Whirlpool AGB 516/WP, AGB 524/WP, AGB 522/WP, AGB 525/WP, AGB 523/WP INSTRUCTION FOR USE

...

005_03

Instructions for installation,

use and maintenance

06/2007

ELECTRIC FRYER

AGB 597/WP · AGB 521/WP

AGB 515/WP · AGB 598/WP

AGB 523/WP · AGB 516/WP

AGB 522/WP · AGB 514/WP

AGB 524/WP · AGB 525/WP

Models and dimensions page 3

Technical data 4

Installation instructions 5

Installation 5

Legal and technical requisites 5

Installation 5

Wiring 5

Unipotential 5

Start-up 5

Using the appliance 6

Ignition 6

Emptying the bath 6

Cleaning and taking care

of the appliance

page 6

What to do if not using the appliance for

a long time 6

What to do if something goes wrong 6

Maintenance 6

WEEE Directive 7

Wiring diagrams 8-12

Warning 13

INDEX

005-03 - Electric fryer

2

005-03 - Electric fryer

3

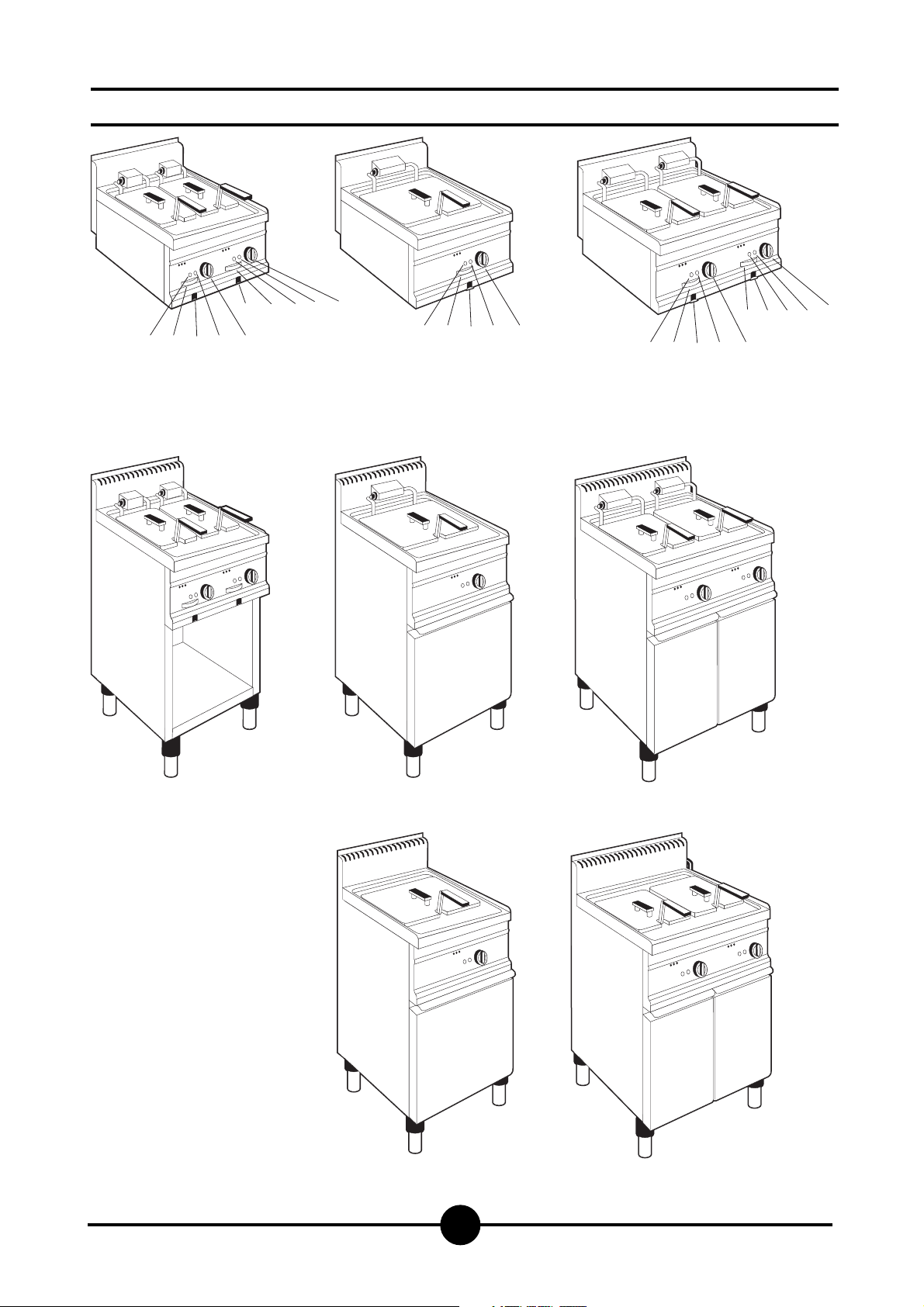

Dimensions

A

B

C

D

E

Main switch

Oil outlet drive

Pilot lamp (voltage)

Pilot lamp (resistences)

Oil outlet

400 x 650 x 270

Weight approx.

21 kg

AGB 514/WP

400 x 700 x 510

Weight approx.

21 kg

AGB 597/WP

400 x 650 x 270

Weight approx.

21 kg

AGB 515/WP

400 x 700 x 510

Weight approx.

21 kg

AGB 598/WP

600 x 650 x 270

Weight approx.

33 kg

AGB 516/WP

600 x 700 x 510

Weight approx.

33 kg

AGB 522/WP

400 x 700 x 875

Weight approx.

51 kg

AGB 521/WP

400 x 700 x 875

Weight approx.

51 kg

AGB 523/WP

600 x 700 x 875

Weight approx.

85 kg

AGB 524/WP

400 x 700 x 875

Weight approx.

53 kg

AGB 525/WP

800 x 700 x 875

Weight approx.

96 kg

CBEDA

EBCDA

CBEDA

CBEDA

BE CD A

Technical data

The data plate is located on the front of the appliance and

contains all the data needed for connecting it up to the

mains electricity supply.

005-03 - Electric fryer

4

FRYER

CAT/KAT GAS/GAZ G30 G31 G20 G25

II2H3B/P P mbar 30 30 20 -

II2H3+ P mbar 30 37 20--

II2H3+ P mbar 28 37 20 -

TIPO/TYPE

MOD.

ART.

N.

N.

Qn kW

MOD.

V AC kW Hz

THE APPLIANCE MUST BE CONNECTED IN COMPLIANCE WITH THE LAWS IN FORCE

AND INSTALLED IN A WELL-VENTILATED ROOM. READ THE INSTRUCTION MANUALS

BEFORE INSTALLING AND USING THE APPLIANCE.

THE APPLIANCE MUST BE INSTALLED BY QUALIFIED PERSONNEL.

II2ELL3B/P P mbar 50 50 20 20

II2E+3+ P mbar 28 37 20 25

II2H3B/P P mbar 50 50 20 -

I2E P mbar - - 20 -

II2H3+ P mbar 28 37 20 -

I3B/P P mbar 30 30

m3/h

I3+ P mbar 28 37

Predisposto a gas: - Gas preset: - Prevu pour gaz:

Eingestelt für Gas: - Preparado para gas: -

--II2H3B/P P mbar 30 30

--

--

Geschuckt voor:

SE FI DK CZ SK SI

IT CH PT

ES IE GB GR

NL

25II2L3B/P P mbar 30 30

DE

FR BE

AT CH

LU

EE LV LT

EE LV LT

NO MT CY IS HU

CY

MADE IN ITALY

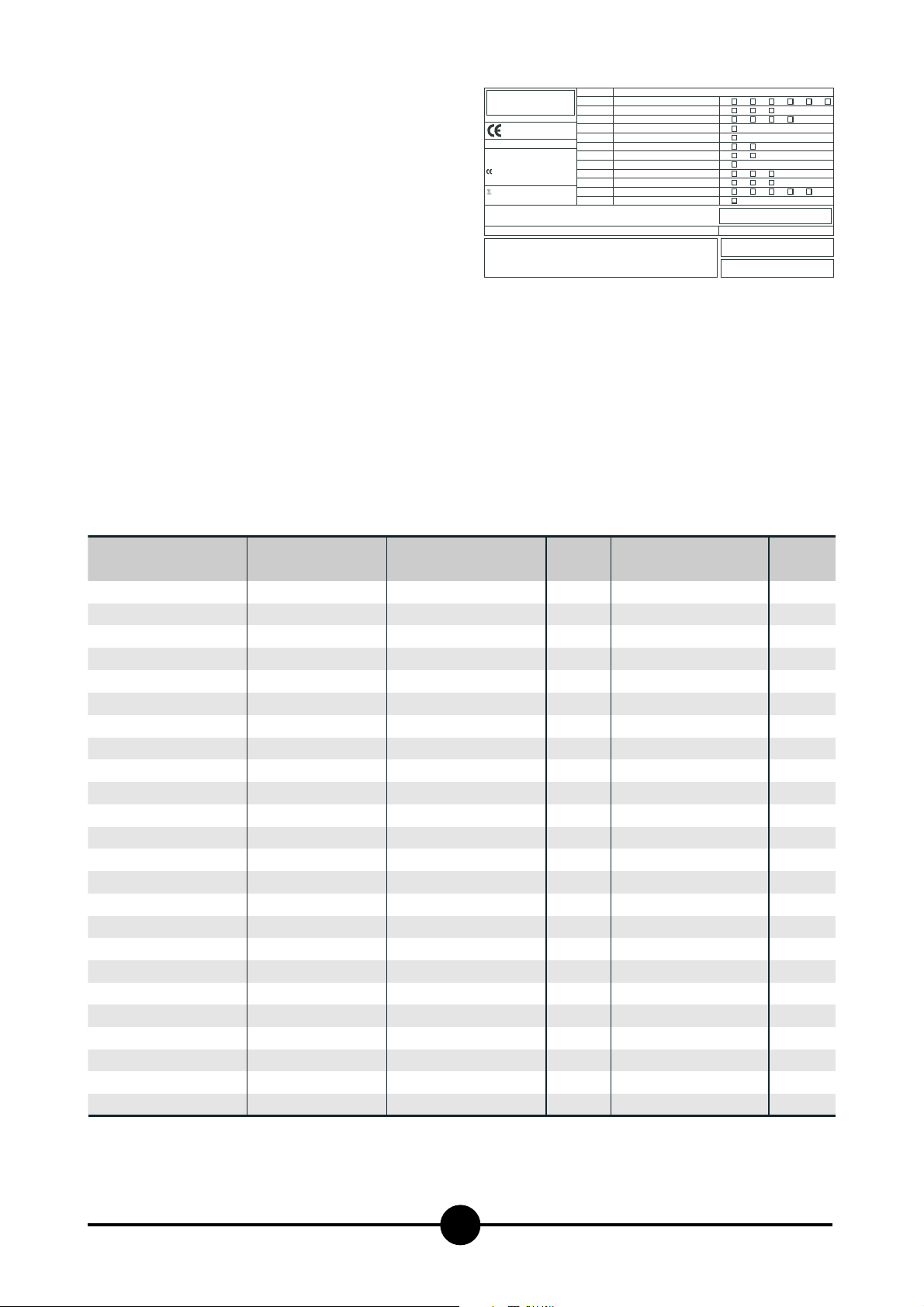

Model

AGB 597/WP

AGB 521/WP

AGB 515/WP

AGB 598/WP

AGB 523/WP

AGB 516/WP

AGB 522/WP

AGB 514/WP

AGB 524/WP

AGB 525/WP

Dim.: LxWxH

400 x 615 x 300

400 x 700 x 875

400 x 700 x 300

600 x 615 x 300

600 x 700 x 875

600 x 700 x 300

400 x 615 x 300

400 x 700 x 875

400 x 700 x 300

400 x 700 x 875

800 x 700 x 875

Voltage rating

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

230 V 3 AC or 400 V 3N AC

Power

7.5 kW

7.5 kW

7.5 kW

15.0 kW

15.0 kW

15.0 kW

6.2 kW

6.2 kW

6.2 kW

12.0 kW

24.0 kW

Lead wire / Section

4 x 2.5 mm

4 x 2.5 mm

4 x 2.5 mm

4 x 6 mm

4 x 6 mm

4 x 6 mm

4 x 2.5 mm

4 x 2.5 mm

4 x 2.5 mm

4 x 6 mm

4 x 10 mm

2

or 5 x 1.5 mm

2

or 5 x 1.5 mm

2

or 5 x 1.5 mm

2

or 5 x 2.5 mm

2

or 5 x 2.5 mm

2

or 5 x 2.5 mm

2

or 5 x 1.5 mm

2

or 5 x 1.5 mm

2

or 5 x 1.5 mm

2

or 5 x 2.5 mm

2

or 5 x 6 mm

2

2

2

2

2

2

2

2

2

2

2

Before beginning installation, remove all packaging from

the appliance. Some parts are protected with an adhesive

film which should be carefully removed.

Any remnants of glue should be thoroughly cleaned using

suitable substances such as benzine. Under no circumstances should abrasive substances be used.

Fit the legs to the appliance; the appliance must be levelled using a spirit level. Slight irregularities can be levelled

by adjusting the feet themselves.

With table models, make sure that the base chosen is capable of supporting the weight of the appliance. The main

switch or plug should be located in the vicinity of the appliance and easy of access. We recommend installing the

machine under a range hood so that all the fumes are removed as quickly as possible. If the appliance is to be installed near walls, dividing walls, kitchen equipment or decorative pannelling, these should be in non-inflammable

material or covered with non-inflammable material.

Make sure that all fire prevention standards and safety precautions are strictly adhered to.

Warning!

MODEL AGB 521/WP, AGB 522/WP, AGB 524/WP

If this model is going to be mounted on its own, it must

be fixed to the floor. Fixing accessories are included.

The appliance should be fitted following the indications given in the drawing below.

Warning!

With Top models, carefully measure the distance

between the appliance and the edge of the base (Fig. 2).

Legal and technical requisites

When installing the appliance, the following safety standards must be adhered to:

- Local accident prevention standards

- Current CEI standards.

Installation

Installation, start-up and maintenance should only be carried out by expert personnel. All work required to install

the appliance should be carried out in compliance with all

local standards and regulations. The manufacturers decline all responsibility where poor performance is due to incorrect installation in disregard of the above conditions.

Warning!

In compliance with international regulations, when

connecting the appliance to the mains power supply, a

device with a minimum aperture of 3 mm between contacts must be fitted upstream of the appliance, allowing omnipolar disconnection of the appliance from

the mains.

Wiring

When choosing the lead wire, make sure it has the following characteristics: it should be at least of the H07 RN-F

type and its section should be large enough for the appliance (see "Technical specifications and dimensions",

page 4).

Wire entry on top models is on the back wall, and underneath all other models. In both cases the terminal board is

at the front, behind the control panel.

Pass the wire through the core hitch and wire clamp, plug

the leads into their terminals on the board and secure

them.

The earth lead must be a little longerthan the others so

that it is the last lead to disconnect if the wire clamp

breaks.

Unipotential

The appliance must be connected up to a unipotential system. The connection screw is located on all top models at

the back on the right hand side, while in other models it is

located underneath the appliance on the right hand side.

It is labelled.

Warning!

The manufacturers cannot be held responsible for any

damage due to inadequate or incorrect installation.

Under such circumstances the guarantee will be considered null and void.

Start-up

Before using the appliance for the first time, thoroughly

clean out the oil bath (see paragraph entitled “Cleaning

and Taking Care of the Appliance”).

Check that the appliance is connected up properly and

start according to instructions overleaf.

INSTALLATION INSTRUCTIONS

005-03 - Electric fryer

5

1

RETRO

BACK

ARRIERE

RÜCKSEITE

Warning!

- Beware of inexpert handling!

- Old and dirty oil or frying fat can represent a real fire

hazard; make sure only new oil or frying fat are used

each time you start frying.

- The food you intend to fry should always be dry; wet

food causes the oil to foam and overflow.

- Frying excessively large quantities of food at a time

also causes the oil to foam; never exceed 1.5 kg.

- If the level of oil in the bath falls below the low level

mark stamped on it, the risk of fire will increase.

- Never leave the appliance on without any oil in it. The

lid delivered with the appliance should always be kept

within easy reach. In case of fire, it should be used to

douse the flames.

Ignition

Check that the oil drain release is closed. Fill the bath with

oil up to the level marked. Turn on the main switch

upstream of the appliance. Turn the knob from ‘0’ to any

temperature between 100°C and 195°C; the pilot lights will

come on. The green light means that the appliance is on,

while the orange one indicates that the resistances are on.

As soon as the required temperature is reached, the orange light will go off. To turn the appliance off, simply turn

the knob back to '0'.

Emptying the bath

First of all a suitable bowl for emptying the oil into should

be found. The bowl should be heat-resistant and designed

not to allow the oil to spill when the bath is being emptied,

since this could be very dangerous. A bowl with these requisites is available separately as an optinal extra from our

sales department. Fit the drainage pipe as shown in the

picture (2). Open the oil drain tap.

Important

With Top models, make sure you respect the distance

between the appliance and the edge of the base.

CLEANING AND TAKING CARE OF THE

MACHINE

Warning!

Never clean the appliance with jets of water, whether

direct or pressurised.

Allow the machine to cool down before cleaning

Before starting to clean the appliance, disconnect from

the mains. Using the hook provided (see drawing 3), you

can lift out the elements to make cleaning the appliance

easier and far more thorough. Lift the elements as far as

they will go. To lower them after cleaning, press the button

on the left hand side. All steel parts should be washed in

warm water, using a neutral detergent, then rinsed thoroughly to eliminate any residual detergent. Dry using a dry

cloth. Avoid using abrasive or corrosive detergents which

could damage the steel.

What to do if not using the appliance

for a long time

Thoroughly clean and dry the machine as described.

Disconnect the power supply.

What to do if something goes wrong

If anything goes wrong, immediately turn the appliance

off, then turn off the power supply at the switch located

upstream of the appliance, and call the aftersales department.

MAINTENANCE

All maintenance should be carried out by qualified personnel only. Before carrying out any maintenance work,

unplug the appliance or turn off the switch upstream of the

appliance.

USING THE APPLIANCE

005-03 - Electric fryer

6

2

3

MAX 120 mm

005-03 - Electric fryer

7

THE 2002/96/EC DIRECTIVE (WEEE):

information to users

This informational note is meant only for owners

of equipment marked with the symbol shown in

Fig. A on the adhesive label featuring the technical specifications applied on the actual pro-

duct (the label also giving the serial number).

This symbol indicates that the product is classified, according to the regulations in force, as an item of electrical

and electronic equipment and conforms to EU Directive

2002/96/EC (WEEE) meaning that, at the end of its service

life, it must be treated separately from domestic waste,

i.e. it must be handed in free of charge to a separate waste electrical and electronic equipment collection centre

or returned to the reseller when buying a new equivalent

item of equipment.

The user is responsible for delivering the unit at the end of

its life to the appropriate collection facilities. Failure to do

so shall result in the user being subject to the penalties

prescribed by the legislation in force on waste.

Suitable separated collection so that the unit no longer

used can be sent off for environmentally compatible recycling, treatment and disposal helps avoid possible negative effects on the environment and on health and facilitates the recycling of the product's component materials.

For more detailed information on available collection systems, contact the local waste disposal service or the

shop you purchased the unit from.

Producers and importers fulfil their responsibility for environmentally compatible recycling, treatment and disposal

both directly and by joining a collective scheme.

005-03 - Electric fryer

8

400 V 3N

400 V 3N

AGB 597/WP

AGB 521/WP

AGB 515/WP

AGB 598/WP

AGB 523/WP

AGB 516/WP

mA

mC

B1

B2

C1

F1

F2

H1

H2

R

Line input terminal board

Commutating terminal board

Switch

Microswitch

Contactor

Working thermostat

Safety thermostat

Green pilot lamp

Orange pilot lamp

Resistance

Wiring diagrams

L1

1

L2

2

L3

3

N

4

5

mA

L1

1

L2

2

L3

3

N

4

5

H1

F1

1

2

3

4

5

6

13

14

A1

C1

H1

1

2

3

4

5

6

13

14

A1

A2

A2

11

21

31

P4

P3

P2

P1 1

B1

F1

11

21

31

12

22

32

4

3

2

12

22

32

H2

H2

F2

mC

L3

L2

L1

N

B2

mC

L3

L2

L1

N

R

R

mA

C1

P4

4

3

P3

P2

2

P1 1

H1

1

2

3

4

5

6

13

14

A2

A1

C1

B1

F1

11

21

31

P4

P3

P2

P1 1

12

22

32

4

3

2

F2

H2

F2

mC

L3

L2

L1

N

B2

R

B2

B1

005-03 - Electric fryer

9

230 V 3

230 V 3

AGB 597/WP

AGB 521/WP

AGB 515/WP

AGB 598/WP

AGB 523/WP

AGB 516/WP

mA

mC

B1

B2

C1

F1

F2

H1

H2

R

Line input terminal board

Commutating terminal board

Switch

Microswitch

Contactor

Working thermostat

Safety thermostat

Green pilot lamp

Orange pilot lamp

Resistance

Wiring diagrams

1

L1

L2

2

L3

3

4

5

mA

L1

1

L2

2

L3

3

4

mA

A1

A1

H1

F1

1

2

3

4

5

6

C1

H1

2

1

4

3

6

5

A2

A2

11

21

31

P4

P3

P2

P1 1

B1

F1

11

21

31

12

22

32

4

3

2

12

22

32

H2

H2

F2

mC

N

L3

L2

L1

B2

mC

N

L3

L2

L1

R

R

A1

C1

P4

4

3

P3

P2

2

P1 1

B1

H1

F1

1

2

3

4

5

6

C1

A2

11

21

31

P4

P3

P2

P1 1

12

22

32

4

3

2

F2

H2

F2

B2

mC

N

L3

L2

L1

B2

R

B1

005-03 - Electric fryer

10

AGB 522/WP

AGB 514/WP

mA

B1

B2

T1

T2

T3

C1/C2

R1

H1

H2

Line input terminal board

Switch

Microswitch

Thermostat

Safety thermostat

Safety thermostat

Contactor

Resistance

Green pilot lamp

Orange pilot lamp

Wiring diagrams

H2

H1

R1

C1

T2

21

11

22

12

23

13

A1

A2

B2

T1

H2

H1

R1

C1

T3

21

11

22

12

23

A1

A2

13

B2

T1

1mA 2 3 4

L1 L2 L3 N

400V 3N

2

1

P1

P2

56

PE

B1

1mA 2 3 4

L1 L2 L3

230 V 3

T3

56

PE

2

1

B1

P1

P2

005-03 - Electric fryer

11

1m2 34

mA

mC

B1

B2

C1

C2

F1

F2

H1

H2

R

Wiring diagrams

Line input terminal board

Commutating terminal board

Switch

Microswitch

Safety contactor

Adjusting contactor

Adjusting thermostat

Safety thermostat

Green pilot lamp

Orange pilot lamp

Resistance

AGB 524/WP

mC

2 4

6

135

R

C2

B2

1mA 2 3 4

L1 L2 L3 N

400V 3N

1mA 2 3 4

L1 L2 L3

230V 3

C1

B1

56

PE

56

PE

F2

6 2 4

H1

F1

1 2 34

mC

H2

1 3 5

005-03 - Electric fryer

12

mA

mC

B1

B2

C1

C2

F1

F2

H1

H2

R

Wiring diagrams

Line input terminal board

Commutating terminal board

Switch

Microswitch

Safety contactor

Adjusting contactor

Adjusting thermostat

Safety thermostat

Green pilot lamp

Orange pilot lamp

Resistance

AGB 525/WP

1m2 34

mC

2 4

6

135

2 4

6

R

135

1m2 34

mC

C2

B2

C1

B1

F2

H1

F1

H2

R

C2

B2

C1

B1

F2

H1

F1

H2

1mA 2 3 4

L1 L2 L3 N

400V 3N

56

PE

1mA 2 3 4

L1 L2 L3

230V 3

56

PE

6 2 4

mC

1 3 5

1 2 34

005-03 - Electric fryer

13

WARNING

DUE TO ITS POLICY OF CONTINUAL PRODUCT IMPROVEMENT, THE MANUFACTURER RESERVES THE RIGHT

TO MAKE ANY CHANGES DEEMED NECESSARY.

THE MANUFACTURER CANNOT BE HELD RESPONSIBLE IF THE INSTRUCTIONS CONTAINED IN THIS MANUAL ARE NOT OBSERVED.

THIS DOCUMENTATION IS ONLY INTENDED FOR

QUALIFIED TECHNICIANS WHO ARE AWARE OF THE

RESPECTIVE SAFETY REGULATIONS.

WHIRLPOOL EUROPE srl

V.le Guido Borghi, 27

I – 21025 Comerio – VA

Loading...

Loading...