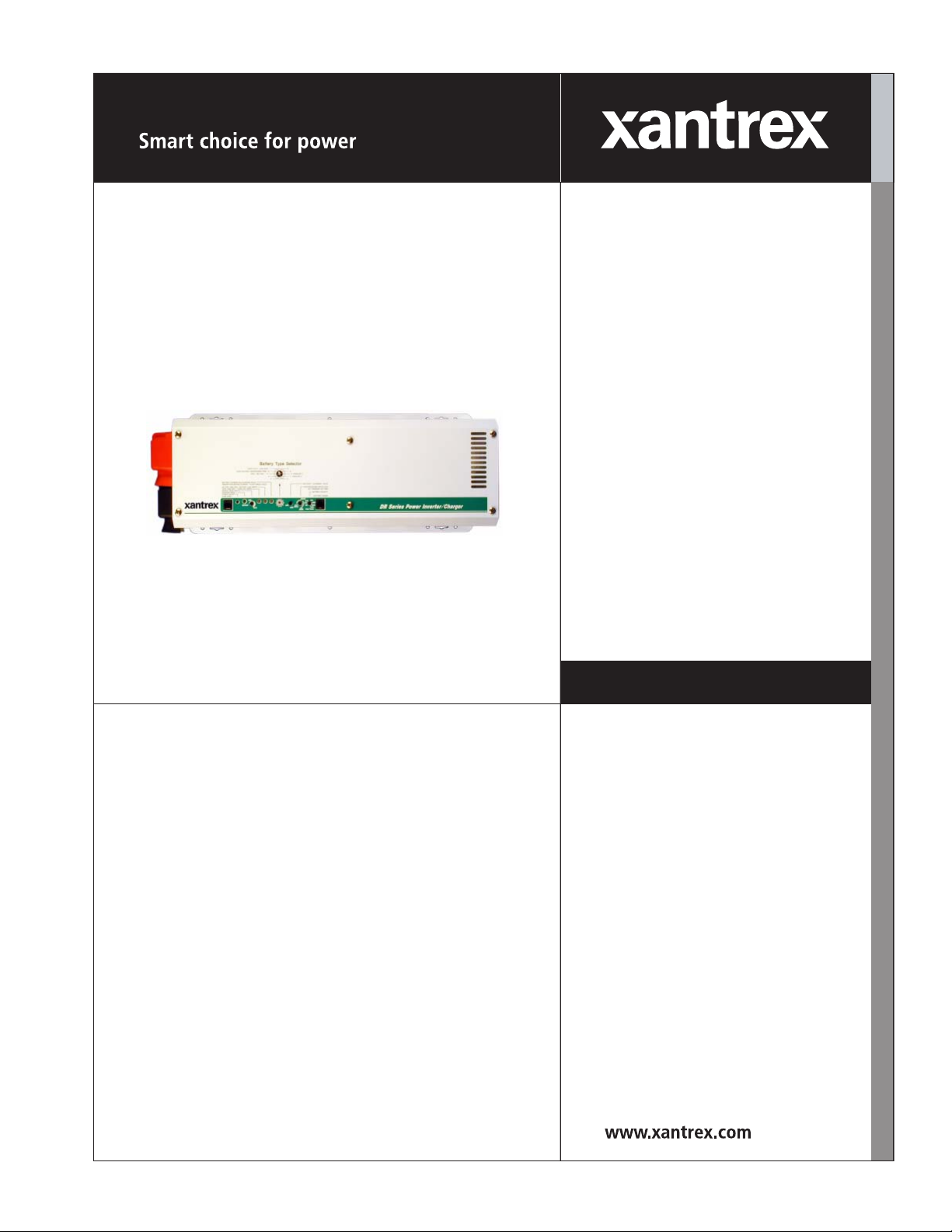

Page 1

DR1512

DR2412

DR1524

DR2424

DR3624

DR1512W

DR1524W

DR1512E

DR1524E

DR1548E

DR2424E

Installation and Operations Manual

DR Inverter/Charger

Page 2

Page 3

DR Inverter/Charger

Installation and Operation Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

DR Inverter/Charger is a trademark of Xantrex International. Xantrex is a registered trademark of Xantrex

International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

DR Inverter/Charger Installation and Operations Manual © March 2005 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

March 2005 Revision

Part Number

975-0012-01-02 Rev A

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 800 994 7828 (toll free North America)

1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Manual

Purpose

The purpose of this Installation and Operation Manual is to provide explanations

and procedures for installing, operating, maintaining, and troubleshooting the DR

Inverter/Charger.

Scope

The Manual provides safety guidelines, detailed planning and setup information,

procedures for installing the inverter, as well as information about operating and

troubleshooting the unit. It does not provide details about particular brands of

batteries. You need to consult individual battery manufacturers for this

information.

Audience

The Manual is intended for anyone who needs to install and operate the DR

Inverter/Charger. Installers should be certified technicians or electricians.

Organization

This Manual is organized into four chapters and three appendices.

Chapter 1, “Introduction” contains information about the features and functions of

the DR Inverter/Charger.

Chapter 2, “Installation” contains information about how to plan for and install

the DR Inverter/Charger.

Chapter 3, “Operation” contains information about how to operate the DR

Inverter/Charger.

Chapter 4, “Troubleshooting” contains information about how to troubleshoot

possible error conditions while using the DR Inverter/Charger.

Appendix A, “Specifications” contains information about the electrical

specifications and environmental specifications of the DR Inverter/Charger.

Appendix B, “Appendix B, “Battery Information” supplies general information

about batteries such as battery types, battery bank sizing, battery configurations,

and battery care. For detailed information, see your battery manufacturer or your

system designer.”

Appendix C, “Multi-wire Branch Circuit Wiring” supplies information about

Multi-wire Branch Circuit Wiring Precautions when using stand-alone 120 Vac

inverters or generators.

975-0012-01-02 Rev A iii

Page 6

About This Manual

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions or practices that could result in personal injury or loss of life

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or other

equipment.

Important:

serious as a caution or warning.

These notes describe things which are important for you to know, but not as

Abbreviations and Acronyms

AC Alternating Current

ASC Authorized Service Center

AHJ Authority Having Jurisdiction

COM COMmunications Port

CW Clockwise (rotates to the right)

CCW Counter-clockwise (rotates to the left)

DC Direct Current

DR Inverter DR Inverter/Charger

DRI DR Interface (for stacking)

LED Light Emitting Diode

PV Photovoltaic

PVGFP PV Ground Fault Protection

RE Renewable Energy

RMA Return Material Authorization

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

iv 975-0012-01-02 Rev A

Page 7

Important Safety Instructions

SAVE THESE INSTRUCTIONS

This manual contains important instructions for all DR Inverter/Charger models

that shall be followed during installation and maintenance of the inverter.

General

1. Before installing and using the DR Inverter/Charger, read all instructions and

cautionary markings on the DR Inverter/Charger and all appropriate sections

of this guide. Be sure to read all instructions and cautionary markings for any

equipment attached to this unit.

2. This unit is designed for indoor use only. Do not expose the DR Inverter/

Charger to rain, snow, or spray.

3. To reduce risk of fire hazard, do not cover or obstruct the ventilation

openings. Do not install the DR Inverter/Charger in a zero-clearance

compartment. Overheating may result.

4. Use only attachments recommended or sold by the manufacturer. Doing

otherwise may result in a risk of fire, electric shock, or injury to persons.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is in

good condition and that wire is not undersized. Do not operate the DR

Inverter/Charger with damaged or substandard wiring.

6. Do not operate the DR Inverter/Charger if it has received a sharp blow, been

dropped, or otherwise damaged in any way. If the DR Inverter/Charger is

damaged, see the Warranty section.

7. Do not disassemble the DR Inverter/Charger. It contains no user-serviceable

parts. See Warranty for instructions on obtaining service. Attempting to

service the DR Inverter/Charger yourself may result in a risk of electrical

shock or fire. Internal capacitors remain charged after all power is

disconnected.

8. The DR Inverter contains more than one live circuit (batteries and AC line).

Power may be present at more than one source. To reduce the risk of electrical

shock, disconnect both AC and DC power from the DR Inverter/Charger

before attempting any maintenance or cleaning or working on any circuits

connected to the DR Inverter/Charger. Turning off controls will not reduce

this risk.

9. Use insulated tools to reduce the chance of short-circuits when installing or

working with the inverter, the batteries, or a PV array.

975-0012-01-02 Rev A v

Page 8

Safety

Wiring Requirements

1. All wiring methods and materials shall be in accordance with the National

Electrical Code ANSI/NFPA 70 (Current Edition). When sizing conductors

and conduits interfacing to the DR Inverter, both shall be in accordance with

the National Electric Code ANSI/NFPA 70, as well as all state and local code

requirements.

2. This product is intended to be installed as part of a permanently grounded

electrical system per the National Electric Code ANSI/NFPA 70 (current

edition). This is the single point earth ground for the inverter system.

3. Use copper conductors only with insulation rated for 75 °C.

4. The grounds on the DR Inverter are marked with this symbol:

5. The AC voltage and current on the DR Inverter is marked with this symbol:

6. The DC voltage and current on the DR Inverter is marked with this

symbol:

7. Phase on the DR Inverter is marked with this symbol:

WARNING Fire Hazard:

Do not install 120 volt AC stand-alone inverters onto 120/240 volt AC multi-branch

circuit wiring. This could pose a fire hazard due to an overloaded neutral return wire in

this configuration. See “Multi-wire Branch Circuit Wiring” on page C–1 for details.

Explosive gas precautions

WARNING: Explosion Hazard

Working in the vicinity of lead-acid batteries is dangerous. Batteries generate

explosive gases during normal operation. Therefore, you must read this guide and

follow the instructions exactly before installing or using your DR Inverter/

Charger.

1. This equipment contains components which tend to produce arcs or sparks.

To prevent fire or explosion, do not install the DR Inverter/Charger in

compartments containing batteries or flammable materials, or in locations

that require ignition-protected equipment. This includes any space containing

gasoline-powered machinery, fuel tanks, as well as joints, fittings, or other

connections between components of the fuel system.

2. To reduce the risk of battery explosion, follow these instructions and those

published by the battery manufacturer and the manufacturer of the equipment

in which the battery is installed.

vi 975-0012-01-02 Rev A

Page 9

Precautions When Working With Batteries

WARNING: Explosion or Fire Hazard

Follow all instructions published by the battery manufacturer and the

manufacturer of the equipment in which the battery is installed.

1. Make sure the area around the battery is well ventilated.

2. Never smoke or allow a spark or flame near the engine or batteries.

3. Use caution to reduce the risk or dropping a metal tool on the battery. It could

spark or short circuit the battery or other electrical parts and could cause an

explosion.

4. Remove all metal items, like rings, bracelets, and watches when working with

lead-acid batteries. Lead-acid batteries produce a short circuit current high

enough to weld metal to skin, causing a severe burn.

5. Have someone within range of your voice or close enough to come to your aid

when you work near a lead-acid battery.

6. Have plenty of fresh water and soap nearby in case battery acid contacts skin,

clothing, or eyes.

7. Wear complete eye protection and clothing protection. Avoid touching your

eyes while working near batteries.

8. If battery acid contacts skin or clothing, wash immediately with soap and

water. If acid enters your eye, immediately flood it with running cold water

for at least twenty minutes and get medical attention immediately.

Safety

9. If you need to remove a battery, always remove the grounded terminal from

the battery first. Make sure all accessories are off so you don’t cause a spark.

10. Always use identical types of batteries.

11. Never install old or untested batteries. Check each battery’s date code or label

to ensure age and type.

12. Batteries are temperature sensitive. For optimum performance, the should be

installed in a stable temperature environment.

13. Always recycle old batteries. Contact your local recycling center for proper

disposal information.

975-0012-01-02 Rev A vii

Page 10

viii

Page 11

Contents

Important Safety Instructions

1

Introduction

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

AC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

DC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Optional Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Remote Control (RC8) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Stacking Interface (DRI) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Conduit Box (DRCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Unpacking and Inspection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Model Identification and Numbering Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

2

Installation

Pre-installation Planning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Ventilation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Hardware / Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Wiring Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

DC Terminal Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Grounding Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

AC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Wire Routing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

Electrical Panels and Circuit Breaker Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

AC Distribution Panel (Sub-Panel) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

DC Disconnect - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Battery Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Battery Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Battery Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Basic Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Inverter Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

DC Circuit Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

General DC Grounding Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -v

975-0012-01-02 Rev A ix

Page 12

Contents

Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Battery Bank Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Battery Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–15

Battery Cable Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–16

DC Disconnect and Over-current Protection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–17

Battery Cable Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Connecting the Battery Bank to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–19

Installing a Battery Temperature Sensor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–21

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–22

AC Distribution Panel (Sub-panel) Mounting and Conduit Installation - - - - - - - - - - - - - - -2–22

Accessing the AC Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–22

AC Output Wiring to the AC Distribution Panel (Sub-panel) - - - - - - - - - - - - - - - - - - - - - -2–25

AC Input Wiring - On-Grid Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–26

AC Input Wiring using a Generator in an On-Grid Application - - - - - - - - - - - - - - - - - - - - -2–27

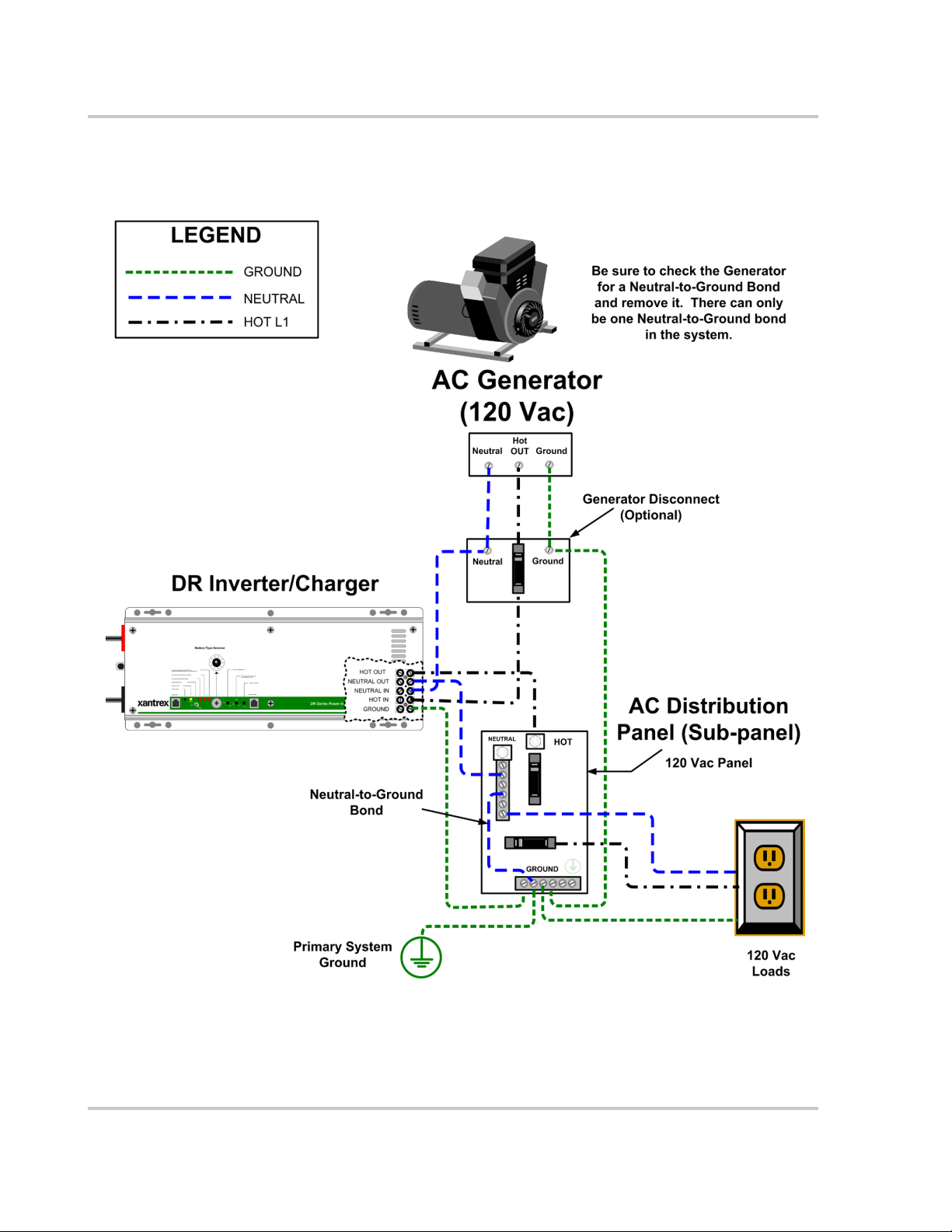

AC Input Wiring - Off-Grid Applications using a 120 Vac Generator - - - - - - - - - - - - - - - -2–28

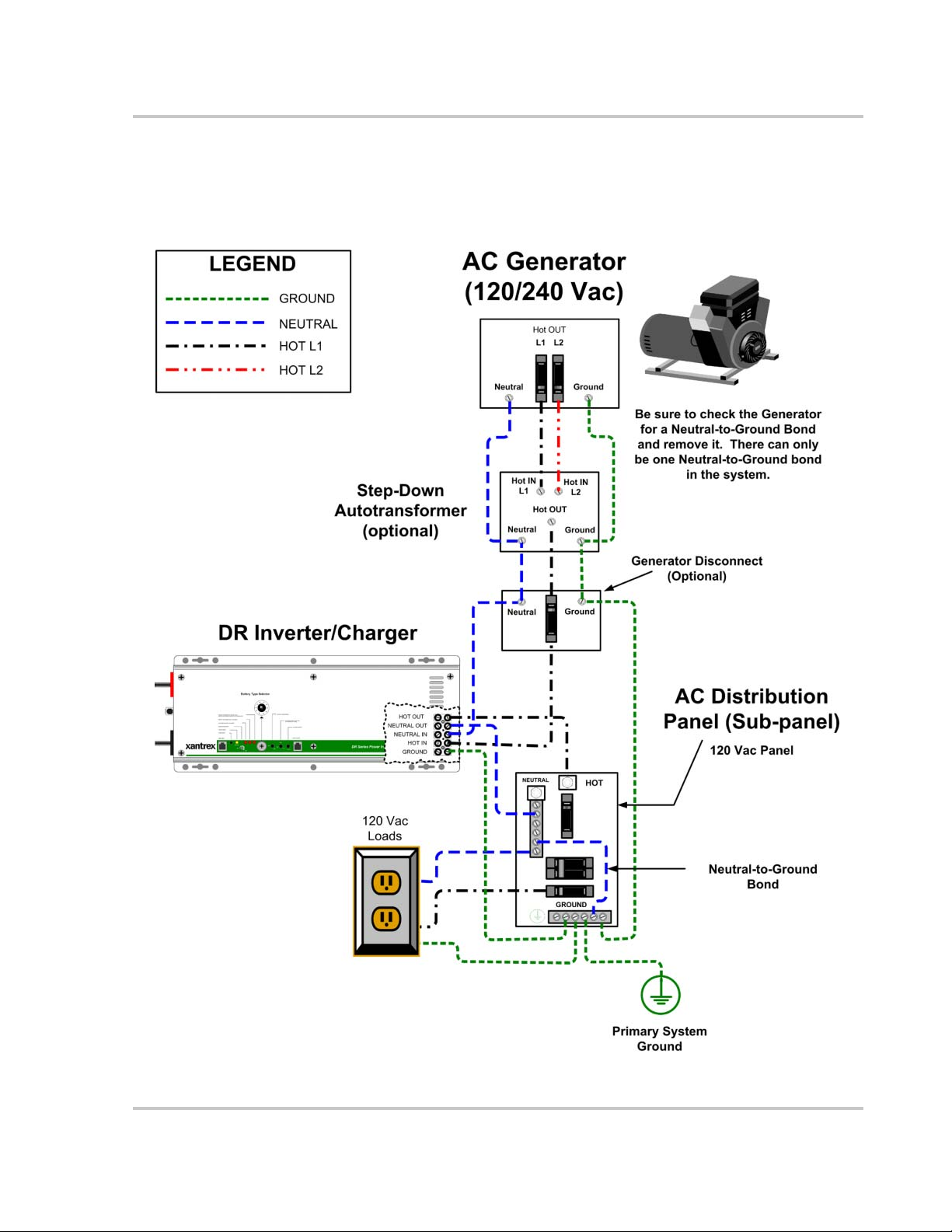

AC Input Wiring - Off-Grid Applications using a 240 Vac Generator for 120 Vac Loads - - -2–29

Series Stacking (120 Vac/60 Hz Models only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–30

3

Operation

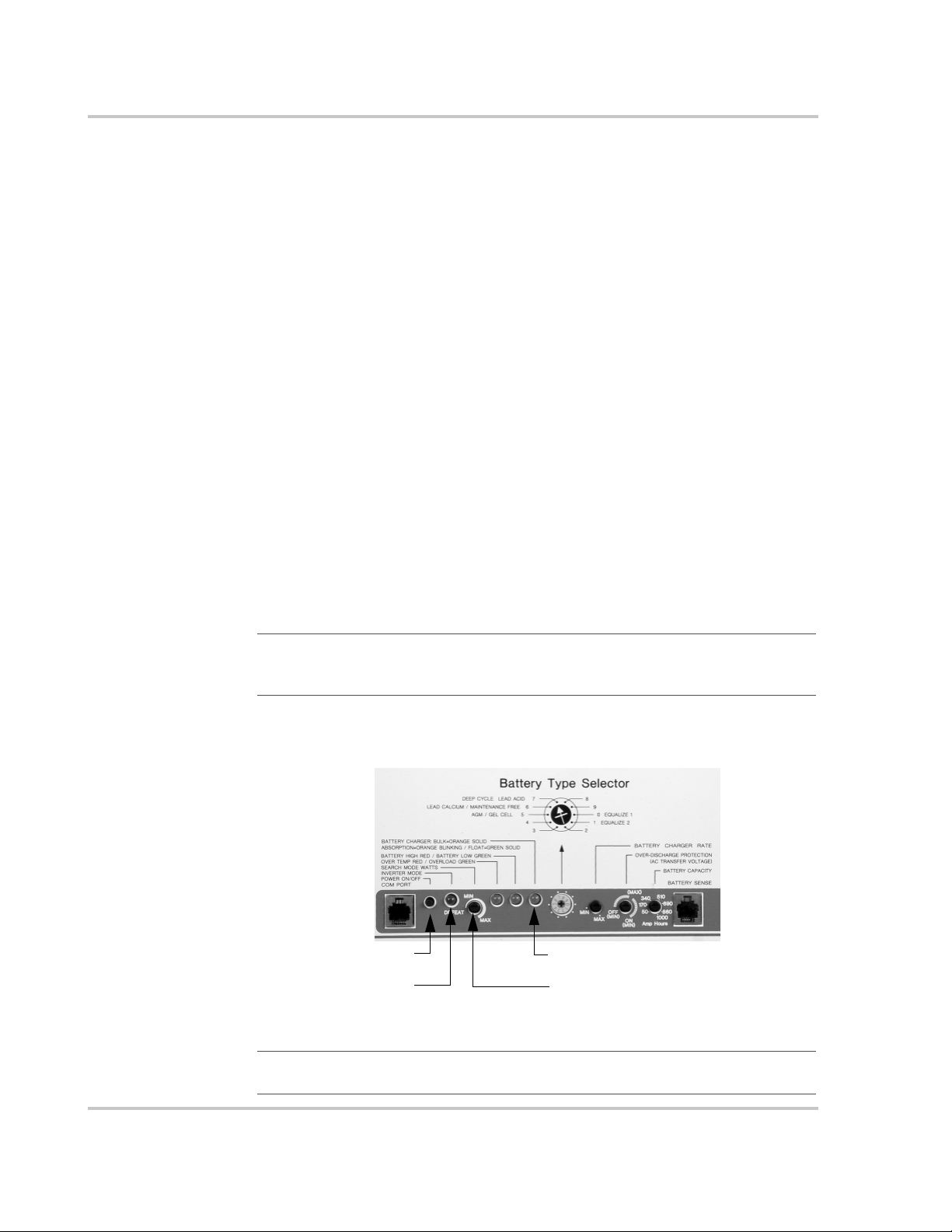

Front Panel Controls and Indicators- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

POWER ON/OFF Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Ports - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

BATTERY SENSE Port - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

COM Port - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Remote Controls (RC8/RC4) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Stacking Interface - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Battery Type Selector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

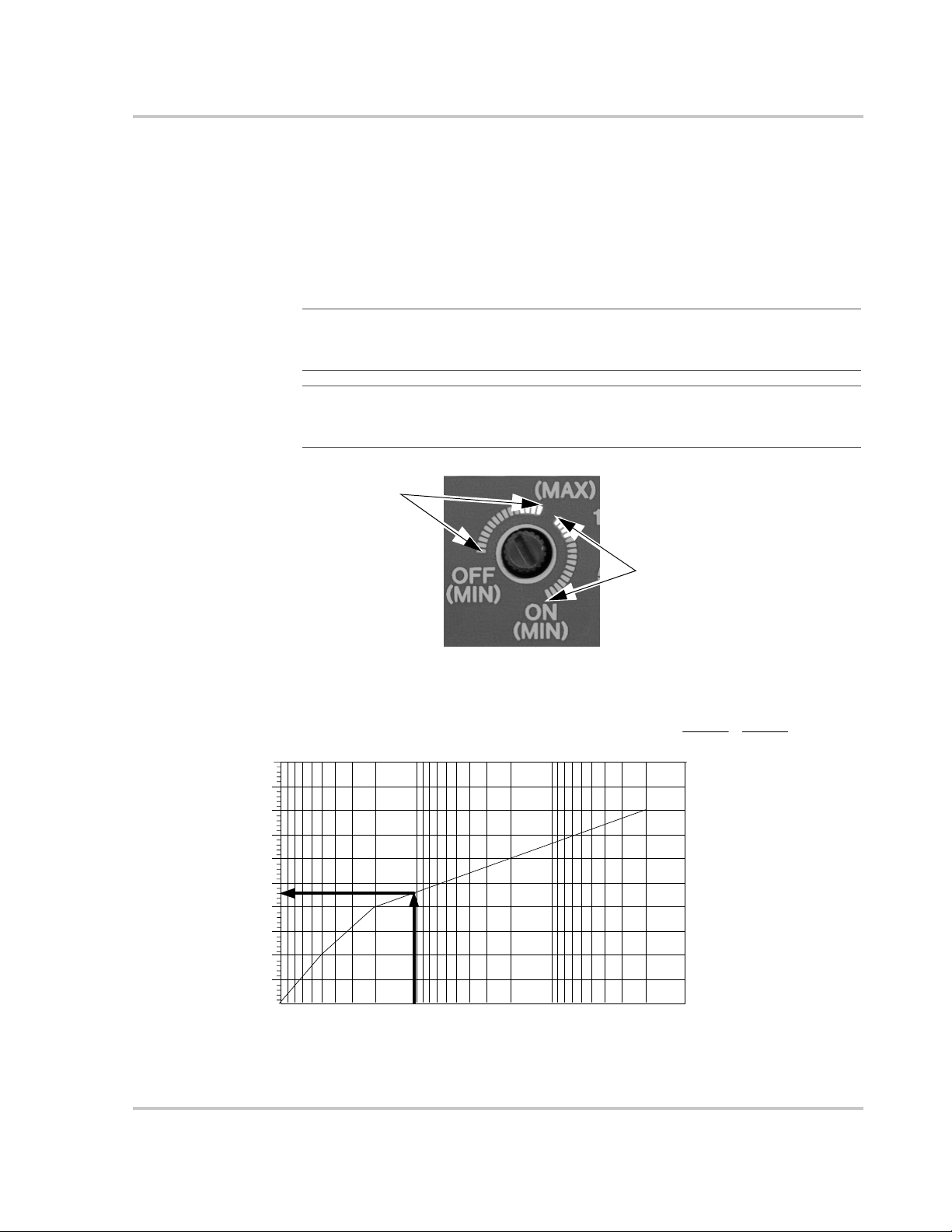

SEARCH MODE WATTS Potentiometer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

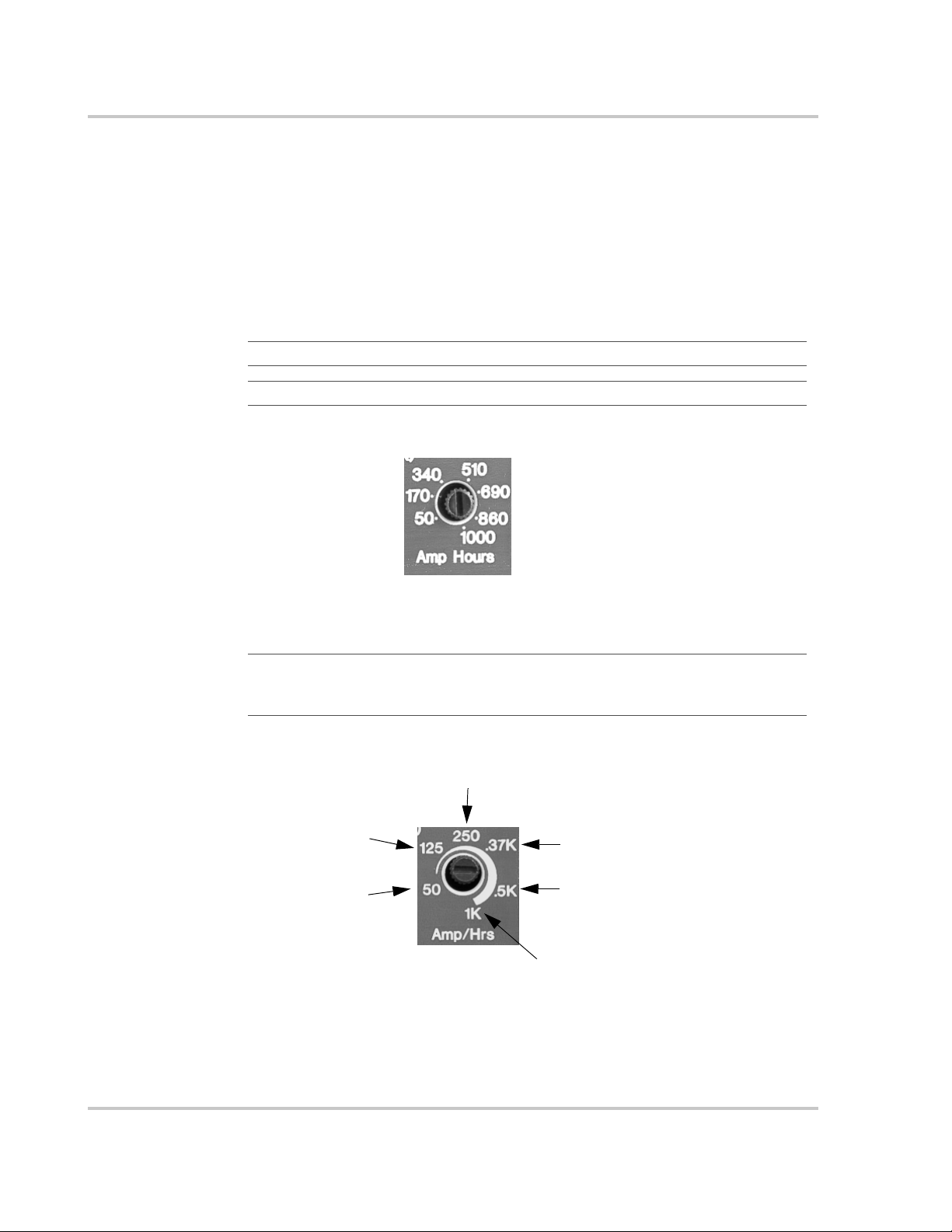

Battery Charger Rate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Over Discharge Protection/AC Transfer Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Over Discharge Protection (ODP) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

AC Transfer Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Battery Capacity - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13

Inverter Mode LED - Green - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13

Over Temp / Overload LED - Red / Green (error condition) - - - - - - - - - - - - - - - - - - - -3–13

Battery High/Battery Low LED - Red/Green (error condition) - - - - - - - - - - - - - - - - - -3–13

Charger LED - Orange / Green - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–14

Audible Indicator (internal) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–14

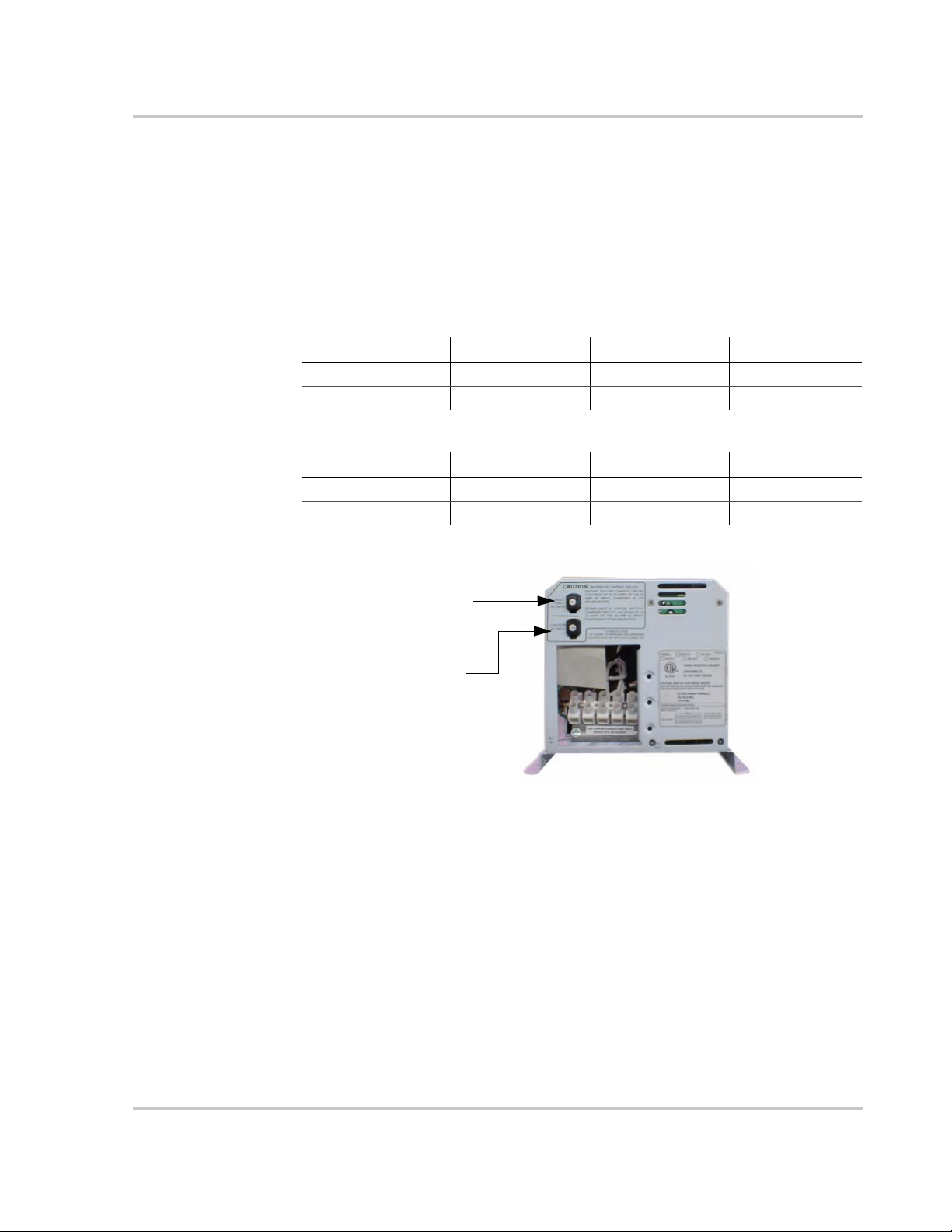

Circuit Breakers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–15

x 975-0012-01-02 Rev A

Page 13

Start-up - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16

Charger Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17

3-Stage Charging Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17

Equalize Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–18

4

Troubleshooting

Troubleshooting the DR Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Problem Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Ceiling Fans - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Cell Phones - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Computers and Sensitive Electronics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Consumer Electronics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Clocks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Decreasing Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Dimmer Switches - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Fluorescent Lights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Heavy Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Microwave Ovens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Printers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Rechargeable Devices - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Undersized Loads - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Contents

A

Specifications

Specifications of the DR Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

B

Battery Information

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–2

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–2

Deep-cycle Flooded Lead Acid (FLA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–2

Sealed Batteries (Gel and AGM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–3

NiCad and NiFe Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–3

Understanding Battery Capacity Ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Battery Bank Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–4

Understanding Amp-hour Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–5

Calculating Amp Hours - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–5

Amp Hour Example Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–6

Battery bank size worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–7

Battery Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–8

Wiring Batteries in Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–8

Wiring Batteries in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–9

Wiring Batteries in Series-Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–10

Battery Connections for Stacked Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–12

975-0012-01-02 Rev A xi

Page 14

Contents

Battery Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–13

Battery Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–13

Equalization Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–15

General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–16

C

Multi-wire Branch Circuit Wiring

Multi-wire Branch Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Identifying Multi-wire Branch Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Correcting Multi-wire Branch Circuit Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–5

Warranty and Return Information

Index

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - IX–1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - WA–1

xii 975-0012-01-02 Rev A

Page 15

Figures

Figure 1-1 Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-2 AC Side of the DR Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-3 DC Side of the DR Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-4 Product Identification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-5 Model/Serial Number Sticker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

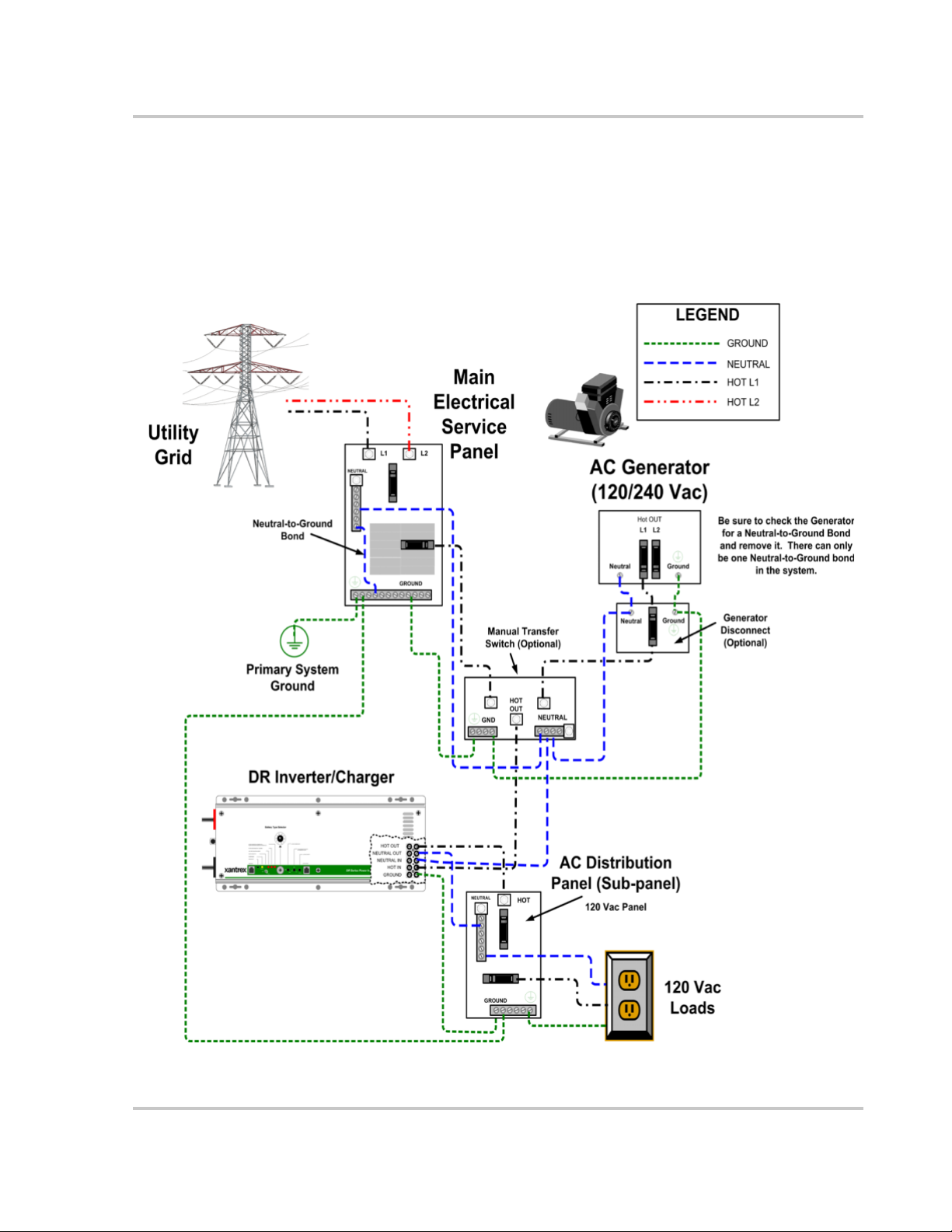

Figure 2-1 On-Grid Basic Configuration (Utility Backup)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-2 Off-Grid Configuration (Generator only) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–7

Figure 2-3 On-Grid Configuration - with Renewable Energy Sources - - - - - - - - - - - - - - - - - - - - - 2–8

Figure 2-4 Off-Grid Configuration - with Renewable Energy Sources- - - - - - - - - - - - - - - - - - - - - 2–9

Figure 2-5 Charge Rate versus Peak AC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-6 Dimensions (not to scale) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Figure 2-7 Suggested Mounting Method - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-8 Mounting on Plywood - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-9 DC Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Figure 2-10 Battery Cable Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Figure 2-11 DC Terminals on the DR Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Figure 2-12 Connecting the Battery Bank to the DR Inverter/Charger- - - - - - - - - - - - - - - - - - - - - 2–20

Figure 2-13 Battery Temperature Sensor (BTS) RJ11 Jack Location - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-14 Connecting the BTS to the DR Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-15 AC Side Cover Panels - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Figure 2-16 AC Terminals for AC Input to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Figure 2-17 AC Terminals for AC output to the Sub-panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Figure 2-18 AC Wiring- On-Grid Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Figure 2-19 AC Wiring using a Generator - On-Grid Application - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-20 AC Wiring using a 120 Vac Generator - Off-Grid Application - - - - - - - - - - - - - - - - - 2–28

Figure 2-21 AC Wiring using a 240 Vac Generator with 120 Vac Loads only- Off-Grid Application2–29

Figure 2-22 AC Wiring for dual-inverters - On-Grid Application (120 Vac models only) - - - - - - - 2–31

Figure 2-23 Wiring for dual-inverters - On-Grid Application (120 Vac models only) - - - - - - - - - - 2–32

Figure 3-1 Front Panel Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Figure 3-2 Battery Type Selector Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-3 Battery Type Selector Adjustment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

Figure 3-4 Battery Charger Rate Potentiometer (DR1512 values used) - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-5 ODP Enabled/Disabled Positions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-6 Automatically Calculated Discharge Cutoff Voltage per Cell - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-7 ODP Enabled/Disabled Positions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Figure 3-8 Typical Setting for Most Utility Application - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

975-0012-01-02 Rev A xiii

Page 16

Figures

Figure 3-9 Battery Capacity Potentiometer (new) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

Figure 3-10 Battery Capacity Potentiometer (old)- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

Figure 3-11 LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–13

Figure 3-12 AC Pass-through and Charger AC Input Circuit Breakers- - - - - - - - - - - - - - - - - - - - -3–15

Figure 3-13 Startup Items - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–16

Figure 3-14 Charger Controls and Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–18

Figure 3-15 Equalize Positions on Battery Type Selector Switch - - - - - - - - - - - - - - - - - - - - - - - -3–19

Figure 3-16 Equalize 1 Battery Charger Rate Potentiometer (Position “1”)- - - - - - - - - - - - - - - - - -3–20

Figure 3-17 Equalize 2 Battery Capacity Rate Potentiometer (Position “0”) - - - - - - - - - - - - - - - - -3–20

Figure B-1 6-volt Battery Wiring - “Series” Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–8

Figure B-2 12-volt Battery Wiring - “Series” Configuration - - - - - - - - - - - - - - - - - - - - - - - - - - - B–9

Figure B-3 Battery Wiring in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–9

Figure B-4 Battery Wiring 24-volt - Parallel Configuration - Step 1 - - - - - - - - - - - - - - - - - - - - - B–10

Figure B-5 Battery Wiring 24-volt - Parallel Configuration - Step 2 - - - - - - - - - - - - - - - - - - - - - B–10

Figure B-6 Battery Wiring 24-volt - Parallel Configuration - Step 3 - - - - - - - - - - - - - - - - - - - - - B–11

Figure B-7 Example of Battery Connections for Stacked Inverters (24 Vdc shown) - - - - - - - - - - B–12

Figure C-1 Conventional Home-type Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Figure C-2 Multi-wire Branch Circuit Wiring and Current Flow - - - - - - - - - - - - - - - - - - - - - - - - C–3

Figure C-3 120 Vac Inverter Incorrectly Wired in a Multi-wire Branch Circuit - - - - - - - - - - - - - - C–3

Figure C-4 Multi-wire Branch Circuit Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Figure C-5 Using a Step-down Autotransformer in Multi-wire Branch Circuit Wiring - - - - - - - - C–6S

xiv 975-0012-01-02 Rev A

Page 17

Tables

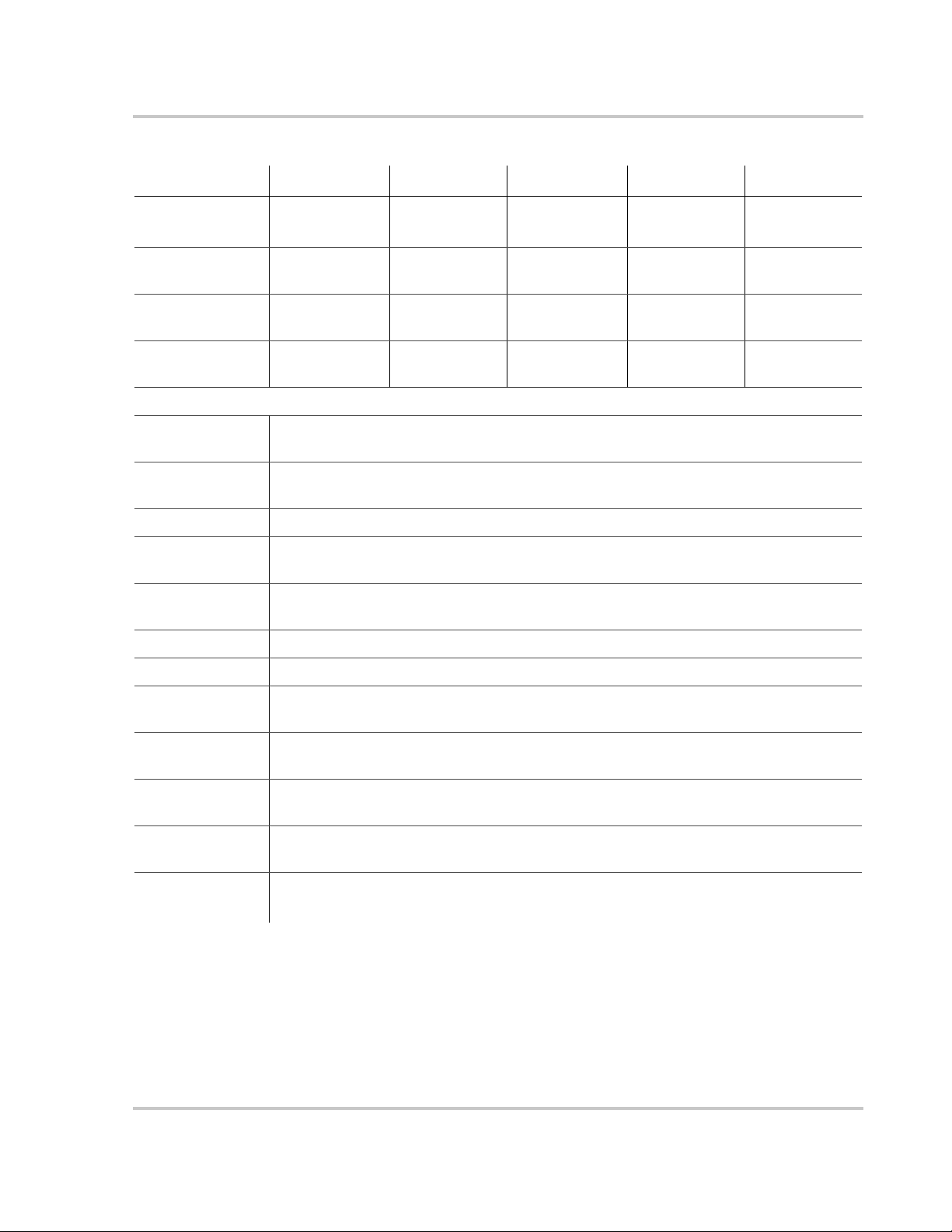

Table 1-1 Model Identification and Numbering Conventions - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Table 1-2 Letter Suffix Code Definitions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

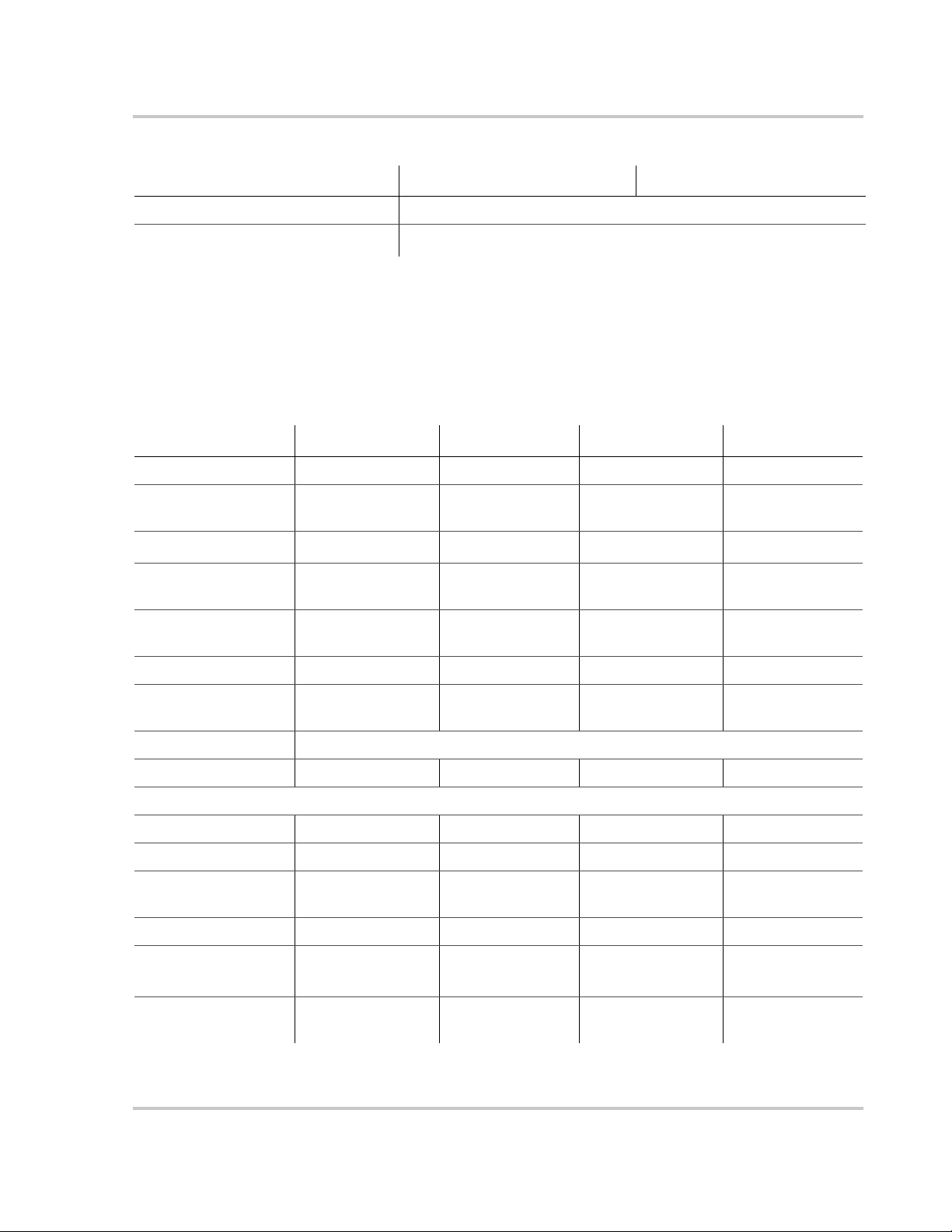

Table 2-1 Peak Input Filtrate versus Charging Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Table 2-2 Safety Ground Conductor Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Table 2-3 Minimum Recommended Battery Cable Size versus Length - - - - - - - - - - - - - - - - - - 2–16

Table 2-4 Battery Cable to Maximum Breaker/Fuse Size- - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Table 2-5 Minimum Recommended Wire Size, Torque Values (Input and Output),

and Maximum Output Breaker Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Table 3-1 Battery Type Selector Switch Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Table 3-2 Approximate Charge rate Setting/Amperage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–8

Table 3-3 ODP/AC Transfer Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

Table 3-4 AC Pass-through Circuit Breakers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Table 3-5 Battery Charger Circuit Breakers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Table 4-1 Troubleshooting the DR Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Table A-1 Electrical Specifications for the DR Inverter/Charger - 120 Vac/60 Hz Models- - - - - - -A–2

Table A-2 Electrical Specifications for the DR Inverter/Chargers - 220 Vac/60 Hz Models - - - - - -A–4

Table A-3 Electrical Specifications for the DR Inverter/Charger - 230 Vac/50 Hz Models- - - - - - -A–5

Table A-4 Environmental Specifications for the DR Inverter/Charger - - - - - - - - - - - - - - - - - - - -A–7

Table B-1 Determining Average Daily Load in Amp-hours (Example - - - - - - - - - - - - - - - - - - - -B–6

Table B-2 Determining Battery Bank Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–7

Table B-3 Typical Appliance Wattage- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -B–7

Table B-4 Variances in Charging Voltage based on Battery Temperature - - - - - - - - - - - - - - - - - B–14

Table B-5 Temperature Compensation Calculation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–14

Table B-6 Battery State-of-Charge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–17

975-0012-01-02 Rev A xv

Page 18

xvi

Page 19

1

Introduction

Chapter 1, “Introduction” contains information about the features and

functions of the DR Inverter/Charger.

Page 20

Introduction

Introduction

Thank you for purchasing the DR Inverter/Charger from Xantrex Technology Inc.

The DR Inverter is one of the finest inverter/chargers on the market today,

incorporating state-of-the-art technology and high reliability.

The inverter features an AC pass-through circuit, powering your home appliances

from utility or generator power while charging the batteries. When utility power

fails, the battery backup system keeps your appliances powered until utility power

is restored. Internal protection circuits prevent over-discharge of the batteries by

shutting down the inverter when a low battery condition occurs. When utility or

generator power is restored, the inverter transfers to the AC source and recharges

the batteries.

The front panel features LEDs for reading system status, and controls to

customize the inverter settings for your battery bank.

The DR Inverter is an economical product designed to provide a reliable supply of

electricity to all the essential circuits in the home or business during a power

outage. The critical loads can be powered for hours or days, depending on the size

of the system battery bank. When utility grid power returns, the batteries are

quickly recharged to ensure they will be ready to supply backup power during the

next outage.

Accessories allow the DR Series to also serve as a central hub of a renewable

energy system.

Modified Sine

Wave P owe r

Battery Charger/AC

Transfer Relay

Simplicity The DR Inverter is simple to operate. All inverter and battery charger controls are

High Efficiency The inverter/charger operates at over 90% efficiency through most of its power

Low Power

Consumption

The DR Inverter provide a modified sine wave output which operates most AC

appliances and equipment.

The inverter/charger includes a 3-stage battery charger designed to recharge any

type of battery in the shortest possible time. The built-in, fully automatic AC

transfer relay automatically transfers power from the utility to the inverter and

handles a full 60 amps of current at 120 Vac (30 amps for pass-through plus

20 to 30 amps for charging - depending on the model).

located on the front panel.

range in Invert-mode.

DR Inverter use extremely low current while in the search mode, consuming less

than 1 watt of power. In the O

of power.

N mode, the inverter/charger uses less than 12 watts

Features

The following sections illustrate the features of the DR Inverter. Figure 1-1 shows

the features of the front side of the DR Inverter and identifies the AC side from the

DC side.

1–2 975-0012-01-02 Rev A

Page 21

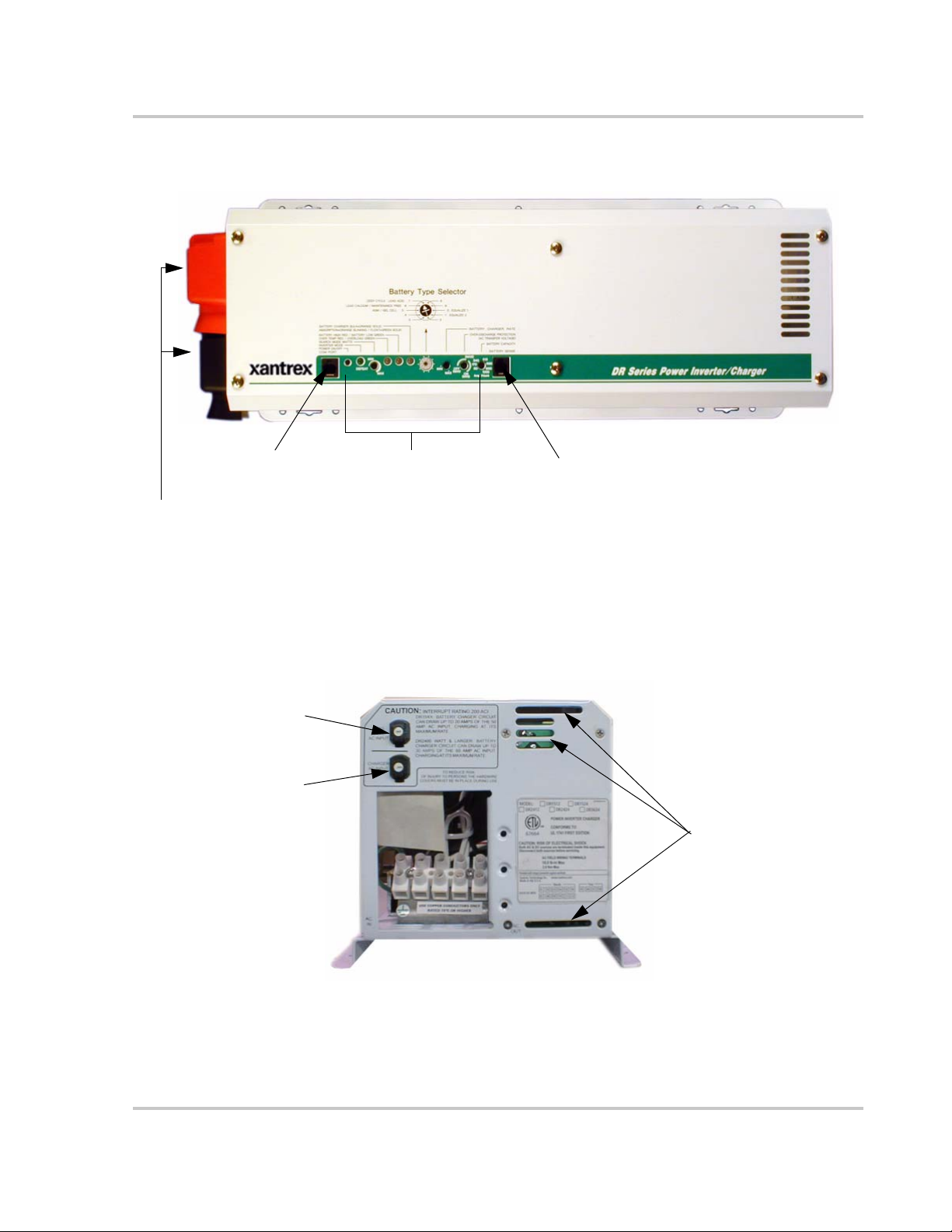

Features

Battery Caps

Figure 1-1

AC Side

DC End

COM Port

Front Panel Features

The AC side of the DR Inverter has one 30-amp breaker for pass-thru AC Input,

and one 30-amp (20 amp in certain models) breaker for charger AC input.

Front Panel Controls

and Indicators

AC End

Battery Sense Port

30 Amp Breaker for

Pass-thru AC Input

20 or 30 Amp Breaker

for Charger AC Input

Ventilation Holes

Cover plate is not shown

in this photo.

Figure 1-2

AC Side of the DR Inverter

975-0012-01-02 Rev A 1–3

Page 22

Introduction

DC Side

The DC side of the DR Inverter has the equipment ground lug, the positive (+)

battery terminal, and the negative (–) battery terminal.

Battery Positive

(+) Terminal

Ventilation Holes

Figure 1-3

DC Side of the DR Inverter

Optional Equipment

The following options are available for the DR Inverter/Chargers.

Remote Control (RC8)

The RC8 allows the inverter to be switched ON or OFF remotely and includes an

LED status indicator. This unit is also compatible with the RC4 (the predecessor

to the RC8); although the RC4 is no longer available for purchase from Xantrex.

Ventilation Holes

Battery Negative

(–) Terminal

Ground Lug

Stacking Interface (DRI)

The DRI stacking interface provides 3-wire 120/240 Vac at twice the power using

dual DR Inverters (120 Vac/60 Hz units only).

Conduit Box (DRCB)

The DRCB conduit box connects to the DC side of the inverter and accepts a DC

conduit run.

Unpacking and Inspection

Carefully unpack the inverter/charger from its shipping carton.

1–4 975-0012-01-02 Rev A

Page 23

Features

Important:

additional help available if necessary, to assist in lifting the unit during installation.

The unit weighs 35–45 lb/15.9–20.4 kg (depending on model). Have

❐ Verify all of the items listed on the packing material sheet are present. Please

call Xantrex Customer Service at (800) 670-0707 if any items are missing.

❐ Save your proof-of-purchase. This is required if the unit should require

warranty service.

❐ Save the original shipping carton and packing materials! If the inverter ever

needs to be returned for service, it should be shipped in the original carton.

This is also a good way to protect the inverter if it ever needs to be moved.

❐ Record the unit’s model, serial number and date of purchase in the appropriate

fields in section “Information About Your System” on page WA–4.

Important:

or illustrations used in this manual may not exactly match your unit. Xantrex Technology

Inc. reserves the right to update this product without notice or releasing an updated

manual when fit, form or function are not affected.

Due to continual improvement through product updates, photographs and/

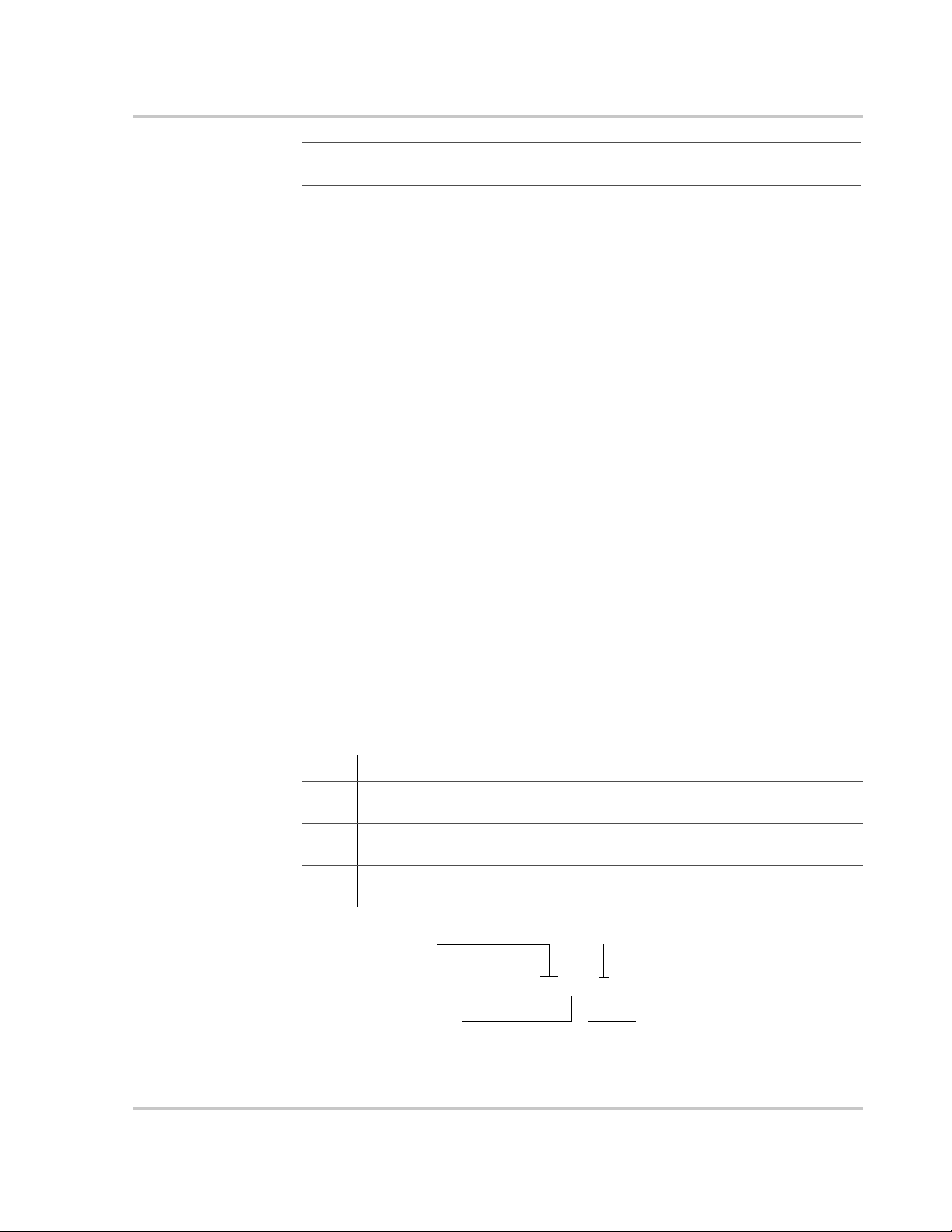

Model Identification and Numbering Conventions

The DR Inverter is identified by the model/serial number labels. The Serial

Number can be located on the mounting rail or inside the top cover. Model

Number labels may be located on the bottom side of the front cover or possibly

inside the front cover. All the necessary information is provided on the label such

as AC output voltage, power and frequency (punch holes).

The inverter also has a letter designator followed by 4 or 5 digits (depending on

revision). The model number describes the type of inverter, the output

specifications, the required battery voltage and the output voltage and frequency

Table 1-1

DR

15

12

E

Product Family

Output Power

Figure 1-4

975-0012-01-02 Rev A 1–5

Model Identification and Numbering Conventions

indicates the type of inverter/charger - DR Series.

the first two digits of the numerical designator indicate the inverter’s output

power - 1500 Watts.

the second two digits indicate the required nominal battery bank voltage 12 Vdc.

the letter suffix code indicates the output voltage and frequency of the inverter 230 Vac/50 Hz.

Country Code

(Letter Suffix)

Example: DR 1512 E

Battery Voltage

Product Identification

Page 24

Introduction

Table 1-2

Letter Suffix Output Voltage Output frequency

(no letter) 120 Vac 60 Hz

E 230 Vac 50 Hz

J 105 Vac 50 Hz

K 105 Vac 60 Hz

W 220 Vac 60 Hz

Letter Suffix Code Definitions

Figure 1-5

Model Number Sticker

Regulatory

The 120 Vac/60 Hz models of the DR Series inverter/charger (models DR1512,

DR1524, DR2412, DR2424, and DR3624) are ETL Listed to UL Standard 1741,

(First Edition) Power Conditioning Units for use in Residential and Commercial

Photovoltaic Power Systems.

These standards guarantee that the DR Inverter/Charger has been tested to

nationally recognized safety standards (UL for the US) and have been found to be

free from reasonably foreseeable risk of fire, electric shock and related hazards.

The DR Inverter/Charger is intended to be used for residential or commercial

applications. Do NOT use this unit for applications for which it is not listed

(i.e., land vehicles or marine craft). It may not comply with the safety code

requirements or could possibly present other operational or safety hazards.

1–6 975-0012-01-02 Rev A

Page 25

2

Installation

Chapter 2, “Installation” contains information about how to plan for

and install the DR Inverter/Charger.

Page 26

Installation

Pre-installation Planning

Location

Important:

and cautionary markings on the DR Inverter/Charger and all appropriate sections of this

guide. Be sure to read all instructions and cautionary markings for any equipment attached

to this unit.

Take some time prior to installing the equipment to pre-plan the installation.

Location, mounting, and ventilation should be taking into consideration before

any cabling can be done.

Before installing and using the DR Inverter/Charger, read all instructions

CAUTION: Personal Injury

The inverter/charger can weigh up to 45 lbs (20.4 kg) depending upon configuration.

Always use proper lifting techniques during installation to prevent personal injury.

Inverters contain sophisticated electronic components and should be located in a

well protected, dry environment away from sources of fluctuating or extreme

temperatures and moisture. Exposure to saltwater is particularly destructive and

potentially hazardous.

Locate the inverter as close to the batteries as possible in order to keep the battery

cable length short. However, do not locate the inverter above the batteries or in the

same compartment as vented batteries. Batteries generate hydrogen sulfide gas

which is corrosive to electronic equipment. They also generate hydrogen and

oxygen. If accumulated, an arc caused by connecting the battery cables or

switching a relay could ignite this mixture. Mounting the inverter in a ventilated

enclosure with sealed batteries is acceptable.

CAUTION: Corrosion Damage

If the inverter is installed in a location where it is exposed to a corrosive or condensing

environment and fails due to corrosion, it will not be covered under warranty.

Important:

sensitive electronic equipment susceptible to RFI as far away from the inverter as

possible. This includes radios and TVs.

2–2 975-0012-01-02 Rev A

Inverters can generate RFI (Radio Frequency Interference). Locate any

Page 27

Mounting

Ventilation

Pre-installation Planning

The National Building Code requires the inverter be mounted on a vertical surface

(or wall). The keyhole slots must not be used as the only method of mounting. The

purpose of the wall mounting requirement is to orient the inverter so that its

bottom cover, which has no holes, will not allow burning material to be ejected in

the event of an internal fire. Use 0.25-inch diameter bolts for mounting. The

mounting surface must be capable of supporting twice the weight of the inverter to

comply with UL 1741.

Install the inverter in a well ventilated area/enclosure for proper operation. The

inverter’s thermal shutdown point will be reached sooner than normal in a poorly

ventilated environment, resulting in reduced peak power output and surge

capability, as well as shorter inverter life.

The inverter contains an internal fan. Ensure the air vents and intakes are not

obstructed in any way. Provide a minimum clearance of 6 inches around the top

and sides of the inverter for ventilation.

Tools Required

The following tools may be required to complete this installation.

❐ #2 Phillips screw driver

❐ Slotted screw driver

❐ Assorted open-end wrenches

❐ Socket wrench and fittings

❐ Multimeter (True rms)

❐ Hole saw

❐ Level

❐ Wire strippers

❐ Torque wrench

❐ Electrical tape

❐ Pencil

❐ Utility knife

975-0012-01-02 Rev A 2–3

Page 28

Installation

Hardware / Materials Required

The following hardware or materials may be required to complete this installation.

❐ 4 ft. x 4 ft. sheet of 3/4" plywood or 2 x 4’s studding material

❐ #12 wood screws (or 1/2" x 1-1/4" lag bolts)

❐ Conduit and appropriate fittings

❐ Wire nuts

Wiring Considerations

All wiring and installation methods should conform to applicable electrical and

building codes.

Pre-plan the wire and conduit runs.

• The AC terminals accept cable sizes up to #6 AWG.

• The DC terminals accept cable sizes up to #4/0 AWG that use ring terminals

with 5/16" holes.

For maximum safety, run both AC and DC cables in conduit.

DC Terminal Connections

Battery-to-inverter cabling should be only as long as required.

For Example: If #4/0 AWG cables are used, do not exceed 5 feet (one way) in

12 Vdc systems; do not exceed 10 feet (one way) in 24 Vdc systems.

For optimum performance, use pre-assembled battery cables designed specifically

for this application (available from Xantrex).

Grounding Considerations

AC Grounding

The inverter/charger should be connected to a grounded, permanent wiring

system. Neutral and ground conductors should only be bonded at the main

electrical service panel.

DC Grounding

The negative battery conductor should be bonded to the grounding system at only

one point in the system. The size for the conductor is usually based on the size of

the largest conductor in the DC system.

2–4 975-0012-01-02 Rev A

Page 29

Wire Routing

Pre-installation Planning

Determine all wire routes both to and from the inverter and which knockouts are

best suited for connecting the AC conduits. Possible routing scenarios include:

• AC input wiring from the main electrical service panel to the inverter/charger

(if used)

• AC input wiring from the generator to the inverter/charger (if used)

• DC input wiring from the RE to the inverter/charger (if used)

• DC input wiring from the batteries to the inverter/charger

• AC output wiring from the inverter/charger to the sub-panel

• Battery Temperature Sensor cable from the batteries to the inverter/charger (if

used)

• Remote control cable to the inverter/charger (if used)

• DC ground from the batteries to an external ground rod

• Load circuit wiring rerouted from the main service panel to the sub-panel

Check for existing electrical or plumbing prior to making cuts in the walls. Cut

holes in the walls at appropriate locations for routing wiring/cables.

Electrical Panels and Circuit Breaker Requirements

The following electrical panels and circuit breakers may be required for this

installation.

AC Distribution Panel (Sub-Panel)

Loads backed up by the inverter will need to be rerouted from the main electrical

panel to a sub-panel. This can be done several different ways, depending upon the

installation. Always refer to electrical codes for safe wiring practices.

DC Disconnect

Install a DC disconnect breaker or fuse in the positive battery line. This breaker

protects the DC wiring in the event of an accidental short. Size the breaker in

accordance with the battery cables. Switch this breaker OFF whenever servicing

the batteries.

Battery Considerations

The DR Inverter can support either 12-volt battery banks or 24-volt battery banks.

The battery voltage MUST match the voltage requirements of the inverter. To

determine the correct voltage for the system, check the last two digits on the

inverter’s model number. For example, the DR1512 is a 12-volt inverter and

requires a 12 Vdc battery system. The DR2424 is a 24-volt inverter and requires a

24 Vdc battery system.

975-0012-01-02 Rev A 2–5

Page 30

Installation

Battery Location

Locate the batteries in an accessible location. Two feet clearance above the

batteries is recommended for access to the battery caps. They should be located as

close to the inverter as possible without limiting access to the inverter’s

disconnects. Install the batteries to the left of a wall mounted inverter for easy

access to the DC side of the inverter and shorter cable runs.

For safety and to limit access to the batteries, a lockable, ventilated, battery

enclosure or dedicated room should be used. If an enclosure is used, it should be

vented to the outside via a one inch vent pipe located at the top of the enclosure.

Install an intake vent at the bottom of the enclosure to promote air circulation.

These vents exhaust explosive hydrogen gases and must not be overlooked when

designing an enclosure.

The enclosure should be made of an acid resistant material or have a finish that

resists acid to prevent corrosion. It should be capable of holding the electrolyte

from at least one battery should a leak occur.

Place a layer of baking soda on the shelves to neutralize any acid that may be

spilled in the future (lead-acid batteries only).

Enclosures located outside must be rainproof and screened to prevent access by

rodents or insects.

Battery Temperature

The battery enclosure should provide a fairly stable temperature for the batteries.

If it is installed in a cold environment, insulation should be used to protect the

batteries from the cold. The insulation also provides a more consistent

temperature and better system performance.

The battery enclosure should not be installed in direct sunlight where the summer

sun can overheat the batteries. Locate the enclosure where it will be protected

from the afternoon sun and provide vents in the top and bottom of the enclosure to

provide air flow. High battery temperatures greatly shortens the life of the

batteries.

Basic Configurations

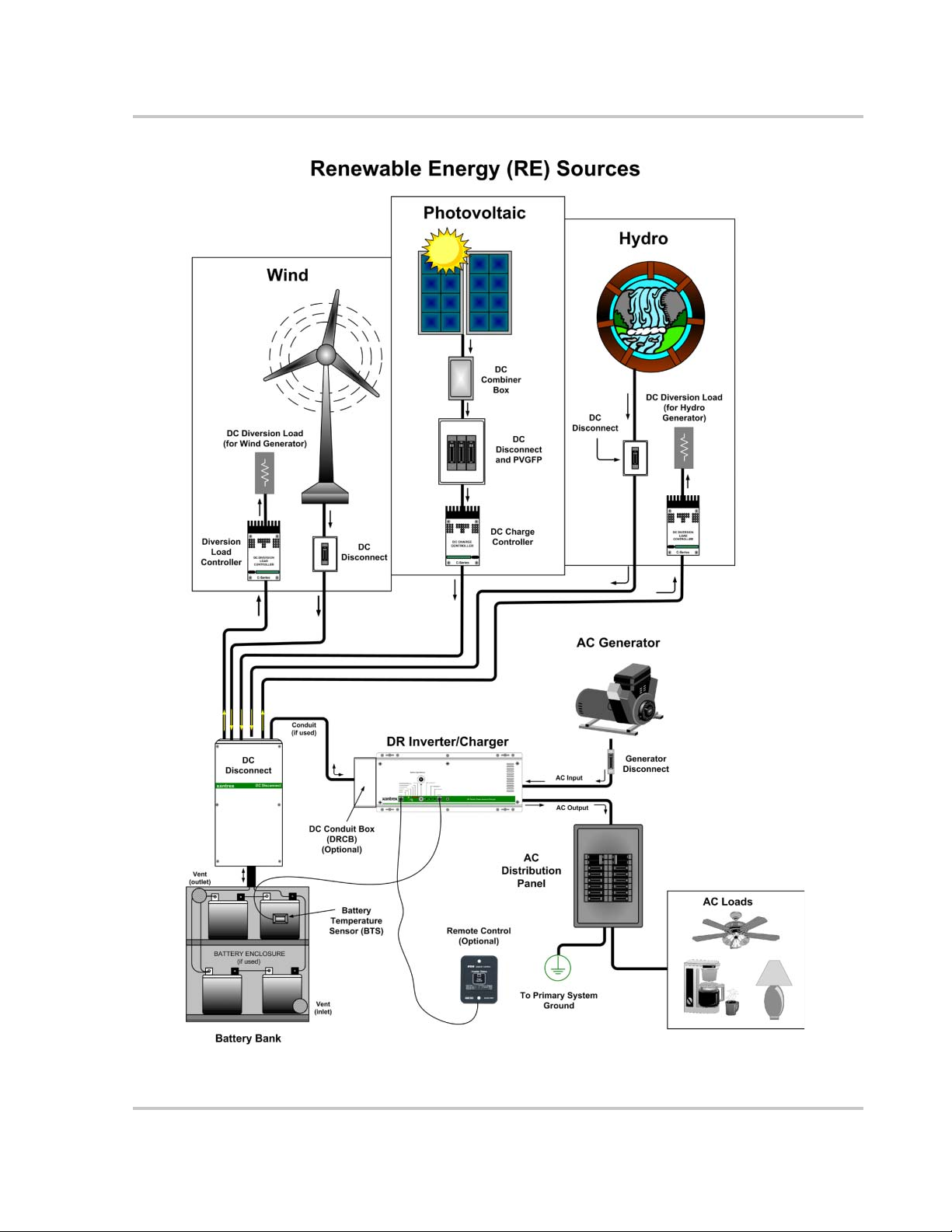

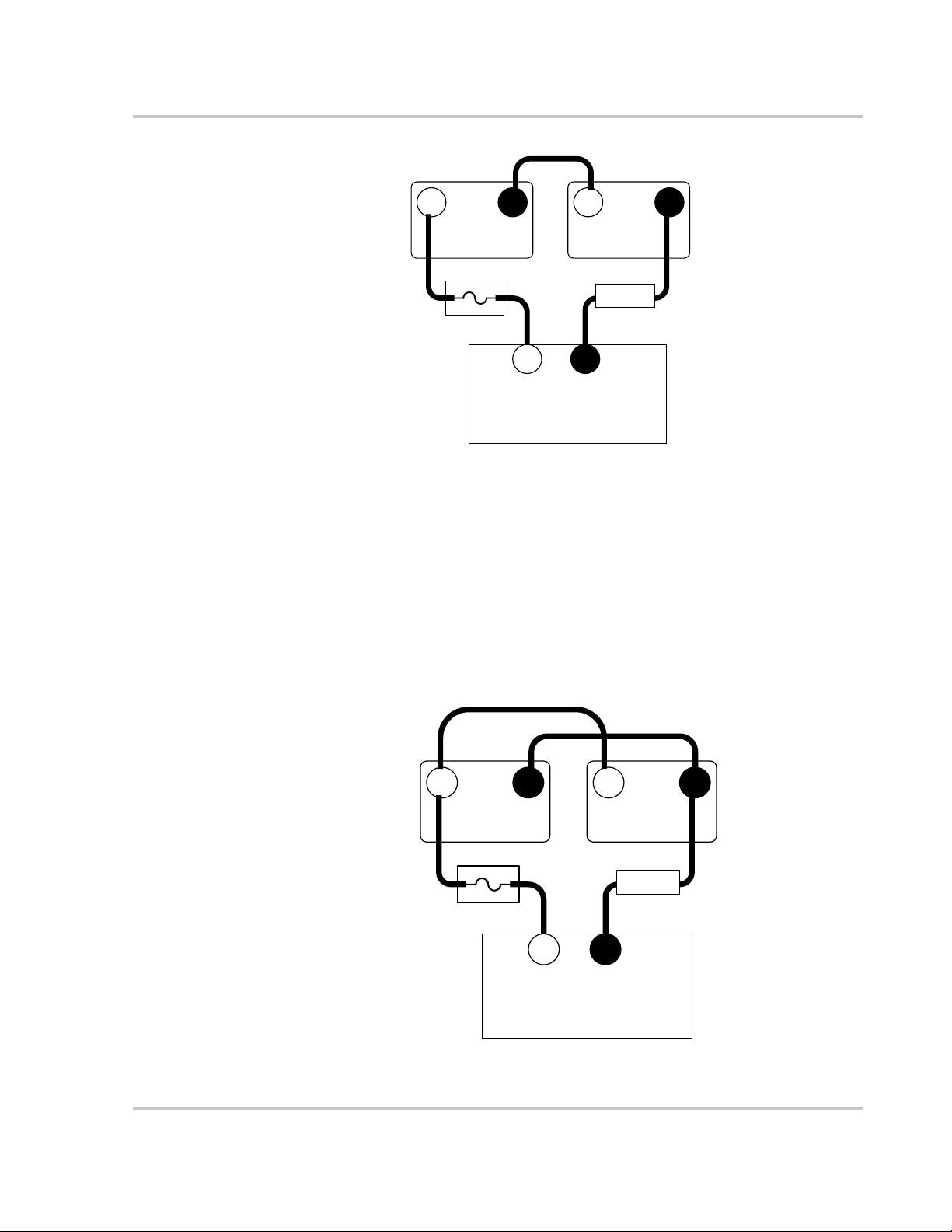

The following illustrations show basic applications for the DR Inverter/Charger.

They include the following configurations.

• On-Grid Configuration - Utility Backup

• Off-Grid Configuration - Generator only

• On-Grid Configuration with Renewable Energy Sources

• Off-Grid Configuration with Renewable Energy Sources and a Generator

Consult with your system design for other possible configurations depending on

site and code requirements.

2–6 975-0012-01-02 Rev A

Page 31

Pre-installation Planning

Figure 2-1

On-Grid Basic Configuration (Utility Backup)

Figure 2-2

975-0012-01-02 Rev A 2–7

Off-Grid Configuration (Generator only)

Page 32

Installation

Figure 2-3

2–8 975-0012-01-02 Rev A

On-Grid Configuration - with Renewable Energy Sources

Page 33

Pre-installation Planning

Figure 2-4

975-0012-01-02 Rev A 2–9

Off-Grid Configuration - with Renewable Energy Sources

Page 34

Installation

Generators

An AC generator can be used as an input source instead of the utility power, or

can be connected (using additional hardware) to power the loads when utility is

not present (utility outage), and to charge the batteries. The generator must be of

the permanently installed type and not a portable type unit used for emergency

power. Small emergency type (lower power) generators may not have a stable

enough voltage for the inverter to synchronize to or provide enough current to

fully charge the batteries.

The maximum charge rate the battery charger can deliver is dependant upon the

peak AC voltage available. Since the battery charger uses only the top portion of

the input sine wave, small variations in peak voltage result in large variations in

the amount of energy to the charger. The charger’s rated output is based on a

utility voltage of 120 Vac RMS (the usual measured value). This should have a

peak voltage of 169 Vac

(230 Vac has a peak voltage of 325 Vac). For every 10

p

p

volts of peak lost, the charge rate is reduced by approximately half.

Size the generator appropriately for the system, including battery charge and load

current (typically twice the wattage output of the inverter).

Table 2-1 and Figure 2-5 demonstrates how the peak voltage available affects the

charging current.

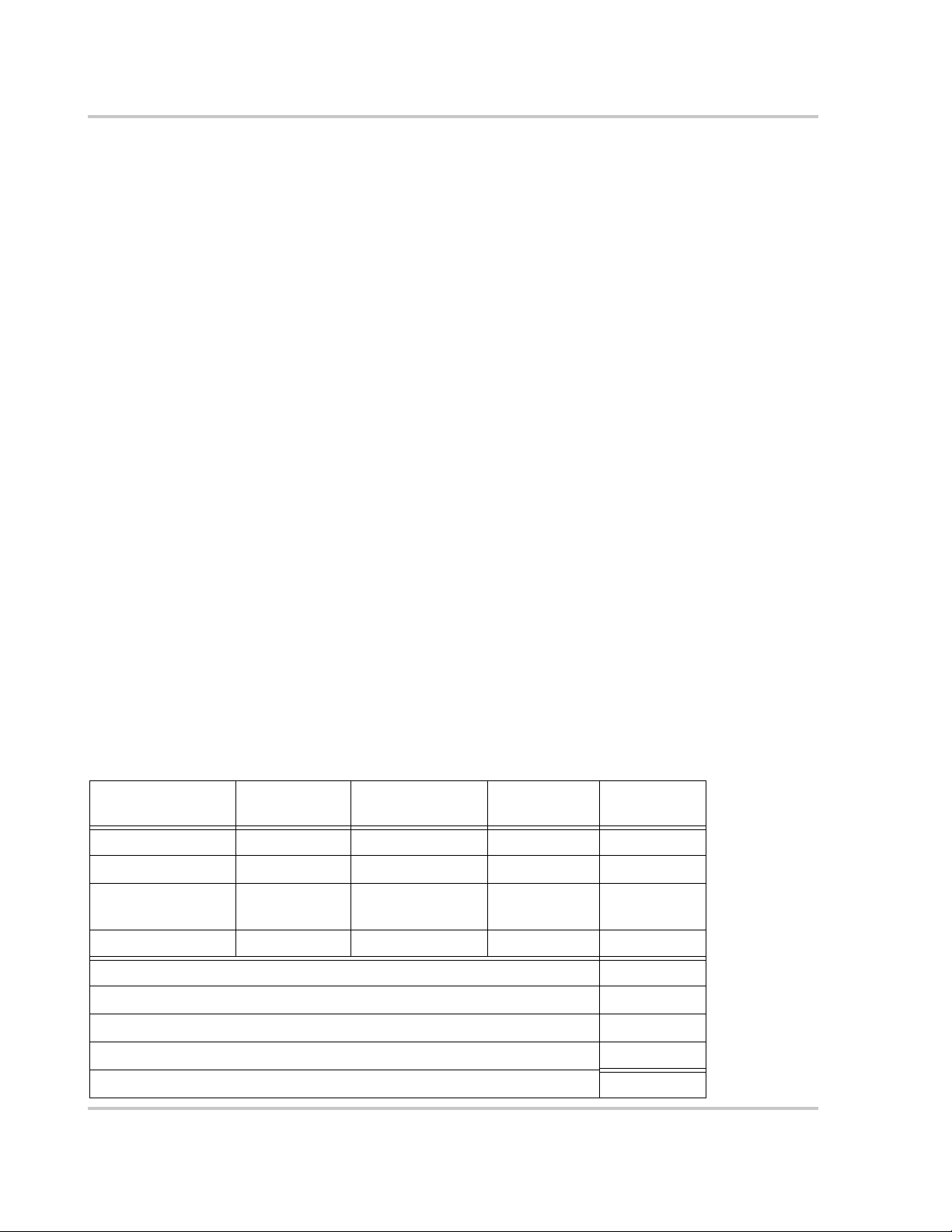

Table 2-1

Peak Voltage

Available DR1512 DR2412 DR1524 DR242 DR3624

170 Vac

160 Vac

145 Vac

Peak Input Filtrate versus Charging Current

p

p

p

70 amps 120 amps 35 amps 70 amps 70 amps

35 amps 60 amps 17.5 amps 35 amps 35 amps

15 amps 25 amps 7 amps 15 amps 15 amps

Figure 2-5

2–10 975-0012-01-02 Rev A

Charge Rate versus Peak AC Voltage

Page 35

Inverter Mounting

Pre-installation Planning

The DR Series inverter can weigh as much as 45 lb. (20.4 kg). Wallboard is not

strong enough to support its weight so additional support must be used or added.

The inverter can be mounted directly to the wall studs if the wall studs are 16"

apart. If not, then 2x4’s or plywood can be used.

WARNING: Personal Injury

Use appropriate lifting techniques. Have extra people on hand to assist in lifting the

inverter into position while it is being secured.

To secure the DR Inverter to the wall studs:

1. Locate the studs and mark their location on the wall.

2. Measure the desired height from the floor for the inverter to be mounted.

3. Using a level, run a horizontal line. The length of the line must span at least

three studs.

4. Using the dimensions illustrated in Figure 2-6, drill mounting holes into the

center of the studs for the inverter.

5. Secure the inverter to the studs using ¼ x 1½ inch lag bolts and washers.

Figure 2-6

975-0012-01-02 Rev A 2–11

Dimensions (not to scale)

To secure the DR Inverter to the mounting location using 2 x 4’s or plywood:

1. Repeat steps 1 through 3 above.

2. Place a pre-cut 2 x 4 (flat side against the wall) on the marked location and

drill pilot holes through the 2 x 4’s and studs.

Page 36

Installation

3. Secure the 2 x 4 with #10 wood screws (length to penetrate 1½ inches into the

studs) as shown in Figure 2-7.

4. Measure 7 5/8" from the center of the first 2 x 4 and draw another level line.

Place the center of the second 2 x 4 over this line and secure to the wall as

described in Step 5.

5. Using the dimensions illustrated in Figure 2-6, drill mounting holes into the

center of the 2 x 4’s for the inverter.

6. Secure the inverter to the 2 x 4’s using ¼ x 1½ inch lag bolts and washers.

Figure 2-7

Figure 2-8

2–12 975-0012-01-02 Rev A

Suggested Mounting Method

Ensure the plywood spans

across a minimum of three wall

studs for adequate support.

Mounting on Plywood

Page 37

DC Wiring

This section describes the DC wiring requirements and how to make the

connections. It provides the required cable and wire sizes, recommended lengths

for cables, and disconnect/circuit breaker requirements.

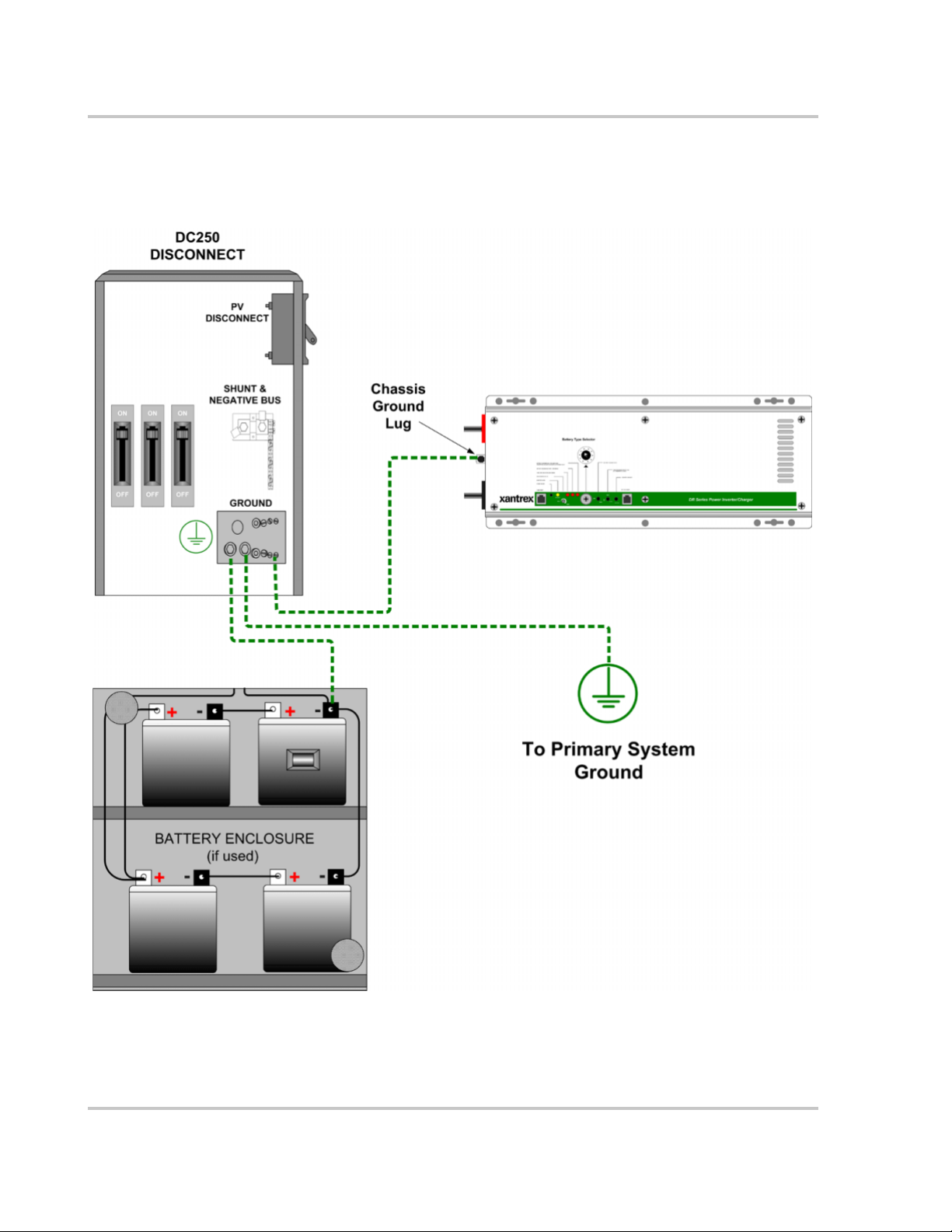

DC Circuit Grounding

Grounding is an important part of the system installation and must be performed

correctly to ensure safe operation of the equipment. Grounding requirements vary

by country and application. Consult the NEC for specific requirements.

The ground conductor should be sized appropriately for the over-current

protection device being used and according to NEC 250-95 (Ninth Edition)

(see Table 2-2 below for a portion of the NEC code).

DC Wiring

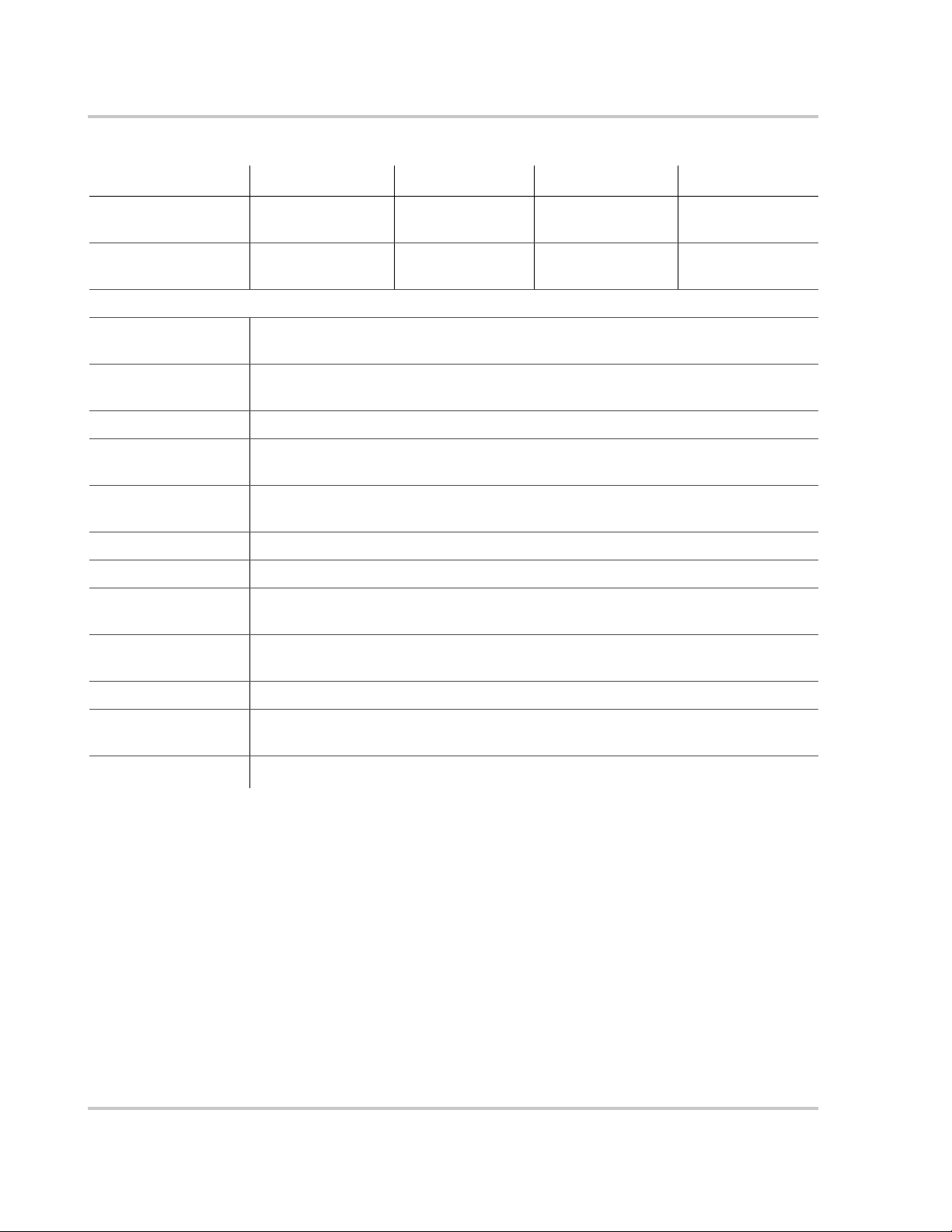

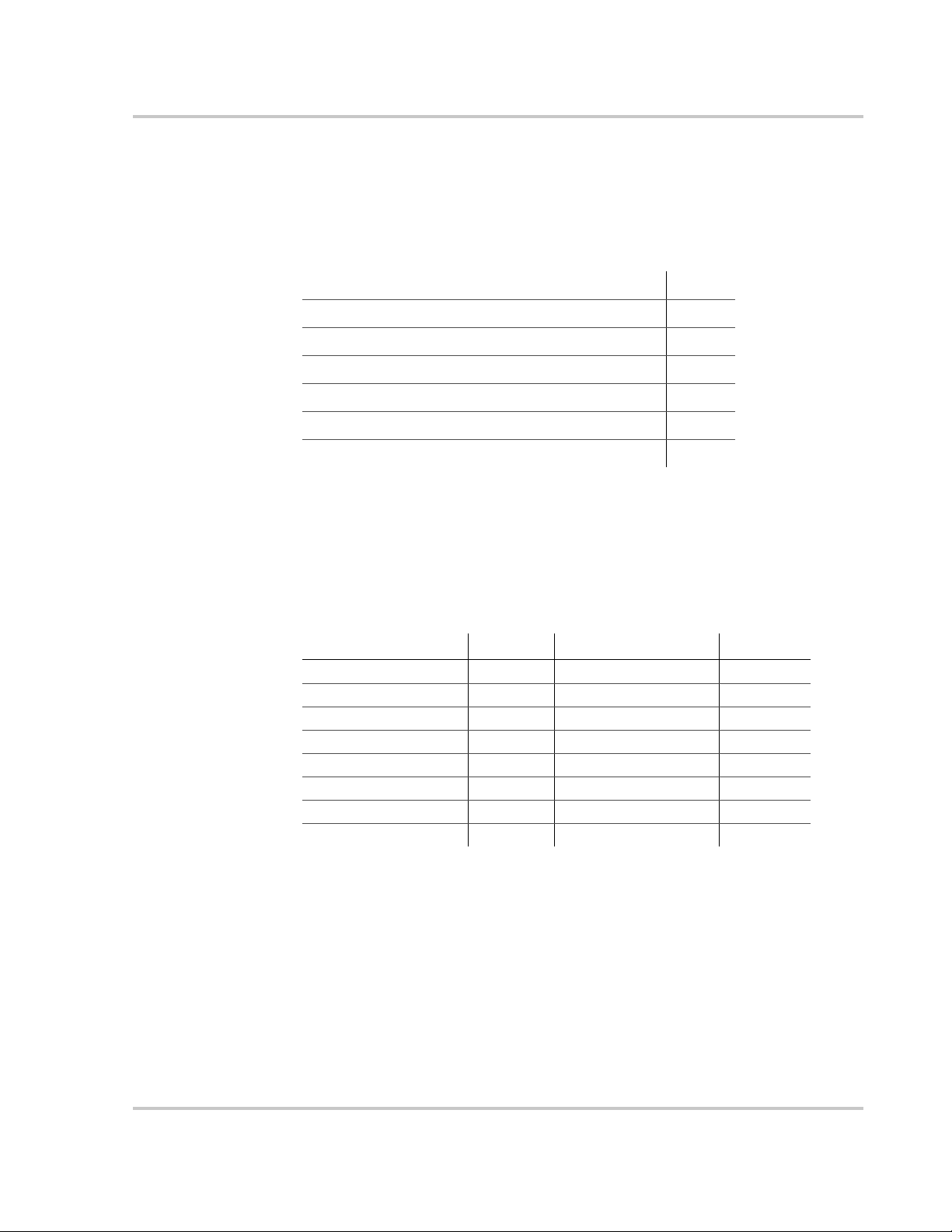

Table 2-2

Size of Over-current Device

Protecting the Conductor

30 or 60 amp #10 AWG

100 amp #8 AWG

200 amp #6 AWG

300 amp #4 AWG

400 amp #3 AWG

Safety Ground Conductor Size

General DC Grounding Requirements

This product is intended to be installed as part of a permanently grounded

electrical system per the National Electric Code ANSI/NFPA 70 (current edition).

This is the single point earth ground for the inverter system.

To ground the DC circuits:

1. Connect the negative (-) terminal of the battery bank to an appropriately sized

conductor and connect it to the ground bus in the DC Disconnect.

2. Connect an appropriately sized conductor to the Ground bus in the DC

Disconnect and connect it to the primary system ground.

The system ground is the same ground used by the AC side of the system.

Minimum Size of the Copper

Ground Wire

975-0012-01-02 Rev A 2–13

Page 38

Installation

Figure 2-9

2–14 975-0012-01-02 Rev A

DC Grounding

Page 39

Batteries

Battery Types

Battery Bank Sizing

DC Wiring

The DR Inverter can support either 12-volt battery banks or 24-volt battery banks.

Before proceeding, ensure you have the appropriate sized batteries for this

inverter.

Batteries are available in different sizes, amp-hour ratings, voltage, liquid or gel,

vented or non-vented, chemistries, etc. They are also available for starting

applications (such as an automobile starting battery) and deep discharge

applications. Only the deep discharge types are recommended for inverter

applications. Choose the batteries best suited for the inverter installation and cost.

Use only the same battery type for all batteries in the bank. For best performance,

all batteries should be from the same lot and date. This information is usually

printed on a label located on the battery.

Additional information regarding batteries can be found in the Appendix B,

“Battery Information”.

Battery Configuration

The size of the battery bank determines how long the AC loads will operate in a

backup mode without utility power. The larger the battery bank, the longer the run

time. Size the battery bank to the AC load requirements and length of time

required to run from the batteries. In general, the battery bank should not be

discharged more than 50%. Additional DC charging devices such as solar, wind,

hydro, etc., can provide longer run times by recharging the batteries in the absence

of AC utility or generator power.

Additional details on estimating battery bank size and capacity can be found in

“Battery Bank Sizing” on page B–4.

The battery bank must be wired to match the inverter’s DC input voltage

specifications (12 Vdc, 24 Vdc, or 48 Vdc). In addition, the batteries can be wired

to provide additional run time. The various wiring configurations are:

• SERIES - Wiring batteries in series increases the total bank output voltage (to

match the inverter’s DC requirements).

• PARALLEL - Wiring the batteries in parallel increases the total run time the

batteries can operate the AC loads.

• SERIES-PARALLEL - Series-parallel configurations increase both the

battery voltage (to match the inverter’s DC requirements) and run-time for

operating the AC loads.

For additional information on how to wire these battery-bank configurations, see

“Battery Configurations” on page B–8.

975-0012-01-02 Rev A 2–15

Page 40

Installation

Battery Cable Sizing

Proper cable sizing (diameter and length) is critical to the safe and efficient

operation of an inverter system. Larger diameter cables (smaller AWG number)

have less voltage drop and are, therefore, more efficient when transferring power

to and from the batteries. If a cable is undersized (diameter too small), it could

potentially overheat, creating a fire hazard.

Cable length is another important factor. Runs should be kept as short as practical.

Longer cable runs increase resistance, thus lowering the overall efficiency of the

system. This is especially true in lower voltage systems (i.e., 12 Vdc) where,

depending upon the length of the cable run, it may be necessary to oversize the

diameter of the wire, or parallel (double) the cables.

Table 2-3

Inverter

Model

DR1512 150 A

DR2412 240 A

DR1524 75 A

DR2424 120 A

DR3624 180 A

Minimum Recommended Battery Cable Size versus Length

Typical

Amperage 1 to 3 feet (one-way) 3 to 5 feet (one-way) 5 to 10 feet (one-way)

Important:

for the amperage of the inverter and batteries.

Only use copper cables. Always use a properly sized cable and length rated

WARNING: Fire Hazard

Undersized cables can overheat and melt, creating a fire hazard when subjected to heavy

(peak) loads.

Table 2-3 provides recommended minimum cable sizes for various cable lengths

and inverter amperages. These recommendations may not meet all local or NEC

requirements.

Important:

possible by taping them together. This reduces the effects of inductance and produces a

better waveform thus increasing efficiency. See Xantrex Technical Note 008 on the

Xantrex website for additional information on Battery Cable Inductance.

#2/0 AWG (67.4 mm

#4/0 AWG (107 mm

#2/0 AWG (67.4 mm

#2/0 AWG (67.4 mm

#4/0 AWG (107 mm

Run the positive and negative battery cables as close to each other as

2

) #2/0 AWG (67.4 mm2) #4/0 AWG (107 mm2)

2

) #2/0 AWG (67.4 mm2) #2/0 AWG (67.4 mm2)

2

) #2/0 AWG (67.4 mm2) #2/0 AWG (67.4 mm2)

2

) #4/0 AWG (107 mm2) #4/0 AWG (107 mm2)

2

) #4/0 AWG (107 mm2) #4/0 AWG (107 mm2)

Important:

micro-hydroelectric plant or wind generator), increasing the size of the cables and

disconnects will greatly reduce the number of nuisance outages associated with breaker

tripping and open fuses.

2–16 975-0012-01-02 Rev A

If the system includes a large battery bank or large DC source (such as a

Page 41

DC Disconnect and Over-current Protection

For safety and to comply with regulations, battery over-current protection is

required. Fuses and disconnects must be sized to protect the wiring in the system

and are required to open before the wire reaches its maximum current carrying

capability.

The National Electrical Code (NEC) requires both over-current protection and a

disconnect switch for residential and commercial electrical systems. These items

are not supplied as part of the inverter. However, Xantrex offers a DC rated, ETL

Listed, circuit breaker disconnect module specifically designed for use with

Xantrex™ inverters to meet NEC compliance. Two amperage ratings are

available: a DC250 (250 amps) and a DC175 (175 amps) in either single or dual

breaker configurations for single- or dual-inverter installations.

DC Wiring

Important:

Xantrex™ DC disconnects are not designed to accept doubled

(paralleled) cables which may be required for long cable runs. Also, the plastic

red and black covers on the DC inverter inputs are not designed to accommodate

dual cables. If dual cables are used, the optional conduit box (DRCB) must be

used.

Some installations may not require conduit or a disconnect device, although

over-current protection is still required. Xantrex offers a fuse block (TFB)

providing the code required inverter over-current protection for these applications.

Refer to the table below for the proper size disconnect device for specific cable

diameters.

Table 2-4

Cable Size

Required Rating in Conduit

#2 AWG 115 amps max N/A 170 amps max TFB200

#2/0 AWG 175 amps max DC175 265 amps max TFB300

#4/0 AWG 250 amps max DC250 360 amps max TFB400

Battery Cable to Maximum Breaker/Fuse Size

Maximum Breaker

Size

Important:

rating (i.e., 150 amp cable size rounds up to a standard 175 amp size). The term “free air”

is defined by the NEC as cabling that is not enclosed in a conduit or a raceway. Cables

enclosed in conduit or raceways have substantially lower continuous current carrying

ability due to heating factors.

The NEC allows rounding to the next standard fuse size from the cable

Rating in “Free

Air”

Maximum Fuse

Size

975-0012-01-02 Rev A 2–17

Page 42

Installation

Battery Cable Connections

Battery cables must have crimped (or preferably, soldered and crimped) copper

compression lugs unless aluminum mechanical lugs are used. Soldered

connections alone are not acceptable. High quality, UL-listed battery cables are

available from Xantrex in an assortment of lengths: 1½ to 10 feet, and in

#2/0 AWG or #4/0 AWG sizes. These cables are color-coded with pressure

crimped, sealed ring terminals.

Figure 2-10 illustrates the proper method to connect the battery cables to the DR

Inverter’s DC terminals.

Do not place anything

between battery cable lug

and terminal surface.

Assemble exactly as shown.

2/0 Copper Compression Lug 2/0 Aluminum Mechanical Lug

Figure 2-10

Battery Cable Connections

CAUTION: Equipment Damage

The inverter is not reverse polarity protected. Reversing the battery polarity on the DC

input connections will cause permanent damage to the inverter which is not covered under

warranty. Always check polarity before making connections to the inverter.

WARNING: Shock Hazard

Ensure the inverter is off before disconnecting the battery cables, and that AC power is

disconnected from the inverter input.

2–18 975-0012-01-02 Rev A

Page 43

Positive (+)

Battery Terminal

DC Wiring

Torque the

Positive (+)

Battery terminal to

10-15 ft-lbs

(13.6 to 20.3 nm)

Torque value for

the Ground Lug

is 10-15 in-lbs

(1.1 to 1.7 nm)

Figure 2-11

DC Terminals on the DR Inverter

Ground Lug

Connecting the Battery Bank to the Inverter

Follow the procedure below to connect the battery bank to the inverter.

WARNING: Shock Hazard

:

Ensure the inverter is off before connecting or disconnecting the battery cables and that all

AC power is disconnected from the inverter’s inputs.

Negative (–)

Battery Terminal

Torque the

Negative (–)

Battery terminal to

10-15 ft-lbs

(13.6 to 20.3 nm)

To connect the battery bank to the inverter:

1. Determine the correct size battery cable to use for installation from Table 2-3

on page 2–16.

2. Determine the correct size disconnect/fuse for installation from Table 2-4 on

page 2–17.

3. Color code the cables with tape or heat shrink tubing. The standard colors are

red for positive (+) and black for negative (–). (NEC requires white for the

negative conductors.)

4. Connect the negative (–) cable to the battery’s negative terminal (torque to

manufacturer’s recommendations).

5. Install the over-current device (fuse or circuit breaker) between the battery’s

positive terminal and the inverter’s positive terminal (as close to the batteries

as possible).

6. Connect the (short) positive cable to the battery’s positive terminal (torque to

manufacturer’s recommendations).

7. Ensure the correct polarity of the cables with a DC voltmeter (DVM).

975-0012-01-02 Rev A 2–19

Page 44

Installation

8. Observing battery polarity, connect the positive battery cable (from the

over-current device) to the inverter’s positive terminal.

Important:

connecting the cable to the inverter. This is normal, and is caused by the inverter’s

capacitors charging up.

The next step may cause a small spark and snapping sound when

9. Observing battery polarity, connect the negative battery cable to the inverter’s

negative terminal.

10. Use an insulated ½ inch wrench or socket to tighten the 5/16 SAE nuts to

10-15 ft-lb (13.6 to 20.3 nm) for each inverter input terminal.

CAUTION: Equipment Damage

: Equip

Do not put anything between the cable ring terminal and the flat metal part of the terminal.

overheating of the terminal may occur. Do not apply any type of antioxidant paste until

after the battery cable wiring is tightened.

11. Apply antioxidant paste to the battery and inverter terminals.

12. Install the battery terminal connection covers (red for positive, black for

negative) over the inverter’s DC terminals and secure with the screws and

washers provided.

Figure 2-12

2–20 975-0012-01-02 Rev A

Connecting the Battery Bank to the DR Inverter/Charger

Page 45

Installing a Battery Temperature Sensor

A battery temperature sensor (BTS) option can easily be installed in the system to

ensure proper charging of the batteries based on temperature. Installing a BTS

extends battery life by preventing overcharging in warm temperatures and

undercharging in cold temperatures.

To install the Battery Temperature Sensor:

1. Run the battery temperature sensor wire in the DC conduit (if used) and route

the RJ11 connector end to the BATTERY SENSE port located on the front of

the inverter.

2. Secure the sensor to one of the batteries located in the center of the battery

pack.

DC Wiring

Battery Sense

(RJ11) port

Figure 2-13

Figure 2-14

Battery Temperature Sensor (BTS) RJ11 Jack Location

Connecting the BTS to the DR Inverter

975-0012-01-02 Rev A 2–21

Page 46

Installation

AC Wiring

This section describes the AC wiring requirements and how to make the

connections. It provides the required wire sizes, recommended lengths for

conductors, and disconnect/circuit breaker requirements.

Important:

qualified person or a licensed electrician following all local and NEC codes.

The installation of sub-panels and wiring should be performed by a

AC Distribution Panel (Sub-panel) Mounting and Conduit Installation

WARNING: Shock Hazard

Disconnect the power from the utility’s main breaker box before proceeding.

1. Determine the location of the sub-panel and install it according to the

manufacturer’s directions.

2. Install the AC conduit between the sub-panel (output) and inverter.

3. Install conduit between the inverter (input) and the main breaker box.

4. Determine which circuits require backup. Install the appropriate circuit

breakers into the sub-panel.

5. Install an appropriately sized circuit breaker (30 amp maximum) in the

sub-panel. This will later be wired to the inverter’s output. If two inverters are

being used in a stacked configuration, install a double-pole circuit breaker for

240 Vac service.

Accessing the AC Terminals

CAUTION: Equipment Damage

The inverter’s AC output must never be wired to the utility or generator output. This will

cause severe damage to the inverter which is not covered under warranty.

All AC wiring connects to the terminal block located on the right-hand side of the

inverter.

To make the AC connections to the inverter:

1. To access the terminal block, remove the side cover panels (if installed) by

removing the two (or three) Phillips screws. Units are shipped without the

covers installed (packed in a small plastic bag with additional hardware).

2. Locate the AC input and output terminals on the block. Refer to Figure 2-15

on page 2–23.

2–22 975-0012-01-02 Rev A

Page 47

AC Wiring

Figure 2-15

Important:

DR36XX models are equipped with a conduit box and not a plate. The conduit box is

required for the larger diameter wire providing ample bending radius.

Standard Cover Plate

DR15XX

AC Side Cover Panels

Before wiring the input of the inverter, refer to Table 2-5 below for the minimum

recommended wire size.

Important:

The lower AC cover varies depending on the model. DR24XX and

Screws

High Power Conduit Box

DR24XX and DR36XX models

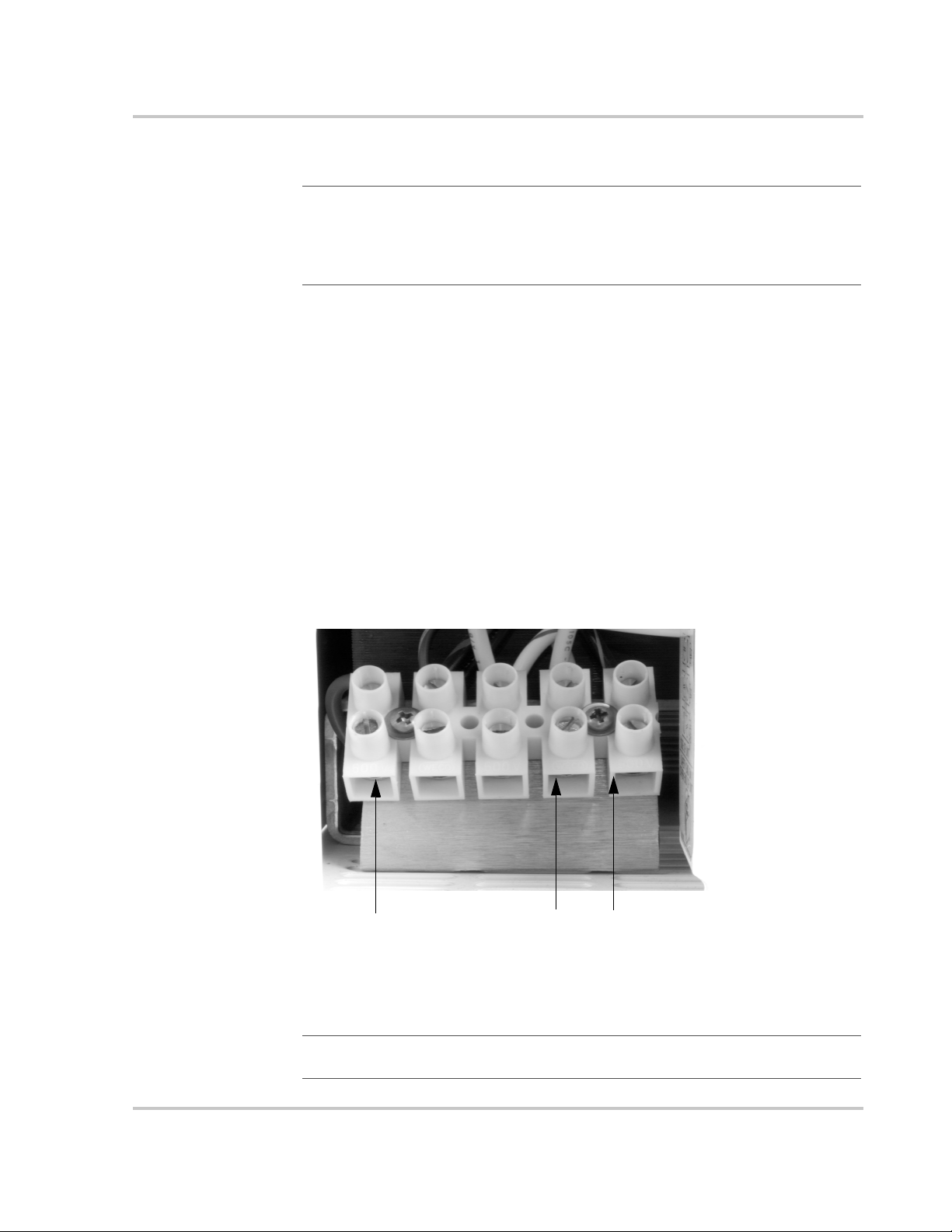

Refer to the NEC for actual wire sizes for specific installations.

Table 2-5

Minimum Recommended Wire Size, Torque Values (Input and Output), and Maximum Output

Breaker Size