Whirlpool LGR4634JQ, LGR4634JT Installation Instructions

29 IN. (73.7 CM) GAS DRYER INSTALLATION INSTRUCTIONS

INSTRUCTIONS POUR L’INSTALLATION DE LA SÉCHEUSE

À GAZ DE 29 PO (73,7 CM)

TableofContents/Tabledesmatières

DRYER SAFETY............................................... |

1 SÉCURITÉ DE LA SÉCHEUSE ............................. |

11 |

INSTALLATION INSTRUCTIONS.................... |

3 |

Tools and Parts ............................................. |

3 |

Location Requirements ................................ |

3 |

Electrical Requirements ................................ |

4 |

Gas Supply Requirements ............................ |

5 |

Venting Requirements................................... |

6 |

Plan Vent System.......................................... |

7 |

Install Vent System........................................ |

8 |

Install Leveling Legs...................................... |

8 |

Level Dryer .................................................... |

9 |

Make Gas Connection .................................. |

9 |

Connect Vent................................................. |

9 |

Reverse Door Swing (Optional)..................... |

9 |

Complete Installation .................................. |

10 |

INSTRUCTIONS D’INSTALLATION...................... |

12 |

Outillage et pièces nécessaires .......................... |

12 |

Emplacement d’installation ................................ |

12 |

Spécifications électriques................................... |

14 |

Alimentation en gaz ............................................ |

14 |

Exigences concernant l’évacuation.................... |

15 |

Planification du système d’évacuation............... |

16 |

Installation du conduit d’évacuation................... |

18 |

Installation des pieds de nivellement.................. |

18 |

Mise à niveau de la sécheuse............................. |

18 |

Raccordement au gaz......................................... |

18 |

Conduit d’évacuation.......................................... |

19 |

Inversion de l’ouverture de la porte (facultatif) ... |

19 |

Achever l’installation ........................................... |

20 |

DRYER SAFETY

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.” These words mean:

DANGER

DANGER

WARNING

WARNING

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can happen if the instructions are not followed.

IMPORTANT SAFETY INSTRUCTIONS

When discarding or storing your old clothes dryer, remove the door.

SAVE THESE INSTRUCTIONS

8535832B

WARNING: For your safety, the information in this manual must be followed to minimize the risk of fire or explosion, or to prevent property damage, personal injury, or death.

–Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

–WHAT TO DO IF YOU SMELL GAS:

•Do not try to light any appliance.

•Do not touch any electrical switch; do not use any phone in your building.

•Clear the room, building, or area of all occupants.

•Immediately call your gas supplier from a neighbor's phone. Follow the gas supplier's instructions.

•If you cannot reach your gas supplier, call the fire department.

–Installation and service must be performed by a qualified installer, service agency, or the gas supplier.

In the State of Massachusetts, the following installation instructions apply:

■Installations and repairs must be performed by a qualified or licensed contractor, plumber, or gasfitter qualified or licensed by the State of Massachusetts.

■If using a ball valve, it shall be a T-handle type.

■A flexible gas connector, when used, must not exceed 3 feet.

2

INSTALLATION INSTRUCTIONS

Tools and Parts

Check that you have everything necessary for correct installation. Proper installation is your responsibility.

■8 in. or 10 in. pipe wrench

■8 in. or 10 in. adjustable wrench (for gas connections)

■Flat-blade screwdriver

■Adjustable wrench that opens to 1 in. (2.5 cm) or hex-head socket wrench (for adjusting dryer feet)

■Level

■¼ in. nut driver or socket wrench

■Knife

■Safety glasses

■Vent clamps

■Pipe-joint compound resistant to L.P. gas

■Caulking gun and compound (for installing new exhaust vent)

■Gloves

■Pliers

Parts supplied:

Remove parts package from dryer drum. Check that all parts were included.

4 leveling legs

Parts needed:

Check local codes and consult gas supplier. Check existing gas supply, electrical supply and venting, and read “Electrical Requirements,” “Gas Supply Requirements” and “Venting Requirements” before purchasing parts.

Mobile home installations require special parts (listed following) that may be ordered by calling the dealer from whom you purchased your dryer. For further information, please reference the front page of your “Dryer User Instructions.”

■Mobile home installation kit. Ask for Part Number 346764.

■Metal exhaust system hardware.

Location Requirements

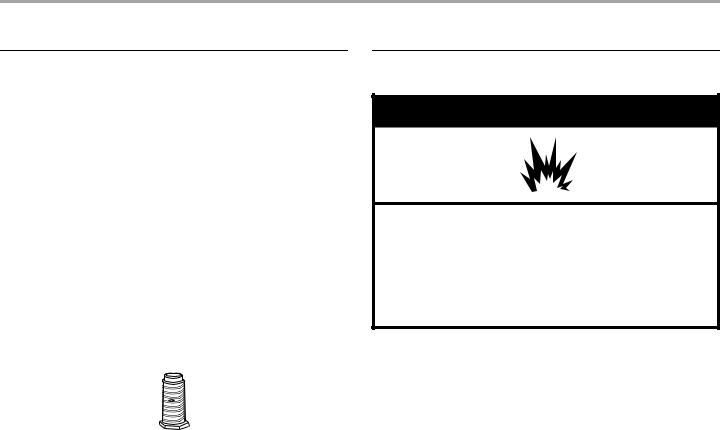

WARNING

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as gasoline, away from dryer.

Place dryer at least 18 inches (46 cm) above the floor for a garage installation.

Failure to do so can result in death, explosion, or fire.

You will need

■A location that allows for proper exhaust installation. A gas dryer must be exhausted to the outdoors. See “Venting Requirements.”

■A grounded electrical outlet located within 2 ft (61 cm) of either side of the dryer. See “Electrical Requirements.”

■A sturdy floor to support the dryer and a total weight (dryer and load) of 200 lbs (90.7 kg). The combined weight of a companion appliance should also be considered.

■A level floor with a maximum slope of 1 in. (2.5 cm) under entire dryer. (If slope is greater than 1 in. [2.5 cm], install Extended Dryer Feet kit, Part No. 279810.) Clothes may not tumble properly and models with automatic sensor cycles may not operate correctly if dryer is not level.

Do not operate your dryer at temperatures below 45ºF (7ºC). At lower temperatures, the dryer might not shut off at the end of an automatic cycle. Drying times can be extended.

The dryer must not be installed or stored in an area where it will be exposed to water and/or weather.

Check code requirements. Some codes limit, or do not permit, installation of the dryer in garages, closets, mobile homes, or sleeping quarters. Contact your local building inspector.

NOTE: No other fuel-burning appliance can be installed in the same closet as a dryer.

3

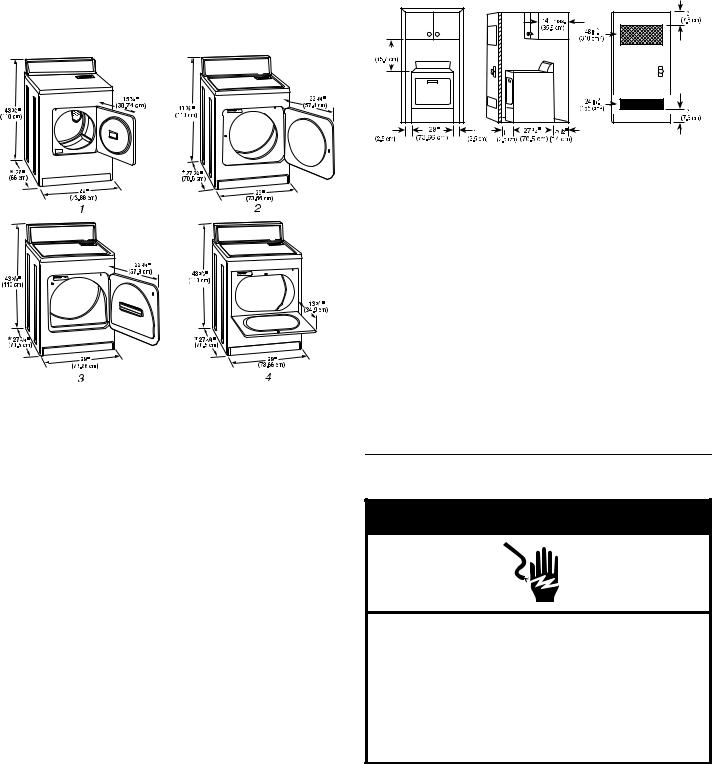

Installation Clearances

The location must be large enough to allow the dryer door to open fully.

Dryer Dimensions

1.Small Opening Side-Swing Door

2.Large Opening Side-Swing Door

3.Wide Opening Side-Swing Door

4.Wide Opening Hamper Door

*Most installations require a minimum 5½ in. (14 cm) clearance behind the dryer for the exhaust vent with elbow. See “Venting Requirements.”

Minimum installation spacing for recessed area or closet installation

The dimensions shown following are for the minimum spacing allowed.

■Additional spacing should be considered for ease of installation and servicing.

■Additional clearances might be required for wall, door and floor moldings.

■Additional spacing of 1 in. (2.5 cm) on all sides of the dryer is recommended to reduce noise transfer.

■For closet installation, with a door, minimum ventilation openings in the top and bottom of the door are required. Louvered doors with equivalent ventilation openings are acceptable.

■Companion appliance spacing should also be considered.

"

"

"

"

1 |

|

|

" |

|

|

" |

|

|

" |

" |

" |

|

|

2 |

3 |

1.Recessed area

2.Side view - closet or confined area

3.Closet door with vents

Mobile Home - Additional Installation Requirements

This dryer is suitable for mobile home installations.

The installation must conform to the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280 (formerly the Federal Standard for Mobile Home Construction and Safety, Title 24, HUD Part 280) or the Canadian Manufactured Home Standard, CAN/CSA-Z240 MH.

Mobile home installations require:

■Metal exhaust system hardware which is available for purchase from your dealer.

■Mobile Home Installation Kit Part #346764. See “Tools and Parts” section for ordering information.

■Special provisions must be made in mobile homes to introduce outside air into the dryer. The opening (such as a nearby window) should be at least twice as large as the dryer exhaust opening.

Electrical Requirements

WARNING

WARNING

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

■120-Volt, 60-Hz., AC-only, 15or 20-amp fused electrical supply is required. (Time-delay fuse or circuit breaker is recommended.) It is recommended that a separate circuit serving only this dryer be provided.

4

IMPORTANT: The dryer must be electrically grounded in accordance with local codes, or in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70 or Canadian Electrical Code, CSA C22.1.

GROUNDING INSTRUCTIONS

■ For a grounded, cord-connected dryer:

This dryer must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path of least resistance for electric current.

This dryer is equipped with a cord having an equipmentgrounding conductor and a grounding plug. The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipmentgrounding conductor can result in a risk of electric shock. Check with a qualified electrician or service representative or personnel if you are in doubt as to whether the dryer is properly grounded. Do not modify the plug provided with the dryer: if it will not fit the outlet, have a proper outlet installed by a qualified electrician.

SAVE THESE INSTRUCTIONS

Gas Supply Requirements

WARNING

WARNING

Explosion Hazard

Use a new AGA or CSA approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas pressure does not exceed 13" (33 cm) water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and authorized service personnel.

Failure to do so can result in death, explosion, or fire.

Gas Type

Natural Gas:

This dryer is equipped for use with NATURAL GAS. It is designcertified by CSA International for L.P. (propane or butane) gases with appropriate conversion.

■Your dryer must have the correct burner for the type of gas in your home. Burner information is located on the rating plate in the door well of your dryer. If this information does not agree with the type of gas available, contact your dealer or call the phone numbers referenced on the front page of your “Dryer User Instructions.”

L.P. gas conversion:

Conversion must be made by a qualified technician.

No attempt shall be made to convert the appliance from the gas specified on the model/serial rating plate for use with a different gas without consulting the serving gas supplier.

IMPORTANT: The gas installation must conform with local codes, or in the absence of local codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 or the Canadian Natural Gas and Propane Installation Code, CSA B149.1.

Gas Supply Line:

■¹⁄ in. IPS pipe is recommended.

■³⁄ in. approved tubing is acceptable for lengths under 20 ft (6.1 m) if local codes and gas supplier permit.

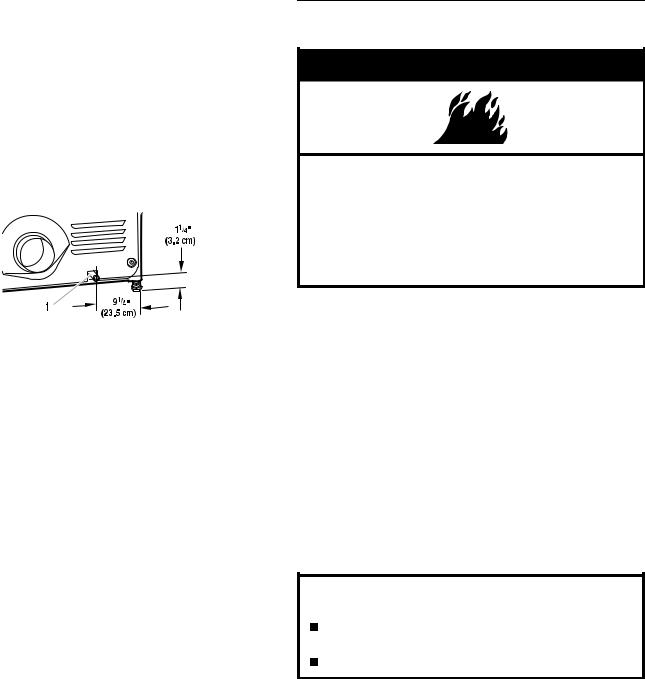

■Must include ¹⁄ in. NPT plugged tapping accessible for test gauge connection, immediately upstream of the gas connection to the dryer (see illustration).

■Must include a shutoff valve:

In the U.S.A.:

An individual shutoff valve must be installed within six (6) feet (1.8 m) of the dryer in accordance with the National Fuel Gas Code, ANSI Z223.1. The location should be easy to reach for opening and closing.

In Canada:

An individual manual shutoff valve must be installed in accordance with the B149, Natural Gas and Propane Installation Code. It is recommended that an individual manual shutoff valve be installed within six (6) feet (1.8 m) of the dryer. The location should be easy to reach for opening and closing.

1 |

|

3 |

5 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

4 |

1.³⁄ in. flexible gas connector

2.³⁄ in. pipe to flare adapter fitting

3.¹⁄ in. NPT plugged tapping

4.½ in. NPT gas supply line

5.Gas shutoff valve

Gas supply connection requirements

There are many methods by which your gas dryer can be connected to the gas supply. Listed here are some guidelines for two different methods of connection.

Option 1 (Recommended Method)

Flexible stainless steel gas connector:

■If local codes permit, use a new flexible stainless steel gas connector (Design Certified by the American Gas Association or CSA International) to connect your dryer to the rigid gas supply line. Use an elbow and a ³⁄ in. flare x ³⁄ in. NPT adapter fitting between the stainless steel gas connector and the dryer gas pipe, as needed to prevent kinking.

Option 2 (Alternate Method)

Approved aluminum or copper tubing:

■Lengths under 20 ft (6.1 m) can use ³⁄ in. approved tubing (if codes and gas supplier permit).

5

■If you are using natural gas, do not use copper tubing.

■³⁄ in. flare x ³⁄ in. NPT adapter fitting between dryer pipe and ³⁄ in. approved tubing.

■Lengths over 20 ft (6.1 m) should use larger tubing and a different size adapter fitting.

■If your dryer has been converted to use L.P. gas, ³⁄ in. L.P. compatible copper tubing can be used. If the total length of the supply line is more than 20 ft (6.1 m), use larger pipe.

NOTE: Pipe joint compounds that resist the action of L.P. gas must be used. Do not use TEFLON®† tape.

Dryer Gas Pipe

■The gas pipe that comes out through the rear of your dryer has a ³⁄ in. male pipe thread.

1. ³⁄ in. NPT dryer pipe

Burner Input Requirements:

Elevations up to 10,000 feet (3,048 meters):

■The design of this dryer is certified by CSA International for use at altitudes up to 10,000 ft (3,048 m) above sea level at the B.T.U. rating indicated on the model/serial number plate. Burner input adjustments are not required when the dryer is operated up to this elevation.

Elevations above 10,000 feet (3,048 meters):

■When installed above 10,000 ft (3,048 m) a 4% reduction of the burner B.T.U. rating shown on the model/serial number plate is required for each 1,000 ft (305 m) increase in elevation.

Gas Supply Pressure Testing

■The dryer must be disconnected from the gas supply piping system during any pressure testing.

†®TEFLON is a registered trademark of E.I. Du Pont De Nemours and Company.

Venting Requirements

WARNING

WARNING

Fire Hazard

Use a heavy metal vent.

Do not use a plastic vent.

Do not use a metal foil vent.

Failure to follow these instructions can result in death or fire.

WARNING: To reduce the risk of fire, this dryer MUST BE EXHAUSTED OUTDOORS.

4 in. (10.2 cm) heavy metal exhaust vent and clamps must be used. DURASAFE™ venting products are recommended.

DURASAFE™ vent products can be purchased from your dealer or by calling Whirlpool Parts and Accessories. For more information, see the “Assistance or Service” section of your “Dryer User Instructions.”

■The dryer exhaust must not be connected into any gas vent, chimney, wall, ceiling, or a concealed space of a building.

■Do not use an exhaust hood with a magnetic latch.

■Do not install flexible metal vent in enclosed walls, ceilings or floors.

■Use clamps to seal all joints. Exhaust vent must not be connected or secured with screws or other fastening devices which extend into the interior of the duct. Do not use duct tape.

IMPORTANT: Observe all governing codes and ordinances.

Improper venting can cause moisture and lint to collect indoors, which may result in:

Moisture damage to woodwork, furniture, paint, wallpaper, carpets, etc.

Housecleaning problems and health problems.

Use a heavy metal vent. Do not use plastic or metal foil vent. Rigid metal vent is recommended to prevent crushing and kinking.

Flexible metal vent must be fully extended and supported when the dryer is in its final position. Remove excess flexible metal vent to avoid sagging and kinking that may result in reduced airflow and poor performance.

An exhaust hood should cap the vent to prevent rodents and insects from entering the home.

Exhaust hood must be at least 12 in. (30.5 cm) from the ground or any object that may be in the path of the exhaust (such as flowers, rocks or bushes, etc.).

If using an existing vent system, clean lint from the entire length of the system and make sure exhaust hood is not plugged with lint. Replace any plastic or metal foil vent with rigid metal or flexible metal vent.

6

Loading...

Loading...