Page 1

SERVICE MANUAL

PZ50W

PZ50GTW

PZ50FXW

PZ50MW

PZ50VTW

PZ50MPW

LIT-12618-02-58 8GC-28197-10

Page 2

Page 3

NOTICE

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers and

their qualified mechanics. It is not possible to put an

entire mechanic’s education into one manual, so it

is assumed that persons using this book to perform

maintenance and repairs on Yamaha snowmobiles

have a basic understanding of the mechanical concepts and procedures inherent in snowmobile

repair. Without such knowledge, attempted repairs

or service to this model may render it unfit and/or

unsafe to use. Yamaha Motor Company, Ltd. is

continually striving to improve all models manufactured by Yamaha. Modifications and significant

changes in specifications or procedures will be forwarded to all authorized Yamaha dealers and will,

where applicable, appear in future editions of this

manual.

HOW TO USE THIS MANUAL

Particularly important information is distinguished in

this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BE

ALERT! YOUR SAFETY IS INVOLVED!

WARNING

Failure to follow WARNING instructions could result

in severe injury or death to the snowmobile operator, a bystander, or a person inspecting or repairing

the snowmobile.

CAUTION:

A CAUTION indicates special precautions that

must be taken to avoid damage to the snowmobile.

NOTE:

A NOTE provides key information that can make

procedures easier or clearer.

PZ50W, PZ50GTW, PZ50FXW, PZ50MW,

PZ50VTW, PZ50MPW

SERVICE MANUAL

©2006 by Yamaha Motor

Corporation, U.S.A.

1st Edition, July 2006

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Corporation,

U.S.A. is expressly prohibited.

Printed in U.S.A.

P/N.LIT-12618-02-58

MANUAL FORMAT

All of the procedures in this manual are organized

in a sequential, step-by-step format. The information has been compiled to provide the mechanic

with an easy to read, handy reference that contains

comprehensive explanations of all inspection,

repair, assembly, and disassembly operations.

In this revised format, the condition of a faulty component will precede an arrow symbol and the

course of action required to correct the problem will

follow the symbol, e.g.,

• Bearings

Pitting/damage → Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before

each disassembly section to facilitate correct disassembly and assembly procedures.

Page 4

1 2

GEN

INFO

34

INSP

ADJ

POWR

CHAS

TR

56

ENG

78

COOL

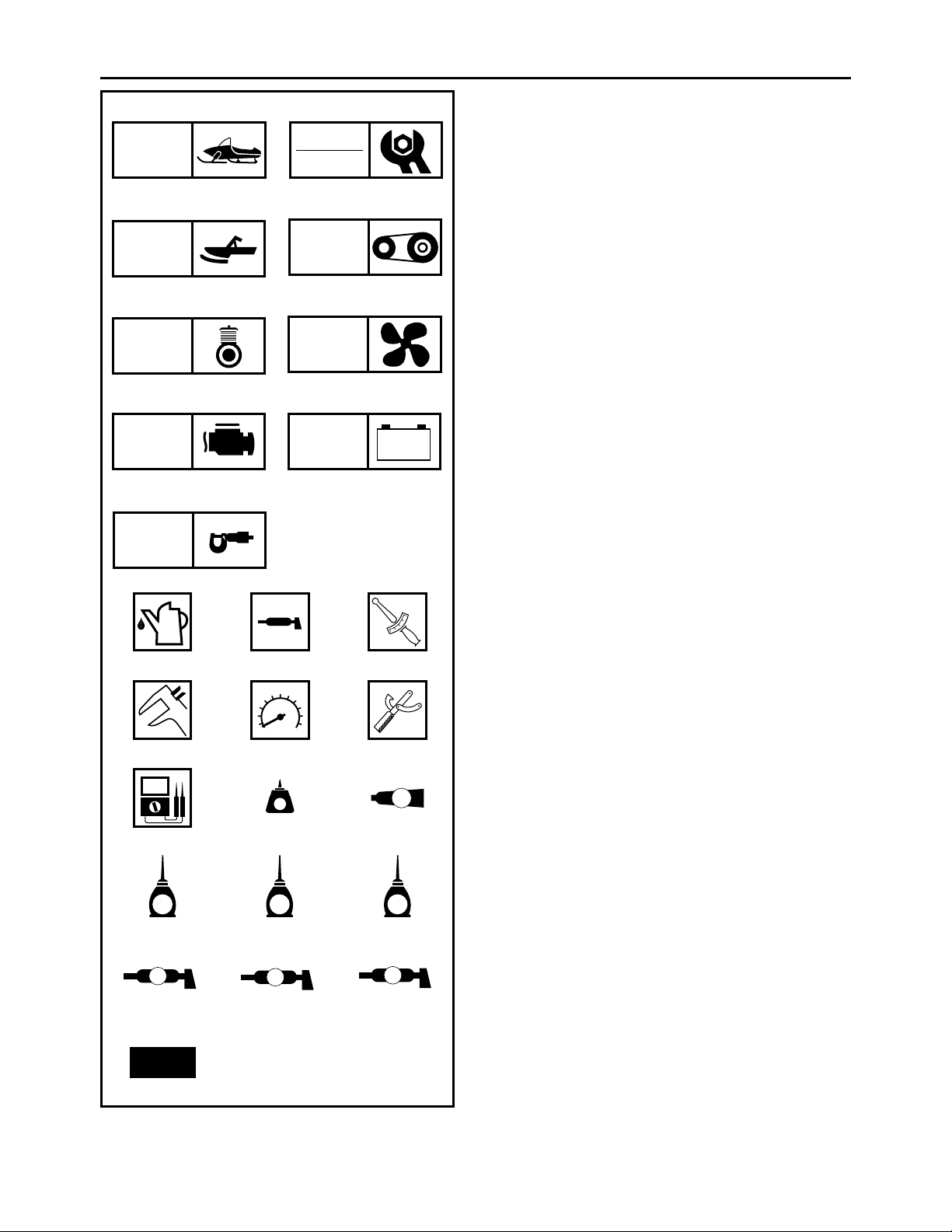

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols 1 to 9 are designed as thumb

tabs to indicate the chapter’s number and content.

1 General information

2 Periodic inspection and adjustment

3 Chassis

4 Power train

5 Engine

6 Cooling system

7 Fuel injection system

8 Electrical

9 Specifications

–+

9

FI

ELEC

SPEC

0AB

T

.

R

.

CDE

FGH

LT

IJK

E

LMN

B

G

LS

5

M

M

Illustrated symbols 0 to F are used to identify the

specifications which appear.

0

Filling fluid

A Lubricant

B Tightening

C Wear limit, clearance

D Engine speed

E Special tool

FΩ, V, A

Illustrated symbols G to O in the exploded diagram

indicate grade of lubricant and location of lubrication point.

G Apply locking agent (LOCTITE

H Apply Yamabond No.5

I Apply engine oil

J Apply gear oil

K Apply molybdenum disulfide oil

L Apply wheel bearing grease

M Apply low-temperature lithium-soap base grease

N Apply molybdenum disulfide grease

O Use new one

®

®

)

O

New

Page 5

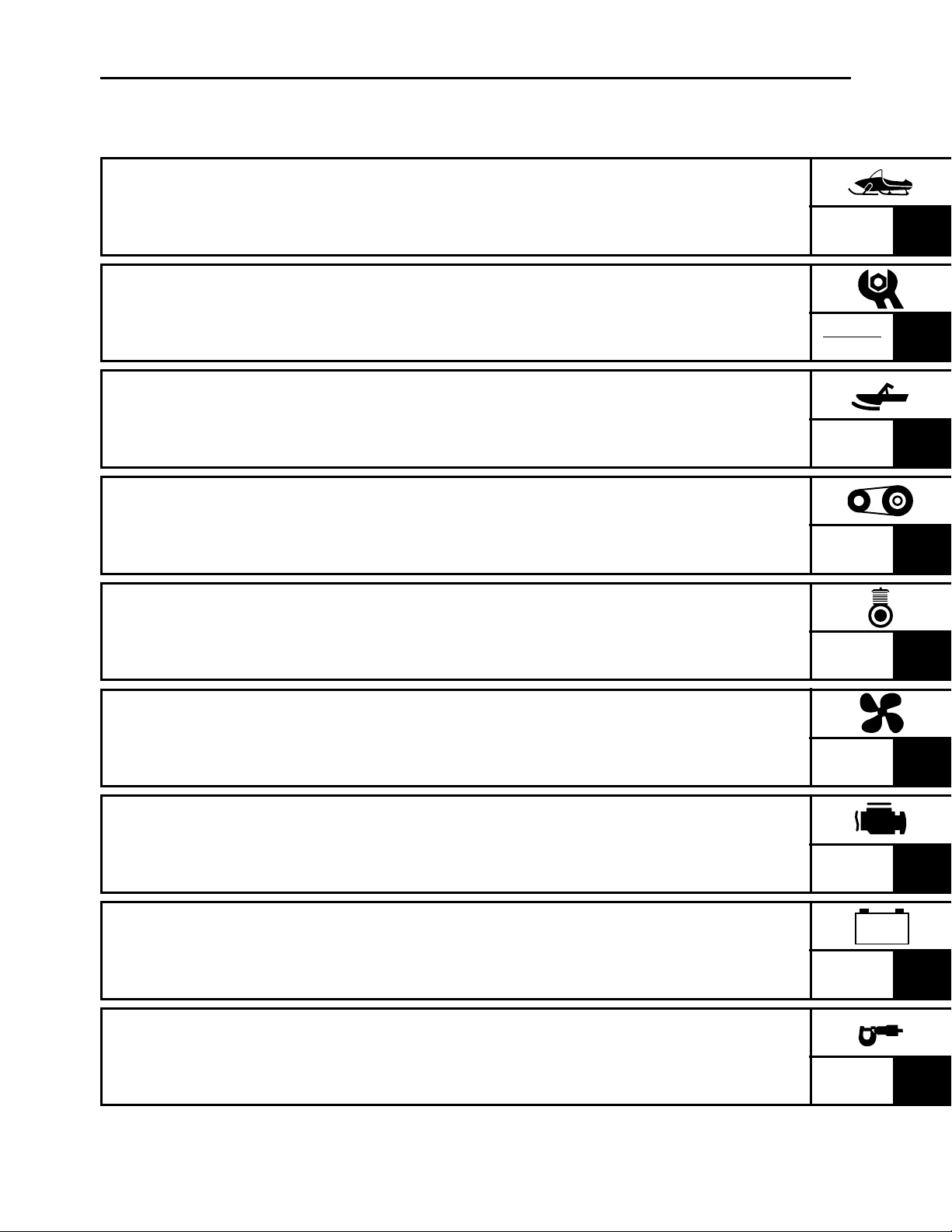

INDEX

GENERAL INFORMATION

PERIODIC INSPECTION AND

ADJUSTMENT

CHASSIS

POWER TRAIN

ENGINE

GEN

INFO

INSP

ADJ

CHAS

POWR

TR

ENG

1

2

3

4

5

COOLING SYSTEM

FUEL INJECTION SYSTEM

ELECTRICAL

SPECIFICATIONS

COOL

FI

– +

ELEC

SPEC

6

7

8

9

Page 6

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION

FRAME SERIAL NUMBER ......................... 1-1

ENGINE SERIAL NUMBER........................ 1-1

............................ 1-1

CYLINDER HEAD BREATHER HOSE

INSPECTION ............................................ 2-23

THROTTLE BODY JOINTS

INSPECTION ............................................ 2-23

CHECKING THE AIR FILTER

ELEMENT ................................................. 2-24

EXHAUST SYSTEM INSPECTION .......... 2-25

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY........................................... 1-2

ALL REPLACEMENT PARTS..................... 1-2

GASKETS, OIL SEALS, AND O-RINGS..... 1-3

LOCK WASHERS/PLATES AND COTTER

PINS............................................................ 1-3

BEARINGS AND OIL SEALS ..................... 1-3

CIRCLIPS ................................................... 1-3

LOCTITE

SPECIAL TOOLS

FOR TUNE UP............................................ 1-4

FOR ENGINE SERVICE............................. 1-4

FOR POWER TRAIN SERVICE ................. 1-7

FOR FUEL INJECTION SERVICE ............. 1-8

FOR ELECTRICAL SERVICE .................... 1-8

®

................................................... 1-3

............................................. 1-4

.......................... 1-2

CHAPTER 2.

PERIODIC INSPECTION

AND ADJUSTMENT

POWER TRAIN

SHEAVE OFFSET ADJUSTMENT ........... 2-26

DRIVE V-BELT.......................................... 2-28

ENGAGEMENT SPEED CHECK.............. 2-29

PARKING BRAKE ADJUSTMENT............ 2-29

BRAKE FLUID LEVEL INSPECTION ....... 2-30

BRAKE PAD INSPECTION....................... 2-31

BRAKE HOSE INSPECTION.................... 2-32

AIR BLEEDING (HYDRAULIC BRAKE

SYSTEM) .................................................. 2-32

DRIVE CHAIN ........................................... 2-33

TRACK TENSION ADJUSTMENT............ 2-35

SLIDE RUNNER INSPECTION ................ 2-37

MAXIMIZING DRIVE TRACK LIFE ........... 2-37

CHASSIS

SKI/SKI RUNNER ..................................... 2-39

STEERING SYSTEM ................................ 2-39

LUBRICATION .......................................... 2-41

ELECTRICAL

HEADLIGHT BEAM ADJUSTMENT ......... 2-42

BATTERY INSPECTION........................... 2-42

FUSE INSPECTION.................................. 2-48

............................................... 2-26

........................................................ 2-39

................................................. 2-42

INTRODUCTION

PERIODIC MAINTENANCE CHART FOR

THE EMISSION CONTROL SYSTEM

GENERAL MAINTENANCE AND

LUBRICATION CHART

ENGINE

............................................................ 2-4

SPARK PLUGS........................................... 2-4

FUEL LINE INSPECTION........................... 2-4

COOLING SYSTEM.................................... 2-5

VALVE CLEARANCE ADJUSTMENT ........ 2-7

THROTTLE BODY

SYNCHRONIZATION ............................... 2-13

ENGINE IDLE SPEED ADJUSTMENT..... 2-14

THROTTLE CABLE FREE PLAY

ADJUSTMENT.......................................... 2-15

THROTTLE OVERRIDE SYSTEM

(T.O.R.S.) CHECK .................................... 2-16

COMPRESSION PRESSURE

MEASUREMENT ...................................... 2-17

ENGINE OIL LEVEL INSPECTION .......... 2-19

ENGINE OIL REPLACEMENT ................. 2-20

............................................... 2-1

.............. 2-1

.................................... 2-2

TUNING

.......................................................... 2-50

CLUTCH.................................................... 2-50

GEAR SELECTION................................... 2-55

FRONT SUSPENSION ............................. 2-61

REAR SUSPENSION................................ 2-63

CHAPTER 3.

CHASSIS

COWLINGS

PZ50/PZ50GT/PZ50FX/PZ50M .................. 3-1

PZ50VT/PZ50MP ........................................ 3-3

STEERING

PZ50W/PZ50GT/PZ50FX/PZ50M............... 3-4

PZ50VT/PZ50MP ........................................ 3-6

REMOVAL................................................. 3-10

INSPECTION ............................................ 3-10

INSTALLATION......................................... 3-11

SKI

.................................................................. 3-14

PZ50/PZ50GT/PZ50FX/PZ50VT “USA/

Canada” .................................................... 3-14

...................................................... 3-1

........................................................ 3-4

Page 7

PZ50VT “Europe”/PZ50MP....................... 3-15

PZ50M ...................................................... 3-16

INSPECTION ............................................ 3-17

FRONT SUSPENSION ................................... 3-18

PZ50/PZ50FX/PZ50M............................... 3-18

PZ50GT/PZ50VT/PZ50MP ....................... 3-20

HANDLING NOTES .................................. 3-22

INSPECTION ............................................ 3-22

INSTALLATION ........................................ 3-23

CHAPTER 4.

POWER TRAIN

PRIMARY SHEAVE AND DRIVE V-BELT ....... 4-1

REMOVAL .................................................. 4-3

DISASSEMBLY........................................... 4-3

INSPECTION .............................................. 4-4

ASSEMBLY................................................. 4-6

INSTALLATION .......................................... 4-9

SECONDARY SHEAVE ................................. 4-10

DISASSEMBLY......................................... 4-12

INSPECTION ............................................ 4-12

ASSEMBLY............................................... 4-13

INSTALLATION ........................................ 4-14

DRIVE CHAIN................................................. 4-15

REMOVAL ................................................ 4-16

INSPECTION ............................................ 4-16

INSTALLATION ........................................ 4-18

SECONDARY SHAFT .................................... 4-19

PZ50 ......................................................... 4-19

REMOVAL ................................................ 4-20

INSPECTION ............................................ 4-20

INSTALLATION ........................................ 4-20

SECONDARY SHAFT AND DRIVE

CHAIN INSTALLATION ............................ 4-22

BRAKE CALIPER ASSEMBLY ................. 4-37

BRAKE CALIPER INSTALLATION ........... 4-37

INSPECTION ............................................ 4-39

BRAKE MASTER CYLINDER

ASSEMBLY............................................... 4-39

INSTALLATION......................................... 4-39

SLIDE RAIL SUSPENSION............................ 4-40

PZ50/PZ50GT/PZ50FX/PZ50M ................ 4-40

PZ50VT/PZ50MP ...................................... 4-45

REMOVAL................................................. 4-51

INSPECTION ............................................ 4-51

ASSEMBLY............................................... 4-51

INSTALLATION......................................... 4-55

FRONT AXLE AND TRACK ........................... 4-56

INSPECTION ............................................ 4-57

INSTALLATION......................................... 4-57

CHAPTER 5.

ENGINE

SEAT AND FUEL TANK................................... 5-1

PZ50/PZ50GT/PZ50FX/PZ50M .................. 5-1

BACKREST AND PASSENGER SEAT ........... 5-3

PZ50VT/PZ50MP ........................................ 5-3

RIDER SEAT AND FUEL TANK ...................... 5-5

PZ50VT/PZ50MP ........................................ 5-5

REMOVAL................................................... 5-7

INSTALLATION........................................... 5-8

EXHAUST PIPE AND MUFFLER ..................... 5-9

PZ50/PZ50GT/PZ50FX/PZ50M .................. 5-9

PZ50VT/PZ50MP ...................................... 5-10

INSTALLATION......................................... 5-11

OIL TANK ....................................................... 5-12

SECONDARY SHAFT AND REVERSE

GEAR CASE................................................... 4-23

PZ50GT/PZ50FX/PZ50M/PZ50VT/

PZ50MP .................................................... 4-23

REMOVAL ................................................ 4-27

INSPECTION ............................................ 4-28

ASSEMBLY............................................... 4-28

INSTALLATION ........................................ 4-29

SECONDARY SHAFT AND DRIVE

CHAIN INSTALLATION ............................ 4-30

BRAKE ........................................................... 4-31

BRAKE PAD REPLACEMENT ................. 4-33

BRAKE CALIPER DISASSEMBLY ........... 4-36

BRAKE CALIPER INSPECTION

AND REPAIR ............................................ 4-36

ENGINE ASSEMBLY ..................................... 5-13

HOSE AND LEADS................................... 5-13

ENGINE ASSEMBLY ................................ 5-15

REMOVAL................................................. 5-16

INSTALLATION......................................... 5-16

CAMSHAFTS.................................................. 5-18

CYLINDER HEAD COVER ....................... 5-18

CAMSHAFTS ............................................ 5-19

REMOVAL................................................. 5-20

INSPECTION ............................................ 5-21

INSTALLATION......................................... 5-25

Page 8

CYLINDER HEAD........................................... 5-28

REMOVAL ................................................ 5-29

INSPECTION ............................................ 5-29

INSTALLATION ........................................ 5-30

VALVES AND VALVE SPRINGS................... 5-32

REMOVAL ................................................ 5-33

INSPECTION ............................................ 5-34

INSTALLATION ........................................ 5-38

A.C. MAGNETO ROTOR AND STARTER

CLUTCH ......................................................... 5-41

REMOVAL ................................................ 5-42

INSPECTION ............................................ 5-43

INSTALLATION ........................................ 5-44

OIL PAN AND OIL PUMP .............................. 5-46

REMOVAL ................................................ 5-49

INSPECTION ............................................ 5-49

INSTALLATION ........................................ 5-50

BALANCER .................................................... 5-52

REMOVAL ................................................ 5-54

INSPECTION ............................................ 5-55

INSTALLATION ........................................ 5-55

CHAPTER 7.

FUEL INJECTION SYSTEM

FUEL INJECTION SYSTEM ............................. 7-1

WIRING DIAGRAM ..................................... 7-2

ECU SELF-DIAGNOSTIC FUNCTION ....... 7-4

SELF-DIAGNOSTIC FUNCTION TABLE.... 7-4

TROUBLESHOOTING CHART................... 7-6

DIAGNOSTIC MODE .................................. 7-7

TROUBLESHOOTING DETAILS .............. 7-14

OIL PRESSURE SWITCH ........................ 7-28

INTAKE AIR TEMPERATURE

SENSOR ................................................... 7-28

THROTTLE BODY.......................................... 7-29

INJECTORS.............................................. 7-30

INSPECTION ............................................ 7-31

PRESSURE REGULATOR

OPERATION ............................................. 7-31

INSPECTION AND ADJUSTMENT .......... 7-32

CHAPTER 8.

ELECTRICAL

CRANKCASE ................................................. 5-58

CRANKCASE............................................ 5-58

CONNECTING RODS AND PISTONS ..... 5-59

CRANKSHAFT.......................................... 5-60

REMOVAL ................................................ 5-61

INSPECTION ............................................ 5-63

INSTALLATION ........................................ 5-73

CHAPTER 6.

COOLING SYSTEM

RADIATOR AND HEAT EXCHANGER............ 6-1

INSPECTION .............................................. 6-3

INSTALLATION .......................................... 6-4

THERMOSTAT ................................................. 6-5

INSPECTION .............................................. 6-6

INSTALLATION .......................................... 6-6

WATER PUMP.................................................. 6-8

DISASSEMBLY......................................... 6-10

INSPECTION ............................................ 6-10

ASSEMBLY............................................... 6-11

INSTALLATION ........................................ 6-12

SWITCH INSPECTION ..................................... 8-1

SWITCH INSPECTION ............................... 8-1

INSPECTING A SWITCH SHOWN IN

THE MANUAL ............................................. 8-1

IGNITION SYSTEM .......................................... 8-2

CIRCUIT DIAGRAM.................................... 8-2

TROUBLESHOOTING ................................ 8-4

IGNITION SPARK GAP .............................. 8-6

IGNITION COIL........................................... 8-6

CRANKSHAFT POSITION SENSOR ......... 8-7

THROTTLE OVERRIDE SYSTEM

(T.O.R.S.).................................................... 8-8

ENGINE STOP SWITCH ............................ 8-9

THROTTLE SWITCH .................................. 8-9

MAIN SWITCH .......................................... 8-10

ELECTRICAL STARTING SYSTEM .............. 8-11

CIRCUIT DIAGRAM.................................. 8-11

TROUBLESHOOTING .............................. 8-12

STARTER MOTOR ................................... 8-14

CHARGING SYSTEM ..................................... 8-19

CIRCUIT DIAGRAM.................................. 8-19

TROUBLESHOOTING .............................. 8-20

BATTERY.................................................. 8-21

A.C. MAGNETO ........................................ 8-21

Page 9

LIGHTING SYSTEM ....................................... 8-22

CIRCUIT DIAGRAM.................................. 8-22

TROUBLESHOOTING.............................. 8-24

BULB(S).................................................... 8-26

HEADLIGHT BEAM SWITCH ................... 8-26

HEADLIGHT RELAY................................. 8-27

LOAD CONTROL RELAY......................... 8-27

SIGNAL SYSTEM........................................... 8-28

CIRCUIT DIAGRAM.................................. 8-28

TROUBLESHOOTING.............................. 8-30

BRAKE LIGHT SWITCH ........................... 8-38

DRIVE POSITION SWITCH AND

REVERSE POSITION SWITCH

(PZ50GT/PZ50FX/PZ50M/PZ50VT/

PZ50MP)................................................... 8-38

DC BACK BUZZER (PZ50GT/PZ50FX/

PZ50M/PZ50VT/PZ50MP) ........................ 8-38

COOLANT TEMPERATURE SENSOR .... 8-39

OIL LEVEL SWITCH................................. 8-40

FUEL SENDER......................................... 8-40

SPEED SENSOR...................................... 8-41

KNOCK SENSOR ..................................... 8-41

GRIP WARMER SYSTEM .............................. 8-42

CIRCUIT DIAGRAM.................................. 8-42

TROUBLESHOOTING.............................. 8-44

GRIP AND THUMB WARMER ................. 8-46

GRIP/THUMB WARMER ADJUSTMENT

SWITCH.................................................... 8-46

PASSENGER GRIP WARMER

(PZ50VT) .................................................. 8-47

PASSENGER GRIP WARMER SWITCH

(PZ50VT) .................................................. 8-47

PASSENGER GRIP WARMER RELAY

(PZ50VT/PZ50MP) ................................... 8-48

CHAPTER 9.

SPECIFICATIONS

GENERAL SPECIFICATIONS.......................... 9-1

MAINTENANCE SPECIFICATIONS................. 9-5

ENGINE ...................................................... 9-5

POWER TRAIN......................................... 9-10

CHASSIS .................................................. 9-16

ELECTRICAL ............................................ 9-18

TIGHTENING TORQUE.................................. 9-21

ENGINE .................................................... 9-21

POWER TRAIN......................................... 9-23

CHASSIS .................................................. 9-25

GENERAL TORQUE SPECIFICATIONS ....... 9-27

DEFINITION OF UNITS .................................. 9-27

CABLE ROUTING .......................................... 9-29

COOLING SYSTEM

(PZ50M/PZ50VT/PZ50MP) ............................. 8-50

CIRCUIT DIAGRAM.................................. 8-50

TROUBLESHOOTING.............................. 8-52

RADIATOR FAN MOTOR......................... 8-53

RADIATOR FAN MOTOR RELAY ............ 8-53

DRIVE/REVERSE SELECTING SYSTEM

(PZ50GT/PZ50FX/PZ50M/PZ50VT/

PZ50MP)......................................................... 8-54

CIRCUIT DIAGRAM.................................. 8-54

TROUBLESHOOTING.............................. 8-56

GEAR MOTOR ......................................... 8-57

GEAR MOTOR RELAY 1.......................... 8-58

GEAR MOTOR RELAY 2.......................... 8-58

GEAR MOTOR RELAY 3.......................... 8-59

Page 10

GEN

MACHINE IDENTIFICATION

GENERAL INFORMATION

MACHINE IDENTIFICATION

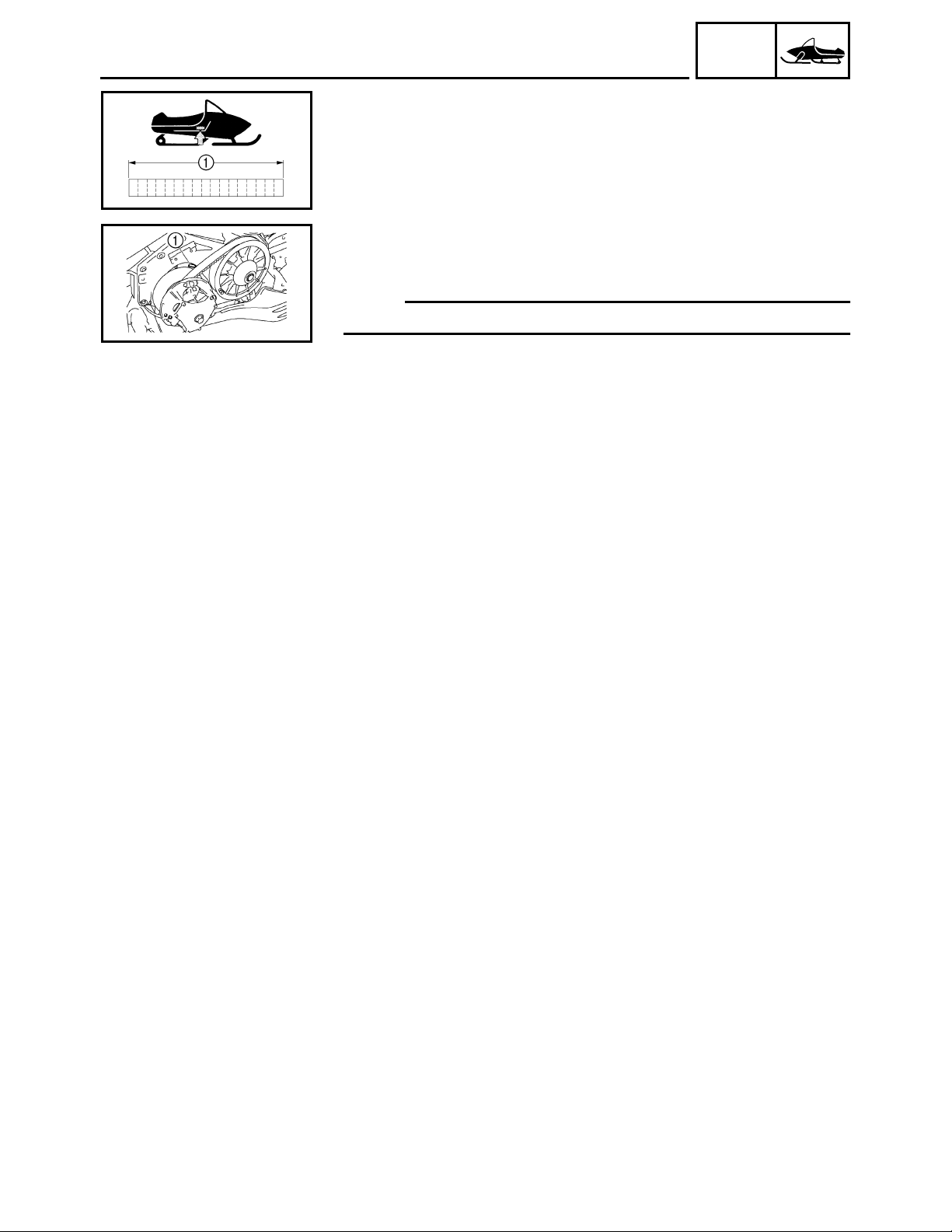

FRAME SERIAL NUMBER

The frame serial number 1 is located on the right-hand side of the frame

(just below the front of the seat).

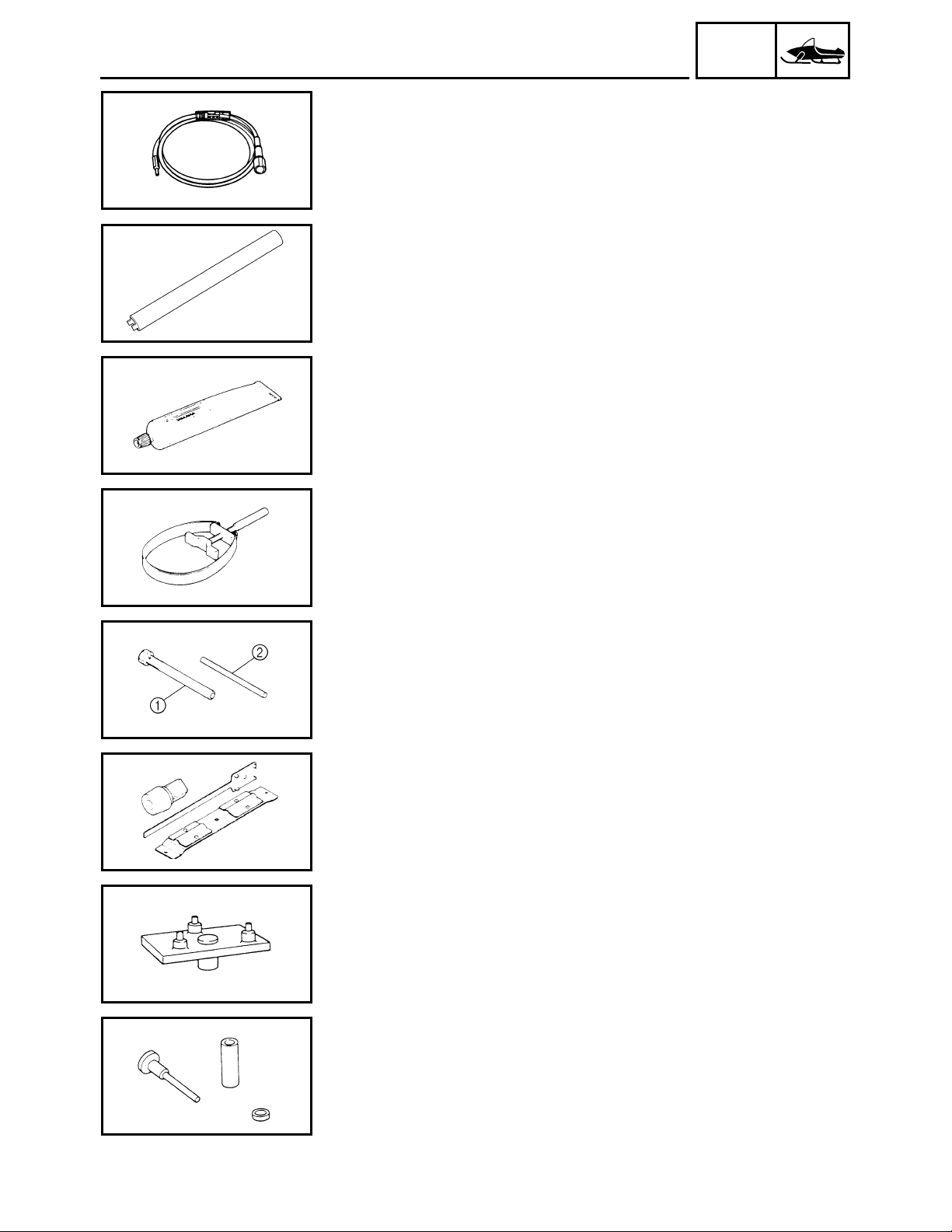

ENGINE SERIAL NUMBER

The engine serial number 1 is located on the left-hand side of the crankcase.

NOTE:

Designs and specifications are subject to change without notice.

INFO

1-1

Page 11

GEN

IMPORTANT INFORMATION

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND DISASSEMBLY

INFO

1. Remove all dirt, mud, dust, and foreign material before removal and

disassembly.

While cleaning, take care to protect the electrical parts, such as relays,

switches, motor, resistors, controllers, etc., from high pressure water

splashes.

2. Use proper tools and cleaning equipment.

Refer to “SPECIAL TOOLS”.

3. When disassembling the machine, keep mated parts together. This

includes gears, cylinders, pistons, and other parts that have been

“mated” through normal wear. Mated parts must be reused or replaced

as an assembly.

4. During disassembly of the machine, clean all parts and place them in

trays in the order of disassembly. This will speed up assembly time and

help ensure that all parts are reinstalled correctly.

1

5. Keep all parts away from any source of fire.

6. Be sure to keep to the tightening torque specifications. When tightening bolts, nuts, and screws, start with those that have larger diameters,

and proceed from the inside to the outside in a crisscross pattern.

ALL REPLACEMENT PARTS

We recommend using genuine Yamaha parts for all replacements. Use oil

and grease recommended by Yamaha for assembly and adjustments.

1-2

Page 12

GEN

IMPORTANT INFORMATION

GASKETS, OIL SEALS, AND O-RINGS

1. All gaskets, seals, and O-rings should be replaced when an engine is

overhauled. All gasket surfaces, oil seal lips, and O-rings must be

cleaned.

2. Properly oil all mating parts and bearings during reassembly. Apply

grease to the oil seal lips.

LOCK WASHERS/PLATES AND COTTER PINS

All lock washers/plates 1 and cotter pins must be replaced if they are

removed. Lock tab(s) should be bent along the bolt or nut flat(s) after the

bolt or nut has been properly tightened.

INFO

BEARINGS AND OIL SEALS

Install the bearings 1 and oil seals 2 with their manufacturer’s marks or

numbers facing outwards. (In other words, the stamped letters must be on

the side exposed to view.) When installing oil seals, apply a light coating

of lightweight lithium base grease to the seal lips. Oil the bearings liberally

when installing.

CAUTION:

Do not use compressed air to spin the bearings dry. This causes

damage to the surface of the bearings.

CIRCLIPS

All circlips should be inspected carefully before reassembly. Always

replace piston pin clips after one use. Replace misshapen circlips. When

installing a circlip 1, make sure that the sharp edged corner 2 is positioned opposite to the thrust 3 it receives. See the sectional view.

Shaft

4

LOCTITE

After installing fasteners that have LOCTITE® applied, wait 24 hours

before using the machine. This will give the LOCTITE

erly.

®

®

time to dry prop-

1-3

Page 13

GEN

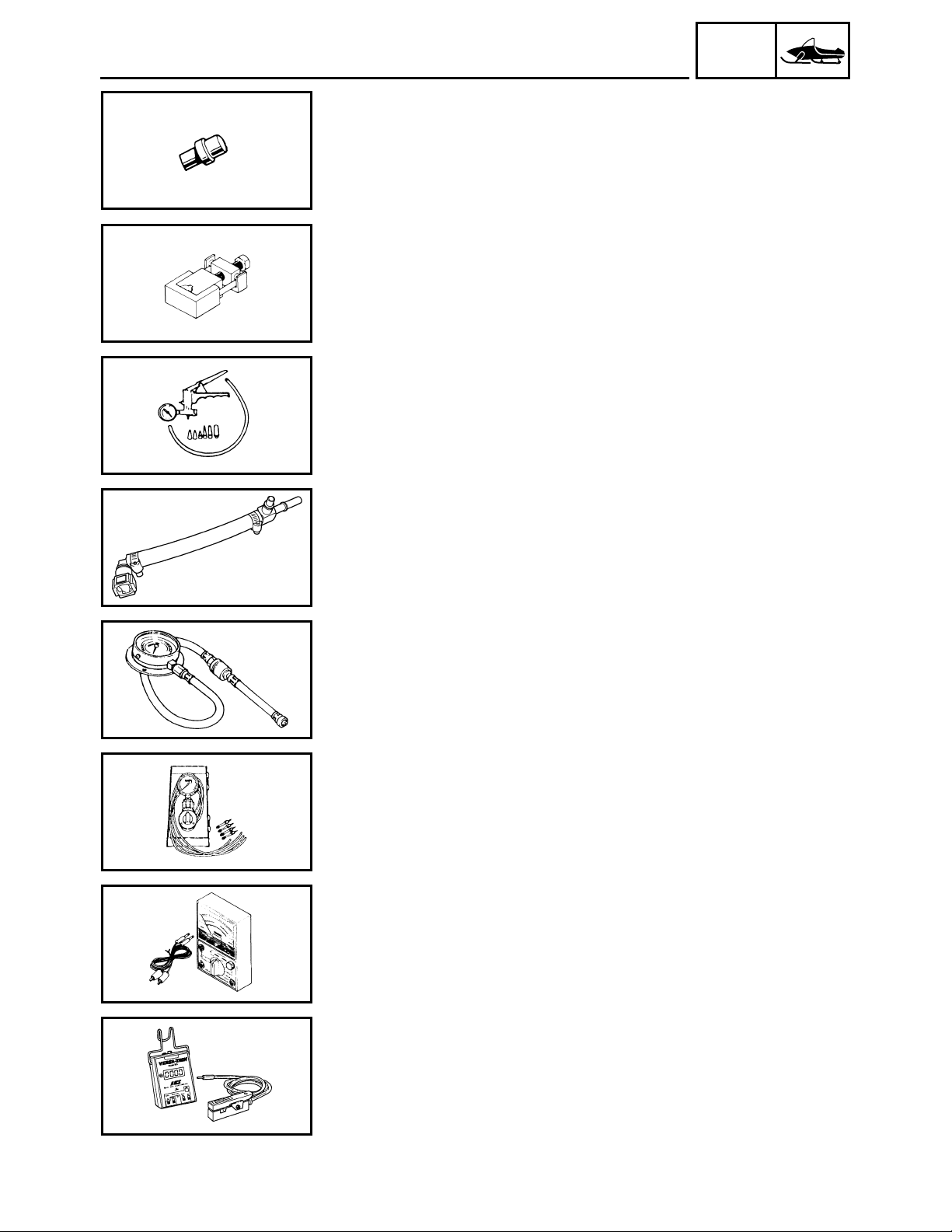

SPECIAL TOOLS

SPECIAL TOOLS

Some special tools are necessary for a completely accurate tune-up and

assembly. Using the correct special tool will help prevent damage that can

be caused by the use of improper tools or improvised techniques.

NOTE:

• Be sure to use the correct part number when ordering the tool, since the

part number may differ according to country.

• For USA and Canada, use part number starting with “YB-”, “YM-”, “YU-”

or “YS-”.

• For others, use part number starting with “90890-”.

FOR TUNE UP

• Dial gauge

P/N: YU-03097

90890-03097

This gauge is used for run out measurement.

INFO

• Angle gauge

Use goods on the market.

This tool is used to tightening the torque.

• Steering linkage alignment plate

P/N: YS-01515

90890-01515

Locks steering relay arm and pivot arm shaft in place while adjusting the

steering linkage for front-end alignment.

FOR ENGINE SERVICE

• Piston pin puller

P/N: YU-01304

90890-01304

This tool is used to remove the piston pin.

• Rotor holding puller

P/N: YU-33270-B

90890-01362

• Flywheel puller attachment

P/N: YM-33282

90890-04089

These tools are used to remove the magneto rotor.

1-4

Page 14

GEN

SPECIAL TOOLS

• Cooling system tester

P/N: YU-24460-01

90890-01325

• Adapter

P/N: YU-33984

90890-01352

This tester and its adapter are used for checking the cooling system.

• Oil filter wrench

P/N: YM-01469

90890-01469

This tool is needed to loosen or tighten the oil filter cartridge.

INFO

• Vacuum gauge

P/N: YU-44456

90890-03094

This guide is used to synchronize the carburetors.

• Compression gauge

P/N: YU-33223 (compression gage)

90890-03081

These tools are used to measure engine compression.

• Valve spring compressor

P/N: YM-04019

90890-04019

• Valve spring compressor attachment

P/N: YM-04108

90890-04108

P/N: YM-04114

90890-04114

These tools are used to remove or install the valve assemblies.

1-5

Page 15

SPECIAL TOOLS

• 40 and 50 mm bearing driver

P/N: YM-04058

90890-04058

• Mechanical seal installer

P/N: YM-04145

90890-04145

These tools are used to install the water pump seal.

• Rotor holding tool

P/N: YU-01235

90890-01235

This tool is used to hold the camshaft sprocket.

GEN

INFO

• Valve guide remover (ø4)

P/N: YM-04111

90890-04111

This tool is used to remove or install the valve guides.

• Valve guide installer (ø4)

P/N: YM-04112

90890-04112

This tool is used to install the valve guides.

• Valve guide reamer (ø4)

P/N: YM-04113

90890-04113

This tool is used to rebore the new valve guides.

• Valve lapper

P/N: 90890-04101

This tool is needed to remove and install the valve lifters.

• Piston ring compressor

P/N: YM-08037

90890-05158

This tool is used to compress the piston rings when installing the piston

into the cylinder.

1-6

Page 16

GEN

SPECIAL TOOLS

• Dynamic spark tester

P/N: YM-34487

• Ignition checker

P/N: 90890-06754

This tool is used to check the ignition system component.

• Engine mount spacer wrench

P/N: YS-01516

90890-01516

Used to turn the engine mounting bolts when removing/installing engine.

• Yamaha bond No. 1215

P/N: 90890-85505

(Three Bond No.1215

This bond is used to seal two mating surfaces (e.g., crankcase mating surfaces.)

®

)

INFO

FOR POWER TRAIN SERVICE

• Sheave holder

P/N: YS-01880-A

90890-01701

This tool is used to hold the primary sheave and A.C. magneto rotor.

• Primary sheave puller (18 mm)

P/N: YS-01881-A 1, YS-01881-1 2

90890-01898

This tool is used for removing the primary sheave.

• Clutch spider separator

P/N: YS-28890-C

90890-01711

This tool is used when disassembling and assembling the primary sheave.

• Clutch separator adapter

P/N: YS-34480

90890-01740

This tool is used when disassembling and assembling the primary sheave.

• YXR clutch bushing jig kit

P/N: YS-39752

This tool is used for removal and installation of primary clutch weight and

roller bushings.

1-7

Page 17

GEN

SPECIAL TOOLS

• Clutch bushing press

P/N: YS-42424

This tool is used for removing and installing the post bushings (primary

sheave cap bush, sliding sheave bush and torque cam bush).

• Track clip installer

P/N: YS-91045-C

90890-01721

This tool is used for installing the track clip.

FOR FUEL INJECTION SERVICE

• Mity vac

P/N: YS-42423

90890-06756

This tool is used to measure the vacuum pressure.

INFO

• Fuel pressure adapter

P/N: YM-03176

90890-03176

This tool is needed to measure fuel pressure.

• Pressure gauge

P/N: YU-03153

90890-03153

This tool is used to measure fuel pressure.

• Vacuum gauge

P/N: YU-08030

90890-03094

This guide is used to synchronize the throttle bodies.

FOR ELECTRICAL SERVICE

• Pocket tester

P/N: YU-03112-C

90890-03112

This instrument is necessary for checking the electrical components.

• Engine tachometer

P/N: YU-08036-C

90793-80009

This tool is used to check engine speed.

1-8

Page 18

GEN

SPECIAL TOOLS

• Digital circuit tester

P/N: YU-A1927

90890-03174

This instrument is necessary for checking the electrical componenets.

INFO

1-9

Page 19

INSP

ADJ

INTRODUCTION/PERIODIC MAINTENANCE CHART FOR

THE EMISSION CONTROL SYSTEM

PERIODIC INSPECTION AND ADJUSTMENT

INTRODUCTION

This chapter includes all information necessary to perform recommended inspections and adjustments. These

preventive maintenance procedures, if followed, will ensure more reliable machine operation and a longer service life. In addition, the need for costly overhaul work will be greatly reduced. This information applies to

machines already in service as well as new machines that are being prepared for sale. All service technicians

should be familiar with this entire chapter.

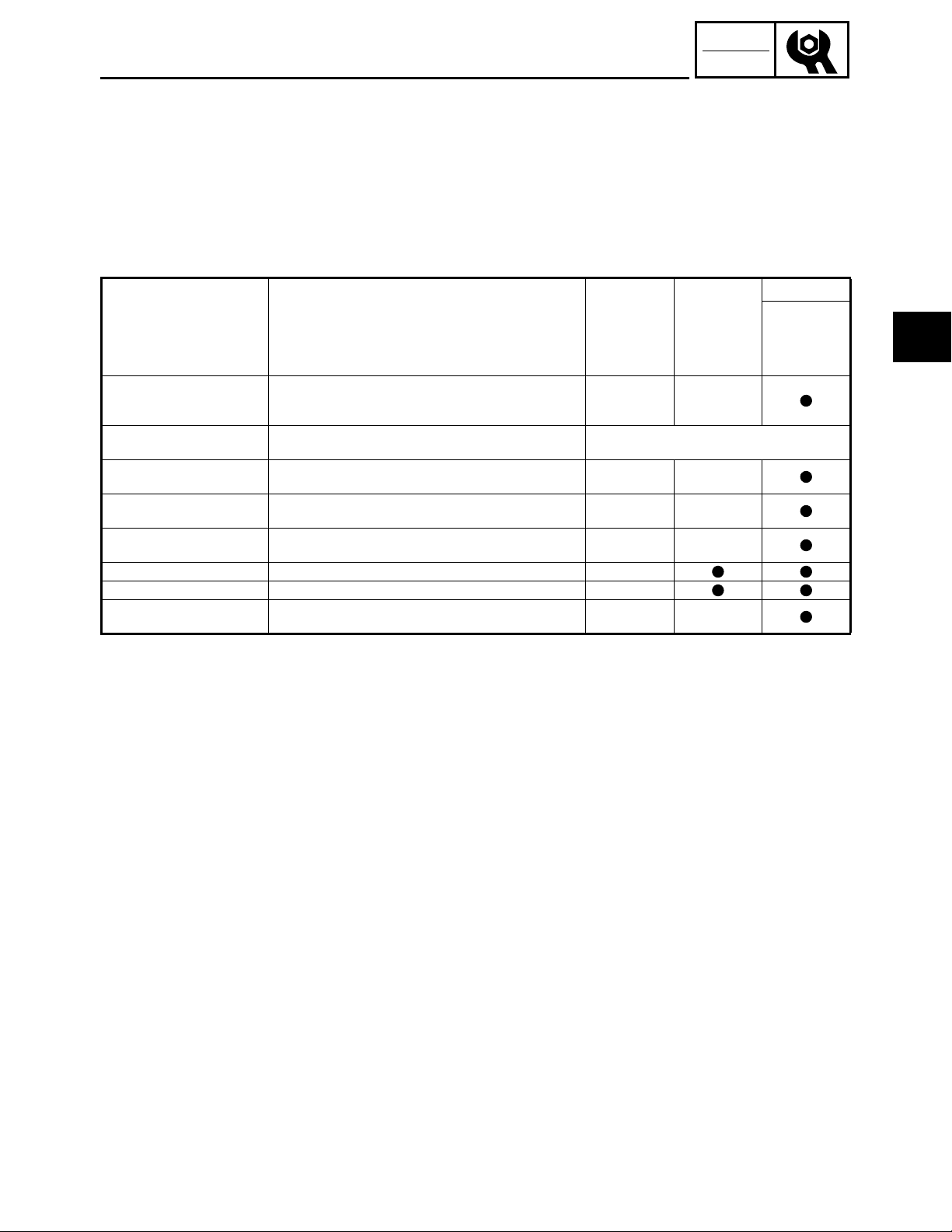

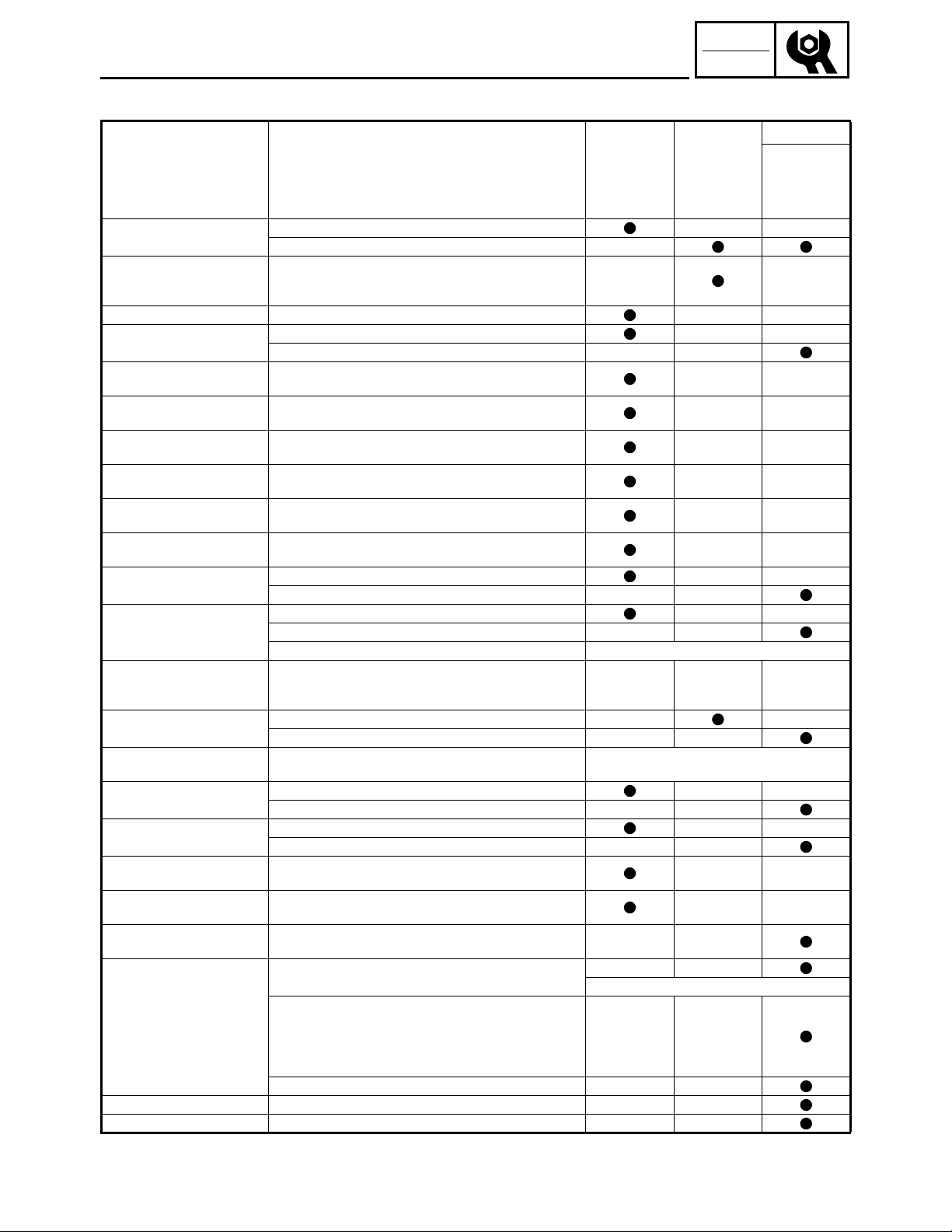

PERIODIC MAINTENANCE CHART FOR THE EMISSION CONTROL SYSTEM

Item Remarks

Spark plugs

∗

Valve clearance

∗

Crankcase breather system

∗

Fuel filter

∗

Fuel line

∗

Idle speed Check and adjust engine idle speed.

∗

Fuel injection Adjust synchronization.

∗

Exhaust system

∗

It is recommended that these items be serviced by a Yamaha dealer.

Check condition.

Adjust gap and clean.

Replace if necessary.

Check clearance.

Adjust clearance when engine is cold.

Check breather hose for cracks or damage.

Replace if necessary.

Check condition.

Replace if necessary.

Check fuel hose for cracks or damage.

Replace if necessary.

Check for leakage.

Tighten or replace gasket if necessary.

Initial

Pre-opera-

tion check

(Daily)

Every 40,000 km (25,000 mi)

1 month or

800 km

(500 mi)

(40 hr)

Every

Seasonally

or 4,000 km

(2,500 mi)

(200 hr)

2

2-1

Page 20

INSP

ADJ

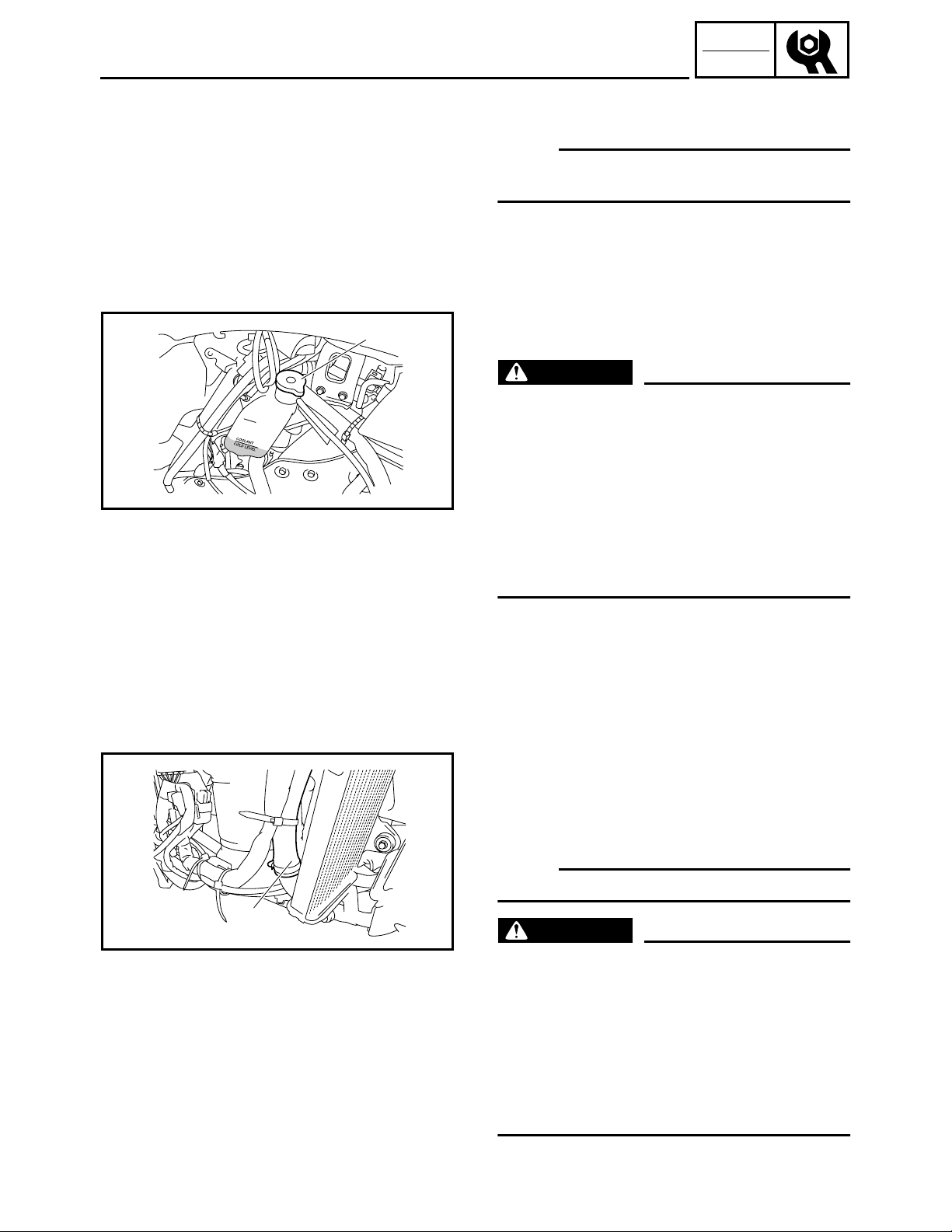

GENERAL MAINTENANCE AND LUBRICATION CHART

GENERAL MAINTENANCE AND LUBRICATION CHART

Item Remarks

Engine oil

∗

Engine oil filter cartridge Replace.

Fuel Check fuel level.

Engine coolant

Throttle lever (handlebar

side)

Throttle override system

(T.O.R.S.)

Engine stop switch

Drive guard

V-belt

Drive track and idler wheels

Slide runners

Brake and parking brake

∗

Disc brake installation

Drive chain oil

Drive chain

Skis and ski runners

Steering system

Strap (PZ50M)

Lights

∗

Battery

∗

Primary and secondary

clutches

∗

Steering column bearing Lubricate with specified grease.

∗

Ski and front suspension Lubricate with specified grease.

∗

It is recommended that these items be serviced by a Yamaha dealer.

Check oil level.

∗

Replace.

Check coolant level.

∗

Air bleed the cooling system if necessary.

Check operation.

∗

Repair if necessary.

Check operation.

∗

Repair if necessary.

Check operation.

∗

Repair if necessary.

Check for cracks, bends or damage.

∗

Replace if necessary.

Check for wear and damage.

Replace if necessary.

Check deflection, and for wear and damage.

∗

Adjust/replace if necessary.

Check for wear and damage.

∗

Replace if necessary.

Check operation and fluid leakage.

∗

Adjust free play and/or replace pads if necessary.

∗

Replace brake fluid. See NOTE on page 2-3.

Check for slight free play.

Lubricate shaft with specified grease as required.

Check oil level.

∗

Replace.

Check deflection.

∗

Adjust if necessary.

Check for wear and damage.

∗

Replace if necessary.

Check operation.

∗

Adjust toe-out if necessary.

Check for damage.

∗

Replace if necessary.

Check operation.

Replace bulbs if necessary.

Check condition.

Charge if necessary.

Check engagement and shift speed.

Adjust if necessary.

Inspect sheaves for wear/damage.

Inspect weights/rollers and bushings for wear-for primary.

Inspect ramp shoes/bushings for wear-for secondary.

Replace if necessary.

Lubricate with specified grease.

Initial

Pre-opera-

tion check

(Daily)

1 month or

800 km

(500 mi)

(40 hr)

Initial at 500 km (300 mi) and every 800 km

(500 mi) thereafter.

Whenever operating elevation is changed.

Every

Seasonally

or 4,000 km

(2,500 mi)

(200 hr)

Every

20,000 km

(12,000 mi)

Every

1,600 km

(1,000 mi)

2-2

Page 21

INSP

ADJ

GENERAL MAINTENANCE AND LUBRICATION CHART

Every

Seasonally

or 4,000 km

(2,500 mi)

(200 hr)

Item Remarks

∗

Suspension component Lubricate with specified grease.

∗

Parking brake cable end

and lever end/throttle cable

end

Shroud and covers

Fittings and fasteners

Tool kit and recommended

equipment

∗

It is recommended that these items be serviced by a Yamaha dealer.

NOTE:

@

Lubricate with specified grease.

Check cable damage.

Replace if necessary.

Make sure that the shroud and covers are securely fas-

tened.

Check tightness.

∗

Repair if necessary.

Check for proper placement.

Pre-opera-

tion check

(Daily)

Initial

1 month or

800 km

(500 mi)

(40 hr)

Brake system:

• After disassembling the master cylinder or caliper cylinder, always change the brake fluid. Regularly check

the brake fluid level and add fluid if necessary.

• Replace the oil seals of the master cylinder and caliper cylinder every two years.

• Replace the brake hose every four years, or if cracked or damaged.

2-3

Page 22

INSP

ADJ

SPARK PLUGS/FUEL LINE INSPECTION

ENGINE

SPARK PLUGS

1. Remove:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

2. Remove:

• Spark plug caps

• Spark plugs

3. Inspect:

• Electrodes 1

Damage/wear → Replace the spark plug.

• Insulator color 2

Abnormal color → Replace the spark plug

Normal color is medium-to-light tan.

4. Measure:

• Spark plug gap a

Out of specification → Regap.

Use a wire thickness gauge.

1

Spark plug gap:

0.6 ~ 0.7 mm (0.024 ~ 0.028 in)

If necessary, clean the spark plugs with a spark

plug cleaner.

Standard spark plug:

NGK R CR9EKB (NGK)

Before installing a spark plug, clean the gasket surface and spark plug surface.

5. Install:

• Spark plugs

Spark plug:

13 Nm (1.3 m · kg, 9.4 ft · lb)

T

.

R

.

NOTE:

Finger-tighten a the spark plug before torquing

it to specification.

b

FUEL LINE INSPECTION

1. Remove:

• Headlight assembly (PZ50/PZ50GT/PZ50FX/

PZ50M)

Refer to “COWLINGS” in CHAPTER 3.

2. Inspect:

• Fuel hose 1

• Fuel return hose

Cracks/damage → Replace.

2-4

Page 23

INSP

ADJ

1

COOLING SYSTEM

COOLING SYSTEM

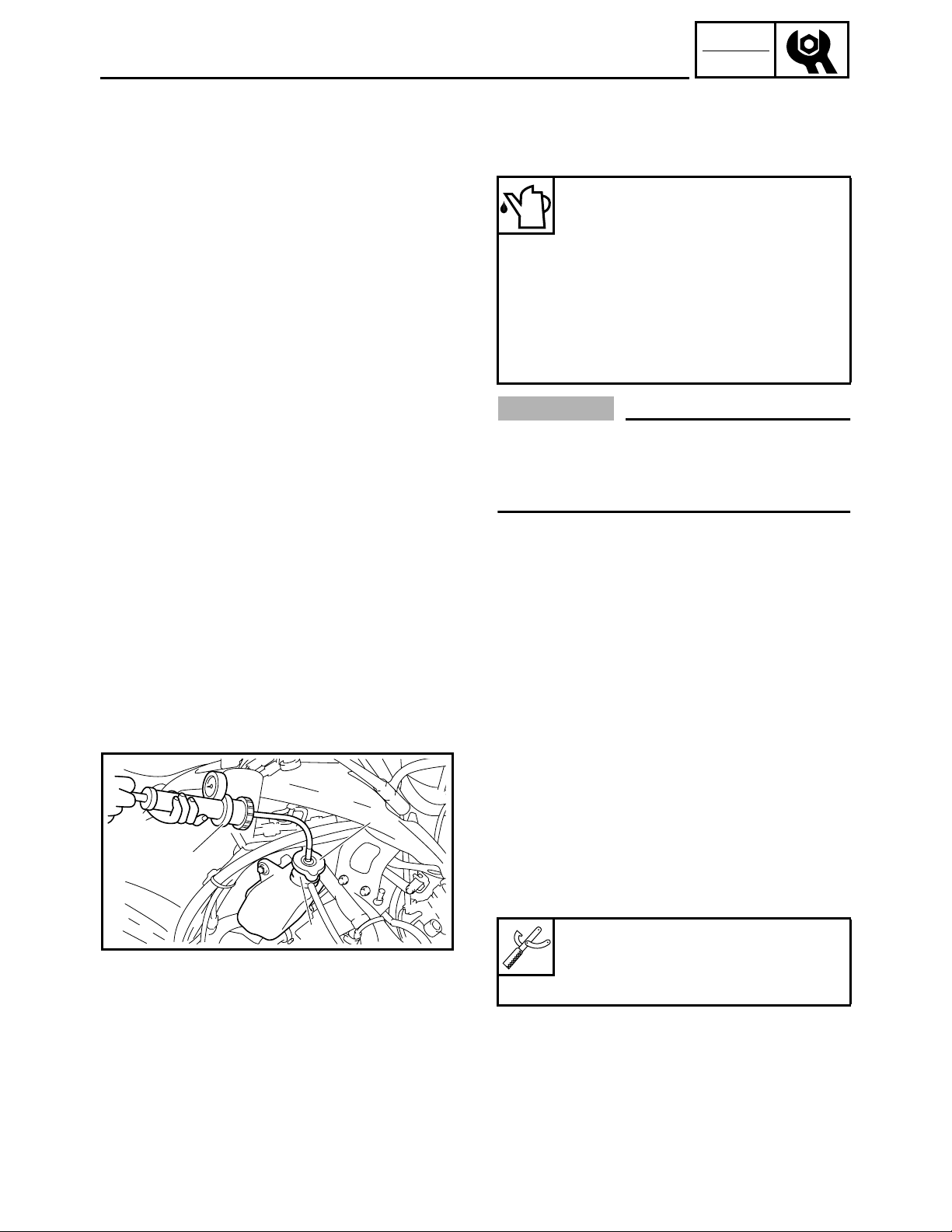

Coolant replacement

NOTE:

The coolant should be changed at least every season.

1. Place the machine on a level surface.

2. Remove:

• Right side panel

• Right side cover

Refer to “COWLINGS” in CHAPTER 3.

3. Remove:

• Coolant filler cap 1

WARNING

Do not remove the coolant filler cap 1 when the

engine is hot. Pressurized scalding hot fluid

and steam may be blown out, which could

cause serious injury. When the engine has

cooled, place a thick rag or a towel over the

coolant filler cap. Slowly turn the cap counterclockwise until it stop. This allows any residual

pressure to escape. When the hissing sound

has stopped, press down on the cap while turning it counterclockwise to remove it.

4. Place an open container under the radiator outlet hose 1.

5. Disconnect:

• Radiator outlet hose 1 1

6. Drain the coolant.

NOTE:

Lift up the tail of the machine to drain the coolant.

1

WARNING

Coolant is poisonous. It is harmful or fatal if

swallowed.

• If coolant is swallowed, induce vomiting

immediately and get immediate medical attention.

• If coolant splashes in your eyes, thoroughly

wash them with water and consult a doctor.

• If coolant splashes on your skin or clothes,

quickly wash it away with soap and water.

2-5

Page 24

INSP

ADJ

COOLING SYSTEM

7. Connect:

• Radiator outlet hose 1

8. Fill:

• Cooling system

Recommended coolant:

High quality silicate-free ethylene

glycol antifreeze containing corrosion inhibitors

Coolant mixing ratio (coolant:water):

3:2 (60%:40%)

Total amount:

PZ50/PZ50GT/PZ50FX/PZ50M

3.6 L (3.17 Imp qt, 3.81 US qt)

PZ50VT/PZ50MP

3.7 L (3.26 Imp qt, 3.91 US qt)

CAUTION:

• Hard water or salt water is harmful to engine

parts. If soft water is not available, use boiled

or distilled water.

• Do not use water containing impurities or oil.

1

3

2

9. Bleed the air from the cooling system.

10. Inspect:

• Cooling system

Decrease of pressure (leaks) → Repair as

required.

Inspection steps:

• Attach the cooling system tester 1 and adapter

to the coolant filler 3.

2

Cooling system tester:

90890-01325, YU-24460-01

Adapter:

90890-01352, YU-33984

• Apply 100 kPa (1.0 kg/cm

• Measure the pressure with the gauge.

2-6

2

, 14 psi).

Page 25

INSP

ADJ

COOLING SYSTEM/VALVE CLEARANCE ADJUSTMENT

1

Air bleeding steps:

• Remove the cap 1 on the radiator outlet pipe 1.

• While slowly adding coolant to the coolant filler,

drain the coolant until no more air bubbles

appear.

• Install the cap 1.

• Add coolant to the full level a.

• Install the coolant filler cap.

Apply and lock the parking brake. Start the

engine and run it at approximately 1,700 ~

3,500 r/min until the coolant circulates (approximately 3 ~ 5 minutes). The heat exchanger will

be warm to the touch.

WARNING

To avoid severe injury or death:

• Make sure the machine is securely supported

with a suitable stand.

• Do not exceed 3,500 r/min. Drive line damage

and excessive V-belt wear could occur, or the

machine could unexpectedly move forward if

the clutch engages.

• Operate the engine only in a well-ventilated

area.

2

b

• Remove the coolant filler cap and bleed the

cooling system again, as described above.

No air bubbles → OK.

• Pour coolant into the coolant reservoir 2 until

the coolant level reaches the “COLD LEVEL”

mark b.

VALVE CLEARANCE ADJUSTMENT

NOTE:

• Valve clearance adjustment should be made on a

cold engine, at room temperature.

• When the valve clearance is to be measured or

adjusted, the piston must be at the top dead center (TDC) on the compression stroke.

1. Drain:

• Engine oil

Refer to “ENGINE OIL REPLACEMENT”.

2. Remove:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

• Oil tank

Refer to “A.C. MAGNETO ROTOR AND

STARTER CLUTCH” in CHAPTER 5.

2-7

Page 26

INSP

ADJ

b

1

2

a

VALVE CLEARANCE ADJUSTMENT

3. Remove:

• Cylinder head cover

Refer to “CAMSHAFTS” in CHAPTER 5.

• Timing mark accessing screw 1

• Crankshaft end accessing screw 2

4. Measure:

• Valve clearance

Out of specification → Adjust.

Valve clearance (cold):

Intake valve:

0.11 ~ 0.20 mm

(0.0043 ~ 0.0079 in)

Exhaust valve:

0.21 ~ 0.25 mm

(0.0083 ~ 0.0098 in)

Checking steps:

• Turn the crankshaft counterclockwise.

• When piston #1 is at TDC on the compression

stroke, align the TDC mark a on the A.C. magneto rotor with the mark b on the A.C. magneto

cover.

1

NOTE:

TDC on the compression stroke can be found when

the camshaft lobes are turned away from each

other.

• Measure the valve clearance with a thickness

gauge 1.

NOTE:

• If the valve clearance is incorrect, record the

measured reading.

• Measure the valve clearance in the following

sequence.

Valve clearance measuring sequence

Cylinder #1 → #2

• Turn the crankshaft 180° counterclockwise and

check the valve clearance of piston #2.

Front

È

2-8

Page 27

INSP

ADJ

VALVE CLEARANCE ADJUSTMENT

5. Remove:

• Intake camshaft

• Exhaust camshaft

NOTE:

• Refer to “CAMSHAFTS” in CHAPTER 5.

• When removing the timing chain and camshafts,

fasten a wire to the timing chain to retrieve it if it

falls into the crankcase.

6. Adjust:

• Valve clearance

Adjustment steps:

• Remove the valve lifter 1 and the valve pad

with a valve lapper 3.

NOTE:

• Cover the timing chain opening with a rag to prevent the valve pad from falling into the crankcase.

• Make a note of the position of each valve lifter

and valve pad 2 so that they can be installed in

the correct place.

2

1

• Select the proper valve pad from the following

table.

Valve pad thickness

range

1.20 ~

Nos.

120 ~ 240

2.40 mm

(0.047 ~

0.094 in)

Available valve pads

25 thicknesses in

0.05 mm (0.0020 in)

increments

NOTE:

• The thickness a of each valve pad is marked in

hundredths of millimeters on the side that

touches the valve lifter.

• Since valve pads of various sizes are originally

installed, the valve pad number must be rounded

in order to reach the closest equivalent to the

original.

• Round off the original valve pad number

according to the following table.

Last digit Rounded value

0 or 2 0

55

810

2-9

Page 28

INSP

ADJ

VALVE CLEARANCE ADJUSTMENT

EXAMPLE:

Original valve pad number = 148 (thickness =

1.48 mm (0.058 in))

Rounded value = 150

• Locate the rounded number of the original valve

pad and the measured valve clearance in the

valve pad selection table. The point where the

column and row intersect is the new valve pad

number.

NOTE:

The new valve pad number is only an approximation. The valve clearance must be measured again

and the above steps should be repeated if the measurement is still incorrect.

2-10

Page 29

INSP

ADJ

VALVE CLEARANCE ADJUSTMENT

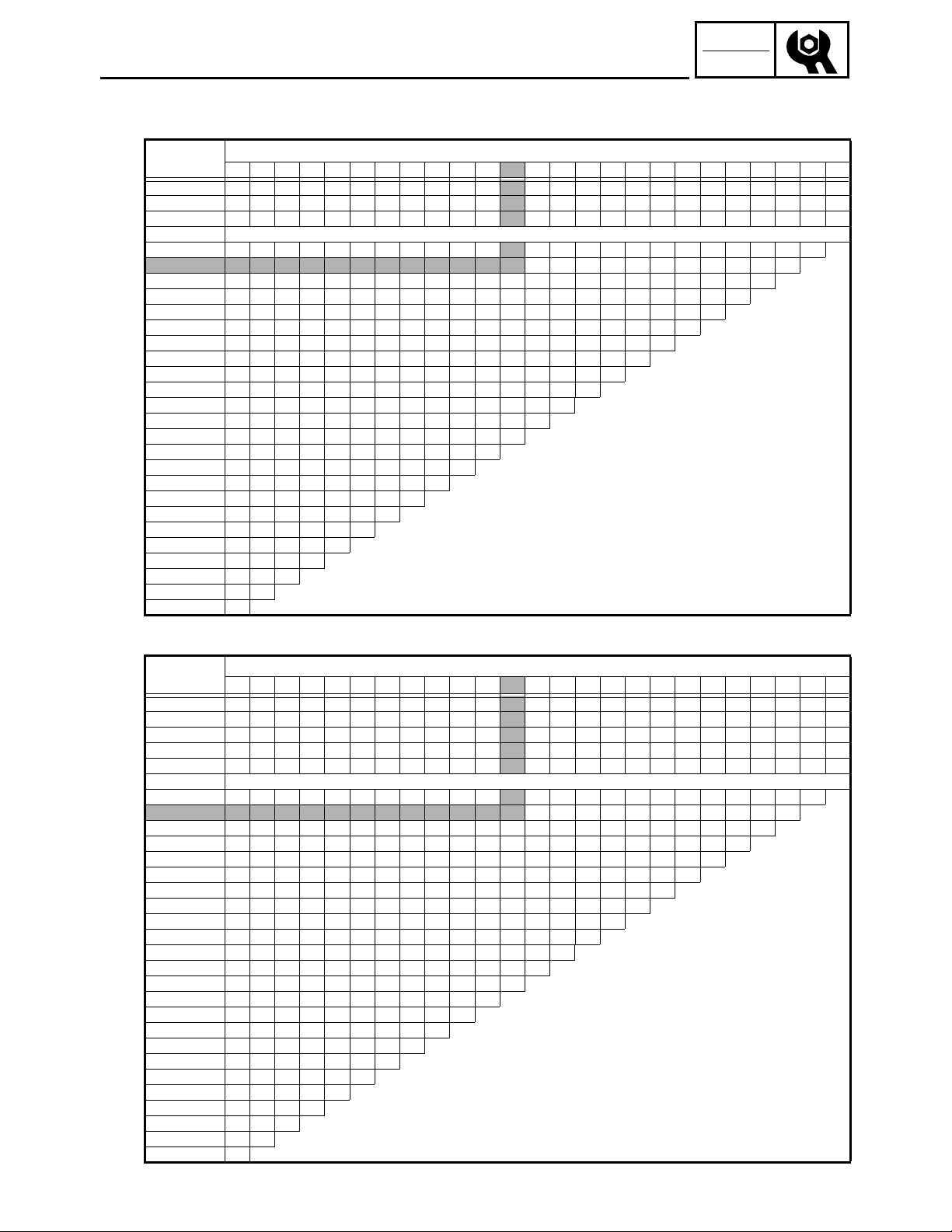

VALVE PAD SELECTION TABLE

INTAKE

Measured

clearance

0.00 ~ 0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.03 ~ 0.07 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.08 ~ 0.10 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.11 ~ 0.20 Specification

exa 0.21 ~ 0.25 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

→

0.26 ~ 0.30 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.31 ~ 0.35 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.36 ~ 0.40 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.41 ~ 0.45 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.46 ~ 0.50 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.51 ~ 0.55 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.56 ~ 0.60 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.61 ~ 0.65 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.66 ~ 0.70 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.71 ~ 0.75 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.76 ~ 0.80 180 185 190 195 200 205 210 215 220 225 230 235 240

0.81 ~ 0.85 185 190 195 200 205 210 215 220 225 230 235 240

0.86 ~ 0.90 190 195 200 205 210 215 220 225 230 235 240

0.91 ~ 0.95 195 200 205 210 215 220 225 230 235 240

0.96 ~ 1.00 200 205 210 215 220 225 230 235 240

1.01 ~ 1.05 205 210 215 220 225 230 235 240 EXAMPLE:

1.06 ~ 1.10 210 215 220 225 230 235 240

1.11 ~ 1.15 215 220 225 230 235 240

1.16 ~ 1.20 220 225 230 235 240

1.21 ~ 1.25 225 230 235 240

1.26 ~ 1.30 230 235 240

1.31 ~ 1.35 235 240

1.36 ~ 1.40 240

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

↓

INSTALLED PAD NUMBER

VALVE CLEARANCE:

0.11 ~ 0.20 mm (0.0043 ~ 0.0079 in)

Installed is 175

Measured clearance is 0.27 mm (0.0106 in)

Replace 175 pad with 185 pad

EXHAUST

Measured

clearance

0.00 ~ 0.02 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215

0.03 ~ 0.07 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220

0.08 ~ 0.12 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225

0.13 ~ 0.17 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230

0.18 ~ 0.20 120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235

0.21 ~ 0.25 Specification

exa 0.26 ~ 0.30 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

→

0.31 ~ 0.35 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.36 ~ 0.40 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.41 ~ 0.45 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.46 ~ 0.50 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.51 ~ 0.55 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.56 ~ 0.60 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.61 ~ 0.65 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.66 ~ 0.70 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.71 ~ 0.75 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.76 ~ 0.80 175 180 185 190 195 200 205 210 215 220 225 230 235 240

0.81 ~ 0.85 180 185 190 195 200 205 210 215 220 225 230 235 240

0.86 ~ 0.90 185 190 195 200 205 210 215 220 225 230 235 240

0.91 ~ 0.95 190 195 200 205 210 215 220 225 230 235 240

0.96 ~ 1.00 195 200 205 210 215 220 225 230 235 240

1.01 ~ 1.05 200 205 210 215 220 225 230 235 240

1.06 ~ 1.10 205 210 215 220 225 230 235 240 EXAMPLE:

1.11 ~ 1.15 210 215 220 225 230 235 240

1.16 ~ 1.20 215 220 225 230 235 240

1.21 ~ 1.25 220 225 230 235 240

1.26 ~ 1.30 225 230 235 240

1.31 ~ 1.35 230 235 240

1.36 ~ 1.40 235 240

1.41 ~ 1.45 240

120 125 130 135 140 145 150 155 160 165 170 175 180 185 190 195 200 205 210 215 220 225 230 235 240

↓

INSTALLED PAD NUMBER

VALVE CLEARANCE:

0.21 ~ 0.25 mm (0.0083 ~ 0.0098 in)

Installed is 175

Measured clearance is 0.35 mm (0.0138 in)

Replace 175 pad with 185 pad

2-11

Page 30

INSP

ADJ

2

VALVE CLEARANCE ADJUSTMENT

• Install the new valve pad 1 and the valve lifter

.

2

NOTE:

• Apply molybdenum disulfide oil to the valve pad

and the valve lifter.

• The valve lifter must turn smoothly when rotated

by hand.

1

• Install the valve lifter and the valve pad in the correct place.

• Install the exhaust and intake camshafts, timing

chain and camshaft caps.

Camshaft cap bolt:

9 Nm (0.9 m · kg, 6.5 ft · lb)

T

.

R

.

NOTE:

• Refer to “CAMSHAFTS” in CHAPTER 5.

• Lubricate the camshaft caps, camshaft lobes,

camshaft journals and camshaft cap bolts.

• Align the camshaft marks with the camshaft cap

marks.

• Rotate the crankshaft counterclockwise several

turns to seat the parts.

• Measure the valve clearance again.

• If the valve clearance is still out of specification,

repeat all of the valve clearance adjustment

steps until the specified clearance is obtained.

7. Install:

• Crankshaft end accessing screw

• Timing mark accessing screw

8. Install:

• Cylinder head cover

Refer to “CAMSHAFTS” in CHAPTER 5.

9. Install:

• All removed parts

NOTE:

For installation, reverse the removal procedure.

Note the following points.

2-12

Page 31

INSP

ADJ

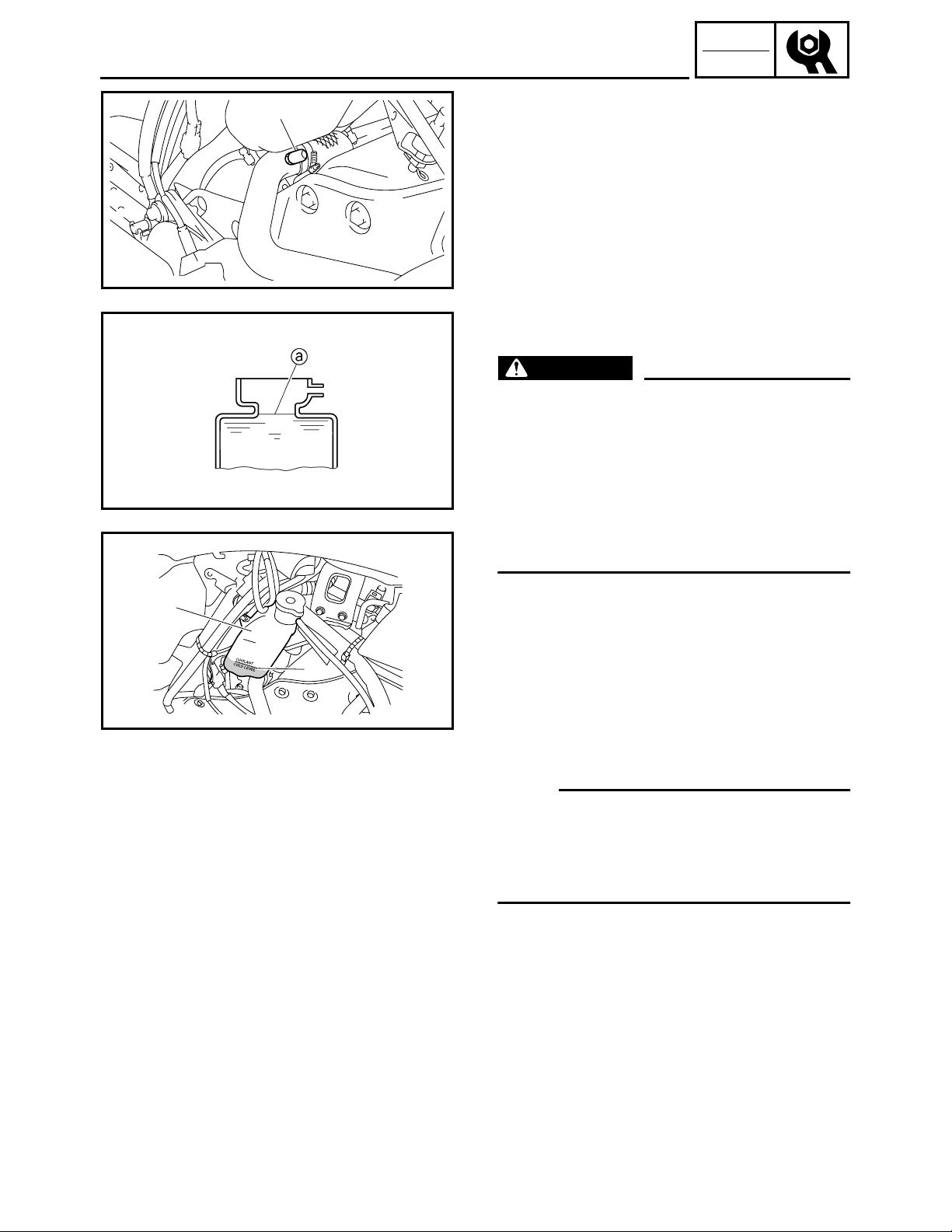

THROTTLE BODY SYNCHRONIZATION

THROTTLE BODY SYNCHRONIZATION

NOTE:

Prior to synchronizing the throttle bodies, the valve

clearance and the engine idle speed should be

properly adjusted.

1. Remove:

• Headlight assembly (PZ50/PZ50GT/PZ50FX/

PZ50M)

• Air filter case assembly

Refer to “COWLINGS” in CHAPTER 3.

2. Remove:

• Vacuum cap 1

1

1

3. Install:

• Vacuum gauge 1

Vacuum gauge:

90890-03094, YU-44456

4. Install:

• Air filter case

Refer to “COWLINGS” in CHAPTER 3.

5. Start the engine and let it warm up for several

minutes.

6. Inspect:

• Engine idle speed

Out of specification

Refer to “ENGINE IDLE SPEED ADJUSTMENT”.

Engine idle speed:

1,700 ~ 1,900 r/min

7. Adjust:

• Throttle body synchronization

Adjust.

→

2-13

Page 32

INSP

ADJ

THROTTLE BODY SYNCHRONIZATION/

ENGINE IDLE SPEED ADJUSTMENT

Adjustment steps:

• Synchronize throttle body #1 and throttle body

#2 by turning the synchronizing screws 1 in

either direction until both gauges read the

same.

NOTE:

After each step, rev the engine two or three times,

each time for less than a second, and check the

1

synchronization again.

Vacuum pressure at engine idling

speed:

20.27 ~ 22.93 kPa

(0.20 ~ 0.23 kg/cm

NOTE:

The difference in vacuum pressure between two

throttle bodies should not exceed 1.33 kPa

(0.01 kg/cm

2

, 0.19 psi).

2

, 2.88 ~ 3.26 psi)

8. Measure:

• Engine idle speed

Out of specification → Adjust.

Make sure that the vacuum pressure is within

specification.

9. Stop the engine and remove the measuring

equipment.

10. Adjust:

• Throttle cable free play

Refer to “THROTTLE CABLE FREE PLAY

ADJUSTMENT”.

ENGINE IDLE SPEED ADJUSTMENT

NOTE:

Prior to adjusting the engine idling speed, the throttle body synchronization should be adjusted properly, the air filter should be clean, and the engine

should have adequate compression.

1. Start the engine and let it warm up for several

minutes.

2. Measure:

• Engine idle speed

Out of specification → Adjust.

Engine idle speed:

1,700 ~ 1,900 r/min

2-14

Page 33

INSP

ADJ

ENGINE IDLE SPEED ADJUSTMENT/

THROTTLE CABLE FREE PLAY ADJUSTMENT

3. Adjust:

• Engine idle speed

Adjustment steps:

• Remove the rubber cap 1.

• Turn the idle adjusting screw 2 in or out until

the specified engine idle speed is obtained.

1

Turning in → Idle speed is increased.

Turning out → Idle speed is decreased.

NOTE:

After adjusting the engine idle speed, the throttle

cable free play should be adjusted.

2

THROTTLE CABLE FREE PLAY

ADJUSTMENT

NOTE:

• Before adjusting the throttle cable free play, the

engine idle speed should be adjusted.

• Adjust the throttle cable free play while the cable

is in the cable guide.

a

2

1

1. Measure:

• Throttle cable free play

Out of specification → Adjust.

Throttle cable free play:

2.0 ~ 3.0 mm (0.08 ~ 0.12 in)

2. Adjust:

• Throttle cable free play

Throttle body side adjustment steps:

• Remove the air filter case.

Refer to “COWLINGS” in CHAPTER 3.

• Loosen the locknut 1.

• Turn the adjusting nut 2 in or out until the spec-

ified free play is obtained.

Turning in → Free play is increased.

Turning out → Free play is decreased.

2-15

a

Page 34

INSP

ADJ

THROTTLE CABLE FREE PLAY ADJUSTMENT/

THROTTLE OVERRIDE SYSTEM (T.O.R.S.) CHECK

• Tighten the locknut.

NOTE:

If the specified throttle cable free play cannot be

obtained on the throttle body side of the cable, use

the adjusting nut on the handlebar side. (PZ50/

PZ50GT/PZ50FX/PZ50M)

Handlebar side adjustment steps:

(PZ50/PZ50GT/PZ50FX/PZ50M)

• Loosen the locknut 1.

• Turn the adjusting nut 2 in or out until the spec-

2

1

ified free play is obtained.

Turning in → Free play is increased.

Turning out → Free play is decreased.

NOTE:

After adjusting the free play, turn the handlebar to

right and left, and make sure that the engine idling

does not run faster.

THROTTLE OVERRIDE SYSTEM (T.O.R.S.)

CHECK

WARNING

When checking T.O.R.S.:

• Be sure the parking brake is applied.

• Be sure the throttle lever moves smoothly.

• Do not run the engine up to the clutch

engagement speed. Otherwise, the machine

could start moving forward unexpectedly,

which could cause an accident.

1. Start the engine.

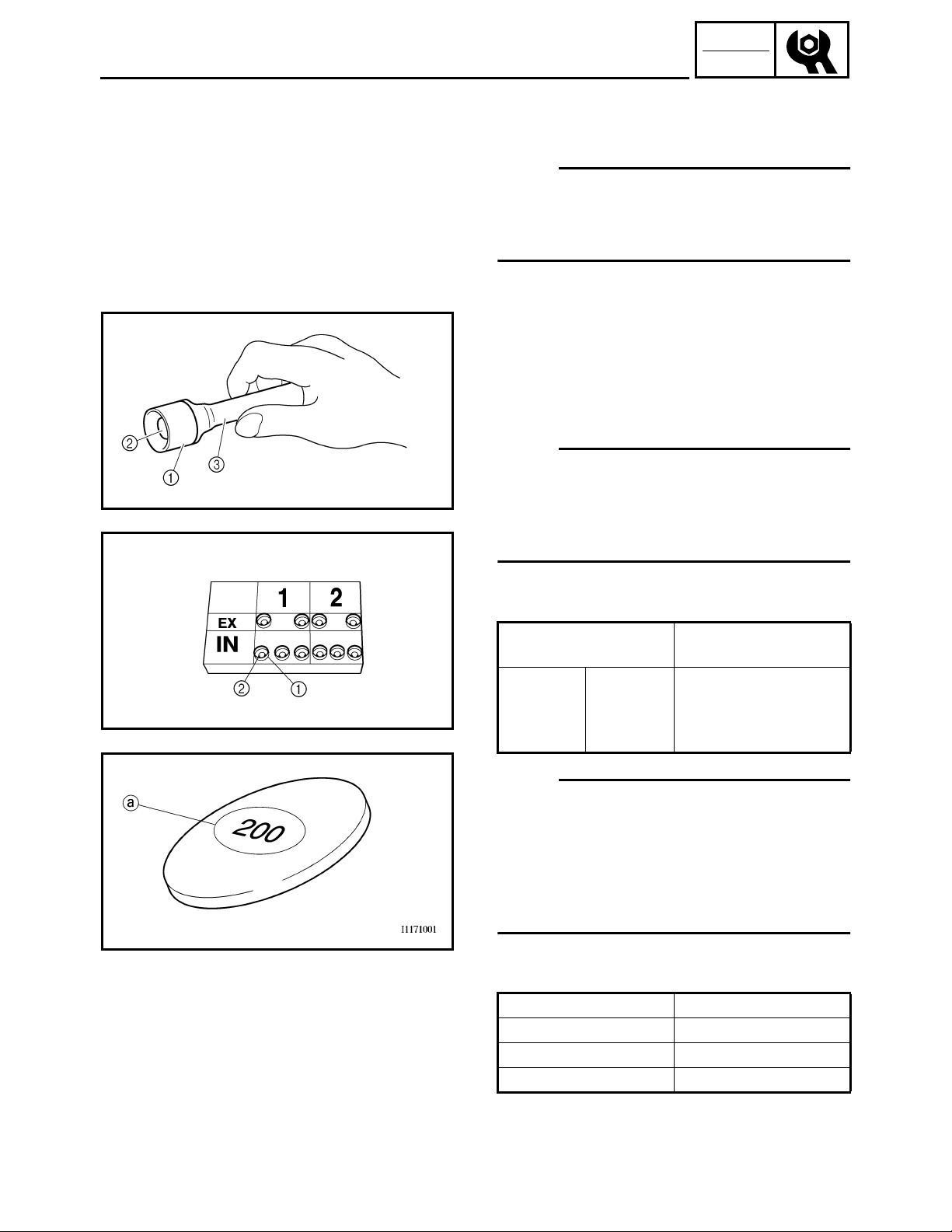

2. Hold the pivot point of the throttle lever away

from the throttle switch by putting your thumb

(above) and forefinger (below) between the

throttle lever pivot 1 and stop switch housing

.

2

While holding as described above, press the

throttle lever 3 gradually.

The T.O.R.S. will operate and the engine

should run between 2,800 and 3,000 r/min.

2-16

Page 35

INSP

ADJ

THROTTLE OVERRIDE SYSTEM (T.O.R.S.) CHECK/

COMPRESSION PRESSURE MEASUREMENT

WARNING

If the engine does not run between 2,800 and

3,000 r/min, stop the engine by turning the main

switch to the “OFF” position and check the

electrical system.

COMPRESSION PRESSURE

MEASUREMENT

NOTE:

Insufficient compression pressure will result in a

loss of performance.

1. Measure:

• Valve clearance

Out of specification → Adjust.

Refer to “VALVE CLEARANCE ADJUSTMENT”.

2. Start the engine, warm it up for several minutes,

and then turn it off.

3. Remove:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

4. Remove:

• Spark plug

CAUTION:

Before removing the spark plugs, use compressed air to blow away any dirt accumulated

in the spark plug wells to prevent it from falling

into the cylinders.

5. Install:

• Compression gauge 1

1

Compression gauge:

90890-03081, YU-33223

2-17

Page 36

INSP

ADJ

COMPRESSION PRESSURE MEASUREMENT

6. Measure:

• Compression pressure

Above the maximum pressure → Inspect the

cylinder head, valve surfaces, and piston

crown for carbon deposits.

Below the minimum pressure → Squirt a few

drops of oil into the affected cylinder and

measure again.

Refer to the following table.

Compression pressure

(with oil applied into cylinder)

Reading Diagnosis

Higher than

without oil

Same as

without oil

Piston ring(-s) wear or

damage → Repair.

Piston, valves, cylinder

head gasket or piston

possibly defective →

Repair.

Compression pressure (at

sea level)

Compression pressure (at sea level):

Standard:

900 kPa (9.0 kg/cm

2

, 128.0 psi) at

400 r/min

Minimum:

700 kPa (7.0 kg/cm

2

, 99.5 psi) at

400 r/min

Maximum:

1,100 kPa (11.0 kg/cm

2

, 156.4 psi)

at 400 r/min

Measurement steps:

• Turn the main switch to “START”.

• With the throttle wide open, crank the engine

until the reading on the compression gauge stabilizes.

WARNING

To prevent sparking, ground all ignition coil

leads before cranking the engine.

NOTE:

The difference in compression pressure between

cylinders should not exceed 100 kPa (1 kg/cm

14.2 psi).

2

,

2-18

7. Install:

• Spark plug

T

.

R

.

Spark plug:

13 Nm (1.3 m · kg, 9.4 ft · lb)

Page 37

INSP

ADJ

1

ENGINE OIL LEVEL INSPECTION

ENGINE OIL LEVEL INSPECTION

1. Inspect:

• Engine oil level

CAUTION:

Do not run the engine with too much or not

enough oil in the oil tank. Oil could flow into the

air filter and the engine could be damaged.

Inspection steps:

• Place the snowmobile on a level surface and

apply the parking brake.

• Start the engine, warm it up for 10 ~ 15 minutes,

and then turn off.

• Remove the right side cover.

Refer to “COWLINGS” in CHAPTER 3.

• Disconnect the oil level switch coupler 1.

2

CAUTION:

Disconnect the oil level switch coupler before

removing the oil level gauge. Otherwise the

lead can twist and become severed.

• Remove the oil level gauge/dipstick 2, wipe it

clean, insert it back into the filler hole (without

screwing it in), and then remove it again to

check the oil level.

• The engine oil level should be between the

maximum level mark “H” a and minimum level

mark “L” b.

Below the minimum level mark → Add the recommended engine oil to the proper level.

CAUTION:

When adding the engine oil, be careful not to fill

above the maximum level mark and minimum

level mark on the oil level gauge.

Recommended oil:

Refer to the chart for the engine oil

grade which is best suited for certain atmospheric temperatures.

API standard:

API SE, SF, SG or higher

SAE 0W-30

CAUTION:

Do not allow foreign materials to enter the

crankcase.

NOTE:

Before checking the engine oil level, wait a few

minutes until the oil has settled.

2-19

Page 38

INSP

ADJ

ENGINE OIL LEVEL INSPECTION/

ENGINE OIL REPLACEMENT

• Start the engine, warm it up for several minutes,

and then turn it off.

• Check the engine oil level again.

NOTE:

Before checking the engine oil level, wait a few

minutes until the oil has settled.

CAUTION:

• Use only 4-stroke engine oil.

• Engine oil also lubricates the starter clutch. In

order to prevent clutch slippage, do not mix

any chemical additives with the oil or use oils

of a higher grade than “CD”. In addition, do

not use oils labeled “ENERGY CONSERVING

II” or higher.

1

ENGINE OIL REPLACEMENT

1. Place the snowmobile on a level surface and

apply the parking brake.

2. Start the engine, warm up for several minutes,

and then turn it off.

3. Place a containers under the engine oil pan and

oil tank.

4. Remove:

• Bottom panel 1

5. Remove:

• Left side panel

• Right side cover

• Right lower cover

Refer to “COWLINGS” in CHAPTER 3.

6. Disconnect:

• Oil level gauge coupler

Refer to “ENGINE OIL LEVEL INSPECTION”.

7. Remove:

• Oil level gauge/dipstick

Refer to “ENGINE OIL LEVEL INSPECTION”.

2-20

Page 39

INSP

ADJ

1

1

ENGINE OIL REPLACEMENT

8. Remove:

• Cylinder head cap 1

9. Remove:

• Oil pan engine oil drain bolt 1

1

1

1

10. Remove:

• Oil tank engine oil drain bolt 1

11. Drain:

• Engine oil

(completely from the oil pan and oil tank)

12. If the oil filter cartridge is also to be replaced,

perform the following procedure.

Replacement steps:

• Remove the air filter case.

Refer to “COWLINGS” in CHAPTER 3.

• Remove the oil filter bolts 1.

• Remove the oil filter cartridge

wrench 3.

Oil filter wrench:

90890-01469, YM-01469

2 with an oil filter

2

3

2-21

Page 40

INSP

ADJ

ENGINE OIL REPLACEMENT

4

• Apply a thin coat of engine oil onto the O-ring

4

of the new oil filter cartridge.

CAUTION:

Make sure that the O-ring 4 is positioned correctly in the groove of the oil filter cartridge.

• Tighten the new oil filter cartridge to specification with an oil filter wrench.

Oil filter cartridge:

17 Nm (1.7 m · kg, 12 ft · lb)

T

.

R

.

• Tighten the oil cooler bolts to specification.

Oil cooler bolt:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

LOCTITE

13. Install:

• Drain bolts

(along with the new gaskets)

Oil tank engine oil drain bolt:

16 Nm (1.6 m · kg, 11 ft · lb)

T

.

R

.

Oil pan engine oil drain bolt:

30 Nm (3.0 m · kg, 22 ft · lb)

®

14. Fill:

• Engine oil

(with the specified amount of the recommended engine oil)

Add 1.5 L (1.3 Imp qt, 1.6 US qt) of the recommended engine oil to the oil tank, and then

install and tighten the oil level gauge/dipstick

and the cylinder head cap.

Quantity:

Total amount:

3.00 L (2.64 Imp qt, 3.17 US qt)

Periodic oil change:

2.45 L (2.16 Imp qt, 2.59 US qt)

With oil filter replacement:

2.63 L (2.31 Imp qt, 2.78 US qt)

15. Inspect:

• Engine and oil tank

(for engine oil leaks)

16. Inspect:

• Engine oil level

Refer to “ENGINE OIL LEVEL INSPECTION”.

2-22

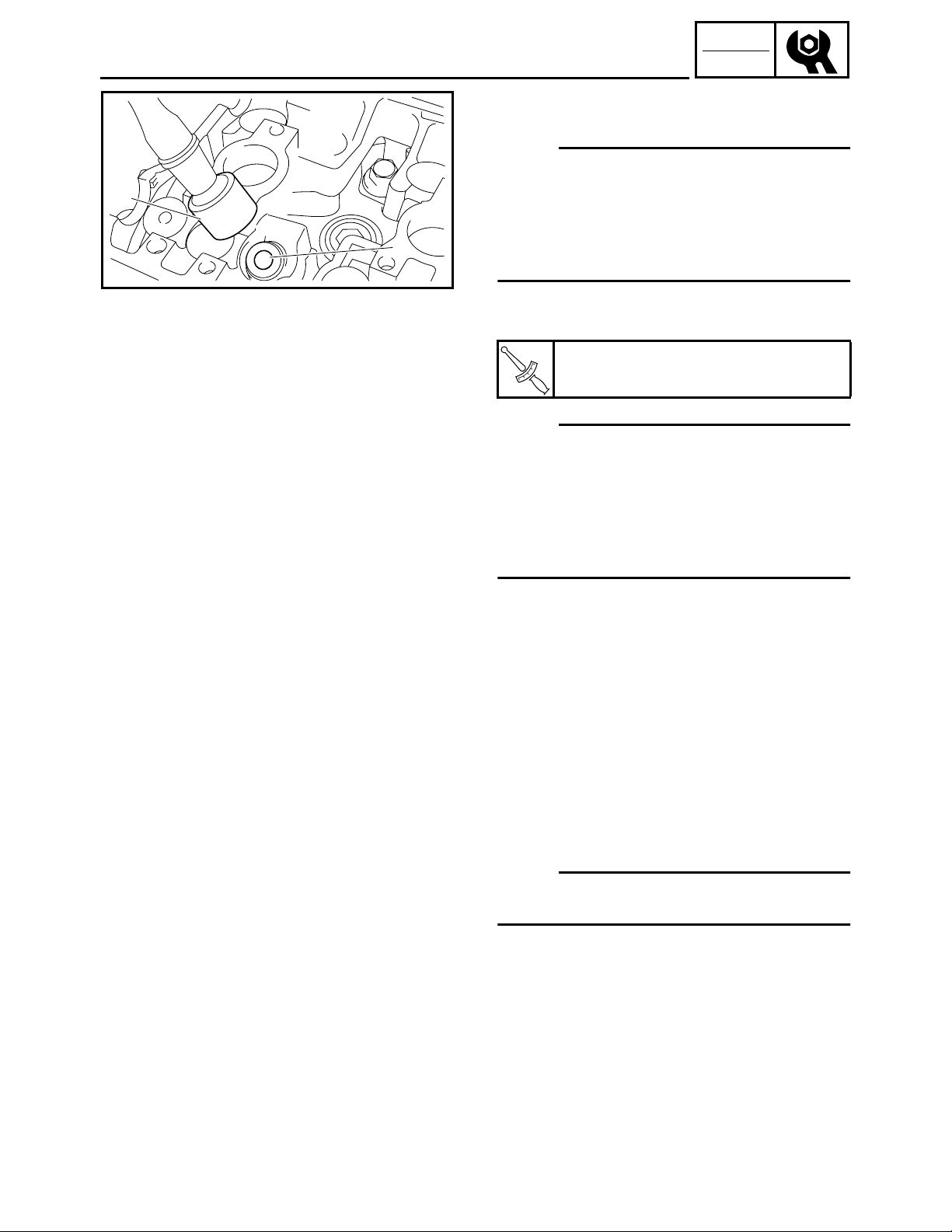

Page 41

INSP

ADJ

ENGINE OIL REPLACEMENT/CYLINDER HEAD BREATHER

HOSE INSPECTION/THROTTLE BODY JOINTS INSPECTION

17. Inspect:

• Engine oil pressure

1

Inspection steps:

• Remove the exhaust pipe joint upper cover.

Refer to “EXHAUST PIPE AND MUFFLER” in

CHAPTER 5.

• Slightly loosen the oil gallery bolt 1.

• Install the fuel tank.

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

• Start the engine and keep it idling until engine

oil starts to seep from the oil check bolt.

If no engine oil comes out after one minute, turn

the engine off so that it will not seize.

• Check the engine oil passages, the oil filter and

the oil pump for damage or leakage.

• Start the engine after solving the problem(-s)

and check the engine oil pressure again.

Tighten the oil check bolt to specification.

Oil check bolt:

10 Nm (1.0 m · kg, 7.2 ft · lb)

T

.

R

.

1

CYLINDER HEAD BREATHER HOSE

INSPECTION

1. Inspect:

• Cylinder head breather hose 1

Cracks/damage → Replace.

Loosen connection → Connect properly.

CAUTION:

Make sure that the cylinder head breather hose

is routed correctly.

THROTTLE BODY JOINTS INSPECTION

1. Remove:

• Air filter case

Refer to “COWLINGS” in CHAPTER 3.

2. Inspect:

• Throttle body joints 1

Cracks/damage → Replace.

Refer to “THROTTLE BODY” in CHAPTER 7.

1

2-23

Page 42

INSP

ADJ

CHECKING THE AIR FILTER ELEMENT

CHECKING THE AIR FILTER ELEMENT

1. Remove:

• Air filter case cover

Refer to “COWLINGS” in CHAPTER 3.

2. Lift up the air filter element frame and remove

the air filter element.

3. Clean:

• Air filter element

NOTE:

Remove the snow.

4. Inspect:

• Air filter element

Damage/clogs → Replace.

5. Install:

• Air filter element

• Air filter case cover

2-24

Page 43

INSP

ADJ

7

8

9

1

3

0

B

1

A

5

A

3

EXHAUST SYSTEM INSPECTION

EXHAUST SYSTEM INSPECTION

1. Remove:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

2. Inspect:

• Exhaust pipe joints 1

• Exhaust pipe/muffler assembly 2

• Exhaust pipe bands 3

• Muffler end cover 4 (PZ50/PZ50GT/PZ50FX/

PZ50M)

• Muffler damper holder 5

• Muffler damper 6

Cracks/damage → Replace.

• Gasket 7

• Gaskets 8

Exhaust gas leaks → Replace.

3. Inspect:

• Tightening torque

6

5

6

4

C

2

Exhaust pipe joint bolt 9:

25 Nm (2.5 m · kg, 18 ft · lb)

T

.

R

.

Exhaust pipe/muffler bolt 0:

33 Nm (3.3 m · kg, 24 ft · lb)

Muffler damper holder bolt A:

10 Nm (1.0 m · kg, 7.2 ft · lb)

Exhaust pipe band bolt B:

18 Nm (1.8 m · kg, 13 ft · lb)

Muffler end cover bolt C:

10 Nm (1.0 m · kg, 7.2 ft · lb)

LOCTITE

4. Install:

• Fuel tank

Refer to “SEAT AND FUEL TANK” in CHAPTER 5. (PZ50/PZ50GT/PZ50FX/PZ50M)

Refer to “RIDER SEAT AND FUEL TANK” in

CHAPTER 5. (PZ50VT/PZ50MP)

®

2-25

Page 44

INSP

ADJ

SHEAVE OFFSET ADJUSTMENT

POWER TRAIN

SHEAVE OFFSET ADJUSTMENT

1. Remove:

• Left side panel

• Left side cover

Refer to “COWLINGS” in CHAPTER 3.

2. Remove:

• Drive V-belt

3. Measure:

• Sheave offset a

Use a straightedge that is approximately

470 mm (18.5 in) long, 20 mm (0.79 in) wide,

and 4 mm (0.16 in) thick.

Out of specification → Adjust.

Sheave offset:

14.5 ~ 17.5 mm (0.57 ~ 0.69 in)

NOTE:

Push the secondary sheave inward towards the

frame, and then measure the sheave offset.

4

3

1

2

4. Adjust:

• Sheave offset

Adjustment steps:

• Apply the brake to lock the secondary sheave.

• Remove the secondary sheave bolt 1, washer

, shim(s) (left), and secondary sheave 3.

2

• Install the appropriate shim(s) (right) 4 from the

following table so that the sheave offset is within

specification.

Shim size

Part number Thickness

90201-252F1 0.5 mm (0.02 in)

90201-25527 1.0 mm (0.04 in)

2-26

Page 45

INSP

ADJ

SHEAVE OFFSET ADJUSTMENT

• Install the secondary sheave, secondary

sheave bolt and washer.

Secondary sheave bolt:

60 Nm (6.0 m · kg, 43 ft · lb)

T

.

R

.

• Recheck the sheave offset. If out of specification, repeat the above steps.

NOTE:

When adjusting the sheave offset, the secondary

sheave free play (clearance) should be adjusted.

a

3

2

1

5. Measure:

• Secondary sheave free play (clearance) a

Use a feeler gauge.

Out of specification → Adjust.

Secondary sheave free play (clearance):

1.0 ~ 2.0 mm (0.04 ~ 0.08 in)

6. Adjust:

• Secondary sheave free play (clearance)

Adjustment steps:

• Apply the brake to lock the secondary sheave.

• Remove the secondary sheave bolt 1 and

washer 2.

• Install the appropriate shim(s) (left) 3 from the

following table so that the secondary sheave

free play is within specification.

Shim size

Part number Thickness

90201-252F1 0.5 mm (0.02 in)

90201-25527 1.0 mm (0.04 in)

2-27

Page 46

INSP

ADJ

a

a

DRIVE V-BELT

DRIVE V-BELT

WARNING

When installing the new V-belt, make sure that

it is positioned from 1.5 mm (0.06 in) above

the edge of the secondary sheave to –0.5 mm

(–0.02 in) below the edge a.

If the V-belt is not positioned correctly, the

clutch engagement speed will be changed. The

machine may move unexpectedly when the

engine is started.

New belt width:

34.1 mm (1.34 in)

Belt wear limit width:

32.5 mm (1.28 in)

1. Inspect:

• Drive V-belt

Cracks/damage/wear → Replace.

Oil or grease on the V-belt → Check the primary and secondary sheaves.

2. Inspect:

• Primary sheave

• Secondary sheave

Oil or grease on the primary and secondary

sheaves → Use a rag soaked in lacquer thinner or solvent to remove the oil or grease.

Check the primary and secondary sheaves.

3. Measure:

• Drive V-belt circumference a

Out of specification → Replace.

V-belt circumference:

1,132 ~ 1,138 mm (44.6 ~ 44.8 in)

2-28

Page 47

INSP

ADJ

ENGAGEMENT SPEED CHECK/

PARKING BRAKE ADJUSTMENT

ENGAGEMENT SPEED CHECK

1. Place the machine on a level surface of hardpacked snow.

2. Inspect:

• Clutch engagement speed

Inspection steps:

• Start the engine, and open the throttle lever

gradually.

• Check the engine speed when the machine

starts moving forward.

Out of specification → Adjust the primary

sheave.

Engagement speed:

PZ50/PZ50GT/PZ50FX:

3,700 ~ 4,100 r/min

PZ50M “USA/Canada”:

4,100 ~ 4,500 r/min

PZ50M “Europe”:

3,900 ~ 4,300 r/min

PZ50VT “USA/Canada”:

3,300 ~ 3,700 r/min

PZ50VT “Europe”/PZ50MP:

2,900 ~ 3,300 r/min

PARKING BRAKE ADJUSTMENT

1. Remove:

• Right side cover

Refer to “COWLINGS” in CHAPTER 3.

2. Measure:

• Parking brake cable distance

Out of specification → Adjust.

Parking brake cable distance:

43.5 ~ 46.5 mm (1.713 ~ 1.831 in)

2-29

Page 48

INSP

ADJ

2

1

PARKING BRAKE ADJUSTMENT/

BRAKE FLUID LEVEL INSPECTION

3. Adjust:

• Parking brake cable

a

Adjustment steps:

• Loosen the locknut 1.

• Turn the adjuster 2 in or out until the specified

distance a is obtained.

Turning in → Distance a is increased.

Turning out → Distance a is decreased.

• Tighten the locknut.

2

1

4. Measure:

• Brake pad clearance (a +

Out of specification → Adjust.

Brake pad clearance (a + b):

1.5 ~ 2.0 mm (0.059 ~ 0.079 in)

5. Adjust:

• Brake pad clearance

Adjustment steps:

• Loosen the locknut 1.

• Turn the adjuster 2 in or out until the specified

clearance between the brake pad 3 and brake

disc 4 is obtained.

• Tighten the locknut.

b)

BRAKE FLUID LEVEL INSPECTION

1. Place the machine on a level surface.

2. Check:

• Fluid level

Fluid level is under the lower level line a →

Fill to the proper level.

Recommended brake fluid:

DOT 4

2-30

Page 49

INSP

ADJ

BRAKE FLUID LEVEL INSPECTION/

BRAKE PAD INSPECTION

NOTE:

For a correct reading of the brake fluid level, make

sure that the top of the handlebar brake master cylinder reservoir is horizontal.

CAUTION:

Brake fluid may corrode painted surfaces or