Page 1

SureTemp

Thermo Menu

Operation Manual

®

Model 767 Thermometer

Technical Manual

Page 2

Technical Manual

© 1997 by Diatek Instruments, Inc., A Welch Allyn Company. All rights reserved. No part of this manual may be reproduced

or transmitted in any form or by any means, electronic or mechanical, including photocopy, without prior consent in writing

from Welch Allyn. Printed in the USA

SureTemp is a trademark of Welch Allyn, Inc. All rights reserved.

Page 3

Technical Manual

TABLE OF CONTENTS

WARRANTY.......................................................................................................................................... 1

SPECIFICATIONS................................................................................................................................. 2

OPERATIONAL CHARACTERISTICS................................................................................................... 2

Introduction ...................................................................................................................................... 2

Basic System Description................................................................................................................. 2

Safety & Warnings ........................................................................................................................... 4

Setup................................................................................................................................................ 4

Changing Probes.............................................................................................................................. 5

Normal Mode.................................................................................................................................... 5

Monitor Mode ................................................................................................................................... 5

Biotech Mode ................................................................................................................................... 5

PREVENTATIVE MAINTENANCE......................................................................................................... 6

Cleaning and Sterilization................................................................................................................. 7

Routine Cleaning................................................................................................................................. 7

ETO Gas Sterilization Procedure......................................................................................................... 7

CALIBRATION TESTING...................................................................................................................... 7

Calibration Key Procedure................................................................................................................ 7

M9600 Procedure............................................................................................................................. 8

THEORY OF OPERATION.................................................................................................................... 8

Technical Overview.......................................................................................................................... 8

Probe Enhancements....................................................................................................................... 8

Probe Switch.................................................................................................................................... 9

Monitor Mode ................................................................................................................................. 10

Normal Mode.................................................................................................................................. 11

Power Supply................................................................................................................................. 11

Microcontroller I/O Assignments..................................................................................................... 12

Memory/IO Input/Output Assignments............................................................................................ 13

IIC Interface to LCD Display Driver................................................................................................. 14

Reset/Self Tests............................................................................................................................. 15

Microprocessor Clock..................................................................................................................... 16

Temperature Measurement and Display......................................................................................... 16

A/D Power Control.......................................................................................................................... 17

Probe Detection.............................................................................................................................. 17

Probe Warming.............................................................................................................................. 17

Liquid Crystal Display..................................................................................................................... 18

i

Page 4

Welch Allyn Model 767T

Backlight (Optional)........................................................................................................................ 18

Horn 19

F/C Switching................................................................................................................................. 19

ERROR CODES.................................................................................................................................. 19

TROUBLESHOOTING......................................................................................................................... 21

Equipment Required....................................................................................................................... 21

Terminology ................................................................................................................................... 22

Troubleshooting Table.................................................................................................................... 23

FIELD SERVICEABLE REPAIRS........................................................................................................ 28

FIELD SERVICEABLE PARTS............................................................................................................ 29

THERMOMETER DISASSEMBLY....................................................................................................... 29

THERMOMETER REASSEMBLY........................................................................................................ 34

SUGGESTED SPARE PARTS LIST.................................................................................................... 35

OPTIONS AND ACCESSORIES .........................................................................................................35

TABLE OF FIGURES

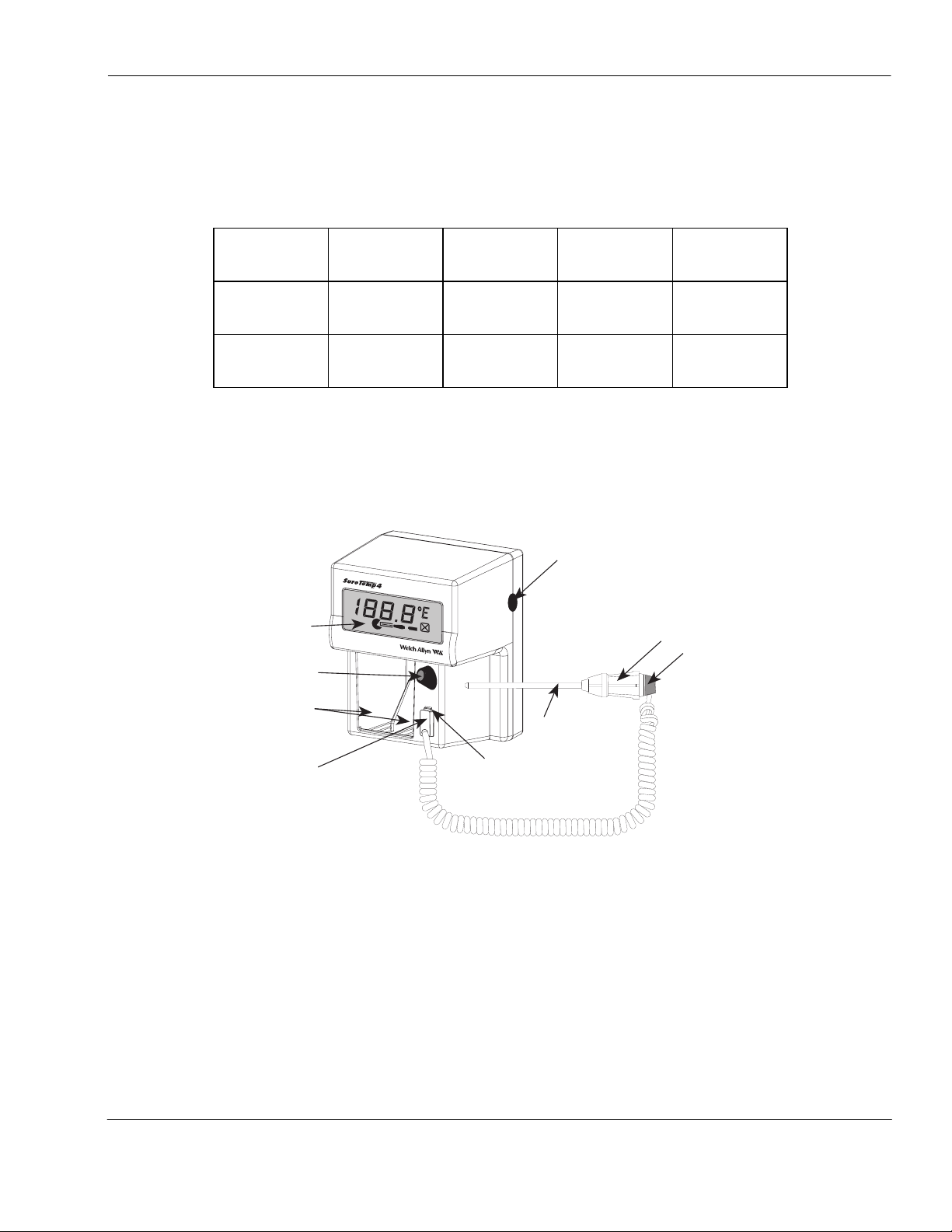

FIGURE 1 - THERMOMETER DIAGRAM.............................................................................................. 3

FIGURE 2 - SYSTEM BLOCK DIAGRAM............................................................................................ 10

FIGURE 3 - LCD DISPLAY.................................................................................................................. 15

FIGURE 4 - THERMOMETER ASSEMBLY DRAWING....................................................................... 30

FIGURE 5 - SYSTEM SCHEMATIC .................................................................................................... 32

FIGURE 6 - PRINTED CIRCUIT ASSEMBLY...................................................................................... 33

ii

Page 5

Technical Manual

WARRANTY

3-YEAR LIMITED WARRANTY ON NEW INSTRUMENTS

Welch Allyn, Inc. (Welch Allyn) is warranted to be free from original defects in material and

workmanship under normal use and service for a period of three years fr om the date of first shipment

from Welch Allyn. This warranty shall be fulfilled by Welch Allyn or its authorized representative

repairing or replacing at Diatek's discretion, any such defect, free of charge for parts and labor.

Welch Allyn should be notified via telephone of any defective product and the item should be

immediately returned, securely packaged and postage prepaid to Welch Allyn. Loss or damage in

shipment shall be at purchaser's risk.

Welch Allyn will not be responsible for loss associated with the use of any Welch Allyn product that ( 1)

has had the serial number defaced, (2) has been repaired by anyone other than an authorized Welch

Allyn Service Representative, (3) has been altered, or (4) has been used in a manner other than in

accordance with instructions.

: Instrumentation purchased new from

90 DAY LIMITED WARRANTY ON PROBES AND PROBE COVERS

Welch Allyn warrants probe covers and probes to meet W elch Allyn’s specifications f or the Product at

the time of purchase and to be free f rom original defects in material and workm anship under normal

use and service for a period equal to 90 days from the date of first shipment of such Product to the

customer by or on behalf of Distributor.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OR

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR OTHER WARRANTY OF

QUALITY, W HETHER EXPRESSED OR IMPLIED. WELCH ALLYN W ILL NOT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES.

The information in this manual has been car efully reviewed and is believed to be accurate; however,

no responsibility is assumed for inaccuracies. Further more, this information does not convey to the

purchaser of Welch Allyn devices any license under the patent rights to the manufacturer.

:

1

Page 6

Welch Allyn Model 767T

SPECIFICATIONS

Case Dimensions: 5.1 inches high x 4.1 inches wide x 4.0 inches deep.

Case Material: ABS Plastic.

Weight: 1.0 lbs

Input: Welch Allyn Thermistor Probe (Oral P/N 02767-000, Rectal P/N 02767-100).

Display range:

Laboratory Accuracy:

Clinical Accuracy: Meets the proposed ASTM clinical test criteria.

Push buttons: Mode button

Probes: Interchangeable Oral, Rectal

Power Source: Model 767 Wall Transformer.

Display Type: Liquid Crystal Display, 3½ digits plus special icons.

Operating temperature:

Storage Temperature:

28.9o C to 42.2o C (84.0o F to 108.0o F).

± 0.2o F in the Monitor mode and in a water bath per Welch Allyn SOP 90565-000.

16o C to 40o C (60.8 o F-104o F) @ 15% to 95% RH non-condensing per ASTM E1112-86.

-20o C to 50o C (-4o F-120o F) @ 15% to 95% RH non-condensing per ASTM E1112-86.

OPERATIONAL CHARACTERISTICS

Introduction

The Welch Allyn 767 SureT emp is a wall mounted thermistor thermomet er to be used f or measuring

patient temperatures rang ing f rom 84 °F to 108 ° F (28.9 °C to 42. 2 °C). Or al and r ectal probes utilize

single-use disposable probe covers which limit cross-contamination. Or al and r ectal tem peratur es ar e

taken using Normal or Monitor operat ing modes. Axillary temperatures are taken with an oral probe

with the unit operating in the Monitor mode. In the

Normal

mode, the thermometer’s microprocessor

“predicts” body temperature in about 4 seconds for oral temperatures and in about 15 seconds for

rectal temperatures. The

Monitor

mode continuously displays the temperature of the pr obe which will

reflect the patient’s actual tem perature in about 3 minutes and will continue for as long as the probe

remains in place.

Basic System Description

The thermometer system consists of four main components: the external AC power supply, the

thermometer instrument, the probe, and the probe cover.

The M767T Thermometer can use either a Welch Allyn Model 767 domestic (120V 60HZ) or

international (230V 50Hz) Wall Transformer or a Welch Allyn Model 77305 AC Adapter for its external

AC power supply. These power supplies are available from Welch Allyn.

The main instrument’s operation is described below.

The Model 767T is easily connected to the Model 767 Wall Transformer. Two screws are used to

secure the Model 767T to the Model 767 Wall Transformer. The use of a 9’ long probe cord with a

safety latch incorporated into its connector housing ensures that the Model 767T can be safely used

with the Model 767 Wall Transformer without slipping out of its connector.

2

Page 7

Technical Manual

The Model 767T probe is similar in appearance to the probe for the M600, M670, and M675; but is

incompatible with any of these instruments. M600, M670, and M675 probe are also incompatible with

the Model 767T instrument.

Welch Allyn’s 767T thermistor based probes can be identified by color combinations as follows:

Handle

Color

Fog White Blue Fog White,

Top Color Connector

Color/Type

Model # Probe Type

M767T Oral

Latching

Fog White Red Fog White,

M767T Rectal

Latching

The Model 767T instrument’s connector receptacle configuration and size disallows insertion of any

but Model 767T probes.

The probe covers are unchanged from previous models and are compatible for use with all of Welch

Allyn’s thermistor based thermometers.

9

E

D

O

M

1

7

8

2

3

4

1. Display 6. Probe

2. Probe storage channel 7. Probe handle collar

3. Dual probe cover storage well 8. Ejection button

4. Probe connector receptacle 9. Mode selection button

5. Probe connector receptacle latch

6

5

FIGURE 1 - THERMOMETER DIAGRAM

3

Page 8

Welch Allyn Model 767T

Safety & Warnings

CAUTION: DISCONNECT THE SYSTEM FROM THE MAINS SUPPLY BEFORE CONNECTING

THE 767 SURETEMP 4 THERMOMETER.

USE THE 767 SURETEMP 4 WITH WELCH ALLYN 3.5V 767 SERIES WALL TRANSFORMER

ONLY.

DO NOT USE IN THE PRESENCE OF FLAMMABLE ANESTHETICS.

Caution: Federal (USA) law restricts this device to sale by or on the order of a physician.

In order to obtain accurate and reliable temperature-taking results and ensure patient safety, it is

important that this booklet be read thoroughly prior to using the instrument. If you have any technical

or clinical questions concerning the thermometer’s use and/or care, please contact our Customer

Service Department at (800) 854-2904.

• Single-use disposable probe covers, available from Welch Allyn or Diatek, will limit patient cross-

contamination. The use of any other probe cover or the failure to use a probe cover may produce

temperature errors and will invalidate the instrument’s warranty.

• Oral probes (blue ejection button) are to be used for taking oral and axillary temperatures only.

Rectal probes (red ejection button) are to be used for taking rectal temperatures only. The use of

the wrong probe will produce temperature errors.

• The thermometer case is not waterproof; do not drip fluids onto it.

• Do not use this instrument for any purpose other than that specified in this booklet. Doing so will

invalidate the instrument’s warranty.

• Do not use the thermometer if you notice any signs of damage to the probe or instrument.

Contact our Customer Service Department for immediate assistance.

Setup

1. Install supplied Oral probe or optional Rectal probe by inserting the latching plug on the end of

the coiled cord into plug receptacle on the unit. The plug snaps into place and cannot be

removed without depressing the latch. (Figure 1).

2. Insert probe shaft completely into probe storage channel.

3. Turn on the 767 Wall Transformer.

4.

displayed, the thermometer is characterizing the probe. The display will clear when complete.

This process will take from 10 - 70 seconds.

5. Remove the probe from the storage channel.

(blinks) and (steady) are displayed when an oral probe is installed. When

is displayed when a rectal probe is installed.

6. Observe the LCD to see that all display segments appear followed by the display of the probe

type OrL = Oral or rEC = Rectal. Replace probe in storage channel.

7. Insert two boxes of disposable probe covers (part number 05031) into the dual storage well.

4

Page 9

Technical Manual

Changing Probes

• Depress the latch and unplug the probe connector from the thermometer.

• Remove the probe from the storage channel.

• Repeat steps 1 through 6 in the SETUP section.

Normal Mode

Most temperatures are taken in the Normal (predictive) mode. The thermometer automatically resets

to the Normal mode after the probe is returned to the storage channel.

Note:

For Oral probes; if the instrument’s display changes to the probe type display,

the probe cover is loaded, the display will change to°F (without

cover. The instrument is not ready for the probe to be inserted into the patient’s mouth until the

display returns to

The thermometer will switch to Monitor Mode automatically under the following conditions:

1. If the prediction algorithm has not been activated within 30 seconds of withdrawing the probe

from the probe storage channel.

2. If the instrument determines that room temperature is above 33.9°C (93.0°F).

The thermometer reads the probe temperature immediately upon removal of the probe’s shaft

from the storage channel. If the probe is extracted immediately after taking a temperature; it will

not have had sufficient time to cool to room temperature. This will cause the instrument to detect

a false room temperature higher than actual room temperature.

OrL°F

.

OrL

) briefly upon loading of the probe

OrL°F

, before

Monitor Mode

Monitor mode is generally used for long term temperature monitoring, taking axillary temperatures, or

when difficult situations prevent accurate temperatures from being taken in the Normal mode.

When used correctly, the instrument will display the patient’s temperature in about 4 seconds. The

instrument will beep briefly to signal completion of the Normal mode temperature cycle.

If the probe’s shaft is not inserted into the storage channel within 30 seconds of completion of a

Normal mode temperature cycle, the instrument will shut off. Simply replace the probe’s shaft into the

storage channel to prepare for the next temperature.

Note:

The instrument will shut off automatically if the probe temperature remains below 28.9°C

(84.0°F) for more than 5 minutes.

Biotech Mode

Biotech mode provides the ability to query the following information:

1. Display test.

2. Software revision.

3. Internal temperature reference measurement to the nearest 1/100 of a degree Fahrenheit.

5

Page 10

Welch Allyn Model 767T

4. Probe temperature to the nearest 1/100 of a degree Fahrenheit (98.30 will be displayed as 830).

Biotech Mode is entered by the following steps:

Note: While in the Biotech mode, the leading digit and decimal point are suppressed in order for the

instrument to display temperatures at higher resolution (i.e., 98.3 °F will be displayed as 830).

1. Ensure that a probe has been installed.

2. Depress and hold the Mode button for 7 seconds.

3. Observe that the instrument completes its display test. This is the same display test as initiated

when power is first applied. Each segment of the display is individually lit. Following this, all

segments are lit briefly.

4. The instrument will then momentarily display the software revision with the left half of the probe

shaft icon and the probe cover icon (indicating Biotech Mode). The display should show “r X.X”

where “X.X” is the revision number (i.e., r1.5). You will need to know the revision number when

discussing operation with Welch Allyn customer support.

5. A temperature display of the internal-reference-resistor measurement comes next. This reading is

generated by the instrument reading an internal, precision, fixed resistor as if it were a probe. If all

of the A/D conversion electronics are functioning properly, this measurement will produce a

reading between 678°C (36.78°C) and 689°C (36.89°C), or 820°F (98.20°F) and 840°F (98.40°F),

inclusive. Momentarily depressing the Mode button will always toggle the reading between Celsius

and Fahrenheit regardless of the mode.

6. A display of the probe tip temperature can now be obtained by withdrawing the probe from its

holder. The display will be of the same form as the internal-reference-resistor measurement

display (see above).

Note: If the probe is not removed from the probe holder within 1 minute, the unit will exit from the

Biotech Mode.

7. To exit Biotech Mode at any time, put the probe back into its holder. If the probe was never

removed from its holder, pull it out from its holder and then return it to its holder.

If you cannot enter the Biotech mode, refer to the

Troubleshooting

section.

Biotech Mode Problems

section of the

PREVENTATIVE MAINTENANCE

The following suggested preventative maintenance is recommended to maximize uninterrupted

service on the Model 767 SureTemp 4 Thermometer

Units which are in service on a regular basis should have the following preventative maintenance

performed every 6 months:

1. Visually inspect the thermometer for physical damage which might cause future product failure.

2. Clean the unit per instructions in your Directions for Use manual supplied with the thermometer

and/or per the instructions below.

6

Page 11

Technical Manual

3. Perform the power up display test, startup display test and Model 9600 Calibration Testing

procedure found in the Model 9600 Operation Manual. Perform calibration adjustment if

determined necessary by following the procedure in this manual.

Cleaning and Sterilization

Routine Cleaning

Refer to the Directions for Use for routine cleaning

ETO Gas Sterilization Procedure

When no other form of decontamination such as a germicidal wipe is acceptable, a low temperature,

(not to exceed 48.9°C (120°F)) ETO gas sterilization cycle may be used. Refer to your institution’s

standard operating procedure for the length of the cycle.

This type of sterilization may cause some hazing of glossy plastic surfaces and should be used only

when absolutely necessary.

1. Disconnect the Model 767 Thermometer from the power supply.

2. Ensure that the probe is removed from its storage channel and disconnected from the instrument.

3. Remove any probe covers from the probe cover storage well

4. Wrap the thermometer in a standard sterilization type packaging such as a Baxter Tower Dualpeel

Sterilization Pouch.

5. ETO gas sterilize at a temperature not to exceed 48.9°C (120°F) and aerate.

6. Remove the sterilization packaging.

7. Before applying power, allow the probe and instrument to stabilize to room temperature for

at least

one hour.

8. Verify proper calibration of the thermometer and probe using the Welch Allyn Model 9600

Calibration Tester.

CALIBRATION TESTING

Calibration Key Procedure

Unplug the probe from the thermometer. Insert the Calibration Key into the probe connector

receptacle on the thermometer. Remove the probe shaft from the probe storage channel to initiate a

temperature taking cycle. Wait for the display test and then observe the display. The display must

read between 97.1°F and 97.5°F inclusive for the calibration of the instrument to be correct. Remove

the Calibration Key and reinstall the probe connector plug. Then install the probe into the probe

storage channel. (This will initiate a probe characterization cycle.)

Note:

This Cal Key test does not test the calibration of the probe. To do so requires the use of the

Welch Allyn Model 9600 Calibration Tester.

7

Page 12

Welch Allyn Model 767T

If the reading from the Cal Key is not within the specified range or you are having other problems with

the use of the Cal Key, refer to the

Cal Key Problems

section of the

Troubleshooting

section.

M9600 Procedure

The M9600 Calibration Tester provides a convenient means of testing the entire thermometer system

(instrument and probe). The 9600 must be warmed up and stable at one of the two available

temperature settings. The thermistor based instrument under test must be in Monitor mode and no

probe cover loaded. The probe is inserted into the small hole in the dry heat well of the 9600 and

allowed to settle to the final temperature. The reading on the thermometer must be within the range

specified on the 9600. Refer to the M9600 Operation Manual for complete instructions.

Note:

All Welch Allyn thermometers (thermistor and infrared ear thermometers can be checked in the

M9600.)

If you are having problems with the use of the M9600, refer to the Troubleshooting section in the

M9600 Operation Manual.

THEORY OF OPERATION

Technical Overview

The heart of the Model 767 Thermometer is comprised of two custom integrated circuits, a standard

microcontroller, and an LCD driver which provide most of the microprocessor and analog circuit

functions. All control functions are governed by the Motorola MC68HC11D0 microcontroller (U1) and

a memory/IO chip (U2). All analog interfacing to the microprocessor, probe, horn, self-calibration

circuit, and backlight is provided by U4, and the LCD is controlled by U5.

Probe resistance measurements are made by measuring pulse widths which are generated by

sequentially switching in two calibration resistors and the probe thermistor, one at a time. These pulse

widths are measured by the microcontroller which calculates the probe resistance. The actual probe

temperature is then calculated from the probe resistance.

Probe Enhancements

The Model 767 Thermometer has the capability to detect probe type - Oral vs. Rectal. This allows the

oral temperatures to be as fast as possible (4 seconds) by using different operating modes based on

probe type. Rectal probes give a Normal mode temperature in about 15 seconds. Probe type

recognition also allows the use of minor differences in prediction parameters tailored to the

temperature taking site to help increase speed over most previous products.

The probe type is configured for thermometer recognition by connecting the appropriate combination

of probe connector contacts to ground within the probe assembly connector.

In addition to the probe type enhancements, Model 767 Thermometer probes have been improved for

thermal time constant (speed of response).

Model 767 Thermometer Oral probes incorporate a warming resistor in the tip to pre-warm the probe

before placement in the mouth thus speeding response even further.

8

Page 13

Technical Manual

Probe Switch

The probe switch (S2) is activated by the probe shaft when the probe is installed or removed from its

storage channel. Placing the probe into the channel, pulls U1-29 high via R27. When the probe is

withdrawn, this line is pulled low. This signal is also routed to test connector J3A, pin 7, to allow

automated testing of this function during factory test. R27 allows this line to be pulled high or low at

J3A during factory test regardless of the actual switch position.

HINT/CAUTION: For the technician, J3A serves as a convenient set of “test points” to monitor proper

operation of all user switch functions, BUT BE CAREFUL WITH STATIC DISCHARGE! J3A TIES

DIRECTLY TO CMOS PROCESSOR INPUTS WHICH ARE EASILY DAMAGED BY STATIC

DISCHARGE. FOLLOW PROPER HANDLING TECHNIQUES.

rs_232_pwr

FACTORY

TEST

SYSTEM

CONNECTOR

PROBE

HORN

PROBE

HEATER

BACKLIGHT

_clear_to_send

RxD

TxD

_request_to_send

probe_1

probe_0

horn_on

_heater_Q

_heater_C

_heater_tst

_heater_pwr

backlight_pwr

MC68HC11D0

MICROCONTROLLER

SYSTEM

_mode_button

_probe_sw

sda

scl

MODE BUTTON

PROBE SWITCH

LCD DISPLAY

PULSE WIDTH

A/D

CONVERTOR

ad_power

_ad_trigger

probe_ad_select

ptb_ad_select

hical_ad_select

local_ad_select

ad_out

7.37 MHZ

CRYSTAL

9

Page 14

Welch Allyn Model 767T

FIGURE 2 - SYSTEM BLOCK DIAGRAM

Monitor Mode

The Monitor mode is selected manually by the Mode button (S1) on the right side of the instrument.

This button, when pressed, ties U1-30 low. When this line (*DMODE) is held low for more than two

seconds with the probe’s shaft withdrawn from its holder, the thermometer enters Monitor mode.

*DMODE is routed to the test connector (J3A-10) to allow automated testing of this function during

factory test

The actual probe temperature, as determined by the A/D conversion electronics, appears directly on

the liquid crystal display which is driven by the LCD driver (U5). See the

and Display

The displayed temperature range (for any mode) is limited to 28.9°C to 42.2°C (84.0°F to 108.0°F).

section for a description of the A/D operation.

Temperature Measurement

Normal Mode

The Oral probe is pre-warmed using a pulse width modulation (PWM) controller to 33.9°C (93°F) upon

extraction from the storage channel. When the probe is first extracted and colder than 33.9°C, the

pulse widths are at a maximum percentage ON vs. OFF to warm the probe quickly. When the probe

reaches 33.9°C, the pulse widths narrow to a duty cycle just enough to maintain temperature. When

the probe is placed in the mouth, the heat supplied by the mouth makes the pulse widths reduce to

zero. This reduction to zero (and the probe being at least up to 33.1°C) triggers the start of the

prediction algorithm.

The shape of the rising temperature curve is monitored and the best fit to a curve is found. When the

curve fit is stable, the final predicted temperature is displayed.

If the prediction criteria explained above are not met within 15 seconds of starting the prediction

process, it will automatically switch to Monitor mode.

If the ambient temperature is above 33.9°C (93.0°F) the unit will automatically switch to Monitor mode.

Rectal probes are not prewarmed. The shape of the rising temperature curve is monitored and a

continuously computed correction factor is added to the actual probe temperature. The temperature

cycle is terminated and the temperature is displayed when the predicted temperature remains stable.

If the thermometer does not detect a rise of two degrees above ambient within 30 seconds of

removing the probe from its holder, it will automatically switch to Monitor mode.

Power Supply

Power is drawn from an 8VAC power supply. This AC voltage is converted to DC by a full wave

bridge rectifier (D1, D2, D7, and D8), regulated by a low dropout 5 volt regulator (U3), and filtered by

capacitors (C3, C4, C5, C16, and C17). The regulated voltage will range from about 4.75 volts to 5.25

volts DC. This +5VDC (Vdd) is further filtered to create an analog 5 volt branch (+5VA).

10

Page 15

Technical Manual

Microcontroller I/O Assignments

The following table depicts the input/output assignments for the microcontroller, with “active low”

signals prefixed with an underscore (refer to schematic and block diagram):

MC68HC11D0 Input/Output Assignments

Signal Name Port In/Out Pin Number

R/_W PD7, R/_W Out 12

AS PD6, AS Out 13

_wake_up _IRQ In 15

RxD PD0, RxD In 16

TxD PD1, TxD Out 17

MISO PD2, MISO In 18

sda PD3, MOSI Out 19

scl PD4, SCK Out 20

backlight_pwr PD5 Out 21

_heater_C PA7 Out 23

_heater_Q PA6 Out 24

_request_to_send PA5 Out 25

horn_on PA4 Out 26

_clear_to_send PA3 In 27

ad_out PA2, IC1 In 28

_probe_sw PA1 In 29

_mode_button PA0 In 30

11

Page 16

Welch Allyn Model 767T

Memory/IO Input/Output Assignments

The following table depicts the input/output assignments for the PSD311L peripheral, with “active low”

signals prefixed with an underscore (refer to attached schematic and block diagram):

PSD311L Peripheral Input/Output Assignments

Signal Name Port In/Out Pin Number

probe_1 PB7 In 4

probe_0 PB6 In 5

not used PB5 Out 6

rs_232_pwr PB4 Out 7

probe_out PB3 Out 8

probe_in PB2 Out 9

_heater_tst PB1 In 10

_heater_pwr PB0 In 11

_ad_trigger PA7 Out 14

ad_power PA6 Out 15

probe_ad_select PA5 Out 16

ptb_ad_select PA4 Out 17

hical_ad_select PA3 Out 18

local_ad_select PA2 Out 19

_batt_ad_select PA1 Out 20

not used PA0 Out 21

not used PC0 Out 40

not used PC1 Out 41

not used PC2 Out 42

NOTE: All unused I/O pins are set to output.

12

Page 17

Technical Manual

IIC Interface to LCD Display Driver

The display driver utilizes an IIC serial interface. Each write to the display (signals

begin with the following four command bytes followed by up to eight data bytes: 70H (device type),

e0H (device select), c8H (device mode), 18H through 26H (LCD driver RAM start address).

externally tied to

sda

to allow a read of the IIC acknowledge as required.

sda

and

scl

) must

MISO

is

With all LCD segments activated, the 767T display appears as shown in

not found.

ram addresses and the corresponding LCD segment, which provide visual enunciators to display

status and/or alarm indications as follows:

• “Instrument Malfunction” icon consists of a square box with an X within it, (segments 28-33), which

indicates that the unit has detected an internal malfunction or the unit is unable to make an

accurate determination due to a failure of the unit’s internal circuitry;

• “Up - Down Arrows” indicate that the patient temperature is above 108o F (42.2 o C), or below 84

F (28.9 o C) respectively. The up arrow is formed by displaying the bottom half of the X,

(segment 30), plus the bottom side of the square box; (segment 33), the down arrow is formed by

displaying the upper half of the X, (segment 32), plus the top side of the square box; (segment

28),

• “Broken Probe” icon consists of a probe silhouette where the distal half of the probe shaft,

(segment 36), and the probe body, (segment 35) are flashed. This icon is displayed whenever the

unit is active and a malfunction within the temperature probe has been detected;

• “Probe Position” icon consists of the “PacMan” open mouth silhouette, (segment 38), and the

probe silhouette, (segments 35, and 36), lit to inform the user of improper probe placement into

the mouth;

• “Monitor Mode” icon consists of a capital “M” formed out of the left and right sides of the square

box, (segments 31 and 29), and the upper half of the X, (segment 32); it is displayed whenever

the unit is active and in Monitor Mode;

Error! Reference source not found.

.

also includes the interface between the LCD driver

Error! Reference source

o

• “Fahrenheit/Celsius” icon is indicated by displaying either a “F”, (segments 25 and 26), or a “C”,

(segments 25 and 27), respectively to indicate the units of the displayed temperature.

• Bio Tech mode icon consists of the distal half of the probe shaft, (segment 36), and the probe

cover, (segment 37). It is displayed whenever the unit is in Bio Tech Mode.

13

Page 18

Welch Allyn Model 767T

•

24

2

7

1

6

1

3

8

4

5

38

9

14

13

37

10

15

11

12

36

16

17

22

21

18

23

19

20

3435

25

25

26

25

27

28

32

31 29

33

30

•

DRIVER

ADDRESS

Bit

7

Bit

6

Bit

5

Bit

4

Bit

3

Bit

2

Bit

1

Bit

0

24 - 25 -------34

26 - 27 -------1

28 - 29 786523430 - 31 14 15 13 12 9 10 11 16

32 - 33 22 23 21 20 17 18 19 34 - 35 ----24252726

36 - 37 30 33 - 29 31 32 - 28

38 - 39 ----35363738

FIGURE 3 - LCD DISPLAY

Reset/Self Tests

Upon power-up, the microcontroller and memory/IO chips (U1 and U2) receive a power-up reset

signal from the components associated with the reset line (U1-14 and U2-3). During power dropout,

the voltage regulator, U3, generates a reset signal. When *RST goes high, C7 is charged slowly

through R13 providing a slow rise reset to the microcontroller and memory/IO chips.

The delay between power-up and the beginning of *RST rise is determined by C1.

When the reset signal is complete, the microcontroller and memory/IO chips launch a series of self

checks which include RAM test, ROM test, EEPROM test, instruction set test, self calibration tests

(PTB test, hi cal, low cal), probe warmer circuitry tests, probe test, and ambient temperature test. Any

failures here will cause a specific error code to be displayed to assist debugging.

14

Page 19

Technical Manual

Microprocessor Clock

The clock for the processor is generated by X1. This is a single 3 pin ceramic resonator with internal

capacitors running at 7.3828 MHz. The microcontroller, U1, drives this component into oscillation by

incorporating an internal inverter.

Temperature Measurement and Display

The thermometer uses probes which incorporate negative temperature coefficient thermistors. When

the temperature of the probe is increased, its electrical resistance decreases. Earlier products (M600,

M650) use “10K” thermistors which means that, at room temperature (25°C), their value is

approximately 10 Kohms. Model 767 Thermometer probes use “20K” thermistors so they are

approximately 20 Kohms at room temperature. At 37°C (patient temperatures) they are near 12

Kohms. The change in resistance is nonlinear with temperature and an equation describing this curve

is programmed into the thermometer.

The thermometer contains three high precision calibration resistors (0.1% tolerance) R20, R21 and

R23. Their values are programmed into the instrument so that A/D conversions from these can be

done to “calibrate” the electronics. This allows results from the unknown probe resistance to be

compared to the known resistance’s. These three resistors are referred to as “hi cal”, “low cal” and

“PTB” resistors. They are equivalent to temperatures in that if the probe were at a high temperature

41.6°C (106.8°F), its resistance would equal the hi cal resistor value. Similarly if the probe were at a

low temperature 33.8°C (92.9°F) its resistance would equal the low cal resistor value. The PTB

resistor is in the middle of the range and equivalent to 36.8°C (98.3°F). Use of these resistors in the

A/D process allows the probe resistance readings to be “ratioed” against known resistance readings

and thus “absolute” readings, which can be affected by drift in the electronics due to aging and

temperature, are eliminated.

The actual A/D conversion consists of converting resistance to a timed pulse width. The components

involved are C6 (the timing capacitor), Q7 (the constant current transistor), any one of R20, R21, R23

or the actual probe resistance, and the associated FET transistors Q3, Q5, Q6, or Q8.

Due to U4 design, on power up R24 and R26 bootstrap U4 to begin the charge of C6. Once a small

voltage is developed on C6, U4 takes over and maintains C6 at 2.4 volts via pin 7 of U4. When an

A/D conversion is to start, prior to the trigger from the processor, it turns on one of the four FETs.

This establishes a constant current through the associated resistor. The current flowing is supplied

from U4 pin 7 while maintaining its voltage at 2.4 volts. Throughout the A/D process, U4 pin 4 is held

at 1.2 volts. This means that while current is flowing through Q7, its emitter sits at 0.6 volts. Since this

is a constant voltage, the current through the selected resistor and FET is also constant. The next

event is to trigger the start of the pulse measurement which occurs via processor control into U4 pin 5.

This makes U4 pin seven go to high impedance ending its supply of current for the selected resistor.

Therefore current must now be supplied by C6. Since it is still a constant current situation, C6

discharges linearly with time. Its voltage is monitored by an internal comparator in U1 and when it

drops to 1.2 volts the A/D OUT line (U4 pin 2) goes active stopping the timer in the processor. The

constant current value is inversely proportional to the resistance value selected so that small

resistance values produce high currents and therefore fast discharges. Since small resistance’s are

related to high temperatures, short pulse widths are also related to high temperatures. L3 is in series

with the discharge current but constitutes a very small constant DC resistance so it has no effect on

results. Its only purpose is for RFI suppression. C9, C10, C11, and C12 are also only for RFI, and

ESD purposes.

15

Page 20

Welch Allyn Model 767T

In Monitor mode a calibration cycle, where each of the fixed resistors is measured by the A/D function,

is performed once every second. In Normal mode a calibration cycle is performed once at the

beginning of the temperature prediction process.

A/D Power Control

When A/D conversions are not needed, power is saved by shutting down U4 via the A/DPWR line on

U2 pin 15. R22 serves as a current limiting resistor and establishes the low power draw for U4’s

internal current sources.

This A/DPWR line is also routed to R9 and R12 for probe detection. This provides a power saving

function so supply current is not drawn through these resistors when probe detection is complete.

Additionally, A/DPWR is routed to U5-5 to supply the LCD driver with power. This provides a power

saving function in that power is not drawn by the LDC driver nor LCD when not needed.

Probe Detection

Upon power-on reset or when a new probe is first installed, the thermometer performs a probe

initialization process. Probe type is first detected and then if it is an Oral probe, its warming

characteristics are determined. No Rectal probes are warmed, so warming characteristics are not

tested in either instrument on these probes.

When the probe connector is removed, U2 pins 4 and 5 are pulled high by R9 and R12, and a “no

probe” logic is detected. Upon determining that the probe has been removed, a software flag is set in

RAM indicating the probe has been removed. (RAM contents are not lost when the processor “goes

to sleep.”) With no probe installed, the unit goes to sleep and turns off the clock and the A/D power

line to save battery power.

Probe connector installation does not wake the instrument up. When the probe shaft is stowed, the

probe switch places voltage on U1 pin 29 via R27. This alerts the microcontroller which then reads

the RAM flag and sees that the probe logic lines are indicating a probe is connected. This situation

triggers a probe characterization routine as described in the Probe Warming section.

The probe type is determined by the probe logic lines at J1-C and F. Oral probes pull both lines low.

Rectal probes pull only J1-C low.

Probe Warming

Probe characteristics vary somewhat due to normal production process variations and it is desirable to

warm the probe as efficiently as possible from a time--to--ready standpoint and from a temperature

stability standpoint when the probe is up to temperature.

The probe warming process is a closed loop feedback control system incorporating PWM (pulse width

modulation) control. To establish proper control parameters, the probe under control must be

characterized.

The probe temperature is read once every 200 mS until the temperature is found to be not changing.

16

Page 21

Technical Manual

Once a stable temperature is determined a 200 mS test pulse of power is applied to the probe via the

warming circuitry. The probe temperature change resulting from this pulse is used to determine

parameters needed for the PWM algorithm. This completes the probe characterization process.

The warming circuitry consists of Q2, Q4, Q10, R8, R15, R16, R18, R25, R28, C14, C15, C202, D6,

L1 and the resistance in the probe connected to J1-B and J1-E. Power is applied to the probe

connection only when both Q2 and Q9 are turned on. When this occurs, both feedback lines to the

processor (U2 pins 10 and 11) are pulled high indicating proper operation. A fail safe hardware shut

off circuit is incorporated consisting of C14, D6, Q10 and R25. This circuit will shut off power to the

probe if the software fails to refresh this circuit. This prevents overheating due to any software errors

leaving the warmer circuit on continuously.

At the start of a warming pulse, the processor drives both warmer control lines (U1-23 and U1-24) low.

This turns on all three transistors Q2, Q9 and Q10. Q10 is turned on because the voltage across

capacitor C14 cannot change instantly. Its positive side goes low when its negative side is pulled low

by the processor. Since Q9 E and B are pulled near the positive rail and Q8 B and E are pulled near

the negative rail, the base current from Q9 flows through R28 and mostly into Q10, but some current

flows through R25 to satisfy the diode drop across Q10 E to B. This current and Q10 base current

flow into C14 charging it. As it charges, the voltage rise eventually shuts off Q9.

This hardware shut off is only allowed to progress to completion during factory test and each time an

Oral probe is installed as part of the instrument self test process. The thermometer checks that the

hardware shut off has occurred within one second of turn on.

Normal probe warming is controlled by the software and if the probe is well below the control

temperature of 33.9°C (93°F) the pulse widths are at a maximum. Every 100 mS the hardware shutoff

circuit is refreshed by the processor driving its pin 54 high briefly. This momentarily shuts off power to

the probe while discharging C14 into the positive supply through D6.

Once the probe has been brought near 33.9°C (93°F), the pulse widths are reduced to maintain this

temperature. This is when the display switches from the all segments display test to “OrL” indicating

that the unit is ready for placement in the mouth.

R8 and R18 in combination with R16 serve as pull down resistors ensuring that the processor

feedback lines (U2 pins 10 and 11) go low immediately upon warmer component shut off. L1, and

C15, and C202 serve as RFI suppression components.

Liquid Crystal Display

The LCD has 7 backplane lines (DS1 pins 1-7) and 12 segment lines (DS1 pins 8-19). The LCD fluid

thresholds require a regulated set of voltages at 1.2, 2.4, and 3.6 volts. These voltages are set by the

voltage that appears on U5-12 (0VDC) and are supplied to the LCD by the display driver (U5

The LCD glass is electrically tied to the display PCB via two elastomeric connectors sandwiched and

compressed between the glass and the PCB by the 8 display retaining screws.

Backlight (Optional)

The backlight is an Electroluminescent style flat panel lamp residing directly under the LCD.

An oscillator is required to convert battery DC voltage to an AC voltage of about 80 volts and 300 Hz.

17

Page 22

Welch Allyn Model 767T

Whenever anything is being displayed, the microcontroller outputs a high to U4-12. U4 then outputs a

low at pin 13, which is sent out to the backlight oscillator on the Display PCA via J2B-5. Vdd is also

supplied to the oscillator via J2B-1. The oscillator consists of Q101, Q102, C102, R106, R107, D101,

T1, and the lamp itself (DS2). R14 acts as a pull up to return this line high when not in use

Horn

The horn is activated at the start of a temperature taking cycle, at the end of a Normal mode

temperature cycle, and for various error conditions.

A short duration high pitch single beep is indicative of normal operation. A short duration double beep

is used to indicate errors.

The horn is a piezoelectric ceramic resonator driven by a processor square wave buffered through U4.

The horn control signal comes from U1-26 and enters U4-3 where it is buffered and inverted and sent

out on pin 1 directly to the horn LS1. R5 is used to limit the current applied to U4-3.

F/C Switching

When momentarily (less than 2 seconds) depressing the Mode button (S1), U1-30 goes low. The

microcontroller then toggles the display from F to C or C to F. This line is also run to the test

connector J3A-10 to allow automated testing of this function during factory test.

ERROR CODES

Error codes fall into three categories. Transitory, Recoverable and Non-Recoverable.

Transitory errors are generated by external events and are not errors generated by the thermometer.

They do require that temperature measuring be inhibited until the error is cleared. There is no limit to

the number of times a transitory error can occur. All probe problems are considered by the

thermometer to be external events and are therefore classified as transitory.

Recoverable errors are generated from internal test failures which are non-catastrophic and require

that temperature measuring be inhibited until the error is cleared. A recoverable error will be

promoted to a non-recoverable error if it occurs 4 times sequentially. After displaying the error code

and any appropriate icon, the instrument will reset itself and attempt to resume normal operation.

After the fourth attempt to clear itself, the error becomes non-recoverable.

Non-recoverable errors are generated from internal test failures that are catastrophic (or from

promoted recoverable errors). The error code and any appropriate icon will be displayed along with

the “[X]” Instrument Malfunction icon.

The only way to continue at this point is to reset the electronics by cycling power.

NOTE: The error codes E1.0, E2.1, E2.3, E3.0, and E4.1 can sometimes be caused by a faulty

probe. It is advisable to remove probe completely from instrument and check functionality as

described in the Setup section before assuming an instrument problem instead of a probe problem. If

another probe is available, this can prove useful in tracking down the source of the problem.

18

Page 23

Error Code Table - Software Version R1.7 and above

NUMBER ERROR TYPE DESCRIPTION

System Hardware/Software Errors

E0.1 NON-RECOVER Internal RAM read/write test failed

E0.2 NON-RECOVER Internal ROM check sum failed

E0.3 NON-RECOVER CPU instruction error

E0.9 NON-RECOVER Fatal Software Errors

System Transitory Errors

E1.0 TRANSITORY Outside ambient operating temperature range

C1.1 TRANSITORY Probe characterization stability time out

E1.2 TRANSITORY Probe broken or missing

E1.3 TRANSITORY Transmit buffer overflow (transmit only, no display)

A/D Converter Errors

E2.0 RECOVERABLE Low cal. resistor pulse width error

E2.1 RECOVERABLE Hi cal. resistor pulse width error

E2.2 RECOVERABLE PTB resistor pulse width error

E2.3 RECOVERABLE Probe pulse width error

System Functional Errors

E3.0 RECOVERABLE PTB test error

Math Errors

E4.0 RECOVERABLE Log of zero is undefined

Heater and Probe Errors

E5.0 RECOVERABLE Heater fail safe time out error

E5.1 RECOVERABLE Heater circuit failure

E5.2 RECOVERABLE Heater overheated

E5.3 RECOVERABLE Heater watch dog time out

E5.4 RECOVERABLE StartHeater initial pulse too large

Technical Manual

Error Code Table - Software Version R1.6 and below

NUMBER ERROR TYPE DESCRIPTION

System Hardware/Software Errors

E0.1 NON-RECOVER Internal RAM read/write test failed

E0.2 NON-RECOVER Internal ROM check sum failed

E0.3 NON-RECOVER CPU instruction error

E0.9 NON-RECOVER Fatal Software Errors

System Transitory Errors

E1.0 TRANSITORY Outside ambient operating temperature range

C1.1 TRANSITORY Probe characterization stability time out

E1.2 TRANSITORY Probe broken or missing

E1.3 TRANSITORY Transmit buffer overflow (transmit only, no display)

19

Page 24

Welch Allyn Model 767T

Error Code Table - Software Version R1.6 and below (continued)

A/D Converter Errors

E2.0 RECOVERABLE Low cal. resistor pulse width error

E2.1 RECOVERABLE Hi cal. resistor pulse width error

E2.2 RECOVERABLE PTB resistor pulse width error

E2.3 RECOVERABLE Probe pulse width error

System Functional Errors

E3.0 RECOVERABLE PTB test error

Math Errors

E4.0 RECOVERABLE Log of zero is undefined

Heater and Probe Errors

E5.0 RECOVERABLE Q heater transistor failure

E5.1 RECOVERABLE C heater transistor failure

E5.2 RECOVERABLE Heater fail safe time out error

E5.3 RECOVERABLE Heater circuit failure

E5.4 RECOVERABLE Heater overheated

E5.5 RECOVERABLE Heater watch dog time out

E5.6 RECOVERABLE StartHeater initial pulse too large

TROUBLESHOOTING

All thermometer operational parameters can be tested for proper operation without the unit being

taken apart and without the need for any tools. Refer to the

in particular to the

Setup

Biotech Mode

and

sections for guidance on preliminary checks.

If the trouble seems to be calibration related, refer to the

Operational Characteristics

Calibration Testing

section.

section and

If these sections do not prove useful in resolving the problem and you are sure that the instrument is

not performing properly, the following sections should guide you through the debugging process,

given the proper tools and equipment.

Equipment Required

Most operations can be performed with standard tools and meters. A 4” long Torx, T-8, driver is

needed for most screws. A #1 Phillips screwdriver is needed for the probe switch screws.

A standard lab 3.5 digit digital multi-meter (DMM) will provide sufficient accuracy for a host of tests. A

needle tipped pair of probes is recommended.

For particularly difficult tasks, a digital storage oscilloscope is sometimes the only way to analyze high

speed signals, but is not generally required.

Standard electronics tools and supplies for small surface mounted and through hole component

rework will be needed to perform any electronics repairs. Some surface mounted components are

extremely small and present a challenge for rework by hand. A light touch, tweezers, sharp soldering

iron tip and low heat (#7 tip) is recommended.

A Model 767 Wall Transformer is recommended for use as a power supply. Power and ground are

available at J5-C and J5-D, respectively.

20

Page 25

Technical Manual

Terminology

Many standard abbreviations are used in this section (and elsewhere):

PCB printed circuit board (the board itself) LCD PCB PCB holding the display assembly

PCA printed circuit assembly (the board with all its

components)

Main PCB large PCB holding the microprocessor O-Scope Oscilloscope

LCD Liquid Crystal Display

Component Reference Designators:

C capacitor Q transistor

D diode R resistor

E test point S switch

J connector jack T transformer

L inductor U integrated circuit

P connector plug X crystal, resonator

DMM Digital Multi-Meter

21

Page 26

Welch Allyn Model 767T

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE PROCEDURE

No operation No power to unit Make sure its power supply is plugged in and turned on. Make

sure the power supply is providing between 5.9 and 10 Volts

AC. Make sure the power contacts are making contact with

the power supply.

Short circuit. The resistance at the power input contacts (J5-A and J5-B)

should be at least 3MΩ. If it is less than this, check the power

circuit for shorts.

The resistance across the 5VDC test points (J5-C and J5-D)

should be at least 20kΩ. If it is less than this, desolder the

display electronics and check it again. If the resistance goes

up, suspect a short on the display board. If the resistance did

not go up upon desoldering the display board, check everything

but the power electronics on the main board for shorts.

Display

problems

Power circuit

component malfunction

Failed component. Check oscillator at U1-44 for 7.38 MHz sine wave. If not

LCD PCB loose. Check that all 8 Torx screws holding the Display PCA to the

Dirty, or crooked

elastomeric LCD

conductor (zebra)

strips. Crooked zebra

strip

Broken/shorted flex

strip cable.

With power turned on, measure 5.0 VDC +\-5% across J5-C

and J5-D (Gnd). If too low, lift J3-3 and check voltage between

here and J5-D. If still too low, suspect U3. Check for a DC

voltage of about 12 VDC at U3-1. If this is below 5.5VDC or is

very unstable, suspect the filter capacitors (C1, C3, and C18

for low voltage), or rectifier diodes (D1, D2, D7, and D8 for

unstable voltage).

present, suspect X1, R1, or U1.

Display housing are tight.

Remove Display PCA by opening the case and unscrewing the

8 Torx screws on the Display PCA. Clean LCD elastomeric

strips, LCD glass contacts, and PCB contacts with lint proof

cloth dampened with alcohol. Check that the EL panel is not

overlapping the black, Carbon ink covered zebra pads on the

display PCB.

Check continuity of all 6 lines. Assure continuity with flexing of

strip.

22

Check for shorts between adjacent lines at both ends.

Page 27

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Technical Manual

Display

problems

(continued)

Dark blotches

near the

bottom of the

display

Failed component in

LCD driver circuit.

Cracked LCD. Inspect LCD for hairline cracks especially in corners.

Short circuit or open

LCD lines.

Microprocessor failure

(U1).

Memory/IO chip failure

(U2)

Moisture between

display window and

LCD glass. Display

screws too tight.

Check that data and clock signals on U5-1 and U5-2 are

toggling between 0 and 5 volts immediately after power up or

after pressing and releasing the Mode button.

Check continuity from LCD driver (U5) through to LCD pads.

Check for shorts between adjacent U5 pins. Check for

continuity from U1-19 and U1-20 to U5-1 and U5-2,

respectively.

Check for improper soldering of pins, crystal operation on Oscope, proper reset.

Check for improper soldering of pins, crystal operation on Oscope, proper reset.

Remove, clean, and reassemble the LCD. Tighten screws

starting from the upper right tooling hole (looking in the back of

the display housing, and continuing counterclockwise.

No beeper

sound

Broken horn wire Inspect horn wires for proper soldering

Defective horn Replace horn

Broken connection Check continuity from U1-26 to U4 3. From U4-1 to red

horn wire. From U4-14 to black horn wire. From U4-3 to

blue wire and R5. From R5 to U1-26.

Defective U4 Replace U4.

Defective U1 Check for a logic high on U1-26 when horn should be on.

If not, replace U1.

23

Page 28

Welch Allyn Model 767T

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

No Backlight

(Backlight is

an Option)

Recalled

temperature

incorrect.

F/C

switching

problems

Broken trace. Check U1-21 and U4-12 for proper signal level (+5V

when LCD is on. U4-13 and the cathode of D101 should

be low when the LCD is on. With backlight off, all of the

oscillator parts (Q101, Q102, R106, R107, C102 and

T1(primary) should be at +5VDC.

Defective

Component

Check U1-21 and U4-12 for proper signal level (+5V

when LCD is on). U4-13 and the cathode of D101

should be low when the LCD is on. With backlight off, all

of the oscillator parts (Q101, Q102, R106, R107, C102

and T1(primary) should be at +5VDC.

Power cycled. On power-up, the last stored temperature is replaced

with 98.6

Defective Mode

switch

Check J3A-10 for proper switch function. Line should go

low only while Mode button is depressed.

o

F.

Broken trace Check U1-30 for proper switch function.

Probe:

Wrong type

displayed.

Probe:

Plugged in

but no

display

24

Missing A/D power to

R9 and/or R12

With no probe installed, check that probe connector pins

J1-C and F are both pulled high when any function is

active (recall)

Incorrect wiring of

probe

Oral probes should have a short between pins C, E and

F. (refer to J1 designators on instrument PCB for probe

pin definition.)

Rectal probes should have a short between pins C and E

but open between pins F and C or E.

Bad probe. Replace probe.

Probe not

characterized

A new probe must be installed and left in the storage

channel until the display goes blank. If probe is

extracted during characterization, display goes blank and

operation is halted.

Page 29

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Technical Manual

Normal/

Monitor

Mode

switching

problems

Cannot enter

Biotech

Mode

Ambient above

33.9°C (93.0°F)

Switched to Monitor

mode before probe

in mouth.

Defective switch Check J3A-10 for proper Mode switch function.

Insufficient Mode

button depression

time

No probe installed A probe must be plugged into the instrument with its

Causes auto switch to Monitor mode.

If 30 seconds pass after ready in Normal mode, unit

switches to Monitor mode.

If probe is still cooling from a previous temperature and

used immediately, it might sense ambient to be above

33.9°C (93.0°F).

Check U1-30 for proper switch function.

Press and hold the Mode button for at least 2 seconds.

shaft fully inserted into the probe holder.

Cal Key

doesn’t

activate

thermometer

Cal Key

shows OrL,

rEC, or ALy

Failed component,

broken trace.

Probe switch not

activated.

Defective Cal Key Replace Cal Key

Check proper switch operation. Refer to F/C, Mode, and

Recall switch troubleshooting.

Model 767 Thermometers need the probe switch

activated before they will start. Place a probe shaft in

the storage channel, then remove it to start Cal Key

measurement.

25

Page 30

Welch Allyn Model 767T

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Cal Key

shows only

“°F”.

Monitor

mode

temperature

reading too

low.

Monitor

mode

temperature

reading too

high

Defective mode

switch or broken

trace.

Probe malfunction Change probe.

Instrument

malfunction.

Improper placement

of probe.

Temperature not

stable.

Probe malfunction Change probe or test calibration of entire system

Check proper switch operation. Refer to F/C, Mode, and

Recall Switch troubleshooting section, above.

Test calibration of entire system (instrument and probe)

with the M9600 Calibration Tester.

Check calibration with Cal Key.

Probe must be under the tongue and as far back as

possible into the sublingual pocket.

Allow three minutes for Monitor mode reading to stabilize

in mouth.

(instrument and probe) with the M9600 Calibration

Tester.

Normal

mode

temperature

reading too

low.

26

Instrument

malfunction.

Probe malfunction. Recharacterize probe. (remove completely from

Check calibration with Cal Key.

instrument and re-install.)

Or change probe.

Or test calibration of entire system using 9600.

Page 31

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Technical Manual

Normal

mode

temperature

reading too

low

(continued)

Normal

mode

temperature

reading too

high.

Instrument

malfunction

Improper placement

of probe.

Probe malfunction. Recharacterize probe. (remove completely from

Instrument

malfunction

Improper technique. Movement in mouth after insertion and before final

Check calibration with Cal Key.

Probe must be under the tongue and as far back as

possible into the sublingual pocket.

instrument and re-install.)

Or change probe.

Or test calibration of entire system using 9600.

Check calibration with Cal Key.

temperature is displayed can cause high readings.

Place probe quickly into sublingual pocket and hold still.

Improper technique. Do not place probe in mouth until display is showing

“OrL”.

FIELD SERVICEABLE REPAIRS

Repairs are considered field serviceable if the repair will not alter the calibration or proper operation of

the instrument. Recalibration requires a computer-based system and is normally performed at the

factory.

All probes designed to work with the thermometer are fully interchangeable.

All components in the Model 767 Thermometer can be replaced without effecting instrument operation

or calibration. Some minor changes to the exact calibration point will be caused by changing R20,

R21 and R23, but as long as the proper type and tolerance resistors are used (0.1%, supplied by

Welch Allyn), the unit will remain within specifications.

27

Page 32

Welch Allyn Model 767T

FIELD SERVICEABLE PARTS

All parts are serviceable by qualified technicians except for the EEPROM and the Monochip

THERMOMETER DISASSEMBLY

Please note that if your thermometer is within the warranty period, you should return the unit

to an authorized service representative for servicing; failure to do so will invalidate the

warranty.

WARNING: This instrument contains microelectronic devices which are highly susceptible to damage

by static discharge. Use proper handling and grounding techniques while working on the internal

electronics.

1. Remove the power supply/power from the unit.

2. Withdraw the probe from the probe storage channel.

3. Unplug the probe connector from the thermometer.

4. Lay the thermometer on its Front and Temperature housings (front surface).

5. Remove the six Torx screws from the rear housing.

6. Carefully lay the thermometer on its Rear housing, making sure that the Front and Temperature

housings do not separate from the Rear housing.

7. Remove the Front and Temperature housings from the Rear housing.

Note: The Front and Temperature housings cannot be completely removed from the Rear housing

unless the Main PCA (and horn)or Display PCA are unscrewed from their housings.

8. Unplug the probe cable (P1) from its header (J1).

9. Unplug the probe switch cable from its header (S2).

10. Remove the Main PCA by unscrewing the 3 Phillips screws holding the PCA to the Rear

housing. Then gently lift the PCA upward while prying the horn loose from the Rear housing.

Note the horn location for reassembly.

Caution:

excessive upward force on the horn can break it.

11. Remove the Display PCA by unscrewing the 8 Torx screws then gently lifting the Display PCA

Caution:

plastic window. This would leave visible scratches and should then be replaced.

Use care when removing the horn. Excessive force on the horn wires can break them, and

out of the Front housing. Often, the zebra strips and LCD lift out with the Display PCA. Only

cohesion holds them together, so take care that the LCD does not drop and break.

While lifting the LCD out of the Front housing, do not allow it to slide along or drop on the

28

Page 33

Technical Manual

FIGURE 4 - THERMOMETER ASSEMBLY DRAWING

29

Page 34

Welch Allyn Model 767T

Item Part Number Description Qty

1 20983-1000 PCA, TEMP/DISP/CONN 1

2 25211-0000 HOUSING, FRONT 1

3 25212-0000 HOUSING, REAR 1

4 25213-0000 HOUSING 1

5 25214-0000 WINDOW, LCD 1

6 25215-0000 PLUG, BP 1

7 25219-0000 HOLDER, PROBE 1

8 43012-0000 BEAD, FERRITE 1

9 58101-000 SWITCH, PROBE 1

10 58102-000 HORN, PIEZO 1

11 58518-0000 CONNECTOR, ZEBRA 2

12 58522-0000 CAP, MODE SWITCH 1

13 60023-0000 LCD, TEMPERTURE 1

15 70827-0000 LABEL, MODEL 767T 1

16 80122-0000 CABLE, 6 CONDUCTOR 21

17 80123-0000 CABLE, 3 CONDUCTOR 1.

18 81054-0000 WASHER, FIBER .187 OD X .089 ID .031 THK 2

19 83047-0000 SCREW, MACH 6-32 X 1/4 P-PL-S-Z 3

20 83140-0000 SCREW, MACHINE, 6-32 X 1/4 SEMS, INT TOOTH

P-PL-S-Z

21 83166-0000 SCREW, PLASTITE #2-28 X 1/2 LONG TORX, PAN

HEAD

22 83167-0000 SCREW, PLASTITE #2-28 X 1/4 LONG TORX, PAN

HEAD

23 83169-0000 SCREW, 2-56 X 3/8 SEMS, INTERNAL, P-PL-S-Z 2

24 85254-0000 PLATE, ATTACHMENT 1

25 85255-0000 BRACKET, PROBE 1

26 95128-0000 TAPE, DOUBLE-SIDED WHITE, .005 X .5 .13 FT

6

6

12

30

27 95129-0000 TAPE, DRAFTING 1 IN WIDE .25 FT

FIGURE 2 - THERMOMETER ASSEMBLY DRAWING (CONTINUED)

Page 35

Technical Manual

FIGURE 5 - SYSTEM SCHEMATIC

31

Page 36

Welch Allyn Model 767T

32

FIGURE 6 - PRINTED CIRCUIT ASSEMBLY

Page 37

Technical Manual

THERMOMETER REASSEMBLY

1. If the Display PCA has been removed from the Front housing, lay the Front housing on a flat

surface. Ensure that the LCD and zebra strips have been installed into the Front housing (the

bump on one end of the LCD should be to the right as you look in the back of the Front housing).

Then, carefully install the Display PCA into the Front housing, with the display flex-strip (J2) on

the left side. Install the eight Torx display retaining screws, starting with the upper right side and

continuing counterclockwise.

2. If the Main PCA has been removed from the Rear housing, lay the Rear housing on a flat

surface and place the Front and Temperature housings (with the Main PCA attached by the flexstrip) immediately to the right. Then reinstall the horn to the Rear housing using the same

double-stick tape.

Note

: If the double-stick tape was destroyed upon horn removal, replace it with the same type of

tape.

Note

: Reinstall the horn in the same position from where it was removed.

Install the Main PCA into the Rear housing, with its three mounting holes aligned with the three

standoffs. Then install and tighten the 3 Phillips retaining screws.

3. Plug the probe switch cable into the probe switch header (S2).

4. Plug the probe cable connector (P1) into the probe cable header (J1).

5. Position the display and Temperature housings onto the Rear housing. Ensure that the Mode

button cover and BP plug have been installed.

6. Carefully lay the instrument on its Front and Temperature housings and install the six Torx

screws.

7. Connect the Model 767 Thermometer to its power supply.

8. Plug the probe connector into the probe connector receptacle.

9. Insert the probe’s shaft into the storage channel.

10. Turn on power and check for the proper power-up sequence.

33

Page 38

Welch Allyn Model 767T

SUGGESTED SPARE PARTS LIST

PART NO. DESCRIPTION QTY PER

100 UNITS

20991-0000 ASSY, CONNECTOR PCA WITH CABLE & FERRITE BEAD 5

20992-0000 ASSY, PROBE SWITCH 5

58102-000 HORN, PIEZO 4

81054-0000 WASHER, FIBER .187 OD X .089 ID .031 THK 8

83166-0000 SCREW, PLASTITE #2-28 X 1/2 LONG TORX, PAN HEAD 12

83167-0000 SCREW, PLASTITE #2-28 X 1/4 LONG TORX, PAN HEAD 12

95128-0000 TAPE, DOUBLE-SIDED WHITE, .005 X .5 A/R

OPTIONS AND ACCESSORIES

• Rectal Probe • Probe covers

• Second Probe Holder • Calibration Tester

• Backlight • Calibration Key for verifying calibration - inserts in place

of probe plug and provides correct reading of 97.3°F.

34

Page 39

7420 Carroll Road, San Diego, California 92121 • (800) 854-2904 • (619) 621-6600 • FAX (619) 621-6610

70841-0000A

Loading...

Loading...