Yaesu FT-227RB Instruction Manual

INSTRUCTION

MANUAL

FT-227RB

YAESU MUSEN CO ,LTD.

TOKYO JAPAN.

TABLE OF CONTENTS

(Page)

INTRODUCTION

1

SPECIFICATIONS

2

CONTROLS AND SWITCHES

3

REAR APRON

5

INSTALLATION

7

OPERATION

9

BLOCK DIAGRAM

11

THEORY OF OPERATION

12

MAINTENANCE AND ALIGNMENT

19

PARTS LIST

26

Ato

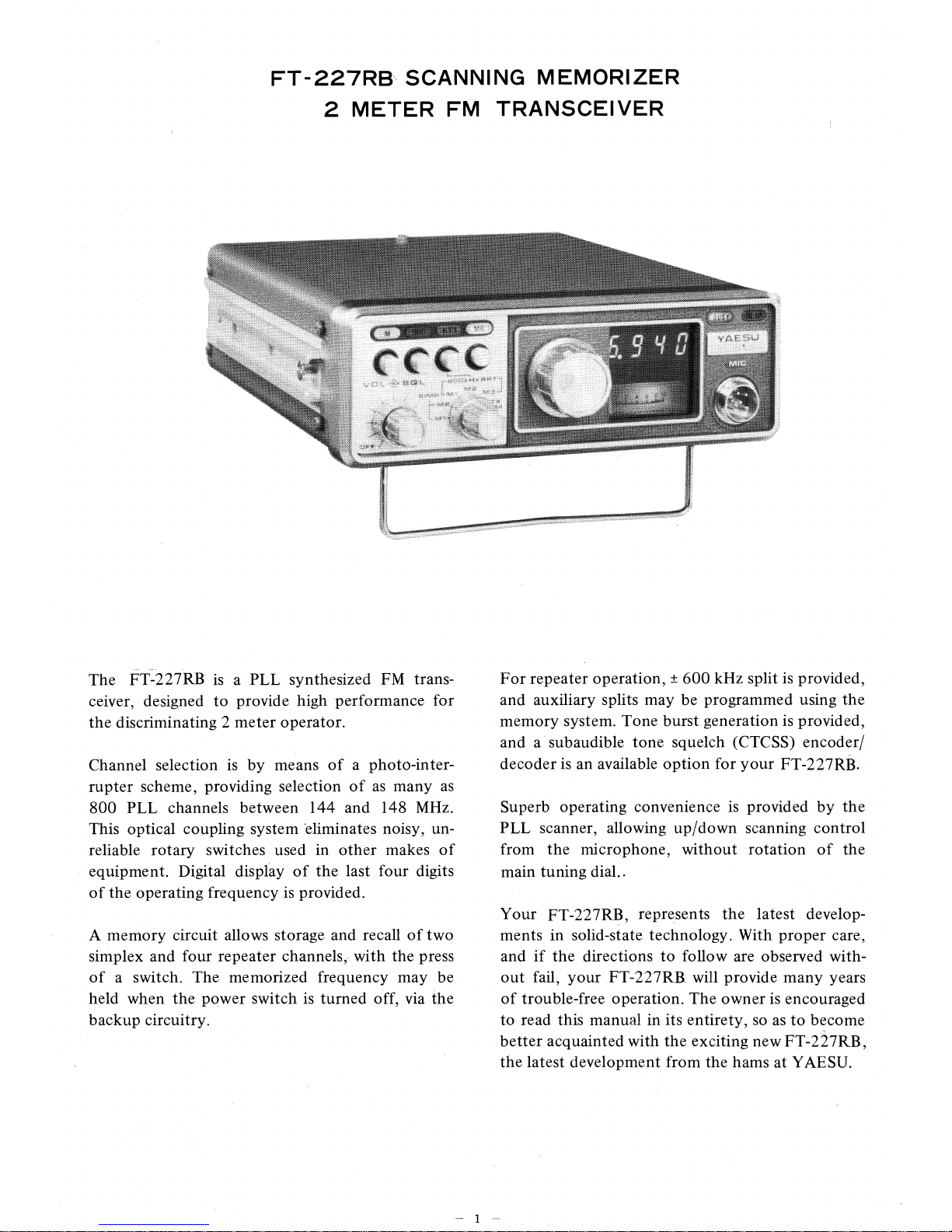

FT-227RB SCANNING MEMORIZER

2 METER FM TRANSCEIVER

The FT-227RB is a PLL synthesized FM transceiver, designed to provide high performance for

the discriminating 2 meter operator.

Channel selection is by means of a photo-interrupter scheme, providing selection of as many as

800 PLL channels between 144 and 148 MHz.

This optical coupling system eliminates noisy, unreliable rotary switches used in other makes of

equipment. Digital display of the last four digits

of the operating frequency is provided.

A memory circuit allows storage and recall of two

simplex and four repeater channels, with the press

of a switch. The memorized frequency may be

held when the power switch is turned off, via the

backup circuitry.

For repeater operation, ± 600 kHz split is provided,

and auxiliary splits may be programmed using the

memory system. Tone burst generation is provided,

and a subaudible tone squelch (CTCSS) encoder/

decoder is an available option for your FT-227RB.

Superb operating convenience is provided by the

PLL scanner, allowing up/down scanning control

from the microphone, without rotation of the

main tuning dial..

Your FT-227RB, represents the latest developments in solid-state technology. With proper care,

and if the directions to follow are observed without fail, your FT-227RB. will provide many years

of trouble-free operation. The owner is encouraged

to read this manual in its entirety, so as to become

better acquainted with the exciting new FT-227RB,

the latest development from the hams at YAESU.

1

SPECIFICATIONS

GENERAL

Frequency Converage

144

to 148

MHz

Number of Channels

800 channels

Speaker

Internal 3" dynamic speaker with provision

for connecting an external 8 ohm dynamic

speaker.

Microphone

Dynamic push-to-talk microphone with retractable coiled cord. Impedance is 600

ohms.

Deviation

±5 kHz.

Audio Response

+1,

—3 dB of 6 dB/Octave pre-emphasis

characteristic from 300 to 2500 Hz.

Spurious Emissions

60 dB below carrier minimum

Tone Burst.

Nominally one second at 1800 H

Repeater Split.

±600

kHz or any frequency in 5 kHz

increments

Power Requirement

RECEIVER

13.8 Volts DC, ±10%.

Current Consumption

0.5 Amps Receive.

2.5 Amps Transmit.

Metering

Illuminated front panel meter indicates

relative received signal strength and transmitter power output.

Type

Double conversion super-heterodyne

Intermediate Frequency

10.7 MHz

first IF; 455 kHz second IF

Sensitivity

0'.3 µV for 20 dB quieting.

Selectivity

Dimensions

±6

kHz at 6 dB: ±12 kHz at 60 dB

180 (W) x 60

(H)

x 220 (D) mm

Audio Output

Weight

1.5 Watts at 8 ohms

2.7 kg.

TRANSMITTER

RF Output

10

Watts into 50 ohm load at 13.8 Volts DC

Frequency Stability

±0.002%.

Modulation

F3.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

2

CD ® io ©

'0

13

CD ©

®

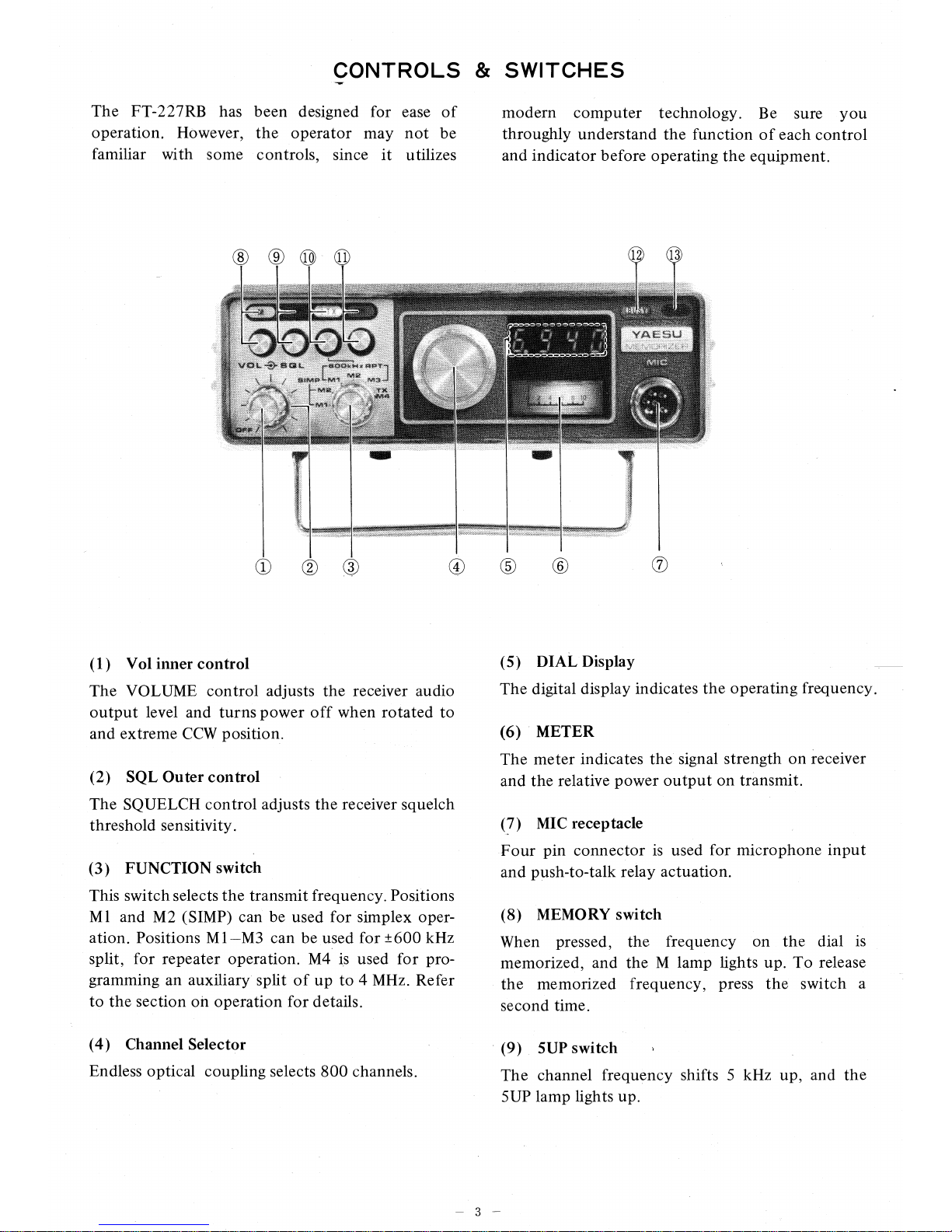

CONTROLS & SWITCHES

-

VW

The FT-227RB has been designed for ease of

modern computer technology. Be sure you

operation. However, the operator may not be

throughly understand the function of each control

familiar with some controls, since it utilizes

and indicator before operating the equipment.

(1)

Vol inner control

The VOLUME control adjusts the receiver audio

output level and turns power off when rotated to

and extreme CCW position.

(2)

SQL Outer control

The SQUELCH control adjusts the receiver squelch

threshold sensitivity.

(3)

FUNCTION switch

This switch selects the transmit frequency. Positions

M l and M2 (SIMP) can be used for simplex operation. Positions Ml—M3 can be used for ±600 kHz

split, for repeater operation. M4 is used for programming an auxiliary split of up to 4 MHz. Refer

to the section on operation for details.

(4)

Channel Selector

Endless optical coupling selects 800 channels.

(5)

DIAL Display

The digital display indicates the operating frequency.

(6) METER

The meter indicates the signal strength on receiver

and the relative power output on transmit.

(7)

MIC receptacle

Four pin connector is used for microphone input

and push-to-talk relay actuation.

(8)

MEMORY switch

When pressed, the frequency on the dial is

memorized, and the M lamp lights up. To release

the memorized frequency, press the switch a

second time.

(9)

5UP switch

The channel frequency shifts 5 kHz up, and the

5UP lamp lights up.

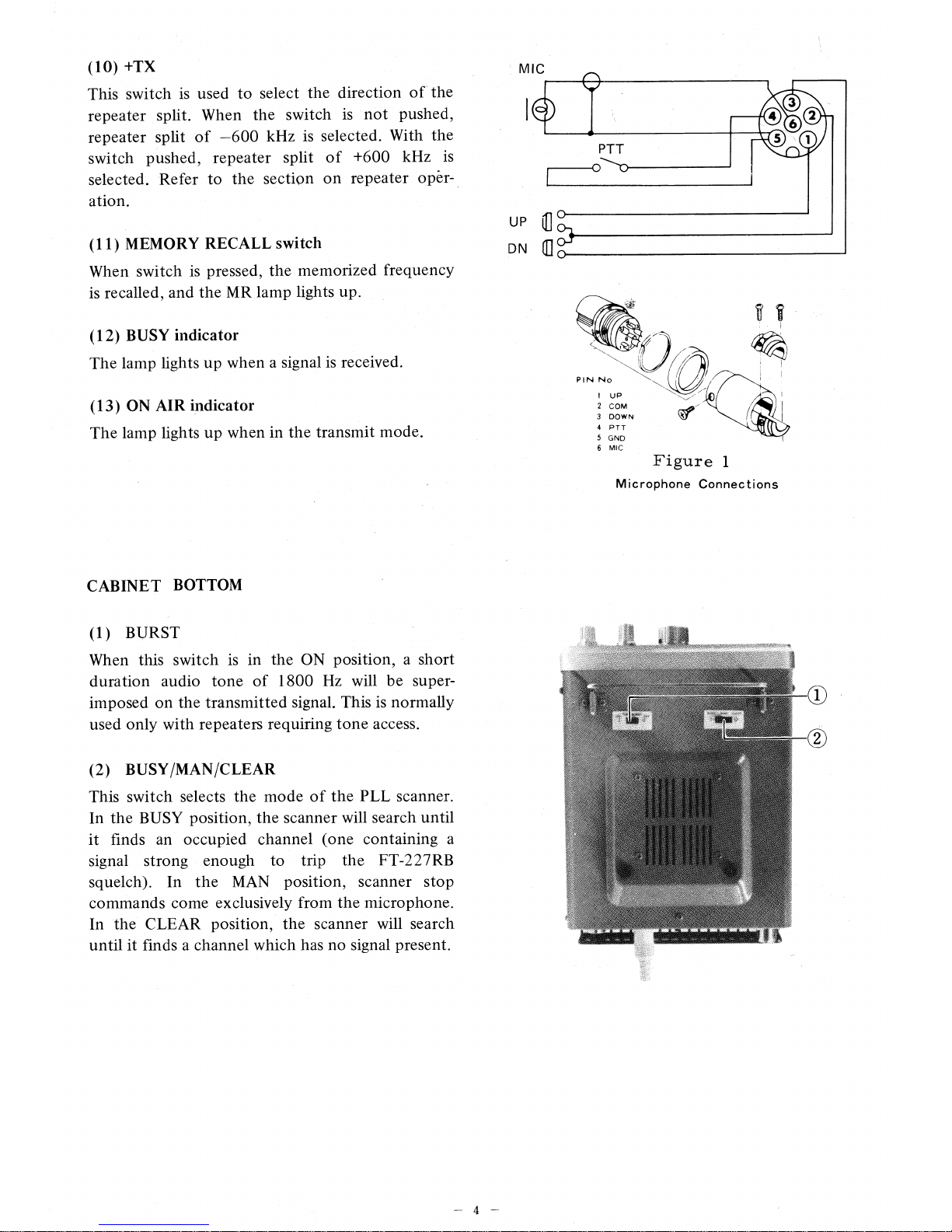

MIC

le

PTT

UP

C

DN

111

0

PIN No

1 UP

2 COM

3 DOWN

4 PTT

5 GND

6 MIC

(10)

+TX

This switch is used to select the direction of the

repeater split. When the switch is not pushed,

repeater split of —600 kHz is selected. With the

switch pushed, repeater split of +600 kHz is

selected. Refer to the section on repeater operation.

(11)

MEMORY RECALL switch

When switch is pressed, the memorized frequency

is recalled, and the MR lamp lights up.

(12)

BUSY indicator

The lamp lights up when a signal is received.

(13)

ON AIR indicator

The lamp lights up when in the transmit mode.

Figure

1

Microphone Connections

CABINET BOTTOM

(1)

BURST

When this switch is in the ON position, a short

duration audio tone of 1800 Hz will be super-

imposed on the transmitted signal. This is normally

used only with repeaters requiring tone access.

(2)

BUSY/MAN/CLEAR

This switch selects the mode of the PLL scanner.

In the BUSY position, the scanner will search until

it finds an occupied channel (one containing a

signal strong enough to trip the FT-227R13

squelch). In the MAN position, scanner stop

commands come exclusively from the microphone.

In the CLEAR position, the scanner will search

until it finds a channel which has no signal present.

NUS

MORIZE

FCC ECE1VER DAlrA

,;wFT;h2274:11

h

plies

u Part

date

Manuf

ctute

VHF FM IRAN

FT-227R8

SERML NO

M0300 7

Vgtallafar..„

O

CD CD CD

O

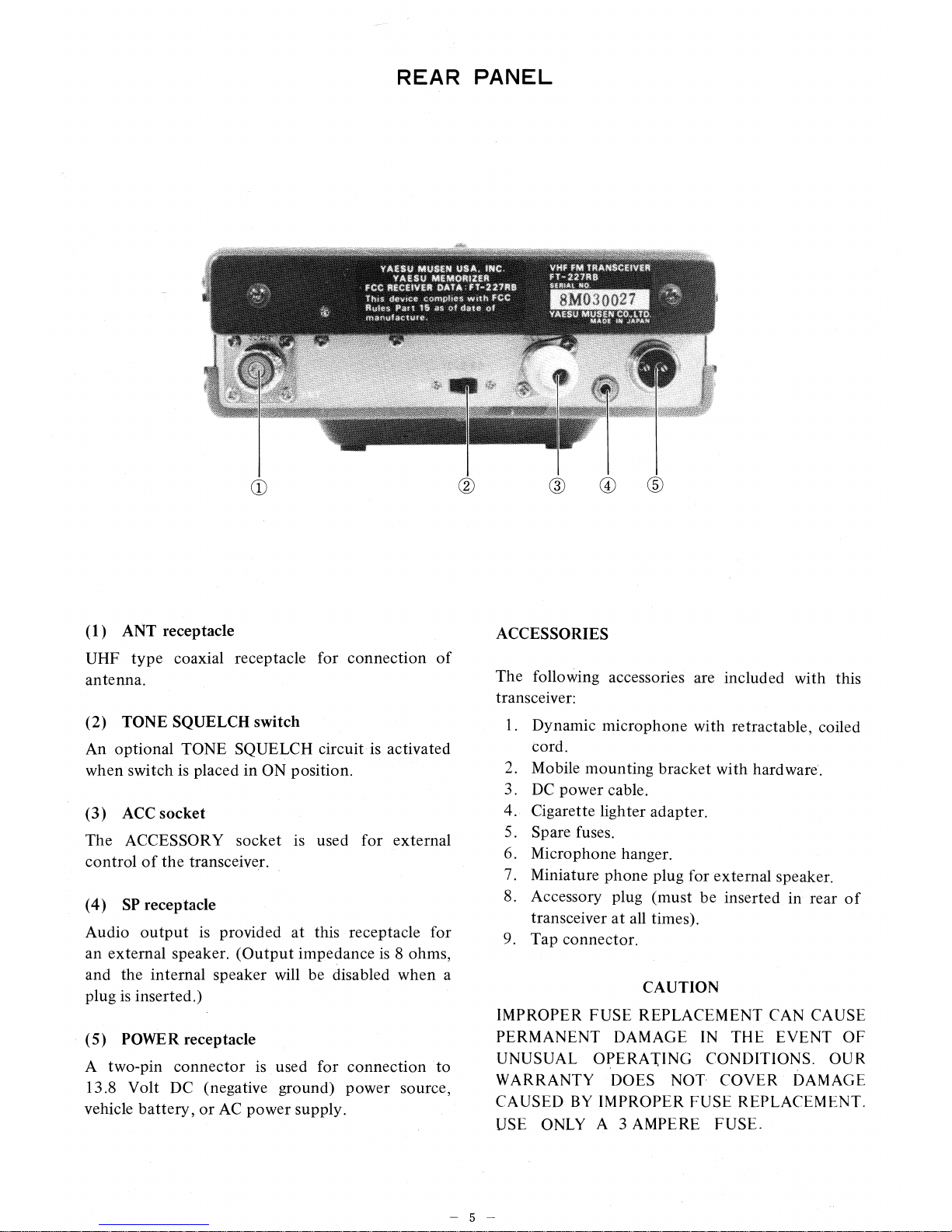

REAR PANEL

(1)

ANT receptacle

UHF type coaxial receptacle for connection of

antenna.

(2)

TONE SQUELCH switch

An optional TONE SQUELCH circuit is activated

when switch is placed in ON position.

(3)

ACC socket

The ACCESSORY socket is used for external

control of the transceiver.

(4)

SP receptacle

Audio output is provided at this receptacle for

an external speaker. (Output impedance is 8 ohms,

and the internal speaker will be disabled when a

plug is inserted.)

(5)

POWER receptacle

A two-pin connector is used for connection to

13.8 Volt DC (negative ground) power source,

vehicle battery, or AC power supply.

ACCESSORIES

The following accessories are included with this

transceiver:

1.

Dynamic microphone with retractable, coiled

cord.

2.

Mobile mounting bracket with hardware.

3.

DC power cable.

4.

Cigarette lighter adapter.

5.

Spare fuses.

6.

Microphone hanger.

7.

Miniature phone plug for external speaker.

8.

Accessory plug (must be inserted in rear of

transceiver at all times).

9.

Tap connector.

CAUTION

IMPROPER FUSE REPLACEMENT CAN CAUSE

PERMANENT DAMAGE IN THE EVENT OF

UNUSUAL OPERATING CONDITIONS. OUR

WARRANTY DOES NOT COVER DAMAGE

CAUSED BY IMPROPER FUSE REPLACEMENT.

USE ONLY A 3 AMPERE FUSE.

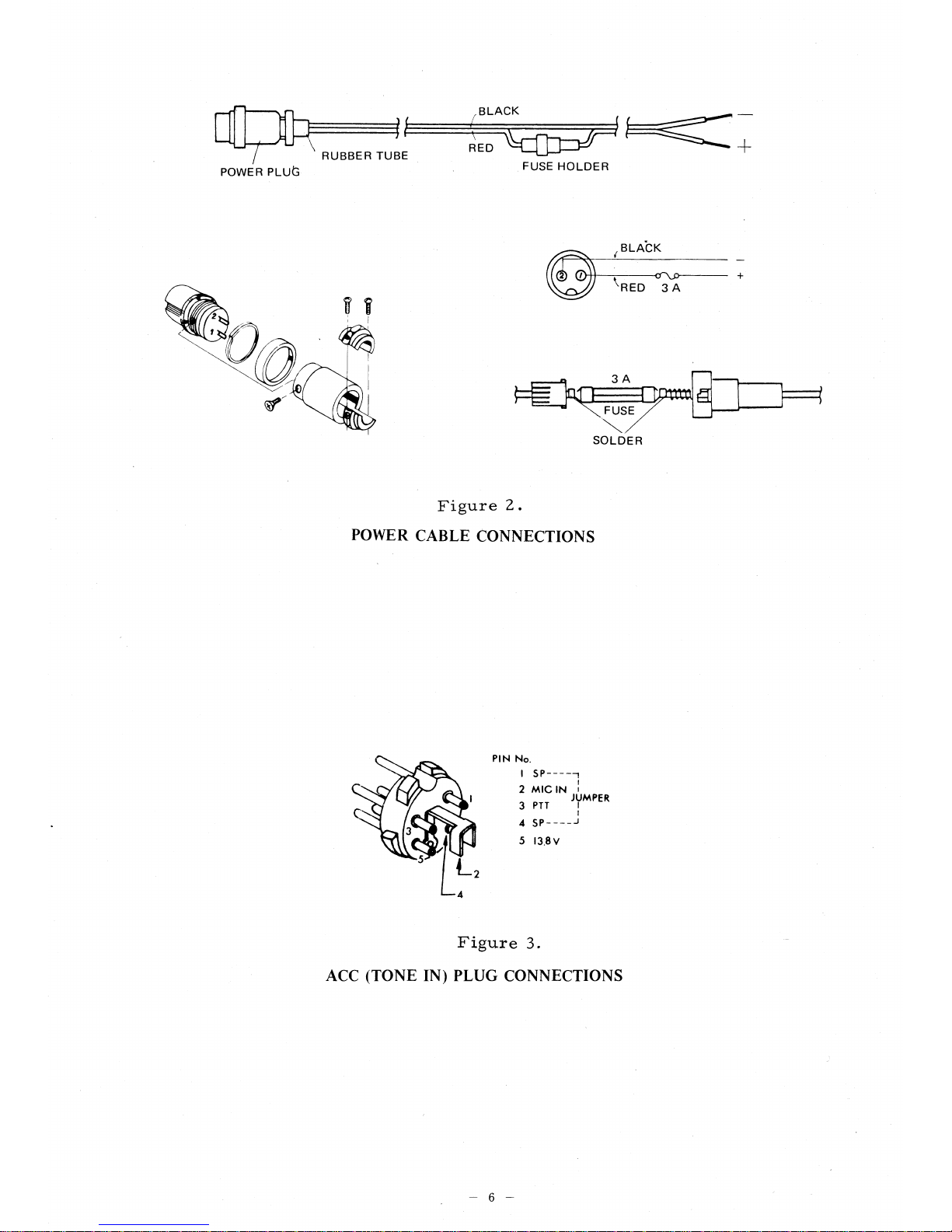

BLACK

1

i

RED

RUBBER TUBE

POWER PLUS

FUSE HOLDER

FUSE

SOLDER

3A

vcca

BLACK

Cr\.0

RED 3 A

Figure 2

.

POWER CABLE CONNECTIONS

PIN No.

I

2 MIC IN I

3 PTT

JUMPER

4 SP5 I3.8V

4

Figure 3.

ACC (TONE IN) PLUG CONNECTIONS

6

INSTALLATION

The FT-227RB transceiver is designed primarily

for mobile service, requiring only an antenna and

13.8 volt DC power source for operation. The

transceiver has been pre-tuned at the factory, and

requires no further adjustment for normal operation into a 50 ohm load.

Under no circumstances should the power cable

ever be connected to AC power. OUR WARRANTY DOES NOT COVER DAMAGE CAUSED

BY APPLICATION OF AC POWER TO THE

POWER JACK ON THE REAR APRON OF THE

TRANSCEIVER.

ANTENNA CONSIDERATIONS

In antenna installations, it is desirable that the

antenna be located as high and in the clear as

possible. In addition, be certain that the SWR on

the feedline is less than 1.5 : 1. A higher SWR may

cause a reduction in power output, because of the

protective circuitry incorporated in design. As well,

high SWR will increase the feedline losses.

In all installations, do not economize on coaxial

cable. For mobile applications, in which the feed-

line length is 20 feet or less, type RG-58A/U cable

is satisfactory, and the foam types are preferred,

because of their lower loss. For base station

systems, type RG8A/U may be used for moderate

lengths; for very long cable installations, we recommend the use of type RG-17A/U, air-dielectric

"heliax" cable, or aluminum-jacketed "foamflex"

coax. Beware of "bargain" coax, as the shield

coverage may be very poor, and this can seriously

degrade system performance.

BASE STATION INSTALLATION

As base station, the FT-227RB requires a power

source of 13.8 volts DC at 2.5 amperes. A base

station stand is included with your transceiver,

for easy viewing.

MOBILE INSTALLATION

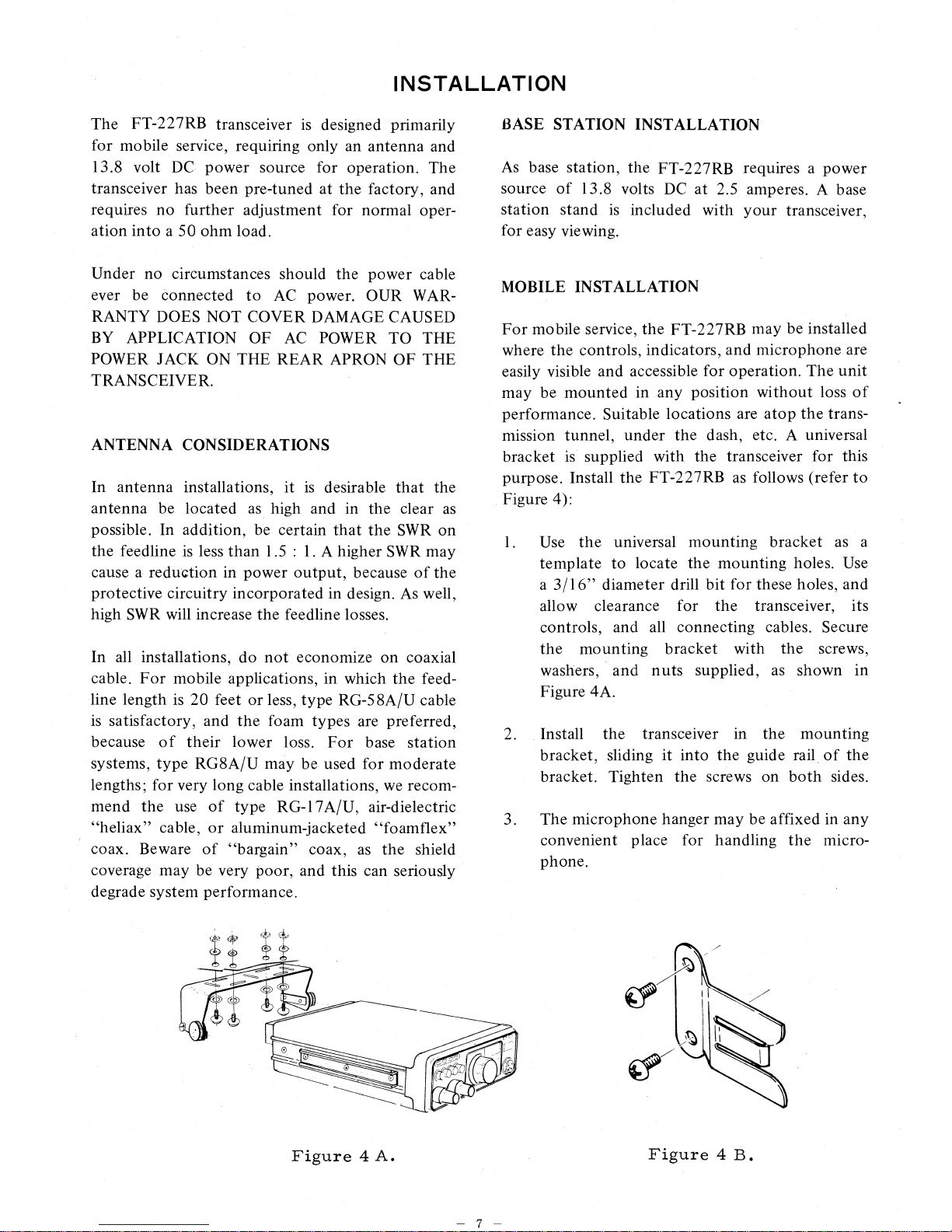

For mobile service, the FT-227RB may be installed

where the controls, indicators, and microphone are

easily visible and accessible for operation. The unit

may be mounted in any position without loss of

performance. Suitable locations are atop the transmission tunnel, under the dash, etc. A universal

bracket is supplied with the transceiver for this

purpose. Install the FT-227RB as follows (refer to

Figure 4):

Use the universal mounting bracket as a

template to locate the mounting holes. Use

a 3/16" diameter drill bit for these holes, and

allow clearance for the transceiver, its

controls, and all connecting cables. Secure

the mounting bracket with the screws,

washers, and nuts supplied, as shown in

Figure 4A.

2.

Install the transceiver in the mounting

bracket, sliding it into the guide rail of the

bracket. Tighten the screws on both sides.

3.

The microphone hanger may be affixed in any

convenient place for handling the microphone.

Figure 4 A.

Figure 4 B.

Loading...

Loading...