Page 1

SureTemp

Thermo Menu

678 Operation Manual

679 Operation Manual

679V Operation Manual

®

Model 678 & Model 679 Thermometer

Technical Manual

Page 2

© 1997 by Welch Allyn, Inc. All rights reserved. No part of this manual may be

reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopy, without prior consent in writing from Welch

Allyn. Printed in the U.S.A.

Welch Allyn and SureTemp are trademarks of Welch Allyn, Inc. All rights

reserved.

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS............................................................................................................. i

LIST OF FIGURES...................................................................................................................iii

WARRANTY.............................................................................................................................iv

SPECIFICATIONS.....................................................................................................................v

TERMINOLOGY.......................................................................................................................vi

1. OPERATIONAL CHARACTERISTICS............................................................................... 1-1

Basic System Description.................................................................................................. 1-1

Self Tests.......................................................................................................................... 1-3

Instrument Reset/Self Tests.......................................................................................1-3

Display Test ............................................................................................................... 1-3

Probe Warmer Circuit Self Tests................................................................................1-4

Battery Life........................................................................................................................1-4

Normal Mode.....................................................................................................................1-5

Monitor Mode ....................................................................................................................1-6

Pulse Timer Mode (Model 678 only)..................................................................................1-6

Backlight (Model 678 only)......................................................................................... 1-6

F/C Conversion ..........................................................................................................1-7

Temperature Recall....................................................................................................1-7

Biotech Mode ....................................................................................................................1-7

2. PREVENTIVE MAINTENANCE ......................................................................................... 2-1

Cleaning and Sterilization.................................................................................................. 2-1

Routine Cleaning........................................................................................................2-1

ETO Gas Sterilization Procedure................................................................................2-1

Battery Removal and Replacement................................................................................... 2-2

3. CALIBRATION TESTING.................................................................................................. 3-1

Calibration Key Procedure.................................................................................................3-1

Model 9600 Calibration Testing Procedure........................................................................3-1

SureTemp® Model 678/SureTemp® Model 679 i

Page 4

4. THEORY OF OPERATION................................................................................................ 4-1

Technical Overview...........................................................................................................4-1

Probe Enhancements.................................................................................................4-2

Probe Switch.....................................................................................................................4-2

Normal Mode.....................................................................................................................4-2

Power Supply....................................................................................................................4-3

Low Battery Detection ................................................................................................4-3

Microcontroller............................................................................................................ 4-3

Reset/Self Tests.........................................................................................................4-4

Microprocessor Clock.................................................................................................4-4

Temperature Measurement and Display.....................................................................4-4

Temperature Measurement A/D Converter.................................................................4-4

Theory of Operation ...................................................................................................4-4

Circuit Description...................................................................................................... 4-5

Probe Identification Logic.................................................................................................. 4-6

Basic Function............................................................................................................ 4-6

Circuit Operation ........................................................................................................4-7

Probe Warming ( Oral probes only)...................................................................................4-7

Theory of Operation ...................................................................................................4-7

Circuit Operation ........................................................................................................4-8

Other Components............................................................................................................4-8

Liquid Crystal Display................................................................................................. 4-8

LCD Backlight (Model 678 Only) ................................................................................4-8

Probe Switch..............................................................................................................4-9

Mode Button...............................................................................................................4-9

Timer Button (678 Only).............................................................................................4-9

Serial Communications Port.......................................................................................4-9

Horn........................................................................................................................... 4-9

5. TROUBLESHOOTING.......................................................................................................5-1

Error Codes....................................................................................................................... 5-1

Equipment Required.......................................................................................................... 5-2

Troubleshooting Table.......................................................................................................5-3

Field Serviceable Repairs..................................................................................................5-8

Field Serviceable Parts...................................................................................................... 5-8

Model 678/679 Replacement Parts....................................................................................5-9

Replacement Parts-Circuit Board Assemblies.................................................................5-10

Thermometer Disassembly.............................................................................................. 5-12

ii Welch-Allyn, Inc.

Page 5

LIST OF FIGURES

FIGURE 1 - THERMOMETER DIAGRAM..............................................................................1-1

FIGURE 2 - M678 DISPLAY.................................................................................................. 1-3

FIGURE 3 - SYSTEM BLOCK DIAGRAM..............................................................................4-1

FIGURE 4 - PROBE LOGIC CIRCUITRY..............................................................................4-6

FIGURE 5 - PROBE LOGIC DIAGRAM.................................................................................4-6

FIGURE 6 - SELF-TEST /ERROR TABLE.............................................................................5-2

FIGURE 7 - THERMOMETER ASSEMBLY DRAWING....................................................... 5-13

FIGURE 8 - MAIN PCA........................................................................................................5-14

FIGURE 9 - ELECTRONICS ASSEMBLY............................................................................5-15

FIGURE 10 - SCHEMATICS................................................................................................5-17

SureTemp® Model 678/SureTemp® Model 679 iii

Page 6

W ARRANTY

3-YEAR LIMITED WARRANTY ON NEW M678 AND ON M679 ONE PER ROOM

INSTRUMENTS. 1-YEAR LIMITED WARRANTY ON NEW M679 INSTRUMENT

Instrumentation purchased new from Welch Allyn, Inc. (Welch Allyn) is warranted to

be free from original defects in material and workmanship under normal use and

service for a period of three years for the

year for the

shall be fulfilled by Welch Allyn or its authorized representative repairing or replacing

at Welch Allyn's discretion, any such defect, free of charge for parts and labor.

Welch Allyn should be notified via telephone of any defective product and the item

should be immediately returned, securely packaged and postage prepaid to Welch

Allyn. Loss or damage in shipment shall be at purchaser's risk.

Welch Allyn will not be responsible for loss associated with the use of any Welch Allyn

product that (1) has had the serial number defaced, (2) has been repaired by anyone

other than an authorized Welch Allyn Service Representative, (3) has been altered, or

(4) has been used in a manner other than in accordance with instructions.

THIS WARRANTY IS EXCLUSIVE AND IN LIEU OF ANY IMPLIED WARRANTY OR

MERCHANTABILITY, FITNESS FOR PARTICULAR PURPOSE, OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED. WELCH ALLYN

WILL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

M678 and one per room M679

M679

from the date of first shipment from Welch Allyn. This warranty

:

and one

The information in this manual has been carefully reviewed and is believed to be

accurate; however, no responsibility is assumed for inaccuracies. Furthermore, this

information does not convey to the purchaser of Welch Allyn or Diatek devices any

license under the patent rights to the manufacturer.

iv Welch-Allyn, Inc.

Page 7

SPECIFICATIONS

Case Dimensions

•

(nominal):

Case Material:

•

Weight (nominal):

•

Input:

•

Display range:

•

Laboratory Accuracy:

•

Clinical Accuracy:

•

Push buttons:

•

Mode Button:

•

Probes:

•

Power Source:

•

Battery Operating Life:

•

2.25 in. x 3 in. x 7 in

5.7 cm x 7.6 cm. x 17.8 cm

ABS Plastic

10.25 ounces with batteries and probe

Welch Allyn Thermistor Probe. P/N 02678-000

(ORAL 4’), P/N 02678-100 (ORAL 9’), 02679-000

(RECTAL 4’), AND 02679 -100 (RECTAL 9’)

28.9o C to 42.2o C (84.0o F to 108.0o F)

± 0.2o F in the Monitor mode and in a water bath

per Welch Allyn document number 90565-000

Meets the ASTM E1112-86 clinical test standard

Mode and Pulse Timer

Selects oF/ oC, Oral, Axillary and Monitor Modes

Interchangeable Oral (also used for Axillary) and

Rectal

Three “AA” Batteries

Approximately 5,000 temperature measurements

(At 72o F ambient temperature)

Display Type:

•

Operating temperature:

•

Storage Temperature:

•

Liquid Crystal Display, 3½ digits plus special icons

16o C to 40o C (60.8 o F-104o F) @ 15% to 95%

RH non-condensing per ASTM E1112-86

-20o C to 50o C (-4o F-120o F) @ 15% to 95%

RH non-condensing per ASTM E1112-86

SureTemp® Model 678/SureTemp® Model 679 v

Page 8

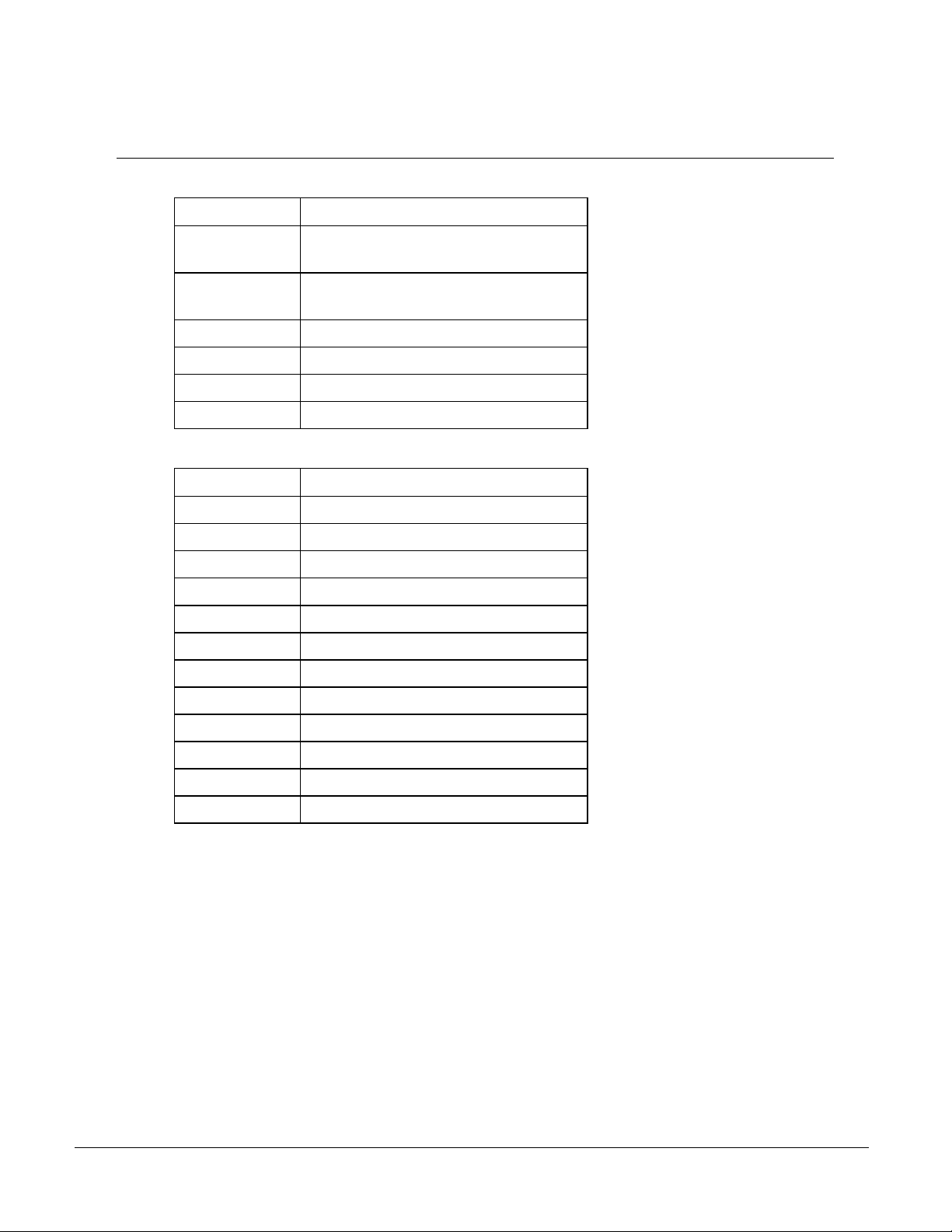

TERMINOLOGY

Many standard abbreviations are used in this Technical Manual.

Abbreviation Definition

PCB printed circuit board

PCA printed circuit assembly

LCD Liquid Crystal Display

BATT Battery

DMM Digital Multi-Meter

O-Scope Oscilloscope

Component Reference Designators include:

Abbreviation Definition

C capacitor

D diode

E test point

J connector jack

(the board itself)

(the board with all its components)

L inductor

P connector plug

Q transistor

R resistor

S switch

T transformer

U integrated circuit

X crystal, resonator

vi Welch-Allyn, Inc.

Page 9

1. OPERATIONAL CHARACTERISTICS

Note:

This manual describes both the Model 678 and the Model 679 thermometers.

The bulk of the discussion is equally applicable to both products. Where there

are differences, it will be noted as to which instrument the discussion applies.

The Welch Allyn Model 678 and 679 Thermometers are the next generation of

thermistor based medical grade thermometers providing the accuracy and ease of use

of thermistor technology as in the well known Model 675. The Model 678 and Model

679 provide a Normal mode oral temperature in about 4 seconds, significantly faster

than the typical 30-40 second average time to temperature in earlier products.

Basic end user operation of the Model 678 and Model 679 is covered in the

Manual

will help you determine if the Model 678/679 is functioning properly and, if it is not,

refer you to the proper section to isolate the problem.

Note:

and this manual assumes an understanding of these operations. This chapter

There are many things that can be done to check operation before the unit is

disassembled. This section will cover these normal operating actions.

User’s

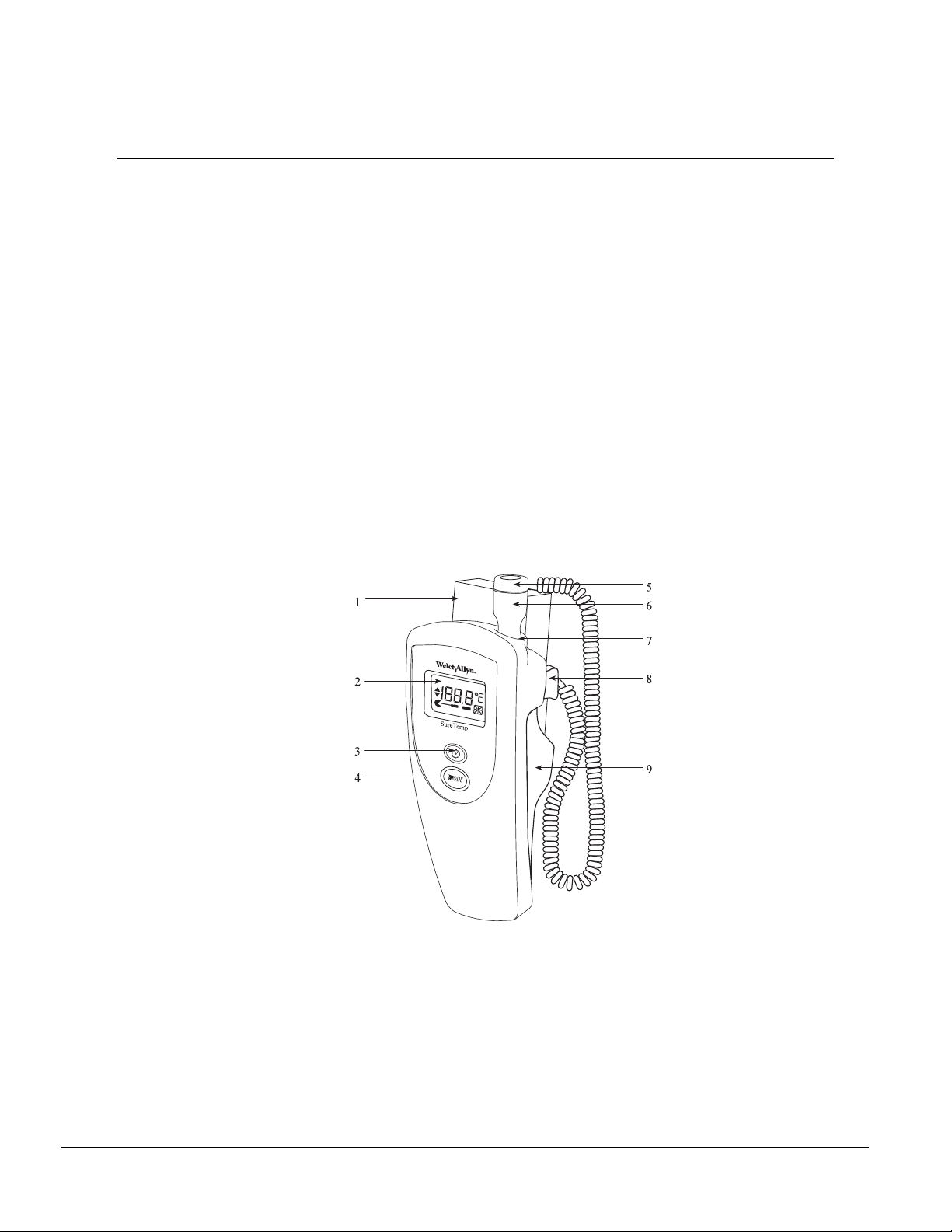

Basic System Description

The thermometer system consists of five main components: The batteries, the

thermometer instrument, the wall mount, the probe and the probe cover.

1. Probe cover box 6. Probe Handle

2. Display 7. Probe storage well

3. Timer button (678 only) 8. Probe connector receptacle

4. Mode button 9. Probe cover storage well/ Battery cover

5. Probe cover ejection button

Figure 1 - Thermometer Diagram

SureTemp® Model 678/SureTemp® Model 679 1-1

Page 10

Technical Manual

Batteries The Model 678 and Model 679 thermometers use three standard

alkaline “AA” cells. These batteries are readily available and

provide long life for reduced down time. No battery charging is

required.

Note:

The use of Ni-Cad rechargeable batteries is allowed. The

nominal cell voltage of 1.2 volts for Ni-Cad (vs. 1.5 volts for

alkaline) combined with the lower actual capacity than

alkaline will result in a much shorter time between battery

charges than alkaline battery life.

Instrument The main instrument operates very similarly to the Model 675.

Basic operation has been kept similar to that of the Model 675 to

ease learning and use.

Wall Mount The wall holder is easily secured to a wall (or rolling stand). An

optional locking mechanism with a removable key for securing the

instrument is available. Through the use of available long probe

cords, the thermometer can be used without removing it from the

wall holder.

Probe The probe is similar to earlier probes. Model 670/675 probes

are incompatible with Model 678/Model 679 instruments, but

Model 767 and Welch Allyn Vital Signs Monitor probes can be

used in Model 678/Model 679 thermometers.

Probe Covers The probe covers are unchanged from previous models and are

compatible across all Welch Allyn and Diatek thermistor based

thermometers.

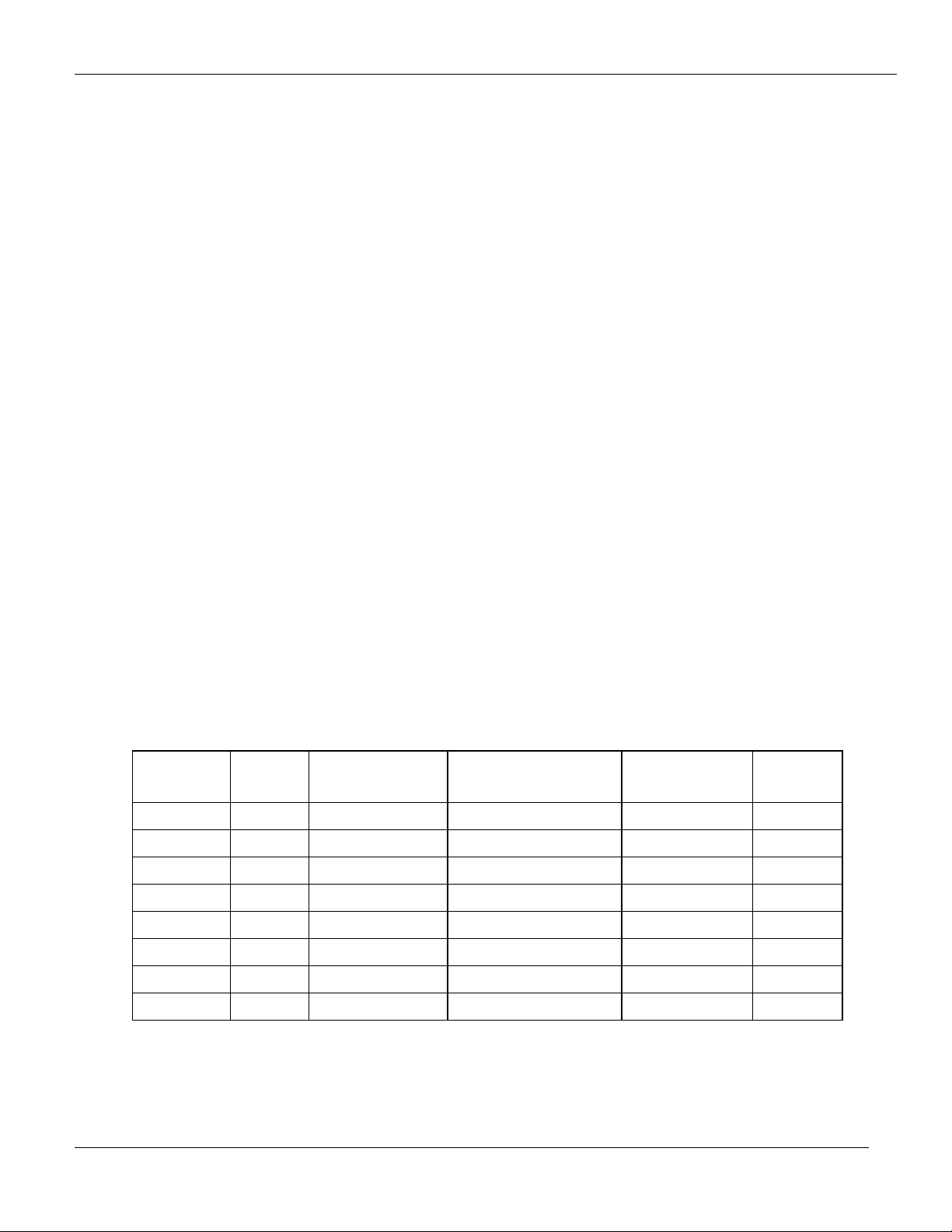

Welch Allyn’s thermistor-based probes can be identified by color

combinations as indicated in the following table.

Handle

Color

Top

Color

Cord

Color

Connector

Color

Model # Probe

Type

Green Green Green or Black Green M600 Oral

Red Red Green or Black Green M600 Rectal

Green Green Green Modular Phone style M650 Oral

Red Red Green Modular Phone style M650 Rectal

White Blue White Blue M670/M675 Oral

White Red White Red M670/M675 Rectal

White Blue White White with latch M678/679/767 Oral

White Red White White with latch M678/679/767 Rectal

1-2 Welch-Allyn, Inc.

Page 11

Operational Characteristics

Self Tests

Instrument Reset/Self Tests

If a problem is reported with an instrument, it is preferred that the user investigate

operation

before

recommended starting point in the checkout process.

The batteries must be removed from the instrument to reset the internal

microprocessor electronics. Follow the battery removal instructions in the

Maintenance

Caution: After battery removal, any remaining charge due to internal

capacitance must be discharged to achieve a proper reset. After the

batteries are out, press the Mode or Timer button for about 5 seconds.

The electronics will now properly reset upon new battery installation.

1. Remove the probe from the probe storage well and unplug the probe connector

from the instrument by depressing the locking tab and pulling on the connector

body. Do not pull on the cord.

2. While watching the display, install the batteries per the instructions in the

Preventive Maintenance

the unit is reset. However, resetting the electronics is the

Preventive

section.

section and observe the power up self test.

The self test includes several internal microprocessor self tests, instrument electronics

tests and the display test. If there are internal electronics problems detected by the

self tests, the error “|X|” icon will be displayed and an audible tone will sound. Refer

to the

Error Codes

in the

Troubleshooting

section for an explanation.

Display Test

The display test begins with each display segment and icon being individually lit in

brief and rapid succession. Immediately after this, all display segments and icons are

simultaneously illuminated briefly followed by a display of the software revision in this

instrument. The beeper also briefly sounds at the beginning of the test. At the end of

the test, the display goes blank.

Figure 2 - M678 Display

Note:

If a probe is installed during this power up time, the probe type will be displayed

as the last item before the display blanks. At this point, there should be no

probe connected to the instrument.

If there is no display, any missing segments, or no beeper, refer to the

Troubleshooting

SureTemp® Model 678/SureTemp® Model 679 1-3

section.

Page 12

Technical Manual

Probe Warmer Circuit Self Tests

Proper instrument functionality should be verified first as described in the

Reset/Self Tests

section (above) before a probe is installed. With a properly

Instrument

functioning instrument, the probe can be run through the self test. If the instrument is

functioning properly and a probe is installed, the instrument will initiate the probe

warmer self test during the instrument reset self test and whenever a probe is

plugged in.

If an instrument has passed the

Instrument Reset/Self Tests

section, install the

probe connector and observe the display of the probe type. For Models 678 and 679,

the probe type will display for approximately 2 seconds.

If the display does not show “OrL” or “Aly” with an Oral/Axillary probe plugged in,

•

or “rEC” with a Rectal probe plugged in, there is a problem with either the probe or

the probe connector in the instrument.

If the display goes blank after the probe type display, the probe has passed its

•

tests and the instrument is ready for use. Do not withdraw the probe during this

self test.

If the display shows the malfunction icon |X|, refer to the

•

Troubleshooting

section.

Note:

Handle the probe only by the probe handle, not the metal shaft. When

removing a probe, disconnect the connector by pressing the locking tab and

pulling on the connector body. Do not pull it by the cord.

If there are any problems with probe initialization, refer to the

Troubleshooting

section.

Battery Life

Under normal use, battery life is expected to provide approximately 5,000 temperature

measurements. This number is based on a 22.2°C (72.0°F) ambient temperature,

with the security features turned off. Colder ambient temperatures, excessive security

alarms, use of non-alkaline batteries, and other usage patterns can reduce battery life.

Instruments are shipped with fresh batteries, but we cannot guarantee full life from the

first set of batteries due to potential long storage times between shipping and actual

use. Battery life can also be reduced by storage at elevated temperatures.

If you are experiencing short battery life, refer to

Troubleshooting

section.

Battery Life Problems

in the

1-4 Welch-Allyn, Inc.

Page 13

Operational Characteristics

Normal Mode

After instrument and probe warmer self tests, the system is ready for use. Normal

mode operation is the rapid mode of temperature taking. This is the default mode and

is automatically selected when the probe is withdrawn from the probe well.

1. Upon withdrawal of the probe from its storage well, every segment on the display

will be illuminated. Watch for the display to change from the all segments test to

the probe type display; “OrL/Aly” or “rEC”, depending on the probe and algorithm

type , followed by °C or °F, whichever is selected. This display might take several

seconds to appear. At the same time that the probe type is displayed, a short

beep will sound.

2. At this point, load a probe cover and take a temperature.

To change between the Oral and the Axillary algorithms; place the instrument in

Ready mode as described above, and press the Mode button for approximately two

seconds. Observe that the display changes between “Orl” and “Aly” every time the

Mode button is pressed for more than two seconds.

Note:

It is possible that the display will switch from the probe type display to the

“walking segments” display and back again several times before the probe is

inserted in the mouth. This is acceptable operation and will not adversely

effect the temperature taken.

The thermometer will automatically switch to Monitor mode under some conditions.

These are:

If the prediction algorithm has not been activated for more than 60 seconds after

•

taking the probe out of the storage well.

If the instrument determines that room temperature is above 33.9°C (93.0°F).

•

If the thermometer is unable to predict an oral temperature after 15 seconds due

•

to improper technique such as excessive probe movement.

With correct use, the patient’s temperature will be displayed in about 4 seconds for

Model 678 and for Model 679. The instrument will beep to signal completion of the

Normal mode temperature cycle.

Note:

The thermometer reads the probe temperature immediately upon removal from

the storage well. If the probe was just placed into the storage well from a

previous temperature and immediately extracted, insufficient time may have

passed to allow the probe to cool to room temperature. This will result in the

instrument determining room temperature to be higher than actual. This could

result in the instrument switching to Monitor mode immediately if it detects

room temperature to be above 33.9°C (93.0°F).

For best results, the user

should wait at least 30 seconds between Normal mode temperatures.

If the probe is left out of the storage well after completion of a Normal mode

temperature, the unit will shut down after 30 seconds to conserve power. Simply

replace the probe in the storage well to prepare for the next temperature.

SureTemp® Model 678/SureTemp® Model 679 1-5

Page 14

Technical Manual

Monitor Mode

The instrument can be placed in Monitor mode by pressing and holding the Mode

switch for two seconds after a predictive (normal) temperature has been taken. This

mode will be indicated on the display by a capital M in the bottom right corner. Monitor

mode provides a direct readout of the probe temperature.

This mode of operation has the ability to provide long term monitoring of a patient’s

temperature. Unlike Predictive mode, Monitor mode will follow a temperature as it

rises or falls.

The typical slow rise in temperature when Monitor mode is used is due mainly to the

mouth temperature slowly recovering from placement of the colder (room

temperature) probe. The probe itself is actually very fast at rising to the temperature

of its surroundings, usually within a few seconds. Because of this slow mouth

recovery, the recommended time to wait before recording a Monitor mode oral

temperature is 3 minutes. Similarly, the recommended waiting period for an axillary

temperature taken in Monitor mode is 5 minutes.

Monitor mode is also useful in testing the accuracy of the combined probe/instrument

system when the probe can be warmed to a known temperature, as with a Welch Allyn

Model 9600 Calibration Tester or in a circulating water bath.

Note:

The instrument will shut off automatically if the probe temperature remains

below 28.9°C (84.0°F) or above 42.2 °C (108.0 °F) for more than 5 minutes.

If Monitor mode does not display expected temperatures or exhibits other problems,

refer to the

Troubleshooting

section.

Pulse Timer Mode (Model 678 only)

Pulse Timer mode is activated from a Low Power or Recall mode by pressing the

Timer button. Whenever the unit enters the Pulse Timer mode, it will emit an audio

beep at 0, 15, 30, 45 and 60 seconds. The display will then count up one second at a

time, “01”, “02”, ..., “60”.

Pulse timer mode will be terminated automatically upon completion of a 60 second

count and go back to low-power mode. The pulse timer can be shut off at anytime

during the 0-60 count by pressing the Timer button, the Mode button or removing the

probe from the probe holder. Connecting a probe will also terminate the pulse timer.

If the timer does not work or exhibits other problems, refer to

Troubleshooting

section.

Backlight (Model 678 only)

The backlight is turned on automatically in any mode except Low Power. Once the

backlight is turned on, it will automatically shut off whenever the instrument goes into

Low Power mode.

Timer Problems

in the

The backlight provides a display light for use in dark rooms. The LCD is backlit such

that all readings are clearly readable in a darkened room from a distance of 18 inches.

If the backlight does not work or is showing other problems refer to the

Problems

1-6 Welch-Allyn, Inc.

section in the

Troubleshooting

section.

Backlight

Page 15

Operational Characteristics

F/C Conversion

When a final temperature is displayed (in Normal, Recall, or Monitor mode), pressing

and releasing the Mode button will toggle the temperature between °F/°C.

Note:

A recalled temperature will be displayed in whichever scale (°F/°C) is selected

at the time of recall. This can also be changed during display.

If pressing the Mode button does not change the scale of the displayed temperature,

refer to

Mode Button Problems

in the

Troubleshooting

section.

Temperature Recall

Whenever the instrument is in Low Power or Pulse Timer mode, pressing and

releasing the Mode button will cause the most recent predicted temperature to be

displayed for 5 seconds. An “A”, “O”, or “R” will be displayed near the lower right

corner of the LCD, designating Axillary, Oral and Rectal temperatures for the recalled

temperature. Pressing the Pulse Timer button will interrupt the temperature recall

function.

Note:

No Monitor temperatures will be saved for recall. When a temperature is

recalled, the mode in which it was obtained (axillary, oral or rectal) will be

shown independent of the present mode.

If the last temperature can not be recalled, refer to

Troubleshooting

the

section.

Temperature Recall Problems

in

Biotech Mode

To enter this special program mode:

1. Place the thermometer in the wall holder.

2. Press and hold the Mode button, and at the same time remove the probe from the

probe well.

Press the Mode button approximately 2 seconds to move sequentially through the

various program categories. Changes within each category can be made by

momentarily pressing and releasing the Mode button.

Upon entering the Biotech mode, the following features and selections become

available. A number is provided in the flag area to indicate which Biotech category is

displayed.

To exit Biotech mode at any time, insert the probe into the probe well. Replacing the

probe into the probe holder returns the unit to normal operation. The Biotech mode

will automatically time out after 5 minutes of inactivity.

SureTemp® Model 678/SureTemp® Model 679 1-7

Page 16

Technical Manual

If you cannot enter the Biotech mode, refer to

Troubleshooting

section.

Biotech Mode Problems

in the

Function Settings

1. Software Version Observe the display, The display should show “r X.X” where

“X.X” is a number such as 2.3. This can be helpful when

discussing operation with Welch Allyn customer support.

Press the Mode button for more than two seconds to

advance to the Default Algorithm.

2. Default Algorithm

Oral/Axillary Modes

Three settings are available to set the default predictive

algorithm: oral, axillary or last prediction. To change the

default algorithm, momentarily press the Mode button to

advance to the next algorithm. The instrument will be placed

in the selected algorithm after the probe has been returned

to the probe well. When replacing the batteries, the power-up

setting is the oral predictive algorithm.

Press the Mode button for more than two seconds to

advance to the Battery Voltage.

3. Battery Voltage This section displays the current battery voltage with 10 mV

resolution. The battery is considered acceptable if it

measures higher than 3.4 volts. New batteries should

produce 4.5 volts or more. Each thermometer is factory

tested for accuracy down to a supply voltage of 2.9 volts. At

3.2 volts, the low battery indicator (battery icon) will flash.

When the battery voltage is 3.0 volts or less, the low battery

indicator will display without flashing. Three double beeps

are generated, followed by a blank display. At this point

temperature taking is disallowed.

4. Predictive Temperature

Counter

This section displays the count of the number of predictive

temperature actuations that have occurred since last cleared

(in 100’s). Replacing the batteries will clear the counter. The

power-up setting is 0.

5. Anti-Theft Temperature

Counter System

(Model 678 only)

The user can select the anti-theft time out based upon a

predictive temperature counter that can be set as 0, 25, 50,

100 and 200 (0=disabled).

The unit will not function when the predictive temperature

•

counter has reached the user set parameter. The unit will

display a warning consisting of a digit representing the

last 5 counts (i.e. 5,4,...1,) and will display “SEC” on the

LCD for five seconds when the probe is returned to the

storage channel after the temperature is complete or

after 30 seconds with the final temperature displayed.

When the unit enters the alarm state, it will double beep

•

for approximately 10 seconds and display “SEC” on the

LCD. This function is deactivated at power-up.

1-8 Welch-Allyn, Inc.

Page 17

Operational Characteristics

6. Instant Anti-Theft

Audio Alarm System

(Model 678 only)

7. Error Log (Function 5

in the Model 679)

The user can select an anti-theft option that instructs the

instrument to beep continuously (beginning after

approximately 5 seconds) whenever the unit is removed from

the wall holder.

The user must defeat the Instant Anti-Theft Audio Alarm

•

within 30 seconds after removal from the wall holder by

holding the Mode button and removing the probe from

the probe well, or by returning the unit to the wall holder.

After 30 seconds, the instrument must be returned to the

•

wall holder to silence and reset the Instant Anti-Theft

Audio Alarm.

Once in the Instant Anti-Theft Audio Alarm state, the

•

instrument will continue the audio alarm until power is

exhausted or until the unit is returned to the wall holder.

Note:

At power-up, this mode is deactivated.

The instrument will save the last 10 error messages that

occur and display those messages in a last in first viewed

sequence. While in error log, the display reads E x.x. To

display the next error, momentarily press the mode button.

Note:

Battery removal will clear the error log of all error

messages.

SureTemp® Model 678/SureTemp® Model 679 1-9

Page 18

Technical Manual

1-10 Welch-Allyn, Inc.

Page 19

2. PREVENTIVE MAINTENANCE

The following preventive maintenance is recommended to maximize uninterrupted

service with the M678 and M679 SureTemp Thermometers. Units which are in service

on a regular basis should have the following preventive maintenance performed every

6 months:

1. Visually inspect the thermometer for physical damage which might cause future

product failure.

2. Clean the unit per instructions in the

Directions for Use

manual supplied with the

thermometer and/or per the instructions below.

3. Perform the Power-Up Display test, Startup Display test and Model 9600

Calibration Testing procedure found in the

Model 9600 Operation Manual

.

Units which are stored for an extended period and not used should have the following

performed every 12 months:

1. Replace the batteries according to the procedures found in the

Directions for Use

manual.

2. Perform the Power-Up Display test, Startup Display test and Model 9600

Calibration Testing procedure found in the

Model 9600 Operation Manual

.

Cleaning and Sterilization

Routine Cleaning

Clean the exterior of both the Model 678 or Model 679 instrument, the wall mount and

the probe as needed. Wipe all surfaces with a clean cloth dampened with warm water

and a mild detergent, alcohol, or a nonstaining disinfectant such as Sporicidin Spray

and Towelettes

LCD faceplate. Make sure that the cloth is damp, but not too wet.

Note:

Do not allow cleaning solution to run inside the instrument.

thermometer into the cleaning solution.

probe.

1

or MetriSpray cleanser2. Care should be taken to not scratch the

Never

immerse the

Never

autoclave the thermometer or

ETO Gas Sterilization Procedure

When no other form of decontamination such as a germicidal wipe is acceptable, a

low temperature (not to exceed 48.9°C [120°F]) ETO gas sterilization cycle may be

used. Refer to your institution’s standard operating procedure for the length of the

cycle.

1

Sporicidin is a registered trademark of Sporicidin International (800) 424-3733.

2

MetriSpray is a trademark of Metrex Research Corporation (800) 841-1428.

SureTemp® Model 678/SureTemp® Model 679 2-1

Page 20

Technical Manual

This type of sterilization may cause some hazing of glossy plastic surfaces and should

be used only when absolutely necessary.

1. Ensure that the probe is removed from its storage well and disconnected from the

2. Remove any probe covers from the probe and from the probe cover storage well.

instrument.

3. Remove the batteries following the instructions in the

Replacement

section below.

Battery Removal and

WARNING: Leaving batteries in the thermometer during the sterilization

procedure

may present an explosion hazard.

4. Wrap the thermometer in a standard sterilization type packaging such as the

Baxter Tower Dualpeel Sterilization Pouch.

5. ETO gas sterilize at a temperature not to exceed 48.9°C (120°F) and aerate.

6. Remove the sterilization packaging.

7. Before installing the batteries and probe, allow the probe and instrument to

stabilize to room temperature for at least one hour.

8. Reinstall the batteries (see

Battery Removal and Replacement

below) and verify

a successful self test.

9. Install the probe connector and insert the probe into the storage well to start the

probe initialization process.

10. Verify proper calibration of the thermometer and probe using the Welch Allyn

Model 9600 Calibration Tester.

Battery Removal and Replacement

1. Using a flat surface, lay the thermometer on its front panel.

2. Remove the

PROBE COVER BOX HOLDER

on the back of the instrument by

pressing with thumb and middle finger on the “dimples” located in the sides of

PROBE COVER BOX HOLDER

COVER BOX HOLDER

.

. The batteries are located under the

PROBE

3. Remove the batteries by pulling on the ribbon located under them.

4. Press either the Mode or the Timer button for approximately five seconds to

discharge the electronics.

5. Install 3 new “AA” batteries according to the battery polarities marked inside the

battery compartment. Verify that the thermometer completes self-test, then goes

blank.

CAUTION:

6. Reinstall the

2-2 Welch-Allyn, Inc.

Incorrect battery polarity may result in damage to the thermometer.

PROBE COVER BOX HOLDER

.

Page 21

3. CALIBRATION TESTING

The Calibration Key provides a convenient means of testing the thermometer.

Calibration Key Procedure

1. Extract the probe and disconnect it from the thermometer.

2. Insert the Calibration Key (part number 01637-000) into the probe connector

receptacle on the thermometer and observe the display. The display should read

CAL for two seconds, and then go blank.

3. Insert a probe shaft into the probe storage well and remove it to initiate a

temperature taking cycle. Wait for the display test and then observe the display.

The display must read between 97.1°F and 97.5°F inclusive for the calibration of

the instrument to be correct.

4. Remove the Calibration Key and reinstall the probe connector plug.

5. Then install the probe into the probe storage well.

Note:

This Cal Key test does

Welch Allyn Model 9600 Calibration Tester.

If the reading from the Cal Key is not within the specified range or you are having

other problems with the use of the Cal Key, refer to

Troubleshooting

section.

not

test the probe. To do so requires the use of the

Cal Key Problems

in the

Model 9600 Calibration Testing Procedure

The Model 9600 Calibration Tester provides a convenient means of testing the entire

thermometer system (instrument and probe).

The 9600 must be warmed up and stable at one of the two available temperature

•

settings.

The thermistor based instrument under test must be in Monitor mode and no probe

•

cover loaded.

The probe is inserted into the small hole in the dry heat well of the 9600 and allowed

to settle for a minimum of 2 minutes to the final temperature. The reading on the

thermometer must be within the range specified on the 9600. Refer to the

Operation Manual

Note:

All Welch Allyn and Diatek thermometers (thermistor and infrared ear

thermometers) can be checked in the Model 9600.

If you are having problems with the use of the Model 9600, refer to the

Troubleshooting

for complete instructions.

section in the

Model 9600 Operation Manual

.

Model 9600

SureTemp® Model 678/SureTemp® Model 679 3-1

Page 22

Technical Manual

3-2 Welch-Allyn, Inc.

Page 23

4. THEORY OF OPERATION

Technical Overview

The heart of the Model 678 and Model 679 is comprised of two integrated circuits

which provide most of the microcontroller and analog circuit functions.

All control and display functions are governed by the microcontroller (U1).

•

All probe analog data interfacing to the microcontroller is provided by U2.

•

U2 functions as an A/D converter.

A/D

Converter

Circuit

Voltage

Referenc e

Circuit

Backlight

Circuit

Battery

Detector

Circuit

Probe

Warmer

Circuit

8 bit

A/D

16 bit

Timer

MODEL 678 PCA

NEC UPD78064 uP

CPU

LCD

Driver

Liquid

Crystal

Display

Serial

Timer

Horn

Driver

I/O

Probe

Logic

Circuit

Serial Port

irDA

Circuitry

Mode Button

Timer Button

Horn

PROBE ASSEMBLY

Probe Connector

Thermistor

Four

Conductor

Coil Cord

Probe

Warmer

3 AA Battery

Pack

Figure 3 - System Block Diagram

Probe resistance measurements are made by ratioing pulse widths which are

generated in U2 by sequentially switching in a calibration resistor and the probe

thermistor. These pulse widths are measured by the microprocessor, which calculates

the probe resistance. The actual probe temperature is then calculated from the probe

resistance.

SureTemp® Model 678/SureTemp® Model 679 4-1

Page 24

Technical Manual

Probe Enhancements

The Model 678 and Model 679 thermometers have the capability to detect probe type oral / axillary vs. rectal. This allows the oral temperature-taking to be as fast as

possible by using different operating modes based on probe type. Axillary

temperatures are measured with oral probes in combination with the axillary mode,

providing a temperature reading in about 15 seconds. Rectal probes give a Normal

mode temperature in about 15 seconds for both models.

Probe type recognition also allows the use of minor differences in prediction

parameters tailored to the temperature taking site to help increase speed over

previous products.

The probe type is communicated to the thermometer by the use of shorting jumpers

between the ground and two of the probe connector contacts. Model 678 / 679

oral/axillary probes also incorporate a warming resistor in the tip to pre-warm the

probe before placement in the mouth or axilla, thus speeding response even further.

Probe Switch

The probe switch (S4) is activated by the probe shaft when the probe is installed or

removed from its storage well. Placing the probe into the storage well pulls processor

pin 15 high via R6. When the probe is removed, this line is pulled low. This signal is

also routed to test connector J4 pin 5 to allow automated testing of this function during

factory test. R6 allows this line to be pulled high or low at J4 during factory test

regardless of the actual switch position.

CAUTION: For the technician, J4 serves as a convenient set of “test points”

to monitor proper operation of all user switch functions.

BE CAREFUL WITH STATIC DISCHARGE! J4 TIES DIRECTLY

TO CMOS PROCESSOR INPUTS WHICH ARE EASILY DAMAGED

BY STATIC DISCHARGE. FOLLOW PROPER ESD HANDLING

TECHNIQUES.

Normal Mode

The Oral/Axillary probe is pre-warmed using a pulse width modulation (PWM)

controller to 33.9°C (93°F) upon extraction from the storage well.

When the probe is first extracted and colder than 33.9°C, the heater pulse widths

•

are at a maximum percentage ON vs. OFF to warm the probe quickly.

When the probe reaches 33.9°C, the pulse widths narrow to a duty cycle just

•

enough to maintain temperature.

When the probe is placed in the mouth, the heat supplied by the mouth makes the

•

pulse widths reduce to zero. This reduction to zero (and the probe being at least

up to 33.1°C / 91.6° F) triggers the start of the prediction algorithm.

4-2 Welch-Allyn, Inc.

Page 25

Theory of Operation

The shape of the rising temperature curve is monitored and the best fit to a curve is

found. When the curve fit is stable, the final predicted temperature is displayed.

In the oral mode, if the prediction criteria is not met within 15 seconds of starting

•

the prediction process, it will automatically switch to Monitor mode.

In the axillary mode, if the prediction criteria is not met within 30 seconds of

•

starting the prediction process, the thermometer displays a final temperature but

also indicates that the probe is out of position.

In the oral or axillary mode, if the ambient temperature is above 33.9°C (93.0°F)

•

the unit will automatically switch to Monitor mode.

Rectal probes are not prewarmed. Rectal temperature measurements will take

•

about 15 seconds.

Within 60 seconds after the probe is removed from the well, if the prediction

•

process has not started, the thermometer will switch to Monitor mode.

Power Supply

The Model 678 contains a battery pack made up of 3 AA size batteries. This provides

a maximum supply voltage of about 4.8 volts. Power is drawn from the three AA

alkaline cells directly to the circuit electronics. The voltage from the batteries is

unregulated but filtered by capacitor C25. The power supply voltage will range from

about 4.8 volts with new batteries to 3.0 volts at shut down.

The thermometer has two low battery voltage indications.

The first is a warning that batteries are getting low and is indicated by the battery

•

icon flashing in the display. This begins when the batteries fall to about 3.2 volts.

Accuracy is not affected during low battery warning indication.

When the batteries fall to approximately 3.0 volts, the low battery error condition is

•

defined to exist. Operation is halted and the E2.1 error message is stored in

memory. At this point, the batteries must be replaced and the thermometer

electronics reset. See

Reset Self/Tests

on page 4 and on page v.

Low Battery Detection

The Model 678 includes a low battery detector circuit which shuts the device off when

the battery degrades to 3 volts. This ensures that erroneous temperature readings

are not given due to a low battery. For this operation, the reference voltage (VREF) is

measured by software using channel 1 of the 8 bit A/D in the microprocessor. The

A/D is powered with the battery voltage (VCC) through Q12. A/D channel 1 is

compared to the full scale on the A/D. As the battery voltage gets lower, channel 1

readings get higher. A reading above a fixed limit indicates a weak battery.

Exceeding another limit indicates a dead battery and the device will shut off.

Microcontroller

A NEC UPD78064 or UPD78063 single chip microcontroller in a QFP package (U1) is

used for signal digitizing, data processing, program memory addressing and storage,

and I/O interfacing. The microcontroller also includes an LCD controller/driver which

allows internal conversion of CMOS logic levels to a data format capable of driving the

Model 678/679 LCD. In this application, the microcontroller is running at

approximately 2.5 MHz, which is achieved by using a 4.9152 MHz Crystal (X1).

SureTemp® Model 678/SureTemp® Model 679 4-3

Page 26

Technical Manual

Reset/Self Tests

Upon battery installation, (assuming that the electronics have been discharged

sufficiently by pressing a user button with batteries removed) the microprocessor

receives a power up reset signal from the components associated with the reset line at

U1-12. When power is applied continuously, C3 is charged slowly through R7,

providing an active low reset to the microprocessor.

When the reset signal is complete, the microprocessor launches a series of self

checks which include RAM test, ROM test, instruction set test, self calibration tests

(electronics accuracy test, hi cal, low cal), probe warmer circuitry tests, probe test,

battery voltage test and ambient temperature test. Any failures here will cause a

specific error code to be displayed to assist debugging.

Microprocessor Clock

The clock for the microprocessor is generated by X1 and capacitors C26 and C27,

which form a 4.9152 MHz. oscillator circuit. The microcontroller is running at

approximately 2.5 MHz, which is achieved by internally dividing the frequency of

oscillation by two.

Temperature Measurement and Display

The thermometer probes incorporate negative temperature coefficient thermistors.

When the temperature of the probe is increased, its electrical resistance decreases.

Model 678 and 679 use “20K” thermistors, so they are at approximately 20 Kohms at

room temperature. At 37 °C (98.6 °F) they are near 12 Kohms. The change in

resistance is nonlinear with temperature, and an equation describing this curve is

programmed into the thermometer.

Temperature Measurement A/D Converter

The primary function of the temperature measurement A/D converter circuit is to

convert a measured resistance into a 16-bit word, which is then used by the

microprocessor to calibrate itself and calculate a temperature.

Theory of Operation

The A/D circuit is made up of 4 major parts:

The resistance to be measured (either the probe thermistor, the PTBCAL resistor,

•

or the HICAL resistor).

The timing capacitor (C21, 0.33uF) and associated driver circuitry

•

(Q1-Q4, Q9, R15, and R30).

A low bias dual voltage comparator (U2, TLC555).

•

A 16 bit timer internal to the microprocessor.

•

4-4 Welch-Allyn, Inc.

Page 27

Theory of Operation

In effect, this is a single slope converter which measures the time constant of the

measured resistance combined with a fixed capacitance. The time constant is

measured by counting the time it takes for the voltage to decay from a fixed initial

voltage level to a fixed lower voltage. The ratio of this pulse width and the pulse width

corresponding to a known calibration resistance (R13, 11.55K) is used to calculate the

measured resistance. Once the resistance is known, the corresponding temperature

is calculated using the thermistor temperature equation. Because the M678 uses this

‘ratio cal’ method for measuring the thermistor resistance, the device is immune to a

number of gain errors which can be measured and corrected using software.

Circuit Description

Initially, the microprocessor simultaneously discharges both sides of the capacitor.

This is accomplished by bringing A/D TRIGGER high which turns on Q9, pulling one

side of capacitor C21 to ground. This also turns on Q1, Q2, and Q3 via PROBE_SEL,

PTBCAL_SEL, and HICAL_SEL, which allows the other side to discharge through the

thermistor R8(12.1K) and R13(11.55K).

Once capacitor C21 has been fully discharged, the probe thermistor is then selected

by switching the PTBCAL and the HICAL resistor paths off. The microprocessor then

forces the A/D TRIGGER signal to go low turning on Q4, which lifts one end of

capacitor C21 up to VREF(2.4v).

Because there can be no instantaneous voltage drop across capacitor C21, the other

side of the capacitor immediately goes to 2.4v. This exceeds the threshold

voltage(1.6v) of U2(TLC555), causing the output A/D_OUT to go low. At this point,

the capacitor begins to discharge from 2.4v to 0v through the thermistor resistor.

The output of the comparator goes high again when its input reaches the trigger

voltage(0.8 volts). This produces a pulse of length equal to the time it takes for the

capacitor to discharge from 1.6v to 0.8v through the thermistor.

The microprocessor measures this pulse width using an internal 16-bit timer and then

the same A/D conversion is performed using the HICAL resistor as the measurand

resistance. The microprocessor performs the following calculation that ratios these

two pulse widths to determine the exact resistance of the thermistor:

Rthermistor

()PWthermistor ( )Rhical

.

PWhical

The microprocessor then uses the following equation to convert the measured

resistance into a temperature:

Temperature_in_Kelvin

Ra.Rb ln( )Rt.Rc ( )ln( )Rt

1

3

SureTemp® Model 678/SureTemp® Model 679 4-5

Page 28

Technical Manual

2

2

Q4 and Q5 and the base resistors R15 and R30 form the level shifter and drive circuit

for the fixed end of the timing capacitor. R15 (4.7K) is selected to give adequate

saturation on-resistance. R30 (10K) is selected so that a float on the input will not

cause damage from cross-conduction if the input is left floating, yet supply enough

current to the timing capacitor during recovery. Q4 and Q9 exhibit only a few millivolts

of saturation voltage, which does not affect the accuracy of the A/D as described

above.

•

•

•

Probe Identification Logic

Basic Function

C21 is the surface mount timing capacitor. This capacitor is selected for low

dielectric absorption, hence the high voltage rating (50V).

D4 and R16 protect the comparator from input undervoltage when the timing

capacitor (C21) is discharged. D4 also reduces the recovery time by limiting the

voltage at the beginning of recovery to 0.6 volts instead of 2/3VREF.

C5 provides the first line of defense from EMI (Electro Magnetic Interference)

coming in on the probe. R33 and C18 protect Q1 from rectifying EMI in the

substrate diode. R16 protects the comparator input from overcurrent.

The probe logic circuitry is needed to determine which type of probe is connected to

the device. This allows the microprocessor to initiate the proper algorithm for

converting a thermistor measurement into a temperature. Figure 4 lists the probe

logic circuitry and Figure 5 shows the logic diagram.

SIGNAL ORAL RECTAL CAL KEY NO PROBE

PROBE_0 0 0 1 1

PROBE_1 0 1 0 1

To Microprocessor

PROBE_1

PROBE_0

PROBE LOGIC

Figure 4 - Probe Logic Circuitry

VCC

1

1

R10

1M

2

1

C20

0.01UF

2

NO CUT F O R ORAL

C19

0.01UF

R11

1M

1

Probe Connector

PCB

C U T H E R E

F O R R E C T A L

J1F

J1C

C U T H E R E

F O R C A L K E Y

Figure 5 - Probe Logic Diagram

4-6 Welch-Allyn, Inc.

Page 29

Theory of Operation

Circuit Operation

R10, R11 (both 1 MΩ pullup resistors to reduce battery drain), J1-F(PROBE_1), J1C(PROBE_0) and J1-E(GND) are used to provide logic 0 or 1 inputs to U1-17 and U118 depending on whether a probe or cal key has been plugged into the Model 678

probe connector receptacle. When a probe has been plugged in, the software

determines whether it is Oral, Axillary, Rectal, or a Cal Key as follows:

When J1-C (CAL) and J1-F (RCTL) are both connected to J1-E (GND) (by

•

jumpers installed in the Model 678 probe PCB), the software determines that the

probe is an Oral probe;

When J1-C (CAL) is connected to J1-E (GND), but J1-F (RCTL) is not connected

•

to J1-E (GND), the software determines that the probe is Rectal probe;

When J1-F (RCTL) is connected to J1-E (GND), but J1-C (CAL) is not connected

•

to J1-E (GND), the software determines that the probe is a Calibration Key;

When neither J1-C (CAL) or J1-F (RCTL) are connected to J1-E (GND), the software

•

determines that no probe has been plugged in.

C19 and C20, both 0.01 uF capacitors, are bypass capacitors used to filter out

spurious noise to the microprocessor on the probe input lines J1-F(PROBE_1) and

J1-C(PROBE_2).

Probe Warming ( Oral probes only)

Probe characteristics vary somewhat due to normal production process variations. It

is desirable to warm the probe as efficiently as possible from a time-to-ready

standpoint and from a temperature stability standpoint when the probe is up to

temperature.

The probe warming process is a closed loop feedback control system incorporating

PWM (pulse width modulation) control.

The probe warmer circuitry is used to heat the probe tip prior to taking a temperature

reading in order to speed the convergence of the prediction algorithm. This allows

quicker temperature readings. A fail safe hardware shutoff circuit is included to ensure

the heater will shut off in the event of a software failure.

Theory of Operation

The microprocessor sends pulses via /HTRC to drive the probe heater resistor which

heats the probe tip. A temperature of about 93°F is maintained prior to taking a

temperature.

A software algorithm calculates the width of the HTRC pulse as a function of the

difference between the probe temperature and 93°F, and as a function of the probe

temperature rate of change. It provides an initial pulse to rapidly heat up the probe tip to

the 90°F region and then supplies progressively shorter pulses as the probe temperature

converges to about 93°F. Once 93°F is reached, software continues to send a “control”

pulse to maintain the temperature.

SureTemp® Model 678/SureTemp® Model 679 4-7

Page 30

Technical Manual

Circuit Operation

The warmer circuitry consists of Q5, Q13, Q14, C1, C2, L1, D1, R1, R2, R3, R4, R5,

R31, R32, and the heater resistor (27 ohms) connected across J1B and J1E.

Line /HTRQ is pulled low by the uP which enables Q13 to turn on. /HTRC is then pulsed

low which brings the base of Q5 low via capacitor C1. Q5 turns on which in turn enables

Q14 on. Base current from Q14 flows through R31 (1K) and R32 (1K). Most of this

current flows through the emitter of Q5 while some flows through R1 (470K) to satisfy the

diode drop of Q5’s BE junction. The base current of Q5 along with the current through

R1 flows into C1(1uF), charging it up. This sets up the mechanism for the hardware

shutoff. As this capacitor charges up, the base voltage of Q5 approaches the emitter

voltage and the transistor shuts off, thereby shutting down the probe warmer. As long as

Q5 remains on, Q14 has a base current flowing which allows current to flow from its

collector through R2 (4.7K) and the heater resistor. With about 150mA flowing through it

([VCC-2VCEsat]/29 ohms), the heater resistor heats up the probe tip.

During normal operation, software turns the warmer circuit on and off. The width of the

pulse on HTRC determines how long Q5 is turned on, thereby determining how long the

heater is heating. Once the HTRC pulse goes high again, the base of Q5 is pulled high

turning it off, and the capacitor discharges to VCC through D1.

Q13 and Q14 are selected for their low saturation on voltage. D1 is a diode clamp

used to keep the base of Q5 from attaining a much higher voltage than VCC. R4(47K)

and R2(4.7K) in combination with R3(47K), serve as pull down resistors ensuring that

the processor feedback lines (U1-34 and U1-35) go low immediately upon warmer

component shut off. C2 serves as an RFI suppression component.

Other Components

Liquid Crystal Display

The model 678 and Model 679 use a liquid crystal display to display data to the user.

Three communication lines and 18 segment lines connect the LCD to the display

driver (U1-60 to U1-80) internal to the NEC microprocessor. The LCD is 3:1

multiplexed with 1/2 bias. The bias voltages (1.5 volts, and 3.0 volts) are supplied to

the display driver by the voltage reference circuit

The LCD glass is electrically tied to the display PCB via an elastomeric connector

sandwiched and compressed between the glass and the PCB by the frame. This

assembly, if taken apart, cannot be reassembled without replacing the frame.

LCD Backlight (Model 678 Only)

The backlight is a low power LED which illuminates the back of the LCD display. The

backlight will be turned on automatically in any mode except Low Power. Once the

backlight is turned on, it will automatically shut off whenever the instrument goes into

Low Power mode.

Battery power is applied to current limiter resistor R23 and LED D3. When

microprocessor signal /BLIGHTCTL at pin 42 goes low, current is allowed to flow

through the LED. The amount of current is approximately 2 milliamps, depending on

the Battery voltage Vcc. When the instrument is in Low Power mode / BLIGHTCTL

goes high, turning the LED backlight off to conserve power.

4-8 Welch-Allyn, Inc.

Page 31

Probe Switch

When the probe has been inserted in the probe holder, the probe switch (S4) brings

PROBE SW (U1-15) high (VCC). When the probe is removed from the probe holder,

the probe switch brings PROBE SW (U1-15) low (GND). R6 (47K) allows the probe

switch to be overridden by the test port.

Mode Button

The mode button (S2) is a momentary contact switch. A pullup internal to the

microprocessor normally pulls /MODE (U1-25) high, placing a logic “1” at this input.

When depressed, S2 provides a momentary contact to ground at /MODE giving it a

logic level of “0”. The software continuously checks /MODE. If the thermometer is not

in the process of taking a temperature, pressing the Mode button will wake up the

thermometer and display the last recorded temperature.

Timer Button (678 Only)

The timer button (S1) is also a momentary contact switch. A pullup internal to the

microprocessor normally pulls /PTIMER (U1-26) high, placing a logic “1” at this input.

When depressed, S1 provides a momentary contact to ground at /PTIMER giving it a

logic level of “0”. The software continuously checks /PTIMER.

Theory of Operation

Serial Communications Port

Transmit , receive data and control CMOS-level signals are made available for test or

system integration via J4. The contacts of J4 are laid out so they are accessible

through a slot in the rear of the case. Communications on a cable length of over one

foot should be driven with external RS232 or other line driving circuitry.

Horn

The horn is activated at the start of a temperature taking cycle, at the end of a Normal

mode temperature cycle, during timer operation at 0, 15, 30, 45 and 60 seconds, and

for various error conditions.

A short duration single beep is indicative of normal operation.

•

A short duration double beep is used to indicate errors and warnings such as

•

switching from Normal mode to Monitor mode during a temperature cycle.

The horn is a piezoelectric ceramic resonator driven by the processor square wave.

The horn control signal comes from U1 pin 49. It directly drives the horn LS1.

SureTemp® Model 678/SureTemp® Model 679 4-9

Page 32

Technical Manual

4-10 Welch-Allyn, Inc.

Page 33

5. TROUBLESHOOTING

Many thermometer operational parameters can be tested for proper operation before

the unit is taken apart and without needing any tools. Refer to

Characteristics

sections for guidance on preliminary checks.

on page 1-1 and in particular to the

Setup

Operational

Biotech Mode

and

If the trouble seems to be calibration related, refer to

page 3-1.

If these sections do not prove useful in resolving the problem and you are sure that

the instrument is not performing properly, the following sections should guide you

through the debugging process given the proper tools and equipment.

Calibration Testing

on

Error Codes

Error codes are divided into four classes:

Probe Probe errors are generated by the probe or the probe connector and are

not errors generated by the thermometer. They do require that

temperature measuring be inhibited until the error is cleared. There is no

limit to the number of times a probe error can occur. All probe problems

are considered by the thermometer to be recoverable. When a probe error

occurs, the probe icon is displayed.

Ambient

Temperature

Dead Battery Dead Battery error occurs when the instrument detects a battery voltage of

Ambient Temperature errors occur when the ambient probe temperature is

above 104.0° F or below 60.8° F. During an ambient temperature error, the

display shows an ”A” with either the up or down arrow icon flashing.

3.0 volts or less. The battery icon is displayed without flashing when this

error occurs.

Instrument

Circuitry

Note:

Error codes E0.1, E0.2, E0.3, can sometimes be caused by a faulty probe. It is

advisable to remove the probe completely from the instrument and check its

functionality as described in the

an instrument problem instead of a probe problem. If another probe is available, this

can prove useful in tracking down the source of the problem.

SureTemp® Model 678/SureTemp® Model 679 5-1

Instrument Circuitry errors are generated from internal test failures and can

be recoverable or non-recoverable. Error code numbers are only available

in Biotech mode.

Recoverable errors require that temperature measuring be

•

inhibited until the error is cleared. After displaying the error |X|

icon, the instrument will shut itself off and store the error code in

memory.

Non-recoverable errors are generated from internal ROM and

•

RAM test failures. The error code will be stored in memory and

the LCD will disply the error |X| Instrument Malfunction icon.The

only way to recover from a ROM or RAM error is to reset the

electronics by removing the batteries.

Operational Characteristics

section before assuming

Page 34

Technical Manual

Instrument circuitry error codes are listed in the table below.

CLASS ERR NUM SELF-TEST DESCRIPTION

Probe E0.1 Probe heater accumulation test.

Probe E0.2 Probe a/d pulse width test.

Probe E0.3 Adaptive probe gain too high or too low test.

Ambient E1.1 Ambient temperature high test.

Ambient E1.2 Ambient temperature low test.

Battery E2.1 “Dead” battery test.

Internal E3.1 RAM read/write test.

Internal E3.2 ROM checksum test.

Internal E3.3 CPU instruction test.

Internal * CPU Watchdog test.

*Will cause hardware reset, but no error.

Internal E4.0 PTB resistor a/d pulse width test.

Internal E4.1 RatioCal resistor a/d pulse width test.

Internal E5.0 Heater circuit test.

Internal E5.1 Heater overheated test.

Internal E5.2 Heater watchdog timeout test.

Internal E6.0 PTB resistor “temperature” test.

Figure 6 - Self-Test /Error Table

Equipment Required

Most troubleshooting operations can be performed with standard tools and meters.

A #1 Phillips screwdriver will remove all instrument screws.

•

A standard lab 3.5 digit digital multi-meter (DMM) will provide sufficient accuracy

•

for most tests. A needle-tipped pair of probes is recommended.

For particularly difficult tasks, an oscilloscope is sometimes the only way to

•

analyze high speed signals, but is not generally required.

Standard electronic tools and supplies for small surface mounted and through hole

•

component rework will be needed to perform any electronics repairs. Some

surface mounted components are extremely small and present a challenge for

rework by hand. A surface mount rework station is recommended.

Power and ground are available at the battery terminals E2 (power) and E3

•

(ground).

5-2 Welch-Allyn, Inc.

70898-0000A

Page 35

Troubleshooting Table

SYMPTOM POSSIBLE CAUSE PROCEDURE

Troubleshooting

No operation Dead batteries, no batteries,

battery missing, battery

incorrectly installed

Broken battery wire Open instrument case, install

Short circuit preventing

operation

Refer to Battery Removal and

Replacement on page 2-2. Check

that all batteries are installed in

proper direction.

Reset electronics (see Instrument

Reset/Self Tests on page 1-3).

If battery voltage is within

specifications, refer to Biotech

Mode on page 1-7 and enter

Biotech mode to measure battery

voltage as seen by electronics.

batteries, check for voltage on

main PCB at battery wire

connections.

Remove batteries, press mode

button 5 seconds, set DMM to

Ohms, measure resistance of

electronics at battery contacts (“+”

to bottom right corner, “-” to top left

corner). Resistance should climb

to more than 2 Megohms as C25

charges.

Failed component Check oscillator at U1-7 for 4.91

MHz sine wave. If not present,

suspect X1 or U1.

Display problems LCD frame loose Check that all 4 plastic hooks for

the LCD frame are tight and not

broken. The frame should not be

lifting off of the PCB.

Dirty LCD elastomeric

conductor strips

Have a new LCD frame handy.

Remove old one by unlatching

plastic hooks. Clean LCD

elastomeric strips, LCD glass

contacts, and PCB contacts with

lint proof cloth dampened with

alcohol.

SureTemp® Model 678/SureTemp® Model 679 5-3

Page 36

Technical Manual

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Display problems

(continued)

No beeper sound Defective horn Replace horn.

No Timer function Defective Timer buttonS1Check for low level (gnd.) signal at U1-26

Cracked LCD Inspect LCD for hairline cracks, especially

in corners.

Microprocessor failure Check for improper soldering of pins,

crystal operation on O-scope, proper reset.

Broken connection Check continuity from U1-49 to horn pin 2

and from ground to horn pin 1.

Defective U1 Check for signal with O-scope at U1-49.

Replace microcontroller U1.

when timer button S1 is pressed. Replace

button if signal is high.

Broken trace Check for low level (gnd.) signal at U1-26

when timer button S1 is pressed. Replace

Button if signal is high.

No Backlight Defective backlight Check LED D3 and resistor R23.

No /BLGTHCTL signal Check that signal at U1-42 goes low when

unit is in on.

Recalled temperature is

not correct.

Unit switched to Monitor

mode

If unit is in Monitor mode (whether by the

user switch or automatically), the stored

temperature is the last one seen by the

instrument. This is usually lower than the

patient temperature since the probe drops

in temperature after removal from the

patient.

Probe: Wrong type

displayed

Missing Vcc power to

R10 and/or R11

With no probe installed, check that probe

connector pins J1-B and E are both pulled

high when any function is active (recall or

timer).

5-4 Welch-Allyn, Inc.

70898-0000A

Page 37

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Probe: Wrong type

displayed (continued)

Incorrect wiring of

probe

Troubleshooting

Oral probes should have a short between

pins B, E and F (refer to instrument PCB

designators for probe pin definition).

Rectal probes should have a short between

pins E and F but open between pins B and

E or F.

Replace with new probe.

Normal/Monitor Mode

switching problems

Cannot enter Biotech

Mode

Ambient above 33.9°C

Causes auto switch to Monitor mode.

(93.0°F)

Switched to Monitor

mode before probe in

mouth

If 60 seconds pass after ready in Normal

mode, unit switches to Monitor mode.

If probe is still cooling from a previous

temperature and used immediately, it might

sense ambient to be above 33.9°C

(93.0°F).

Defective Mode button Check mode button for proper function.

Check U1-25 for low level signal when

button is pressed.

Deffective Probe Replace probe.

Mode button not

pressed, and or

Mode button must be pressed while

instrument is in the wall holder.

Instrument not in wall

holder (678 only)

Probe not connected

and or probe shaft not

inserted and removed

from probe well

Must connect probe to instrument and

remove the probe shaft from the probe well

while the instrument is in wall holder and

mode button is pressed.

Failed component,

broken trace

SureTemp® Model 678/SureTemp® Model 679 5-5

Check proper Mode button, Probe switch

and security switch operation.

Page 38

Technical Manual

Troubleshooting Table (continued)

SYMPTOM POSSIBLE CAUSE PROCEDURE

Battery Life Problems Excessive alarms

Excessive use in monitor

mode

Dead cell If cell voltage is down significantly in

First set shelf life Due to possibly long stocking times

Cal Key doesn’t activate

thermometer

Cal Key shows OrL,

Probe switch not also

activated

Defective Cal Key Replace Cal Key.

rEC, or ALy

Monitor mode

Probe malfunction Change probe.

temperature reading too

low

The horn draws significant current.

During monitor mode the instrument is

continously drawing current.

only one cell, this battery is defective.

All batteries should drain at the same

rate.

between fabrication and end use, the

first set of batteries may have reduced

life.

When the cal key is connected the

display must read CAL

for two

seconds and then blank. The probe

shaft must be inserted and removed

from the probe well to activate the

probe switch.

Test calibration of entire system

(instrument and probe) with the M9600

Calibration Tester.

Instrument malfunction Check calibration with Cal Key.

Improper placement of

probe

Probe must be under the tongue and