Page 1

..

Cardio Menu

Operator Manual

.

SCHILLER

SERVICE

SP-I

WDBOOK

Spirometry

Issue

7

Unit

2

July

I998

Sp

SP=l

irom

etry

Unit

.

Service

CH-6340

Phone:

Fax:

Home page:

Hundbook

SCHILLER

Altgasse

Baar, Switzerland

41

A141

http://www.schiller-ag.ch

68

41

760 87 87

761

AG

08

80

July1

998

Article Number:

i

2.

540

OII

Page 2

Issue

Issue

1:

2

March

July

1998,

1996

Update

SP-1

Article

and

revision

Service

Number

to

incorporate

SERVICE

Handbook

2.540

011

latest

hardware

SCHlUER

SP-I

HANDBOOK

and

software.

Spirornetry

Issue 2 July

Unit

1998

f

Associated

Guide

and

SCHILLER

SCHILLER SP-1 USER GUIDE

SCHILLER SP-1 USER GUIDE

Documents

to

SCHILLER Interpretation

Measurement Rogram

SP-1

USER GUIDE - English / German

v/

E

/

D / F

-

French

/

Italian

-

Spanish

I

Portuguese

93/42/EEC Medical Devices: 0124

'Notified Body'

DEKRA

AG

Article

Article

Article

Article

No.

No.

No.

No.

2.510

2.510

2.510

2.510

179

196

197

103

0

Copyright

1998

by

SCHILLER

AG

11

Page 3

SCHILLER

SERVICE

HANDBOOK

SP-I

Spiromem

Issue

Unit

2

July

1998

DECLARATION

Diagnostic

Serial numbers

Year of manufacture:

System

starting

:

with:

OF'

CONFORMITY

Spirovit

SP-1

040.

1997 Onwards

We, the undersigned, hereby declare that the medical device (class

above conforms with the essential requirement listed

in

Annex 1 of

93/42/EEC.

This

declaration

Certificate

of

is

approval

supported

No.:

11425-01

45112-60-01

45112-16-01

by:

IS0

9001

(REV.

1994)

IS0

9001/08.94EN46001/

Annex

II,

Section

3

of

EN

the

directive

46001

12.93

IIa)

specified

EC

Directive

by

SQS

byDEKRAmd

93/42"EEC

Baar

(Switzerland) Dated 30.06.1998

J.J.

Schmid

&

Research

Development Manager

(€01

.

24

Markus

Butler

Quality Assurance Manager

...

111

Page 4

SCHILLER

SERVICE

SP-1

HANDBOOK

Spirometry

Issue

2

July

Unit

1998

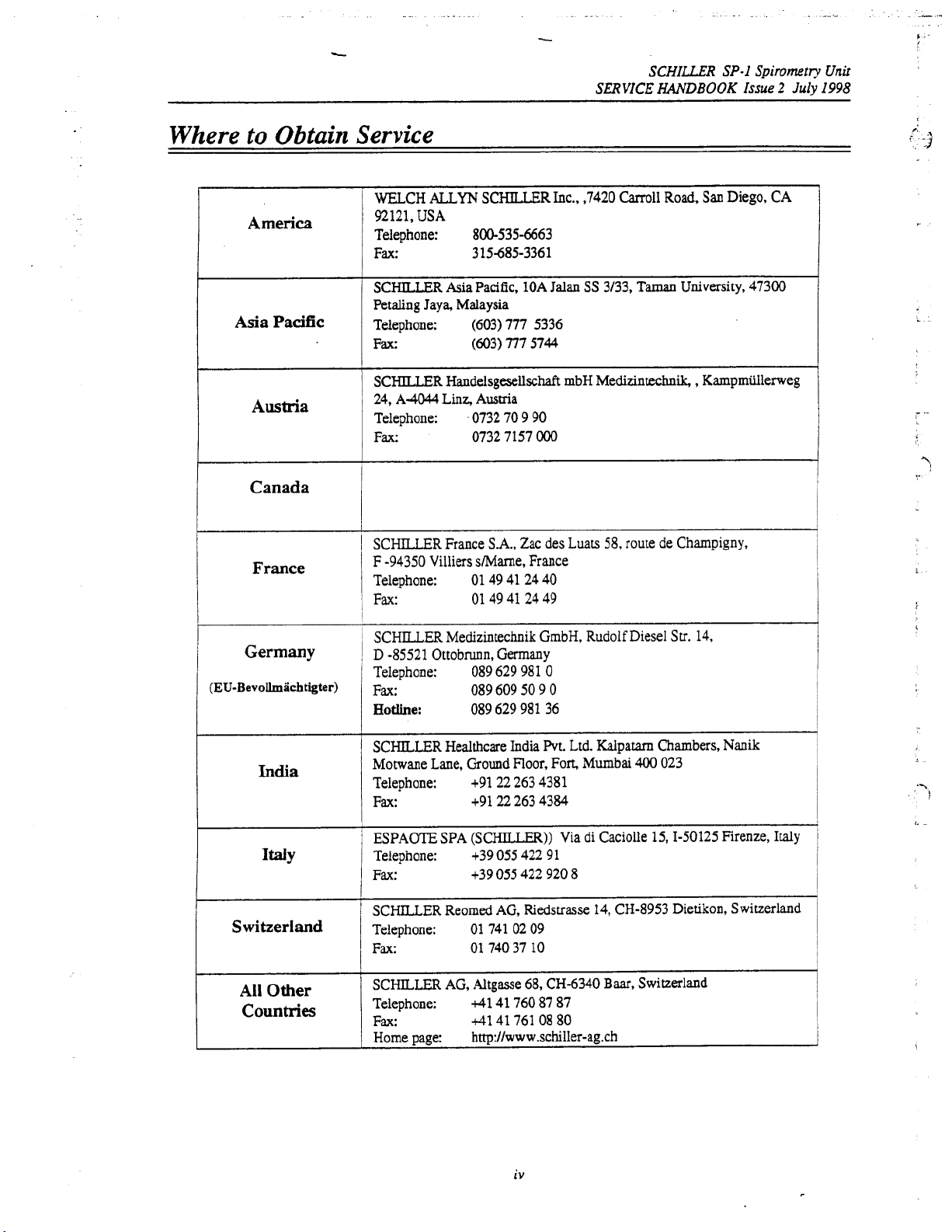

Where

Asia Pacific

to

Obtain

America

Austria

Canada

France

Service

1

WELCH

92121,

Telephone:

Fax:

SCHILLER Asia Pacific,

Petaling Jaya, Malaysia

Telephone:

Fax:

I

I

SCHlLLER Handelsgesellschaft mbH Medizintechnik, , Kampmiillerweg

24,

Telephone:

Fax:

I

I

SCHILLER France

F

Telephone:

Fax:

ALLYN

USA

800-535-6663

315-685-3361

(603) 777 5336

(603) 777

A4044

Linz,

0732 70 9 90

0732 7157

-94350

Villiers s/Marne, France

01 49 41 24 40

01

SCHILLER Inc.,

1OA

Jalan

5744

Ausma

OOO

SA.,

Zac des Luats

49 41 24 49

,7420 Carroll

SS

3/33,

58,

Road, San Diego, CA

Taman University,

route de Champigny,

47300

1

Germany

(EU-Bevollmachtigter))

India

IMY

Switzerland

All

Other

Countries

SCHILLER Medizintechnik GmbH, Rudolf Diesel

D

-85521

i

Telephone:

1

F~:

~

Hotline:

SCHILLER Healthcare India Pvt. Ltd. Kalpatarn

Motwane Lane, Ground Floor, Fon Mumbai

Telephone:

Fax:

ESPAOTE SPA (SCHILLER)) Via di Caciolle

Telephone:

Fax:

SCHILLER Reomed AG, Riedstrasse

Telephone:

Fax:

SCHILLER AG, Altgasse

Telephone:

Fax:

1

Home page:

Ottobrunn, Germany

089 629 981

089 609

089 629 981 36

+91 22 263 4381

+9122 263 4384

+39

055

+39

055

01 741 02 09

01 740 37 10

41

41 760 87 87

41

41 761 08 80

http://www.schiller-agxh

0

50

9

422 91

422 920 8

68,

CH-6340

0

14, CH-8953

Baar,

Su.

14,

Chambers,

400

023

15,1-50125

Dietikon, Switzerland

Switzerland

Nanik

Firenze, Italy

I

iv

Page 5

-

&.

-.

SCHILLER

SERVICE

SP-1

HANDBOOK

Warranty

Disclaimer

The Information

given

as

regarding the contents

changes

any person of such revision

Trademarks

SCHILLERandSP-1

of their

Copyright Notice

0

Copyright

transcribe, store in a retrieval system

electronic, mechanical, magnetic, optical, chemical,

publication without express written permission

Spiromev Unit

issue

2

July

1998

in

this

guide

has

been carefully checked for reliability; however no guarantee is

to

the correcmess

in

the

specification of the product described within at any

owners.

1998

of

the

contents and SCHILLERmakes no representations

of

this

manual. We

or

change.

areregisteredtrademarksofSCHlLLERAG.All

by

SCHILLER

AG.

reserve

All

rights reserved.

or

translate into any language, in any

of

the

right

to

You

manual

SCHILLER

AG.

or

revise

this

document and make

time

without obligation

mdemarksare the property

may

not reproduce, transmit,

fonn

or

by any means,

or

otherwise,

any

part

warranties

to

notify

of

this

Terms

of

Warranty

The SCHILLER SP- 1 is warranted against defects in material and manufacture for

one year

or

Any

unqualified persons attempt

In case

The manufacturer

apparatus

'

persons authorized by

'

instructions.

THERE

WARRANTES

MERCHANTABILITY ORFITNESS FOR APARTICULARPURPOSE

THE

(as

from date of purchase). Excluded from

as

a result of improper handling. The warranty entitles free replacement of the defective part.

liability

assembly operations, extensions, readjustments, modifications, or repairs

the

PRODUCT

for subsequent damage

to

make repairs.

of

a

defect send the apparatus to your dealer or directly

can

only be held responsible for the safety, reliability, and

if:

him,

and

unit

and approved attached equipment is

ARE

NO

EXPRESS

HEFEINABOVE

OR

OR

PARTS

THEREOF.

is

IMPLIED

SET

FORTH. SCHTLLER

this

guarantee is damage

excluded. The warranty

to

the manufacturer.

used

in

accordance with

WARRANTES WHICH

MAKES

is

void

EXTEND

NO

the

duration

caused

by

an

accident

if

unauthorized or

performance

are

carried out by

the

manufacturers

BEYOND

WARRANTY OF

WITH

RESPECTTO

of

the

THE

of

V

Page 6

-.

.

..

.

c

...

.-

SCHILLER

SERVICE

.

._

.

_.

...

.

i

.

Safety

Notices

TO

PREVENTELECTRICSHOCKDONOTDISASSEMBLETHEUNIT.NOSERVICEABLE

PARTS INSIDE.

DO NOT USE

THE

OR

PRESENCE

REFER

THIS

UNIT

SERVICING TO

IN AREAS

OF

FLAMMABLE

QUALIFIED

WHERE

THERE

GASES SUCH

PERSONNEL ONLY.

IS

ANY

AS

ANAESTHETIC AGENTS.

HANDBOOK

DANGER

SP- I Spirometry

OF

EXPLOSION

Issue

2

July

Unit

I998

IFTHEDISPL.AY IS DAMAGED, ALEAKAGEOFFLUIDMAY OCCUR.DONOTINHALE

THE

VAPOUR FROM THIS

CONTACT

IS

MADE, CLEAN CONTAMINATED AREA

FLUID

AND

AVOID CONTACT

WITH

MOUTH

IMMEDIATELY

AND

WITH

SKIN.

FRESH

IF

WATER.

THIS PRODUCT IS NOT DESIGNED FOR

SWITCH

DONOT,LJNDERANY

IN

DO NOT OPERATE

MAINS

THE

UNIT

OFF

BEFORE CLEANING

CIRCUMSTANCES,JMMERSETHEUNITORCABLEASSEMBLIES

LIQUID.

THE

UNIT

IF

THE

LEAD IS DAMAGED OR SUSPECTED

STERILE

USE.

AND

DISCONNECT FROM

THE

EARTH CONNECTION IS SUSPECT OR

OF

BEING DAMAGED.

MAINS.

IF

THE

I

DO

NOT USE HIGH TEMPERAW STERILISATION PROCESSES (SUCH AS

AUTOCLAVING). DO NOT USE E-BEAM OR GAMMA RADIATION STERDLISATION.

DO

NOT

USE

SOLVENT

USE ONLY ACCESSORIES

SCHILLER AG. USE

RESULT

THE

AFFORDS

IN

INJURY INACCURATE INFORMATION

SP-1 COMPLIES WITH EMC REGULATIONS FOR MEDICAL PRODUCTS WHICH

PROTECTION AGAINST EMISSIONS

HOWEVERSPECIALCAREMUSTBEEXERCISEDWHENTHESP-1

CLEANERS

AND

OF

OTHER

OTHER PARTS RECOMMENDED OR SUPPLIED BY

THAN

RECOMMENDED

AM)

OR SUPPLIED PARTS MAY

AND/

OR DAMAGE TO

THE

UNIT.

ELECTRICAL INTERFERENCE.

ISUSED WITHHIGH

FREQUENCY EQUIPMEN?:

IT

MUST BE ENSURED THAT NEITHER THE PATIENT NOR

(INCLUDING

PERSONS OR CONDUCTING OBJECTS

WHEN

ENSURE

THE

NEUI'RAL

NON-LMEDICAL DEVICES

ELECTRODE) COME

EVEN

IF

THESE

ARE

CONNECI'ED TO

INTO

THAT BOTH UNITS ARE SECURELY CONNECTED TO

ARE

THE

ELECTRODES

CONTACT

WITH

EARTHED).

THE

Rs-232 INTERFACE

THE

SAME

OTHER

EARTH

POTENTIAL.

WHEN

NONMDICAL DEVICES,

OPERATING

THE

UNIT ON BA?TERY

THE

RS-232

AND

INTERFACE

MUST BE FULLY ISOLATED.

SIMULTANEOUSLY USING

vi

Page 7

SCHILLER

SERVICE

HANDBOOK

SP-1

Spirometry

c

Unit

Issue

2

July

1998

Safety

BEFORE USING

UNIT

SCHLLER REPRESENTATIVE.

THE GUIDELINES FOR PATIENT ELECI'RODE PLACEMENT

OVERVIEW

~

THE

PHYSICIANS ORPERSONNEL UNDERTHEIRDIRECTSUPERVISION. THENUMERICAL

AND

RECORDING

CLINICAL CONDITION.

GENERAL RECORDED DATA QUALITY, WHICH COULD EFFECT

ACCURACY, MUST

IT IS THE PHYSICIANS RESPONSIBILITY

EXPERT OPINION ON

INDICATED.

Notices

THE

UNIT,

ENSURE

FUNCTIONS

SP-1 ECG UNIT IS PROVIDED FOR

GRAPHICAL RESULTS

ONLY.

MUST

AND

THEY

BE

ALSO

THE

THE

SAFETY

ARE

NOT A

AND

EXAMINED

THE

RECORDING PREPARATION QUALITY AND

BE TAKEN

RESULTS,

THAT

AN

INTRODUCTION REGARDING THE

PRECAUTIONS

SUBSTl"E

THE

ANY

INTERPRETATION DERIVED

WITH

RESPECT

INTO

ACCOUNT.

TO

MAKE

AND

TO

INSTITUTE

HAS

FOR MEDICAL EXPERTISE.

EXCLUSIVE USE

TO

THE

THE

DIAGNOSIS OR TO OBTAIN

CORRECT TREATMENT

BEEN PROVIDED BY A

ARE

PROVIDED AS

OF

QUALIFIED

PATlENTS

OVERALL

FROM

ON

A

THE

THE

REPORT DATA

IF

vii

Page 8

-

SCHILLER SP-1

SERVICE

HANDBOOK

Spirometr?,

Issue

2

July

Unit

1998

~

._..

_-

What’s

in

THE

SERVICE

MODULE

TION

NECESSARY

AND

REPLACE A FAULTY

EDGEOFTHESP-1

WITH

STANDARD

The

book

Chapter

The purpose

to give a basic introduction

operation and function of each key briefly explained. The information in

background to

SCHILLER

Chapter

This chapter provides a functional overview

by functional block diagrams.

Chapter

2

3

this

Book

PHILOSOPHY

LEVEL.

is

1

-

Operating Elements

SP-1

-

Functional Overview

-

Fault Diagnosis

THE

TO

BUTDOESREQUIRETHATTHESERVICE~G~RISFAMlLIAR

WORKSHOP PRACTICES.

divided

into the following

of

this chapter is

the

operating functions

Operating Manual.

PURPOSE OFTHIS

ENABLE

to

to

the

FOR

ALL

THE

MODULE.

chapters:

provide

an

SP-1.

This chapter gives details of the operator controls with the

only.

SCHILLER

BOOK

SERVICE

THIS

BOOK

easy reference for all the

Complete opting information is provided in the

of

the

SP-1

UMTS

IS

TO

ENGINEER

ASSUMES

The functional description

IS FAULT

PROVIDE

TO

EFFlCIENTLY LOCATE

NO

main

ALL

DETAILED

operator functions and

this

FINDING

THE

INFORMA-

KNOWL-

chapter provides

is

supported

TO

a

!-

-\

7’

3

1

This chapter provides a guide

logical sequence of

the text where needed.

Chapter

and after replacement. Functional checks that must be

also

Chapter

test procedures

Chapter

This Chapter provides the part numbers and reordering information for

Also

adjustment or fault finding procedures.

Chapter

4

-

This

chapter gives

attributes of the unit briefly described. The physical description

showing the internal location of all modules. Removal and Replacement instructions for

replaceable modules are also provided in

of

tools,

jumper settings, adjustments,

provided.

5

-

Adjustments

This chapter provides

6

-

Spare Parts

included

7

-

Technical

fault

Module Removal

an

all

that

can

in

this chapter

to

locate a fault

finding algorithms and procedures. Illustrations are provided to support

and

overview of the physical construction of the

and

adjustments and settings.

be

performed to check the functioning

are

details of my

to

module level. The diagnostics are presented in a

Replacement

SP-1

with the main physical

is

supported by illustrations

this

chapter. Each procedure

settings or

special

carried

Also

detailed in

special

test

requirements

out after replacing a new module are

equipment or

is

autonomous with details

that

are

this

chapter are basic functional

of

the unit.

all

replaceable modules.

special

tools

required before

Data

all

required for

The full technical specification of the

Chapter

This Chapter explains

diagrams.

8

-

Glossary

all

the acronyms and signal titles used in

SP-1

is

given in

...

Vlll

this

chapter.

this

book and in the

SP-1

circuit

Page 9

,

..

SCHILUR

SERVICE

.-.

.

What’s in this

SP-I

HANDBOOK

Index

Spiromrry

Issue

Book

Unit

2

July

I998

Circuit

The

circuit

for

information

Diagrams & Board

diagrams

and component

only.

The philosophy

ment.

Our

aim

information and the latest technological developments. We

reserve the right

improvements at any time.

Your

suggestions and comments are welcome. Please contact

the

SCHILLER

Fax

41

41

Layouts

layouts

are

provided

We

Need

Your

of

SCHILLER

is

to provide the

to

revise

this

document and make changes

Technical Documentation Department:

761

03

34

for

all

boards.

Help

is

one

of

continuous improve-

user

with the most up-to-date

These details are provided

or

Page 10

.

. . .

.

-

__

.

.

__

.

.

.

-

.

.

.

-

List

qf

Symbols

6

A

Mains

Supply

Battery Operation

FllSe

LCD Contrast

Potential

Attention - General Warning

Equalisation

(common

SCHILLER

SERWCE

Ground)

Sign

-

see accompanying documentation

HANDBOOK

SP-I

Spirometry

Issue

2

July

Unit

I998

Type

BF

equipment - safe for external applications

Manufacturers Take-back

0

-

Mains Power

I

-

Mains Power

ONlOFF

Off

-

mains supply disconnected from unit

On

-

mains

guarantee

supply

for used batteries

connected

to

unit

X

Page 11

SCHILLER

SERVICE

HANDBOOK

SP-1

Spirometry

Issue

Unit

2

July

1998

Chapter

Operating Elements

I

Procedure Overview

Introduction

Location

Keyboard

Main

Menu Overview

Setting Screen Contrast

System

Pulmonary

Obtaining

Flow Sensors

Setup Menu

Sending

Function Test Procedure

a

Printout

and

Contents

Entering

Operating

Data

Chapter

Elem

1.2

1.3

1.4

1.5

1.6

1.7

1.8

1.10

1.13

1.15

1.16

en

1

ts

Page

1.1

Page 12

Chapter

Operaring Elements

I

SCHILLER

SERVICE

HANDBOOK

SP-I

Spirometry Unit

Issue

2

July

I998

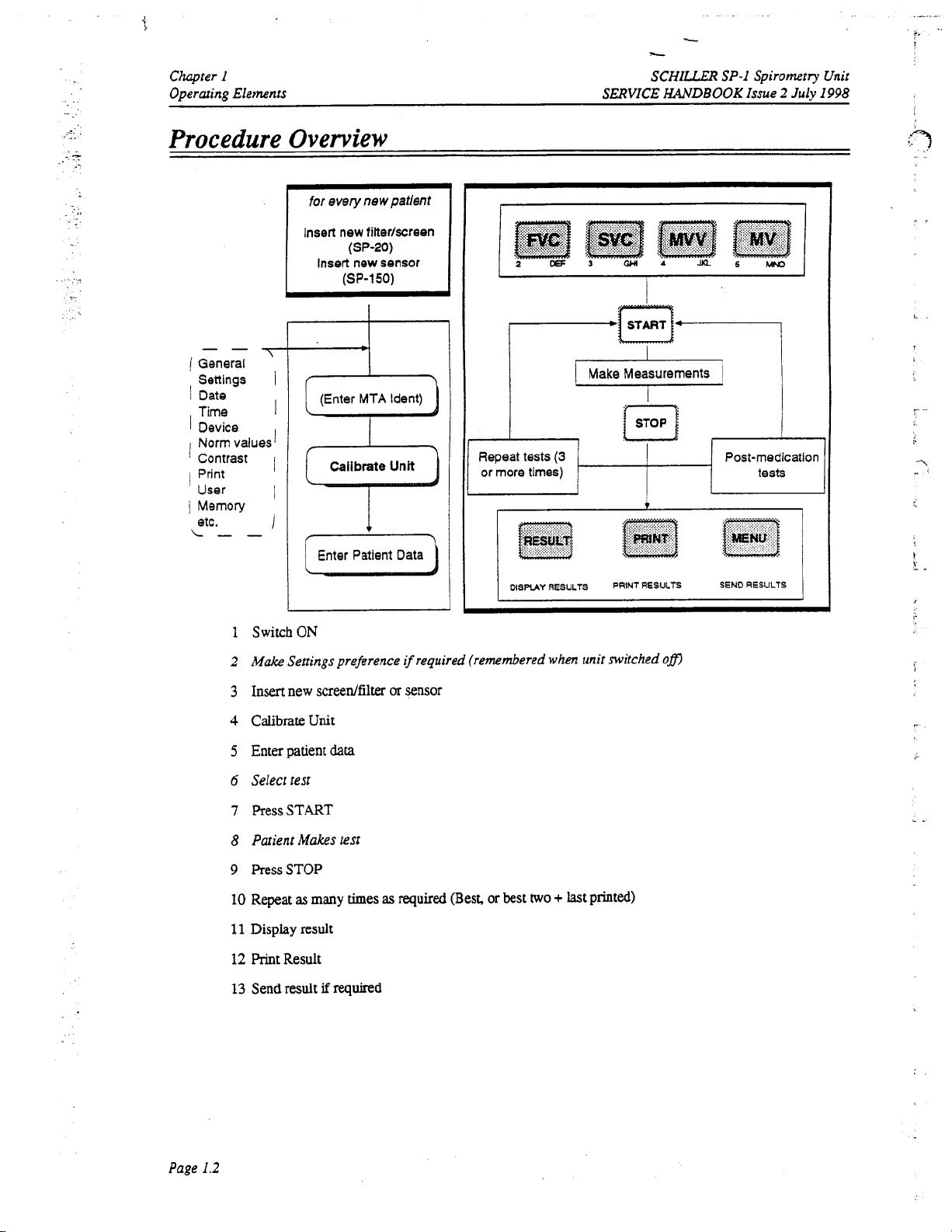

Procedure

.

.

.,

--

/

General

Settings

1

Date

Time

1

Device

Norm values

1

Contrast

1

Print

User

1

Memory

etc.

L--

Overview

for

every

Insert new filterkcreen

Insert new sensor

-7

I

I

I

I

I

I

Enter Patient Data

newpafient

(SP-20)

I

Repeat tests

or

I

(3

more times)

1

Make Measurements

P

1

I

Post-medication

tests

1

Switch

ON

2

Make

Settings preference

3

Insert new screen/filter

4

Calibrateunit

5

Enter patient

6

Select test

7

PressSTART

8

Patient Makes test

9

RessSTOP

10

Repeat

11

Display

12

PrintResult

13

Send

result

as

many

result

data

if

required

times

if

required (remembered

or

sensor

as

required

(Best,

or

best

two

when

+

unit switched

last printed)

ofl

Page

1.2

Page 13

SCHILLER

SERVICE

HANDBOOK

SP-I

Spirometry

Issue

Unit

2

July

1998

Chapter

Operming

I

Elements

-

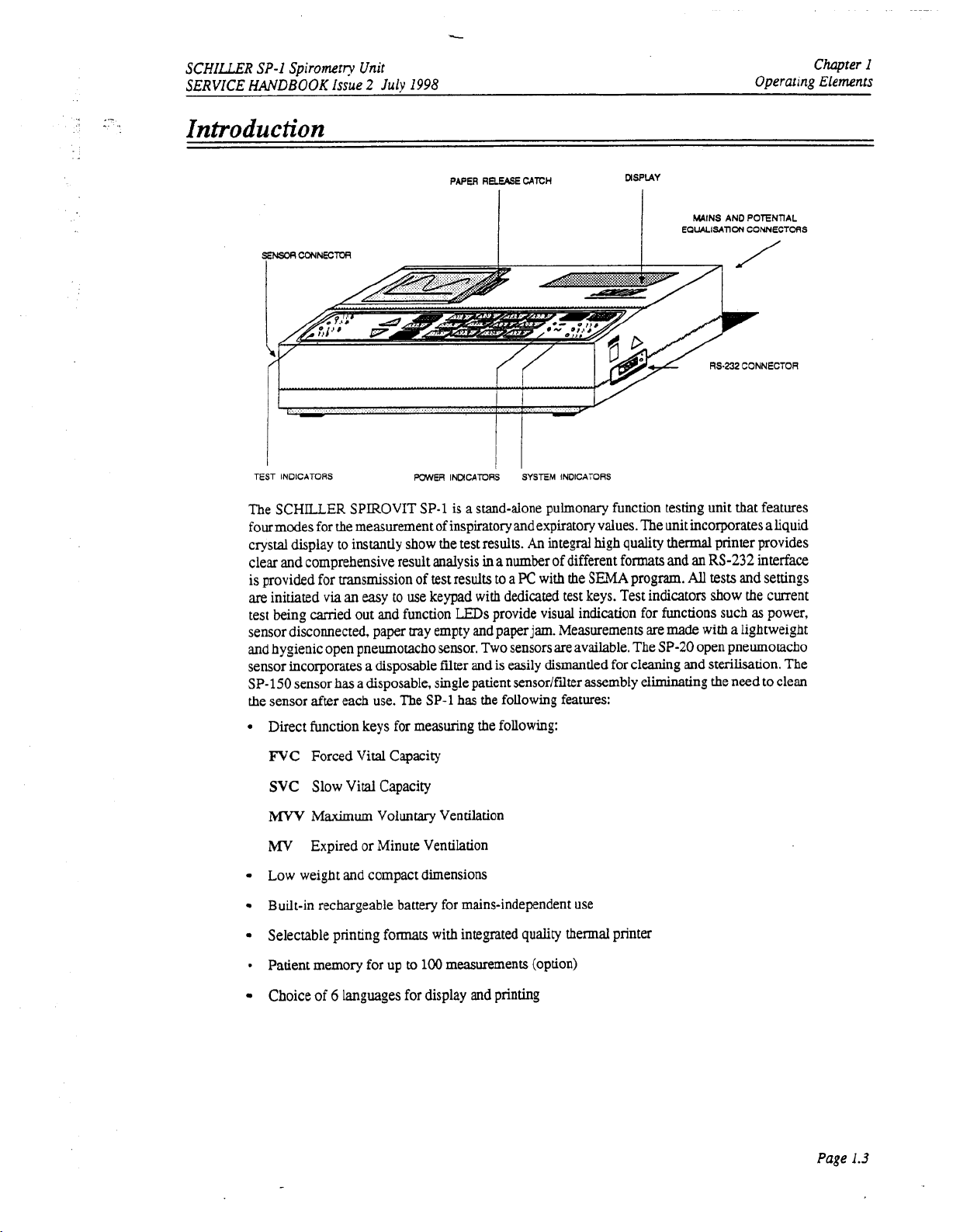

Introduction

TEST INDICATORS POWER

The SCHILLER SPIROVIT

SP-1

PAPER REEASE

INMCATORS

is

a stand-alone pulmonary function

CATCH

SYSTEM

INDICATORS

MSPUY

WINS

AN0

RS-232

tb

POTENTIAL

CONNECTOR

features

EauALlSAnONCONNECTORS

sting unit

four modes for the measurement of inspiratory andexpiratory values. The unit incorporates aliquid

crystal display

clear and comprehensive result analysis

is provided for msmission of

are

initiated

test being carried out and function

sensor disconnected, paper

and hygienic open pneumotacho sensor. Two sensors are available. The

to

instantly show the test results.

test

results to

via

an

easy to use keypad with dedicated test keys. Test indicators show the current

LEDs

tray

empty and paperjam. Measurements are

An

integral high quality thermal printer provides

in

anumber of different formats and

a

PC

with the

provide visual indication

SEMA

program.

for

an

RS-232

All

tests

functions such

made

with a lightweight

SP-20

open pneumotacho

interface

and settings

as

power,

sensor incorporates a disposable filter and is easily dismantled for cleaning and sterilisation. The

SP-150 sensor

the sensor after each use. The SP-1

has

a disposable, single patient sensor/fdter assembly eliminating the need to clean

has

the following features:

Direct function keys for measuring the following:

FVC

Forced Vital Capacity

SVC

Slow

Vital

Capacity

MVV

Maximum Voluntary Ventilation

MV

Expired or Minute Ventilation

Low weight and compact dimensions

Built-in rechargeable battery for mains-independent use

Selectable printing formats with integrated quality thermal printer

9

Patient memory for up

Choice

of

6

languages for display and printing

to

100

measurements (option)

Page

1.3

Page 14

ic

Chapter

I

Operating Elements

Location

As

with

all

The

unit

The

unit

The

unit

transformers

unit

and

Potential Equalisation

In certain

equipment. Connect the earth potential'equalisation

hospital common

frame. Note

same common ground. The part number of

Power Supply

SERVICE

medical

should

units,

the following general

not

be

stored

or

rules

are

to

be

not&

operated in a wet, humid or dusty environment.

may not come into contact with acidic steams or liquids.

should not

the

circumstances

be

set up near radiology or diathermic systems, or near Iarge

or

electrical motors.

mains

supply

intederence

Ensure

is

maintained

can

that

a

minimum

be

caused by externai electrical equipment or

distance of 1 meter between the

connection

ground

or,

if

a

that

all

other electrical equipment

common

ground is

not

present,

in

close

proximity

the

potential equalisation cable is

to

should

SCHILLER

HANDBOOK

at the back

of

the

SP-1

SP-1

Issue

to

a metal framework e.g. the

also

be

connected to the

2.310

005.

Spirometry

2

July

radio

the

bed

Unit

1998

The unit can

connection

connected to the

battery capacity

the

mains

15

hours

A

fully

remain connected to the

Switching

The

SPIROVlT

be

operated from the

is

on the

mains

is

supply

by

to

be

fully

rear

of the unit. The

supply. A battery indicator lamp confirms

limited, the indicator flashes.

means of the supplied power cable. A totally discharged battery needs less than

recharged

(60%

mains

in less

or

from

mains

than

To

charged battery lasts approximately 7 hours of normal use

mains

supply without any danger of damage toeither the battery or the

On

and

Off

SP-1

is

switched on and off with the

the built-in rechargeable battery. The mains

indicator lamp

is

always lit when the unit

battery

operation. When the

recharge the battery, connect the apparatus

3

hours,

90%

in 6 hours).

(SP-1R

6

hours). The unit can

ON

and

OFF

keys.

is

to

unit.

Page

1.4

Page 15

..

.

:-

..

..

SCHILLEU

SERVICE

SP-I

HANDBOOK

Keyboard

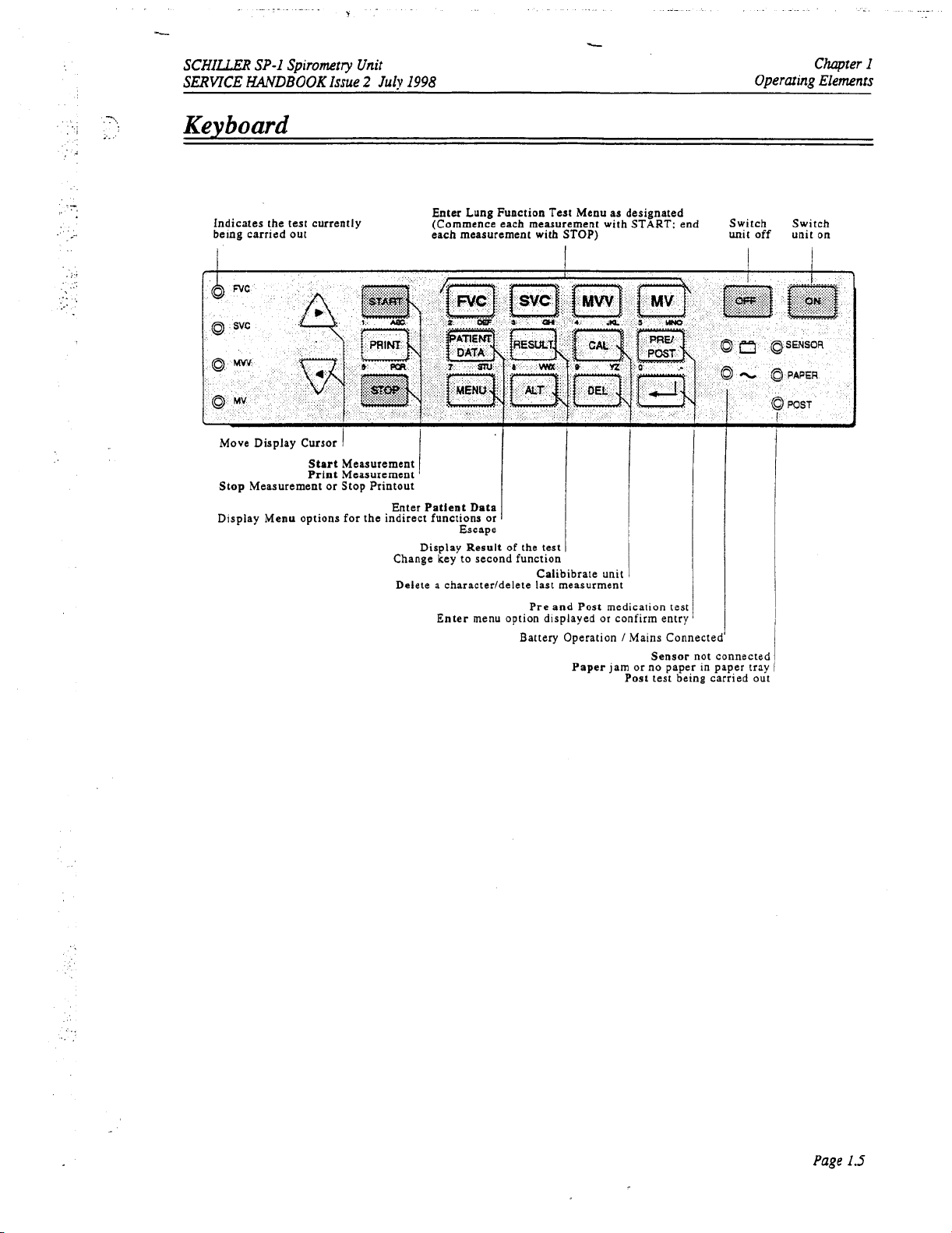

Indicates the

being carried

Spirometv

test

out

Unit

Issue

2

July

1998

currently (Commence each measurement with

Enter Lung Function Test Menu as designated

each measurement with STOP) unit

L

START;

Chapter

Operaring Elements

end Switch Switch

off

unit on

I

Move Display

Stop Measurement

Display Menu options

Cursor

Start

Print Measurement

or

1

Measurement

Stop Printout

for

Enter Patlent Data

the indirect functions

Display Result

Change key to second function

Delete a character/delete last measurment

or

Escape

of

the test

1

Calibibrate unit

Enter menu option displayed

Pre and Post medication test

Battery Operation

Paper jam

or

confirm entry

/

Mains Connected'

Sensor not connected

or

no paper in paper tray

Post test being carried out

Page

IS

Page 16

Chapter

Operating

I

Elements

Main Menu Overview

SCHILLER

SERVICE

SP-I

HANDBOOK

Issue

Spirometry Unit

2

July

1998

1

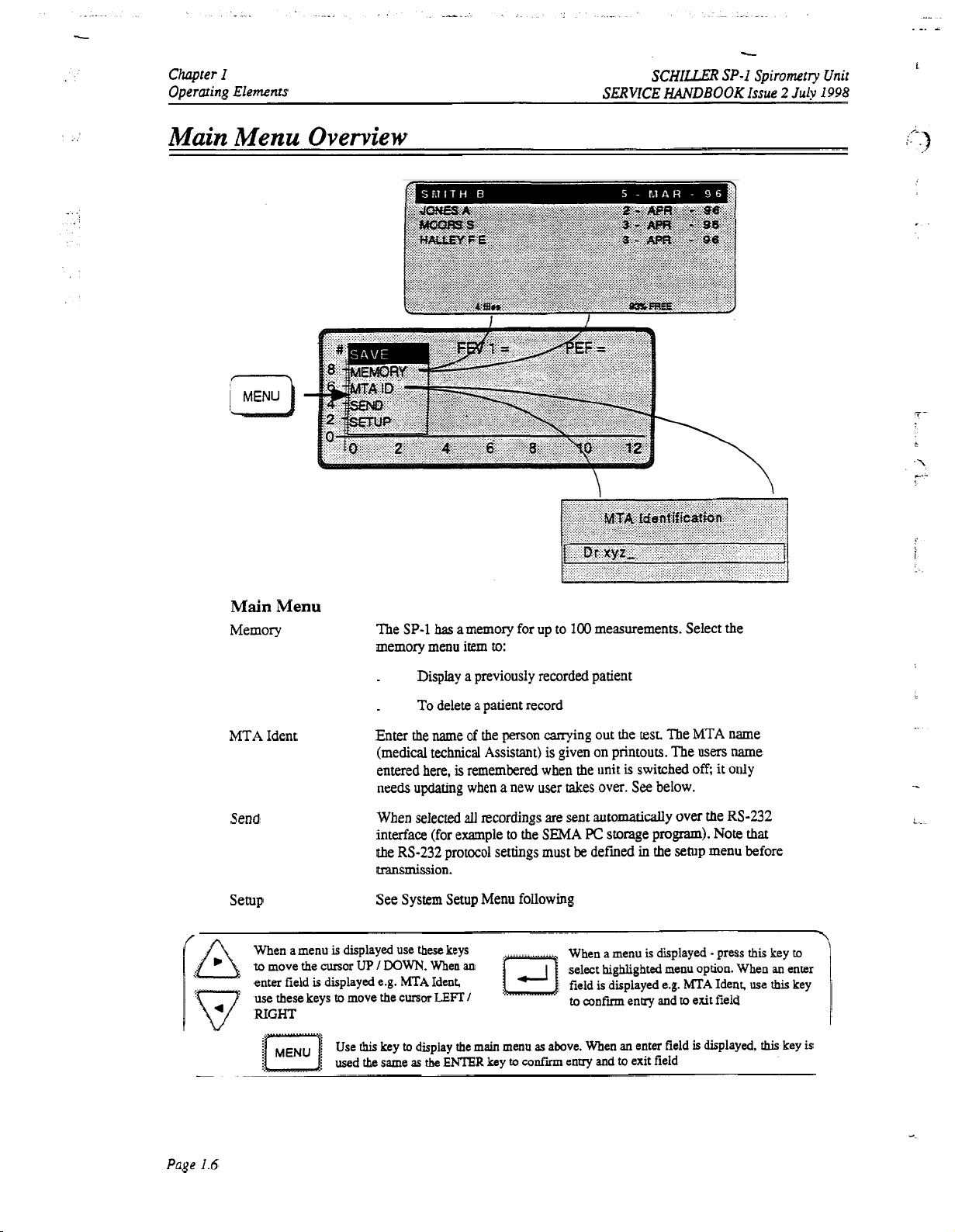

Main

Menu

Memory

MTA Ident

Send

Setup

When a menu

to

move the cursor

enter field

use these keys

RIGHT

:/

. . . .

is

.

....

..c

is

displayed use these keys

UP

displayed e.g.

to

move the

Use

this

used the same

The

SP-1

has

a memory for up to

memory menu item

Display a previously recorded patient

.

To

.

Enter the name

(medical technical Assistant) is given on printouts. The users name

entered here,

needs updating when a new user takes over. See below.

When selected

interface (for example

the

delete a patient record

RS-232

protocol settings must

to:

of

the person carrying out the

is

remembered when the unit

all

recordings are

to

the

100

sent

SEMA

be

measurements. Select the

test.

The

MTA

is

switched

automatically

PC

storage program).

defined

in

the

off;

over the

Note

setup

menu before

it

name

only

RS-232

that

transmission.

See System Setup Menu following

I

WWN.

When

h4TA

Ident

cursor

LEn

key

to

display the main menu

as

the

ENTER

an

I

key

to

confii

When a menu

select highlighted menu option. When

is displayed e.g.

field

to

confm

as

above. When

entry and

is

displayed - press this key

entry and

an

enter field

to

exit field

h4TA

to

exit field

is

Ideat, use

displayed,

an

this

this

-.

to

enter

key

I

key

is

Page

1.6

Page 17

_-

-

..-

SCHILLER

SERVICE

SP-I

Spirometry Unit

HANDBOOK

Issue

2

July

I998

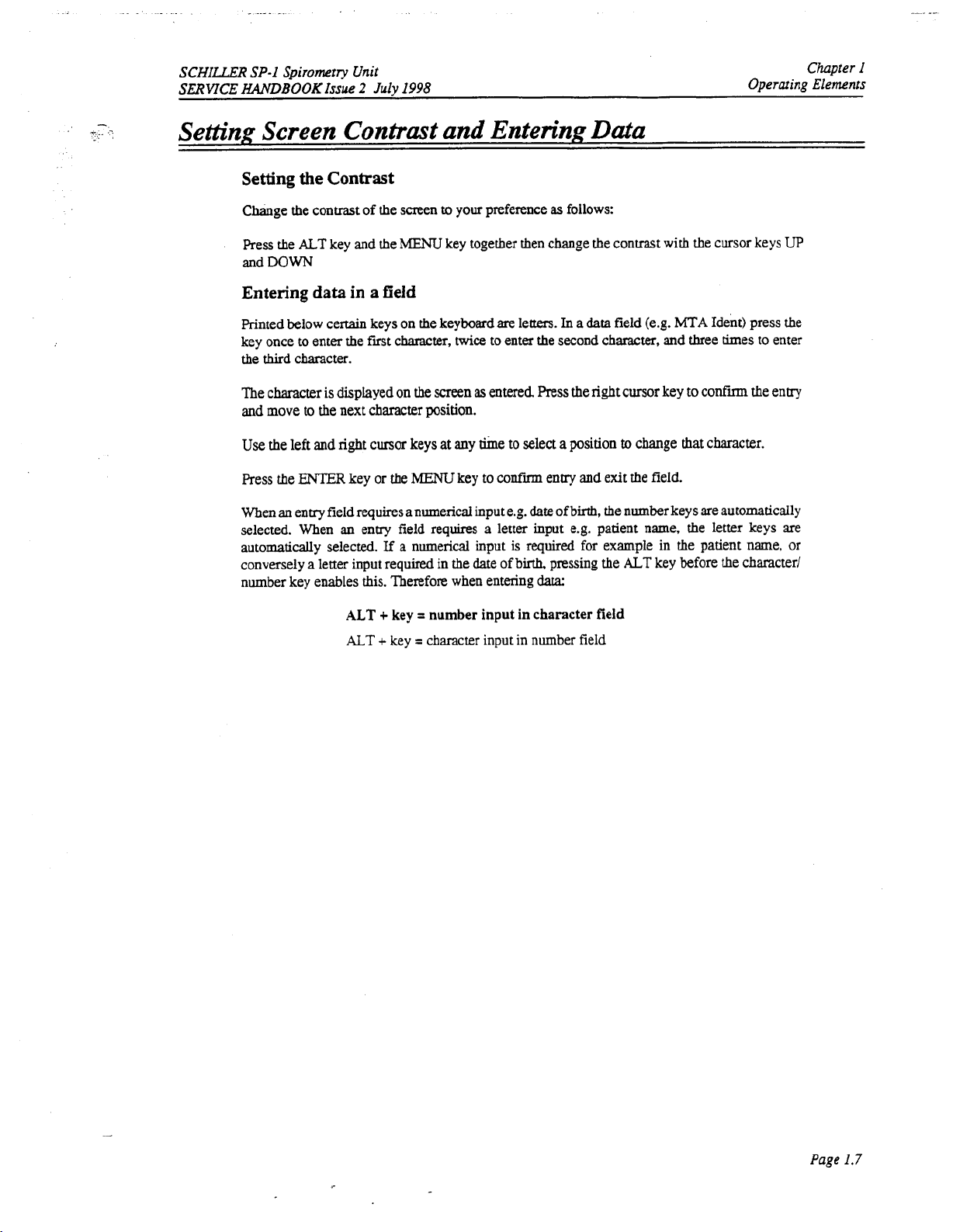

Setting Screen Contrast

Setting

Change the contrast

Press the

and

Entering

Printed below certain keys on the keyboard

key once to enter the first

the third character.

The character is displayed on the screen

and move

Use

Press the

When an enuy field requires anumericai input e.g. date of

selected. When an entry field requires a letter input e.g. patient name, the letter keys are

automatically selected.

conversely a letter input required

number key enables

the

Contrast

of

the screen

ALT

key and the

MENU

DOWN

data

in

a field

character,

to

the

next character position.

the left and right cursor keys at any the to select a position

ENTER

key or the MENU key to

If

a numerical input is required for example in the patient name, or

in

this.

Therefore when entering

Operaring Elements

and

to

Entering

your preference

key together then change the contrast with the cursor keys

are

letters.

twice

to enter the second character, and three times to enter

as

entered.

the date

Press

confum

of

birth,

dam

Data

as

follows:

In

a

data

field (e.g.

the right cursor key to confm the entry

to

entry and exit the field.

birth,

the number keys are automatically

pressing the

ALT

MTA

Ident) press the

change that character.

key before the character/

UP

Chapter

I

ALT

+

key = number input in character field

ALT

+

key = character input in number field

Page

1.7

Page 18

L

Chapter

Operating Elements

I

SCHULER

SERVICE

SP-I

HANDBOOK

Spirometry

Issue

2

July

Unit

I998

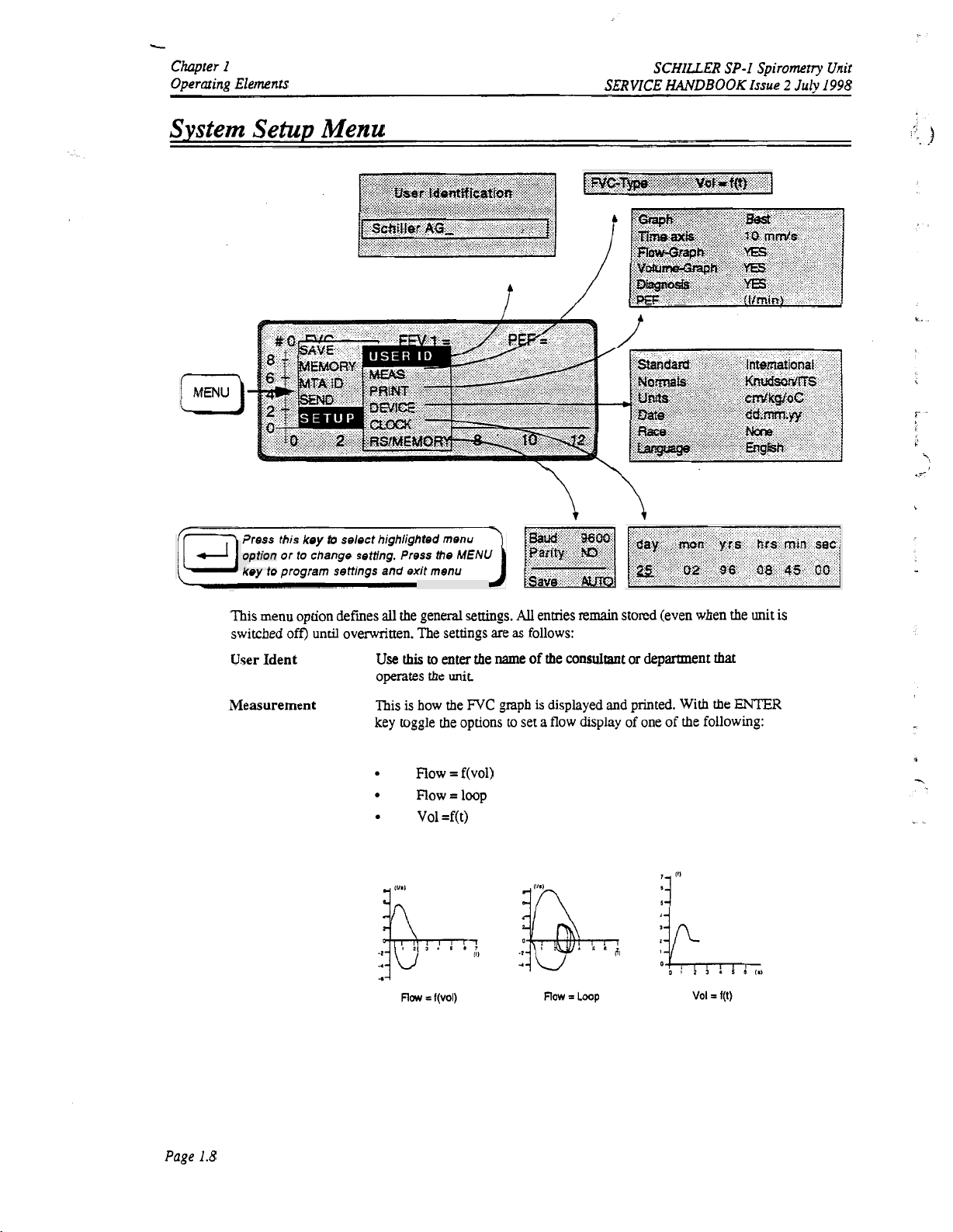

System

Press this

option

key

Setup

to

Menu

key

or

to

change setting.

program

to

select highlighted menu

Press

the

settings and

exit

menu

i

.=-

\\

MENU

This menu option defmes

switched off) until overwritten. The settings are

User Ident

Measurement

all

the general

Use

this

operates

This

is how the

key toggle the options

Row

Row=lOop

Vol

settings.

to

enter the name of the consultant

the

unit

FVC

gmph is displayed and printed. With the

=

f(v0l)

=f(t)

All

enaies remain stored (even when the unit is

as

follows:

or

department

to

set a flow display of one of the following:

that

ENTER

Page

1.8

Page 19

SCHILLXR

SERVICE

SP-I

Spirometry Unit

HANDBOOK Issue 2 July

I998

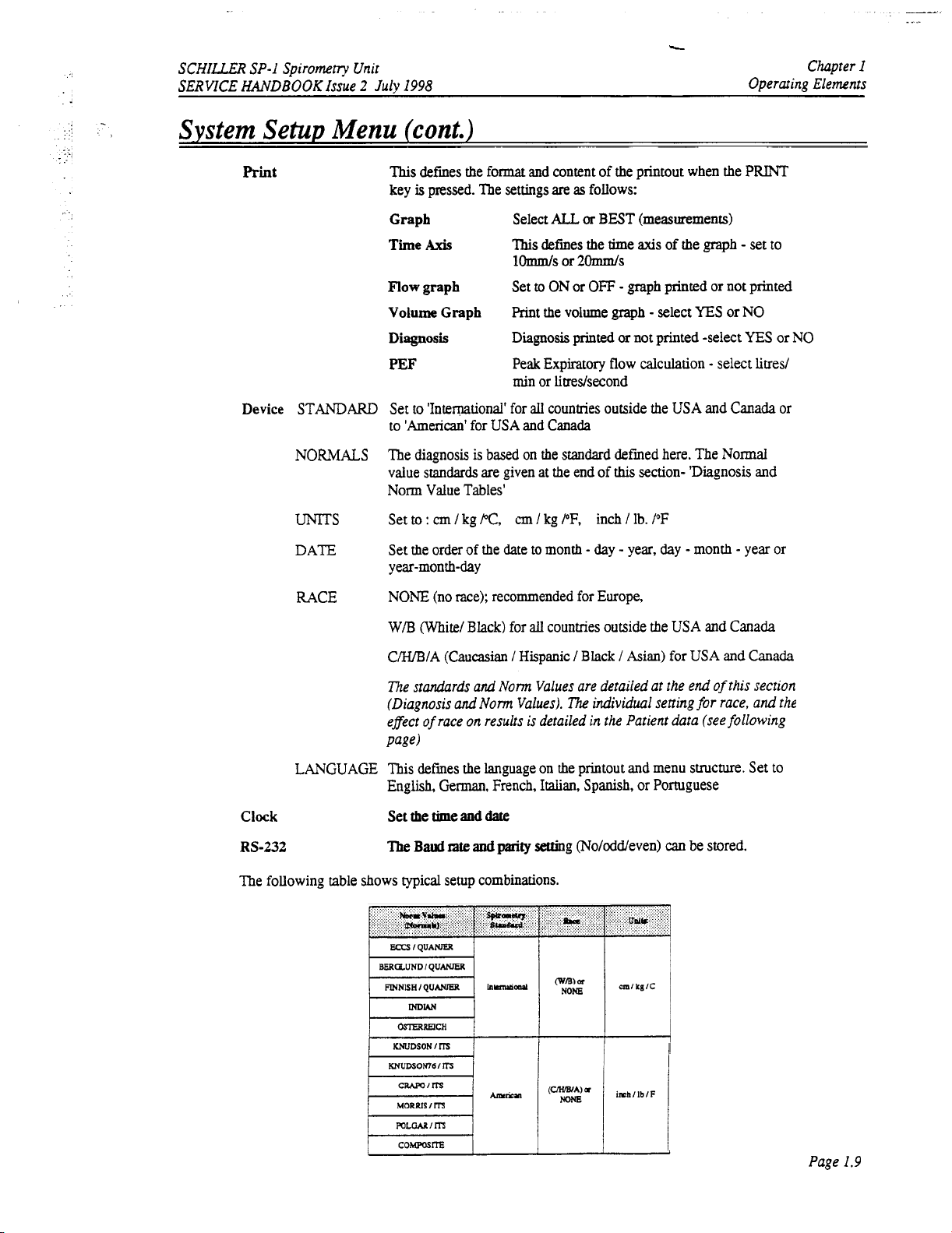

System Setup Menu (cont.)

This

Print

defines the format and content of the printout when the

key

is

pressed. The settings

are

as

follows:

\

Chapter

Operating Elements

I

PRINT

Device

STANDARD

NORMALS

UNITS

DATE

RACE

Graph

Time

Axis

Flow

graph

Volume

Diagnosis

Graph

PEF

Select

ALL

or

BEST

(measurements)

This

defines

the

time

axis

1-s

Set

to

ON

or

or

2Ws

OFF

-

gaph printed or not printed

Print the volume graph - select

Diagnosis

printed

or

not printed -select

Peak Expiratory flow calculation - select litred

min or litredsecond

Set

to

'International' for

all

countries outside the USA and Canada or

to 'American' for USA and Canada

The

diagnosis

value standards are given at the end

is

based on the standard defrned here. The Normal

of

this

section- 'Diagnosis

Norm Value Tables'

cm

/

kg

PF,

Set

to

:

cm

/

kg PC,

Set the order of the date to month

y

ear-month-day

inch / Ib. /OF

-

day - year,

NONE (no race); recommended for Europe,

W/B

(White/ Black) for

C/H/B/A (Caucasian

all

countries outside the

/

Hispanic / Black / Asian) for USA and Canada

of

the

graph

YES

day

-

month - year or

USA

and Canada

or

-

set

NO

YES

to

or NO

and

The standards and

(Diagnosis and

of

effect

page)

race

Norm

Values are detailed at the end

Norm

Values).

on

results is detailed in the Patient data (see following

LANGUAGE This defines the language on the printout and menu smcture. Set to

Clock

RS-232

English, German, French,

Set the time and date

The

Baud rate and parity setting (Noloddeven) can be stored.

Italian,

The following table shows typical setup combinations.

The

dividual

setting

Spanish, or Portuguese

iohl

IblF

of

for

race,

this section

and

the

Page

I.9

Page 20

Chapter

Operating

I

Elements

SCHILLER

SERVICE

SP-I

HANDBOOK

Spirometry Unit

Issue

2

July

I998

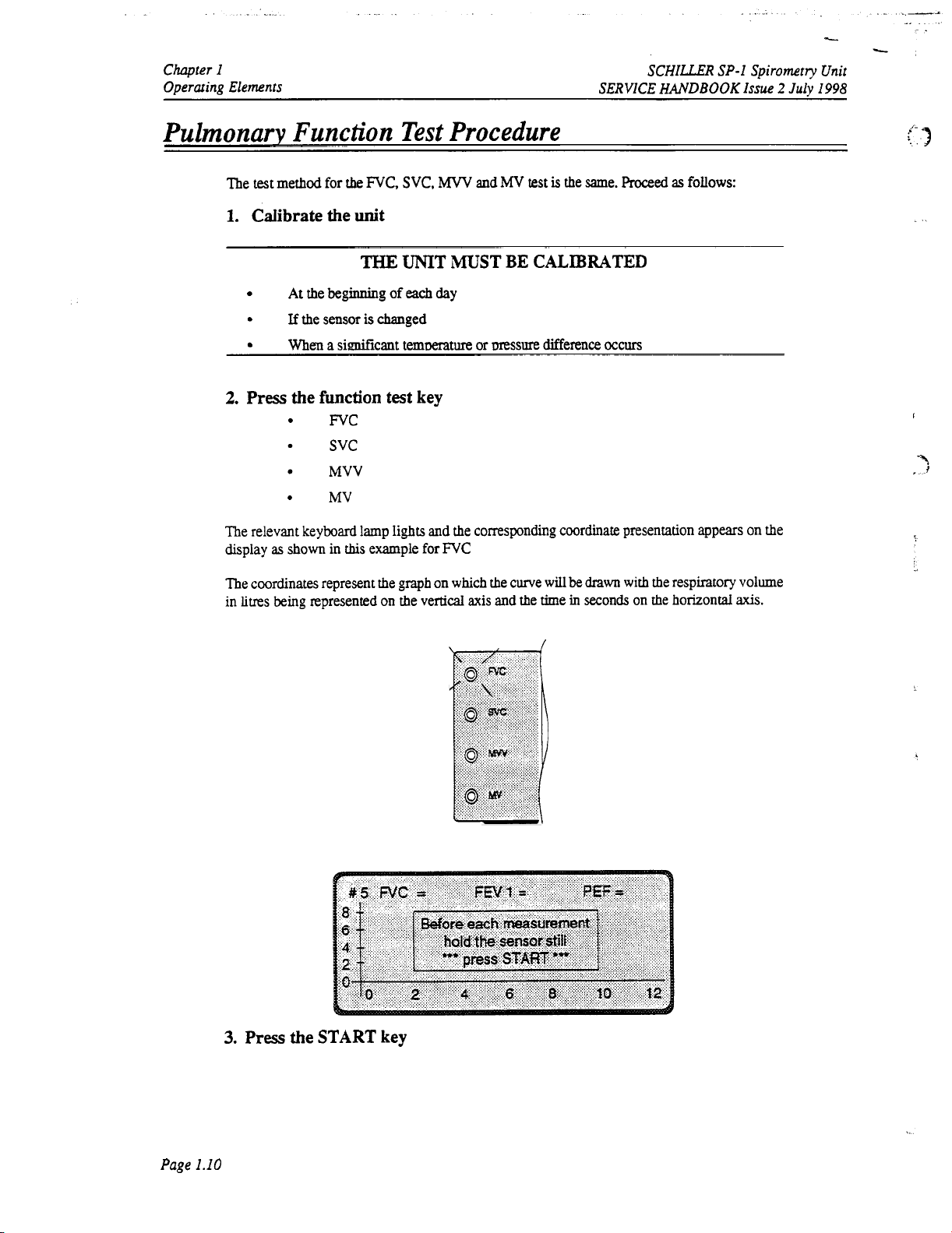

Pulmonary

The

1.

2.

The relevant keyboard lamp

display

The coordinates represent the

in

litres

Function

test

method for

Calibrate

At

If

When

Press the

as

shown

being represented on the vertical

the

FVC, SVC,

the

unit

THE

the beginning

the sensor

is

a

siNicant

function

FVC

SVC

MVV

MV

in

this

example for

Test Procedure

MVV

and

MV

UNIT

of

changed

ternmature or

test key

lights

graph

MUST

each

day

and the corresponding coordinate presentation appears on the

FVC

on

which

BE

mssure

the curve

axis

and the time in seconds

test

is

the same.

Proceed

CALIBRATED

difference

will

be

drawn

occurs

with

on

as

follows:

the respiratory volume

the horizontal

axis.

:-

I

.”;

3

Page

1.10

3.

Press

the START key

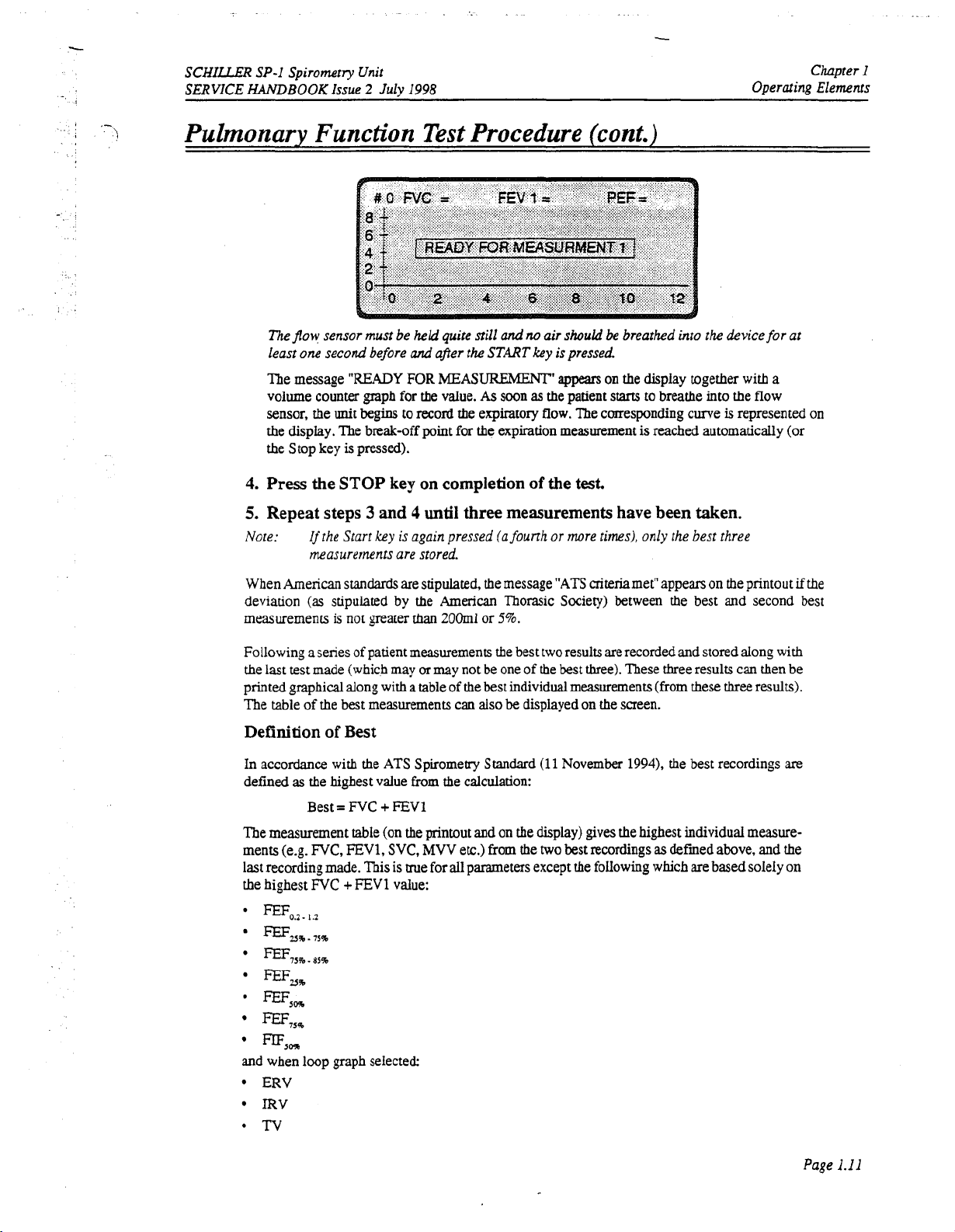

Page 21

c

SCHILLER SP-I Spirometry

SERVICE

Pulmonary

HANDBOOK

Issue

Function

The

flow

sensor must be

least one second before

The message

volume counter graph for

sensor,

the display. The break-off point for the expiration measurement

the Stop key

4.

Press the

5.

Repeat steps 3 and 4 until three measurements have

Note:

"READY

the

unit

is

STOP

Ifthe Start

measurements are stored.

Unit

2

July

1998

Test

held

quite

and

after the

FOR

MEASUREMENT'

the

value.

begins to

pressed).

record

the expiratory

key on completion

key

is again pressed (a founh

Procedure

still

and

no

air

should

START

key

is

pressed

appears

As

soon

as

the

patient

flow.

The corresponding curve

of

the

test.

or

more times), only the best three

(cont.)

be

breathed into the device

on

the display together with a

starts

to

breathe into the flow

is

reached automatically (or

been

taken.

Chapter

Operating Elements

for

at

is

represented on

I

When American

deviation

measurements

Following a series

the

last

test

printed graphical dong with

The table of the best measurements can

Definition

In accordance with the

defined

The measurement table (on the printout and on the display) gives the highest individual measurements (e.g.

last recording made. This is true for all parameters except the folIowing which are

the highest

'

as

FEFo.2.

EEF,%.75%

FEF,,%.,S%

standards

(as

stipulated by the

is

not greater than

of

made (which may

of

Best

the highest value from the calculation:

Best

=

FVC + FEVl

FVC,

FEV1,

FVC

+

1.2

are stipulated,

patient measurements the best two results are recorded and stored along

or

may

a

table of

ATS

Spirometry Standard

SVC,

MVV

FEVl

value:

the

message

American

2OOml

Thorasic Society) between

or

5%.

not

be

one of the

the

best individual measurements (from

also

be displayed on

etc.) from

the

"ATS

criteriamet" appears on the printout

the

best and second best

best

three). These three results can then be

these

the

screen.

(11

November

two

best recordings

19941,

the

best recordings

as

defined above, and the

three

based

if

with

results).

are

soleIy on

FEFZ5

'

FEF,,

FEF,,%

%?%

and

when loop graph selected:

ERV

IRV

*Tv

the

Page

I.11

Page 22

Chapter

I

Operating Elements

_-.

.

-..

L

c

SCHILLER

SERVICE

HANDBOOK

SP-I

Spirometry

Issue

2

July

Unit

1998

i'

F

,

_.

I-

Pulmonary Function

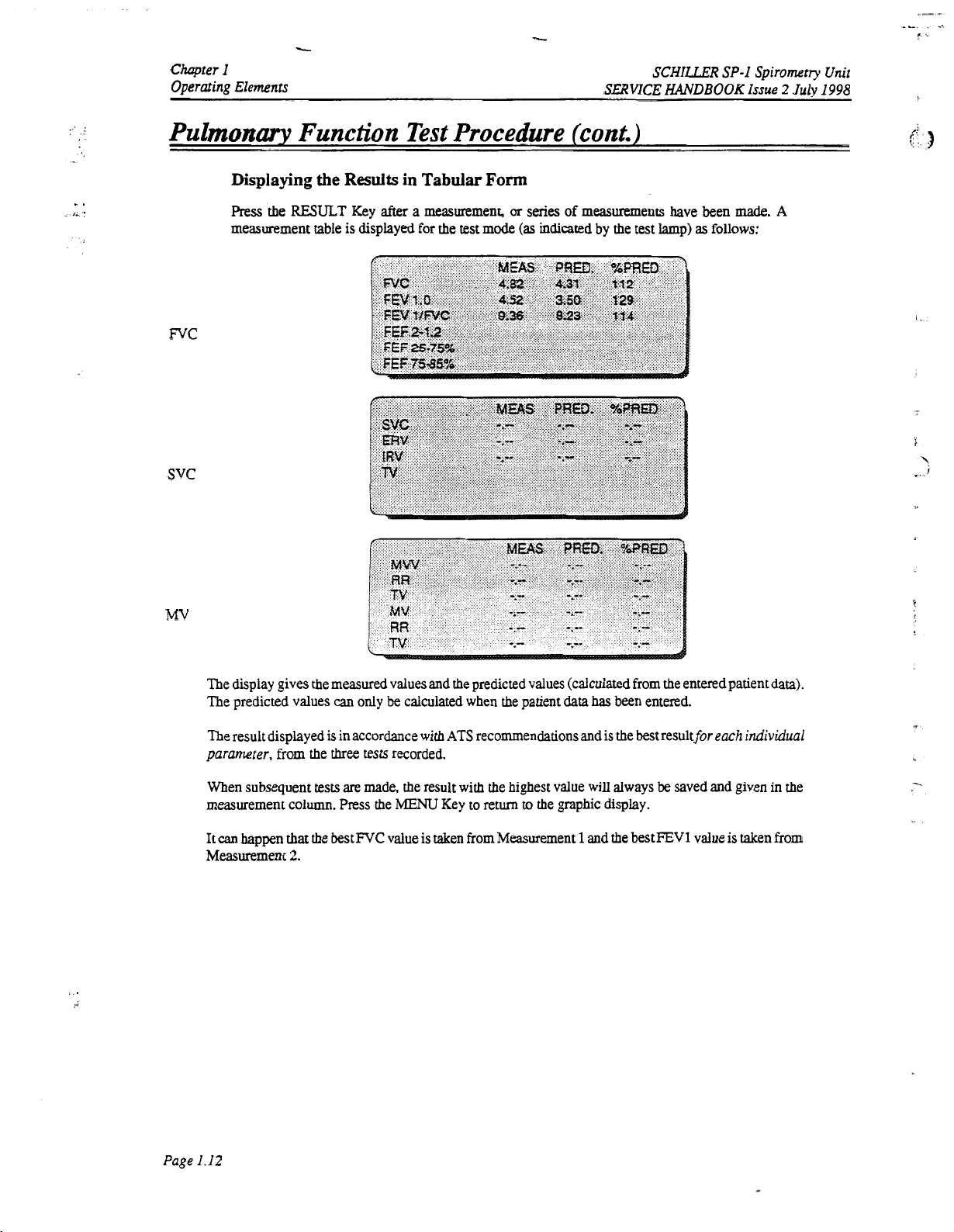

Displaying

Press

.

the

measurement table is displayed for the

the

Results

RESULT

Key

Test

in Tabular

after

a

measurement,

Procedure (cont.)

Form

or

series

of

measurements have been

test

mode

(as

indicated by the test lamp)

as

follows:

made.

A

FVC

svc

..

;

MV

The display gives the measured values and the predicted values (calculated from the entered patient

The predicted values

The result displayed is in accordance with

parameter,

from the

When subsequent

measurement column.

It

can

happen that

Measurement

three

tests

the

bestlVC value

2.

can

only

tests recorded.

are

made,

Press

the

be

calculated when the patient

ATS

recommendations and is the best resultfor

the

result with the highest

MENU

Key to return

is

taken from Measurement 1 and the best FEVl value is taken from

data

has

been entered.

value

will

always

to

the graphic display.

be

saved and given in the

data).

each individual

Page

1.12

Page 23

SCHILLER

SERVICE

SP-I

Spiromtry

HANDBOOKIssue

Unit

2

July

Obtaining a Printout

1998

Chapter

Operaring

I

Elements

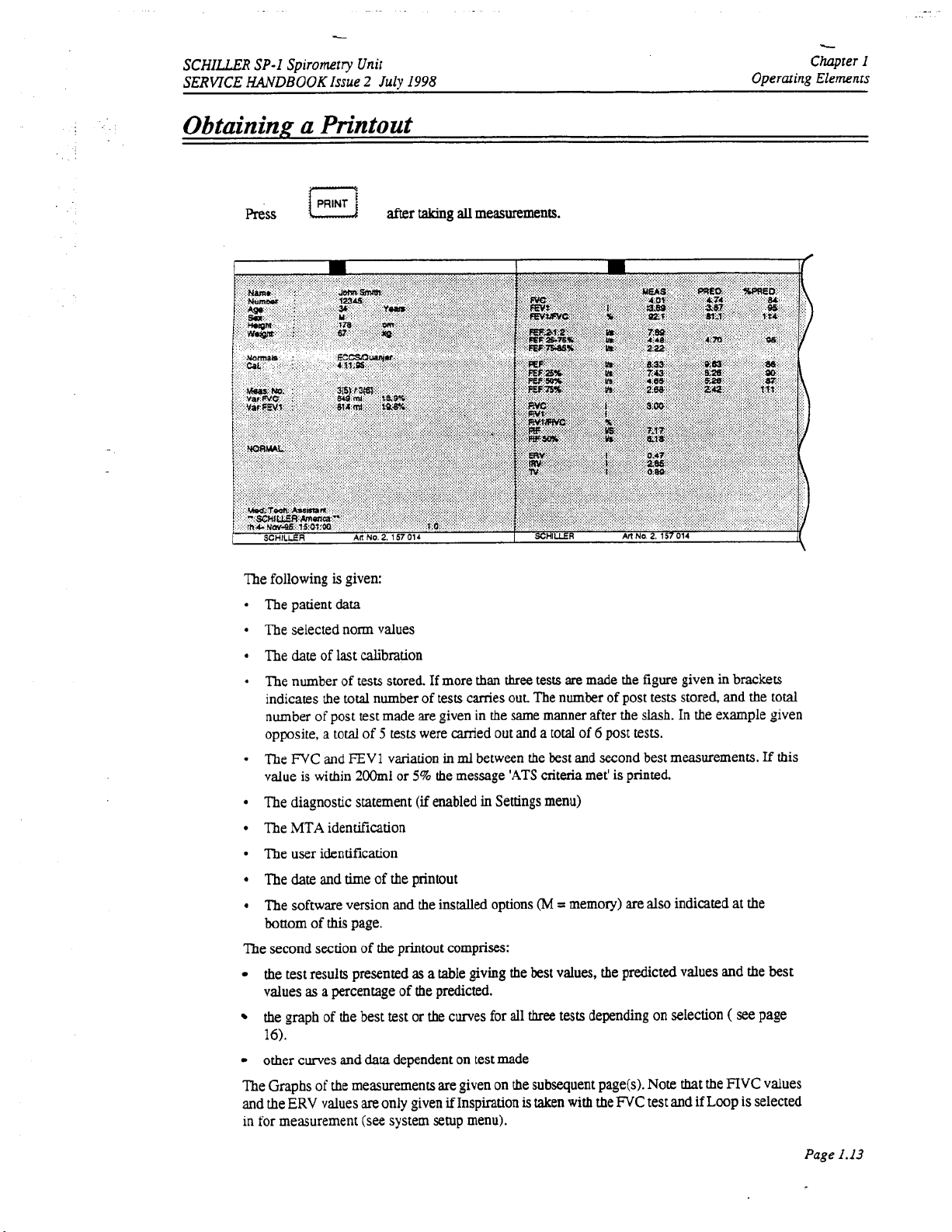

Press

The following

The patient

is

data

given:

after

taking

all

measurements.

The selected norm values

The

date

of

last calibration

The number of tests stored. If more than

three

tests

are

made the figure given in brackets

indicates the total number of tests wries out The number of post tests stored, and the total

number of post test made are given in

opposite, a

The

value

The diagnostic statement

The

FVC

and

is

within

MTA

identification

total

of

5

tests were canied out and a total of 6 post tests.

FEVl variation

2oOml

or

in

5%

the message

(if

enabled

the

same manner after the slash. In

ml

between the best and second best measurements.

'ATS

criteria

met'

is

printed.

in

Settings menu)

the

example given

The user identification

The date and

The software version and the

bottom

The second section

the test results presented

values

the graph of the best test or the curves for

16).

other curves and

time

of

the printout

installed

of

this

page.

of

the printout comprises:

as

a

table

as

a

percentage of the predicted.

data

dependent on test made

options

giving the

all

(M

=

memory) are also indicated

best

values, the predicted values and

three

tests depending on selection

at

(

see

the

the

If

this

best

page

The Graphs of the measurements are given on the subsequent page(s). Note

and the

ERV

values

are

only given

if

Inspiration

is

taken with the

FVC

test and if Loop is selected

in for measurement (see system setup menu).

that

the

FIVC

values

Page

1.13

Page 24

c

Chapter

I

Operating Elements

Pulmonary

_.

..

..

-.

-.

..~

SERVICE

Function Test Procedure (cont.)

. . . . .

SCHILLER

HANDBOOK

SP-1

.

..

. . .

Spirometry Unit

Issue

2

July

1998

._.

-.

T.

L

crl

::.

.

j

Forced

For

Note:

To

Vital

this

Capacity (FVC)

test

the

patient must exhale

Test

as

quickly

as

possible

The FVC test employs the "Back extrapolation" method.

(>0.15

lim

or

5%

of

FVO,

is too large

carry

out

the

test

for Forced

Vital

Capacity

then a waming appears

0,

from

press

key

the time of

If

"FVC"

coordinate presentation appears on the display

The patient must exhale

understands what

be

immediately followed by a

is

required

as

quickly

as

of

him.

If inspimtory

maximum

possible &om the time

measurements

of

starring

are

required, the exhaiation can

inhalation. The inspimion results will

printout.

Before initiating a printout

previously. Press the

Slow

Vital

PRINT

Capacity (SVC)

key to

obtain

Test

ensure that the

if

printout

as

seuings

defined.

of

the

FVC

Test,

The patient should breathe normally 3 times and then inhale maximally

then exhale maximally. Make

MVV

Test

The patient should breathe

make

sure

that he understands what is required of him.

sure

as

deeply and

that

the patient understands

as

rapidly

as

what

possible over a

period

starring

the test.

the extrapolated volume

on

the display

and the corresponding

the test

so

be

sure

that

be

given on the

are

correct

as

detailed

to

total lung capacity and

is

required

of 6 to

of

him.

12

seconds

he

so

,

WARNING

EXTREMECARESHOULDBEEXERCISEDWHENPERFORMINGTHIS~TAS

IS

A

DANGER

OF

HYPERVENTILATION.

ENSURE

THAT

THE

PATIENT

DOWN.

MV

Test

The patient should breathe

that

Make sure

the patient understands what is required

as

normally

as

possible for up

to

of

60

seconds,

him.

but

for at

least

THERE

IS

SITTING

20

seconds.

Page

1.14

Page 25

SCHILLER

SERVICE

HANDBOOK

SP-I

Spiromrry

Issue 2 July

Unit-

I998

Chapter

Operating Elements

I

Pulmonary Function

...

.

:.

7

Post-Medication

In

order

to

cany

Lamp

lights

The post-medication

measurements stored). The printout following post-medication

pre and post-medication

shown

as

the best results (pre/post), results

and the percentage change (i.e. difference) between pre and post-medication results.

Tests

out

post-medication

tests

tests

Test

are carried

Procedure

tests

for

comparison,

out

in

the

(the premedication curve is bold). The measurement results are

as

a percentage

(cont.)

press

same way

of

the

PEWPOST

as

the premedication tests (three

tests

will give the curves

those predicted,

key and

(both

pre and post)

"POST"

of

both

The

diagnosis resulting

from

the premedicarion

Sending

Measurements can be sent

cation parameters,

side. See Chapter

Connect the

Carry out the measurement(s)

Press the

When the transmission is complete a message

has

been completed.

PC

and on the unit. Check the cable connection. Ensure

are

the

same

3

PC

MENU

in

both the

to

the

ie

baud

rate, parity etc. are

(RS-232

Check) forfurtherdetails.

to

the

RS-232

key and select

If

an error message

PC

and the

SEMA

connector on the right hand side

as

descriid previously.

SEND

is

unit

fest

is

also

given

on

data

management system. Make sure

set

the Same on the transmitting

To

send ameasurement proceed

is

displayed showing

displayed e.g.

(SETUP

'serial

that

menu).

link

time-out' check settings in the

the

Baud rate and the parity settings

this

printout.

that

the communi-

and

the receiving

as

of

the

unit.

that

successful transmission

follows:

Page

1.15

Page 26

Chuprer

I

Operating

Elements

SCHILLER

SERVICE

HANDBOOKIssue

SP-1

Spirometry

2

July

Unit

1998

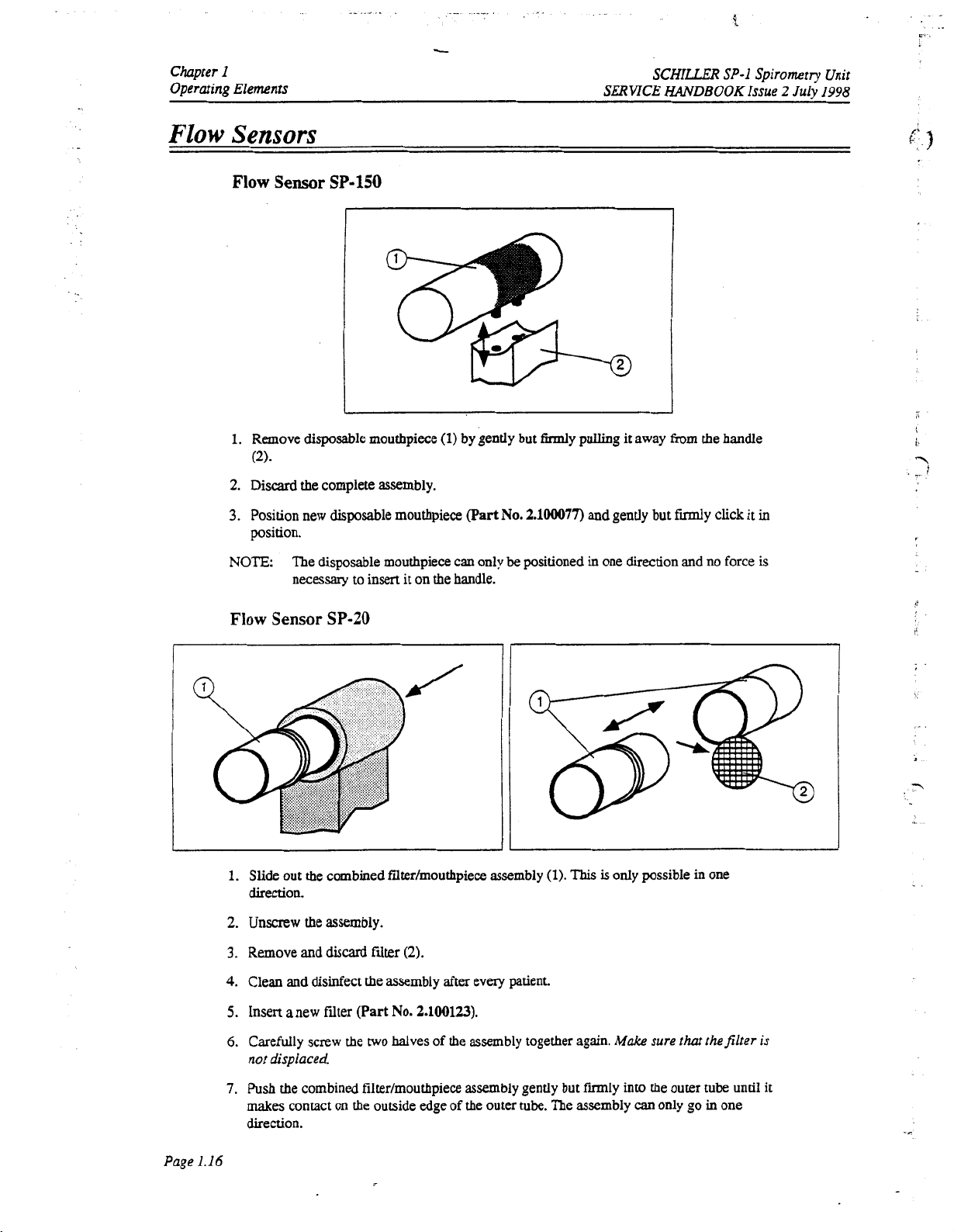

Flow

Sensors

Flow

Sensor

1.

Remove disposable mouthpiece

(2).

2.

Discard

3.

Position new disposable mouthpiece

position.

NOTE:

SP-150

the complete assembly.

The disposable mouthpiece can only

necessary to insert it on the handle.

(1)

by gently but firmly pulling it away from the handle

(Part

No.

2.100077)

be

positioned

and gently but fdy click it

in

one direction and

no

force

in

is

d'

.

1

-.

Flow

Sensor

I

1.

Slide out

SP-20

the

combined filter/mouthpiece assembly

II

(1).

This

is

only possible

in

one

direction.

2.

Unscrew

3.

Remove and

4.

Clean

5.

Insert a new filter

6.

Carefully screw

not

the

assembly.

discard

Nter

and

disinfect the assembly after

(Part

the

two

displaced

(2).

No.

2.100123).

halves

every

patient.

of

the assembly together again.

Make

sure

that

thefilter

is

Page

1.16

7.

Push

makes

direction.

the combined filtedmouthpiece assembly gently but fmly

contact on the outside edge

of

the

outer

tube.

The assembly

into

the outer tube until it

can

only go in

one

Page 27

.-

SCHILLER

SERVICE

HANDBOOK

SP-I Spiromtly

Introduction

SPll-

Power Supply

CPU and Processing Circuits

Memory

Them1 Print Head Controller

Paper Mark

Power

Stepper Motor Controller

Issue

1

On

Unit

2

July

Reset

1998

Chapter

Functional

Contents

Chapter

Functional Overview

2

2

Overview

2.2

2.4

2.4

2.4

2.4

2.5

2.5

2.5

2.5

Page

2.

I

Page 28

Chapter

Functional

2

Overview

Introduction

SCHILLER

SERVICE

SP-I

HANDBOOK

Spiromtv

Issue

2

July

Unit

I998

..

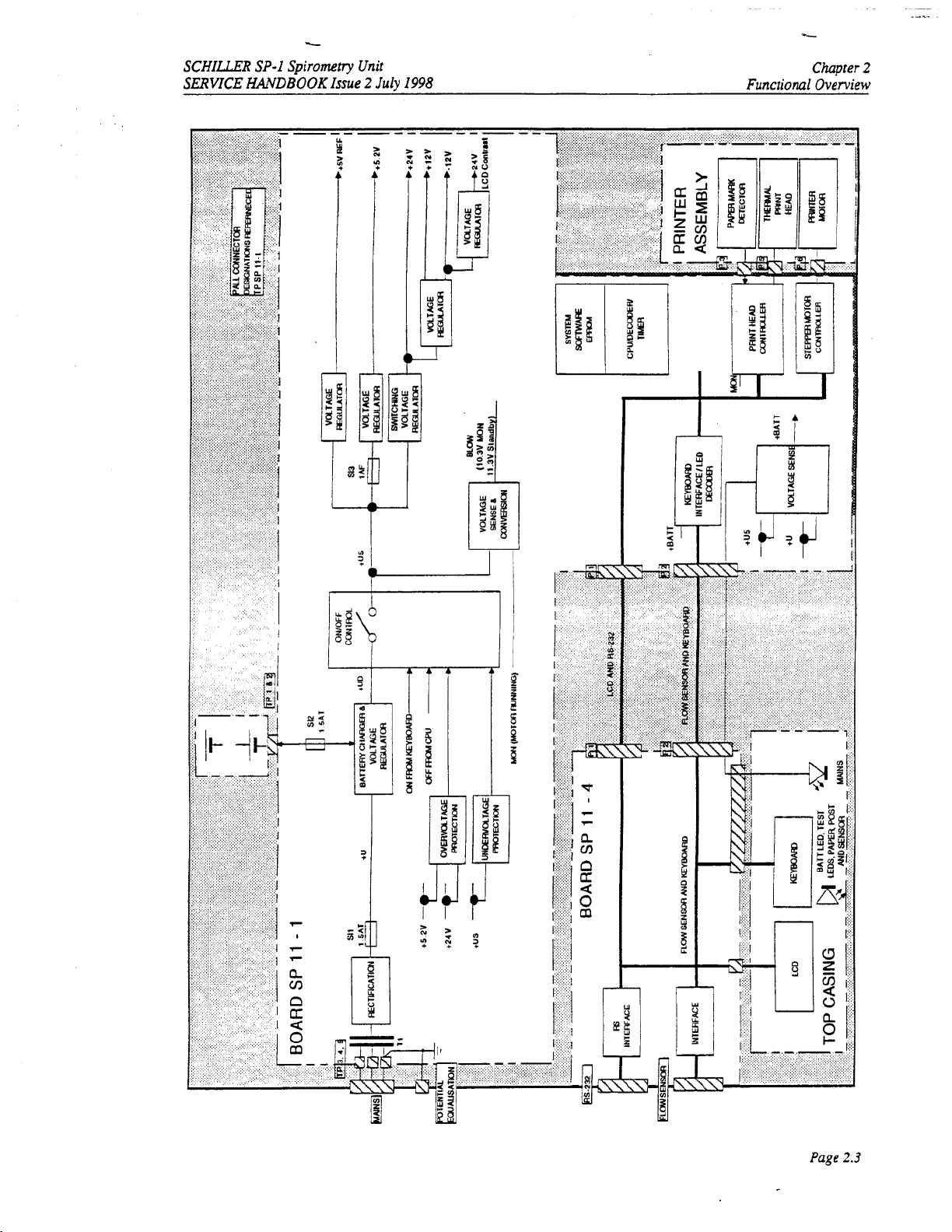

This

Chapter

to

enable

modules.

provides a functional overview

the

service

engineer

A

functional block diagram supports the

to

identify

processing

of

the

SP-1

electronics. The

paths in

text.

order

aim

of

this

overview is

to

help iden@ possible faulty

Page

2.2

Page 29

SCHILLZR

SERVICE

HANDBOOK

SP-I

Spirometry

Issue

Unit

2

July

1998

Chapter

Functional

2

Overview

I

i

*

?

w

Page

2.3

Page 30

Chapter

Functionul

2

Oveniew

\

SERVICE

c

SCHILLLB

HANDBOOK

SP-1

Issue

Spirometry

2

July

Unit

1998

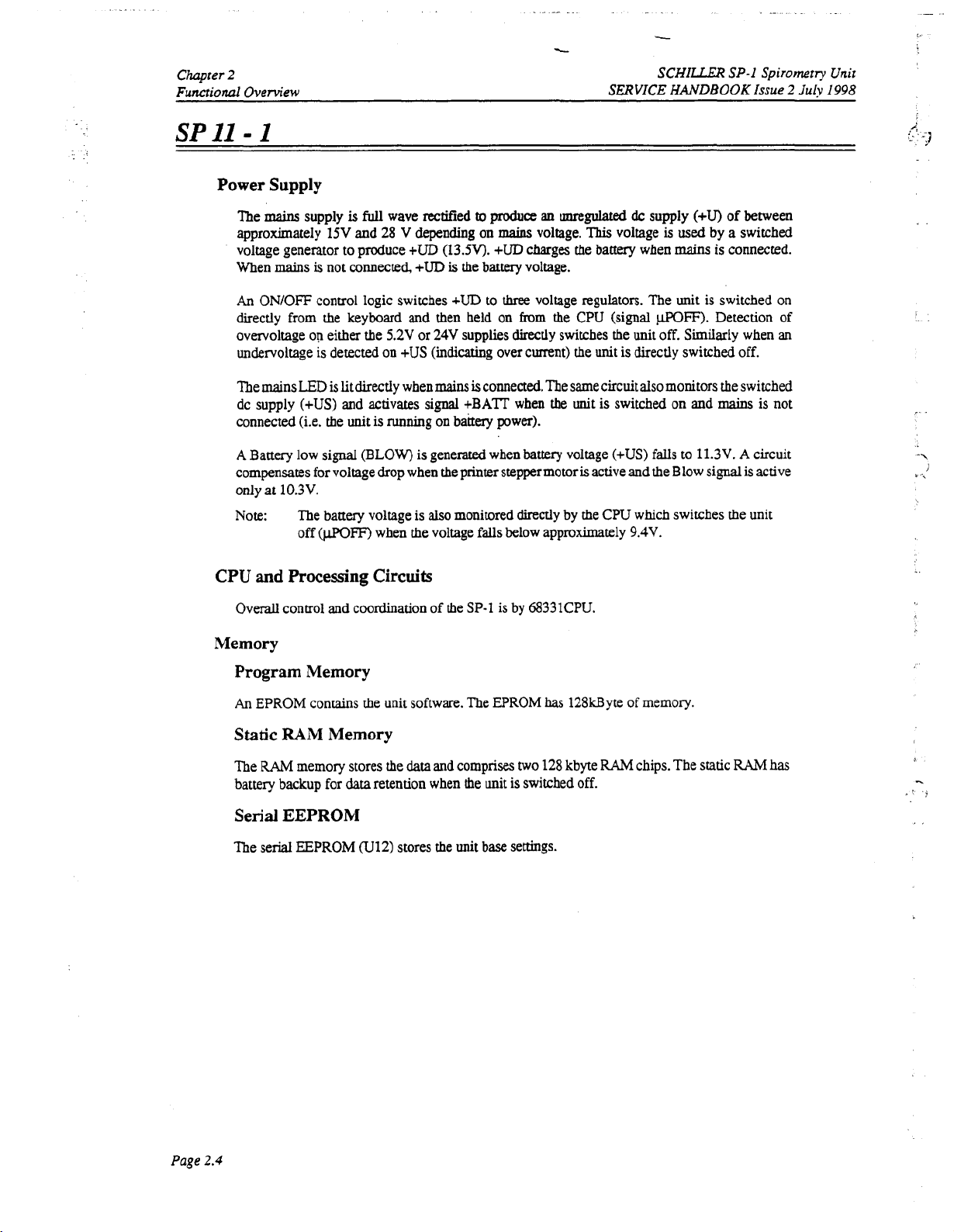

SPll-

Power

The

1

Supply

mains

approximately

voltage generator

When

An

ON/OFF

directly from the keyboard

overvoltage

undervoltage

The mains

dc supply (+US) and activates signal

connected (i.e. the

A

Battery low signal

compensates

only

at

Note:

CPU

and

supply

is

full

15V

and

to

produce

mains

is

not connected,

control logic switches

on

either the

is

detected on

LED

is

lit

directly when mains

unit

(BLOW)

for

voltage drop when the printer stepper motor

1O.W.

The battery voltage is

off

(WFF)

Processing

wave

28 V

depending on

+UD

+UD

and

5.2V

+US

is

running on

is

rectified

or

also

to

produce

(13.5V).

is

the

battq

+UD

to

+m

an

unregulated

mains

voltage.

This

chges the battery when

voltage.

three

voltage

regulators.

voltage

then held on from the CPU (signal

24V

supplies directly switches

(indicating over current) the

is

connected. The same circuit

+BAIT

battery

generated when

monitored directly

when

power).

battexy

the

by

the

unit

is directly switched off.

unit is switched on and

voltage

(+US)

is

active and the Blow signal is active

the CPU which switches

when the voltage falls below approxhately

Circuits

dc

supply

(+W

of

between

is

used

by a switched

mains

is

connected.

The unit is switched on

WE).

unit

off.

also

monitors the switched

falls

Detection

Similarly when an

mains

to

11.3V.

A

the

9.4V.

is not

circuit

unit

of

-\

Overall control and coordination

of

the SP-1

Memory

Program Memory

An

EPROM contains the unit software. The EPROM

Static

The

battery backup for

Serial

The serial EEPROM

RAM

RAM

memory stores

EEPROM

Memory

data

retention when the unit is switched off.

(U12)

the

data

and comprises

stores the unit

is

base

by

68331CPU.

has

two

128

settings.

128kByte of memory.

kbyte

RAM

chips. The static

RAM

has

-.

.,

Page

2.4

Page 31

SCHILLER

SERVICE

SP-I

HANDBOOK

Spiroinetry

Unit

Issue 2 July

1998

Chapter

Functional Overview

2

SPII

-

I

Thermal Print Head Controller

The

Thermal

controller

applied

Print

serialises

to

the

head,

Head

the

and

Printer Timing

Strobe

generation

written. The first output

pulse 1ength.defined

passed through a decoder

Paper

Power

Mark

The Paper Mark

input to the comparator between approhtely

PMARK signal

On

Reset

The Power

follows:

To

provide a delay on

and

give the

is

aiggered

signal

is

logic

on

reset circuit controls the master reset of the CPU. This circuit

20Oms

is

controlled

data

for

thus

the

from

by

the

tempexam

to

set

from the printer is fed to a comparator. The paper

1.

initial

reset time required by the processor.

by

a

print head controller and timer

the print head and the

intensity

by

signal

4bit

STROBE

switch-on

of

the

TPS

when one complete pixel line

binary

counters trigger a monostable multivibrator (U37) at a

and resistance

1

signal.

to

ensure that the power supply

timer

printout.

of

the print-head

2.5

V

and 3.5V and when

circuit controls how long current is

circuit

The print head

of

data

is ready to

(TPHT).

mark

detection voltage

this

is present the

has

two

is

fully stabilized

be

The pulse is

functions

as

To

disable the

unit

if

the

+5V

rail

drops

Stepper Motor Controller

The printer stepper motor controller

dictated

The purpose

the Microprocessor is achieved and maintained.

by

the master CPU.

of

the stepper motor controIIer circuit

Paper Speed

25ds

(motor

sets

speed)

below

4.75V.

the speed of the printer motor with a clock frequency

is

to ensure that the motor speed requested

MCLOCK

Frequency

by

1.4kHz

Page

2.5

Page 32

.

.

f

c

.

.-

-

~

._

-..:

.

:r.

Chapter

Functional Overview

..

.

.

..

..

2

SERVlCE

SCHILLER

HANDBOOK

SP-I

Issue

Spirometly

2

July

Unit

1998

i

..

..

Page

2.6

Page 33

SCHILLER

SERVICE

SP-I

HAMlBOOK

Spiromm

Issue

Unit

2

July

1998

Fault

Chapter

Diagnosis

3

Introduction

Fault

Dingnosis

General

Calibrat5on

Service

Check

Screen

LCD Check

EEPROM

RS-232

Prinrer

Sensor

Check

Check

Flow

Chart

Procedures

Check

Check

Contents

Fault

Chapter

3

Diagnosis

3.2

3.3

3.4

3.5

3.7

3.8

3.8

3.8

3.13

3.13

Page

3.1

Page 34

Chapter

Fault

3

Diagnosis

Introduction

The

SP-1

is

designed to

1

ismodulereplacementandnotboardrepakThepurposeofthischapteris

procedures

procedures

An

finding

cases the

module

given

parameters

instructions for all replaceable modules. along with

given

that

are

initial

fault diagnosis chan

charts

fault

is

stated,

should

and

in

Chapters

be

simple

to

use

will

quickly and efficiently identify

designed

and

finding

.b

setfinpup

so

that

procedures

the

first

checked

4

and

on the following pages

charts

should indicate the most likely faulty area. When more

module given is the one most

in

the order given. When a module

of

5.

test

equipment

is

provided

the module

and

simple to

derailing

may

SCHILLER

SERVICE

is

kept

service:

a

to

the

service phiIosophy

toprovide fault-finding

fault

to a specific module. Fault-finding

a

minimum.

all the general fault indications.

to

indicate a

likely

faulty

area or module.

to contain the fault. Other modules

has

been replaced specific test

be applicable. The removal

any

setup or check

procedures

SP-1

HANDBOOK

Use

Issue

of

the

the fault

In

than

and

replacement

required,

Spirometry

2

Jury

1998

SP-

most

one

are

Unit

If the initial fault-finding

settings

and

parameters

that

chart

does

notindicate the

have been entered.

If

area

where the fault exists, re-check all the

these

are

correct, check the software.

Page

3.2

Page 35

SCHILLER

SERVICE

SP-I

Spirometry

HANDBOOKIssue

Unit

2

July

I998

Fault

Chapter

Diagnosis

3

Fault

Diagnosis

Chart

Page

3.3

Page 36

Chapter

Fault

Diagnosis

3

SERVICE

SCHILLER

HANDBOOK

SP-I

Spiromtry

Issue

2

Julv

Unit

I998

General

The procedure detailed here

boardhas been replaced. It

equipment

1

functional

information

relevant

To

carry

1.

Connect

2.

Switch the unit

and the welcome Screen

3.

Carry out the Printer Check

4.

Connect flow

5.

Carry out calibration

6

Carry out the

7.

Switch the unit

the battery.

8.

Disconnect the

unit on battery power for approximately

the

Check

User

out

battery has limited capacity (not before

Procedures

in

the factory) but

areas.

The

instructions

is

required

ManuaI

the general

mains

(general seaings, comprehensive menu guides em.) please refer

for

power

on

by pressing the

sensor

EEPROM

off

and leave connected

mains

is

a

general confidence check

isnotam

is

functional

intended

to

given

the

software

SP-1

functional check

to

the

unit

version

and

<ON>

is

displayed.

detailed

to

the

sensor

procedure

check detailed

and switch

in

connector

as

detailed in this chapter

the

unit

here

ensure

in

the unit

test (whichcan

provide ageneral confidence check

are

guides

to

the basic

applicable.

procedure,

that

key

on

this

chapter

on

in

this

chapter

to

the mains supply for

on.

Ensure that

an

hour. Ensure that the battery

45

minutes).

proceed

the

green

the keyboard.

the

side panel and switch on.

the

only

mains

Ensure

10

Battery

after

an

be

carriedout with

functions.

as

follows:

LED

lights.

that

hours or more

LED

internal module

dedicated

in

all

the major

If more

operating

the LCD lights

to

charge

is

lit. Run the

LED

flashes when

SP-

to

or

the

Page

3.4

Page 37

SCHILLER

SERVICE

HtWDBOOK

To

SP-I

Spirometry

Issue

calibrate, proceed

Unit

2

July

as

I998

follows:

-

Chapter

3

Fault Diagnosis

Last calib.

BTPS

Factor

Calib. Factor

Temperature

Measured

Syringe

Vol.

Vol.

23.1

1.090

1

.ooo

20

0.00

4.00

1.95

"C

I

I

IMPORTANT

THE

UNIT

MUST BE CALIBRATED

OF

THE DAY, AFTER EVERY SIGNIFICANT TEMPERATURE CHANGE OR

CHANGING

Last Calibration

BTPS

THE

SENSOR.

date of last calibration

Factory calculated

Saturated with water vapour) value.

difference in inhaled and exhaled humidity.

measuring exhaled volume

when inhaled volume is measured

ambient temperature to calculate the

for accurate

WITH

THE

FIRST

BTPS

(=>

Body Temperature, Ambient Pressure,

(100%

humidity, Temp 36.8"), and

this

FIVC

calculation. The formula used

PULMONARY FUNCTION

This

value

compensates for the

The

unit

factor

is

applied.

BTPS

factor.

This

is

as

is

set

for

The

SP-

is sufficient

follow:

TEST

AFTER

so

1

uses

Calibration Factor

Temperature

Measured Volume

Syringe Volume

273.15

+

BTPS

=

0.033

+

273.15

Tu

is

ambient temperature degrees centigrade

0.033

is

273.15

equivialent

is

degrees absolute

to

760mmHg

36.8

+

Tu

at

22 degrees

C

calculated value between measured and effective calibration

volume

ambient temperature in

air

volume measured by the system from the calibration pump

entered

air

volume depending on the size

times the

air

was pumped through

times amounts

pump is

4

litres;

to

6

litres

with

"C

(or

OF)

dependent on device setting

the

sensor, e.g. pumping 2 litres 3

(the

recommended volume with

3

litre

pump, 6 litres)

of

the calibration pump and

a

2

air

litre

Page

3.5

Page 38

f

..

-.

..

.

.,:

.

I.

..- -.

.:.-

Chapter

3

Fault Diagnosis

Calibration

Calibration

To

calibrate

Connect the calibration pump

Press the

The cursor

Press

ENTER

Wait 1 second.

Press the

Pump

4

Note:

While pumping, the unit records the volume being pumped

it on the display.

Make

Press the

Enter the pumped

litres).

The message "Calibration completed"

to

(cont.)

Procedure

the

unit proceed

CAL

key - the menu

is

positioned

when the correct temperature entered

START

to

6

litres

sure

STOP

the calibration pump and times

Press

ENTER.

obtain a printout

as

follows:

to

the sensor. Ensure

is

displayed

at

temperaaxe. Enter the ambient temperature

key

of

air

through

that

thejlow sensor

the'sensor

key when finished pumping.

air

volume at syringe volume prompt (depending on the size

of

the calibration report with the following information:

SCHILLER

SERVICE HANDBOOK Issue

that

there

are

no

air

leaks

as

shown on the previous page

is

kept still during the pumping operation.

of

pumping; i.e.

appears

through

a

on

the

flow

sensor

2

lirre pump pumped 3 times

the display, press the

SP-I

Spirometry Unit

and indicates

of

=

6

PRINT

key

2

July

I998

L

Page

Ifthe message

that

the difference between the measured volume andthe entered volume is

the

temperature sening, the syringe volume andthe entered syringe volume. rfthese are all correct

'EXCESSNE DEVMTION!

change the screedfilter and recalibrate

3.6

'appears

on

the screen after a calibration,

too

big

it

indicates

(>25%).

Check

Page 39

SCHILLER

SERVICE

SP-I

Spiromtry

HANDBOOK

Issue

Service Screen

To

check

the printer

To

carry

out

the

printer

Unit

2

July

and

I998

to

emure

check

press:

that

every

pixel is

operational,

a

built-in

printer

test

Fault

is

provided.

Chapter

Diagnosis

3

MENU

then press the

The following Menu options

LCD

EEPROM

RS-232

PRINTER

SENSOR

These are explained

following

on

keys simultaneously, in

the

following

key

ALT

are

then

-

given:

pages

select

MENU

<SETUP,

the

order given:

-PRE/POST

<DEVICE>

Page

3.7

Page 40

-

Chapter

Fault

3

Diagnosis

-

-

.-

-

c

SCHILLER

SERVICE

HANDBOOK

SP-1

Spirometry Unit

Issue

2

July

I998

c\

I

Service

LCD

EEPROM

RS-232

The following error messages

are

SERIAL

Screen

(cont.)

Check

Select

LCD

from

the

All

characters

screen

Press

any key. The designation

screen.

Return

pixels

All

keys

to

the

are

displayed. Select more characters with the up and down arrow keys.

can

be

can

service

service menu (page

checked

this

written

be

checked

menu by pressing the

m

way

this

7)

on

the key

way.

MENU

Check

Select EEPROM

The message 'EEPROM Working' is displayed.

On successful completion of the

Return

to

from

the

service

manu

(page

test

the

message 'EEPROM

the service menu by pressing the

7)

MENU

Check

are

associated with the

displayed,

carry

LINK

out the checks suggested.

TIME-OUT

This

indication appears

remote unit

(after

is

displayed on the right hand side of

key

okay'

is displayed

key

RS

Interface. If any

if

approximately

no

of

these error messages

signal

is

received

30

seconds).

All

from

(3

the

\

>

the

TRANSMISSION ERROR

NO

DATA

0

Check

that

the remote unit is switched on and set

correct parameters

0

Check the correct setup

0

Check that the connecting cable

0

Check the integrity of the cable assemblies (at both

units)

0

If

using a modem ensure

the remote modem

This

is

a

general fault indication

Check

that

0

cmect parameters

0

Check that the connecting cable

0

Check the integrity of the cable assemblies (at both

the remote unit is switched on and set

in

both units

that

it

is

is

correctly plugged in

communicating with

is

correctly plugged

units)

0

Ifusing amodem, ensure

the

remote modem

A

transnission

the

units'

and attempt the transmission again. If the

appears, change the processor board.

has

been

memory. Store a measurement in the memory

that

it

is

communicating with

attempted, but

no

data

same

is

stored

message

to

to

the

i

the

in

in

Page

3.8

Page 41

SCHILLER

SERVICE

SP-1

HANDBOOK

Spirometry Unit

Issue

2

July

1998

Chapter

Fault Diagnosis

3

Service

RS-232

When

changed

The test uansmission I test reception options enables

Use these test options to ensure that the receiving and transmitting

the

The test message generated

the

unit are displayed

indicating that a test transmission

To perform these tests, you will need a second

connected to

95TM.

Screen

(cont.)

Check

RS-232

cable assemblies, connectors etc. between

test

The following equipment

A

personal computer

is

by

pressing the

selected,

the

screen

START

is

asuing of

key

transmission I reception option

on

the LCD in the receiving unit.

is

in progress.

an

active terminal, for example the

is

needed:

(PC)

with Windows

shows

and

the parity by pressing the

all

ASCII

is

selected,

the Baud

rate

a

test

sequence to

the

communicating

and the parity.

characters - ABCD....

the

string

of

In

the transmitting unit amessage

SP-1

unit, or the

Hyperterminal,

95TM

Hyperterminal

PRINT

be

units

units

characters

SP-1

RS-232

which

is

installed.

The

Baud rate

can

be

key.

generated and received.

can

communicate and that

are

good.

12

34....

abcd...

etc.

When

sent by

the

transmitting

is

displayed

interface

has

to

be

available under Windows

An

1.

RS-232

SP-1

and

Start

cable assembly,

with the

an

COM

adapter DB

from Windows

Art.

port

of the

9

I

DB

25,

Art.

95

desktop. Click on

Hyperterminal.

2.

Double-click on Hypertrm(.exe). Enter

OK.

No.

PC.