Page 1

Printing Guide

English

653-00298A

CXP6000 Color Server for

DocuColor 2060/2045

version 3.0

www.creo.com

Page 2

Page 3

CXP6000 Color Server for DocuColor 2060/2045

version 3.0

Printing Guide

Page 4

This Page is Intentionally Left Blank

Page 5

Copyright

Trademarks

Copyright © 2003 Creo Inc. All rights reserved.

No copying, distribution, publication, modification, or incorporation of this document, in whole or part, is

permitted without the express written permission of Creo. In the event of any permitted copying, distribution,

publication, modification, or incorporation of this document, no changes in or deletion of author attribution,

trademark legend, or copyright notice shall be made.

No part of this document may be reproduced, stored in a retrieval system, published, used for commercial

exploitation, or transmitted, in any form by any means, electronic, mechanical, photocopying, recording, or

otherwise, without the express written permission of Creo Inc.

This document is also distributed in Adobe Systems Incorporated's PDF (Portable Document Format). You may

reproduce the document from the PDF file for internal use. Copies produced from the PDF file must be

reproduced in whole.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Creo wordmark, Creo logo, and the names of the Creo products and services referred to in this document are

trademarks of Creo Inc.

Adobe, Acrobat, the Acrobat logo and PDF are registered trademarks of Adobe Systems Inc., and are registered in

the US Patents and Trademark Office and may be registered in other jurisdictions.

Apple, AppleTalk, AppleShare, EtherTalk, LocalTalk, Macintosh, and Laserwriter are trademarks of Apple

Computer Inc.

Microsoft, Microsoft Windows NT, Microsoft Windows 2000, Microsoft Windows 98, Microsoft Windows XP,

Microsoft Windows ME and Windows are trademarks or registered trademarks of Microsoft Corp.

Xerox is a registered trademark of Xerox Corp.

Other brand or product names are the trademarks or registered trademarks of their respective owners.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC Compliance

The Creo equipment referred to in this document complies with the requirements in Part 15 of FCC Rules for a

Class A computing device. Operation of the Creo equipment in a residential area may cause unacceptable

interference to radio and TV reception, requiring the operator to take whatever steps are necessary to correct the

interference.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limitation of Liability

The product, software or services are being provided on an "as is" and "as available" basis. Except as may be stated

specifically in your contract, Creo Inc. expressly disclaims all warranties of any kind, whether express or implied,

including, but not limited to, any implied warranties of merchantability, fitness for a particular purpose and noninfringement.

You understand and agree that Creo Inc. shall not be liable for any direct, indirect, incidental, special,

consequential or exemplary damages, including but not limited to, damages for loss of profits, goodwill, use, data

or other intangible losses (even if Creo has been advised of the possibility of such damages), resulting from: (i)

the use or the inability to use the product or software; (ii) the cost of procurement of substitute goods and

services resulting from any products, goods, data, software, information or services purchased; (iii) unauthorized

access to or alteration of your products, software or data; (iv) statements or conduct of any third party; (v) any

other matter relating to the product, software, or services.

Page 6

Patents

The text and drawings herein are for illustration and reference only. The specifications on which they are based

are subject to change. Creo Inc. may, at any time and without notice, make changes to this document. Creo Inc.,

for itself and on behalf of its subsidiaries, assumes no liability for technical or editorial errors or omissions made

herein, and shall not be liable for incidental, consequential, indirect, or special damages, including, without

limitation, loss of use, loss or alteration of data, delays, or lost profits or savings arising from the use of this

document.

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

This product is covered by one or more of the following U.S. patents:

RE37,376

4,456,924

4,500,919

4,558,302

4,743,091

4,992,864

5,049,901

5,079,721

5,081,617

5,103,407

5,111,308

5,113,249

5,122,871

5,124,547

5,132,723

5,150,225

5,153,769

5,155,782

5,157,516

5,208,818

5,208,888

5,247,174

5,249,067

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creo Inc.

3700 Gilmore Way

Burnaby, B.C., Canada

V5G 4M1

Tel: 1-604-451-2700

Fax: 1-604-437-9891

http://www.creo.com

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

653-00298A

March 10, 2003

5,283,140

5,291,273

5,323,248

5,325,217

5,339,176

5,343,059

5,355,446

5,359,451

5,359,458

5,367,360

5,384,648

5,384,899

5,412,491

5,412,737

5,420,702

5,420,722

5,459,505

5,473,733

5,481,379

5,488,906

5,497,252

5,508,828

5,509,561

5,517,359

5,519,852

5,526,143

5,532,728

5,561,691

5,568,595

5,576,754

5,579,115

5,592,309

5,594,556

5,600,448

5,608,822

5,615,282

5,625,766

5,636,330

5,649,220

5,650,076

5,652,804

5,680,129

5,691,823

5,691,828

5,696,393

5,699,174

5,699,740

5,708,736

5,713,287

5,742,743

5,764,374

5,764,381

5,771,794

5,785,309

5,802,034

5,813,346

5,818,498

5,854,883

5,861,904

5,861,992

5,875,288

5,894,342

5,900,981

5,934,196

5,942,137

5,946,426

5,947,028

5,958,647

5,966,504

5,969,872

5,973,801

5,986,819

5,995,475

5,996,499

5,998,067

6,003,442

6,014,471

6,016,752

6,031,932

6,043,865

6,060,208

6,063,528

6,063,546

6,072,518

6,090,529

6,096,461

6,098,544

6,107,011

6,112,663

6,115,056

6,121,996

6,130,702

6,134,393

6,136,509

6,137,580

6,147,789

6,158,345

6,159,659

6,164,637

6,180,325

6,181,362

6,181,439

6,186,068

6,189,452

6,191,882

6,204,874

6,208,369

6,214,276

6,217,965

6,252,522

6,260,482

6,266,080

6,266,134

6,267,054

6,268,948

6,283,589

6,295,076

6,299,572

6,318,266

6,340,817

6,352,816

6,353,216

6,366,339

6,371,026

6,377,739

6,387,597

6,396,422

6,396,618

6,407,849

6,414,755

6,422,801

6,435,091

Page 7

Environment Management System (EMS)

EMS Overview

Creo is committed to the Environment Management System (EMS). According to this policy, we are

committed to keeping customers and service engineers informed about the principles of handling

company products with an emphasis on environmental conservation.

The Triple-R principles are

reduce, reuse, and recycle.

Any item that can be recycled should be recycled and any item that can be reused should be reused, to

reduce the quantities of trash that municipalities must handle.

Recycling

Used items such as paper, plastic, electronic parts, and glass – should be sent for recycling.

Packaging Materials

Packaging materials will be kept at the customer’s premises. For disposal, they should be sent to a plant

for paper, carton, and wood recycling.

End of Product Life

When the product reaches its end of life, it should be sent for recycling to a recognized company in each

country.

Page 8

This Page is Intentionally Left Blank

Page 9

Contents

Using This Guide xiii

Printing Guide Purpose ........................................................................................................................... xiv

Who Should Use This Guide ................................................................................................................... xiv

Chapter Content and Description ........................................................................................................... xiv

Conventions Used in This Guide ..............................................................................................................xv

Fonts ................................................................................................................................................ xv

Terminology .................................................................................................................................... xvi

Symbols.......................................................................................................................................... xvii

For More Information ............................................................................................................................ xvii

1 Welcome 1

Welcome to the CXP6000 Color Server Printing Guide ............................................................................. 2

Product Overview ..................................................................................................................................... 2

Composition...................................................................................................................................... 4

Features............................................................................................................................................. 4

Workflow .......................................................................................................................................... 7

Data Flow .......................................................................................................................................... 9

CXP6000 Color Server Network Printers...........................................................................................10

2 Quick Tour 11

Powering Up .......................................................................................................................................... 12

CXP6000 Color Server in the Start Menu ......................................................................................... 13

The CXP6000 Color Server Workspace ................................................................................................... 14

The DFE & Printer Animation .................................................................................................................. 16

The DFE Monitor.............................................................................................................................. 16

The Printer Monitor ......................................................................................................................... 18

Shut Down and Power Off...................................................................................................................... 22

3 Printing and Setting Job Parameters 23

Introduction ........................................................................................................................................... 24

Printing from Client Workstations........................................................................................................... 24

Printing from a PC ........................................................................................................................... 25

Printing from a Macintosh ............................................................................................................... 27

Printing from a UNIX Client Workstation.......................................................................................... 29

Using Hot Folders ............................................................................................................................ 30

Setting PPD Parameters from Client Workstations................................................................................... 39

PPD Parameters ............................................................................................................................... 39

Spire Web Center ................................................................................................................................... 47

The Web Viewer .............................................................................................................................. 49

Downloads ...................................................................................................................................... 53

Page 10

viii CXP6000 Color Server Printing Guide

Links................................................................................................................................................ 54

Printing from the CXP6000 Color Server................................................................................................. 55

Importing Files................................................................................................................................. 55

The Storage Folder .......................................................................................................................... 58

Reprinting Files ................................................................................................................................ 59

Setting Job Parameters on the CXP6000 Color Server............................................................................. 60

Adjusting Job Parameters Post-RIP ................................................................................................... 60

Job Parameters Window......................................................................................................................... 62

The Print Settings Tab...................................................................................................................... 64

The Paper Stock Tab ........................................................................................................................ 75

The Print Quality Tab ....................................................................................................................... 88

The Color Tab.................................................................................................................................. 97

The Imposition Tab ........................................................................................................................ 116

The Services Tab ............................................................................................................................ 140

The Finishing Tab........................................................................................................................... 154

The Exception Tab ......................................................................................................................... 164

Job Ticket Report.................................................................................................................................. 171

4 Workflows & Tools 173

Introduction ......................................................................................................................................... 174

High-Resolution (APR) Workflow .......................................................................................................... 174

APR (Automatic Picture Replacement)............................................................................................ 175

OPI (Open Prepress Interface)......................................................................................................... 176

APR and OPI File Formats............................................................................................................... 176

Setting the High-Resolution File Path ............................................................................................. 176

Preparing to Print Using APR or OPI ............................................................................................... 178

Printing with APR or OPI ................................................................................................................ 179

Organizing High-Resolution Files.................................................................................................... 180

Sample Job: Printing a Brochure Using the APR Workflow ............................................................. 180

VI (Variable Information) Workflow ...................................................................................................... 182

Using Creo Variable Print Specification to Print a VI Job ................................................................. 183

VI Document Formats .................................................................................................................... 184

Creo Variable Print Specification (VPS) ........................................................................................... 186

Organizing VI Elements.................................................................................................................. 188

CXP6000 Color Server Job Parameters and VI Jobs ........................................................................ 189

Imposition Workflow............................................................................................................................ 192

Editing Imposition Jobs .................................................................................................................. 193

Color Workflow ................................................................................................................................... 194

Job Batching Workflow ........................................................................................................................ 195

PDF Workflow ...................................................................................................................................... 196

Export as PDF2Go.......................................................................................................................... 199

The Gradation Tool .............................................................................................................................. 201

The Calibration Tool ............................................................................................................................. 213

Connecting, Configuring and Calibrating the X-Rite DTP34 QuickCal Densitometer....................... 214

Using the Printer Calibration Wizard with the X-Rite DTP34 ........................................................... 218

Color Density Information.............................................................................................................. 240

Page 11

Contents ix

The Spot Color Editor ........................................................................................................................... 243

Printing PrePress Files - Graphic Art Port (GAP)...................................................................................... 248

Importing GAP Files ....................................................................................................................... 248

Supporting Graphic Arts Port (GAP) Files........................................................................................ 248

Gap File Structure .......................................................................................................................... 249

5 Administrating the System 251

The Administration Window ................................................................................................................. 252

General Setup ...................................................................................................................................... 253

Changing the Server Name ............................................................................................................ 254

Changing the Date & Time ............................................................................................................ 256

Selecting the User Interface Language ........................................................................................... 258

Setting the Default Unit of Measurement....................................................................................... 259

Resource Manager................................................................................................................................ 260

Virtual Printers ............................................................................................................................... 261

Fonts ............................................................................................................................................. 267

High-Res........................................................................................................................................ 281

VI Elements.................................................................................................................................... 282

Profile Manager ............................................................................................................................. 285

User Defined Imposition Template ................................................................................................. 294

Network Setup ..................................................................................................................................... 297

IPX Printing.................................................................................................................................... 298

TCP/IP Setup .................................................................................................................................. 300

AppleTalk Setup ............................................................................................................................ 302

Preferences........................................................................................................................................... 303

Color - Spire Spot Color Dictionary ................................................................................................ 305

Color - Calibration Methods .......................................................................................................... 306

Color - Emulations ......................................................................................................................... 307

Color - Automatic Screening Method............................................................................................. 309

Color - Color Conversion Tables..................................................................................................... 310

Accounting/Message Viewer Log Setup ......................................................................................... 311

System Disks.................................................................................................................................. 312

Alert Messages .............................................................................................................................. 313

Pre-RIP Preview .............................................................................................................................. 314

Default Archiving Path ................................................................................................................... 315

PDF Optimization........................................................................................................................... 316

OPI ................................................................................................................................................ 316

Default Paper Size.......................................................................................................................... 318

Print Queue Manager .................................................................................................................... 319

Remote Tools Setup....................................................................................................................... 321

Utilities ................................................................................................................................................. 326

View Configuration ....................................................................................................................... 327

Configuration Backup and Restore................................................................................................. 329

Page 12

x CXP6000 Color Server Printing Guide

6 Managing Jobs 333

Overview.............................................................................................................................................. 334

Queue Manager ................................................................................................................................... 334

Reordering Jobs in Queues ............................................................................................................ 340

Suspending and Resuming Queues ................................................................................................ 341

Handling Jobs in Queues ...................................................................................................................... 341

Aborting a Running Job................................................................................................................. 342

Moving Waiting Jobs to Storage .................................................................................................... 343

Deleting Jobs................................................................................................................................. 345

Viewing and Editing the Job Parameters ........................................................................................ 346

Viewing the Job History ................................................................................................................. 347

Running a Job Immediately............................................................................................................ 347

Managing the Storage Folder ............................................................................................................... 348

Filtering the List ............................................................................................................................. 351

Switching List View Modes ............................................................................................................ 354

Sorting the List .............................................................................................................................. 357

Resizing Columns .......................................................................................................................... 359

Handling Jobs in the Storage Folder...................................................................................................... 360

Submitting Jobs............................................................................................................................. 361

Archiving and Retrieving Jobs ........................................................................................................ 361

Duplicating Jobs ............................................................................................................................ 364

Export as InSite Job........................................................................................................................ 365

Managing Disk Space ........................................................................................................................... 367

Thumbnail Window.............................................................................................................................. 368

Job Preview & Editor............................................................................................................................. 371

The Job Editor Tabs ....................................................................................................................... 372

The Job Editor Buttons................................................................................................................... 375

Viewing Pages in the Job Editor ..................................................................................................... 376

Editing RTP Jobs ............................................................................................................................ 381

Previewing and Editing PDL Jobs.................................................................................................... 391

7 System Messages 393

Overview.............................................................................................................................................. 394

The Alerts Window............................................................................................................................... 394

System Disks Threshold Message ................................................................................................... 395

Job History ........................................................................................................................................... 396

The Message Viewer ............................................................................................................................ 398

Managing Messages...................................................................................................................... 399

Pop-up messages ................................................................................................................................. 403

8 Job Accounting 405

Handling Job Accounting ..................................................................................................................... 406

Viewing the Accounting Information ............................................................................................. 406

Managing the Accounting Information................................................................................................. 409

Page 13

Contents xi

Reordering Columns ...................................................................................................................... 409

Resizing Columns .......................................................................................................................... 410

Filtering the Information by Date ................................................................................................... 411

Sorting the Information ................................................................................................................. 412

Accounting / Message Viewer Log Setup ....................................................................................... 413

Exporting the Accounting Report ................................................................................................... 413

Printing the Accounting Report...................................................................................................... 414

A Color Theory 417

Color Theory ........................................................................................................................................ 418

Light.............................................................................................................................................. 418

Visible Spectrum ............................................................................................................................ 419

The Perception, Physiology and Psychology of Color ...................................................................... 420

Additive Color ............................................................................................................................... 423

Subtractive Color ........................................................................................................................... 425

Color Separation............................................................................................................................ 430

Glossary 433

Index 445

Page 14

This Page is Intentionally Left Blank

Page 15

Using This Guide

Printing Guide Purpose .....................................................................xiv

Who Should Use This Guide..............................................................xiv

Chapter Content and Description......................................................xiv

Conventions Used in This Guide........................................................ xv

Page 16

xiv Using This Guide

Printing Guide Purpose

This Printing Guide will help you operate the CXP6000 Color Server. It

can also be used as a reference Guide for questions or procedures. Study

this Printing Guide to take full advantage of the many unique and

advanced features of the CXP6000 Color Server.

Who Should Use This Guide

This Printing Guide is for CXP6000 Color Server operators and system

administrators. This guide explains how you can quickly and easily print

from the CXP6000 Color Server or from a client workstation. Step-by-step

procedures are included for new and occasional CXP6000 Color Server

users. Detailed information is provided for users who require in-depth

knowledge of the CXP6000 Color Server.

Chapter Content and Description

Chapter Contents Description

Chapter 1 Welcome Provides an introduction and product overview

of the CXP6000 Color Server.

Chapter 2 Quick Tour Includes powering up, powering down, and a

presentation of the CXP6000 Color Server

workspace.

Chapter 3 Printing and Setting

Job Parameters

Chapter 4 Workflows & Tools

Chapter 5

Administrating the

System

Explains how to print, set job parameters and

monitor jobs from client workstations and from

the CXP6000 Color Server. This chapter also

details the several job parameters, and the Job

Ticket report.

Describes the CXP6000 Color Server printing

workflows: Imposition, VI, PDF, Color and High

Resolution (APR and OPI).

This chapter also provides information on the

CXP6000 Color Server tools.

Explains how to administrate your system using

the Administration window utilities.

Page 17

Conventions Used in This Guide xv

Chapter Contents Description

Chapter 6

Chapter 7

Chapter 8

Appendix A

Managing Jobs Provides details on handling jobs in the

System Messages

Job Accounting Provides details about managing job accounting

Color Theory Provides background information on color.

Conventions Used in This Guide

This section describes the fonts, terminology, and symbols used in this

guide.

Queue

Manager

explains

and in the Storage Folder. It also

how to manage disk space by deleting

jobs, and how to use the Thumbnail window

and the Job Preview & Editor tool to preview

and edit your jobs.

Describes the various alerts and error messages.

This chapter also provides explanations about

viewing messages in the Job History, Message

Viewer, and Alerts windows.

using the Accounting window.

Fonts

Frutiger bold is used to refer to buttons and other items in a dialog box, file

names, folders, menu names, and menu commands.

Minion Italic is used to refer to other chapters in the guide, book titles, and

titles of other guides.

Frutiger is used for figure and table captions.

Letter Gothic is used for messages on your computer screen and for

information that you must type.

SMALL CAPS is used for a key or key combination on your keyboard.

Page 18

xvi Using This Guide

Terminology

Clear

Click

Double-click

Drag

Enter

Point

Press

Right-click

Place the mouse pointer over the check box for the

specified option, and click the left mouse button so

that the X or check mark is removed from the check

box.

Place the mouse pointer over the specified option or

button and press and release the left mouse button.

Place the mouse pointer over the specified option or

button and quickly press and release the left mouse

button twice.

Hold down the left mouse button while moving the

mouse and release the button.

Type the information and press the ENTER or RETURN

key.

Position the mouse pointer over a submenu or menu

command. For example, point to the

File menu.

Press the specified key or key combination on your

keyboard, for example, press

CTRL+ALT+DEL.

Place the mouse pointer over an area of the

application window, and then press and release the

right mouse button to display the shortcut menu. For

more information about using shortcut menus, see

your Windows documentation.

Select

Place the mouse pointer over the check box for the

specified option, then click the left mouse button so

that an X or check mark appears in the check box.

Or:

Place the mouse pointer over the specified box or

button, and then click the left mouse button.

Ty pe

Type the information. Do not press the ENTER or

RETURN key.

Page 19

For More Information xvii

Symbols

Attention: This symbol alerts you to things that may cause loss of data or

damage to your computer hardware.

Important: This symbol tells you about things that may cause process delays

or reduce functionality, reliability, or quality.

Note: A note provides additional information that you may need to consider.

Tip: This symbol draws attention to information that can help you perform a

task more quickly or easily.

This symbol tells you that related information on the topic is available in the

online help.

The reference symbol tells you that related information on the topic is available

in another document or in another place in the guide.

This symbol indicates that you should perform a spot check to ensure equipment

and / or software has been correctly installed and is in working order.

For More Information

Visit Creo at www.creo.com for documentation, training courses,

downloads, and service and support contacts.

Page 20

This Page is Intentionally Left Blank

Page 21

Welcome

Welcome to the CXP6000 Color Server Printing Guide........................2

Product Overview................................................................................2

Page 22

2 Chapter 1 – Welcome

Welcome to the CXP6000 Color Server Printing Guide

Welcome to your CXP6000 Color Server Printing Guide.

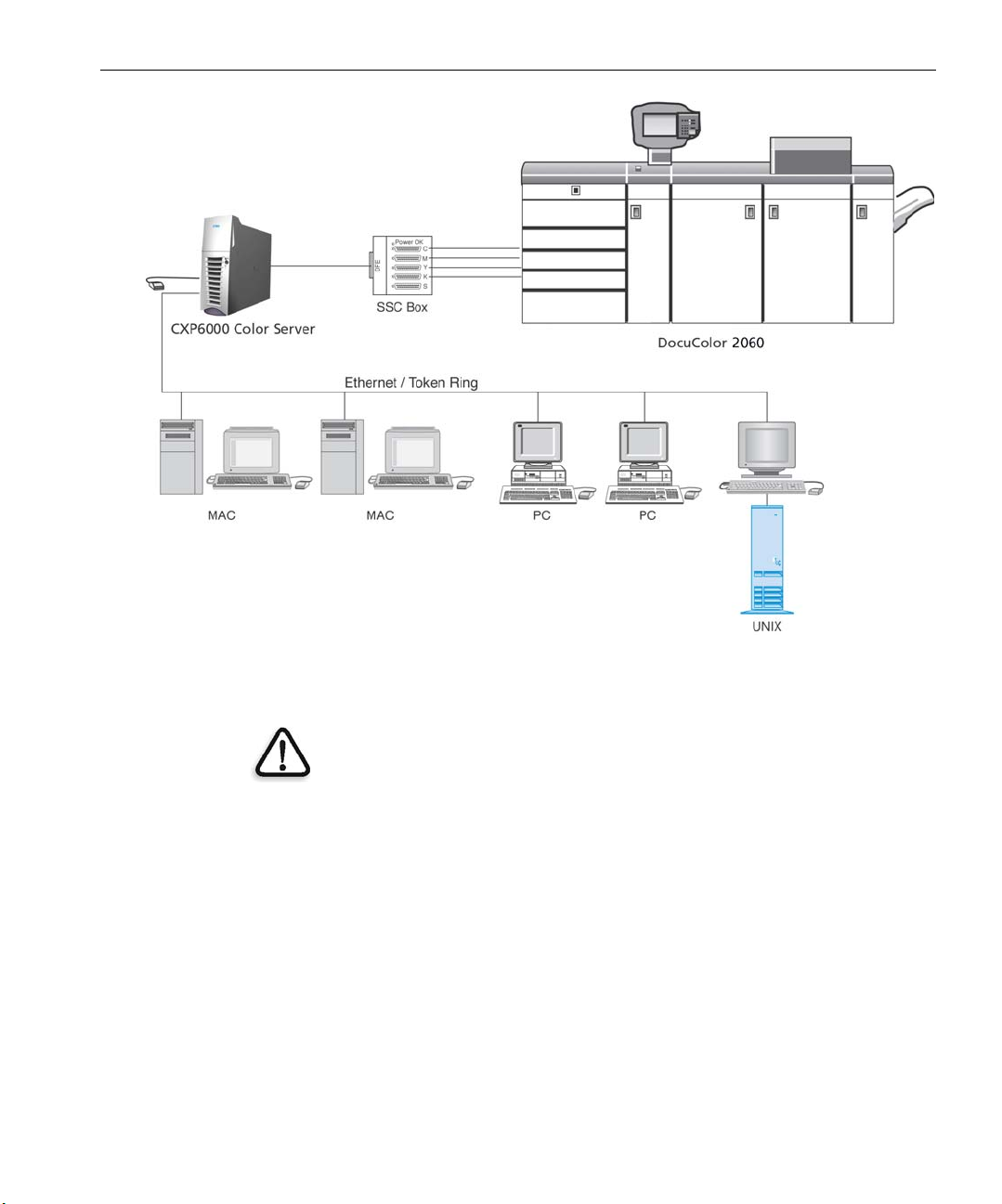

The CXP6000 Color Server is a powerful, comprehensive color server

providing high throughput and print predictability to digital workflows. In

combination with the Xerox DocuColor 2060/2045 Printer, the CXP6000

Color Server effectively addresses the growth of on-demand printing needs

and delivers the best output quality available.

Throughout this guide, we look forward to supporting you all the way

from prepress to print.

Product Overview

The CXP6000 Color Server is an on-demand pre-press system that uses

Creo Spire advanced pre-press technologies, to drive a Xerox DocuColor

2060/2045 Printer.

As an optimal digital color solution for printers, the CXP6000 Color Server

enables you to print from PC, Macintosh, and UNIX client workstations.

The CXP6000 Color Server processes image files in PDL formats (for

example, PostScript, PDF, and Variable Information), using RIP (Raster

Image Processor) technology. The system converts image files into a

suitable RTP (Ready-To-Print) format for direct, high-quality digital

printing. The CXP6000 Color Server also streamlines the printing process

by allowing printing with preset workflows.

In combination with the Xerox DocuColor 2060/2045 Printer, the

CXP6000 Color Server enables you to efficiently print flyers, brochures,

pamphlets, dummy catalogs, short-run trials, and print-on-demand

publications. When installed as a fast, network printer with the CXP6000

Color Server, the Xerox DocuColor 2060/2045 Printer prints up to 60 fullcolor A4 (210mm x 297mm) or Letter (8.5 inches x 11 inches) pages per

minute.

The CXP6000 Color Server combines RIP functionalities, automation,

control tools and special hardware development capabilities with PC

architecture.

Page 23

Product Overview 3

CXP6000 Color Server for Xerox DocuColor 2060/2045 Printer

WARNING: A shielded ethernet cable must be used from the Token Ring board

to the Token Ring Hub to maintain compliance with Council Directive 89/336/

EEC.

Page 24

4 Chapter 1 – Welcome

Composition

The CXP6000 Color Server is a dedicated Creo platform running in a

Windows 2000 environment.

The CXP6000 Color Server includes:

• Creo hardware, including the interface board

• Software, including:

Creo Application Software

Windows 2000 Professional Operating System

The latest version of Adobe Acrobat

Ultimate InSpire Software

Features

The CXP6000 Color Server provides the following:

• Creating jobs in RTP format

Using the CXP6000 Color Server, RTP files can be created and stored

on the CXP6000 Color Server itself. This enables you to print RTP data

at any time without further processing.

• Powerful document printing capabilities

In combination with the Xerox DocuColor 2060/2045 Printer, the

CXP6000 Color Server enables complete printing and processing of

documents, including the production of covers and pages on different

paper stocks.

• Enhanced job editing

The CXP6000 Color Server enables you to edit jobs, both pre- and

post-RIP. Pre-RIP editing includes full Adobe Acrobat functionality

including: deletion, extraction, rotating, adding, and cropping of

pages. Post-RIP editing includes deleting job pages and merging pages

from different jobs to a new job. This minimizes the need to re-RIP

jobs.

Page 25

Product Overview 5

• RIP - Adobe Postscript Level III and Extreme Certified technologies

The CXP6000 Color Server uses the industry-standard Adobe RIP,

with enhancements for Continuous Tone and Linework. Data are

processed separately as Continuous Tone and Vector Data layers for

increased efficiency and merged during printing.

• Ready-to-Print job preview and editing

The CXP6000 Color Server enables you to preview RTP jobs up to

pixel levels to see all job details and to verify job quality and content

post-RIP. It is also possible to view a thumbnail list of job pages, or the

actual raster pages.

• Job management

The CXP6000 Color Server enables you to monitor job progress during

all stages of printing. Among other functions, you can promote,

demote, delete, monitor the import process, and estimate when a job

will be fully imported. You can also abort jobs during RIPing or

printing, as well as archive and retrieve jobs.

• Enhanced text and line art quality – FAF (Full Auto Frame)

You can choose superior text quality with the Creo proprietary

algorithm. This function enhances the quality of diagonal lines,

borders, blends, and small text. The Creo anti-aliasing causes blends to

appear smooth with no banding and diagonal lines to appear crisp

without jagged edges (do not use this option with VI jobs).

You can choose superior image quality with the Creo proprietary

smooth scale algorithm. This function improves the quality of images

containing various resolutions (such as images taken from the

Internet).

• Trapping

The CXP6000 Color Server uses the well-known Creo algorithm to

trap job information easily. The FAF algorithm has been tailored for

digital printing.

Page 26

6 Chapter 1 – Welcome

• Imposition

The CXP6000 Color Server offers a full suite of Imposition functions,

based on the well-known Ultimate Imposition engine. On the

CXP6000 Color Server, imposition is robust with user-friendly

operation. And only the CXP6000 Color Server enables imposition of

Variable Information jobs.

• Color Management

The CXP6000 Color Server has a number of color management tools

and utilities that will help you to improve the quality of your jobs. The

CXP6000 Color Server enables you to modify color on-the-fly, even for

images that have already been RIPped. This functionality includes

application of brightness and contrast adjustments, as well as changes

to image gradation and calibration.

• Variable Information printing

The CXP6000 Color Server enables processing of Creo Variable Print

Specification and Xerox VIPP file formats and PPML for efficient VI

(Variable Information) processing and printing. Repeated elements are

RIPped once and cached, so there is no need to continually re-RIP

them.

The CXP6000 Color Server also provides easy management of VI

elements, including previewing, deleting and updating. The CXP6000

Color Server also offers imposition for VI jobs, the only digital solution

in the industry with this capability.

• Creo workflow extenders

This is a set of Adobe Photoshop and Quark Express software plug-ins

and extensions that facilitate printing with the CXP6000 Color Server.

These extensions are located in the shared

CXP6000 Color Server or on CD #3 supplied with the CXP6000 Color

Server software kit.

Utilities folder on the

Page 27

Product Overview 7

The CXP6000 Color Server supports the following file formats:

• Post-script (composite or pre-separated files)

• PDF

• EPS

• Creo VPS (Variable Print Specification)

• VIPP (Variable Data Intelligent PostScript Params)

• PPML (Personalized Print Markup Language)

• GAP (Graphic Art Port) files (file formats from various PrePress

systems, for example Brisque job and TIFF / IT)

• Creo CT & LW

• JPG, TIFF

Workflow

The CXP6000 Color Server receives and processes files from the following

client workstations:

• Macintosh: running Mac OS 8.5.x or higher and Mac OS X (10.1 and

higher).

• PC: running Windows 98 / ME / Windows NT 4.0 / 2000 / and XP

• UNIX Workstations and Servers

Page 28

8 Chapter 1 – Welcome

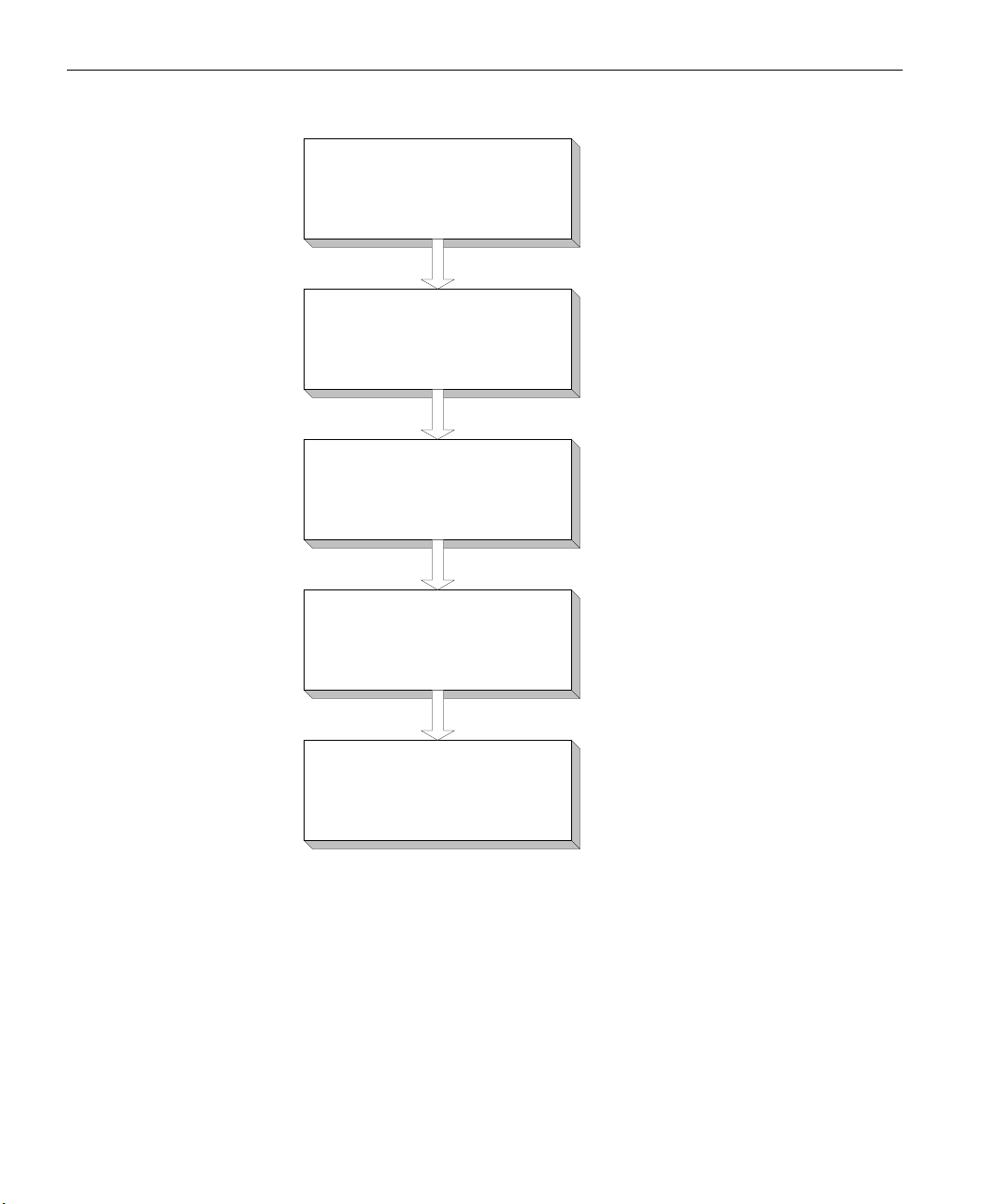

The CXP6000 Color Server basic workflow is as follows:

User activates Print in the DTP

Application (For example, in

Microsoft PowerPoint)

User selects one of the default

CXP6000 Color Server Virtual

Printers (for example ProcessPrint)

The file is spooled to the

CXP6000 Color Server

The file processing begins

according to the settings

predefined in the file or for the

selcted Virtual Printer

The job is stored in an RTP format

in the Storage Folder of the

CXP6000 Color Server and is sent

for printing (depending on the

selected Virtual Printer)

Page 29

Product Overview 9

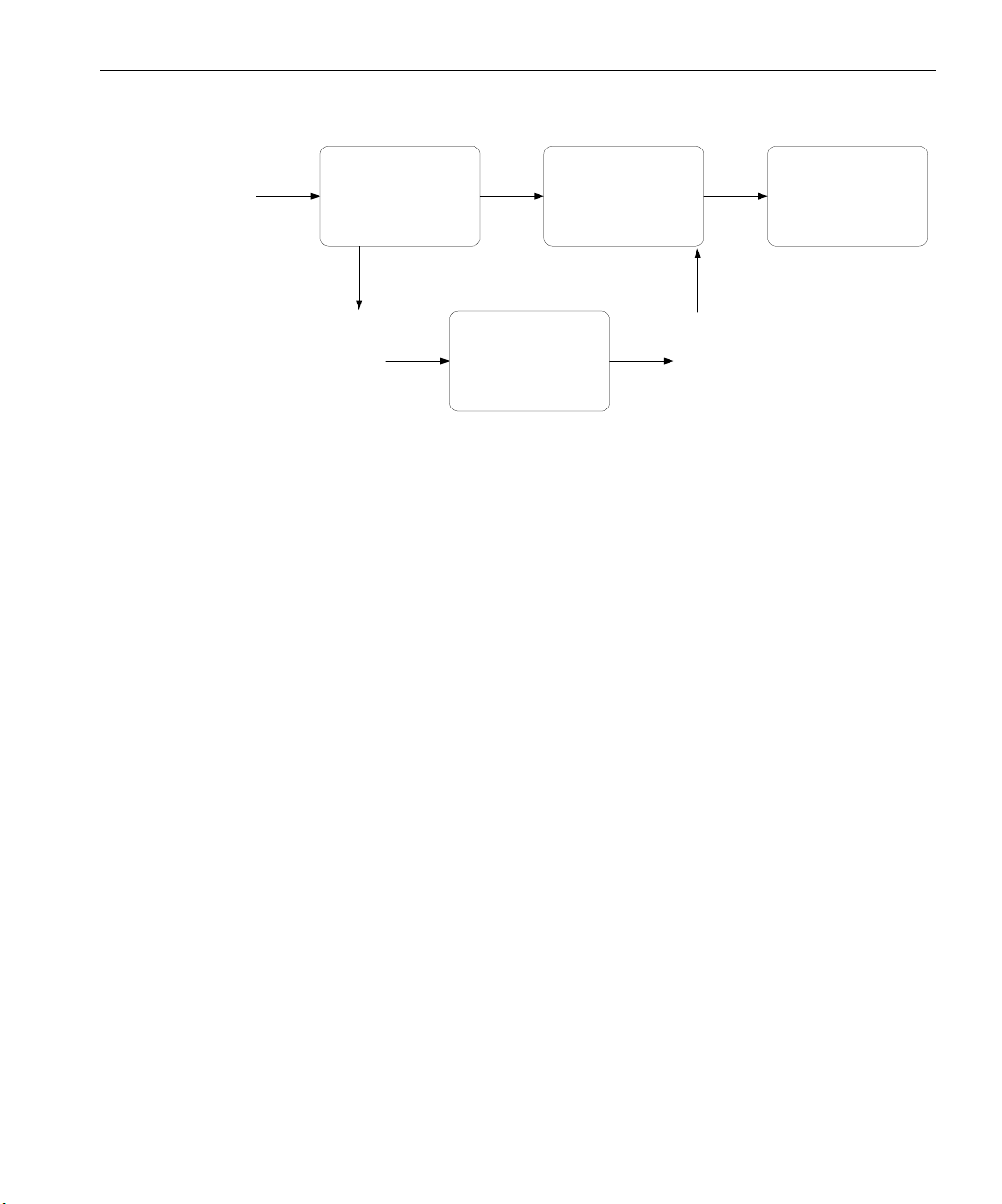

Data Flow

PDL

Processing

Software

RTP

Printer Disks RTP

Decompress and

Page Assembly

(Hardware)

Image Delivery

(Printed Page)

The CXP6000 Color Server Data Flow is as follows:

1. The input file arrives at the CXP6000 Color Server from either a client

workstation, local hard disk, or external media and is submitted to the

Process queue.

2. The processing sub-system produces an RTP job from the input file.

3. The RTP job is stored on an image disk.

4. When printing starts, the RTP job elements on the disk are

decompressed and merged to the correct location on the page. This is

done using Creo hardware.

5. The image delivery sub-system converts the RTP information into the

print engine format.

6. The image delivery sub-system transmits the page information to the

print engine.

7. The page data is delivered to the Print Engine and the job is printed.

Page 30

10 Chapter 1 – Welcome

CXP6000 Color Server Network Printers

For Macintosh and PC networks, the CXP6000 Color Server provides three

default network printers, known also as virtual printers.

Virtual printers are a function used for automating workflows, which then

define job streaming. They contain preset workflows that are automatically

applied to all print jobs processed with that virtual printer. There is no

need to reset job settings for each job, thus increasing printing efficiency.

Note: The job (print) parameters set in the job (from the client) override the

parameters set in the virtual printer.

The three default virtual printers are:

• SpoolStore

Files are spooled directly to the Storage Folder and await operator

processing. You can only import PDL files (such as: PS, PDF, VIPP,

VPS) to the spool store, not RIPped - RTP files.

• ProcessPrint

Files sent to this virtual printer are processed and printed directly to

the Xerox DocuColor 2060/2045 Printer via the CXP6000 Color

Server.

• ProcessStore

Files sent to this virtual printer are automatically processed and stored

in RTP format. After processing, the files are stored in the

Folder

of the CXP6000 Color Server until the print operator re-

submits them for printing.

With printing workflows tailored to your job requirements, the CXP6000

Color Server enables you to:

Storage

• Define new virtual printers

• Choose from which virtual printer to print

For information on defining and editing virtual printers, see Virtual Printers on

page 261.

Page 31

Quick Tour

Powering Up.....................................................................................12

The CXP6000 Color Server Workspace..............................................14

The DFE & Printer Animation.............................................................16

Shut Down and Power Off ................................................................22

Page 32

12 Chapter 2 – Quick Tour

Powering Up

To power up the CXP6000 Color Server:

1. Switch on the monitor.

2. Click the Power button on the front panel of the CXP6000 Color

Server.

The power LED on the front panel lights-up. The Windows 2000

System starts and the CXP6000 Color Server splash appears.

Note: If the CXP6000 Color Server is already powered up, open the workspace

using the Start menu (as described on the following page).

Page 33

Powering Up 13

CXP6000 Color Server in the Start Menu

The CXP6000 Color Server program group appears in the Windows Start

menu.

To open the CXP6000 Color Server workspace:

Click the Start button and follow the path CXP6000>CXP6000.

¾

The Loading Drivers window appears followed by the CXP6000 Color

Server workspace.

Note: The CXP6000 Color Server includes a diagnostics utility for checking

the hardware components of the system. This application should only be

started by a Service Engineer.

For further information about the diagnostics utility, see the CXP6000

Color Server Technical Manual.

Page 34

14 Chapter 2 – Quick Tour

The CXP6000 Color Server Workspace

After the CXP6000 Color Server is powered up, the CXP6000 Color Server

workspace automatically appears.

The workspace area items are described on the following page.

1

2

3

6

45

Page 35

The CXP6000 Color Server Workspace 15

Item Name Description

1

Menu Bar

The Menu bar includes the Job, Selection, Too l s, Control and Help

menus. Click on a menu name to open the corresponding drop-down

menu.

2

Status Panel

The Status panel includes the Logo Pane, In Process pane, In Print

pane and the Storage Folder pane. In addition, the DFE & Printer

Animation

3

4

Pathways

Panel

Queue

Manager

The Pathways panel buttons enable you to open / close a workspace

window.

The lower area of the Queue Manager consists of the In Process

queue, which lists the files to be processed. After a file has been

processed successfully, it moves to the upper area - the

and waits to be printed, or the file moves to the

is displayed on the right.

In Print queue

Storage Folder for

future printing (depending on the job flow). Failed jobs and jobs that

cannot be successfully RIPped also move to the

5

Job Thumbnail

The Job Thumbnail displays the thumbnail view of a specific page in

Storage Folder.

an RTP job that has finished processing.

6

Storage Folder

The Storage Folder contains files that:

• completed printing

• were held, aborted or failed during processing or printing

• were sent directly from the client to storage or were imported to

the

Storage Folder.

Page 36

16 Chapter 2 – Quick Tour

The DFE & Printer Animation

The DFE & Printer Animation is displayed on the right of the Status panel

and presents an animation of the DFE and Printer in their current

configuration. If for example an HCS is connected to the printer, an HCS

representation will also appear in the printer animation. You may click the

Printer or DFE animation to display related information.

DFE Animation Printer Animation

The DFE Monitor

Clicking the DFE Animation opens the DFE Monitor window. This window

displays information regarding Disk space, Network details and connected

Virtual Printers.

The Disk Usage Tab

The Disk Usage tab enables you to view of the free and used disk space

details, in the User and Printer disks.

Page 37

The DFE & Printer Animation 17

The Network Tab

The Network tab enables you to view the network details such as Host

name, IP address, etc.

The Virtual Printers Tab

The Virtual Printers tab enables you to view the defined virtual printers

and their published status.

Page 38

18 Chapter 2 – Quick Tour

The Printer Monitor

Clicking the Printer Animation, opens the Printer Monitor window.

The Printer Monitor window enables you to view information related to

the printer resources such as paper stock, connected devices, toner and

other consumables status.

The Paper Stock Tab

The Paper Stock tab displays the details of the paper stock in each tray and

also shows if this tray is ready or empty.

Page 39

The DFE & Printer Animation 19

The Finisher Tab

The Finisher tab displays the details of connected finishing devices.

Page 40

20 Chapter 2 – Quick Tour

The Toner Tab

The Toner tab displays the CMYK toner availability.

Page 41

The DFE & Printer Animation 21

The Consumables Tab

The Consumables tab displays the status of other refillables.

Page 42

22 Chapter 2 – Quick Tour

Shut Down and Power Off

To shut down and power off the CXP6000 Color Server:

1. In the CXP6000 Color Server workspace, from the Job menu select

Exit

.

Or:

Click in the top right hand corner of the CXP6000 Color Server

workspace.

The CXP6000 Color Server workspace closes and you are returned to

the Windows desktop.

Note: If there are jobs that are being processed or printed a message will be

displayed.

2. Verify that the Spire icon has disappeared from your taskbar.

Taskbar without Spire logo

3. From the Windows desktop, select Start>Shut Down.

4. In the Shutdown window, select Shut down.

5. When the Windows shutdown is complete, switch off the monitor.

6. On the CXP6000 Color Server, click the Power button behind the

Taskbar without Spire logo

front door.

The power LED on the front panel goes off.

Note: Some situations may require the Power button to be depressed for

more than 4 seconds.

Page 43

Printing and Setting

Job Parameters

Introduction......................................................................................24

Printing from Client Workstations .....................................................24

Setting PPD Parameters from Client Workstations .............................39

Spire Web Center..............................................................................47

Printing from the CXP6000 Color Server ...........................................55

Setting Job Parameters on the CXP6000 Color Server .......................60

Job Parameters Window ...................................................................62

Job Ticket Report ............................................................................171

Page 44

24 Chapter 3 – Printing and Setting Job Parameters

Introduction

This chapter explains how to print from client workstations (PC,

Macintosh and Unix) and how to set job parameters using the PPD

parameters. It also provides information about the Spire Web Center and

how this web tool can be used to monitor your jobs in the CXP6000 Color

Server queues, from your client workstation.

This chapter also explains how to import files to the CXP6000 Color Server

for printing and set job parameters using the Job Parameters window.

In addition, detailed information is provided on the various job

parameters and about the Job Ticket report.

Printing from Client Workstations

In order to print a job from a client workstation you may select one of the

following methods:

• Print the job on one of the CXP6000 Color Server network (virtual)

printers, for example ProcessPrint.

The job will then be spooled and processed or printed (according to

the selected job flow of the virtual printer). Using this method, you

may print from any application (for example, Microsoft Word) using

any file format, from any client workstation (PC, Macintosh and

UNIX).

• Drag the job to a required hot folder.

The job will then be spooled and processed / printed (according to the

selected job flow of the corresponding virtual printer).

For further information on hot folders, see Using Hot Folders on page 30.

Using this method, you may print most PDL (Page Description

Language) files, for example, PostScript, PDF, EPS, VPS, VIPP are

supported for print on the CXP6000 Color Server.

Note: PDL jobs that are spooled to the CXP6000 Color Server, must have the

appropriate name extensions, for example: *.ps or *.pdf.

Page 45

Printing from Client Workstations 25

Printing from a PC

To print from a PC:

1. Open the file you would like to print, in the corresponding application

(for example open a PDF file in Adobe Acrobat).

2. From the File menu, select Print.

The Print window appears.

3. From the Name list, select the required CXP6000 Color Server

network printer (for example, Spire_ProcessPrint).

For details on installing the CXP6000 Color Server network printers on

client workstations see the CXP6000 Color Server Installation Guide.

Page 46

26 Chapter 3 – Printing and Setting Job Parameters

4. If required, click the Properties button and modify the job

parameters.

Notes:

Any changes to the printer parameters override the parameters of the

selected virtual printer, unless the virtual printer was specified the

Override PPD Parameters options was selected.

Printer's Default indicates that the value is taken from settings of the

selected virtual printer on the CXP6000 Color Server.

5. Click OK.

6. Click OK in the Print window.

The file is sent to the CXP6000 Color Server.

Page 47

Printing from Client Workstations 27

Printing from a Macintosh

To print from a Macintosh computer:

1. Open the file you would like to print, in the corresponding application

(for example open a Word document in Microsoft Word).

2. From the File menu, select Print.

The Print window appears.

3. From the Printer list, select the required printer (for example,

Color_ProcessPrint).

For details on installing the CXP6000 Color Server network printers on

client workstations see the CXP6000 Color Server Installation Guide.

Page 48

28 Chapter 3 – Printing and Setting Job Parameters

4. To set job parameters, click General and from the pop-up menu,

select one of the Printer Specific Options.

A window similar to the one shown below appears.

5. Adjust the printer options as required.

Notes:

Printer's Default indicates that the value is taken from the currently

selected virtual printer.

The PPD parameters are divided up into five Printer Specific Options in the

drop-down menu.

6. After modifying the job settings, click Print.

The file is sent to the CXP6000 Color Server.

Page 49

Printing from Client Workstations 29

Printing from a UNIX Client Workstation

To print from a UNIX client through LPR:

1. Typ e th e fo llo w in g:

<lpr><space><-S><space><server name><space>

<-P><space><local UNIX printer name><space><PS file

name>

For example, to print frog.ps on a printer named ProcessPrint, type:

lpr -S OPAL4-P ProcessPrint frog.ps.

For details on installing the CXP6000 Color Server network printers on

client workstations see the CXP6000 Color Server Installation Guide.

2.

Press ENTER.

The PostScript file is downloaded to the printer. All settings are taken

from the remote printer on the CXP6000 Color Server.

Notes:

Use alphanumeric and underscores for names. Names are case sensitive,

for example ProcessPrint not processprint.

UNIX does not require PPDs to print jobs.

Page 50

30 Chapter 3 – Printing and Setting Job Parameters

Using Hot Folders

For every published CXP6000 Color Server network printer that is defined

on a client workstation, a corresponding hot folder is automatically

created in the CXP6000 Color Server

Each hot folder carries the virtual printer's name (HF_printer’s name). See

the following graphic.

D:\Hot Folders folder.

Use the hot folder to submit PDL jobs to the CXP6000 Color Server, by

connecting from a client workstation to the CXP6000 Color Server over

the network. When connection is established, drag and drop your jobs

onto the required hot folder (according to the selected workflow).

Tip: You may also drag the hot folder icon to your desktop to create a short

cut to the folder for future usage.

Jobs that reside in the hot folder will automatically be submitted to the

CXP6000 Color Server through the corresponding virtual printer.

Consequently, all of the virtual printer job parameters, inclusive of the

workflow, will be applied to the job.

Page 51

Printing from Client Workstations 31

As soon as the job has been spooled to the CXP6000 Color Server, it

disappears from the hot folder and enters the CXP6000 Color Server

Process

Note: If files are sent for printing through a hot folder while the CXP6000 Color

Server application is down, whenever the application restarts, the files that reside

in hot folders will immediately be imported to the system.

queue or Storage Folder, according to the selected workflow.

In

Hot Folder File Formats

Hot folders may contain all PDL files formats that are supported by the

CXP6000 Color Server: PS, PDF, EPS, PRN, VPS, VIPP, PPML, TIF, JPG

and GAP.

Files with unsupported formats that are moved to a hot folder, will not be

imported to the CXP6000 Color Server and will remain in the hot folder.

Hot folders and Brisque / Prinergy jobs (GAP formats)

While using hot folders to print GAP format jobs, the process is automated

and the job is converted to a PDF that is displayed in the CXP6000 Color

Server queues. The PDF files can then be programmed and printed as any

other PDF file.

For further information on supported GAP formats see Printing PrePress Files Graphic Art Port (GAP) on page 248.

Using Hot Folders from Client Workstations

You may process and print files from any client workstation, using hot

folders. Following are detailed explanations for printing using hot folders

from a PC, from Macintosh O/S 9 and from Macintosh O/S X.

Page 52

32 Chapter 3 – Printing and Setting Job Parameters

To print a job through a hot folder from a PC:

1. On your Windows desktop, double-click the Network Neighborhood

icon.

2. Browse to the location of your CXP6000 Color Server.

3. Double-click the CXP6000 Color Server.

A list of all the shared folders and hot folders appears.

4. Double-click the required hot folder, for example HF_ProcessPrint.

Tip: You may also drag the hot folder icon to your desktop to create a

short cut to the folder for future usage.

5. You may now drag and drop the required files to the hot folder.

All the files are processed and printed automatically to the printer,

according to the hot folder workflow.

Page 53

Printing from Client Workstations 33

To print a job through a hot folder from Macintosh O/S 9:

1. Click the Apple menu and then select Chooser.

The Chooser window appears.

2. Browse the network to the CXP6000 Color Server, and click OK.

The Login window appears.

Page 54

34 Chapter 3 – Printing and Setting Job Parameters

3. Select Guest and click the Connect button.

4. From the list, select the required hot folder, for example

HF_ProcessPrint, and click OK.

The hot folder

icon appears on your desktop.

5. You may now drag and drop the required files to the hot folder icon.

All the files are processed and printed automatically to the printer,

according to the hot folder workflow.

Page 55

Printing from Client Workstations 35

To print a job through a hot folder from a Macintosh O/S X:

1. From the Finder menu bar select Go > Connect to Server.

Page 56

36 Chapter 3 – Printing and Setting Job Parameters

The Connect to Server window appears.

2. Browse the network to your CXP6000 Color Server and click the

Connect button.

Page 57

Printing from Client Workstations 37

The Login window appears.

3. Select Guest and click the Connect button.

Page 58

38 Chapter 3 – Printing and Setting Job Parameters

4. From the list, select the required hot folder, for example

HF_ProcessPrint, and click OK.

The hot folder

5. You may now drag and drop the required files to the hot folder icon.

icon appears on your desktop.

All the files are processed and printed automatically to the printer,

according to the hot folder workflow.

Page 59

Setting PPD Parameters from Client Workstations 39

Setting PPD Parameters from Client Workstations

Setting job parameters from a client workstation can be done through the

CXP6000 Color Server PPD or by defining a virtual printer with

predefined PPD settings.

By using the CXP6000 Color Server PPD:

Through the Print window of your application, select print settings

¾

specific to printing to the CXP6000 Color Server.

By defining a virtual printer:

Set job parameters when creating or editing a Virtual Printer.

¾

These settings become the

PPD Parameters

The following table lists the PPD (PostScript Printer Description)

parameters and the printing options that can be selected from the Print

window of an application.

Notes:

Printer's Default options.

In the PPD file, the Printer Default option is presented for all PPD parameters.

Printer's Default corresponds to the settings of the currently-selected virtual

printer.

When setting or adjusting job parameters, the last-modified or applied

parameter settings are the settings that are applied to the job. However, the

print settings defined in the job file override the settings of the virtual printer.

Grayscale images created in RGB applications (such as PowerPoint) should be

specified as Monochrome or submitted to the system with BW Printing selected

in the PPD. This selection ensures that grayscale images are counted as black and

white instead of color in both the CXP6000 Color Server and in the Xerox

DocuColor 2060/2045 Printer billing meters.

Page 60

40 Chapter 3 – Printing and Setting Job Parameters

PPD Parameter Printing Options

Print Method

Image orientation

for imposition

Face-Up

Reverse Print

Order

Collation

Color Mode

Simplex prints single-sided pages (Printer Default).

In

Duplex Head to Toe, the image on the reverse side of sheet is rotated

180 degrees. It used for calendar-style hard copies and presentation-style

copies (usually used with Landscape jobs).

In

Duplex Head to Head, the head of the image appears at the top of the

page on both sides of the sheet. It is used for normal book-style hard

copies (usually used with Portrait jobs).

Landscape specifies a landscape orientating for imposition.

Portrait specifies a portrait orientation for imposition.

Face Up delivers the pages facing up on the printer.

Face Down delivers the pages face-down on the printer (when printing

confidential documents).

Yes starts printing from the last page.

No starts printing from the first page.

Yes prints a complete copy of the job before the first page of the next

copy is printed.

No prints all the copies of each page before all the copies of the next page

are printed.

Grayscale prints all pages using black (K) toner only.

Color prints all pages using all CMYK toners.

With

Color, Print grays using black toner all grayscale RGB images are

printed using black toner only. If you would like grayscale CMYK

elements to be printed using black toner only, you need to select

Perceptual as the rendering intent.

RGB Workflow

This option changes gamma values, thus producing more color depth

for RGB images. To use CSA in the image, select

replace CSA with RGB, select:

Spire RGB 2.4

, Use sRGB, or Use Adobe RGB.

Use Spire RGB 1.8, Use Spire RGB2.1, Use

Use Source CSA. To

Page 61

Setting PPD Parameters from Client Workstations 41

PPD Parameter Printing Options

Rendering Intent

for RGB

CMYK Workflow

Rendering Intent

for CMYK

Rendering Intent defines how colors are compressed from Lab values to

printer color space.

Relative Colorimetric provides an accurate general-purpose gamut

mapping for all applications. The lowest density is mapped to white.

Absolute Colorimetric preserves the substrate tint.

Saturated (presentation) produces saturated colors that are suitable for

office environment applications (for example text documents and

presentations).

Perceptual (photographic) yields the most effective results on

continuous tone and images.

Saturated (presentation) and Perceptual (photographic) are the most

effective RI methods for RGB images.)

Select whether to Use Source CSA or Ignore Source CSA for your CMYK

image.

Rendering Intent defines how colors are compressed from Lab values to

printer color space.

Relative Colorimetric provides an accurate general-purpose gamut

mapping for all applications. The lowest density is mapped to white.

Perceptual (photographic) yields the most effective results on

continuous tone and images.

Saturated (presentation) produces saturated colors that are suitable for

office environment applications (for example text documents and

presentations).

Absolute Colorimetric preserves the substrate tint.

Relative Colorimetric and Absolute Colorimetric are the most effective

RI methods for CMYK images.)

Calibration

Normal prints using the normal LUT (Look-Up table, which is the

calibration table name).

Saturated prints using the saturated LUT.

None prints without calibration, thus there is no balance between colors

and gives no color calibration data.

Page 62

42 Chapter 3 – Printing and Setting Job Parameters

PPD Parameter Printing Options

Screening Method

Ink Saving (GCR)

Brightness

Automatic applies two types of screens:

• For CT, the system uses Dot type screen of 200 lpi.

• For LW (text / line-art elements), the system uses Line type screen

of 200 lpi.

Dot 150 applies Dot type screen of 150 lpi.

Dot 200 applies Dot type screen of 200 lpi.

Line 200 applies line type screen of 200 lpi.

Line 300 applies line type screen of 300 lpi.

Line 600 applies line type screen of 600 lpi.

No does not use GCR and uses default maximum toner settings.

Use

Low, Medium, or High to set the amount of CMY toners to be

replaced by the black toner.

on toner (this prevents the occasional peeling of ink and the curling

effect that may occur when printing transparencies).

Brightness settings can be applied to RTP jobs without reprocessing (reRIPing the file).

Normal keeps the current job setting and does not apply extra

brightness.

To apply brightness, select one of the range options:

(10%), Lightest (15%), Dark (5%), Darker (10%), Darkest (15%).

High provides low ink coverage while saving

Light (5%), Lighter

Contrast

Type

Weight

Coating

Contrast settings can be applied to RTP jobs without re-processing (reRIPing the file).

Normal keeps the current job setting and does not apply extra contrast.

To apply contrast, select

Less Contrast or More Contrast.

Select Paper or Transparency as the media.

Select the required paper weight from the drop-down list. The following

ranges are listed:

For example,

Coated prints on coated paper.

UnCoated prints on uncoated paper.

64-74, 81-105, 106-135, 136-150, 151-220 and 221-300

81-105 gs/ m prints on 81-105 gsm paper.

Page 63