Operator’s Manual

PART NO. 769-00936 (1/04)

English

Straight Shaft

Electric Trimmer

Model

YM137

SAVE THESE INSTRUCTIONS DO NOT THROW AWAY

2

INTRODUCTION

Copy the serial number

here:

THANK YOU

Thank you for buying this quality product. This modern

outdoor power tool will provide many hours of useful

service. You will find it to be a great labor-saving device.

This operator’s manual provides you with easy-tounderstand operating instructions. Read the whole

manual and follow all the instructions to keep your new

outdoor power tool in top operating condition.

PRODUCT REFERENCES, ILLUSTRATIONS

AND SPECIFICATIONS

All information, illustrations, and specifications in this

manual are based on the latest product information

available at the time of printing. We reserve the right to

make changes at any time without notice.

Copyright© 2003 MTD SOUTHWEST INC, All Rights

Reserved.

SERVICE INFORMATION

Service on this unit both within and after the warranty

period should be performed only by an authorized and

approved service dealer.

For service call 1-800-345-8746, or 1-800-668-1238 in

Canada to obtain a list of authorized service dealers near

you. For more details about your unit, visit our website at

www.yardman.com.

If you have difficulty assembling this product or have any

questions regarding the controls, operation or maintenance of this unit, please call the Customer Support

Department.

DO NOT RETURN THE UNIT TO THE RETAILER.

PROOF OF PURCHASE WILL BE REQUIRED FOR

WARRANTY SERVICE.

Make sure you carefully read and understand this manual before starting or operating this equipment.

THIS PRODUCT IS COVERED BY ONE OR MORE U.S. PATENTS. OTHER PATENTS PENDING.

TABLE OF CONTENTS

Service Information . . . . . . . . . . . . . . . . . . . . . . . . .2

Rules for Safe Operation . . . . . . . . . . . . . . . . . . . . .3

Know Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Assembly Instructions . . . . . . . . . . . . . . . . . . . . . . .7

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . .8

Maintenance and Repair Instructions . . . . . . . . . . .11

Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . .14

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Warranty Information . . . . . . . . . . . . . . . . . . . . . . .18

Parts List . . . . . . . . . . . . . . . . . . . .Inside Back Cover

Copy the model and parent

part number here:

Before beginning, locate the unit’s model plate. It lists

the model and serial numbers of your unit. Refer to the

sample plate below and copy the information for future

reference.

MODEL :

S/N :

ITEM :

3

SYMBOL MEANING

The purpose of safety symbols is to attract your

attention to possible dangers. The safety symbols,

and their explanations, deserve your careful attention

and understanding. The safety warnings do not by

themselves eliminate any danger. The instructions or

warnings they give are not substitutes for proper

accident prevention measures.

NOTE: Advises you of information or instructions vital

to the operation or maintenance of the

equipment.

SYMBOL MEANING

READ ALL INSTRUCTIONS

BEFORE OPERATING

• Read the instructions carefully. Be familiar with the

controls and proper use of the unit.

• Do not operate this unit when tired, ill or under the

influence of alcohol, drugs or medication.

• Children and teens under the age of 15 must not use

the unit, except for teens guided by an adult.

• Inspect the unit before use. Replace damaged parts.

Make sure all fasteners are in place and secure.

Replace cutting attachment parts that are cracked,

chipped or damaged in any way. Make sure the cutting

attachment is properly installed and securely fastened.

Be sure that the cutting attachment shield is properly

attached, and positioned as recommended. Failure to

do so can result in personal injury to the operator and

bystanders, as well as damage to the unit.

• This unit was not designed to be used as a

brushcutter. Do not attach or operate this unit with any

type of brushcutting blade or brushcutting attachment.

• Use only a 0.080-inch (2.03 mm) diameter original

equipment manufacturer replacement line. Never use

metal-reinforced line, wire, chain or rope. These can

break off and become dangerous projectiles.

• Be aware of risk of injury to the head, hands and feet.

• Clear the area to be cut before each use. Remove

rocks, broken glass, nails, wire, string and other

objects which may be thrown or become entangled in

the cutting attachment. Clear the area of children,

bystanders and pets; keep them outside a 50-foot

(15 m.) radius, at a minimum. Even then, they are still

at risk from thrown objects. Encourage bystanders to

wear eye protection. If you are approached, stop the

unit immediately.

ELECTRICAL SAFETY WARNINGS

• Since the tool is double-insulated, a 2-wire extension

cord (an extension cord without a ground) may be

used. A 3-wire extension cord (an extension cord with

a ground) that uses a NEMA type connector (parallel

blade, U ground) is recommended. Extension cords

are available from your local retailer. Use only roundjacketed extension cords approved for outdoor use.

• This tool is double-insulated. Repair or replace damaged

cords.

RULES FOR SAFE OPERATION

When using the unit,

you must follow the

safety rules. Please read these instructions

before operating the unit in order to ensure

the safety of the operator and any bystanders.

Please keep these instructions for later use.

WARNING:

• IMPORTANT SAFETY INSTRUCTIONS •

Failure to obey a

safety warning can

result in injury to yourself and others.

Always follow the safety precautions to

reduce the risk of fire, electric shock and

personal injury.

WARNING:

Failure to obey a

safety warning will

result in serious injury to yourself or to

others. Always follow the safety precautions

to reduce the risk of fire, electric shock and

personal injury.

DANGER:

Failure to obey a

safety warning may

result in property damage or personal injury

to yourself or to others. Always follow the

safety precautions to reduce the risk of fire,

electric shock and personal injury.

CAUTION:

Indicates

danger,

warning or caution. Attention is required in

order to avoid serious personal injury. May

be used in conjunction with other symbols

or pictographs.

SAFETY ALERT:

When using electric

gardening appliances,

basic safety precautions should always be

followed to reduce the risk of fire, electric shock

and personal injury. Carefully read and

understand the entire operator's manual before

using your unit. Pay close attention to the

operating instructions and safety warnings.

DANGER:

To reduce the risk of

electrical shock, use

only SW-A, SOW-A, STW-A, STOW-A, SJW-A,

SJOW-A, SJTW-W or SJTOW-A cord types.

WARNING:

4

• To reduce the risk of electrical shock, this unit has a

polarized plug (one blade is wider than the other). This

unit will fit with a polarized plug in one way only. If the

plug does not fit fully into the unit, reverse the plug. If

it still does not fit, use a cord with the correct

connection. Do not modify the unit in any way.

*The wire size (AWG) for appliances using 12 to 16

amps is 14 AWG for 25 feet, 12 AWG for 50 feet, and

not recommended for 100 or 150 feet.

• CORD SETS: Make sure your cord set is in good

condition, with a cord that is heavy enough to carry

the current that your unit will draw. An undersized cord

set will cause a drop in line voltage resulting in a loss

of power, as well as overheating. The table shown

above illustrates the correct size to use depending on

the cord length and nameplate amperage rating. If in

doubt, use the next heavier size line gauge. The

smaller the gauge number, the heavier the cord. To

prevent the cord from disconnecting from the unit, use

the cord hook shown in the Operating Instructions.

• Ground Fault Circuit Interrupter (GFCI) protection

should be provided on the circuit(s) or outlet(s) that will

be used for the unit. Use receptacles with built-in

GFCI protection for an extra measure of safety.

• Do not abuse the power cord. Never carry the unit by

the cord or yank the cord to disconnect from receptacle.

Keep the cord from heat, oil and sharp edges.

• A nameplate on your unit indicates the voltage used.

Never connect the unit to an AC voltage that differs

from this voltage.

• Inspect all extension cords and the unit power connection

periodically. Look closely for deterioration, cuts or cracks

in the insulation. Also inspect the connections for damage.

Repair or replace the cords if any defects appear.

• Avoid dangerous environments. Never operate your unit

in damp or wet conditions. Moisture is a shock hazard.

• Do not use the unit in the rain.

• Do not handle the plug or the unit with wet hands.

WHILE OPERATING

• Wear safety glasses or goggles that are marked as

meeting ANSI Z87.1-1989 standards. Also wear

ear/hearing protection when operating this unit. Wear

a face or dust mask if the operation is dusty. Long

sleeve shirts are recommended.

• Wear heavy, long pants, boots and gloves. Do not

wear loose clothing, jewelry, short pants, sandals or

go barefoot. Secure hair above shoulder level.

• The cutting attachment shield must always be in place

while operating the unit. Do not operate unit without

both trimming lines extended, and the proper line

installed. Do not extend the trimming line beyond the

length of the shield.

• Adjust the D-handle to your size to provide the best

grip.

• Be sure the cutting attachment is not in contact with

anything before starting the unit.

• Use the unit only in daylight or good artificial light.

• Avoid accidental starting. Do not carry around a unit

that is plugged in with your finger on the trigger

switch. Be sure the switch is in the off position when

plugging in the unit.

• Use the right tool. Only use this tool for its intended

purpose.

• Do not overreach. Always keep proper footing and

balance.

• Always hold the unit with both hands when operating.

Keep a firm grip on both handles or grips.

• Keep hands, face, and feet at a distance from all

moving parts. Do not touch or try to stop the cutting

attachment when it rotates.

• Always stop the motor when cutting is delayed or

when walking from one cutting location to another.

• If you strike or become entangled with a foreign

object, stop the motor immediately and check for

damage. Do not operate before repairing damage. Do

not operate the unit with loose or damaged parts.

• Stop the unit and unplug it for maintenance or repair.

• Use only genuine original equipment manufacturer

replacement parts and accessories for this unit. These

are available from your authorized service dealer. Use

of any non-original parts or accessories could lead to

serious injury to the user, or damage to the unit, and

void your warranty.

• Keep unit clean of vegetation and other materials.

They may become lodged between the cutting

attachment and shield.

OTHER SAFETY WARNINGS

• Be sure to secure the unit while transporting.

• Store the unit in a dry area, locked up to prevent

unauthorized use or damage, and stored in a high

place out of the reach of children.

• Never douse or squirt the unit with water or any other

liquid. Keep handles dry, clean and free from debris.

Clean after each use. See the Cleaning and Storage

instructions.

• Keep these instructions. Refer to them often and use

them to instruct other users. If you loan someone this

unit, also loan them these instructions.

SAVE THESE INSTRUCTIONS

RULES FOR SAFE OPERATION

Cord length (ft.) 25 50 100 150

Wire size (AWG)* 16 16 16 14

MINIMUM WIRE SIZE FOR EXTENSION CORDS FOR

120 VOLT APPLIANCES USING 0-12 AMPS*

5

RULES FOR SAFE OPERATION

SYMBOL MEANING

• SAFETY ALERT SYMBOL

Indicates danger, warning, or

caution. May be used in conjunction

with other symbols or pictographs.

• WARNING - READ

OPERATOR'S MANUAL

Read the Operator’s Manual(s) and

follow all warnings and safety

instructions. Failure to do so can

result in serious injury to the

operator and/or bystanders.

• WEAR EYE AND HEARING

PROTECTION

WARNING:Thrown

objects and loud noise can cause

severe eye injury and hearing loss.

Wear eye protection meeting ANSI

Z87.1-1989 standards and ear

protection when operating this unit.

Use a full face shield when needed.

• THROWN OBJECTS AND

ROTATING CUTTER CAN

CAUSE SEVERE INJURY

WARNING:Keep clear

of blower outlet. Never point the

blower at yourself or others. Objects

can be thrown from blower. Do not

operate unit without proper

attachments and guards in place.

SAFETY AND INTERNATIONAL SYMBOLS

This operator's manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator's manual for complete safety, assembly, operating and maintenance and repair information.

SYMBOL MEANING

• DO NOT USE IN THE RAIN

WARNING:Avoid

dangerous environments. Never

operate your unit in the rain, or in

damp or wet conditions. Moisture is

a shock hazard.

• KEEP BYSTANDERS AWAY

WARNING:Keep all

bystanders, especially children and

pets, at least 50 feet (15 m.) from the

operating area.

• THROTTLE CONTROL

Indicates “HIGH” or “FASTEST” speed.

• THROTTLE CONTROL

Indicates “IDLE”, “LOW” or

“SLOWEST” speed.

• DOUBLE INSULATED

Two systems of insulation are

provided instead of grounding.

There is no grounding provided

and no means of grounding should

be added to this unit.

6

RULES FOR SAFE OPERATION

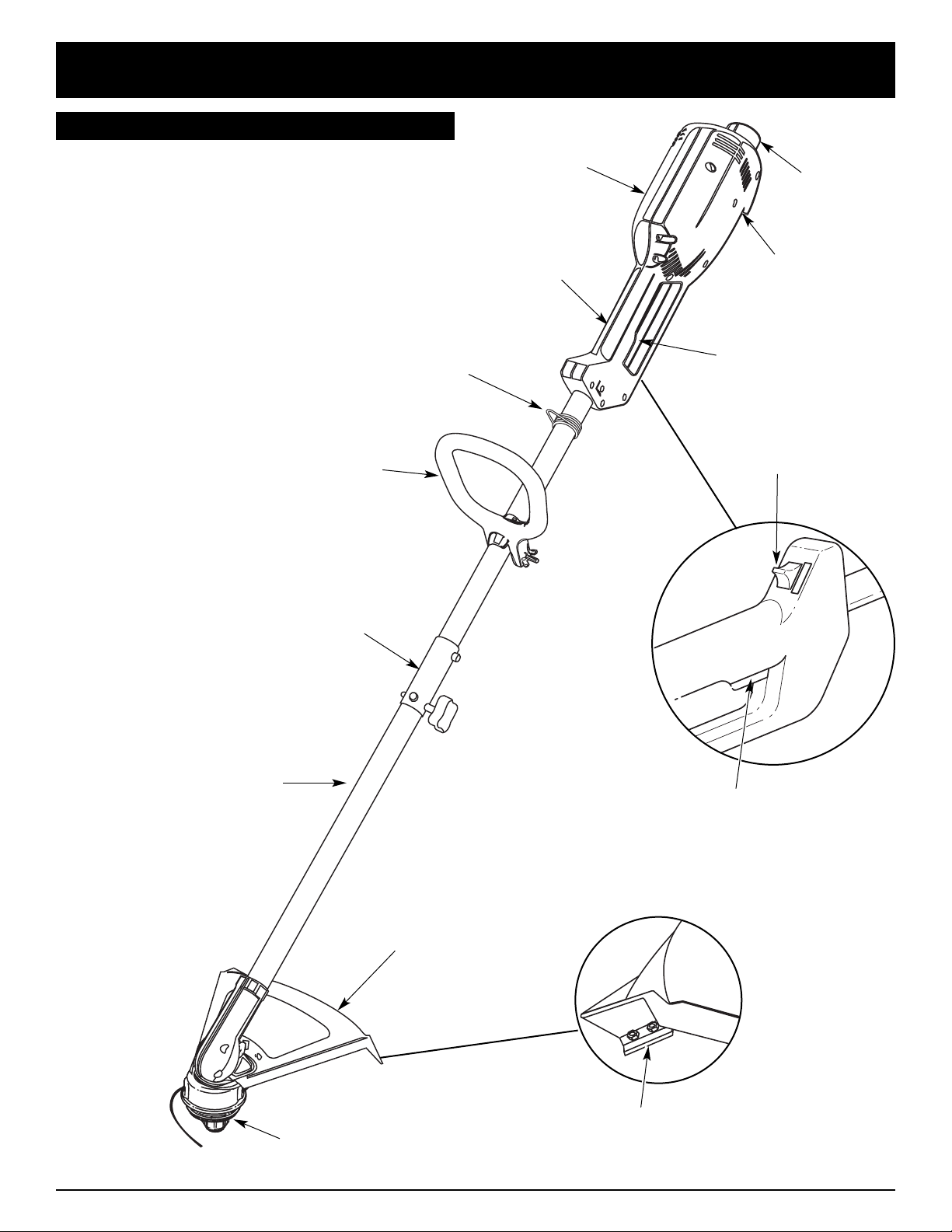

KNOW YOUR UNIT

As a trimmer:

• Cutting grass and light weeds

• Decorative trimming around trees, fences, etc.

Cutting Attachment

Shield

D-Handle

Cutting Attachment

Shaft Housing

Line Cutting Blade

Housing Grip

Switch Trigger

Recessed

Plug

Motor Housing

Switch Trigger

Two-Speed

Switch

EZ-Link™

Cord Hook

Shoulder

Harness

7

ASSEMBLY INSTRUCTIONS

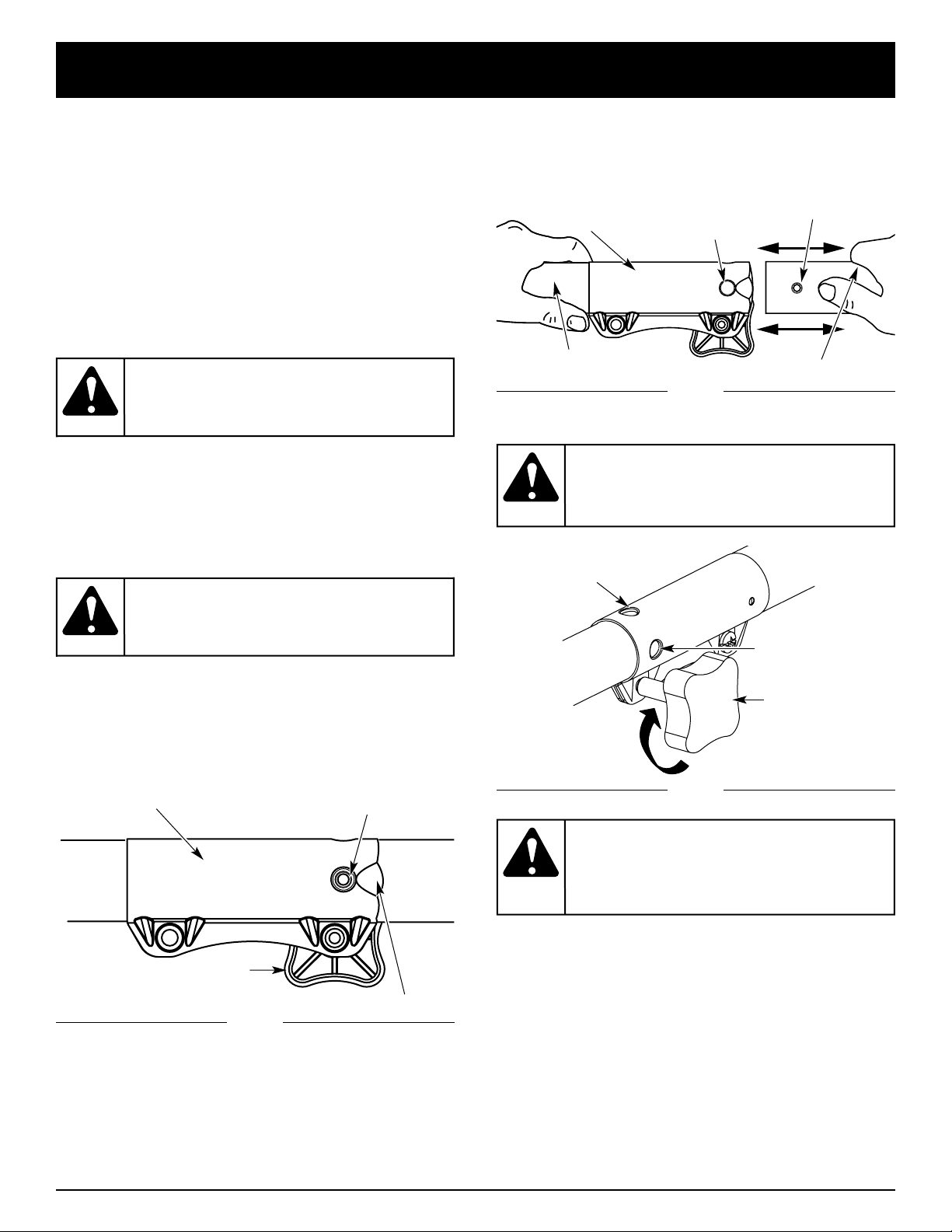

INSTALL THE CUTTING ATTACHMENT SHIELD

Use the following instructions if the cutting attachment

shield on your unit is not installed or if you ever need to

re-install it.

1. Slide the cutting attachment shield into the shield

mount on the cutting attachment. Align the screw

holes in the shield with the holes in the cutting

attachment (Fig. 3).

Fig. 3

Fig. 5

Fig. 4

Cutting Attachment

Shield

Screws

Shaft Housing

Hex Lock Nut

Cutting Attachment

Shield

Cutting Attachment

2. Place a hex lock nut into one of the three recessed

holes on the top of the cutting attachment shield (Fig 4).

3. Install a screw into the hole from the bottom of the

cutting attachment shield and screw it into the nut

installed in step 2 (Fig 5). Do not tighten.

4. Repeat steps 2 and 3 until all three screws have

been started, then tighten securely.

Recessed Holes

Shield Mount

Never operate the

trimmer without the

cutting attachment shield in place to

prevent serious personal injury.

WARNING:

On some units, the D-handle may be pre-installed. In this

case you must loosen screws and adjust the handle to fit

the operator. Go to step 4 if the D-handle is pre-installed.

INSTALL AND ADJUST THE D-HANDLE

1. Remove the items that were installed on the D-handle

for shipping.

2. Place the D-handle over the shaft housing and push

it on the boom (Fig. 1).

3, Install the bolt, washer and wing nut. Tighten them.

4. If the D-handle was pre-installed, loosen the wing nut

on it just enough so it is movable.

5. While holding the unit in the operating position,

arrange or rotate the D-handle to the location that

provides you the best grip (Fig. 2).

6. Tighten the wing nut until the D-handle is secure.

Fig. 1

Fig. 2

8

OPERATING INSTRUCTIONS

For decorative trimming/edging with the line head cutting

attachment, lock the release button of the cutting

attachment into the 90° hole or the 180° hole (Fig. 8).

For edging with the edger add-on, lock the release

button of the cutting attachment only into the 180°

trimming hole/ primary hole (Fig. 8).

OPERATING THE EZ-LINK™ SYSTEM

The EZ-Link™ system enables the use of these optional

Add-Ons:

Blower/Vacuum . . . . . . . . . . . . . . . . . . . . . . . . . . BV720r

Cultivator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GC720r

Edger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . LE720r

Snow Thrower . . . . . . . . . . . . . . . . . . . . . . . . . . . ST720r

Straight Shaft Trimmer . . . . . . . . . . . . . . . . . . . . SS725r

Tree Pruner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TP720r

Turbo Blower . . . . . . . . . . . . . . . . . . . . . . . . . . . . TB720r

Removing the Cutting Attachment or Add-Ons

1. Turn the knob counterclockwise to loosen (Fig. 6).

2. Press and hold the release button (Fig. 6).

3. While firmly holding the upper shaft housing, pull

the cutting attachment or add-on straight out of the

EZ-Link™ coupler (Fig. 7).

Installing the Cutting Attachment or Add-Ons

NOTE: To make installing or removing the add-on

easier, place the unit on the ground or on a work

bench.

1. Turn knob counterclockwise to loosen (Fig. 6).

Fig. 6

EZ-Link™ Coupler

Release Button

Guide Recess

Knob

Primary Hole

Upper Shaft Housing

90˚ Edge

Trimming Hole

EZ-Link™ Coupler

2. While firmly holding the add-on, push it straight into

the EZ-Link™ coupler (Fig. 7).

NOTE: Aligning the release button with the guide recess

will help installation (Fig. 6).

3. Turn the knob clockwise to tighten (Fig. 8).

Fig. 7

Fig. 8

Knob

180˚ Trimming Hole/

Primary Hole

Lower Shaft Housing

Release Button

Prior to operation,

read and understand

the operator’s manual for unit to be used with

this add-on.

WARNING:

To avoid serious

personal injury and

damage to the unit, shut the unit off before

removing or installing add-ons.

WARNING:

The add-ons with the

coupler system is to

be used in the primary hole only. Using the

wrong hole could lead to personal injury or

damage to the unit.

CAUTION:

Lock the release

button in the primary

hole (Fig. 10) and securely tighten the knob

before operating this unit.

CAUTION:

9

OPERATING INSTRUCTIONS

Always wear eye,

hearing, foot and

body protection to reduce the risk of injury

when operating this unit.

WARNING:

CONNECTING THE CORD

Use the cord hook when connecting the extension cord to

the power cord outlet. This helps prevent any

disconnection.

1. Make a narrow loop with the extension cord.

2. Push the loop through the opening and move it onto

the hook on the motor housing (Fig. 9).

3. Plug the cord properly into the socket.

Only use outdoor-approved extension cords. Cord sets

are specified in the Important Safety Information section.

STARTING/STOPPING INSTRUCTIONS

Once the unit is plugged in, stand in the operating

position (Fig. 11). Squeeze the trigger to start the unit. To

stop the unit, release the trigger (Fig. 10).

Trigger

HOLDING THE TRIMMER

Before operating the unit, stand in the operating position

(Fig. 11). Check for the following:

• The operator is wearing eye protection and proper

clothing

• With a slightly-bent right arm, the operator’s hand is

holding the shaft grip

• The operator’s left arm is straight, the left hand

holding the D-handle

• The unit is at waist level

•

The cutting attachment is parallel to the ground and

easily contacts the grass without the need to bend ove

r

• The extension cord is safely behind the operator

Fig. 11

ADJUSTING TRIMMING LINE LENGTH

The Bump Head™ cutting attachment allows you to

release trimming line without stopping the motor. To

release more line, lightly tap the cutting attachment on the

ground (Fig. 12) while operating the trimmer at high speed.

NOTE: Always keep the trimming line fully extended.

Line release becomes more difficult when the

cutting line gets shorter.

Always wear eye,

hearing, foot and

body protection to reduce the risk of injury

when operating this unit.

WARNING:

Fig. 9

TWO-SPEED SWITCH

This unit is equipped with a two-speed switch: a

powerful high speed for demanding yard work, and a

precision low speed for light-duty yard work.

Push the switch up for high speed trimming. Push the

switch down for low speed trimming (Fig. 10).

Fig. 10

10

OPERATING INSTRUCTIONS

TIPS FOR BEST TRIMMING RESULTS

• Keep the cutting attachment parallel to the ground.

• Do not force the cutting attachment. Allow the tip of

the line to do the cutting, especially along walls.

Cutting with more than the tip will reduce cutting

efficiency and may overload the motor.

• Cut grass over 8 inches (200 mm) by working from

top to bottom in small increments to avoid

premature line wear or motor drag.

Fig. 12

Each time the head is bumped, about 1 inch (25.4 mm)

of trimming line releases. A blade in the cutting

attachment shield will cut the line to the proper length if

any excess line is released.

For best results, tap the bump knob on bare ground or

hard soil. If you attempt a line release in tall grass, the

motor may stall. Always keep the trimming line fully

extended. Line release becomes more difficult when the

cutting line gets shorter.

NOTE: Do not rest the Bump Head™ on the ground

while the unit is running.

Some line breakage will occur from:

• Entanglement with foreign matter

• Normal line fatigue

• Attempting to cut thick, stalky weeds

• Forcing the line into objects such as walls or fence

posts

Do not remove or alter

the line cutting blade

assembly. Excessive line length will make the

clutch overheat. This may lead to serious

personal injury or damage to the unit.

CAUTION:

DECORATIVE TRIMMING

Decorative trimming is accomplished by removing all

vegetation around trees, posts, fences and more.

Rotate the whole unit so that the cutting attachment is at

a 30° angle to the ground (Fig. 13).

Fig. 13

• Cut from right to left whenever possible. Cutting to

the left improves the unit's cutting efficiency.

Clippings are thrown away from the operator.

• Slowly move the trimmer into and out of the cutting

area at the desired height. Move either in a forwardbackward or side-to-side motion. Cutting shorter

lengths produces the best results.

• Trim only when grass and weeds are dry.

• The life of your cutting line is dependent upon:

• Following the trimming techniques

• What vegetation is being cut

• Where vegetation is cut

For example, the line will wear faster when trimming

against a foundation wall as opposed to trimming

around a tree.

11

MAINTENANCE AND REPAIR INSTRUCTIONS

SERVICING DOUBLE INSULATED UNITS

This unit is double-insulated. In a double-insulated unit,

two systems of insulation are provided instead of

grounding. There is no grounding provided and no

means of grounding should be added to this unit.

Extreme care and knowledge of the system is required

when servicing a double-insulated unit. Service should

be performed by qualified service personnel only.

Replacement parts for a double-insulated unit must be

identical to the parts they replace. Refer any repair to an

authorized service dealer. A double-insulated unit is

marked with the words “double insulation” or “double

insulated.”

LINE INSTALLATION FOR THE SPEEDSPOOL

®

Always use original equipment manufacturer 0.080 inch

(2.03 mm) replacement line. Line other than the specified

may make the motor overheat or fail.

There are two methods to replace the SpeedSpool

®

trimming line:

• Wind the inner reel with new line

• Install a pre-wound inner reel

Winding the Inner Reel With New Line

NOTE: It Is unnecessary to remove the bump knob to

install a new trimming line.

1. Cut two pieces of 0.080 inch (2.03 mm) trimming

line, 10 feet (3 m) long.

2. Hold the outer spool and turn the inner reel

counterclockwise to line up the arrows on the outer

spool and inner reel (Fig. 14).

Top View Of The SpeedSpool

®

Outer Spool

Inner Reel

Fig. 14

Bump Knob

Arrows

Never use metal-

reinforced line, wire,

chain or rope. These can break off and

become dangerous projectiles.

WARNING:

Always use the

correct line length

when installing trimming line on the unit.

The line may not release properly if the line

is too long.

WARNING:

Trimming Line

Line Loading Hole

Eyelet

5. Insert the line into the locking hole. Do not push the

line more than a 1/2 inch (12.7 mm) into the line

locking hole. The line will form a small loop (Fig. 16)

when it is inserted correctly.

3. Pull old line out of the line loading and line locking

holes (Fig. 14 and 15).

4. Insert a piece of trimming line straight into one of the

two eyelets in the outer spool. Push it up through the

line loading hole in the inner reel (Fig. 15). Do not

bend the line when inserting it into the eyelet.

Fig. 15

12

6. Pull the line from the outer spool until the line is tight

against the inner reel (Fig. 17).

Fig. 17

INSTALLING A PRE-WOUND REEL

1. Turn the bump knob counterclockwise and remove

the bump knob, spring and foam seal (Fig. 20).

9. If winding the line becomes difficult or if the line

jams, pull the ends of the line from the spool

(Fig. 19). Continue winding the inner reel

counterclockwise.

Fig. 18

Fig. 19

7. Repeat procedures 4-6 with the second piece of line.

8. Hold the outer spool. Wind the inner reel

counterclockwise until approximately four (4) inches

(102 mm) of line remain (Fig. 18).

NOTE: Do not wind the inner reel before installing the

second piece of line.

Bump Knob

Foam Seal

Spring

Inner Reel

Fig. 20

2. Pull the old inner reel with existing line from the outer

spool.

3. Insert the ends of the prewound inner reel line into

the outer spool eyelets (Fig. 21). Push the new inner

reel, arrow side up, into the outer spool.

Fig. 21

Line Locking Hole

Fig. 16

4. Hold the inner reel in place and install the bump

knob, spring and foam seal. Press down and turn the

bump knob clockwise. Grasp the ends and pull firmly

to release the line from the holding slots in the inner

reel (Fig. 19).

MAINTENANCE AND REPAIR INSTRUCTIONS

13

SPEEDSPOOL REPLACEMENT PARTS

Replacement Line . . . . . . . . . . . . . . . . . . . . . . . . 181472

Replacement Line Cartridge . . . . . . . . . . . . . . . . 181460

Inner Reel Spring . . . . . . . . . . . . . . . . . . . . . . . . 181465

Foam Seal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181467

Inner Reel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181464

Bump Knob Assembly . . . . . . . . . . . . . . . . . . . . 181468

These SpeedSpool®replacement parts can be

purchased from your local authorized dealer.

Releasing the Inner Reel

If the SpeedSpool®does not release line correctly, pull

the ends of the line firmly from the spool (Fig. 19). If this

does not the release line, follow the Cleaning the

SpeedSpool®instructions.

4. Remove any existing line from the inner reel before

cleaning. Remove any debris or grass from the knob,

spring, inner reel and foam seal. Wash the inner reel

with warm soapy water (Fig. 23).

Fig. 22

CLEANING THE SPEEDSPOOL

®

Cleaning the SpeedSpool®may be necessary if:

• A jammed or excessive line must be removed

• The SpeedSpool®becomes difficult to wind or does

not operate correctly when bumping the head on the

ground

1. Hold the outer spool, and unscrew the bump knob

counterclockwise (Fig. 22).

2. Pull out the bump knob, spring and foam seal (Fig. 20).

Shaft

Plunger

7. Place the bump knob, spring and foam seal into the

inner reel (Fig. 20).

8. Press the bump knob down and tighten clockwise.

9. Install new line as described in Line Installation for

the SpeedSpool

®

.

5. Clean the shaft and the inner surface of the outer

spool. To clean the shaft underneath the plunger,

press down on the plunger (Fig. 24). Remove any dirt

or debris from the shaft.

NOTE: The inner reel must be totally dry before

reinstalling it into the outer spool. Do not lubricate

the inner reel or outer spool assembly.

6. Place the inner reel into the outer spool.

Fig. 24

Inner Reel

Fig. 23

3. Pull the inner reel with existing line from the outer

spool (Fig. 21).

CLEANING THE UNIT

Switch off the unit and disconnect it from the power

source. Use a small brush to clean off the outside of the

unit. Do not use strong detergents. Household cleaners

that contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic housing

or handle. Wipe off any moisture with a soft cloth. Also

keep the air vents free of obstructions.

STORAGE

• Store the unit locked up to prevent unauthorized use

or damage.

• Store the unit in a dry, well-ventilated area.

• Store the unit out of the reach of children.

INSPECT EXTENSION CORDS

Inspect all extension cords periodically. Look closely for

deterioration, cuts or cracks in the insulation. Inspect the

connectors for damage. Replace cords if defective or

damaged.

To avoid serious

personal injury,

always turn your unit off and unplug it

before you clean or service it.

WARNING:

MAINTENANCE AND REPAIR INSTRUCTIONS

14

TROUBLESHOOTING

If further assistance is required, contact your authorized service dealer.

CAUSE ACTION

Cutting attachment bound with grass Stop the motor and clean cutting attachment

Cutting attachment out of line Refill with new line

Inner reel bound up Replace the inner reel

Cutting head dirty Clean inner reel and outer spool

Line welded Disassemble, remove the welded section and rewind

Line twisted when refilled Disassemble and rewind the line

Not enough line is exposed Push the bump knob and pull out line until 4 inches

(102 mm) of line is outside of the cutting attachment

CAUSE ACTION

Unit is unplugged Check cord to make sure it is still plugged into an

electrical outlet

MOTOR WILL NOT START

CUTTING ATTACHMENT WILL NOT ADVANCE LINE

CAUSE ACTION

Oil, cleaner or lubricant in cutting head Clean and thoroughly dry the cutting head

CUTTING LINE ADVANCES UNCONTROLLABLY

15

SPECIFICATIONS

Motor type..........................................................................................................................................A.C.,120 Volts Electric

Operating RPM............................................................................................................................................ up to 7,800 rpm

Ignition Switch ........................................................................................................................................................... Trigger

Amperage............................................................................................................................................................... 5.5 amps

MOTOR

DRIVE SHAFT and CUTTING ATTACHMENT

Drive Shaft Housing....................................................................................................................................... Steel (EZ-Link)

Shoulder Strap ........................................................................................................................................................ Optional

Approximate Unit Weight (cutting attachment shield and D-handle)..................................................................9 lbs. (4 kg)

Cutting Mechanism................................................................................................ SpeedSpool®Dual String Cutting Head

Line Spool............................................................................................................................................. Bump Line Releaser

Line Spool Diameter .......................................................................................................................3 inches (76.2 mm)

Cutting Path Diameter................................................................................................................................... 15 in (381 mm)

Trimming Line Diameter .......................................................................................................................... 0.080 in (2.03 mm)

16

NOTES

17

NOTES

MANUFACTURER’S LIMITED WARRANTY FOR:

No implied warranty, including any implied warranty of

merchantability or fitness for a particular purpose,

applies after the applicable period of express written

warranty above as to the parts as identified. No other

express warranty or guaranty, whether written or oral,

except as mentioned above, given by any person or

entity, including a dealer or retailer, with respect to any

product shall bind MTD. During the period of the

Warranty, the exclusive remedy is repair or replacement

of the product as set forth above. (Some states do not

allow limitations on how long an implied warranty lasts, so

the above limitation may not apply to you.)

The provisions as set forth in this Warranty provide the

sole and exclusive remedy arising from the sales. MTD

shall not be liable for incidental or consequential loss or

damages including, without limitation, expenses incurred

for substitute or replacement lawn care services, for

transportation or for related expenses, or for rental

expenses to temporarily replace a warranted product.

(Some states do not allow limitations on how long an implied

warranty lasts, so the above limitation may not apply to you.)

In no event shall recovery of any kind be greater than the

amount of the purchase price of the product sold. Alteration

of the safety features of the product shall void this Warranty.

You assume the risk and liability for loss, damage, or injury

to you and your property and/or to others and their property

arising out of the use or misuse or inability to use the

product.

This limited warranty shall not extend to anyone other than

the original purchaser, original lessee or the person for whom

it was purchased as a gift.

How State Law Relates to this Warranty: This warranty

gives you specific legal rights, and you may also have other

rights which vary from state to state.

To locate your nearest service dealer dial 1-800-345-8746

in the United States or 1-800-668-1238 in Canada.

MTD LLC

P.O. Box 361131

Cleveland, OH 44136-0019

The limited warranty set forth below is given by MTD

LLC (“MTD”) with respect to new merchandise purchased and

used in the United States, its possessions and territories.

MTD warrants this product against defects in material and

workmanship for a period of two (2) years commencing on the

date of original purchase and will, at its option, repair or

replace, free of charge, any part found to be defective in

material or workmanship. This limited warranty shall only apply

if this product has been operated and maintained in

accordance with the Operator’s Manual furnished with the

product, and has not been subject to misuse, abuse,

commercial use, neglect, accident, improper maintenance,

alteration, vandalism, theft, fire, water or damage because of

other peril or natural disaster. Damage resulting from the

installation or use of any accessory or attachment not

approved by MTD for use with the product(s) covered by this

manual will void your warranty as to any resulting damage. This

warranty is limited to ninety (90) days from the date of original

retail purchase for any MTD product that is used for rental or

commercial purposes, or any other income-producing purpose.

HOW TO OBTAIN SERVICE: Warranty service is available,

WITH PROOF OF PURCHASE THROUGH YOUR LOCAL

AUTHORIZED SERVICE DEALER. To locate the dealer in your

area, please check for a listing in the Yellow Pages or contact

the Customer Service Department of MTD LLC by calling

1-800-345-8746 or writing to P.O. Box 361131, Cleveland OH

44136-0019 or if in Canada call 1-800-668-1238. No product

returned directly to the factory will be accepted unless prior

written permission has been extended by the Customer

Service Department of MTD LLC.

This limited warranty does not provide coverage in the

following cases:

A. Tune-ups - Spark Plugs, Carburetor Adjustments, Filters.

B. Wear items - Bump Knobs, Outer Spools, Cutting Line,

Inner Reels, Starter Pulley, Starter Ropes, Drive Belts.

C. MTD does not extend any warranty for products sold or

exported outside of the United States of America, its

possessions and territories, except those sold through

MTD’s authorized channels of export distribution.

MTD reserves the right to change or improve the design of

any MTD Product without assuming any obligation to modify

any product previously manufactured.

Manuel de l'utilisateur

Français

PARTIE NUMÉRO. 769-00936 (1/04)

Désherbeuse

Electrique

Model

YM137

MANUEL IMPORTANT À NE PAS JETER

F2

Copiez le numéro

de série ici :

Copiez le numéro de

modèle / pièce mère ici :

TOUS NOS REMERCIEMENTS

Nous vous remercions d'avoir acheté ce produit de

qualité. Cet outil mécanique de plein air moderne est

conçu pour vous rendre service pendant longtemps. Il

vous sauvera beaucoup de temps comme vous pourrez

vous en rendre compte. Ce manuel de l'utilisateur

comporte un mode d'emploi facile à comprendre. Prenez

soin de lire le manuel au complet et suivez toutes ses

instructions à la lettre afin de conserver votre nouvel outil

mécanique de plein air en excellent état de

fonctionnement.

RÉFÉRENCES, ILLUSTRATIONS ET

SPÉCIFICATIONS RELATIVES AU PRODUIT

Toutes les informations, illustrations et spécifications

contenues dans ce manuel tiennent compte des

dernières informations techniques disponibles au

moment de mettre sous presse. Nous nous réservons le

droit d'y apporter des modifications à tout moment, sans

préavis.

Copyright© 2003 MTD SOUTHWEST INC., Tous droits

réservés.

NFORMATIONS D’ENTRETIEN

Tout entretien effectué sur cet appareil pendant et après

la période de garantie doit être fait par un concessionnaire agréé uniquement. Obtenez la liste des

concessionnaires agréés appelez le 1-800-345-8746, ou

le 1-800-668-1238 au Canada. Pour de plus amples

informations à propos de votre appareil, visitez

www.yardman.com.

NE RETOURNEZ PAS L'APPAREIL AU DÉTAILLANT

CHEZ QUI VOUS L'AVEZ ACHETÉ. TOUT SERVICE

SOUS GARANTIE NÉCESSITE UNE PREUVE D'ACHAT.

Avant d'assembler votre nouvel équipement, repérez la

plaque signalétique de l'appareil et copiez ses

informations dans l'espace ci-dessous. Ces informations

sont essentielles si vous désirez obtenir de l'aide auprès

de notre service technique ou d'un distributeur agréé. Un

exemple de plaque signalétique est présenté ci-dessous.

Prenez soin de lire et de bien comprendre ce manuel avant de démarrer ou de faire fonctionner cet équipement.

CE PRODUIT EST COUVERT PAR UN OU PLUSIEURS BREVETS AMÉRICAINS, ET D’AUTRES SONT EN INSTANCE.

TABLE DES MATIÈRES

Service technique . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Consignes de sécurité . . . . . . . . . . . . . . . . . . . . . . .3

Familiarisez-vous avec votre appareil . . . . . . . . . . .6

Instructions de montage . . . . . . . . . . . . . . . . . . . . . .7

Mode d'emploi . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Entretien et réparations . . . . . . . . . . . . . . . . . . . . .11

Tableau de dépannage . . . . . . . . . . . . . . . . . . . . . .14

Caractéristiques . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Liste des pièces . . . .Intérieure de la Couverture Arrière

Numéro de modèle

Numéro de série

Numéro de pièce mère

INTRODUCTION

Si vous éprouvez des difficultés à assembler ce produit

ou si vous avez des questions concernant les

commandes, le fonctionnement ou l’entretien de cet

appareil, veuillez communiquer avec notre service

technique.

MODEL :

S/N :

ITEM :

F3

CONSIGNES DE SÉCURITÉ

SYMBOLE SIGNIFICATION

SYMBOLE SIGNIFICATION

LIRE TOUTES LES INSTRUCTIONS

AVANT UTILISATION

• Lire les instructions attentivement. Se familiariser avec

les commandes et l’utilisation correcte de cet outil.

• Ne pas utiliser l’outil si vous êtes fatigué, malade ou

sous l’effet de l’alcool, de drogues ou de médicaments.

• Inspectez l'appareil avant utilisation. Remplacez les

pièces endommagées.. Assurez-vous que les fixations

sont solidement en place. Remplacez les pièces de

l'accessoire de coupe qui sont fendillées, ébréchées

ou endommagées. Assurez-vous que l'accessoire de

coupe est correctement installé et solidement fixé.

Assurez-vous que le protecteur d'accessoire de coupe

est correctement fixé et positionné comme

recommandé. Vous risquez sinon de causer des

blessures à l'opérateur et aux spectateurs, et

d'endommager l'appareil.

• N'utilisez que du fil de remplacement d’origine du

fabrican de 2,03 mm (0,080 po) de diamètre. N'utilisez

jamais de fil, de chaîne ou de cordon à renfort

métallique car ils peuvent se briser et se transformer

en projectile dangereux.

• Soyez conscient des risques de blessure à la tête, aux

mains et aux pieds.

• Dégagez la zone de coupe avant chaque usage.

Enlevez tous les objets pouvant être projetés ou

happés par l'accessoire de coupe : cailloux, verre

brisé, clous, fil ou ficelle. Éloignez enfants, spectateurs

et animaux de la zone de coupe. Tenez-les à au moins

15 m (50 pi) de là mais sachez que les spectateurs

risquent quand même d'être atteints par des objets

projetés. Les spectateurs doivent porter des

protections oculaires. Arrêtez immédiatement le

moteur et l'accessoire de coupe si quelqu'un

s'approche de vous.

• Cet appareil n'est pas conçu pour servir de

débroussailleuse. N'utilisez cet appareil avec aucun

type de lame ou d'accessoire de débroussaillage.

AVERTISSEMENTS DE SÉCURITÉ ÉLECTRIQUE

• Comme cet outil comporte une isolation double, il est

donc possible d’utiliser des rallonges à 2 conducteurs

(rallonges sans terre). Cependant, il est tout à fait possible

d’utiliser des rallonges à 3 conducteurs (rallonges avec fil

de terre), qui comportent des fiches de type NEMA (fiches

parallèles, fiche terre en forme de U). Ces rallonges sont

disponibles auprès de votre revendeur local. Veillez à

n’utiliser que des rallonges à section circulaire,

approuvées pour une utilisation extérieure.

• Cet outil comporte une isolation double. Pour toutes

les réparations, utilisez uniquement des pièces de

rechange identiques. Tout cordon électrique

endommagé doit être réparé ou remplacé.

• IMPORTANTES CONSIGNES DE SÉCURITÉ •

Les symboles de sécurité attirent votre attention sur

des dangers potentiels. Ces symboles et leurs détails

explicatifs méritent que vous les lisiez et compreniez

bien. Les avertissements de sécurité ne peuvent éviter

les dangers de par eux-mêmes. Les consignes ou

mises en garde qu'ils donnent ne remplacent pas des

mesures préventives appropriées contre les accidents.

REMARQUE: donne des informations ou des

instructions vitales pour le fonctionnement ou

l'entretien de l'équipement.

le non-

respect d’un

avertissement peut causer dommages matériels

ou blessures graves pour tous. Respectez les

consignes de sécurité afin de réduire les risques

d'incendie, d'électrocution et de blessures.

AVERTISSEMENT:

le non-respect d’un

avertissement peut

causer dommages matériels ou blessures

graves pour tous. Respectez les consignes de

sécurité afin de réduire les risques d'incendie,

d'électrocution et de blessures.

DANGER:

le non-

respect

d’un avertissement peut causer dommages

matériels ou blessures graves pour tous.

Respectez toujours les consignes de sécurité

afin de réduire les risques d'incendie,

d'électrocution et de blessures.

MISE EN GARDE:

indique un danger, un avertissement ou une

mise en garde. Soyez vigilant afin d'éviter toute

blessure grave. Ce symbole peut être combiné

à d'autres symboles ou pictogrammes.

ALERTE DE SÉCURITÉ:

respectez toujours les

consignes de sécurité

durant l’utilisation d’appareils de jardinage

électriques afin de réduire les risques

d’incendie, d’électrocution et de blessures.

Prenez soin de bien lire et comprendre tout le

manuel de l’utilisateur avant d’utiliser la

souffleuse/aspirateur. Faites particulièrement

attention au mode d'emploi et aux

avertissements de sécurité.

DANGER:

Pour

réduire le

risque de choc électrique, utilisez uniquement

des rallonges électriques approuvées pour une

utilisation extérieure., comme par exemple les

rallonges à cordons de type SW-A, SOW-A, STWA, STOW-A, SJW-A, SJOW-A, SJTW-W ou SJTOW.

AVERTISSEMENT:

F4

CONSIGNES DE SÉCURITÉ

• Pour réduire le risque de choc électrique, cet appareil est

pourvu d’une fiche polarisée (une lame est plus large que

l’autre). Cet appareil ne peut être inséré dans une prise

polarisée que d’une seule manière. S’il n’est pas possible

d’insérer entièrement la fiche dans la prise, essayez de

brancher la fiche dans l’autre sens. Si malgré tout, il n’est

pas possible d’insérer la fiche, remplacez le cordon par un

cordon qui comporte les bonnes fiches. Ne modifiez cet

appareil en aucun cas.

*La grosseur du fil (AWG) pour l’ampérage de 12 à 19

ampères est de 14 AWG pour 25 pieds, de 12 AWG pour

50 pieds et n’est pas recommandé pour 100 ou 150 pieds.

• JEUX DE CORDONS: Vérifiez que votre jeu de cordons est

en bon état de fonctionnement. Si vous utilisez un jeu de

cordons, assurez vous de bien utiliser un cordon de calibre

suffisant pour laisser passer le courant de charge de votre

appareil. Un jeu de cordons à section trop faible risque de

provoquer des chutes de tension de ligne, qui entraînent une

perte de puissance et une surchauffe. Le tableau ci-dessous

donne les calibres corrects à utiliser, en fonction de la

longueur du cordon et de la valeur de l’intensité nominale.

En cas de doute, utilisez la section de câble immédiate-ment

supérieure. Un numéro de calibre faible correspond à une

forte section de câble. Référez vous à la Mode D’emploi

pour réduire le risque de débranchement du cordon de

l’appareil pendant le fonctionnement, du jeu de cordons.

• Le(s) circuit(s) électrique(s) ou la(les) prise(s)

d’alimentation de cet outil de jardinage doit(doivent)

comporter une protection de type GFCI (qui coupe le

circuit en cas de défaut de terre). Il existe des prises qui

comportent une protection GFCI, et que l’on peut utiliser

dans ce cas de figure.

• Votre appareil est pourvu d’une plaquette du

constructeur, qui indique le type de tension à utiliser.

N’alimentez jamais cet appareil avec une tension

alternative différente de celle affichée.

• Ne maltraitez pas le cordon. Ne tirez jamais l’appareil par

le cordon et ne le débranchez pas en tirant sur le cordon.

Protégez celui-ci de la chaleur, de l’huile et des bords

tranchants.

• Procédez à une inspection périodique de vos rallonges

électriques et de la fiche de raccord de votre appareil.

Examinez plus particulièrement l’isolation qui ne doit pas

présenter de traces de détérioration, de coupures ou de

mise à nu. Inspectez également les raccords qui doivent être

en bon état. Si les cordons paraissent endommagés,

remplacez les ou réparez les.

• Evitez d’utiliser cet appareil dans des conditions

dangereuses. Ne le faites jamais fonctionner en

atmosphère humide ou mouillée. L’humidité constitue un

danger réel de choc électrique.

• N’utilisez pas cet appareil sous la pluie.

• Ne touchez pas la fiche ou l’appareil lui même si vos

mains sont mouillées.

PENDANT L’UTILISATION

• Portez des lunettes de sécurité conformes aux normes

ANSI Z87.1 ainsi que des protège-oreilles durant

l'utilisation de l'appareil. Portez un masque facial ou

antipoussières si vous travaillez dans un lieu poussiéreux.

• Ajustez la poignée en D selon votre taille pour mieux

l'agripper.

• N'utilisez l'appareil qu'en plein jour ou avec un bon

éclairage artificiel.

• Portez des pantalons épais et longs, des bottes, des

gants et une chemise à manches longues. Ne marchez

pas pieds nus et évitez les vêtements lâches, bijoux,

pantalons courts et sandales. Relevez les cheveux audessus des épaules.

• Le protecteur d'accessoire de coupe doit toujours être en

place lors de l'utilisation de l'appareil. Ne faites pas marcher

l'appareil sans que les deux fils soient bien déployés, en

supposant qu'un fil approprié a été installé. Assurez-vous que

le fil ne dépasse pas le protecteur de sécurité.

• Évitez tout démarrage accidentel. Ne transportez pas

l'appareil branché, le doigt sur l’interrupteur. Mettez ce

dernier hors tension avant de brancher.

• Ne vous étirez pas. Tenez-vous toujours bien sur vos

pieds en position d'équilibre.

• Tenez toujours l'appareil des deux mains lorsque vous le

faites marcher. Agrippez fermement les poignées avant et

arrière.

• Gardez les mains, le visage et les pieds éloignés des

pièces mobiles. Ne touchez pas et n'essayez pas

d'arrêter l'accessoire de coupe en rotation.

• Servez-vous des outils appropriés. N'utilisez cet outil que

pour son usage prévu.

• Ne faites pas fonctionner le moteur à un régime plus

élevé que nécessaire pour couper, tailler ou faire les

bordures. Ne faites pas tourner le moteur à haut régime si

vous ne vous faites pas de coupe.

• Arrêtez toujours le moteur lorsque vous suspendez la

coupe ou lorsque vous vous déplacez d'un lieu de travail

vers un autre.

• Si vous heurtez un corps étranger ou que celui-ci est

happé, arrêtez le moteur immédiatement et vérifiez que

rien n'a été endommagé. Ne faites pas fonctionner avant

réparation des dommages. Ne faites pas marcher l'appareil

si les pièces sont desserrées ou endommagées.

• Arrêtez et éteignez le moteur dans les cas suivants:

entretien, réparation ou changement d'accessoires ou

autres.

• N'utilisez que des pièces de rechange

d’origine du fabrican

pour l'entretien de cet appareil. Ces pièces sont disponibles

auprès de votre concessionnaire agréé. N'utilisez pas de

pièces ou accessoires non conçus par original pour cet

appareil. Cela pourrait causer des blessures graves à

l'utilisateur ou endommager l'appareil et annuler la garantie.

• Gardez l'appareil exempt d'accumulation de végétation

ou autres matières. Celles-ci peuvent rester logées entre

l'accessoire de coupe et le protecteur.

AUTRES AVERTISSEMENTS DE SÉCURITÉ

• Bien arrimer l’outil pour le transport.

• Remiser l’outil dans un endroit sec pouvant être verrouillé

ou en hauteur afin d’empêcher des dommages ou un usage

non autorisé. Garder l’outils hors de portée des enfants.

• Ne jamais immerger l’outil et ne jamais l’arroser avec de

l’eau ou tout autre liquide. Garder les poignées sèches,

propres et exemptes de débris. Nettoyer après chaque

usage. Voir les sections Nettoyage et Remisage.

• Conserver ces instructions. Les consulter fréquemment

et les utiliser pour instruire d’autres utilisateurs. Si l’outil

est prêté, il doit être accompagné de ces instructions.

CONSERVER CES

INSTRUCTIONS

Long. de cordon (pieds)

25 50 100 150

Calibre du cordon (AWG)*

16 16 16 14

CALIBRE MINIMUM DES RALLONGES ALIMENTANT DES

APPAREILS 120V, A COURANT DE CHARGE DE 0-12 AMPS*

F5

CONSIGNES DE SÉCURITÉ

SYMBOLES DE SÉCURITÉ ET INTERNATIONAUX

Ce manuel de l'utilisateur décrit les symboles et pictogrammes de sécurité et internationaux pouvant apparaître sur ce

produit. Consultez le manuel de l'utilisateur pour les informations concernant la sécurité, le montage, le fonctionnement,

l'entretien et les réparations.

SYMBOLE SIGNIFICATION

• SYMBOLE ALERTE DE

SÉCURITÉ

Indique un danger, un avertissement ou

une mise en garde. Ce symbole peut

être combiné à d'autres symboles ou

pictogrammes.

• AVERTISSEMENT - LISEZ LE

MANUEL DE L'UTILISATEUR

Lisez le manuel de l'utilisateur et suivez

tous les avertissements et consignes de

sécurité. Vous pourriez à défaut

entraîner des blessures graves pour

vous ou d'autres personnes.

• PORTEZ DES PROTECTIONS

(YEUX ET OREILLES)

AVERTISSEMENT:

les objets projetés et les bruits forts

peuvent endommager la vue et l’ouïe.

Portez une visière de norme ANSI Z87.11989 et des protège-oreilles pendant

l'utilisation.

• LES OBJETS PROJETÉS ET LA

TÊTE ROTATIVE PEUVENT CAUSER

DES BLESSURES GRAVES

AVERTISSEMENT:

Tenez-vous à l'écart de la sortie de

souffleuse. Ne dirigez jamais la

souffleuse vers vous ou vers les autres.

La souffleuse peut projeter des objets.

Ne faites pas fonctionner l'appareil sans

les accessoires et protections

nécessaires

.

SYMBOLE SIGNIFICATION

• N’UTILISEZ PAS L’APPAREIL

SOUS LA PLUIE

AVERTISSEMENT:

évitez les lieux dangereux.

N’utilisez jamais l’appareil sous la

pluie ou dans des conditions

humides ou mouillées. L’humidité

peut provoquer l’électrocution.

• ÉLOIGNEZ LES SPECTATEURS

AVERTISSEMENT:

éloignez tout spectateur, les enfants

et les animaux domestiques en

particulier, d'au moins 15 m (50 pi)

de la zone de coupe.

• MANETTE DES GAZ

"HAUTE" vitesse ou vitesse

"MAXIMUM"

• MANETTE DES GAZ

"RALENTI" ou vitesse "BASSE" ou

"MINIMUM"

• DOUBLE ISOLEMENT

Les appareils à double isolement

comportent deux systèmes

d’isolement. Comme il se doit,

aucun moyen de mise à la terre

n’est fourni sur ce type d’appareil.

F6

CONSIGNES DE SÉCURITÉ

USAGE

Comme désherbeuse :

• Coupe d'herbe et de mauvaises herbes légères

• Taille autour des arbres, des clôtures, etc.

FAMILIARISEZ-VOUS AVEC L’APPAREIL

Protecteur d'accessoire

de coupe

Poignée en D

Accessoire de coupe

Corps de

l'arbre

Lame coupante

Poignée du boîtier

Déclencheur de commutateur

Carter

Prise

encastrée

Déclencheur de

commutateur

EZ-Link

MC

Raccord de

soutien

F7

INSTRUCTIONS DE MONTAGE

INSTALLATION DU PROTECTEUR

D'ACCESSOIRE DE COUPE

Suivez les instructions suivantes si le protecteur

d'accessoire de coupe n'est pas installé sur l'appareil.

1. Glissez le protecteur d'accessoire de coupe dans

son support, situé sur l'accessoire. Alignez les trous

à vis du protecteur avec ceux de l'accessoire de

coupe (Fig. 3).

Fig. 3

Fig. 4

Fig. 5

2. Placez un écrou de blocage hex dans l'un des trois

trous encastré, sur le dessus du protecteur

d'accessoire de coupe (Fig. 4).

3. Introduisez une vis dans le trou du bas du protecteur

d'accessoire de coupe et vissez-la dans l'écrou posé

à l'étape 2 (Fig. 5). Évitez de serrer.

4. Répétez les étapes 2 et 3 jusqu'à ce que les trois vis

soient bien posées, puis serrez-les bien.

Corps de l'arbre

Protecteur d'accessoire

de coupe

Protecteur d'accessoire de coupe

Accessoire de coupe

Trous encastrés

Support du protecteur

Écrou de

blocage hex

Vis

n'utilisez

jamais la

désherbeuse sans protecteur d'accessoire

de coupe pour éviter des blessures graves.

AVERTISSEMENT:

RÉGLAGE DE LA POIGNÉE EN D

1. Tenez l’appareil en position de fonctionnement (Fig. 1).

2. Desserrez l'écrou papillon (Fig. 2). Il n’est pas

nécessaire d’enlever l’écrou papillon, la rondelle ou le

boulon.

3. Placez la poignée en D de manière à assurer une

prise idéale, puis serrez l'écrou papillon (Fig. 2).

Fig. 1

Fig. 2

Poignée en D

Écrou papillon

F8

INSTRUCTIONS DE MONTAGE

FONCTIONNEMENT DU EZ-Link

MD

Le système EZ-LinkMDpermet d'utiliser ces

accessoires optionnels :

Souffleuse/aspirateur . . . . . . . . . . . . . . . . . . . . . BV720r

Cultivateur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . GC720r

Coupe-bordure . . . . . . . . . . . . . . . . . . . . . . . . . . LE720r

Souffleuse (à neige) . . . . . . . . . . . . . . . . . . . . . . . ST720r

Désherbeuse à arbre droit . . . . . . . . . . . . . . . . . SS725r

Élagueuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . TP720r

Turbosouffleuse . . . . . . . . . . . . . . . . . . . . . . . . . . TB720r

Retrait de l'accessoire de coupe ou autre

1. Dévissez le bouton vers la gauche (Fig. 6).

2. Appuyez sur le bouton de déclenchement et

maintenez-le enfoncé (Fig. 6).

3. Tenez fermement le corps de l'arbre supérieur et

retirez l'accessoire de coupe ou autre du coupleur

EZ-LinkMD.

Installation de l'accessoire de coupe ou autre

NOTE : pour faciliter l'installation ou le retrait

d'accessoires, placez l'appareil au sol ou sur un

établi.

1. Dévissez le bouton vers la gauche (Fig. 6).

Fig. 6

Fig. 7

Fig. 8

2. Tenez fermement l'accessoire et enfoncez-le tout

droit dans le coupleur EZ-LinkMD(Fig. 7).

NOTE :aligner le bouton de déclenchement avec le

renfoncement-guide facilitera l'installation (Fig. 6).

3. Serrez le bouton en le tournant à droite (Fig. 8).

Coupleur EZ-Link

MD

Bouton de déclenchement

Renfonce-

ment-guide

Bouton

Trou principal

Corps de l'arbre

supérieur

Corps de l'arbre

inférieur

Bouton de déclenchement

Trou de coupe de

bordures de 90°

Trou de coupe

de bordures

de 180°

Bouton

Coupleur EZ-Link

MD

Pour couper les bordures à l’aide de la tête d'accessoire

de coupe sur les modèle EZ-LinkMD, verrouillez le bouton

de déclenchement de l'accessoire de coupe dans le

trou de 90° ou de 180° (Fig. 8).

veuillez bien

assimiler le

manuel des accessoires avant utilisation.

AVERTISSEMENT:

verrouillez

le bouton

de déclenchement dans le trou principal et

vissez bien le bouton avant de faire marcher

l'appareil.

MISE EN GARDE:

l'access-

oire de

coupe et autres ajouts du système EZ-Link

MD

doivent utiliser le trou principal sauf indication

contraire de leurs manuels. L'utilisation du

mauvais trou pourrait causer des blessures

graves ou endommager l'appareil.

MISE EN GARDE:

pour éviter

des

blessures graves, éteignez l'appareil avant

d'enlever ou d'installer des accessoires.

AVERTISSEMENT:

F9

MODE D'EMPLOI

CONNEXION DU CORDON

D'ALIMENTATION

1. Utilisez le crochet de cordon lorsque vous connectez

la rallonge au fil d’alimentation pour éviter toute

déconnexion (Fig. 9). Utilisez uniquement des

rallonges homologuées pour l'usage à l'extérieur tel

que spécifié dans la section Consignes de sécurité.

2. Fixez la rallonge au carter tel qu'indiqué (Fig. 9).

ÉMARRAGE/ ARRÊT DE L’APPAREIL

Tenez-vous en position de fonctionnement (Fig. 11).

Appuyez sur la détente pour démarrer la désherbeuse

(Fig. 10). Pour arrêter la désherbeuse, relâchez la détente.

Détente

Fig. 11

Fig. 9

COMMUTATEUR A 2 VITESSES

Cet appareil est équipé d’un commutateur à deux

vitesses, à savoir une vitesse rapide qui procure la

puissance nécessaire pour des travaux de jardinage

intenses, et une vitesse lente, de précision, pour des

travaux plus légers.

Poussez le commutateur vers le haut pour tailler à

grande vitesse. Poussez le commutateur vers le bas

pour tailler à une vitesse plus faible (Fig. 10).

Fig. 10

N'utilisez

pas

l'appareil pour des travaux exigeants avec le

commutateur en position de basse vitesse. Cela

pourrait surchauffer ou endommager l’appareil.

MISE EN GARDE:

TENUE DE LA DÉSHERBEUSE

Avant de faire marcher l'appareil, tenez-vous en position

de fonctionnement (Fig. 11). Vérifiez les points suivants:

• L'opérateur porte une visière et des vêtements appropriés.

• Le bras droit est légèrement plié et la main tient l'arbre

par sa prise.

• Le bras gauche est droit et la main tient la poignée en D

.

• L'appareil est au-dessous de la ceinture.

• L'accessoire de coupe est parallèle au sol et touche

facilement la végétation sans que l'opérateur ne doive

se pencher.

RÉGLAGE DE LA LONGUEUR DU FIL

L'accessoire de coupe Bump Head

MC

vous permet de

donner du fil sans arrêter le moteur. Pour avoir plus de fil,

tapez doucement l'accessoire de coupe sur le sol (Fig.

12) tout en faisant marcher la désherbeuse à haut régime.

REMARQUE : gardez toujours le fil bien déroulé. Il

devient plus difficile de donner du fil à mesure

que le fil de coupe devient plus court.

portez

toujours

des protections (yeux, oreilles, pieds et corps)

pour diminuer les risques de blessures durant

l'utilisation de l'appareil.

AVERTISSEMENT:

F10

MODE D'EMPLOI

CONSEILS POUR BIEN DÉSHERBER

• Le bon angle pour l'accessoire de coupe est parallèle

au sol.

•

Ne forcez pas l'accessoire. Coupez avec la pointe du fil

(surtout le long des murs). Utiliser plus que la pointe diminue

l'efficacité de la coupe et peut surcharger le moteur.

• Coupez l'herbe de plus de 200 mm (8 po) en procédant

de haut en bas par petits incréments pour éviter d'user

le fil prématurément ou de freiner le moteur.

Fig. 12

Chaque fois que vous donnez un coup sur la tête, vous

déroulez environ 25,4 mm (1 po) de fil. La lame du

protecteur d'accessoire de coupe est conçue pour couper

le fil à la bonne longueur si vous déroulez trop de fil.

Pour de meilleurs résultats, tapez la tête de butée sur un

sol dégagé ou dur. Si vous donnez du fil dans un lieu

d'herbe haute, vous risquez de caler le moteur. Gardez

toujours le fil bien déroulé. Il devient plus difficile de

donner du fil à mesure que le fil de coupe se raccourci.

REMARQUE : Ne posez pas la tête de butée sur le sol

lorsque l’appareil est en marche.

Le fil peut se briser dans les cas suivants :

• Happement de corps étrangers

• Usure normale du fil

• Coupe de mauvaises herbes épaisses à longues tiges

• Forcer le fil dans des objets comme des murs ou des

poteaux de clôture

COUPE DÉCORATIVE

La coupe décorative consiste à déblayer la végétation

autour des arbres, des bornes, des clôtures, etc.

Tournez entièrement l'appareil de manière à ce que

l'accessoire de coupe soit à un angle de 30° par rapport

au sol (Fig. 13).

Fig. 13

• Coupez de droite à gauche chaque fois que possible.

Cela améliore l'efficacité de coupe de l'appareil et les

résidus de coupe sont projetés loin de l'opérateur.

• Déplacez lentement la désherbeuse dans et hors de la

zone de coupe à la hauteur voulue. Procédez d'avant

en arrière ou d'un côté à l'autre. Les coupes de

longueur plus courte donnent les meilleurs résultats.

• Ne désherbez que lorsque l'herbe et les mauvaises

herbes sont sèches.

• La durée de vie de votre fil de coupe dépend

• de l’application des techniques de coupe précédentes

• du type de végétation à couper

• du lieu de coupe

Par exemple, le fil s'use plus vite si vous coupez le long d'un

mur de fondation que si vous coupez autour d'un arbre.

n'enlevez

pas ni

n'altérez l'ensemble de la lame coupante. Un

excès de fil surchauffera l'embrayage. Ceci

pourrait causer des blessures graves ou

endommager l'appareil.

MISE EN GARDE:

F11

ENTRETIEN ET RÉPARATIONS

ENTRETIEN D’APPAREILS À DOUBLE

ISOLEMENT

Cet appareil possède un double isolement. Au lieu d’une

mise à la terre, les appareils à double isolement

comportent deux systèmes d’isolement. Comme il se

doit, aucun moyen de mise à la terre n’est fourni sur ce

type d’appareil.

L’entretien de ces appareils exige soins minutieux et

compétence technique, et doit être effectué par un

personnel qualifié uniquement. Les pièces de rechange

doivent être identiques aux pièces remplacées. Confiez

toute réparation à un concessionnaire agréé. Un appareil

à double isolement porte l’indication « double insulation »

ou « double insulated ».

INSTALLATION DU FIL DU SPEEDSPOOL

MD

Utilisez toujours un fil de remplacement du fabrican

d'origine de 2,03 mm (0,080 po). Un fil plus épais

pourrait surchauffer ou endommager le moteur.

Vous pouvez remplacer le fil du SpeedSpoolMDde deux

façons:

• Rembobinez du fil neuf dans le moulinet intérieur

• Installez un moulinet intérieur pré-enroulé

Rembobiner le fil neuf sur le moulinet intérieur

REMARQUE : il est inutile d'enlever le bouton de butée

pour installer un fil neuf.

1. Découpez deux morceaux de fil de 2,03 mm

(0,080 po) de 3 m (10 pi) de long.

2. Alignez la flèche du moulinet intérieur avec celle de

la bobine extérieure (Fig. 14).

Fig. 14

SpeedSpool

MD

vu de haut

Bobine

extérieure

Flèches

Moulinet

intérieur

Bouton de butée

Fig. 15

3. Tirez le vieux fil des trous de chargement et de

blocage du fil (Fig. 15 et 16).

4. Insérez un morceau de fil dans l'un des deux œillets

de la bobine extérieure. Enfoncez-le dans le trou de

chargement du moulinet intérieur (Fig. 15). Ne pliez

pas le fil en l'insérant dans l'œillet.

Fil

Trou de chargement du fil

Œillet

5. Insérez le fil dans le trou de blocage. N'enfoncez pas

le fil de plus de 12,7 mm (1/2 po) dans le trou. S'il

est inséré correctement, le fil forme une petite

boucle (Fig. 16).

utilisez

toujours

la bonne longueur de fil lorsque vous posez le

fil sur l'appareil. Le fil risque de ne pas se

dérouler correctement s'il est trop long.

AVERTISSEMENT:

n'utilisez

jamais de

fil, de chaîne ou de cordon à renfort métallique

car ils peuvent se briser et se transformer en

projectile dangereux.

AVERTISSEMENT:

F12

ENTRETIEN ET RÉPARATIONS

Fig. 17

Fig. 16

6. Tirez le fil de la bobine extérieure jusqu'à ce qu'il soit

bien serré contre le moulinet intérieur (Fig. 17).

Trou de blocage du fil

Fig. 18

Fig. 19

9. Si le rembobinage du fil devient difficile ou si le fil se

coince, tirez-en les extrémités de la bobine.

Continuez de rembobiner le moulinet intérieur vers la

gauche (Fig. 19).

7. Répétez les procédures 4-6 pour le second morceau de fil.

8. Tenez la bobine extérieure. Rembobinez le moulinet

intérieur vers la gauche jusqu'à ce qu'il ne reste plus

qu'environ 102 mm (4 po) de fil (Fig. 18).

REMARQUE : ne rembobinez pas le moulinet intérieur

avant de poser le second fil.

Fig. 20

Installation d'un moulinet pré-enroulé

1. Retirez le bouton de butée, le ressort et le joint en

mousse en tournant le bouton de butée à gauche

(Fig. 20).

Bouton de butée

Joint en mousse

Ressort

Moulinet

intérieur

Fig. 21

2. Retirez de la bobine extérieure le vieux moulinet

intérieur avec son fil.

3. Insérez les extrémités du fil du moulinet intérieur

neuf dans les œillets de la bobine extérieure (Fig. 21).

Enfoncez le moulinet intérieur neuf, flèche vers le

haut, dans la bobine extérieure.

4. Maintenez le moulinet intérieur et installez le bouton

de butée, le ressort, et le joint en mousse en

poussant le bouton de butée vers le bas et en le

tournant à droite. Saisissez les extrémités et tirez

fermement pour dégager le fil des fentes de retenue

du moulinet intérieur (Fig. 20).

F13

ENTRETIEN ET RÉPARATIONS

NETTOYAGE DE L’APPAREIL

Arrêtez l’appareil et débranchez-le de sa source

d’alimentation. Nettoyez les évents avec une petite

brosse ou un aspirateur équipé d’une petite brosse.

N'employez pas de détergents concentrés sur le boîtier

ou les pièces en plastique. Ils peuvent être endommagés

par certains nettoyants ménagers contenant des huiles

aromatiques tel que le pin et le citron, et par des

solvants tel que le kérosène ou l’acétone. L’humidité

peut aussi provoquer l’électrocution. Essuyez toute trace

d'humidité à l'aide d'un tissu doux.

INSPECTION DES FILS DE RALLONGE

Inspectez régulièrement les rallonges. Soyez à l’affût de

signes de détérioration, de coupures ou de fissures dans

l’isolation. Vérifiez que les connexions ne sont pas

endommagées. Remplacez les cordons défectueux ou

endommagés.

ENTREPOSAGE

• Rangez l’appareil dans un endroit sec, élevé ou

verrouillé, hors de portée des enfants.

• Rangez l'appareil dans un lieu verrouillé pour éviter

toute utilisation ou accident indésirable.

• Rangez l'appareil dans un lieu sec et bien aéré.

pour

éviter des

blessures graves, éteignez toujours l'appareil

et laissez-le refroidir avant tout nettoyage ou

entretien.

AVERTISSEMENT:

Déroulement du moulinet intérieur

Si le SpeedSpoolMDne déroule pas le fil correctement,

tirez fermement les extrémités du fil loin de la bobine

(Fig. 19). Si cela ne suffit pas, suivez les instructions de

Nettoyage du SpeedSpoolMDci-dessous.

Fig. 23

4. Retirez tout le fil du moulinet intérieur avant de

nettoyer. Enlevez tout débris ou trace d'herbe du

bouton, du ressort, du moulinet et du joint en

mousse. Lavez le moulinet intérieur avec de l'eau

tiède savonneuse (Fig. 23).

Nettoyage du SpeedSpool

MD

Le nettoyage du SpeedSpoolMDpeut s'avérer nécessaire:

• Pour retirer du fil coincé ou trop long

• Si le SpeedSpool

MD

devient difficile à rembobiner ou

s'il ne fonctionne pas correctement lorsque vous

tapez sa tête sur le sol

1. Tenez la bobine extérieure et dévissez le bouton de

butée à gauche (Fig. 22).

2. Tirez le bouton de butée, le ressort et le joint en

mousse (Fig. 20).

Moulinet

intérieur

Fig. 24

5. Nettoyez l'axe et la surface intérieure de la bobine

extérieure. Pour nettoyer l'axe dissimulé sous le

plongeur, appuyez sur celui-ci (Fig. 24). Enlevez

toute trace de saleté et de débris de l'axe.

REMARQUE: le moulinet intérieur doit être

complètement sec avant de le réinstaller dans la

bobine extérieure. Ne lubrifiez pas le moulinet

intérieur ni la bobine extérieure.

6. Placez le moulinet intérieur dans la bobine extérieure.

7. Placez le bouton de butée, le ressort et le joint en

mousse dans la bobine extérieure (Fig. 20).

Axe

Plongeur

PIÉCES DE RECHANGE SPEEDSPOOL

Fil de remplacement . . . . . . . . . . . . . . . . . . . . . . 181472

Cartouche de fil de remplacement . . . . . . . . . . . 181460

Ressort du moulinet intérieur . . . . . . . . . . . . . . . 181465

Joint en mousse . . . . . . . . . . . . . . . . . . . . . . . . . 181467

Moulinet intérieur . . . . . . . . . . . . . . . . . . . . . . . . 181464

Ens. du bouton Bump Knob . . . . . . . . . . . . . . . . 181468

(Bouton de butée, joint en mousse et ressort)

Vous pouvez vous procurer ces pièces de rechange

SpeedSpoolMDauprès de votre concessionnaire agréé.

3. Retirez de la bobine extérieure le moulinet intérieur

avec son fil (Fig. 21).

Fig. 22

8. Serrez le bouton de butée en appuyant dessus et en

tournant à droite.

9. Posez le fil neuf tel qu'indiqué dans Installation du fil

de SpeedSpoolMD.

F14

DÉPANNAGE

CAUSE SOLUTION

Accessoire de coupe engorgé d'herbes Arrêtez le moteur et nettoyez l'accessoire

Accessoire de coupe mal aligné Chargez du fil neuf

Moulinet intérieur bloqué Remplacez le moulinet

Tête de coupe sale Nettoyez le moulinet intérieur et la bobine extérieure

Fil soudé Démontez et déposez la partie soudée, et

rembobinez le fil

Fil tordu durant la recharge Démontez puis rembobinez le fil

Quantité insuffisante de fil exposée Enfoncez le bouton de butée et tirez le fil jusqu’à en

extraire 102 mm (4 po) à l’extérieur de l’accessoire

de coupe

CAUSE SOLUTION

Moteur s’arrête ou le cordon électrique Vérifier le cordon électrique et s’assurer qu’il est