Whirlpool WTW5790ST2, WTW5790SQ2, WTW5790SQ0, WTW5590ST2, WTW5590SQ2 Installation Guide

...

WASHERINSTAILATIONINSTRUCTIONS

INSTRUCTIONSD'INSTAILATIONDELALAVEUSE

Tableof Contents/Tabledes matibres

WASHER SAFETY .................................................................................. 1

INSTALLATION REQUIREMENTS ........................................................ 2

Tools and Parts ................................................................................... 2

Location Requirements ....................................................................... 3

Drain System ....................................................................................... 3

Electrical Requirements ...................................................................... 4

INSTALLATION INSTRUCTIONS .......................................................... 4

Before You Star_ .................................................................................. 4

Remove Shipping Materials ................................................................ 4

Connect Drain Hose ............................................................................ 6

Connect the Inlet Hoses ...................................................................... 6

Secure the Drain Hose ........................................................................ 7

Level the Washer ................................................................................. 7

Complete Installation ........................................................................... 8

Para obtener acceso al manual de uso y cuidado en espa_ol, o para obtener informaci6n adicional acerca de su producto, visite:

www.whirlpool.com.

Tenga listo su nOmero de modelo completo. Podra encontrar el nOmero de modelo y de serie en la etiqueta ubicada debajo de la tapa

de la lavadora.

SECURITF: DE LA LAVEUSE ...................................................................... 9

EXIGENCES D'INSTALLATION ................................................................. 9

Outillage et pieces .................................................................................... 9

Exigences d'emplacement .................................................................... 10

Systeme de vidange .............................................................................. 10

Specifications _lectriques ...................................................................... 11

INSTRUCTIONS D'INSTALLATION ......................................................... 12

Avant de commencer ............................................................................. 12

Retrait du materiel d'exp_dition ............................................................. 12

Raccordement du tuyau de vidange ..................................................... 13

Raccordement des tuyaux d'arriv_e d'eau ........................................... 13

Immobilisation du tuyau de vidange ...................................................... 14

R_glage de I'aplomb de la laveuse ........................................................ 15

Achever I'installation .............................................................................. 16

WASHERSAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word "DANGER" or "WARNING."

These words mean:

You can be killed or seriously injured if you don't immediately

follow instructions.

You can be killed or seriously injured if you don't follow

instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

W10150593A

INSTALLATIONREQUIREMENTS

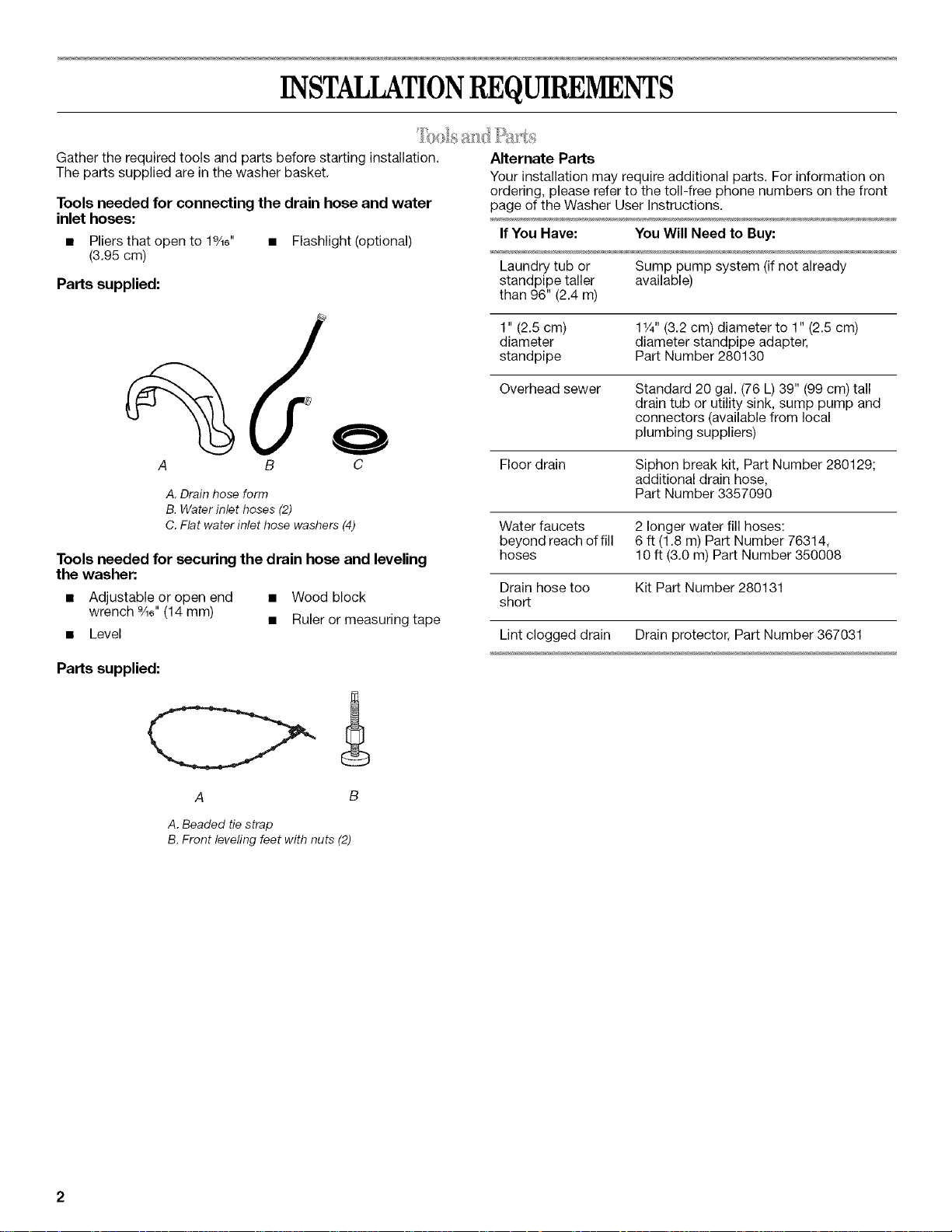

Gather the required tools and parts before starting installation.

The parts supplied are in the washer basket.

Tools needed for connecting the drain hose and water

inlet hoses:

• Pliersthat open to 1%6" • Flashlight (optional)

(3.95 cm)

Parts supplied:

A B C

A. Drain hose form

B. Water inlet hoses (2)

C. Flat water inlet hose washers (4)

Tools needed for securing the drain hose and leveling

the washer:.

• Adjustable or open end • Wood block

wrench %6" (14 mm) • Ruler or measuring tape

• Level

Alternate Parts

Your installation may require additional parts. For information on

ordering, please refer to the toll-free phone numbers on the front

page of the Washer User Instructions.

If You Have: You Will Need to Buy:

Laundry tub or Sump pump system (if not already

standpipe taller available)

than 96" (2.4 m)

1" (2.5 cm) 11/4"(3.2 cm) diameter to 1" (2.5 cm)

diameter diameter standpipe adapter,

standpipe Part Number 280130

Overhead sewer Standard 20 gal. (76 L) 39" (99 cm) tall

drain tub or utility sink, sump pump and

connectors (available from local

plumbing suppliers)

Floor drain Siphon break kit, Part Number 280129;

additional drain hose,

Part Number 3357090

Water faucets 2 longer water fill hoses:

beyond reach of fill 6 ft (1.8 m) Part Number 76314,

hoses 10 ft (3.0 m) Part Number 350008

Drain hose too Kit Part Number 280131

short

Lint clogged drain Drain protector, Part Number 367031

Parts supplied:

A B

A. Beaded tie strap

B. Front leveling feet with nuts (2)

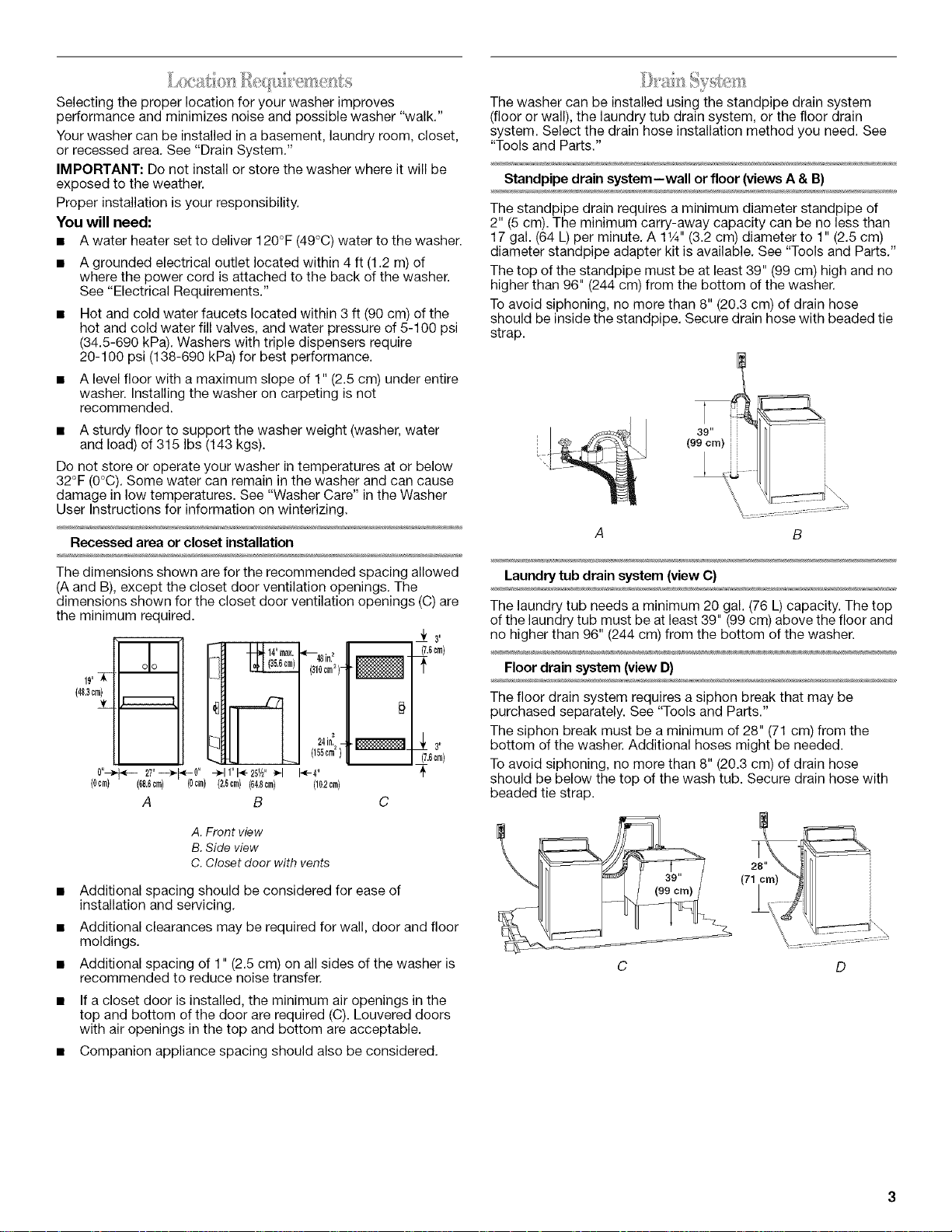

Selecting the proper location for your washer improves

performance and minimizes noise and possible washer "walk."

Your washer can be installed in a basement, laundry room, closet,

or recessed area. See "Drain System."

IMPORTANT: Do not install or store the washer where it will be

exposed to the weather.

Proper installation is your responsibility.

You will need:

• A water heater set to deliver 120°F (49°C) water to the washer.

• A grounded electrical outlet located within 4 ft (1.2 m) of

where the power cord is attached to the back of the washer.

See "Electrical Requirements."

• Hot and cold water faucets located within 3 ft (90 cm) of the

hot and cold water fill valves, and water pressure of 5-100 psi

(34.5-690 kPa), Washers with triple dispensers require

20-100 psi (138-690 kPa) for best performance.

• A level floor with a maximum slope of 1" (2.5 cm) under entire

washer. Installing the washer on carpeting is not

recommended.

• A sturdy floor to support the washer weight (washer, water

and load) of 315 Ibs (143 kgs).

Do not store or operate your washer in temperatures at or below

32°F (O°C). Some water can remain in the washer and can cause

damage in low temperatures. See "Washer Care" in the Washer

User Instructions for information on winterizing.

Recessed area or closet installation

The washer can be installed using the standpipe drain system

(floor or wall), the laundry tub drain system, or the floor drain

system. Select the drain hose installation method you need. See

"Tools and Parts."

Standpipe drain system--wall or floor (views A & B)

The standpipe drain requires a minimum diameter standpipe of

2" (5 cm). The minimum carry-away capacity can be no less than

17 gal. (64 L) per minute, A 1V4"(3.2 cm) diameter to 1" (2,5 cm)

diameter standpipe adapter kit is available, See "Tools and Parts,"

The top of the standpipe must be at least 39" (99 cm) high and no

higher than 96" (244 cm) from the bottom of the washer.

Toavoid siphoning, no more than 8" (20.3 cm) of drain hose

should be inside the standpipe, Secure drain hose with beaded tie

strap.

A

The dimensions shown are for the recommended spacing allowed

(A and B), except the closet door ventilation openings. The

dimensions shown for the closet door ventilation openings (C) are

the minimum required.

__ 0_'

(7.6crn)

__ 3_

17.6crn}

19,5E

(48.3crn)

JL

0"_ 27"---_N0" -_11"1_-25½" _'1

(0cm) (60,6crn)(0crn)(2.Scrn)(04.8crn)

A

A. Front view

B. Side view

C. Closet door with vents

B C

(310crn2}1" _

24in._.__

(100crn2)1

I-<-4"

(10.2cm)

m

• Additional spacing should be considered for ease of

installation and servicing.

• Additional clearances may be required for wall, door and floor

moldings.

• Additional spacing of 1" (2.5 cm) on all sides of the washer is

recommended to reduce noise transfer.

If a closet door is installed, the minimum air openings in the

top and bottom of the door are required (C). Louvered doors

with air openings in the top and bottom are acceptable.

Companion appliance spacing should also be considered.

Laundry tub drain system (view C)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top

of the laundry tub must be at least 39" (99 cm) above the floor and

no higher than 96" (244 cm) from the bottom of the washer.

Floor drain system (view D)

The floor drain system requires a siphon break that may be

purchased separately. See "Tools and Parts."

The siphon break must be a minimum of 28" (71 cm) from the

bottom of the washer. Additional hoses might be needed.

Toavoid siphoning, no more than 8" (20.3 cm) of drain hose

should be below the top of the wash tub. Secure drain hose with

beaded tie strap.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

• A 120 volt, 60 Hz., AC only, 15- or 20-amp, fused electrical

supply is required. A time-delay fuse or circuit breaker is

recommended. It is recommended that a separate circuit

serving only this appliance be provided.

• This washer is equipped with a power supply cord having a

3 prong grounding plug.

• To minimize possible shock hazard, the cord must be plugged

into a mating, 3 prong, grounding-type outlet, grounded in

accordance with local codes and ordinances. If a mating

outlet is not available, it is the personal responsibility and

obligation of the customer to have the properly grounded

outlet installed by a qualified electrician.

• If codes permit and a separate ground wire is used, it is

recommended that a qualified electrician determine that the

ground path is adequate.

• Do not ground to a gas pipe.

• Check with a qualified electrician if you are not sure the

washer is properly grounded.

• Do not have a fuse in the neutral or ground circuit.

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a malfunction

or breakdown, grounding will reduce the risk of electrical

shock by providing a path of least resistance for electric

current. This washer is equipped with a cord having an

equipment-grounding conductor and a grounding plug. The

plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

WARNING: Improper connection of the equipment-

grounding conductor can result in a risk of electric shock.

Check with a qualified electrician or serviceman if you are in

doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance - if it will

not fit the outlet, have a proper outlet installed by a qualified

electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal,

permanent wiring system, or an equipment grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead on

the appliance.

INSTALLATIONINSTRUCTIONS

Excessive Weight Hazard

Use two or more people to move and install washer.

Failure to do so can result in back or other injury.

NOTE: To avoid floor damage, set the washer onto cardboard

before moving across floor.

Removing the shipping material is necessary for proper operation.

If the shipping material is not removed, the washer will make

excessive noise.

1. Move the washer to within approximately 3 ft (90 cm) of its

final location.

2. The washer must be in the upright position and not tilted

before removing the shipping material.

3. Locate the yellow shipping materials on the rear of the

machine, near the bottom. Follow the steps for your particular

model, either the one with the straight power cord and cord

restraint or the looped power cord version.

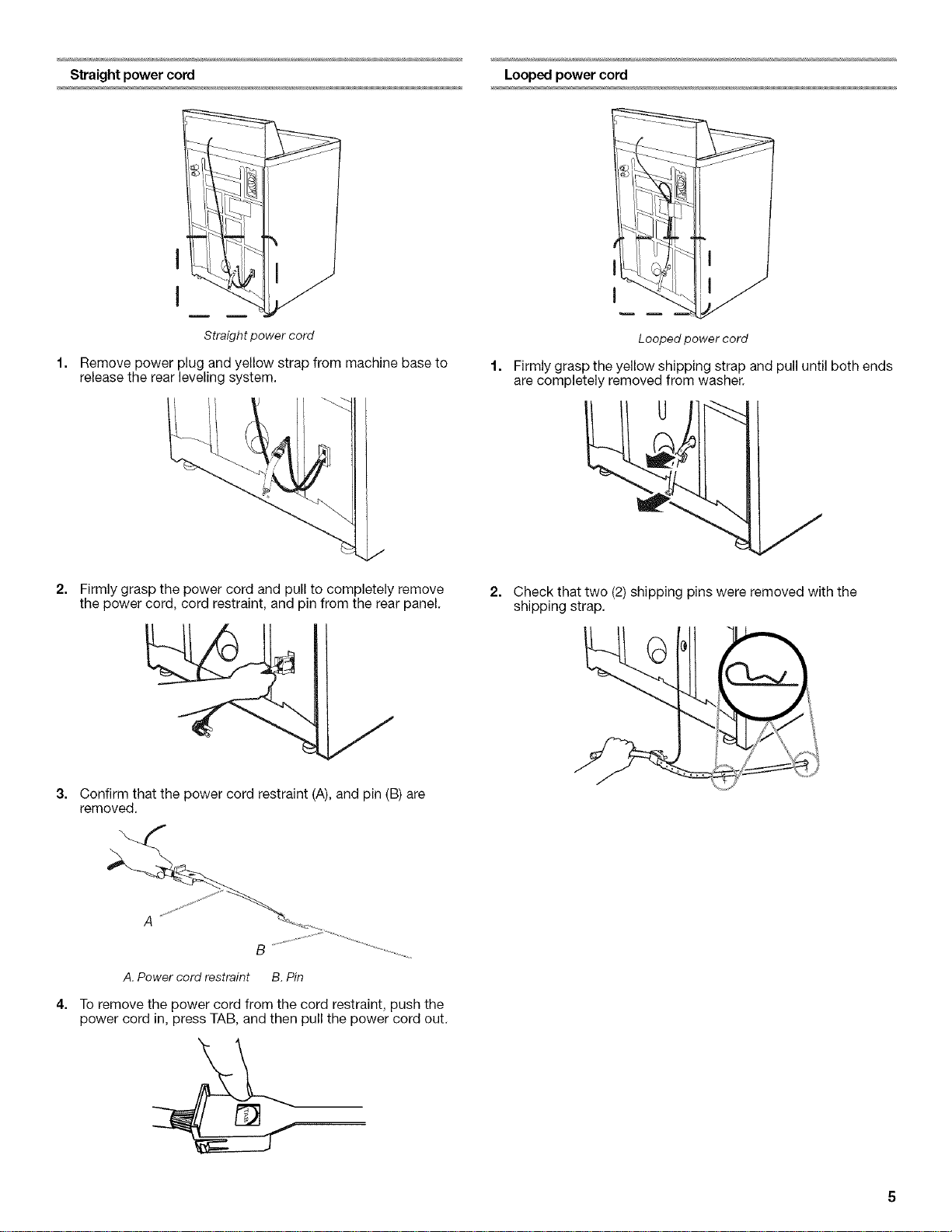

Straight power cord Looped power cord

I

I

Straight power cord

Remove power plug and yellow strap from machine base to

release the rear leveling system.

J

2=

Firmly grasp the power cord and pull to completely remove

the power cord, cord restraint, and pin from the rear panel.

Looped power cord

Firmly grasp the yellow shipping strap and pull until both ends

are completely removed from washer.

2. Check that two (2) shipping pins were removed with the

shipping strap.

3. Confirm that the power cord restraint (A), and pin (B) are

removed.

A

B

A. Power cord restraint B. Pin

4=

To remove the power cord from the cord restraint, push the

power cord in, press TAB, and then pull the power cord out.

Loading...

Loading...