Whirlpool LSR7133KQ1 User Manual

WASHER INSTALLATION INSTRUCTIONS

INSTRUCCIONES PARA LA INSTALACIÓN DE LA LAVADORA INSTRUCTIONS POUR L’INSTALLATION DE LA LAVEUSE

TableofContents/Índice/TabledesMatières

WASHER SAFETY............................................ |

1 |

SEGURIDAD DE LA LAVADORA.................... |

8 |

SÉCURITÉ DE LA LAVEUSE......................... |

14 |

INSTALLATION REQUIREMENTS ................. |

2 |

REQUISITOS DE INSTALACIÓN .................... |

8 |

EXIGENCES D’INSTALLATION .................... |

14 |

Tools and Parts ............................................. |

2 |

Herramientas y piezas................................... |

8 |

Outillage et pièces....................................... |

14 |

Location Requirements................................. |

2 |

Requisitos de ubicación................................ |

9 |

Exigences de l’emplacement |

|

Drain System................................................. |

3 |

Sistema de desagüe ..................................... |

9 |

d’installation ................................................ |

15 |

Electrical Requirements ................................ |

3 |

Requisitos eléctricos................................... |

10 |

Système de vidange ................................... |

15 |

INSTALLATION INSTRUCTIONS ................... |

4 |

INSTRUCCIONES DE INSTALACIÓN .......... |

11 |

Installation électrique .................................. |

16 |

Before You Start............................................ |

4 |

Antes de empezar ....................................... |

11 |

INSTRUCTIONS D’INSTALLATION.............. |

17 |

Remove Shipping Strap................................ |

4 |

Quite el fleje de embalaje............................ |

11 |

Avant de commencer.................................. |

17 |

Connect Drain Hose...................................... |

5 |

Conecte la manguera de desagüe.............. |

11 |

Élimination de la sangle d’expédition ......... |

17 |

Connect the Inlet Hoses ............................... |

6 |

Conecte las mangueras de entrada ........... |

12 |

Raccordement du tuyau de vidange .......... |

17 |

Secure the Drain Hose.................................. |

6 |

Asegure la manguera de desagüe.............. |

13 |

Raccordement des tuyaux |

|

Level the Washer........................................... |

7 |

Nivele la lavadora........................................ |

13 |

d’arrivée d’eau ............................................ |

18 |

Complete Installation .................................... |

7 |

Complete la instalación............................... |

13 |

Immobilisation du tuyau de vidange........... |

19 |

|

|

|

|

Réglage de l’aplomb de la laveuse............. |

19 |

|

|

|

|

Achever l’installation ................................... |

19 |

WASHER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean:

DANGER

DANGER

WARNING

WARNING

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

3956025

INSTALLATION REQUIREMENTS

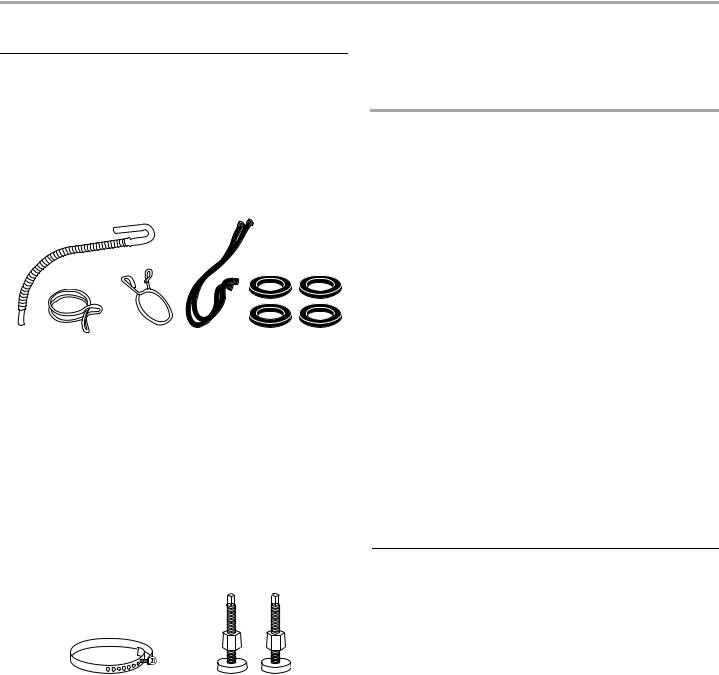

Tools and Parts

Assemble the necessary tools and supplies before beginning the washer installation. The parts supplied are in the washer basket.

Tools needed for connecting the drain hose and water inlet hoses:

■Pliers that open to 1⁄ in. (3.95 cm)

■Flashlight (optional)

Parts supplied:

1 |

2 |

3 |

4 |

5 |

1.Drain hose

2.Silver, double-wire hose clamp (for the bottom of the drain hose)

3.Yellow, single-wire hose clamp (for the top of the drain hose)

4.Water inlet hoses (2)

5.Flat water inlet hose washers (4)

Tools needed for securing the drain hose and leveling the washer:

■Adjustable or open end wrench ⁄ in. (14 mm)

■Level

■Wood block

■Ruler or measuring tape

Parts supplied:

1 |

2 |

1.Shipping strap with fastener

2.Front leveling feet with nuts (2)

Alternate Parts

Your installation may require additional parts. For ordering information, please refer to the toll free phone numbers on the front page of your “Washer User Instructions.”

If You Have: |

You Will Need to Buy: |

|

|

Laundry tub or |

Sump pump system (if not already |

standpipe taller |

available) |

than 96 in. (2.4 m) |

|

|

|

1 in. (2.5 cm) |

2 in. (5 cm) diameter to 1 in. (2.5 cm) |

diameter |

diameter standpipe adapter, Part No. |

standpipe |

3363920 |

|

|

Overhead sewer |

Standard 20 gal. (76 L) 39 in. (99 cm) tall |

|

drain tub or utility sink, sump pump and |

|

connectors (available from local |

|

plumbing suppliers) |

|

|

Floor drain |

Siphon break, Part Number 285320; |

|

additional drain hose, Part Number |

|

3357090 and connector kit, |

|

Part Number 285442 |

|

|

Water faucets |

2 longer water fill hoses: |

beyond reach of |

6 ft (1.8 m) Part Number 76314, |

fill hoses |

10 ft (3.0 m) Part Number 350008 |

|

|

Drain hose too |

Drain hose, Part No. 388423 and hose |

short |

kit, Part No. 285442 |

|

|

Drain hose that is |

Hose kit, Part No. 285442 |

too long |

|

|

|

Lint clogged drain |

Drain protector, Part No. 367031 |

Location Requirements

Selecting the proper location for your washer improves performance and minimizes noise and possible washer “walk.”

Your washer can be installed in a basement, laundry room, closet, or recessed area. (See “Drain System.”)

IMPORTANT: Do not install or store the washer where it will be exposed to the weather.

Proper installation is your responsibility.

You will need:

■A water heater set to deliver 120°F (49°C) water to the washer.

■A grounded electrical outlet located within 4 ft (1.2 m) of where the power cord is attached to the back of the washer. (See “Electrical Requirements.”)

■Hot and cold water faucets located within 4 ft (1.2 m) of the hot and cold water fill valves, and water pressure of 5-100 psi (34.5-690 kPa). Washers with triple dispensers require 20-100 psi (138-690 kPa) for best performance.

■A level floor with a maximum slope of 1 in. (2.5 cm) under entire washer. Installing the washer on carpeting is not recommended.

■A sturdy floor to support the washer weight (washer, water and load) of 315 lbs (143 kgs).

2

Do not store or operate your washer in temperatures at or below 32°F (0°C). Some water can remain in the washer and can cause damage in low temperatures. See “Washer Care” in the

Washer User Instructions for winterizing information.

Recessed area or closet installation

The dimensions shown are for the recommended spacing allowed, except the closet door ventilation openings. The dimensions shown for the closet door ventilation openings are the minimum required.

|

|

|

|

|

" |

|

|

|

|

|

" |

|

|

|

|

|

" |

|

" |

|

|

|

|

|

|

|

|

|

" |

|

|

|

|

|

" |

" |

" |

" |

" |

" |

" |

1 |

2 |

3 |

1.Front view

2.Side view

3.Closet door with vents

■Additional spacing should be considered for ease of installation and servicing.

■Additional clearances may be required for wall, door and floor moldings.

■Additional spacing of 1 in. (2.5 cm) on all sides of the washer is recommended to reduce noise transfer.

■If a closet door is installed, the minimum air openings in the top and bottom of the door are required. Louvered doors with air openings in the top and bottom are acceptable.

■Companion appliance spacing should also be considered.

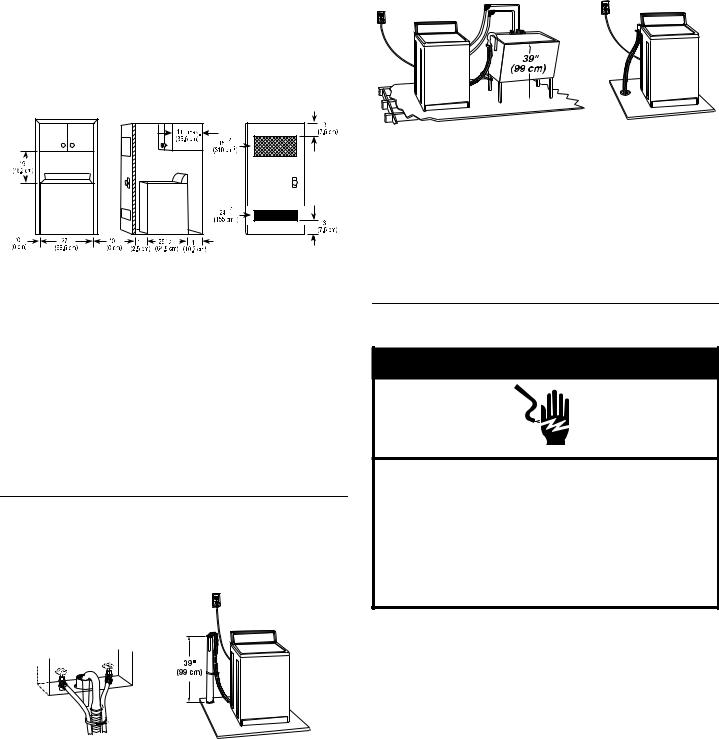

Drain System

The washer can be installed using the standpipe drain system (floor or wall), the laundry tub drain system, or the floor drain system. Select the drain hose installation method you need. See “Alternate Parts.”

1 |

2 |

Standpipe drain system - wall or floor (view 1 & 2)

The standpipe drain requires a minimum diameter standpipe of 2 in. (5 cm). The minimum carry-away capacity can be no less than 17 gal. (64 L) per minute. A 2 in. (5 cm) diameter to 1 in.

(2.5 cm) diameter standpipe adapter kit is available. See “Alternate Parts.”

The top of the standpipe must be at least 39 in. (99 cm) high and no higher than 96 in. (244 cm) from the bottom of the washer.

1 |

2 |

Laundry tub drain system (view 1)

The laundry tub needs a minimum 20 gal. (76 L) capacity. The top of the laundry tub must be at least 39 in. (99 cm) above the floor and no higher than 96 in. (244 cm) from the bottom of the washer.

Floor drain system (view 2)

The floor drain system requires a siphon break that may be purchased separately. See “Alternate Parts.”

The siphon break must be a minimum of 28 in. (71 cm) from the bottom of the washer. Additional hoses might be needed.

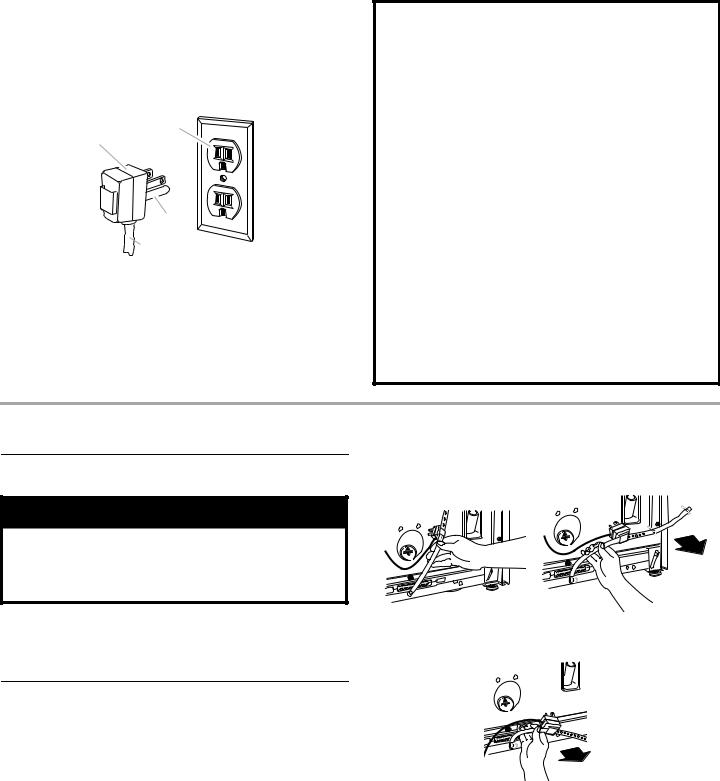

Electrical Requirements

WARNING

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

■A 120-volt, 60-Hz., AC-only, 15or 20-ampere, fused electrical supply is required. Time-delay fuse or circuit breaker is recommended. It is recommended that a separate circuit serving only this appliance be provided.

■This washer is equipped with a power supply cord having a 3 prong ground plug.

■To minimize possible shock hazard, the cord must be plugged into a mating, 3 prong, ground-type outlet, grounded in accordance with local codes and ordinances. If a mating outlet is not available, it is the personal responsibility and obligation of the customer to have the properly grounded outlet installed by a qualified electrician.

3

■If codes permit and a separate ground wire is used, it is recommended that a qualified electrician determine that the ground path is adequate.

■Do not ground to a gas pipe.

■Check with a qualified electrician if you are not sure the washer is properly grounded.

■Do not have a fuse in the neutral or ground circuit.

2

1

3

4

4

1.3 prong grounding plug

2.3 prong grounding-type outlet

3.Ground prong

4.Power supply cord

GROUNDING INSTRUCTIONS

For a grounded, cord-connected washer:

This washer must be grounded. In the event of a malfunction or breakdown, grounding will reduce the risk of electrical shock by providing a path of least resistance for electric current. This washer is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipmentgrounding conductor can result in a risk of electric shock. Check with a qualified electrician or serviceman if you are in doubt as to whether the appliance is properly grounded.

Do not modify the plug provided with the appliance – if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

For a permanently connected washer:

This washer must be connected to a grounded metal, permanent wiring system, or an equipment grounding conductor must be run with the circuit conductors and connected to the equipment-grounding terminal or lead on the appliance.

INSTALLATION INSTRUCTIONS

Before You Start

pins on the end of the shipping strap when it is pulled out of the washer. The electrical plug is attached to this shipping strap.

WARNING

WARNING

Excessive Weight Hazard

Use two or more people to move and install washer. Failure to do so can result in back or other injury.

■To prevent floor damage, set the washer onto cardboard before moving across floor.

■Move the washer to within approximately 3 ft (90 cm) of the final location.

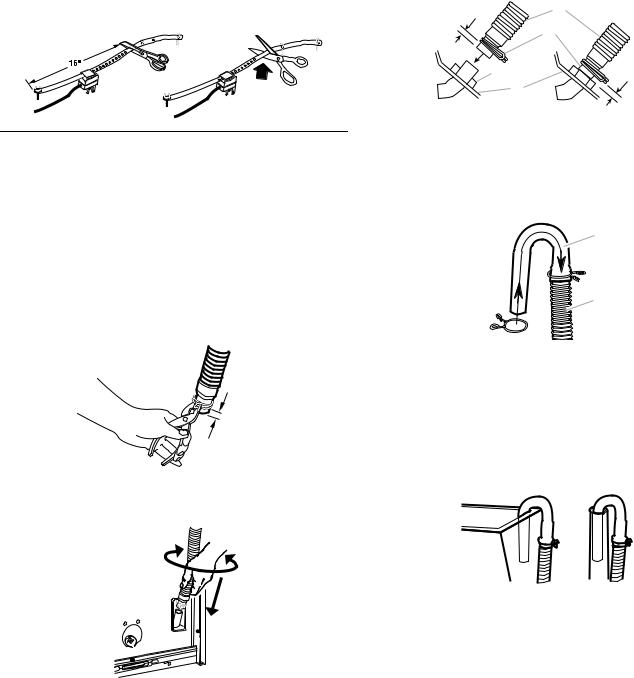

Remove Shipping Strap

Removing the shipping strap is necessary for smooth operation. If the shipping strap is not removed, the washer will make excessive noise. The washer must be in the upright position before removinig the shipping strap.

1.Do not cut yellow strap. Pull yellow strap firmly, until completely removed from washer. There will be two cotter

2.Pull firmly to remove the end of the shipping strap that remains pinned to the back of the washer. This will release the rear self-leveling feet.

4

3.Cut the shipping strap about 16 in. (40 cm) from plug end. Look for the words “CUT HERE.” Discard end with the cotter pins. Slide remainder of shipping strap from the power cord. You will use the remainder of the shipping strap later to secure the drain hose.

HERE

CUT

Connect Drain Hose

Proper connection of the drain hose will protect your floors from damage due to water leakage. To prevent the drain hose from coming off or leaking, it must be installed per the following instructions.

IMPORTANT: To ensure proper installation, this procedure must be followed exactly.

1.Check the drain hose to see if it is the proper length.

2.Wet the inside of the straight end of the drain hose with tap water. DO NOT USE ANY OTHER LUBRICANT.

3.Squeeze ears of silver, double-wire clamp with pliers to open. Place clamp over the straight end of the drain hose ¹⁄ in.

(6 mm) from the end.

1/4"

(6 mm)

4.Open clamp. Twist hose back and forth while pushing down onto drain connector at the bottom of the washer. Continue until hose contacts the ribbed stop on the cabinet.

5

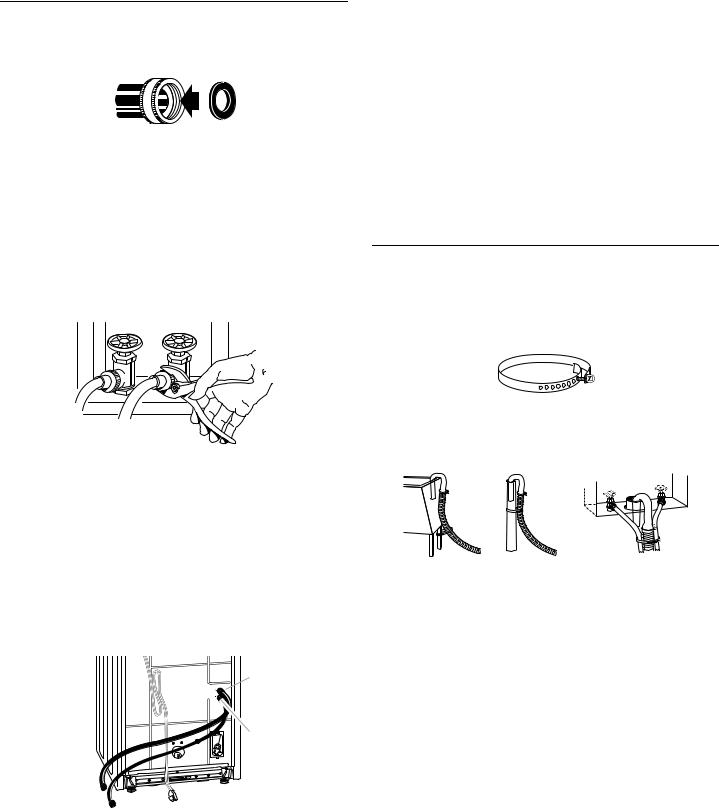

Connect the Inlet Hoses

1.Insert new flat washers (supplied) into each end of the inlet hoses. Firmly seat the washers in the couplings.

12

1.Coupling

2.Washer

Connect the inlet hoses to the water faucets

Make sure the washer basket is empty.

2.Attach the hose with the red coupling to the hot water faucet. Screw on coupling by hand until seated on the washer.

3.Attach the hose with the blue coupling to the cold water faucet. Screw on coupling by hand until seated on the washer.

4.Using pliers, tighten the couplings with an additional twothirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

Clear the water lines

5.Run water through both faucets and inlet hoses, into a bucket or laundry tub, to get rid of particles in the water lines that might clog the inlet valve screens.

Connect the inlet hoses to the washer

6.Attach the hose with the red coupling to the HOT (bottom) inlet valve. Attaching the red coupling first makes it easier to tighten connection with pliers. Screw on coupling by hand until seated on the washer. Using pliers, tighten the couplings with an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

1

1

2

1.Cold water inlet valve (blue)

2.Hot water inlet valve (red)

NOTE: The inlet valve may be on the right or the left side of the washer, depending on your model.

7.Attach the hose with the blue coupling to the COLD water (top) inlet valve. Screw on coupling by hand until seated on the washer. Using pliers, tighten the couplings with an additional two-thirds turn.

NOTE: Do not overtighten. Damage to the valves can result.

Check for leaks

8.Turn on the water faucets and check for leaks. A small amount of water might enter the washer. You will drain this later.

NOTE: Replace inlet hoses after 5 years of use to reduce the risk of hose failure. Record hose installation or replacement dates for future reference.

■If you connect only one water hose, you must cap off the remaining water inlet port.

■Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found.

Secure the Drain Hose

1.Drape the power cord over the console.

2.Remove any cardboard used to move washer.

3.Locate the remaining portion of shipping strap (not the end with the cotter pins) from step 3 of “Remove Shipping Strap.”

Remaining portion of Shipping Strap

4.Wrap the drain hose to the laundry tub leg or standpipe with the tie strap. Push fastener into the nearest hole in the shipping strap. (See illustration 1 or 2 below.)

1 |

2 |

3 |

If the washer faucets and the drain standpipe are recessed, put the hooked end of the drain hose in the standpipe. Tightly wrap the tie strap around the water inlet hoses and the drain hose. (See illustration 3 above.)

6

Loading...

Loading...