Page 1

Service Manual

Manuals

Repair Parts Catalog

Traditional Instruments

Service Manual

Traditional Instruments

PN 117081-1

Medical Division

4341 State Street Road, P.O. Box 220

Skaneateles Falls, NY 13153-0220

PN 117081-1

Welch Allyn Corp. Copyright 1995

Page 2

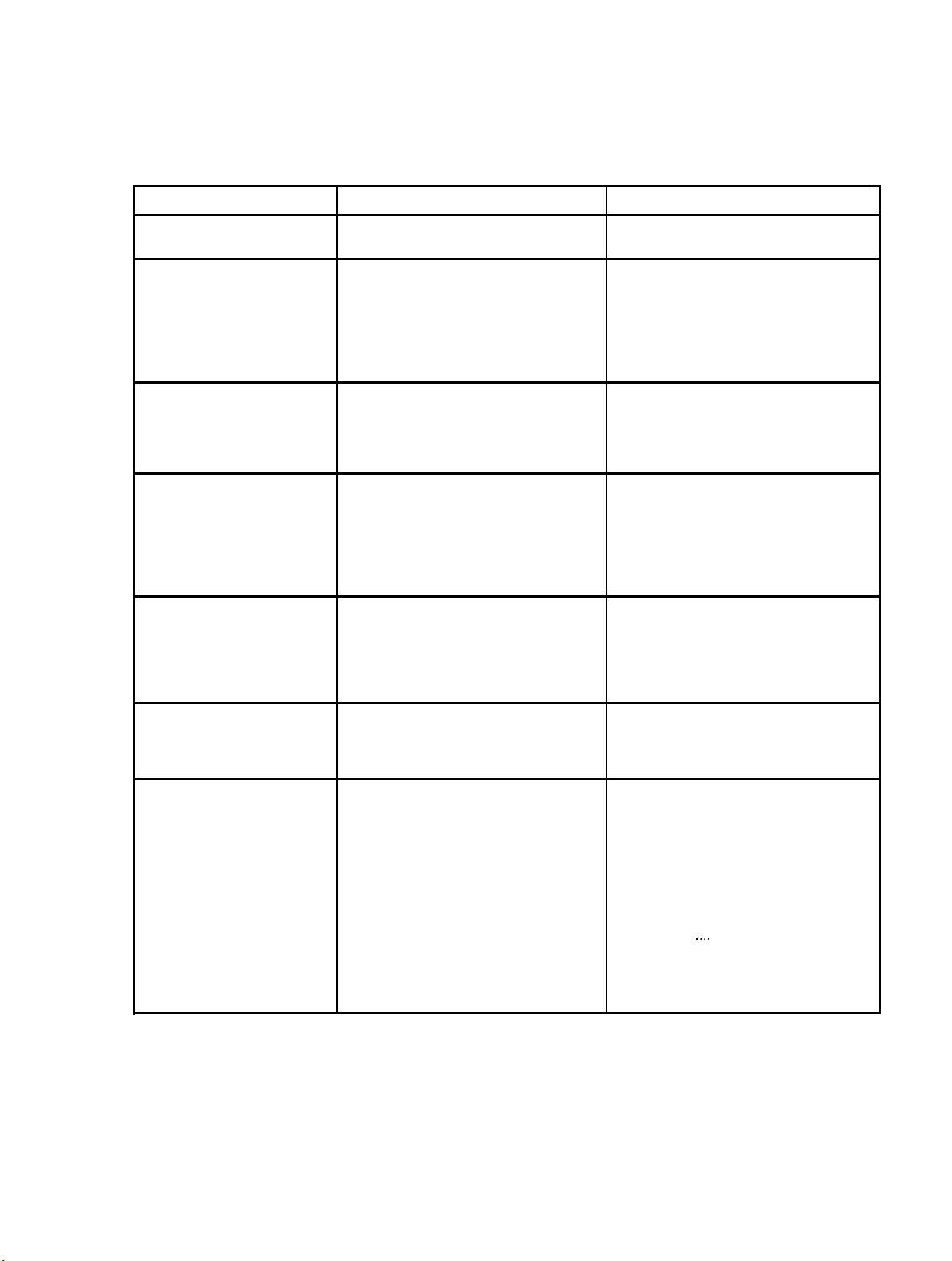

veRegnahcfonoitpircseD#NCEetaDrotaitinI

AesaeleRweN43443-579/01/1erbmetteS.R

B12-71snoitceSdedda,nwardeRdnadesiveR05104-599/32/8erbmetteS.R

Drawings and/or illustrations and/or part numbers contained in this document are for reference

purposes only. For current revisions call Welch Allyn Customer Service 1-800-535-6663.

If during servicing these products, you require further technical assistance, call Welch Allyn.

Traditional Instruments Service Manual PN 117081-1

Page 3

TABLE OF CONTENTS

Section 1 ................................................................ Ophthalmoscope

Section 2 ..................................................................Strabismoscope

Section3 ....................................................................... Retinoscopes

Section 4 ...........................................................................Otoscopes

Section 5 ................................ Illuminated Bivalve Nasal Speculum

Section 6 ............................................................ Larynx Illuminator

Nasopharynx Illuminator

Larynx Illuminator

Nasopharynx Illuminator

Section 7 ..............................................................Tongue Depressor

Section 8 ...................................................... Fiber Optic Anoscopes

Procto-Sigmoidoscopes

Fiber Optic Light Head

Standard Anoscopes

Rotating Anoscope

Section 9 ..........................................................................Headlights

Section 10 ...........................................................................Episcope

Section 11 .................................................... Laryngoscope Handles

Section 12 ....................................................................... Illuminator

Section 13 .......................................................Laryngoscope Blades

Section 14 ............................................................... Battery Handles

Section 15 .................................................................. Light Handles

Section 16 .......................................................................... Penlights

Pocket Lights

Section 17 ..............................Binocular Indirect Ophthalmoscoope

Section 18 ........................... Binocular Indirect Ophthlamoscope II

Section 19 .......................................................................CompacSet

Section 20 ...................................................CompacSet Ophthalmic

Section 21 ................................................... 767 Wall Transformner

Page 4

Section 1

OPHTHALMOSCOPES

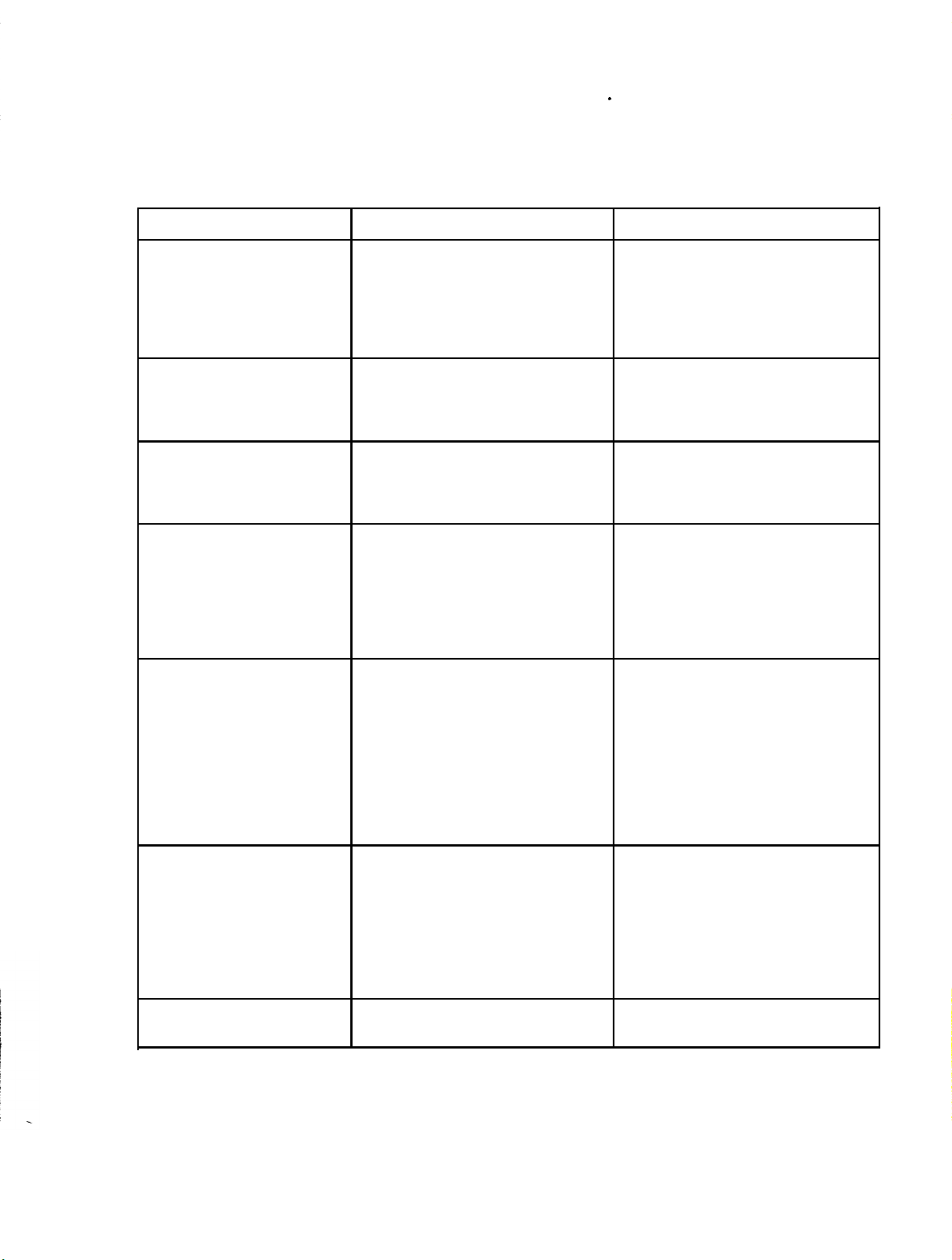

MODEL # SUB-SECTION PAGE

11110 A 1-2,

11400, 11411 B 3

11470, 11475, C 4

11500, 11511 D 5-6

11600 E 7

11605 F 8

11610 G 9

11620 H 10

11630 I 11-12

11650 J 12-13

11660, 11710 K, L 14

11720 M 15-16

11730 N 17-18

12810, 12813,

12814, 12830 0 19-20

APPENDIX 1 21

APPENDIX 2 22

APPENDIX 3 23

APPENDIX 4 24-26

Page 5

OPHTHALMOSCOPES

Special Instructions Ophthalmoscope Service:

Clean all returned ophthalmoscopes by wiping with a solution of 10% Clorox / 90% water.

Do not apply alcohol, chemicals or water to the mirror or lenses. Follow disassembly and assembly

sequences as printed. Disassembly of the Optical Tube Base is not recommended or covered by this

Service Manual. Always begin service work with a thorough understanding of the customer’s

complaint and its cause. Avoid overtightening of fasteners by applying light tightening torque.

Notes: 1. “*SLP*” means “Small Loose Parts” and cautions you to disassemble carefully,

reducing the chances of losing small, possibly spring-loaded, parts.

2. Use T-10913 for loosening the lock ring.

3. Refer to corresponding diagrams in Welch Allyn Repair Parts Catalog PN

900299.

A. 11110 2.5 Volt Halogen Lite Set ™ Ophthalmoscope Disassembly:

A1 Lamp -- Pull lamp from bottom of optical tube.

A2 Bumper -- Pull corner, peel back.

A3 Cover Ass'y -- Loosen retaining ring.

(Doctor-side)

A4 2 Screws -- Un-screw 2 screws, (torx 05).

Remove cover assembly (doctor-side) *SLP*.

Remove (from doctor-side cover): lens disc, lens

dial index spring, magnifier lens.

1

Page 6

A. 11110 2.5 V Halogen Lite Set™ Ophthalmoscope Cont'd:

A5 Ophthalmoscope -- Remove: Horseshoe (PN111026)

Body Assembly Numeral Illuminator

Aperture Disc Assembly

Index Spring

2 Screws (Holding the lens holder ass'y)

Lens Holder Assembly

Filter Housing and Filter *

Optical Tube Base

*Filter is easily scratched.

**** 11110 Reassembly ****

A6 Ophthalmoscope -- Insert optical tube base assembly into ophthalmoscope body.

Body Assembly Inspect filter over shiny metal surface and look through filter at

its own shadow. One side will show a ‘blue’ tint. Place tint side

of the filter towards the inside of the scope during reassembly.

When using new replacement filter, remove protective

polyethylene films 2 sides. Insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards top of the scope. Place lens holder assembly into position

and fasten with 2 screws. Place index spring onto raised anchor.

Rounded indexing spring end should face the hub. Place aperture

disc assembly onto hub with apertures at bottom. Place numeral

illuminator on top of the center of the aperture disc assembly with

pivot in hole at base. Place horseshoe over numeral illuminator

with open end of horseshoe at top as shown in parts diagram and

notch directly over numeral illuminator.

A7 Cover Assembly -- Place lens dial index spring onto the raise anchor. (Rounded

(Doctor Side) end of indexing spring towards lens disc assembly hub).

A8 Lens Disc Assy. -- Clean disc. Place disc on hub. (Number side down) engage

with detent.

A9 Cover Ass'y -- Place cover onto ophthalmoscope body assembly. Place ring

(Doctor Side) onto base with numbers “128” right-side-up. Tighten ring,

screws. Install bumper.

A10 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 11110 Reassembly

2

Page 7

B 11400 and 11411 2.5 Volt Ophthalmoscope Disassembly:

B1 Bumper -- Pull corner, peel back.

B2 Back Cover -- Loosen and remove retaining ring.

(Doctor-side)

B3 2 Screws -- Remove 2 screws, (torx .05) separate covers. *SLP*

Remove (from doctor-side cover):lens disc, center hub (metal)

indexing spring, lens retainer, magnifying lens.

B4 Housing -- Separate housing from optical tube base assembly.

(Patient-side)

B5 Lamp -- Pull lamp from bottom of optical tube.

**** 11400 and 11411 Reassembly ****

B6 Cover -- Insert optical tube base assembly.

(Patient-side)

B7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover. (Return bend on left side)

B8 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

B9 Lens Retainer -- Place lens retainer on top of lens.

B10 Lens Disc Ass'y. -- Clean disc. Place disc in cover. (Number side down, engaged

with detent) place hub in center of lens disc (small pivot side up).

B11 Cover -- Place cover onto patient-sidecover/optical tube base assembly.

Install and tighten ring (undercut knurl or smooth edge at bottom)

screws. Install bumper.

B12 Lamp -- (Only halogen lamps are available for the 14000).

Align pin of lamp into groove of lamp socket and press lamp in.

Test.

End 11400 and 11411

3

Page 8

C 11470 and 11475 2.5 Volt Ophthalmoscope Disassembly:

C1 Bumper -- Pull corner, peel back.

C2 Back Cover -- Loosen and remove retaining ring.

(Doctor-side)

C3 2 Screws -- Remove 2 screws, (torx .05) separate halves.*SLP*. Remove

(from doctor-side cover): lens disc, indexing spring and button,

lens retainer, magnifying lens.

C4 Housing -- Separate housing from optical tube base assembly.

(Patient-side)

C5 Lamp -- Pull lamp from bottom of optical tube.

**** 11470 and 11475 Reassembly ****

C6 Cover -- Insert un-printed plug (tabs pointing to top of instrument),

(Patient-Side) optical tube base assembly.

C7 Indexing spring -- Place spring into position below bumper cut-out of doctor-side

cover. (2 tabs on spring facing down).

C8 Indexing Button -- Place button, into guides beneath spring, flat side to spring.

C9 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

C10 Lens Retainer -- Place lens retainer on top of lens.

C11 Lens Disc Ass'y. -- Clean disc. Place disc in cover.

(Number side down, engaged with detent)

C12 Cover -- Place cover onto patient-side cover/optical tube base assembly.

(Doctor-Side) Install and tighten ring (undercut knurl or smooth edge at

bottom), screws. Install bumper.

C13 Lamp -- Align pin of lamp into groove of lamp socket and press in. Test.

End 11470 and 11475

4

Page 9

D 11500 and 11511 2.5 Volt Ophthalmoscope Disassembly:

D1 Rubber Hood -- Pull corner, lift up.

D2 Light Carrier -- Pry/pull out light carrier assembly and remove condensing

Assembly lens and lamp.

D3 Back Cover --

(Doctor-Side) key). Remove light carrier retaining spring from ring nut if

D4 Ophthalmoscope -- Remove lens disc and small glass lens. Do not remove

Body aperture assembly disc now. Clean lens disc. Check tightness

D5 Aperture Ass'y -- Pull aperture assembly (disc) straight up. Remove small detent

Loosen/remove

damaged. Remove base. Remove cover. *SLP* (Glass lens

PN106006)

of the three small brass screws in center of lens disc. (Do not

disassemble lens disc) *SLP* clean in ultrasonic bath. Optional

upgrade: Replace multi-lens disc with acrylic lens disc. Remove

clear plastic washer (.76" or 19.4mm outside diameter / .45" or

11.58mm inside diameter, PN 106017) brass insert (disc) from

hub. Remove lens disc indexing spring detent at top. Un-screw

screws from mirror holder assembly, and remove mirror

assembly.

spring, clear plastic spacer (.75" or 19.19 mm outside diameter

/ .223" or 5.67 mm inside diameter, PN 106019; not found on

all 115 scopes)

set screw first and then ring nut. (Use .035" hex

**** 11500 and 11511 Reassembly ****

D6 Ophthalmoscope -- Insert both detent springs (top spring return bend to the left;

Body bottom spring return bend to the right). Place clear plastic

spacer (small hole) onto hub. Place aperture disc ass’y on hub

(engage detent spring). Place mirror holder assembly over edge

of aperture disc and fasten with 2 screws. Place clear plastic

washer (large hole) and hub insert onto mirror holder assembly

hub.

5

Page 10

D 11500 and 11511 2.5 Volt Ophthalmoscope Reassembly:

D7 Lens Disc Ass'y -- Place lens disc assembly onto hub (number side up) and engage

in detent. Optional upgrade: Acrylic disc PN 116041-502.

D8 Magnifying Lens -- Place lens (flat side onto lens disc) onto horizontal lens disc and

position it over the bottom-most number. This will line up with

opening in doctor-side cover. Gently engage and lower doctorside cover onto the ophthalmoscope body assembly and

magnifying lens. Make sure the lens is still aligned to fit into the

hole in the doctor-side cover. Do not chip or scratch the

magnifying lens.

D9 Base -- Install base. Temporarily engage the base set screw into the hole

in bottom of scope casting. Install light carrier retaining spring

onto base retaining ring nut, and screw the ring nut into the base

(use Welch Allyn wrench T-11896). Do not thread ring nut into

the base if the set screw extends into the thread area. This will

damage set screw and ring nut. Make sure the set screw will not

interfere with the ring nut by first partially unscrewing the set

screw. Then tighten the ring nut. Tighten set screw and inspect

for burrs on set screw head. Install rubber hood.

D10 Light Carrier -- Clean lamp, lens. Install lamp into light carrier. Engage alignment

pin of lamp into groove of lamp socket. Slide condensing lens

assembly over lamp. Insert light carrier into base of scope. Test.

End 11500 and 11511

6

Page 11

E 11600 3.5 Volt Halogen Ophthalmoscope Disassembly:

E1 Bumper -- Pull corner, peel back.

E2 Back Cover -- Loosen retaining ring.

(Doctor-Side)

E3 2 Screws -- Remove 2 screws, (torx .05) separate halves. *SLP*

From the doctor-side cover, remove: Lens disc, center hub

(metal) indexing spring, magnifying lens. (Early11600 models

have separate glass lenses (23) in lens disc, and a glass magnifying

lens.) Do not disassemble lens disc for cleaning.*SLP* Clean in

ultrasonic bath. Optional upgrade: replace glass lens assembly

with acrylic lens disc, new cover acrylic magnifying lens.

E4 Housing -- Separate housing from optical tube base assembly.

(Patient-side)

E5 Lamp -- Pull lamp from bottom of optical tube.

**** 11600 Reassembly ****

E6 Cover -- Insert optical tube base assembly.

(Patient-side)

E7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover. (Return bend on left side)

E8 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

E9 Lens Disc Ass'y -- Clean disc. Check tightness of 3 small brass screws on disc.

Do not unscrew these 3 screws. Place disc in cover with number

side down and engaged with detent. Place hub in center of lens

disc (small pivot side up)

E10 Cover -- Place cover onto patient-side cover/optical tube base assembly.

(Doctor-Side) Tighten ring, screws. Install bumper.

E11 Lamp -- Align pin if lamp into groove of lamp socket and press lamp in.

Test.

End 11600

7

Page 12

F 11605 3.5 Volt Halogen Ophthalmoscope Disassembly:

F1 Bumper -- Pull corner, peel back.

F2 Back Cover -- Loosen retaining ring.

(Doctor-Side)

F3 2 Screws -- Un-screw 2 screws, (torx .05) separate halves. *SLP*

Remove (from doctor-side cover): lens disc, indexing spring,

magnifying lens retainer & lens.

F4 Housing -- Separate housing from optical tube base.

(Patient-Side)

Assembly

F5 Lamp -- Pull lamp from bottom of optical tube.

**** 11605 Reassembly ****

F6 Cover -- Insert optical tube base assembly.

(Patient-Side)

F7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover. (Return bend on left side).

F8 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

F9 Lens Retainer -- Place lens retainer on top of lens.

F10 Lens Disc Ass'y. -- Clean disc. Place disc in cover. (Number side down, engaged

with detent)

F11 Cover -- Place cover onto patient-side cover/optical tube base assembly.

(Doctor-side) Tighten ring, screws. Install bumper.

F12 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 11605

8

Page 13

G 11610 3.5V Halogen Coaxial Sealed Ophthalmoscope Disassembly:

G1 Bumper -- Pull corner, peel back.

G2 Back Cover -- Loosen retaining ring.

(Doctor-Side)

G3 2 Screws -- Remove 2 screws, (torx 05) separate halves. *SLP*

Remove: lens disc, indexing spring, magnifying lens retainer &

lens from doctor-side cover.

G4 Optical Tube -- Remove optical tube base, filter retainer, filter assembly.

Base Assembly *SLP*

G5 Lamp -- Pull lamp from bottom of optical tube.

**** 11610 Reassembly ****

G6 Ophthalmoscope -- Inspect filter over shiny metal surface and look through filterat its

Body Assembly own shadow. One side will show a ‘blue’ tint.Place tint side of

(Patient-side) the filter will be towards the inside of the scope during

reassembly. (When using replacement filter, remove protective

polyethylene film 2 sides). Insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards bottom outside of scope. Insert filter retainer, & optical

tube base assembly.

G7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover. (Return bend on left side)

G8 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

G9 Lens Retainer -- Place lens retainer on top of lens.

G10 Lens Disc Ass'y. -- Clean disc. Place disc in cover.

(Number side down, engaged with detent)

G11 Cover -- Place cover onto patient-side cover/optical tube base assembly.

(Doctor-side) Tighten ring, screws. Install bumper.

G12 Lamp -- Align pin of lamp into groove of lamp socket and press in.

Test.

End 11610

9

Page 14

H 11620 3.5V Halogen Coaxial Sealed Ophthalmoscope Disassembly:

H1 Bumper -- Pull corner, peel back.

H2 Back Cover -- Loosen retaining ring.

(Doctor-Side)

H3 2 Screws -- Remove 2 screws, (torx 05) separate halves. *SLP*

Remove (from doctor-side cover): lens disc, indexing spring,

indexing button, magnifying lens retainer & lens.

H4 Optical Tube -- Remove optical tube base, filter retainer, filter assembly.

Base Assembly *SLP*

H5 Lamp -- Pull lamp from bottom of optical tube.

**** 11620 Reassembly ****

H6 Ophthalmoscope -- Inspect filter over shiny metal surface and look through filter at

Body Assembly its own shadow. One side will show a ‘blue’ tint. Place tint side

(Patient-side) of the filter will be towards the inside of the scope during

reassembly. (When using replacement filter, remove protective

polyethylene film 2 sides). Insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards bottom outside of scope. Insert filter retainer, &

optical tube base assembly.

H7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover.

H8 Indexing Button -- Place button into guides beneath spring. (Flat side to spring).

H9 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

H10 Lens Retainer -- Place lens retainer on top of lens.

H11 Lens Disc Ass'y. -- Clean disc. Place disc in cover.

(Number side down, engaged with detent)

H12 Cover -- Place cover onto patient-side cover/optical tube base assembly ,

(Doctor-Side) tighten rin g, screws. Install bumper.

H13 Lamp -- Align pin of lamp into groove of lamp socket and press

lamp in. Test.

End 11620

10

Page 15

I 11630 3.5 Volt Halogen Coaxial™ Ophthalmoscope(With Multiplier) Disassembly:

I-1 Bumper -- Pull corner, peel back.

I-2 Back Cover -- Loosen retaining ring.

(Doctor-side)

I-3 2 Screws -- Remove 2 screws, (tprx 05) separate halves. *SLP*

Remove: lens disc, cam, multiplier disc, plastic spring detent.

I-4 Optical Tube -- Remove optical tube base, filter retainer, filter assembly.

Base assembly *SLP*

I-5 Lamp -- Pull lamp from bottom of optical tube.

**** 11630 Reassembly ****

I-6 Ophthalmoscope -- Inspect filter over shiny metal surface and look through filter

Body Assembly at its own shadow. One side will show a ‘blue’ tint. Place tint

(Patient-side) side of the filter will be towards the inside of the scope during

reassembly. (When using replacement filter, remove protective

polyethylene film 2 sides). Insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards bottom outside of scope. Insert filter retainer, & optical

tube base assembly.

I-7 Multiplier Disc -- Install multiplier disc, baffle side up, lenses at top of doctor-side

cover.

I-8 Cam -- Install cam on top of multiplier disc, slotted side up, hole of

cam engaged over pivot molded into cover.

I-9 Lens Disc Ass'y. -- Install lens disc, number side down, onto hub, with metal pin

away from cam ramp.

I-10 Spring Detent -- Place plastic spring detent into position below bumper cut-out

of doctor-side cover, smooth side up, detent bumps to engage

both multiplier and lens disc.

11

Page 16

I 11630 Ophthalmoscope Reassembly Continued

I-11 Cover -- Place cover/disc assembly onto patient-side cover/optical

(Doctor-Side) tube base assembly. Tighten ring, screws. Install bumper.

I-12 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 11630

J

J1 Bumper -- Pull corner, peel back.

J2 Back Cover -- Loosen retaining ring.

J3 2 Screws -- Remove 2 screws, (torx 05) separate halves. *SLP*

J4

J5 Lamp -- Pull lamp from bottom of optical tube.

J6 Ophthalmoscope -- Inspect filter over shiny metal surface and look through filter

11650 3.5 Volt Halogen Coaxial ™ Sealed Ophthalmoscope Disassembly:

(Doctor-side)

Remove (from doctor-side cover): lens disc, indexing spring,

indexing button, magnifying lens retainer & lens.

Optical Tube Base -- Remove optical tube base, filter retainer, filter assembly.*SLP*

Assembly

**** 11650 Reassembly ****

Body Assembly at its own shadow. One side will show a ‘blue’ tint. Place tint

(Patient-side) side of the filter will be towards the inside of the scope during

reassembly. (When using replacement filter, remove protective

polyethylene film 2 sides.) Insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards bottom outside of scope. Insert filter retainer, &

optical tube base assembly.

J7 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover.

J8 Indexing Button -- Place button, into guides beneath spring, flat side to spring.

J9 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

J10 Lens Retainer -- Place lens retainer on top of lens.

12

Page 17

J 11650 Ophthalmoscope Reassembly Continued

J11 Lens Disc Assy. -- Clean disc. Place disc on hub.

(Number side down, engaged with detent)

J12 Cover -- Place cover onto patient-side cover/optical tube base assembly.

(Doctor-side) Tighten ring, screws. Install bumper.

J13 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End11650

13

Page 18

K 11660 3.5 Volt Halogen Coaxial™ Autostep Sealed Ophthalmoscope with Multiplier:

Disassembly and reassembly for the 11660 are the same as for the 11630 (as explained earlier on

pages 11 and 12). Follow the same procedure but use the correct parts for the 11660.

Basic differences between the 11660 and the 11630 are as follows:

K1 The tube base assembly on the 11660 has a covered aperture assembly and the 11630

does not.

K2 The doctor side cover peep hole on the 11660 does not have a window and the 11630

does have a window.

End 11660

L 11710 3.5 Volt Halogen Sealed Ophthalmoscope:

Disassembly and reassembly of the 11710 are the same as for the 11720 as explained below.

Follow the same procedure but use the correct parts for the model you are working on.

Basic differences between the 11710 and the 11720 are as follows:

L1 The 11710 does not have the slide switch/rack and pinion gear mechanism. Instead it has

a small square Welch Allyn logo in the place made for the slide switch button.

L2 The 11710 does not have aperture windows on either side of the instrument.

End 11710

14

Page 19

M 11720 3.5 Volt Coaxial Sealed Ophthalmoscope Disassembly:

M1 Bumper -- Pull corner, peel back.

M2 Back Cover -- Loosen retaining ring.

(Doctor-side)

M3 2 Screws -- Remove 2 screws, (torx 05) and separate halves. *SLP*

Remove (from doctor-side cover): lens disc, indexing spring,

indexing button, magnifying lens retainer & lens.

M4 Housing -- Separate housing from optical tube base assembly. *SLP*

(Patient-side)

M5 Switch, Gear, -- Remove individual components. *SLP*

Ball and Spring,

Rack Assembly

M6 Lamp -- Pull lamp from bottom of optical tube.

**** 11720 Reassembly ****

M7 Switch, Gear -- Place spring in hole on right side ( base towards you), place

ball on top of spring. Put rack into position and place gear into

engagement with rack. Center rack in housing. Put switch in

slot of tool T-8118 and place switch over spring and ball in a

centered position. Slide patient-side cover onto T-8118 at the

switch slot and lower patient-side cover onto optical tube base

assembly. Check that ball detent is properly engaged when

switch is moved left and right.

M8 Indexing Spring -- Place spring into position below bumper cut-out of doctor-side

cover.

M9 Indexing Button -- Place button, into guides beneath spring, flat side to spring.

M10 Magnifying Lens -- Place lens into opening of body cover, round side down, flat

side facing you.

M11 Lens Retainer -- Place lens retainer on top of lens.

15

Page 20

M 11720 Reassembly Continued

M12 Lens Disc Assy. -- Clean disc. Place disc on hub.

(Number side down, engaged with detent)

M13 Cover -- Place cover onto patient-side cover/optical tube base

(Doctor-side) assembly. Tighten ring, screws. Install bumper.

M14 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 11720

16

Page 21

N 11730 3.5 Volt Coaxial Autostep Sealed Ophthalmoscope (With Multiplier) Disassembly:

N1 Bumper -- Pull corner, peel back.

N2 Back Cover -- Loosen retaining ring.

(Doctor-Side)

N3 2 Screws -- Remove 2 screws, torx 05) and separate halves. *SLP*

Remove: lens disc, cam, multiplier disc, plastic spring detent.

N4 Housing -- Separate housing from optical tube base assembly. *SLP*

(Patient-side)

N5 Switch, Gear, -- Remove individual components. *SLP*

Ball and Spring,

Rack Assembly

N6 Lamp -- Pull lamp from bottom of optical tube.

**** 11730 Reassembly ****

N7 Switch, G ear -- Place spring in hole on right side (base towards you), place

ball on top of spring. Put rack into position and place gear into

engagement with rack. Center rack in housing. Put switch in

slot of tool T-8118 and place switch over spring and ball in a

centered position. Slide patient-side cover onto T-8118 at the

switch slot and lower patient-side cover onto optical tube base

assembly. Check that ball detent is properly engaged when

switch is moved left and right.

N8 Multiplier Disc -- Install multiplier disc, baffle side up, lenses at top of doctor-side

cover.

N9 Cam -- Place cam on top of multiplier disc, slotted side up, with the hole

of cam engaged over pivot molded into cover.

N10 Lens Disc Assy. -- Install the lens disc with the number side down, onto the hub,

with the metal pin facing away from the cam ramp.

17

Page 22

N 11730 Reassembly Continued

N11 Spring Detent -- Place plastic spring detent into position below bumper cut-out

of doctor-side cover, smooth side up, detent bumps to

engage both multiplier and lens disc.

N12 Cover -- Place cover/disc assembly onto patient-side cover/optical

(Doctor-Side) tube base assembly. Tighten ring, screws. Install bumper.

N13 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 11730

18

Page 23

O

O1 Lamp -- Pull lamp from bottom of optical tube.

O2 Bumper -- Pull corner, peel back.

O3 Cover Ass’y -- Loosen retaining ring.

O4 2 Screws -- Remove 2 screws, (use .050" hex key) remove cover assembly

12810, 12813, 12814, 12830 2.5 Volt Pocket Scope Ophthalmoscope Disassembly:

SPECIAL NOTE: The12810, 12813, 12814, and 12830 Ophthalmoscopes are similar in repair

procedures with the exception of : Aperture combinations for the 12810-12814, and base thread

construction for the 12830 export model.

(Doctor-side)

(doctor-side) *SLP*. Remove (from doctor-side cover): Lens

disc, indexing spring (PN128013), lever, multiplier and magnifier

link. (These last two items will be installed into the doctor side

cover during reassembly. During disassembly,however, they

usually fall off their respective pivots and lay on top of the

aperture dial assembly.)

O5 Ophthalmoscope -- Remove N.D.(number dial) filter assembly. (On newer models,

Body Assembly this part will not have the small filter on top). Remove

aperture disc assembly, detent ball and indexing (coil) spring

(116119), indexing spring (128024). Remove 2 screws holding

lens holder assembly. Remove lens holder assembly and filter

assembly.

**** Reassembly ****

O6 Ophthalmoscope -- Insert optical tube base assembly into ophthalmoscope body.

Body Assembly Inspect filter over shiny metal surface and look through filter at

its own shadow. One side will show a‘blue’ tint. Place tint side

of the filter towards the inside of the scope during reassembly.

(When using new replacement filter, remove protective

polyethylene films 2 sides) insert filter into filter housing and

place into ophthalmoscope body with filter housing finger tab

towards top of the scope. Place lens holder assembly into position

and fasten with 2 screws. Place indexing spring (128024) onto

raised anchor. Round end of indexing spring should face hub.

Aperture disc assembly onto hub, hole in disc at top, apertures

at bottom. Insert indexing spring (coil spring PN 116119) into

hole and place ball bearing on top of it. Place N.D. filter

assembly on top of the center of the aperture disc assembly with

filter assembly pivot in hole at base.

19

Page 24

O 12810, 12813, 12814, 12830 2.5 Volt Pocket Scope Ophthalmoscope Disassembly Cont'd

O7 Cover Assembly -- Place lever into position in the ( - ) negative with magnifier lens

(Doctor-Side) position, ( - ) side. Place indexing spring (128013) over lever and

onto the raised anchor. (Rounded end of indexing spring should

face the lens disc assembly hub as shown in repair parts diagram).

O8 Lens Disc Assy. -- Clean disc. Place disc on hub.

(Number side down, engaged with detent)

O9 Multiplier -- Place multiplier on top of lens disc, engaged with hub, pivot

facing up, and lenses at the top of the assembly (as shown

in the repair parts diagram). Connect multiplier to lever with

magnifier link, thick end of link towards the magnifier,

and with the curved side towards the hub as shown in the parts

diagram.

O10 Cover Ass’y -- Place cover onto ophthalmoscope body assembly. Place ring

(Doctor-Side) onto base with numbers “128” right-side-up. Tighten ring,

screws.Install bumper.

O11 Lamp -- Align pin of lamp into groove of lamp socket and press lamp

in. Test.

End 12810, 12813, 12814, 12830

20

Page 25

APPENDIX 1

TOOLS/MATERIALS/SUPPLIES

OPHTHALMOSCOPE: 11110, 11400, 11411, 11470, 11475, 11500, 11511, 11600, 11605,

11610, 11620, 11630, 11650, 11660, 11710, 11720, 11730, 12810,

12813, 12814, 12830.

Bayonet Pliers (For removing lamps) Welch Allyn T-10802

Strap Wrench Welch Allyn T-10913

Ring-Nut Wrench (‘TEE’Handle) Welch Allyn T-11896

Switch Tool Welch Allyn T-8118

T5 Torx Flag Style WHA #30-13 Torx ™ Bit # 440-TX-05 or Torx Screwdriver (Torx .05)

Replaceable-Bit 1/4" Driver (APEX M-1505-P)For use with Torx .05 bit

Tweezers ( Grobet Peer #7 Stainless Steel )

12" X 12" (approximately) Foam Pad (Mouse Mar American Covers Inc.)

Windex ™ Glass Cleaner or Vestal Glass Cleaner #8618-21

Lint Free Wipes / Swabs

Jewelers Screwdriver With 1/16" Flat Blade

Small Ultasonic Bath ie:* Pro-Craft Model 23.577-1

Ultra Sonic Bath Cleaning Solution

Miller Stephenson Aero-Duster #MS-222

De-Ionized Water.

Small Stainless Steel Tubs (1 QT. Capacity or less)

One each of the following items: Taps are used to clean up threads or open the hole up to the next

size where permissible.

TAP/DRILL/KEY: TAP DRILL KEY

2-56 #50 (.0700") .035"

3-48 #47 (.0785") .050"

4-40 #43 (.0890") .050"

21

Page 26

APPENDIX 2

Inspections for Repaired Ophthalmoscopes:

1. Operate all slide switches.

2. Rotate knobs and discs to determine whether or not detents are operating correctly and

operating smoothly, positively, and through full stroke.

3. View through the scope to determine that the aperture, filter, or lens are correctly aligned

through each detent position.

4. Inspect the cleanliness and condition of the lens dial. No scratches, dirt, glue, or any material

should be visible.

5. Check the illuminated and non-illuminated numbers on the lens dial. They should be in the

center of the aperture.

6. Check projected images for shadows, dirt, and filament images using the aperture dial and

the slide switch if so equipped.

7. Check windows for cracks, streaks, spots or anything that would obscure the viewed

image.

8. Check for any stray light that interferes with looking through the scope. Project a fixation

spot into a darkened box. Look through the peephole with a lens setting of ‘0’. There should

be no bright streaks in the image, or any light appearing in the dark area surrounding the

projected spot.

9. Check the scope for scratches or physical damage before the repair as well as after.

10. Clean the repaired scope and wrap it in a plastic bag to protect it from dust and fingerprint

contamination.

22

Page 27

APPENDIX 3

Checklist for:

F inal Inspection of Ophthalmoscopes

Ophthalmoscope Checklist: Ref#: Model:

1. [] Bumper in place A02387 (V1)* all

2. [] Retaining ring up (body&cover) all

3. [] Lens disc turns freely A02121 all

4. [] Leave lens disc assy on ‘0’ all

5. [] Lever does not jump 12810

6. [] Lamp makes contact w/ handle all

7. [] Numbers readable on lens disc A02121 all

8. [] No cracks in cello when illuminated 116 & 115

9. [] No glare with filters A02387 (V8)** all w/filter

10.[] Filter window is secure A02787 (V8) 11720 & 30

11.[] Retainer secure in mirror assembly all

12.[] Filter assy. not catching on mirror all w/mirror

13.[] Lens clarity A02121 all

14.[] Aperture turns freely all

15.[] Aperture on large circle all

16.[] Filter window open all

* V1=visual measurement (repair operator judgement)

** V8=remove from fixture or handle and apply General Electric RTV #108 to adjustment hole.

(clear translucent silicone sealant, WA M#30313).

23

Page 28

APPENDIX 4

Troubleshooting Ophthalmoscopes

Model #'s: 11400,11411, 11610, 11620,11630, 11650,11660

Problem

Dirty

Optics

Obstruction in viewing area

Apart

Glare

‘Reflection of extra light seen a) mirror

through Oph. with filter down.”

VOTE: Plastic lenses

[objective lens and filter)

scratch easily. To clean, use a

soft lens paper and or cotton

swab.

Normal use

Heavy dirt or scratch on lens disc.

Filter Assembly:

discolored

a)

scratched

b)

fingerprinted

c)

Mirror hood bent up

Insert pulled out from overtightning

of screws.

User disassembled.

Dirt or scratches on:

b) filter

objective lens

c)

Cause

Clean optics but do not use alcohol

on 116 series.

Replace lens disc.

Replace filter assembly.

Replace filter assembly.

Clean

Replace mirror.

Replace body set.

Replace missing or damaged parts

and reassemble.

Clean parts if dirty.

Replace if scratched.

Corrective Action

Shadows on light spot

Dirty Optics

Lamp filament asymmetrical.

Lamp envelope dirty.

Loose condensing lens or

retaining ring. Condensed lens

tipped.

Scratch or chip

Objective lens loose

Wrong lamp

Clean

Turn lamp around to opposite slot in

sleeve or replace if this does not

remove shadows.

Clean with soft cloth.

Check lens (tap with small needle

and check for movement if loose).

Press down to tighten. Lens should

If

be flat.

center”.

Replace condensing lens on

condensing lens.

Remove retaining ring from mirror

mount and reset. (Refer to mirror

assembly procedure).

Replace with correct lamp.

tilted it will project light “off

24

Page 29

APPENDIX 4 continued....

Troubleshooting Ophthalmoscopes

MODEL #:

11400,11411,11610 11620,11630,11650,11660

Problem

Numbers

ens assembly.

No

Broken mirror

Will not focus

Intermittent light output

not readable on

light

Cause

Alcohol damage (improper cleaning)

Lamp problem

a) pin off-jammed in sleeve, not

pinned correctly

b) blown

or gray

c) shadow

d) wrong

Dropped

Customer tampered with Ophth.

Mirror or hood unglued

Alcohol damage (alcohol will discolor

mirror and lenses)

Objective lens loose.

Lens carrier out of position

Loose connection with power source

-

envelope will appear white

-

bent filament

lamp/

not Welch Allyn lamp

Corrective Action

Replace magnifier lens disc (clean with

Vestal cleaner or window cleaner)

Replace lamp

Replace lamp

Turn lamp in sleeve or replace lamp.

Replace with correct Welch Allyn lamp.

Replace mirror

Replace mirror, lenses

Remove from mirror and reset.

Adjust lens carrier (Refer to adjustable

mirror assembly instructions)

Check base/handle. ( See problem

below)

Loose condensing or objective lens

Wrong lamp

Poor connection with power

source.

Lens assembly sticks or

drags (friction) a) rubs on body

NOTE:

When changing new style cover from the old style (index spring to new spring and

Optical tube base:

a) worn (loose fit)

b) bent (tight fit)

c) misaligned optic sleeve or lamp

Aperture dial:

b) ball bearing rotation stiff

Lens disc assembly:

a) warped

b) 11630 lens:

1) film warped or pin not engaging

in cam properly.

2) multiplier disc baffle warped

3) not cleaned properlly.

Inspect and secure

Replace with correct Welch Allyn lamp

Replace base

(a)

&

(b)

Remove and realign

Shave cut out area in cover (body)

slightly.

Ream bearing hole in base. Apply

small dot of molykote 33 grease.

Replace lens disc.

b-l, b-2, b-3

multiplier, or cam. (Visually check for

warp. It is not easily detected).

button), be sure to exchange old style filter retainer ( different design

in stiff rotation of lens assembly.

..__

Replace lens disc,

)

.

Failure to do so will result

25

Page 30

APPENDIX 4 continued. . .

.

Troubleshooting Ophthalmoscopes

MODEL #:

Problem

Mirror

unglued, broken

scratched

Glare

Lever sticks.

Lever moves by itself when

ens assembly is rotated.

Poor focus

,

12810 (PocketScope)

Mirror adheres to RTV during

disassembly.

Cracked (Ophth dropped)

Cleaned improperly.

Film on mirror filter or lenses caused

by improper cleaning.

Dirty optics.

Cover Assy warped.

Multiplier catches edge of lens disc.

Dirty optics

Objective lens

Cause

Corrective Action

Remove mirror from lens older and

replace with new body/mirror assembly.

Replace body with mirror assemlby or

filter.

Clean with window cleaner.

Replace cover.

Replace disc or multiplier.

Clean lenses (no alcohol)

Place open aperture hole over lens

area, adjust focus, re-seal with G.E.

108 RTV

objective with RTV. Make flush so that

turning aperture does not interfere).

M30313 (surround peg on

Intermittent or no light

Loose filter window or

polarized) filter catching.

NOTE: For “shadow in ‘light

circle", be sure filter is

completely open or closed.

Check

that lamp is in sleeve

lightly.

Loose

film on numeral

lluminator

Bulb blown.

Retainer not on tight.

Loose sleeve.

Minor unglued from body.

Poor connection with power source.

Rubber tube worn.

Glue failure

Replace bulb.

Tighten retainer with strap wrench.

Tighten screw on back of optical base

(be sure sleeves is aligned).

Replace body-withmirror assembly.

Check with known good handle.

Replace rubber tube.

Replace with new illuminator. (New

style has no film).

26

Page 31

Section 2

STRABISMOSCOPE

MODEL # PAGE

12400 1-6

Page 32

STRABISMOSCOPE

12401 3.5V Strabismoscope (OCCLUDER) Disassembly:

1. Lamp — Pull lamp from base. (Use tweezers)

2. Beam Splitter —

3. Base — Remove base from cover.

4. Lamp Collar — Remove lamp collar from base.

**12400 Reassembly **

5. Beam Splitter — Clean beam splitter seating surfaces shown in FIG.1

Loosen retaining ring all the way towards base.

(Use T-1413 rubber jaw ring pliers or T-10913 strap

wrench to loosen retaining ring.)

CAUTION: ON : Beam splitter may fall out. Carefully

separate body halves by pivoting halves apart at top of

instrument. Unhook halves at top. Use a fine point

blade to separate RTV bond between beam splitter

and physician side cover.

by shading and X's

PATIENT SIDE DOCTOR SIDE

FIG. 1

Posistion Doctor Side Cover (black) on flat surface

and apply one .06" drop of clear RTV sealer to center

of each of three circled locations in FIG. 2.

FIG. 2

1

Page 33

12401 Reassembly Continued.....

5. Beam Splitter Reassembly cont'd Determine which side of beam splitter is coated by

placing a pencil point onto the surface as in FIG. 3.

Pencil point and reflected image meet on coated side

/ patient side. Image does not touch pencil point on

uncoated side (doctor side).

FIG. 3

Clean beam splitter with lens cleaner and place it into

RTV treated doctor side (black) cover.

P a t i e n t s i d e u p.

Apply .18" drop of clear RTV sealer to each of six

places shown circled in FIG. 4. Drop should contact

both beam splitter and the cover.

FIG. 4

Insert the light carrier base into the doctor side cover

as shown in FIG. 5.

2

Page 34

12401 Reassembly Continued.....

5. Beam Splitter

Reassembly Continued

FIG. 5

Assemble both cover halves together by first engaging

the latch at the top of the instrument. See FIG. 6. Then

close the covers together at the bottom. Screw the

lock ring up to the covers and tighten. (Smooth ridge

towards bottom of base.)

FIG. 6

6. Lamp Collar — Insert replacement lamp collar into base. (Use

tweezers). Push in and turn to seat lamp collar.

7. Lamp — Clean lamp with alcohol and cotton ball. Align the rib

in the lamp base with either of the two slots in the lamp

collar. Gently press the lamp into the collar. Clean

both sides of the beam splitter. Connect to battery

handle and test.

End 12401 Reassembly

3

Page 35

STRABISMOSCOPE

TOOLS/MATERIALS/SUPPLIES

Bayonet Pliers Welch Allyn T-10802

Only one of the next two T-tools is required:

Rubber Jaw Ring Pliers Welch Allyn T-1413

Strap Wrench Welch Allyn T-10913

Tweezers (Stainless Steel or Plastic, must be

Non-Magnetic, Grobet Peer # 7 )

12"X 12" (Approximately) Foam Pad Mouse Mat ™,

American Covers Inc.

Windex™ Glass Cleaner or Vestal Glass Cleaner #8618-21

Lint Free Wipes / Swabs

Aero-Duster #MS-222

De-Ionized Water.

Small Stainless Steel Tubs (1 Qt. Capacity Or Less)

Silicone RTV Sealant M-30380 (Dow Medical Adhesive Silicone) or

(G.E. Translucent RTV 108 )

4

Page 36

Inspections For Repaired Strabismoscopes:

1. Check locking ring for tightness.

2. Check to see that instrument fits on handle before repairing. Base rim may be bent if dropped

on hard surface.

3. Check beam splitter for cracks, chips or other defects. Check for any stray light that interferes

with the viewed image.

4. Check the scope for scratches, physical damage, rough surface before repairing.

5. Clean the repaired scope and wrap it in plastic to protect it from dust and fingerprint

contamination.

6. Check for function.

5

Page 37

STRABISMOSCOPE TROUBLESHOOTING

MODEL #: 12401

Problem

1

Broken beam splitter (Mirror)

I

Apart

I

Scratched beam splitter

Lamp loose

Cause Corrective Action

1

Dropped

I

Loose retaining ring

Beam splitter unglued

Dropped

Not cleaned properly

Lamp collar worn or missing.

1

Replace beam splitter.

I

I

Tighten ring.

I

Reglue (RTV)

Replace

Clean (Refer to cleaning instructions).

Replace collar.

I

I

I

6

Page 38

Section 3

RETINOSCOPES

MODEL # SUB-SECTION PAGE

18201 A 1-2

17201 B 2

18100 C 3-4

17710 D 4-5

17610 F 6

18000 F 6

18010 E 6

17600 G 7-8

17700 H 8-9

Page 39

RETINOSCOPES

Retinoscope Disassembly:

A. 18201 3.5 Volt Retinoscope Disassembly:

A1. Lamp — Pull lamp from bottom. (Use tweezers).

A2. Bumper — Pull corner, peel back. (Use fingers).

A3. Magnetic Overlay — Lift corner, peel off. (Use thin blade).

A4. Sleeve Grip — Pull bottom edge off by inserting tweezers under bottom edge

of grip and removing grip from circumference. Pull whole

grip off. (Use tweezers carefully).

A5. Nameplate — Lift corner, peel off. (Use thin blade).

A6. Doctor-side — Remove 3 screws (.05 Torx) and separate covers. Remove

Cover doctor-side window retainer and window.

A7. Patient-side — Remove : Optics carrier subassembly, main sleeve assembly,

lens positional control device (small square).

NOTE: New spring style introduced early 1999. Coil spring

182047 and cap 182048 can be removed from patient-side

cover 182020-4.

**** 18201 Reassembly ****

A8. Patient-side __ Replace small spring and spring cap into patient-side cover

Install small square lens positional control device and main

sleeve assembly. Insert spring and ball under slide switch

tab of optics carrier subassembly. Hold in place with T-

8118. Place optics carrier subassembly into cover.

1

Page 40

18201 Retinoscope Reassembly Continued

A9. Doctor-side Cover __ Install doctor-side window and window retainer. Join doctor

side and patient side assemblies. Install 3 screws. Polarizing

slide switch should operate with click detents at both ends of

stroke.

A10. Sleeve grip — Push on and smooth out between top and bottom of edge of

adjustment barrel. (Use fingers).

A11. Magnetic Overlay — Position over center of overlay recess and press into place.

A12. Bumper — Press into slot.(Use fingers).

A13. Lamp — Align pin on lamp base with groove of lampsocket and

press into position. Clean lamp with alcohol and swab then

turn on. (Use tweezers to position lamp, then press with

fingers).

End 18201

—————————————————————————————————

B. 17201 2.5 Volt Retinoscope:

NOTE: The 17201 2.5 volt retinoscope is slightly different from its ‘look-alike’, the 18201 3.5 volt

retinoscope. Disassembly and reassembly are similar. Differences are listed below:

* Lamp and power source voltage.

* No polarizer in the 17201.

* No windows (either side) in the 17201.

* Mounting configuration (bases are not iterchangeable).

—————————————————————————————————

2

Page 41

C. 18100 3.5. Volt Halogen Streak Retinoscope Disassembly:

C1. Lamp Carrier — Pull lamp carrier from bottom. (Use needle-nose pliers).

Inspect small spring near flange.

C2. Lamp — Unscrew lamp from lamp carrier.

C3. Bumper — Pull corner, peel back. (Use fingers).

C4. Eyepiece __ Unscrew eyepiece assembly. (Use fingernails to grip).

Assembly

C5. Head Assembly — Unscrew sleeve assembly from head. (Use strap wrench T-

10913 to hold head collar).

C6. Control Sleeve — Remove stop washer from top of control sleeve sub-assembly.

Subassembly Pull control sleeve sub-assembly from outer sleeve assembly.

**** 18100 Reassembly ****

C7. Control Sleeve — Insert control sleeve sub-assembly into outer sleeve assembly

Subassembly knurled end first. (Squeeze plastic split ring with fingers to

move it beyond:top Of outer sleeve and cutout of outer sleeve.

Use fingers). Install stop washer onto top of control sleeve

subassembly.

C8. Head assembly — Screw sleeve assembly into collar of head assembly. (Use

strap wrench to tighten). Align as per parts diagram.

C9. Eyepiece — Screw eyepiece assembly into head assembly. (Use fingernails

Assembly to tighten).

C10. Bumper — Press into slot. (Use fingers).

C11. Lamp — Screw lamp into light carrier assembly. (Use fingers to tighten

lamp). Clean lamp with alcohol and soft wipe.

3

Page 42

18100 Retinoscope Reassembly Continued

C12. Lamp Carrier — Position lamp carrier into control sleeve with very light

pressure and slight rotation to align two tabs near lamp with

grooves in the interior of the control sleeve. Do not force.

When lamp carrier is lined up with grooves, insert lamp

carrier into control sleeve. Test.

End 18100 Reassembly

—————————————————————————————————

D. 17710 2.5 Volt Halogen Streak Retinoscope Disassembly:

D1. Lamp carrier — Unscrew base assembly (collar) from outer sleeve.(Use strap

wrench T-10913). Remove lamp carrier. Inspect small spring

near flange.

D2. Lamp — Unscrew lamp from lamp carrier.

D3. Bumper — Pull corner, peel back. (Use fingers).

D4. Eyepiece — Unscrew eyepiece assembly. (Use fingernails to grip).

Assembly

D5. Head Assembly — Unscrew sleeve assembly from head. (Use strap wrench to

hold head collar).

D6. Control Sleeve — Remove stop washer from top of control sleeve subassembly.

Subassembly Pull control sleeve subassembly from outer sleeve assembly.

**** 17710 Reassembly ****

D7. Control Sleeve — Insert control sleeve subassembly into outer sleeve assembly

Subassembly knurled end first. (Squeeze plastic split ring with fingers to

get it beyond: top of outer sleeve and cutout of outer sleeve).

Install stop washer onto top of control sleeve subassembly.

4

Page 43

17710 Retinoscope Reassembly Continued

D8. Head Assembly — Screw sleeve assembly into collar of head assembly. (Use

strap wrench to tighten). Align as per parts diagram.

D9. Eyepiece Assembly — Screw eyepiece assembly into head assembly. (Use fingernails

to tighten).

D10. Bumper — Press into slot. (Use fingers).

D11. Lamp — Screw lamp into light carrier assembly. (Use fingers to

tighten lamp). Clean lamp with alcohol and soft wipe.

D12. Lamp Carrier — Position lamp carrier into control sleeve with very light

pressure and slight rotation to align two tabs near lamp with

grooves in the interior of the control sleeve. Do not force.

When lamp carrier is lined up with grooves, insert lamp

carrier into control sleeve. Secure light carrier assembly by

screwing on base assembly. (Tighten with strap wrench).

Test.

End 17710 Reassembly

5

Page 44

E. 18010 3.5. Volt Halogen Spot Retinoscope Disassembly:

E1. Lamp — Pull 3.5 v. Lamp from base. (Use needle nose pliers).

E2. Bumper — Pull corner, peel back. (Use fingers).

E3. Eyepiece — Unscrew eyepiece assembly. (Use fingernails to grip).

Assembly

E4. Head Assembly — Unscrew optical base subassembly from head. (Use strap

wrench T-10913 to hold head collar).

**** 18010 Reassembly ****

E5. Head Assembly — Screw optical base subassembly into collar of head assembly.

(Use strap wrench to tighten).

E6. Eyepiece — Screw eyepiece assembly into head assembly. (Use fingernails

Assembly to tighten).

E7. Bumper — Press into slot.(Use fingers).

E8. Lamp — Clean lamp with alcohol and soft wipe. Press lamp into base.

End 18010 Reassembly

—————————————————————————————————

F. 17610 2.5 Volt and 18000 3.5 Volt Spot Retinoscopes:

Note: The 17610 and 18000 spot retinoscopes differ slightly from the 18010 as listed below.

Disassembly and reassembly are similar however.

* Lamp voltage

* Base configuration

* Length of optical base assembly

6

Page 45

G. 17600 Spot Retinoscope Disassembly:

G1. Lamp Carrier — Unscrew light carrier from body subassembly.

G2. Lamp — Remove diaphragm assembly. Unscrew lamp from light carrier.

G3. Bumper — Unscrew 3 screws and remove cover.

G4. Eyepiece — Unscrew eyepiece assembly (use fingernails to grip).

G5. Mirror Assembly — Unscrew 1 screw. Remove assembly from body subassembly.

G6. Lens Mount — Remove lens mount assembly.

Assembly

G7. Contact and — Unscrew and remove contact and bayonet assembly from base.

Bayonet Assy Use bayonet pliers T-10802.

**** 17600 Reassembly ****

G8. Contact and __ Replace contact and bayonet assembly into base. Install and

Bayonet Assy tighten with bayonet pliers T-10802.

G9. Lens mount — Insert lens mount assembly into body subassembly. Align hole in

Assembly assembly with hole in body subassembly.

G10. Mirror Assembly — Install assembly into body subassembly and secure with screw.

G11. Bumper — Position bumper over top of cover and attach cover to body sub-

assembly with 3 screws. (Insert the 2 short screws at the top). The

long screw must engage hole in lens mount assembly.

G12. Eyepiece — Screw eyepiece assembly into cover. (Use fingernails to tighten).

G13. Lamp — Screw lamp into light carrier assembly. (Use fingers to tighten

lamp).

Clean lamp with alcohol and soft wipe.

7

Page 46

17600 Reassembly Continued

G14. Lamp Carrier — Screw light carrier to body subassembly.

Test.

End 17600 Reassembly

—————————————————————————————————

H. 17700 Streak Retinoscope Disassembly:

H1. Lamp Control — Unscrew lamp control assembly from body subassembly.

Assembly

H2. Lamp — Unscrew lamp from lamp control subassembly.

H3. Bumper — Unscrew 3 screws and remove cover. Remove bumper from

cover.

H4. Eyepiece — Unscrew eyepiece assembly from cover. (Use fingernails to

grip).

H5. Mirror Assembly — Unscrew 1 screw. Remove assembly from body subassembly.

H6. Lens Mount — Remove lens mount assembly.

Assembly

H7. Contact and — Unscrew and remove contact and bayonet assembly from

Bayonet Assy base. Use bayonet pliers T-10802

**** 17700 Reassembly ****

H8. Contact and — Replace contact and bayonet assembly into base. Use bayonet

Bayonet Assy pliers T-10802

H9. Lens Mount — Insert lens mount assembly into body subassembly. Align

hole in assembly with hole in body sub-assembly.

H10. Mirror Assembly — Install assembly into body sub-assembly and secure with

screw.

8

Page 47

17700 Reassembly Continued

H11. Bumper — Position bumper over top of cover and attach cover to body

sub-assembly with 3 screws (2 short screws at top). Long

screw must engage hole in lens mount assembly.

H12. Eyepiece — Screw eyepiece assembly into cover. (Use fingernails to

Assembly tighten).

H13. Lamp — Screw lamp into light carrier assembly. (Use fingers to tighten

lamp). Clean lamp with alcohol and soft wipe.

H14. Lamp Carrier — Screw light carrier to body sub-assembly.

Test.

End 17700 Reassembly

9

Page 48

APPENDIX

RETINOSCOPES TOOLS/MATERIALS/SUPPLIES

Needle Nose Pliers

.028 Hex Key

Torx .05 Screwdriver

Strap Wrench Welch Allyn T-10913

Slide Switch Holding Tool Welch Allyn T-8118-30

Tweezers (Grobet Peer #7 Stainless Steel)

12"X 12" (Approximately) Foam Pad

Windex™ Glass Cleaner or Vestal Glass Cleaner #8618-21

Lint Free Wipes / Swabs

Jewelers Screwdriver with 1/16" Flat Blade

Small Ultrasonic Bath

Ultra Sonic Bath Cleaning Solution Ie: Micro™ Liquid Laboratory Cleaner.

Miller Stephenson Aero-Duster #MS-222

De-Ionized Water.

Small Stainless Steel Tubs (1 Qt. Capacity Or Less)

10

Page 49

Inspections For Repaired Retinoscopes

1. Check streak focus and out of focus uniformity.

2. Check polarizer switch for positive detent and smooth operation.

3. Check control sleeve for both rotational and vertical smooth operation.

4. Check optics for cleanliness and clarity.

5. Clean and seal retinoscope in plastic bag to protect from dust and fingerprint contamination.

11

Page 50

TROUBLESHOOTING RETINOSCOPES

Instrument: Retinoscopes (Streak)

Model #:

18100

Problem Cause

Control sleeve

Does not fit in handle properly Tight or no fit (dropped) bent.

Poor focus

Intermittent light

operation difficult

Light carrier inserted incorrectly.

worn

Tension spring

Outer sleeve bent.

Chemical build up (residue) inside of sleeve

from improper cleaning.

Loose. Worn.

Lamp filament not aligned properly.

Dirty optics.

Contact between light carrier and inner

ledge of outer sleeve.

on control sleeve.

Corrective Action

Remove and align groove in control sleeve

with 2 slots on band at top of light carrier.

Replace control sleeve.

Replace outer sleeve.

Use window cleaner.

Replace outer sleeve at base of outer

sleeve.

Replace outer sleeve.

Replace lamp

Clean mirror, eyepiece and control sleeve

lens with glass cleaner. Clean lamp.

Remove eyepiece to clean back side of

mirror and eyepiece lens.

Remove light carrier and apply small

amount of conductive grease to ledge.

carrier

Put in light

position repeatedly to test.

and rotate in down

Replace light carrier contact on light

carrier.

lighten down lamp so that it makes

proper contact

Replace head assembly.

If loose, push ring down with screwdriver.

If still

loose, replace retaining ring.

Install washer.

Broken mirror

Loose head assembly

Worn or loose wire.

Lamp not inserted properly.

Dropped

Worn or loose retaining ring on collar.

Washer missing.

Note: Damage to the head assembly, other than eyepiece, requires replacement of the head since

it does not disassemble.

Note: The head assembly of the 17610 (2.5 v), 17710 (2.5 v), and the 18010 (3.5 v) spot retinoscopes

are the same as the 18100 streak retinoscope. However, they have a different sleeve assembly. The

problems are the same as the 18100 streak retinoscope with the following exceptions: 17710, the light

carrier looks much like the 18 100 light carrier. They are not interchangeable as they have a different lamp

(see parts catalog) and control sleeve operation would be affected.

12

Page 51

TROUBLESHOOTING RETINOSCOPES

Instrument:

Model #:

Film on window (difficult to see

image)

Not focusing properly

Control sleeve too loose

Control sleeve too tight

Magnetic overlay missing

No light

Windows scratched or loose

Retinoscopes

18200 streak and 18300 spot

Problem

Cause

Fingerprints

scratches

Incomplete cleaning

Lamp filament not aligned.

Lens positional control device.

Lens positional control device out of

position.

Self adhesive is not sticking. Replace with new magnetic overlay.

Lamp problem

a) lamp blown

b) lamp not seated

Cleaned improperly

Window unglued Replace cover assembly.

Clean lenses with alcohol and soft cloth.

Use cotton covered toothpick to clean

small peephole.

Replace lamp.

Replace PN 182025, (black rubber part).

Reposition or replace with

Replace lamp

Align pin on lamp with groove in socket.

Replace cover assembly.

Corrective Action

new

part.

Scope rattles

Lens has fallen out of scope. Uses old

style retaining

ring.

Replace control sleeve.

NOTE: Do not take cover assembly apart more than twice. Repeated insertion and removal of self

tapping screws in plastic screw holes in patient side cover reduces the gripping power of plastic holes.

13

Page 52

Section 4

OTOSCOPES

MODEL # SUB-SECTION PAGE

20000 A 1

23520 A 1

24020 B 2

23510 B 2

23570 B 2

24033 B 2

24031 B 2

25020 B 2

21110 C 2-3

21130 D 3

20100 E 4-6

20150 E 4-6

20200 F 6

20250 F 6

20202 G 7-8

20262 G 7-8

21600 H 8-10

21700 I 11

APPENDIX SECTION

Tools and Material 12

Inspections 13

Troubleshooting 14-16

Otoscope Pneumatic Tests 18

Schematic 19

Page 53

OTOSCOPES

SPECIAL INSTRUCTIONS:

Refer to corresponding diagrams in Welch Allyn Repair Parts Catalog PN 900299. Clean all

returned scopes by wiping with a solution of 10% Clorox / 90% Water. Use special tools, lens cleaner,

and lens tissue as listed in Appendix. Do not apply alcohol, chemicals or water to the mirror or lenses.

Follow disassembly and assembly sequences as printed. Begin with a thorough inspection to understand

the customer complaint and its cause. Perform tests as specified in the Appendix.

—————————————————————————————————

A. 20000 (20002 without Speculum) 3.5V Otoscope Disassembly:

23520 (stamped 20000A) Screw-on 3.5V Otoscope Disassembly:

23520 (stamped 20000R) Snap-on 3.5V Otoscope Disassembly:

A1. Lens Holder — Slide lens holder assembly out of otoscope body assembly.

Assembly Inspect lens and seal.

A2. Base Assembly — 20000R, pull the base assembly from the 20000 otoscope body.

23520, unscrew (counter-clockwise) the base assembly from the

23520 otoscope body.

A3. Lamp — Pull lamp straight out of bottom of base assembly.

A4. Lamp Collar — Remove lamp collar from bottom end base assembly. (Use

tweezers).

**** 20000 / 23520 Reassembly ****

A5. Lamp Collar — Insert replacement lamp collar into base assembly through

bottom. (Points of collar should face up).

A6. Lamp — Clean replacement lamp and carefully insert into bottom of

base assembly.

A7. Base Assembly — 20000R, press the base assembly onto the 20000 otoscope body.

23520, screw (clockwise) the base assembly onto the 23520

otoscope body.

A8. Lens Holder — Clean lens and slide lens holder assembly into otoscope body

Assembly assembly. Inspect. Perform Otoscope Pneumatic Test A00181.

End 20000R / 23520

1

Page 54

B. 24020 (24033 without Speculum) 2.5V Ototscope Disassembly:

24033 (24031 without Speculum) 2.5V Otoscope Disassembly:

25020 (25022 without Speculum) 3.5V Otoscope Disassembly:

23510 (stamped-25020A) 3.5V Otoscope Disassembly

23570 (stamped-240A) International 2.5V Otoscope Disassembly

B1. Lens Holder — Slide lens holder assembly out of otoscope body assembly.

Assembly Inspect lens and seal.

B2. Lamp — Pull lamp straight out of bottom of base.

**** 24020 / 24033 / 25020 / 23510 / 23570 Reassembly ****

B3. Lamp — Select appropriate replacement lamp. Clean lamp and

carefully insert into bottom of base.

B4. Lens Holder — Clean lens and slide lens holder assembly into otoscope body

Assembly assembly. Inspect. Perform Otoscope Pneumatic Test A00181.

End 24020 / 24033 / 25020 / 23510 / 23570

—————————————————————————————————

C. 21110 2.5v Otoscope Disassembly:

C1. Otoscope Body — Unscrew otoscope body from battery handle. Check tightness of

threaded ring.

C2. Otoscope — Unscrew illuminator assembly from battery handle.

Illuminator

Assembly

C3. Lamp — Pull lamp straight out of bottom of otoscope illuminator

assembly.

C4. Lamp Collar — Remove lamp collar from bottom end of otoscope illuminator

assembly. (Use tweezers).

C5. Lens — Slide lens out of otoscope body. Inspect lens and seal.

**** 21110 Reassembly ****

C6. Lens — Clean lens and slide lens into otoscope body assembly.

C7. Lamp Collar — Insert replacement lamp collar into otoscope illuminator

assembly through bottom. (Points of collar should face up.)

C8. Lamp — Clean lamp and carefully insert into bottom of otoscope

illuminator assembly.

2

Page 55

C. 21110 Otoscope Disassembly Continued

C9. Otoscope — Screw illuminator assembly onto battery handle.

Illuminator

Assembly

C10. Otoscope Body — Screw otoscope body onto battery handle.

Inspect.

End 21110

—————————————————————————————————

D. 21130 2.5. Otoscope Disassembly:

D1. Otoscope Body — Unscrew otoscope body from battery handle. Check tightness of

threaded ring.

D2. Lamp — Pull lamp straight out of bottom of otoscope body assembly.

D3. Lamp Collar — Remove lamp collar from bottom end of otoscope body assembly.

(Use fine tweezers).

D4. Lens — Slide lens out of otoscope body. Inspect lens and seal.

**** 21130 Reassembly ****

D5. Lens — Clean lens and slide lens into otoscope body assembly.

D6. Lamp Collar — Insert replacement lamp collar into otoscope body assembly.

(Points of collar should face up).

D7. Lamp — Clean lamp and carefully insert into bottom of otoscope body

assembly.

D8. Otoscope Body — Screw otoscope body onto battery handle.

Inspect.

End 21130

3

Page 56

E. 20100 (20101without Speculum) 2.5V Otoscope Disassembly:

20150 2.5V OotoscopeDisassembly:

(Above otoscopes are WIRED and not fiber-optic.)

E1. Lamp — Pull lamp hood off. Unscrew lamp.

E2. Window Assembly — Unscrew spring cup screw. Remove spring cup, spring, and wear

plate. Remove window assembly.

E3. Lens — Unscrew lens retainer. (Use lens window wrench tool #T-847)

remove lens. Remove and discard gasket.

E4. Contact Assembly __ Remove bayonet contact. Unscrew bayonet assembly and pull

off of wire. (Wire is sealed into the bayonet assembly with RTV

silicone sealant. Therefore do not remove bayonet contact and

assembly unless you are planning to replace the contact assembly).

Unscrew flat screw. Push out old contact assembly and pull out

wire. Clean out RTV from both the bayonet and the otoscope light

guide wire channel.

**** 20100, 20150 Reassembly ****

E5. Contact Assembly __ See FIG. 1 through 3. Position replacement contact assembly

on doctor-side of otoscope light guide. With wire down,

insert contact assembly into hole as shown in FIG. 1 below.

Push contact assembly into hole slightly beyond wire channel

as shown in FIG. 2. Insert the end of the wire into the wire

channel and push through the wire channel so that it comes

out of the bottom of the scope as shown in FIG. 3. Reposition

the contact assembly slightly rearward so that the wire goes

directly down into the wire channel hole. Screw flat screw

flush with light guide.

4

Page 57

20100, 20150 Otoscope Reassembly Continued

FIG. 1 FIG. 2 FIG. 3

E6. Bayonet Assembly __ Insert wire through the bayonet assy. Fill with medical grade

RTV sealant. Screw bayonet assy into scope while carefully

applying slight tension on the wire to remove excess wire from

the scope.

E7. Bayonet Contact — Remove insulation from the wire that protrudes from the end of

the bayonet assembly. Press bayonet contact into the small hole

in the end-insulation of the bayonet assembly so that it has good

electrical contact with the wire. Remove excess wire as in

FIG 4.

FIG. 4

5

Page 58

20100, 20150 Otoscope Reassembly Continued

E8. Lens — Install lens in window assembly and secure with lens retainer.

Screw and tighten lens retainer with tool T-847. Install new

gasket seal on lens window assembly.

E9. Window Assembly — Assemble spring cup screw through washer, spring and spring

cup. Attach lens window assembly to otoscope.

E10. Lamp — Screw lamp into light carrier. Slide lamp hood over lamp. Clean

lamp. Inspect. Perform Pneumatic Test A01303.

End 20100, 21050 Reassembly

—————————————————————————————————

F. 20200 (20201 without Speculum) 3.5v Otoscope Disassembly:

20250 (20251 without Speculum) 3.5v Otoscope Disassembly:

F1. Lamp — Pull lamp out of base of scope.

F2. Window Assembly — Unscrew spring cup screw. Remove spring cup, spring, and wear

plate. Remove window assembly.

F3. Lens — Unscrew lens retainer. (Use lens window wrench tool T-847)

remove lens. Remove and discard gasket.

**** 20200, 20250 Reassembly ****

F4. Lens — Install lens in window assembly and secure with lens retainer.

Screw and tighten lens retainer with tool T-847. Install new

gasket seal on lens window assembly.

F5. Window Assembly — Assemble spring cup screw through washer, spring and spring

cup. Attach lens window assembly to otoscope.

F6. Lamp — Clean lamp and press lamp into base of scope. Inpect.

Perform Pneumatic Test A01303.

End 20200, 20250 Reassembly

6

Page 59

G. 20202 (20203 without Speculum) 3.5V Otoscope Disassembly:

20262 (20263 without Speculum) 3.5V Otoscope Disassembly:

G1. Lamp — Pull lamp out of base of scope.

G2. Double Viewer — Loosen knurled ring and remove double viewer assembly.

Assembly Remove ‘o’ ring from body & light pipe assembly.

G3. Lenses — Unscrew both lens retainers and remove both lenses.

G4. Liner Blank — Pull liner blank out with finger tip.

G5. Beam Splitter — Unscrew 2-56 x 3/32' set screw. Pull beam splitter subassembly

Subassembly out.

G6. Window — (For broken or scratched windows only) remove window

retaining ring and window from double viewer assembly.

Remove RTV from window area.

**** 20202, 20262 Reassembly ****

G7. Window — Clean window and apply RTV sealant and install new window.

Secure with window retaining ring.

G8. Beam Slpitter — Clean mirror carefully on both sides. Insert beam splitter sub-

Subassembly assembly into long end of double viewer subassembly and

align to create view for side view port. Secure with 2-56 x 3/32'

set screw.

G9. Liner Blank — Insert liner blank into side view port.

G10. Lenses — Clean lens and place lens on double viewer subassembly with

convex surface out / flat side in. Determine that lens is

centered over port and then screw on lens retainer and fingertighten. Repeat for other lens.

7

Page 60

20202, 20262 Reassembly Continued

G11. Double Viewer — Install new ‘o’ ring on body & light pipe assembly. Attach

Assembly double viewer subassembly to body & light pipe assembly.

Fingertighten knurled ring.

G12. Lamp — Clean lamp and press lamp into base of scope. Inspect. Perform

Pnuematic Test A01303.

End 20202, 20262 Reassembly

—————————————————————————————————

H. 21600 (21601 without Speculum) 2.5v Otoscope Disassembly:

(Above otoscope is WIRED and not fiber-optic).

H1. Lamp — Unscrew lamp.

H2. Lens Holder — Unscrew lens holder screw. Remove lens holder spring washer,

Assembly 2 lens holder washers, and lens holder.

H3. Speculum — Unscrew lock nut clockwise from patient side perspective.

Holder Remove prism screw (set screw). Remove speculum holder.

H4. Lock Nut — Remove 2 lock ring halves. Remove lock nut.

H5. Contact Assembly __ Remove bayonet contact. Unscrew bayonet assembly and pull

off of wire. (Wire is sealed into the bayonet assembly with RTV

silicone sealant. Therefore, do not remove bayonet contact and

assembly unless you are planning to replace the contact

assembly). Pull out old contact assembly and wire. Clean out

RTV from both the bayonet and the body assembly.

8

Page 61

**** 21600 Reassembly ****

H6. Contact Assembly — See FIG. 5. Position the wire downwards relative to the

replacement contact assembly. Insert the wire into the threaded

hole (lamp socket) and guide it down into the small hole in the

bottom of the lamp socket. See FIG.6. It will come out of the

bottom of base as you push it in. Insert the contact assembly while

gently pulling on the end of the wire.

FIG. 5 FIG.6

H7. Bayonet Assembly __ Insert wire through the bayonet assy. Fill with medical grade

RTV sealant. Screw bayonet assy into scope while carefully

applying slight tension on the wire to remove excess wire from

the scope.

H8. Bayonet Contact — Remove insulation from the wire that protrudes from the end

of the bayonet assembly. Press bayonet contact into the small

hole in the end-insulation of the bayonet assembly so that it

has a good electrical connection to the wire ends. Remove excess

wire as in FIG. 7.

9

Page 62

21600 Reassembly Continued

FIG. 7

H9. Lock Nut — Place lock nut over body assembly stem. Insert speculum holder

into stem of body assembly in ‘up’ position. Insert prism screw

and tighten. Place 2 lock ring halves in groove of stem and slide

lock ring toward speculum holder and finger tighten.

H10. Lens Holder — Place lens holder spring washer onto body assembly. Place lens

Assembly holder assembly over washer (with lens recess towards doctor

side). Fasten it with lens holder screw and 2 lens holder washers.

H11. Lamp — Screw lamp into light guide. Clean lamp. Inspect.

End 21600 Reassembly

10

Page 63

I. 21700 (21701) 3.5V Otoscope:

I1. Lamp — Pull lamp out of base.

I2. Lens Holder — Unscrew lens holder screw. Remove lens holder spring washer,

Assembly 2 lens holder washers, and lens holder.

I3. Speculum — Unscrew lock nut clockwise from patient side perspective.

Holder Remove prism screw (set screw). Remove speculum holder.

I4. Lock Nut — Remove 2 lock ring halves. Remove lock nut.

I5. Lamp Collar — Remove lamp collar. (Use tweezers)

**** 21700 Reassembly ****

I6. Lamp Collar — Insert replacement lamp collar into body subassembly base

(points up).

I7. Lock Nut — Place lock nut over body assembly stem. Insert speculum holder

into stem of body assembly in ‘up’ position. Insert prism screw

and tighten. Place 2 lock ring halves in groove of stem and slide

lock ring toward speculum holder and finger tighten.