Page 1

Service Manual

Thermo Menu

Operator Manual

®

SureTemp

Model 986 Thermometer

Welch Allyn, Inc.

7420 Carroll Road

San Diego, CA 92121

Page 2

70995-0000B Technical Manual M986 © 2001

© 2000, 2001 by Welch Allyn, Inc. All rights reserved. No part of this manual may be

reproduced or transmitted in any form or by any means, electronic or mechanical, including

photocopy, without prior consent in writing from Welch Allyn, Inc. Printed in the USA

Welch Allyn and SureTemp are trademarks of Welch Allyn, Inc. All rights reserved.

Page 3

Contents

1. General Information...................................................................................................... 1

1.1 About the Model 986................................................................................................. 1

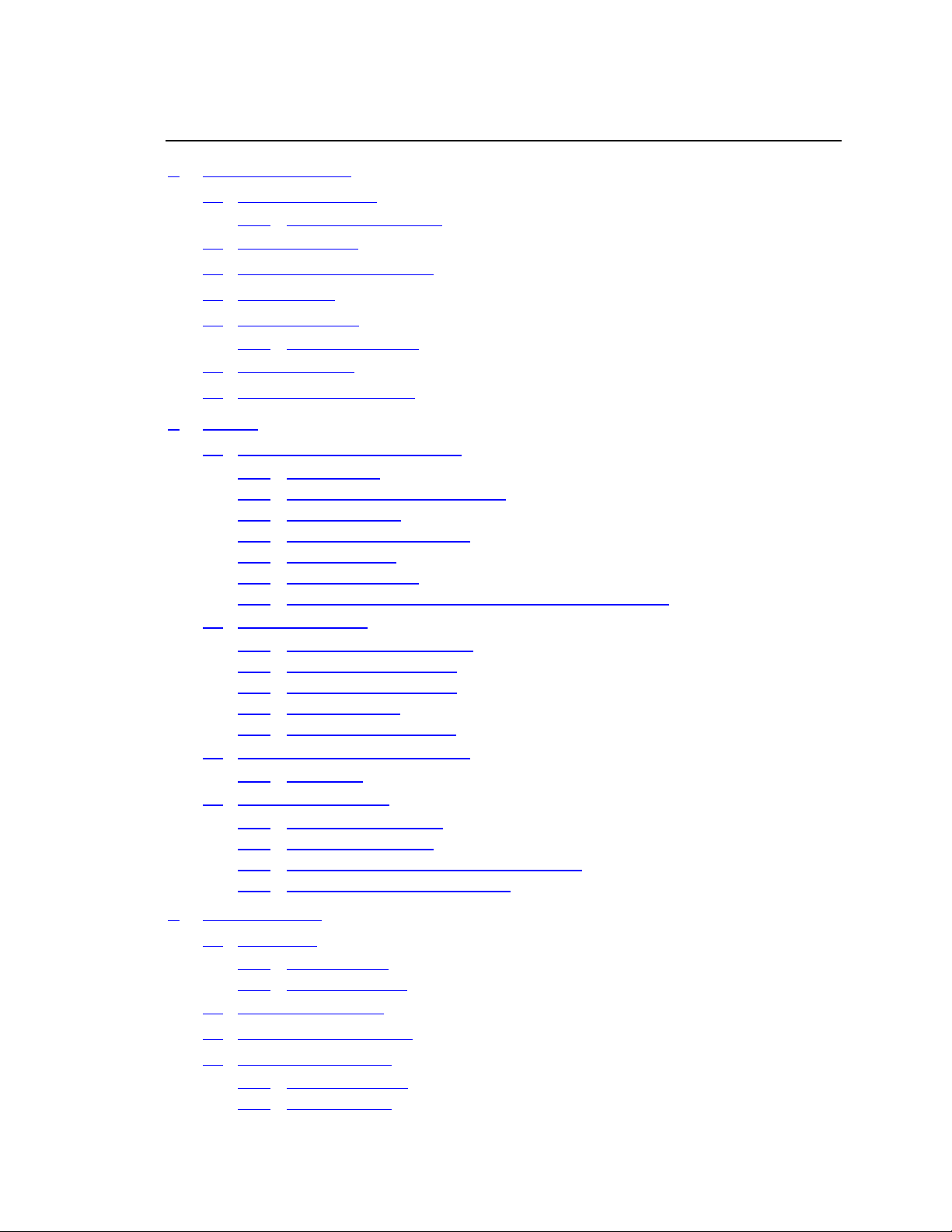

1.1.1 System Block Diagram................................................................................... 1

1.2 Technical Support .....................................................................................................1

1.3 Safety Warnings and Notices .................................................................................... 2

1.4 Classifications.......................................................................................................... 2

1.5 About this Manual .................................................................................................... 3

1.5.1 Related Documents........................................................................................ 3

1.6 Return Procedure ..................................................................................................... 3

1.7 Terms used in this Manual ........................................................................................ 4

2. Service .......................................................................................................................... 5

2.1 Basic Operation of the Model 986 .............................................................................. 5

2.1.1 Types of units ................................................................................................5

2.1.2 Major Thermometer Components .....................................................................6

2.1.3 Instrument Reset ........................................................................................... 6

2.1.4 POST (Power Up Self-Test)............................................................................. 7

2.1.5 Probe Type Test ............................................................................................ 7

2.1.6 Operational Checks........................................................................................ 8

2.1.7 Default algorithm for oral and axillary modes (blue probe) ................................11

2.2 Service Procedures .................................................................................................11

2.2.1 List of Tools and Equipment..........................................................................11

2.2.2 Preventative maintenance.............................................................................12

2.2.3 Cleaning and Sterilization .............................................................................13

2.2.4 Service Activities ..........................................................................................14

2.2.5 Component Replacement ..............................................................................14

2.3 Battery Removal and Replacement ...........................................................................15

2.3.1 Battery Life..................................................................................................15

2.4 Calibration Procedures............................................................................................16

2.4.1 Calibration Limits Table ................................................................................16

2.4.2 Water Bath procedure ..................................................................................16

2.4.3 Variable Temperature Water Bath procedure...................................................16

2.4.4 Model 9600 Calibration procedure ..................................................................17

3. Troubleshooting ..........................................................................................................19

3.1 Error Codes ...........................................................................................................19

3.1.1 Types of Errors ............................................................................................20

3.1.2 Error Recall Mode........................................................................................21

3.2 Troubleshooting Table.............................................................................................22

3.3 Disassembly/Reassembly.......................................................................................24

3.4 Field Serviceable Parts ...........................................................................................24

3.4.1 Main Components ........................................................................................24

3.4.2 Model 986 PCA ...........................................................................................26

Model 986 Thermometer i

Page 4

3.4.3 Replacement Parts for PCA ..........................................................................27

Appendix A. Theory of Operation.....................................................................................29

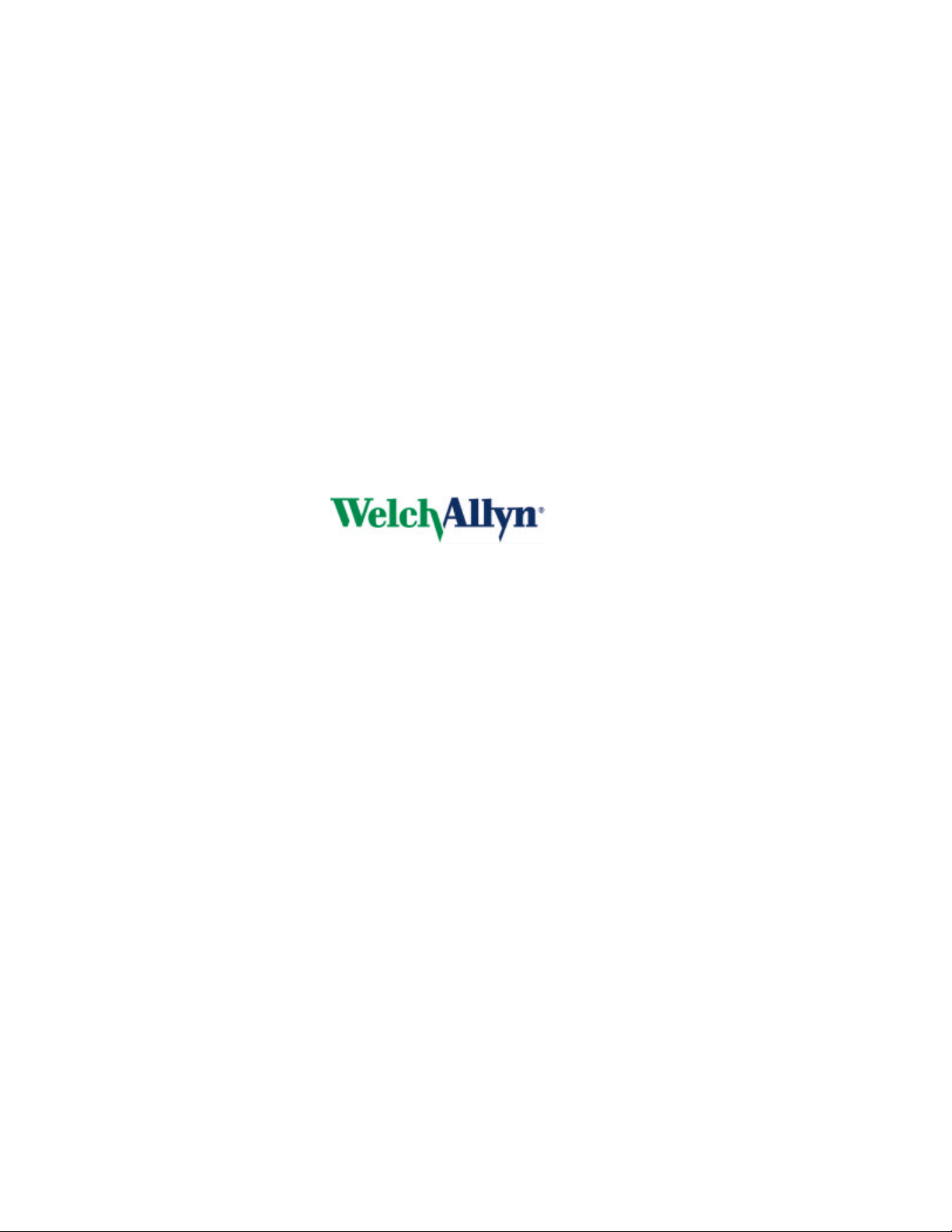

A.1 Overview................................................................................................................29

A.1.1 Temperature Probes.....................................................................................30

A.1.2 Probe Switch...............................................................................................30

A.1.3 Normal Mode Description..............................................................................30

A.1.4 Power Supply..............................................................................................31

A.1.5 Microcontroller.............................................................................................31

A.1.6 Reset/Self Tests..........................................................................................31

A.1.7 Microprocessor Clock...................................................................................32

A.1.8 Temperature Measurement And Display.........................................................32

A.2 Temperature Measurement A/D Converter .................................................................32

A.2.1 Use of Analog Circuitry.................................................................................32

A.2.2 A/D Theory of Operation ...............................................................................32

A.2.3 Circuit Description........................................................................................33

A.2.4 Probe Type Detection ...................................................................................34

A.2.5 Instrument ID Logic......................................................................................34

A.2.6 Circuit Operation ..........................................................................................34

A.3 Probe warming (Oral probes only)............................................................................35

A.3.1 Theory of Operation ......................................................................................35

A.3.2 Circuit Operation ..........................................................................................35

A.3.3 Liquid Crystal Display ...................................................................................36

A.3.4 Probe Switch...............................................................................................36

A.3.5 Mode Button................................................................................................36

A.3.6 Horn ...........................................................................................................37

Appendix B. Specifications .............................................................................................. 39

Appendix C. Limited Warranty ......................................................................................... 41

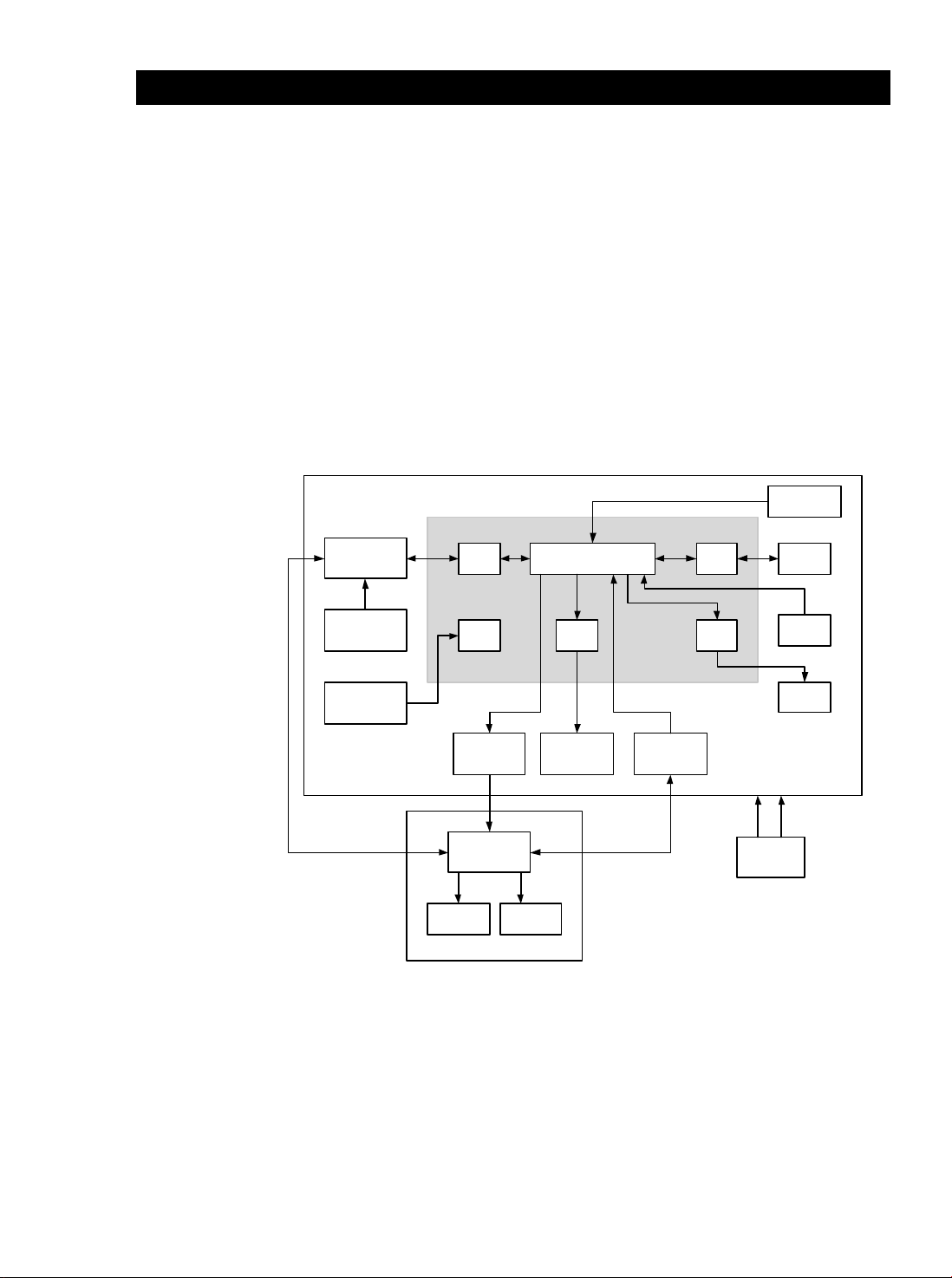

Appendix D. Wiring Diagram ...........................................................................................43

ii 70995-0000B M986

Page 5

List of Figures

Figure 1: System Block Diagram .............................................................................................. 1

Figure 2: Model 986 Thermometer .............................................................................................5

Figure 3: M986 Display ............................................................................................................ 7

Figure 4: Peak Monitor Mode.................................................................................................... 9

Figure 5: Battery Removal and Replacement............................................................................15

Figure 6: Thermometer Assembly ...........................................................................................24

Figure 7: Printed Circuit Assembly ..........................................................................................26

Figure 8: System Block Diagram ............................................................................................29

Figure 9: Schematic Diagram .................................................................................................43

List of Tables

Table 1: Self-Test Error Table..................................................................................................20

Table 2: Main Components .....................................................................................................25

Table 3: Replacement Parts for PCA .......................................................................................27

Table 4: Configuration Truth Table ...........................................................................................34

Model 986 Thermometer iii

Page 6

iv 70995-0000B M986

Page 7

1. General Information

1.1 About the Model 986

The Welch Allyn Model 986 SureTemp is a portable, predictive

thermometer that accurately measures body temperatures in a

few seconds at oral, axillary, or rectal sites. Oral/axillary and rectal

probes utilize single use disposable probe covers to help limit

cross-contamination.

This instrument was developed for use by medical professionals

and day care providers. The predictive technology allows the user

to take oral temperatures in approximately four seconds, axillary

temperatures in approximately 10 seconds (for children under four

years), and rectal temperatures in approximately 15 seconds.

1.1.1 System Block Diagram

Model 986 PCA

A/D Converter

Circuit

Voltage

Reference Circuit

Battery Detector

Circuit

NEC UPD 789407 uP

16 Bit

Timer

8 Bit

A/D

Probe Warmer

Circuit

Four Conductor

Coil Cord

Thermistor

Probe Assembly

Probe

Warmer

CPU

LCD

Driver

Liquid Crystal

Display

Probe

Configuration

Jumpers

Serial

I/O

Horn

Driver

2 AAA

Batteries

Configuration

Serial

Port

Mode

Button

Horn

Figure 1: System Block Diagram

1.2 Technical Support

Contact Welch Allyn Customer Service at:

Welch Allyn, Inc

7420 Carroll Road

San Diego, CA 92121

Model 986 Thermometer 1

800-535-6663

Page 8

1. General Information

1.3 Safety Warnings and Notices

1. DO NOT USE THIS INSTRUMENT IN THE PRESENCE OF

FLAMMABLE ANESTHETICS.

2. Do not use this instrument for any purpose other than those

specified in the User’s Guide. Doing so will invalidate the

instrument’s warranty.

3. Oral/Axillary SureTemp thermometer models (with a blue

ejection button at the top of the probe) are to be used for taking

oral and axillary temperatures only. Rectal models (red

ejection button) are to be used for taking rectal temperatures

only. Use of a probe at the wrong type of site will result in

temperature errors.

4. Use only single-use Welch Allyn disposable probe covers. The

use of any other probe cover or the failure to use a probe cover

may produce temperature measurement errors and increase

the chances for cross-contamination.

5. The thermometer case is not waterproof. Do not immerse it in

liquids or drip fluids onto it.

6. Dispose of batteries in accordance with all local, state and

federal environmental guidelines.

7. This instrument consists of high quality precision parts and

should be protected from severe impact and shock. Do not use

the thermometer if you notice any signs of damage to the

probe or instrument. Contact Welch Allyn Customer Service at

(800) 535-6663 for immediate assistance.

Note: This thermometer complies with current required

1.4 Classifications

Type of protection against

Degree of protection against

Degree of protection against

standards for electromagnetic interference and should

not present a problem to other equipment or be affected

by other devices. As a precaution, avoid using this

device in close proximity to other equipment.

Internally Powered Equipment

electric shock

Type BF Applied Part

electric shock

Ordinary (IPXO)

ingress of liquids

Degree of safety in the

presence of flammable

anesthetics

Mode of operation Continuous

2 70995-0000B M986

Equipment not suitable for use

with flammable anesthetics

Page 9

1.5 About this Manual

This manual describes both the Model 986 Oral/Axillary and Rectal

thermometers. Most topics and procedures are equally applicable

to both products. Where there are differences, we will note which

instrument is being discussed.

1.5.1 Related Documents

End user operation of the Model 986 is covered in the M986

User Guide and Quick Reference Guide.

Model 986 User Guide 70994-1000

Model 986 Quick Reference Guide 71019-0000

This Service Manual assumes that the technician understands

these operations.

1.6 Return Procedure

1. General Information

Contact Welch Allyn Customer Service at (800) 535-6663 before

returning an M986 Thermometer to the factory for service.

Model 986 Thermometer 3

Page 10

1. General Information

1.7 Terms used in this Manual

The following abbreviations are used in this manual:

Main Component Terms

PCB Printed circuit board (the board itself)

PCA Printed circuit assembly (with all components)

LCD Liquid Crystal Display

BATT. Battery.

DMM Digital Multi-Meter

O-Scope Oscilloscope

Component Reference Terms

C Capacitor

D Diode

E Test point

J Connector jack

L Inductor

LS1 Horn

P Connector plug

Q Transistor

R Resistor

S Switch

U Integrated circuit

X Crystal, resonator

4 70995-0000B M986

Page 11

2. Service

2.1 Basic Operation of the Model 986

The Model 986 is a portable digital thermometer. Service

technicians should check the basic operation of the instrument

before it is disassembled.

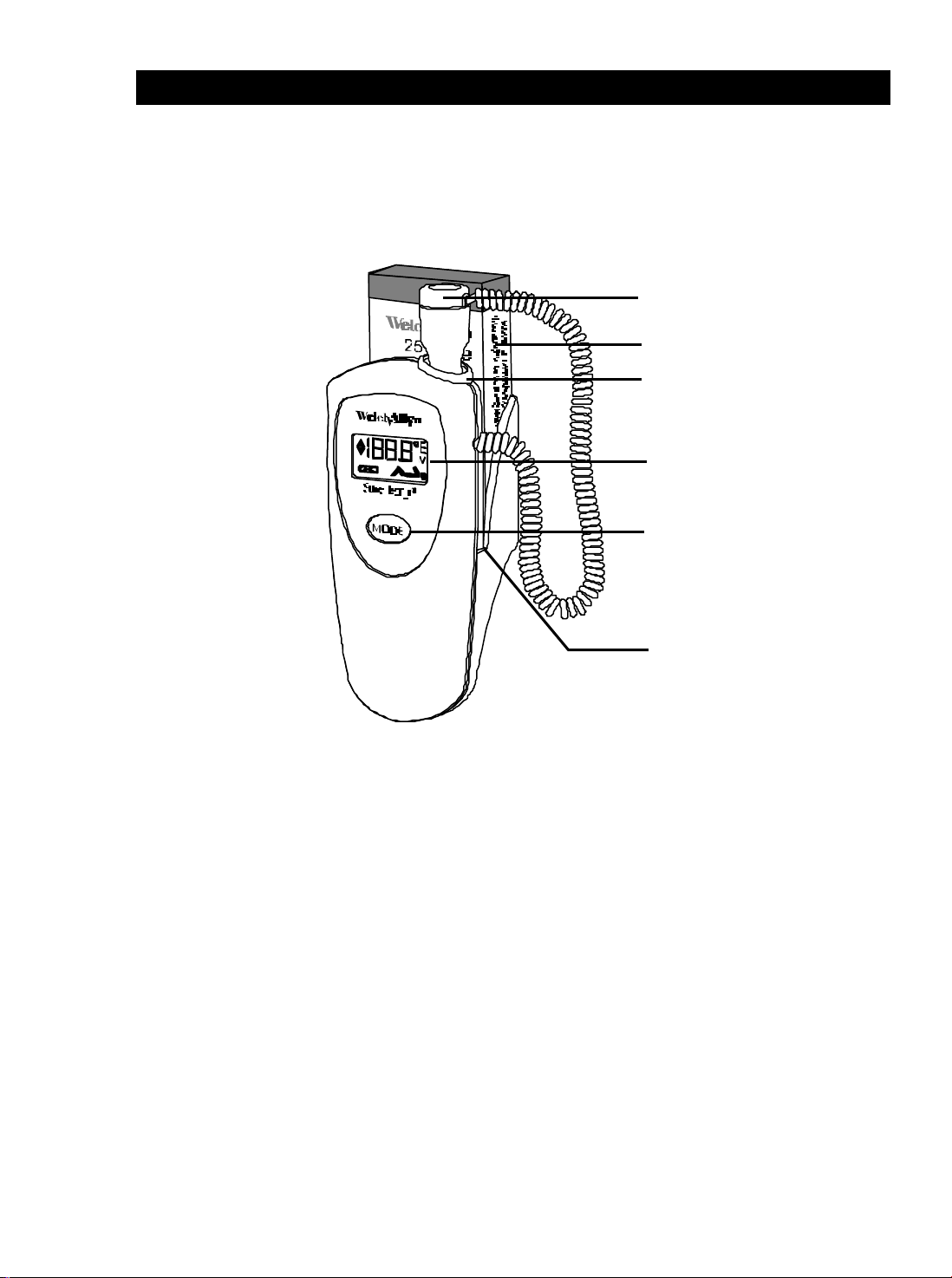

1 Probe cover ejection button

2 Probe cover box

3 Probe storage channel

4 LCD display

5 Mode button

2.1.1 Types of units

The M986 is available from the factory in the following

configurations:

• Oral /Axillary or Rectal Probe

• ° F/°C, ° F Only, °C Only

Note: Thermometer configuration cannot be modified in the field.

6 Battery Compartment

Figure 2: Model 986 Thermometer

Model 986 Thermometer 5

Page 12

2. Service

2.1.2 Major Thermometer Components

Batteries The Model 986 thermometer uses two standard

disposable alkaline AAA cells. These batteries

provide long life for reduced down time. No battery

charging is required or possible.

Probe Two types of probes are available: Oral/Axillary

(blue), and Rectal (red). The probe is not detachable

and is connected to the printed circuit board at the

factory.

Probe

Covers

The probe covers are unchanged from previous

models and are compatible across all of Welch

Allyn’s thermistor-based thermometers.

Note: The use of probe covers other than Welch

2.1.3 Instrument Reset

If a problem is reported with an instrument, please check its

operation before resetting it.

Reset Procedure

1. Remove the batteries from the instrument (see page 15).

2. After battery removal, any remaining charge due to internal

capacitance must be discharged to achieve a proper reset.

After the batteries are removed, press the Mode button for

about five seconds. The electronics will now properly reset

when the batteries are replaced.

3. Reinstall the batteries. Watch the display and observe the

power up self-test (page 7).

Allyn PN 05031 is not allowed, and will affect

the accuracy of the instrument.

6 70995-0000B M986

Page 13

2.1.4 POST (Power Up Self-Test)

The self-test includes a series of internal microprocessor self

tests, instrument electronics tests, and the display test. If there are

internal electronics problems detected by the self-tests, the Err

(error) icon will be displayed and an audible tone will sound. Refer

to the Error Codes table in the Troubleshooting section (page 19)

for an explanation of any error code. The M986 electronics are

tested each time the batteries are replaced.

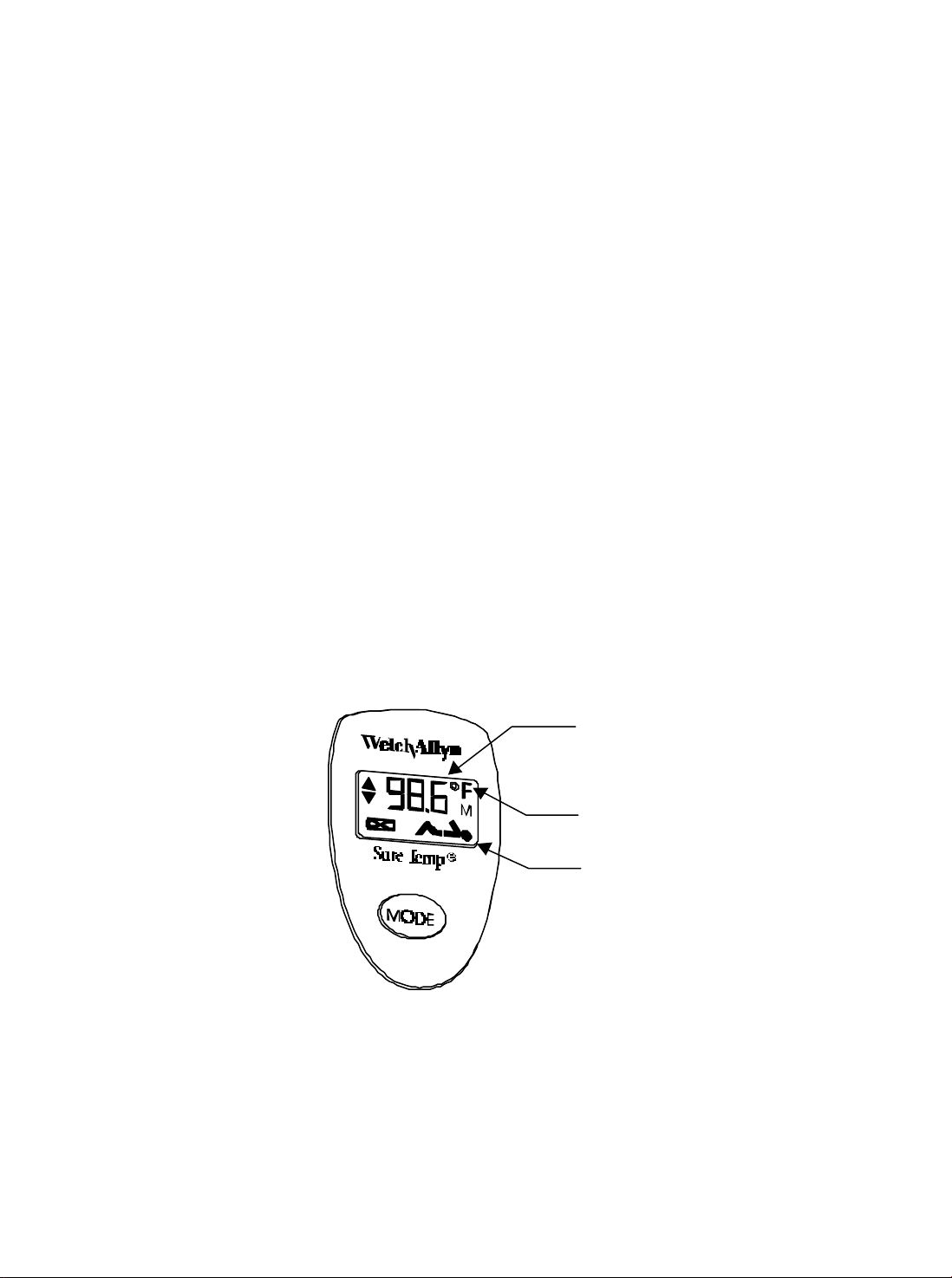

• The Power up test begins with all display segments and icons

simultaneously illuminated, followed by a display of the

software revision in this instrument. The M986 beeper also

briefly sounds at the beginning of the test.

Figure 3: M986 Display

2. Service

• At the end of the test, the display goes blank and the unit is

ready to operate.

If there is no display, any missing segments, or no beeper, refer to

the Troubleshooting table (page 22).

2.1.5 Probe Type Test

Test the probe to make sure that the correct type of probe is

attached to the unit.

With the probe shaft in the probe well and the display blank, press

the Mode button for three seconds. After three seconds, the

instrument will beep and the display shows the icon with

the measuring site blinking.

• For a blue (oral/axillary) probe, either the head or arm should

blink, depending on whether the instrument is configured for

Oral or Axillary measurements.

• With a red (rectal) probe, the leg icon should blink.

If the wrong icon is blinking, there is a problem with either the probe

or the probe type configuration in the instrument.

1. Refer to the mode table on the schematic diagram (Appendix D).

2. In the mode table, locate the type of instrument – oral only,

rectal only, etc. that you are using.

3. Open the thermometer and locate the jumpers. Verify that the

jumpers are configured for your type of unit.

4. If the jumpers are not configured properly, contact Welch Allyn

Customer service for assistance.

Model 986 Thermometer 7

Page 14

2. Service

2.1.6 Operational Checks

Normal Mode

Normal mode operation is the rapid mode of temperature taking.

This is the default mode and is automatically selected when the

probe is withdrawn from the probe well.

1. When the probe is withdrawn from its storage well, every

segment on the display will be illuminated. Watch for the

display to change from the all segments test to the body icon

display.

2. When the unit is ready, it will beep. The °F or °C symbol

(whichever is selected) will illuminate, and the measuring site

(oral, axillary, rectal) will begin to blink.

3. Load the probe cover at this time. The instrument is now ready

for the probe to be placed in the measuring site.

Note: It is possible that the display will switch from the measuring

site display to the “walking segments” display and back

again several times before the probe is inserted in the site.

This is acceptable operation and will not adversely affect

the temperature taken.

Monitor Mode

The thermometer will automatically switch to Monitor Mode under

certain conditions:

• If the instrument determines that room temperature is above

33.9°C (93.0°F).

• If the thermometer is unable to predict a temperature, after 15

seconds for Oral/Axillary and 30 seconds for rectal, due to

improper technique such as excessive probe movement at any

patient site (i.e. mouth, rectum, axillary).

Note: The thermometer reads the probe temperature immediately

upon removal from the storage well. If the probe was just

replaced from a previous temperature and immediately

extracted, insufficient time may have passed to allow the

probe to cool to room temperature. This will cause the

instrument to determine room temperature to be higher

than actual. The instrument will switch to Monitor mode

immediately if it detects room temperature to be above 33.9

°C (93.0°F). For best results, the user should wait at least

30 seconds between Normal mode temperature

measurements.

If Monitor mode does not display expected temperatures, refer to

the Troubleshooting table on page 22.

8 70995-0000B M986

Page 15

2. Service

Temperature Display

With correct use, the patient’s temperature will be displayed in

about four seconds in oral mode, about 10 seconds in axillary

mode, and about 15 seconds with a rectal probe. The instrument

will beep to signal completion of the Normal Mode temperature

cycle.

Automatic Shutoff

If the probe is left out of the storage well after completion of a

Normal mode temperature, the unit will shut off automatically after

10 seconds to conserve power. Simply replace the probe in the

storage well to prepare for the next temperature.

The instrument will shut off automatically if the probe temperature

remains below 28.9°C (84.0°F) for more than 30 seconds.

Peak Monitor Mode

Peak Monitor mode allows long term monitoring of a patient’s peak

temperature. Unlike predictive mode, Peak Monitor mode will follow

a temperature as it rises and display this temperature until the

probe detects a higher temperature. When this occurs, the higher

temperature is displayed.

Peak Monitor mode provides a direct readout of the peak probe

temperature. The instrument can set in Peak Monitor mode by

immediately pressing the Mode button for two seconds after a

predictive (normal) temperature has been taken.

Constant

Temperature

Flashing

Body icon disappears

Figure 4: Peak Monitor Mode

Peak Monitor mode will be indicated on the display by a continuous

temperature reading with a blinking °°F or °°C Icon at the upper right

corner of the LCD, and by the body icon disappearing.

Model 986 Thermometer 9

Page 16

2. Service

The typical slow rise in temperature when Peak Monitor mode is

used is due mainly to the mouth temperature slowly recovering

from placement of the colder (room temperature) probe. The probe

itself is actually very fast at rising to the temperature of its

surroundings, usually reaching it within a few seconds. Because of

this slow mouth recovery, three minutes is the recommended time

to wait before recording a Peak Monitor mode temperature.

Peak Monitor mode is also useful in testing the accuracy of the

thermometer when the probe can be warmed to a known

temperature, as with a Welch Allyn Model 9600 Calibration Tester

or in a water bath (see section 2.4).

In Peak Monitor mode, after approximately 60 seconds of no

increase in temperature, the °°C / °°F icon stops flashing. You will

hear two triple beep sounds, and the peak temperature will be

displayed on the LCD.

Note: If the unit is left in Peak Monitor Mode for a total of five

minutes, it will automatically shut off to conserve power.

If Peak Monitor mode does not display expected temperatures,

refer to the Troubleshooting table on page 22.

°F / °C Conversion

When a final temperature is displayed (in Normal, Recall, or

Monitor mode), press and release the Mode button to toggle the

temperature between °F/°C.

Note: A recalled temperature will be displayed in whichever scale

(°F/°C) is selected at the time of recall. This setting can be

changed during display.

If pressing the Mode button does not change the scale of the

displayed temperature, refer to Mode Button Problems in the

Troubleshooting table on page 22.

Temperature Recall

With the instrument in low-power mode (sleep mode or blank display),

press and release the Mode button to cause the most recent

measured temperature to be displayed for five seconds. The stored

temperature value appears with a °F or °C symbol (whichever is

selected) and an M indicating it is from memory.

• If the recalled temperature was a normal mode temperature,

the flashing symbol of the measurement site is also displayed.

• If the recalled temperature was a Peak Monitor temperature,

only the temperature is displayed, with no site indicated.

Activation of the probe well switch (place the probe in the well) will

interrupt the temperature recall function.

10 70995-0000B M986

Page 17

Temperature recall problems

If the last temperature cannot be recalled, refer to Temperature

Recall Problems in the Troubleshooting table on page 22.

If pressing the Mode button does not change the scale of the

displayed temperature, refer to Mode Button problems in the

Troubleshooting table.

2.1.7 Default algorithm for oral and axillary modes

(blue probe)

Two predictive algorithms are available: oral and axillary. To

change the default algorithm:

1. Place the unit in low power mode.

2. Press and hold the Mode button for at least two seconds, until

a short beep is heard. The current algorithm will be displayed.

3. To advance to the next algorithm, press the Mode button

momentarily.

2. Service

Note: When replacing the batteries, the default power up setting is

the oral predictive algorithm.

2.2 Service Procedures

2.2.1 List of Tools and Equipment

Most service operations can be performed with standard tools and

test meters:

• A #1 Phillips screwdriver can be used for all instrument

screws.

• A standard lab 3.5 digit digital multi-meter (DMM) will provide

sufficient accuracy for most tests. A needle-tipped pair of

probes is recommended. An oscilloscope is sometimes the

only way to analyze high speed signals, but is not generally

required.

• Standard electronics tools and supplies for small surface-

mounted and through-hole component rework will be needed to

perform any electronics repairs. Some surface-mounted

components are extremely small and present a challenge for

rework by hand. A light touch, tweezers, sharp soldering iron

tip, and low heat (#7 tip) are recommended.

• Power (+) and ground (-) are available at the battery terminals.

• Be sure to service the instrument in an ESD-safe work area.

Model 986 Thermometer 11

Page 18

2. Service

2.2.2 Preventative maintenance

Units that are used on a regular basis should have the following

preventative maintenance performed at least every six months:

1. Visually inspect the thermometer for physical damage that

might cause future product failure.

2. Clean the unit per the instructions in the User Guide supplied

with the thermometer and/or per the instructions below.

3. Perform the Power on Self Test (page 7), Startup Display Test

(page 7), and the Calibration Test procedure (page 16).

Long Term Storage

Remove the batteries from units that are to be stored for an

extended period and not used.

Regular Tests and Calibration

Perform the following tests every 12 months regardless of storage

and usage levels:

1. Replace the batteries (page 15).

2. Perform the Power on Self Test (page 7), Startup Display Test

(page 7), and the Calibration Test procedure (page 16).

12 70995-0000B M986

Page 19

2.2.3 Cleaning and Sterilization

Routine Cleaning

Clean the exterior of the Model 986 and the probe as needed.

• Use a Q-Tip to clean the probe well.

• Wipe all surfaces with a clean cloth dampened with warm

water and a mild detergent, alcohol, or a nonstaining

disinfectant such as Sporicidin Spray1 and Towelettes

cleanser.

Care should be taken not to scratch the LCD faceplate. Make sure

that the cloth is damp, but not too wet.

• Do not allow cleaning solution to flow inside the instrument.

• Never immerse the thermometer into the cleaning solution.

• Never autoclave the thermometer or probe.

Gas Sterilization

2. Service

When no other form of decontamination such as a germicidal wipe

is acceptable, a low temperature (not to exceed 48.9°C or 120°F)

ETO gas sterilization cycle may be used. Refer to your institution’s

standard operating procedure for the length of the cycle.

Note: Gas sterilization may cause some hazing of glossy plastic

surfaces and should be used only when absolutely necessary.

1. Remove the probe from its storage well and disconnect it from

the instrument.

2. Remove any probe covers from the probe and from the probe

cover storage well.

3. Remove the batteries following the instructions on page 15.

WARNING: Leaving batteries in the thermometer during the

sterilization procedure may present an explosion

hazard.

4. Wrap the thermometer in standard sterilization packaging such

as the Baxter Tower Dualpeel Sterilization Pouch.

5. ETO gas sterilize the instrument at a temperature not to

exceed 48.9°C (120°F) and aerate.

6. Remove the sterilization packaging.

7. Allow the probe and instrument to stabilize to room

temperature for at least one hour before reinstalling the

batteries and probe.

1

Sporicidin is a registered trademark of Sporicidin International (800) 424-3733.

Model 986 Thermometer 13

Page 20

2. Service

8. Reinstall the batteries (see page 15) and verify a successful

self-test.

9. Reinstall the probe connector and insert the probe into the

storage well to start the probe initialization process.

10. Verify proper calibration of the thermometer and probe using

the Welch Allyn Model 9600 Calibration Tester.

2.2.4 Service Activities

Field Service Repairs

Repairs are considered field serviceable if the repair will not alter

the calibration or proper operation of the instrument. Recalibration

requires a computer-based system and is normally performed at

the factory.

Factory Repairs

Because of programming requirements, if problems are traced to

microcontroller U1, the unit must be returned to the factory or

properly equipped service center for repair.

2.2.5 Component Replacement

All components in the Model 986 can be replaced without affecting

instrument operation or calibration. Changing R13 will cause some

minor changes to the exact calibration point, but as long as the

proper type and tolerance resistors are used (0.05%, as supplied

by Welch Allyn), the unit will remain within specifications.

LCD Frame Repair or Replacement

Replacement of the LCD frame is somewhat difficult due to the

need to assemble it while under pressure to assure proper

compression of the elastomeric connector.

Note: Do not glue the LCD frame to the display PCB if the frame

pins are broken. This will destroy the display PCB. Replace

the LCD frame with a new LCD frame.

14 70995-0000B M986

Page 21

2.3 Battery Removal and Replacement

Figure 5: Battery Removal and Replacement

1. Remove the Probe Cover box holder on the back of the

instrument by pressing with your index finger on the latch

located on the rear of the Probe Cover box holder.

2. Service

2. Remove the batteries.

3. Press the Mode button for approximately five seconds to

discharge the electronics.

4. Install two new AAA, alkaline batteries according to the

battery polarities marked inside the battery compartment.

Verify that the thermometer completes a power on reset

test (page 7), and then goes blank.

CAUTION: Incorrect battery polarity may result in damage

5. Snap the probe cover storage assembly in place by inserting the

bottom tabs first and then snapping the latch on top.

2.3.1 Battery Life

Under normal use, battery life will provide approximately 3,000

normal temperature measurements, based on an average 22.2°C

(72.0°F) ambient temperature. Colder ambient temperatures,

excessive peak monitor measurements, and other usage patterns

can reduce battery life.

Instruments are shipped with fresh batteries, but we cannot

guarantee full life from the first set of batteries due to potential long

storage times between shipping and actual use. Battery life can

also be reduced by storage at elevated temperatures.

to the thermometer.

If you are experiencing short battery life, refer to Battery Life

Problems in the Troubleshooting table on page 22.

Model 986 Thermometer 15

Page 22

2. Service

2.4 Calibration Procedures

2.4.1 Calibration Limits Table

Patient Temperature

Ambient Temperature Range 9.0° C to 40.0° C (48.2° F to 104.0° F)

Laboratory Accuracy ± 0.1° C (± 0.2° F) in the Monitor Mode

Battery Operating Life Approximately 3,000 normal mode

2.4.2 Water Bath procedure

The target patient temperature for the M986 ranges from 96° F to

109.4°.

Oral/Axillary 35.5° C to 43.0° C (96° F to 109.4° F)

Rectal 30.0°C to 43.0° C (86° F to 109.4° F)

In a water bath, must meet ASTM

E1112-86 and EN12470-3 Standards

measurements at 22.2°C (72o F)

ambient temperature

1. Adjust the water bath to 109.6°F. Apply a probe cover to the

thermometer probe, and let the probe tip sit in the water

bath.

2. Place the thermometer in Peak Monitor Mode (page 9).

Wait three minutes. Verify that the water bath temperature

is displayed on the LCD with the up arrow flashing.

3. For temperatures below the minimum target temperature,

verify that the minimum temperature is displayed on the

LCD, and the down arrow is flashing.

2.4.3 Variable Temperature Water Bath procedure

Adjust the water bath to 46.0°F. Apply a probe cover to the

thermometer probe, and let the probe sit in the water bath for one

minute.

1. Press and release the Mode button. Verify that a Low

Ambient error (E1.2) occurs, but that a probe A/D pulse

width error (E0.2) does NOT occur.

2. Repeat with the water bath set to 106.0°F, and verify that a

High Ambient error (E1.1) occurs, but that a probe A/D

pulse width error (E0.2) does NOT occur.

16 70995-0000B M986

Page 23

2.4.4 Model 9600 Calibration procedure

The Model 9600 Calibration Tester provides a convenient means of

testing the entire thermometer system (instrument and probe).

• The 9600 must be warmed up and stable at one of the two

available temperature settings: 106º F/41º C or 96.4º F/35.8º C.

• The instrument under test must be in Peak Monitor mode

(page 9) with no probe cover loaded.

The probe is inserted into the small hole in the dry heat well of the

Model 9600 and allowed to settle for a minimum of two minutes at

the final temperature. The reading on the thermometer must be

within the range specified on the Model 9600. Refer to the Model

9600 Operation Manual for complete instructions.

Note: All Welch Allyn thermometers, (thermistor and infrared ear

thermometers) can be checked in the Model 9600.

If you are having problems with the use of the Model 9600, refer to

the Troubleshooting section in the Model 9600 Operation Manual.

2. Service

Model 986 Thermometer 17

Page 24

2. Service

18 70995-0000B M986

Page 25

3. Troubleshooting

Many operational parameters of the thermometer can be tested

before the unit is taken apart.

• Refer to Operational Checks (section 2.1.6) and Error Recall

Mode (section 3.1.2) to complete preliminary checks.

• If the trouble seems to be calibration related, refer to

Calibration Testing (page 16).

If these operational tests do not resolve the problem and you are

sure that the instrument is not performing properly, use the

following sections to complete the debugging process. Be sure to

have the proper tools and equipment (page 11).

3.1 Error Codes

Errors can fall into three categories: Transitory, Recoverable and

Non-Recoverable.

Transitory Transitory errors are generated by external

3. Troubleshooting

events, not by the thermometer. Temperature

measuring will be inhibited until the error is

cleared. There is no limit to the number of times

a transitory error can occur.

Note: All probe problems are considered by the

thermometer to be external events and are

therefore classified as transitory.

Recoverable Recoverable errors are generated from internal

test failures. These are non-catastrophic, but

they prevent temperature measurement until the

error is cleared.

After displaying an error code, the instrument will

reset itself and attempt to resume normal

operation. After the fourth attempt to clear itself,

the error becomes non-recoverable.

Non-Recoverable Non-recoverable errors are generated from

internal test failures that are catastrophic (or

from promoted recoverable errors). The error

code will be stored in memory and the LCD will

display Err.

The only way to continue at this point is to reset

the electronics by removing the batteries.

Model 986 Thermometer 19

Page 26

3. Troubleshooting

3.1.1 Types of Errors

There are three types of recoverable and non-recoverable errors, and

each type of error has a unique display that will last about five seconds

before the unit goes into Low Power Mode (blank display).

Ambient Error The Operating Temperature is out of limits.

An Ambient Temperature Too High error display

(E1.1) shows a flashing two times per second,

together with an A and the °F or °C icon.

An Ambient temperature Too Low error (E1.2)

display shows a flashing two times per second,

together with an A and the °F or °C icon.

Battery Error The display shows a non-flashing battery icon,

with no other LCD icons visible.

Instrument

Error

The display shows a non-flashing Err in the lower

numeric LCD digits, with no other LCD icons.

Each error type can be viewed using the Error Recall Mode

(Section 3.1.2).

Table 1: Self-Test Error Table

Error Class Description Action

E0.1 Instrument Probe heater energy accumulator

test.

E0.2 Instrument Probe A/D pulse width test. Contact Welch Allyn

E1.1 Ambient Ambient temperature high test. Move unit to lower ambient

E1.2 Ambient Ambient temperature low test. Move unit to a higher ambient

E2.1 Battery “Dead” battery test. Replace batteries

E3.1 Instrument RAM error Contact Welch Allyn

E4.1 Instrument Ratio Cal resistor A/D pulse width

test.

E5.0 Instrument Heater circuit test.

Contact Welch Allyn

temperature area and retry

temperature area and retry

Contact Welch Allyn

E5.1 Instrument Heater overheated test.

E5.2 Instrument Heater hardware watchdog time

out test.

E5.3 Instrument No Probe Heater Try a different probe, then

E5.7 Instrument Data Overrun test Contact Welch Allyn

E5.8 Instrument Stack Overflow test Contact Welch Allyn

20 70995-0000B M986

Contact Welch Allyn

contact Welch Allyn

Page 27

3.1.2 Error Recall Mode

The M986 has the ability to recall the most recent error condition

from memory.

To enter this program mode:

1. Place the unit in low power (sleep) mode by allowing it to

rest for about 30 seconds. The display will go blank.

2. Press and hold the Mode button and, at the same time,

remove the probe from the probe well. In this mode the

M986 will display the letter “E” followed by an error code.

(for example, E0.1)

If the E is not followed by an error number, the instrument

has not had any errors since its last power-on reset

(Battery replacement).

The instrument exits Error Recall mode automatically after five

seconds. Replacing the probe in the probe holder returns the unit

to normal operation.

If you cannot enter the Error Recall Mode, refer to Error Recall

Mode Problems in the Troubleshooting table on page 22.

3. Troubleshooting

Model 986 Thermometer 21

Page 28

3. Troubleshooting

3.2 Troubleshooting Table

If the unit fails to operate properly after completing the suggested

procedure listed in the following table, contact Welch Allyn

Customer Service at 1-800-535-6663.

Symptom Possible Cause Procedure

No operation Dead batteries, no batteries,

battery missing, battery

incorrectly installed

Broken battery wire Open instrument case, install batteries, check

Short circuit preventing

operation

Failed component Check oscillator at U1-68 for 2.4975 MHz sine

Display

problems

LCD frame loose Check that all 3 plastic hooks for the LCD

Dirty LCD elastomeric

conductor strips

Refer to Battery Removal and Replacement

section on page 15. Check that all batteries are

installed in proper direction.

Reset electronics. (See Instrument Reset/Self

Tests section on page 6)

for voltage on main PCB at battery wire

connections.

Remove batteries, press mode button 5

seconds, set DMM to Ohms, measure

resistance of electronics at battery contacts

(“+” to bottom right corner, “-” to top left corner)

Resistance should climb to more than 2 Mega

ohms as C25 charges.

wave. If not present, suspect X1, U1, C6, and

C7.

frame are tight and not broken. The frame

should not be lifting off of PCB.

Remove LCD frame by unlatching plastic

hooks. Clean LCD elastomeric strips, LCD

glass contacts, and PCB contacts with lint

proof cloth dampened with alcohol.

Failed Component Check R17 for open component

Cracked LCD Inspect LCD for hairline cracks

Display

problems

(Continued)

No beeper

sound

Normal/Monitor

Mode switching

problems

22 70995-0000B M986

Microprocessor failure Check for improper soldering of pins, crystal

operation on O-scope, proper reset.

Defective horn Replace horn.

Broken connection Check continuity from U1-50. to horn pin 2 and

from ground to horn pin 1.

Defective U1 Check for signal with O-scope at U1-50.

Replace microcontroller U1.

Ambient above 33.9°C

(93.0°F)

Will cause auto switch to Monitor mode.

Page 29

Symptom Possible Cause Procedure

3. Troubleshooting

Probe: Wrong

type displayed

Battery Life

Problems

Monitor mode

temperature

reading too low

Switched to Monitor mode

before probe in mouth

If probe is still cooling from a previous

temperature and used immediately, it might

sense ambient to be above 33.9°C (93.0°F).

Missing one or more

configuration Jumpers

JP1-JP4

Excessive alarms Excessive

use in monitor mode

Check that the configuration Jumpers are

installed according to the Probe Type truth

table.

The horn draws significant current. During

monitor mode the instrument is continuously

drawing current.

Dead cell If cell voltage is down significantly in only one

cell, this battery is defective. All batteries are

drained at the same rate by the instrument.

First Set Shelf Life Due to possibly long stocking times between

fabrication and end use, the first set of

batteries may have reduced life.

Probe or Instrument

malfunction

Test calibration of thermometer with the M9600

Calibration Tester

Improper placement of probe Probe must be under the tongue and as far

back as possible into the sublingual pocket.

Temperature not stable Allow three minutes for Monitor mode reading

to stabilize in mouth.

Monitor mode

temperature

reading too high

Normal mode

temperature

reading too low

Normal mode

temperature

reading too high

Probe or Instrument

malfunction

Test calibration of thermometer with the M9600

Calibration Tester.

Instrument malfunction Test calibration of thermometer with the M9600

Calibration Tester.

Improper placement of probe Probe must be under the tongue and as far

back as possible into the sublingual pocket.

Probe or Instrument

malfunction

Test calibration of thermometer with the M9600

Calibration Tester.

Improper technique Movement in mouth after insertion and before

final temperature is displayed can cause high

readings. Place probe quickly into sublingual

pocket and hold still.

Improper technique Do not place probe in mouth until display is

showing the body icon.

Model 986 Thermometer 23

Page 30

3. Troubleshooting

3.3 Disassembly/Reassembly

Refer to section 1.3 and review all safety warnings before

attempting to disassemble the Model 986.

3.4 Field Serviceable Parts

3.4.1 Main Components

1

2

5

11

12

4

13

14

6

7

8

Figure 6: Thermometer Assembly

Note: All parts are serviceable by qualified technicians. Please

refer to Table 2 to check the part number for the items

shown on this diagram.

9

10

24 70995-0000B M986

Page 31

Table 2: Main Components

Dwg Item Part # Description

8 21288-XXXX Printed Circuit Assembly

9 25245-0000 HSG, Front

6 25246-0000 HSG, Rear

1 25248-0000 HSG, Probe Cover

3 25249-0000 HSG, Battery

25244-0000 Frame, LCD

5 02986-000 ASSY, Probe, Oral

60028-0000 LCD, 2V

58582-0000 ZEBRA Strip LCD Connector

58577-0000 Horn

25247-0000 Switch Mode

4 58578-0000 Contact, Pos/Neg

3. Troubleshooting

12 58579-0000 Contact, Pos.

13 58580-0000 Contact, Neg

11 53009-000 Batteries AAA Alkaline (2)

80128-0000 Tubing, Silicone

14 83174-0000 Screws (4)

7 85259-0000 O-Rings (3)

85257-0001 Die Cut Foam

70994-0000 User’s Manual

2 70855-0000 S/N Tracking Label

10 71004-0001 Front Label

75063-101 Probe Covers

Model 986 Thermometer 25

Page 32

3. Troubleshooting

3.4.2 Model 986 PCA

Jumper JP9

Figure 7: Printed Circuit Assembly

Battery

Negative

Battery

Positive

Jumper

JP1-JP6

26 70995-0000B M986

Page 33

3. Troubleshooting

3.4.3 Replacement Parts for PCA

Table 3: Replacement Parts for PCA

Part Number Reference # Description Qty/Per UOM

21288-0011 PC ASSY. MAIN, M986 1 EA

56142-0000 PC BOARD,MAIN,M986 1 EA

40290-0000 JP1, JP2, JP3,JP4 RES, 0 OHM, 5%, 0805 SIZE 6 EA

JP5, JP6,R62,R63

40290-1020 R5, R16, R31, R32 RES 1K, 5% 0805 SIZE 4 EA

40290-1030 R21, R30 RES 10K, 5% 0805 SIZE 2 EA

40290-1040 R7 RES 100K SM 5% 0805 SIZE 1 EA

40290-4720 R2, R14, R15, R17 RES 4.7K SM 5% 0805 SIZE 4 EA

40290-4730 R3, R4, R61 RES 47K S, 5% 0805 SIZE 4 EA

40301-2420 R28 RES 12.4K SM .1% 0805 SIZE 1 EA

40320-0000 R13 RES, 11.55K, 0.05% 25PPM 1 EA

40322-0000 R1 RES,SMD,3M,1/10W,5%,0805 1 EA

40315-1120 R33 RESISTOR,23.68K,5%,0805 1 EA

40312-3720 R34 RESISTOR,51.1K,5%,0805 1 EA

43010-0000 L1 INDUCTOR 10UH LOWRES CHIP 1 EA

44047-0000 D1, D2, D4 DIODE, DUAL, MMBD1203 3 EA

44048-0000 D5 DIODE,BAT54,SOT23 1 EA

46022-000 C3, C4 CAP 0.1UF 50V +80%-20% Z5 2 EA

46127-1030 C2, C5, C8, C9, CAP 0.01UF 100V X7R CHIP 7 EA

C10, C12, C22

46129-1050 C1 CAP 1UF TANTCHIP 16V +/-20% 1 EA

46136-0000 C21 CAP, .33UF, 10%, 50V TANT 1 EA

46137-0000 C25 CAP, CHIP, 1UF, 20%, 50V 1 EA

46138-0000 C17 CAP, 10UF, 20%, 16V ALUM 1 EA

46140-0000 C6, C7 CAP, CHIP, 22PF, 5%, 50V 2 EA

50029-0000 Q9 TRANS XX2222A NPN SOT-23 1 EA

50030-0000 Q4, Q5 TRANS XX5087 PNP SOT-23 2 EA

50031-0000 Q13, Q14 TRANS BCX69 PNP SOT-89 2 EA

50032-0000 Q1, Q3 TRANS BSS138 FET, SOT-23 2 EA

50035-0000 Q12, Q15 TRANSISTOR, PNP W/BIAS RE 2 EA

54277-0000 U2 IC, TIMER, 1.5V,LMC555CM 1 EA

54278-0001 U1 IC, ASSSY, MICROCONTROLLER 1 EA

54279-0000 U9 IC, VOLT RGLTR,SOT-23 1 EA

58540-0000 S1 SWITCH PROBE, M986 1 EA

58577-0000 HORN SPEAKER, MINI, PIEZO ELECT, 1 EA

Model 986 Thermometer 27

Page 34

3. Troubleshooting

28 70995-0000B M986

Page 35

Appendix A. Theory of Operation

A.1 Overview

The Model 986 includes two integrated circuits which provide most

of the microcontroller and analog circuit functions.

• All control and display functions are governed by the

microcontroller (U1).

• All probe analog data interfacing to the microcontroller is

provided by U2. U2 functions as an A/D converter.

Probe resistance measurements are made by taking the ratio of

two pulse widths that are generated in U2 by sequentially switching

in one calibration resistor and the probe thermistor. These pulse

widths are measured by the microprocessor, which calculates the

probe resistance. The actual probe temperature is then calculated

from the probe resistance.

Model 986 PCA

A/D Converter

Circuit

Voltage

Reference Circuit

Battery Detector

Circuit

NEC UPD 789407 uP

16 Bit

Timer

8 Bit

A/D

Probe Warmer

Circuit

Four Conductor

Coil Cord

CPU

LCD

Driver

Liquid Crystal

Display

Probe

Configuration

Jumpers

Serial

I/O

Horn

Driver

2 AAA

Batteries

Configuration

Serial

Port

Mode

Button

Horn

Thermistor

Probe Assembly

Probe

Warmer

Figure 8: System Block Diagram

Model 986 Thermometer 29

Page 36

Appendix A. Theory of Operation

A.1.1 Temperature Probes

Model 986 thermometers are configured at the factory for

Oral/Axillary or Rectal probe types. The probe type is configured at

the factory by the absence or presence of the MODE jumpers JP1

through JP4.

• Axillary temperatures are measured with oral probes in

• Rectal temperatures are measured with rectal probes in

Model 986 oral probes have a warming resistor in the tip to prewarm the probe before placement in the mouth, thus speeding

typical response.

A.1.2 Probe Switch

combination with the axillary mode algorithm, and provide a

temperature reading in about 10 seconds.

combination with the rectal mode algorithm, and provide a

Normal mode temperature in about 15 seconds.

The probe shaft activates the probe switch (S1) when the probe is

installed or removed from its storage well. Placing the probe into

the well pulls microprocessor pin 76 high via an internal pull up

resistor. When the probe is removed, this line is pulled low. This

signal is also routed to test connector J2 pin 3 to allow automated

testing of this function during factory test.

CAUTION: J2 provides a convenient set of test points to monitor

proper operation of all user switch functions. BE

CAREFUL WITH STATIC DISCHARGE! J2 ties

directly to CMOS processor inputs, which are easily

damaged by static discharge. Follow proper static

handling techniques.

A.1.3 Normal Mode Description

The Oral probe is pre-warmed using a pulse width modulation

(PWM) controller to 33.9°C (93°F) upon extraction from the

storage well. When the probe is first extracted and colder than

33.9°C, the pulse widths are at a maximum percentage ON vs.

OFF to warm the probe quickly. When the probe reaches 33.9°C,

the pulse widths narrow to a duty cycle just high enough to

maintain temperature.

When the probe is placed in the mouth, the heat supplied by the

mouth causes the pulse widths to reduce to zero. This reduction to

zero (and the probe being at least up to 33.1°C) triggers the start

of the prediction algorithm.

30 70995-0000B M986

Page 37

The shape of the rising temperature curve is monitored and the

best fit to a curve is found. When the curve fit is stable, the final

predicted temperature is displayed.

If the prediction criteria explained above are not met within 15

seconds of starting the prediction process, the instrument will

automatically switch to Monitor mode. If the ambient temperature is

above 33.9°C (93.0°F) the unit will automatically switch to Monitor

mode.

Note: Rectal probes are not pre-warmed.

A.1.4 Power Supply

Power is drawn from the two AAA alkaline cells directly to the

circuit electronics. The voltage from the batteries is unregulated

but filtered by capacitor C25. The power supply voltage will range

from about 3.2 volts with new batteries to 2.6 volts at shutdown.

The thermometer has two battery voltage indicators:

• The first is a warning that batteries are getting low (2.8 volts)

and is indicated by the battery icon flashing in the display.

Accuracy is not affected during low battery warning indication.

Appendix A. Theory of Operation

• When the batteries fall to approximately 2.6 volts, the dead

battery error condition is defined to exist. Operation is halted

and the E2.1 error message is displayed. At this point, the

batteries must be replaced and the thermometer electronics

reset. See Reset Self/Tests, Operational Checks, and Battery

Replacement.

A.1.5 Microcontroller

An NEC UPD789407 single chip microcontroller in a QFP package

(U1) is used for signal digitizing, data processing, program

memory addressing and storage, and I/O interfacing. The

microcontroller also includes an LCD controller/driver that allows

internal conversion of CMOS logic levels to a data format capable

of driving the Model 986 LCD. In this application, the

microcontroller is running at 2.4576 MHz.

A.1.6 Reset/Self Tests

Upon battery installation, (assuming that the electronics have been

discharged sufficiently by pressing the Mode button with batteries

removed) the microprocessor receives a power up reset signal

from the components associated with the reset line U1-67. When

power is applied continuously, C3 is charged slowly through R7

providing an active low reset to the microprocessor.

Model 986 Thermometer 31

Page 38

Appendix A. Theory of Operation

When the reset signal is complete, the microprocessor launches a

series of self-checks, which include RAM, probe warmer circuitry,

probe, battery voltage, and ambient temperature tests. Any failures

will cause a specific error code to be displayed.

A.1.7 Microprocessor Clock

The clock for the microprocessor is generated by X1 and capacitors

C26 and C27, which form a 2.4576 MHz. oscillator circuit. The

microcontroller is running at approximately 2.5 MHz, which is achieved

by internally dividing the frequency of oscillation by two.

A.1.8 Temperature Measurement And Display

The thermometer probes incorporate negative temperature

coefficient thermistors. When the temperature of the probe is

increased, its electrical resistance decreases.

Model 986 uses 20K thermistors, providing a resistance of

approximately 20 Kohms at room temperature. At 37°C (patient

temperatures) they are near 12 Kohms. The change in resistance

is nonlinear with temperature and an equation describing this curve

is programmed into the thermometer.

A.2 Temperature Measurement A/D Converter

This section provides a detailed description of the analog hardware

implemented in the Model 986.

A.2.1 Use of Analog Circuitry

The primary function of the temperature measurement A/D

converter circuit is to convert a measured resistance into a 16-bit

word, which is then used by the microprocessor to calibrate itself

and calculate a temperature.

A.2.2 A/D Theory of Operation

The A/D circuit is made up of 4 major parts:

• The resistance to be measured (either the probe thermistor or

the RATIOCAL resistor)

• The timing capacitor (C21, 0.33uF) and associated driver

circuitry (Q1, Q3, Q4, Q9, R15, and R30)

• A low bias current comparator (U2, LMC555)

• A 16 bit timer internal to the microprocessor.

Via software this becomes, in effect, a single slope converter that

measures the time constant of the measured resistance combined

with a fixed capacitance.

32 70995-0000B M986

Page 39

The time constant is measured by counting the time it takes for the

.

voltage to decay from a fixed initial voltage level to a fixed lower

voltage. The ratio of this pulse width and the pulse width

corresponding to a known calibration resistance (R13, 11.55K) is

used to calculate the measured resistance.

Once the resistance is known, the corresponding temperature is

calculated using the thermistor temperature equation. Because the

M986 uses this ‘ratio cal’ method for measuring the thermistor

resistance, the device is immune to the variability in gain of

external hardware devices.

A.2.3 Circuit Description

Initially, the microprocessor simultaneously discharges both sides

of the capacitor. This is accomplished by bringing A/D TRIGGER

high which turns on Q9 pulling one side of the capacitor (C21) to

ground and turns on Q1 and Q3 via PROBE_SEL, and

RATIOCAL_SEL which allows the other side to discharge through

the thermistor, and R13 (11.55K).

Appendix A. Theory of Operation

Once the capacitor has been fully discharged, the RATIOCAL

resistor is then selected by switching the probe resistor path off.

The microprocessor then forces the A/D TRIGGER signal to go

low, turning on Q4, which lifts one end of the capacitor up to VREF

(1.8V). Because there can be no instantaneous voltage drop

across the capacitor, the other side of the capacitor immediately

goes to 1.8V. This exceeds the threshold voltage (1.2V) of U2

(LMC555), causing the output A/D_OUT to go low.

At this point, the capacitor begins to discharge from 1.8 V to 0V

through the RATIOCAL resistor. The output of the comparator

goes high again when its input reaches the trigger voltage (0.6

volts). This produces a pulse of length equal to the time it takes for

the capacitor to discharge from 1.8V to 0.6V through the

RATIOCAL resistor.

The microprocessor measures this pulse width using a firmware

implemented 16-bit timer and then after repeating the capacitive

discharge cycle, the same A/D conversion is performed using the

probe resistor as the measured resistance. The microprocessor

performs the following calculation that ratios these two pulse

widths to determine the exact resistance of the thermistor:

Rthermistor

( )PWthermistor ( )Rhical

PWhical

The microprocessor then uses the following equation to convert

the measured resistance into a temperature:

Temperature_in_Kelvin

Ra.Rb ln( )Rt.Rc ln( )Rt

Model 986 Thermometer 33

1

3

Page 40

Appendix A. Theory of Operation

A.2.4 Probe Type Detection

Upon power reset, the thermometer performs a probe test. Probe

type is first detected and then, if it is an oral probe, its warming

characteristics are determined. Rectal probes are not warmed, so

warming characteristics are not tested on these probes.

A.2.5 Instrument ID Logic

The instrument logic is used to determine the type of probe the

thermometer is configured for (Oral/Axillary or Rectal). This allows

the microprocessor to initiate the proper algorithm for converting a

thermistor measurement into a temperature. The configuration

truth table is listed below.

Table 4: Configuration Truth Table

Zero Ohm Resistor to be Installed at:

JP1 JP2 JP3 JP4 JP5 JP6 CNFG# Configuration

Y Y Y Y Y Y

Y Y Y N Y Y

Y Y Y Y Y N

Y Y Y N Y Y

N Y Y Y Y N

Y Y Y N Y N

N Y N N Y N

Y Y Y N Y N

A.2.6 Circuit Operation

Jumpers JP1 through JP4 are used to provide logic 0 or 1 inputs to

U1-27, 28, 29 and 30 depending on what probe and algorithm the

instrument was configured with at the factory. When a probe has

been connected, the software determines what algorithm to use

based on the jumper connections listed above.

-0000 ORAL

-0001 RECTAL

-0002 INT’L

-0003 VET

-0004 ORAL, JAPAN

-0005 INT’L, RECTAL

-0006 RECTAL, JAPAN

-0007 INT’L VET

34 70995-0000B M986

Page 41

A.3 Probe warming (Oral probes only)

The probe warmer circuitry is used to heat the probe tip prior to

taking a temperature reading in order to speed the convergence of

the prediction algorithm. This allows quicker temperature readings.

A fail-safe hardware shutoff circuit is included to ensure the heater

will shut off in the event of a software failure.

A.3.1 Theory of Operation

The microprocessor sends pulses via HTRC to drive the probe

heater resistor, which heats the probe tip. A temperature of about

93°F is maintained prior to taking a patient temperature.

Software has a built in algorithm that determines the width of the

HTRC pulse, which varies depending upon the temperature of the

probe. It provides an initial pulse to rapidly heat up the probe tip to

the 90°F region and then supplies progressively shorter pulses as

the probe temperature converges to about 93°F. Once 93°F is

reached, software continues to send a control pulse, which

maintains the temperature.

Appendix A. Theory of Operation

A.3.2 Circuit Operation

The warmer circuitry consists of Q5, Q13, Q14, C1, C2, L1, D1,

R1, R2, R3, R4, R5, R31, R32, along with the heater resistor

inside the probe (27 ohms) connected across J1-3 and J1-4.

/HTRQ is pulled low by the microprocessor, which enables Q13 to

turn on. /HTRC is then pulled low, which brings the base of Q5

low, which in turn drives the base of Q14 low. Since Q14 E and B

are pulled near the positive rail and Q5 E and B are pulled near the

negative rail, the base current from Q14 flows through R31 (1K)

and R32 (1K).

This current flows through the emitter of Q5. The base current of

Q5, along with the current through R1 (3M) flows in to C1 (1uF),

charging it up. This sets up the mechanism for the hardware to

shut off. As this capacitor charges up, the base voltage of Q5

approaches the emitter voltage and the transistor shuts off,

thereby shutting down the probe warmer.

As long as Q5 remains on, Q14 has a base current flowing which

allows current to flow from its collector through R2 (4.7K) and the

heater resistor. With about 122mA flowing through it (VCC2VCEsat)/26 ohms), the heater resistor heats up the probe tip.

During normal operation, software turns the warmer circuit on and

off. The width of the pulse on /HTRC determines how long Q5 is

turned on, thereby determining how long the heater is heating. Once

the /HTRC pulse goes high again, the base of Q5 is pulled high

turning it off, and the capacitor discharges to VCC through D1.

Model 986 Thermometer 35

Page 42

Appendix A. Theory of Operation

Q13 and Q14 are selected for their low saturation on voltage.

D1 is a diode clamp used to keep the base of Q5 from attaining a

much higher voltage than VCC. R4 (47K) and R2 (4.7K) in

combination with R3 (47K) serve as pull-down resistors, ensuring

that the processor feedback lines (U1-43 and U1-44) go low

immediately upon warmer component shutoff. C2 serves as an

RFI suppression component.

A.3.3 Liquid Crystal Display

The model 986 uses a transreflective liquid crystal display to

display data to the user. Three common lines and 12 segment

lines connect the LCD to the display driver (U1-7 to U1-22) internal

to the NEC microprocessor. The LCD is 3:1 multiplexed with 1/2

bias. The bias voltages (1.0 volts, and 2.0 volts) are supplied to the

display driver by the voltage reference circuit

The LCD glass is electrically tied to the display PCB via an

elastomeric connector sandwiched and compressed between the

glass and the PCB by the frame. This assembly, if taken apart,

cannot be reassembled without replacing the frame.

A.3.4 Probe Switch

When the probe has been inserted in the probe holder, the probe

switch (S1) brings PROBE SW (U1-75) high (VCC). When the

probe is removed from the probe holder, the probe switch brings

PROBE SW (U1-75) low (GND).

A.3.5 Mode Button

The Mode button (P2) is a momentary contact switch.

• A pull up internal to the microprocessor normally pulls /MODE

(U1-76) high, placing a logic “1” at this input.

• When depressed, P2 provides a momentary contact to ground

at MODE giving it a logic level of “0”.

The software continuously checks MODE. If the thermometer is not in

the process of taking a temperature, pressing the Mode button will

wake up the thermometer and display the last recorded temperature.

36 70995-0000B M986

Page 43

A.3.6 Horn

The horn is activated at the start of a temperature taking cycle, at

the end of a Normal mode temperature cycle, and for various error

conditions.

• A short duration high pitch single beep indicates normal

operation.

• A long duration beep, approximately one second, indicates

errors such as temperature out of range during a temperature

measurement cycle.

The horn (LS1) is a miniature piezoelectric speaker with a

resonant frequency of 2 kHz driven by processor square wave.

The horn control signal comes from U1 pin 50 to produce the

audible tones.

Appendix A. Theory of Operation

Model 986 Thermometer 37

Page 44

Appendix A. Theory of Operation

38 70995-0000B M986

Page 45

Appendix B. Specifications

Dimensions (nominal) 2.3 in. W, 6.6 in. H, 1.9 in D

5.8 cm W, 16.8 cm. H, 4.8 cm. D (with probe cover storage)

Case Material ABS Plastic.

Weight (nominal) 6.0 ounces (171 grams).

Ambient Temperature

Range

Patient Temperature

Oral/Axillary

Rectal

Laboratory Accuracy ± 0.1° C (± 0.2° F) in the Monitor Mode and in a water bath meets the

Mode Button Selects °F/ °C. Oral and Axillary Modes

Probe Types Factory set to either: Oral/Axillary or Rectal.

Power Source Two “AAA” alkaline batteries.

Battery Operating Life Approximately 3,000 normal temperature measurements at 72° F

Display Type Liquid Crystal Display, 3.5 digits plus special icons.

9.0° C to 40.0° C (48.2° F to 104.0° F).

The patient temperature range is 35.5° C to 43.0° C (96° F to 109.4° F).

The patient temperature range is 30.0°C to 43.0° C (86° F to 109.4° F).

ASTM E1112-86 and EN12470-3 Standards.

ambient temperature.

Model 986 Thermometer 39

Page 46

Appendix B. Specifications

40 70995-0000B M986

Page 47

Appendix C. Limited Warranty

1-YEAR LIMITED WARRANTY ON NEW M986 INSTRUMENTS

Instrumentation purchased new from Welch Allyn, Inc. is

warranted to be free from original defects in material and

workmanship under normal use and service for a period of one

year from the date of first shipment from Welch Allyn. This

warranty shall be fulfilled by Welch Allyn or its authorized

representative repairing or replacing at Welch Allyn's discretion,

any such defect, free of charge for parts and labor.

Welch Allyn should be notified via telephone of any defective

product and the item should be immediately returned, securely

packaged and postage prepaid to Welch Allyn. Loss or damage in

shipment shall be at purchaser's risk.

Welch Allyn will not be responsible for loss associated with the use

of any Welch Allyn product that (1) has had the serial number

defaced, (2) has been repaired by anyone other than an authorized

Welch Allyn Service Representative, (3) has been altered, or (4)

has been used in a manner other than in accordance with

instructions.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED

WARRANTY OR MERCHANTABILITY, FITNESS FOR

PARTICULAR PURPOSE, OR OTHER WARRANTY OF

QUALITY, WHETHER EXPRESSED OR IMPLIED. WELCH

ALLYN WILL NOT BE LIABLE FOR ANY INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

The information in this manual has been carefully reviewed and is

believed to be accurate; however, no responsibility is assumed for

inaccuracies. Furthermore, this information does not convey to the

purchaser of Welch Allyn devices, any license under the patent

rights to the manufacturer.

Model 986 Thermometer 41

Page 48

Appendix C. Limited Warranty

42 70995-0000B M986

Page 49

1

VCC

+

-

R15

4.7k

R30

10k

Probe

Thermistor

20k

E4

12

B1

E2

TLOW

1

THIGH

1

1

E3

1

C5

0.01uF

1 2

12

1

C11

0.01uF

12

C25

1uF/50V

23

Q4

XX5087

C21

0.33uF/50V

CAP+

1 2

Q9

XX2222

2 3

RES

E10

RES2

1

32

Q1

BSS138

2 AAA

Batteries

A A

E1

1 2

1

1 2

B B

Not Populated

Jumper Logic Diagram:

CF1 CF0 Configuration

---------------------------------------------------------------------------- 0 0 Able to Select C or F (Default F)

C C

0 1 Able to Select C or F (Default C)

1 0 F Only

1 1 C Only

Mode3 Mode2 Mode1 Mode0 Configuration

---------------------------------------------------------------------------- 0 0 0 0 Oral + Axillary

0 0 0 1 Rectal Only

0 0 1 0 Oral + Axillary + Rectal + Basal

0 0 1 1 Basal Only

0 1 0 0 Oral Only

0 1 0 1 Axillary Only

0 1 1 0 Oral + Axillary + Basal

0 1 1 1 Reserved

1 0 0 0 Japanese Oral + Axillary

1 0 0 1 Japanese Rectal Only

1 0 1 0 Japanese Oral + Axillary + Rectal + Basal

1 0 1 1 Japanese Basal Only

1 1 0 0 Japanese Oral Only

1 1 0 1 Japanese Axillary Only

1 1 1 0 Japanese Oral + Axillary + Basal

1 1 1 1 Reserved

ANY CHANGE TO LOGIC DIAGRAM REQUIRES CHANGE TO DOCUMENT P/N 21289-XXXX

2

TEST PORT

C22

0.01uF

1 2

J2

1

2

3

4

5

6

7

8

9

10

CON10

CTRL

TRG

E7

1

1

E6

VCC

GND_DIGITAL

ON/OFF

MODE

/HOST_WAKEUP

/TxD

/RxD

/CTS

/RTS

E5

R16

1k

1 2

1

A/D CONVERTER

12

D4

MMBD1203

3

1 2

E11

1

1

E12

CALD

1

32

Q3

BSS138

C25 R64Q15 U9E72 J3 JP9

C13-C16

C18-C20

C23

C24

3

RES

RES2

HOUT

VREF

4

8

R

V+

OUT

DSC

V-

1

RCAL_SEL

LAST USED

NOT USED

JP7D3

3

7

U2

LMC555

12

R9

11.55k ALT

Not Populated

E13

Q6Q2JP8

R10-R12

Q7

R18-R20

Q8

R22-R27

Q10

Q11

R35-R59

5

CTRL

6

THR

2

TRG

R13

11.55k, 0.05%

1

REFERENCE DESIGNATIONS

D5

E22

E29

E30

E68

E70

E71

3

D

C

SOT23

RCAL_SEL

OUT

A/D_TRIGGER

1

PROBE_SEL

R6

R8

R29

4

C

SOT-89

PROBE TEST

J3

1

2

3

4

5

CON5

VCCVREF

12

E8

1

E20

U3

|

U8

R14

4.7k

1

E9

A/D_OUT

1

/PWR_ENABLE

0.01uF

5

SOT23-A

15

14

13

12

11

10

LCD

MUN2111

C8

4

S1

1 2

Not Populated

VARISTOR

E59

E55

E56

E57

E58

1

1

1

1

1

VREF

GND

R33

51.1K 1%

R34

E60

E65

VR1

E61

1

1

1

P2

E62

1

1 2

1 2

1 2

1 2

1 2

1 2

12

12

23.7k 1%

12

SEG0

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

1.8V

C9

E63

R62

0.0

1 2

E48

E49

E50

E51

E52

E53

E54

1

1

1

1

1

1

1

23

U9

MIC5205BM5

1 5

VIN VO

3 4

/SD ADJ

1

2

15

14

13

12

11

10

9

9

8

8

7

7

6

6

5

5

4

4

3

3

2

2

1

1

VCC

Q15

1

E21

1

12

4

ON/OFF

VCC

E45

E46

E47

JP1

JP2

JP3

JP4

JP5

JP6

12

0.01uF

5

MODE

/HOST_WAKEUP

BIAS

1

VLC0

1

VLC1

1

COM0

COM1

COM2

MODE3

MODE2

MODE1

MODE0

CF1

CF0

E23

1

12

C17

10uF/16V

C6

22 50V

1 2

1 2

C7

22 50V

E43

1

1

VDD1

2

BIAS

3

VLC0

4

VLC1

5

VLC2

6

VSS1

7

COM0

8

COM1

9

COM2

10

COM3

11

S0

12

S1

13

S2

14

S3

15

S4

16

S5

17

S6

18

S7

19

S8

20

S9

E14

1

R63

0.0

1 2

2

X2

X1

2.4576Mz

1 3

X1

E44

1