Page 1

©2014 Welch Allyn, Inc.

MM 721357 Ver. C

Standard laryngoscope handles

Directions for use

1

Intended

About this

use

The

laryngoscope blades which are used to examine

placement of a tracheal

document

This directions for use apply to Welch Allyn reusable standard laryngoscope handles REF:

60200, 60300, 60400, 60305. Welch Allyn

used

MacIntosh

Warnings and

WARNING: Welch Allyn reusable standard laryngoscope handles must be reprocessed

after each use.

WARNING: The reprocessing procedure and the equipment and materials described

must be followed and conducted by persons trained and familiar

reprocessing.

WARNING: Consult cleaning and disinfecting agent manufacturer

proper preparation and use.

WARNING: Repeated

inspection procedures to assure damage has not occurred to the handle.

WARNING: High level disinfection and/or sterilization are not achieved by these

methods.

WARNING: Discard any component that shows evidence of damage or

deterioration.

WARNING: Do not modify this equipment. Any modification of this

lead to patient injury. Any modification of this equipment voids the

WARNING: Personnel shall

appropriate personal protective equipment when handling

equipment.

WARNING:

CAUTION:

CAUTION: Do not immerse/soak handle, damage to handle may occur.

CAUTION: If the device will be unused for several months or longer, remove

batteries prior to storing the device.

standard laryngoscope handle is an accessory used w i t h c o m p at i b l e r i g i d st a n d a r d

and visualize

tube.

reusable standard

with

Welch Allyn standard laryngoscope blades MacIntosh

REF:

6924X, and Miller REF: 6804X and REF 68470.

a patient’s airway

laryngoscope handles may be

REF:

and

aid

6904X, English

cautions

with

medical device

reprocessing may

follow their facility policies

Laryngoscope equipment is not suitable for use in intense

Failure

to follow these instructions may cause damage to this han d l e .

degrade

elements of the handle.

and

procedures

potentially

instructions

product warranty.

and

contaminated

magnetic

for their

Follow

equipment may

wear

the

fields

Page 2

2

Directions for use

Welch Allyn standard laryngoscope handles

Reprocessing

instructions

These reprocessing instructions refer to procedures for cleaning and intermediate level

disinfection.

between each use using

• Cleaning

Standard

laryngoscope handles must be reprocessed prior to first use and

the

and intermediate level

following method as outlined in this

disinfection

Welch Allyn has validated the above instruction as being capable of preparin g these

laryngoscope handles for re-use. The user must ensure that the reprocessing as actually

performed by the user's personnel, with the user's equipment and materials, achieves the

desired result. This may require validation and routine monitoring of the user's actual proce ss

NOTE: The main handle and bottom cap components of handles marked “AUTOCLAVE” are

compatible with the autoclave methods identified which are provided for facilities who wish to

autoclave after cleaning and intermediate level disinfection.

Cleaning and intermediate level disinfection instructions

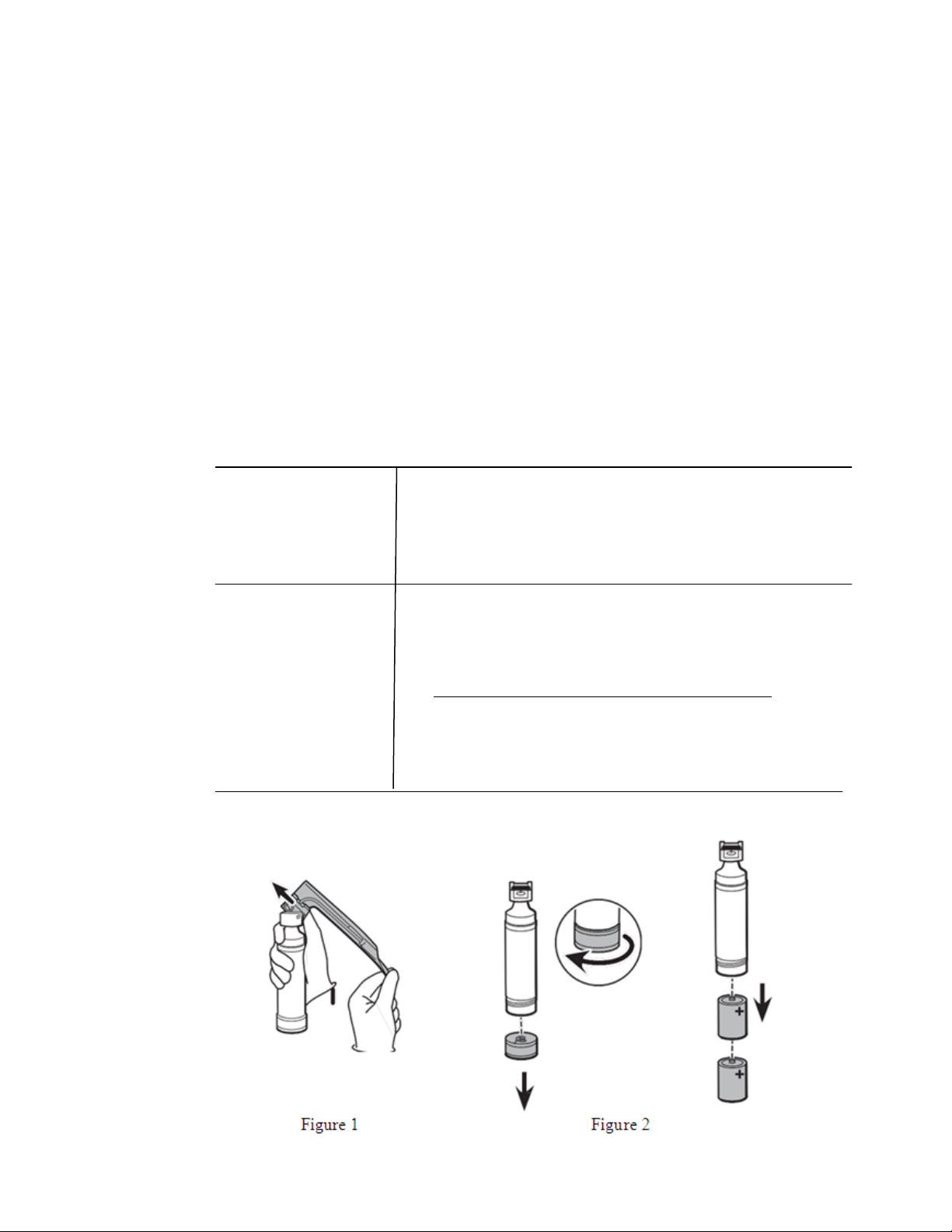

Point of use: 1.

Preparation

for

decontamination:

Separate

blade assembly from handle and place handle

into suitable containment for subsequent reprocessing

per figure 1. Do not place handle with sharp devi ce s.

2. Prevent the handle from drying (i.e. wrap/cover in moist

germicidal

wipe).

1. Select an appropriate quaternary ammonium

isopropanol based germicidal cleaner labeled suitable

for use on healthcare equipment and capable

intermediate level disinfection. Reference EPAregistered disinfectants:

http://www.epa.gov/oppad001/chemregindex.htm

Outside of the U.S., please consult applicable

regulatory body for equivalent quaternary ammonium

isopropanol germicidal cleaner.

2. Remove batteries per figure 3.

document:

Page 3

Directions for use

Cleaning

and

intermediate level

disinfection:

Drying:

Maintenance,

Inspection and Testing

Storage: Store handle per facility practice to allow device to remain

End of

reprocessing

Welch Allyn standard laryngoscope handles

3

1. Follow the ge r m i c i da l w i p e manufacturer’s instructions

to clean all exposed surfaces of the handle and end

cap.

2. If necessary, brush with a dry, soft-bristled brush and

re-wipe to loosen/remove excessive visible soil.

3. After all visible soil is removed, re-wipe to wet all

surfaces and allow adequate contact time for

disinfection as directed by the germicidal wipe

manufacturer.

CAUTION: Only use quaternary ammonium

isopropanol based germicidal wipes.

Allow components to air dry.

1. Inspect

each

component

area (per f

igure

3)

for

damage

or

deterioration.

WARNING: Discard any component that

shows

evidence of damage or deterioration.

Contact Welch Allyn for component replacement.

2. Reassemble batteries into handle per figure 4 with

new or batteries in known good condition.

3 . Attach handle to a clean and disinfected test blade

assembly in known working condition. Verify

•

Blade assembly engages and locks onto handle.

•

Blade assembly deploys into its locked position on

handle

•

Light output is satisfactory.

If the la mp fails to

replace the

AND lamp illuminates.

light or output is low

batteries.

that:

, check or

clean, dry, and ready for service.

instructions for intermediate level disinfection.

Page 4

4

Directions for use

Autoclave

Welch Allyn standard laryngoscope handles

instructions

NOTE: The main handle and bottom cap components of handles marked “AUTOCLAVE” are

compatible with the autoclave methods identified which are provided for facilities who wish to

autoclave after cleaning and intermediate level disinfection.

Disassembly: Remove batteries per figure 2 and set aside.

After battery removal, select ONE of the following autoclave methods below

main handle and bottom cap (only):

Gravity autoclave: Follow equipment manufacturer and

set-up and operation of autoclave e quipment. Gravity autoclave settings are as

follows:

•

Temperature: 132 C (270 F)

•

Exposure time: 3 minutes (unwrapped)

•

Minimum dry time: 1

minute

Pre-vacuum autoclave: Follow equipment manufacturer and

set-up and operation of autoclave e quipment.

follows:

•

Temperature: 132 C (270 F)

•

Exposure time: 3 minutes (unwrapped)

•

Minimum dry time: 1

minute

Pre-vacuum

each

Maintenance,

Inspection and Testing

1. Inspect

deterioration.

component

WARNING: Discard any component that

evidence of damage or deterioration.

Contact Welch Allyn for component replacement.

2. Reassemble b a t t e r i e s i n t o h andle per figure 4.

3. Attach handle to a clean and disinfected test blade

assembly in known working condition. Verify

•

Blade assembly engages and locks onto handle.

•

Blade assembly deploys into its locked position on

handle AND lamp

•

Light output is satisfactory.

If the la mp fails to

replace the

illuminates.

batteries

light or output is low

Storage: Store handle per facility practice to allow device to remain

clean, dry, and ready for service.

facility

procedures in the

facility

procedures in the

autoclave settings are as

area per f

igure 3 for

damage

shows

, check or

for

that:

the

or

Page 5

Directions for use

Welch Allyn standard laryngoscope handles

5

Maintenance

Replace

the

batteries

1. Unscrew bottom cap of handle per figure 5 and remove batteries.

2. Alkaline batteries are supplied with your handle for maximum performance and

3. Insert batteries and reinstall bottom cap per figure 5.

4. Reprocess repaired assembly as appropriate per these instructions

instructions

are recommended as replacements; however

used.

•

Large handle, REF 60200 uses two “D” size

•

Medium handle, REF 60300 uses two “C” size

•

Penlight handle, REF 60400 uses two “AA” size

•

Stubby handle, REF 60305 uses two “AA” size

carbon-zinc

batteries may also be

Figure 5

Page 6

6

Directions for use

Specifications

Electrical:

For information about electromagnetic compatibility (EMC) see Welch Allyn website:

http://www.welchallyn.com

Operating:

32

(0 C)

Approvals:

Con fo rm s t o A S TM F 965 and

Warranty:

One year

Service Information:

For

Welch Allyn

Storage/Transport:

104 F

(40 C)

F

-4 F

(-20 C)

120 F

(49 C)

ISO-7376-1, IEC/EN

The

CE

mark on this product indicates that it has been tested to and

with the provisions noted within the

Complies with EMC Framework of Australia

Technical

Support or to obtain information about any Welch Allyn product,

Technical

Support: w

ww.welchallyn.com/support.

93/42/EEC

Welch Allyn standard laryngoscope handles

60601-1,

Medical Device

IEC/EN

60601-1-2

conforms

Directive.

contact

Welch Allyn, Inc.

4341 State Street Road

Skaneateles Falls, NY 13153-0220 USA

www.welchallyn.com

Authorized European Repre sentative Address:

Regulatory Affairs Representative

Welch Allyn, Limited

Navan Business Park

Dublin Road

Navan, County Meath, Republic

of Ireland

Loading...

Loading...