Xerox DocuColor 2060

NPS/IPS

Guide to Performing Routine Maintenance

721P90561

Version 8.0

October 2002

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

©2002 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of copyrightable

material and information now allowed by statutory or judicial law or hereinafter

granted, including without limitation, material generated from the software

programs which are displayed on the screen, such as icons, screen displays,

looks, etc.

Printed in the United States of America.

Publication number: 721P90561

Xerox® and all Xerox products mentioned in this publication are trademarks of

Xerox Corporation. Products and trademarks of other companies are also

acknowledged.

Changes are periodically made to this document. Changes, technical

inaccuracies, and typographic errors will be corrected in subsequent editions.

Table of contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Ozone information: U. S. only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Operation safety: U. S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Operation safety: Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Warning markings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ix

Electrical supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Operator accessible areas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Before cleaning your product . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

CE mark: Europe only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Radio and telecommunications equipment directive (Europe only) . . . . xii

For further information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Related publications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

1. Feeder trays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Guidelines for loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Loading paper trays 1, 2, or 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Loading paper tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Selecting the paper weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Loading special stock in tray 4 . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Tabbed inserts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Drilled paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Non-standard size paper . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Letterhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Coated paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Guide to Performing Routine Maintenance iii

Table of contents

2. Stackers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Unloading the HCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Unloading the HCSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Loading staples in the HCSS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

3. Fuser oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

4. Inks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

5. Waste dry ink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

6. Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6-1

Cleaning the keyboard, monitor, and the exterior of the printer controller .

6-1

Cleaning the 4mm cartridge tape drive . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Cleaning the touch screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Cleaning the printer and the optional devices . . . . . . . . . . . . . . . . . . . . 6-3

7. Default settings for the printer engin e. . . . . . . . . . . . . . . . . . . . . .7-1

Accessing the Tools mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Setting the initial screen to display . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Setting the system timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Accessing the timers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

Power Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Job Spacing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Tools Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Auto Resume Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Setting the audio tone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-12

Setting the system productivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-13

Setting the paper registration adjustment . . . . . . . . . . . . . . . . . . . . . . 7-14

Measuring misregistration . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-15

Adjusting the paper registration . . . . . . . . . . . . . . . . . . . . . . . . 7-16

Setting date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Setting the date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-19

Setting the time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-20

Setting the language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-21

Setting for printing on non- standard or oversize paper . . . . . . . . . . . . 7-22

Setting for printing on non-standard paper size . . . . . . . . . . . . 7-22

Setting for printing on oversize paper . . . . . . . . . . . . . . . . . . . . 7-23

Setting the decurler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-24

Decurler specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-25

Changing the decurler setting . . . . . . . . . . . . . . . . . . . . . . . . . . 7-26

iv Guide to Performing Routine Maintenance

Table of conte nts

8. Maintenance and support s e rvices . . . . . . . . . . . . . . . . . . . . . . . .8-1

Xerox Customer Service Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Xerox Documentation and Software Services . . . . . . . . . . . . . . . . . . . . 8-1

Xerox Font Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Operator training . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Xerox Customer Education . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Reporting billing meters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Guide to Performing Routine Maintenance v

Table of contents

vi Guide to Performing Routine Maintenance

Laser safety

Safety

WARNING

Adjustments, use of controls, or performance of procedures

other than those specified herein may result in hazardous

light exposure.

The Xerox DocuColor printers are certified to comply with the

performance stan dards of the U.S. Department of Health,

Education, and Welfare for Class 1 laser products. Class 1 laser

products do not emit hazardous radiation. The DocuColor

printers do not emit hazardous radiation because the laser beam

is completely enclosed during all modes of customer operation.

The laser danger labels on the system are for Xerox service

representatives and are on or near panels or shields that must

be removed with a tool.

DO NOT REMOVE LABELED PANELS OR PANELS NEAR

LABELS. ONLY XEROX SERVICE REPRESENTATIVES HAVE

ACCESS TO THESE PANELS.

vii

Safety

Ozone information: U. S. only

This product produces ozone during normal operation. The

amount of ozone produced depends on copy volume. Ozone is

heavier than air. The environmental parameters specified in the

Xerox installation instructions ensure that concentration levels

are within safe limits. If you need additional informat ion

concerning ozone, call 1-800-828-6571 to request the Xerox

publicat ion 600P83222,

Operation safety: U. S.

Your Xerox equipment and supplies have been designed and

tested to meet strict safety requirements. They have been

approved by safety agencies, and they comply with

environmental standards. Please observe the following

precautions to ensure your continued safety.

OZONE

.

WARNING

Improper connection of the equipment grounding conductor

may result in risk of electrical shock.

• Always connect equipment to a properly grounded electrical

outlet. If in doubt, have the outlet checked by a qualified

electrician.

• Never use a g r oun d adapter plug to connect equip m ent to an

electrical outlet that lacks a ground connection terminal.

• Always place equipment on a solid support surface with

adequate strength for its weight.

• Always use materials and supplies specifically designed for

your Xerox equipment. Use of unsuitable materials may result

in poor performance and may create a hazardous situation.

• Never move either the printer or the printer controller without

first contacting Xerox for approval.

• Never attempt any maintenance that is not specifically

described in this documentation.

• Never remove any covers or guards that are fastened with

screws. Th ere are no oper ator-serviceable areas within these

covers.

• Never override electrical or mechanical interlocks.

viii Guide to Performing Routine Maintenance

• Never use supplies or cleaning materials for other than the i r

intended purposes. Keep all materials out of the reach of

children.

• Never operate the equipment if you notice unusual noises or

odors. Disconnect the power cord from the electrical outlet

and call service to correct the problem.

If you need any additional safety information concerning the

equipment or materials Xerox supplies, call Xerox Product Safety

at the following toll-free number in the United States:

1-800-828-6571

For customers outside the United States, contact your loc al

Xerox representative or operating company.

Operation safety: Eur o pe

Safety

This Xerox product and supplies are manufactured, test ed and

certified to strict safety regulations, electromagnetic regulations

and established environmental standards.

Any unauthorised al teration, which may include the addition of

new functions or conn ection of external devices, may impact the

product certification.

Please contact your Xerox representative for more information.

Warning markings

All warning ins tructions ma rked on or supplied with the product

should be followed.

This WARNING alerts users to areas of the product where there

is the possibility of personal damage.

This WARNING alerts users to areas of the product where there

are heated surf ace s, which should not be touched.

Guide to Performing Routine Maintenance ix

Safety

Electrical supply

This product shall be operated from the type of electrical supply

indicated on the product’s data plate label. If you are not sure

that your electrical supply meet s the requirem ents, please

consult your local power co mpany for advice.

WARNING

This product must b e connected t o a protectiv e earth circuit. This

product is supplied with a plug that has a protective earth pin.

This plug will fit only into an earthed electrical outlet. This is a

safety f eature . Always co nnect equipment to a properly gr ounded

electrical outlet. If in doubt, ha ve the ou tlet check ed b y a qualified

electrician.

To disconnect all electrical power to the product, the disconnect

device is the power cord. Remove the plug from the electrical

outlet.

Ventilation

Slots and ope ning in the enclosure of the product are provid ed

for ventilation. Do not block or cover the ventilation vents, as this

could result in the product overheating.

This product should not be placed in a built-in installation unless

proper ventilation is provided, please contact your Xerox

representative for advice.

Never push objects of any kind into the ventilation vents of the

product.

Operator accessible areas

This product has been designed to restrict operator access to

safe areas only. Operator access to hazardous areas is

restricted with covers or guards, which would require a tool to

remove. Never remove these covers or guards.

x Guide to Performing Routine Maintenance

Maintenance

Any operator product maintenance procedures will be described

in the user docume ntation supplied with the product. Do not

carry out any maintenance on the product, which is not

described in the customer documentation.

Before cleaning your product

Before cleaning this product, unplug the product from the

electrical outlet. Always use materials specifically designated for

this product, the use of other materials may result in poor

performance and may create a hazardous situation. Do not use

aerosol cleaners , they may be flammable under certain

circumstances.

Safety

CE mark: Europe only

January 1, 1995: Council Directive 73/23/EEC, amended by

Council Directive 93/68/EEC, approximation of the laws of the

member states related to low voltage equipment.

January 1, 1996: Council Directive 89/336 /EEC, approximation

of the laws of the member states related to electr omagnetic

compatibility.

March 9, 1999: Council Directive 99/5/EC, on radio equipment

and telecommunications terminal equipment and the mutual

recognition of their conformity.

A full declaration of conformity, defining the relevant directives

and referenced standards, can be obtained from your Xerox

representative.

In order to allow this equipment to operate in proximity to

Industrial, Scientific and Medical (ISM) equipment, the external

radiation for the ISM equipment may have to be limited or special

mitigation measures taken.

This is a Class A product. In a domestic environment this product

may cause radio frequency interference, in which case the user

may be required to take adequate measures.

Shielded interface cables must be used with this pr oduct to

maintain compliance with Council Directive 89/36/EEC.

Guide to Performing Routine Maintenance xi

Safety

Radio and telecommunications equipment directive (Europe only)

Certification to 1999/5/EC Radio Equipment and

Telecommunications Terminal Equipment Directive:

This Xerox product has been self-certified by Xerox for panEuropean single terminal connection to the analog public

switched telephone network (PSTN) in accordance with Directive

1999/5/EC.

The product has been design ed to w ork with the nation al PSTNs

and compatible PBXs of th e following countries:

Austria Germany Luxembourg Sweden

Belgium Greece Netherlands Switzerland

Denmark Iceland Norway United Kingdom

Finland Ireland Portugal

France Italy Spain

In the event of problems, contact y our local Xe ro x r epres entative

in the first instance.

This product has bee n tested to, and is compliant with, TBR2 1, a

specification for terminal equipment for use on analog switched

telephone networks in the European Economic area.

The product may be configured to be compatible with other

country networks. Please contact your Xerox representative if

your product needs to be reconnected to a network in another

country. This product has no us er-adjustable settings.

NOTE: Although this product can use either loop disconnect

(pulse) or DTMF (tone) signaling, it should be set to use DTMF

signaling. DTMF signaling provides reliable and faster call setup.

Modification or connection to external control software, or to

external control apparatus not authorized by Xerox, invalidates

its certification.

xii Guide to Performing Routine Maintenance

For further information

For more information on Enviro nment, Health and Safety in

relation to this Xerox product and supplies, please contact the

following customer help lines:

Europe:+44 1707 353434

USA:1 800 8286571

Canada:1 800 8286571

Safety

Guide to Performing Routine Maintenance xiii

Safety

xiv Guide to Performing Routine Maintenance

About this guide

Introduction

This guide provides information on how to perform basic

maintenance tasks on the Xerox DocuColor 2060 NPS/IPS.

This guide is designed for Xerox DocuColor 2060 NPS/IPS

operators whose job consists of operating each of the system

components, running print jobs, solving simple system prob lems,

and performing basic maintenance tasks, such as replenishing

printer supplies.

Refer to the entire list of documentation in th e “Related

publications” section for information on other tasks required for

printing with your NPS/IPS printer.

Contents

Users should have an understanding of printer controller

operations.

Before using this guide, become familiar with its contents and

conventions.

This section lists the contents of this guide.

• Chapter 1, “Feeder trays,” explains how to load paper in the

feeder trays and indicate the paper weight.

• Chapter 2, “Stackers” explains how to unload the optional

HCS and HCSS, and how to load staples in the HCSS.

• Chapter 3, “Fuser oil,” explains how to add fuser oil.

• Chapter 4, “Inks,” explains how to replace a dry ink cartridge.

• Chapter 5, “W ast e dry ink,” expl ains ho w to replac e the w aste

dry ink/toner bottle.

• Chapter 6, “Cleaning,” provides instructions on how to clean

the various printing system components.

Guide to Performing Routine Maintenance xv

Introduction

Conventions

• Chapter 7, “Default settings for the printer engine,” explains

how to change the defa ult settings through the Tools mode on

the control panel.

• Chapter 8, “Maintenance and support services,” provides

information on how to call for service, order documentation,

and report meter readings.

An index is provided at the back of the guide.

This guide uses the following conventions:

• All caps and angle brackets: Withi n procedures , the names

of keys are shown in all caps within angle brackets (for

example, press <ENTER>).

• Angle brackets: Variable information, or the positi on of a

specified argument in the command syntax, appears in angle

brackets (for example, List Fonts <Pattern>).

• Bold: Within procedures , te xt and number s that you e nter are

shown in bold (for example, enter privilege operator).

• The word “enter” within pr ocedures: The two-step process

of keying in data and p ressing <ENT ER> (for example,

enter y).

• Italics: Document and library names are shown in italics (for

example, the

Print Jobs

• Quotation marks: Keywords you can enter as arguments

appear in quotes (for example, “USLetter”).

• Vertical bars: Alternatives to specifie d argum e nts ar e

separated by vertical bars (for example, Set Time <Time |

Remote Host Name | IP Address>).

Xerox DocuPrint NPS/IPS Guide to Managing

).

xvi Guide to Performing Routine Maintenance

NOTE: Notes are hints that h elp you perform a task or

understand the text.

Cautions alert you to an a ction that could damage hardware or

software.

Warnings alert you to conditions that may affect the safety

of people.

Related publications

The Xerox DocuColor NPS/IPS documentation set includes the

documents listed below.

Introduction

CAUTION

WARNING

NOTE: For a list of IBM reference manuals for IPDS printi ng,

refer to the Solutions Guide for IPDS Printing.

•

Guide to Configuring and Managing the System

•

Guide to Managing Print Jobs

•

Guide to Performing Routine Maintenance

•

Guide to Submitting Jobs from the Client

•

Guide to Using Page Description Language

•

Installation Planni ng Guid e

•

System Overview Guide

•

Troubleshooting Guide

•

Solutions Guide for IPDS Printing

•

Decomposition Service and Tools Guide

•

Glossary

•

Master Index

•

Customer Information Quick Reference Card

s

•

Printer Contr oller Commands Quic k Reference Card

•

Operator Quick Reference Card

•

Submitting your Jobs from Macintosh Quick Reference Card

•

Submitting your Jobs from UNIX & DOS Quick Reference

Card

Guide to Performing Routine Ma intenance xvii

Introduction

•

Submitting your Jobs from Windows NT 4.0 (QuickPrint)

Quick Reference Card

•

Submitting your Jobs Using Windows NT 4.0 Drivers Quick

Reference Card

The documentation set also includes an electronic version, the

DocuPrint NPS/IPS Interactive Custome r Documenta tion CD.

xviii Guide to Performing Routine Maintenance

Loading paper

1. Feeder trays

This chapter explains how to load paper in the feeder trays and

indicate the paper weight.

It is important to load paper properly in the trays to prevent jams

and loss of production time. The following guidelines will help

ensure maximum efficiency of your printer operation.

NOTE: When loading paper in the printer, you must use the

procedure to set trays at the printer controller:

• If you are using the command line interface (CLI), refer to the

Guide to Configuring and Managing the System.

• If you are using the g raph ical user inter fa ce (GUI), ref er t o the

online help.

Guidelines for loading paper

When you are loading the paper, follow these guidelines to

prevent paper jams:

• Remove damaged sheet s.

• Load the paper with the package wrapper seam side up.

• Make sure that the direction of the curl is consistent.

• Avoid fanning the paper unless the stock is predrilled.

• Do not load the paper above the MAX line on the Edge

Guide.

• Place any paper left in the bottom of the tray on top of the

new paper stack.

• When loading predrilled paper, fan the paper and remove

loose paper plugs.

• Load all media of the same size in the same orientation (SEF

or LEF).

Guide to Performing Routine Maintenance 1-1

Feeder trays

Loading paper trays 1, 2, or 3

Be sure to use the tray weight indicator to specify the correct

weight. This is essential for correct paper handling. For tray 3,

you must also set the paper size (Non Standard or Standard),

and the paper type (Coated or Unco ate d) .

NOTE: The paper weight you specify using the tray weight

indicator may be a different number than the one specified using

the procedure to set trays at the printer controller. This is

because you must specify weight in grams per square meter

(gsm, or g/m2) at the printer, but you can specify weight using

any unit of measurement at the printer controller.

To load paper tray 1, 2, or 3:

1. Pull out the tray slowly until it stops.

2. Load the correct siz e paper i nto the tra y in the correct f eeding

orientation. Refer to the orientation labels on each tray. Do

not load materials above the MAX line located on the edge

guide.

NOTE: In all trays that have the same size media, the m edi a

must be loaded in the same orientation (SEF or LEF).

• Load the paper seam side (the side where the ream of

paper is sealed) down in tray 1 and tray 2.

Figure 1-1. Paper orientation for trays 1 and 2

1-2 Guide to Performing Routine Maintenance

Feeder trays

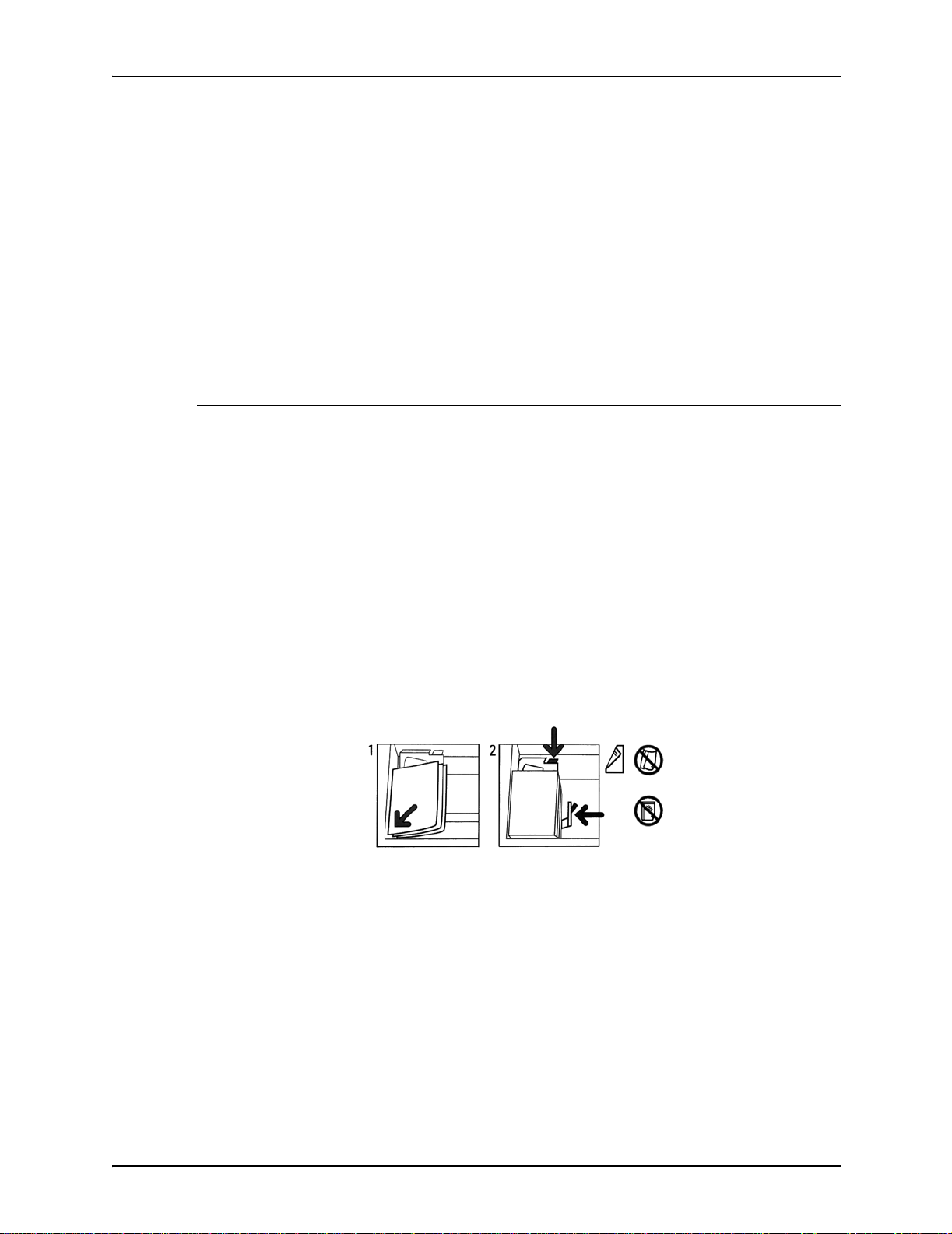

• Load the paper seam side (the side where the ream of

paper is sealed) up in tray 3.

Figure 1-2. Paper orientation for tray 3

NOTE: Many suppliers use arrows on the product labels to

indicate the preferred side to image first. Use this side (as

signaled by the arrow) as equivalent to the seam side whe n

loading the paper.

3. Adjust the paper gu i de s by pressing in the guide release an d

carefully moving the Edge Guide until it lightly touches the

edge of the material in the tray.

4. Select the paper wei ght .

Although the trays have auto size detection capability, the

paper weight (gsm) range must be selected on the Weight

Indicator . Sele cting the correct pape r weig ht range aff ects the

feed performance and image quality. Press the selection

button until the light next to the correct weight is illuminated.

Tray 1 has a chart that converts pounds into g sm for easy

selection, or refer to the conversion tables in the section

“Selecting the paper weight” later in this chapter.

Guide to Performing Routine Maintenance 1-3

Feeder trays

NOTE: The Indicator light illuminates for the paper weight

that you select. The Indicator is on the printer frame to the

right of the tray and can be seen on ly when the tray is pulled

out.

Figure 1-3. Paper trays 1 and 2 weight indicator on the

frame

5. For tray 3 only: Select the paper size (Non Standard or

Standard), and the paper type (Coated or Uncoated).

Figure 1-4. Paper tray 3 Indicator

6. Close the tray slowly to avoid shifting the paper stack.

NOTE: If you hear paper being crumpled or torn, stop

closing the tray. Remove all pieces of any damaged paper

and close the tra y slowly.

1-4 Guide to Performing Routine Maintenance

Loading paper tray 4

NOTE: In all trays that have the same size media, the media

must be loaded in the same orientation (SEF or LEF).

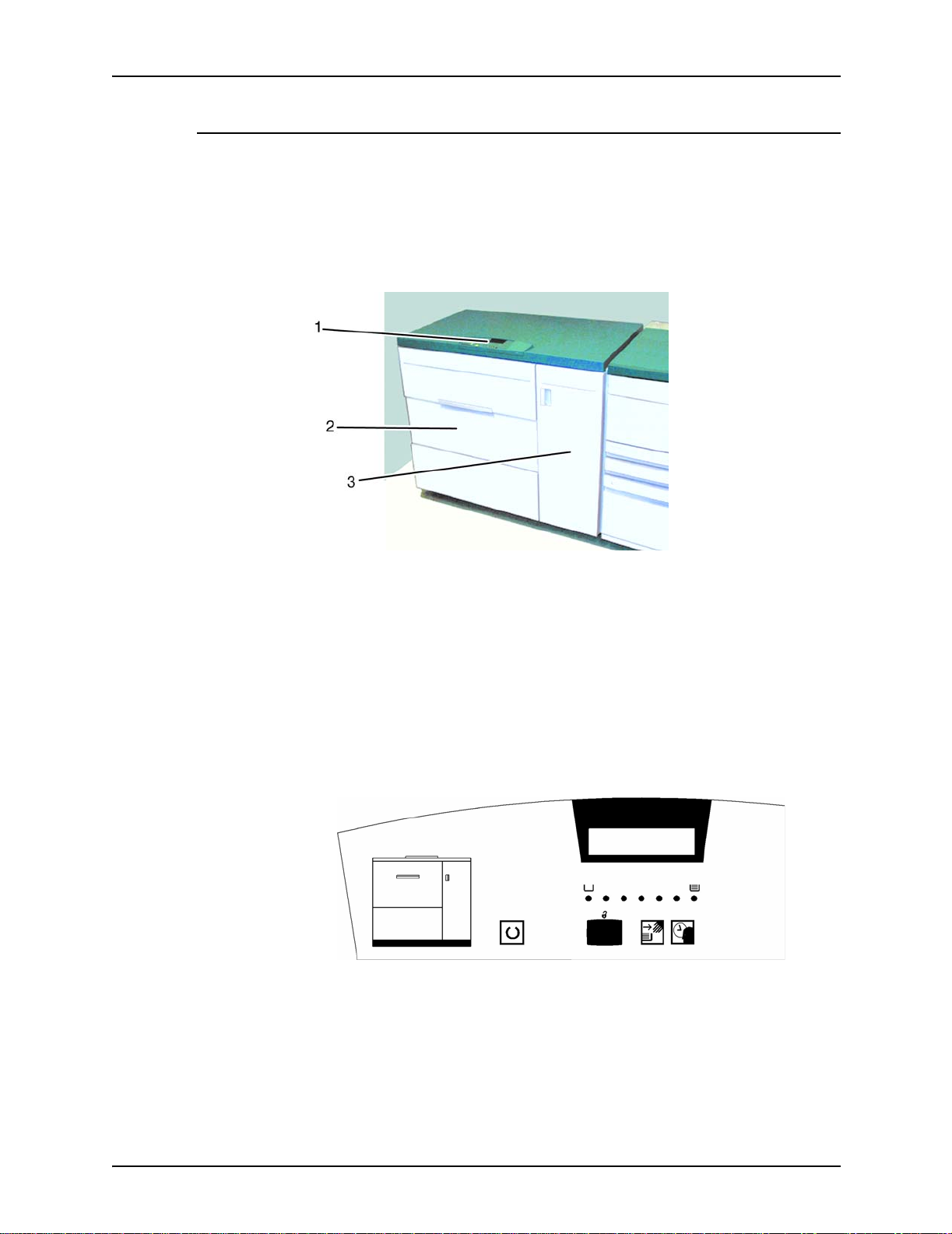

Tray 4 , the op ti on al hi gh cap aci ty pa pe r t r ay, is operated through

the control panel.

Feeder trays

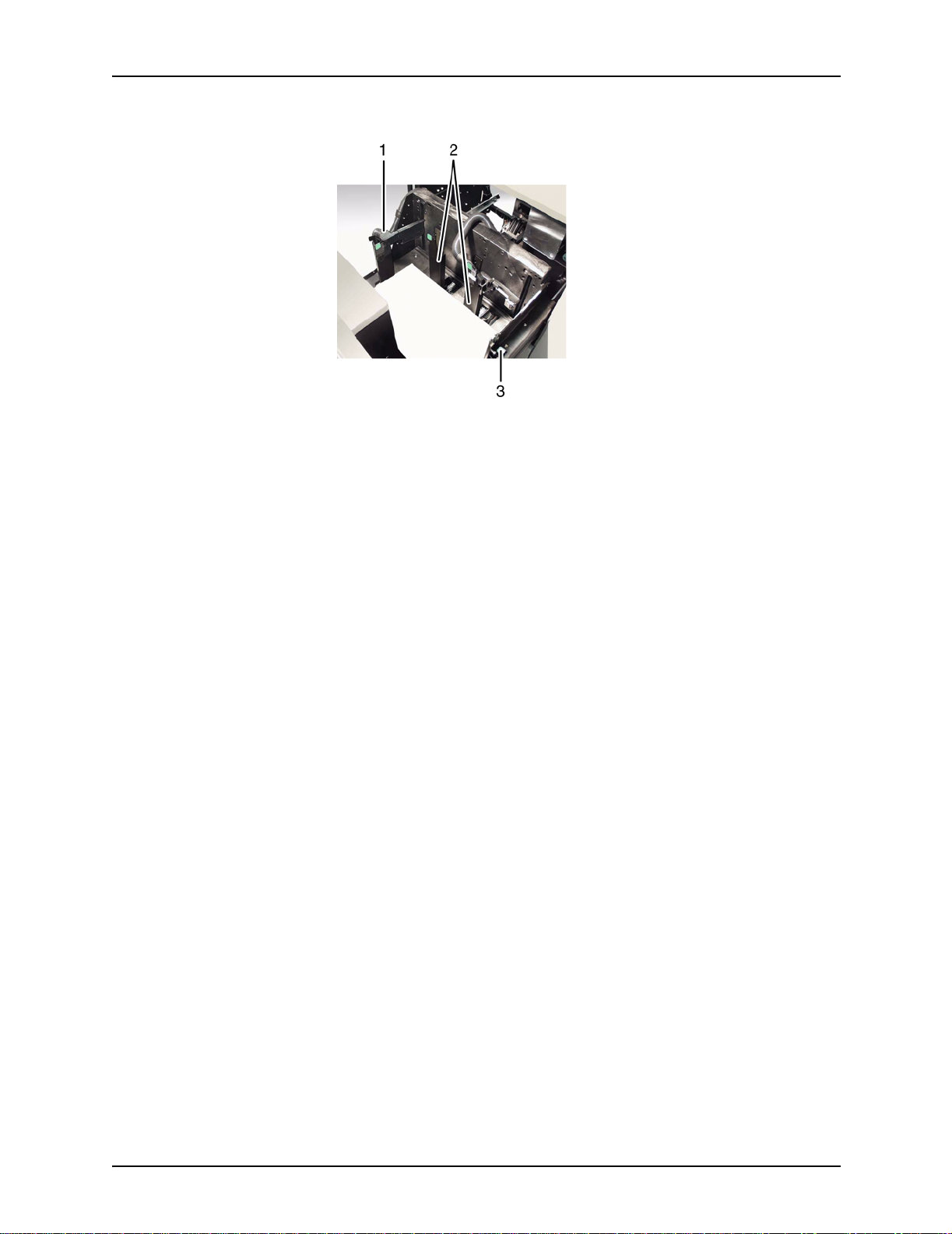

Figure 1-5. Tray 4

1. Control panel

2. Left door

3. Right door

To load paper tray 4:

1. Press the Tray Unlock button on the tray 4 control panel.

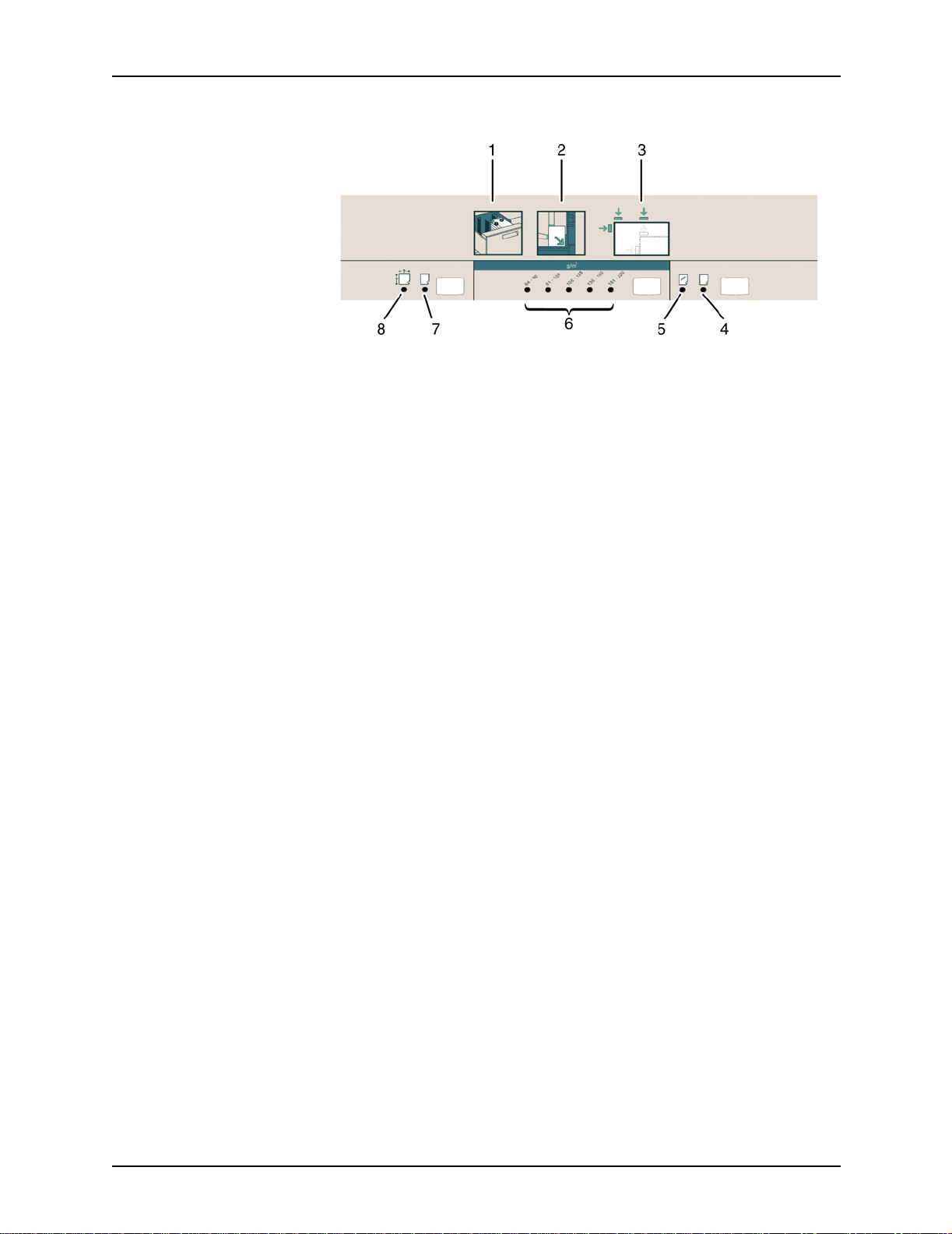

Figure 1-6. Tray Unlock button on tray 4 control panel

Guide to Performing Routine Maintenance 1-5

Feeder trays

2. Wait until the Ready to Open indicator is illuminated.

Figure 1-7. Ready to Open indicator on tray 4 control

panel

3. Open the tray 4 door.

Figure 1-8. Tray 4 door open

4. Remove any remaining sheets from the elevator tray if you

are changing paper stock.

5. Load the paper sea m sid e ( th e side where the ream of paper

is sealed) up in tray 4.

Load the paper onto the elevator tray with the sheets even

against the front an d le ad edg e regi stra tion gu ides. Do not fill

above the MAX line. Ensure that the side edge and end

guides are against the paper. Incorrect loading of paper can

result in excessive sheet skew, misfeeds, or multiple feeds

due to paper guides not being aligned properly.

1-6 Guide to Performing Routine Maintenance

Figure 1-9. Tray 4 paper guides

1. Side guide

2. End guides

Feeder trays

3. Front edge paper stop

NOTE: The Front Edge Paper Stop button has no functional

use on the Xerox DocuColor 2060 NPS/IPS.

6. Select the paper wei ght .

Although the trays have auto size detection capability, the

paper weight (gsm) range must be selected on the weight

indicator. Selecting the correct paper weight range affects the

feed performance and image quality. Press the selection

button until the light next to the correct weight is illuminated.

Refer to the version tables in the section “Selecting the paper

weight” later in this chapter.

NOTE: The Indicator light illuminates for the paper weight

selected. The Indicator light is on the printer fram e to the right

of the tray and can only be seen when the tray is pulled out.

7. Select the paper size (Non Standard or Standard), and the

paper type (Coated or Uncoated).

Guide to Performing Routine Maintenance 1-7

Feeder trays

Figure 1-10. Paper tray 4 Indicator

1. Paper guides

2. Orientat ion

3. Paper guides

4. Uncoated

5. Coated

6. Weights

7. Standard size

8. Non-standard size

8. Close the tray 4 door.

The elevator tray automatically rises and stops at the correct

feeding height.

NOTE: If you hear paper being crumpled or torn, stop

closing the tray. Remove all pieces of any damaged paper

and close the tra y slowly.

1-8 Guide to Performing Routine Maintenance

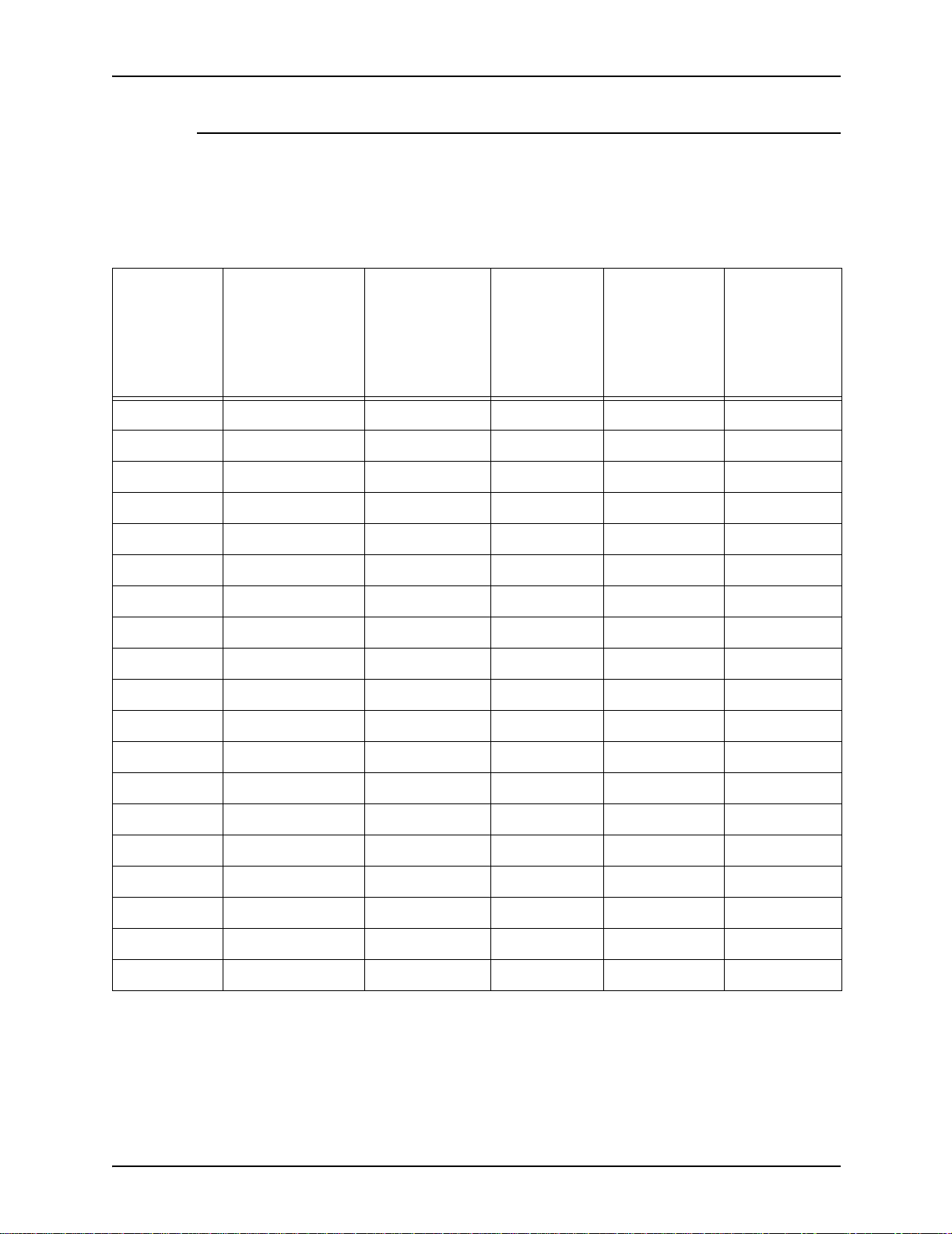

Selecting the paper weight

When loading paper in the trays, you must select the paper

weight. The following tables list the conversion figures from gsm

to pounds for specific weights and for weight ranges.

Table 1-1. Specific weight conver sion

Feeder trays

Xerographic

bond and

writing (pounds)

Grams per

square

meter (gsm)

50 13 34 18 28 23

60 16 41 22 33 27

64 17 43 24 35 29

75 20 50 28 41 34

80 21 54 30 44 36

90 24 60 33 50 41

105 28 70 39 58 48

120 32 80 44 66 55

135 35 90 50 75 62

150 40 100 55 83 67

158 42 107 58 87 72

17 x 22 inch, 500

sheets

Offset, text,

and book

(pounds)

25 x 38 inch,

500 sheets

Cover

(pounds)

20 x 26 inch,

500 sheets

Index

(pounds)

25.5 x 30.5

inch, 500

sheets

Bristol and

tag (pounds)

22.5 x 28.5

inch, 500

sheets

163 43 110 60 90 74

176 47 119 65 97 80

200 53 135 74 110 91

203 54 137 75 112 93

216 57 146 80 119 98

220 59 149 81 122 100

259 66 169 92 140 114

280 74 189 104 155 128

Guide to Performing Routine Maintenance 1-9

Loading...

Loading...