Whirlpool 3354199 User Manual

IMPORTANT

Installer:

Owner:

Save

Leave Installation lnstructlons

with the owner.

Keep lnstallatlon Instructions for

future reference.

Installation Instructions for local

electrtcal Inspector’s use.

I

~

Part No. 3354199 Rev A

COMMERCIAL

WASHER

I

1 120volt, 60 Hz Models 1

7

PRODUCTS

Before you start.. .

Check location where washer will

be installed. Proper installation is

your responsibility Make sure you

have everything necessary for

correct installation,

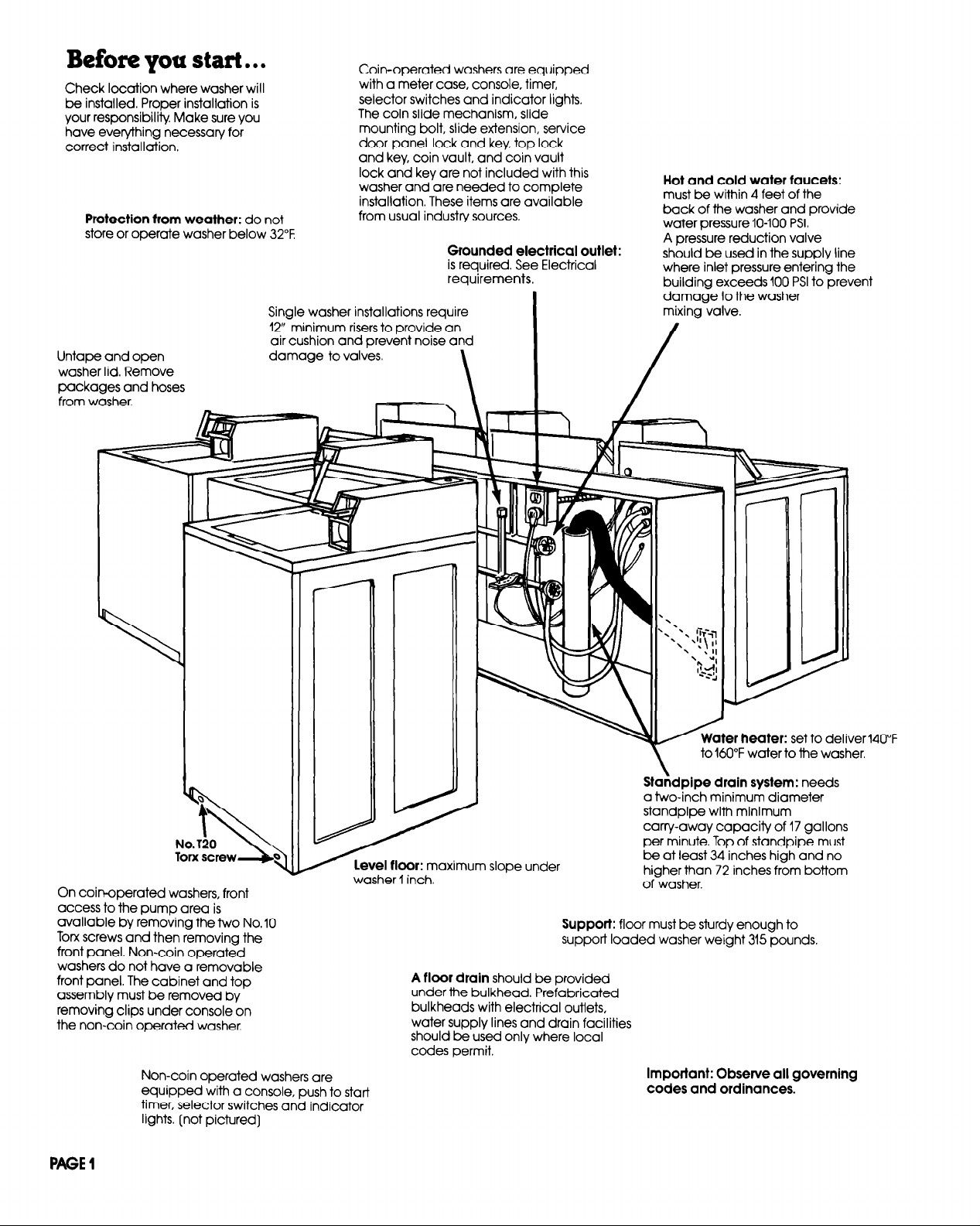

Protection from weather: do not

store or operate washer below 32°F

Untape and open

washer lid. Remove

packages and hoses

7

washer.

fron

Coin-operated washers are equipped

with a meter case, console, timer,

selector switches and indicator lights.

The coin slide mechanism, slide

mounting bolt, slide extension, service

door panel lock and key, top lock

and key, coin vault, and coin vault

lock and key are not included with this

washer and are needed to complete

installation. These items are available

from usual industry sources.

Grounded electrical outlet:

is required. See Electrical

requirements.

Single washer installations require

V’minimum risers to provide an

air cushion and prevent noise and

damage to valves.

I

\I /

Hot and cold water faucets:

must be within 4 feet of the

back of the washer and provide

water pressure IO-100 PSI.

A pressure reduction valve

should be used in the supply line

where inlet pressure entering the

building exceeds 100 PSI to prevent

damage to the washer

mixing valve.

On coin-operated washers, front

access to the pump area is

available by removing the two No. 10

Tot-x screws and then removing the

front panel. Non-coin operated

washers do not have a removable

front panel. The cabinet and top

assembly must be removed by

removing clips under console on

the non-coin operated washer.

Non-coin operated washers are

equipped with a console, push to start

timer, selector switches and indicator

lights. (not pictured]

PAGE1

9

level floor: maximurr

washer 1 inch.

I slope under

Support: floor must be sturdy enough to

support loaded washer weight 315 pounds.

A floor drain should be provided

under the bulkhead. Prefabricated

bulkheads with electrical outlets,

water supply lines and drain facilities

should be used only where local

codes permit.

r heater: set to deliver

“F water to the washer.

Staidpipe drain system: needs

a two-inch minimum diameter

standpipe with minimum

carry-away capacity of 17 gallons

per minute. Top of standpipe must

be at least 34 inches high and no

higher than 72 inches from bottom

of washer.

Important: Observe all governing

codes and ordinances.

.14o”F

TooIs needed for

instaIIation:

Parts supplied

for fnstalIation:

Remove parts from packages, Check

that all parts were included.

1 hose clamp

2 inlet hoses

4 flat water

hose washers

2 front leveling

legs with nuts

grounding clamp

and screw

1 drain hose

PAGE 2

Electrical

requirements

Electrical Shock Hazard

l

Electrical ground is required on

this product.

l

Improper connection of the

equipment-groundtng conductor

can result in electrical shock.

l

Check with a quallfled

electrician If you are In doubt as

to whether the appliance is

properly grounded.

l

Do Not modify the power supply

cord plug. If It will not fit the

outlet, have a proper outlet

installed by a quallfied electrician. Modifying the power

supply cord plug could result in

electrical shock.

l

Do Not use an extension cord

with thts appltance. Such use

could result in a fire, electrical

shock or other personal injury.

l

Do Not have a fuse in the neutral

or grounding circuit. This could

result In electrical shock.

120-Volt, 60-Hz, AC-only, 15 or 20-

mpere fused electrical supply is

required. (Time-delay fuse or circuit

breaker is recommended.) It is

recommended that a separate

circuit serving only this appliance

be provided.

Recommended

grounding method

Do Not, under any circumstances

remove the power supply cord

grounding prong.

For your personal safety, this appliance

must be grounded. This appliance is

equipped with a power supply cord

having a 3-prong grounding plug. To

minimize possible shock hazard, the

cord must be plugged into a mating 3prong grounding-type wall receptacle,

grounding in accordance with National

Electrical Code, ANSI/NFPA 70 - latest

edition, and all local codes

and ordinances. See Figurel. If a

mating wall receptacle

is not available, it is the

personal responsi-

bility and obligation

of the customer to

have a properly

grounded 3-prong

wall receptacle installed

by a qualified electrician.

For added personal safety, use clamp

and green colored copper grounding

wire. Connect the grounding wire

(#IS minimum] from the external

grounding connector on the back

of the washer to a grounded cold

water pipe.’ See Figure 2.

Do Not ground to a gas supply pipe

or hot water pipe.

J-prong grounding

type wall

receptacra

Figure 1

Electrical ground is required on thls

appliance.

* Grounded cold water pipe must have metal

continuity to electrical ground and not be

interrupted by plastic, rubber or other electrical

insulating connectors such os hoses. finings.

washer or gaskets (including water meter or

pump). Any electrical insulating connector should

be jumped os shown in FiQUre 2 with No 4 wire

securely clamped to bare metal ot both ends.

Temporary

grounding method

Do Not, under any circumstances

remove the power supply cord

grounding prong.

This method is not recommended.

If changing and properly grounding the

wall receptacle is impossible and

where local codes permit (consult your

electrical inspector), a temporary

adaptor may be plugged into the

existing 2-prong wall receptacle to

mate with the J-prong power supply

cord. If this is done, you must connect a

separate copper grounding wire as

(#I8 minimum) to a grounded cold

water pipe* by means of a clamp and

then to the external grounding

connector screw. Do not connect the

power cord to outlet until the appliance

is permanently grounded. See Figure 2.

Now Start...

With

Washer in laundry Area.

Remove tape that covers

1

n

shipping strap. Firmly jerk, then

pull to completely remove the shipping

strap from the inside of the washer.

Remove the power cord from the

basket Peel the tape down and off

each side of cabinet.

Loading...

Loading...