Whirlpool MULLION EVAPORATOR DESIGN, OLD DESIGN, MID-LINE DESIGN, NEW DESIGN User Manual

CONSUMER SERVICES TECHNICAL

ORPORATION

EDUCATION GROUP PRESENTS

AM-4

APARTMENT MAINTENANCE SERIES

TOP-MOUNT

REFRIGERATOR/FREEZERS

“MULLION EVAPORATOR

DESIGN”

“OLD DESIGN”

14 cu. ft.

12 cu. ft.

“MID-LINE DESIGN”

16 thru 22 cu. ft.

“NEW DESIGN”

14 cu. ft.

Job Aid

Part No. 4322309

I

INTRODUCTION

This Job Aid,

4322309) has been compiled to provide the most recent information on design, features, operation,

troubleshooting and repair procedures of 12 through 22 cu. ft. top-mount refrigerator/freezers.

Four distinct series of top-mount refrigerator/freezers will be covered. See Page V for more details:

1) 12 cu. ft. “Mullion Evaporator Design” - These units are available as Roper Brand only

and have the evaporator located in the mullion divider between the freezer and refrigerator

sections. There are louvers located at the front of the freezer floor.

1) 14 cu. ft. “Old Design” - These units were manufactured through the early part of 1997

and are equipped with electric mullion heaters. There is an escutcheon box at the upper

rear of the freezer section with louvers across the top of the box.

2) 14 cu. ft. “New Design” - These units were manufactured from 1993 to the present and are

currently designated Model “F” and are equipped with heat loops and a stack condenser.

There is an air tower located on the back wall of the freezer with horizontal louvers on the

sides of the tower.

3) 16, thru 22 cu. ft. “Mid-Line Design” - These units were manufactured from 1994 to the

present and are equipped with heat loops and forced air condensers. There is an air tower

located on the back wall of the freezer with a curved face and vertical louvers.

This Job Aid is not intended to replace or substitute for the Service Manuals, Use and Care Guides

or Tech Sheets associated with any of the models covered. Particular attention should be given to

the Tech Sheets provided with each individual unit for the latest engineering design changes.

“APARTMENT MAINTENANCE SERIES: Servicing Refrigerators,”

(Part Number LIT

GOALS AND OBJECTIVES

The goal of this Job aid is to provide detailed information that will enable the service technician to

properly diagnose malfunctions and repair 12 through 22 cu. ft. top-mount refrigerator/freezers.

The objectives of this Job Aid are:

The service technician will --

• Understand proper safety precautions.

• Successfully troubleshoot and diagnose malfunctions.

• Successfully perform necessary repairs.

• Successfully return the unit to proper operational status.

TO THE INSTRUCTOR/INDEPENDENT STUDENT

At the end of certain sections of this Job Aid you will find a

You will need a pencil or pen and in some cases two “Hi-Light” markers to complete these exercises. Certain exercises may require that service procedures be performed, if an appropriate

appliance is available.

“Confirmation of Learning Exercise.”

CORPORATION

WHIRLPOOL CORPORATION ASSUMES NO RESPONSIBILITY

FOR ANY REPAIRS MADE ON OUR PRODUCTS BY ANYONE

OTHER THAN AUTHORIZED SERVICE TECHNICIANS.

© 1998 Whirlpool Corporation, Benton Harbor, MI 49022

II

TABLE OF CONTENTS

INTRODUCTION.............................................................................................II

GOALS AND OBJECTIVES ........................................................................... II

TO THE INSTRUCTOR/INDEPENDENT STUDENT ...................................... II

TABLE OF CONTENTS.................................................................................III

SAFETY ........................................................................................................ IV

PRODUCT IDENTIFICATION ........................................................................ V

SECTION ONE - SECTION ONE -

SECTION ONE - Mullion Evaporator Design 12 cu. ft. Top-Mount

SECTION ONE - SECTION ONE -

INSTALLATION CONSIDERATIONS .......................................................1

THEORY OF OPERATION........................................................................ 4

COMPONENT ACCESS............................................................................ 6

WIRING DIAGRAMS and STRIP CIRCUITS .......................................... 10

SECTION TWO SECTION TWO

SECTION TWO - Old Design 14 cu. ft. Top-Mount

SECTION TWO SECTION TWO

INSTALLATION CONSIDERATIONS .....................................................13

THEORY OF OPERATION......................................................................17

COMPONENT ACCESS..........................................................................19

WIRING DIAGRAMS and STRIP CIRCUITS .......................................... 24

SECTION THREE SECTION THREE

SECTION THREE - New Design 14 cu. ft. Top-Mount

SECTION THREE SECTION THREE

INSTALLATION CONSIDERATIONS .....................................................33

THEORY OF OPERATION......................................................................37

COMPONENT ACCESS..........................................................................39

WIRING DIAGRAMS and STRIP CIRCUITS .......................................... 46

SECTION FOUR SECTION FOUR

SECTION FOUR - Mid-Line Design 16 & 22 cu. ft. Top-Mount

SECTION FOUR SECTION FOUR

INSTALLATION CONSIDERATIONS .....................................................49

THEORY OF OPERATION......................................................................53

COMPONENT ACCESS..........................................................................55

WIRING DIAGRAMS and STRIP CIRCUITS .......................................... 64

SECTION FIVE - TROUBLESHOOTING AND DIAGNOSISSECTION FIVE - TROUBLESHOOTING AND DIAGNOSIS

SECTION FIVE - TROUBLESHOOTING AND DIAGNOSIS

SECTION FIVE - TROUBLESHOOTING AND DIAGNOSISSECTION FIVE - TROUBLESHOOTING AND DIAGNOSIS

GENERAL ...............................................................................................71

SEALED SYSTEM DIAGNOSIS .............................................................72

TROUBLESHOOTING CHART...............................................................73

TYPICAL TESTING PROCEDURES.......................................................80

SECTION SIX - TECH TIPSSECTION SIX - TECH TIPS

SECTION SIX - TECH TIPS

SECTION SIX - TECH TIPSSECTION SIX - TECH TIPS

REPLACING ELECTROMECHANICAL TIMERS ...................................89

DOOR GASKET REPLACEMENT ..........................................................90

SERVICING THE ADAPTIVE DEFROST CONTROL ............................. 9 4

SERIAL AND MODEL NUMBER DESIGNATORS ................................. 9 5

III

SAFETY

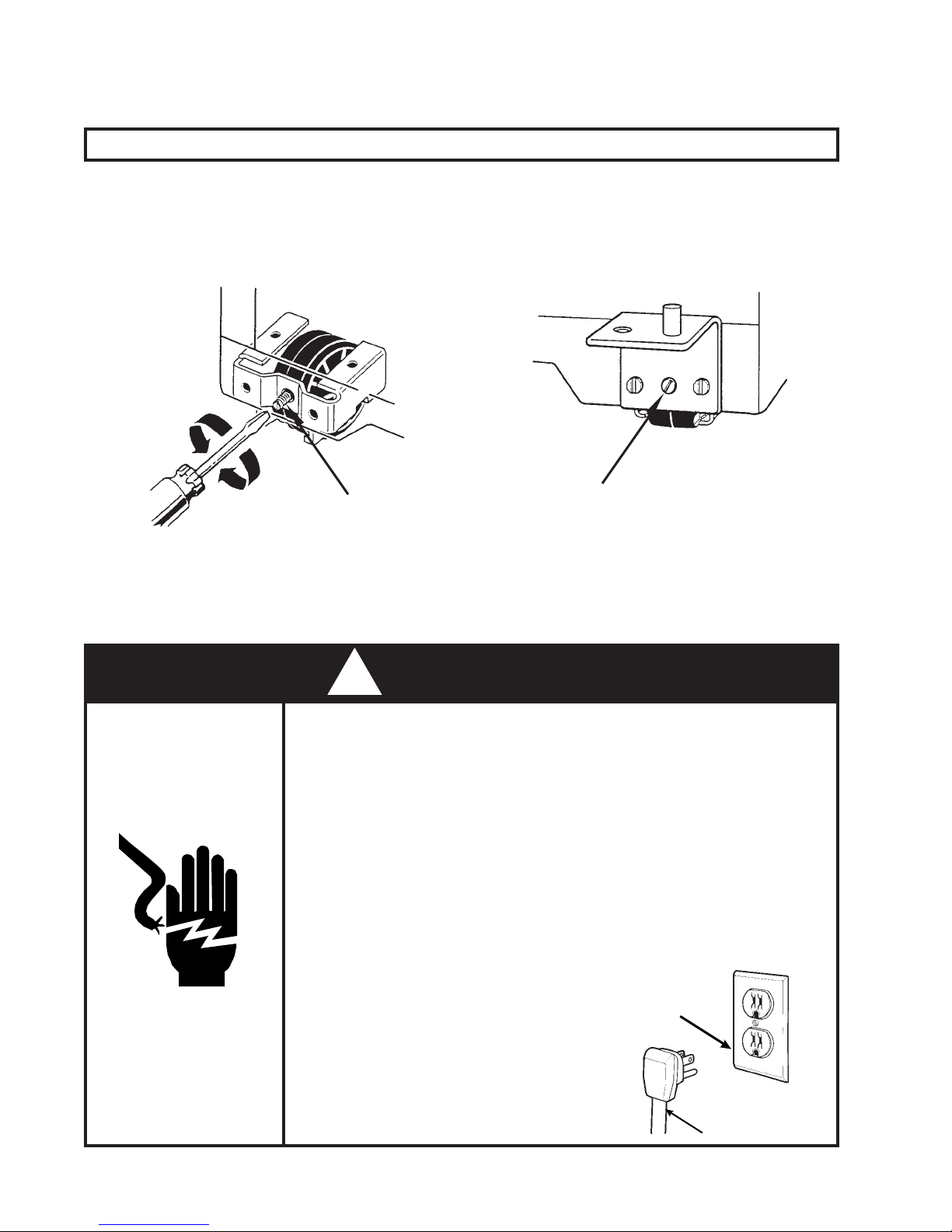

! WARNING

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong grounding-type

wall receptacle, grounded in accordance with the National

Electrical Code, ANSI/NFPA 70 - latest edition, and local codes

and ordinances.

• It is the personal responsibility of the consumer to have a proper

3-prong wall receptacle installed by a qualified electrician.

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE THE

POWER CORD GROUNDING PRONG.

• A separate adequately fused and grounded circuit should be

available for this appliance.

• Do not remove any grounding wires

from individual components while

servicing, unless the component is

to be removed and replaced.

extremely

grounding wires when components

are replaced.

important to replace all

It is

Grounding

Type

Wall

Receptacle

Power Supply

Cord

with 3-Prong

Grounding Plug

Disconnect the electrical power before servicing any components .

! WARNING

ELECTRIC SHOCK HAZARD

Failure to do so can result in death or electrical shock.

IV

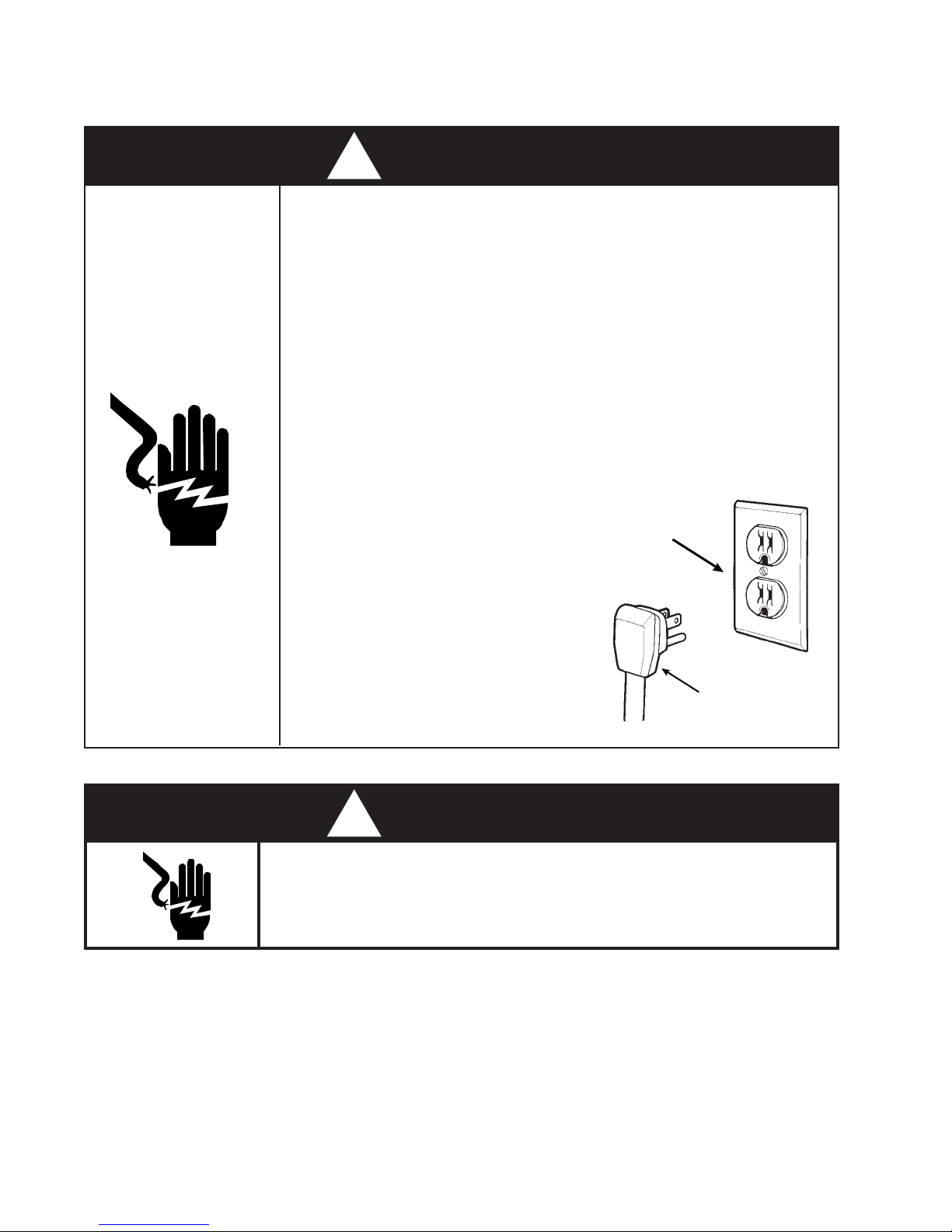

PRODUCT IDENTIFICATION

Four distinct series of top-mount refrigerator/freezers will be covered in the Job Aid. Each series can

be identified by a number of distinguishing features:

A) Air circulation in the freezer compartment

B) Type of condenser

C) Location of the Evaporator

D) Method of outside condensation control

12 cu. ft. “Mullion Evaporator Design” -

Distinguishing Characteristics:

• Air return louvers located at the front of

the freezer floor.

• A stack condenser on the back of the

unit.

• Has heat loop mullion and stile heat.

• Evaporator located in the divider between the freezer and refrigerator sections.

• Roper brand only

12 & 14 cu. ft. “Old Design” -

Distinguishing Characteristics:

• Air discharge louvers located at the top

rear of the freezer section.

• A stack condenser on the back of the

unit.

• Has electric mullion and stile heaters.

• Evaporator vertically mounted behind

rear panel of freezer compartment.

• May be equipped with Adaptive Defrost

Control.

Louvers at Front of

Freezer Floor

Component Access - Section One, page 6.

Wiring Diagram - Section One, page 10.

Louvers Across

Top Rear

Component Access - Section Two, page 19.

Wiring Diagram - Section Two, page 24.

Adaptive Defrost Control - Section Six, page 92.

14 cu. ft. “New Design” -

Distinguishing Characteristics:

• Air tower at the rear of the freezer section

with horizontal louvers.

• Has heat loop mullion and stile heat.

• A stack condenser on the back of the

unit.

• Model “F” designation

• Manufactured from 1993 to present

16, thru 22 cu. ft. “Mid-Line Design” -

Distinguishing Characteristics:

• Air tower at the rear of the freezer section

with vertical louvers.

• Has heat loop mullion and stile heat.

• A forced air condenser at the bottom of

the unit.

• Manufactured from 1994 to present.

Air Tower

with

Horizontal Louvers

Component Access - Section Three, page 36.

Wiring Diagram - Section Three, page 46.

Air Tower

with

Vertical Louvers

Component Access - Section Four, page 55.

Wiring Diagram - Section Four, page 64.

V

-- NOTES --

VI

Section One

Mullion Evaporator Design

12 cu. ft. Top-Mount

INSTALLATION CONSIDERATIONS

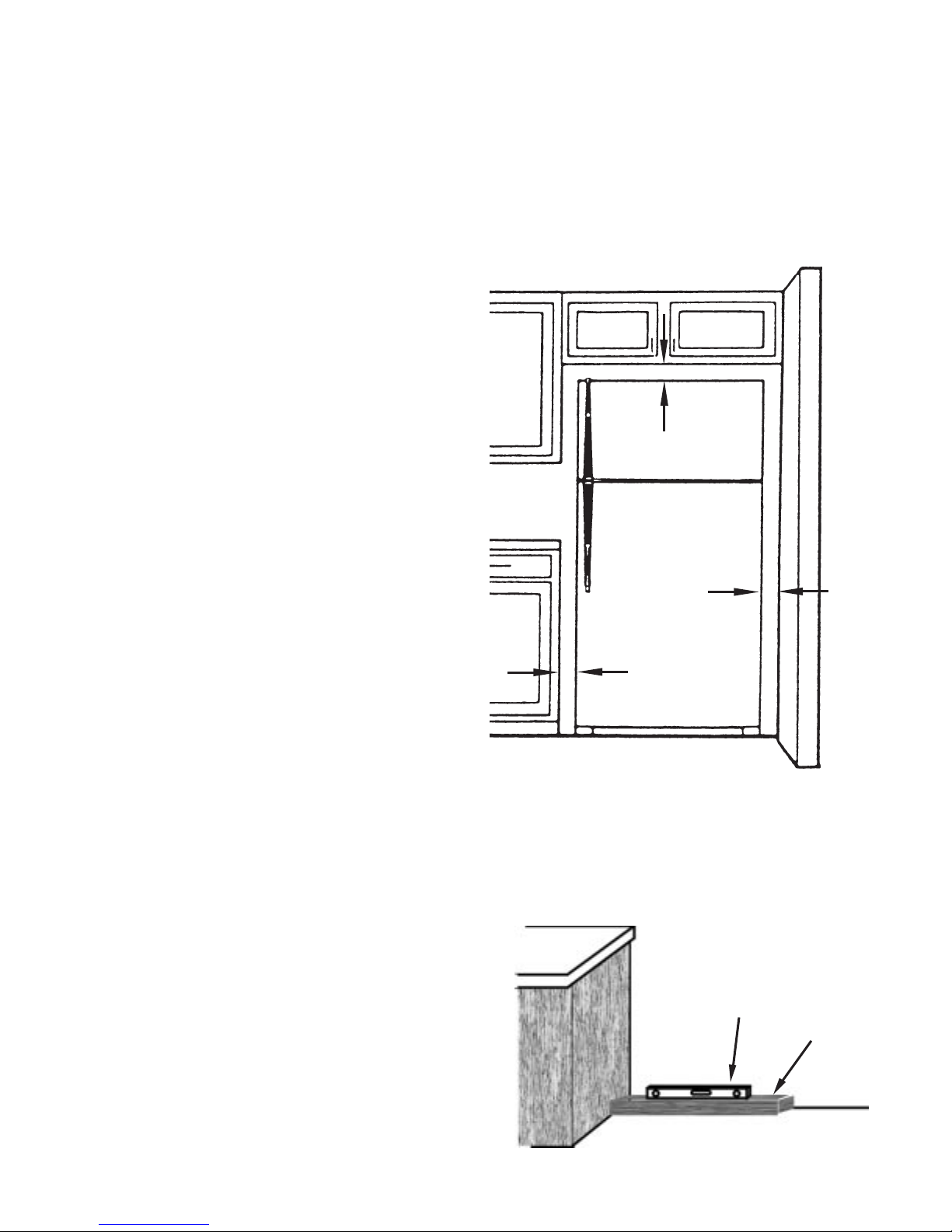

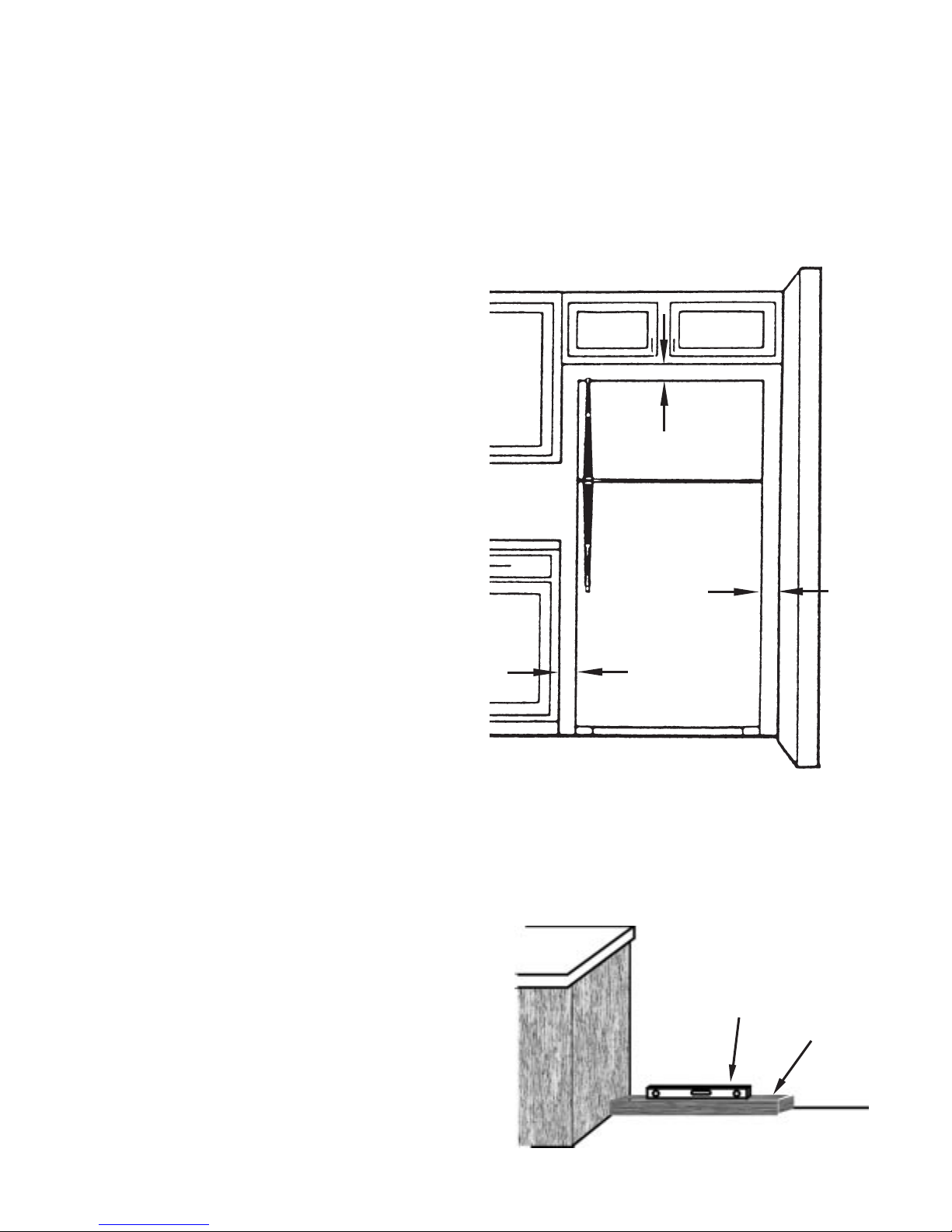

Minimum Clearance

Measure the opening at the location in which the refrigerator/freezer is to be installed and make

sure the following minimum clearance dimensions are followed.

Top: At least 3” (7.5cm) clearance between

the overhead cabinet and the refrigerator/

freezer top. (Dimension A)

Sides: At least 1” (2.5cm) clearance on each side

of the refrigerator/freezer. (Dimension B)

(Fig. 1)

Back: At least ½” (1.25cm) clearance between

the condenser (“Old Design” 14 cu. ft.

Top-Mount) and the wall.

(Fig. 1)

A

B

B

Fig 1

Leveling the Refrigerator/Freezer

It is critical that the refrigerator/freezer be properly leveled. Both the back and front of the unit should

be carefully leveled before it is turned on.

1. Place a board across the rear of the installed position and set a level on the board.

2. Place shims where the rear rollers will sit to level the board.

3. Remove the board and leave the shims in place.

4. Place the unit in its installed position.

Level

(Fig. 2)

Board

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

Fig. 2

1

Once the unit is located in the final installed location and the rear of the unit is level, proceed to

level the front.

NOTE: Using a spirit level, the front of the unit should be ½ bubble higher than the back.

1. Use a flat blade screwdriver to rotate the front roller leveling screws in the appropriate direction

to level the unit side to side.

2. Use a level and check to make sure the rollers are set so the unit is level side to side and ½

bubble higher in front.

Fig. 3

(Fig. 3 & 4))

VIEW OF ROLLER WITH HINGE IN PLACEVIEW OF ROLLER WITH NO HINGE

LOWER

RAISE

Leveling

Screw

Fig. 4

Leveling

Screw

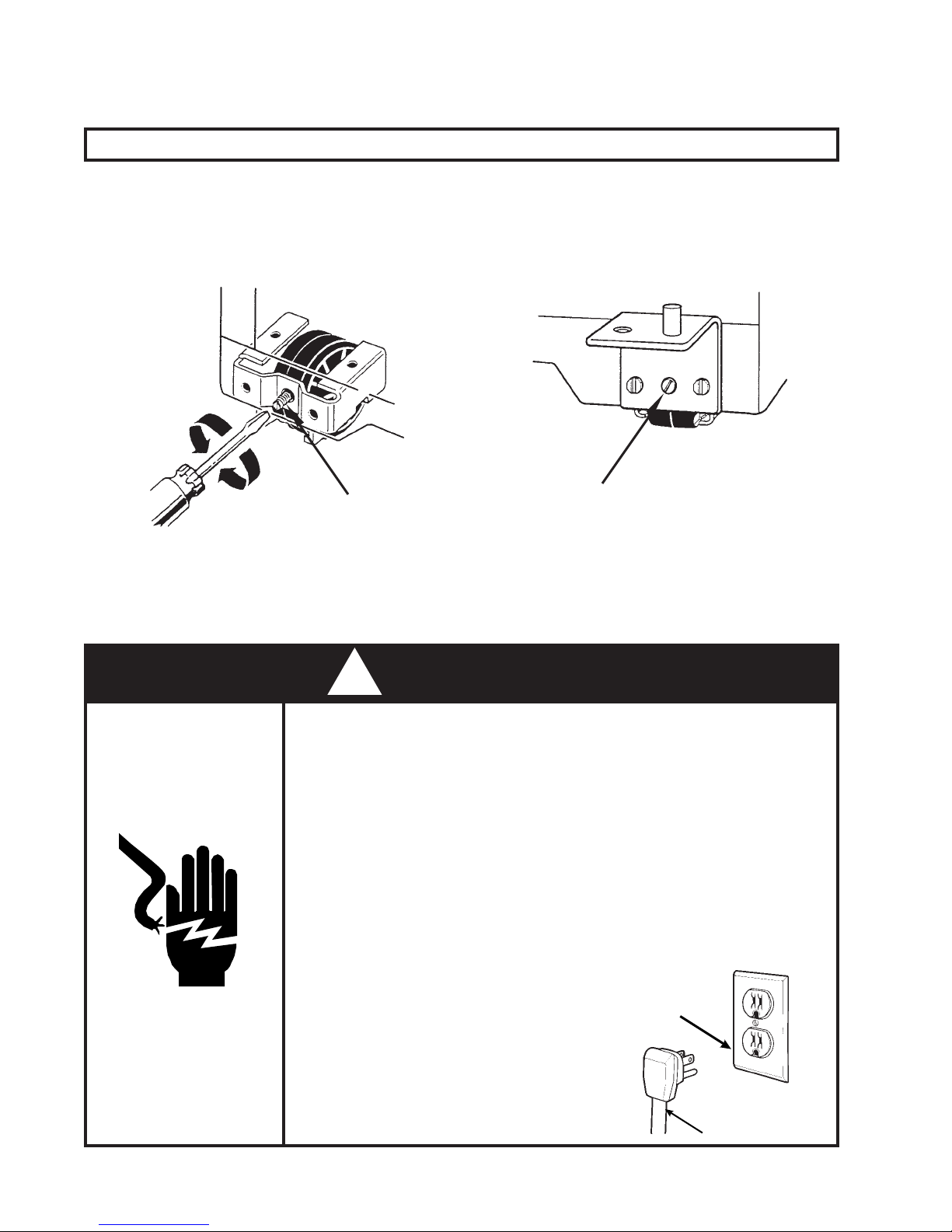

Electrical Requirements

A 115 V, 60 Hz, 15 TO 20 Amp fused circuit utilizing a 3-wire grounding receptacle meeting all

national and local electrical codes is required. It is recommended that a separate circuit serving

only this appliance be provided.

! WARNING

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong grounding-type

wall receptacle, grounded in accordance with the National

Electrical Code, ANSI/NFPA 70 - latest edition, and local codes

and ordinances.

• It is the personal responsibility of the consumer to have a proper

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE THE

• Do not remove any grounding wires

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

3-prong wall receptacle installed by a qualified electrician.

POWER CORD GROUNDING PRONG.

Grounding Type

from individual components while

servicing, unless the component is

to be removed and replaced.

extremely

grounding wires when components

are replaced.

important to replace all

2

It is

Receptacle

3-Prong

Grounding Plug

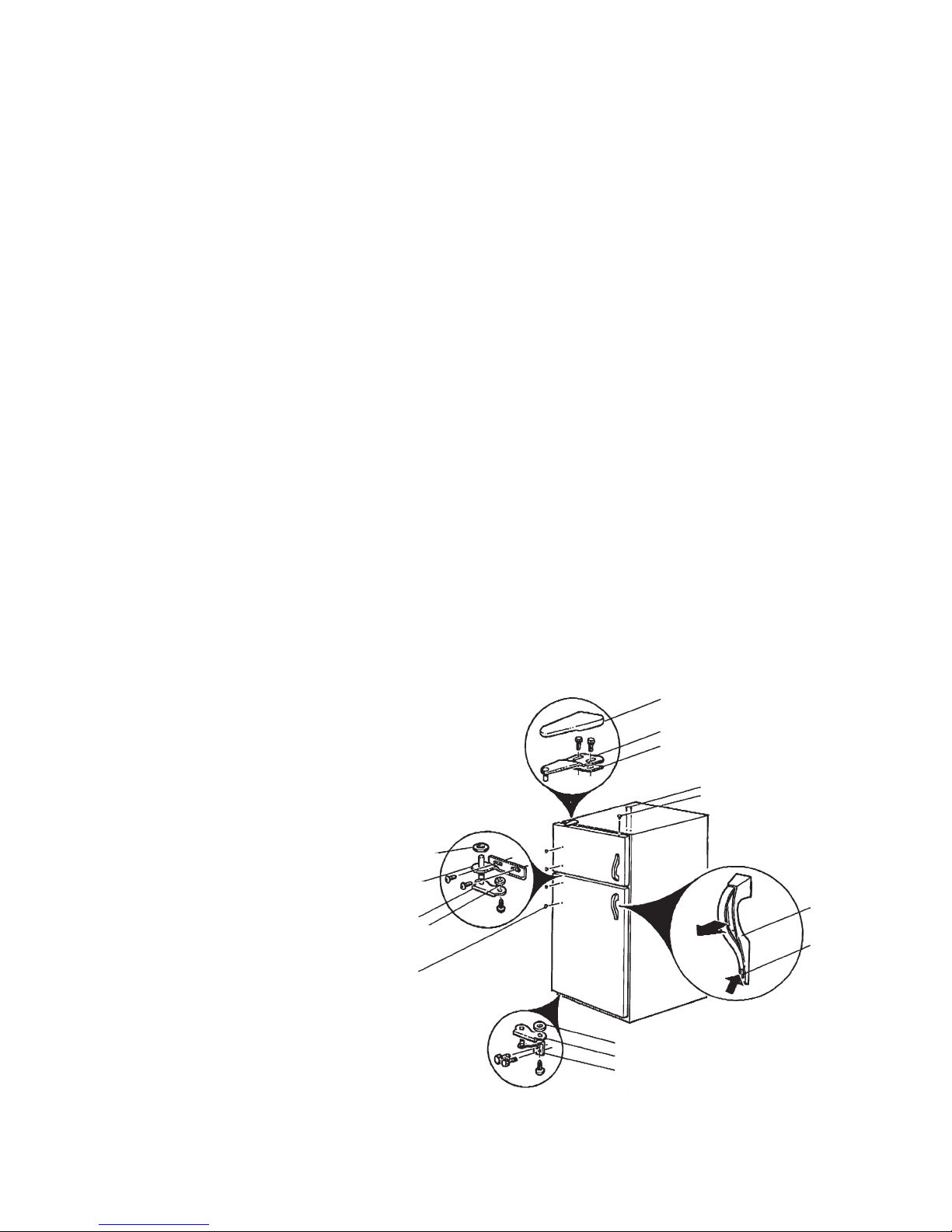

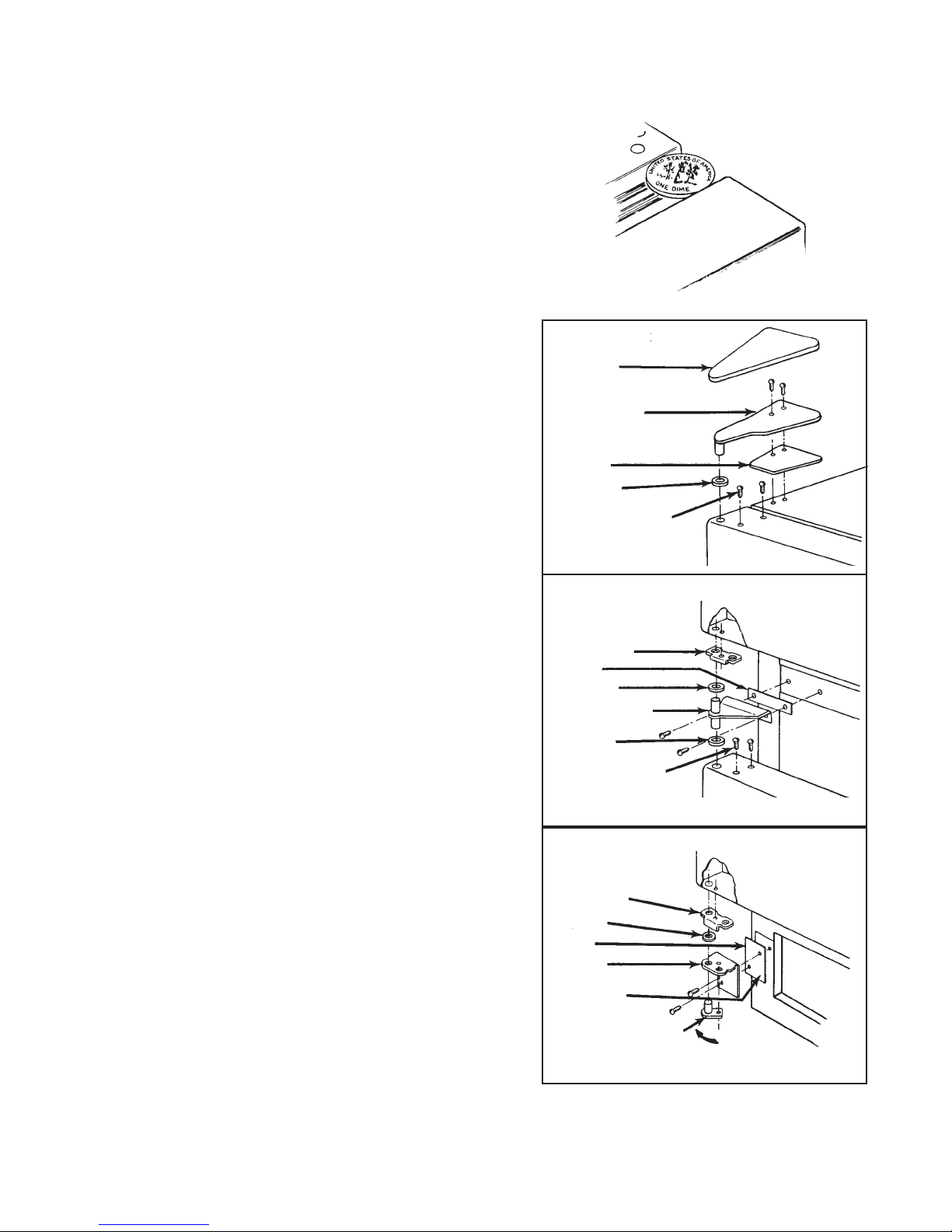

DOOR SWING REVERSAL

1. Open the refrigerator door and remove the toe panel at the bottom of the unit.

2. Remove the top hinge.

(Fig. 5)

3. Remove the freezer door.

4. Remove the center hinge.

(Fig. 5)

5. Remove the refrigerator door.

6. Remove the bottom hinge.

7. Lay the freezer door on a flat protected surface and remove the door handle.

(Fig. 5)

(Fig. 5)

8. Reinstall the freezer door handle on the opposite side of the door.

9. Lay the refrigerator door on a flat protected surface and remove the door handle.

(Fig. 5)

10. Reinstall the refrigerator door handle on the opposite side of the door.

11. Move the bottom hinge to the opposite side of the cabinet and reinstall it.

12. Set the refrigerator door on the bottom hinge and close the door to keep it in place.

13. Reinstall the center hinge.

14. Set the freezer door in the center hinge and close the door to keep it in place.

15. Reinstall the top hinge.

16. To align the refrigerator door:

a) DO NOT ADJUST THE BOTTOM HINGE. Use the bottom hinge as an establishing point.

b) Loosen the center hinge

(Figs. 5)

and align the refrigerator door with the cabinet edge.

c) Tighten the center hinge.

17. To align the freezer door:

a) If the refrigerator door is properly aligned,

DO NOT ADJUST THE CENTER HINGE.

b) Loosen the top hinge

(Fig. 5)

the top of the freezer door with the top

of the cabinet.

c) Tighten the top hinge.

Plastic Washer

Center Hinge

Door Stop

Fiber Washer

Handle

Hole Plug

and align

Cover

Top Hinge

Shim

Hinge Hole Plug

Hinge Bushing

Plug

Handle

Handle

Insert

Fiber Washer

Door Stop

Bottom

Hinge

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

Fig. 5

3

THEORY OF OPERATION

TEMPERATURE CONTROL

Temperature control is provided by an adjustable thermostat located behind the control panel escutcheon in the refrigerator compartment.

both the freezer section and the refrigerator section. There is no damper to adjust air flow between the

two sections.

(Fig. 6)

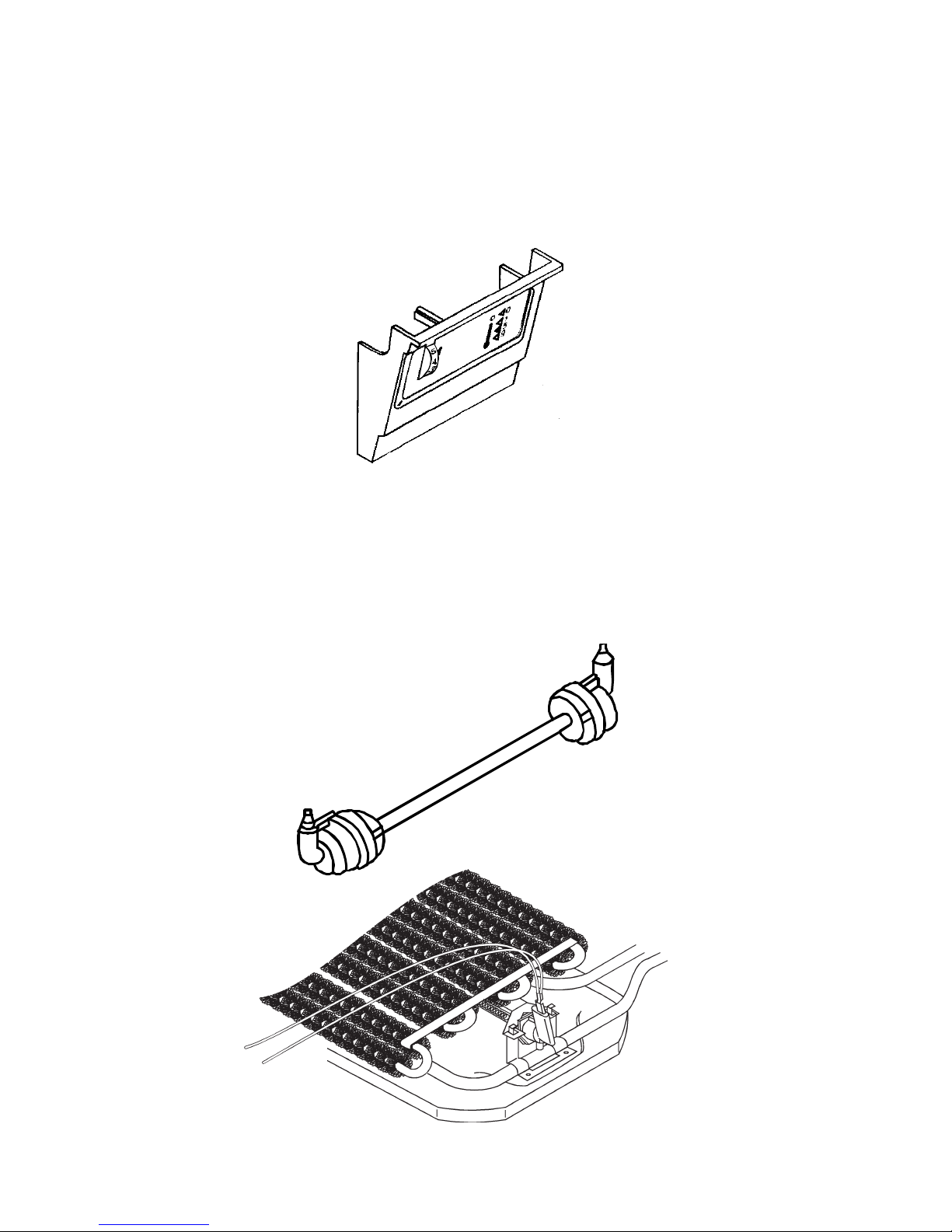

DEFROST HEATER

This thermostat influences the temperatures in

Fig. 6

The defrost heat is provided by a quartz tube radiant heater

coils in the divider mullion.

must be taken when handling this heater element to insure that the quartz tube does not come in

contact with any contaminants such as skin oil, perspiration or lubricants. Always wear a pair of clean

gloves when handling the defrost heater assembly. Contaminating the surface of the quartz tube will

cause premature failure.

(Fig. 8)

A coiled wire element is encased in a quartz tube. Special care

Fig. 7

(Fig. 7)

lying underneath the evaporator

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

Fig. 8

4

HEAT LOOP ROUTING

The heat loop is routed from the condenser outlet up the right side of the cabinet to the right stile (A).

It then loops through the mullion between the refrigerator and freezer sections (B) and up around the

freezer section (C & D), where it then returns to component compartment ( E) and connects to the

sealed system at the filter-drier.

(Fig. 9)

D

C

B

E

A

HEAT LOOP

Fig. 9

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

5

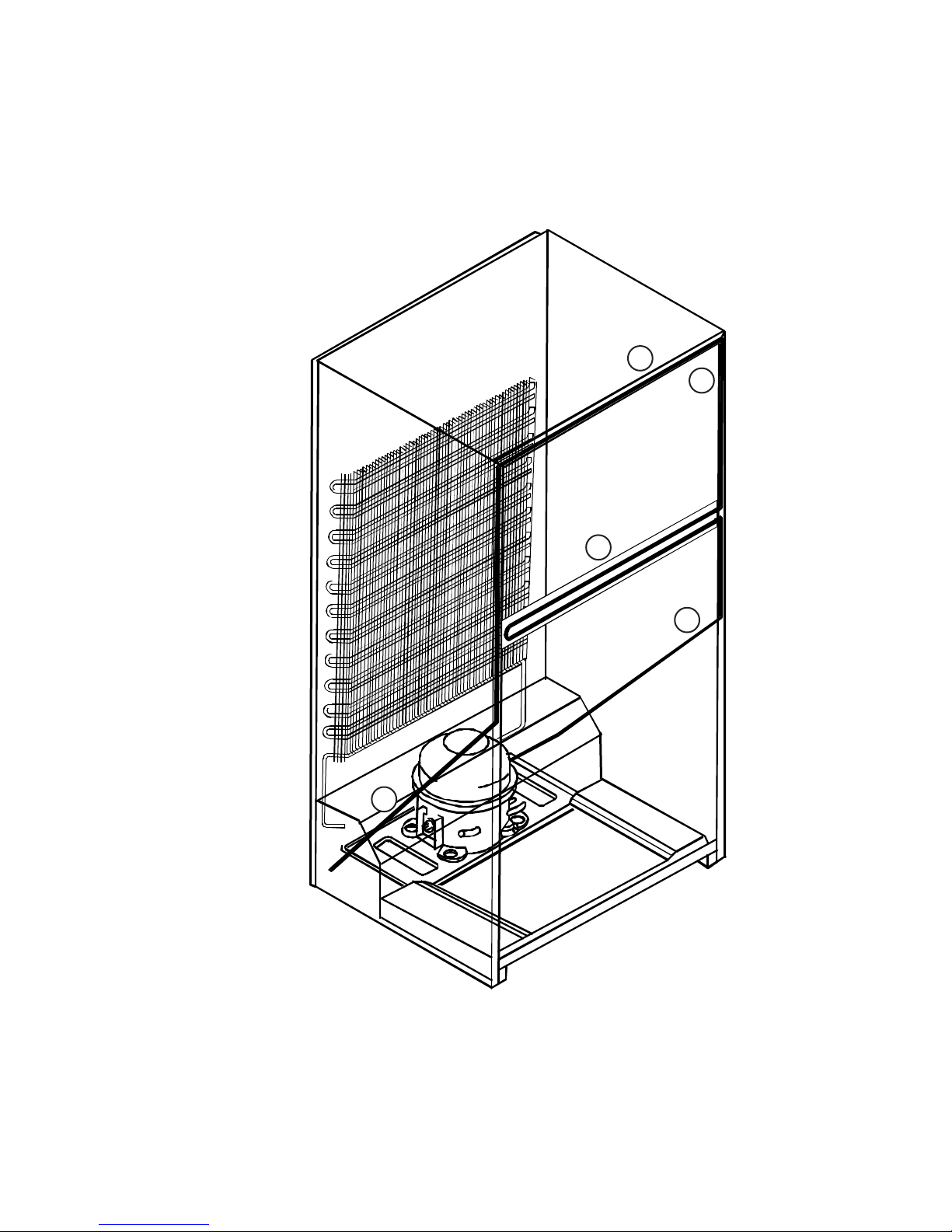

COMPONENT ACCESS

Disconnect the electrical power before servicing any components.

EVAPORATOR

FAN

! WARNING

ELECTRIC SHOCK HAZARD

Failure to do so can result in death or electrical shock.

DEFROST

HEATER

CONDENSER

THERMOSTAT

COMPRESSOR

DRIP PAN/

COMPRESSOR

BASE

EVAPORATOR

BI-METAL

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

Fig. 10

6

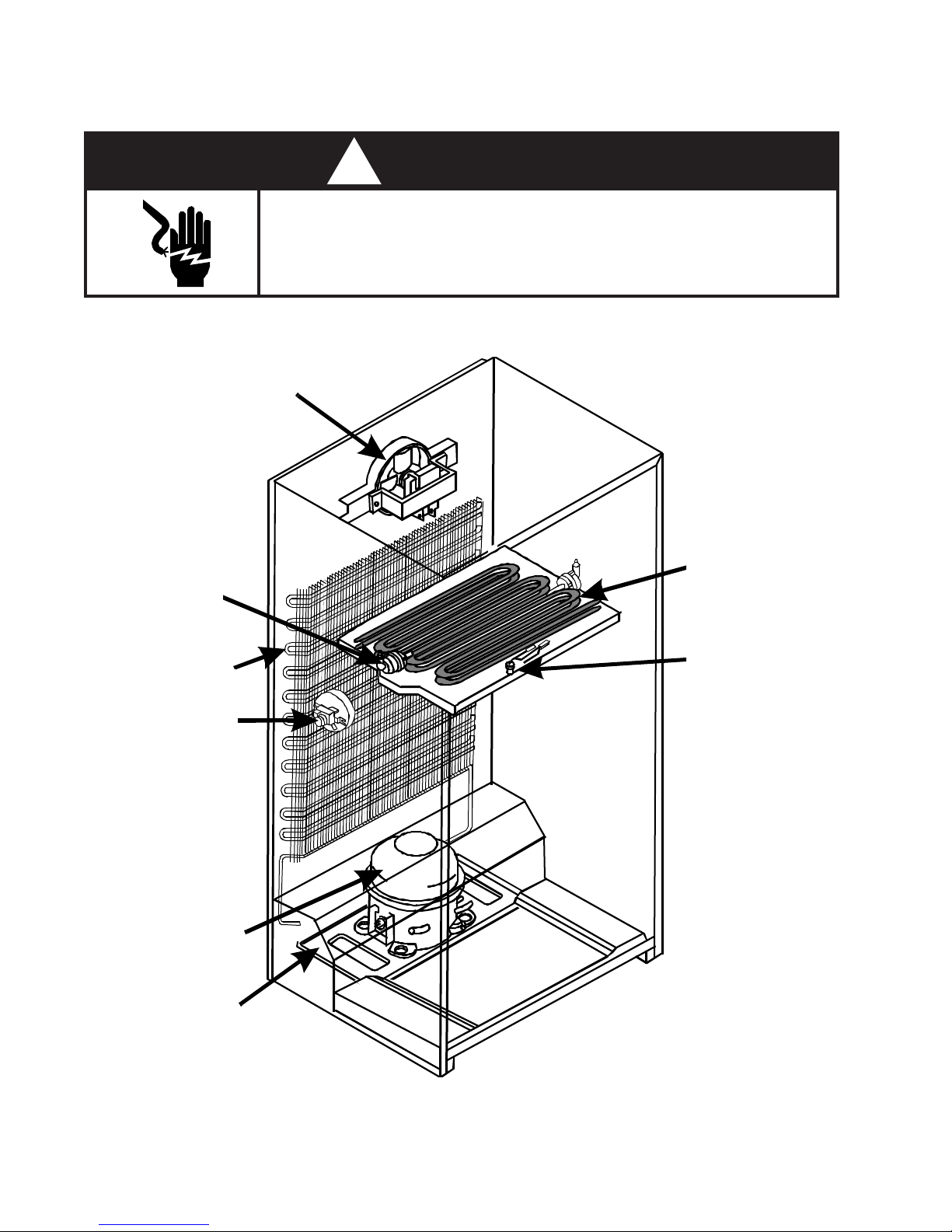

Servicing Components in the Compressor Compartment

Fig. 11

CONDENSER

DRAIN

TUBE

HEAT LOOP

COMPRESSOR

FILTER

DRIER

MOUNTING BOLTS

HEAT

EXCHANGER

CAPILLARY

TUBE

COMPONENT

TRAY

The compressor and related components are located at the bottom back of the refrigerator/freezer

in an open compartment.

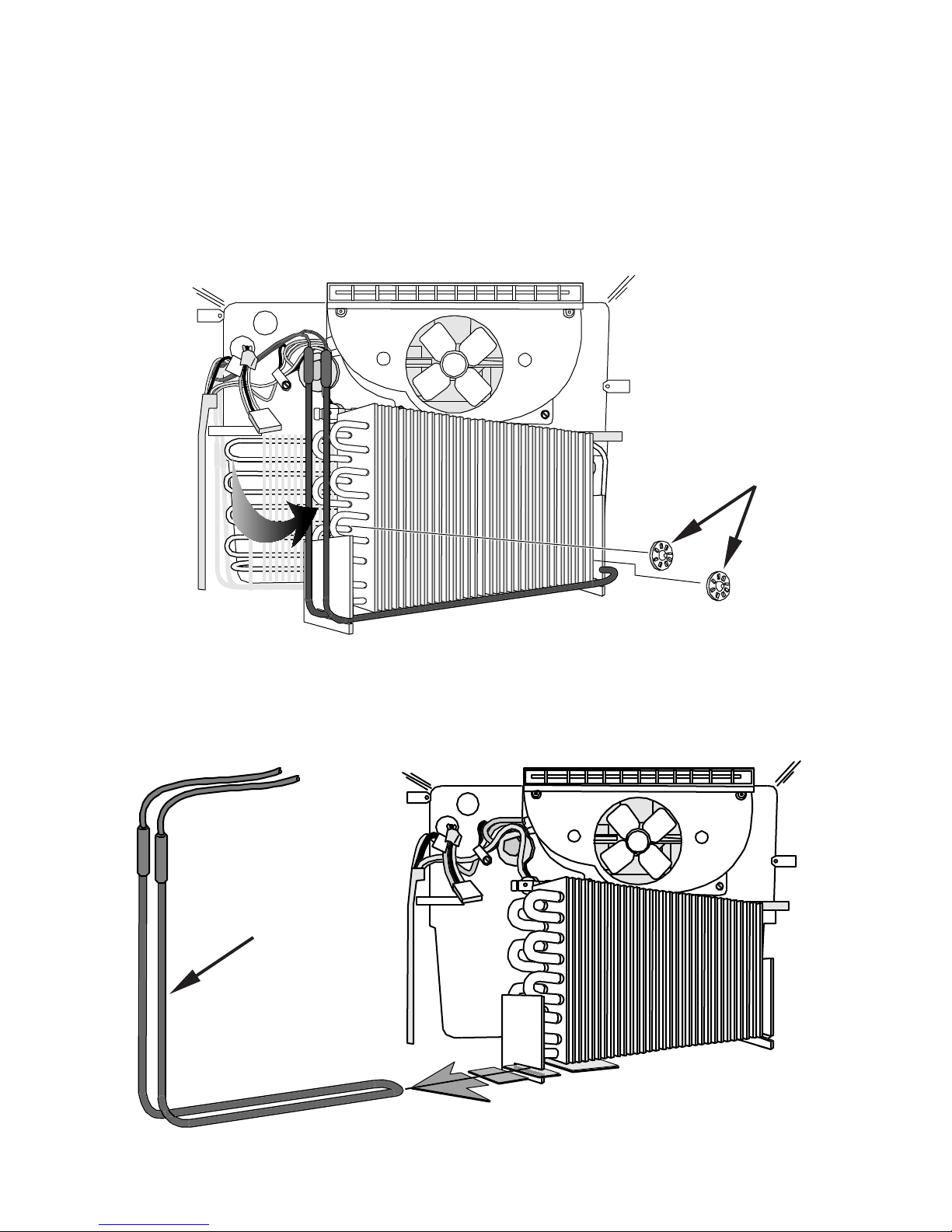

DEFROST DRAIN

The drain tube from the freezer section is routed down the outside back of the cabinet underneath

the condenser to the component tray at the bottom. The component tray serves as the drain pan.

1. Remove the screws from the four (4) clips securing the condenser to the back of the cabinet

and lean the condenser away from the cabinet far enough to gain access to the drain tube.

2. Loosen the clamp securing the drain hose to the outlet on the back of the cabinet.

3. Remove the screw from the clip securing the lower portion of the drain hose to the cabinet.

4. When replacing the drain hose be sure to put a loop in it near the connection to the freezer.

The loop creates a trap which prevents warm air and moisture from migrating into the freezer

compartment.

SERVICING THE COMPRESSOR

1. Remove the four (4) screws securing the component tray to the cabinet. There are two screws

on each side of the unit.

2. Carefully slide the component tray out from the refrigerator/freezer far enough for the compressor to clear the back of the cabinet. Watch that the tubing is not kinked when sliding the tray

out.

3. Follow standard Sweep Charge Procedures for replacing the compressor.

4. Slide the component tray back into the unit and secure it with to the cabinet the four (4) screws

removed earlier.

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

7

Servicing Components in the Freezer Compartment

EVAPORATOR

FAN MOTOR

EVAPORATOR

DEFROST

HEATER

(Under Evaporator)

Fig. 12

CENTER

RAIL

BRACKET

HEAT

SHIELD

HEAT

LOOP

Accessing Freezer Compartment Components

The center rail covering the mullion between the freezer and refrigerator compartments and the

freezer floor must be removed to gain access to components in the freezer compartment.

1. Remove both doors and the center hinge. Also remove the screws on the other side of the

center rail.

2. Press in on the left side of the center rail while sliding it to the left. This will release the right end

of the center rail from the cabinet.

3. Slide the center rail to the right to release the left end from the cabinet.

4. Carefully slide the freezer floor out of the freezer compartment.

5. Lift the Styrofoam evaporator housing cover and aluminum heater shield from the bottom of the

freezer compartment.

The evaporator is surrounded by Styrofoam insulation inside the compartment separator.

Servicing the Evaporator Fan Motor

1. Disconnect the two (2) wire connectors from the evaporator fan motor.

2. Remove the two (2) screws securing the evaporator fan motor bracket to the fan scroll.

3. The fan blade is pressed onto the motor shaft. The motor shaft should not extend past the fan

blade hub.

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

8

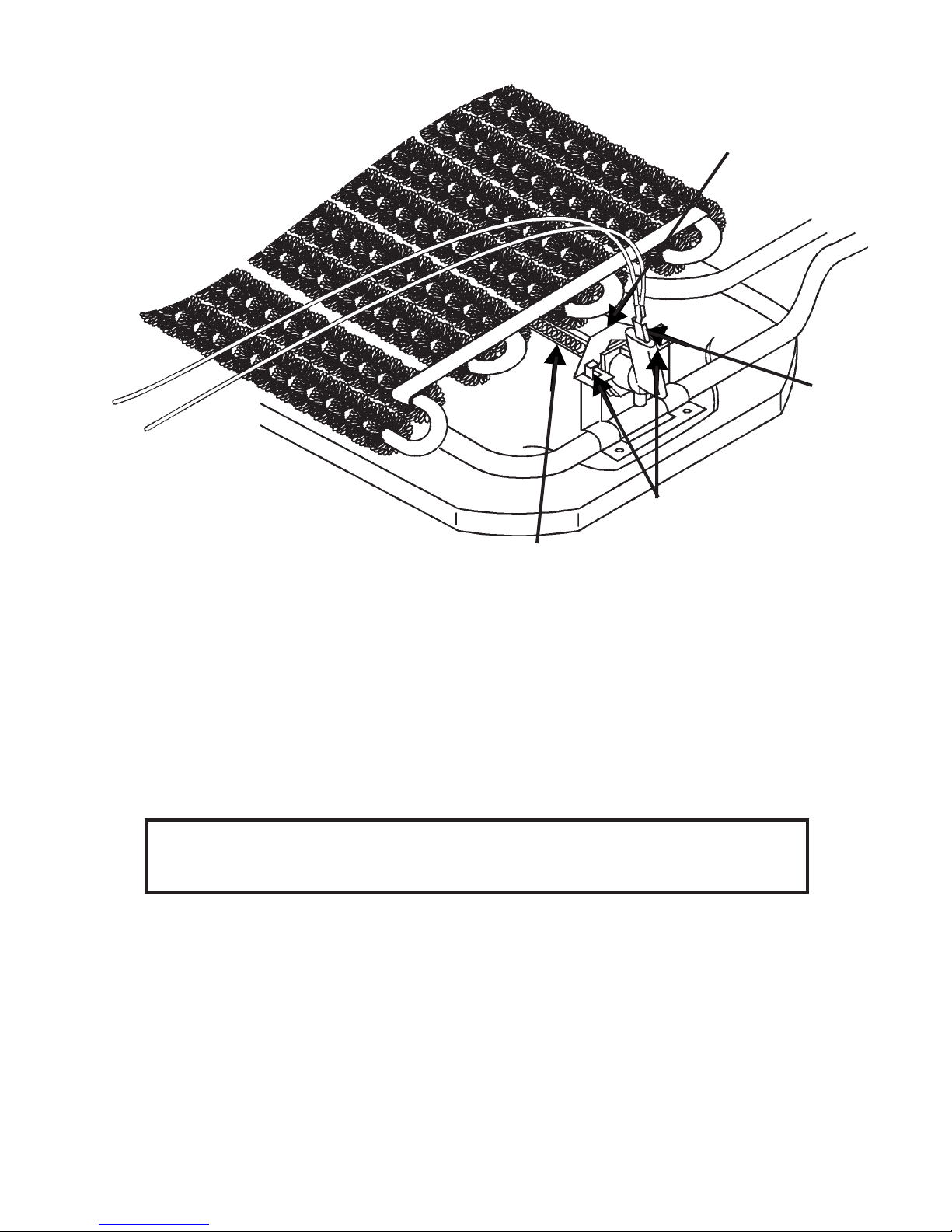

DEFROST HEATER

DRIP COVER

CONNECTOR

WIRE

Fig. 13

DEFROST

HEATER

BRACKET

TABS

Servicing the Defrost Heater

1. Disconnect the wire connectors from both ends of the defrost heater.

2. Carefully lift up on the evaporator far enough to expose the defrost heater and drip cover.

3. Carefully bend the tabs on the defrost heater mounting brackets up to release the defrost heater

drip cover and remove the drip cover.

4. Remove the defrost heater from the mounting brackets.

5. Place the new defrost heater in the mounting brackets.

NOTE: Do not touch the glass tube of the defrost heater with bare hands. Body oils

and other contaminants will cause the glass tube to break when it gets hot.

Wear a pair of clean soft gloves.

6. Reinstall the defrost heater drip cover and secure it in place by bending the mounting bracket

tabs down.

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

9

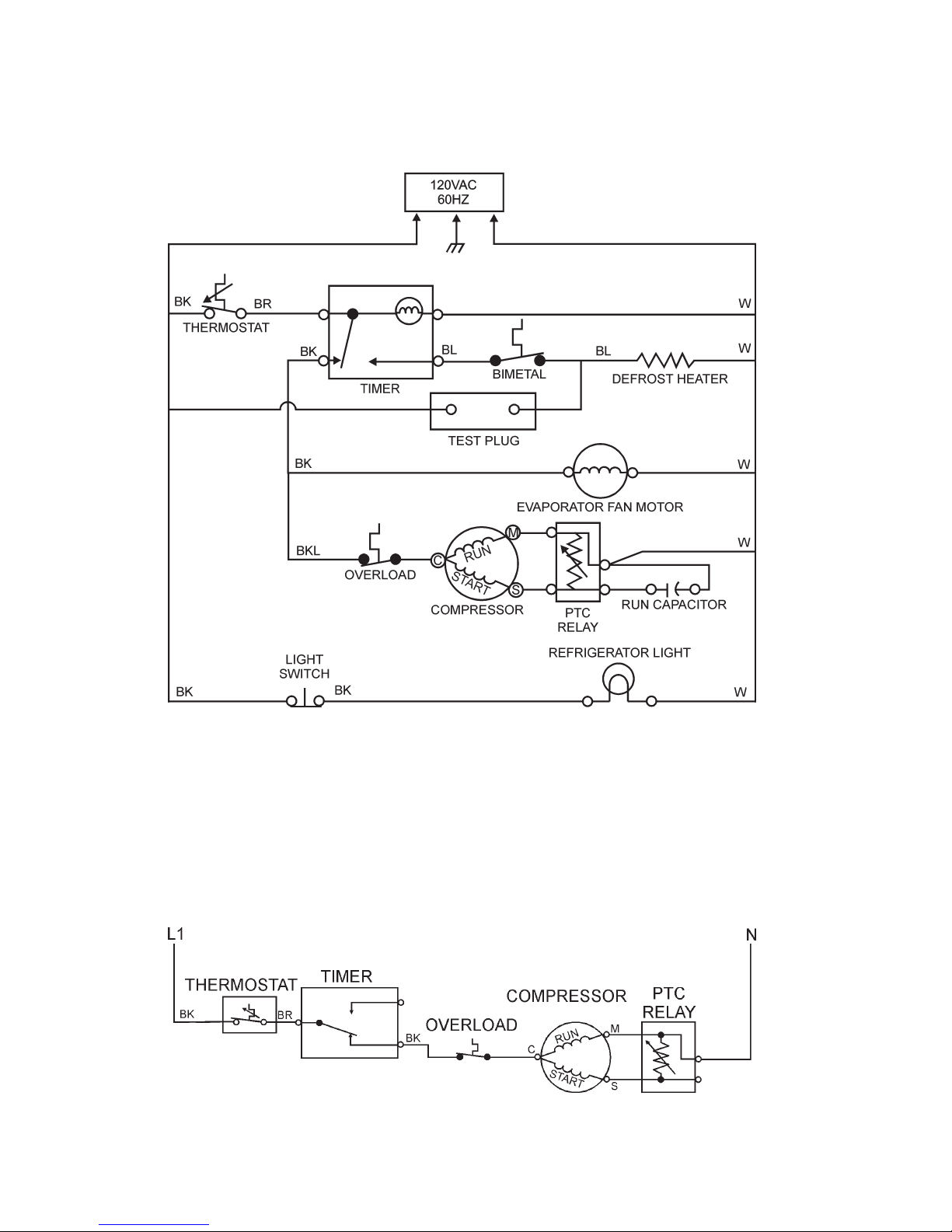

WIRING DIAGRAM

COOLING CYCLE

Compressor Circuit (at instant of start)

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

STRIP CIRCUITS

10

Compressor Circuit (running)

Defrost Timer Motor Circuit

Evaporator Fan Motor Circuit

DEFROST CYCLE

Defrost Timer and Defrost Heater Circuit

REFRIGERATOR LIGHT

Refrigerator Light Circuit

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

11

-- NOTES --

MULLION EVAPORATOR DESIGN 12 cu. ft. Top-Mount

12

Section Two

Old Design

12 & 14 cu. ft. Top-Mount

INSTALLATION CONSIDERATIONS

Minimum Clearance

Measure the opening at the location in which the refrigerator/freezer is to be installed and make

sure the following minimum clearance dimensions are followed.

Top: At least 3” (7.5cm) clearance between

the overhead cabinet and the refrigerator/

freezer top. (Dimension A)

Sides: At least 1” (2.5cm) clearance on each side

of the refrigerator/freezer. (Dimension B)

(Fig. 14)

Back: At least ½” (1.25cm) clearance between

the condenser (“Old Design” 14 cu. ft.

Top-Mount) and the wall.

(Fig. 14)

A

B

B

Fig. 14

Leveling the Refrigerator/Freezer

It is critical that the refrigerator/freezer be properly leveled. Both the back and front of the unit should

be carefully leveled before it is turned on.

1. Place a board across the rear of the installed position and set a level on the board.

2. Place shims where the rear rollers will sit to level the board.

3. Remove the board and leave the shims in place.

4. Place the unit in its installed position.

Level

(Fig. 15)

Board

OLD DESIGN 12 & 14 cu. ft. Top-Mount

Fig. 15

13

Once the unit is located in the final installed location and the rear of the unit is level, proceed to

level the front.

NOTE: When leveling the front of the unit, the front should be ½ bubble higher than the back.

1. Use a flat blade screwdriver to rotate the front roller leveling screws in the appropriate direction

to level the unit side to side.

2. Use a level and check to make sure the rollers are set so the unit is level side to side and ½

bubble higher in front.

Fig. 16

(Fig. 16 & 17)

VIEW OF ROLLER WITH HINGE IN PLACEVIEW OF ROLLER WITH NO HINGE

LOWER

RAISE

Leveling

Screw

Fig. 17

Leveling

Screw

Electrical Requirements

A 115 V, 60 Hz, 15 TO 20 Amp fused circuit utilizing a 3-wire grounding receptacle meeting all

national and local electrical codes is required. It is recommended that a separate circuit serving

only this appliance be provided.

! WARNING

To avoid the risk of electrical shock,

property damage, personal injury or death:

• The power cord must be plugged into a 3-prong grounding-type

wall receptacle, grounded in accordance with the National

Electrical Code, ANSI/NFPA 70 - latest edition, and local codes

and ordinances.

• It is the personal responsibility of the consumer to have a proper

• DO NOT, UNDER ANY CIRCUMSTANCES, REMOVE THE

• Do not remove any grounding wires

OLD DESIGN 12 & 14 cu. ft. Top-Mount

3-prong wall receptacle installed by a qualified electrician.

POWER CORD GROUNDING PRONG.

Grounding Type

from individual components while

servicing, unless the component is

to be removed and replaced.

extremely

grounding wires when components

are replaced.

important to replace all

14

It is

Receptacle

3-Prong

Grounding Plug

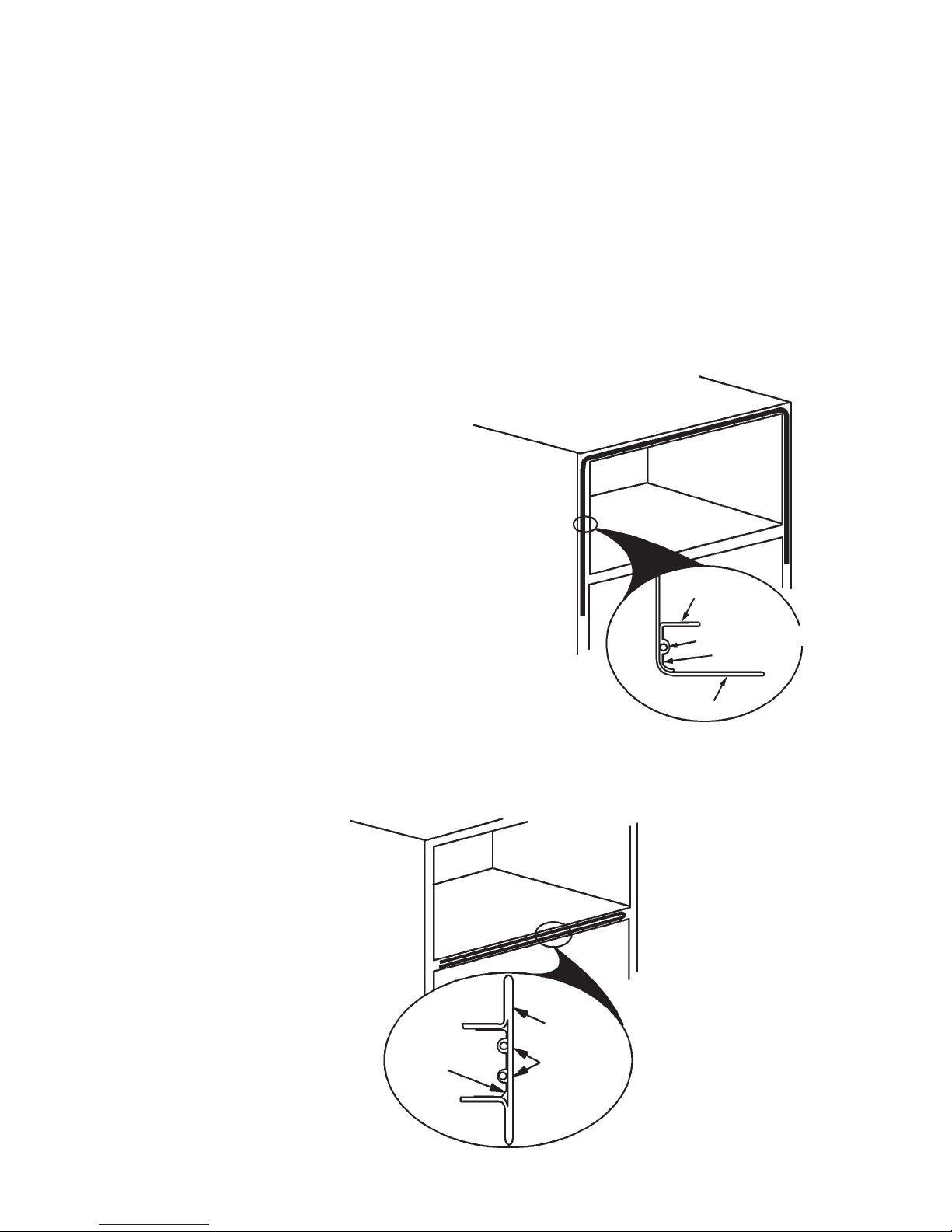

Door Alignment

Occasionally, the refrigerator or freezer doors

may need to be realigned. Evidence of improperly aligned doors includes a generally poor

appearance of the unit and/or sweating/frosting

on both the inside and outside of the cabinet

due to poor gasket seal.

1. Check for proper door gasket seal by

placing an American dime between the

inside of the door and the cabinet. The gap

should not be less than, or greater, than

then diameter of the dime (11/16”).

(Fig. 18)

2. Before making any attempt to realign the

doors by adjusting the hinges, make sure

the unit is solidly supported and level. (See

page 13 in this section on procedures to

level the unit.)

3. To align the refrigerator door:

a) DO NOT ADJUST THE BOTTOM

HINGE. Use the bottom hinge as an

establishing point.

b) Loosen the center hinge

(Figs. 19)

and align the refrigerator door with the

cabinet edge.

c) Tighten the center hinge.

4. To align the freezer door:

a) If the refrigerator door is properly

aligned, DO NOT ADJUST THE

CENTER HINGE.

b) Loosen the top hinge

(Fig. 19)

and

align the top of the freezer door with

the top of the cabinet.

c) Tighten the top hinge.

Fig. 18

TOP HINGE

Cover

Top Hinge

Shim

Spacer

Sealing Screws

CENTER HINGE

Door Stop

Shim

Spacer

Center Hinge

Spacer

Sealing Screws

5. Check the door gasket gap on the hinged

side of the door. The gap should be straight

and even and the proper width (11/16” or

the diameter of an American dime) from

the top hinge to the bottom hinge.

a) If the gap is uneven or too narrow or if

the doors hit each other when opened

together, add shims at the center

hinge to even out the gap.

b) If the gap is uneven or too wide, or the

space between the refrigerator and

freezer door widens when opened

together, remove shims at the center

hinge to even out the gap.

OLD DESIGN 12 & 14 cu. ft. Top-Mount

BOTTOM HINGE

Door Stop

Spacer

Shim

Bottom

Hinge

Tap Plate

(in cabinet)

Moveable Hinge

Pin

(left hole for left swing)

Fig. 19

15

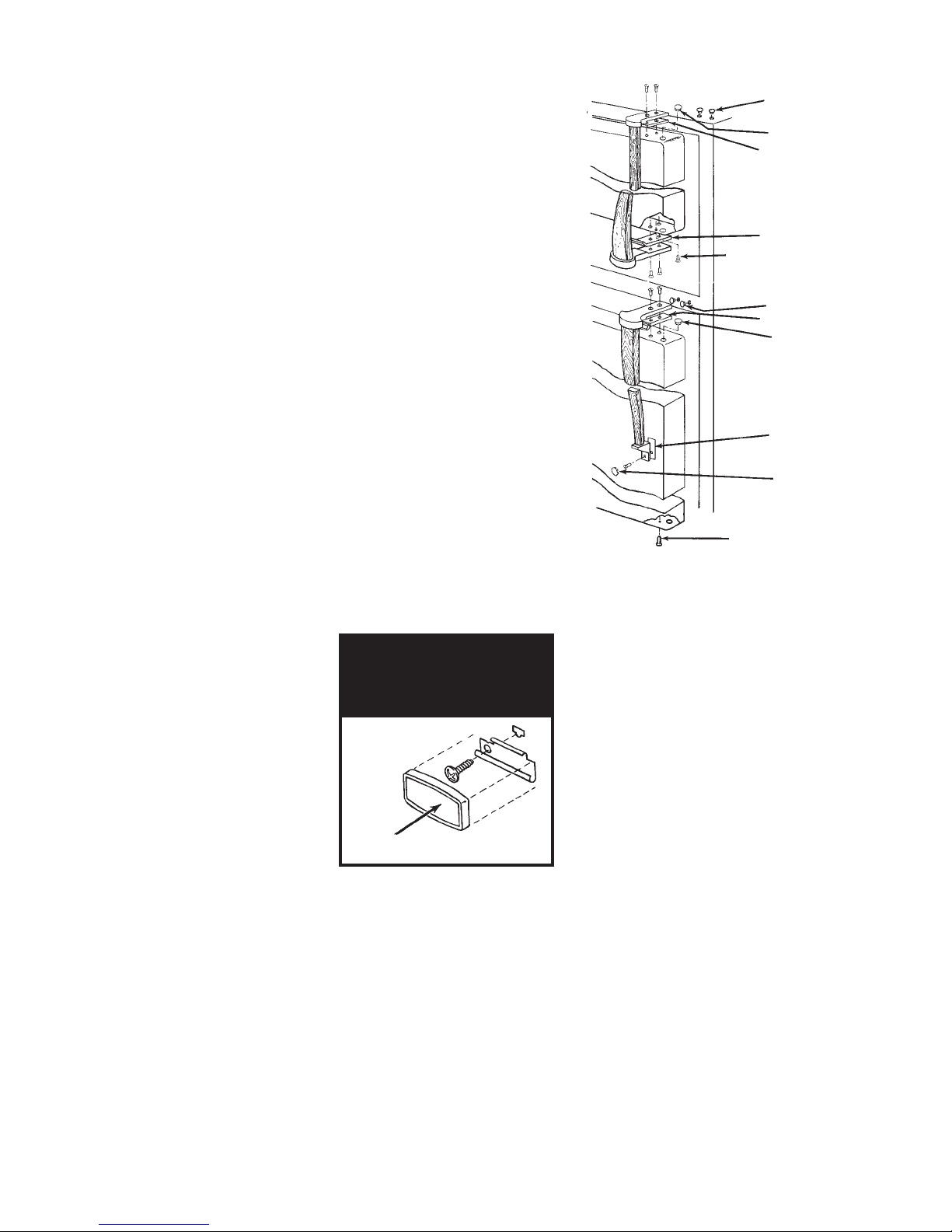

Door Swing Reversal

Cap

1. Open the refrigerator door and remove the toe

panel at the bottom of the unit.

2. Remove the top hinge.

(Fig. 20)

3. Remove the freezer door.

4. Remove the center hinge.

(Fig. 20)

5. Remove the refrigerator door.

6. Remove the bottom hinge.

(Fig. 20)

7. Lay the freezer door on a flat protected surface

and remove the door handle.

(Fig. 20)

8. Reinstall the freezer door handle on the opposite side of the door.

9. Lay the refrigerator door on a flat protected

surface and remove the door handle.

(Fig. 20)

10. Reinstall the refrigerator door handle on the

opposite side of the door.

11. Move the bottom hinge to the opposite side of

the cabinet and reinstall it.

12. Set the refrigerator door on the bottom hinge

and close the door to keep it in place.

13. Reinstall the center hinge.

14. Set the freezer door in the center hinge and

close the door to keep it in place.

15. Reinstall the top hinge.

16. Align the doors. (See procedures on page 15.)

Cap

Spacer

Spacer

Screw

Cap

Spacer

Cap

Spacer

Cap

Screw

Fig. 11

14, 16 & 18 cu. ft. Top-Mount

Cover for Refrigerator

Door Handle

Cover

Fig. 9

OLD DESIGN 12 & 14 cu. ft. Top-Mount

16

THEORY OF OPERATION

MULLION AND STILE HEATERS

All refrigerators have a tendency to sweat around the door openings due to the differences between

the ambient room temperature and the cold compartments of the refrigerator. On “Old Design” units

low-wattage resistance heaters are installed to the front flange area of the cabinet to help prevent

sweating.

Stile Heaters

Stile heaters are foil-wrapped resistance-type heating elements in the 5 - 30 watt range. These

heating elements fit on the inside of the cabinet flange across the top of the freezer and about 1/3

of the way down both sides.

Stile heaters are on 100% of the time the

refrigerator is plugged in, except during

the defrost cycle, or on models with power

saver switches. See the wiring diagrams

for units with stile heaters at the end of this

section.

Mullion Heaters

(Fig. 22)

Mullion heaters are foil-wrapped resistancetype heating elements in the 8 - 12 watt range.

These heating elements fit on the inside of the

rail that separates the refrigerator and freezer

sections.

The mullion heater element is normally wired

in parallel with the stile heater element. It is on

100% of the time the refrigerator is plugged in,

except during the defrost cycle or on models

with power saver switches.

(Fig. 23)

Fig. 23

CABINET

HEATER ELEMENT

FOIL

CABINET

Fig. 22

OLD DESIGN 12 & 14 cu. ft. Top-Mount

FOIL

MULLION

HEATER

ELEMENT

17

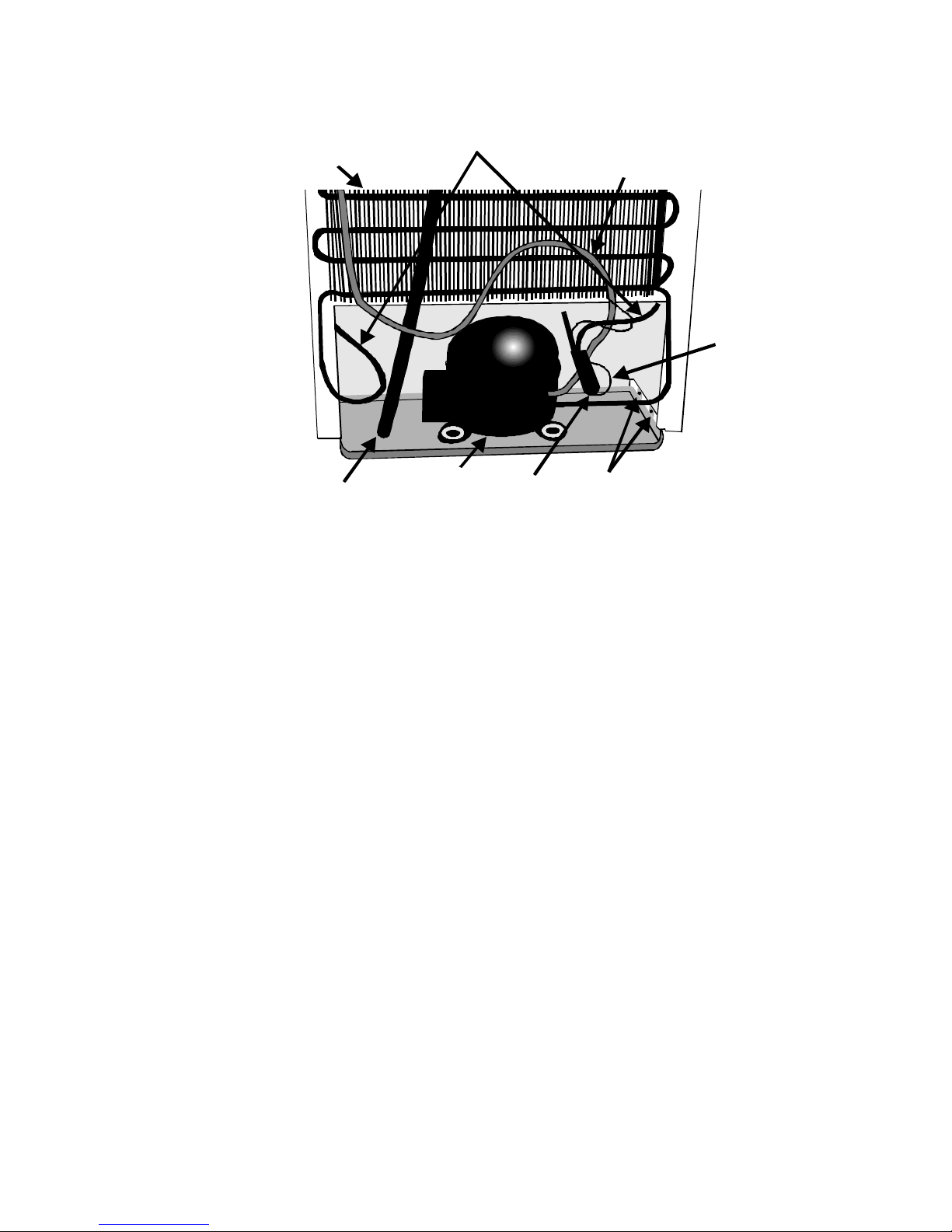

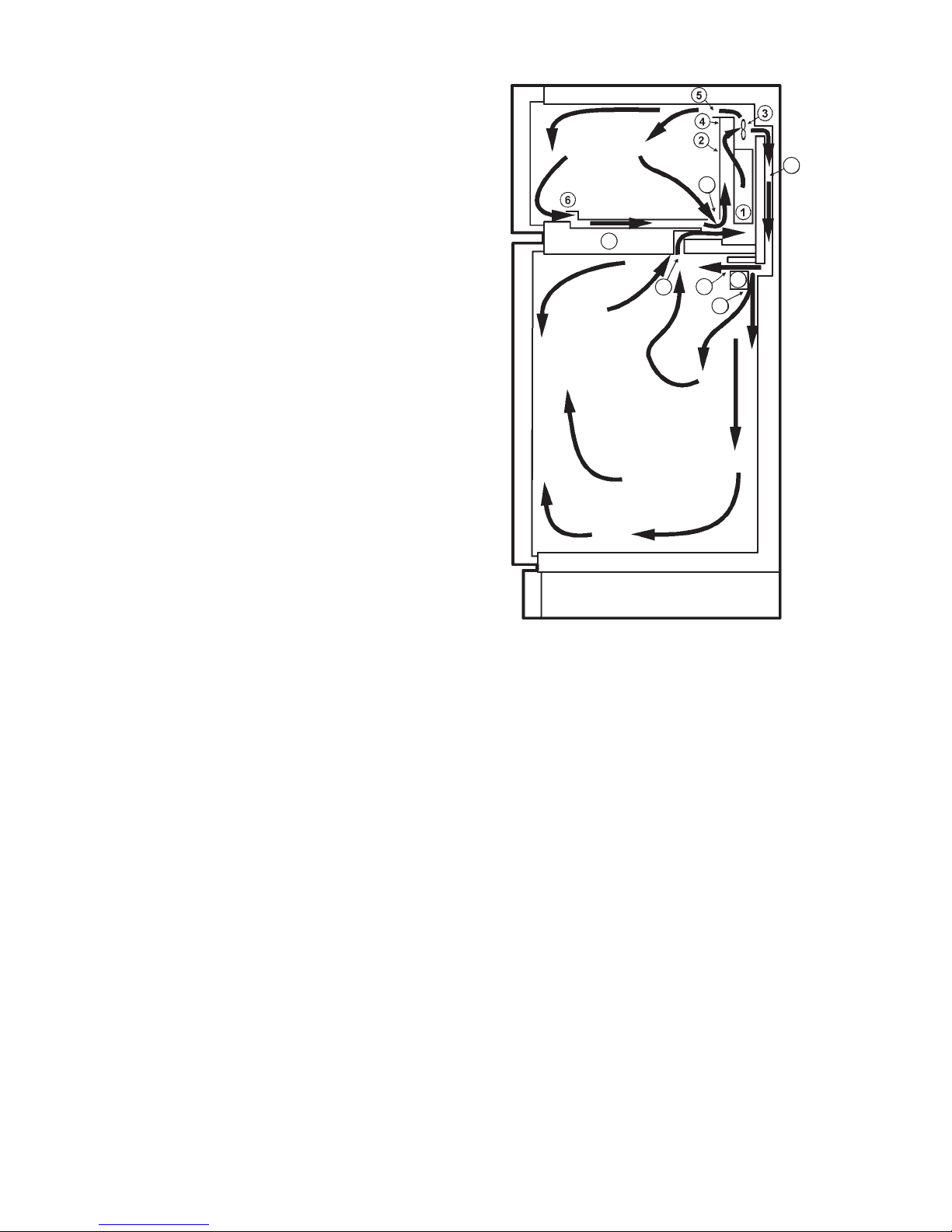

AIR CIRCULATION

The evaporator fan circulates air inside the refrigerator and freezer sections. (

Fig. 24)

air circulates inside the freezer compartment, and

returns to the evaporator from slots in the front and

rear of the freezer floor. The return air travels between the floor and the liner, where it joins other

return air at the back, flowing beneath the evaporator cover and up through the evaporator coil.

Cold air is also sent to the refrigerator section

through the air duct at the rear of the freezer section. The cold air enters the refrigerator section

through a diffuser. Part of the air is forced forward

where is passes through the front part of the compartment and the shelves in the door. Part of the

cold air is directed down the back of the compartment to cool the lower portion of the refrigerator

section. The warmed air is then returned to the

freezer section through two air return ducts.

Figure 24 Key:

1 - Evaporator 7 - Separator

2 - Evaporator Cover 8 - Air Duct

3 - Evaporator Fan 9 - Diffuser

4 - Fan Scroll 10 - Cold Air Discharge

5 - Cold Air Discharge 11 - Cold Air Discharge

6 - Return Air Louvers 12 - Air Return (2)

Most of the

7

Fig. 24

8

6

9

10

12

11

OLD DESIGN 12 & 14 cu. ft. Top-Mount

18

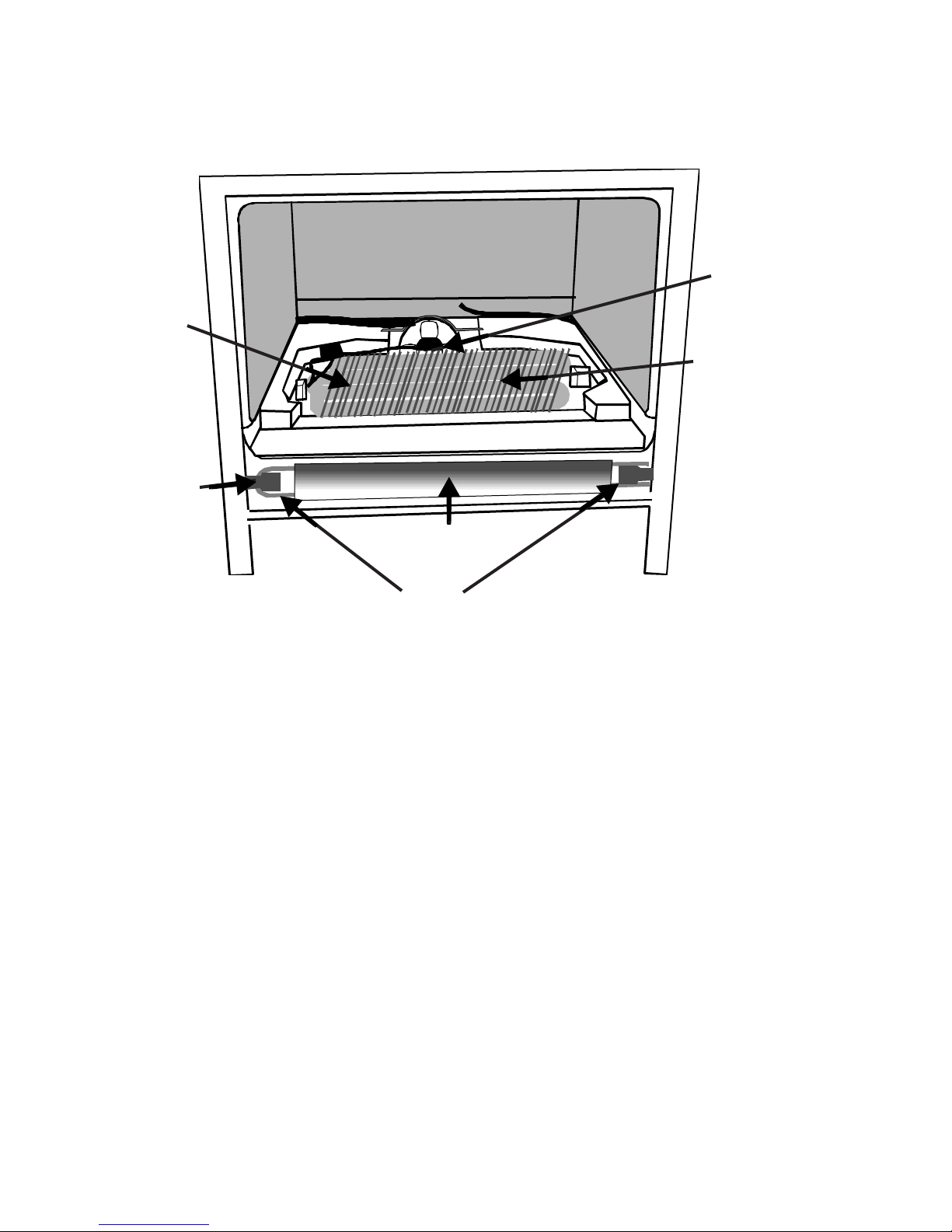

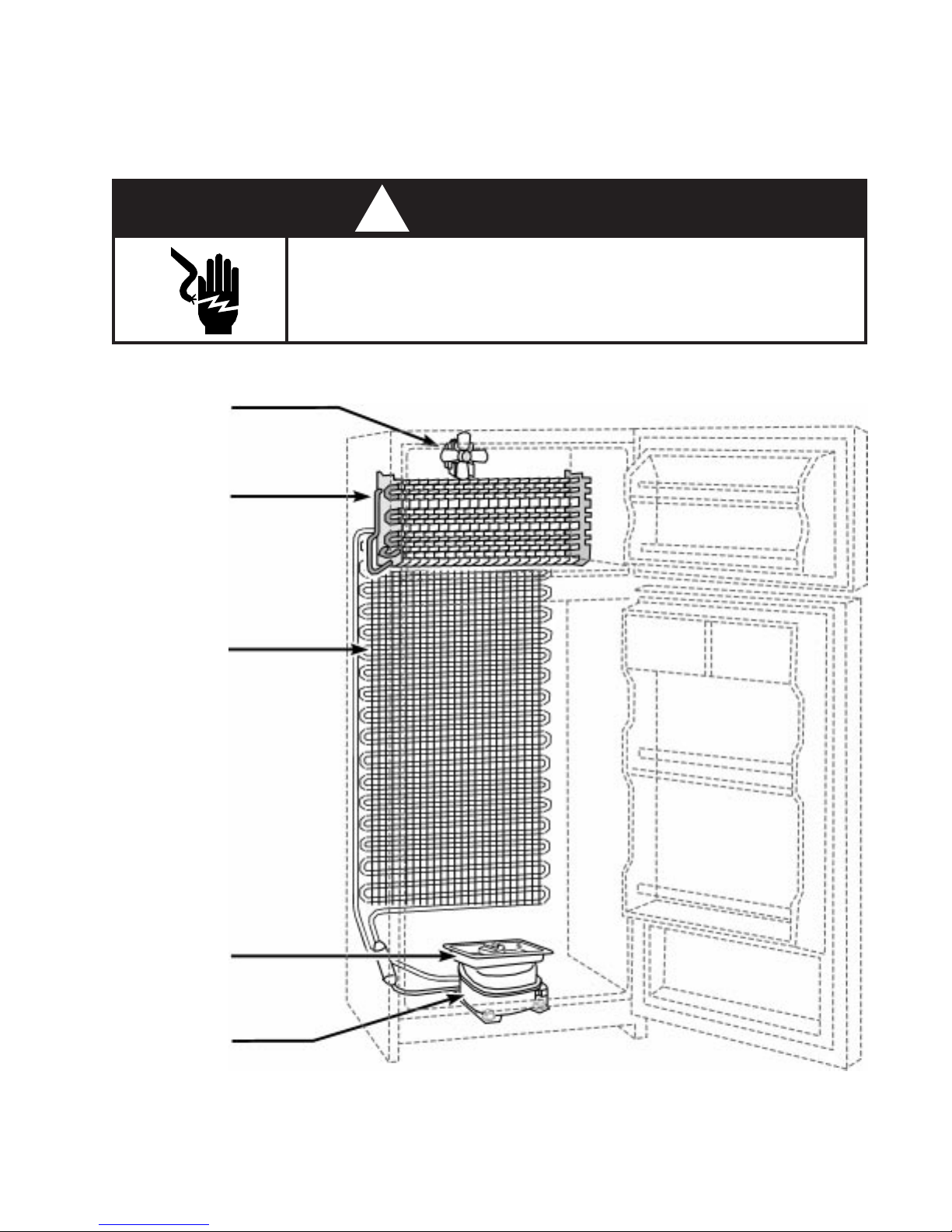

COMPONENT ACCESS

Component Location

Disconnect the electrical power before servicing any components.

EVAPORATOR

FAN

EVAPORATOR

! WARNING

ELECTRIC SHOCK HAZARD

Failure to do so can result in death or electrical shock.

CONDENSER

COLLECTOR

PAN

COMPRESSOR

Fig. 25

OLD DESIGN 12 & 14 cu. ft. Top-Mount

19

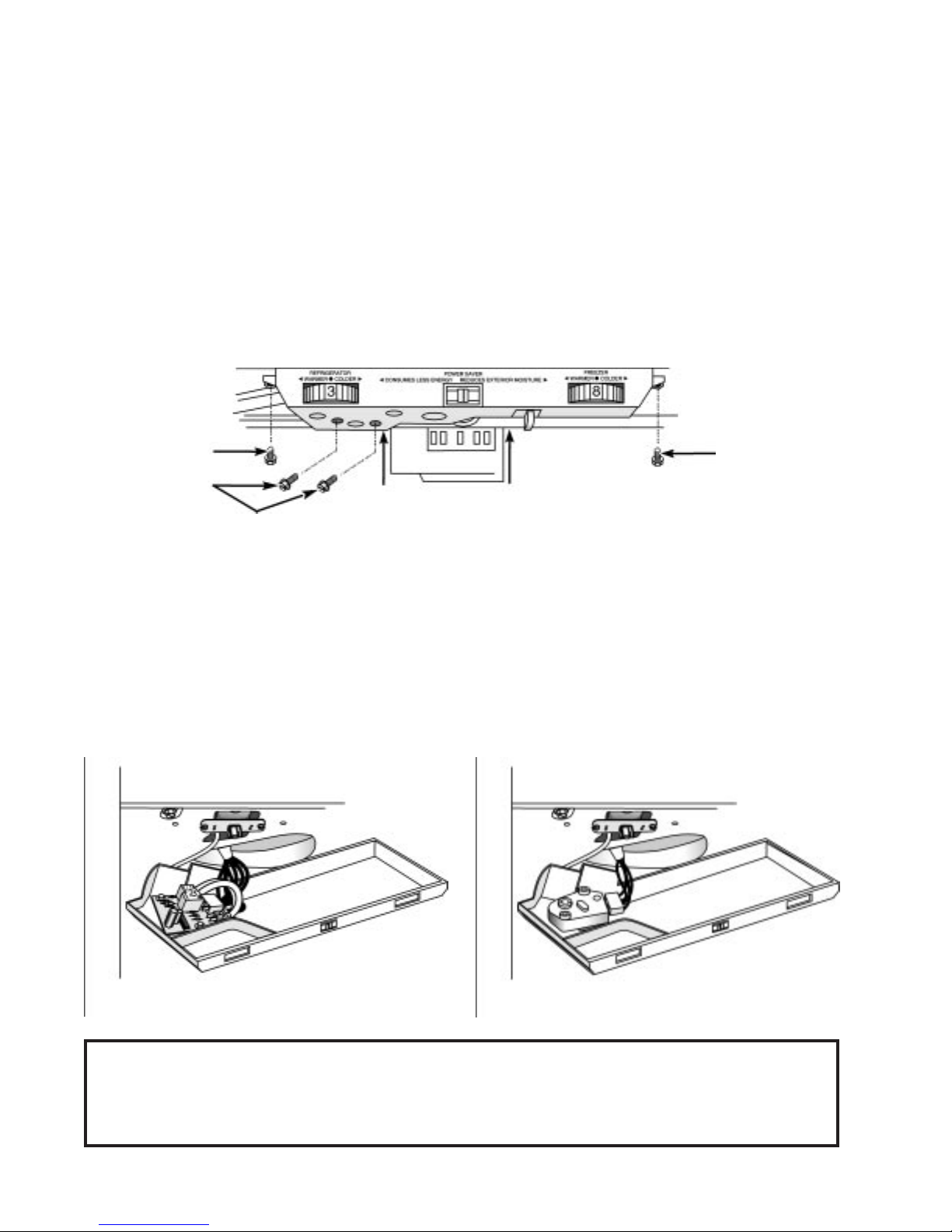

Servicing the Defrost Timer and Thermostat

Removing the Control Box

The Control box is attached to the bottom of the divider wall separating the freezer and refrigerator

compartments. The control box contains the defrost timer and the operating thermostat.

1. Remove the two (2) mounting screws securing the front of the control box to the bottom of

the separator.

2. Pull the control box forward to release the two (2) tabs securing the back of the control box

to the bottom of the separator.

3. The control box can now be dropped down to allow access to the defrost timer and the

thermostat.

COVER

MOUNTING

SCREW

DEFROST TIMER

MOUNTING

SCREWS

(Fig. 26)

TAB

AT

REAR OF

CONTROL BOX

DEFROST TIMER

MOUNTING

SCREWS

TAB

AT

REAR OF

CONTROL BOX

Fig. 26

Servicing the Defrost Timer

There are two different types of defrost timers, depending on the model being serviced. Figure 27

shows an Electronic Defrost Control. Figure 28 shows a typical Electromechanical Defrost Timer.

Both types of defrost timers are secured in the control box with the same mounting screws as

shown in Figure 28.

Fig. 27

Fig. 28

NOTE: Units with Adaptive Defrost Control will have the ADC printed circuit board mounted in

the same location as the Electromechanical Defrost Timer pictured above. Two

additional wires (Brown and White) are provided and connect to terminals 5 and 6 of

the ADC.

OLD DESIGN 12 & 14 cu. ft. Top-Mount

20

Servicing the Thermostat

SENSOR TUBE

The thermostat is mounted in the cross rail area

by two (2) mounting screws.

When removing the thermostat the sensing tube

will also have to be removed. The sensing tube is

THERMOSTAT

routed back to the deffuser. To access the sensing

tube, remove the two (2) screws securing the deffuser cover.

(Fig. 29)

Fig. 29

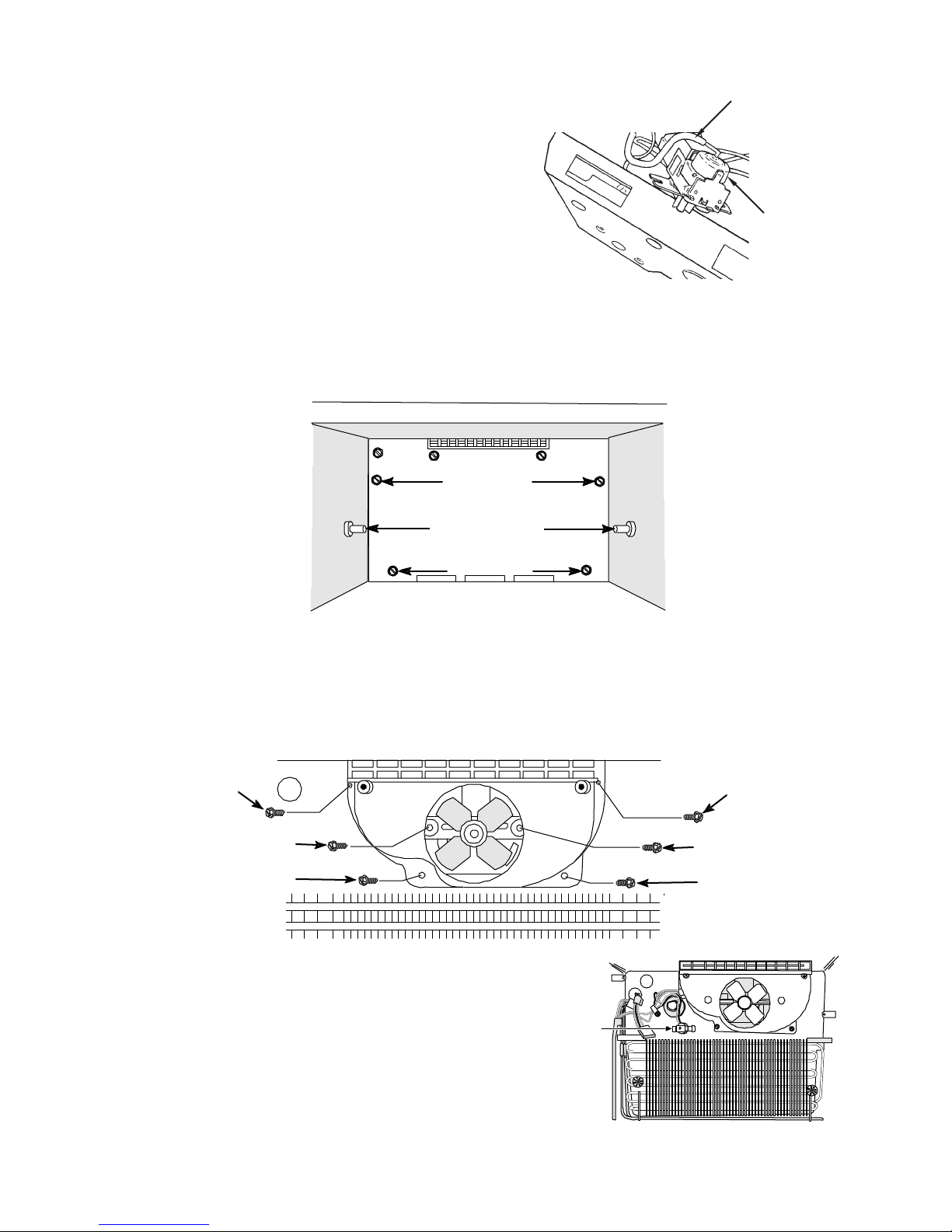

Servicing the Evaporator Fan

Access to the Evaporator Fan is possible once the Evaporator Cover has been removed.

1. Remove the evaporator mounting screws and remove the evaporator cover.

MOUNTING

SCREWS

SHELF STUDS

MOUNTING

SCREWS

(Fig. 30)

Fig. 30

2. Remove the four (4) screws securing the fan shroud to the back wall of the freezer section

and lift the shroud off.

(Fig. 31)

3. Remove the two (2) screws securing the fan motor mounting bracket to the back wall of the

freezer section and lift the fan motor assembly from its location.

(Fig. 31)

4. Disconnect the wiring harness connector from the fan motor terminals.

SHROUD

MOUNTING

SCREW

SHROUD

MOUNTING

SCREW

FAN MOUNTING SCREW

SHROUD MOUNTING

SCREW

Servicing the Bi-Metal

The Bi-Metal

on the back wall of the freezer section.

1. Gently pry the bi-metal retaining clip up

2. Disconnect the bi-metal wire connector from

OLD DESIGN 12 & 14 cu. ft. Top-Mount

(Fig. 32)

is attached to the heat shield

and slide the bi-metal out from under the clip.

the wiring harness plug.

FAN MOUNTING SCREW

SHROUD MOUNTING

SCREW

Fig. 31

BIMETAL

Fig. 32

21

Servicing the Defrost Heater

The defrost heater is located on the left side and bottom of the evaporator and is held in place by

two slotted retainers at the bottom of the evaporator.

1. Release the evaporator from its position by first pulling the two plastic retaining clips from

the bosses that secure the evaporator to the heat shield.

2. Gently pull the left end of the evaporator away from the heat shield. Be careful not to kink

the evaporator outlet tubing.

(Fig. 33)

PLASTIC

RETAINING

CLIPS

Fig. 33

3. Gently slide the defrost heater by pulling it to the left and out of the retaining slots on the

evaporator.

(Fig. 34)

4. Disconnect the defrost heater wire connector from the wiring harness plug.

DEFROST

HEATER

OLD DESIGN 12 & 14 cu. ft. Top-Mount

Fig. 34

22

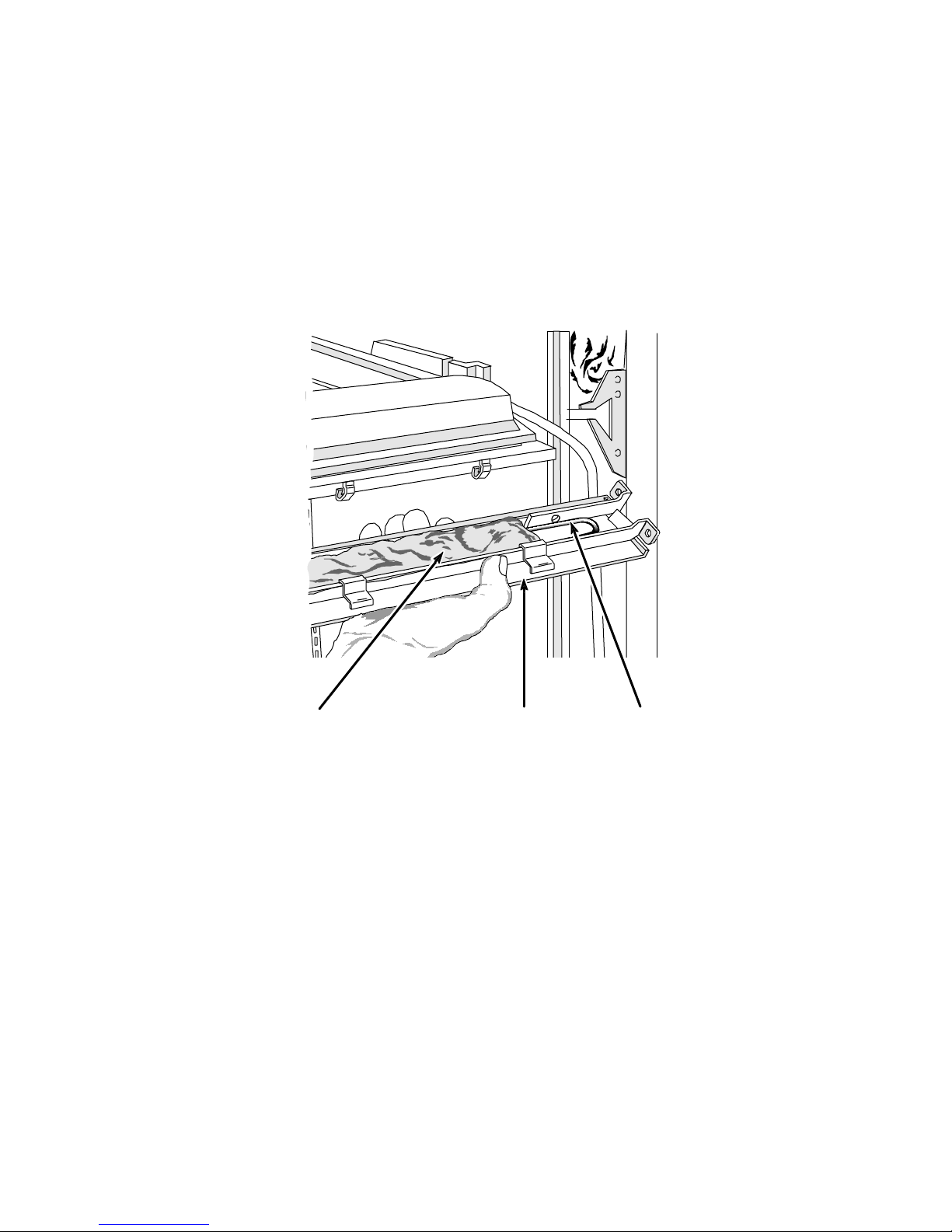

Servicing the Mullion Heater

The electrical mullion rail heater can be replaced and can be accessed by removing the mullion rail

cover.

1. Remove the doors following the procedures described in earlier in this section.

2. Remove the two screws on the opposite side of the mullion from the hinges.

3. Slide one end of the mullion rail cover to the left or right under the cabinet flange enough to

free the other end of the cover.

4. Slide the mullion in the opposite direction and remove it from the mullion rail.

5. Disconnect the mullion heater wire connector from the wiring harness plug.

(Fig. 35)

INSULATION

MULLION

RAIL COVER

Fig. 35

MULLION

HEATER

ELEMENT

OLD DESIGN 12 & 14 cu. ft. Top-Mount

23

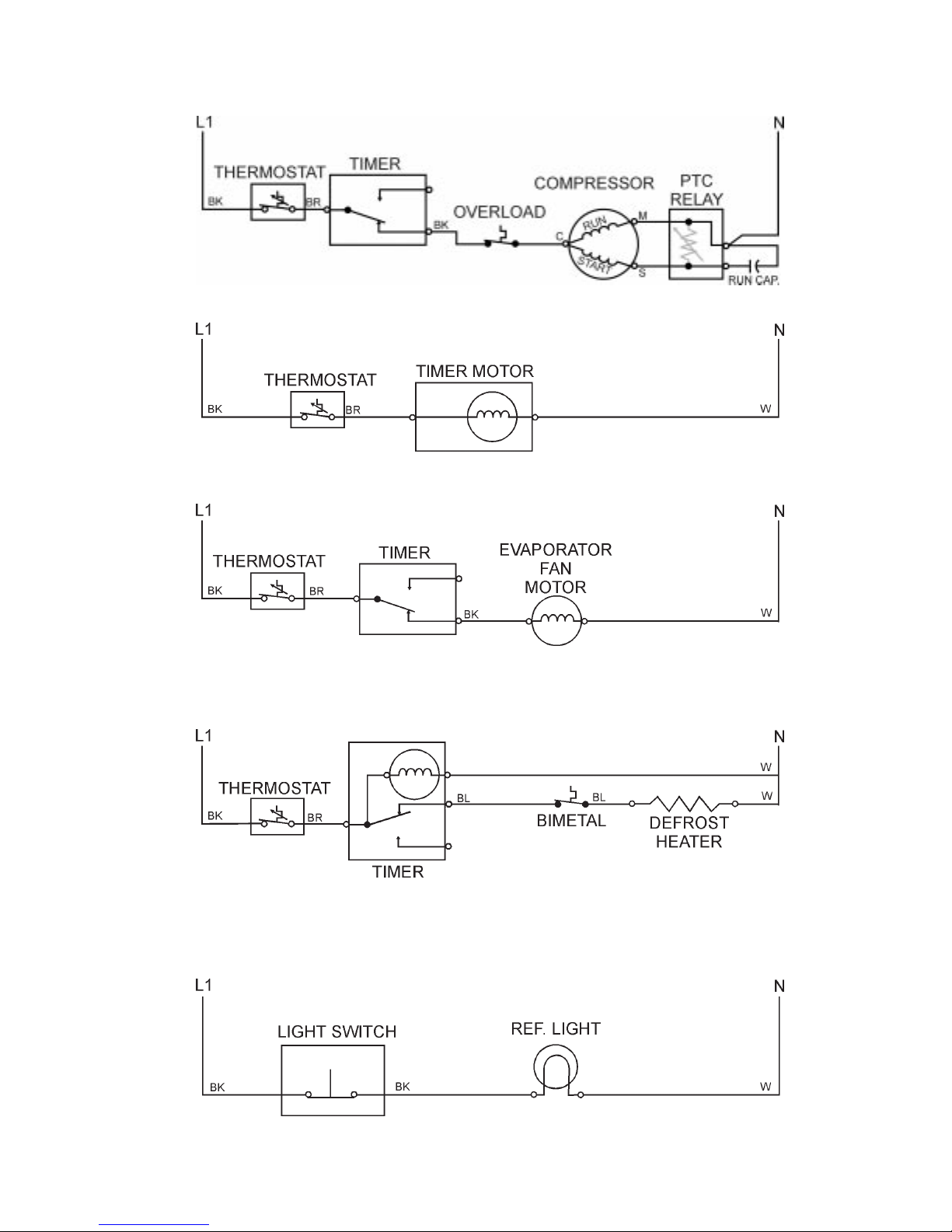

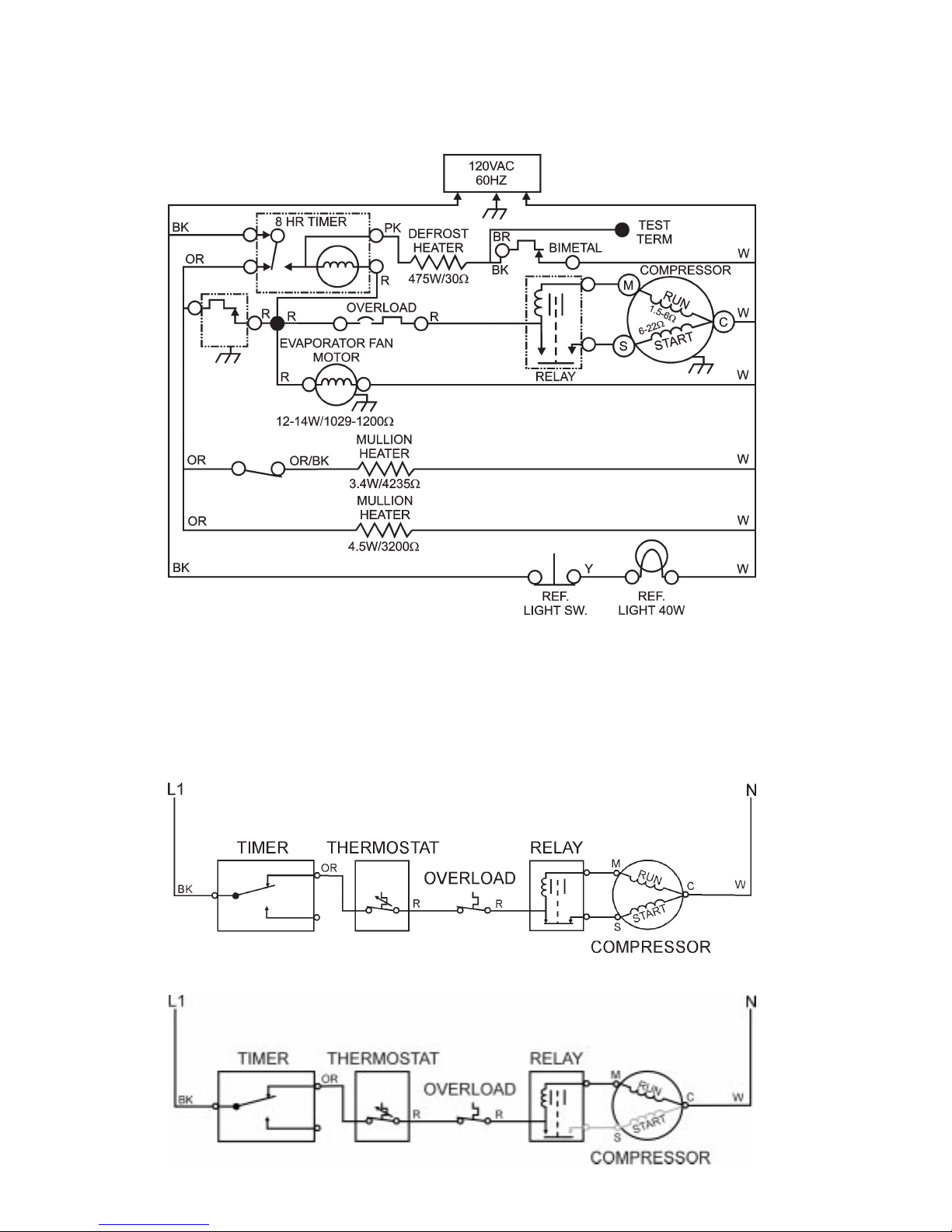

WIRING DIAGRAM

(Early Mullion & Stile Heater Design)

STRIP CIRCUITS

(Early Mullion & Stile Heater Design)

COOLING CYCLE

Compressor Circuit (at instant of start)

Compressor Circuit (running)

OLD DESIGN 12 & 14 cu. ft. Top-Mount

24

Loading...

Loading...