Page 1

LogiCORE IP

MicroBlaze Micro

Controller System v1.3

Product Guide

PG048 December 18, 2012

Page 2

Table of Contents

SECTION I: SUMMARY

IP Facts

Chapter 1: Overview

Feature Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Licensing and Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2: Product Specification

Standards Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Resource Utilization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Port Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Register Space . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 3: Designing with the Core

General Design Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Clocking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Resets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Protocol Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

SECTION II: VIVADO DESIGN SUITE

Chapter 4: Customizing and Generating the Core

GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Parameter Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Parameter - Port Dependencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Tool Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Chapter 5: Constraining the Core

Required Constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

MicroBlaze Micro Controller System v1.3 www.xilinx.com 1

PG048 December 18, 2012

Page 3

Device, Package, and Speed Grade Selections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Clock Frequencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Clock Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Clock Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Banking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Transceiver Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

I/O Standard and Placement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

SECTION III: ISE DESIGN SUITE

Chapter 6: Customizing and Generating the Core

GUI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Parameter Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Parameter - Port Dependencies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Tool Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 7: Constraining the Core

Clock Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

SECTION IV: APPENDICES

Appendix A: Application Software Development

Xilinx Software Development Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Device Drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Appendix B: Debugging

Finding Help on Xilinx.com . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Debug Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Simulation Debug. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Hardware Debug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Appendix C: Additional Resources

Xilinx Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Revision History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Notice of Disclaimer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Automotive Applications Disclaimer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

MicroBlaze Micro Controller System v1.3 www.xilinx.com 2

PG048 December 18, 2012

Page 4

SECTION I: SUMMARY

IP Facts

Overview

Product Specification

Designing with the Core

MicroBlaze Micro Controller System v1.3 www.xilinx.com 3

PG048 December 18, 2012

Page 5

IP Facts

Introduction

The LogiCORE™ MicroBlaze™ Micro Controller

System (MCS) is a complete standalone

processor system intended for controller

applications. It is highly integrated and includes

the MicroBlaze processor, local memory for

program and data storage as well as a tightly

coupled I/O module implementing a standard

set of peripherals.

The MicroBlaze processor included in the MCS

has a fixed configuration, optimized for

minimal area. The full-featured MicroBlaze

processor is available in the ISE® Design Suite

Embedded Edition and the Vivado™ IP

integrator.

Features

• MicroBlaze processor

•Local Memory

• MicroBlaze Debug Module (MDM)

LogiCORE IP Facts Table

Core Specifics

Supported

Device Family

Supported User

Interfaces

Resources See Ta b le 2 -2 .

Zynq™-7000

(1)

(2)

, Virtex®-7, Kintex™-7, Artix™-7,

Virtex-6, Virtex-5, Spartan

Local Memory Bus (LMB), Dynamic

Reconfiguration Port (DRP)

®-6, Virtex-4,

Spartan-3

Provided with Core

Design Files

Example

Design

Test Bench Not Provided

Constraints File Not Provided

Simulation

Model

Supported

S/W Driver

Design Entry

Simulation

Synthesis

(3)

Tested Design Flows

Verilog and/or VHDL Structural

(4)

ISE Design Suite 14.4

Vivado Design Suite 2012.4

Mentor Graphics ModelSim

Xilinx Synthesis Technology (XST)

ISE: VHDL

Vivado: RTL

Not Provided

Standalone

Vivado Simulator

Vivado Synthesis

(5)

• Tightly Coupled I/O Module including

I/O Bus

°

Interrupt Controller using fast interrupt

°

mode

UART

°

Fixed Interval Timers

°

Programmable Interval Timers

°

General Purpose Inputs

°

General Purpose Outputs

°

Provided by Xilinx @ www.xilinx.com/support

Notes:

1. For a complete listing of supported devices, see the release

notes for this core.

2. Supported in ISE Design Suite implementations only.

3. Standalone driver details can be found in the EDK or SDK

directory (<install_directory>/doc/usenglish/

xilinx_drivers.htm). Linux OS and driver support information is

available from //wiki.xilinx.com

4. For the supported versions of the tools, see the Xilinx Design

Tools: Release Notes Guide.

5. Supports only 7 series devices.

Support

.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 4

PG048 December 18, 2012 Product Specification

Page 6

Overview

ILMB

MicroBlaze

Local

Memory Bus

LMB BRAM

Interface Controller

Block RAM

(Dual Port)

DLMB

Local

Memory Bus

LMB BRAM

Interface Controller

I/O Module

MicroBlaze

Debug

Optional Feature

The MicroBlaze™ Micro Controller System (MCS) is highly integrated standalone processor

system intended for controller applications. Data and program is stored in a local memory,

debug is facilitated by the MicroBlaze Debug Module, MDM. A standard set of peripherals

is also included, providing basic functionality like interrupt controller, UART, timers and

general purpose input and outputs.

X-Ref Target - Figure 1-1

Chapter 1

MicroBlaze Micro Controller System v1.3 www.xilinx.com 5

PG048 December 18, 2012

Figure 1-1: MicroBlaze Micro Controller System (MCS)

Feature Summary

MicroBlaze

The MicroBlaze embedded processor soft core is a reduced instruction set computer (RISC)

optimized for implementation in Xilinx® Field Programmable Gate Arrays (FPGAs). Detailed

information on the MicroBlaze processor can be found in the MicroBlaze Processor

Reference Guide [Ref 5].

The MicroBlaze parameters in MicroBlaze MCS are fixed except for the possibility to enable/

disable the debug functionality. The values of all MicroBlaze parameters in MicroBlaze MCS

can be found in Tab le 4- 2. These values correspond to the MicroBlaze Configuration Wizard

Minimum Area configuration.

Page 7

Chapter 1: Overview

Local Memory

Local memory is used for data and program storage and is implemented using block RAM.

The size of the local memory is parameterized and can be between 4kB and 64kB. The local

memory is connected to MicroBlaze through the Local Memory Bus, LMB, and the LMB

BRAM Interface Controllers. Detailed information on LMB can be found in the Local Memory

Bus (LMB) V10 data sheet [Ref 1] and detailed information on the LMB BRAM Interface

Controller can be found in the LMB BRAM Interface Controller data sheet [Ref 2].

The LMB Bus and the LMB BRAM Interface Controller parameters are fixed except for the

memory size. The value of the parameters can be found in Tabl e 4 -4, Ta ble 4-5 , Tab le 4- 6

and Tab le 4- 7.

Debug

The MicroBlaze Debug Module, MDM, connects MicroBlaze debug logic to the XMD low

level debugger. XMD can be used for downloading software, to set break points, view

register and memory contents. Detailed information about MDM can be found in the

MicroBlaze Debug Module (MDM) data sheet [Ref 3].

The MDM parameters, except the JTAG user-defined register, are fixed and their values can

be found in Tab le 4- 8.

When more than one MicroBlaze MCS instance with debug enabled is included in the same

design, a unique JTAG register must be used for each instance. When a single instance is

used, the default value USER2 should be kept unchanged.

I/O Module

The I/O Module is a light-weight implementation of a set of standard I/O functions

commonly used in a MicroBlaze processor sub-system. Detailed information about the I/O

Module can be found in the I/O Module product guide [Ref 4].

The I/O Module registers are mapped at address 0x4000000, and the I/O Bus is mapped at

address 0xC0000000-0xFFFFFFFF in the MicroBlaze memory space. The fixed I/O Module

parameter values can be found in Tabl e 4-3 .

Licensing and Ordering Information

This Xilinx LogiCORE™ IP module is provided at no additional cost with the Xilinx Vivado™

Design Suite and ISE® Design Suite tools under the terms of the Xilinx End User License

Information about this and other Xilinx LogiCORE IP modules is available at the Xilinx

Intellectual Property page. For information about pricing and availability of other Xilinx

LogiCORE IP modules and tools, contact your local Xilinx sales representative

MicroBlaze Micro Controller System v1.3 www.xilinx.com 6

PG048 December 18, 2012

.

.

Page 8

Product Specification

Standards Compliance

The I/O Bus interface provided by the I/O Module is fully compatible with the Xilinx®

Dynamic Reconfiguration Port (DRP). For a detailed description of the DRP, see the 7 Series

FPGAs Configuration User Guide [Ref 10].

Performance

The frequency and latency of the modules in the MicroBlaze™ MCS are optimized for use

together with MicroBlaze. This means that the frequency targets are aligned to MicroBlaze

targets as well as the access latency optimized for MicroBlaze data access.

Chapter 2

Maximum Frequencies

The following are clock frequencies for the target families. The maximum achievable clock

frequency can vary. The maximum achievable clock frequency and all resource counts can

be affected by the used tool flow, other tool options, additional logic in the FPGA, using

different versions of Xilinx tools, and other factors.

Table 2-1: Maximum Frequencies

Architecture Speed grade Max Frequency

Spartan®-6 -4 195

Virtex®-6 -3 300

Artix™-7 -3 225

Kintex™-7 -3 320

Virtex-7 -3 320

Latency

Data read from I/O Module registers is available two clock cycles after the MicroBlaze load

instruction is executed.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 7

PG048 December 18, 2012

Page 9

Chapter 2: Product Specification

Data write to I/O Module registers is performed the clock cycle after the MicroBlaze store

instruction is executed.

Data accesses to peripherals connected on the I/O Bus take three clock cycles plus the

number of wait states introduced by the accessed peripheral.

Throughput

The maximum throughput when using the I/O Bus is one read or write access every three

clock cycles.

Resource Utilization

Because the MicroBlaze MCS is a module that is used together with other parts of the

design in the FPGA, the utilization and timing numbers reported in this section are just

estimates, and the actual utilization of FPGA resources and timing of the MicroBlaze MCS

design will vary from the results reported here. All parameters not given in Tab le 2- 2 have

their default values.

Table 2-2:

Parameter Values (other parameters at default value) Device Resources

C_USE_UART_RX

11000 0 00000000 546 276

11150 0 00000000 606 340

1115165000 00000000 620 353

1115165000 1 32 000000 656 441

1115165000 1 32 1 32 0 0 0 0 658 473

1115165000 1 32 1 32 1 32 0 0 659 505

1115165000 1 32 1 32 1 32 1 0 675 610

1115165000 1 32 1 32 1 32 1 1 882 946

Performance and Resource Utilization Benchmarks on Virtex-6 (xc6vlx240t-1-ff1156)

LUTs Flip-Flops

C_USE_UART_TX

C_USE_FIT1

C_INTC_INTR_SIZE

C_INTC_USE_EXT_INTR

C_FIT1_No_CLOCKS

C_USE_PIT1

C_PIT1_SIZE

C_USE_GPI1

C_GPI1_SIZE

C_USE_GPO1

C_GPO1_SIZE

C_USE_IO_BUS

C_DEBUG_ENABLE

MicroBlaze Micro Controller System v1.3 www.xilinx.com 8

PG048 December 18, 2012

Page 10

Chapter 2: Product Specification

Port Descriptions

The I/O ports and signals for MicroBlaze MCS are listed and described in Tabl e 2- 3.

Table 2-3: MicroBlaze MCS Signals

Port Name MSB:LSB I/O Description

System Signals

Clk I System clock

Reset I System reset

MicroBlaze Signals

Trace_Valid_Instr O Valid instruction on trace port

Trace_Instruction 0:31 O Instruction code

Trace_PC 0:31 O Program counter

Trace_Reg_Write O Instruction writes to the register file

Trace_Reg_Addr 0:4 O Destination register address

Trace_MSR_Reg 0:14 O Machine status register

Trace_New_Reg_Value 0:31 O Destination register update value

Trace_Jump_Taken O Branch instruction evaluated TRUE (taken)

Trace_Delay_Slot O Instruction is in delay slot of a taken branch

Trace_Data_AccessT O Valid D-side memory access

Trace_Data_Address 0:31 O Address for D-side memory access

Trace_Data_Write_Value 0:31 O Value for D-side memory write access

Trace_Data_Byte_Enable 0:3 O Byte enables for D-side memory access

Trace_Data_Read O D-side memory access is a read

Trace_Data_Write O D-side memory access is a write

I/O Bus Signals

IO_Addr_Strobe O Address strobe signals valid I/O Bus output

signals

IO_Read_Strobe O I/O Bus access is a read

IO_Write_Strobe O I/O Bus access is a write

IO_Address 31:0 O Address for access

IO_Byte_Enable 3:0 O Byte enables for access

IO_Write_Data 31:0 O Data to write for I/O Bus write access

IO_Read_Data 31:0 I Read data for I/O Bus read access

IO_Ready I Ready handshake to end I/O Bus access

MicroBlaze Micro Controller System v1.3 www.xilinx.com 9

PG048 December 18, 2012

Page 11

Table 2-3: MicroBlaze MCS Signals (Cont’d)

Port Name MSB:LSB I/O Description

UART Signals

UART_Rx_IO I Receive Data

UART_Tx_IO O Transmit Data

UART_Interrupt O UART Interrupt

FIT Signals

(1)

(1)

OFITx timer lapsed

O Inverted FITx_Toggle when FITx timer lapses

FITx_Interrupt

FITx_Toggle

PIT Signals

PITx_Enable

PITx_Interrupt

PITx_Toggle

(1)

(1)

(1)

IPITx count enable when C_PITx_PRESCALER =

External

OPITx timer lapsed

O Inverted PITx_Toggle when PITx lapses

GPO Signals

(1)

GPOx

[C_GPOx_SIZE - 1]:0 O GPOx Output

Chapter 2: Product Specification

GPI Signals

(1)

GPIx

GPIx_Interrupt

(1)

[C_GPIx_SIZE - 1]:0 I GPIx Input

OGPIx input changed

INTC Signals

INTC_Interrupt 0:[C_INTC_INTR_SIZE - 1] I External interrupt inputs

1. x = 1, 2, 3 or 4

Register Space

Table 2-4: MicroBlaze MCS Address Map

Address (hex) Name Access Type Description

0x0 - C_MEMSIZE-1 Local Memory RW Local Memory for MicroBlaze software

C_MEMSIZE - 0x7FFFFFFF Reserved

0x80000000 - 0x800000FF

0x80000100 - 0xBFFFFFFF Reserved

0xC0000000 - 0xFFFFFFFF I/O Bus RW Mapped to I/O Bus address output

I/O Module RW Mapped to I/O Module registers

MicroBlaze Micro Controller System v1.3 www.xilinx.com 10

PG048 December 18, 2012

Page 12

Designing with the Core

This chapter includes guidelines and additional information to make designing with the

core easier.

General Design Guidelines

I/O Module Interfaces

See the I/O Module Product Guide [Ref 4] for design guidelines for the I/O Bus, UART, Fixed

Interval Timer, Programmable Interval Timer, General Purpose Output, General Purpose

Input, and Interrupt Controller. All of these interfaces are directly connected to the I/O

Module inside the MicroBlaze™ MCS.

Chapter 3

MicroBlaze Trace Signals

See the MicroBlaze Processor Reference Guide [Ref 5] for a detailed description of the

MicroBlaze Trace signals. The Trace signals are directly connected to the MicroBlaze

processor inside the MicroBlaze MCS.

MicroBlaze Debug Module

See the Xilinx SDK Help [Ref 6] and the MicroBlaze Debug Module Product Guide [Ref 3] for

a description of debugging with the MicroBlaze Debug Module (MDM).

Clocking

MicroBlaze MCS is fully synchronous with all clocked elements clocked with the Clk input.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 11

PG048 December 18, 2012

Page 13

Chapter 3: Designing with the Core

Resets

The Reset input is the master reset input signal for the entire MicroBlaze MCS. In addition,

the entire MicroBlaze MCS or just the MicroBlaze processor can be reset from the Xilinx

MicroProcessor Debugger (XMD), provided that debug is enabled.

Protocol Description

See the I/O Bus timing diagrams in the I/O Module Product Guide [Ref 4].

MicroBlaze Micro Controller System v1.3 www.xilinx.com 12

PG048 December 18, 2012

Page 14

SECTION II: VIVADO DESIGN SUITE

Customizing and Generating the Core

Constraining the Core

MicroBlaze Micro Controller System v1.3 www.xilinx.com 13

PG048 December 18, 2012

Page 15

Chapter 4

Customizing and Generating the Core

This chapter includes information on using Xilinx tools to customize and generate the core

using the Vivado™ Design Suite.

GUI

MicroBlaze™ MCS parameters are divided in seven tabs: MCS, UART, FIT, PIT, GPO, GPI and

Interrupts. The MCS parameter tab is shown in Figure 4-1.

X-Ref Target - Figure 4-1

Figure 4-1: MCS Parameter Tab

MicroBlaze Micro Controller System v1.3 www.xilinx.com 14

PG048 December 18, 2012

Page 16

Chapter 4: Customizing and Generating the Core

• Input Clock Frequency (MHz) - This parameter should be set to the frequency of the

core input clock in MHz. The value is used to calculate the correct UART baud rate.

• Memory Size - Defines the local memory size, used to store the MicroBlaze processor

software program instructions and data. Increase this value if the software program

does not fit in available memory.

• Enable I/O Bus - Enables I/O Bus port.

• Enable Debug Support - When debug support is enabled, it is possible to debug

software via JTAG, from Xilinx Software Development Kit (SDK) or directly using the

Xilinx Microprocessor Debugger (XMD).

• Debug JTAG User-defined Register - Specifies the JTAG user-defined register for

debug. When more than one MicroBlaze MCS instance with debug enabled is included

in the same design, a unique JTAG register must be used for each instance. When a

single instance is used, the default value USER2 should be kept unchanged.

• Enable MicroBlaze Trace Bus - This option enables the MicroBlaze Trace bus, which

provides access to several internal processor signals for trace purposes.

The UART parameter tab is shown in Figure 4-2.

X-Ref Target - Figure 4-2

Figure 4-2: UART Parameter Tab

MicroBlaze Micro Controller System v1.3 www.xilinx.com 15

PG048 December 18, 2012

Page 17

Chapter 4: Customizing and Generating the Core

• Enable Receiver - Enables UART receiver for character input. This is automatically

connected to standard input (stdin) in the software program.

• Enable Transmitter - Enables UART transmitter for character output. This is

automatically connected to standard output (stdout) in the software program.

• Define Baud Rate - Sets the UART baud rate. To get the correct baud rate, the input

clock frequency must also be correctly defined.

• Programmable Baud Rate - Determines if the UART baud rate is programmable. The

default baud rate is calculated based on the input clock frequency and the defined

baud rate.

• Number of Data Bits - Defines the number of data bits used by the UART. Should

almost always be set to 8.

• Use Parity - Enable this parameter to use parity checking of the UART characters.

• Even or Odd Parity - Select odd or even parity. Only available when parity is used.

• Implement Receive Interrupt - Generate an interrupt when the UART has received a

character. When the interrupt is not enabled the UART must be polled to check if data

has been received.

• Implement Transmit Interrupt - Generate an interrupt when the UART has sent a

character. When the interrupt is not enabled the UART must be polled to wait until data

has been transmitted.

• Implement Error Interrupt - Generate an interrupt if an error occurs when the UART

receives a character. This error can be a framing error, an overrun error or a parity error

(if parity is used), When the interrupt is not enabled the UART must be polled to check

if an error has occurred after a character has been received.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 16

PG048 December 18, 2012

Page 18

Chapter 4: Customizing and Generating the Core

The FIT parameter tab showing the parameters for one of the four timers is shown in

Figure 4-3.

X-Ref Target - Figure 4-3

Figure 4-3: FIT Parameter Tab

• Use FIT - Enable the Fixed Interval Timer.

• Number of Clocks Between Strobes - The number of clock cycles between each

strobe.

• Generate Interrupt - Generate an interrupt for each Fixed Interval Timer strobe.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 17

PG048 December 18, 2012

Page 19

Chapter 4: Customizing and Generating the Core

The PIT parameter tab showing the parameters for one of the four timers is shown in

Figure 4-4.

X-Ref Target - Figure 4-4

Figure 4-4: PIT Parameter Tab

• Use PIT - Enable the Programmable Interval Timer.

• Number of Bits for Timer - The maximum number of cycles to count before stopping

or restarting.

• Shall Counter Value be Readable - The Programmable Interval Timer counter is

readable by software when this parameter is set.

RECOMMENDED: Unless resource usage is critical it is recommended that you keep this

enabled.

• Define Prescaler - Selects a prescaler as source for the Programmable Interval Timer

count. When no prescaler is selected the core input clock is used. Any Programmable

Interval Timer or Fixed Interval Timer can be used as prescaler, as well as a dedicated

external enable input.

• Generate Interrupt - Generate an interrupt when the Programmable Interval Timer has

counted down to zero.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 18

PG048 December 18, 2012

Page 20

Chapter 4: Customizing and Generating the Core

The GPO parameter tab showing the parameters for one of the four General Purpose Output

ports is shown in Figure 4-5.

X-Ref Target - Figure 4-5

Figure 4-5: GPO Parameter Tab

• Use GPO - Enable the General Purpose Output port.

• Number of Bits - Set the number of bits of the General Purpose Output port.

• Initial Value of GPO - Set the initial value of the General Purpose Output port. The

right most bit in the value is assigned to bit 0 of the port, the next right most to bit 1,

and so on.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 19

PG048 December 18, 2012

Page 21

Chapter 4: Customizing and Generating the Core

The GPI parameter tab showing the parameters for one of the four General Purpose Input

ports is shown in Figure 4-6.

X-Ref Target - Figure 4-6

Figure 4-6: GPI Parameter Tab

• Use GPI - Enable the General Purpose Input port.

• Number of Bits - Set the number of bits of the General Purpose Input port.

• Generate Interrupt - Generate an interrupt when a General Purpose Input changes.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 20

PG048 December 18, 2012

Page 22

Chapter 4: Customizing and Generating the Core

The Interrupts parameter tab is shown in Figure 4-7.

X-Ref Target - Figure 4-7

Figure 4-7: Interrupts Parameter Tab

• Use External Interrupts - Enable the use of external interrupt inputs.

• Number of External Inputs - Select the number of used external interrupt inputs.

• Level or Edge of External Interrupts - Select whether the input is considered level

sensitive or edge triggered. Each bit in the value corresponds to the equivalent

interrupt input. When a bit is set to one, the interrupt is edge triggered, otherwise it is

level sensitive.

• Positive or Negative External Interrupts - Set whether to use high or low level for

level sensitive interrupts, and rising or falling edge for edge triggered interrupts. Each

bit in the value corresponds to the equivalent interrupt input When a bit is set to one,

high level or rising edge is used, otherwise low level or falling edge is used.

• Use Low-latency Interrupt Handling - Enable the use of low-latency interrupt

handling.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 21

PG048 December 18, 2012

Page 23

Chapter 4: Customizing and Generating the Core

Parameter Values

To create a MicroBlaze MCS that is uniquely tailored for a specific system, certain features

can be parameterized. This makes it possible for the user to configure a component that

only uses the resources required by the system, and operates with the best possible

performance. The features that can be parameterized in MicroBlaze MCS are shown in

Tab le 4 -1.

The internal modules of the MicroBlaze MCS have fixed configurations detailed in:

• Ta bl e 4 -2 - MicroBlaze

• Ta bl e 4 -3 - I/O Module

• Ta bl e 4 -4 and Ta ble 4 -5 - LMB v10

• Ta bl e 4 -6 and Ta ble 4 -7 - LMB BRAM IF Controller

• Ta bl e 4 -8 - MicroBlaze Debug Module

Table 4-1: MicroBlaze MCS Parameters

Parameter Name Feature/Description

Allowable

Values

Default

Value

VHDL

Type

MCS Parameters

C_FAMILY

C_XDEVICE

C_XPACKAGE

C_XSPEEDGRADE

C_MICROBLAZE_

INSTANCE

C_PATH Hierarchical path from top of

C_FREQ Frequency of CLK input 100000000 integer

C_MEMSIZE Local memory size in bytes

C_DEBUG_ENABLE Enable implementation of

(1)

(1)

(1)

(1)

(1)

FPGA architecture Supported

architectures

Device name Supported

devices

FPGA package name Supported

packages

FPGA speed grade Supported

speed grades

Instance name

design to MCS instance

4096, 8192, 16384,

32768, 65536

0 = Not Used

debug

1 = Used

virtex5 string

xc5vlx50t string

ff1136 string

-1 string

microblaze_0 string

mb/UO

8192 integer

0 Integer

C_JTAG_CHAIN Select JTAG user-defined

register

1 = USER1

2 = USER2

3 = USER3

4 = USER4

2 Integer

MicroBlaze Micro Controller System v1.3 www.xilinx.com 22

PG048 December 18, 2012

Page 24

Table 4-1: MicroBlaze MCS Parameters (Cont’d)

Chapter 4: Customizing and Generating the Core

Parameter Name Feature/Description

Allowable

Values

I/O Bus Parameter

C_USE_IO_BUS Use I/O Bus 0 = Not Used

1 = Used

UART Parameters

C_USE_UART_RX Use UART Receive 0 = Not Used

1 = Used

C_USE_UART_TX Use UART Transmit 0 = Not Used

1 = Used

C_UART_BAUDRATE Baud rate of the UART in bits

per second

C_UART_PROG_

BAUDRATE

C_UART_DATA_BITS The number of data bits in the

C_UART_USE_PARITY Determines whether parity is

C_UART_ODD_PARITY If parity is used, determines

Programmable UART baud rate 0 = Not Used

serial frame

used or not

whether parity is odd or even

integer

(for example

115200)

1 = Used

5 - 8

0 = No Parity

1 = Use Parity

0 = Even Parity

1 = Odd Parity

Default

Value

0integer

0integer

0integer

9600 integer

0integer

8integer

0integer

0integer

VHDL

Type

C_UART_RX_INTERRUPT Use UART RX Interrupt in INTC 0 = Not Used

1 = Used

C_UART_TX_INTERRUPT Use UART TX Interrupt in INTC 0 = Not Used

1 = Used

C_UART_ERROR_

INTERRUPT

Use UART ERROR Interrupt in

INTC

0 = Not Used

1 = Used

FIT Parameters

C_USE_FITx

C_FITx_No_CLOCKS

C_FITx_INTERRUPT

(1)

(2)

(2)

Enable implementation of FIT 0 = Not Used

1 = Used

The number of clock cycles

between strobes

Use FITx_Interrupt in INTC 0 = Not Used

>2

1 = Used

PIT Parameters

C_USE_PITx

C_PITx_SIZE

C_PITx_READABLE

(2)

(2)

(2)

Enable implementation of PIT 0 = Not Used

1 = Used

Size of PITx counter 1 - 32 1 integer

Make PITx counter software

readable

0 = Not SW

readable

1 = SW readable

0integer

0integer

0integer

0integer

6216 integer

0integer

0integer

1integer

MicroBlaze Micro Controller System v1.3 www.xilinx.com 23

PG048 December 18, 2012

Page 25

Table 4-1: MicroBlaze MCS Parameters (Cont’d)

Chapter 4: Customizing and Generating the Core

Parameter Name Feature/Description

C_PITx_PRESCALER

C_PITx_INTERRUPT

(2)(3)

(2)

Select PITx prescaler 0 = No prescaler

Use PITx_Interrupt in INTC 0 = Not Used

GPO Parameters

C_USE_GPOx

C_GPOx_SIZE

C_GPOx_INIT

(2)

(2)

(2)

Use GPOx 0 = Not Used

Size of GPOx 1 - 32 32 integer

Initial value for GPOx Fit Range (31:0)

GPI Parameters

C_USE_GPIx

C_GPIx_SIZE

C_GPIx_INTERRUPT

(2)

(2)

(2)

Use GPIx 0 = Not Used

Size of GPIx 1 - 32 32 integer

Use GPIx_Interrupt in INTC 0 = Not Used

Allowable

Values

1 = FIT1

2 = FIT2

3 = FIT3

4 = FIT4

5 = PIT1

6 = PIT2

7 = PIT3

8 = PIT4

9 = External

1 = Used

1 = Used

1 = Used

1 = Used

Default

Value

0integer

0integer

0integer

all zeros

0integer

0integer

VHDL

Type

std_logic_

vector

INTC Parameters

C_INTC_USE_EXT_INTR Use I/O Module external

interrupt inputs

C_INTC_INTR_SIZE Number of external interrupt

inputs used

C_INTC_LEVEL_EDGE Level or edge triggered for

each external interrupt

C_INTC_POSITIVE Polarity for each external

interrupt

C_INTC_HAS_FAST Use fast interrupt mode 0 = Not Used

1. Values automatically populated by tool.

2. x=1, 2, 3 or 4.

3. Selecting PIT prescaler the same as PITx is illegal; for example, PIT2 cannot be prescaler to itself.

0 = Not Used

1 = Used

1 - 16

For each bit:

0 = Level

1 = Edge

For each bit:

0 = active-Low

1 = active-High

1 = Used

0integer

1integer

level

active-High

0integer

std_logic_

vector

std_logic_

vector

MicroBlaze Micro Controller System v1.3 www.xilinx.com 24

PG048 December 18, 2012

Page 26

Chapter 4: Customizing and Generating the Core

Table 4-2: Internal MicroBlaze Parameters Settings

Parameter Name Feature/Description Value

C_FAMILY Target family Value of MicroBlaze MCS

parameter C_FAMILY

C_AREA_OPTIMIZED Select implementation to optimize area

with lower instruction throughput

C_INTERCONNECT Select interconnect

1 = PLBv46

C_ENDIANNESS Select endianness (1 = Little endian) 1

C_FAULT_TOLERANT Implement fault tolerance 0

C_LOCKSTEP_SLAVE Lockstep Slave 0

C_AVOID_PRIMITIVES Disallow FPGA primitives 0

C_PVR Processor version register mode

selection

All other PVR parameters are don’t care.

C_RESET_MSR Reset value for MSR register 0x00

C_INSTANCE Instance Name Value of MicroBlaze MCS

C_MICROBLAZE_INSTANCE

C_D_PLB Data side PLB interface.

All other data side PLB parameters are

don’t care.

C_D_AXI Data side AXI interface

All other data side AXI parameters are

don’t care.

1

1

0

parameter

0

0

C_D_LMB Data side LMB interface 1

C_I_PLB Instruction side PLB interface.

All other instruction side PLB parameters

are don’t care.

C_I_AXI Instruction side AXI interface.

All other instruction side AXI parameters

are don’t care.

C_I_LMB Instruction side LMB interface 1

C_USE_BARREL Include barrel shifter 0

C_USE_DIV Include hardware divider 0

C_USE_HW_MUL Include hardware multiplier 0

C_USE_FPU Include hardware floating point unit 0

C_USE_MSR_INSTR Enable use of instructions: MSRSET and

MSRCLR

C_USE_PCMP_INSTR Enable use of instructions: CLZ, PCMPBF,

PCMPEQ, and PCMPNE

C_USE_REORDER_INSTR Enable use of instructions: LBUR, LHUR,

LWR, SBR,SHR, SWR, SWAPB, and SWAPH

1

0

0

0

0

MicroBlaze Micro Controller System v1.3 www.xilinx.com 25

PG048 December 18, 2012

Page 27

Chapter 4: Customizing and Generating the Core

Table 4-2: Internal MicroBlaze Parameters Settings (Cont’d)

Parameter Name Feature/Description Value

C_*EXCEPTION*

C_OPCODE_0x0_ILLEGAL

C_USE_STACK_PROTECTION

C_DEBUG_ENABLED MDM Debug interface Value of MicroBlaze MCS

C_NUMBER_OF_PC_BRK Number of hardware breakpoints Value of MicroBlaze MCS

C_NUMBER_OF_RD_ADDR_BRK Number of read address watchpoints 0

C_NUMBER_OF_WR_ADDR_BRK Number of write address watchpoints 0

C_INTERRUPT_IS_EDGE Level/Edge interrupt 0

C_EDGE_IS_POSITIVE Negative/positive edge interrupt 1

(1)

No exceptions are used 0

parameter

C_DEBUG_ENABLED

parameter

C_DEBUG_ENABLED

C_FSL_LINKS Number of stream interfaces (FSL or AXI)

All other stream parameters are don’t

care

C_USE_ICACHE Instruction cache

All other instruction cache parameters

are don’t care

C_USE_DCACHE Data cache

All other data cache parameters are don’t

care

C_USE_MMU Memory management

All other MMU parameters are don’t care

C_USE_INTERRUPT Enable interrupt handling 2

C_USE_EXT_BRK Enable external break handling Value of MicroBlaze MCS

C_DEBUG_ENABLED

C_USE_EXT_NM_BRK Enable external non-maskable break

handling

C_USE_BRANCH_TARGET_CACHE Enable branch target cache

All other BTC parameters are don’t care

1. * denotes wildcard and represents any number of characters or numbers.

Value of MicroBlaze MCS

C_DEBUG_ENABLED

0

0

0

0

parameter

parameter

0

Table 4-3: Internal I/O Module Parameters Settings

Parameter Name Feature/Description Value

C_BASEADDR LMB I/O Module register base address 0x80000000

C_HIGHADDR LMB I/O Module register high address 0x8000FFFF

C_MASK LMB I/O Module register address space decode mask 0xC0000000

C_IO_HIGHADDR LMB I/O Module I/O bus base address 0xC0000000

MicroBlaze Micro Controller System v1.3 www.xilinx.com 26

PG048 December 18, 2012

Page 28

Chapter 4: Customizing and Generating the Core

Table 4-3: Internal I/O Module Parameters Settings (Cont’d)

Parameter Name Feature/Description Value

C_IO_LOWADDR LMB I/O Module I/O bus address 0xFFFFFFFF

C_IO_MASK LMB I/O Module I/O bus address space decode mask 0xC0000000

C_LMB_AWIDTH LMB address bus width 32

C_LMB_DWIDTH LMB data bus width 32

C_INTC_HAS_FAST Use fast interrupt mode 1

C_INTC_ADDR_WIDTH Interrupt address width 12 - 16

1. Value depends on C_MEMSIZE: 12 for 4096, 13 for 8192, 14 for 16384, 15 for 32768, and 16 for 65536.

.

Table 4-4: Internal LMB_v10 Parameters Settings (ILMB)

Parameter Name Feature/Description Value

C_LMB_NUM_SLAVES Number of LMB slaves 1

C_LMB_AWIDTH LMB address bus width 32

C_LMB_DWIDTH LMB data bus width 32

(1)

C_EXT_RESET_HIGH Level of external reset 1 = active-High reset

Table 4-5: Internal LMB_v10 Parameters Settings (DLMB)

Parameter Name Feature/Description Value

C_LMB_NUM_SLAVES Number of LMB slaves 2

C_LMB_AWIDTH LMB address bus width 32

C_LMB_DWIDTH LMB data bus width 32

C_EXT_RESET_HIGH Level of external reset 1 = active-High reset

Table 4-6: Internal LMB BRAM IF Controller Parameters Settings (ILMB Controller)

Parameter Name Feature/Description Value

C_BASEADDR LMB BRAM base address 0

C_HIGHADDR LMB BRAM high address Value of MicroBlaze

MCS Parameter

C_MEMSIZE

C_MASK LMB decode mask 0x80000000

C_LMB_AWIDTH LMB address bus width 32

C_LMB_DWIDTH LMB data bus width 32

C_ECC Implement error correction and detection

All other ECC as well AXI and PLB parameters are don’t

care

0 = No ECC

MicroBlaze Micro Controller System v1.3 www.xilinx.com 27

PG048 December 18, 2012

Page 29

Chapter 4: Customizing and Generating the Core

Table 4-7: Internal LMB BRAM IF Controller Parameters Settings (DLMB Controller)

Parameter Name Feature/Description Value

C_BASEADDR LMB BRAM base address 0

C_HIGHADDR LMB BRAM high address Value of MicroBlaze

MCS

Parameter C_MEMSIZE

C_MASK LMB decode mask 0x80000000

C_LMB_AWIDTH LMB address bus width 32

C_LMB_DWIDTH LMB data bus width 32

C_ECC Implement error correction and detection

All other ECC as well as AXI and PLB parameters are don’t

care

0 = No ECC

Table 4-8: MicroBlaze Debug Module Parameters Settings

Parameter Name Feature/Description Value

C_FAMILY FPGA architecture Value of MicroBlaze

MCS

Parameter C_FAMILY

C_MB_DBG_PORTS Number of MicroBlaze debug ports 1

C_USE_UART Enables the UART interface.

All other UART as well as AXI and PLB parameters are

don’t care

0

Parameter - Port Dependencies

The width of many of the MicroBlaze MCS signals depends on design parameters. The

dependencies between the design parameters and I/O signals are shown in Tab le 4 -9.

Table 4-9: Parameter-Port Dependencies

Parameter Name Ports (Port width depends on parameter)

C_INTC_INTR_SIZE INTC_Interrupt

C_GPO1_SIZE GPO1

C_GPO2_SIZE GPO2

C_GPO3_SIZE GPO3

C_GPO4_SIZE GPO4

C_GPI1_SIZE GPI1

C_GPI2_SIZE GPI2

C_GPI3_SIZE GPI3

C_GPI4_SIZE GPI4

MicroBlaze Micro Controller System v1.3 www.xilinx.com 28

PG048 December 18, 2012

Page 30

Chapter 4: Customizing and Generating the Core

Add IP

Implement

Project

Import

Hardware

Description

Import

Hardware

Create

Software

Software Development KitVivado

Implementation

Download and Run

START

Synthesize

Project

Ge ne r at e

Bitstream

Download and Run Software

or Debug Software

Simulate

Software

Executable program (program.elf)

HW description XML file (instance_sdk.xml)

Bitstream (toplevel.bit)

Associate

ELF

Files

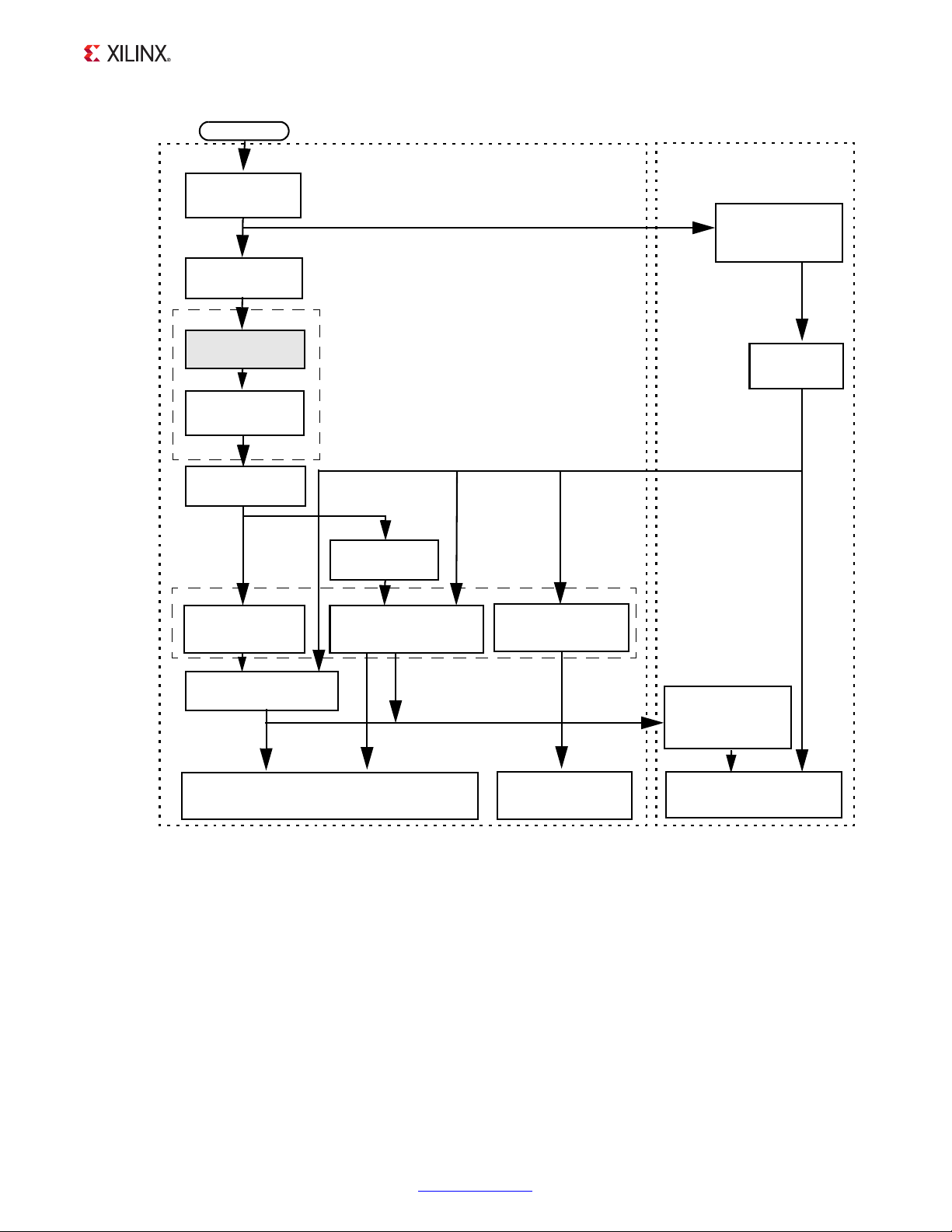

Tool Flow

The MicroBlaze MCS uses the generic tool flow of all Vivado IP. The SDK software

development flow is briefly described here.

Generic Vivado Tool Flow

The generic tool flow in Vivado is shown in Figure 4-8.

X-Ref Target - Figure 4-8

Figure 4-8: Generic Vivado Tool Flow

MicroBlaze Micro Controller System v1.3 www.xilinx.com 29

PG048 December 18, 2012

Page 31

Chapter 4: Customizing and Generating the Core

This flow shows the specific steps required to implement a project with the MicroBlaze MCS

in Vivado, and the relationship between the hardware and software tools.

• Associate ELF Files:

This is the only manual step in Vivado, performed by selecting Tools > Associate ELF

Files... in the menu. Initially, the default infinite loop ELF file, mb_bootloop_le.elf, is

associated with the MicroBlaze MCS core. ELF files for implementation and simulation

are specified separately.

Note:

by changes during software development in SDK, but need to be re-imported to apply any

changes.

The associated ELF files are imported into the project. This means that they are unaffected

The final bitstream updated with software is named download.bit, and is normally located

in the project directory project-name.runs/impl_1.

For additional information, see the Xilinx Vivado Manuals [Ref 9].

SDK

The SDK commands to achieve the MicroBlaze MCS specific steps above are detailed here:

• Import Hardware Description - For each MicroBlaze MCS component to import:

Select File > New > Project... in the menu.

°

Expand Xilinx, and select Hardware Platform Specification.

°

Click Next.

°

Click Browse, and navigate to the hardware description file:

°

- In PlanAhead™ this file is typically called project-name.srcs/sources_1/

ip/component-name/component-name_sdk.xml.

- In Project Navigator this file is typically called ipcore_dir/

component-name_sdk.xml.

Click Finish to perform the import.

°

After the hardware description has been imported, a standalone board support package

can be created, which provides MicroBlaze processor-specific code, and the I/O Module

software driver. The MicroBlaze MCS configuration is available in the generated file

microblaze_0/include/xparameters.h.

• Import Hardware Implementation:

Select Xilinx Tools > Program FPGA in the menu.

°

Click the first Browse button, and navigate to the bitstream:

°

MicroBlaze Micro Controller System v1.3 www.xilinx.com 30

PG048 December 18, 2012

Page 32

Chapter 4: Customizing and Generating the Core

-In Vivado or PlanAhead this file is typically called project-name.runs/

impl_1/toplevel.bit.

- In Project Navigator this file is typically called toplevel.bit.

Click the second Browse button, and navigate to the BMM file updated with block

°

RAM placement.

- In Vivado this file is typically called project-name.runs/impl_1/

toplevel_bd.bmm.

- In PlanAhead with one MicroBlaze MCS component, this file is typically called

project-name.srcs/sources_1/ip/component-name/

component_name_bd.bmm. With more than one MicroBlaze MCS component,

the merged BMM file updated with block RAM placement must be selected

instead.

- In Project Navigator with one MicroBlaze MCS component, this file is typically

called ipcore_dir/component_name_bd.bmm. With more than one

MicroBlaze MCS component, the merged BMM file updated with block RAM

placement must be selected instead.

Click Program to perform the import and program the FPGA.

°

For additional information, see the Xilinx SDK Help [Ref 6].

MicroBlaze Micro Controller System v1.3 www.xilinx.com 31

PG048 December 18, 2012

Page 33

Constraining the Core

Required Constraints

There are no required constraints for this core.

Device, Package, and Speed Grade Selections

There are no Device, Package or Speed Grade requirements for this core.

Chapter 5

Clock Frequencies

There are no specific clock frequency requirements for this core.

Clock Management

MicroBlaze MCS is fully synchronous with all clocked elements clocked by the Clk input.

Clock Placement

There are no specific Clock placement requirements for this core.

Banking

There are no specific Banking rules for this core.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 32

PG048 December 18, 2012

Page 34

Chapter 5: Constraining the Core

Transceiver Placement

There are no Transceiver Placement requirements for this core.

I/O Standard and Placement

There are no specific I/O standards and placement requirements for this core.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 33

PG048 December 18, 2012

Page 35

SECTION III: ISE DESIGN SUITE

Customizing and Generating the Core

Constraining the Core

MicroBlaze Micro Controller System v1.3 www.xilinx.com 34

PG048 December 18, 2012

Page 36

Chapter 6

Customizing and Generating the Core

This chapter includes information on using Xilinx tools to customize and generate the core

using the ISE® Design Suite.

GUI

The I/O Module parameters are divided in seven tabs: MCS, UART, FIT, PIT, GPO, GPI and

Interrupts. The MCS parameter tab is shown in Figure 6-1.

X-Ref Target - Figure 6-1

Figure 6-1: MCS Parameter Tab

• Instance Hierarchical Design Name - Defines the unique instance name of the core in

the design hierarchy. The path should indicate the full hierarchy from the top level. If

the core is directly instantiated at the top level, this is just the instance name.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 35

PG048 December 18, 2012

Page 37

Chapter 6: Customizing and Generating the Core

• Input Clock Frequency (MHz) - This parameter should be set to the frequency of the

core input clock in MHz. The value is used to calculate the correct UART baud rate.

• Memory Size - Defines the local memory size, used to store the MicroBlaze processor

software program instructions and data. Increase this value if the software program

does not fit in available memory.

• Enable I/O Bus - Enables I/O Bus port.

• Enable Debug Support - When debug support is enabled, it is possible to debug

software via JTAG, from Xilinx Software Development Kit (SDK) or directly using the

Xilinx Microprocessor Debugger (XMD).

• Debug JTAG User-defined Register - Specifies the JTAG user-defined register for

debug. When more than one MicroBlaze MCS instance with debug enabled is included

in the same design, a unique JTAG register must be used for each instance. When a

single instance is used, the default value USER2 should be kept unchanged.

• Enable MicroBlaze Trace Bus - This option enables the MicroBlaze Trace bus, which

provides access to several internal processor signals for trace purposes.

The UART parameter tab is shown in Figure 6-2.

X-Ref Target - Figure 6-2

Figure 6-2: UART Parameter Tab

• Enable Receiver - Enables UART receiver for character input. This is automatically

connected to standard input (stdin) in the software program.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 36

PG048 December 18, 2012

Page 38

Chapter 6: Customizing and Generating the Core

• Enable Transmitter - Enables UART transmitter for character output. This is

automatically connected to standard output (stdout) in the software program.

• Define Baud Rate - Sets the UART baud rate. To get the correct baud rate, the input

clock frequency must also be correctly defined.

• Programmable Baud Rate - Determines if the UART baud rate is programmable. The

default baud rate is calculated based on the input clock frequency and the defined

baud rate.

• Number of Data Bits - Defines the number of data bits used by the UART. Should

almost always be set to 8.

• Use Parity - Enable this parameter to use parity checking of the UART characters.

• Even or Odd Parity - Select odd or even parity. Only available when parity is used.

• Implement Receive Interrupt - Generate an interrupt when the UART has received a

character. When the interrupt is not enabled the UART must be polled to check if data

has been received.

• Implement Transmit Interrupt - Generate an interrupt when the UART has sent a

character. When the interrupt is not enabled the UART must be polled to wait until data

has been transmitted.

• Implement Error Interrupt - Generate an interrupt if an error occurs when the UART

receives a character. This error can be a framing error, an overrun error or a parity error

(if parity is used), When the interrupt is not enabled the UART must be polled to check

if an error has occurred after a character has been received.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 37

PG048 December 18, 2012

Page 39

Chapter 6: Customizing and Generating the Core

The FIT parameter tab showing the parameters for one of the four timers is shown in

Figure 6-3.

X-Ref Target - Figure 6-3

Figure 6-3: FIT Parameter Tab

• Use FIT - Enable the Fixed Interval Timer.

• Number of Clocks Between Strobes - The number of clock cycles between each

strobe.

• Generate Interrupt - Generate an interrupt for each Fixed Interval Timer strobe.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 38

PG048 December 18, 2012

Page 40

Chapter 6: Customizing and Generating the Core

The PIT parameter tab showing the parameters for one of the four timers is shown in

Figure 6-4.

X-Ref Target - Figure 6-4

Figure 6-4: PIT Parameter Tab

• Use PIT - Enable the Programmable Interval Timer.

• Number of Bits for Timer - The maximum number of cycles to count before stopping

or restarting.

• Shall Counter Value be Readable - The Programmable Interval Timer counter is

readable by software when this parameter is set.

RECOMMENDED: Unless resource usage is critical it is recommended that you keep this

enabled.

• Define Prescaler - Selects a prescaler as source for the Programmable Interval Timer

count. When no prescaler is selected the core input clock is used. Any Programmable

Interval Timer or Fixed Interval Timer can be used as prescaler, as well as a dedicated

external enable input.

• Generate Interrupt - Generate an interrupt when the Programmable Interval Timer has

counted down to zero.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 39

PG048 December 18, 2012

Page 41

Chapter 6: Customizing and Generating the Core

The GPO parameter tab showing the parameters with one of the four General Purpose

Output ports enabled is shown in Figure 6-5.

X-Ref Target - Figure 6-5

Figure 6-5: GPO Parameter Tab

• Use GPO - Enable the General Purpose Output port.

• Number of Bits - Set the number of bits of the General Purpose Output port.

• Initial Value of GPO - Set the initial value of the General Purpose Output port. The

right most bit in the value is assigned to bit 0 of the port, the next right most to bit 1,

and so on.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 40

PG048 December 18, 2012

Page 42

Chapter 6: Customizing and Generating the Core

The GPI parameter tab showing the parameters with one of the four General Purpose Input

ports enabled is shown in Figure 6-6.

X-Ref Target - Figure 6-6

Figure 6-6: GPI Parameter Tab

• Use GPI - Enable the General Purpose Input port.

• Number of Bits - Set the number of bits of the General Purpose Input port.

• Generate Interrupt - Generate an interrupt when a General Purpose Input changes.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 41

PG048 December 18, 2012

Page 43

Chapter 6: Customizing and Generating the Core

The Interrupts parameter tab is shown in Figure 6-7.

X-Ref Target - Figure 6-7

Figure 6-7: Interrupts Parameter Tab

• Use External Interrupts - Enable the use of external interrupt inputs.

• Number of External Inputs - Select the number of used external interrupt inputs.

• Level or Edge of External Interrupts - Select whether the input is considered level

sensitive or edge triggered. Each bit in the value corresponds to the equivalent

interrupt input. When a bit is set to one, the interrupt is edge triggered, otherwise it is

level sensitive.

• Positive or Negative External Interrupts - Set whether to use high or low level for

level sensitive interrupts, and rising or falling edge for edge triggered interrupts. Each

bit in the value corresponds to the equivalent interrupt input When a bit is set to one,

high level or rising edge is used, otherwise low level or falling edge is used.

• Use Low-latency Interrupt Handling - Enable the use of low-latency interrupt

handling.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 42

PG048 December 18, 2012

Page 44

Chapter 6: Customizing and Generating the Core

Parameter Values

To create a MicroBlaze™ MCS that is uniquely tailored for a specific system, certain features

can be parameterized. This makes it possible to configure a component that only uses the

resources required by the system, and operates with the best possible performance. The

features that can be parameterized in MicroBlaze MCS are shown in Tabl e 4-1 .

The internal modules of the MicroBlaze MCS have fixed configurations detailed in:

• Ta bl e 4 -2 - MicroBlaze

• Ta bl e 4 -3 - I/O Module

• Ta bl e 4 -4 and Ta ble 4 -5 - LMB v10

• Ta bl e 4 -6 and Ta ble 4 -7 - LMB BRAM IF Controller

• Ta bl e 4 -8 - MicroBlaze Debug Module

Parameter - Port Dependencies

The width of many of the MicroBlaze MCS signals depends on design parameters. The

dependencies between the design parameters and I/O signals are shown in Tab le 4 -9.

Tool Flow

The MicroBlaze MCS uses the generic tool flow of all LogiCORE™ IP. This flow requires some

manual steps in PlanAhead™ and Project Navigator primarily to support software

development. For a brief description of the SDK software flow see SDK in Chapter 4.

Generic PlanAhead and Project Navigator Tool Flow

The generic tool flow in PlanAhead and Project Navigator is shown in Figure 6-8.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 43

PG048 December 18, 2012

Page 45

X-Ref Target - Figure 6-8

Add CORE

Generator IP

Create

Merged

BMM

Implement

Project

Import

Hardware

Description

Import

Hardware

Create

Software

Software Development Kit

PlanAhead

Project Navigator

Implementation

Download

and Run

START

Update Tool

to Use BMM

Synthesize

Project

Update

Too l to

Use

Software

Ge ne r at e

Bitstream

Update

Bitstream

with

Software

Gen er at e

Bitstream

Download

and Run Software

Script

or

Debug Software

Gen er at e

Simulation

Files

Simulate

Software

Executable program (

program

.elf)

HW description XML file (

instance

_sdk.xml)

Bitstream (

toplevel

.bit)

Script

Create

Chapter 6: Customizing and Generating the Core

Figure 6-8: Generic PlanAhead and Project Navigator Tool Flow

This flow shows the specific steps required to implement a project with the MicroBlaze MCS

in PlanAhead or Project Navigator, and the relationship between the hardware and software

tools.

Each of the steps are described in general here. Specific commands used in PlanAhead, ISE

Project Navigator and Xilinx Software Development Kit (SDK) are covered in the following

sections.

• Add CORE Generator™ IP: In this step the specific MicroBlaze MCS component

parameters are defined using the configuration dialog, and the component is

generated and synthesized. Several files are created during this step:

MicroBlaze Micro Controller System v1.3 www.xilinx.com 44

PG048 December 18, 2012

Page 46

Chapter 6: Customizing and Generating the Core

component-name_sdk.xml - Hardware description of the specific component,

°

imported into SDK.

component-name.bmm - The BMM file of the specific component, which defines

°

the configuration of the block RAMs used by the component. This file is necessary

to update the bitstream with the software to be executed by MicroBlaze.

microblaze_mcs_setup.tcl - A script that is available to automate certain

°

steps in the flow.

mb_bootloop_le.elf - An infinite loop, which is the default program used to

°

update the bitstream.

Note:

frequency must be decided in this step, and adhered to when the component is later

instantiated.

The full hierarchical name of the component in the design as well as the input clock

• Create Merged BMM: This step is optional, and is only required when the project

contains more than one MicroBlaze MCS core.

The step can be performed by executing the script microblaze_mcs_setup.tcl in

the tool Tcl Console. The script creates a merged BMM file, called

microblaze_mcs_merged.bmm, which includes all MicroBlaze MCS components in

the project.

To perform the step manually, find all the MicroBlaze MCS core BMM files in the project,

and merge them using a text editor. The contents of the files can be concatenated in any

order, except that the id number at the end of each ADDRESS_MAP line (100 in the input

files) must be changed to a unique number for each ADDRESS MAP line. It is suggested

that you use the numbers 100, 200, ...

• Update Tool to Use BMM: This step informs the tool about the BMM file to use, either

the component BMM file, component-name.bmm, or he merged file from the previous

step when the project contains more than one MicroBlaze MCS core.

The step is also performed by executing the script microblaze_mcs_setup.tcl in

the tool Tcl Console. Project properties are updated to use the appropriate BMM file, by

adding a command line option to the ngdbuild command.

To perform the step manually, see the specific commands for PlanAhead or ISE Project

Navigator below.

• Implement Project: This is the normal step to create the implemented netlist.

• Update Tool to Use Software: This step informs the tool about the software

executable files to use, one for each MicroBlaze MCS component in the project. After

this step, whenever the bitstream is generated, it is updated with the contents of the

software executable files.

The step can be performed by invoking the microblaze_mcs_data2mem Tcl

procedure, with one argument for each MicroBlaze MCS component in the project,

MicroBlaze Micro Controller System v1.3 www.xilinx.com 45

PG048 December 18, 2012

Page 47

Chapter 6: Customizing and Generating the Core

indicating the corresponding software executable ELF file. Project properties are

updated to use the appropriate files, by adding a command line option to the bitgen

command.

To perform the step manually, see the specific commands for PlanAhead or ISE Project

Navigator below.

Note:

enter the ELF file arguments can be determined by first invoking the Tcl procedure without

arguments.

With more than one MicroBlaze MCS component in the project, the order in which to

• Gen erat e Bits tre am: This is the normal step to generate the bitstream, which creates

two hardware implementation files that can be imported into SDK, for running or

debugging software:

toplevel.bit - The bitstream created by the tools.

°

component-name_bd.bmm or microblaze_mcs_merged_bd.bmm - The BMM

°

file updated with block RAM placement. This file is used when updating the

bitstream with the software created in SDK.

If this step is performed after the tool has been updated to use software, the bitstream

is updated with the contents of the software executable files. If not, the bitstream can be

updated with software after it has been generated.

• Update Bitstream with Software: This step is used to update the previously generated

bitstream with all software executable files. If the software has been changed, this is the

only step necessary to modify the bitstream. It is not necessary to regenerate the

bitstream in this case.

The step is also performed by invoking the microblaze_mcs_data2mem Tcl

procedure. The procedure invokes data2mem to update the bitstream.

To perform the step manually, see the specific commands for PlanAhead or ISE Project

Navigator below.

• Gen erat e Sim ula tion Fil es: This step is used to generate MEM files used when

simulating the project. These files contain the memory content of all block RAMs used

when simulating the project. When behavioral simulation is started, the files are

automatically read by the simulator when elaborating the design.

The step is also performed by invoking the microblaze_mcs_data2mem Tcl

procedure. The procedure invokes data2mem to create the files

component-name.lmb_bram_n.mem for each MicroBlaze MCS component.

To perform the step manually, see the specific commands for PlanAhead or ISE Project

Navigator below.

• Download and Run Software: When downloading the updated bitstream to the FPGA

with impact, the software immediately starts to run as soon as reset is deactivated.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 46

PG048 December 18, 2012

Page 48

Chapter 6: Customizing and Generating the Core

• Import Hardware Description: This step is performed in SDK, using the hardware

description file component-name_sdk.xml created when the MicroBlaze MCS

component was generated. If there are more than one component in the project, a

hardware platform specification must be imported for each component.

• Import Hardware Implementation: This step is performed in SDK, using the

toplevel.bit bitstream and the component-name_bd.bmm or

microblaze_mcs_merged_bd.bmm BMM file.

• Download and Run or Debug Software: When the FPGA has been programmed,

software can be run or debugged as usual in SDK.

PlanAhead

The PlanAhead commands to achieve the MicroBlaze MCS specific steps above are detailed

here.

Using the script provided to perform the steps:

• Create Merged BMM and Update Tool to Use BMM:

In the Tcl Console type the following commands:

cd project-path

source project-name.srcs/sources_1/ip/component-name/microblaze_mcs_setup.tcl

• Update Tool to Use Software, Update Bitstream with Software and Generate

Simulation Files:

Type the following command in the Tcl Console, to perform this with one MicroBlaze

MCS component:

microblaze_mcs_data2mem /sdk-workspace-path/sdk-program/Debug/sdk-program.elf

For each additional MicroBlaze MCS component, add an additional executable ELF file

to the command line.

Performing the steps manually:

• Update Tool to Use BMM:

With one MicroBlaze MCS component, type the following command in the Tcl Console,

using the appropriate absolute directory path:

config_run [current_run] -program ngdbuild -option {More Options} -value \

{-bm /project-path/project-name.srcs/sources_1/ip/component-name/

component-name_bd.bmm}

With more than one MicroBlaze MCS component, the -bm option must indicate the

merged BMM file instead.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 47

PG048 December 18, 2012

Page 49

Chapter 6: Customizing and Generating the Core

• Update Tool to Use Software:

With one MicroBlaze MCS component, type the following command in the Tcl Console,

using the appropriate absolute directory path:

config_run [current_run] -program bitgen -option {More Options} -value \

{-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name}

With more than one MicroBlaze MCS component, the -bd option must be repeated for

each component.

• Update Bitstream with Software:

To perform this step with one MicroBlaze MCS component, invoke data2mem with, for

example, the following command line options, using the appropriate directory paths to

the indicated files:

cd project-path

data2mem -p part \

-bm project-name.srcs/sources_1/ip/component-name/component-name_bd.bmm \

-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name \

-bt project-name.runs/impl_1/toplevel.bit \

-o b project-name.runs/impl_1/download.bit

Here part is the complete part name, consisting of device, package, and speed

concatenated.

With more than one MicroBlaze MCS component, the -bm option must indicate the

merged BMM file.updated with block RAM placement.

For each additional MicroBlaze MCS component, the -bd option has to be repeated,

followed by the appropriate executable ELF file, the keyword tag, and the component

name.

• Gen erat e Sim ula tion Fil es:

To perform this step manually with one MicroBlaze MCS component, invoke data2mem

with, for example, the following command line options, using the appropriate directory

paths for the indicated files:

cd project-path

data2mem -p part \

-bm project-name.srcs/sources_1/ip/component-name/component-name.bmm \

-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name \

-bx project-name.sim/sim_1 -u

Here part is the complete part name, consisting of device, package, and speed

concatenated.

For each additional MicroBlaze MCS component, the -bd option has to be repeated,

followed by the appropriate executable ELF file, the keyword tag, and the component

name.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 48

PG048 December 18, 2012

Page 50

Chapter 6: Customizing and Generating the Core

If the output directory indicated by the -bx option does not exist, it has to be created

manually.

For additional information, see the Xilinx PlanAhead Manuals [Ref 8].

Project Navigator

The Project Navigator commands to achieve the MicroBlaze MCS specific steps above are

detailed here.

Using the provided script to perform the steps:

• Create Merged BMM and Update Tool to Use BMM:

If the Tcl Console is not visible, select View > Panels > Tcl Console in the menu.

°

In the Tcl Console type the following command:

°

source ipcore_dir/microblaze_mcs_setup.tcl

• Update Tool to Use Software, Update Bitstream with Software and Generate

Simulation Files:

Type the following command in the Tcl Console, to perform this with one MicroBlaze

MCS component:

microblaze_mcs_data2mem /sdk-workspace-path/sdk-program/Debug/sdk-program.elf

For each additional MicroBlaze MCS component, add an additional executable ELF file

to the command line.

Performing the steps manually:

• Update Tool to Use BMM:

With one MicroBlaze MCS component, type the following command in the Tcl Console:

project set {Other Ngdbuild Command Line Options} {-bm ipcore_dir/

component-name_bd.bmm}

With more than one MicroBlaze MCS component, the -bm option must indicate the

merged BMM file instead.

• Update Tool to Use Software:

With one MicroBlaze MCS component, type the following command in the Tcl Console,

using the appropriate absolute directory path:

project set {Other Bitgen Command Line Options} \

{-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name}

MicroBlaze Micro Controller System v1.3 www.xilinx.com 49

PG048 December 18, 2012

Page 51

Chapter 6: Customizing and Generating the Core

With more than one MicroBlaze MCS component, the -bd option must be repeated for

each component.

• Update Bitstream with Software:

To perform this step with one MicroBlaze MCS component, invoke data2mem with, for

example, the following command line options, using the appropriate directory paths to

the indicated files:

cd project-path

data2mem -p part \

-bm ipcore_dir/component-name_bd.bmm \

-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name \

-bt project-name.runs/impl_1/toplevel.bit \

-o b project-name.runs/impl_1/download.bit

Here part is the complete part name, consisting of device, package, and speed

concatenated.

With more than one MicroBlaze MCS component, the -bm option must indicate the

merged BMM file, updated with block RAM placement.

For each additional MicroBlaze MCS component, the -bd option has to be repeated,

followed by the appropriate executable ELF file, the keyword tag, and the component

name.

• Gen erat e Sim ula tion Fil es:

To perform this step manually with one MicroBlaze MCS component, invoke data2mem

with, for example, the following command line options, using the appropriate directory

paths for the indicated files:

cd project-path

data2mem -p part \

-bm ipcore_dir/component-name.bmm \

-bd /sdk-workspace-path/sdk-program/Debug/sdk-program.elf tag component-name \

-bx . -u

Here part is the complete part name, consisting of device, package, and speed

concatenated.

For each additional MicroBlaze MCS component, the -bd option has to be repeated,

followed by the appropriate executable ELF file, the keyword tag, and the component

name.

For additional information, see the Xilinx ISE Manuals [Ref 7].

MicroBlaze Micro Controller System v1.3 www.xilinx.com 50

PG048 December 18, 2012

Page 52

Constraining the Core

Clock Management

MicroBlaze MCS is fully synchronous with all clocked elements clocked by the Clk input.

Chapter 7

MicroBlaze Micro Controller System v1.3 www.xilinx.com 51

PG048 December 18, 2012

Page 53

SECTION IV: APPENDICES

Application Software Development

Debugging

Additional Resources

MicroBlaze Micro Controller System v1.3 www.xilinx.com 52

PG048 December 18, 2012

Page 54

Appendix A

Application Software Development

Xilinx Software Development Kit

MicroBlaze MCS can be used with the Xilinx Software Development Kit (SDK), in the same

way as any embedded system.

The specific steps needed with MicroBlaze MCS are described in SDK in Chapter 4.

Device Drivers

The I/O Module is supported by the I/O Module driver, included with Xilinx Software

Development Kit.

MicroBlaze Micro Controller System v1.3 www.xilinx.com 53

PG048 December 18, 2012

Page 55

Debugging

This appendix includes details about resources available on the Xilinx Support website and

debugging tools. In addition, this appendix provides a step-by-step debugging process to

guide you through debugging the MicroBlaze MCS core.

The following topics are included in this appendix:

• Finding Help on Xilinx.com

• Debug Tools

• Troubleshooting

• Simulation Debug

• Hardware Debug

Appendix B

Finding Help on Xilinx.com

To help in the design and debug process when using the MicroBlaze MCS, the Xilinx

Support web page (www.xilinx.com/support) contains key resources such as product

documentation, release notes, answer records, information about known issues, and links

for opening a Technical Support WebCase.

Documentation

This product guide is the main document associated with the MicroBlaze MCS. This guide,

along with documentation related to all products that aid in the design process, can be

found on the Xilinx Support web page (www.xilinx.com/support

Documentation Navigator.

Download the Xilinx Documentation Navigator from the Design Tools tab on the Downloads

page (www.xilinx.com/download