Page 1

Xantrex

Fleet PowerTM 3000-12

Inverter/Charger

FP 3000-12

Owner's Manual

Page 2

Thank you for purchasing a Xantrex Fleet PowerTM 3000-12 Inverter/Charger. Xantrex

Technology Inc. takes pride in manufacturing quality products specifically designed to meet

your power requirements.

The FP3000-12 provides silent, efficient and reliable AC power for a variety of applications. It features “hands-free” operation, automatic three-stage battery charging and automatic AC transfer switching. For your convenience, service is available world-wide from

qualified service centers.

If you have any questions about your Fleet Power 3000-12, please contact Xantrex

toll free at 1-800-670-0707.

For technical support and additional information about Xantrex products, visit our Web

site at www.xantrex.com or email us at CustomerService@xantrex.com

SAFETY SUMMARY

Safety information for installation and

operation is contained throughout this

manual where it applies and is not included

in this summary.

Definitions:

Warning statements identify conditions or

practices which could result in personal injury,

loss of life, damage to equipment or other

property.

Notice of Copyright

Xantrex Fleet Power 3000-12 Inverter/Charger © January 2003 Xantrex International. All rights reserved.

Fleet Power is a registered trademark of Xantrex International. Xantrex is a registered trademark of Xantrex International.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY TECHNICAL OR

OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT, INDIRECT,

CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH INFORMATION. THE

USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision January 2003, Revision 2 Part Number 445-0206-01-01

Contact Information Web: www.xantrex.com Email: CustomerService@xantrex.com

Phone: 1-800-670-0707 (toll free in North America) 1-604-422-2777 (direct) Fax: 1-604-420-2145

Fuse Replacement For continued protection

against the possibility of fire, replace the fuse

only with a fuse of the specified voltage,

current and type ratings.

Power Source To avoid damage, operate the

equipment only within the specified AC (line)

and DC (battery) voltages.

Servicing To reduce the risk of electric shock

do not open this unit. There are no user

serviceable parts inside. Refer all service to

qualified personnel.

2

Page 3

TABLE OF CONTENTS

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . 4

Things You Should Know . . . . . . . . . . . . . 5

Circuit Breaker Protection

Thermostat Controlled Cooling

Inverter Idle Circuit

Low and High Battery Shutdown

Power Sharing

Temperature Sensitive Charging

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Optional Remote Control Panel . . . . . . . . .10

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Types

Battery Interconnection

Battery Bank Ratings and Sizing

Battery Charging. . . . . . . . . . . . . . . . . . . . 15

Fleet Power Battery Chargers

Battery Charger Voltage Table . . . . . . . . . 20

Installation Precautions . . . . . . . . . . . . . . 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . 22

Key Installation Points

Grounding

Neutral Bonding

AC Wiring

AC Input

AC Output

Ground Fault Circuit Interrupters

Remote Control Wiring

TSC Temperature Sensitive Charging

DC Wiring

Battery Cable Fusing

Power ON Checks

Troubleshooting . . . . . . . . . . . . . . . . . . . . .31

LED Fault Status

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . 35

Installation Diagrams . . . . . . . . . . . . . . . . . . . 37

Warranty . . . . . . . . . . . . . . . . . . . 43

Not recommended for use in marine environment

3

Page 4

INTRODUCTION

This owner’s manual describes the

Fleet Power

Xantrex Technology Inc. This unit performs

three distinct functions:

1. DC to AC power inverting.

2. Automatic transfer switching between

inverter power and incoming AC power.

3. Automatic three-stage battery charging

plus manual battery equalizing.

• The inverter provides regulated 120 volt AC

power at a crystal controlled frequency from a

deep-cycle battery bank and is rated at 3000

watts.

The output is a modified sine wave and is

compatible with most appliances, tools and

other 120 VAC equipment. (Note: certain laser

printers, breadmakers, digital clocks and small

battery chargers may not operate on modfied

sine wave.) An idle mode reduces battery

power consumption when loads are removed

from the inverter. There is a low battery cutout

protection circuit and momentary surge power

of more than twice the inverter rating for starting electric motors. High efficiency ensures the

longest possible battery life between charges.

TM

3000-12 Inverter/Charger from

• The FP3000-12 battery charger is

electronically controlled and rated at a

maximum output current of 140 amps DC.

It is designed to rapidly and optimally charge

wet, gel, or Absorbed Glass Mat (AGM)** cell

deep-cycle batteries. Battery charging is

automatically accomplished in three stages:

Bulk Charge, Acceptance Charge and Float

Charge.

Using a Remote Control Panel, a manually

engaged Equalizing Charge cycle is possible.

Simple, automatic operation is made possible

by the microprocessor in the FP3000-12. In

most cases, no attention or maintenance is

required.

Electronic Protection

Fast-acting electronic circuits protect the

inverter from overloads and short circuits.

Other protection includes a low and high

battery voltage cutoff and automatic shutdown

if an over-temperature condition occurs. When

the fault condition is corrected, the unit will

automatically reset. Example: remove overload, charge batteries or allow to cool.

• The internal transfer switch allows the

FP3000-12 to be connected to an external AC

source and transfer the source power through

directly to the loads. When the external AC

power source is disconnected, the transfer

switch allows automatic switching back to the

inverter.

The FP3000-12 operates as a self-contained

backup power system—just add batteries.

4

**Battery type selection is set on the front of the unit

or with the Remote Control Panel.

Page 5

THINGS YOU SHOULD KNOW

Circuit Breaker Protection

The FP3000-12 is supplemental breaker

protected.

The INVERT/CHARGE breaker on the front of

the unit protects against sustained inverter/

charger over-current conditions. These breakers

are reset by pushing the button back in. The

output circuit breakers protect the output AC

circuits. The FP3000-12 is available with one

or two outputs.

Thermostat Controlled Cooling

The FP3000-12 is equipped with a thermostatically controlled fan that cools the unit so it can

operate continually at its rated Units with only

supplemental circuit breakers between the unit

and the load. Appropriate wire gauges must be

used throughtout the installation. Refer to NEC

specifications.

noitcetorPrekaerBtiucriC

Inverter Idle Circuit

This automatic energy-saving feature

reduces battery power consumption when no

AC load is present. Response from idle is

instantaneous. In most cases, the operation of

the idle circuit is not noticeable. Use of the

Remote Control Panel allows the idle threshold

to be adjusted. The unit does not put out 120

volts when in idle. To bring the unit out of the

idle condition, apply a load.

Low and High Battery Shutdown

When in inverter mode, if the battery

voltage drops to 10.0 volts, the inverter will

automatically shut off. Charge the batteries to

13.5 volts to automatically resume operation.

Voltage shutdown also occurs for a high battery

condition at 15.5 volts. Operation will resume

automatically when the battery voltage drops

below 15.5 volts. Check all DC sources on

the system for the reason for the excessive

voltage.

GHC/VNI1TUO2TUO

03A/NA/N

Note: Supplemental circuit breakers are reset by pushing the

button back in. The fault must be removed before resetting the

circuit breaker. Integral branch circuit rated breakers are reset

by setting the appropriate breaker switch to the “on” position.

The fault must be removed before resetting the circuit breaker.

If a 30-ampere service supplies the input to the unit, a model

with integral branch circuit rated breakers allows direct wiring

from the unit to the load.

Power Sharing

When connected to an external AC source

the battery charger and transfer functions are

engaged. A unique Power Sharing feature

automatically reduces the AC power consumption of the battery charger allowing necessary

AC power to go to the load. This prevents the

source AC INPUT circuit breaker from tripping

within the specified rating of the AC circuit

breaker.

The Power Sharing set point of each unit has a

factory default setting of 30 amps. This can be

changed using the Remote Control Panel.

5

Page 6

THINGS YOU SHOULD KNOW

Temperature Sensitive Charging (TSC)

When the supplied battery temperature sensor is

connected to the unit and the batteries, the

charge voltage is controlled based on battery

temperature. The charger adjusts the charge

voltage to the best level, minimizing water loss in

wet cell batteries. Charge voltage regulation optimizes the battery life cycle.

TSC Sensor

Battery

6

Page 7

OPERATION

The FP3000-12 provides 120 volt AC power

from auxiliary DC batteries, automatic battery

charging and automatic AC transfer switching

between an external AC source and inverter

mode.

External AC Power

When external AC power is available, the

three-stage battery charger, transfer switching,

and Power Sharing automatically function.

When external AC power is not available and

the INVERT switch is ON (either through the

auxiliary switch or the INVERT button on the

remote), the inverter will automatically turn ON.

If the INVERT switch is OFF (the INVERT LED

will not be illuminated), the inverter will be OFF.

If installed with the Remote Control Panel, the

unit will be set up and controlled from the

remote. Refer to the remote manual for more

information.

Front Panel Controls and Indicators

INVERT MODE

The INVERT push-button switch is located on

the front of the unit and has two functions:

• Turn the inverter ON/OFF and reset after a

fault condition. Pressing the INVERT switch

turns the inverter ON. The green INVERT LED

will be ON when the inverter is inverting.

When the inverter is ON, pressing the INVERT

switch turns the inverter OFF.

INVERT

CHARGE

• Battery type setup. To enter the battery type

select mode, press and hold the INVERT

switch for five seconds. The status LEDs will

change from indicating status information to

indicating battery type. The selection of the

battery type is made with the Charge switch.

Turning the INVERT OFF will reduce battery

power consumption to a very low level. This is

recommended if the unit will not be used for an

extended period of time.

CHARGE MODE

The CHARGE push-button switch has two

functions:

• Turn the charger ON and OFF

If external AC is present, pressing the CHARGE

switch will turn the charger ON. The green

CHARGE LED will be ON when the charger is

charging. When the charger is ON, pressing

this switch will turn the charger OFF.

• Select the battery type After holding the

INVERT switch for five seconds, press the

CHARGE switch to select the battery type.

One of the four LEDs will rapidly blink,

indicating the present battery type setting.

Press the CHARGE switch again to change

the battery type. Continue to press until the

desired battery type is selected. If the CHARGE

switch is not pressed for five seconds, the unit

will return to normal operation and the battery

type selection will have been made.

When the 12 volt input to the unit is

disconnected, the battery type setting is stored

in non-volatile memory. When the unit is

reconnected, the battery type selection

conveniently returns to the setting.

7

Page 8

OPERATION

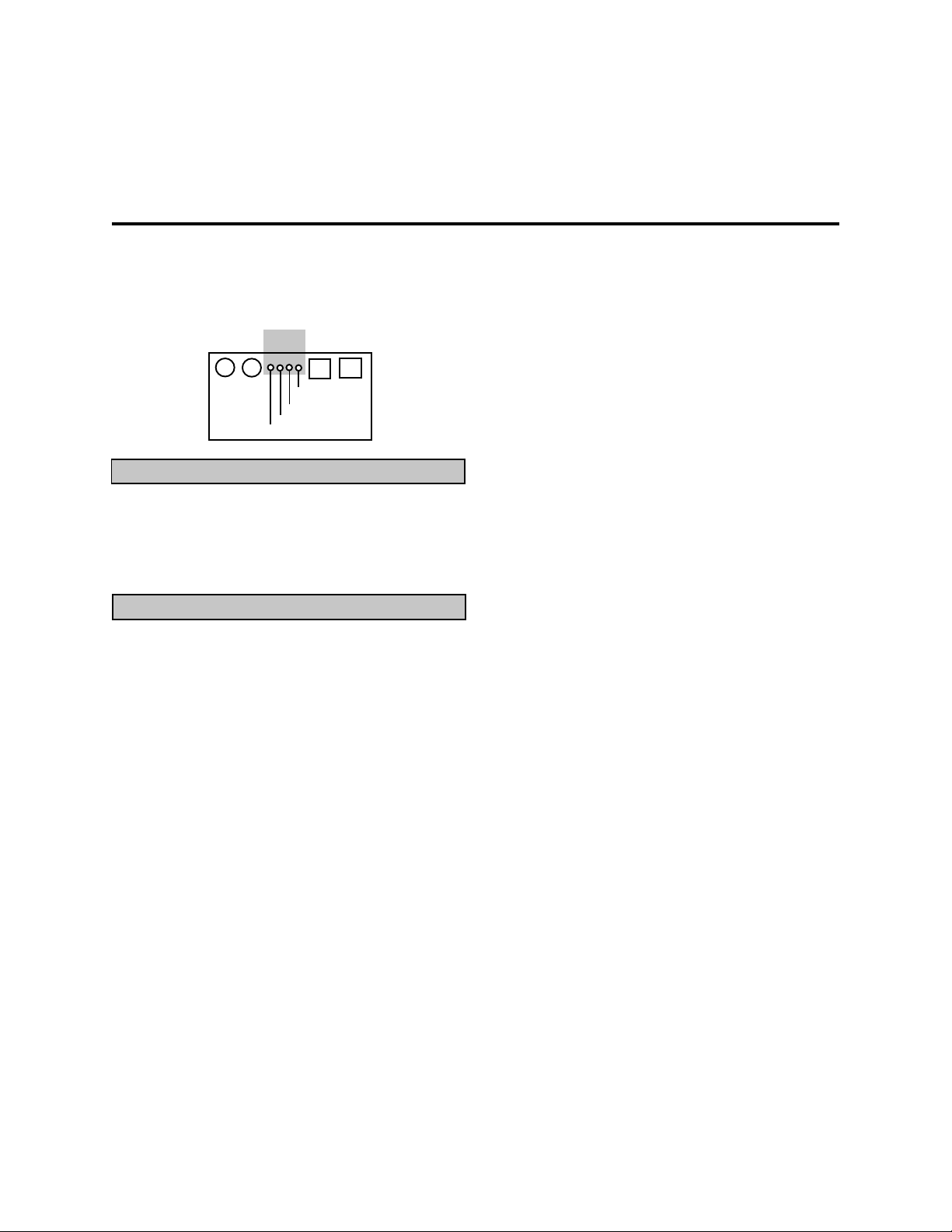

STATUS LEDs

Each Status LED performs two functions,

providing battery type selection and operation

status.

Status LEDs

INVERT

CHARGE

OVERTEMP

OVERLOAD / AGM

LOW BATTERY / GEL 2

CHARGE / GEL1

INVERT / WET

REMOTE

TSC

Battery Type Selection

After holding the INVERT button down for five

seconds, use the CHARGE button to select

battery type :

WET GEL 1 GEL 2 AGM

Operation Status

INVERT - Green LED

The INVERT push-button switch is located on

the front of the unit.

• When the LED is solid green, the unit is

in invert mode. This occurs by pressing the

INVERT switch (for three to five seconds).

• When the LED is blinking slowly (once

per second), the inverter is in standby with AC

power applied and the transfer switch engaged

• Press the INVERT switch again to turn

the inverter OFF.

CHARGE - Green LED

• The CHARGE push-button switch is

located on the front of the unit.

When external AC is applied to the AC input of

the unit, the charger automatically turns ON.

The CHARGE LED will be solid green.

• When the LED is blinking slowly, (once

per second) the charger is ready, but external

AC power is not available.

• Press the CHARGE switch again to turn

the charger OFF. The charger defaults to ON

when operating without a remote or with the

Remote Control Panel.

• When the LED is OFF, the charger has

been manually turned OFF. This can only be

accomplished while AC power is being supplied.

NOTE: When AC power is available, the default

setting for the charger is ON. If the unit was

manually turned OFF and AC power is interrupted and becomes available again, the

charger will return to ON.

LOW BATTERY - Red LED

• When the LED is OFF the battery voltage

is normal, between 10.5 and 15.0 volts DC.

• When the LED is solid red, it indicates a

battery warning condition, the battery voltage is

below 10.5 volts DC or above 15.0 volts DC.

• When the LED is blinking slowly (once

per second), a battery shutdown has occurred.

The voltage is either below 10.0 volts DC or

above 15.5 volts DC.

• When the LED is blinking rapidly (five

times per second), a potential problem in the

DC system has been detected. Check your

batteries, battery cables and DC loads.

OVERTEMP/OVERLOAD - Red LED

• When the LED is OFF, operation is

normal.

• When the LED is red, there is an over

temp or overload condition. Check for

excessive loads or short circuit on the output

of the inverter. Correct the condition and restart

by pushing the INVERT switch.

8

Page 9

• When the LED is blinking slowly (once

per second), an over-current condition or a

short circuit has occured. The system has

shut OFF and will not automatically restart.

Correct the fault condition and manually restart

the system.

LOW BATTERY & OVERTEMP/OVERLOAD

- Red LEDs

• When both LEDs are blinking, an AC

backfeed has been detected. A backfeed occurs

when AC power from an external source is

connected to the output of the inverter. Inspect

wiring for a possible input/output wiring error.

This condition will damage the unit and must

be corrected before further operation.

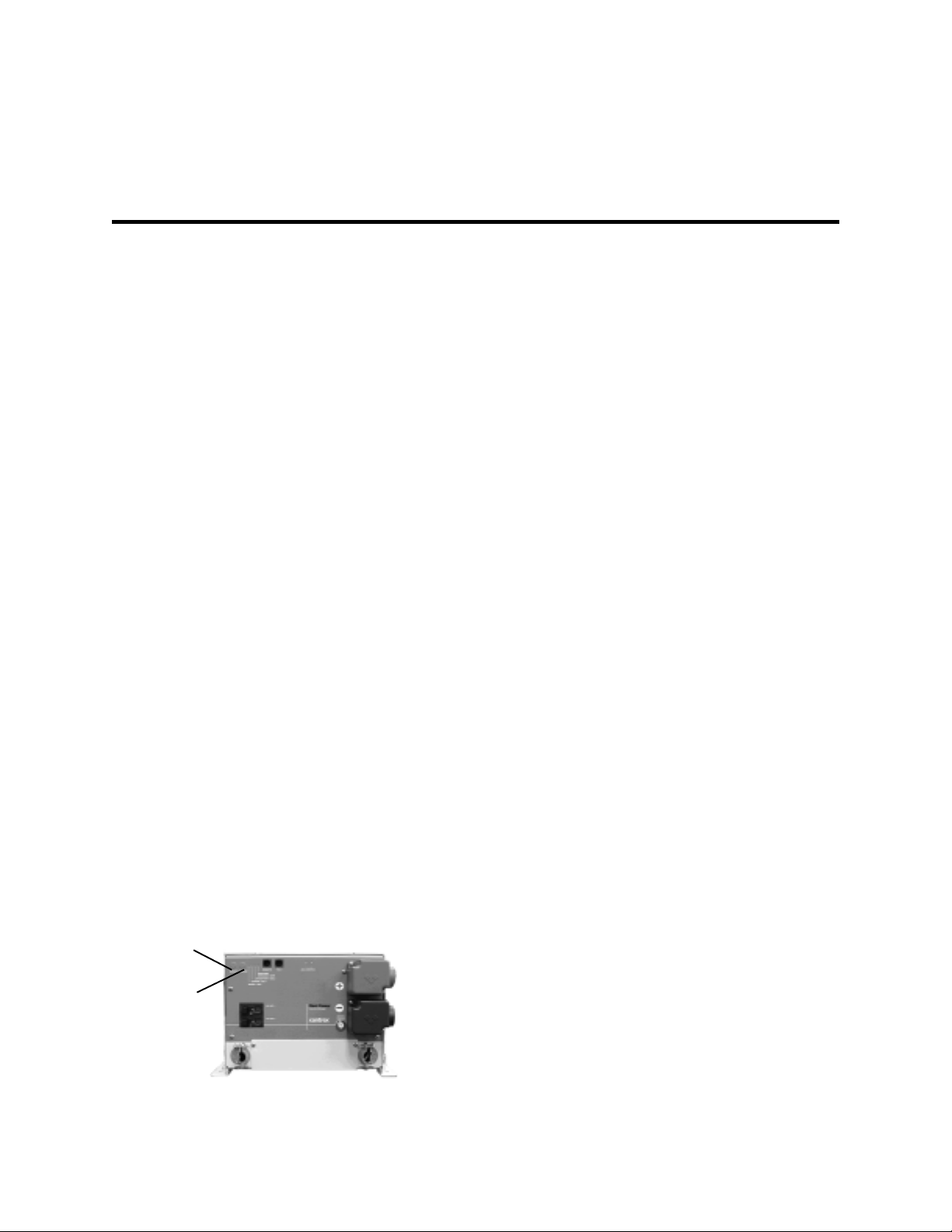

TSC (Temperature Sensitive Charging)

This provides for the connection of a sensor to

measure battery temperature for compensated

charging. If no sensor is connected the charge

voltage levels are set to defaults based on

battery type.

Low

Battery

Overtemp

Remote

OPERATION

TSC

Auxiliary Port

OPTIONAL REMOTES

If using a remote, refer to the installation

instructions included with the remote.

Note: When a Remote Control Panel is installed,

the jumper included in the parts plastic bag is

not used in the Auxiliary Switch Port (AUX

SWITCH) on the front panel of the inverter/

charger. See page 23 for more details.

9

Page 10

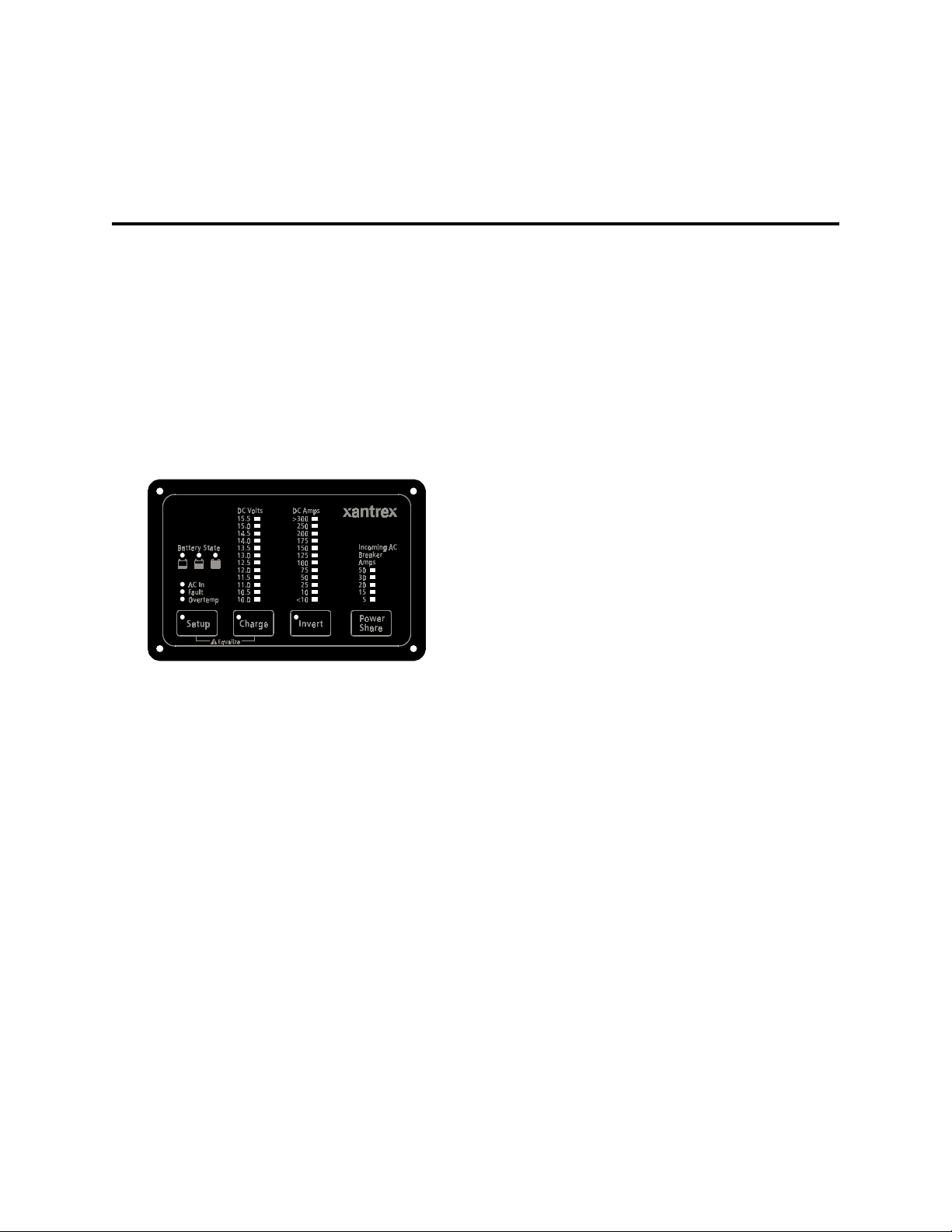

OPTIONAL REMOTE CONTROL PANEL

Remote Control Panel

An optional remote control panel is available.

The LED bar graphs on the remote control

panel show battery voltage and DC current in

both inverter and charger modes.

Easy-to-see red, yellow and green LEDs show

the battery state-of-charge. Power

Sharing, charger ON/OFF, inverter ON/OFF

controls are provided. Set-up features include

selection of Idle Threshold, Battery Type and

Battery Capacity.

Remote Control Panel

10

Page 11

BATTERIES

Wet cell batteries will give off gas as a natural

result of charging and will experience some

water loss. It is very important that the

electrolyte level be checked frequently and

topped off with distilled water when necessary.

Follow the battery manufacturer’s

recommendations for maintenance.

Never allow the top of the battery plates to be

exposed to air, as contamination of the cell will

result. Keep the top of batteries clean. Always

provide adequate ventilation for the battery

storage compartment.

BATTERY TYPES

Use only deep-cycle batteries with your

FP3000-12. These fall into three broad

categories: wet cell, gel cell and Advanced

AGM (Absorbed Glass Mat) batteries.

Wet Cell Batteries

True deep-cycle wet cell batteries are

characterized by relatively thick internal plates

that are alloyed with antimony.

Common 12-volt marine/RV deep-cycle

batteries are acceptable. Golf cart

batteries perform well and may have a

longer life. These 6-volt batteries must be

used in series connected in pairs. High

quality deep-cycle batteries offer good

performance and are available in a wide

variety of sizes.

Do not use ordinary car batteries or engine

starting batteries with your inverter

Beware of any battery that is rated in Cold

Cranking Amps (CCA). This is a rating which

applies only to engine starting batteries. In

general, most wet cell batteries that are

described as hybrid type batteries, suitable for

either engine starting or deep-cycle applications,

are a compromise and will have limited life if

deeply discharged.

·charger.

11

Page 12

BATTERIES

All batteries can be maintenance free, but not

all of them are deep-cycling batteries. Beware

of batteries that are described as

maintenance free only. These batteries have

calcium alloyed with the lead and hold the

liquid electrolyte in a sponge-like material. They

are sealed and water cannot be added. Do not

confuse them with true gel cell or AGM

batteries—they will not hold up well to deep

discharging and repeated cycling.

Gel Cell Batteries

Gel cell batteries are lead-acid batteries similar

in many ways to the common wet cell battery,

but differences in the chemistry and

construction provide some unique features.

• No maintenance

• Low self-discharge rate

• Low internal resistance

Even though gel cells are sealed batteries, the

battery compartment should still be ventilated.

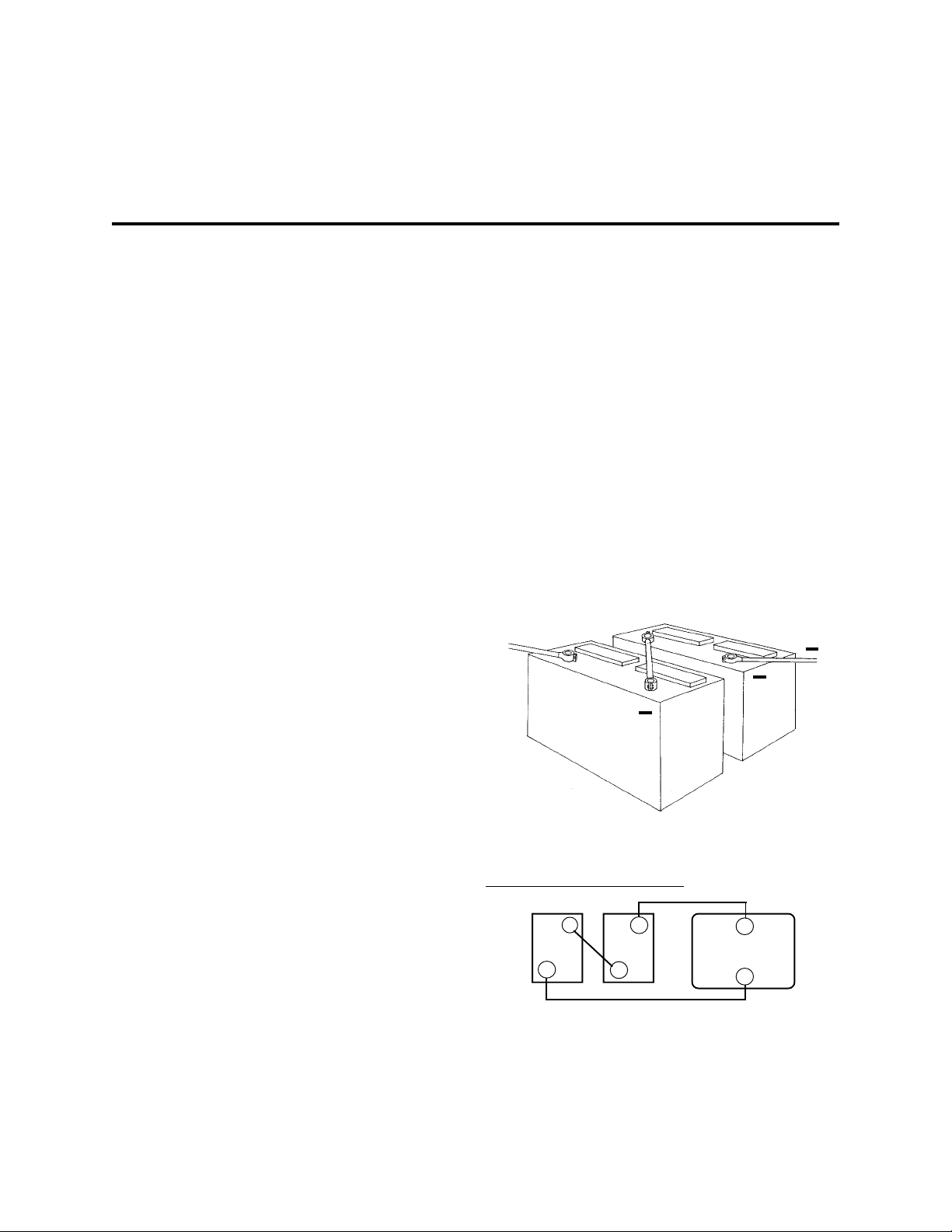

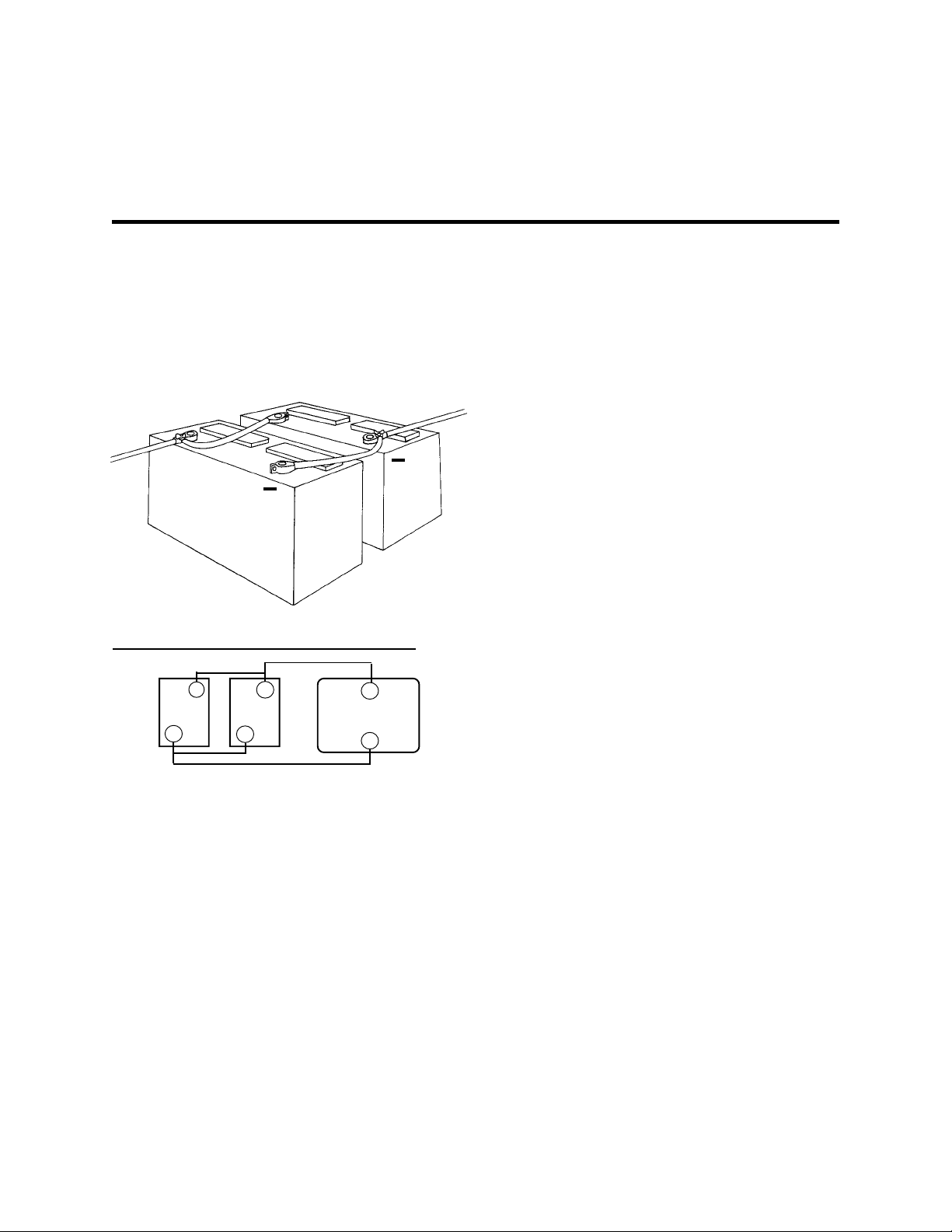

BATTERY INTERCONNECTION

In most cases, you will be using a bank of two

or more batteries with your inverter

/charger.

You may connect batteries together in two

configurations, series and parallel, depending

on their voltage.

Series

Connecting two batteries in series will double

the voltage of the battery bank. For instance,

two 6-volt batteries connected in series will

produce 12 volts. The amp-hour capacity of

the battery bank will be the same as each

individual battery. For example, two 6-volt 220

amp-hour batteries in series will produce one

12-volt 220 amp-hour battery bank.

+

+

+

Advanced AGM (Absorbed Glass Mat)

Batteries

This battery is lead acid but maintenance-free.

The performance is similar to gel cell batteries.

The charge parameters are similar to wet cell

batteries.

Battery Selection

The most important feature to consider in

making your battery selection is to select true

deep-cycle batteries rated in amp hours (Ah)

and sized to match your power requirements.

12

Series Increase Voltage

+

6V

_

EACH BATTERY

CAPACITY:

220

AMP HOURS

@ 6 VDC

+

6V

_

Series

+

12V INVERTER

_

TOTAL BATTERY

BANK CAPACITY:

220

AMP HOURS

@ 12 VDC

Page 13

BATTERIES

Parallel

Connecting two batteries in parallel will double

the amp-hour rating of the battery bank, while

the voltage will be the same as each individual

battery. For example, two 12-volt 105 amp-hour

batteries in parallel will produce one 12-volt

210 amp-hour battery bank.

+

+

Parallel

Parallel Increase Amp-hour Capacity

+

12V

_

EACH BATTERY

CAPACITY:

105

AMP HOURS

@ 12 VDC

12V

_

+

+

1

2V INVERTER

_

TOTAL BATTERY

BANK CAPACITY:

210

AMP HOURS

@ 12 VDC

Note: It is not advisable to connect batteries of

different case sizes or amp-hour ratings in the

same battery bank.

Always use properly sized wire and

terminals for your interconnecting battery

cables. For size information refer to NEC

requirements or contact your local

electrician.

BATTERY BANK RATINGS AND SIZING

Deep-cycle batteries are usually rated in amp

hours. The amp-hour rating is based on a 20hour discharge rate. Therefore, a 100

amp-hour battery can deliver 5 amps for 20

hours. If the discharge rate is greater than 5

amps, the available amp hours are decreased.

For example, if the load is increased to 100

amps, only about 45 amp hours will be available at this rate of discharge.

Deep-cycle batteries can be discharged about

80% of capacity before damage occurs.

Shallow cycling will result in much longer

battery life. Calculating a battery bank size

based on 50% discharge cycling is generally

considered to be a good compromise between

long battery life and size.

Only similar batteries should be connected

together in one bank. Do not connect old

and new batteries together or wet and gel cell

batteries together. In the above drawing, the

load is connected to the positive terminal of

the first battery and the negative terminal of the

last battery. This practice helps to balance the

battery bank and is called cross-connecting

the battery bank.

13

Page 14

BATTERIES

To achieve 50% cycling you should calculate

your amp-hour consumption between charging

cycles and use a battery bank with twice that

capacity**. Each AC appliance or tool has a

rating plate on it and will be rated in either AC

amps or watts or AC VA (volt-amps) apparent

power. To calculate amp-hour consumption,

use one of the formulas to the right to calculate

the DC amp-hour draw for a 12 volt system.

Calculate the amp hours for every AC

appliance or tool that will be operated on the

inverter. This will provide the total number of

amp hours used between recharges. Size the

battery bank using this number as a guideline.

A good rule to follow is to size the battery bank

a minimum of two times larger than the total

amp-hour load requirement. Plan on recharging

when 50% discharged.

**Batteries are typically charged to 85% of full charge

when charging with alternators without three-stage

regulators.

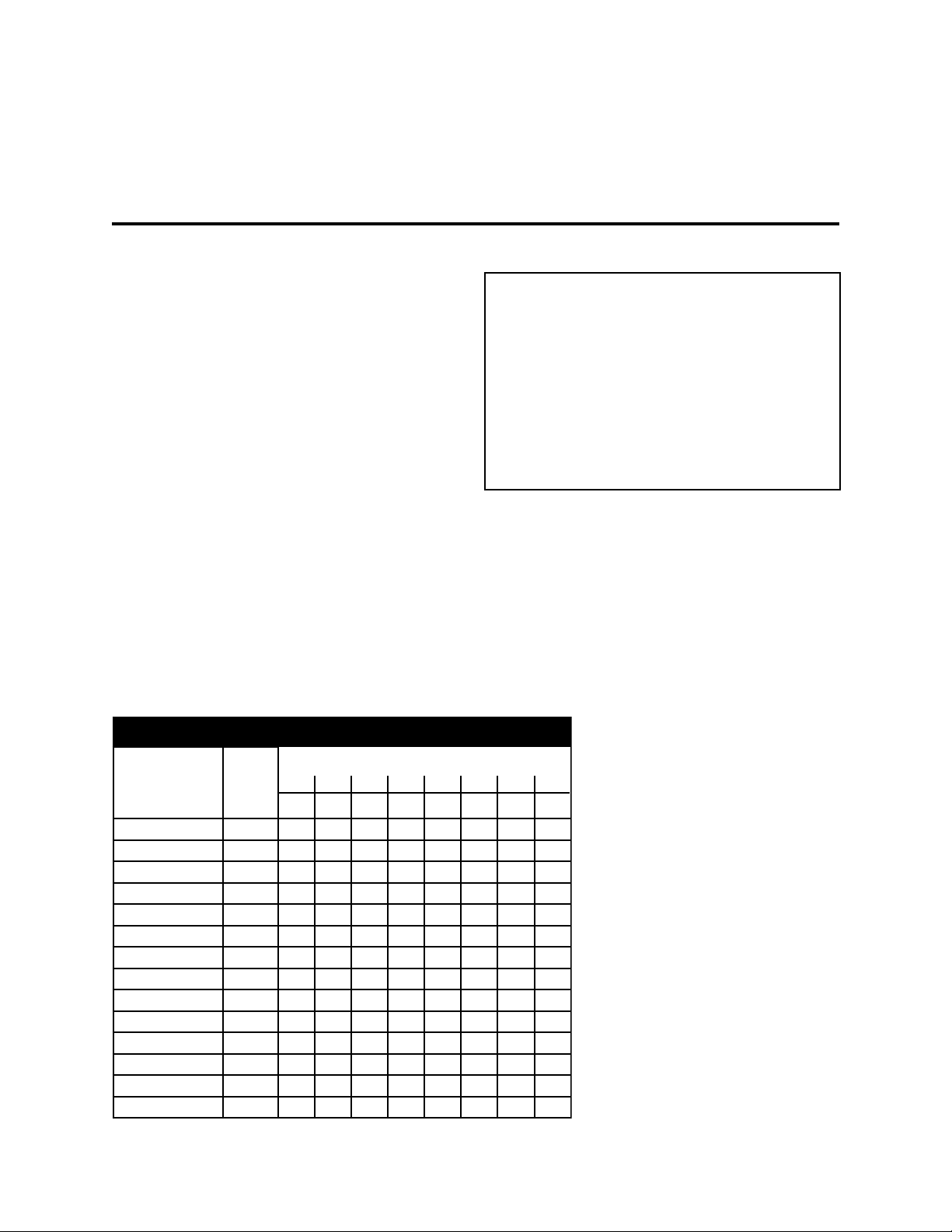

noitpmusnoCrewoPlacipyT

ecnailppA

VTroloC"310533.1248212369

VTroloC"9100166.248614246291

RCV0533.1248212369

pmaL00166.248614246291

rednelB0032621

retupmoCpotpaL0533.1248

norIgnilruC0533.12

llirDrewoP8/30053.30102

*rekamecI0026.22.54.016.516.142.38

rekaMeeffoC00016.6020408061

*rotaregirfeR'uc3051248212369

*rotaregirfeR'uc02057122448621633276

evaworciMtcapmoC0575510306021081

evaworciMeziSlluF0051010306021042063

muucaV00113.7224488671462

lacipyT

egattaW

.niM5.niM51.niM03.rH1.rH2.rH3.rH8.rH42

14

AMP-HOUR CONSUMPTION FORMULAS

(AC amps x 10) x 1.1 x hours of

operation = DC amp hours

(watts/ DC voltage) x 1.1 x hours of

operation = DC amp hours

(AC VA/ DC voltage) x 1.1 x hours of

operation = DC amp hours

DC voltage is 12, 24 or 32,

depending on your system.

In all formulas, 1.1 is the correction factor for

inverter efficiency.

Typical Power Consumptlon

The chart identifies typical power consumption

for common AC loads. Use it as a guide when

identifying your power requirements.

Many electric motors have momentary starting

requirements well above their

operational rating. Start-up watts

are listed where appropriate.

sruoHpmA/semiTnuRecnailppA

Individual styles and brands of

appliances may vary.

If using the same battery bank

for the inverter and other DC

loads, be sure to consider the

power consumption of the DC

loads when sizing the battery

bank.

NOTE Certain laser printers, breadmakers,

digital clocks and appliance/tool chargers

.semitnursuounitnocsuoiravnodesab)CDtlov21@(desusruohpmAlatotehtstneserperxobhcaenirebmuN

.elycytud-3/1agnisudetaluclacyllacipytsinoitaregirferetoN*

may not operate on modified sine wave.

Page 15

BATTERY CHARGING

Battery Charging

Completely charging wet cell deep-cycle batteries requires the battery voltage to be raised

beyond what is known as the gassing point.

This is the voltage at which the battery begins

to bubble and gas is given off. If charging stops

short of this point, sulfate is left on the plates

and deterioration of the battery begins. The

gassing point will vary with battery temperature.

At 77 °F, the gassing point of a 12-volt battery

is about 14.0 volts.

AGM and gel cell batteries must not be

charged to their gassing point. In fact, high

voltage charging which gasses these batteries

is harmful to them. They typically require a

lower bulk charge voltage and a higher float

voltage than wet cell batteries. Consult the

battery manufacturer for specifications.

Fleet Power Battery Chargers

Fleet Power battery chargers are designed to

overcome the limitations of conventional

chargers by utilizing three distinct charge

stages, each designed for optimal charging of

wet, gel cell and AGM deep-cycle batteries.

Battery type selection is made on the front

panel of the inverter/charger or through the

Remote Control Panel. For more information

on battery type selection, see page 7 or refer to

the Remote Control Panel manual.

15

Page 16

BATTERY CHARGING

NOTE: The FP3000-12 is ON whenever AC

power is connected to the charger input. The

charger can be turned OFF using the

CHARGE switch on the front of the unit. This

sequence will occur each time external AC

power is available. The charger can be turned

ON/OFF using the Remote Control Panel.

Each time the battery charger is engaged, the

three-stage charger proceeds automatically,

resulting in an efficient complete charge and

safe battery maintenance. Use of the Remote

Control Panel provides the ability to periodically

apply an equalizing charge.

Refer to Remote Control Panel owner’s

manual for more information.

16

The battery charger stages are:

Stage 1 - Bulk Charge During the bulk

charge stage most of the energy that has been

consumed during discharge is returned to the

battery bank. This phase is engaged as soon as

the battery charger is activated. Full rated charger

current is delivered to the battery bank until the

acceptance charge voltage limit is reached.

This results in a relatively rapid recharge.

Generally, a wet cell battery bank should not

be charged at a rate that exceeds 25% of its

capacity.

Page 17

BATTERY CHARGING

Gel cell and Advanced AGM batteries can

accept a higher rate of charge. Consult the

manufacturer for specifications.

Stage 2 - Acceptance Charge The

acceptance stage immediately follows the bulk

charge stage. During this stage the battery

voltage is held constant at the bulk charge

voltage limit and the current gradually ramps

down. During this stage the battery is accepting

its final amount of charge current and the last

of the sulfate on the plates is removed.

The acceptance stage lasts until the charge

current reaches the transition point. A timer will

terminate the acceptance stage if this current

level is not reached.

ACCEPTANCE TO FLOAT TRANSITION POINT

FP3000-12

Maximum acceptance time is one hour for wet

and AGM cells and three hours for gel cells.

Gel cell acceptance time can be longer because

they are less likely to gas. Expect wet cell batteries to gas somewhat during acceptance—this

is a necessary part of the charging process.

15 Ampere DC

The float charge stage holds the battery voltage

constant at a preset lower level, where it is

safe for long-term battery maintenance. During

the float charge stage, the full output current of

the battery charger is available to operate any

DC appliances that may be on the system,

while constantly maintaining the float charge

voltage.

The battery charger remains in the float charge

stage indefinitely until the charger is disconnected from incoming AC power or turned OFF

on the unit or with the Remote Control Panel.

Stage 4 - Equalizing Charge This is the only

battery charger stage which is not engaged

automatically. It must be manually initiated

each time. Applying an equalizing charge is

possible only with a Remote Control Panel.

Periodic equalizing is recommended by most

wet cell deep-cycle battery manufacturers.

There are no firm rules for how often an equalizing

charge should be applied. Follow the battery

manufacturer’s recommendations for equalizing.

Stage 3 - Float Charge When the

acceptance stage is terminated, either

because the charge current ramped down to

the transition point or the timer engaged, the

charge current will shut off. The unit monitors

the battery voltage while it drifts down from the

acceptance charge voltage limit. When it

reaches the float voltage set point, the float

charge stage is engaged.

17

Page 18

BATTERY CHARGING

The equalizing charge is a timed, eight-hour

cycle. The cycle can be ended early by interrupting the AC power to the charger at any

time during the cycle. Equalizing should only

be engaged after the batteries have been fully

charged by a normal battery charging cycle.

During this equalizing stage, the battery

voltage will increase to the equalize voltage.

This will cause the battery bank to gas

profusely and will accomplish the following:

1. Removal of residual sulfate. Each time a

battery is cycled (discharged and charged), a

small amount of sulfate is left on the plates.

Over time, this gradual buildup of sulfate will

compromise the performance of the battery.

By applying an equalizing charge, the sulfate is

returned back to the electrolyte, raising the

specific gravity and fully exposing the active

material of the plates.

2. Bring all cells to the same potential.

All lead-acid batteries are made up of individual

2-volt cells. As the battery bank is cycled, slight

differences in the cells result in different cell

voltages, affecting the overall charge

effectiveness. Equalizing brings all cells to the

same voltage and the electrolyte in each cell to

the same specific gravity.

3. Mixing up of the electrolyte. Electrolyte in

battery cells tend to separate into layers of acid

and water. The vigorous bubbling action of the

battery during equalizing serves to physically

mix the electrolyte. Refer to the Remote

Control Panel owner’s manual for additional

cautions on equalizing.

Note: Do not equalize gel cell batteries.

18

Page 19

WARNINGS

1. Do not equalize gel cell batteries.

Check remote default settings.

2. Always monitor the equalize charge

cycle. Provide proper ventilation for

battery fumes. Do not allow any sparks

during equalizing. If one or more cells begin

to overflow, terminate the equalize cycle.

3. Check the battery electrolyte both

before and after the equalizing charge.

Do not expose the battery plates to air.

Leave the battery caps on while equalizing.

Top off after equalizing.

4. Remove all loads from the DC system

before equalizing. Some DC loads may

not tolerate the high charge voltage.

BATTERY CHARGING

5. With the Remote Control Panel the

battery state-of-charge LEDs sequence

during equalizing. When the equalization

cycle is complete, the charge automatically

goes to float and the green float LED battery status light is on.

19

Page 20

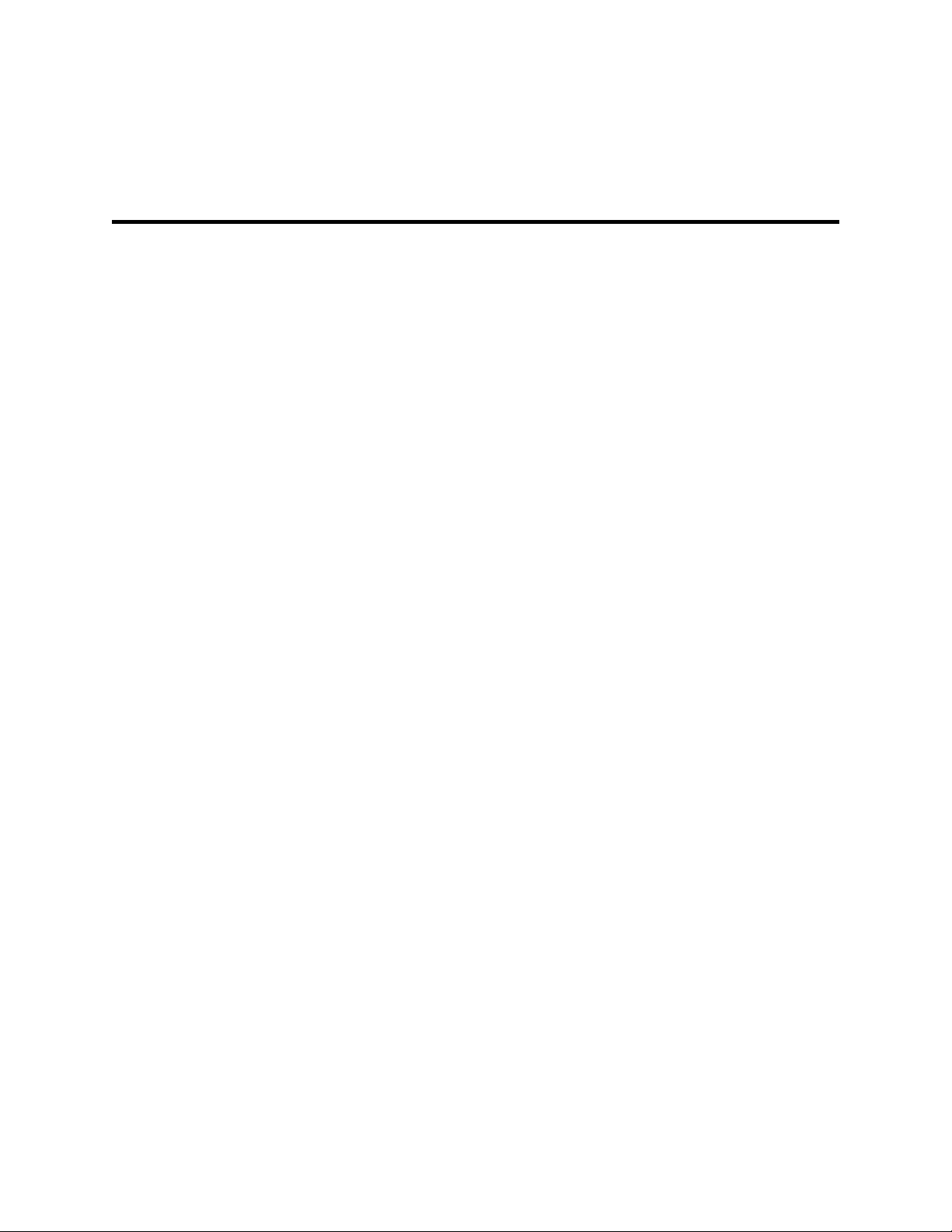

BATTERY CHARGER VOLTAGE SETTINGS

PMET 0EPYT 1EPYT 2EPYT 3EPYT

lleCteW *1leG *2leG MGA

F° C°TPECCATAOLFTPECCATAOLFTPECCATAOLFTPECCATAOLF

021 945.215.210.310.310.310.319.219.21

011 346.317.215.310.310.414.319.319.21

001 838.319.217.312.311.415.310.410.31

09 230.411.318.313.312.416.311.411.31

08 722.413.310.415.313.417.312.412.31

**07 **124.415.311.416.314.418.313.413.31

06 616.417.313.418.315.419.314.414.31

05 018.419.314.419.316.410.415.415.31

04 50.511.416.411.417.411.416.416.31

03 1-2.513.417.412.418.412.417.417.31

* There are two gel battery settings. Check with the battery manufacturer to determine the

proper setting for your batteries. Usually, Gel 1 is for long battery life; Gel 2 is for rapid charging.

**Default setting when the temperature sensor is not connected.

20

Page 21

INSTALLATION PRECAUTIONS

CAUTION This equipment is not ignition

protected and employs components that can

produce arcs or sparks. To reduce the risk of

fire or explosions, do not install in unvented

compartments containing batteries or

flammable gasses or areas in which

ignition-protected equipment is required.

WARNING

For continued protection against risk of

electric shock, use only the ground-fault

circuit interrupter (GFCI) type receptacles

detailed in this manual. Other types may

fail to operate properly when connected to

this inverter, resulting in a potential shock

hazard.

CAUTION To reduce the risk of electric shock

and prevent premature failure due to corrosion,

do not mount where exposed to rain,

dripping or spray.

CAUTION To reduce the risk of fire, do not

obstruct ventilation openings. Do not mount

in a zero clearance compartment—

overheating may result.

Confirm that your shipping carton contains:

• Inverter

• TSC temperature sensor with 15' cable

• Owner’s manual

• Warranty card

• Jumper for AUX Switch (only used

Remote Control Panel)

• Wire nuts

Typical Tools Needed

Flathead and Phillips screwdrivers

Allen (Hex) screwdriver (1/8'')

Wrench for connecting battery cables (9/16'')

Wire cutters

Wire strippers

Misc. assortment of wire ties and connectors

Accessories Needed for Installation

Fuse - UL Listed DC Rated slow blow fuse as

required by NEC.

Electrical wire (10 gauge) for AC input wiring.

Consult NEC for proper size for output wiring.

Battery cables 1-Positive, 1-Negative

Consult NEC for proper size

DC fuse cable

Mounting screws (4)

/Charger

without

CAUTION Risk of electrical shock. Both

AC & DC voltage sources are terminated

inside this equipment. Before servicing,

disconnect all inputs and outputs.

21

Page 22

INSTALLATION

CAUTION Risk of electrical shock. Do not

remove cover, no user serviceable parts

inside. Refer servicing to qualified service

personnel.

The FP3000-12 is appropriate for

installation in recreational vehicles (RVs), work

vehicles, and other applications.

It is recommended that installation be completed by an authorized Xantrex technical

dealer or experienced electrician.

Key Installation Points

1. The unit is designed to mount

horizontally (on a shelf).

2. Allow several inches of clearance around

the unit to permit a supply of fresh air to the

cooling fan. Do not block any of the vents or

louvers. The thermostat controlled fan pulls air

from outside the unit. It pulls air across the

internal components, particularly the transformer and heat sinks, then out the fan vent.

3. Keep the inverter

elements and out of direct contact with

water or spray. Failure to do so may result in

premature malfunction from corrosion and void

the warranty.

4. Mount the unit as close to the batteries

as possible but not in the presence of

flammable fumes or in an enclosed battery

compartment.

/charger out of the

5. Keep the overall length of each battery

cable less than 10 feet. Do not use frame

ground or a ground bonding system as a

current-carrying conductor. Run the negative

(-) cable directly to the battery bank. If the

positive (+) and negative (-) cables run parallel

to each other, twist the cables together. This

will minimize the inductive adverse effects of

cable length. Be sure the cable size meets

with NEC requirements for your installation.

6. Make sure all wiring conforms to local

and national electrical codes. If in doubt,

consult with a qualified electrician.

7. To meet electrical codes, a UL Listed DC

Rated slow blow fuse must be installed in the

positive battery cable within 18 inches of the

battery post. This fuse is intended to protect

the battery and cables against a short circuit.

The inverter is protected internally and will not

blow a properly sized fuse.

8. Do not connect the battery until you

have read the remainder of the installation

section. Observe proper polarity when

connecting batteries. Reverse DC polarity will

result in damage to the unit and will void the

warranty. Use care when making the DC

connections.

WARNING

Do not mount the unit in an enclosed

battery compartment. Take precautions to

keep dirt and spray off the unit.

22

WARNING

The FP3000-12 is not DC reverse polarity

protected. Be very careful to connect the

negative and positive cables correctly,

otherwise damage will result and the

warranty will be void.

Page 23

INSTALLATION

9. Do not backfeed the AC output of the inverter with incoming AC power. A backfeed

occurs when AC power from shorepower or

generator is connected to the output of the inverter. This will damage the inverter and void

the warranty. Remember that

must be fed only to the AC input and never the

AC output. Always check for AC voltage before

connecting wires to the AC output. Do NOT

turn the inverter ON until all AC connections

have been made. Backfeeding the inverter

voids the warranty.

incoming AC

WARNING

Do not connect incoming AC from any

source to the AC output of the inverter.

This is known as backfeeding and will

damage the unit and void the warranty.

10. Do not connect the AC input to the AC

output. This would be equivalent to plugging

the battery charger into the inverter. This could

occur if the unit’s AC output is connected to the

entire leg of a circuit breaker panel, then a circuit

breaker on that leg is used to feed the battery

charger input. This will cause the unit to oscillate

ON and OFF when the unit is in inverter mode.

tons using a hexagonal die. The T&B die has a

code number of 54. After the crimp is made,

the barrel of the terminal and the first inch of

the cable needs to be covered in UL Listed or

UL Recognized heat shrink tubing. Xantrex

recommends a 2-inch length of 3M HDT 0800

tubing. Other heat shrink may be used if it is

UL Listed or UL Recognized as long as the

manufacturer’s directions are followed.

12. If installing in a system which includes an

existing battery charger or AC to DC converter,

make sure these do not operate from the

inverter output AC power. This sets up a

power loop which, due to inefficiencies, will

quickly drain the batteries.

13. An Auxiliary Switch port is located on the

front panel of the unit, covered by a flap. When

installing the unit for operation without a

Remote Control Panel, a jumper must be

installed in the Aux Switch port. The jumper is

shipped in a plastic bag with other installation

parts. DO NOT install the jumper until all cable

connections have been made.

When using a Remote Control Panel, the

jumper is not used.

11. Always use proper wire and connectors.

The proper battery cable size is critical. Considerable amperage flows in the DC circuit.

For the FP3000-12, use 3/0 AWG UL Listed

Welding Cable terminated on each with UL

Listed or UL Recognized ring terminal connectors. For the terminal, use Thomas & Betts

(T&B) part number BAL 2038. Be sure the

connectors are attached to the cable using a

method approved by the connector manufacturer. For the connections to meet all requirements, T&B recommends that each terminal

be crimped in two places with a pressure of 15

Auxiliary Switch Port

Jumper

Actual size 3/8''L x 3/16''W

23

Page 24

INSTALLATION

Grounding

For safety purposes, the chassis of the inverter

charger must be connected to your AC ground

system. Use 8 AWG bare copper or green

insulated wire, strip one end and use a screwdriver to secure it to the chassis ground bonding

lug on the side of the unit. This wire will connect

to the ground in your AC electrical system.

Make sure the connection is clean and tight.

The system AC ground bonding terminal is

located on the front of the unit under the

wiring cover at the bottom of the unit. This

connector is for the bare copper or green

ground wires from the AC branch circuit supply

and to the AC loads or distribution panel. It is

important that these AC input and AC output

ground wires connect to the AC ground bus in

the circuit breaker panels.

Some installations require heavier grounding

wire. Conform to local and national electrical

codes.

More information on grounding can be found

in the National Electrical Code and local

electrical codes.

/

Note: The battery cables are not connected

to the AC ground strip or to the chassis lug

of the unit.

Neutral Bonding

For safety purposes and NEC code

requirements, the FP3000-12 unit internally

bonds the AC output neutral (white) to the AC

output ground (green), when the unit is OFF or

in the inverter mode. When incoming AC

power is applied and the transfer switch is

engaged, the internal neutral-to-ground bond is

automatically lifted.

When external AC power is applied, the

grounding system is connected to the source

power ground, where neutral and earth ground

are bonded together. This technique ensures

safety in all conditions and conforms to the

requirements of the NEC.

WARNING

Do not connect incoming AC from any

source to the AC output of the inverter

charger. This is known as backfeeding

and will damage the unit and void the

warranty. The Over Temp/Overload and

Low Battery LEDs will be blinking rapidly if

this condition exists.

/

24

Ground Lug

Page 25

INSTALLATION

AC Wiring

The AC wires route through the strain relief

mounted in holes on the front of the unit. Use a

screwdriver to remove the screws which

secure the AC wiring compartment cover

plate. The labeling for the pigtails is on the front

of the unit and is visible when the cover plate is

removed. Note: green wires are connected to

the AC ground strip.

Black . . . . . . . . . . . . . . . . . Hot or Line

White . . . . . . . . . . . . . . . . . Neutral

Conventional metal strain reliefs are provided.

These can be replaced with plastic strain

reliefs for additional corrosion resistance or

3/4-inch conduit fittings if the wiring will be

routed through a conduit.

Appropriate wire gauges must be used

throughout the installation. Refer to NEC

specifications.

AC Input: All inputs from other AC sources

must be protected by branch circuit rated

circuit breakers.

In the United States, no additional circuit

breakers are required between the inverter

/

charger and the loads if the service to the

inverter

/charger is protected by a 20 ampere

branch circuit rated breaker. This also applies

to dual input models where the inputs may be

20 amperes each. In Canada, 15 ampere branch

circuit(s) maximum shall provide the service.

If a 30 ampere service supplies the inverter/

charger, additional 20 ampere (15 ampere in

Canada) maximum branch circuit rated circuit

breakers will be required between the inverter/

charger and the loads.

wiring compartment. Allow 6 inches of

individual insulated black, white and green wire

to work with. Strip 1/2 inch of insulation off

each conductor and connect to the pigtails:

black to black, white to white, and green to AC

ground strip.

Use the wire nuts provided to make the wire

connections. You may choose to use butt splices

(not included) to make the wire connections.

AC Output: Depending on the model you

have, feed one or two three-conductor AC

output wire groups for the two branch circuit

loads through its strain relief. Remember to

allow 6 inches of individual insulated black,

white and green wire to work with. Strip 1/2

inch of insulation off each conductor and

connect to the pigtails: black to black, white to

white, and green to AC ground strip.

Tug firmly on each connection to make sure

they are secure. Later, if the unit is not

operating properly, check these connections

first. Carefully tuck the wires into the AC wiring

compartment. Replace the cover plate.

Dual AC Output

STRAIN

RELIEF

INPUT

AC GROUND

STRIP

AC OUTPUT

STRAIN

RELIEF

Feed one or two three-conductor AC input

wire(s) through the strain relief and into the AC

25

Page 26

INSTALLATION

Ground Fault Circult Interrupters

To conform to NEC regulations, certain branch

circuits must be equipped with a Ground Fault

Circuit Interrupter (GFCI). Please consult the

code or a qualified electrician for details. Any

such branch circuits must be protected by a

brand rated circuit breaker consistent with the

GFCI rating. Underwriters Laboratories has

tested the following GFCI, and its use is

recommended. Receptacle Type:

Pass & Seymour

Catalog Number 1591

Rated: 15 Amps at 120 Volts AC

Remote Control Wiring

If installing a remote panel, route the remote

cable and connect to the Remote jack on the

front of the unit. Refer to the Remote Control

Panel Owner’s Manual for more information.

TSC Temperature Sensor

If installing the TSC (Temperature Sensitive

Charging) sensor, connect the ring terminal

end to the positive battery post, complete the

routing of the RJ11 cable (15 feet supplied) and

connect the plug end to the TSC jack on the

front of the unit.

DC Wiring

DC wiring is generally very simple—the

positive (+, may be red for identification) and

negative (-, may be black or yellow for

identification) cables from the inverter/charger

terminal posts are connected to the house or

auxiliary battery. Connection to the engine

starter battery is not recommended.

High current will pass through the DC wiring.

All wires must be properly sized and all

connections clean and tight. It is

recommended that the battery cable length

does not exceed 10 feet.

Battery cables should be connected to the

inverter/charger before any connections are

made to the battery. Follow the battery

hardware stackup diagram.

• Remove the negative (-) battery cable

cover from the unit and attach the battery

cable. Tighten the battery terminal bolts to a

torque value between 160 inch-pounds and

180 inch-pounds. Replace the cover for the

negative terminal before removing the cover for

the positive terminal.

TSC Jack

RJ11 Cable

Battery Cable

Hardware Stackup

Diagram

Battery

Bolt

Lock Washer

CAUTION Improper stackup may result in

excessive heat and damage to the unit.

WARNING

The FP3000-12 is not protected against DC reverse polarity. Be very careful to connect the negative and

positive cables correctly or damage will result and the warranty will be void.

26

Flat Washer

Battery Cable

Inverter/Charger

Page 27

INSTALLATION

• Remove the positive (+) battery cable

terminal cover from the unit and attach the

battery cable. Tighten the battery terminal bolts

to a torque value between 160 inch-pounds

and 180 inch-pounds. Replace the cover for

the positive terminal.

The negative (-) cable should be connected

directly to the negative post of the house or

auxiliary battery bank or the ground side of a

current shunt. Tighten securely.

The positive (+) battery cable must be fused

and connected to the positive post of the

house or auxiliary battery bank, or through a

selector switch to one or more battery banks.

A spark may be generated when the final

battery connection is made. This is normal; do

not be alarmed. However, do not make the final

connection in the presence of flammable fumes.

If multiple batteries are used, the

interconnecting jumper cables must be the

same AWG or larger as those connected to

the inverter/charger.

If multiple battery banks are to be charged, a

battery bank selector switch can be installed,

allowing the banks to be charged either

individually or simultaneously. A solenoid can

also be used.

NOTE: If installing in a vehicle, do not use the

vehicle frame as the negative conductor.

POSITIVE (+)

(Battery Cable

Cover on)

NEGATIVE (-)

(Battery Cable

Cover on)

27

Page 28

INSTALLATION

Battery Cable Fusing

A fuse is required by the NEC to protect the

battery and cables. A UL Listed DC rated slow

blow fuse must be installed in the positive (+)

battery cable, within 18 inches of the battery.

Recommended Fuse: UL Listed Class T

JLLN with a DC Rating. This fuse with fuse

holder is available from your dealer.

For the FP3000-12

350 Amp Fuse & Holder PN# 84-4159-00

350 Amp Fuse Only PN# 84-4152-00

HARDWARE STACK-UP OPTIONS

_

+

+ (red)

COMPRESSION / RING TERMINAL

NUT

LOCK WASHER

FLAT WASHER

INVERTER

CABLE

BATTERY

CABLE

FUSE

FUSE HOLDER

WARNING

Improper stack up of hardware will cause

excessive heat and fuse failure. Stack up

as shown.

28

EXPLODED VIEWS

OF FUSE ASSEMBLY

INVERTER

CABLE

RING / RING TERMINAL

NUT

LOCK WASHER

FLAT WASHER

BATTERY

CABLE

FUSE

FUSE HOLDER

Page 29

Follow these instructions to ensure proper

startup and confirm that the installation is correct.

1. Check to make sure Invert and Charge are

OFF. The INVERT LED should not be

illuminated, the CHARGE LED should be

blinking (charger ready but no external AC

power available). If using a Remote Control

Panel, make sure inverter and charger are OFF.

2. Check battery polarity. If the unit was connected to the battery with reverse polarity, the

unit will be damaged.

INSTALLATION

WARNING

Do not turn the inverter ON before

eliminating any possibility of backfeed.

• Add a load of 7 watts or more to the output

of the inverter. A 40-watt incandescent light

bulb will work fine. The DC Amps LEDs on the

remote will indicate the DC draw from the

battery through the inverter.

3. Check the battery voltage and ensure it is

within proper range for the unit (10–15.5 VDC).

4. Install the jumper in the Auxiliary Switch port

(AUX SWITCH), if using the inverter without remote. If operating the inverter with a remote,

the jumper should

Do not apply shorepower or generator

power without performing the following

steps:

1. Test the inverter function:

• With no loads connected to the output of

the inverter, turn the INVERT Switch ON. The

INVERT LED should be blinking green. If using

a remote, turn ON the inverter with the switch

on the Remote Control Panel.

• The FP3000-12 will produce a slight buzz.

If using a Remote Control Panel, the INVERT/

CHARGE LEDs will illuminate and the voltage

indicator will display the battery voltage. The

DC Amps LED will not be lit because the unit

is in the idle mode.

not be used.

• Leave the load connected and turn OFF

the INVERT mode by pressing the INVERT

switch or turn OFF the INVERT mode from the

Remote Control Panel.

2. Test the transfer function:

• Be sure the unit is OFF, the INVERT and

CHARGE LEDs are not illuminated. Apply

shorepower. If there is a backfeed in the

installation, the unit will protect itself, the LOW

BATTERY and OVERTEMP/OVERLOAD LED

will both be blinking rapidly (five times per

second). Do not proceed until the backfeed

condition has been corrected.

• Once shorepower has been applied to the

unit, there will be approximately an eightsecond delay. Then the unit should transfer

shorepower and power the load. If this does

not happen, do not proceed. If the LOW BATTERY and OVERLOAD/OVERTEMP LEDs

are blinking rapidly or if you are using a Remote

Control Panel, check the panel for backfeed

indication. The panel will show an overload

condition. Eliminate the backfeed condition.

29

Page 30

INSTALLATION

• Testing for backfeed. If a backfeed

condition is indicated, disconnect from

shorepower and disconnect the AC output

wires on the inverter. Make sure the inverter is

OFF. Apply shorepower and measure for voltage between the black and white wires that

were attached to the inverter output feeding the

electrical panel or loads, not the inverter output

wires. If there is voltage on these wires, a

backfeed condition exists and must be corrected

or damage will result.

3. Test the battery charger function:

• With shorepower applied and the transfer

switch engaged, the battery charger should be

in operation. The CHARGE LED will blink for

eight seconds. After the eight seconds, the unit

will enter the charge mode and the LED will be

illuminated. (NOTE: When using Temperature

Sensitive Charging, this time may be longer.)

NOTE: When AC is available, the unit will automatically default to charge mode without the

operator setting the unit in CHARGE mode. If

you do not want to charge, it is necessary to

press the CHARGE switch OFF.

• Turn the INVERT ON—the green LED

should blink. Remove shorepower and the

inverter should automatically pick up the AC load.

NOTE: For low power system shut down

mode, both the INVERT and CHARGE LEDs

must be OFF.

Repeat the test for transfer and battery charger

with the generator if you have one.

Congratulations, you have completed a

successful installation.

Verify the charger is working by using a

voltmeter. The battery voltage should gradually

increase. If using a Remote Control Panel, the

DC Amps LED indicates the current the

charger is putting out and the DC Volts LED

indicates an increase in battery voltage.

30

Page 31

TROUBLESHOOTING LED STATUS

sutatSDELsutatSnoitarepOsetoN

TREVNIEGRAHCYRETTABWOLPMETREVO

DAOLREVO

neerGdiloSneerGgniknilBFFOFFOontubydaerregrahC.gnitrevnI

.elbaliavaCAlanretxe

gniknilB

neerG

gniknilB

neerG

FFOneerGdiloSFFOFFO.gnigrahC.FFOretrevnIybretrevniehtteseR

neerGdiloSneerGgniknilBdeRdiloS* ontubydaerregrahC.gnitrevnI

neerGdiloSneerGgniknilB* deRdiloSontubydaerregrahC.gnitrevnI

FFOneerGgniknilBgniknilBwolS

FFOneerGgniknilB* gniknilBwolS

neerGdiloSFFOFFO.ybdnatsnisiretrevnI

FFOFFOFFO.ybdnatsinisiretrevnI

*:nwodtuhsegatloVyrettaB

deR

deR

.degrahcgniebsiyrettaB

.ffodenrutyllaunamregrahC

yrettaB.elbaliavaCAlanretxe

:gninraWegatloV

V51>CDV<V01

-revO.elbaliavaCAlanretxe

gninraWerutarepmet

V51>CDV<V01

lanretxeontubydaerregrahC

regrahC.elbaliavarewopCA

nwodtuhSerutarepmet-revo

lamroN

tnerrucgnigrahc,lamroN

sdeecxedaolCAfidetimil

.gnittesgnirahSrewoP

devomersirewopCAfI

regrahceht,deilppaerdna

.NOnrutyllacitamotualliw

.nottubTREVNIgnihsup

.knilbdluohsDEL

egatlovyrettaB.gninraW

nahteromro01nahtssel

stlov51

.nwodtuhsretrevnI.gninraW

.nwodtuhSretrevnI

nehwemuserlliwnoitarepO

stlov5.31sehcaeryrettab

yllacitamotualliwnoitarepO

sahtinuretfaemuser

nwoddelooc

FFOneerGgniknilB* gniknilBtsaF

FFOneerGgniknilBgniknilBtsaF

deR

FFOneerGgniknilBgniknilBtsaF

deR

.sutatsFFOroNOrehtieebdluoC*

nwodtuhSdaolrevOretrevnIyllaunaM.daolCAecudeR

deR

gniknilBtsaF

deR

FFOelppiRyrettaBgninraW

gniriwCA

tcerrocnI.nwodtuhSdeefkcaB

metsysehttratser

erofebgniriwniCAtcerroC

ehttratseryllaunaM.esu

.metsys

31

Page 32

32

page intentionally blank.

Page 33

GLOSSARY

Alternating Current (AC) An electric current

that reverses direction at regular intervals.

Sources of alternating current are shorepower,

generator power, inverter power or household

current.

Ampere (amp, A) The unit of measure of

electron flow rate of current through a circuit.

Amp hour (Amp-Hr., Ah) A unit of measure for

a battery’s electrical storage capacity, obtained

by multiplying the current in amperes by the

time in hours of discharge. (Example: a battery

which delivers 5 amperes for 20 hours delivers

5 amperes times 20 hours, or 100 amp hours

of capacity.)

Amp-Hour Capacity The ability of a fully

charged battery to deliver a specified quantity

of electricity (Amp-Hr., Ah) at a given rate

(amp, A) over a definite period of time (Hr.).

The capacity of a battery depends upon a

number of factors such as: active material,

weight, density, adhesion to grid, number,

design and dimensions of plates, plate spacing

design of separators, specific gravity and

quantity of available electrolyte, grid alloys, final

limiting voltage, discharge rate, temperature,

internal and external resistance, age and life of

the battery (bank).

AGM (Absorbed Glass Mat) Battery A lead

acid, maintenance-free battery.

AWG (American Wire Gauge) A standard

used to measure the size of wire.

Circuit An electric circuit is the path of an

electric current. A closed circuit has a

complete path. An open circuit has a broken or

disconnected path.

Circuit (Series) A circuit which has only one

path for the current to flow. Batteries arranged

in series are connected with the negative of the

first to the positive of the second, negative of

the second to the positive of the third, etc. If

two 6-volt batteries of 50 amp-hours capacity

are connected in series, the circuit voltage is

equal to the sum of the two battery voltages, or

12 volts, and the amp-hour capacity of the

combination is 50 amp hours.

Circuit (Parallel) A circuit which provides

more than one path for current flow. A parallel

arrangement of batteries (of like voltage and

capacity) would have all positive terminals

connected to a conductor and all negative

terminals connected to another conductor. If two

12-volt batteries of 50 amp-hour capacity each

are connected in parallel, the circuit voltage is 12

volts, and the amp-hour capacity of the

combination is 100 amp hours.

Current The rate of flow of electricity or the

movement rate of electrons along a conductor.

It is comparable to the flow of a stream of water.

The unit of measure for current is ampere.

Cycle In a battery, one discharge plus one

recharge equals one cycle.

Direct Current (DC) Current that flows

continuously in one direction such as that from

batteries, photovoltaics, alternators, chargers

and DC generators.

Equalize Charge A controlled overcharge of

the batteries which brings all cells up to the

same voltage potential, extends the battery life,

restores capacity and mixes the electrolyte.

This can only be done using the Remote

Control Panel.

Gel Cell Battery A type of battery that uses a

gelled electrolyte solution. These batteries are

sealed and are virtually maintenance free. Not

all sealed batteries are the gel cell type.

33

Page 34

GLOSSARY

GFCI (Ground Fault Circuit Interrupter) A

protective device that rapidly de-energizes a

circuit when current to ground exceeds a

predetermined value.

Ground The reference potential of a circuit. In

automotive use, the result of attaching one

battery cable to the body or frame which is

used as a path for completing a circuit in lieu of

a direct wire from a component. This method is

not suitable for connecting the negative cable of

the inverter to ground. Instead, route the cable

directly to the negative terminal of the battery.

LED (Light Emitting Diode) Indicator light.

NEC National Electric Code

Negative Designating or pertaining to electrical

potential. The negative terminal is the point from

which electrons flow during discharge.

Ohm A unit for measuring electrical resistance.

Ohm’s Law Expresses the relationship

between voltage (V) and current (I) in an

electrical circuit with resistance (R). It can be

expressed as follows: V=IR. If any two of the

three values are known, the third value can be

calculated by using the above formula.

TSC Abbreviation for Temperature Sensitive

Charging. The ability of the charger to adjust its

charging voltage based on the temperature

sensed at the battery bank if a temperature

probe is used.

Volt The unit of measure for electric potential.

Watt The unit for measuring electrical power,

i.e., the rate of doing work, in moving electrons

by or against an electric potential.

Watt-Hour (Watt-HR, WH) The unit for

measuring electrical energy which equals

watts x hours.

Wet Cell Battery A type of battery that uses

liquid as an electrolyte. The wet cell battery

requires periodic maintenance: cleaning the

connections, checking the electrolyte level and

performing an equalization cycle.

Positive Designating or pertaining to electrical

potential; opposite of negative. The positive

battery terminal is the point where electrons

return to the battery during discharge.

Power Sharing The feature of the charger to

reduce its output when the AC power being

consumed by the charger and external AC

loads connected to the output of the inverter

are in excess of the input breaker rating.

34

Page 35

Fleet Power 3000-12

SPECIFICATIONS

Nominal Battery Charge

Battery Voltage Range

Low Battery Cutout

AC Input Voltage Range

Frequency Regulation

Inverter Output Power (Continuous)

Inverter Voltage Regulation

Wave Shape

Surge Power

No Load Current Drain (Idle Mode)

Power Factors Allowed

Full Load Efficiency

Peak Efficiency

Protection

Charging Rate

12 VDC

10.0 to 15.5 VDC

10.0 VDC (+/- 0.5)

Minimum 90 VAC/Normal 130 VAC

50 or 60 Hz Quartz Regulated

3000 VA

120 V +/- 5% true RMS

Modified Sine Wave

75 amps

.12 amps

All

86% (60 Hz)

93%

Over/under utility voltage, over/under battery voltage, short circuit,

circuit breaker, over temperature, backfeed

140 amps (three stage)

AC Input (Max. Charge Mode)

Bulk Charge Voltage

Float Charge Voltage

Equalizing Charge Voltage

Status Panel

Weight

Dimensions

*variable on unit with Temperature Sensor installed and adjustable by Battery Type selected on the inverter/charger control panel

or from the Remote Control Panel.

28 amps

14.3 VDC*

13.4 VDC*

16.3 VDC*

Optional remote

50 lbs.

13.2'' L x 11.5'' W x 7.9'' H

35

Page 36

36

page intentionally blank.

Page 37

INSTALLATION

Installation examples for the FP3000-12

The following installation examples are the most commonly used applications involving

specific shorepower connections, generator power options, and AC load configurations.

Shorepower configurations:

Systems with one 30 amp single-phase shorepower source with optional generator.

Systems with two 30-amp shorepower sources with optional generator.

Systems with a 50-amp 120-volt single-phase (three wire) shorepower source with optional

generator.

Systems with a 50-amp 120/240 volt split-phase (four wire) shorepower source with optional

generator.

Inverter/charger configuration:

Single input/single output

FP3000-12 DC Cable and Fuse General Guide

Fuse size: 350 A

Typical DC amps: 300 A

Cable AWG by length*: 1 to 3 ft.—3/0

3 to 6 ft.—3/0

6 to 10 ft.—4/0

*This guide is intended to provide general recommendations for fuse and cable sizing. Always consult local

and national electrical codes for proper fuse and cable size prior to installation.

The chassis grounding wire must be no smaller than 1 gauge under that of the postitive battery cable.

37

Page 38

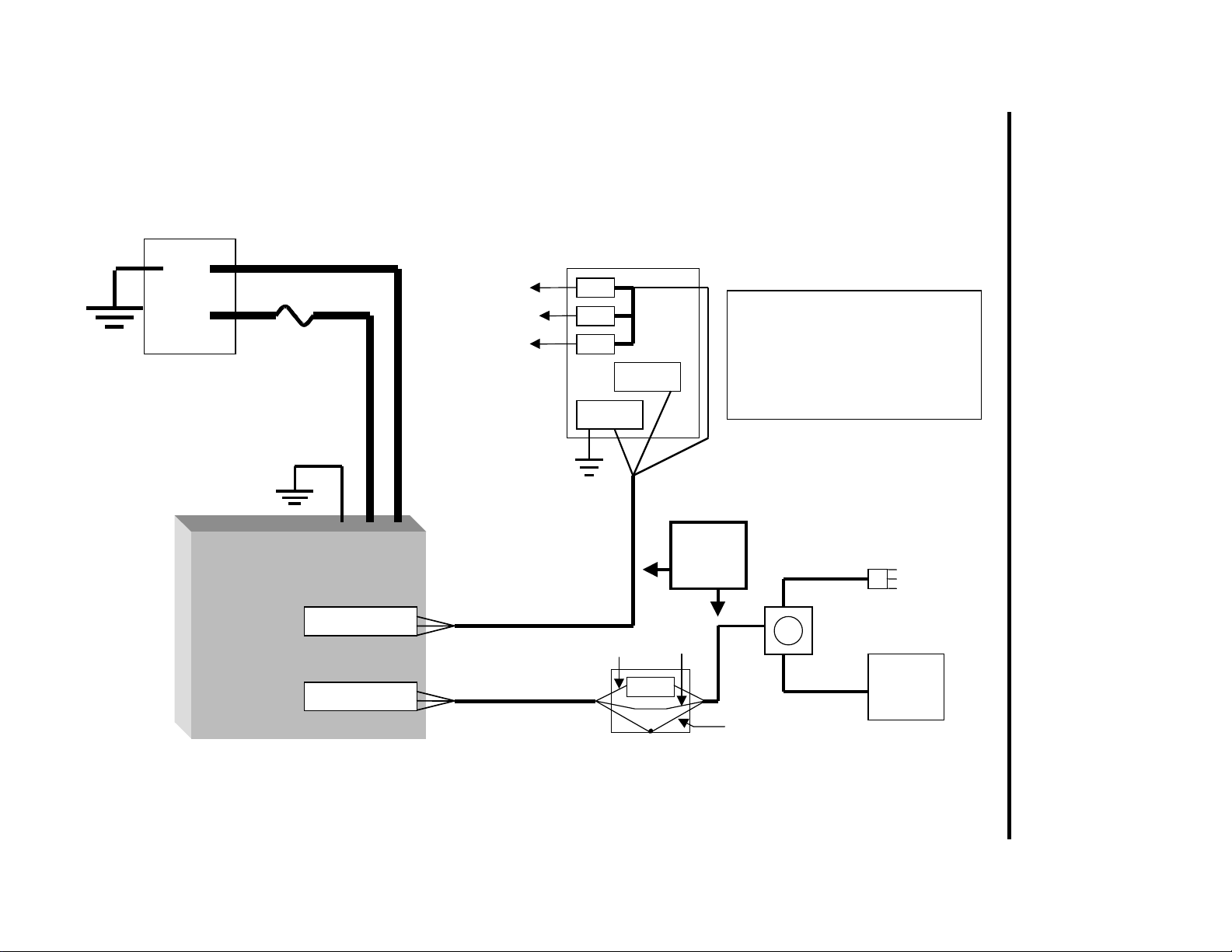

INSTALLATION OPTIONS

Installation Option #1

The inverter is used in a Single Input/Single Output mode. Up to 30 amps is transferred

through the FP3000-12 with the charger sharing power with all of the AC loads.

In this installation example, a single 30-amp shorepower source is available and all AC loads are

supplied power through the inverter in charge/transfer mode, or by the inverter in invert mode.

The charger shares power with the AC loads and can transfer up to 30 amps. The AC input

power must be supplied through a 30-amp branch rated main breaker.

In this type of system, the panel loads would normally not include any heavy loads such as

space heaters, stove, water heaters, air conditioners, AC to DC converters, or other battery

chargers. If these types of loads are present, they should be turned OFF when the inverter

power is being used to prevent overloading the inverter or rapidly discharging the battery

bank. To avoid the need for this manual form of energy management, installation option #2

should be considered.

If a generator is installed in the system, a break-before-make AC transfer switch is used to select between shore or generator power. The transfer switch AC output is then routed to the input

of the inverter/charger.

38

Page 39

12 VDC Battery Bank

-

FP3000-12 Installation Option 1

Inverter AC Sub Panel

+

Class T

Fuse

AC Output

AC Input

FP3000-12

+

To

Inverter

AC

Loads

Ground Bus

-

AC Wire Colors

Hot = Black

Neutral = White

Ground = Green/bare

30 A Main Breaker

Hot

Bus

Neutral Bus

Hot (Line)

30 A

10/3

AWG

Wire**

Neutral

Single Input/ Single Output

30 Amp Transfer Switch Power

Shares with Charger.

** Always consult Local and National

Electrical Codes for proper wire size

prior to installation.

30 A Shorepower

Transfer Switch

Optional

Generator

Ground

INSTALLATION OPTIONS

39

Page 40

INSTALLATION OPTIONS

Installation Option #2

The AC loads are split between main loads and “inverter loads.” The external sources

of AC power can be a single 30-amp shorepower source or a 30-amp breaker from a

panel fed by a 50-amp 120 volt single phase (three wire) shorepower source, 1 leg of a

50-amp 120/240 split phase (four wire) shorepower source, or a generator. The charter

shares power with the “inverter loads” only.

In this installation example, one single-phase shorepower source is available or only one leg of a

split-phase source is used to supply the AC input of the inverter/charger. It is highly recommended that only the lighter appliance and outlet circuits be connected to the inverter AC panel.

These loads are supplied power through the inverter in charge/transfer mode, or by the inverter

in invert mode. The charger shares power with the “inverter loads” only and can transfer up to 30

amps. The heavier loads such as space heaters, stove, water heater, air conditioners, AC to DC

converters, or other battery chargers, should remain connected to the main AC panel. These

loads are only supplied by shore or generator power from the main panel. This split load approach

will help avoid problems such as overloading the inverter or rapidly discharging the battery bank,

and eliminate the need to manually manage the energy usage of these loads when using

inverter power.

The inverter AC input must be supplied power from a 30-amp breaker in the main panel and

from the main neutral bus. The inverter’s AC output supplies a separate sub panel. The appliance and outlet loads are then supplied with power from the inverter hot and neutral bus in the

sub panel.

If a generator is installed in the system, a break-before-make AC transfer switch is used to select

between shore or generator power. The transfer switch AC output is then routed to the input of

the main AC panel.

40

Page 41

12 VDC Battery Bank

-

+

FP3000-12 Installation Option 2

Inverter AC Sub Panel

Class T

Fuse

To

Inverter

AC

Loads

Hot

Bus

Neutral Bus

Single Input/ Single Output

30 Amp Transfer Switch Power

Shares with Charger.

**Always consult Local and National

Electrical Codes for proper wire size

prior to installation.

.

INSTALLATION OPTIONS

41

AC Output

AC Input

FP3000-12

+

Ground Bus

-

AC Wire Colors

Hot = Black

Neutral = White

Ground = Green/bare

10/3

AWG

Wire**

From Shore or Optional Generator

L1 Neu. Gnd.

Main

Hot

Bus

30

Neutral Bus

Ground Bus

Main AC Panel

Page 42

42

page intentionally blank.

Page 43

WARRANTY

What does this warranty cover? This Limited Warranty is provided by Xantrex Technology, Inc.

(“Xantrex”) and covers defects in workmanship and materials in your Xantrex Fleet Power 300012 Inverter/Charger. This warranty lasts for a Warranty Period of one year from the date of

purchase at point of sale to you, the original end user customer.

This Limited Warranty is transferable to subsequent owners but only for the unexpired portion of

the Warranty Period.

What will Xantrex do? Xantrex will, at its option, repair or replace the defective product free of

charge, provided that you notify Xantrex of the product defect within the Warranty Period, and

provided that Xantrex through inspection establishes the existence of such a defect and that it is

covered by this Limited Warranty.

Xantrex will, at its option, use new and/or reconditioned parts in performing warranty repair and

building replacement products. Xantrex reserves the right to use parts or products of original or

improved design in the repair or replacement. If Xantrex repairs or replaces a product, its

warranty continues for the remaining portion of the original Warranty Period or 90 days from the

date of the return shipment to the customer, whichever is greater. All replaced products and all

parts removed from repaired products become the property of Xantrex.

Xantrex covers both parts and labor necessary to repair the product, and return shipment to the

customer via a Xantrex-selected non-expedited surface freight within the contiguous United

States and Canada. Alaska and Hawaii are excluded. Contact Xantrex Customer Service for

details on freight policy for return shipments outside of the contiguous United States and Canada.

How do you get service? If your product requires troubleshooting or warranty service, contact

your merchant. If you are unable to contact your merchant, or the merchant is unable to provide

service, contact Xantrex directly at: