Page 1

Technical Supplement

HF/VHF/UHF ALL MODE TRANSCEIVER

FT-991

EH057M90B

©2015 YAESU MUSEN CO., LTD.

Introduction

This manual provides the technical information necessary

for servicing the FT-991 HF/VHF/UHF ALL MODE

TRANSCEIVER.

Servicing this equipment requires expertise in handing surface-mount chip components. Attempts by nonqualied persons to service this equipment may result

in permanent damage not covered by the warranty, and

may be illegal in some countries.

Two PCB layout diagrams provided for each doublesided board in this transceiver. Each side of the board

is referred to by the type of the majority of components

installed on that side ("Side A" or "Side B"). In most

cases one side has only chip components, and the other

has either a mixture of both chip and leaded components

(trimmers, coils, electrolytic capacitors, ICs, etc.), or

leaded components only.

While we believe the information in this manual to be

correct, YAESU assumes no liability for damage that

may occur as a result of typographical or other errors

that may be present. Your cooperation in pointing out

any inconsistencies in the technical information would

be appreciated.

Contents

Specications

Exploded View & Miscellaneous Parts

Block Diagram

Connection Diagram

Alignment

Board Unit (Schematics, Layouts & Parts)

MAIN Unit

PLL Unit

EDSP Unit

CNTL Unit

HF-PA Unit

V_U-PA Unit

PANEL Unit

FAN-CNTL Unit

TUNER Unit

JACK Unit

DSP Unit

Important Note

This transceiver was assembled using Pb (lead) free solder, based on the RoHS specication.

Only lead-free solder (Alloy Composition: Sn-3.0Ag-0.5Cu) should be used for repairs performed on this apparatus. The solder stated

above utilizes the alloy composition required for compliance with the lead-free specication, and any solder with the above alloy composition may be used.

Caution

Risk of explosion if battery is replaced by an incorrect type. Dispose of used batteries according to the instructions.

Page 2

Specications

General

Rx Frequency Range: 30 kHz - 56 MHz, 118 MHz - 164 MHz, 420 MHz - 470 MHz (operating)

1.8MHz-54MHz,144MHz-148MHz,430MHz-450MHz(specied

performance,Amateurbandsonly)

Tx Frequency Ranges: 1.8 MHz - 54 MHz, 144 MHz - 148 MHz, 430 MHz - 450 MHz (Amateur

bandsonly)

Frequency Stability: ±0.5ppm(aer1minute@+14°Fto+122°F[–10°Cto+50°C])

Operating Temperature Range: +14°Fto+122°F(–10°Cto+50°C)

Emission Modes: A1A(CW),A3E(AM),J3E(LSB,USB),F3E(FM),F7W(C4FM),F2D

Frequency Steps: 5/10Hz(SSB,CW,&AM),100Hz(FM,C4FM)

Antenna Impedance: 50Ohms,unbalanced

16.7-150Ohms,unbalanced(TunerON,1.8MHz-30MHzAmateur

bands)

25-100Ohms,unbalanced(TunerON,50 MHz Amateurband)

Power Consumption(Approx.): Rx(nosignal) 1.8A

Rx(signalpresent) 2.2A

Tx 23A(HF/50MHz100W)

15A(144/430MHz50W)

Supply Voltage: DC13.8V±15%(NegativeGround)

Dimensions(WxHxD): 9.0”x3.2”x10.0”(229x80x253mm)

Weight(Approx.): 9.5lbs(4.3kg)

Transmier

Power Output: 5-100was(2-25wasAMcarrier)

Modulation Types: J3E(SSB):Balanced,

A3E(AM):Low-Level(EarlyStage),

F3E(FM):VariableReactance

F7W(C4FM):4-levelFSK

Maximum FM Deviation: ±5.0 kHz/±2.5 kHz

Harmonic Radiation: Beerthan–50dB(1.8MHz-30MHzAmateurbands)

Beerthan–63dB(30MHzAmateurband)

Beerthan–60dB(144MHz,430MHzAmateurbands)

SSB Carrier Suppression: Atleast50dBbelowpeakoutput

Undesired Sideband Suppression: Atleast50dBbelowpeakoutput

Bandwidth: 3kHz(LSB/USB),500Hz(CW),6kHz(AM),16kHz(FM/C4FM)

Audio Response(SSB): Notmorethan–6dBfrom300to2700Hz

Microphone Impedance: 600 Ohms (200 to 10 kOhms)

SPECIFICATIONS-1

FT-991 Technical Supplement

Page 3

Specications

Receiver

Circuit Type: SSB/CW/AM:Triple-conversionSuperheterodyne

FM/C4FM:Double-conversionSuperheterodyne

Intermediate Frequencies: 40.455 MHz

SSB/CW/AM:69.450MHz/9.000MHz/24kHz

FM/C4FM:69.450MHz/450kHz

Sensitivity: SSB/CW(BW:2.4kHz,10dBS+N/N)

0.158µV(1.8-30MHz)(AMP2“ON”)

0.125µV(50-54MHz)(AMP2“ON”)

0.11µV(144-148MHz)

0.11µV(430-450MHz)

AM(BW:6kHz,10dBS+N/N,30%modulation@400Hz)

5µV(0.5-1.8MHz)(AMP2“ON”)

1.6µV(1.8-30MHz)(AMP2“ON”)

1.25µV(50-54MHz)(AMP2“ON”)

FM(BW:15kHz,12dBSINAD)

0.35µV(28-30MHz)(AMP2“ON”)

0.35µV(50-54MHz)(AMP2“ON”)

0.18µV(144-148MHz)

0.18µV(430-440MHz)

Thereisnospecicationforfrequencyrangesnotlisted.

Squelch Sensitivity (TYP.): SSB/CW/AM

1.0µV(1.8-30MHz,50-54MHz)(AMP2“ON”)

1.0µV(144-148MHz,430 - 450 MHz)

FM

0.35µV(28-30MHz,50-54MHz)(AMP2“ON”)

0.125µV(144-148MHz,430 - 450 MHz)

Thereisnospecicationforfrequencyrangesnotlisted.

Selectivity: Mode –6dB –60dB

CW/RTTY/PKT 0.5kHzorbeer 750Hzorless

SSB 2.4kHzorbeer 3.6kHzorless

AM 6kHzorbeer 15kHzorless

FM 12kHzorbeer 30kHzorless(–50dB)

Image Rejection: 70dBorbeer(1.8MHz-50MHzAmateurbands)

60dBorbeer(144/430MHzAmateurband)

Maximum Audio Output: 2.5Winto4Ohmswith10%THD

Audio Output Impedance: 4to8Ohms(4Ohms:nominal)

Conducted Radiation: Lessthan4nW

Specications are subject to change, in the interest of technical improvement, without notice or obligation,

and are guaranteed only within the amateur bands.

SPECIFICATIONS-2

FT-991 Technical Supplement

Page 4

①

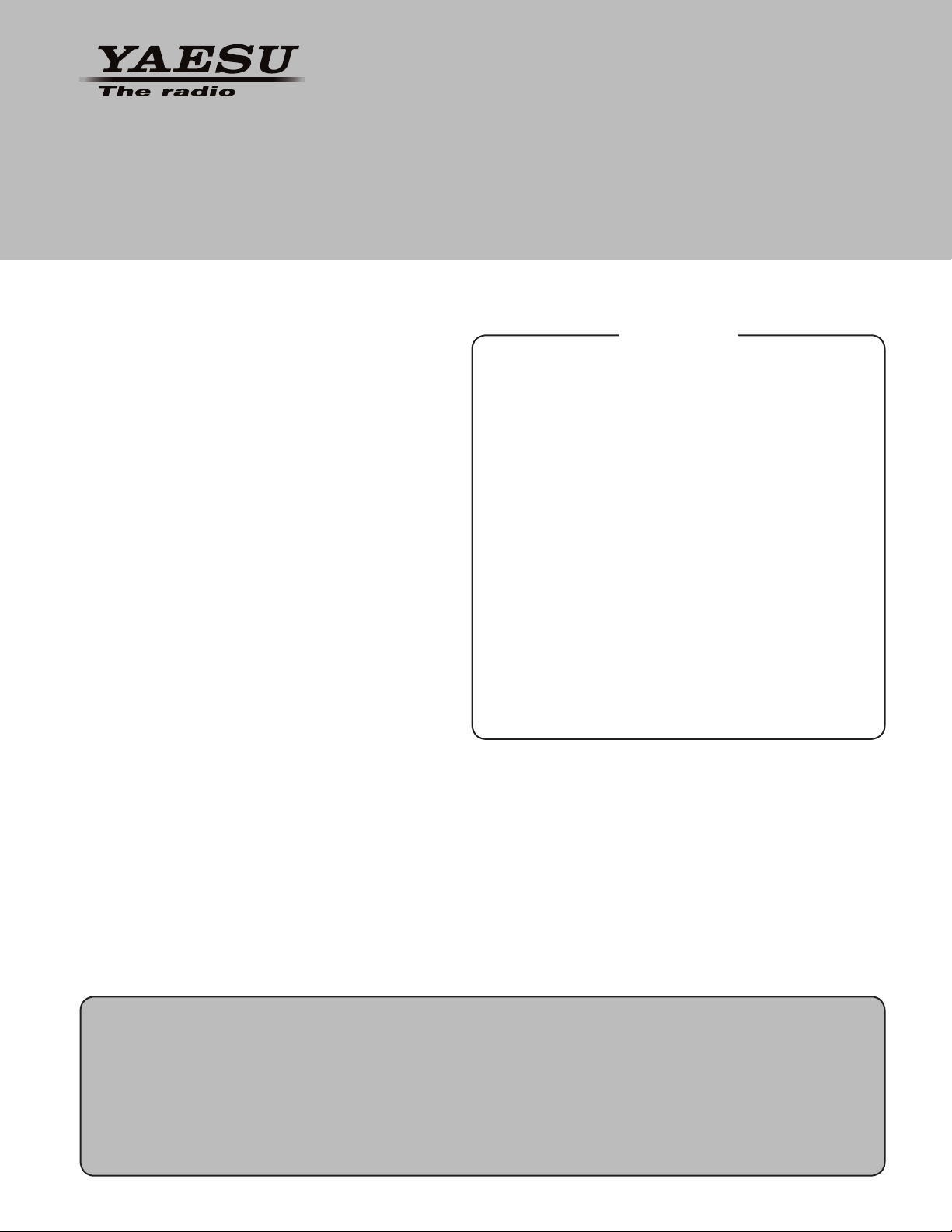

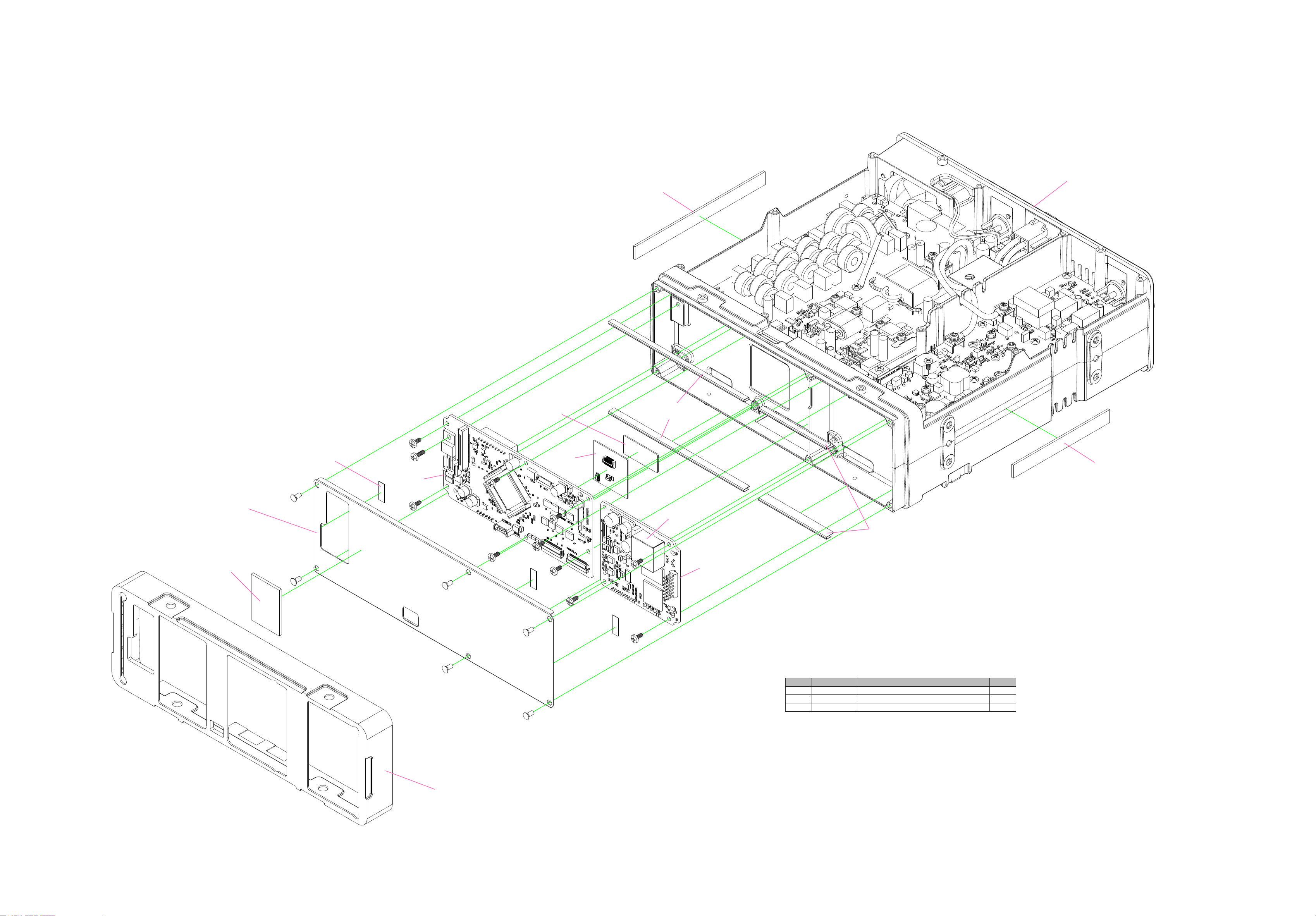

Exploded View

RA6024400

PORON SHEET(6x25)

①

①

R7153663

HIMERON

①

①

RA600120A

TOP CASE

①

①

①

RA6033500

GASKET (10x20)

②

RA6017300

SPONGE RUBBER(10x98)

②

RA0471500

ELEC. COND TAPE(C)

RA131710A

SPONGE RUBBER(SP-CE)

②

RA123330A

SHEEET

M4090229

SP 66S-A3627

②

RA0994000

PORON SHEET(151505)

②

③

③

③

②

②

②

③

RA6046900

BLIND SHEET (0715)

RA089840A

SP NET

②

②

RA6032500

DOUBLE FACE (19x9)

RA6032300

HEATSINK

RA6000700

SHIELD CASE COVER

②

RA6033500

GASKET (10x20)

②

RA1550600

SP HOLDER(H034M)

S5000260

LEAD CLAMP

④

R3520660A

HANDLE

④

R4150130

HANDLE END

REF. YAESU P/N Description Qty.

U31306007 OVAL HEAD SCREW M3X6B 8

①

U24206001 BIND HEAD TAPTITE-B M2.6X6 12

②

U31206007 OVAL HEAD SCREW M2.6X6B 4

③

U31415007 OVAL HEAD SCREW M4X15B 2

④

Non-designated parts are available only as psrt of a designated assembly.

EXPLODED VIEW-1

FT-991 Technical Supplement

Page 5

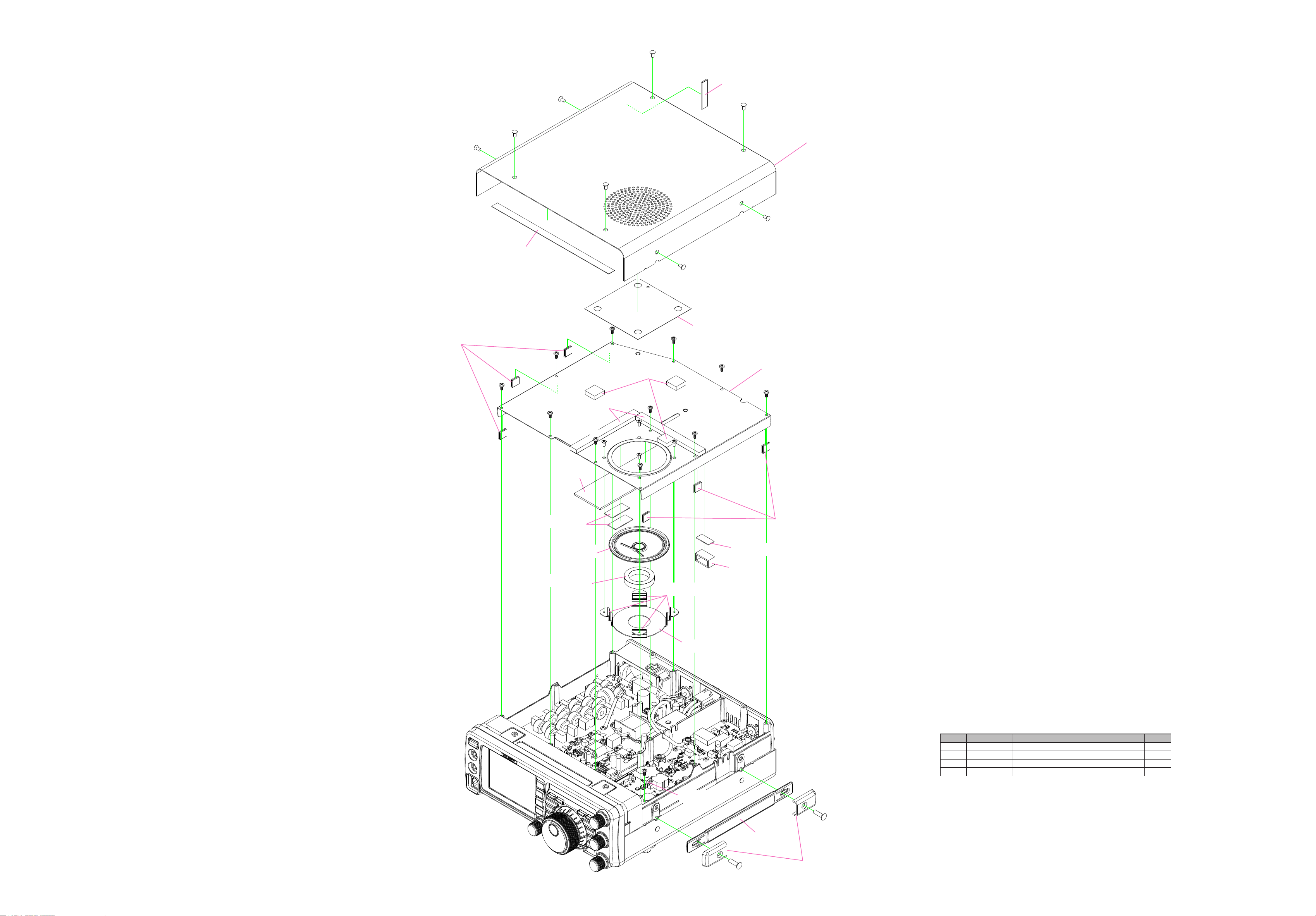

S4000052

CASE LEG FF-004-AR791

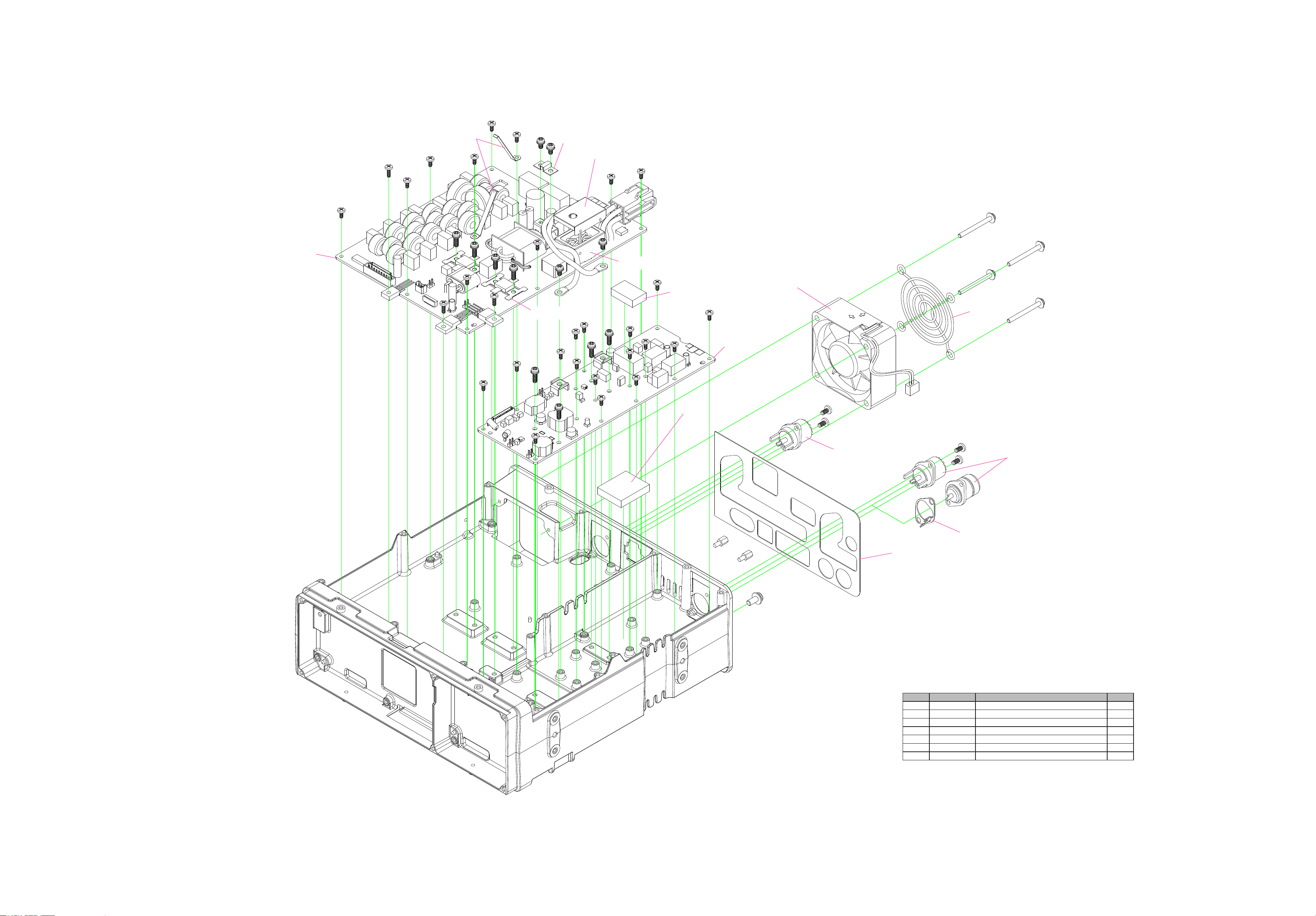

Exploded View

①

②

①

R7153663

HIMERON

RA600110A

BOTTOM CASE

①

R0145630

STAND

R3100700A

FOOT

①

②

①

①

①

RA6024400

PORON SHEET(6x25)

①

RA0423200

LOCK PLATE

RA089560A

GASKETW9H4L40

①

RA1236600

PORON SHEET(10X10t3)

RA6048700

GASKET(70x70)

③

③

RA6000800

SHIELD CASE COVER

③

③

RA6033500

GASKET (10x20)

REF. YAESU P/N Description Qty.

U31306007 OVAL HEAD SCREW M3X6B 9

①

U20406007 BINDING HEAD SCREW M4X6B 2

②

U30305002 FLAT HEAD SCREW M3X5NI 4

③

Non-designated parts are available only as psrt of a designated assembly.

EXPLODED VIEW-2

FT-991 Technical Supplement

Page 6

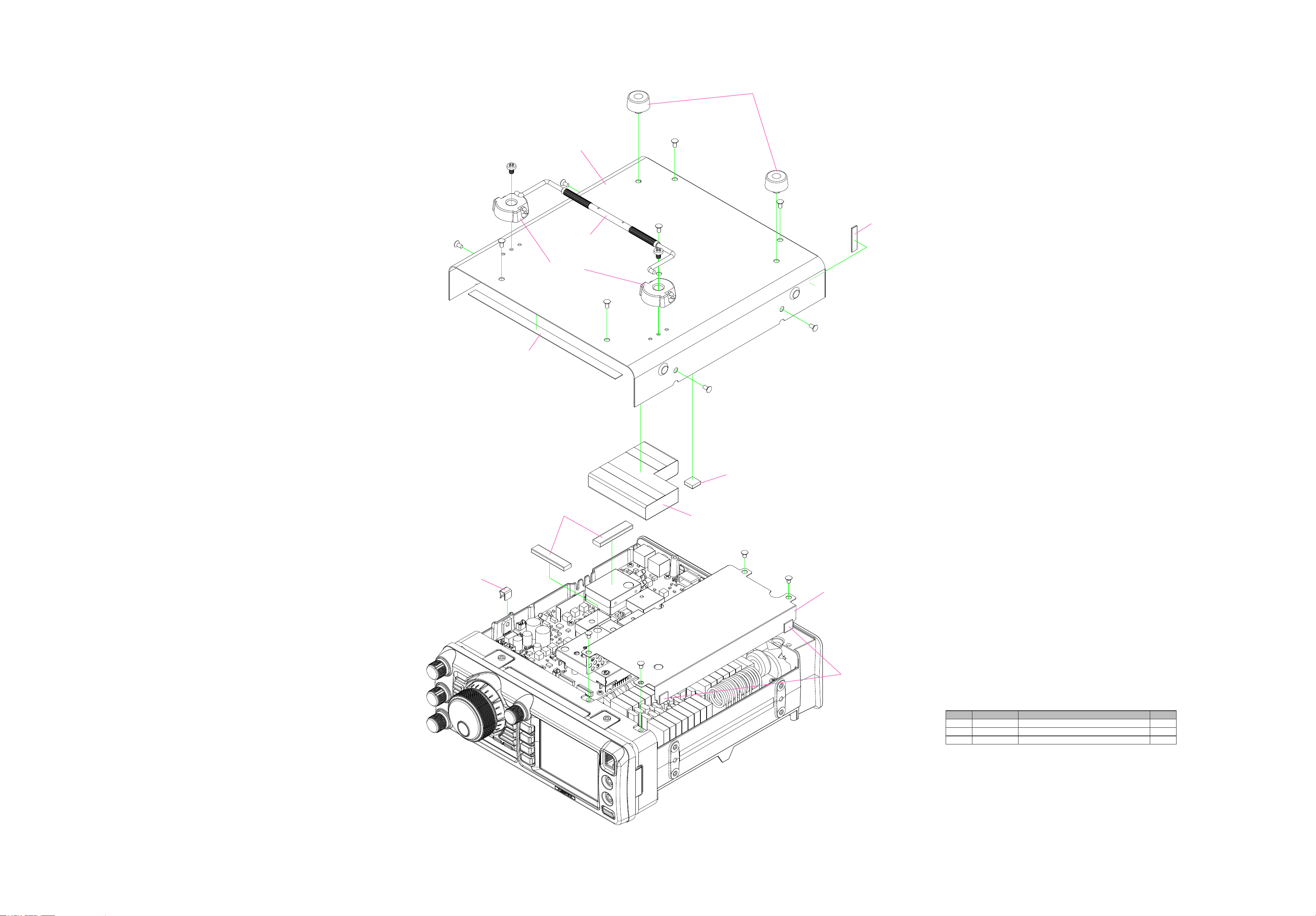

Exploded View

RA6003500

RUBBER KNOB(PWR)

Q7000653

LCD MODULE

RA1340000

LCD SPACER (A)

RA6003400

LCD SPACER(57B)

PANEL-UNIT

①

RA6030000

GASKET(8x10)

①

①

①

①

①

①

JACK-UNIT

①

①

①

①

①

Q9001000

ROTARY ENCODER

①

RA6025300

BLIND SHEET(9x28)

RA6018200

NAME PLATE

U62009001

VOLUME NUT 9X12X2

RA6004600

KNOB SKIRT

RA6003200

WINDOW(LED)

RA6004000

KNOB ASSY (ENC)

Q9000996

ROTARY ENCODER (w/ ø1, ø2)

RA6054500

PORON SHEET(10x3.5) (2 pcs)

Q9000758

ROTARY ENCODER (w/ ø1, ø2)

RA6003600

RUBBER KNOB(H057)

ø

2

ø

1

ø

ø

ø

2

1

RA600300A

FRONT PANEL(PRT)

ø

2

1

RA6025300

BLIND SHEET(9x28)

J60800322

POT (w/ ø1, ø2)

RA1528400

WASHER(PE)

RA6004500

RUBBER RING(MAIN)

②

②

RA152820A

WASHER(FELT)

RA6004200

KNOB MAIN ASSY

U9900211

WAVE WASHER WW-16011(SUS)

RA0979300

HOLDER(SPRING)

RA6003700

KNOB ASSY(VOL)

U70015001

PLAIN WASHER FW9X14X0.5

ø

ø

2

1

REF. YAESU P/N Description Qty.

U24108001 BIND HEAD TAPTITE-B M2X8(3) 13

①

U24206001 BIND HEAD TAPTITE-B M2.6X6 2

②

Non-designated parts are available only as psrt of a designated assembly.

EXPLODED VIEW-3

FT-991 Technical Supplement

Page 7

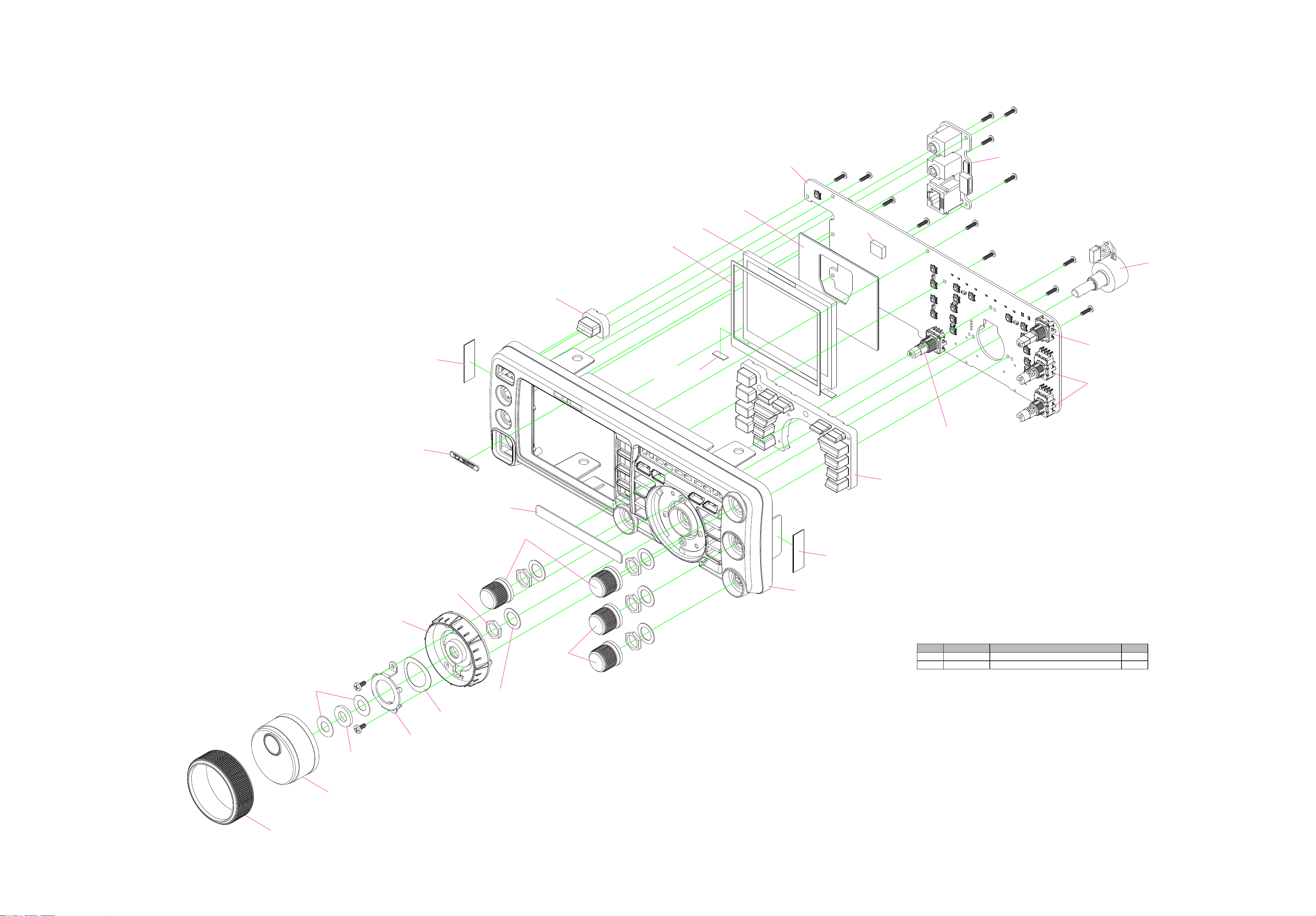

RA602540A

PORON SHEET (10x115)

Exploded View

RA6000300

CHASSIS

RA6000900

SHIELD CASE COVER

RA1499500

PORON SHEET(25x35)

RA1559100

GASKET(5x12) (3 pcs)

①

①

②

③

CNTL-UNIT

②

①

②

②

RA1391800

SPACER(DSP)

DSP-UNIT

②

②

②

RA6015300

GASKET(120x10)

RA602550A

PORON SHEET (10x85)

RA0060200

SHIELD CASE

RA1558800

GASKET(60x12)

②

EDSP-UNIT

②

①

RA6001000

RUBBER PACKING

①

①

②

REF. YAESU P/N Description Qty.

U34206001 FLAT HEAD TAPTITE-B M2.6X6 6

①

U24206001 BIND HEAD TAPTITE-B M2.6X6 10

②

U24208007 BIND HEAD TAPTITE-B M2.6X8B 1

③

Non-designated parts are available only as psrt of a designated assembly.

EXPLODED VIEW-4

FT-991 Technical Supplement

Page 8

①

②

①

RA6035100

LEAF SPRING

①

①

①

①

④

④

S5000331

TERMINAL

R0131680

SHIELD COVER

①

Exploded View

①

⑤

HF-PA-UNIT

②

③

①

③

①

③

②

①

④

③

RA0415200

GROUND PLATE (4 pcs)

①

①

③

③

①

①

①

①

③

④

①

①

R0131670A

SHIELD CASE

①

③

①

①

①

①

RA6032400

Thermal Conductive Pad

①

RA6049000

Thermal Conductive Pad

①

V_U-PA-UNIT

M2090052

FAN

⑥

⑥

P1091158A

CONNECTOR

S5000320

FAN GUARD

⑥

⑥

⑤

⑤

⑤

P1091158A (CE OFF)

P1090547 (CE ON)

CONNECTOR

⑦

S5000236 (CE ON)

LUG WASHER FOR MDR-2

RA6000400

DISPLAY PANEL

REF. YAESU P/N Description Qty.

U24206001 BIND HEAD TAPTITE-B M2.6X6 26

①

U24208007 BIND HEAD TAPTITE-B M2.6X8B 3

②

U03310002 SEMS SCREW ASM3X10NI 8

③

U03306002 PAN HEAD SCREW ASM3X6NI 4

④

U04333007 SEMS SCREW HSM3X33B 4

⑤

U24306001 BIND HEAD TAPTITE-B M3X6 4

⑥

U04410002 SEMS SCREW HSM4X10NI 1

⑦

EXPLODED VIEW-5

Non-designated parts are available only as psrt of a designated assembly.

FT-991 Technical Supplement

Page 9

①

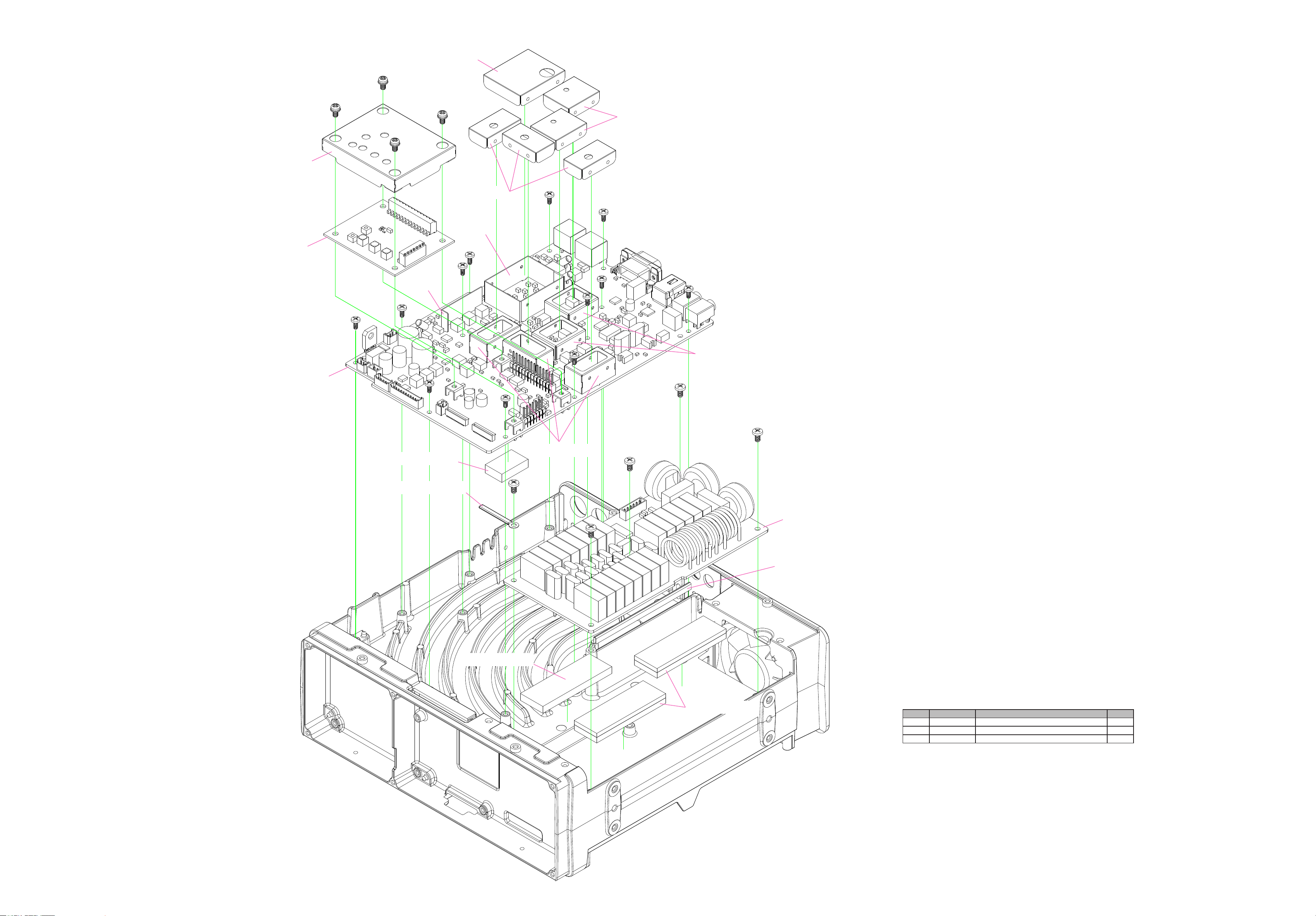

Exploded View

RA1152400

SHIELD CASE COVER

RA6001700

SHIELD CASE COVER

PLL-UNIT

①

②

①

RA6002100

SHIELD PLATE

②

①

RA1152300

SHIELD CASE COVER

RA0659300

SHIELD CASE

②

②

②

②

RA0830400

SHIELD CASE COVER

②

②

②

MAIN-UNIT

②

RA6032400

Thermal Conductive Pad

S5000260

LEAD CLAMP CC-1002

②

RA1152200

SHIELD CASE(28x15)

③

②

RA0830300

SHIELD CASE(21X25)

③

③

③

TUNER-UNIT

③

RA6015400

GASKET(80x10)

RA6025100

Thermal Conductive Pad

RA6025200

Thermal Conductive Pad

REF. YAESU P/N Description Qty.

U03306002 PAN HEAD SCREW ASM3X6NI 4

①

U24206001 BIND HEAD TAPTITE-B M2.6X6 12

②

U24306001 BIND HEAD TAPTITE-B M3X6 5

③

Non-designated parts are available only as psrt of a designated assembly.

EXPLODED VIEW-6

FT-991 Technical Supplement

Page 10

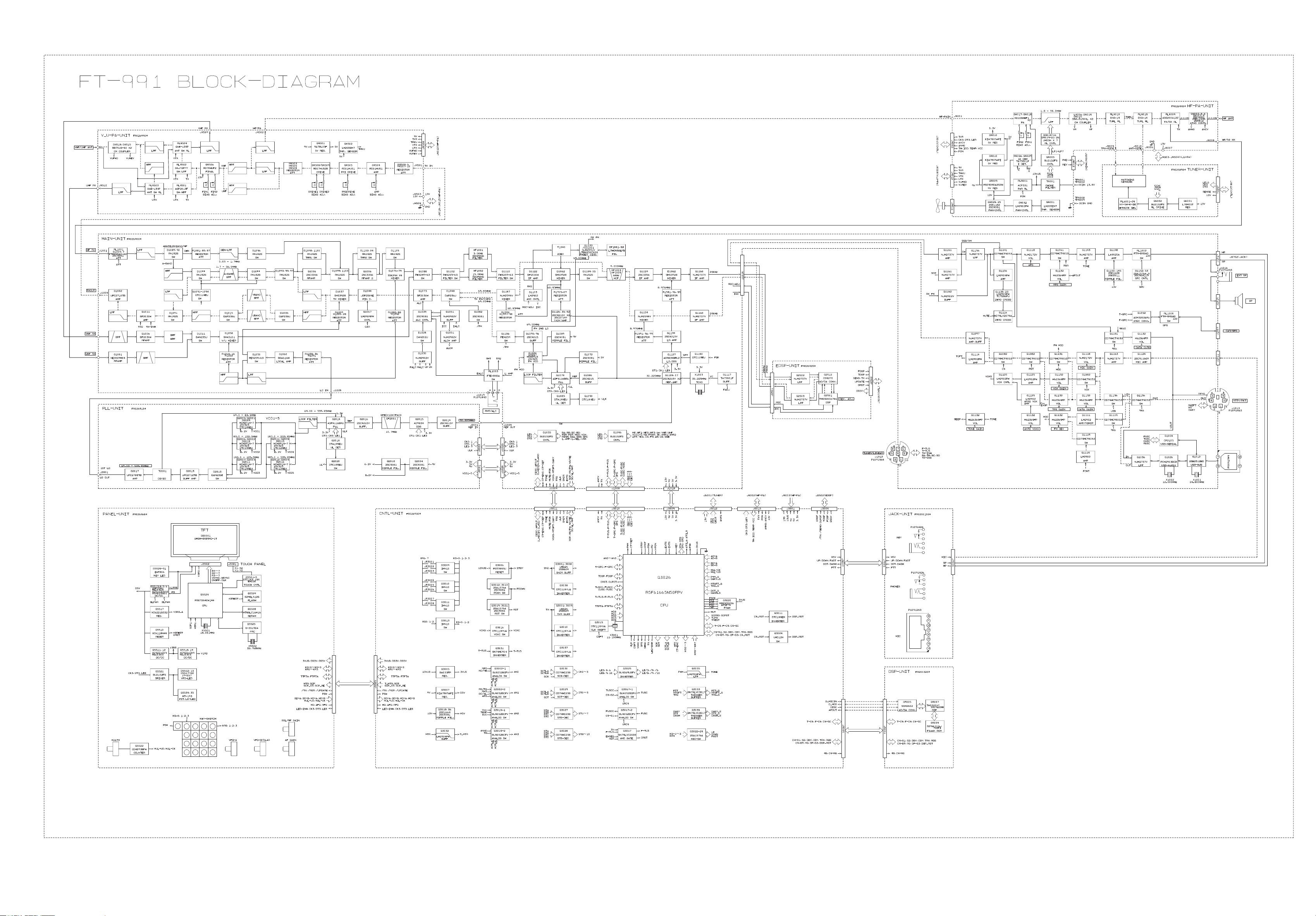

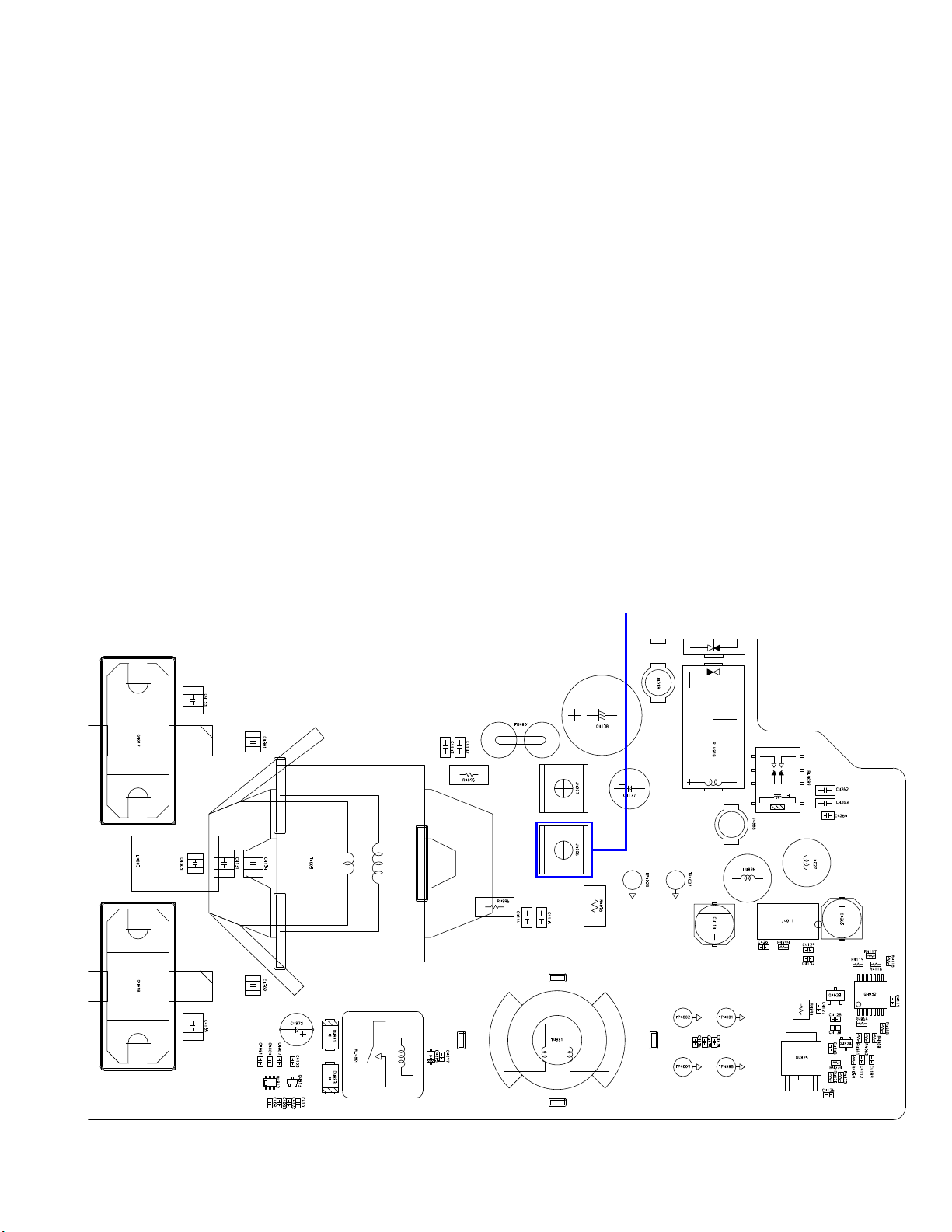

Block Diagram

BLOCK DIAGRAM-1

FT-991 Technical Supplement

Page 11

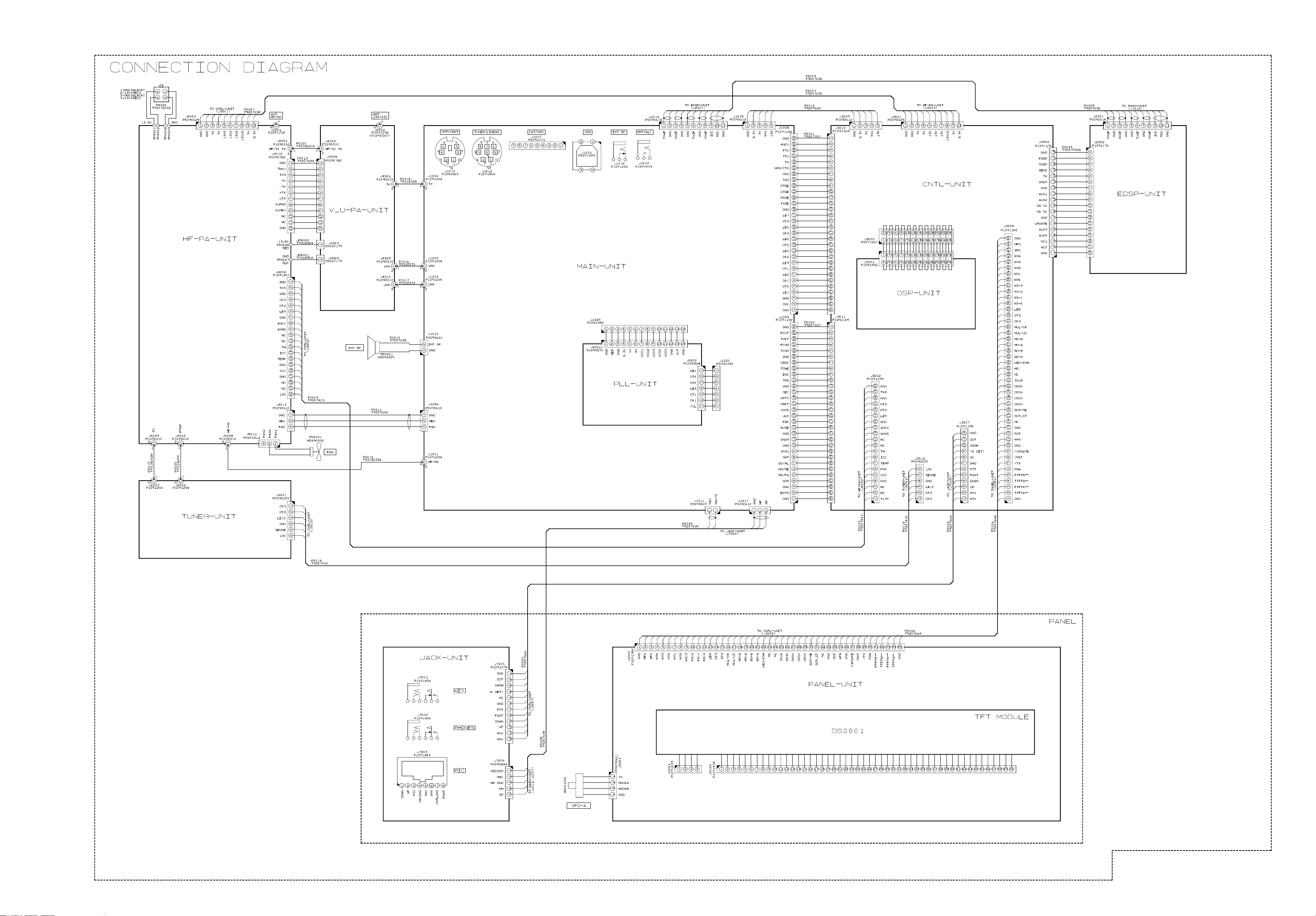

Connection Diagram

CONNECTION DIAGRAM-1

FT-991 Technical Supplement

Page 12

Alignment

Introduction and Precautions

The following procedures cover adjustments that

are not normally required once the transceiver

has le the factory. However, if a problem occurs

during normal operation due to component failure;

realignment may be required aer the faulty components have been replaced.

We recommend that authorized Yaesu Techni-

cians, who are experienced with the circuitry and

fully equipped to repair and align our products,

perform repairs. If a fault is suspected, contact the

selling dealer for instructions regarding repair.

Authorized Yaesu Technicians have the latest information to align all circuits and make complete performance checks to ensure compliance with factory

specications aer repairs.

Those who do undertake any of the following

alignments are cautioned to proceed at their own

risk. Problems caused by unauthorized aempts at

realignment are not covered by the warranty policy.

Yaesu must reserve the right to change circuits and

alignment procedures in the interest of improved

performance, without notifying owners.

Under no circumstances should any alignment be

aempted unless the normal functions and operation of the transceiver are clearly understood, the

cause of the malfunction has been clearly identied

and all faulty components replaced. The need for

realignment should be determined to be absolutely

necessary.

The following test equipment (and a thorough familiarity with its correct use) is necessary for cor-

rect realignment. Most steps do not require all of

the equipment listed. The interactions of some adjustments may require that more complex adjustments be performed in a sequence. Do not aempt

to perform only a single step unless it is clearly iso-

lated electrically from all other steps. Have all test

equipment ready before beginning, and follow all

of the steps in a section in the order they are pre-

sented.

Required Test Equipment

RF Signal Generator

AF Signal Generator

Spectrum Analyzer good to at least 1 GHz.

Frequency Counter

SINAD Meter

RF Millivoltmeter

Electronic Load

Digital DC Voltmeter (high-Z, 1 M-Ohm/V)

DC Voltmeter

DC Ammeter (23 A)

Ohmmeter

50-Ohm Dummy Load (100/200 was)

In-Line Wameter (150/300 was, 50-Ohm)

Linear Detector

RF Coupler

4-Ohm AF Dummy Load (3 was)

1/4-inch 3-contact Plug

Alignment Preparation & Precautions

A 50-ohm RF Dummy load and in-line wameter

must be connected to the ANT jack in all procedures that call for transmission, except where specied otherwise. Correct alignment is not possible

with an antenna.

Aer completing one step, read the following step

to determine whether the same test equipment

will be required. If not, remove the unneeded test

equipment before proceeding. (except the dummy

load and wameter).

Correct alignment requires that the ambient temperature be maintained constant between 68 °F ~ 86

°F (20 °C ~ 30 °C). When the transceiver is brought

into the shop from a hot or cold environment, it

should be allowed time to come to room temperature before alignment. Also, the test equipment

must be thoroughly warmed up before beginning.

Whenever possible, alignments should be made

with oscillator shields and circuit boards rmly afxed in place.

Note: Signal levels in dB referred to in this proce-

dure are based on 0 dBµ = 0.5 µV (closed circuit).

Important Notice

Do not adjust the alignment menus that are

not mentioned in this manual.

ALIGNMENT-1

FT-991 Technical Supplement

Page 13

Alignment

VDD Meter Adjustment

Connect the DC voltmeter to J4006 on the HF-

PA-Unit.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] dial knob to select the

alignment menu item “01-01 VDD MTR”.

Press the [F(M-LIST)] key, then rotate the

[CLAR/VFO-B] knob so the VDD meter reading

is the same as the reading on the DC voltmeter

(13.8 V).

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

COMP Meter Adjustment

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “22-02 COMP MTR

10dB”, then rotate the [CLAR/VFO-B] knob for

"10 dB" on the COMP meter.

Rotate the [MULTI] Dial knob to select the

alignment menu item “22-03 COMP MTR

20dB”, then rotate the [CLAR/VFO-B] knob for

"20 dB" on the COMP meter.

Rotate the [MULTI] Dial knob to select the

alignment menu item “22-04 COMP MTR

30dB”, then rotate the [CLAR/VFO-B] knob so

the COMP meter deects to full scale.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seings and exit

the alignment mode.

J4006

ALIGNMENT-2

FT-991 Technical Supplement

Page 14

Alignment

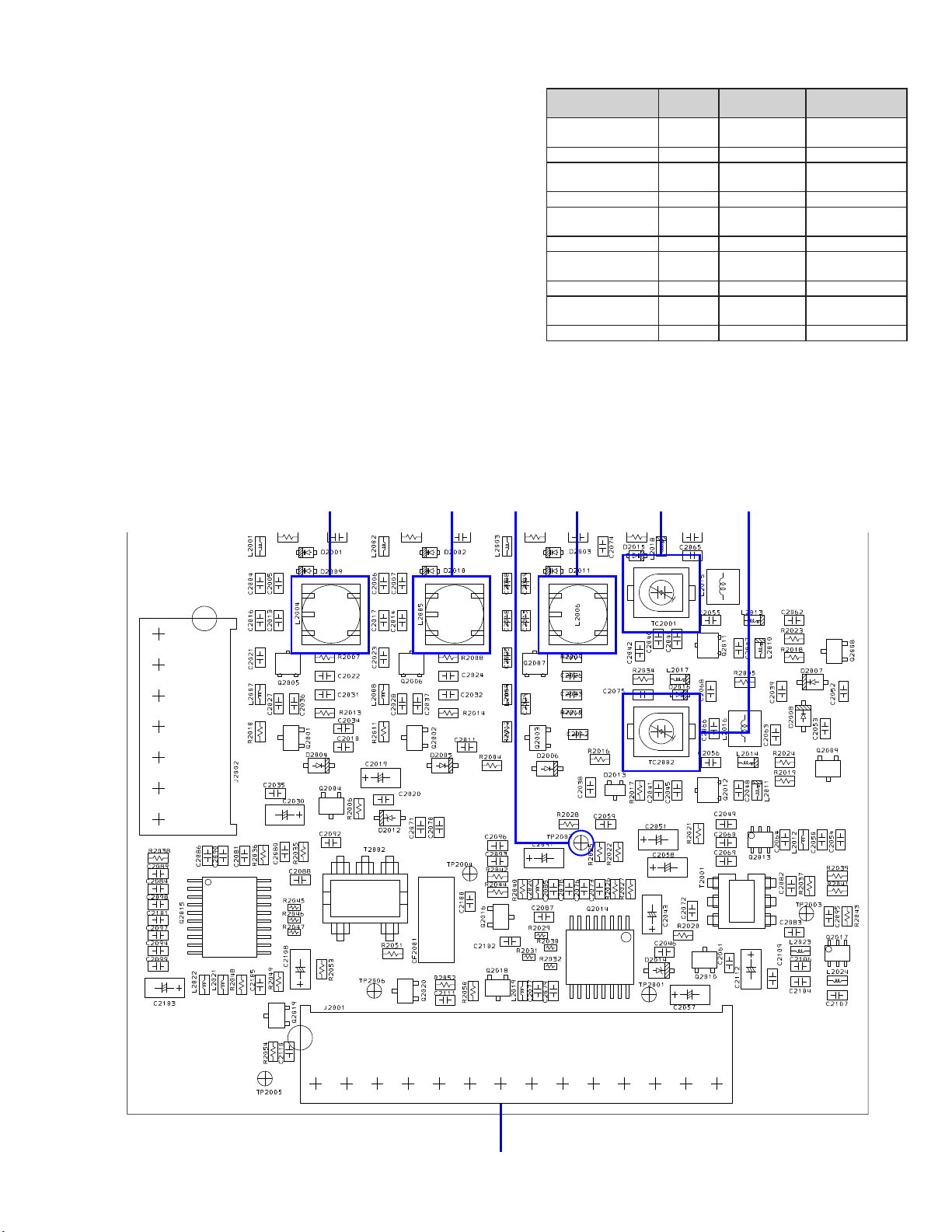

VCO Adjustment

Connect the Digital DC voltmeter (high-Z) to

TP2002 on the PLL Unit.

Disconnect the coaxial cable from J2001 on the

PLL Unit, then connect the RF millivoltmeter to

pin 13 of J2001.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Referring to the table below, select the appropri-

ate “Alignment menu item” using the [MULTI]

Dial knob per the chart right, and adjust the

listed components for the required voltage, or

confirm that the correct voltage is present on

each alignment menu item.

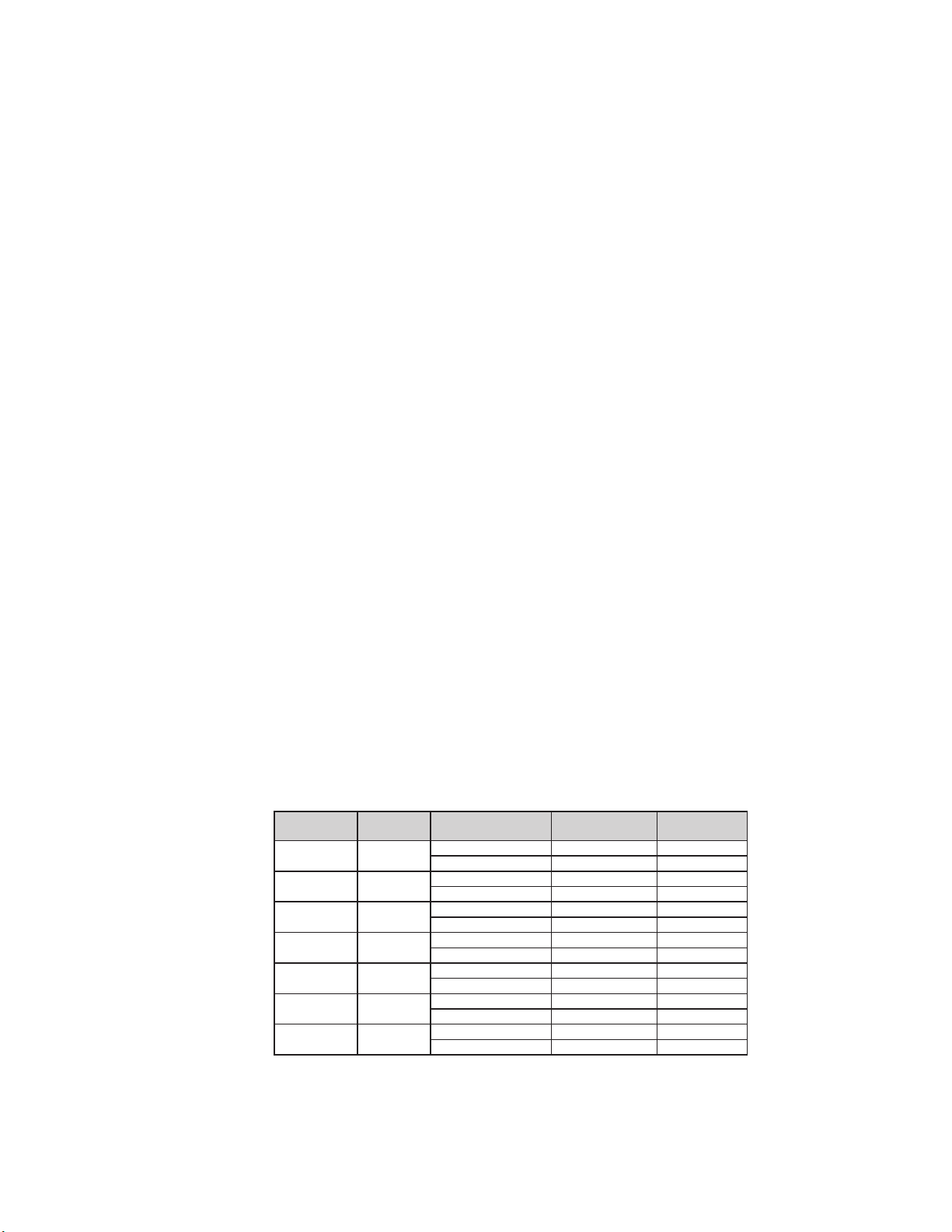

Alignment

Menu Item

01-05 VCO1-HIGH

(TXI)

01-06 VCO1-LOW Conrm At least 0.3 V At least –10 dBm

01-07 VCO2-HIGH

01-08 VCO2-LOW Conrm At least 0.6 V At least –10 dBm

01-09 VCO3-HIGH

01-10 VCO3-LOW Conrm At least 0.4 V At least –10 dBm

01-11 VCO4-HIGH

01-12 VCO4-LOW Conrm At least 0.5 V At least –10 dBm

01-13 VCO5-HIGH

01-14 VCO5-LOW Conrm At least 0.8 V At least –10 dBm

Disconnect the RF millivoltmeter from J2001,

Adjust /

Conrm

Adjust

L2004

Adjust

L2005

Adjust

L2006

Adjust

TC2001

Adjust

TC2002

DC voltmeter RF millivoltmeter

5.1 V ±0.1 V At least 3 dBm

5.1 V ±0.1 V At least –10 dBm

4.1 V ±0.1 V At least –10 dBm

5.0 V ±0.1 V At least –10 dBm

5.0 V ±0.1 V At least –10 dBm

then re-connect the coaxial cable to J2001.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

TP2002

TC2001

TC2002L2006L2005L2004

J2001

ALIGNMENT-3

FT-991 Technical Supplement

Page 15

Alignment

2nd/3rd Local Oscillator Adjustment

Set the VFO-A frequency to 14.200 MHz in the

CW-USB mode.

Set the following controls as indicated:

[IPO] : AMP1

[ATT] : OFF

[NB] : OFF

[AGC] : AUTO

[RF GAIN] : Fully clockwise

3rd Local Level Adjustment

Connect the RF millivoltmeter to TP1024 on the

MAIN Unit.

Adjust T1029 on the MAIN Unit for maximum

deection on the RF millivoltmeter.

2nd

Local Level Adjustment

Connect the RF millivoltmeter to TP1025 on the

MAIN Unit.

Adjust T1027, T1028, T1030, and T1033 on the

MAIN Unit for maximum deection on the RF

millivoltmeter.

TP1005

TP1024

TP1025

T1033

T1030

TC1006

TP1008

T1028

T1027

T1029

ALIGNMENT-4

FT-991 Technical Supplement

Page 16

Alignment

REF OSC Adjustment

Connect the frequency counter to TP1025.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “01-04 REF FREQ”.

Rotate the [CLAR/VFO-B] knob so that the

frequency counter reading is “60.450000 ±4

Hz”.

Disconnect the frequency counter from TP1025.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

FM Local Oscillator Adjustment

Set the FM mode.

Connect the Digital DC voltmeter (high-Z)

TP1008 on the MAIN Unit.

Adjust TC1006 on the MAIN Unit for 3.6 V ±0.1

V on the Digital DC voltmeter.

Set the CW mode.

TP1025

TC1006

TP1008

ALIGNMENT-5

FT-991 Technical Supplement

Page 17

1st Local Oscillator Adjustment

Connect the RF millivoltmeter to TP1005 on the

MAIN Unit.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-01 Local 1.8”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-02 Local HFL”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-03 Local HFM”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-04 Local HFH”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-05 Local 50”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+11.5 dBm ±0.5 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-06 Local 144”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “02-07 Local 430”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob so that the RF millivoltmeter reading is “+10 dBm ±1 dBm”.

Release the PTT buon.

Alignment

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seings and exit

the alignment mode.

Alignment

Menu Item

02-01 Local 1.8 +10 dBm ±1 dBm

02-02 Local HFL +10 dBm ±1 dBm

02-03 Local HFM +10 dBm ±1 dBm

02-04 Local HFH +10 dBm ±1 dBm

02-05 Local 50 +11.5 dBm ±0.5 dBm

02-06 Local 144 +10 dBm ±1 dBm

02-07 Local 430 +10 dBm ±1 dBm

RF millivoltmeter

ALIGNMENT-6

TP1005

FT-991 Technical Supplement

Page 18

Alignment

MCF Adjustment (1)

Set the VFO-A frequency to 145.900 MHz in the

CW-USB mode.

Set the following controls as indicated:

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the AF millivoltmeter and 4 Ohm

dummy load to the EXT SP jack.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to +0

dBµ at the 145.900 MHz.

Adjust T1001, T1003 and T1025, T1026 on the

MAIN Unit in succession several times for

maximum deection on the AF millivoltmeter.

Note: If the S-meter deflects while adjusting,

reduce the RF Signal Generator output so that the

S-meter does not deect.

Set the FM mode.

Connect the SINAD meter and 4 Ohm dummy

load to the EXT SP jack.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to –9

dBµ at the 145.900 MHz with ±3.5 kHz deviation FM modulation of a 1 kHz audio signal.

Adjust T1025 on the MAIN Unit in succession

several times for maximum deflection on the

SINAD meter.

Note: Do not adjust T1025 more than 180 degrees

rotation.

MCF Adjustment (2)

Set the VFO-A frequency to 439.900 MHz in the

CW-USB mode.

Set the following controls as indicated:

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the AF millivoltmeter and 4 Ohm

dummy load to the EXT SP jack.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to +0

dBµ at the 439.900 MHz.

Adjust TC1001 and TC1007 on the MAIN

Unit in succession several times for maximum

deection on the AF millivoltmeter.

Note: If the S-meter deflects while adjusting,

reduce the RF Signal Generator output so that the

S-meter does not deect.

T1001

T1003

TC1001

TC1007

ALIGNMENT-7

T1025

T1026

FT-991 Technical Supplement

Page 19

Alignment

IF Trap Adjustment

Set the VFO-A frequency to 51.900 MHz in the

CW-USB mode.

Set the following controls as indicated:

[IPO] : AMP2

[ATT] : OFF

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the AF millivoltmeter and 4 Ohm

dummy load to the EXT SP jack.

Connect the RF Signal Generator to the “HF/50

MHz” ANT jack, then set the output level to

+40 ~ +80 dBµ at the 69.450000 MHz.

Adjust T1017 on the MAIN Unit for minimum

deection on the AF millivoltmeter.

Note: If the S-meter deflects while adjusting,

reduce the RF Signal Generator output so that the

S-meter does not deect.

RF AGC Adjustment

Set the VFO-A frequency to 14.200 MHz in the

CW-USB mode.

Set the following controls as indicated:

[IPO] : AMP1

[ATT] : OFF

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the RF Signal Generator to the "HF/50

MHz" ANT jack, then set the output level to

+76dBµ at the 14.200 MHz.

Connect the Digital DC voltmeter (high-Z) to

TP1016 on the MAIN Unit.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “03-03 RF-AGC HFM”.

Adjusting the [CLAR/VFO-B] knob so the Digi-

tal DC voltmeter reading is "2.6 V ±0.2 V".

Set to the same parameter of the alignment

menu item “03-03 RF-AGC HFM” for the Alignment Menu items “03-01 RF-AGC 1.8”, “03-02

RF-AGC HFL”, “03-04 RF-AGC HFH”, “03-05

RF-AGC 50”, “03-06 RF-AGC 144” and “03-07

RF-AGC 430”

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

TP1016

T1017

ALIGNMENT-8

FT-991 Technical Supplement

Page 20

IF Gain Adjustment

Set the following controls as indicated:

[IPO] : AMP1

[ATT] : OFF

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the AF millivoltmeter and 4 Ohm

dummy load to the EXT SP jack.

Connect the RF Signal Generator to the “HF/50

MHz” ANT jack, then set the output level to

+36 dBµ at 1.900 MHz.

Set the VFO-A frequency to 1.900 MHz in the

USB mode.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Adjust the [AF GAIN] knob so that the AF mil-

livoltmeter reading is “0 dB”.

Set the RF Signal Generator output level to +10

dBµ.

Adjust the [CLAR/VFO-B] knob so that the AF

millivoltmeter reading is “-1.5 ± 0.5 dB”.

Select the appropriate “Alignment menu item”

using the [MULTI] Dial knob per the chart below, then set the RF Signal Generator output to

each frequency & level, and adjust the [CLAR/

VFO-B] knob for the corresponding AF millivoltmeter reading at each frequency.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seings and exit

the alignment mode.

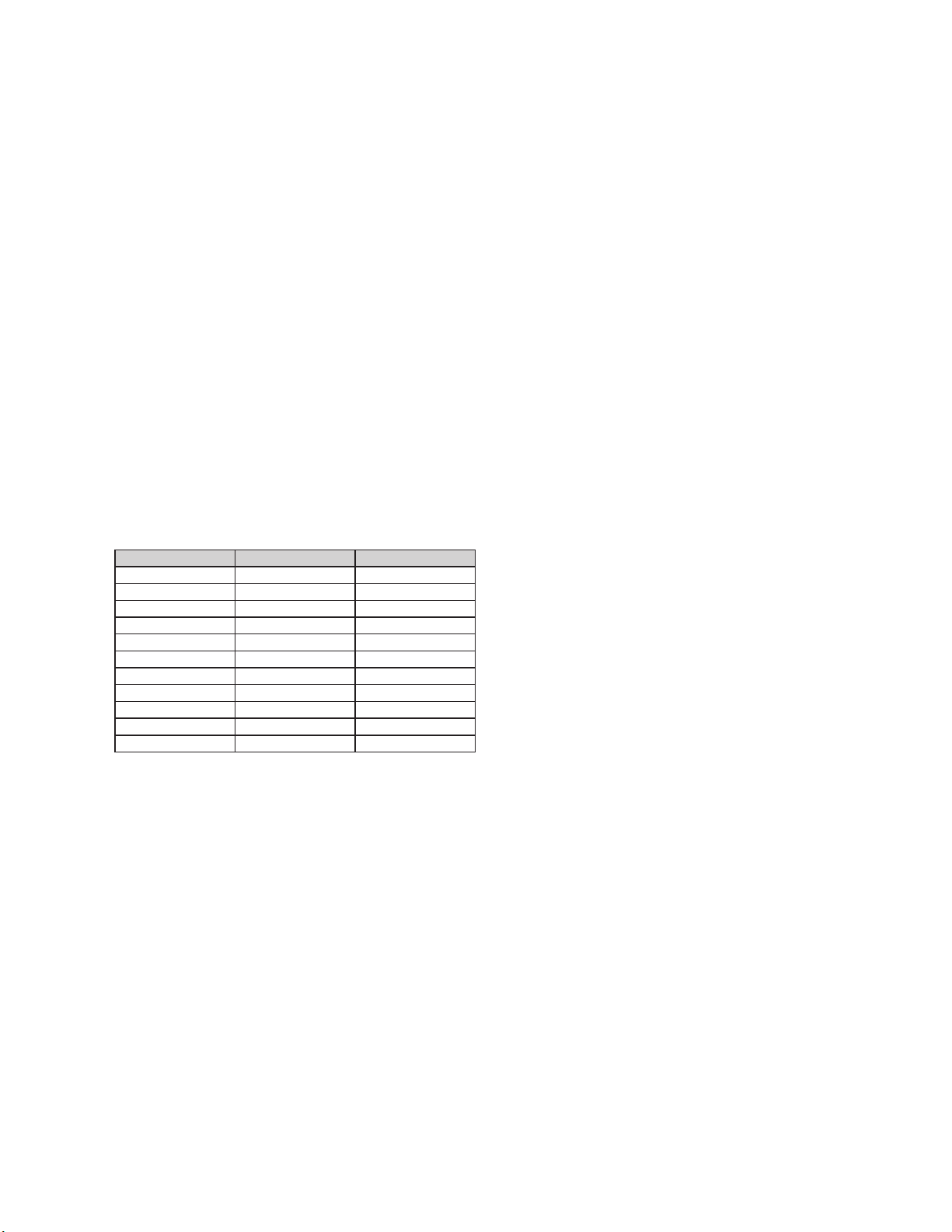

Alignment

Alignment

menu item

04-01 IGC 1.8 1.900 MHz

04-02 IGC HFL 7.100 MHz

04-03 IGC HFM 14.200 MHz

04-04 IGC HFH 21.230 MHz

04-05 IGC 50 51.900 MHz

04-06 IGC 144 145.900 MHz

04-07 IGC 430 439.900 MHz

VFO-A

Frequency

RF Signal

Generator

1.900 MHz, +36 dBµ

1.900 MHz, +10 dBµ

7.100 MHz, +36 dBµ

7.100 MHz, +10 dBµ

14.200 MHz, +36 dBµ

14.200 MHz, +10 dBµ

21.230 MHz, +36 dBµ

21.230 MHz, +10 dBµ

51.900 MHz, +36 dBµ

51.900 MHz, +7 dBµ

145.900 MHz, +30 dBµ

145.900 MHz, -3 dBµ

439.900 MHz, +30 dBµ

439.900 MHz, -3dBµ

ALIGNMENT-9

Adjust AF millivoltmeter

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

[AF GAIN] knob

[CLAR/VFO-B] knob

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

-1.5 dB (±0.5 dB)

0 dB

0 dB

0 dB

0 dB

0 dB

0 dB

0 dB

FT-991 Technical Supplement

Page 21

Alignment

S-meter Adjustment

Set the VFO-A frequency to 14.200 MHz in the

USB mode.

Set the following controls as indicated:

[IPO] : AMP1

[ATT] : OFF

[AGC] : AUTO

[RF GAIN] : Fully clockwise

Connect the RF Signal Generator to the “HF/50

MHz” ANT jack, then set the frequency to

14.200 MHz.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Refer to the chart below and select the

appropriate “Alignment menu item” using the

[MULTI] Dial knob. Set the RF Signal Generator

output to each level, and adjust the [CLAR/

VFO-B] knob for the corresponding S-meter

reading. Press the [F(M-LIST)] key to save the

new seing at each level.

Alignment menu item RF Signal Generator S-meter

05-01 S-MTR 0 OFF S-0

05-02 S-MTR 1 +14 dBµ S-1

05-03 S-MTR 5 +24 dBµ S-5

05-04 S-MTR 7 +30 dBµ S-7

05-05 S-MTR 9 +36 dBµ S-9

05-06 S-MTR +10 +46 dBµ S-9+10dB

05-07 S-MTR +20 +56 dBµ S-9+20dB

05-08 S-MTR +30 +66 dBµ S-9+30dB

05-09 S-MTR +40 +76 dBµ S-9+40dB

05-10 S-MTR +50 +86 dBµ S-9+50dB

05-11 S-MTR +60 +96 dBµ S-9+60dB

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seings and exit

the alignment mode.

S-meter Adjustment (FM)

Set the VFO-A frequency to 145.900 MHz in the

FM mode.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to 0

dBµ at the 145.900 MHz with ±3.5 kHz deviation FM modulation of a 1 kHz audio signal.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “07-01 FM S1”.

Rotate the [CLAR/VFO-B] knob so that the

S-meter reading is “S-1”.

Press the [F(M-LIST)] button to save the new

seing.

Set the RF Signal Generator to +20 dBµ.

Rotate the [MULTI] Dial knob to select the

alignment menu item “07-02 FM S9”.

Rotate the [CLAR/VFO-B] knob so that the

S-meter reading is “S-9”.

Press the [F(M-LIST)] button to save the new

seing.

Set the RF Signal Generator to +40 dBµ.

Rotate the [MULTI] Dial knob to select the

alignment menu item “07-03 FM S60”.

Rotate the [CLAR/VFO-B] knob so that the

S-meter reading is “S-9+60”.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

FIL Gain Adjustment

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “06-01 R. FIL 3k”.

Rotate the [CLAR/VFO-B] knob to set the pa-

rameter is "180".

Rotate the [MULTI] Dial knob to select the

alignment menu item “06-02 R. FIL 15k”.

Rotate the [CLAR/VFO-B] knob to set the pa-

rameter is "180".

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seings and exit

the alignment mode.

ALIGNMENT-10

FT-991 Technical Supplement

Page 22

Alignment

FM Squelch Adjustment

Set the VFO-A frequency to 145.900 MHz in the

FM-WIDE mode.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to -14

dBµ at the 145.900 MHz with ±3.5 kHz deviation FM modulation of a 1 kHz audio signal.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “08-01 FM SQL THW”.

Press the [F(M-LIST)] button to save the new

seing.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

Set the FM-NARROW mode.

Set the RF Signal Generator output level to -14

dBµ at the 145.900 MHz with ±1.75 kHz deviation FM modulation of a 1 kHz audio signal.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “08-02 FM SQL THN”.

Press the [F(M-LIST)] button to save the new

seing.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

Set the FM-WIDE mode.

Set the RF Signal Generator output level to +3

dBµ at the 145.900 MHz with ±3.5 kHz deviation FM modulation of a 1 kHz audio signal.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “08-03 FM SQL TI”.

Press the [F(M-LIST)] button to save the new

seing.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

FM Center Stop Adjustment

Set the VFO-A frequency to 145.900 MHz in the

FM-WIDE mode.

Connect the RF Signal Generator to the “144/430

MHz” ANT jack, then set the output level to

+10 dBµ at the 145.900 MHz.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “09-01 FM CTR-L”.

Press the [F(M-LIST)] button to save the new

seing.

Set the RF Signal Generator to 145.903 MHz.

Rotate the [MULTI] Dial knob to select the

alignment menu item “09-02 FM CTR-H”.

Press the [F(M-LIST)] button to save the new

seing.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

ALIGNMENT-11

FT-991 Technical Supplement

Page 23

Transmier Adjustment

TX IFT Adjustment

Disconnect the coaxial cable from J1004 on the

MAIN Unit, then connect the RF millivoltmeter

to J1004.

Set the VFO-A frequency to 14.200 MHz in the

CW-USB mode.

Set the TX Power to 100 W.

Connect the Microphone to the front panel MIC

jack.

Press the PTT button, adjust T1024, T1022,

T1021 and T1018 for maximum deflection on

the RF millivoltmeter.

Release the PTT buon.

Set the VFO-A frequency to 145.900 MHz in the

FM mode.

Press the PTT buon, adjust T1008, T1007 and

T1006 for maximum deection on the RF millivoltmeter.

Alignment

Release the PTT buon.

Set the VFO-A frequency to 439.900 MHz in the

FM mode.

Press the PTT button, adjust TC1004, TC1003

and TC1002 for maximum deection on the RF

millivoltmeter.

Release the PTT buon.

Disconnect the RF millivoltmeter from J1004 on

the MAIN Unit, then connect the Spectrum Analyzer to J1004.

Set the VFO-A frequency to 52.000 MHz in the

CW-USB mode.

Press the PTT buon, adjust T1005 on the spu-

rious (69.450 MHz) for minimum deection on

the Spectrum Analyzer.

Release the PTT buon.

Disconnect the Spectrum Analyzer from J1004,

then re-connect the coaxial cable to J1004.

T1005

TC1002

T1006

TC1003

T1007

T1008

TC1004

J1004

T1018

T1021

T1022

T1024

ALIGNMENT-12

FT-991 Technical Supplement

Page 24

Alignment

V-U PA Unit Adjustment

Preparation

Connect the Microphone to the front panel MIC

jack.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “144/430 MHz” ANT jack.

Disconnect the coaxial cables from J4501 and

J4502 on the V_U-PA Unit, then terminate J4501

and J4502, each with a 50-Ohm resistor.

Disconnect the jumper plugs from J4505, J4506

and J4507 on the V_U-PA Unit.

Disconnect the red cable from J4503 on the V_

U-PA Unit.

J4501J4502

Pre-Drive Stage Idling Current Adjustment

Connect the DC ammeter to J4505 on the V_

U-PA Unit.

Press and hold the PTT button, while adjust

VR4501 so the DC ammeter reading is “40 mA

(±5 mA)”.

Release the PTT buon.

Disconnect the DC ammeter from J4505.

J4507 J4503

J4505 VR4501J4506

ALIGNMENT-13

FT-991 Technical Supplement

Page 25

Alignment

Drive Stage Idling Current Adjustment

Connect the DC ammeter to J4506 on the V_

U-PA Unit.

Press and hold the PTT button, while adjust

VR4502 so the DC ammeter reading is “100 mA

(±10 mA)”.

Release the PTT buon.

Disconnect the DC ammeter from J4506.

Re-connect the red cable to J4503 on the V_

U-PA Unit.

Semi-Final Stage Idling Current Adjustment

Connect the DC ammeter to J4507 on the V_

U-PA Unit.

Press and hold the PTT button, while adjust

VR4505 so the DC ammeter reading is “600 mA

(±50 mA)”.

Adjust VR4506 so the DC ammeter reading is

“1.2 A (±0.1 A)”.

Release the PTT buon.

Disconnect the DC ammeter from J4507.

Final Stage Idling Current Adjustment

Disconnect the red cable from J4503 on the V_

U-PA Unit.

Connect the DC ammeter between J4503 and

red cable.

Press and hold the PTT button, while adjust

VR4503 so the DC ammeter reading is “800 mA

(±50 mA)”.

Release the PTT buon.

Disconnect the DC ammeter from J4503 and red

cable, then connect the red cable to J4503.

Disconnect the 50-Ohm resistors from J4501

and J4502, then connect the coaxial cables to

J4501 and J4502.

Re-connect the jumper plugs to J4505, J4506 and

J4507.

V_U-PA Unit TX Adjustment

Set the VFO-A frequency to 439.990 MHz in the

USB mode.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “144/430 MHz” ANT jack.

Connect the Audio Generator to pin 8 of the

MIC jack (pin 7: GND), then set the output level

to 0.5 mV @1 kHz.

Press the PTT buon, then adjust the MIC gain

to set the RF Power output to 25 W on the Wameter.

Press the PTT buon, adjust TC4501 for maxi-

mum deection on the Wameter.

Release the PTT buon.

J4501J4502

VR4505

J4507 J4503

VR4502 VR4506J4506

J4505 TC4501

ALIGNMENT-14

VR4503

FT-991 Technical Supplement

Page 26

HF PA Unit Adjustment

Preparation

Connect the Microphone to the front panel MIC

jack.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Disconnect the coaxial cables from J4001 on the

HF-PA Unit, then terminate J4001 with a 50Ohm resistor.

Connect the DC ammeter between J4006 and

J4007.

Disconnect the jumper plugs from J4004 and

J4005 on the HF-PA Unit.

Re-connect the jumper plugs to J4004.

Alignment

Press and hold the PTT button, while adjust

VR4001 so the DC ammeter reading is “1.5 A

(±0.1 A)”.

ReleasethePTTbuon.

Disconnect the jumper plugs from J4004.

Re-connect the jumper plugs to J4005.

Press and hold the PTT button, while adjust

VR4002 so the DC ammeter reading is “1.5 A

(±0.1 A)”.

ReleasethePTTbuon.

Re-connect the jumper plugs to J4004.

Disconnect the DC ammeter from J4006 and

4007.

Disconnect the 50-Ohm resistors from J4001 ,

then connect the coaxial cable to J4001.

ALIGNMENT-15

J4006 J4007J4004 VR4001J4001 J4005VR4002

FT-991 Technical Supplement

Page 27

Alignment

CM Coupler Balance Adjustment

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Connect the Digital DC voltmeter (high-Z) to

pin 2 of J4013 on the HF-PA Unit.

Turn o the [TUNE] switch, then set the VFO-A

frequency to 24.900 MHz in the USB mode.

Press the PTT buon, then adjust the MIC gain

to set the RF Power output to 50 W on the Wameter.

Press the PTT buon, adjust TC4001 for mini-

mum deection on the DC voltmeter (less than

0.1 V).

Release the PTT buon.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “144/430 MHz” ANT jack.

Set the VFO-A frequency to 430.000 MHz.

Press the PTT buon, then adjust the MIC gain

to set the RF Power output to 25 W on the Wameter.

Press the PTT buon, adjust VR4507 for mini-

mum deection on the DC voltmeter (less than

0.3 V).

Release the PTT buon.

TC4001J4013

ALIGNMENT-16

VR4507

FT-991 Technical Supplement

Page 28

Current ALC Adjustment

If the Main Firmware version of your

transceiver is “V10-13 or later”, see next

section.

Connect the Microphone to the front panel MIC

jack.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-01 I-ALC 1.8” for the

1.8 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 1.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "33".

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“5” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-02 I-ALC HFL” for

the 7 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 7.10 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "39".

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-03 I-ALC HFM” for

the 14 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 14.20 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "37".

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-04 I-ALC HFH” for

the 21 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 21.240 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "37".

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-05 I-ALC 50” for the

50 MHz amateur band's ALC Adjustment.

Alignment

Set the VFO-A frequency to 51.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "33".

Release the PTT buon.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “144/430 MHz” ANT jack.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-06 I-ALC 144” for the

144 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 145.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "29".

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-07 I-ALC 430” for the

430 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 439.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob to set the parameter is "31".

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

ALIGNMENT-17

FT-991 Technical Supplement

Page 29

Alignment

If the Main Firmware version of your

transceiver is “V10-13 or later”.

Connect the Microphone to the front panel MIC

jack.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-01 I-ALC 1.8” for the

1.8 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 1.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“10” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-02 I-ALC HFL” for

the 7 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 7.10 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“10” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-03 I-ALC HFM” for

the 14 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 14.20 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“10” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-04 I-ALC HFH” for

the 21 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 21.240 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“10” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-05 I-ALC 50” for the

50 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 51.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“10” in-crease.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “144/430 MHz” ANT jack.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-06 I-ALC 144” for the

144 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 145.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 50 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“5” in-crease.

Rotate the [MULTI] Dial knob to select the

alignment menu item “10-07 I-ALC 430” for the

430 MHz amateur band's ALC Adjustment.

Set the VFO-A frequency to 439.90 MHz in the

CW mode.

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 50 W on the Wameter.

Release the PTT buon, then rotate the [CLAR/

VFO-B] knob so that the parameter indication

“5” in-crease.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

ALIGNMENT-18

FT-991 Technical Supplement

Page 30

ALC Meter Adjustment

Connect the Microphone to the front panel MIC

jack.

Connect the 50-Ohm Dummy Load and

Wameter to the “HF/50 MHz” ANT jack.

Set the VFO-A frequency to 14.20 MHz in the

CW mode.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “13-03 100W TXG HFM”.

Rotate the [CLAR/VFO-B] knob to set the

parameter is "255".

Rotate the [MULTI] Dial knob to select the

alignment menu item “18-01 TX CAR USB”.

Rotate the [CLAR/VFO-B] knob to set the

parameter is "255".

Rotate the [MULTI] Dial knob to select the

alignment menu item “13-01 100W FALC

HFM”.

Rotate the [CLAR/VFO-B] knob to set the

parameter is "0".

Press the PTT button, then adjust the [CLAR/

VFO-B] knob for 100 W ±2.5 W on the Wameter.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

Set the USB mode.

Set the MIC GAIN to "50".

Connect the Audio Generator to pin 8 of the

MIC jack (pin 7: GND).

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item “20-01 ALC-MTR”.

Press the PTT button, then adjust the Audio

Generator output level to the position where RF

Power output to 88 - 92 W on the Wameter.

Release the PTT buon.

Increase the Audio Generator output level by

“+10 dB”.

Press the PTT buon, then press the [F(M-LIST)]

key while pressing and holding in the PTT

buon.

Release the PTT buon.

Alignment

Rotate the [CLAR/VFO-B] knob for maximum

deection on the ALC meter zone (S9 +10 dB),

then press the [F(M-LIST)] key, while pressing

and holding in the PTT buon.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

TX Output Power/PO Meter/TXG Adjustment

Referring to table below, tune the transceiver to

each frequency listed.

Band VFO-a Frequency MOde

1.8 MHz Band 1.90 MHz CW-USB

7 MHz Band 7.10 MHz CW-USB

14 MHz Band 14.20 MHz CW-USB

21 MHz Band 21.20 MHz CW-USB

50 MHz Band 51.90 MHz CW-USB

144 MHz Band 145.900 MHz CW-USB

430 MHz Band 439.900 MHz CW-USB

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” and “144/430 MHz”

ANT jack.

Connect the Microphone to the front panel MIC

jack.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “11-01 100W FALC 1.8".

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 100 W ±3W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “11-02 MTR 1.8”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 100 W on the PO meter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “11-03 TXG 1.8”.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for "S9+10dB" on the ALC

meter zone.

Release the PTT buon.

Perform the same procedures for the Alignment

Menu Items “11-04 50W FALC 1.8” through

“11-15 5W TXG 1.8” per the chart at the below.

ALIGNMENT-19

FT-991 Technical Supplement

Page 31

Alignment

Alignment menu

11-01 100W FALC 1.8

11-02 100W MTR 1.8

11-03 100W TXG 1.8

11-04 50W FALC 1.8

11-05 50W MTR 1.8

11-06 50W TXG 1.8

11-07 20W FALC 1.8

11-08 20W MTR 1.8

1.9 mHZ

11-09 20W TXG 1.8

11-10 10W FALC 1.8

11-11 10W MTR 1.8

11-12 10W TXG 1.8

11-13 5W FALC 1.8

11-14 5W MTR 1.8

11-15 5W TXG 1.8

Perform the same procedures for the Alignment

OperAtiOn

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Menu Items “12-01 100W FALC HFL” through

“17-12 5W TXG 430” per the chart at the above.

Alignment menu

12-01 100W FALC HFL

12-02 100W MTR HFL

12-03 100W TXG HFL

12-04 50W FALC HFL

12-05 50W MTR HFL

12-06 50W TXG HFL

12-07 20W FALC HFL

12-08 20W MTR HFL

7 mHZ

12-09 20W TXG HFL

12-10 10W FALC HFL

12-11 10W MTR HFL

12-12 10W TXG HFL

12-13 5W FALC HFL

12-14 5WMTR HFL

12-15 5W TXG HFL

13-01 100W FALC HFM

13-02 100W MTR HFM

13-03 100W TXG HFM

13-04 50W FALC HFM

13-05 50W MTR HFM

13-06 50W TXG HFM

13-07 20W FALC HFM

13-08 20W MTR HFM

14 mHZ

13-09 20W TXG HFM

13-10 10W FALC HFM

13-11 10W MTR HFM

13-12 10W TXG HFM

13-13 5W FALC HFM

13-14 5W MTR HFM

13-15 5W TXG HFM

14-01 100W FALC HFH

14-02 100W MTR HFH

14-03 100W TXG HFH

14-04 50W FALC HFH

14-05 50W MTR HFH

14-06 50W TXG HFH

14-07 20W FALC HFH

14-08 20W MTR HFH

21 mHZ

14-09 20W TXG HFH

14-10 10W FALC HFH

14-11 10W MTR HFH

14-12 10W TXG HFH

14-13 5W FALC HFH

14-14 5W MTR HFH

14-15 5W TXG HFH

OperAtiOn

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

WAtt meter

)

(

Adjust tO

100 W (+3 W / –3 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

WAtt meter

)

(

Adjust tO

100 W (+3 W / –3 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

100 W (+3 W / –3 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

100 W (+3 W / –3 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

pO meter

(

Adjust tO

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

–

100 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

pO meter

(

Adjust tO

)

)

)

–

100 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

–

100 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

–

100 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

AlC meter ZOne

)

S9 +10dB (or 205)

S9 +10dB (or 205)

S9 +10dB (or 205)

S9 +10dB (or 205)

S9 +10dB (or 205)

)

S9 + more than 1 dot

)

(

Adjust tO

–

–

–

–

–

–

–

–

–

–

AlC meter ZOne

S9 +10dB (or )

S9 +10dB +2ø

S9 +10dB +3

S9 +10dB +2

S9 +10dB +2

S9 +10dB +2

(

Adjust tO

–

–

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

S9 +10dB

–

–

or

–

–

–

–

–

–

–

–

)

ø

ø

ø

ø

ALIGNMENT-20

FT-991 Technical Supplement

Page 32

Alignment

Alignment menu

15-01 100W FALC 50

15-02 100W MTR 50

15-03 100W TXG 50

15-04 50W FALC 50

15-05 50W MTR 50

15-06 50W TXG 50

15-07 20W FALC 50

15-08 20W MTR 50

50 mHZ

15-09 20W TXG 50

15-10 10W FALC 50

15-11 10W MTR 50

15-12 10W TXG 50

15-13 5W FALC 50

15-14 5W MTR 50

15-15 5W TXG 50

16-01 50W FALC 144

16-02 50W MTR 144

16-03 50W TXG 144

16-04 20W FALC 144

16-05 20W MTR 144

16-06 20W TXG 144

16-07 10W FALC 144

144 mHZ430 mHZ

16-08 10W MTR 144

16-09 10W TXG 144

16-10 5W FALC 144

16-11 5W MTR 144

16-12 5W TXG 144

17-01 50W FALC 430

17-02 50W MTR 430

17-03 50W TXG 430

17-04 20W FALC 430

17-05 20W MTR 430

17-06 20W TXG 430

17-07 10W FALC 430

17-08 10W MTR 430

17-09 10W TXG 430

17-10 5W FALC 430

17-11 5W MTR 430

17-12 5W TXG 430

OperAtiOn

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

Rotate the [CLAR/VFO-B] knob

WAtt meter

)

(

Adjust tO

96 W (+1 W / –1 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

50 W (+3 W / –3 W

–

–

20 W (+2 W / –2 W

–

–

10 W (+1 W / –1 W

–

–

5 W (+1 W / –1 W

–

–

)

AlC meter ZOne

S9 +10dB +3

S9 +10dB +3

S9 +10dB +3

S9 +10dB +2

S9 +10dB +2

S9 +10dB +3

S9 +10dB +2

S9 +10dB +1

S9 +10dB +1

S9 +10dB +3

S9 +10dB +2

S9 +10dB +1

S9 +10dB +1

(

Adjust tO

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

–

)

ø

ø

ø

ø

ø

ø

ø

ø

ø

ø

ø

ø

ø

pO meter

(

Adjust tO

)

)

)

)

)

)

)

)

)

)

)

)

)

–

100 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

–

50 W

–

–

20 W

–

–

10 W

–

–

5 W

–

: Rotate the [CLAR/VFO-B] Dial knob so that the parameter of the alignment menu item "+n" increase.

ø

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

AM-TXG Adjustment

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Connect the Microphone to the front panel MIC

jack.

Set the VFO-A frequency to 14.200 MHz in the

AM mode.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “18-02 TX CAR AM".

Press and hold the PTT buon without micro-

phone input, then rotate the [CLAR/VFO-B]

knob so the ALC meter turns on S7.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

ALIGNMENT-21

FT-991 Technical Supplement

Page 33

REV-ALC Adjustment

Connect the 16.6-Ohm Dummy Load and Wa-

meter to the “HF/50 MHz” ANT jack.

Connect the Microphone to the front panel MIC

jack.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-01 REV ALC 1.8".

Set the VFO-A frequency to 1.900 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 40 W ±10 W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-02 REV ALC HFL".

Set the VFO-A frequency to 7.100 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 40 W ±10 W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-03 REV ALC

HFM".

Set the VFO-A frequency to 14.200 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 40 W ±10 W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-04 REV ALC

HFH".

Set the VFO-A frequency to 21.200 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 40 W ±10 W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-05 REV ALC 50".

Set the VFO-A frequency to 52.000 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 40 W ±10 W on the

Wameter.

Alignment

Release the PTT buon.

Connect the 16.6-Ohm Dummy Load and Wa-

meter to the “144/430 MHz” ANT jack.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-06 REV ALC 144".

Set the VFO-A frequency to 145.90 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 25 W ±5 W on the

Wameter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “19-07 REV ALC 430".

Set the VFO-A frequency to 439.90 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[CLAR/VFO-B] knob for 15 W ±3 W on the

Wameter.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

FM MAX Deviation Adjustment

Connect the Dummy Load, Wameter, and De-

viation Meter to the “144/430 MHz” ANT Jack.

Set the MIC GAIN to "50".

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “20-02 FM DEV".

Set the VFO-A frequency to 145.90 MHz in the

FM mode.

Connect the Audio Generator to pin 8 of the

MIC jack (pin 7: GND), then set the output level

to 5.0 mV @1 kHz.

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob for 4.5 kHz ±0.2 kHz on

the Deviation Meter.

Release the PTT buon.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “20-03 FM-N DEV".

Set the VFO-A frequency to 439.90 MHz in the

FM-N mode.

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob for 2.25 kHz ±0.1 kHz on

the Deviation Meter.

Release the PTT buon.

ALIGNMENT-22

FT-991 Technical Supplement

Page 34

Rotate the [MULTI] Dial knob to select the

alignment menu item to “20-04 C4FM DEV".

Set the VFO-A frequency to 439.90 MHz in the

C4FM mode.

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob for 4.5 kHz ±0.2 kHz on

the Deviation Meter.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

Alignment

IDD Meter Adjustment

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” ANT jack.

Remove the jumper that is connected between

J4006 and J4007 on the HF-PA-Unit, then connect the DC ammeter (20-A range) between

J4006 and J4007.

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “22-01 IDD MTR".

Set the VFO-A frequency to 14.200 MHz in the

CW mode.

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob so the IDD meter reading

is the same as the DC ammeter.

Press the PTT buon, then press the [F(M-LIST)]

key while pressing and holding in the PTT

buon.

Release the PTT button, then press and hold

in the [MENU(SETUP)] buon for one second

to save the new seing and exit the alignment

mode.

ALIGNMENT-23

J4007

J4006

FT-991 Technical Supplement

Page 35

SWR Meter Adjustment

Set the VFO-A frequency to 1.850 MHz in the

USB mode.

Connect the 50-Ohm Dummy Load and Watt-

meter to the “HF/50 MHz” and “144/430 MHz”

ANT jack.

Disconnect the 3-pin plug from J1006 on the

MAIN Unit, then apply a 4.20 ±0.05 V DC voltage to pin 3 of J1006, and 0.84 ±0.05 V DC to pin

2 of J1006.

Set the MIC GAIN to "Minimum".

Press and hold in the [A=B], [A/B], and [FAST]

keys, while turning the radio on, to enter the

alignment mode.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “21-01 SWR-MTR1.5

1.8".

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob so that the SWR meter

reading is “1.5”. The SWR meter reading (1.5) is

broad (few points). Therefore, set the [VFO-B/

CLAR] knob to the center of this broad range.

Release the PTT buon.

Apply a 4.20 ±0.05 V DC voltage to pin 3 of

J1006, and 1.40 ±0.05 V DC to pin 2 of J1006.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “21-02 SWR-MTR2.0

1.8".

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob so that the SWR meter

reading is “2.0.” The SWR meter reading (2.0) is

broad (few points). Therefore, set the [VFO-B/

CLAR] knob to the center of this broad range.

Alignment

Release the PTT buon.

Apply a 4.20 ±0.05 V DC voltage to pin 3 of

J1006, and 2.10 ±0.05 V DC to pin 2 of J1006.

Rotate the [MULTI] Dial knob to select the

alignment menu item to “21-03 SWR-MTR3.0

1.8".

Press and hold the PTT buon, then rotate the

[VFO-B/CLAR] knob so that the SWR meter

reading is “3.0.” The SWR meter reading (3.0) is

broad (few points). Therefore, set the [VFO-B/

CLAR] knob to the center of this broad range.

Release the PTT buon.

Perform the same procedures for the Alignment

Menus “21-05 SWR-MTR1.5 14” through “2107 SWR-MTR3.0 14”, “21-09 SWR-MTR1.5 50”

through “21-11 SWR-MTR3.0 50”, “21-13 SWRMTR1.5 144” through “21-15 SWR-MTR3.0 144”

and “21-17 SWR-MTR1.5 430” through “21-19

SWR-MTR3.0 430”.

Note: Please do not change the Alignment Menus

“21-04 SWR-MTR CO 1.8”, “21-08 SWRMTR CO

14”, “21-12 SWRMTR CO 50”, “21-16 SWRMTR CO

144” and “21-20 SWR-MTR CO 430”.

These parameters are always 128.

Press and hold in the [MENU(SETUP)] buon

for one second to save the new seing and exit

the alignment mode.

Connect the 3-pin plug to J1006 on the MAIN

Unit.

Important Notice: If it will be in a transceiver trans-

miing state, without connecting the 3-pin plug

to J1006, there is a possibility that a nal transistor may break.

J1006

ALIGNMENT-24

FT-991 Technical Supplement

Page 36

MAIN Unit (Lot. 1 - 2)

Circuit Diagram

MAIN-1

FT-991 Technical Supplement

Page 37

MAIN Unit (Lot. 1 - 2)

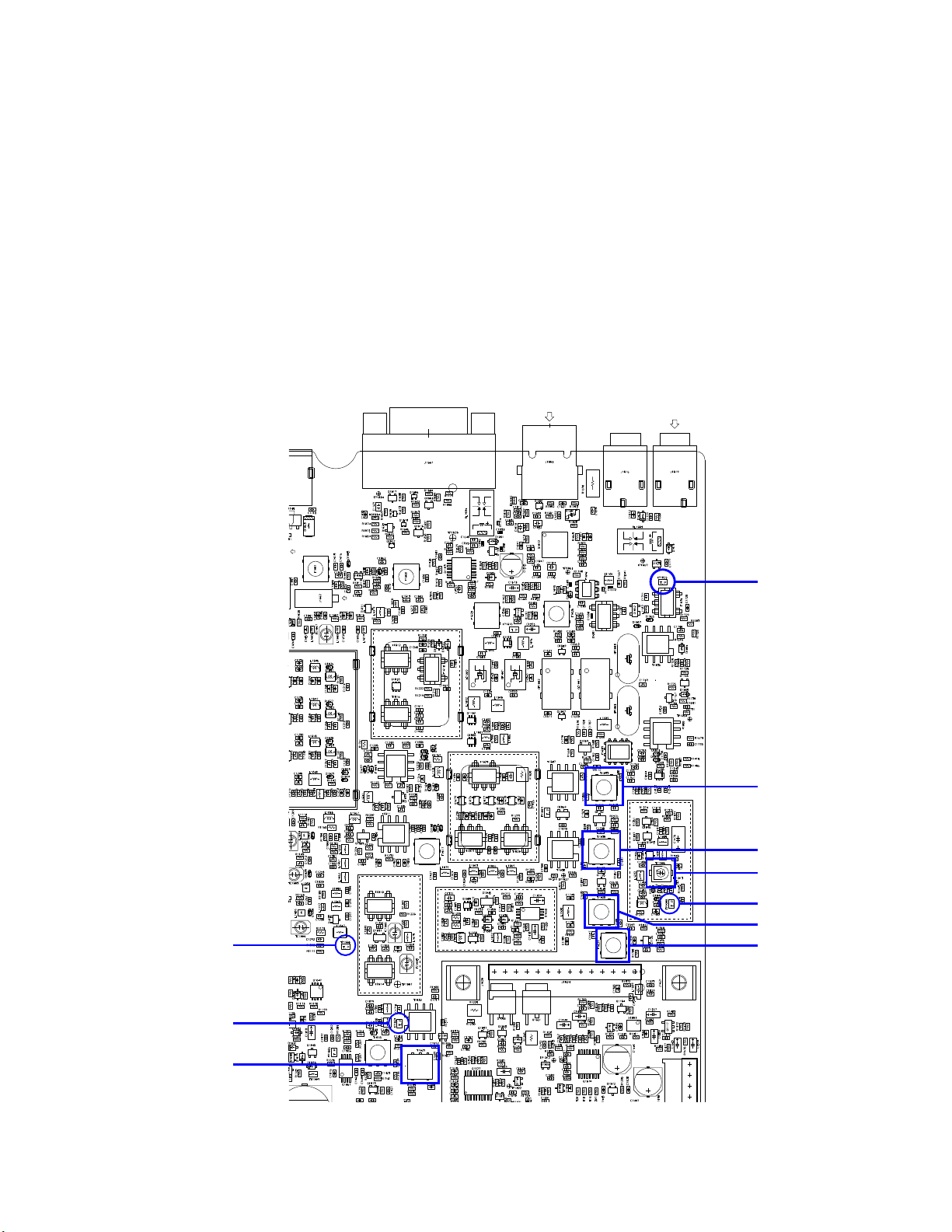

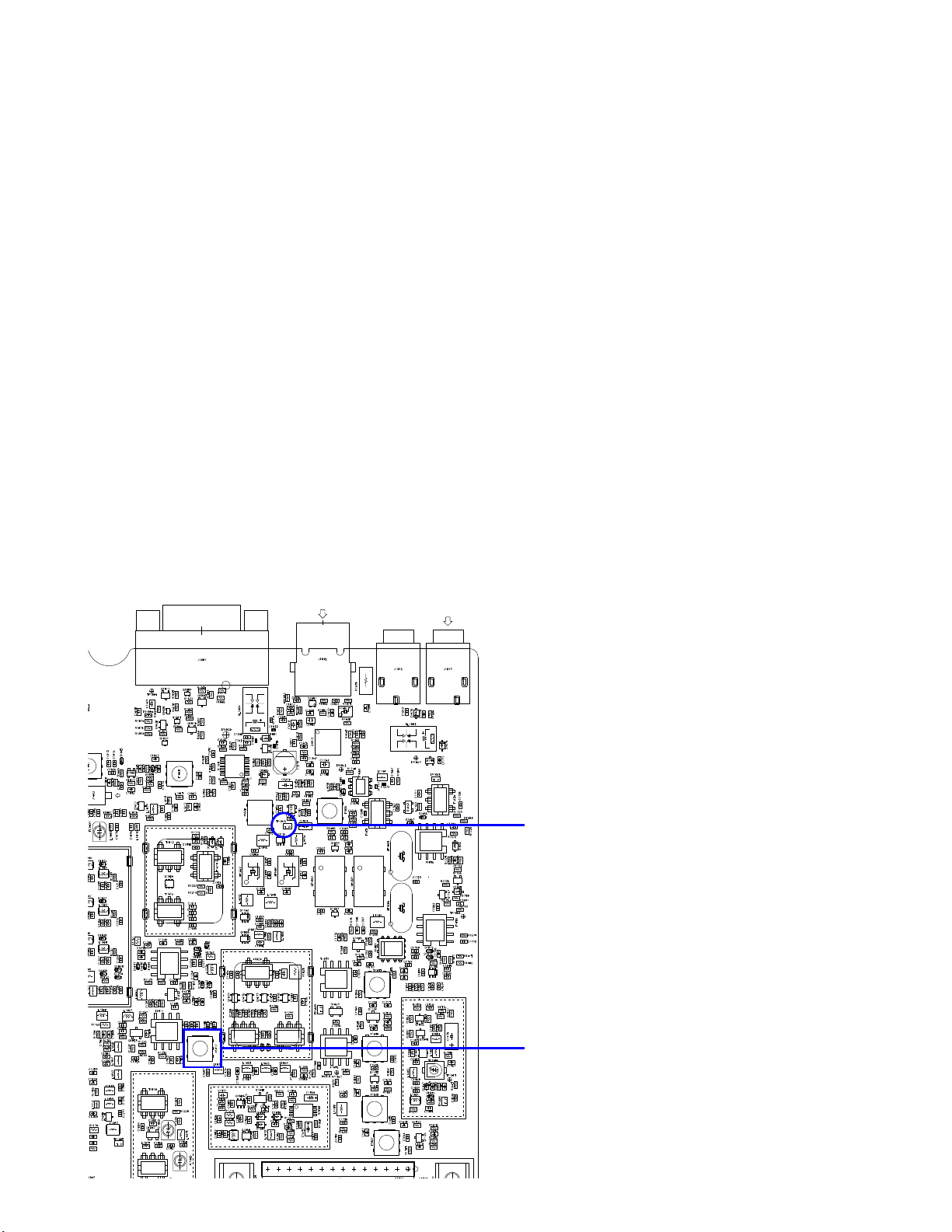

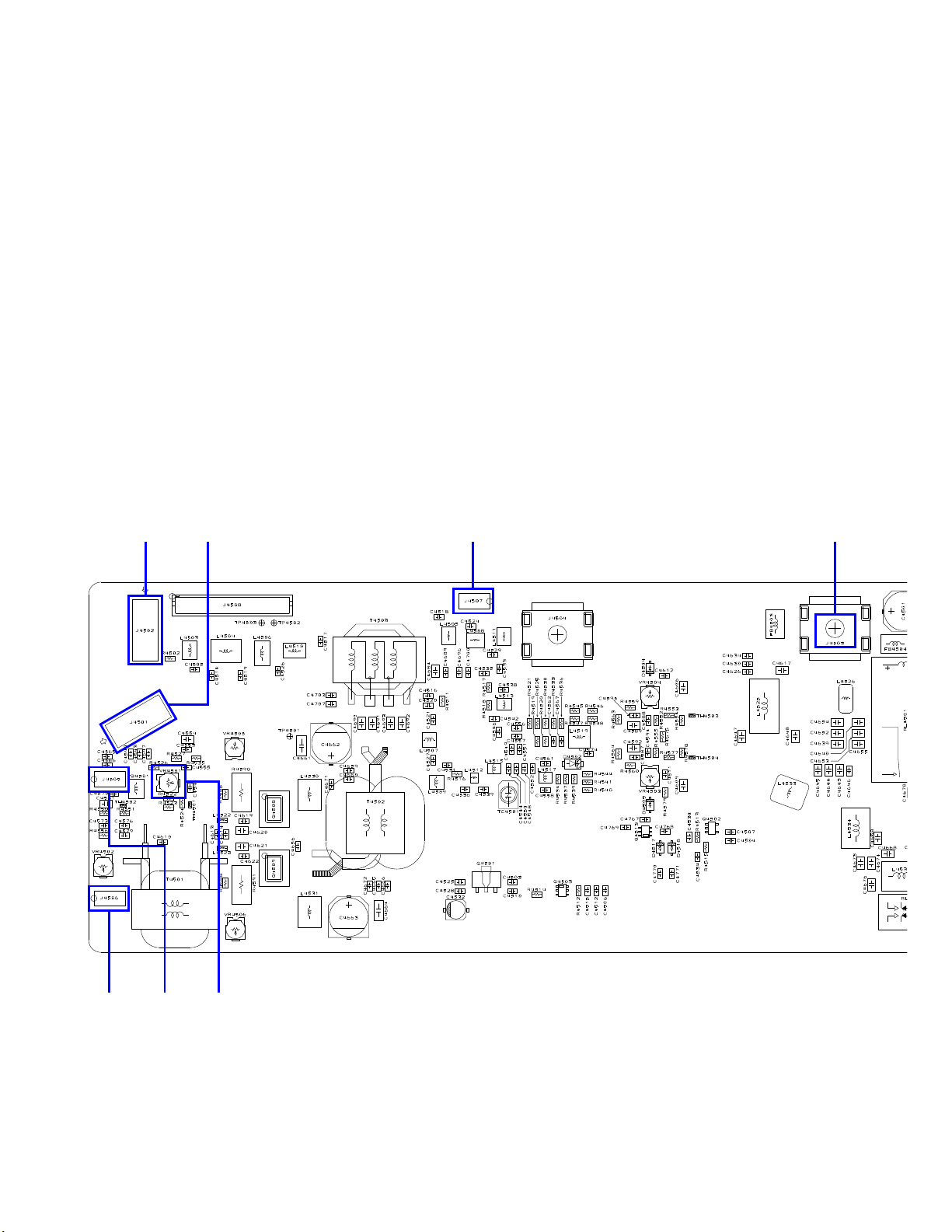

Parts Layout (side A)

A B C D E F G

1

2

3

4

5

MAIN-2

FT-991 Technical Supplement

Page 38

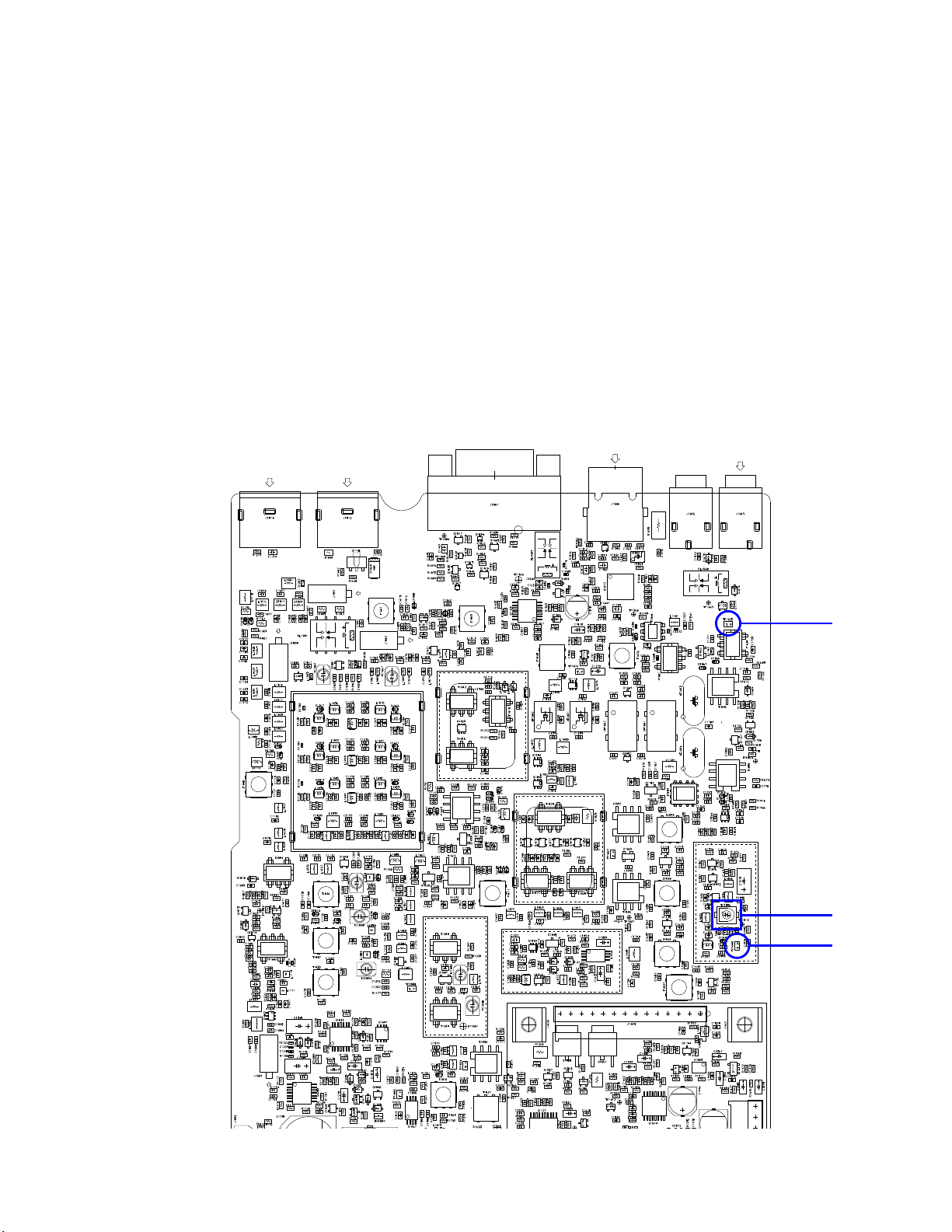

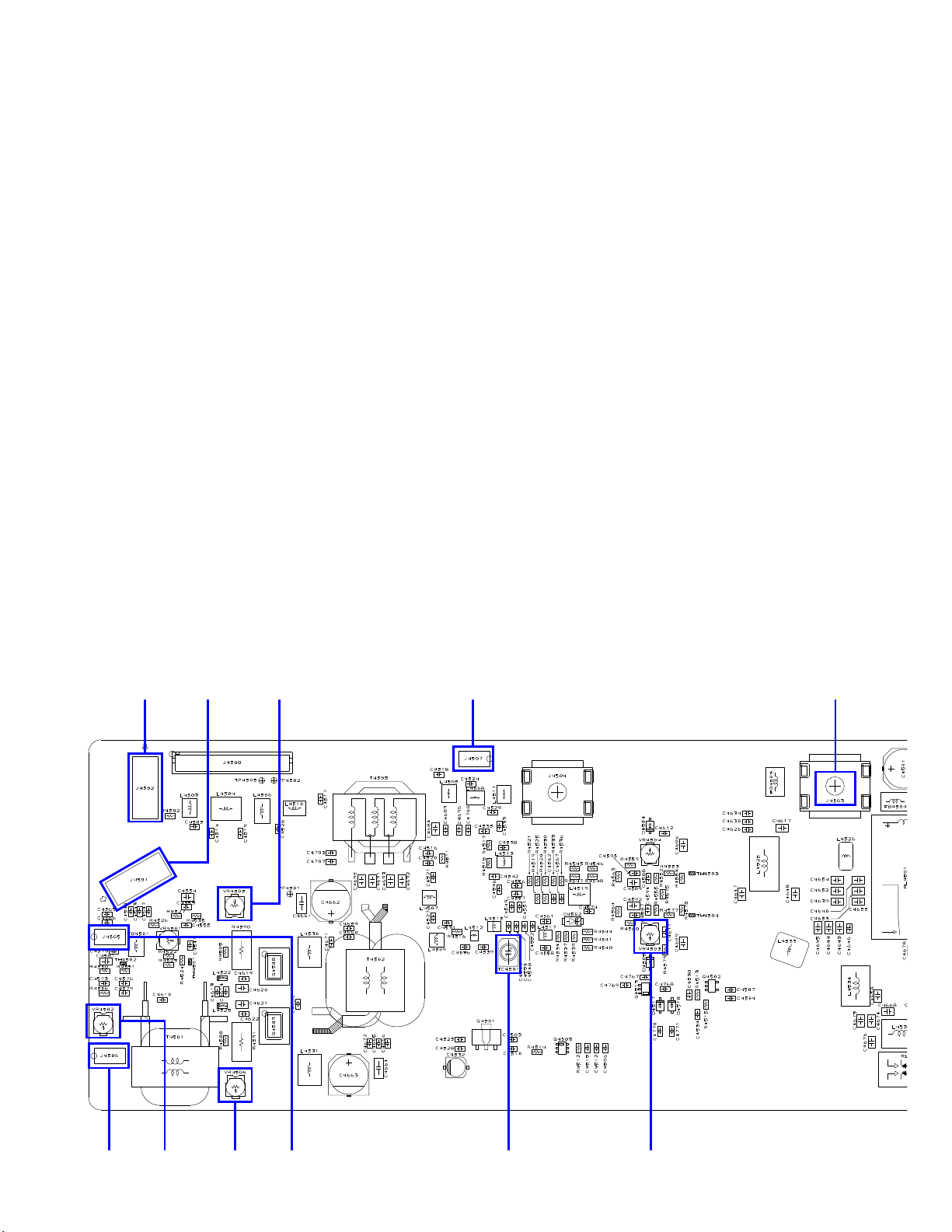

MAIN Unit (Lot. 1 - 2)

Parts Layout (side B)

a b c d e f g

1

2

3

4

5

MAIN-3

FT-991 Technical Supplement

Page 39

MAIN Unit (Lot. 3)

Circuit Diagram

MAIN-4

FT-991 Technical Supplement

Page 40

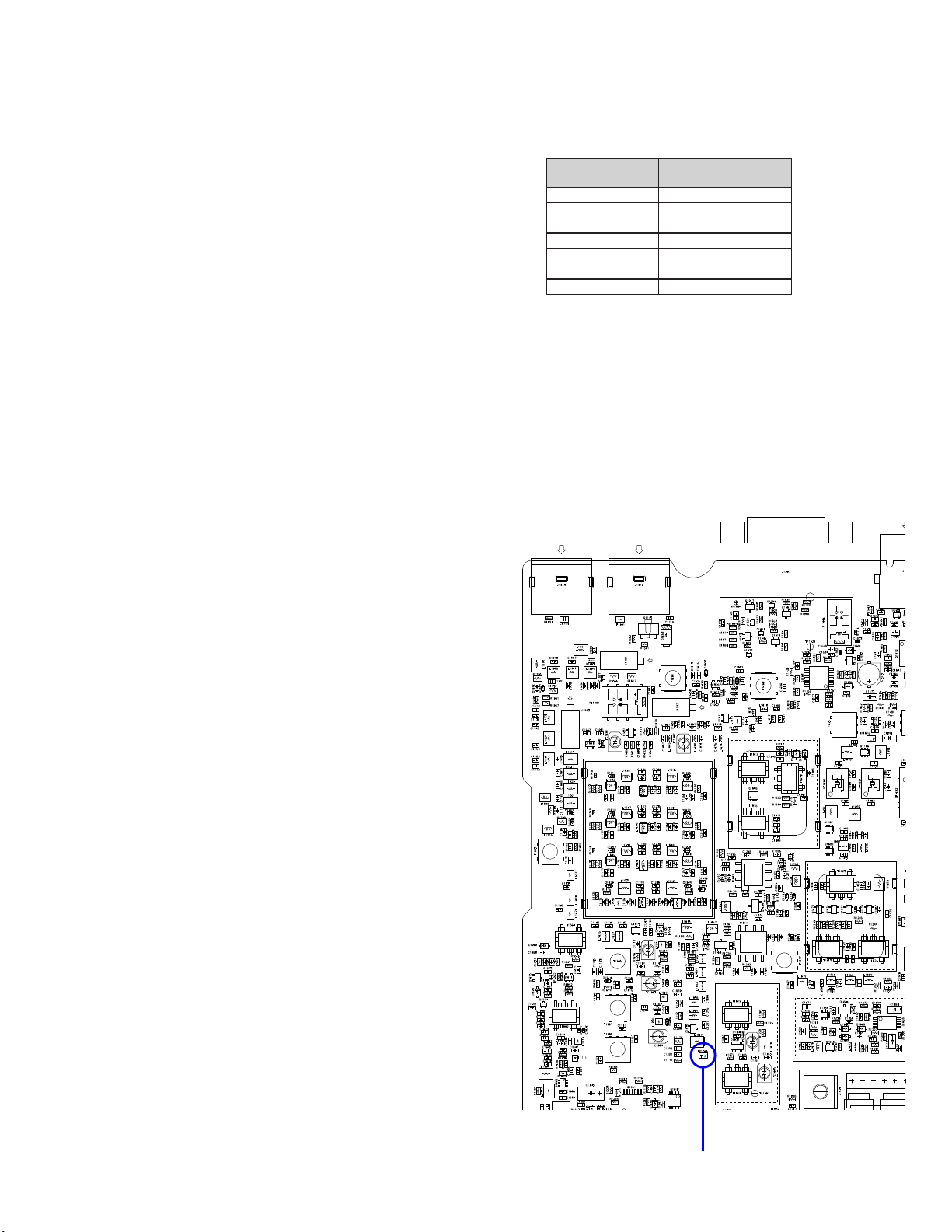

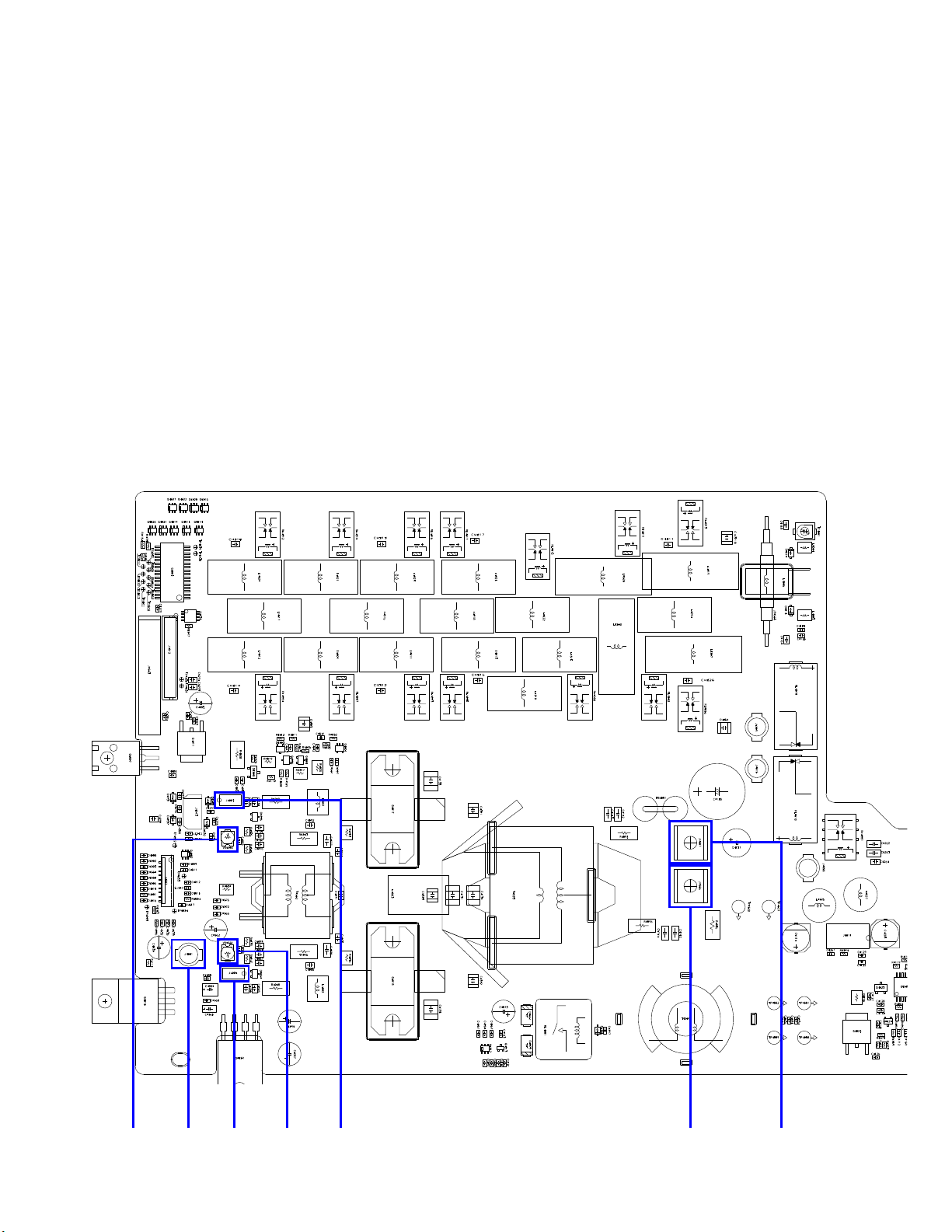

MAIN Unit (Lot. 3)

Parts Layout (side A)

A B C D E F G

1

2

3

4

5

MAIN-5

FT-991 Technical Supplement

Page 41

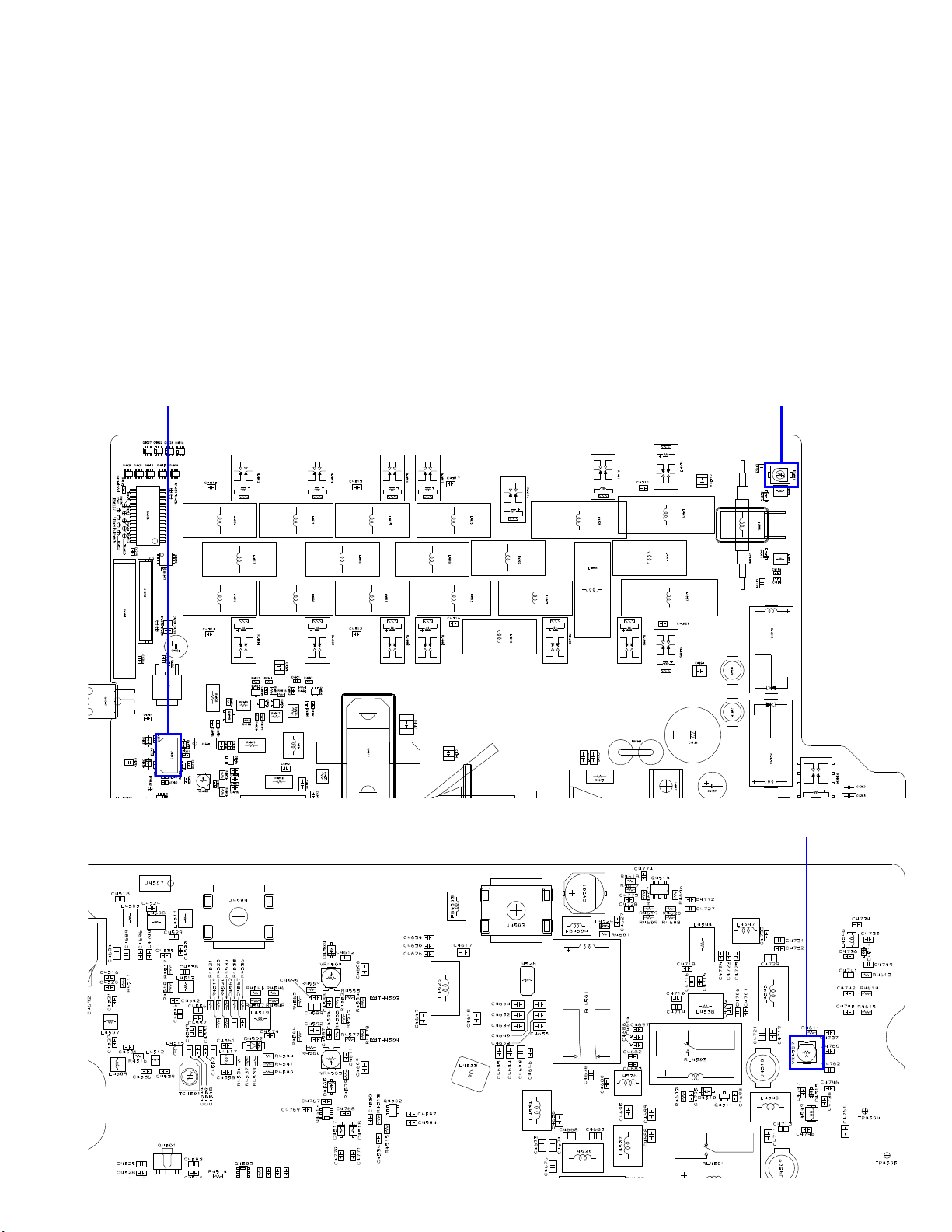

MAIN Unit (Lot. 3)

Parts Layout (side B)

a b c d e f g

1

2

3

4

5

MAIN-6

FT-991 Technical Supplement

Page 42

MAIN Unit (Lot. 4 - 6)

Circuit Diagram

MAIN-7

FT-991 Technical Supplement

Page 43

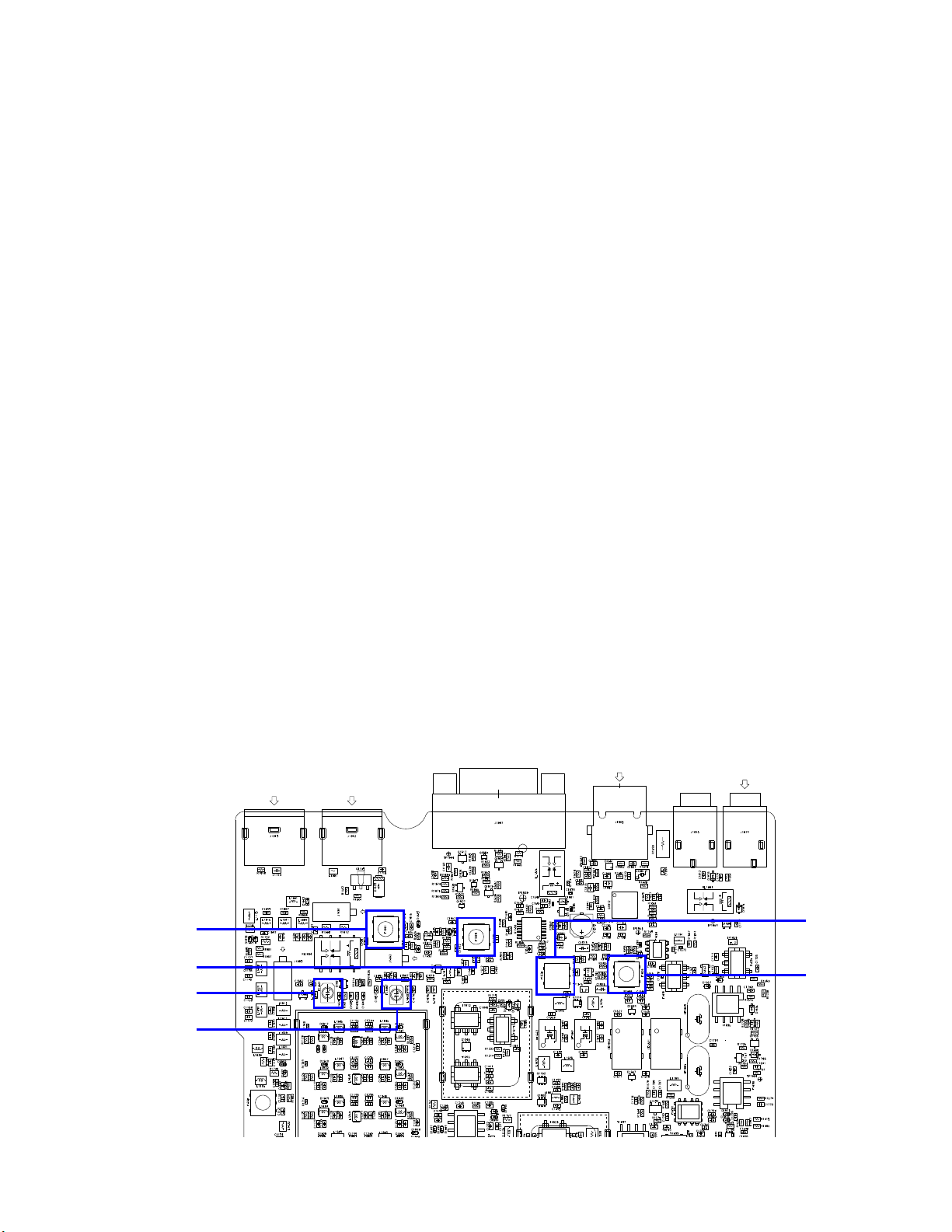

MAIN Unit (Lot. 4 - 6)

Parts Layout (side A)

A B C D E F G

1

2

3

4

5

MAIN-8

FT-991 Technical Supplement

Page 44

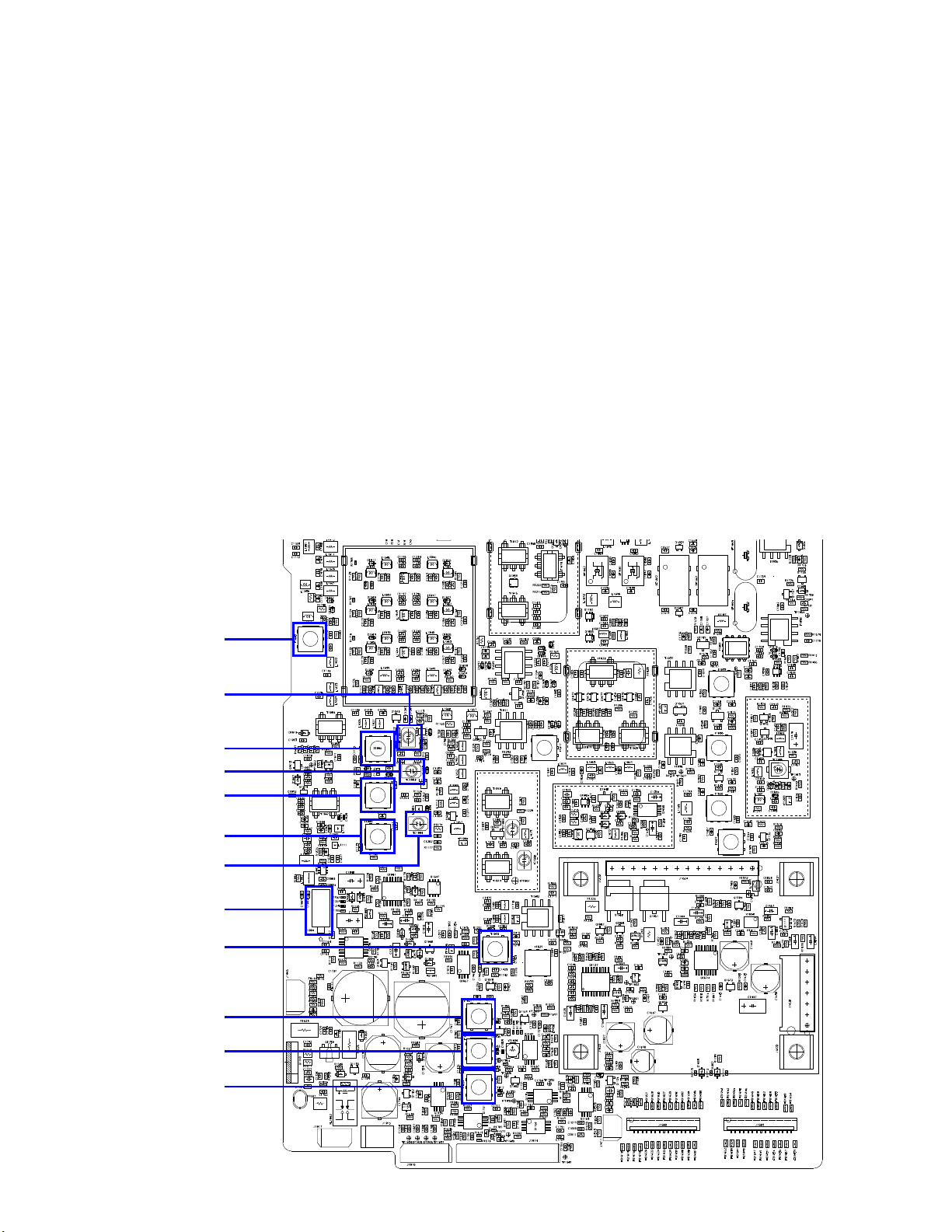

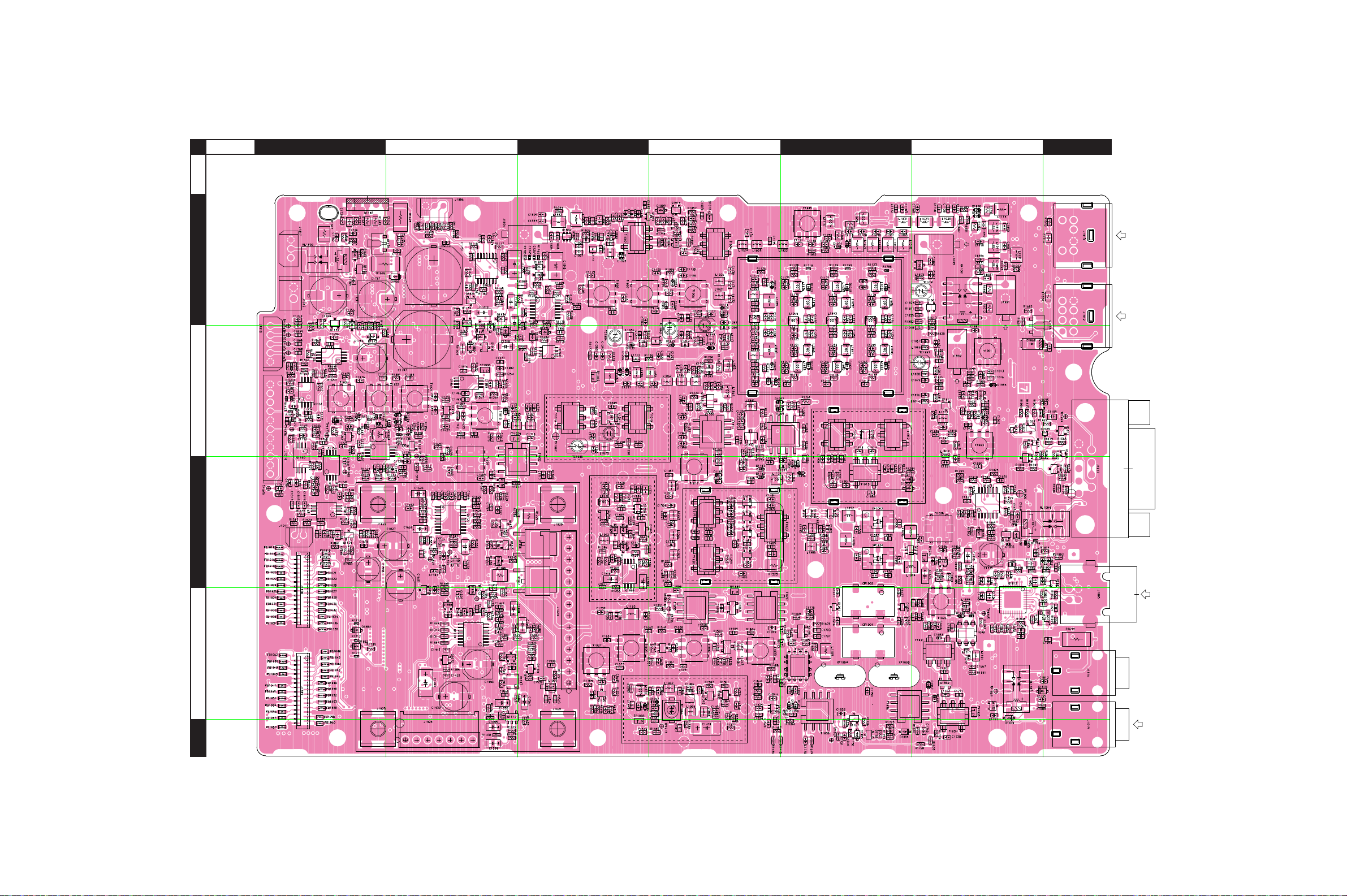

MAIN Unit (Lot. 4 - 6)

Parts Layout (side B)

a b c d e f g

1

2

3

4

5

MAIN-9

FT-991 Technical Supplement

Page 45

MAIN Unit (Lot. 7 - 8)

Circuit Diagram

MAIN-10

FT-991 Technical Supplement

Page 46

MAIN Unit (Lot. 7 - 8)

Parts Layout (side A)

A B C D E F G

1

2

3

4

5

MAIN-11

FT-991 Technical Supplement

Page 47

MAIN Unit (Lot. 7 - 8)

Parts Layout (side B)

a b c d e f g

1

2

3

4

5

MAIN-12

FT-991 Technical Supplement

Page 48

MAIN Unit (Lot. 9 -)

Circuit Diagram

MAIN-13

FT-991 Technical Supplement

Page 49

MAIN Unit (Lot. 9 -)

Parts Layout (side A)

A B C D E F G

1

2

3

4

5

MAIN-14

FT-991 Technical Supplement

Page 50

MAIN Unit (Lot. 9 -)

Parts Layout (side B)

a b c d e f g

1

2

3

4

5

MAIN-15

FT-991 Technical Supplement

Page 51

MAIN Unit

Parts List

REF DESCRIPTION VALUE V/W TOL. MFR'S DESIG YAESU P/N VERS.

PCB with Components CS2343701

C 1001 CHIP CAP. 0.001uF 50V CH GRM1882C1H102JA01D K22174275 1- A F2

C 1002 CHIP CAP. 22pF 50V CH GRM1882C1H220JA01D K22174219 1- A F1

C 1003 CHIP CAP. 0.1uF 25V B GRM188B11E104KA01D K22144814 1- A C1

C 1004 CHIP CAP. 0.1uF 25V B GRM188B11E104KA01D K22144814 1- A C1

C 1005 CHIP CAP. 0.001uF 50V CH GRM1882C1H102JA01D K22174275 1- A C1

C 1006 CHIP CAP. 0.001uF 50V B GRM188B11H102KA01D K22174821 1- A F3

C 1007 CHIP CAP. 2pF 200V CK GRM1884C2D2R0CV01D K22234204 1- B b1

C 1008 CHIP CAP. 22pF 50V CH GRM1882C1H220JA01D K22174219 1- B b1

C 1009 CHIP CAP. 0.001uF 50V B GRM188B11H102KA01D K22174821 1- A C1