/

f.I

~

~

MAN CO..

PRINTED !N U.S.A.

and

I

'r~"

YARD.

--

1410 West Ganson Street -Jackson, Michigan 49202

I

P. O. BOX 36940

CLEVELAND, OHIO 44136

0611-7588

Your SNOW THROWER is a precision piece of snow throwing equipment. Engineering skill and experience have been combined to

provide the ultimate in safety and efficiency. As with any type of power equipment, carelessness or error on the part of the operator

can result in injury. EXERCISE EXTREME CAUTION AT ALL TIMES.

1.. READ THE OWNER'S MANUAL CAREFULLY. Know the controls to operate your SNOW THROWER properly and how

to quickly stop th~unit.

BEFORE STARTING ENGINE, disengage all clutches and shift unit into neutral. Keep hands, feet and clothing away from

power driven parts.

DISENGAGE POWER AND STOP MOTOR before cleaning discharge, removing obstacles, making adjustments, or when

leaving operating position.

NEVER DIRECT DISCHARGE AT BYSTANDERS or allow anyone in front of machine -debris may be hidden in the

snow. .'.

KEEP CHILDREN AND PETS a safe distance away.

DO NOT ALLOW CHILDREN TO OPERATE MACHINE or allow adults to operate machine without proper instruction.

ADJUST SCOOP HE IGHT to clear gravel or crushed rock surface.

EXERCISE CAUTION to avoid slipping or falling, especially when operating in reverse.

HANDLE GASOLINE WITH CARE -it is highly flammable.

Use approved gasoline container.

Never add gasoline to a running motor. Fill tank outdoors and wipe up spilled gasoline.

b.

gasoline cap securely.

Open doors if motor is running indoors -exhaust fumes are dangerous.

d.

USE A GROUNDED THREE-WI RE PLUG-IN for all units equipped with electric starting kits.

11. KEEP UNIT IN GOOD OPERATING CONDITION and keep safety devices in place.

2

2.

3.

4.

5.

6.

7.

8.

9.

a.

Replace

c.

10.

CE~

FREE OPERATION

,

GENERAL SNOW~THROWING

1.~ Always keep area to be cleaned cleared before~owfall~. .

2.~. Always start engine with machine on level surface with master clutch disengaged: After starting, let engine warm up several

minutes at slow speed before starting to remove ~now~ Ifinachine is stored indoors, let engine and machine adjust to outdoor

temperatures before starting to throw snow': ...

';;;.. ""i" '-.

3. When throwing snow, ~u!:, machln.eat.~ull throttl~ for best re~lts:

When in deep heavy snow, shift to slowest speed, and start at the edge of area to be cleared, discharging snow to the outside.

."

5. Always run engine a few minutes before storing, to dry moisture that collects inside of engine from blowing snow.

., ,~~,.;..,., ;",c.~i:,j;'i-",o\;,-, "",,";"""""""J,""""';'._' .

NOTE: NEVER RUN ENGINE INDOORS OR IN AN ENCLOSED AREA.

'- -."-"","...~ .,

..'co

.4.

MAINTENANCE:

Your SNOW THROWER like all machines with moving parts, must receive care and maintenance. The following tips, if used, will

contribute many trouble-free hours to your machine.

1. Check engine oil level frequently, or every 5 hours of use. When changing oil, make sure dirt and debris is cleaned from oil

,~ drain area before rem~ving oil plug. c ..'.

2; Keep fan and auger housings clean. .y ..

3. Check all nuts, bolts and screws occasio~ally for tightness to be sure machine is in good operating condition.

Should excessive vibration develop,'check your fan and fan shaft immediately. Do not operate the machine with a bent fan or

shaft. .

f

..4:

5. The machine is pre-lubricated at the factory. However, lubrication with each usage will prolong life of working parts.

6. If you are going to store your SNOW TH ROWER for any length of time (30 days or longer) it is important that the following

-.steps betaken.: , .I

Drain the gas tank and carburetor. Start the engine and run it until out of gas.

Gasoline left in the engine will leave gum deposits in the carburetor and gas tank.

Clean engine of all foreign matter:~

.-' -'

, .'

Lubricate cylinder by removing the sparkplug and pouring one ounce of clean

lubricating oil through the sparkplug hole into the cylinder. Crank engine slowly to

spread oil and replace sparkplug.

'

7

Should unusual vibration develop in transmission, remove rubber panel in rear cover and check rubber drive disc condition. For

reference see page 11.

The belt tension is adjustable. The tensioning of belt should be checked every 5-10 hours of operation. Refer to adjustments

section for re-setting.

To prevent recoil freezing, when snow thrower is to be stored outside or in sub-freezing shelter, pull recoil rope out 6" to 12"

and tie knot in rope or fasten handle to keep rope from re-winding. This procedure will set inner parts in position for starting.

Just as your automobile nec:ds professional mechanical maintenance from time to time, so does your air-cooled engine. A yearly

tune-up and check by a qualified service center is recommended to avoid breakdowns and unnecessary delays during the snow

throwing season.

MA1NTENAN

b.c.

8.9.10.

3

AND SET-UP

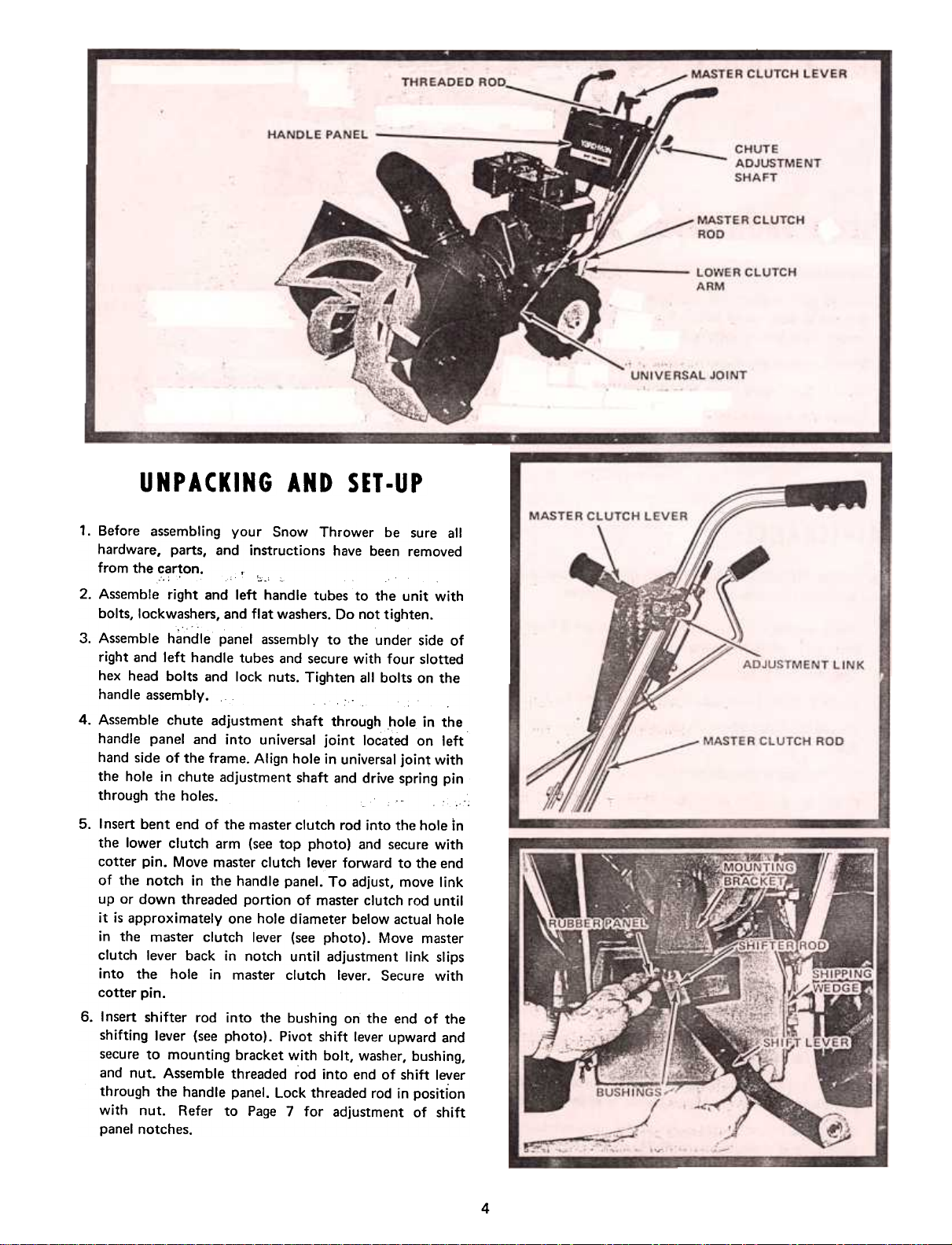

1. Before assembling your Snow Thrower be sure all

hardware, parts, and instructions have been removed

from the carton. ,

Assemble right and left handle tubes to the unit with

bolts, lockwashers, and flat washers. Do not tighten.3.

Assemble handle panel assembly to the under side of

right and left handle tubes and secure with four slotted

hex head bolts and lock nuts. Tighten all bolts on the

handle assembly.4.

Assemble chute adjustment shaft through hole in the

handle panel and into universal joint located on left

hand side of the frame. Align hole in universal joint with

the hole in chute adjustment shaft and drive spring pin

through the holes. .':5.

Insert bent end of the master clutch rod into the hole in

the lower clutch arm (see top photo) and secure with

cotter pin. Move master clutch lever forward to the end

of the notch in the handle panel. To adjust, move link

up or down threaded portion of master clutch rod until

it is approximately one hole diameter below actual hole

in the master clutch lever (see photo). Move master

clutch lever back in notch until adjustment link slips

into the hole in master clutch lever. Secure with

cotter pin.

6. Insert shifter rod into the bushing on the end of the

shifting lever (see photo). Pivot shift lever upward and

secure to mounting bracket with bolt, washer, bushing,

and nut. Assemble threaded rod into end of shift lever

through the handle panel. Lock threaded rod in position

with nut. Refer to Page 7 for adjustment of shift

panel notches.

...:' ':;.' '-2.

UNPACKING

4

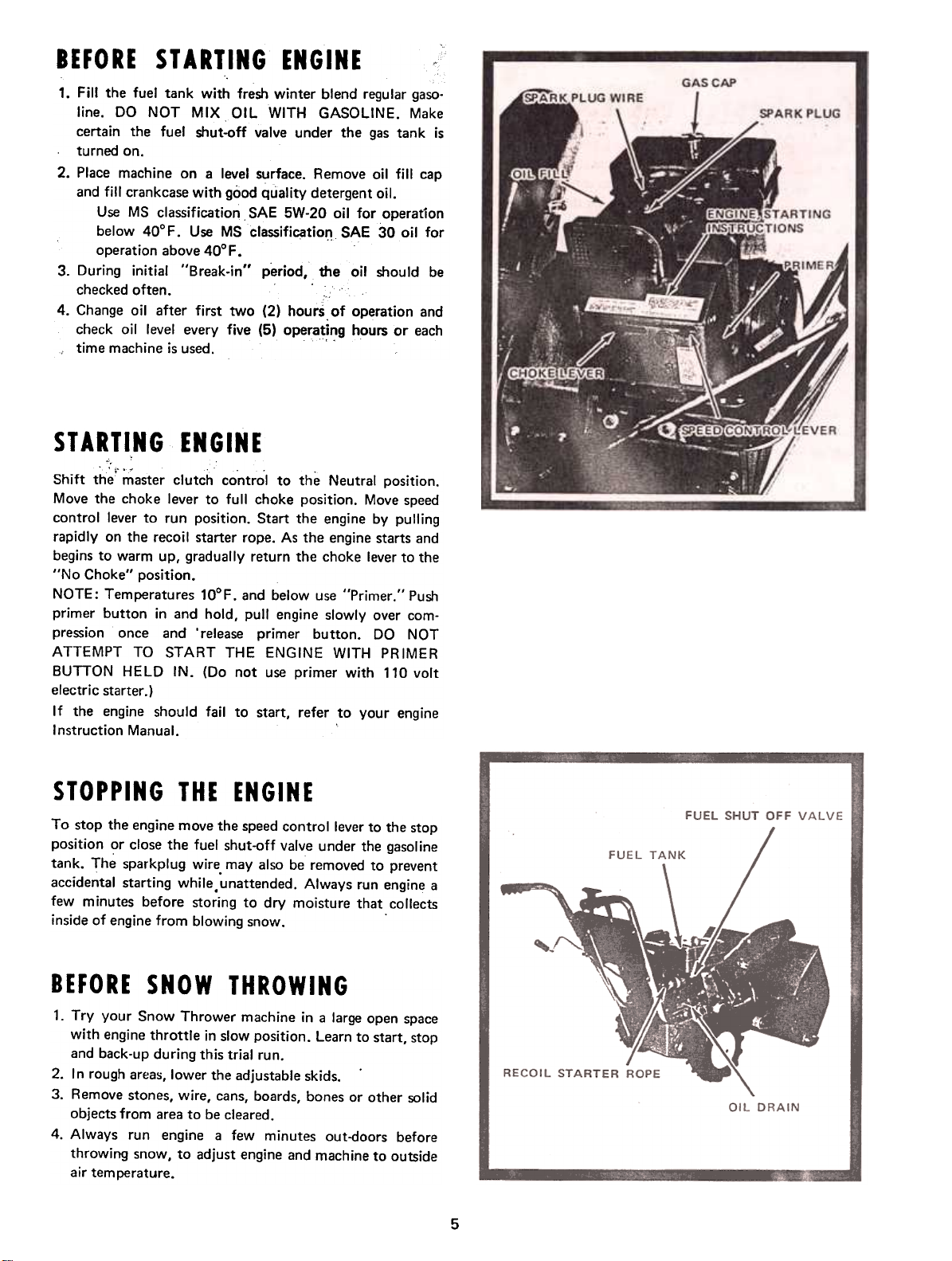

BEFORE STARTING ENGINE

1. Fill the fuel tank with fresh winter blend regular gasoline. DO NOT MIX OIL WITH GASOLINE. Make

certain the fuel shut-off valve under the gas tank is

turned on.

2. Place machine on a level surface. Remove oil fill cap

and fill crankcase with good quality detergent oil.

Use MS classification SAE 5W-20 oil for operation

below 400 F. Use MS classific:atio~ SAE 30 oil for

operation above 400 F .

3. During initial "Break-in" period, the oil should be

checked often. .

4. Change oil after first two (2) hours. of operation and

check oil level every five (5) operat~,:,g hours or each

time machine is used.

"

: 'f"

Shift the master clutch control to the Neutral position.

Move the choke lever to full choke position. Move speed

control lever to run position. Start the engine by pulling

rapidly on the recoil starter rope. As the engine starts and

begins to warm up, gradually return the choke lever to the

"No Choke" position.

NOTE: Temperatures 10°F. and below use "Primer." Push

primer button in and hold, pull engine slowly over compression once and 'release primer button. DO NOT

ATTEMPT TO START THE ENGINE WITH PRIMER

BUTTON HELD IN. (Do not use primer with 110 volt

electric starter.)

If the engine should fail to start, refer to your engine

Instruction Manual.

ENGINE

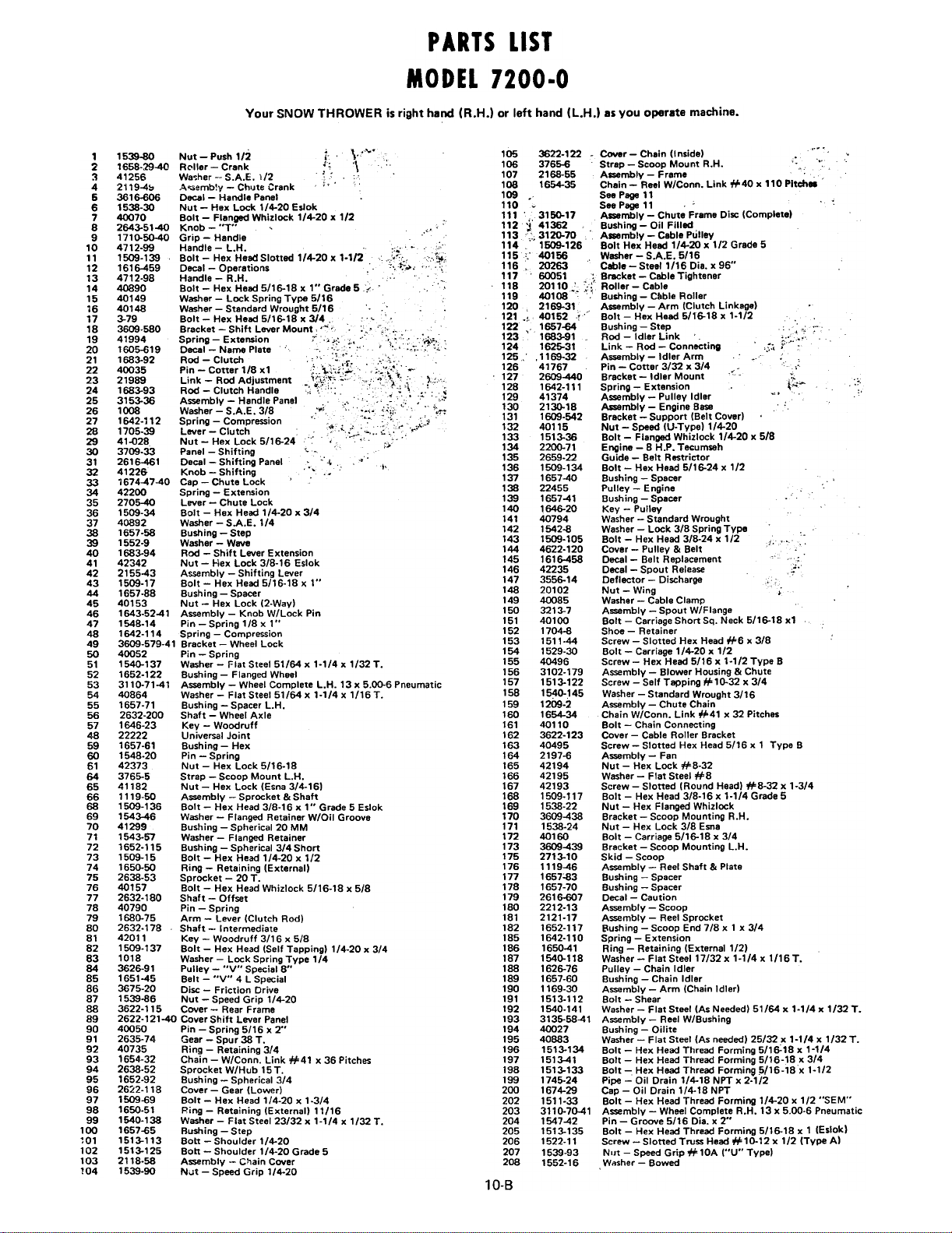

STOPPING THE ENGINE

To stop the engine move the speed control lever to the stop

position or close the fuel shut-off valve under the gasoline

tank. The sparkplug wire. may also be removed to prevent

accidental starting while. unattended. Always run engine a

few minutes before storing to dry moisture that collects

inside of engine from blowing snow.

BEFORE SNOW THROWING

1. Try your Snow Thrower machine in a large open space

with engine throttle in slow position. Learn to start, stop

and back-up during this trial run.2.

In rough areas, lower the adjustable skids.3.

Remove stones, wire, cans, boards, bones or other solid

objects from area to be cleared.4.

Always run engine a few minutes out-doors before

throwing snow, to adjust engine and machine to outside

air temperature.

STARTING

5

OPERATION OF

CONTROLS

MASTERCLUrCH

The master clutch control is located on handle panel and IS

used to engage, all power~Select:8 forward speed or rever~

with shift lever, then release master clutch control and push

f,orward to engage ?rive diS?: f~~: reel. To disengage, pu II

master clutch control back and lock in notch. The master

." " , ,,'.. '

clutch control must always'beln: neutral position before

-, '~-""'" ,.' -' -' ":!, , .

starting engine,;"'~ "'..

FREE~'

;' ".

The wheel clutches are located on wheels' and are used to

engage or disengage powerto.wheels.,Tofree the wheels for

-' ,-"', "c., , """,,~~,,: ."

pushing,'pull out 011 the knob' and turn to lock. To provide

'.. "",t.,.. " ;~;' -""". ., -

self-propelling,power:to ~he wheels.turn"clutches in the

opposite direction and release.:':Thec wheel clutches are

spring-loaded, .move unit until'theC~lutches lock to wheels.

" ' ",,'c,';""...c"":,

W'- HEELING" .~""", ~

...;;ii;F=::;i.'~

"~""'- ...

, "".. c. '._1 -, ,. ,

CONTROL

, '.. c, ,," ,. -

, "

DEFLECTOR

The deflector may be positioned in either a vertical or a 450

position in relation to the spout as needed for proper snow

deflection by loosening the two wing nuts on both sides of

the deflector. NOTE: For shipping purposes the deflector is

lowered off the hinging pin. Loosen the wing nuts and

reposition the deflector over the pin before operating the

Snow Thrower.

DISCHARGE

To rotate the discharge chute to the right or left, release

chute lock lever, then rotate with chute adjustment shaft to

desir~d position and lock. NOTE: The spout and deflector

rotates automatically when rotating the discharge chute to

the right and left. If it is desired to change position of the

spout, lift spout lock lever on the right hand side of unit

and hold while rotating the spout. Release the lever and

turn spout slightly until it !ocks into position.

CHUTE AND

SPOUT

ADJUSTMENTS

NOTE: Make all adjustments with the engine turned off

and wire "removed from the sparkplug. (Fasten wire to

cylinder head at least 1" away from sparkplug.)

DEPTH ADJUSTMENT

The adjustable skids may be set lower to prevent picking up

loose stone!; and foreign material. Also they can be raised 'to

allow the reel to slightly touch the ground for additional

pulling power.

6

REPLACING SAFETY SHEAR BOLT

If the intake snow reel should jam causing the safety shear

bolt to shear, it may be replaced with a new bolt, furnished

in the parts bag, after removing the broken pieces in the

shaft. NOTE: Always align the hole in the reel shaft and the

sprocket shaft before driving out the broken bolt. Do NOT

remove solid pin located near shear bolt hole.

CHUTE CHAIN AND-ADJUSTMENT

To tight~n the chute chain, rotate the chute all the way to

the left, until the adjustment bolt is accessible. Tighten the

adjustment nut to tighten the chain. ..' :

CAUTION: Chain must be kept snug on chute housing. "

." .,,' ,

.

CHUTE CABLE ADJUSTMENT

Remove cable roller cover, loosen the locking bolt on top

! of the cable roller bracket and tighten the adjustment bolt

on the side.

CAUTION: The cable should not be adjusted too tightly,

adjustment should allow the spout to rotate freely.

Retighten the locking bolt and replace the cable roller

cover.

SHIFT PANEL ADJUSTMENT

set or adjust the shift panel for correct speeds, place

master clutch control in neutral position and the shift lever

into the fifth speed notch. Loosen the two mounting bolts

and push shift lever right as far as allowed, hold, and

tighten mounting bolts. DO NOT ATTEMPT TH IS ADJUSTMENT WITH THE ENGINE RUNNING. To check

adjustment, start engine, move shift lever to first speed

notch and engage master clutch control. Unit should move

forward very slowly.

.

To

If first or reverse speeds are not satisfactory with this ad-

justment, move panel to the right for a faster first speed.

Move panel to the left for a faster reverse speed.

NOTE: Adjustment section continued on page 12.

PARTS LIST

MODEL 7200-0

Your SNOW THROWER is right hand (R.H.I or left hand (L.H.I as you operate machine.

1539-80 Nut -Push 1/2 i \."..-

1

2

1658-29-40 Roller -Crenk :; '\'

41256 Wa,her-S.A,E, 1/2 ',' ,

:I

2119-4b A...mb!y-ChIJteCrank'" "

4

3616-006 Decal- Handle Panel

6

1538-30 Nut -Hex Lock 1/4-20 EsJok

6

40070 Bolt -Flanged Whizlock 1/4-20 x 1/2

7

8

2643-51-40 Knob -"T" "

1710-50-40 Grip -Handle .'

9

4712-99 Handle-L.H. ,,;;,. ,.-

10

1509-139 Bolt -Hex Head Slotted 1/4-20 x 1.1/2 c";-' ~1i;

11

1616-459 Decal- Oparations , ", " ';

12

13

4712-98 Handle -R.H.

40890 Bolt -Hex Heed 5/16-18 x 1" Grade 5 f '

14

40149 Washer -Lock Spring Type 5/16

16

16

40148 Washer -Standard Wrought 5/16

3-79 Bolt -Hex Head 5/16-18 x 3/4 '.'

17

3609-580 Bracket-ShiftLeverMount.'::...,. ~\'c' ,~~~.

18

19

20

21

22

23

24

3153-36 Assembly -Handle Panel '"- ',,';... ".

25

26

1 ~:~ 2 f~~r:~ -=-c~~~;~~~n

27

28

41'{)28 Nut -Hex Lock 5/16-24 .., ,,'

29

3709-33 Panel -Shifting " .

30

2616-461 Decal-ShiftingPanel ,-"" .' i.

31

4122& Knob -Shifting'. ,..

32

1674-47-40 Cap -Chute Lock

33

34

42200 Spring -Extension

2705-40 Lever -Chute Lock

35

1509-34 Bolt -Hex Head 1/4-20 x 3/4

36

37

40892 Washer -S.A..E. 1/4

38

1657-58 Bushing -Step

39

1552-9 Washer -Wave

40

1683-94 Rod -Shift Lever Extension

41

42342 Nut -Hex Lock 3/8-16 Eslok

42

2155-43 Assembly -Shifting Lever

43

1509-17 Bolt -Hex Head 5/16-18 xl"

44

1657..88 Bushing -Spacer

45

40153 Nut -Hex Lock (2-Way)

1643-52-41 Assembly -Knob WI Lock Pin

46

47

1548-14 Pin-Spring1/8x1"

48

1642-114 Spring -Compression

49

3609-579-41 Bracket -Wheel Lock

50

40052 Pin -Spring

51

1540-137 Washer-FlatSteeI51/64x1-1/4x1/32T.

52

1652-122 Bushing -Flanged Wheal

53

3110-71-41 Assembly -Wheel Complete L.H. 13 x 5.00-6 Pneumatic

54

40864 Washer- Flat Steel 51/64 x 1-1/4x 1/16T.

55

1657-71 Bushing -Spacer L.H.

56

2632-200 Shaft -Wheel Axle

57

1646-23 Key -Woodruff

48

22222 Universal Joint

59

1657-61 Bushing -Hex

60

1548-20 Pin -Spring

61

42373 Nut -Hex Lock 5/16-18

64

3765-5 Strap -Scoop Mount L.H.

65

41182 Nut-Hex Lock (Esna3/4-16)

66

1119-50 Assembly -Sprocket & Shaft

68

1509-136 Bolt -Hex Head 3/8-16 x 1" Grade 5 Eslok

69

1543-46 Washer -Flanged Retainer W/Oil Groove

70

41299 Bushing -Spherical 20 MM

71

1543-57 Washer -Flanged Retainer

72

1652-115 Bushing-Spherical 3/4 Short

73

1509-15 Bolt -Hex Head 1/4-20 x 1/2

74

1650-50 Ring -Retaining (External)

75

2638-53 Sprocket -20 T.

76

40157 Bolt -Hex Head Whizlock 5/16-18 x 5/8

77

2632-180 Shaft -Offset

78

40790 Pin -Spring

79

1680-75 Arm -Lever (Clutch Rod)

80

2632-178 Shaft -Intermediate

81

42011 Key -Woodruff 3/16 x 5/8

82

1509-137 Bolt -Hex Head (Self Tapping) 1/4-20 x 3/4

83

1018 Washer -Lock Spring Type 1/4

84

3626-91 Pulley -"V" Special 8"

85

1651-45 Belt -"V" 4 L Special

86

3675-20 Disc -Friction Drive

87

1539-86 Nut -Speed Grip 1/4-20

88

3622-115 Cover-Rear Frame

89

2622-121-40 Cover Shift Lever Panel

90

40050 Pin -Spring 5/16 x 2"

91

2635-74 Gear -Spur 38 T.

92

40735 Ring -Retaining 3/4

93

1654-32 Chain -W/Conn. Link #41 x 36 Pitches

94

2638-52 SprocketWIHub 15T..

95

1652-92 Bushing -Spherical 3/4

96

2622-118 Cover -Gear (Lower)

97

1509-69 Bolt -Hex Head 1/4-20 x 1-3/4

98

1650-51 Ring -Retaining (External) 11/16

99

1540-138 Washer -Flat Steel 23/32 x 1-1/4 x 1/32 T.

100

1657-65 Rushing -Step

101

1513-113 Bol1- Shoulder 1/4-20

102

1513-125 Bolt -Shoulder 1/4-20 Grade 5

103

2118-58 Assembly -Chain Cover

104

1539-90 Nut -Speed Grip 1/4-20

~~~~~~

105 3622-122 -Cover-Chain (Inside) ..'.

106 3765-6 Strap -Scoop Mount R.H. ,.

107 2168-55 Assembly -Freme

108 1654-35 Chain -Reel W/Conn. Link ~ 40 x 110 Pitch.

109 SeePage 11

110 c SeePage 11 , "

111 '3150-17 Assembly -Chute Frame Disc (Complete)

112 ~'41362 Bushing-Oil Filled

113 ':; 3120-70 Aaembly -Cable Pulley

114' 1509-126 Bolt Hex Heed 1/4-20 x 1/2 Grade 5

115 :: 40156 ,Wesher-S.A.E.5/16

116 , 20263 Ceble-SteeI1/16Dia.x96"

117 60051 : Bracket -Cable Tightener

118 20110' ",' Roiler-Cabla

119 40108" ,\ Bushing -Chble Roller

120 2169-31 Assembly -Arm (Clutch Linkaga)

121 ,40152 ;/ Bolt -Hex Haed 5/16-18 x 1-1/2

122. 1657.04 8ushing -Step.' .'"

, , '" ,

123 1683-91 Rod -Idler LInk 0",

124 1625-31 Link -Rod -Connecting' ,;:, i"',

125 ,1169-32 Assembly -Idler Arm; ..

126 41767 Pin-Cotter 3/32 x 3/4 -c,

127 2609-440 Bracket -Idler Mount :,

1281642-111 Spring-Extension t:;'~':,

129 41374 Assembly-Pulley Idler .,. ,

130 2130-18 Assembly -Engine Bese

131 1609-542 Brecket -Support (Belt Cover)

132 40115 Nut -Speed (U-Type) 1/4-20

133 1513-36 Bolt -Flenged Whizlock 1/4-20 x 5/8

134 2200-71 Engine -8 H.P. Tecumseh

135 2659-22 Guide -8elt Restrictor

136 1509-134 Bolt -Hex Heed 5/16-24 x 1/2

137 1657-40 Bushing -Spacer

138 22455 Pulley -Engine

139 1657-41 Bushing-Spacer _C

140 1646-20 Key -Pulley

141 40794 Washer -Standard Wrought

142 1542-8 Washer -Lock 3/8 Spring Type

143 1509-105 Bolt -Hex Heed 3/8-24 x 1/2

144 4622-120 Cover -Pulley & Belt

145 1616-458 Decal- Belt Replacement ;

146 42235 Decal -Spout Release ;:.

147 3556-14 Deflector -Discharge

148 20102 Nut -Wing

149 40085 Washer -Cable Clamp

150 3213-7 Assembly -Spout W/Flange

151 40100 Bolt-CarriageShortSq,Neck5/16-18x1

152 1704-8 Shoe -Retainer

153 1511-44 Screw -Slotted Hex Head #6 x 3/8

154 1529-30 Bolt -Carriage 1/4-20 x 1/2

155 40496 Screw -Hex Heed 5/16 x 1-1/2 Type B

156 3102-179 Assembly -Blower Housing & Chute

157 1513-122 Screw-SelfTapping~10-32x3/4

158 1~0-145 Washer -Standard Wrought 3/16

159 1209-2 Assembly -Chute Chain

160 1654-34 Chain W/Conn. Link ~41 x 32 Pitches

161 40110 Bolt -Chain Connecting

162 3622-123 Cover -Cable Roller Bracket

163 40495 Screw -Slotted Hex Head 5/16 x 1 Type B

164 2197-6 Assembly -Fan

165 42194 Nut -Hex Lock #8-32

166 42195 Washer -Flat Steel ~8

167 42193 Screw -Slotted (Round Head) #8-32 x 1-3/4

168 1509-117 Bolt-HexHead3/8-16xl-1/4Grade5

169 1538-22 Nut -Hex Flanged Whizlock

170 3609-438 Bracket -Scoop Mounting R.H.

171 1538-24 Nut -Hex Lock 3/8 Ema

172 40160 Bolt -Carriage 5/16-18 x 3/4

173 3609-439 Bracket -Scoop Mounting L,H.

175 2713-10 Skid-Scoop

176 1119-46 Assembly-ReeIShaft&Plate

177 1657-83 Bushing -Spacer

178 1657-70 Bushing -Spacer

179 2616-607 Decal- Caution

180 2212-13 Assembly-Scoop

181 2121-17 Assembly -Reel Sprocket

182 1652-117 Bushing-Scoop End7/8x 1 x 3/4

185 1642-110 Spring-Extension

186 1650-41 Ring -Retaining (External 1/2)

187 1540-118 Washer- Flat Steel 17/32 x 1-1/4x 1/16T.

188 1626-76 Pulley -Chain Idler

189 1657-60 8ushing -Chain Idler

190 1169-30 Assembly -Arm (Chain Idler)

191 1513-112 Bolt -Shear

192 1540-141 Washer-FlatSteel(AsNeeded)51/64x1-1/4x1/32T.

193 3135-58-41 Assembly -Reel W/Bushing

194 40027 Bushing -Oilite

195 40883 Washer -Flat Steel (As needed) 25/32 x 1-1/4 x 1/32 T.

196 1513-134 Bolt -Hex Head Thread Forming 5/1~18 x 1-1/4

197 1513-41 Bolt -Hex Head Thread Forming 5/16-18 x 3/4

198 1513-133 Bolt -Hex Head Thread Formin95/16-18 x 1-1/2

199 1745-24 Pipe -Oil Drain 1/4-18 NPT x 2-1/2

200 1674-29 Cap -Oil Drain 1/4-18 NPT

202 1511-33 Bolt -Hex Head Thread Forming 1/4-20 x 1/2 "SEM"

203 3110-70-41 Assembly -Wheel Complete R.H. 13 x 5.00-6 Pneumatic

204 1547-42 Pin -Groove 5/16 Dia. x 2"

205 1513-135 Bolt -Hex Head Thread Forming 5/16-18 x 1 (Eslok)

206 1522-11 Screw -Slotted Truss Head #10-12 x 1/2 (Type A)

207 1539-93 NIJt -Speed Grip ~10A r'u" Type)

208 1552-16 Washer -Bowed10-B

P ARTS LIST

REF. PART REF.

NO. NO. DESCRIPTION NO.

t 1654-31 Chain -W/Connactlng Link 22

2 1624-192 Spacer-Gear Sprocket 24

-3 1652-114 Baaring-Needla7/16x 1/2 L. 25

4 1149-5 A-mbly -Gaar & Sprocket W/Bearlng 26~,c

.6 42342 Nut -Hex Lock 3/8.16 (Eslok) 27

6 1008 Washer -SA.E. 3/8 28

7 1646-24 Key -Woodruff 3/32 x 5/8 ~ 29

a 2638-51 Sprocket -aT

9 1624-191 Spacer -Sprocket 30

10 1632.177 Shaft -Gear & Sprocket 31

11 2111.107 A_mbly-PlataPivotL.H. 32

12 1538-30 Nut -Hax Lock 1/4-20 Eslok 33

13 1018 Washer -Lock Spring Type (Light 1/4) 34

14 1657-60 Bushing -Pivot .35

15 40148 Washer-Standard Wrought 5/16 36

16 42373 Nut -Hex Lock 5/16-18 Esna 37

17 3150-20 Assembly -Disc Drive Wheel W/Hub 3s

18 2675.26 Ring -Rubber Drive 39

20 1509.90 Bolt -Hex Head 1/4.20 x 1.1/4 40

21 2632.175 Shaft -Hex

No.41 x 28 pitches 23

(Included Ref. No.3)

GEAR

PART

NO. DESCRIPTION

42180 Nut -Hex Lock No. 10-24 Esne

3606-146 Plate -Pivot R.H.

1652-108 Bearing -Ball Saaled

1629-14 Flange -Retainer

1511-39 Screw -Slotted Truss Head

1540-99 Washer -Standard Wrought 114

40070 Bolt -Flanged Whizlock 114-20 x 1/2

40890 J .Bolt -Hex Heed 5116-18 x 1"

1542-8 Washar -Lock Spring Type (Med) 318

2609-432 8racket -Mount (Pivot Plata)

1632-176 Shaft -Step

1657-63 Bushing -Sintered Bronza 314 x 718 x 1"

40035 Pin -Cotter 1/8 x 1"

1704-1 Shoe -Shifting Yoke

2147-14 Assembly -Shifting Yoka

1777.6 Ear -Shift Yoke Stop

1683-90 Rod -Shifter

40735 Ring -Retaining 314

3114-19 Assembly -Friction Drive Wheel, Complete

No. 10-24 x 518

(Grade 5) (Eslokl

11-8

PART REF.

REF.

NO.

NO. DESCRIPTION NO.

2632-174 Shaft-Fan20MM 13

1

1652-111 Bearing-Ball (Double Sealed) 204 14

2

2635-72 Gear-BaveI18T. 15

3

4

40052 Pin -Spring 5/16 Dia. x 1-1/2 16

5

4609-441 Bracket -Gear Carrier 17

1652-125 Bearing -Shaft Intagral 18

6

40735 Ring -Retaining (External) 3/4 19

7

40883 Washar- Flat Steel 25/32 x 1-1/4x 1/32 20

8

2635-70 Gear-Spur 14T. 21

9

10

1624-213-40 Sleeve -Shaft Cover 22

11

1650-49 Ring -Retaining (External) 13/16 23

1540-136 Washer-FletSteel 27/32 x 1-1/4x 1/32T. 24

12

PART

NO. DESCRIPTION

2635-69 Geer -Spur 30 T.

42011 Key-Woodruff3/16x5/S

1624-190 Spacer -Gear

1543-60 Washer -Thrust

1652.124 Searing-Thrust

1656-13 Seal- Oil 13/16 x 1-1/16

1652-113 Bearing-Roller(NeedleJI3/16

2119-57 A_mbly -Shaft W/Sprocket

1650-50 Ring -Retaining (Externall 25/32

1540-137 Washer-FlatSteeI51/64xl.1/4x1/32T.

263s-71 Gear -Bevel 27 T.

40220 Pin -Spring 5/16 x 1-3/4

4132-138 Assembly -Gear Carrier Complete

25

NOTE: Make all adjustments with the engine turned off

and wire removed from th~- sparkplug. (Fasten wire to

cylinder head at least 1 away.from sparkplug.)

...,

II ..,

IDLER LINKAGE ADJUSTMENT

Should the drive belt stretch enough to prevent the ad

.:.~. :a~.!...L:.

justment link from moving freely in the idler arm, slot, with

the master clutch lever in drive position, adjust' as follows.

With master clutch in drive position, remove cotter pin

from adjustment link. Thread the link up the rod untir it.

is centered in the slot. Place the link in the slot and secure

..'--" ' c.'

with washer and cotter PI,:!. ..

To check the adjustment, return the master clutch lever to

neutral position and pull engine recoil over to see if belt is

not driving. If belt does not release, lower the adjustment

link slightly below center or until belt does release in

" ,

neutral. These adjustments must also be checked when belt

is replaced or the idler is adjusted in the idler arm slot.

~

.~

IDLER PULLEY

ADJUSTMENT

For more adjustment to gain proper tension on the belt, the

idler pulley can be moved in or out in the adjustment slot.

Refer to idler linkage adjustments after making this adjust-

ment.

BELT REPLACEMENT

First. remove plastic cap on spout lock lever, then remove

belt cover. Unhook idler spring to release idler tension on

belt. Remove belt restrictor. Remove rear cover (after

shift lever is removed). This will allow one to reach in from

back of unit. Remove master clutch rod from lower arm.

Remove belt from engine pulley and push belt down off

drive pulley. Push belt,toward rear of unit around drive

disc, then pull belt up b:'!tween rubber drive disc and pulley

disc. Push down on Ic'.'er arm on left side of unit, this

allows more room between rubber disc and pulley disc.

Reach in from back of unit and push belt up, then pull belt

out. To install new belt, reverse steps using only original

equipment replacement belt No. 1651-45.

I

12

LUBRICA TION-

CHANGING ENGINE OIL

Drain oil when engine is warm. To drain oil, place pan

under frame directly beneath oil drain extension. Remove

oil drain cap and allow oil to drain completely. Replace

drain cap and tighten securely. Refill to "Full", approximately 1 pint. See engine manual for complete engine lub.

rication and service instructions.

LUBRICATION POINTS

lUBRICATE THE PARTS PERIODICAllY AS IllUS-TRATED.

The following points are to be lubricated every

five hours of operation with SAE 20 weight light duty oil.

unless otherwise noted.

1. Spherical Bearings (Both Sides)

2. Wheels

3. Discharge Spout

4. Blower Housing

5. Reel Chain' .;':

6. Chute Adjustment Chain

7. Chain Guard Bushing

8. Universal Joint

9. Reel Bearings ;.:,

10. Cable Rollers ,1

11. Idler Arm & Linkage

12. Clutch Handle Pivot :~'

13. Shift Yoke Slide "AFTER

,..

BREAK IN PERIOD (FIRST 3 TO 4 HOURS OFOPERATION).

CHECK All BOLTS AND NUTS FORTIGHTNESS.

END OF SEASON STORAGE

In the event the engine is to be stored for any length oftime

(30 days or more) or at the end of the snow throwing

season, prepare it as outlined in the following steps:

1. Drain gas tank completely. by J_emoving -fuel line -at the

carburetor or fuel "tank, whichever is easier.2.

Drain the carburetor by pressing upward on the bowl

drain.3.

To protect the engine when storing, remove the spark-

plug and inject one ounce of SAE 10 weight oil through

the sparkplug hole into the cylinder. Crank the engine

(without starting) several times to spread the oil over the

cylinder walls.4.

Lubricate all lubrication points as outlined in Lubrication Section.5.

Handles can be removed to save space by disconnecting

master clutch rod, universal joint and shift lever.

CHUTE CABLE REPLACEMENT

OR REPAIR

1. REMOVE THE BLOWER HOUSIN~ FROM THE

MACHINE.

A. Remove the ~ain guard and disconnect the reel drive

chain at the chain connecting link.

B. Re!:':1°ve the !.Ou! carriage- bolts, fastening the scoop

to the mounting brackets. Remove the: scoop and

, -.,' .,,'" .'

reel assembly' intact.' Do not remove~~ mounting

"- ". .",. c-

brackets from frame straps.

C. Remove the spring pin and remove fan;

D. Loosen chute chain-to allow for removal of blower

housing.

E. Remove the blower housing fromthe_unit;;-

2. REMOVE THE WORN CABLE.

A. Place the blower housing on a bench with the cable

pulley exposed. .

--

"."'- .-.',c"".

cable roller bracket and down to the right hole in the

top of the blower housing.

C. Turn the cable pulley with the cable bolt toward the

bottom of the blower housing.

D. Put the ends of the cable up through the holes in the

bottom of the cable pulley and cross the ends up and

over the cable bolt and under the washer. Pull the

cable tight and tighten the' ~ble bolt and nut, making

sure the cable remains in the track around the cable

pulley.

E. Slide cable pulley back into place.

F. Tighten cable with adjusting cable bolt.

5. REPLACE THE BLOWER HOUSING

A. Reverse the steps outlined in Step 1 to replace the

blower housing and parts to the Snow Thrower.

, , " .'\ ' .

B. Remove the cable roller cover.

C. Loosen the lock bolt on top of the cable roller

bracket and adjust the' cable adjusting bolt and cable

roller in as far as possible.

D. Lift the cable pulley away from the blower housing

:c. approximately 3 inches.

E. Loosen the cable mounting bolt and remove the'cable

ends from the cable pulley.

F. Loosen the nut on the cable washer which holds the

c. cable to the upper spout assembly and remove the

worn cable.

3. REPLACE NEW CABLE.:

A. Fasten a loop in center of the cable under the cable

washer making certain that both ends of the cable are

, .

even.

B. With the cable crossed, wrap each end of the cable

around the upper spout.

4. PLACING THE NEW CABLE OVER THE CABLE

ROLLERS.

A. Rotate the upper spout assembly with the discharge

side in the opposite direction from the cabie pulley

side of the blower housing.

B. Extend the cable from the right si~e of the upper

spout assembly over the roller on the left side of the

cable roller bracket and through the left cable hole in

the top of the blower housing. Extend the cable from

the left side of the spout assembly across the center

cable roll~r. back and around the cable adjustment

roller and over the cable roller on the right side of the

14

.~';:;j

1~

15

30" SNOW THROWERyou

enjoy these outstanding features

~

7/73

Loading...

Loading...