings and the Normal Duty ratings for the Drive are the rated input and output current, overload capacity, carrier frequency, current limit, and

maximum output frequency. Parameter C6-01 must be set to value of “0” for Heavy Duty ratings and “2” for Normal Duty ratings. Factory default is Heavy Duty (C6-01=0).

*2 Horsepower ratings are based on 230V or 460V NEC Table 430.150. The maximum applicable motor output is given for a standard 4-pole motor. When selecting the actual motor

and Drive, be sure that the Drive's rated output current is appropria te for the mot or's rated current.

*3 Model 2110 has an overload rating of 138% of rated outp ut curren t for 60 sec onds and a current limi t rating of 138%. Models 4220 and 4300 have an overload rating of 150% of

rated output current for 45 seconds and a current limit rating of 150%.

*4 Wh en setting the carrier frequency above the factory default, the Drive mus t be derated.

*5 Heavy Duty ratings for models 2110, 4220 and 4300 are effective in software version VSF103021 and higher.

20P4 20P7 21P5 22P2 23P7 25P5 27P5 2011 2015 2018 2022 2030 2037 2045 2055 2075 2090

1.2 1.6 2.7 3.7 5.7 8.8 12.0 17.0 22.0 27.0 32.0 44.0 55.0 69.0 82.0 110.0 130.0 140.0

0.5/0.75 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125 150

3.2 4.2 7.0 9.6 15.2 23.0 31.0 45.0 58.0 71 85.0 115.0 145.0 180.0 215 283.0 346.0 360.0

*3

150

150

*4

2kHz

300.0Hz

1.4 1.8 3.0 4.1 6.4 8.8 12.0 18.0 23.0 29.0 34.0 44.0 62.0 73.0 82.0 120.0 140.0 160.0

0.5/0.75 1 2 3 5 7.5 10 15 20 25 30 40 50/60 75 75 100/125 150 150

3.6 4.6 7.8 10.8 16.8 23.0 31.0 46.2 59.4 74.8 88.0 115.0 162.0 192.0 215 312.0 360.0 415.0

*3

107 107 108 107 107 120 120 117 117 114 116 120 107 113 120 109 115 120

120

10 1010 81015158101010105 5 8 2 2 2

400.0Hz

3-phase; 200, 208, 220, 230, or 240Vac

(Proportional to input voltage)

2110

138

138

*5

*3

*3

iv

Page 7

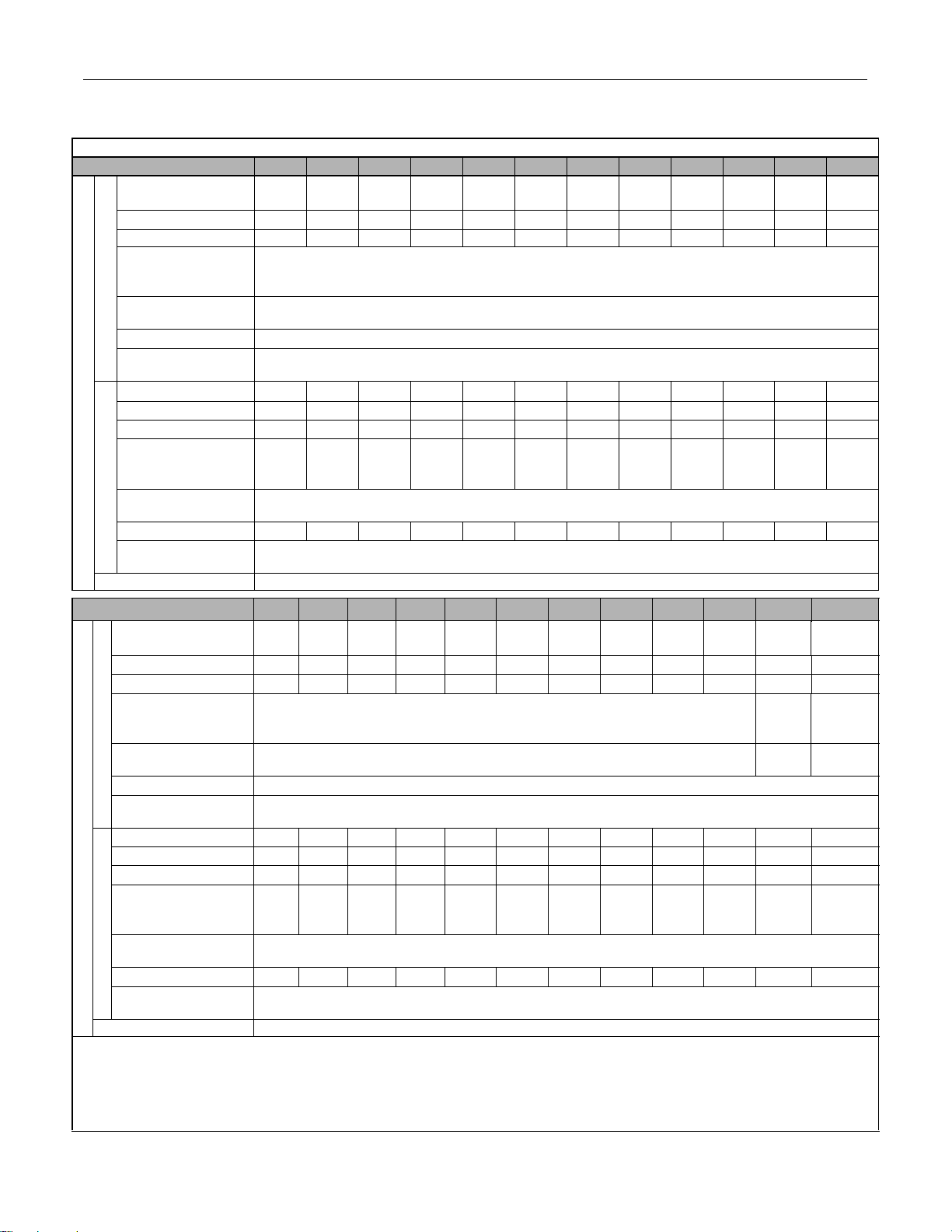

Output ratings

*1

*1

Output ratings

*1

*1

480Vac

Table i.3 480Vac Drive Specifications

Model Number CIMR-F7U 40P4 40P7 41P5 42P2 43P7 44P0 45P5 47P5 4011 4015 4018 4022

Rated output

capacity

(kVA)

Horsepower

*2

Rated output current (A) 1.8 2.1 3.7 5.3 7.6 8.7 12.5 17.0 24.0 31.0 39.0 45.0

Overload capacit y

*3

(% of rated ou tput

current for 60 sec.)

Heavy Duty

Current limit (% of rated

output current)

Carrier frequency

*4

Maximum output

frequency

Rated output capacity

Horsepower

Rated output current

Overload capacit y

(kVA)

*2

(A)

*3

(% of rated ou tput

current for 60 sec.)

Current limit (% of rated

Normal Duty

output current)

Carrier frequency (kHz)

Maximum output

frequency

Maximum output voltage 3-phase; 380, 400, 415, 440, 460, or 480Vac (Proportional to input voltage)

Model Number CIMR-F7U 4030 4037 4045 4055

*4

*3

*3

(A)

(kVA)

(A)

Rated output capacity

(kVA)

Horsepower

*2

Rated outpu t cu rrent

Overload capacity

(% of rated output

current for 60 sec.)

Current limit (% of rated

Heavy Duty

output current)

Carrier frequency

Maximum output

frequency

Rated output capac ity

Horsepower

*2

Rated outpu t cu rrent

Overload capacity

(% of rated output

current for 60 sec.)

Current limit (% of rated

Normal Duty

output current)

Carrier frequency (kHz)

Maximum output

frequency

Maximum output voltage 3-phase, 380, 400, 415, 440, 46 0 or 480Vac (Proportional to input voltage)

*1 The difference between Heavy Duty ratings and the Normal Duty ratings for the Drive are the rated input and output current, overload capacity, carrier frequency, current limit, and

maximum output frequency. Parameter C6-01 must be set to value of “0” for Heavy Duty ratings and “2” for Normal Duty ratings. Factory default is Heavy Duty (C6-01=0).

*2 Horsepower ratings are based on 230V or 460V NEC Table 430.150. The maximum applicable motor output is given for a standard 4-pole motor. When selecting the actual motor

and Drive, be sure that the Drive's rated output current is appropriate for the motor's rated current.

*3 Model 2110 has an overload rating of 138% of rated output current for 60 seconds and a current limit rating of 138%. Models 4220 and 4300 have an overload rating of 150% of

rated output current for 45 seconds and a current limit rating of 150%.

*4 When setting the carrier frequency above the factory default, the Drive must be derated.

*5 Heavy Duty ratings for models 2110, 4220 and 4300 are effective in software version VSF103021 and higher.

1.4 1.6 2.8 4.0 5.8 6.6 9.5 13.0 18.0 24.0 30.0 34.0

0.5/0.75 1 1.5/2 3 5 - 7.5 10 15 20 25 30

150

150

2kHz

300.0Hz

1.4 1.6 2.8 4.0 5.8 6.6 9.5 13.0 21.0 26.0 30.0 38.0

0.5/0.75 1 1.5/2 3 5 - 7.5 10 15/20 25 30 30

1.8 2.1 3.7 5.3 7.6 8.7 12.5 17.0 27.0 34.0 40.0 50.4

120 120 120 120 120 120 120 120 107 109 117 107

120

*5

15 15 15 15 15 15 15 15 8 10 10 10

400.0Hz

4075 4090 4110

4132 4160 4185

4220*54300

46.0 57.0 69.0 85.0 110.0 140.0 160.0 200.0 230.0 280.0 315.0 450.0

40 50 60 75 100 125/150 - 200 250 300 350 500

60.0 75.0 91.0 112.0 150.0 180.0 216.0 260.0 304.0 370.0 414.0 590.0

150

150

150

150

*3

*3

2kHz

300.0Hz

51.0 59.0 73.0 95.0 120.0 140.0 180.0 200.0 230.0 315.0 390.0 510.0

40/50 60 75 100 125 150 200 - 250 300/350 400/450 500+

67.2 77.0 96.0 125.0 156.0 180.0 240.0 260.0 304.0 414.0 515.0 675.0

107 117 114 108 115 120 108 120 120 107 118 120

120

*5

88855855522 2

400.0Hz

v

150

150

*5

*3

*3

Page 8

Notes:

vi

Page 9

Table of Contents

Warnings and Cautions................................................................................................ i

Introduction .................................................................................................................iii

Table of Contents .......................................................................................................vii

Chapter 1- Physical Installation ................................................................................1-1

F7 Model Number, Enclosure, Heat Loss, and Weight ............................................1-2

Confirmations Upon Delivery ...................................................................................1-3

Component Names ..................................................................................................1-5

Exterior and Mounting Dimensions ..........................................................................1-7

Checking and Controlling Installation Site.............................................................. 1-11

Installation Orientation and Clearances .................................................................1-12

Removing and Attaching the Terminal Cover.........................................................1-13

Removing/Attaching the Digital Operator and Front Cover....................................1-14

Chapter 2- Electrical Installation...............................................................................2-1

Terminal Block Configuration ................................................................................... 2-2

Wiring Main Circuit Terminals................................................................................... 2-3

Control Wiring ........................................................................................................2-20

Electromagnetic Compatibility (EMC) ....................................................................2-26

Installing and Wiring Option Boards.......................................................................2-30

Chapter 3- Digital Operator........................................................................................3-1

Digital Operator Display ...........................................................................................3-2

Digital Operator Keys ...............................................................................................3-3

Drive Mode Indicators..............................................................................................3-4

Drive Main Menus ....................................................................................................3-6

Quick Setting Menu (-QUICK-)...............................................................................3-11

Programming Menu (-ADV-)...................................................................................3-12

Example of Changing a Parameter........................................................................3-15

Table of Contents vii

Page 10

Chapter 4- Start-Up.....................................................................................................4-1

Drive Start-Up Preparation ....................................................................................... 4-2

Drive Start-Up Procedures ....................................................................................... 4-5

Chapter 5- Basic Programming................................................................................. 5-1

Description of Parameter Tables.............................................................................. 5-2

Control Method.........................................................................................................5-2

Speed Command Source......................................................................................... 5-3

Run Command Source............................................................................................. 5-4

Stopping Method ..................................................................................................... 5-5

Accel/Decel Time ..................................................................................................... 5-8

Carrier Frequency .................................................................................................... 5-9

Preset Reference ................................................................................................... 5-10

Input Voltage Setting.............................................................................................. 5-11

V/F Pattern ............................................................................................................. 5-11

Motor Setup............................................................................................................ 5-19

PG Option .............................................................................................................. 5-19

Analog Output Gain................................................................................................ 5-20

Motor Overload Fault .............................................................................................5-21

Stall Prevention ...................................................................................................... 5-22

Chapter 6- Diagnostic & Troubleshooting .............................................................. 6-1

Fault Detection ......................................................................................................... 6-2

Alarm Detection........................................................................................................ 6-9

Operator Programming Errors (OPE)..................................................................... 6-13

Auto-Tuning Faults .................................................................................................6-15

Digital Operator COPY Function Faults .................................................................6-17

Troubleshooting ..................................................................................................... 6-18

Main Circuit Test Procedure ...................................................................................6-26

Drive Date Stamp Information ................................................................................ 6-29

Table of Contents viii

Page 11

Chapter 7- Maintenance ............................................................................................. 7-1

Periodic Inspection................................................................................................... 7-2

Preventative Maintenance........................................................................................ 7-3

Periodic Maintenance of Parts ................................................................................. 7-4

Heatsink Cooling Fan Replacement.........................................................................7-5

Removing and Mounting the Terminal Card.............................................................7-7

Appendix A - Parameters.......................................................................................... A-1

F7 Parameter List.....................................................................................................A-3

F7 Monitor List .......................................................................................................A-40

F7 Fault Trace List .................................................................................................A-43

F7 Fault Trace History............................................................................................A-43

Appendix B - Capacity Related Parameters............................................................ B-1

Drive Capacity Selection ..........................................................................................B-2

Parameters Affected by Drive Capacity Setting .......................................................B-3

Appendix C - Specifications ..................................................................................... C-1

Standard Drive Specifications ................................................................................. C-2

Appendix D - Communications ................................................................................ D-1

Using Modbus Communication ............................................................................... D-2

Modbus Function Code Details ............................................................................... D-8

Modbus Data Tables ............................................................................................. D-10

Modbus Self-Diagnosis ......................................................................................... D-18

Table of Contents ix

Page 12

Appendix E - Peripheral Devices ............................................................................. E-1

Branch Circuit Short Circuit Protection.....................................................................E-2

Branch Circuit Overload Protection..........................................................................E-5

Peripheral Devices...................................................................................................E-6

Appendix F - Spare Parts...........................................................................................F-1

F7 Primary Spare Parts - 208/230/240Vac...............................................................F-2

F7 Primary Spare Parts - 480Vac.............................................................................F-3

Index ................................................................................................................. Index-1

Support Services................................................................................ Inside rear cover

Table of Contents x

Page 13

Chapter 1

Physical Installation

This chapter describes the requirements for receiving and installing the F7 Drive.

F7 Model Number, Enclosure, Heat Loss, and Weight. 1-2

Confirmations upon Delivery ........................................ 1-3

Component Names....................................................... 1-5

Exterior and Mounting Dimensions............................... 1-7

Checking and Controlling the Installation Site ............ 1-11

Installation Orientation and Clearances......................1-12

Removing and Attaching the Terminal Cover .............1-13

Removing/Attaching the Digital Operator

and Front Cover.......................................................... 1-14

Physical Installation 1 - 1

Page 14

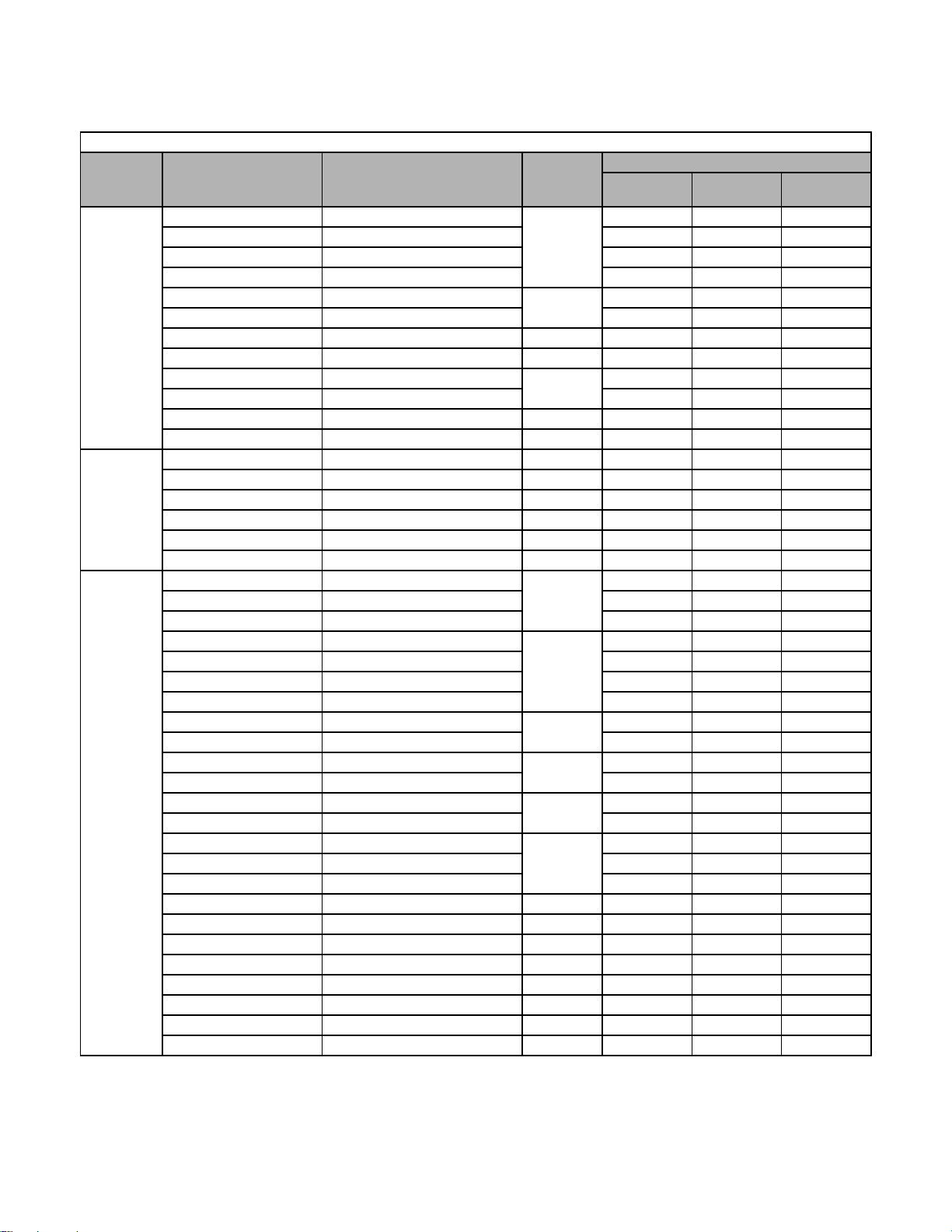

F7 Model Number, Enclosure, Heat Loss, and Weight

Table 1.1 F7 Model Number and Enclosure Style

Input

Volta ge

3-Phase

208-240V ac

208-230Vac

480 Vac

F7

Model-Number

CIMR- F7U2 0P4 NEMA T ype 1 (IP20)

CIMR-F7U20P 7 NEMA Type 1 (IP20) 26 42 68

CIMR-F7U21P 5 NEMA Type 1 (IP20) 48 50 98

CIMR-F7U22P 2 NEMA Type 1 (IP20) 68 59 127

CIMR- F7U2 3P7 NEMA T ype 1 (IP20)

CIMR-F7U25P5 NEMA Type 1 (IP20) 164 84 248

CIMR-F7U27P5 NEMA Type 1 (IP20) 13.2 (6.0) 219 113 332

CIMR-F7U2011 NEMA Type 1 (IP20) 15.4 (7.0) 357 168 525

CIMR- F7U2 015 NEMA Type 1 (IP20)

CIMR-F7U201 8 NEMA Type 1 (IP20) 472 208 680

CIMR-F7U202 2 NEMA Type 1 (IP20) 53 (2 4) 583 252 835

CIMR-F7U2030 NEMA Type 1 (IP20) 59 (27) 883 333 1216

CIMR-F7U203 7 Open Chassis (IP00) 125 (57) 1010 421 1431

CIMR-F7U204 5 Open Chassis (IP00) 139 (63) 1228 499 1727

CIMR-F7U205 5 Open Chassis (IP00) 189 (86) 1588 619 2207

CIMR-F7U207 5 Open Chassis (IP00) 191 (87) 1956 844 2800

CIMR-F7U2090 Open Chassis (IP00) 238 (108) 2194 964 3158

CIMR-F7U 2110 Open Chassis (IP00) 330 (150) 2733 1234 3967

CIMR- F7U4 0P4 NEMA T ype 1 (IP20)

CIMR-F7U40P 7 NEMA Type 1 (IP20) 17 41 58

CIMR-F7U41P 5 NEMA Type 1 (IP20) 36 48 84

CIMR- F7U4 2P2 NEMA T ype 1 (IP20)

CIMR-F7U43P 7 NEMA Type 1 (IP20) 80 68 148

CIMR-F7U44P 0 NEMA Type 1 (IP20) 90 70 160

CIMR-F7U45P5 NEMA Type 1 (IP20) 127 81 208

CIMR- F7U4 7P5 NEMA T ype 1 (IP20)

CIMR-F7U40 11 NEMA Type 1 (IP20) 232 158 390

CIMR- F7U4 015 NEMA Type 1 (IP20)

CIMR-F7U401 8 NEMA Type 1 (IP20) 389 201 590

CIMR- F7U4 022 NEMA Type 1 (IP20)

CIMR-F7U403 0 NEMA Type 1 (IP20) 691 298 989

CIMR- F7U4 037 NEMA Type 1 (IP20)

CIMR-F7U4045 NEMA Type 1 (IP20) 901 386 1287

CIMR-F7U4055 NEMA Type 1 (IP20) 1204 478 1682

CIMR-F7U407 5 Open Chassis (IP00) 194 (88) 1285 562 1847

CIMR-F7U409 0 Open Chassis (IP00) 196 (89) 1614 673 2287

CIMR-F7U4110 Open Chassis (IP00) 224 (102) 1889 847 2736

CIMR-F7U413 2 Open Chassis (IP00) 265 (120) 2388 1005 3393

CIMR-F7U41 60 Open Chassis (IP00) 352 (160) 2791 1144 3935

CIMR-F7U418 5 Open Chassis (IP00) 572 (259) 2636 1328 3964

CIMR-F7U422 0 Open Chassis (IP00) 616 (279) 3797 1712 5509

CIMR-F7U430 0 Open Chassis (IP00) 891 (404) 5838 2482 8320

Enclosure Style

Weight

lb (kg)

6.6 (3.0)

8.8 (4.0)

24.2 (11.0)

6.6 (3.0)

8.8 (4.0)

13.2 (6.0)

22 (10)

53 (24)

88 (40)

Heatsink Internal To ta l

110 74 184

416 182 598

193 114 307

296 169 465

420 233 653

801 332 1133

Heat Loss (watts)

19 39 58

14 39 53

59 56 115

Physical Installation 1 - 2

Page 15

Confirmations upon Delivery

N

e.

Receiving Checks

Check the following items as soon as the Drive is received.

Table 1.2 Receiving Checks

Item Method

Has the correct model of Drive been delivered?

Check the model number on the nameplate on the right side of the Drive.

Reconcile with packing slip and/or order information.

Is the Drive damaged in any way?

Are any screws or other components loose? Use a screwdriver or other tool to check for tightness.

Inspect the entire exterior of the Drive to see if there are any dents, scratches or other

damage resulting from shipping.

If there are any irregularities in the above items, contact the shipping comp any, or the distributor / representative who sold the

Drive, or a Yaskawa office immediately.

Nameplate Information

A nameplate is attached to the right side of each Drive. The following nameplate is an example for a standard Drive.

Drive Mode l Number

Input Power Rating

Output Power Rating

Serial Number

UL File Number

Drive Spec Number

Weight

Software Number

ote: The Drive Model Number, Drive Spec Number, Software Number, and Serial Number are required to co mpletely identify a Driv

HD - Heavy Duty; ND - Normal Duty

Fig 1.1 F7 Drive Nameplate

Physical Installation 1 - 3

Page 16

Drive Model Numbers

The model number on the nameplate indicates the design specification, voltage, and rating of the Drive in alphanumeric codes.

CIMR – F7 U 2 0 2 2

AC Drive

F7 Family

No.

U

Spec

UL Specification

Rating

No.

2

4

Voltage

3-phase, 208-240Vac

3-phase, 480Vac

Fig 1.2 Drive Model Number Structure

Drive Enclosure and Revision Code

The SPEC number on the nameplate indicates the voltage, Drive rating, enclosure type, and the revision code of the Drive in

alphanumeric codes. The SPEC number for Drives that have custom features, i.e. CASE software, will have a SPEC number

that indicates the custom features installed.

2

0 2 2 1 E

No.

2

4

Voltage

3-phase, 208 - 240Vac

3-phase, 480Vac

Rating

Hardware Revision

No.

0 Open chassis (IEC IP00)

1

Enclosure Type

NEMA Type 1 (IEC IP20)

TERMS

Fig 1.3 SPEC Number Structure

Open Chassis Type (IEC IP00)

Protected so that parts of the human body cannot reach electrically charged parts from the front when the

Drive is mounted in a control panel, also called protected chassis.

NEMA Type 1 (IEC IP20)

The Drive is shielded from the exterior, and can thus be mounted to the interior wall of a building

(not necessarily enclosed in a control panel). The protective structure conforms to the standards of NEMA 1

in the USA. All protective covers (Fig 1.4 and Fig 1.6) must be installed to conform with IEC IP20 and NEMA

Type 1 requirements.

Physical Installation 1 - 4

Page 17

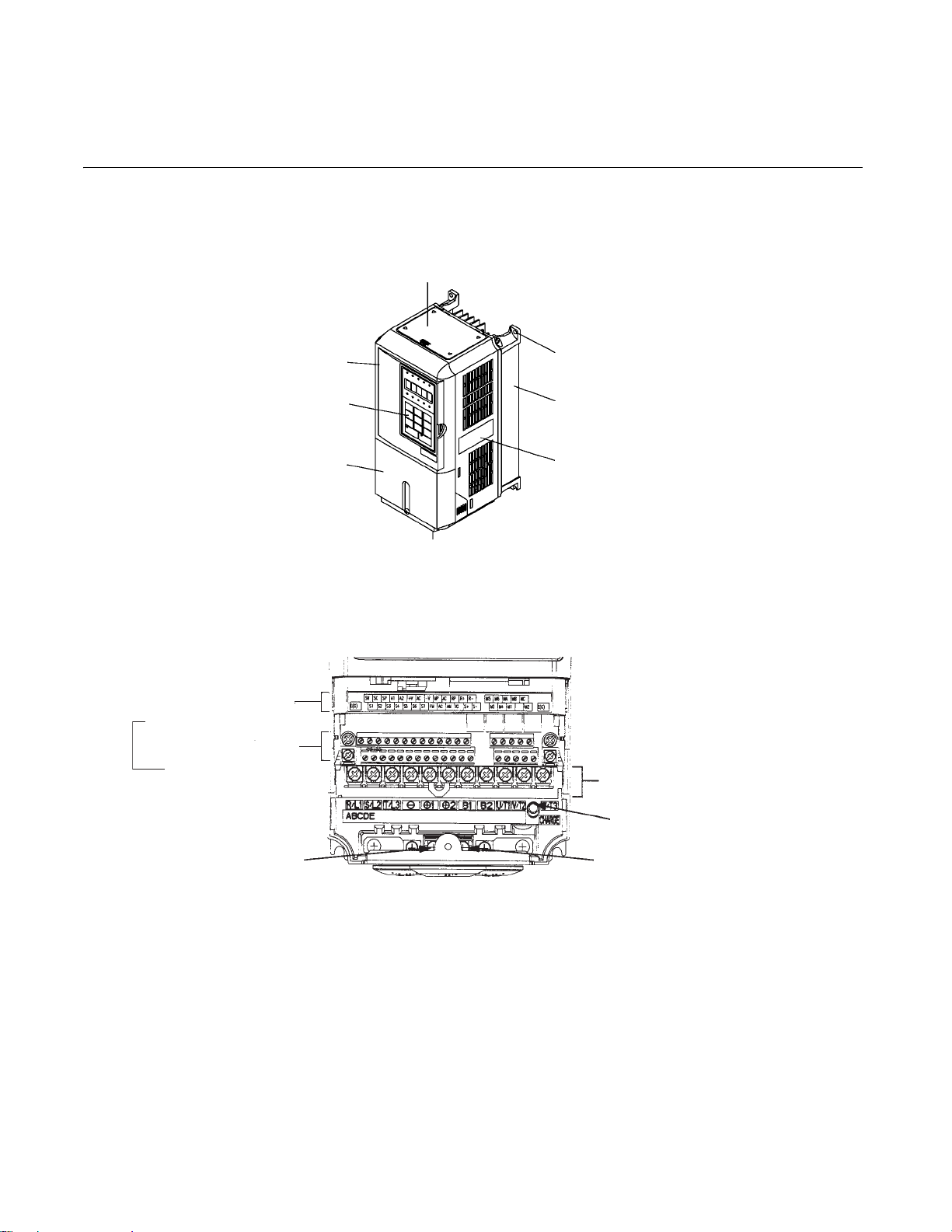

Component Names

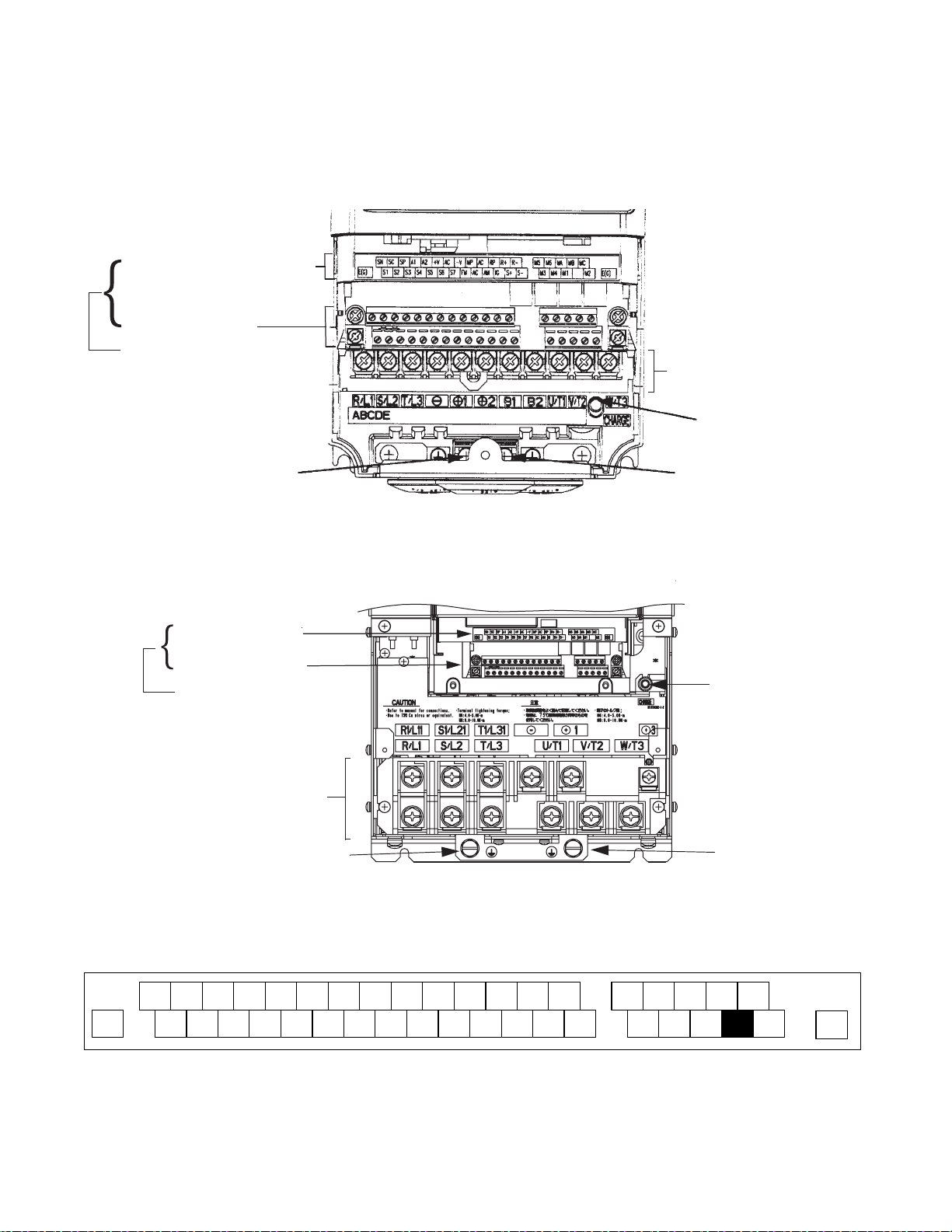

Models CIMR-F7U20P4 thru 2018 and 40P4 thru 4018

The external appearance, component names, and terminal arrangement of the Drive are shown in Fig 1.4. and 1.5.

Control circuit terminal

layout label

{

Cont

rol circuit terminals

See Fig. 2.3 for actual

terminal layout

[Required for NEMA Type 1 (IEC IP20)]

Front cover

Digital Operator

Terminal cover

Top protective cover

Mounting hole

Die-cast Heat Sink

Nameplate

Bottom protective cover

Fig 1.4 Drive Appearance

Main circuit terminals

Ground terminal

Charge indicator

Ground terminal

Fig 1.5 Terminal Arrangement (Terminal Cover Removed)

Physical Installation 1 - 5

Page 18

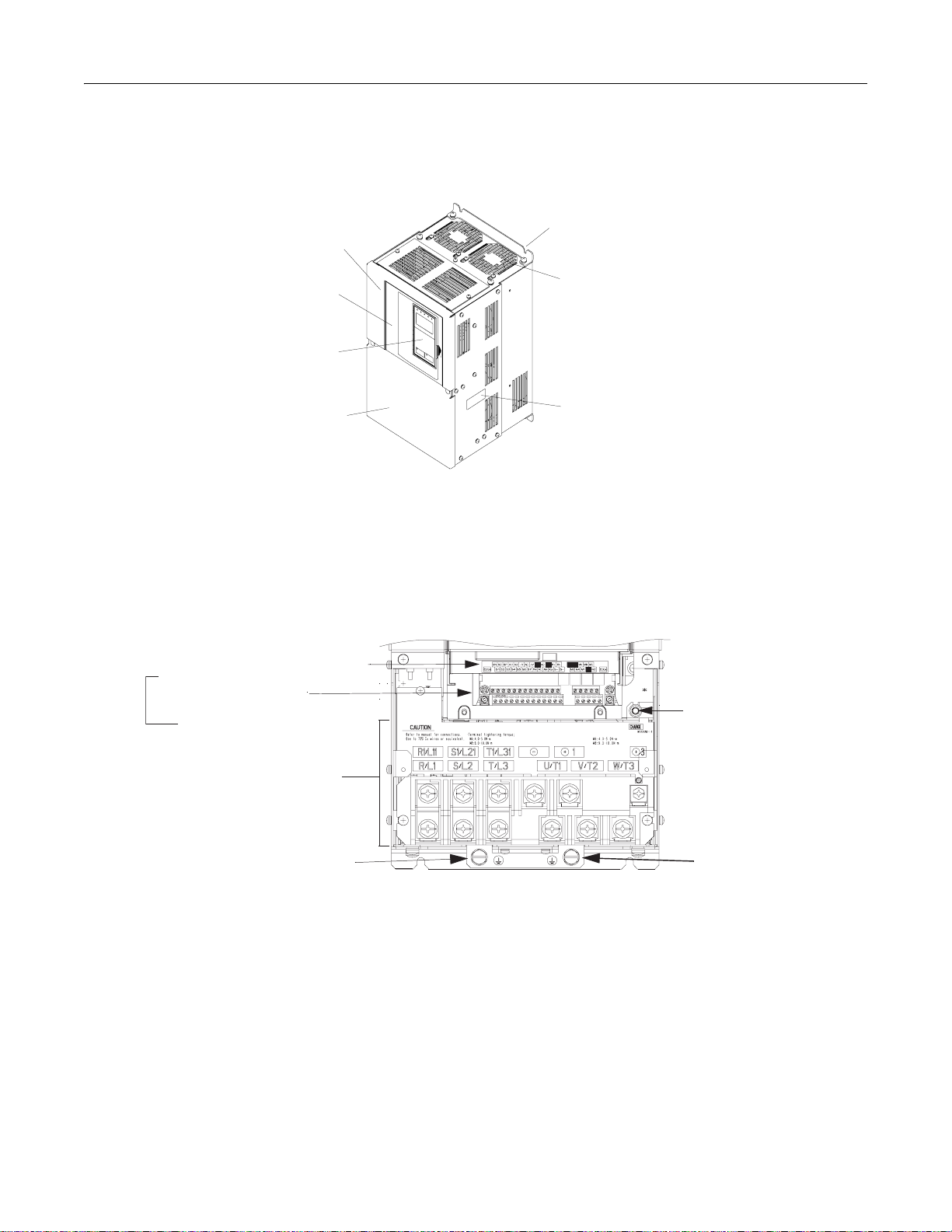

Models CIMR-F7U2022 thru 2110 and 4030 thru 4300

The external appearance, component names, and terminal arrangement of the Drive are shown in Fig 1.6 and 1.7.

Mounting holes

Mounting holes

Drive cover

Drive cover

Cooling fan

Front cover

Front cover

Digital Operator

Digital Operator

Terminal cover

Terminal cover

Fig 1.6 Drive Appearance

Cooling fan

Nameplate

Nameplate

Control circuit terminal layout label

{

Control circuit terminals

See Fig. 2.3 for actual

terminal layout

Main circuit

terminals

Ground terminal

Fig 1.7 Terminal Arrangement (Terminal Cover Removed)

Charge indicator

Ground terminal

Physical Installation 1 - 6

Page 19

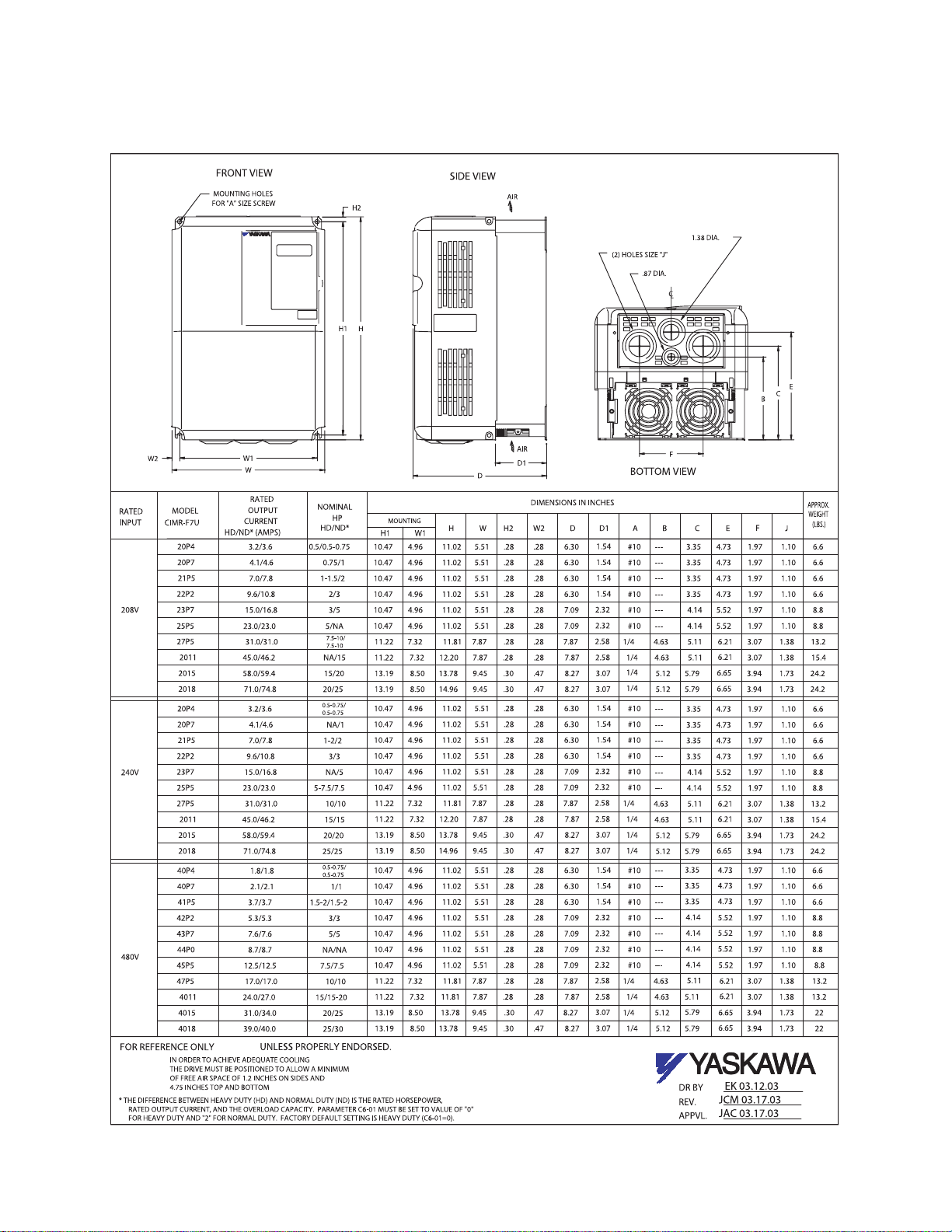

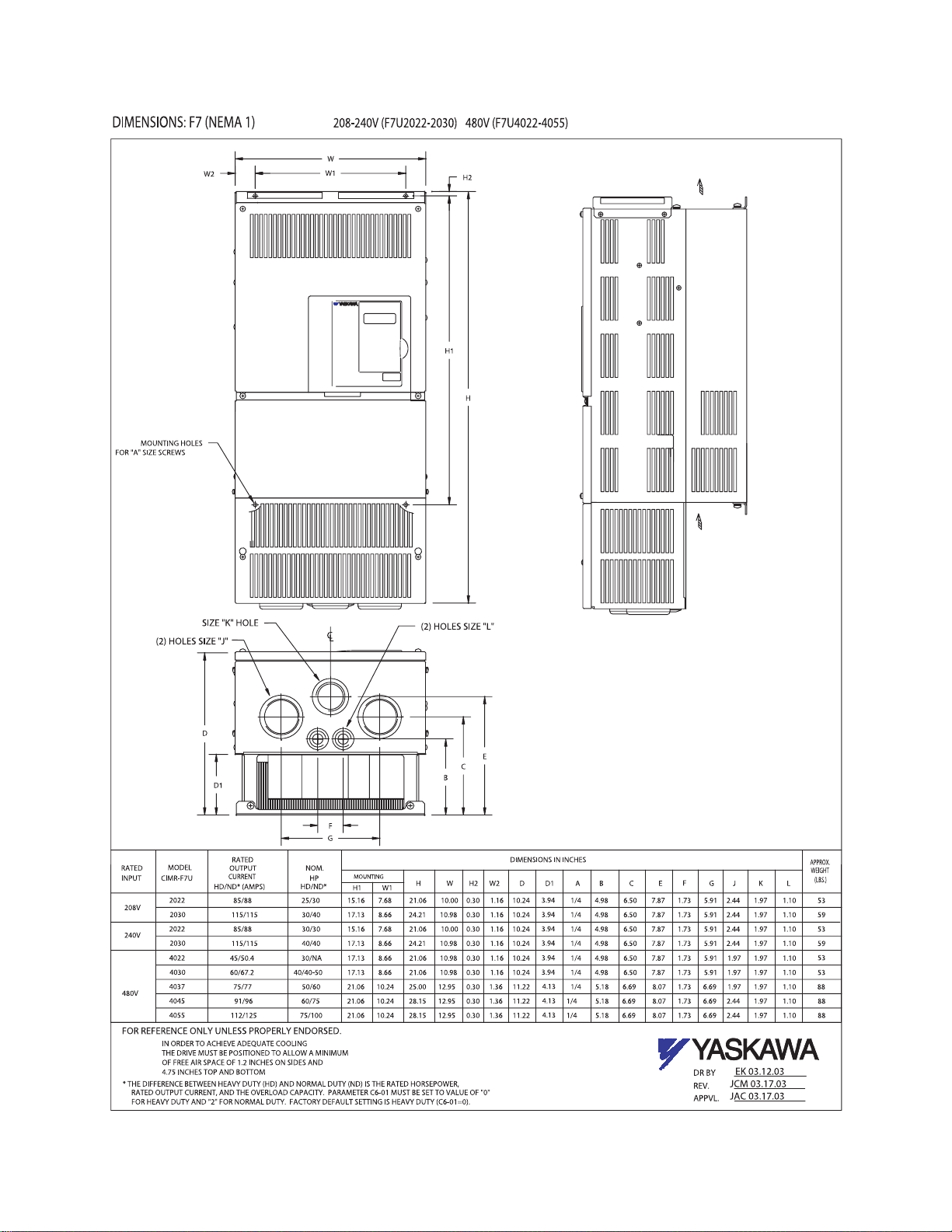

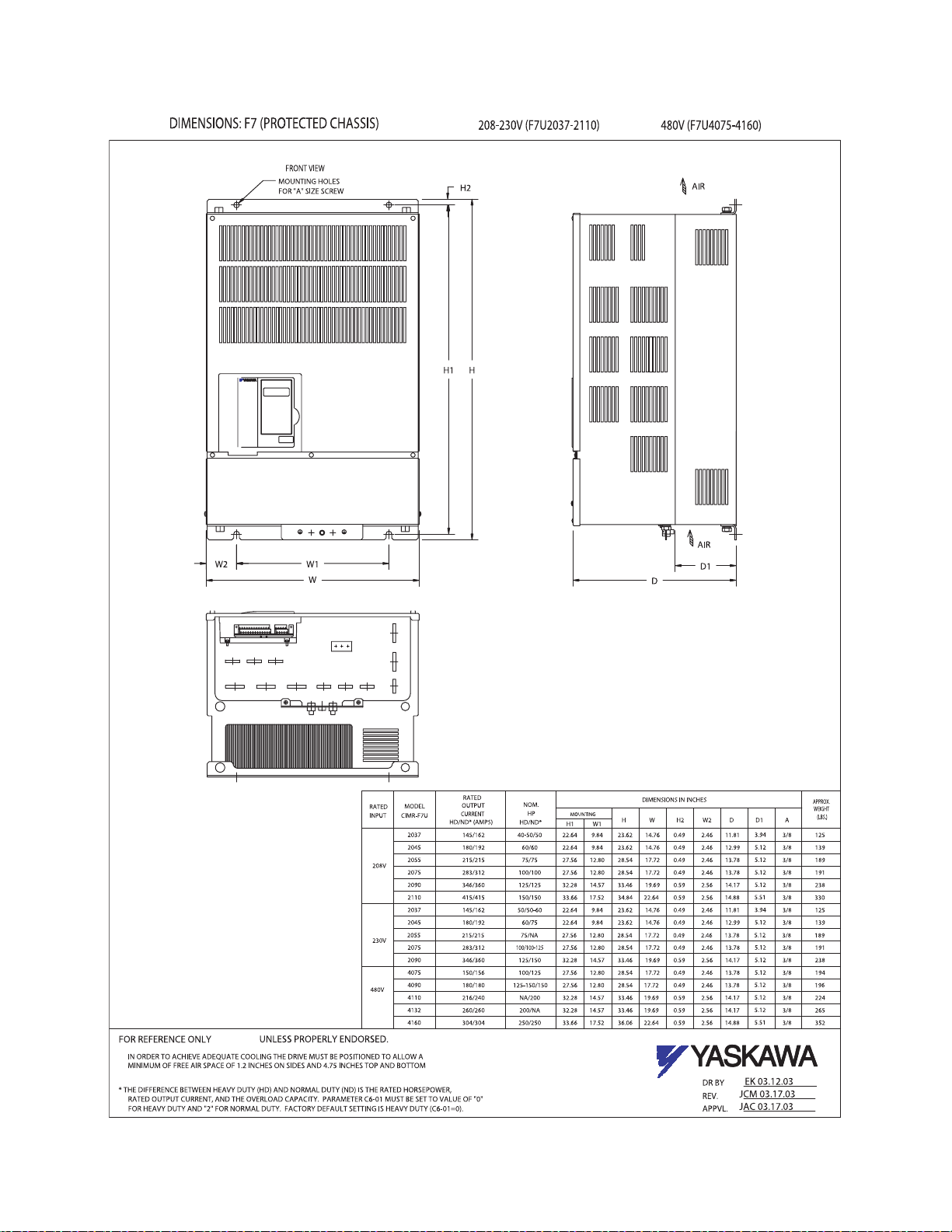

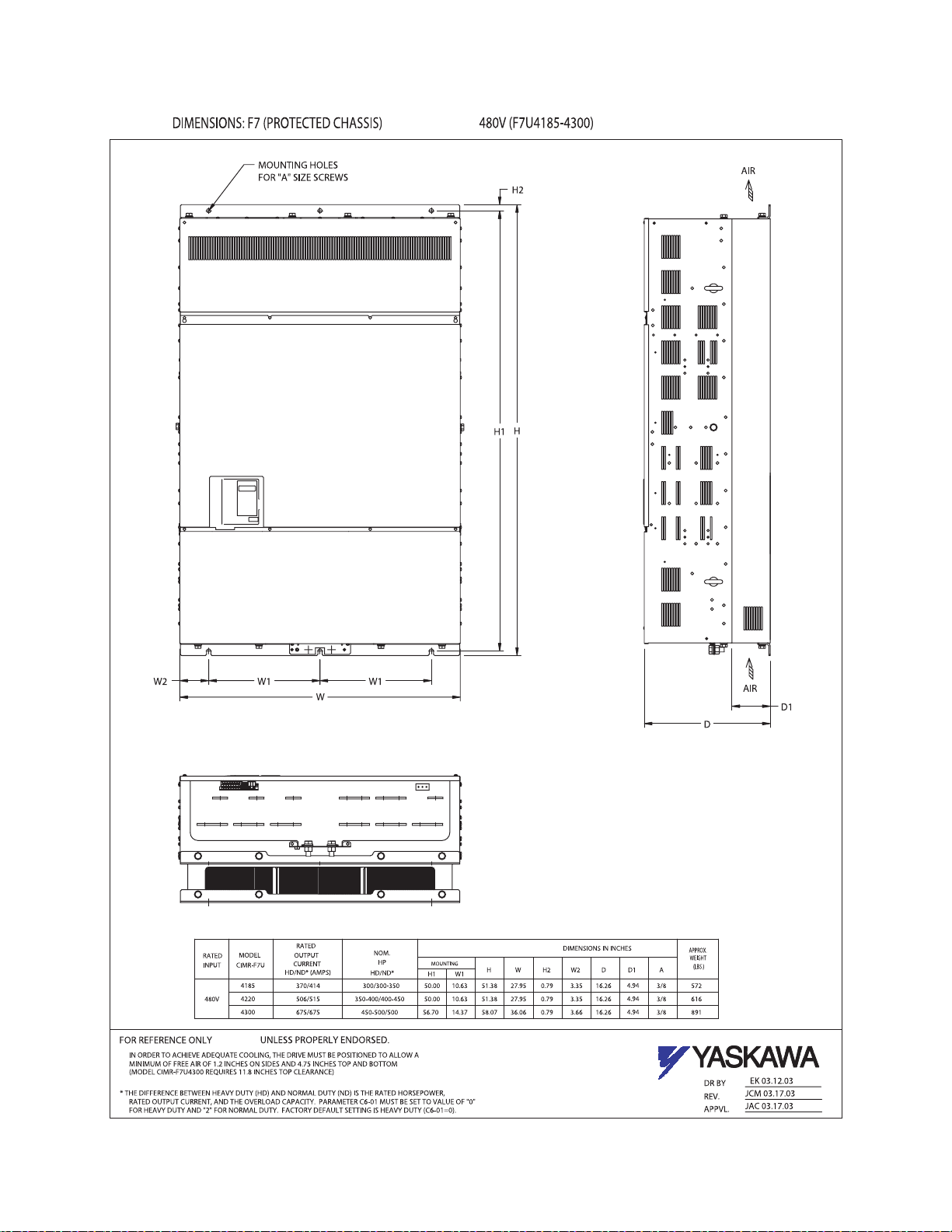

Exterior and Mounting Dimensions

DIMENSIONS: F7 (NEMA 1)

208-240V (F7U20P4-2018) 480V (F7U40P4-4018)

Physical Installation 1 - 7

Page 20

Physical Installation 1 - 8

Page 21

Physical Installation 1 - 9

Page 22

Physical Installation 1 - 10

Page 23

Checking and Controlling the Installation Site

Install the Drive as described below and maintain optimum conditions.

Installation Site

Install the Drive to a non-combustible surface under the following conditions in UL Pollution Degree 2 environments. This

excludes wet locations where pollution may become conductive due to moisture, and locations containing conductive foreign

matter.

Table 1.3 Installation Site Specifications

Type Ambient Operating Temperature Humidity Plenum Rated

NEMA Type 1 14° F -to- 104°F ( - 1 0 -to- + 40 °C) 95%-RH-or-less-(no-condensation) Yes

Open Chassis 14° F -to- 113°F ( - 1 0 - to -+ 45 °C ) 9 5 % -RH-or-less-(no-condensation) No

Protective covers are attached to the top and bottom of the Drive. It is recommended to remove the protective covers before

operating a NEMA Type 1 Drive (Models CIMR-F7U2030/4055 and smaller) in a panel to obtain the 113° (45°C) ambient

operating temperature.

Observe the following precautions when installing the Drive. Make sure to install:

• in a clean location which is free from oil mist and dust.

• in an environment where metal shavings, oil, water, or other foreign materials do not get into the Drive.

• in a location free from radioactive materials and combustible materials (e.g. wood).

• in a location free from harmful gases and liquids.

• in a location free from excessive vibration.

• in a location free from chlorides.

• in a location away from direct sunlight.

Controlling the Ambient Temperature

To enhance the reliability of operation, the Drive should be installed in an environment free from extreme temperature

variation. If the Drive is installed in an enclosure, use a cooling fan or air conditioner to maintain the internal air temperature

below 113°

F (45°C).

Protecting the Drive from Foreign Matter

During Drive installation and project construction, it is possible to have foreign matter such as metal shavings or wire

clippings fall inside the Drive. To prevent foreign matter from falling into the Drive, place a temporary cover over the Drive.

Always remove the temporary cover from the Drive before start-up. Otherwise, ventilation will be reduced, causing the Drive

to overheat.

Physical Installation 1 - 11

Page 24

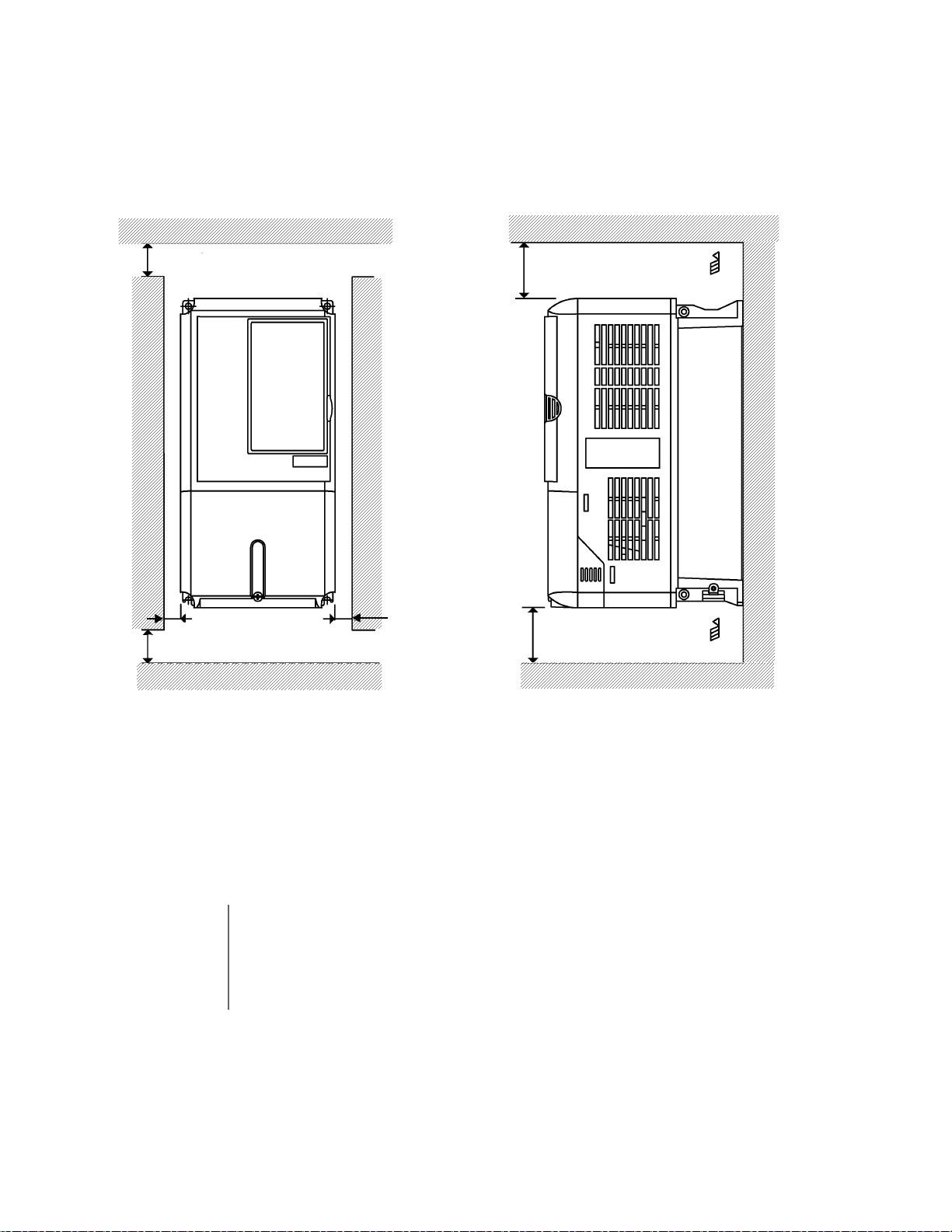

Installation Orientation and Clearances

Install the Drive vertically so as not to reduce the cooling efficiency. When installing the Drive, always provide the following

installation clearances to allow normal heat dissipation and air flow. Ensure that the heatsink is against a closed surface to

avoid diverting cooling air around the heatsink.

1

1.97in *

(50mm) minimum

4.75in *2 (120mm) minimum

Air

1.2in

(30.5mm) minimum

1.97in (50mm) minimum

*1For Drive models F7U2110, F7U4160, and F7U4220, this clearance dimension is 4.75in (120mm) minimum.

For Drive model F7U4300, this clearance dimension is 11.8in (300mm) minimum.

All other models require 1.97in (50mm) minimum.

2

For Drive model F7U4300, this clearance dimension is 11.8in (300mm) minimum. All other models require 4.75in (120mm) minimum.

*

1.2in

(30.5mm) minimum

4.75in (120mm) minimum

Air

Vertical ClearanceHorizontal Clearance

Fig 1.8 Drive Installation Orientation and Clearance

1. The same clearance is required horizontally and vertically for both Open Chassis (IP00)

IMPORTANT

and NEMA Type 1 Drives.

2. Always remove the top and bottom protection covers before installing a CIMR-F7U2018/

4018 and smaller Drive in a panel.

3. Always provide enough clearance for lifting eye bolts and the main circuit wiring when

installing a CIMR-F7U2022/4030 and larger Drive in a panel.

Physical Installation 1 - 12

Page 25

Removing and Attaching the Terminal Cover

Remove the terminal cover to connect cables to the control circuit and main circuit terminals.

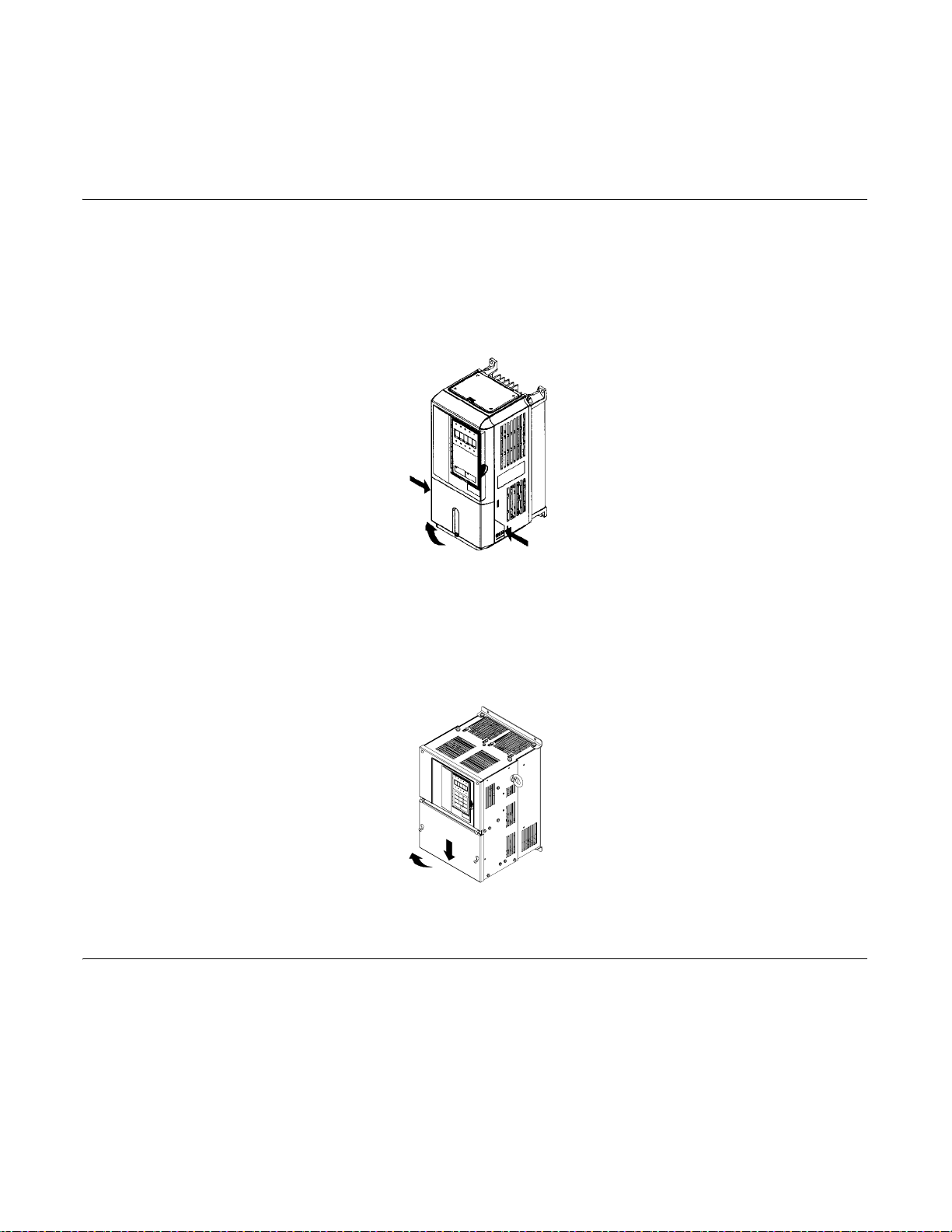

Removing the Terminal Cover

Models CIMR-F7U20P4 thru 2018 and 40P4 thru 4018

Loosen the screw at the bottom of th e termin al cove r, press in on the sid es of the terminal cover in th e directio ns of arrow s 1,

and then lift up on the terminal in the direction of arrow 2.

1

2

1

Fig 1.9 Removing the Terminal Cover

Models CIMR-F7U2022 thru 2110 and 4030 thru 4300

Loosen the screws on the left and right at the top of the terminal cover, pull down the terminal cover in the direction of arrow

1, and then lift up on the terminal cover in the direction of arrow 2.

1

2

Fig 1.10 Removing the Terminal Cover

Attaching the Terminal Cover

After wiring the terminal block, attach the terminal cover by reversing the removal procedure.

For Models CIMR-F7U2018/4018 and smaller, insert the tab on the top of the terminal cover into the groove on the Drive, and

press in on the bottom of the terminal cover until it clicks into place.

For Drives CIMR-F7U2022/4030 and larger, insert the tab on the top of the terminal cover into the groove on the Drive, and

secure the terminal cover by lifting it up toward the top of the Drive.

Physical Installation 1 - 13

Page 26

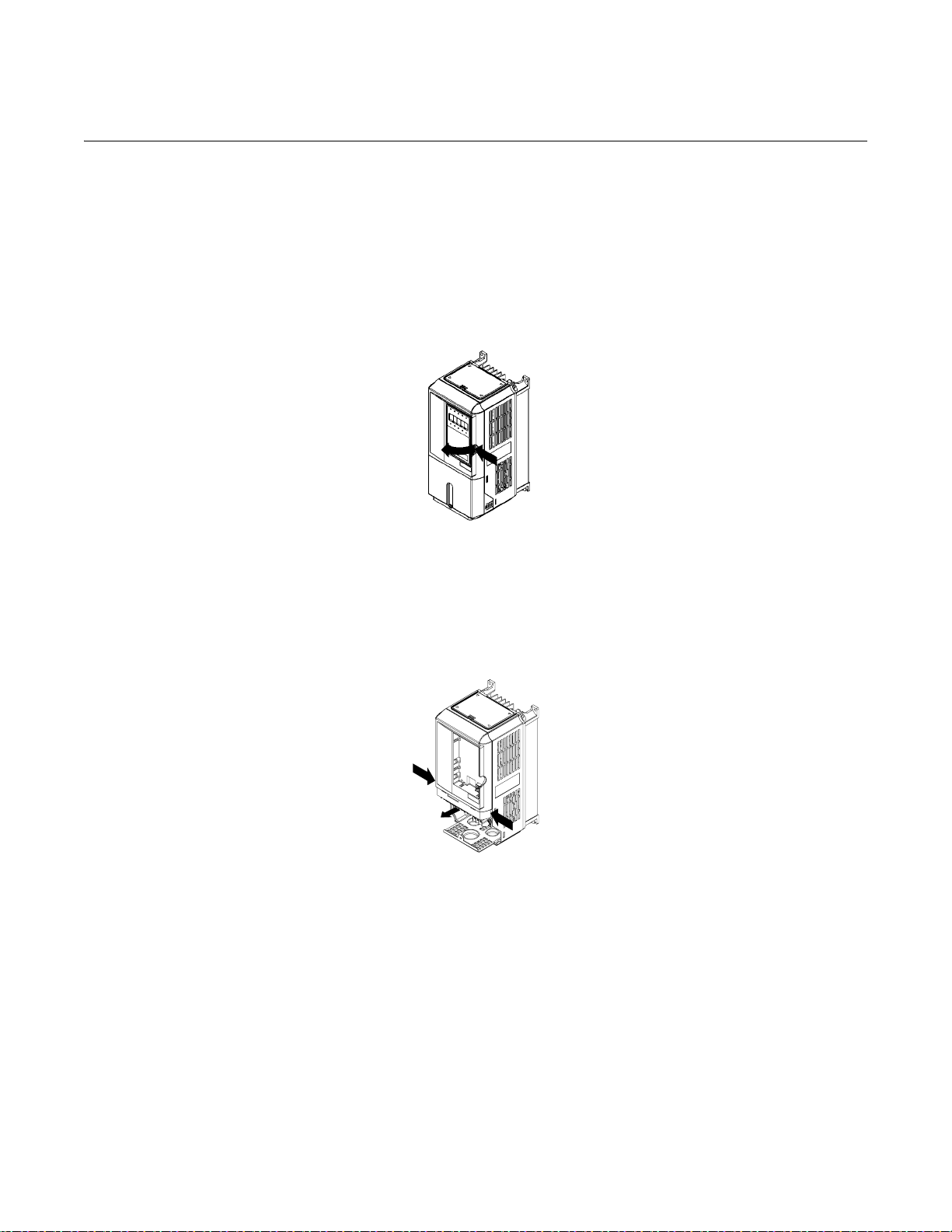

Removing/Attaching the Digital Operator and Front Cover

Models CIMR-F7U20P4 thru 2018 and 40P4 thru 4018

For Models CIMR-F7U2018/4018 and smaller, remove the terminal cover and then use the following procedures to remove

the Digital Operator and front cover.

Removing the Digital Operator

Press on the side of the Digital Operator in the direction of arrow 1 to unlock, then li ft the Digital Operato r in the direction of

arrow 2 to remove it as shown in Fig 1.11.

2

Fig 1.11 Removing the Digital Operator

1

Removing the Front Cover

Press the left and right s ides of th e fr ont co ver in t he di recti on of arrows 1 and lift the bottom of cover in t he d irect ion o f ar row

2 to remove it as shown in Fig 1.12.

1

2

Fig 1.12 Removing the Front Cover

1

Mounting the Front Cover

Mount the front cover to the Drive by performing the steps to remove the front cover in reverse order.

1.Do not mount the front cover with the Digital Operator attached as this may cause the Digital Operator to malfunction due to

improper mating with its connector.

2.Insert the tab of the upper part of the front cover into the groove of the Drive and press the lower part of the front cover onto

the Drive until it snaps into place.

Physical Installation 1 - 14

Page 27

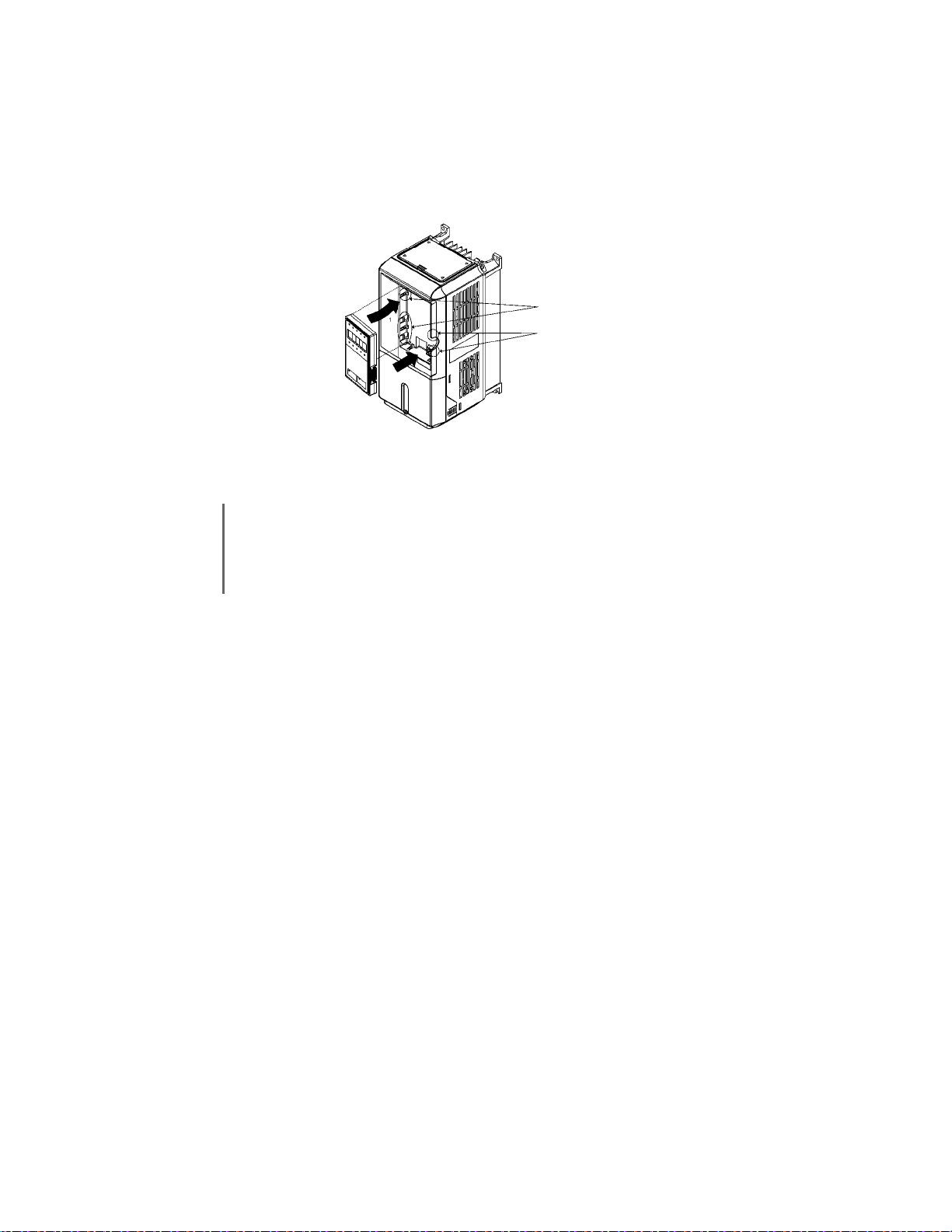

Mounting the Digital Operator

After attaching the front cover, mount the Digital Operator onto the Drive using the following procedure:

1.Hook the Dig ital Operator at A (two locations) on the left side of the opening on the front cover by moving in the direction

of arrow 1 as shown in the following illustration.

2.Press the Digital Operator in the direction of arrow 2 until it snaps in place at B (two locations).

A

IMPORTANT

1

2

Fig 1.13 Mounting the Digital Operator

1. Do not remove or attach the Digital Operator and do not mount or remove the front cover using methods

other than those described above, or damage to the Digital Operator or Drive may occur.

2. Never attach the front cover to the Drive with the Digital Operator already attached. Damage to the Digital

Operator may occur. Always attach the front cover to the Drive first, and then attach the Digital Operator

to the front cover.

B

Physical Installation 1 - 15

Page 28

Models CIMR-F7U2022 thru 2110 and 4030 thru 4300

For Models CIMR-F7U2022/4030 and larger, remove the terminal cover and then use the following procedures to remove the

Digital Operator and front cover.

Removing the Digital Operator

Use the same procedure for Models CIMR-F7U20P4 thru 2018 and 40P4 thru 4018.

Removing the Front Cover

Loosen all screws on the front cover. Lift up at the location labelled 1 at the top of the control circui t termin al card an d move

in the direction of arrow 2.

2

1

Fig 1.14 Removing the Front Cover

Mounting the Front Cover

Attach the front cover by reversing the procedure to remove it.

1. Confirm that the Digital Operator is not mounted o n the front cover. If the cover is attached while the Digital Operator is

mounted to it, the Digital Operator may malfunction due to improper mating with its connector.

2. Insert the tab on the top of the front cover into the slot on the Drive and press in on the cover until it clicks into place on the

Drive.

Mounting the Digital Operator

Use the same procedure for Models CIMR-F7U20P4 thru 2018 and 40P4 thru 4018.

Physical Installation 1 - 16

Page 29

Chapter 2

Electrical Installation

This chapter describes wiring terminals, main circuit terminal connections, main

circuit terminal wiring specifications, control circuit terminals, and control circuit

wiring specifications.

Terminal Block Configuration .............................................2-2

Wiring Main Circuit Terminals............................................ 2-3

Control Wiring ................................................................. 2-20

Electromagnetic Compatibility (EMC)...............................2-26

Installing and Wiring Option Boards .................................2-30

Electrical Installation 2 - 1

Page 30

Terminal Block Configuration

The wiring terminals are shown in Fig 2.1, Fig 2.2 and Fig 2.3.

Control circuit terminal layout label

Control circuit terminals

See Fig. 2.3 below for

actual terminal layout

Ground terminal

Control circuit terminal

layout label

Control circuit terminals

See Fig. 2.3 below for

actual terminal layout

Ground terminal

Main circuit terminals

Charge indicator

Ground terminal

Fig 2.1 Terminal Configuration for Models CIMR-F7U2018/4018 and smaller

Charge indicator

E(G)

Main circuit terminals

Ground terminal

Ground terminal

Fig 2.2 Terminal Configuration for Models CIMR-F7U2022/4022 and larger

SN SC SP A1 A2 +V AC -V A3 MP AC RP R+ R- MCM5 M6 MA MB

S1 S2 S3 S4 S5 S6 S7 S8 FM AC AM IG S+ S- M2M3 M4 M1

Fig 2.3 Control Circuit Terminal Layout

Electrical Installation 2 - 2

E(G)

Page 31

Wiring Main Circuit Terminals

Applicable Wire Sizes and Closed-loop Connectors

Select the appropriate wires and crimp terminals from Table 2.1 and Table 2.2. Refer to instruction manual TOE-C726-2 for

Braking Resistor Unit and Braking Unit wire sizes.

Table 2.1 208-240Vac Wire Sizes and Connector Specifications

Drive Model

CIMR-F7U

20P4

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3 M4

Te rm i na l

Screws

Clamping

To rq u e

lb. in.

(N•m)

10.6 to 13.2

(1.2 to 1.5)

Possible Wire

Sizes AWG

(mm

*1

14 to 10

(2 to 5.5)

2

)

Recommended

Wire Size AWG

2

)

(mm

*2

14

(2)

Wire

Type

20P7

21P5

22P2

23P7

25P5

27P5

2011

2015

2018

2022

2030

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, 2, B1, B2

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L31

U/T1, V/T2, W/T3

U/T1, V/T2, W/T3 M4

U/T1, V/T2, W/T3

U/T1, V/T2, W/T3

U/T1, V/T2, W/T3 M4

U/T1, V/T2, W/T3

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2

U/T1, V/T2, W/T3

B1, B2 M5

R/L1, S/L2, T/L3, , 1, 2

U/T1, V/T2, W/T3

B1, B2 M5

U/T1, V/T2, W/T3,

3

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R 1 /L11, S1/L21, T1/L31

3

M4

M4

M4

M5

M5

M6

M6

M8

M6

M8

M6

M8

M8

M6

M8

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

21.99

(2.5)

21.99

(2.5)

35.2 to 43.99

(4.0 to 5.0)

21.99

(2.5)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

21.99

(2.5)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

79.2 to 87.97

(9.0 to 10.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

14 to 10

(2 to 5.5)

14 to 10

(2 to 5.5)

14 to 10

(2 to 5.5)

12 to 10

(3.5 to 5.5)

12 to 10

(3.5 to 5.5)

8 to 6

(8 to 14)

6 to 4

(14 to 22)

4 to 2

(22 to 38)

8 to 6

(8 to 14)

4

(22)

3 to 2

(30 to 38)

8 to 6

(8 to 14)

4

(22)

N/A

N/A

N/A

N/A

N/A

N/A

14

(2)

14

(2)

14

(2)

12

(3.5)

10

(5.5)

8

(8)

4

(22)

6

(14)

3

(30)

4

(22)

Application

Dependent

4

(22)

2

(38)

3

(30)

Application

Dependent

4

(22)

1

(50)

2

(38)

Application

Dependent

4

(22)

1/0

(60)

Application

Dependent

4

(22)

600Vac

UL Approved

vinyl-sheathed

or equivalent

Electrical Installation 2 - 3

Page 32

Table 2.1 208-240Vac Wire Sizes and Connector Specifications (Continued)

Drive Model

CIMR-F7U

2037

2045

2055

2075

2090

2110

Terminal Symbol

R/L1, S/L2, T/L3, , 1 U/T1,

V/T2, W/T3, R1 / L11, S1/L21, T1/L31

3

r/

l1, s/l2

R/L1, S/L2, T/L3, , 1, R1/L11 , S1 /L21, T1/L31

U/T1, V/T2, W/T3

3

r/

l1, s/l2

R/L1, S/L2, T/L3, , 1, U/T1, V/T2, W/T3,

R/L1, S/L2, T/L3, , 1, R1/L11 , S1 /L21, T1/L31

R/L1, S/L2, T/L3, , 1, R1/L11 , S1 /L21, T1/L31

R1/L11, S1/L21, T1/L31

3

r/

l1, s/l2

R/L1, S/L2, T/L3, R1/L11, S1/L21, T1 /L31

U/T1, V/T2, W/T3 N/A

, 1

3

r/

l1, s/l2

U/T1, V/T2, W/T3 N/A

3

r/

l1, s/l2

U/T1, V/T2, W/T3 N/A

3

r/

l1, s/l2

Te rm i na l

Screws

M10

M8

M10

M4

M10

M8

M10

M4

M10

M8

M10

M4

M10

M12

M8

M12

M4

M12

M8

M12

M4

M12

M8

M12

M4

Clamping

To rq u e

lb. in.

(N•m)

154.8 to 197.9

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

154.8 to 197.9

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.9

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

154.8 to 197.9

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.9

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

154.8 to 197.9

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.9

(17.6 to 22.5)

276.2 to 344.8

(31.4 to 39.2)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

276.2 to 344.8

(31.4 to 39.2)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

276.2 to 344.8

(31.4 to 39.2)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

Possible Wire

Sizes AWG

(mm

*1

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

*1 Wire size range provided for Drives using insulated screw-type terminal blocks. All other models require the use of UL listed connectors. Refer to Table 2.3.

*2 Recommended wire sizes are based on the normal duty (ND) current ratings and NEC Article 310 Table 310.16, 75 degree Celsius copper or equivalent.

When sizing wiring based on th e heavy duty (HD) current rating s, consul t NEC Article 430 and any other ap pli cable codes.

2

)

Recommended

Wire Size AWG

2

)

(mm

*2

4/0

(100)

Application

Dependent

2

(38)

16

(1.25)

300

(150)

250

(125)

Application

Dependent

1

(50)

16

(1.25)

1/0 X 2P

(60 X 2P)

Application

Dependent

1/0

(60)

16

(1.25)

4/0 X 2P

(100 X 2P)

3/0 X 2P

(80 X 2P)

3/0 X 2P

(80 X 2P)

Application

Dependent

3/0

(80)

16

(1.25)

250 X 2P

(125 X 2P)

4/0 X 2P

(100 X 2P)

Application

Dependent

2/0 X 2P

(70 X 2P)

16

(1.25)

350 X 2P

(200 X 2P)

300 X 2P

(150 X 2P)

Application

Dependent

300 X 2P

(150 X 2P)

16

(1.25)

Wire

Type

600V ac

UL Approved

vinyl-sheathed

or equivalent

Electrical Installation 2 - 4

Page 33

Drive Model

CIMR-F7U

40P4

Table 2.2 480Vac Wire Sizes and Connector Specifications

Ter m i n a l S y mb o l

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

Terminal

Screws

M4

Clamping

To rq u e

lb. in.

(N•m)

10.6 to 13.2

(1.2 to 1.5)

Possible Wire

Sizes AWG

2)

(mm

*

1

14 to 10

(2 to 5.5)

Recommended

Wire Size AWG

2

)

(mm

*2

14

(2)

Wire Type

40P7

41P5

42P2

43P7

44P0

45P5

47P5

4011

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2, B1, B2

U/T1, V/T2, W/T3

M4

M4

M4

M4

M4

M4

M5

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

10.6 to 13.2

(1.2 to 1.5)

15.6

(1.8)

21.99

(2.5)

14 to 10

(2 to 5.5)

14 to 10

(2 to 5.5)

14 to 10

(2 to 5.5)

14 to 10

(2 to 5.5)

12 to 10

(3.5 to 5.5)

14 to 10

(2 to 5.5)

10

(5.5)

12 to 10

(3.5 to 5.5)

10 to 6

(5.5 to 14)

14

(2)

14

(2)

14

(2)

12

(3.5)

14

(2)

12

(3.5)

14

(2)

10

(5.5)

12

(3.5)

8

(8)

10

(5.5)

600Vac

UL Approved

vinyl-sheathed

or equivalent

4015

4018

4022

R/L1, S/L2, T/L3, , 1, 2,B1, B2

U/T1, V/T2, W/T3

R/L1, S/L2, T/L3, , 1, 2

U/T1, V/T2, W/T3

B1, B2 M5

R/L1, S/L2, T/L3, , 1, 3, R1/L11, S1/L21,

T1/L31

U/T1, V/T2, W/T3

Electrical Installation 2 - 5

M5

M5 21.99

M6

M6

M6

M6

M8

21.99

(2.5)

(2.5)

35.2 to 43.99

(4.0 to 5.0)

35.2 to 43.99

(4.0 to 5.0)

21.99

(2.5)

35.2 to 43.99

(4.0 to 5.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

8 to 6

(8 to 14)

10 to 6

(5.5 to 14)

8 to 2

(8 to 38)

8

(8)

8 to 4

(8 to 22)

N/A

N/A

8

(8)

10

(5.5)

6

(14)

8

(8)

8

(8)

8

(8)

4

(22)

6

(14)

6

(14)

Page 34

Drive Model

CIMR-F7U

4030

4037

4045

4055

4075

4090

4110

Table 2.2 480Vac Wire Sizes and Connector Specifications (Continued)

Terminal Symbol

R/L1, S/L2, T/L3, , 1, 3, R1/L11, S1/L21,

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, U/T1, V/T2,

W/T3, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L31

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L33

T1/L31

U/T1, V/T2, W/T3

U/T1, V/T2, W/T3

3

U/T1, V/T2, W/T3

3

3

U/T1, V/T2, W/T3 N/A

3

r/

l1, s200/l

200, s400/l2400 M4

2

U/T1, V/T2, W/T3 N/A

3

r/

l1, s200/l

200, s400/l2400 M4

2

U/T1, V/T2, W/T3 N/A

3

r/

l1, s200/l

200, s400/l2400 M4

2

Te rm i na l

Screws

M6

M8

M8

M6

M8

M8

M6

M8

M8

M6

M8

M10

M8

M10

M10

M8

M10

M10

M8

M12

Clamping

To rq u e

lb. in.

(N•m)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

79.2 to 87.97

(9.0 to 10.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

79.2 to 87.97

(9.0 to 10.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

79.2 to 87.97

(9.0 to 10.0)

35.2 to 43.99

(4.0 to 5.0)

79.2 to 87.97

(9.0 to 10.0)

154.8 to 197.5

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.5

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

154.8 to 197.5

(17.6 to 22.5)

11.4 to 12.3

(1.3 to 1.4)

154.8 to 197.5

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

Possible Wire

Sizes AWG

2)

(mm

*

1

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

Recommended

Wire Size AWG

2

)

(mm

*2

3

(30)

4

(22)

4

(22)

2

(38)

3

(30)

Application

Dependent

4

(22)

1/0

(60)

1

(50)

Application

Dependent

4

(22)

2/0

(70)

Application

Dependent

4

(22)

4/0

(100)

3/0

(80)

Application

Dependent

2

(38)

16

(1.25)

250

(125)

4/0

(100)

Application

Dependent

1

(50)

16

(1.25)

2/0 × 2P

(70 × 2P)

1/0 × 2P

(60 × 2P)

Application

Dependent

2/0

(70)

16

(1.25)

Wire Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

Electrical Installation 2 - 6

Page 35

Table 2.2 480Vac Wire Sizes and Connector Specifications (Continued)

Drive Model

CIMR-F7U

4132

4160

4185

4220

4300

Terminal Symbol

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L33

U/T1, V/T2, W/T3 N/A

3

r/

l1, s200/l

200, s400/l2400 M4

2

R/L1, S/L2, T/L3, , 1, R1/L11, S1/L21, T1/L33

U/T1, V/T2, W/T3 N/A

3

r/

l1, s200/l

200, s400/l2400 M4

2

U/T1, V/T2, W/T3, R1/L11, S1/L21, T1/L33

R/L1, S/L2, T/L3 , R1/L11, S1/L21, T1/L 33

R/L1, S/L2, T/L3 , R1/L11, S1/L21, T1/L 33

R/L1, S/L2, T/L3,

, 1

3

r/

l1, s200/l

200, s400/l2400 M4

2

U/T1, V/T2, W/T3 N/A

, 1

3

r/

l1, s200/l

200, s400/l2400 M4

2

U/T1, V/T2, W/T3 N/A

, 1

3

r/

l1, s200/l

200, s400/l2400 M4

2

Te rm i na l

Screws

M10

M8

M12

M12

M8

M12

M16

M16

M16

Clamping

To rq u e

lb. in.

(N•m)

154.8 to 197.5

(17.6 to 22.5)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

276.2 to 344.8

(31.4 to 39.2)

77.4 to 95.0

(8.8 to 10.8)

276.2 to 344.8

(31.4 to 39.2)

11.4 to 12.3

(1.3 to 1.4)

693.9 to 867.4

(78.4 to 98.0)

11.4 to 12.3

(1.3 to 1.4)

693.9 to 867.4

(78.4 to 98.0)

11.4 to 12.3

(1.3 to 1.4)

693.9 to 867.4

(78.4 to 98.0)

11.4 to 12.3

(1.3 to 1.4)

Possible Wire

Sizes AWG

(mm

*

1

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

N/A

*1 Wire size range provided for Drives using insulated screw-type terminal blocks. All other models require the use of UL listed connectors. Refer to Table 2.3.

*2 Recomm ended wire sizes are based on the norm a l dut y (N D) current ratings and NEC Arti cl e 310 Table 310.16, 75 Degree Celsius copper or

equivalent. When sizing w iring based on the heavy duty (HD) current ratings, consult NEC Articl e 430 and any other applicable codes.

2)

Recommended

Wire Size AWG

2

)

(mm

*2

3/0 × 2P

(80 × 2P)

2/0 × 2P

(70 × 2P)

Application

Dependent

4/0

(100)

16

(1.25)

4/0 × 2P

(100 × 2P)

3/0 × 2P

(80 × 2P)

Application

Dependent

1/0 × 2P

(60 × 2P)

16

(1.25)

300 x 2P

(150 x 2P)

600 X 2P

(325 X 2P)

Application

Dependent

3/0 x 2P

(80 x 2P)

16

(1.25)

500 x 2P

(325 x 2P)

400 x 2P

(200 x 2P)

250 X 4P

(125 X 4P)

Application

Dependent

250 x 2P

(125 x 2P)

16

(1.25)

250 x 4P

(125 x 4P)

4/0 x 4P

(100 x 4P)

400 X 4P

(200 X 4P)

Application

Dependent

400 x 2P

(203 x 2P)

16

(1.25)

Wire Type

600Vac

UL Approved

vinyl-sheathed

or equivalent

IMPORTANT

Determine the wire size for the main circuit so that line voltage drop is within 2% of the rated voltage. Line

voltage drop is calculated as follows:

Line voltage drop (V) =

x wire resistance (Ω/km) x wire length (m) x current (A) x 10

3

-3

Electrical Installation 2 - 7

Page 36

The use of UL listed closed-loop connectors or CSA certified ring connectors sized for the selected wire gauge is recommended to maintain

proper clearances when wiring the Drive. Install connectors per manufacturer recommendation using the correct crimp tool. Table 2.3 lists a

suitable closed-loop connector manufactured by JST Corporation.

Table 2.3 Recommended Connectors for Terminal Connections

Wire Size *

AWG mm

20 0.5

18 0.75

16 1.25

14 2

12 / 10 3.5 / 5.5

88

614

422

3 / 2 30 / 38

1 / 1/0 50 / 60

2/0 70

3/0 80

4/0 100

250 / 300MCM 125 / 150

400MCM 200 M12 200 - 12

650MCM 325

2

Terminal Screw

M3.5 1.25 - 3.7

M4 1.25 - 4

M3.5 1.25 - 3.7

M4 1.25 - 4

M3.5 1.25 - 3.7

M4 1.25 - 4

M3.5 2 - 3.7

M4 2 - 4

M5 2 - 5

M6 2 - 6

M8 2 - 8

M4 5.5 - 4

M5 5.5 - 5

M6 5.5 - 6

M8 5.5 - 8

M5 8 - 5

M6 8 - 6

M8 8 - 8

M5 14 - 5

M6 14 - 6

M8 14 - 8

M5 22 - 5

M6 22 - 6

M8 22 - 8

M6 38 - 6

M8 38 - 8

M8 60 - 8

M10 60 - 10

M8 70 - 8

M10 70 - 10

M10 80 - 10

M16 80 - 16

M10 100 - 10

M12 100 - 12

M16 100 - 16

M10 150 - 10

M12 150 - 12

M16 150 - 16

M12 x 2 325 - 12

M16 325 - 16

* Wire sizes are based on 75 degrees Celsius copper wire.

** Equivalent conne ct or can be used.

Ring Tongue (R-Type) Closed-Loop Connectors (Lugs)

JST Corporation Part Numbers **

Electrical Installation 2 - 8

Page 37

Main Circuit Terminal Functions

Main circuit terminal functions are summarized according to terminal symbols in Table 2.4. Wire the terminals correctly for

the desired purpose.

Table 2.4 Main Circuit Terminal Functions (208-240Vac and 480Vac)

Purpose Terminal Designation

Main circuit power input

Drive outputs U/T1, V/T2, W/T3 20P4 to 2110 40P4 to 4300

DC power input

Braking Resistor

Unit Connection

Braking Transist o r

Unit Connection

DC link choke connection

Ground 20P4 to 2110 40P4 to 4300

R/L1, S/L2, T/L3 20P4 to 2110 40P4 to 4300

R1/L11, S1/L21, T1/L31 2022 to 2110 4030 to 4300

1,

B1, B2 20P4 to 2018 40P4 to 4018

3,

1, 2

Model: CIMR-F7UFFFF

208-240Vac 480Vac

20P4 to 2110 40P4 to 4300

2022 to 2110 4022 to 4300

20P4 to 2018 40P4 to 4018

Main Circuit Configurations 208-240Vac

The 208-240Vac main circuit configurations of the Drive are shown in Table 2.5.

Table 2.5 Drive Main Circuit Configurations

208-240Vac

CIMR-F7U20P4 to 2018

CIMR-F7U2022 and 2030

* 1

{

*1, 2

{

Power

supply

Control

circuits

Control

circuits

-

Power

supply

Power

supply

CIMR-F7U2037 to 2110

*1, 2

{

*1 Input fuses or molded case circui t breakers are required for proper bra nch circuit protection for all Dri ve s . Fail ure to use

recommended fuses/ci rcuit breakers (See Appendix E) may result in damage to the Drive and/or personal injury.

*2 Consult your Y a skawa representative before using 12-pulse rectification circuit configuration.

Control

circuits

Electrical Installation 2 - 9

Page 38

Main Circuit Configurations 480Vac

The 480Vac main circuit configurations of the Drive are shown in Table 2.6.

Table 2.6 Drive Main Circuit Configurations

480Vac

*1

*1, 2

CIMR-F7U40P4 to 4018

{

Power

supply

CIMR-F7U4075 to 4300

3

{

Power

supply

Control

circuits

Control

circuits

*1, 2

CIMR-F7U4022 to 4055

{

-

Power

supply

Control

circuits

*1 Input fuses or molded case circuit breakers are required for proper branch circuit protection for all Drives. Failure to use recommended fuses/ci r cuit

breakers (See Appendix E ) ma y result in damage to the Drive and/ or pe rsonal injury.

*2 Consult your Yaskawa representative before using 12-pulse rectification circuit configuration.

Electrical Installation 2 - 10

Page 39

Cable Length between Drive and Motor

If the cable between the Drive and the motor is long, the high-frequency leakage current will increase, causing the Drive

output current to increase as well. This may affect peripheral devices. To prevent this, reduce cable length, or if necessary,

adjust the carrier frequency (set in parameter C6-02) as shown in Table 2.7.

Table 2.7 Motor Cable Length vs. Carrier Frequency

Motor Cable Length 164 ft. (50m) maximum 328 ft. (100m) maximum More than 328 ft.(100m)

Carrier Frequency 15kHz maximum 10kHz maximum 5kHz maximum

Ground Wiring

Observe the following precautions when connecting the ground wire:

1. 208-240Vac Drives should have a ground connection with resistance of less than 100Ω

2. 480Vac Drives should have a ground connection with resistance of less than 10Ω

3. Do not share the ground wire with other devices, such as welding machines or large-current electrical equipment.

4. Always use a ground wire that complies with technical standards on electrical equipment and minimize the length of the

ground wire. Leakage current flows through the Drive. Therefore, if the distance between the ground rod and the ground

terminal is too long, potential on the ground terminal of the Drive could develop.

5. When using more than one Drive, be careful not to loop the ground wire. See Fig 2.4.

.

.

OK

NOT OK

Fig 2.4 Ground Wiring Examples

Electrical Installation 2 - 11

Page 40

Dynamic Braking Connections

General

Dynamic braking (DB) enables the motor to be brought to a smooth and rapid stop. This is achieved by dissipating the

regenerative energy of the AC motor across the resistive components of the Dynamic Braking option. For further details on

dynamic braking operation, see the instruction sheet shipped with dynamic braking components.

Drives F7U20P4 thru F7U2018 and F7U40P4 thru F7U4018 have an integral braking transistor and require the addition of a

Remote Mounted Resistor Unit or a Heat Sink Mount Resistor (ERF). All higher rated Drives require the use of a Braking

Transist or Uni t (CDB R) and a Remot e Mount Resi stor Unit.

Remote Mount Resistor U n its typ ic a lly mou nt outside of the electrical enclosure. Braking Transistor Units mou nt i ns ide of t he

electrical enclosure. Heat Sink Mount Resistors mount to the back of the Drive, attaching directly to the heat sink.

Table 2.8 Heat Sink Mount Dynamic Braking Resistor - 3% Duty Cycle

Drive Heat Sink Mount Resistor

Rated

Input

Vac

Approx.

Drive Model

No. F7U

20P4 R7505 1 200 150 220 7.16 1.73 0.51

Part No.

Qty.

Reqd.

Resistance

(Ohms)

Power

(Watts)

Braking

Torque

(%)

Dimensions (Inches)

Height Width Depth

20P7 R7505 1 200 150 125 7.16 1.73 0.51

208-240

480

21P5 R7504 1 100 150 125 7.16 1.73 0.51

22P2 R7503 1 70 150 120 7.16 1.73 0.51

23P7 R7510 1 62 150 100 7.16 1.73 0.51

40P4 R7508 1 750 150 230 7.16 1.73 0.51

40P7 R7508 1 750 150 130 7.16 1.73 0.51

41P5 R7507 1 400 150 125 7.16 1.73 0.51

42P2 R7506 1 300 150 115 7.16 1.73 0.51

43P7 R7505 1 200 150 110 7.16 1.73 0.51

Installation

This option should only be in stalled by a technically qu alified ind ividual who i s familiar with this typ e of equipmen t and the

hazards involved.

WARNING

Hazardous voltages can cause severe injury or death. Lock all power sources feeding the Drive in the “OFF” position.

Failure to follow these installation steps may cause equipment damage or personal injury.

Preliminary Procedures

1. Disconnect all electrical power to the Drive.

2. Remove Drive front cover.

3. Use a voltmeter to verify that voltage is disconnected from incoming power terminals and that the DC bus has dissipated.

Electrical Installation 2 - 12

Page 41

Heat Sink Mount Resistor Installation

1. Remove the Drive from its mounting for access to the rear of the heat sink.

2. Attach the Heat Sink Mount Resistor on the back of the Drive’s heat sink with screws M4 x 10mm (0.7mm pitch), as shown

in figure below.

3. Remove the rubber plug and run the braking resistor wires into the h ole that leads to the terminal block.

4. Reinstall the Drive in its mountin g p os ition.

5. Connect the leads from the Heat Sink Mount Resistor to the Drive terminals B1 and B2.

6. Proceed to “Adjustments” section on page 2-18.

Fig 2.5 Attaching Heat Sink Mount Resistor on Heat Sink

Electrical Installation 2 - 13

Page 42

Remote Mount Resistor Unit Installation Using Internal Braking Transistor

‡

(for F7U20P4 thru F7U2018 and F7U40P4 thru F7U4018)

Since the Remote Mount Resistor Unit generates heat during dynamic brakin g operation, install it in a location away from

other equipment.

1.Install the Remote Mount Resistor Unit to a noncomb ustible surface, maintaining a minimum 1. 97 inches (5 0mm) clearan ce

on each side and a minimum 7.87 inches (200mm) clearance on top.

2.Remove the Remote Mount Resistor Unit cover to access its terminal block. Connect the Remote Mount Resistor Unit to the

Drive and to external control circuitry according to Fig 2.6 below.

Table 2.9 Wire Size for Remote Mount Resistor Unit

Terminals B, P, R1, R2 1, 2*

Wire Size (AWG) 12-10 18-14*

Wire Type 600V Ethylene pro pylene rubber insulated, or equivalent

Terminal Screw M4

* Power Leads for the Remote Mount Resistor Unit generate high levels of electrical noise - these sign al leads must be grouped separately.

120 VAC

S3

SN

IM

3% DUTY CYCLE

RESISTOR ASSEMBLY

(R2)*

(R1)*

* Terminal markings in parentheses

are for resistors manufactured by

Powerohm Resistors Inc.

‡

Applies when SC is jumpered to SP

and S3 is programmed as External

Fault.

Fig 2.6 Wiring Remote Mount Resistor Unit (for F7U20P4 thru F7U2018 and F7U40P4 thru F7U4018)

3. Reinstall and secure Remote Mount Resistor Unit cover and Drive front cover.

4. Proceed to “Adjustments” section on Page 2-18.

Electrical Installation 2 - 14

Page 43

Braking Transistor Unit(s) and Remote Mount Resistor Unit(s) Installation (for F7U2022 thru F7U2110 and

F7U4022 thru F7U4300)

Since the Remote Mount Resis t or Un it g e nerate s heat du ri ng dyn amic br aki ng oper a tio n, ins tal l it t o a non comb us tib le surface

in a location away from other equipment.

Select mounting locations for Braking Transistor Unit(s) and Remote Mount Resistor Unit(s) so that wiring between the Drive

and the Braking Trans istor Unit is 16 feet (5m ) or les s, and the wiring between each Braking Transistor Unit and its associated

Remote Mount Resistor Unit, is less than 33 feet (10m).

1. Mount the Braking Transistor Unit(s) on a vertical surface. Th e Braking Transistor Unit requires a minimum of 1.18 inches

(30mm) clearance on each side and a minimum 3.94 inches (100mm) clearance top and bottom. Attach the Remote Mount

Resistor Unit maintaining a minimum 1.97 inches (50mm) clearance on each side and a minimum 7.87 inches (200mm)

clearance on top.

2. In each Braking Transistor Unit, set the nominal line voltage jumper plug to the correct setting for the installation; this is

factory set at the 220V/440V/575V position. To access jumper plugs, remove the plastic cover.

WARNING

• Be sure to set the nominal line voltage selection jumper to match the level of the AC supply being applied to the Drive.

• Failure to do so may result in improper operation.

3. If multiple Braking Transistor Units are being installed, the unit closest to the Drive s hould have the Slave/M aster jumper

plug set to the “Master” position (factory setting); all others must have this jumper plug set to the “Slave” position.

4. If a single Braking Transistor Unit and Remote Mount Resistor Unit are being installed, connect them to the Drive and

external control circuitry according to the chart and figure below.

5. Power leads for the Remote Mount Resistor Unit generate high levels of electrical noise - these power leads must be

grouped separately from all other leads.

Table 2.10 Wire Size for Remote Mount Resistor Unit and Braking Transistor Unit

Name Circuit Terminals

Braking Transistor Unit

(Models CDBR-2015B,

-2022B, -4030B, -4045B)

Braking Transistor Unit

(Model CDBR-2 045, -4090)

Braking Transistor Unit

(Model CDB R -2110)

Braking Transistor Unit

(Model CDBR -4220)

Braking Resistor Unit

(Model LKEB-F )

*1 For wire size of 8-6 (8-14), use UL1283 heat-re sist ant vinyl-insulated wire or equivalent.

*2 M4 for Models LKEB-20P7 to -27P5 or -40P7 to -40 15.

M5 for Models LKEB-2011 to -2022 or -4018 to -4045.

Main

Control

Main P, Po, N, B 12-10 (3.5-5.5)

Control

Main

Control

Main

Control

Main B P 12-10 (3.5-5.5)

Control 1 2 18-14 (0.75-2) M4

0

0

1 2 3

4 5 6

1 2 3

4 5 6

P, Po, N, B

r s

1 2 3

4 5 6

P, Po, N, B

r s

1 2 3

4 5 6

Wire Size AWG (mm2)

12-10 (3.5-5.5)

18-14 (0.75-2)

18-14 (0.75-2) M4

4 (22)

8-6 (8-14) *1

12-10 (3.5-5.5)

18-14 (0.75-2)

4 (22)

8-6 (8-14) *1

12-10 (3.5-5.5)

18-14 (0.75-2)

Wire Type Terminal Screw

600V vinyl sheathed wire

or equivalent

600V vinyl sheathed wire

or equivalent

600V vinyl sheathed wire

or equivalent

600V vinyl sheathed wire

or equivalent

600V vinyl sheathed wire

or equivalent

M4

M4

M5