Installation Instructions

for 49572A L.P. (Propane and Butane)

Gas Conversion Kit

Converting 22,000 BTU/hr Gas Burners from Natural Gas to Liquefied

Petroleum (Bottled Gas)

Parts included in Kit:

1 Instruction Sheet

1 Blocking Pin

1 Orifice, Burner-Butane No. 55

1 Orifice, Burner-Propane No. 54

1 Label, Rating Plate Conversion (English)

1 Label, Rating Plate Conversion (French)

1 Label, Conversion Record (English)

1 Label, Conversion Record (French)

1 Label, Burner Baseplate (English/French )

NOTE: This instruction sheet contains information for converting two different design gas valves. Read

instructions thoroughly and follow steps.

Warning: This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements of the

authority having jurisdiction. The information in these

instructions must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury, or

death. The qualified service agency is responsible for the

proper installation of this kit. The installation is not proper and

complete until the operation of the converted appliance is

checked as specified in the manufacturer’s instructions

supplied with this kit.

NOTE: A qualified service technician is any person or

representative of a company who is experienced or trained in

servicing gas equipment and is familiar with necessary

precautions.

Canada Only

THIS CONVERSION KIT SHALL BE CARRIED OUT IN

ACCORDANCE WITH THE REQUIREMENTS OF THE

PROVINCIAL AUTHORITIES HAVING JURISDICTION AND

IN ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN-B49.1 AND CAN1-B149.2 INSTALLATION CODE.

NOTE: Read these instructions before proceeding.

IMPORTANT: The LP Conversion Kit you received is an

approved kit for converting your gas dryer from natural to LP

propane or butane gas. The kit no. shown on the Burner Data

Label located on the Burner Base may not match the kit you

receive due to kit consolidation.

Do not use on burner assembly no. 693037.

This dryer has been manufactured for use with Natural (city)

gas. Installation of this conversion kit converts the dryer for use

with L.P. gas with manifold pressure of 10” water column and

supply pressure between 8” and 13” water column. If this dryer

is converted for use with L.P. gas by means of this kit, the input

rating will be 22,000 BTU’s per hour, for altitudes up to 10,000

Instruction Sheet W10367612 Rev A 12/10 - 1 -

feet. For installations above 10,000 feet, contact a qualified

service agency

GAINING ACCESS TO BURNER ASSEMBLY

1. Unplug dryer or disconnect power.

2. Turn off gas supply using the shut-off valve that supplies

the dryer.

3. Fill out information on conversion decal and apply in a

conspicuous location adjacent to model and serial tag

located in the door well.

4. Remove toe panel. On some models, a small flat-head

screwdriver is required to release the clips at the top of the

toe panel. Then proceed to step 10. If dryer has full front

panel proceed to step 5.

5. Remove the lint screen. Remove the two (2) screws from

the lint screen area.

6. Raise dryer top by pulling forward on the back corners and

up on front corners (top is hinged at rear). Lean dryer top

toward the wall, taking precautions not to damage the

dryer top or wall. Position top so it cannot fall.

7. Remove wire harness clip and door switch wires from front

r

panel.

8. Remove the two (2) internal screws from the upper inside

edge of the front panel flanges. Using gloves, lift front

panel off the lower clips (front of drum will drop slightly).

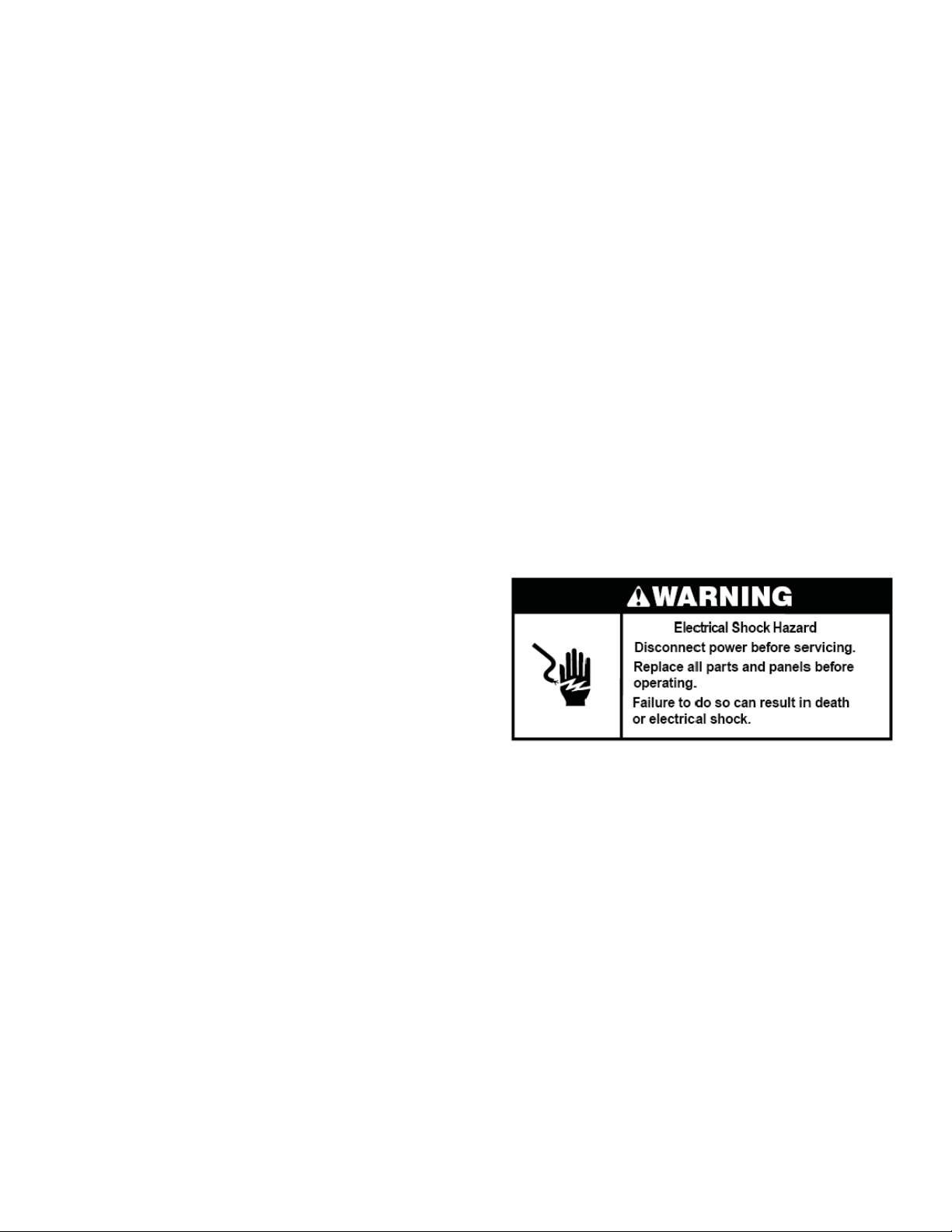

Set front panel aside. See Figure 1.

11. Remove the burner tube from the burner assembly by

removing two (2) screws securing it to the burner base.

See Figure 4.

FIGURE 1

9. Remove drum belt by lifting idler pulley upward and sliding

belt off of motor pulley. Remove drum from cabinet.

See Figure 2.

FIGURE 2

10. Disconnect ignitor connector from the main harness ignitor

connector. See Figure 3.

NOTE: The ignitor is fragile.

Main

Harness

FIGURE 4

CHANGING THE ORIFICE

12. Remove the burner orifice from the valve and replace it

with the proper orifice furnished in this kit. Orifice number

is stamped on one edge of the hex head of orifice.

Securely tighten. See Figure 4.

Use Orifice No. 54 for Propane gas.

Use Orifice No. 55 for Butane gas.

13. Put the burner tube back on the burner assembly.

Securely tighten the two (2) mounting screws. Reconnect

the ignitor to the harness. See Figure 3 and 4.

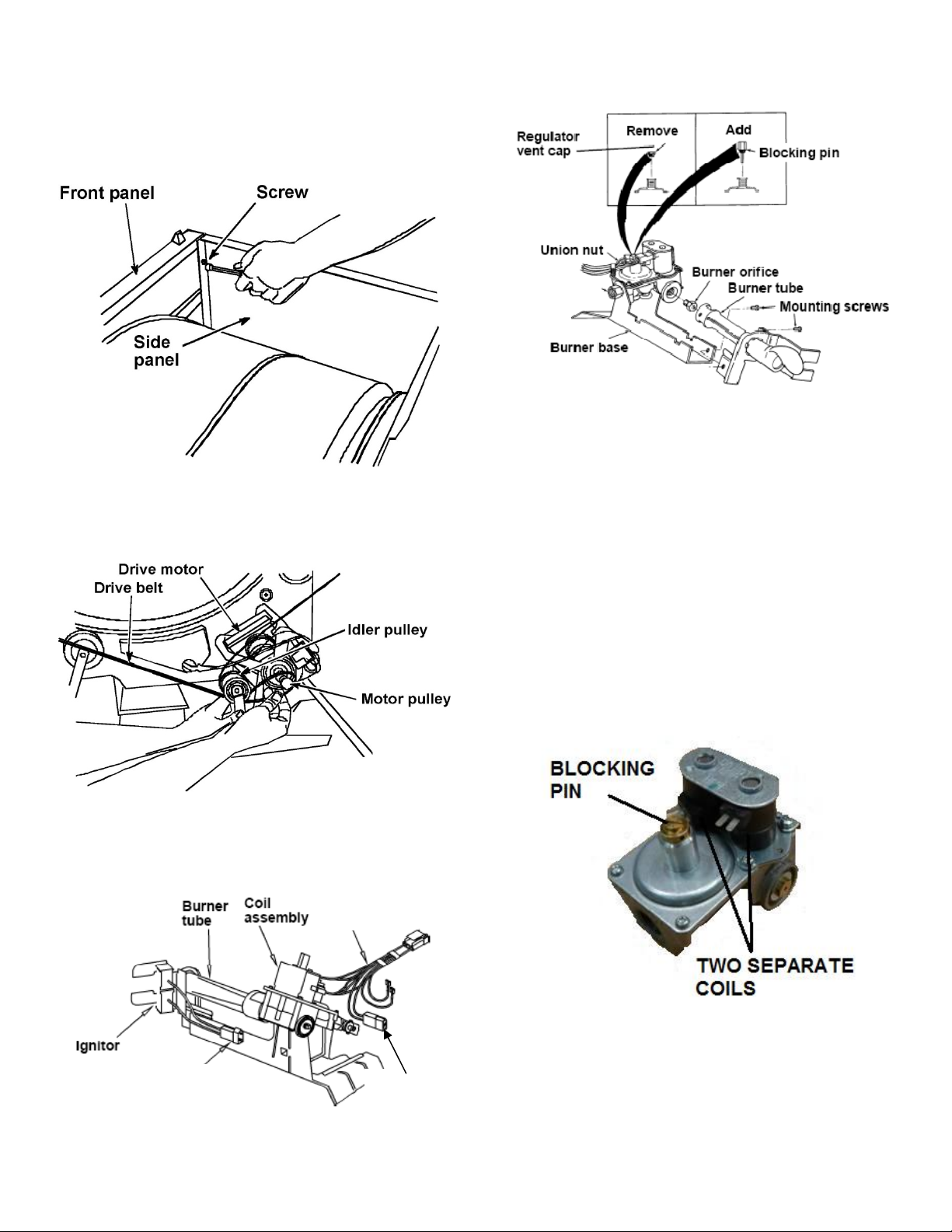

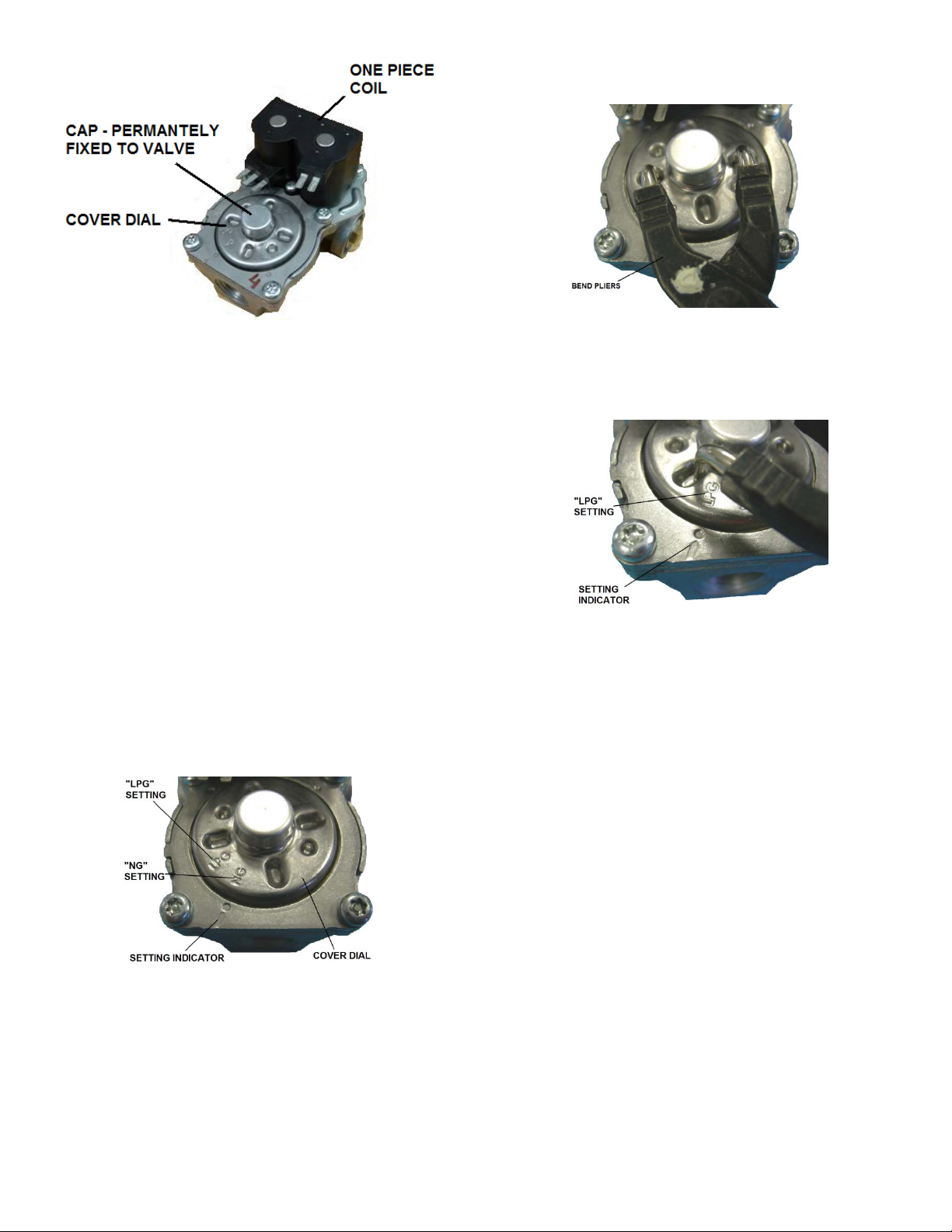

14. Before proceeding, you must first determine which gas

valve style is on the unit.

Refer to Figure 5 - Style “A” and “B”.

FIGURE 5 - STYLE “A”

Ignitor

Connecto

FIGURE 3

Main Harness

Ignitor Connector

- 2 - W10367612A

19. Position a pair of bend pliers into the slots of the cover dial.

See Figure 6.

FIGURE 5 - STYLE “B’

NOTE: IF YOUR GAS DRYER HAS STYLE “A” FOLLOW

STEPS 15 TO 17. FOR STYLE “B” FOLLOW STEPS 18 TO 21.

STYLE A GAS VALVE CONVERSION

15. Remove the regulator vent cap (leak limiting device) from

the pressure regulator. See Figure 4.

16. Install the new blocking pin fin ger-tight. Do not tighten

more than 1/8 turn to seal it. See Figure 4.

17. Apply English or French conversion decal on top of the

burner data decal located on the burner baseplate.

NOTE: Proceed to next section ‘Installation Checklist’

STYLE B GAS VALVE CONVERSION

18. Observe the cover dial settings indicated as NG (Natural

gas) and LPG (Liquefied Propane gas) along with the gas

type indicator. See Figure 5.

FIGURE 6

FIGURE 6

20. Rotate cover dial 25 degrees counter clockwise lining up

“LPG” marking with the indicator on the gas valve.

See Figure 7.

FIGURE 7

21 Apply English or French conversion label on top of the

burner data decal located on the burner baseplate.

NOTE: The blocking pin included with this kit is NOT used

with Style “B” gas valve.

Installation Checklist

Check that both labels have been installed as described in

steps 3, 17 or 21

If converting to Propane, check that the number 54 is not

marked on either of the remaining orifices. If converting to

Butane, check that the number 55 is not marked on either

of the remaining orifices.

Check that the regulator vent cap has been replaced by

the blocking pin as in Figure 4. (Style “A’ application only)

W10367612A - 3 -