Page 1

Internal Ethernet and

RS-232 Interface for

XFR Series

Programmable DC

Power Supplies

ENET-XFR

ENET-XFR3

Operating Manual

Page 2

Page 3

XFR 1.2kW and 2.8kW

Ethernet/RS-232 Interface

Option

Operating Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with

products from 50 watt mobile units to one MW util ity-s cale system s for wind, sol ar , ba tteri es, fuel cel ls,

microturbin es, and backup powe r appl icat ions in bot h grid- connec ted and sta nd-alone systems . Xantrex

products inc lude inverters, battery chargers, programmable power supplies, and variable speed drives

that convert, su pply, control, clea n, and distribute elec trical power.

Trademarks

XFR 1.2kW and 2.8kW Ethernet/RS-232 Interface Option is a trade mark of Xantrex International.

Xantrex is a registe r ed trademark of Xantrex International.

Other trademar ks, registered trademarks, and product names are the property of their respective owners

and are us ed herein for identification purposes only.

Notice of Copyright

XFR 1.2kW and 2.8kW Ethernet/RS-232 Interface Option Operating Manual © April 2004 Xantrex

Intern ational. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC.

(“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF

ANY TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER

DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER

DIRECT, INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF

THE USE OF SUCH INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE

ENTIRELY AT THE USER’S RISK.

Date and Revision

April 2004 Revi si on B

Part Number

TM-XR9B-01XN

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America)

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Page 5

About This Manual

Purpose

This Operating Manual is for the XFR 1.2kW and 2.8kW Ethernet/RS-

232 Interface Option; a microproces sor-controlled option card for all

models of XFR Seri es DC output power supplies. This manual provides

you with specifications, user options, and configuration instructions for

the interface, along with a command set whic h allows you to control

your power supply from a computer console. Error messages and

calibration proc edures are also included.

Scope

This Operating Manual covers the inter face only. Refer to your power

supply manual for install ation, configuratio n, an d operating procedures

for your power supply.

Audience

This manual is de signed for t he user who is fami liar with bas ic el ectrica l

theory especiall y as it applie s to the operation of power supplies. This

implies a recognition of C onstant Voltage and Constant Current

operation modes and the control of input and output power, as well as

the observance of safe techniques while effecting supply or pin

connections and any changes in switch settings. The user should also

have experience with networ k-based communications software and

protocols.

iii

Page 6

About This Manual

Organization

This Manual is organized into 4 chapters and 2 appendixes.

Chapter 1, “Features” Desc ribe s the in terface an d lists its featu r e s .

Chapter 2, “In stallation and Configuration” Explains basic setup

procedures for Ethernet mode and RS-232 mode. Describes inspection,

cleaning, shipping, and storage procedure s.

Chapter 3, “Operation” Lists the complete command set, status

registers, and error codes.

Chapter 4, “Calibration” Provides detail ed procedures f or volta ge and

current mode calibration as well as ove r voltage protection (OVP)

calibration. Includes calibration for programming and readback accuracy.

Appendix A, “Spec ifications ” Details the interface specifications.

Appendix B, “Advanc ed Ethernet Administration” Details how to

change network pa ssword, view port sta tistics and interpre t LED

information.

“Warranty and Product Information” Explains Warranty and return

information.

iv TM-XR9B-01XN

Page 7

Conventions Used

The following conventions are used in this guide.

Note: These notes des cribe an i mportant a ction item o r an i tem that you

must pay attention to.

About This Manual

WARNING

W arnings ident ify condition s that could result in pe rsonal injury

or loss of life.

CAUTION

Cautions identify conditions or practices that could result in

damage to the unit or other equipment.

Important:

know , but not as serious as a caution or warning.

These notes describe thin gs which are important for you to

Related Information

You can find more information about Xantrex Technology Inc. as well as

its products and servic es at www.xantrex.com

TM-XR9B-01XN v

Page 8

vi

Page 9

Important Safety Instructions

WARNING: High Energy and High Voltage

Exercise caution when using a nd calibrating a power supply.

High energy le vels can be stor ed at the output volta ge te rminals

on a power supply in normal operation. In addition, potential ly

lethal voltages exist in the power circuit and on the output and

sense connectors of a power supply with a rated output greater

than 40 V. Filter capacitors sto re potentially dangerous energy

for some time aft er po w er is rem ov ed .

CAUTION

Operate the power supply in an environment free of flammable

gases or fumes. To ensure that the power supply’ s safe ty

features are not compromised, use the power supply as specified

in this manual and do not substitute parts or make any

unauthorized modifications. Conta ct the service technician for

service and repair help. Repairs must be made by experienced

service technicians only.

vii

Page 10

viii

Page 11

Contents

Important Safety Instructions

1

Features

Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–1

Features and Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Interface Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Ethernet Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Programmable Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

Readback Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

2

Installation and Configuration

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–1

Initial Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–3

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Ethernet/ RS -2 32 Int erf ace Subplate and PCB - - - - - - - - - - - - - - - - - - - - - - - -2–5

Changing Internal Jumpers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Procedure for 1.2kW XFR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Procedure for 2.8kW XFR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Basic Setup Procedure - Ethernet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

Basic Setup Procedure - RS-232- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–11

Configuring for Etherne t or RS-232 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Ethernet Communicatio ns - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–13

Ethernet Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Connecting to a Network - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Connecting Directly to your Computer - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Locating the Power Supply on Your Network - - - - - - - - - - - - - - - - - - - - - - - 2–14

Configuring Etherne t Bridge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Installing and Using Real Port® - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

Background - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Using RealPort® - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

RS-232 Communications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

RS-232 Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - vii

TM-XR9B-01XN ix

Page 12

Contents

Baud Rate Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Flow Control Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Remote/Local Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

Remote/Local Mode Startup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

Remote Mode Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

Local Mode Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Remote Enable (REN) Command - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Local Lockout (LLO) Command - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Power Supply Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Additional User Options and Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

OVP Selection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

TTL Shutdown Polarity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

User Signals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

User Lines Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

User Lines Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

3

Operation

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–1

RS-232 Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Ethernet Operation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Command Syntax - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Manual Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Command Format and Parameters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Floating Point Number <float> - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Command Strings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Command Terminators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Order - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Command Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Command Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Accumulated Status, Status, and Fault Registers- - - - - - - - - - - - - - - - - - - - - - - - 3–17

Error Codes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–19

Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–20

Diagnostic LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–20

Computer Operating Properly (COP) LEDs - - - - - - - - - - - - - - - - - - - - - 3–20

Ethernet Mode Troubleshooting Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

RS-232 Mode Troubleshooting Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

RS-232 and/or Ethernet Mode Troubleshooting Tips - - - - - - - - - - - - - - - - - - 3–23

x TM-XR9B-01XN

Page 13

4

Calibration

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–1

Voltage Mode Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

Voltage Calibration Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

Voltage Program Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

Voltage Readback Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Current Mode Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

Current Calibration Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

Current Program Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

Current Readback Calibration Procedure - - - - - - - - - - - - - - - - - - - - - - - - - - -4–6

Over Voltage Protection (OVP) Calibration - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–7

A

Specifications

Specifications for XFR 1.2kW with Ethernet/RS-232 Interface Installe d- - - - - - - - A – 2

Specifications for XFR 2.8kW with Ethernet/RS-232 Interface Installe d- - - - - - - - A – 4

B

Advanced Ethernet Administration

Changing the Root Password - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Resetting the Configuration to Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–3

Resetting the Configuration from a Browser - - - - - - - - - - - - - - - - - - - - - - - - B–3

Copying the Configurati on to and from a Server- - - - - - - - - - - - - - - - - - - - - - - - B–4

Viewing Port Statistics and Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Viewing Network Statistics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–4

Interpreting LED Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Contents

Warranty and Product Information

TM-XR9B-01XN xi

- - - - - - - - - - - - - - - - - - - - - - - - - -WA–1

Page 14

xii

Page 15

Figures

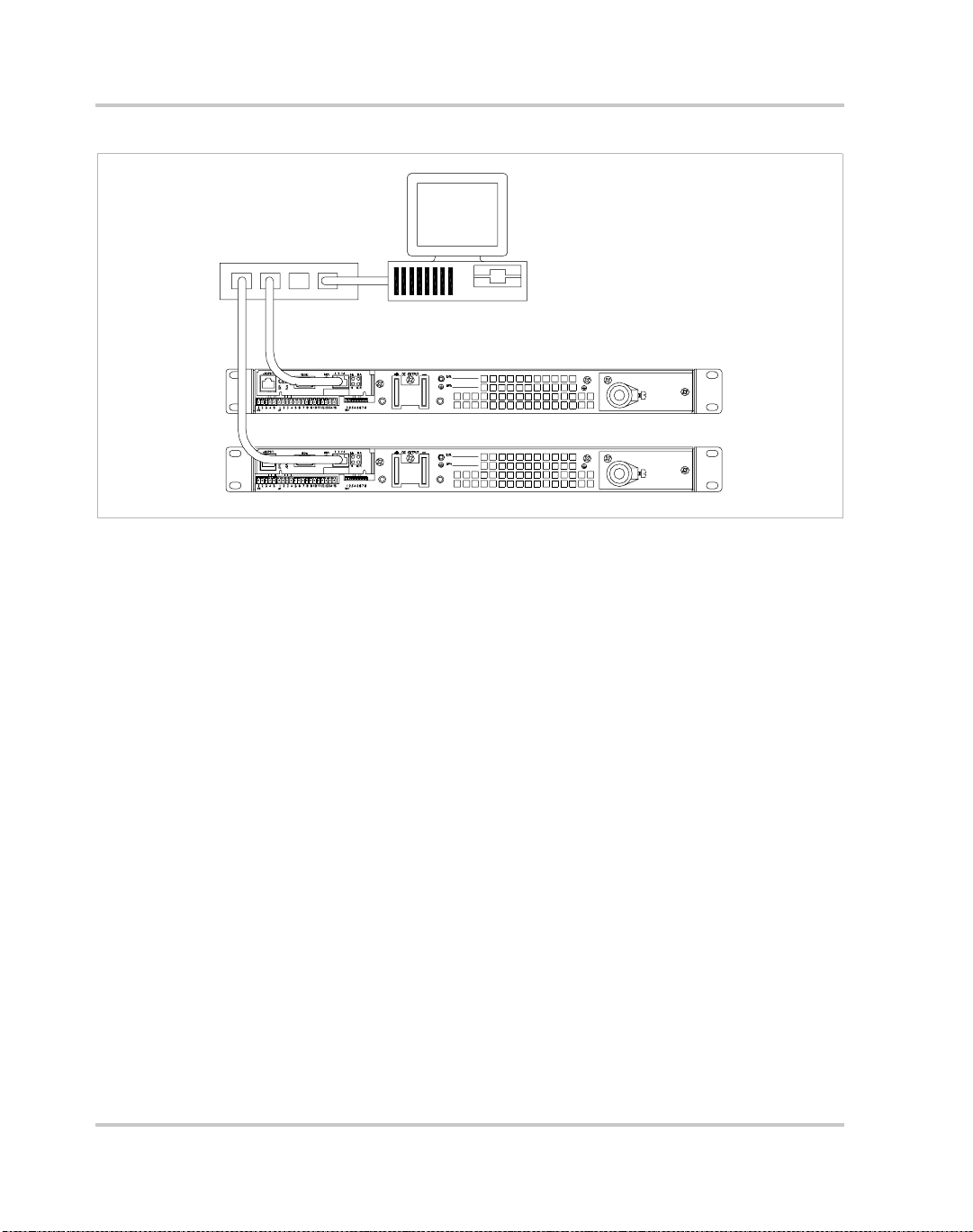

Figure 1-1 Sample configuration using Ethernet/RS-232 Interface

(1200 Watt DC Power Supplies Shown) - - - - - - - - - - - - - - - - - - - - 1–2

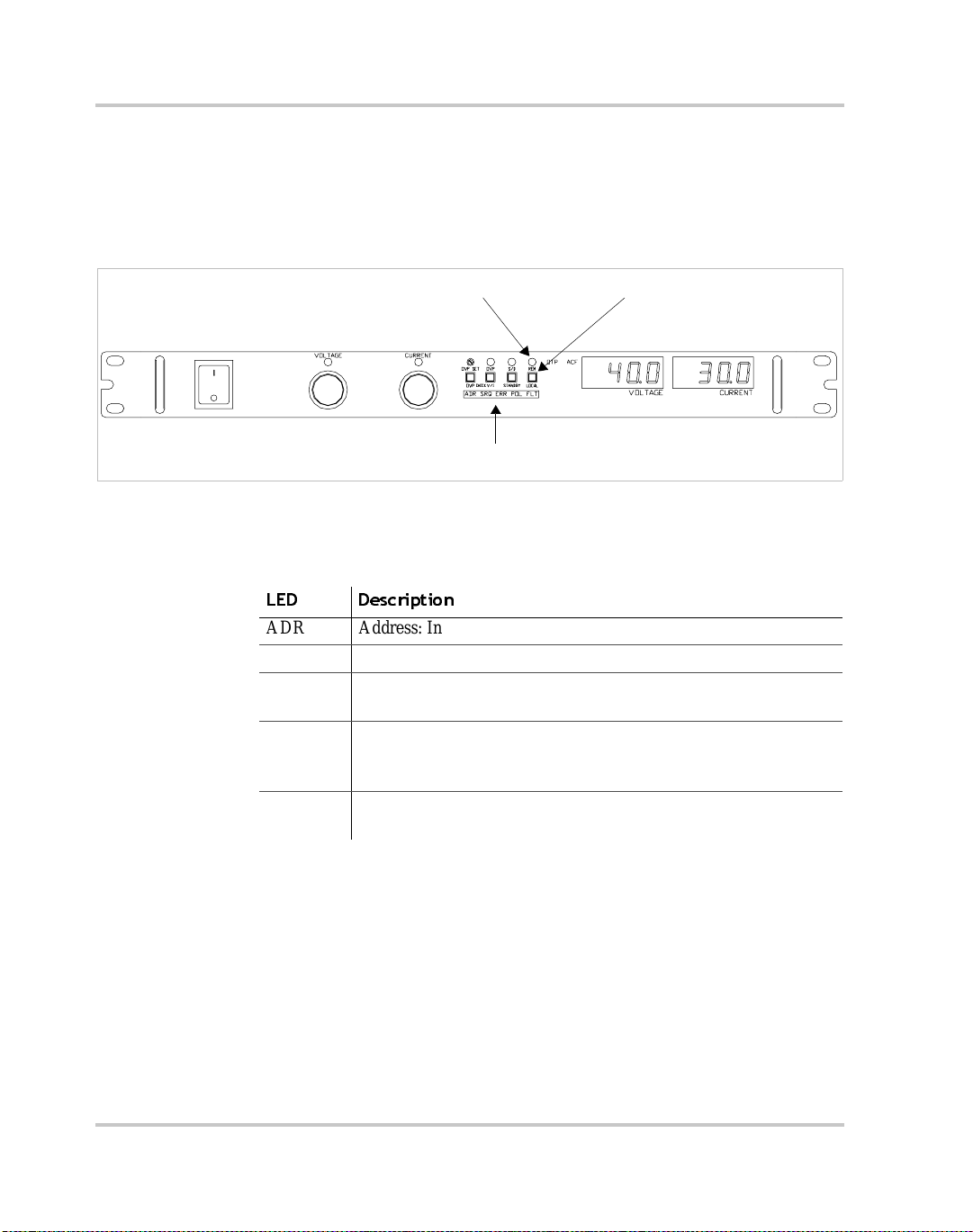

Figure 2-1 Power Supply Front Panel with Ethernet/RS-232 I nterface Installed

(1200 Watt Power Supply Shown) - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Figure 2-2 Ethernet/ RS -2 32 Int erf ace Subplate - - - - - - - - - - - - - - - - - - - - - - - 2–5

Figure 2-3 Ethernet/ RS -2 32 Int erf ace PCB - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Figure 2-4 Removing the PCB- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-5 RS-232 Connector Pinouts- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Figure 2-6 User Lines Signal Connector Circuit Block Diagram - - - - - - - - - - - 2–27

Figure 2-7 User Lines Cable with Ferrite Block - - - - - - - - - - - - - - - - - - - - - - 2–28

Figure 4-1 Voltage Calibration Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Figure 4-2 Current Calibration Setup - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Figure B-1 Ethernet Bridge LEDs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

TM-XR9B-01XN xiii

Page 16

xiv

Page 17

Tables

Table 2-1 Remote Programming LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Table 2-2 Ethernet/RS -23 2 Int erf ace Jumper Selections - - - - - - - - - - - - - - - - - 2–7

Table 2-3 Ethernet Setup P rocedure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-4 RS-232 Setup Procedur e - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Table 2-5 Jumper positions for Ethernet or RS-232 - - - - - - - - - - - - - - - - - - - 2–12

Table 2-6 Jumper J2 Settings f or Baud Rate - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Table 2-7 Jumper J2 Flow Control Section - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Table 2-8 Jumper J2 Flow Control Prot ocol Selection - - - - - - - - - - - - - - - - - 2–19

Table 2-9 Jumper J2 Remote/Loc al Start-up Settings. - - - - - - - - - - - - - - - - - 2–20

Table 2-10 Remote Mode Power On Conditions- - - - - - - - - - - - - - - - - - - - - - 2–21

Table 2-11 Power Supply Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Table 2-12 OVP Control Mode Select ion- - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Table 2-13 Jumper Set tings for TTL Shutdown Circuit Logic - - - - - - - - - - - - - 2–25

Table 2-14 User Signals Connector- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Table 3-1 Command Parameters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Table 3-2 Floating Point Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Table 3-3 Programming Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Table 3-4 Query Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Table 3-5 Calibration Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Table 3-6 Status Commands - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Table 3-7 Command Reference - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Table 3-8 Accumulated St atus, Status and Fault Registers - - - - - - - - - - - - - - 3–18

Table 3-9 Error Codes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–19

Table 3-10 Ethernet Mode Tips - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Table 3-11 RS-232 Mode Tips- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Table 3-12 RS-232 and/or Ethernet Mode Tips- - - - - - - - - - - - - - - - - - - - - - - 3–23

Table A-1 XFR 1.2kW 7.5 V to 40 V- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Table A-2 XFR 1.2kW 60 V to 600 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–3

Table A-3 XFR 2.8kW 7.5 V to 40 V- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–4

Table A-4 XFR 2.8kW 60 V to 600 V - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–5

Table B-1 Ethernet Bridge LEDs Interpretation - - - - - - - - - - - - - - - - - - - - - - - B–5

TM-XR9B-01XN xv

Page 18

xvi

Page 19

1

Description

Features

The Ethernet/RS-232 Interface is a microprocessor-controlled

option card for all models of the XFR series of DC output power

supply. Installed internally, the interface card allows you to

remotely control your power supply through your existing

network, or via a direct connection to your computer. It features

an auto-sensing 10/100Base-T network interface that provides fast

programming and readback utilizing an extensive command set.

You are able to select between Ethernet (factory default) or RS-

232 control by adjusting internal jumpers on the interface card.

Page 20

Features

CONTROLLER

HUB

Figure 1-1

Sample configuration using Ethernet/RS-232 Interface

(1200 Watt DC Power Supplies Shown)

Features and Functions

Interface Features

• Programmable soft limits for voltage and current

• Programmable over voltage protection with reset

• Easy-to-use, self-documenting command set

• Standardized commands for complete communic ation wit h any of th e

supplies in the system

• User-programmable isolated fault, polarity, isolation, and auxiliary,

user-defined outp ut signals.

• LED status signals: error, address, remote/local operation, and over

voltage protection.

• Foldback in CV or CC mode with reset

• Software calibration

1–2 TM-XR9B-01XN

Page 21

Ethernet Features

• Auto-sensing 10/100Base-T network interface

• Robust onboard TCP/IP stack supports:

•TCP/UDP

• UDP Multicast

• Universal IP Address Assignment via:

• DHCP

•RARP

•ARP-Ping

• Easy configuration via web browser (HTTP)

• RealPort® COM/TTY port redirection software

• Status LEDs for Link, Activity, and Diagnostics

• Reset switch to reboot Ethernet Bridge

Programmable Functions

• Output voltage and current

• Soft limits for voltage and current

• Over voltage protection

• Output enable/disable

• Maskable fault interrupt

• Hold and trigger

• Output relay signals

Features and Functions

Readback Functions

• Actual voltage and current

• Voltage and current settings

• Soft voltage and current limits

• Over voltage protection se tting

• Present and accumulated power supply status

• Programming error codes

• Fault codes

• Power supply model and software version identification

TM-XR9B-01XN 1–3

Page 22

1–4

Page 23

Installation and

2

Introduction

Configuration

The Ethernet/RS-232 Interface is usually installed at the factor y. Your

local distributor or service center can also install the interface,

especially for use in a previously-purchased supply already on site. You

must then configure the Inter f ace-enhanced supply for your system

using the “Basic Setup Procedur e - Ethernet” on page 2–10, or the

“Basic Setup Procedure - RS-232” on page 2–11.

To use this product, you must have the following equipment:

• a Xantrex XFR DC output power supply

• computer-based communications software package

Page 24

Installation and Configuration

Also, depending on your specific configuration, you will need additional

items.

For Ethernet (via network):

• CAT 5 network cable to connect XFR to your network

• computer connected to the network

For Ethernet (direct to computer):

• CAT 5 crossover cable to connect XFR directly to your computer

• computer with network interface card (NIC)

For RS-232:

• null modem serial cable (cross over)

• computer with an RS-232 interface (serial/COM port)

2–2 TM-XR9B-01XN

Page 25

Initial Inspection

On first receiving your unit, perform a quick physical check.

• Ensure each package contains a power supply with its Ethernet/RS-

232 Interface board installed, and manuals for the power supply and

the Ethernet/RS-232 Interface. Any additional parts shipped with the

power supply will be identifie d in the supply's documentation.

• Inspect the unit for any signs of physical damage such as scratches,

cracks, or broken switches, connectors, or displays.

• Check the printed circuit boa rd and components if you suspect

internal damage.

If the unit is damaged, save all packing materials and notify the carrier

immediately. For additional information, plea se see the section titles,

“Returning Power Supplies to the Manufacturer” in the manual shipped

with your complete unit.

Initial Inspection

CAUTION

If you remove the unit's cover, use proper static control

techniques to avoid damage to static-sensitive components on

the printed circuit board.

CAUTION

Use proper static control techniques to avoid damage to staticsensitive components on the printed circuit board.

TM-XR9B-01XN 2–3

Page 26

Installation and Configuration

Front Panel

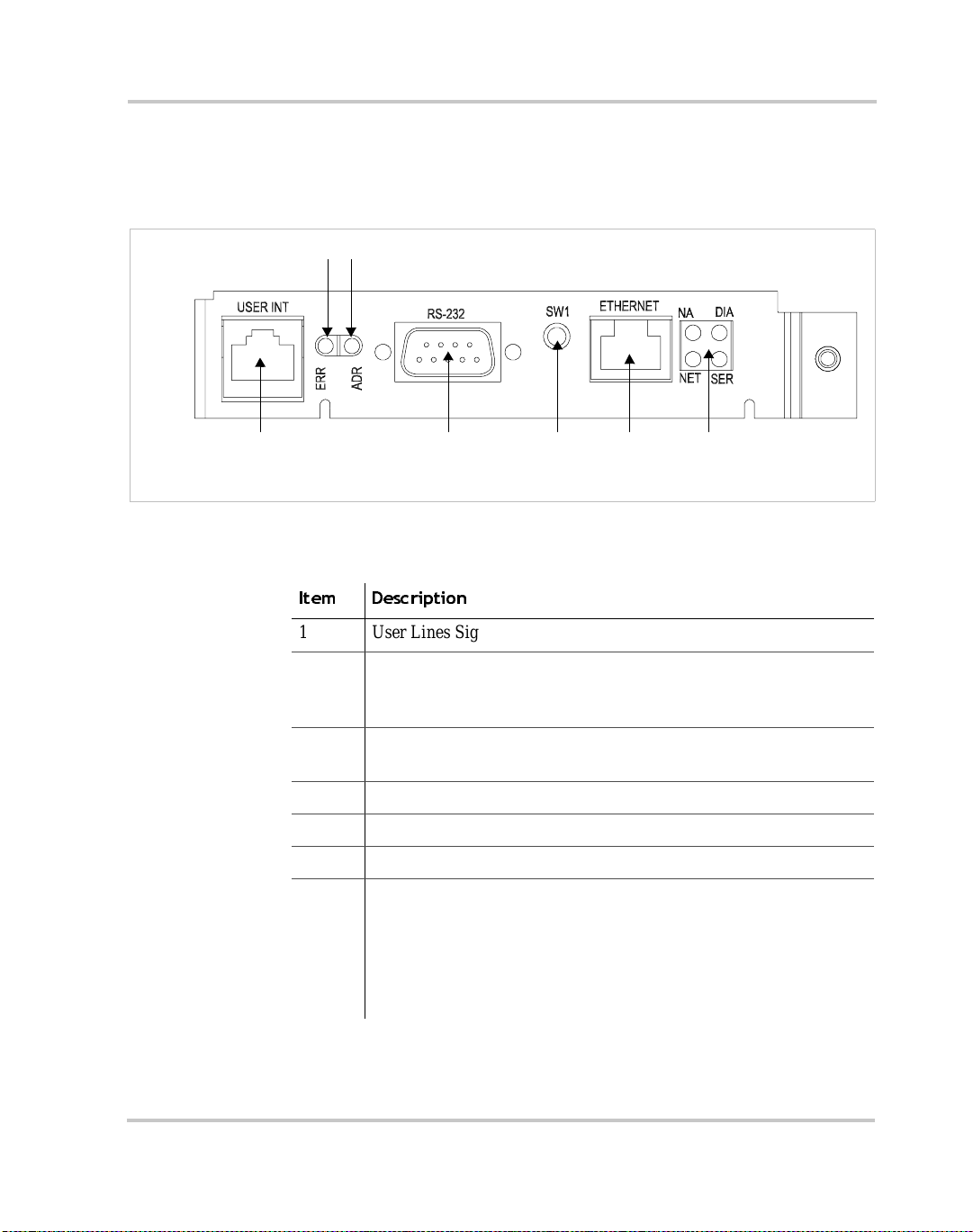

Figure 2-1 shows the front panel of an XFR 1200 Watt supply with

Ethernet/ RS -2 32 Int erf ace installed. There is a further desc ription of the

Remote Programming LEDs in Table 2-1.

Remote Programming LEDs. See table.

Local Switch (LOCAL)Remote LED (REM)

Figure 2-1

Power Supply Front Panel with Ethernet/RS-232 Interface Installed

(1200 Watt Power Supply Shown)

Table 2-1

LED Description

ADR Address : Indicates that the m aster controller is addressing t he unit.

SRQ Service Request: (GPIB only)

ERR Error: Indicate s when a programming error has occurred. You can

FLT Fault: Indicates that a fault has occurred. The fault bit must be

POL Polarity: Indicates that the polarit y use r line has been activated.

Remote Programming LEDs

clear the ERR LED with an error query command.

unmasked. Refer to the status register in Table 3-8 on page 3–18.

Momentarily lights if PON SRQ is set to on.

See “User Lines Connector” on page 2–26.

2–4 TM-XR9B-01XN

Page 27

Ethernet/RS-232 Interface Subplate and PCB

The Ethernet/RS-232 Interface Subplate is visible from the rear panel of

the unit. Rear panel components are identified in Figure 2-2.

3

2

Initial Inspection

1

Note: On some models, the subplate is rotated 180 degrees.

Figure 2-2

Ethernet/RS-232 Interface Subplate

4

(XFR 1.2kW shown - located on power supply rear cover)

Item Description

1 User Lines Signal Connector

2 Error LED (ERR)

Indicates that a programming error has occurred.

Clear with error query command.

3 Address LED (ADR)

Indicates that the unit is being addres sed by the master controller.

4 RS-232 Connector

5 Ethernet Br idge Reset Switch

6 RJ45 Ethernet Connector

7 Ethernet Bridge LEDs

NA: Reserved

DIA: Diagnostics

NET: Network link status

SER: Serial port activity

See page B–5.

5

6

7

TM-XR9B-01XN 2–5

Page 28

Installation and Configuration

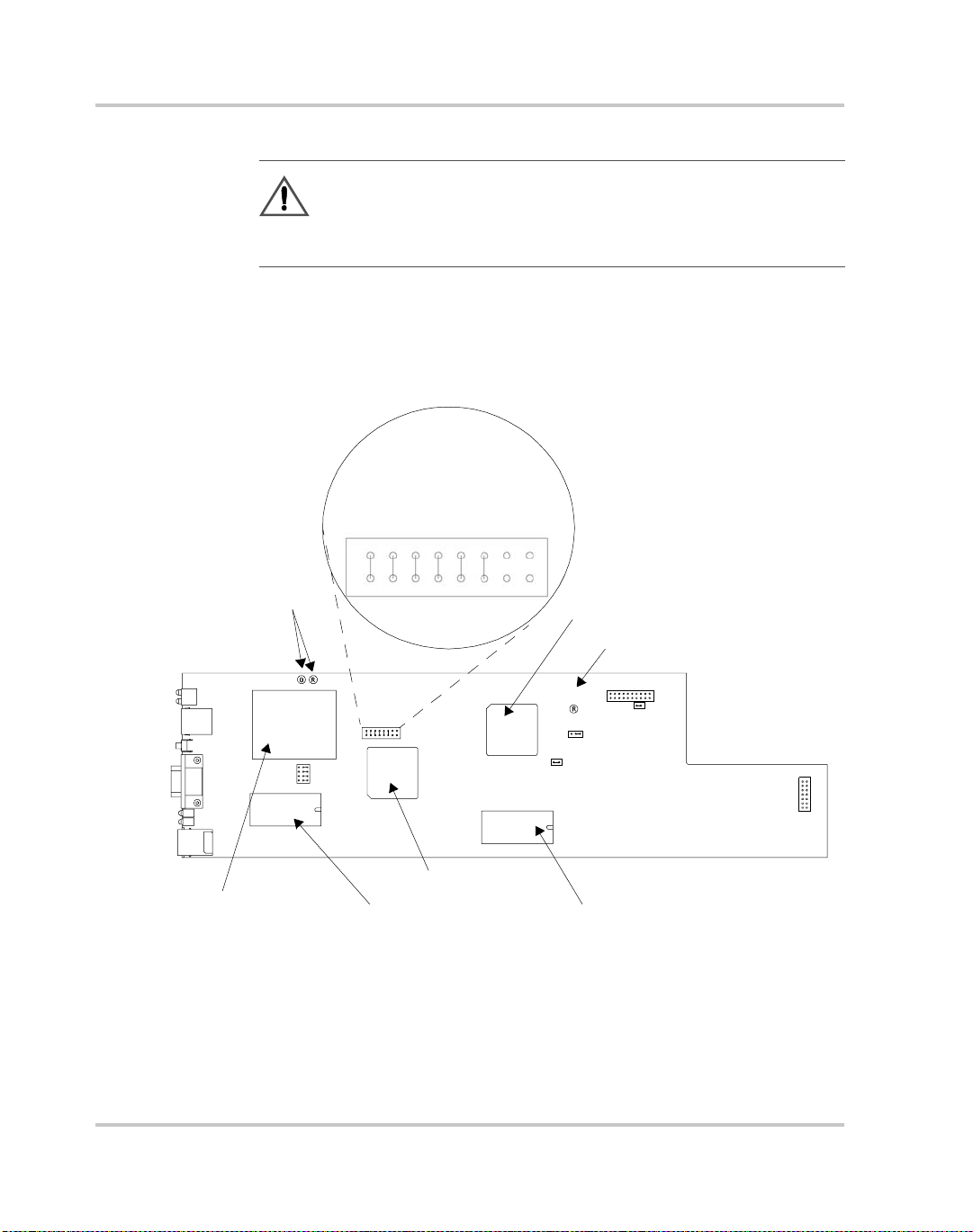

Figure 2-3 shows the inte rnal components on the Ethernet/RS-232

Interface PCB. Table 2-5 shows which jumpers need to be modified to

change modes or settings.

CAUTION

Use proper static control techniques to avoid damage to staticsensitive components on the printed circuit board

PONREM

XON

B3

B2

FLW

B1

NA

NA

Subplate

Ethernet Bridge

Figure 2-3

COP LEDs

CR167

CR166

J3

J4

J5

J6

123

J2

J2

Master EPROM

Ethernet/RS-232 Interface PCB

J103

Master Controller

Slave Controller

COP LED

J64

J65

1

3

J93

1

CR89

2

Slave EPROM

1

J1

2–6 TM-XR9B-01XN

Page 29

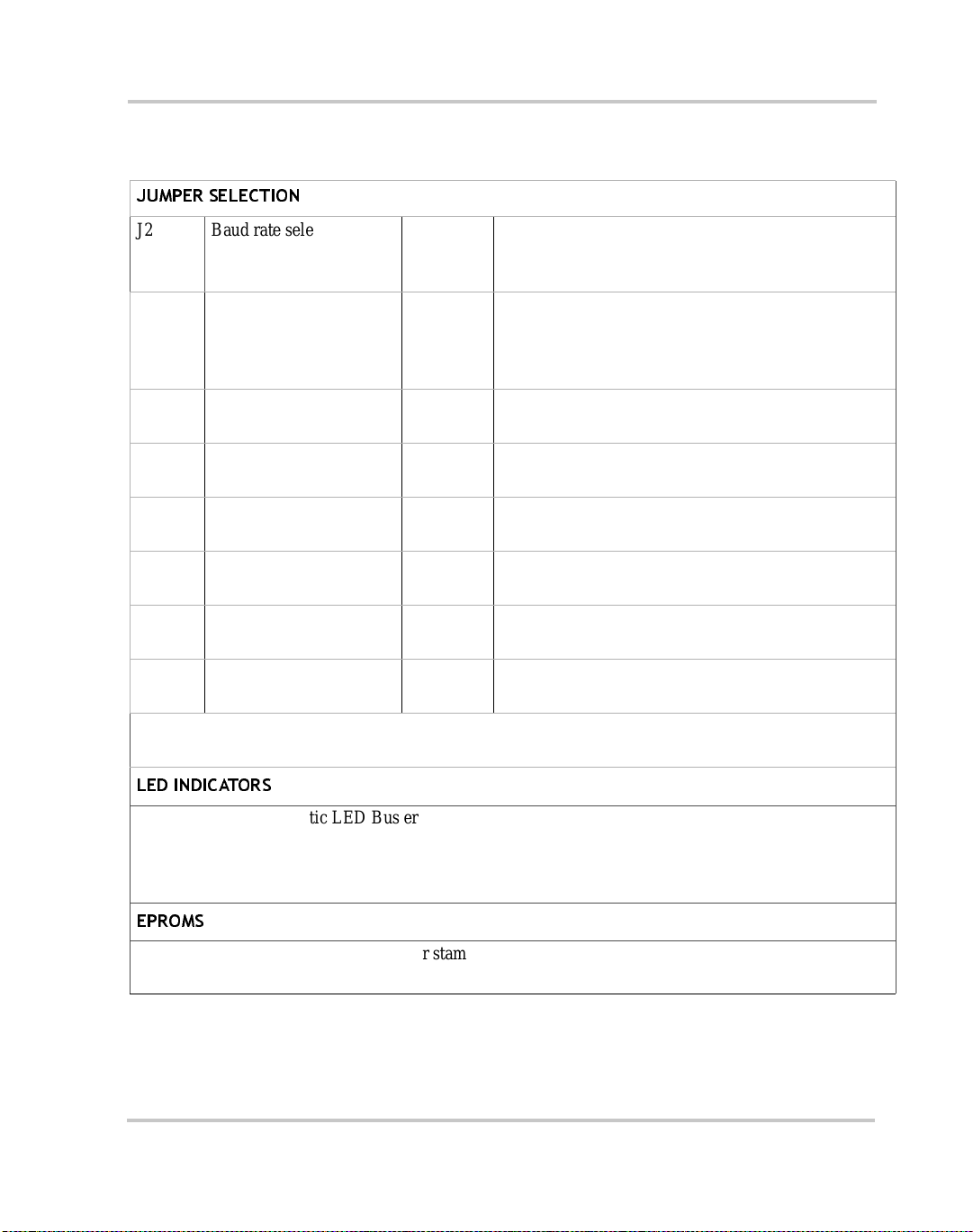

Initial Inspection

Table 2-2

JUMPER SELECTION

J2 Baud rate selection

J2 RS-232 flow control

J2 Unused (11-12) [closed] [default] Provides extra jumper.

J2 Power-On remote/local page 2–20 PONREM (15-16) [open] [default] PON in remote.

J3, J4,

J5, J 6

J65 Local OVP control

J93 User TTL shutdown (S/D)

J103 Remote OVP control

Ethernet/RS-232 Interface Jumper Selections

page 2–18 B1 (5-6) [closed] [default]

(default 9600)

page 2–19 FLW (7-8) [c losed] [default] Flow control disabled.

selection hardware (RTS /

CTS) or software (X ON/

XOFF)

Ethernet or RS232 mode page 2–12 (2-3) [default] Ethernet.

page 2–24 [closed] [default]

selection

page 2–25 (1-2) User TTL S /D line active low.

selection

page 2–24 [closed] [default]

selection

B2 (3-4) [closed] [default]

B3 (1-2) [closed] [default]

FLW (7-8) [open] Flow control enabled.

XON (9-10) [closed] [default] Hardware flow control.

XON (9-10) [open] Software flow control.

(13-14) [open] Not used.

PONREM (15-16) [closed] PON in local.

(1-2) RS232.

[open] Front Panel OVP Control.

(2-3) [default] User TTL S/D line active high.

[open]

Note: All other jumpers are not user-selectable.

LED INDICATORS

CR89 Red Diagnostic LED Bus error or Soft restart on Master circuitry

CR166 Red Diagnosti c LED Sof t restart on Master circuitry

CR167 Green Diagnostic LED Bus error on Master circuitry

Refer to “Tr oubleshooting” on page 3–20 for more information on these LEDs.

EPROMS

Slave EPROM See revision number stamped on EPROM

Master EPROM See revision numb er stamped on EPROM

TM-XR9B-01XN 2–7

Page 30

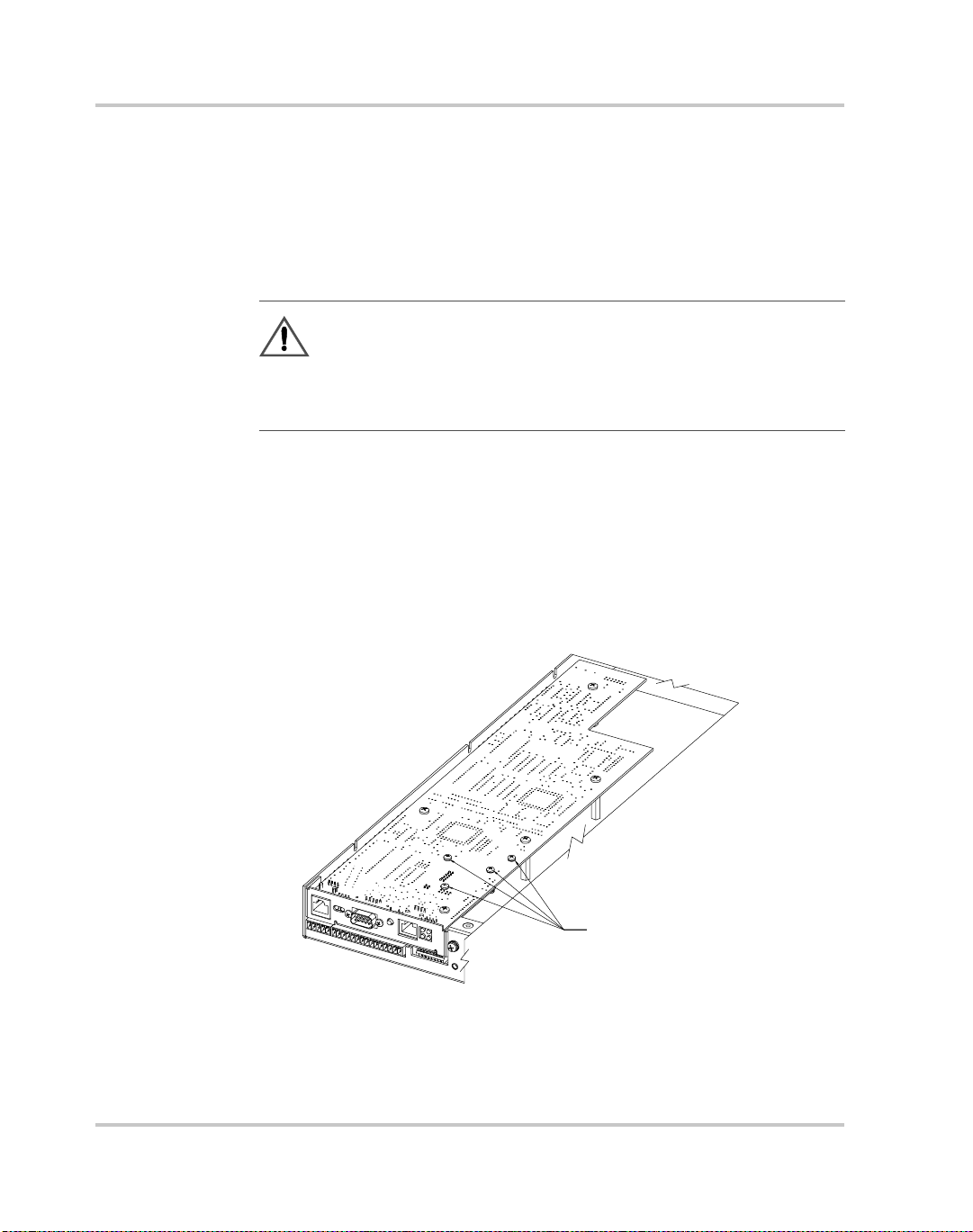

Installation and Configuration

Changing Internal Jumpers

Some of the settings on the Ethernet/RS-232 Interface card are user

selectable by way of jumpers on the print ed circuit board. The procedure

for changing the jumpers varies depending on if you have a 1.2kW XF R,

or a 2.8kW XFR.

CAUTION

If you remove the unit's cover, use proper static control

techniques to avoid damage to static-sensitive components on

the printed circuit board.

Procedure for 1.2kW XFR

Ensure that the input power connection has been disconnected and the

unit is powe red off before you attempt to remove the top cover. Remove

all the screws holding down the top cover and then remove the cover. The

printed circuit boa rd that you need access to is upside down (component

side down), so you must remove all the screws that a re holding it in place .

Refer to Figure 2-4 to see which screws should not be removed.

During service , do no t

DURING SERVICE, PLEASE DO NOT

REMOVE THESE SCREWS

remove these screws

Figure 2-4

2–8 TM-XR9B-01XN

Removing the PCB

Page 31

Once that is complete, turn the board over and, if necessary, remove the

short ribbon cab le co nn ect ed t o J6 4 on the int erf ace card to ge t acces s to

the under side of the PCB. You can now scan t he board and r efer to Figure

2-3 to locate the various compone nts and jumpers on the PCB. Once you

have made the necessary changes, rec onnect the ribbon cable, screw the

PCB back in place, and screw the top c over on.

Procedure for 2.8kW XFR

Ensure that the input power connection has been disconnected and

the unit is powered off before you attempt to remove the top cover.

Remove all the screws holding down the top cover and then remove

the cover. The printed circuit board that you need access to is right

side up (component side up), so refer to Figure 2-3 to locate the

various components and jumpers on the PCB. Once you have

located the jumpers and made the necessary changes, return the top

cover to its proper position, and screw it back in place.

Changing Internal Jumpers

TM-XR9B-01XN 2–9

Page 32

Installation and Configuration

Basic Setup Procedure - Ethernet

This procedure can be used as a quick reference for those familiar with

the configuration requirements for the Ethernet/R S-232 Interface as

installed in the DC power supply. For those who want more information,

each step refers to more detai led procedures located in subsequent

sections. Execute each step of the procedure in the sequence given.

Table 2-3

Step # Descrip ti on Action Reference

1 Mode

2 Ethernet

3 User Signal

4 Power ON Power on the unit and wait 45

5 L oc at e y o ur

6 Configure the

7 Test Begin Communicating with your

Ethernet Setup Procedure

Configure for Ethernet

Configuration

Connection

Connector

power supply on

your network

Ethernet Bridge

communications.

Connect the CAT 5 network c able to

the Ethernet connector on the

supply.

Configure and use the us er line

connector signals, if required.

seconds for the Ethernet Bridge to

complete its start-up routine. Before

proceeding, chec k to ens ure that the

green NETwork LED on the back

panel is ON.

Load the Setup Software that ships

with this interface card.

Access the device’s web server/

configuration page.

instrument.

See “Configuring for Ethe rnet or RS-

232” on page 2–12.

See “Ethernet Connection” on

page 2–13.

See “User Lines Connector” on

page 2–26.

See “Troubleshooting” on page 3–20

if the NETwork LED does not stay

illuminated after startup has

completed.

See “Locating the Power Supply on

Your Network” on page 2–14.

See “Configuring Ethernet Bridge”

on page 2–15.

If you do not have a TCP/IP based

software application suitable for this

application, and are familiar with RS232 type communica tions, see

“Installing and Using RealPort®” on

page 2–16.

2–10 TM-XR9B-01XN

Page 33

Basic Setup Procedure - RS-232

This procedure can be used as a quick reference for those familiar with

the configuration requirements for the Ethernet/R S-232 Interface as

installed in the DC power supply. For those who want more information,

each step refers to more detai led procedures located in subsequent

sections. Execute each step of the procedure in the sequence given.

Basic Setup Procedure - RS-232

Table 2-4

Step Description Action Reference

1 Mode

2Baud Rate

3 Flow Control

4 Remote/Local

5 RS-232

6 User Signal

7 Power ON Power on the unit. See “Additional User Options and

8 Power Supply

9 Test Test the link by communicati ng with

RS-232 Setup Procedure

Configure for RS-232

Configuration

Selection

Selection

Operation

Connection

Connector

Settings

communications.

Select transmi ssion speed.

(Default 9600)

Select flow control ON or OFF.

(Default is OFF) If flow control is

set ON, choose software-based

XON/XOFF or hardware-based

RTS/CTS communication control.

The factory default is PON REM. See “Remote/Local Operation” on

Connect the RS-232 cable assembly

to the RS232 connector on the

supply.

Configure and use the user line

connector signals, if req u ired.

Configure the controller’s operating

parameters to ma tch the power

supply settings.

the power supply.

See “Configuring for Ethernet or RS-

232” on page 2–12.

See “Baud Rate Se lection” on

page 2–18.

See “Flow Control Selection” on

page 2–19.

page 2–20.

See “Power Supply Settings” on

page 2–23

See “User Lines Connector” on

page 2–26.

Settings” on page 2–24 and “User

Signals” on page 2–26 for

information about Loc al/Remote

OVP, TTL Shutdown, and auxiliary

connecto r user signals .

See “Power Supply Settings” on

page 2–23.

Example: VSET2;ISET1

This co m mand s tr i ng sets po w er

supply voltage to 2V and its current

limit to 1A.

See “Operation”.

TM-XR9B-01XN 2–11

Page 34

Installation and Configuration

Configuring for Ethernet or RS-232

This interface card can be configured for Ethernet communication, or for

RS-232 communication, but not both simultane ously. From the factory,

the instrument wil l be configured for Ethernet communication. Therefore

you should only need to follow these instr uctions if you are switching

over to RS-232, or back to Ethernet. To switch between the two

configuration s, you must change internal jumpers on the interfac e card.

See “Changing Internal Jumpers” on page 2–8. Also refer to Ta ble 2-2

and Figure 2-3 on page 2–6 to locate the corre sponding jumpers.

Table 2-5

Jumper RS-232 Ethernet

J3 1-2 2-3

J4 1-2 2-3

J5 1-2 2-3

J6 1-2 2-3

When you have finished changing the jumper positions, ensure that the

baud rate, flow control, and power-on state are configured properly for

your new setup. These settings are also changed by adding or removing

jumpers, so it is best to perform this adjustment, if necessary, while the

interface card is accessible. Refer to “Baud Rate Selectio n” on page 2–18,

“Flow Control Selection” on page 2–19 and “Remote/Local Mode

Startup” on page 2–20 for m ore detailed information on how to

reconfigure these settings.

Jumper positions for Ethernet or RS-232

Note: If you are switching the interface card back to Ethernet it is

recommended to se t the baud rate to 9600, turn flow control off, and

have the unit power-on in remote m ode (these are the default settings).

2–12 TM-XR9B-01XN

Page 35

Ethernet Communications

Ethernet Connection

There are two options for controlling your XFR power supply via

Ethernet - "Connecting to a Networ k" or "Connecting Directly to your

Computer." The first option is to connect the power supply to a network,

and control the unit from your computer which is also connected to the

network. The second option is to connect the XFR directly to your

computer's network inte rface card (NIC). This bypasses the need for an

existing network.

Connecting to a Network

All that is requir ed to connect your XFR to a network is a straig ht through

CAT 5 network cable and an available network port.

Connecting Directly to your Computer

To connect your XFR directly to your computer you will need a crossover CAT 5 network cable. You will also need to check your network

settings on your computer to ensure that you are using a static IP address.

Check with your IT department for assistance.

Ethernet Communications

TM-XR9B-01XN 2–13

Page 36

Installation and Configuration

Locating the Power Supply on Your Network

1. Record the MAC address for your power supply. This will be visible

at the back of the XFR, on the interface card subplate. For example,

MAC Address

00429D 22EF45

MAC Address:

______________________________

2. Insert the Xantrex XFR Ethernet Software Utilities CD into your CD

drive.

3. If the CD does not start automatically, double-click the My Computer

icon, double-click the CD icon and then double-click

autorun_main.htm.

4. When the menu appe ars, click Xantrex Device Discov ery to instal l

and run the application. This app lication will find and list all XFR’s

with an Ethe rnet/RS-232 Interfa ce card on your ne twork.

5. You can now scan the list and locate your new XFR by its MAC

address.

6. If your network uses a DHCP server and DHCP was enabled on the

XFR, your new inst ru ment will al ready have an IP addr ess. If not, y ou

will have to configure an IP address manually. Refer to steps 2 and 3

in “Configuring Ethernet Bridge” on page 2–15 for more information.

7. Write down the IP address so tha t you can access the instrument via

its web server, and for when you start communi cating with the power

supply.

2–14 TM-XR9B-01XN

Page 37

Configuring Ethernet Bridge

The Ethernet/RS-232 Interface card has an Ethernet Bridge that converts

the ethernet pa ckets to serial data signals for processing by the embedded

microcontroller. The Ethernet Bridge must be properly configured for

serial communicati ons with the microcontroller. For example, settings on

the Bridge, such as Baud Rate and Flow C ontrol, must match the jumper

settings on the interfa ce board.

There are two ways to gain access to the configuration menu for the

Ethernet Bridge. One is to run the Setup program tha t is available on the

Software CD. This program will find your instrument and allow you to

configure it by clickin g on th e instr ument ’ s I P ad dress. You will the n n eed

to enter the correct username and password to be able to configure the

device.

Default Username: root

Default Password: dbps

The other method is to ope n up a web browser like Internet Explorer, and

type in the IP addr ess for the instrument. Again, you will be asked for the

username and password. Once you have accessed the configuration page,

follow these steps for prope r setup.

1. Click Configuration > Serial Port, and ensure that the foll owing

settings have been selec ted:

• Baud Rate: 9600

• Data Bits: 8

• Parity: None

• Stop Bits: 1

• Flow Control: None

Click Apply onc e you have finished a djusting the above settings.

Ethernet Communications

2. Now click Configuration > Network. If your network uses a DHCP

server (ask your IT department) you should se lect Obtain IP addre ss

automatically usi ng DHCP and then click Apply . I f your net work

doesn’t use a DHCP s erver, select Use the following IP address: and

enter an appropriate IP addre ss, Subnet Mask and Default Gateway. .

3. Ask for assistance from your IT depar tment to obta in an appropriate

IP address, Subnet Mask, Default Ga teway, Name Server, a nd

Domain. Once you ha ve made the appr opriate changes, clic k Apply. If

this changed the setting, the device will reboot, so you will have to

renew your connection to its configuration webpage for any further

configuration changes.

TM-XR9B-01XN 2–15

Page 38

Installation and Configuration

Installing and Using RealPort®

Background

RealPort® software allows you to keep using your existing applications

that rely on COM ports and RS-232 links for communication purposes,

instead of ha ving t o de velop TCP/IP based ne twork applic ations. Inst alle d

on a network-enabled PC, RealPort® cre a tes a virtual COM port. As

such, your applica tion still thi nks it is working with a real s erial port, such

as COM1. When the application sends data to this ser ial port, RealPort®

ships the data across the network to the Ethernet Bridge in your power

supply. By doing this, the network is transparent to your existing

application.

Installation

RealPort® can be installed on any PC running Windows NT 4.0,

Windows 2000, or Windows XP.

1. Insert the Xantrex XFR Ethernet Software Utilities CD into your CD

drive

2. If the CD does not start automatically, double-click the My Computer

icon, double-click the CD icon and then double-click

autorun_main.htm.

3. When the menu appe ars, click Digi RealPort ®.

1

4. Follow the on-screen instructions for proper installation.

Note: RealPort® drivers for UNIX syst ems are available . Contac t your

Xantrex representative to obtain these drivers if necessary.

Using RealPort®

Once you have installed the RealPort® driver for your power supply,

using it is as simple as running your existing application (such as

HyperTerminal, or a custom RS-232 application) and setting the COM

port to be the one created by the RealPort® drive r for your instrument.

1.RealPort® is a registered trademark of Digi International.

2–16 TM-XR9B-01XN

Page 39

RS-232 Communications

RS-232 Connection

WARNING

Do not operate the power supply and the computer at

significantly different frame potentials. The interface

connection syste m may not be c apabl e of hand ling the resul ting

excessive ground currents.

Use an approved RS-232 connector and null modem cabl e when

connecting the Ethernet/RS-232 Interface to your computer . The RS-232

connector uses the 9 pin mating connector on the rear panel. Figure 2-5

shows the pinouts for the RS-232 connect or.

Refer to Figure 2-2 on pa ge 2–5 for the position of the RS-232 connector

on the rear panel subplate.

RS-232 Communications

1 NC

2 RXD

3 TXD

4 NC

5 GND

6 NC

7 RTS

8 CTS

9 NC

Figure 2-5 RS-232 Connector Pinouts

TM-XR9B-01XN 2–17

Page 40

Installation and Configuration

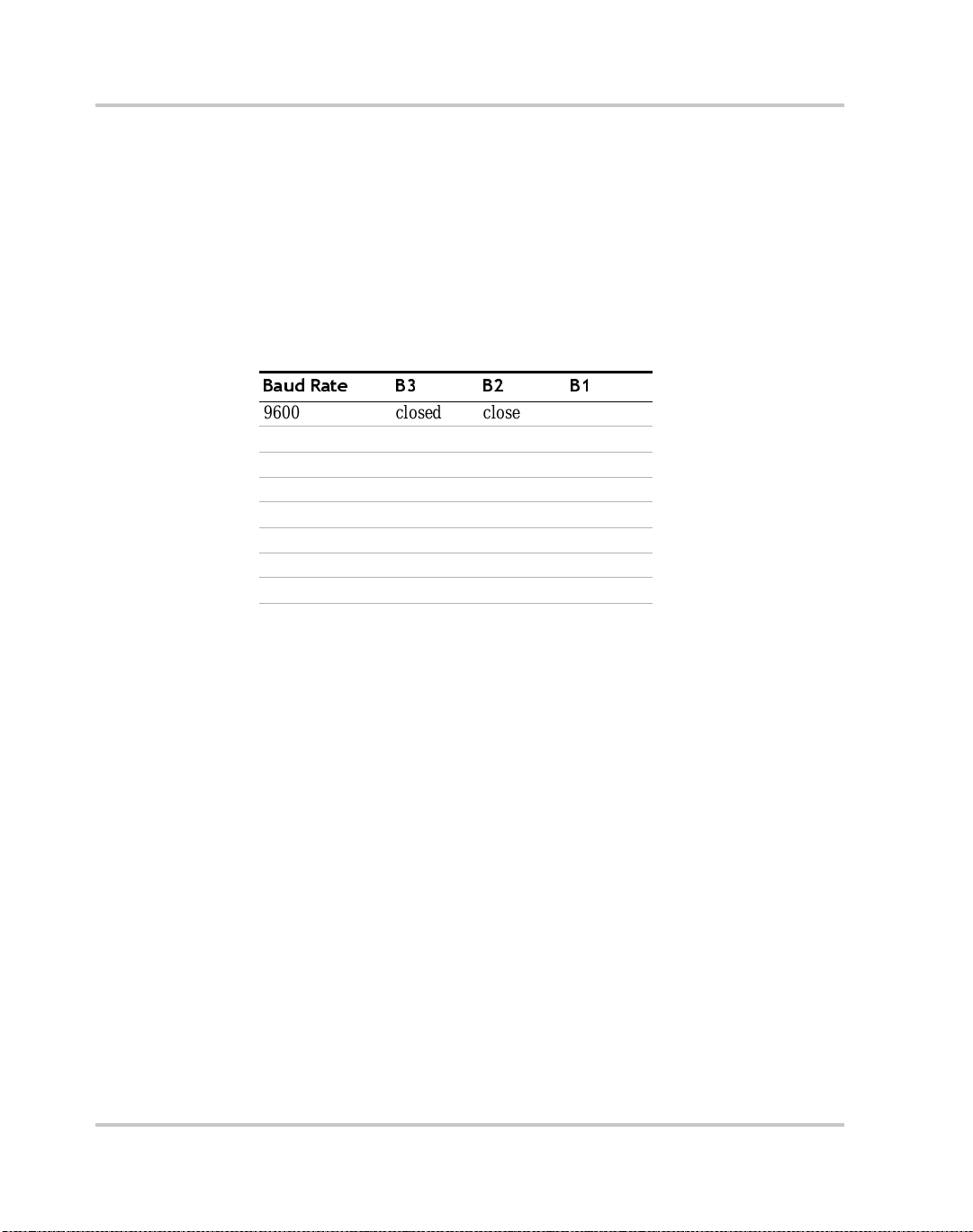

Baud Rate Selection

Serial transmission sends and receives data in bit streams at f ixed bit

rates. Both the computer and the inter face must have the same bit rate

setting for proper communic ation. The default baud rate is 9600. We

recommend that you do not change this setting. If the setting must be

changed, use Table 2-6 to select the correct jumper positions. You will

need to remove the cover to change any jumpers. See “Changing Internal

Jumpers” on page 2–8.

Table 2-6

Baud Rate B3 B2 B1

9600 closed closed closed

4800 open closed closed

2400 closed open closed

1200 open open closed

600 closed closed open

300 open closed open

150 closed open open

75 open open open

Jumper J2 Settings for Baud Rate

2–18 TM-XR9B-01XN

Page 41

Flow Control Selection

Flow control signals regu late data flow for proper communication. To

enable or disable the flow control, change the J2 FLW jumper according

to Table 2-7. With flow control enabled, you can use either software or

hardware pr otoco l s to co n trol fl ow rates. You wi ll ne ed to rem o ve the

cover to change any jumpers. See “Changing In ternal Jumpers” on

page 2–8.

RS-232 Communications

Table 2-7

J2 FLW Jumper Setting C on dit io n

closed (default) Disable Flow Control

open Enable Flow Control

Jumper J2 Flow Control Section

Once flow control is enabled, two flow contr ol methods are available.

You can select software based XON/XOFF flow protocol or hardware

based RTS/CTS by changing an interna l j umper. Table 2-8 shows the flow

control conditions with r egards to the J2 XON jumper.

Table 2-8

J2 XON Jumper Setting Condition

closed (default) Hardware Flow Control

open Software Flow Control

Jumper J2 Flow Control Protocol Selection

(RTS/CTS protoco l)

(XON/XOFF protocol)

TM-XR9B-01XN 2–19

Page 42

Installation and Configuration

Remote/Local Operation

Remote/Local Mode Startup

The power supply can be set to start-up in remote or local mode. To

change this se tting, the PON REM jumper must be adjusted according to

T able 2-9. You will need to remove the cover to change any jumpers. See

“Changing Inte rnal Jumpers” on page 2–8 for information on how t o

change internal jumper se ttings.

See Table 2-9 for the switch settings.

Table 2-9

J2 PON REM Jum per Sett in g Power ON result s

open (default) Unit in remote mode

closed Unit in local mode

With the PON REM jumper open, the power suppl y will start up in

remote mode. The green REM LED on the front panel will be lit,

signaling that the power supply i s under the contr ol of th e digital i nte rface

card. The output of the power sup ply is activ e on start up. To promote load

safety, power ON defaults are zero for the output voltage and current

limit, and 110% of maximum output voltage for the OVP trip point. See

T abl e 2-10. Refer to “Operation” for more infor mation about the inte rface

commands listed in the table.

If the PON REM jumper is closed, the power supply will power up in

local mode. Power supply control is at the front panel. During an

operating sessio n, you can toggle between local mode and remote mode

by using the front panel LOCAL button or sending commands as

described in Table 2-10.

Jumper J2 Remote/Local Start-up Settings.

Note: The default setti ng for thi s jumper is ope n. If you require it to be close d

(PON in local mode) you can obtain a spare jumper by removin g the one that

connects pins 11 and 12 on J2 as these pins are unused.

2–20 TM-XR9B-01XN

Page 43

Remote/Local Operation

Table 2-10

Condition Default Settings 7.5-140 Model Example

Voltage 0 V VSET 0

Current 0 A ISET 0

Soft Voltage Limit VMAX (see models ) VMAX 7.5

Soft Current Limit IMAX (see models) IMAX 140

OVP Trip Voltage Model VMAX + 10% OVSE T 8.25

Delay 0.5 s DLY 0.5S

Remote Enable ON REN ON

Foldback Protection OFF FOLD OFF

Output ON OUT ON

Hold OFF HOLD OFF

Unmask NONE UNMASK NONE

AUXA OFF AUXA OFF

AUXB OFF AUXB OFF

Remote Mode Operation

While in re mote mode, use the interface commands to control the output

of the power su pply from a computer. See “Operation” for a complete list

of device-dependent commands available with this interface.

From remote mode, change to local mode operation by pressing the front

panel LOCAL button or by sending either the GTL command or the

REN OFF command. You can disable the LOCAL button by using the

LLO command. For an example of how to use Local Loc kout, see “Local

Lockout (LLO) Com mand” on page 2–23.

T o retur n to re mote mode, en sure that t he REN command is s et to ON and

then send any valid device-dependent command. Since the remote mode

output setting s may be di ff erent from t he local m ode sett ings, t he output i s

programmed to prote ct the l oad by turni ng of f when you tog gle from loc al

to remote mode during a session. Check your remote settings and the n

send OUT ON to restore the output.

Remote Mode Power On Conditions

TM-XR9B-01XN 2–21

Page 44

Installation and Configuration

Local Mode Operation

In local mode ope ration, you set t he voltage and current output level s a nd

the OVP trip level with controls loc ated on the front panel. Refer to the

operating manual for a description of the functions available at the front

panel.

While in local mode operation, you can change power supply control to

remote mode by ensuring tha t REN is ON, then sending any software

command and OUT ON to restore the output. Return to loc al mode by

pressing the front panel LOCAL button, u nless Loc al Lockout is in ef fe ct.

If LLO is in effect, use the GTL command to send the power supply into

local mode, or use the REN OFF command to turn off LLO and retur n the

power supply to local mode.

Example:

Press the LOCAL button Set unit to local mode

Id? Put the unit into remote mode

Press the LOCAL button

Remote Enable (REN) Command

(Use any command to do this.)

Retu r n to local mod e .

You can use the R emote Enable command to toggle between local mode

and remote mode. The default setting at startup is REN ON. With the

remote enable command set at REN ON, you can return the power supply

to remote mode whenever you send any command from the computer.

Any time that you change from local to remote mode dur ing a se ssion, th e

output is programmed to turn off, since the remote mode settings may be

different f rom the local mode settings. Send the OUT ON command to

restore the output.

You can turn off Remote Enable and move power supply control to the

front panel by sending the REN OFF command. If the Local Lockout

condition is in eff ect, sending the REN OFF command will turn off the

LLO condition be fore sending the unit into local mode.

T o check whether the power supply is remote enabled, use the REN?

query command.

Example:

REN ON Enable the power supply to be sent into

remote mode

VSET 10;ISET 2 Put the unit into remote operation mode

(Use any command to do this.)

2–22 TM-XR9B-01XN

Page 45

Local Lockout (LLO) Command

Use the Local Lockout command to disable the LOCAL button on the

power supply fr ont panel. With LLO in effect, you cannot return to local

control by press ing the front panel LOCAL switch. You can still return to

local mode by sending the Go to Local (G TL) command. However , to turn

off LLO a nd return the power supply to local mode, send the REN OFF

command. Only the REN OFF command will remove the LLO condition.

Example:

LLO Set Local Lockout

GTL Return the power supply to local mode.

REN OFF Turn off Local Lockout and return the

Power Supply Settings

For serial c ommunication, the computer and the Ethernet/RS-232

Interface must share the same communicati on setti ngs. Mak e sure that th e

settings of the computer and of the power supply agree with those shown

in Table 2-11.

Power Supply Settings

Local Lockout is still in effect

power supply to local mode

Table 2-11

Parameter Setting

Transmissi on Asynchronous

Mode Full Duplex

Speeds 75, 150, 300, 600, 1200, 2400, 4800, 9600 (default)

Parity None

Connector DB9-pin Male

Start Bit 1

Stop Bit 1

Data Bits 8

Protocols XON/XOFF

TM-XR9B-01XN 2–23

Power Supply Settings

RTS/CTS

NONE (default)

Page 46

Installation and Configuration

Additional User Options and Settings

You can customize rem ote operation settings for OVP (over voltage

protection) contr ol and TTL shutdown by changing jumper positions on

the Ethernet/RS-232 Interface card. Refer to the operating manual for

information on how to use over voltage pro tection and TTL shutdown.

OVP Selection

Over voltage protection (OVP) on the Ethe rnet/RS-232 Interface is set at

the factory for remote soft ware operation. When operating the power

supply in remote mode, you control the OVP trip level using the OVSET

software command. If you return the power supply to local operation by

using the REN software command or the front panel LOCAL switch,

control of the OVP trip level changes from software control to the front

panel OVP potentiometer . The default OVP trip level is set as 110% of the

power supply's rated outpu t voltage. See Table 2-10 on page 2–21 for a

complete list of remote power ON default settings.

You can isolate the location of OVP control by changing the posit ions of

the Local OVP Control jumper J65 and the Remote OVP Control jumper

J103, both on the Ethernet/RS-232 Interface PCB. The default jumper

settings allow contr ol of OVP to depend on the operating state of the

power supply. By physically ch anging th e jumper sett ings, you can i solate

the location of OVP contr ol to soft ware contr ol on ly or fr ont panel con trol

only. Table 2-12, “OVP Control Mode Selection” on page 2–24 shows a

table of jumper settings and OVP programmin g selection. Refer to Figure

2-3 on page 2–6 for the location of the jumpers on the Ethernet/RS-232

Interface PCB. You will need to remove the cover to change any jumpers.

See “Changing Internal Jumpers” on page 2–8.

Table 2-12

PCB Jumper

J65 Position

Closed (default) Closed (default) Software or Front Panel OVP control

Closed Open Software OVP control only

Open Closed Front Panel OVP control only

Open Open Front Panel OVP contr ol only

2–24 TM-XR9B-01XN

OVP Control Mode Selection

PCB Jump er

J103 Position OV P Programm in g Selecti on

(dependent on the power supply operat ing

state)

Page 47

TTL Shutdown Polarity

You can use the Shutdown function to disable or enable the supply's

output. Disabling the supply using TTL shutdown allows you to make

adjustments to the load or to the power supply without shutting down the

power supply. With the Ethernet/RS-232 Interface installed, TTL

shutdown is ac tivated by a TTL signal to Pin 1 of the user lines connector

on the interface subpla te. The shutdown user line uses a 0-5Vdc TTL

input with a high signal range of 2.2-5. 0Vdc. The current range of the

shutdown line is 1-10mA. See Figure 2-6, “Us er Lines Signal Connector

Circuit Block Diagram” on page 2–27 for a schematic of the user lines

connector contain ing the shutdown user line.

You can select the logic level of the TTL input by changing the J93

connector on the Ethernet/RS-232 Int erface PCB. Table 2-13 shows the

TTL signal levels for the J93 jumper set tings. See Figure 2-3 for the

location of the J93 jumper on the printe d circ uit board. You will need to

remove the cover to change any jumpers. See “Changing Internal

Jumpers” on page 2–8.

Additional User Options and Settings

Table 2-13

PCB Jumper J93 Position TTL Signal Level Supply Output Condition

Pin 2 to Pin 3 (default) HIGH

Pin 1 to Pin 2 HIGH

Jumper Settings for TTL Shutdown Circuit Logic

OFF

LOW

LOW

ON

ON

OFF

TM-XR9B-01XN 2–25

Page 48

Installation and Configuration

User Signals

User Lines Connector

Auxiliary User Lines c onnector, located on the Ethernet/RS-232 Inte rface

rear panel, provides sever al signals to increase your operating control of

the supply. These signals are dependent on the operator's design and uses.

The operation of the user lines connector signal requires that you provide

external Vcc and ground. Use a standard 8-position telephone jack and

data cable to connect to the user lines connector. To locate the connector,

refer to the Ethernet/RS-232 Interface subpla te drawing in Figure 2-2 on

page 2–5. See Table 2-14 for pin descriptions. The user lines connector

outputs can sink a current of 5mA each. Figure 2-6 on page 2–27 shows

the portion of the option board sche matic which contains the user line

connector. Use the schematic as a reference when making input or output

connections.

Table 2-14

Pin Function

1 External TTL shutdown input signal (See “TTL Shutdown

2 Polarity signal, open collector (assert ed by VSET -x)

3 Isolation signal, open collector (asserted by OUT OFF)

4 Fault signal, open collector (asserted wh en bit set in fault register)

5 External Vcc, 15V maximum (supplied by connecting and

6 External ground and shutdown return (supplied by connecting and

7 Open collector user signal (asse rted by AUXA ON)

8 Open collector user signal (asse rted by AUXB ON)

User Signals Connector

Polarity” on page 2–25)

operating an external source)

operating an external source)

User Line

Note: On some models, the

connector is rotated 180°.

2–26 TM-XR9B-01XN

Page 49

User Signals

Figure 2-6

TM-XR9B-01XN 2–27

User Lines Signal Connector Circuit Block Diagram

Page 50

Installation and Configuration

User Lines Cable Connection

Use a standard 8-position telephone jack and data cable to connect to the

user line connector. Add a ferrite block to reduce radiated emission. The

one inch squa re ferrite block with built-in housing clip is packaged and

shipped with the power supply interface card.

To install the ferrite block:

1. Position the block no more than 5 cm (2 in.) from the power supply

end of the user line connector cabl e.

2. Open the ferrite block housi ng.

3. Loop the cable through the ferr ite block. See Figure 2-7, “User Line s

Cable with Ferrite Block” on page 2–28.

4. Close the housing clip.

The ferrite bloc k ens ures tha t the pow er su pply sys tem meets radiat ed

emission requiremen t 89/336/EEC for CE mark approval. See the power

supply's oper ating manual for noise specifications.

Figure 2-7

User Lines Cable

Ferrite Block

To User Cus to m In te r fa ceTo Connector

on XF R

User Lines Cable with Ferrite Block

2–28 TM-XR9B-01XN

Page 51

3

Introduction

Operation

This section covers Ethe rnet /RS-232 Interf ace programming, including

an extensive set of device-dependent commands, er ror codes, and status

and fault register inf ormation.

Page 52

Operation

RS-232 Operation

When the Ethernet/RS-232 Interface ca rd is confi gured for RS-232 you

can send and receive data between your power supply and computer ,

relying on bit serial co mmunication. You can use the computer controller

to issue com mands to the power supply for programming, queries,

calibration, or status. The power supply responds to the complet e

command set of device dependent softwa re commands shown in

“Command Reference” on page 3–9.

Ethernet Operation

When the card is config ured for Ethernet, you can send and receive data

between you power supply and computer via your network. The same

command set is used for RS-232 and Ethernet. The only difference is

medium and protoc ol used.

Command Syntax

Manual Conventions

The manual uses these conventions when displaying command

information. These ch aract ers are not par t of the command but are us ed to

denote parameters used with the command.

< > (angle brackets) Angle brackets enclose a parameter. Do not include

/ (slash) Separates two alternative parameters. When a slash

the angle brackets in the com mand line you se nd to

the computer.

separates two para meters, you can use either

parame ter to achieve the s ame result.

Example:

Entering

<1/ON>

1 or ON will achieve the same result.

3–2 TM-XR9B-01XN

Page 53

Command Format and Parameters

The device-dependent language for the Ethernet/R S- 2 32 In terface

consists of commands and parameter s. A command is a one word code

which either gives instr uctions to the interface or asks for information

from the interface. A command may be followed by one or more

parameters, a short code that changes the state of the power supply or the

state of the bit register. Table 3-1, “Command Parameters” on page 3–4

lists the parameters that affect the command set.

Format:

COMMAND or

COMMAND <parameter> or

COMMAND <parameter>,<pa rame ter>

• You can enter commands in upper or lower case lettering.

Example: MASK FOLD = mask fold

• Do not further abbreviate command names or parameters.

Example: MASK FOLD ≠ MK FOLD

MASK FOLD ≠ MASK FD

• Use a space between the command and the first paramet er. Any

number of consecutive spaces is treated as one space. Numeric data

may contain leading spaces. Embedded spaces between digits or

between a digit and a decimal point are not accepted.

Example: MASK FOLD = MASK FOLD

VOUT 3.4 = VOUT 3.4

VOUT 3.4 ≠ VOUT 3. 4

• Use commas between parameters in those commands with more than

one parameter, and between mnemonic parameters as in the MASK

and UNMASK commands. Only one comma is a ll owed and it may be

preceded or followed by any number of spaces.

Example: MASK CV, OV, FOLD

Command Syntax

TM-XR9B-01XN 3–3

Page 54

Operation

Table 3-1

Parameter Description Form

<current>, <Ihi>, <Ilo> The current in amps or milliam ps. If no unit is given,

<time> The time in seconds or mill is econd s. If no unit is gi ven,

<voltage>, <Vlo>,

<Vhi>

<mnemon i cs> A combination of CV, CC, CV, OV, OT, SD, FOLD,

<state> The state of a binary condition. <1/ON, 0/OFF >

Command Parameters

the default unit is amps.

the default unit is seconds.

The voltage in volts or mil livolts. If no unit is given,

the default unit is volts.

ERR, PON, REM, ACF, OPF, and SNSP. See MASK

and UNMASK commands in the command reference

for use of the ALL and NONE parameters.

<float>

<float>A

<float>mA

<float>

<float>s

<float>ms

<float>

<float>V

<float>mV

See registers on

page 3–17.

Floating Point Number <float>

Variables sent with command parameters are floating point numbers.

T able 3-2 defines the structure of floating point numbers for use with the

software commands.

Table 3-2

Floating Point Numbers

Floating Number Definition Example

The floating point number has four significant figures.

It can be of either sign, positive or negative.

A floating point number can have one decimal point. 0.123

Scientifi c Notation

Use E or e after the number for a base ten exponent.

An integer of either sign must follow an exponent.

3–4 TM-XR9B-01XN

1.234

-1.234

+1.234

1.2

123.4

123.0E-1

1.2E-1

10.00E+1

Page 55

Command Strings

If you send more than one command line, separate the commands with a

semicolon. The semicolon may be preceded or followed by spaces.

Example:

ISET 2.0A; VSET 5V

ISET 2.0A; VSET 5V

Command Terminators

T erminators indicate the end of a command string and tell the power

supply to execute the command. The termination character is CR

(Carriage Return).

Format:

COMMAND <parameter>; COMMAND <parameter>,

<parameter><CR>

Order

You may send commands in any order, keeping in mind that only those

commands received after a HOLD and before a TRG (trigger) will be

released by the TRG command. In addition, only these commands

received after a supply disable (OVP or foldback protection) and before a

RST (reset) or OUT ON command will be released by the RST command

or the OUT command. Commands are executed in the order they are

received.

Command Syntax

TM-XR9B-01XN 3–5

Page 56

Operation

Command Summary

Use these commands to control the operation of the supply. They are

listed here in order of funct ion such as PROGRAMMING, QUERY,

CALIBRATION, and STA TUS commands. See “Command Reference”

on page 3–9 for more detailed information about each command and its

use.

Table 3-3

Command Description

AUXA Selects the state of the AUXA output signal on the Pin 7 of the

AUXB Selects the state of the AUXB output signal on the Pin 8 of the

CLR Initializes the power supply to its Power ON (PON) state.

DLY Sets a programmable ti me delay which is executed by the supply

GTL Sends the supply to local mode.

FOLD Sets foldba ck mode for the supply.

HOLD Enables or disabl es voltage/current setting hold mode for the

IMAX Sets an upper soft limit on th e programmed output current for the

ISET Sets the output current of the supply in amps (default) or in

LLO Local Lockout. Disables the front panel LOCAL button.

OUT Enables or disables voltage/c urrent output for the supply.

OVSET Sets the over voltage protection trip point for the supply in volts

REN Sets remote mode or local mode.

RST Resets the supply to the present voltage and current settings if the

TRG Implements programmed voltage and current settings which had

VMAX Sets an upper soft limit on the supply’s programmed output

VSET Set s the output voltage of t he power supply in volts (de f ault) or in

Programming Commands

user lines connector.

user lines connector.

before reporting fault conditions after a new output voltage or

current is sp ec if ied.

supply.

supply.

milliamps.

(default) or in millivolts.

output is disabled by OVP or foldback protection.

been in hold mode.

voltage.

millivolts.

3–6 TM-XR9B-01XN

Page 57

Command Summary

Table 3-4

Command Description

AUXA? Asks for the state of the set value for the AUXA command

AUXB? Asks for the state of the set value for the AUXB command

CMODE? Asks for the power supply’s c alibration mode status.

DLY? Asks for the programmable time delay se tting before the supply

ERR? Asks for the most recent remote programming error which

FOLD? Asks for the supply’s present foldback setting.

HOLD? Asks for the present hold mode setting.

ID? A s ks for the power supply’s model name and master EPROM

IMAX? Asks for the supply’s soft current limit setting.

IOUT? Measures the supply’s actual current output.

ISET? Asks for the supply’s present output current limi t se tting.

OUT? Asks for the present enabled/disable d status of the supply’s

OVSET? Asks for the supply’s present over voltage protection limit.

REN? Asks for the state of remote enable.

ROM? Asks for the ve rsion number of the master and slave EPROMs on

VMAX? Asks for the supply’s soft voltage limit setting.

VOUT? Measures the supply’s actual voltage output.

VSET? Asks for the supply’s present output vol tage setting.

Query Commands

reports fault conditions.

occurred in the supply since the last time the error query

command (ERR?) was us ed.

version.

output.

the interfac e PCB.

TM-XR9B-01XN 3–7

Page 58

Operation

Table 3-5

Command Description

CMODE Places the supply into calibration mode.

IDATA Calculates the slope and intercept for current programming.

IHI Sets the current output to the high calibration point.

ILO Sets the current output to the low calibration point.

IRDAT Calculates the slope and intercept for current readback.

IRHI Sets the current output to the high readba ck point.

IRLO Sets the current output to the low re adback point.

OVCAL Calibrates the over vol tage protection (OVP).

VDATA Calcula tes the slope and intercept for voltage programming.

VHI Sets the voltag e output to the high calibration point.

VLO Sets the voltage outpu t to the low calibration point.

VRDAT Calculates the slope and intercept for voltage readback.

VRHI Sets the voltage output to the high readback point.

VRLO Sets the volt age output to the low readback point.

Table 3-6

Command Description

ASTS? Asks for the supply’s accumulated status register.

FAULT? Asks for the supply’s fault register for the status preset opera ting

MASK Prevents the supply's previously unmasked operating conditions

STS? Asks for the supply’s present status regi s ter.

UNMASK Enables you to select those supply's operating conditions t hat you

UNMASK? Asks for the supply's fault conditions which are currently ena bled

Calibration Commands

Status Commands

conditions.

from setting bits in the fault register.

are most interested in monitoring for fault occurrence.

(unmasked).

3–8 TM-XR9B-01XN

Page 59

Command Reference

Command Reference

Table 3-7

Command Description

ASTS? Asks for the supply’s accumulated status register. The accumulated status registe r

AUXA <1/ON>,

<0/OFF>

AUXA? Asks for the present set value of the AUXA output s ignal.

AUXB <1/ON>,

<0/OFF>

AUXB? Asks for the present set value of the AUXB output signal.

CLR Initializes the power supply to its power ON condi tion. If issued while in local

Command Reference

stores an y bit th at was ent er ed in the st at u s regi s t er sin c e th e accumul ated statu s

query command (ASTS?) was last used, reg ardless of whether the condition still

exists. The accumulated status register has the same bits, weights, and condi tions

as the status register. A bit in the accumulated status register will be set at 1 if the

corresponding bit in the status register has been 1 (TRUE) at any time since the

register was last read . See “Accumulated Status, Status, and Fault Registe r s” on

page 3–17. The ASTS? query clears the st atus register.

Response: ASTS <statu s mask> whe re stat us mask is the decima l equiva le nt of the

total bit weight s for th e operating conditions as listed in the status register.

Controls the AUXA output signal level at rear panel connector Pin 7. Acti ve low.

Initial value: AUXA 0

Response: AUXA 0 (OFF) or AUXA 1 (ON)

Controls the AUXB output signal le vel at rear panel connector Pin 8. Active low.

Initial value: AUXB 0

Response: AUXB 0 (OFF) or AUXB 1 (ON)

mode, CLR will force power supp ly settings to register default va lues as in but

these defa ult sett ing s will not com e in to ef f ect unti l t he po wer supp ly i s swi tch ed to

remote mode operation. The CLR commands will clear faults from the fault

register. CLR will not reset CMODE.

CMODE <1/ON>,

<0/OFF>

CMODE? Asks for the power supply’s calibration mode status .

TM-XR9B-01XN 3–9

CMODE ON places the power supply into calibration mode for proc essing

calibration commands.

Initial value: CMODE OFF or CMODE 0

Res p on s e : CMOD E 0 ( d is able d )

CMODE 1 (enabled)

Page 60

Operation

Table 3-7

Command Description

DLY <seconds> Sets a programmable time delay employed by the supply before reporting fault

DLY? Asks for the setting of the programmable time delay be fore the supply reports fault

ERR? Asks for the most recent remote programming error. When the power supply

FAULT? Asks for the state of the f ault register. A bit is set in the f ault register when a fault

Command Reference

conditions. The power s upply uses the time delay aft er re ceiving a new output

voltage or current s etting via VSET or ISET, or after receiving RST, TRG, or OUT

ON commands. During the time delay, the power supply disables CV, CC, and

FOLD conditions from generating faults, preventing possible nuisance foldback if

the supply momentarily switches modes while changing an output setting.

Range: 0 to 32 seconds, with 32ms resolution

Initial va lue: 0.5 second

conditions.

Response: DLY <seconds>

detects a programmi ng error, it lights the ERR LED and sets the ERR bit in the

accumulated status and fa ult registers. I f the error bit has been masked using the

MASK command, then the ERR bit in the registers will not set. Once an err or is

detected, the remaining portion of the command line is discarded. An error que ry

clears the ERR bit in the accumulated status register. See “Error Codes” on page 3–

19.

Response: ERR <error number> Example: ERR 0 (if no error)

arises for that condition. Lists the conditions which activate a fault bit . You can use

the MASK command to disable bits from being set in the fault register.

When a bit is set in the fault register it also asserts a signal on the Pin 4 user signal

line. You can tie the Pin 4 fault line signal to the power supply's own External

Shutdown user line, Pin 1, so that the shutdown s ignal goes low (active) in the case

of a user-defined fa u l t.

The FAULT? query clears bits in the supply's fault register and fault line.

Response: FAULT <fault mask> where fault mask is the decimal equivalent of the

total bit weight s for th e operating conditions as listed in the fault register. See

“Accumulated Status, Stat us, and Fault Registers” on page 3–17.

FOLD

<2/CC>, <1 /CV>,

<0/OFF>

3–10 TM-XR9B-01XN

Sets foldback mode for the su pply. Foldback protection disables the power supply

output when the output enters the fold condition. Reset with the RST command.

Example: Specify FOLD 1 or FOLD CV (Constant Vol tage) when you want the

supply to operate in Cons tant Current mode and have foldback protecti on disable

the output if the supply swit ches to Constant Voltage mode.

Initial value: FOLD 0/OFF

Page 61

Command Reference

Table 3-7

Command Description

FOLD? Asks for the supply’ s pres ent foldback setting.

GTL Go to local. Returns the power supply to local cont rol. See LLO (Local Lockout).

HOLD <1/ON>,