Page 1

OXYWAY

Single-stage pressure reducer, fixed:

Fix I; Fix I side outlet; Fix II; Fix III; Fix III left

Single-stage pressure reducer, variable:

Fine I; Fine II; Fine III

Single-stage pressure reducer, indexed:

Fast I; Fast II; Fast II High Flow; Fast III

Indexed flowmeter OXYWAY Click

Two-stage pressure reducer, fixed:

OXYTRON

Service and Repair Instructions

Page 2

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . 3

1. Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1 Explanation of Numbers . . . . . . . . . . . .6

1.2 Information about conformity with

standards . . . . . . . . . . . . . . . . . . . . . .6

2. Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1 General. . . . . . . . . . . . . . . . . . . . . . .7

2.2 Fixed pressure reducer FIX

(WM 30050; 30100; 30200;

30300; 30350) . . . . . . . . . . . . . . . . .7

2.3 Variable pressure reducer FINE

(WM 30500; 30700; 30750). . . . . . .8

2.4 Indexed pressure reducer FAST

(WM 30600; 30800; 30850). . . . . . .8

2.5 Multistep pressure reducer Fast II High

Flow (WM 31899) . . . . . . . . . . . . . . .8

2.6 Two-stage pressure reducer OXYTRON

(WM 30150). . . . . . . . . . . . . . . . . . .9

2.7 Indexed flowmeter OXYWAY Click . . . . .9

2.8 Oxygen outlets pressure reducer

OXYWAY . . . . . . . . . . . . . . . . . . . . 10

3. Final Check . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 General. . . . . . . . . . . . . . . . . . . . . .11

3.2 Intervals . . . . . . . . . . . . . . . . . . . . . .11

3.3 Performing check . . . . . . . . . . . . . . . .12

3.4 Checking the adjustable output (flow)

on the OXYWAY Click . . . . . . . . . . . .15

4. Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.1 General. . . . . . . . . . . . . . . . . . . . . .16

4.2 Intervals and scope for OXYWAY and

OXYTRON pressure reducers . . . . . . . . 16

4.3 Intervals and scope for OXYWAY Click

flowmeter . . . . . . . . . . . . . . . . . . . . .16

4.4 Storage . . . . . . . . . . . . . . . . . . . . . .17

4.5 Disposal . . . . . . . . . . . . . . . . . . . . .17

5. Troubleshooting . . . . . . . . . . . . . . . . . . . . . 18

5.1 Pressure reducer OXYWAY and

OXYTRON . . . . . . . . . . . . . . . . . . . . 18

5.2 Flowmeter OXYWAY Click . . . . . . . . .19

6. Repair Information and Repair Instructions

for pressure reducer OXYWAY and

OXYTRON . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.1 General. . . . . . . . . . . . . . . . . . . . . .20

6.2 Replacing sealing ring in connector. . . . 20

6.3 Replacing filter screw . . . . . . . . . . . . .21

6.4 Replacing oxygen outlet . . . . . . . . . . .21

6.5 Replacing gage . . . . . . . . . . . . . . . .27

6.6 Replacing piston in pressure reducer

FIX (WM 30050, 30100, 30200,

30300, 30350) . . . . . . . . . . . . . . . .28

6.7 Replacing piston in pressure reducer

FINE (WM 30500, 30700, 30750) . .30

6.8 Replacing piston in pressure reducer

FAST (WM 30600, 30800, 30850) . .33

6.9 Replacing piston in pressure reducer

Fast II High Flow (WM 31899) . . . . . .36

6.10 Replacing index head / cover . . . . . . .39

6.11 Replacing index head/cover on Fast II

High Flow pressure reducer . . . . . . . . .45

6.12 Replacing Connector and Sinter Filter . . 50

6.13 Changing connector and sinter filter in

OXYTRON pressure reducer . . . . . . . .52

6.14 Replacing second stage of OXYTRON

pressure reducer (WM 30150) . . . . . .54

6.15 Replacing first-stage piston in OXYTRON

pressure reducer (WM 30150) . . . . . .55

6.16 Replacing second-stage piston in

OXYTRON pressure reducer

(WM 30150). . . . . . . . . . . . . . . . . . 56

7. Repair Information and Repair Instructions for

flowmeter OXYWAY Click . . . . . . . . . . . . . . 58

7.1 General. . . . . . . . . . . . . . . . . . . . . .58

7.2 Replacing index head / cover . . . . . . .58

7.3 Changing filter screw . . . . . . . . . . . . .63

7.4 Replace central gas supply system plug

connection . . . . . . . . . . . . . . . . . . . .63

8. Replacement Parts . . . . . . . . . . . . . . . . . . . 64

8.1 Information about conformity with

standards. . . . . . . . . . . . . . . . . . . . .64

8.2 Replacement parts list for all

pressure reducers. . . . . . . . . . . . . . . .65

8.3 Additional replacement parts for

WM 30050 . . . . . . . . . . . . . . . . . .66

8.4 Additional replacement parts for

WM 30100, 30150, 30200, 30300 67

8.5 Additional replacement parts for

WM 30500, 30700, 30750 . . . . . .68

8.6 Additional replacement parts for

WM 30800, 30850 . . . . . . . . . . . .69

8.7 Additional replacement parts for

WM 31899 . . . . . . . . . . . . . . . . . .70

8.8 Additional replacement parts for

WM 30600 . . . . . . . . . . . . . . . . . .71

8.9 Additional replacement parts for

OXYWAY Click . . . . . . . . . . . . . . . .72

8.10 Additional replacement parts 2nd stage

OXYTRON WM 30150. . . . . . . . . . .73

8.11 Connections for pressure reducer . . . . .74

9. Tools, Inspection/Measuring/Test Equipment 76

9.1 General tools and resources . . . . . . . .76

9.2 Special tools. . . . . . . . . . . . . . . . . . . 76

9.3 Inspection, measuring and test

equipment . . . . . . . . . . . . . . . . . . . .77

10. Technical Data . . . . . . . . . . . . . . . . . . . . . . 79

10.1 Pressure reducer OXYWAY up to

SN 0849999 and OXYTRON . . . . . .79

10.2 Pressure reducer OXYWAY from

SN 0850000 . . . . . . . . . . . . . . . . .80

10.3 Technical Data for flowmeter

OXYWAY Click . . . . . . . . . . . . . . . .81

11. Technical amendments . . . . . . . . . . . . . . . . 82

© Copyright WEINMANN GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised WEINMANN Service Partners in

the course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with WEINMANN.

2

Page 3

Introduction

For many decades WEINMANN has developed,

produced and marketed appliances for oxygen

therapy, inhalation therapy and emergency

medicine.

In 1957 WEINMANN put the first diaphragm

pressure reducer on the market.

Pressure reducers are used in medical oxygen

inhalation. They reduce the pressure delivered by

oxygen bottles from 200 bar to the specified

operating pressure.

The flowmeter is used during the inhalation of medical oxygen via the central gas supply system of a

hospital, for example.

Pressure reducers are a functional component of a

wide range of appliance combinations such as

stationary oxygen appliances and portable oxygen devices. They are therefore an important

component in the treatment of chronic respiratory

diseases and/or disorders of the cardiovascular

system.

The aim of these Service and Repair Instructions is to

familiarize you, a

the function, technology, servicing and repair of

pressure reducers and flowmeters. In conjunction

with a training course that you have already been

trained and competent expert,

with

given by WEINMANN, you now belong to that

group of “trained and competent experts”, which

means you can give your customers proper instruction, rectify faults yourself and perform the prescribed functional check and any repairs in

accordance with these Service and Repair Instructions.

In the event of any warranty claim the device must be

sent to WEINMANN

So that we can process any warranty claims or

requests for favorable treatment, please send us

the customer’s purchase slip (invoice) with the

appliance.

Repairs and/or repair work may only be performed by WEINMANN or by trained and competent experts.

You are responsible for any repairs you carry out

yourself and the relevant guarantees!

Only genuine WEINMANN replacement parts

used for repairs.

Please remember:

Your customers put their trust in you and rely on

your efficiency, just as you rely on WEINMANN.

.

may be

Note:

You will find the following information in the operating instructions for the devices:

• Safety information

• Assembly

• Operation

• Hygienic preparation

• Functional Check

• Warranty.

Introduction

3

Page 4

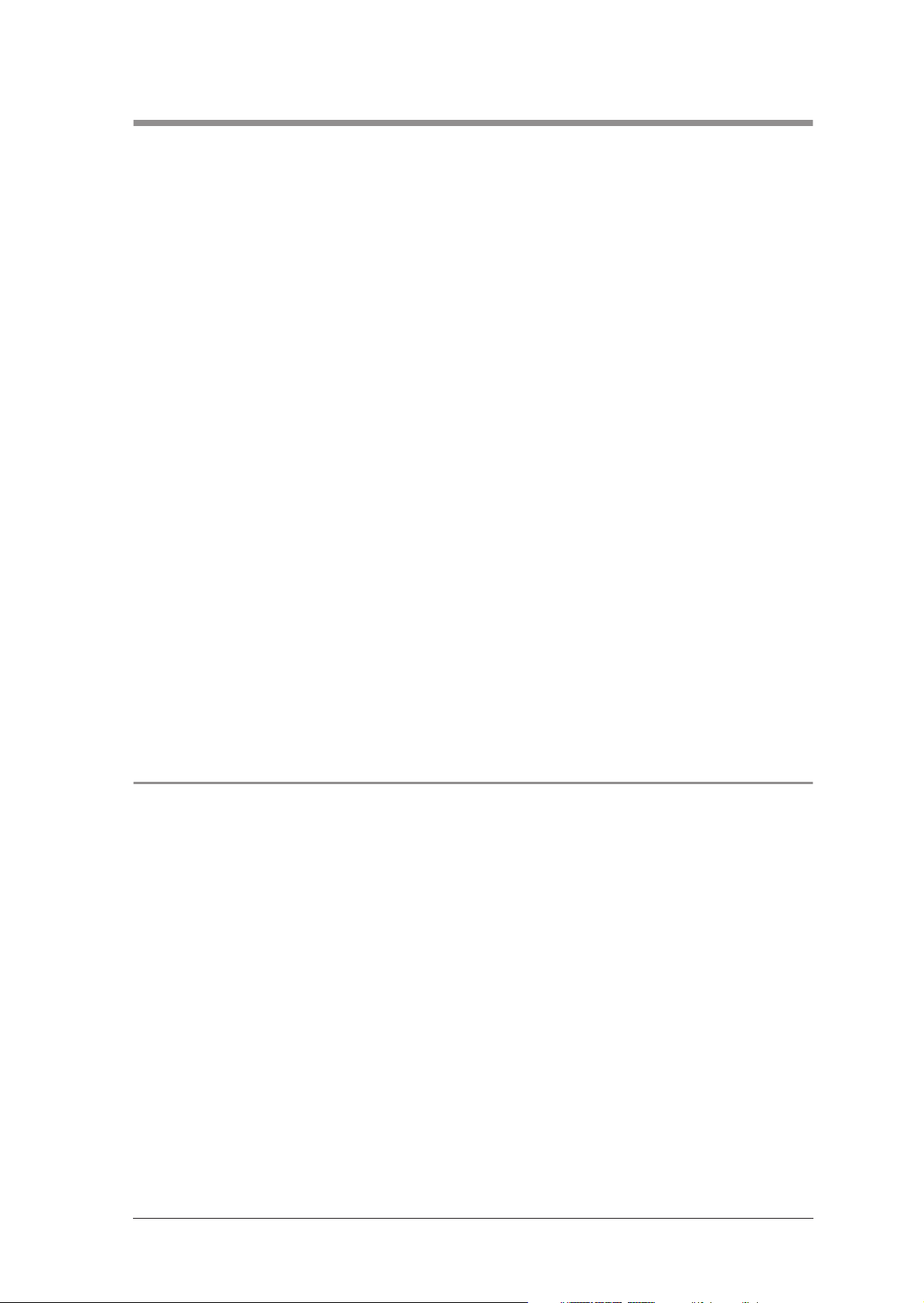

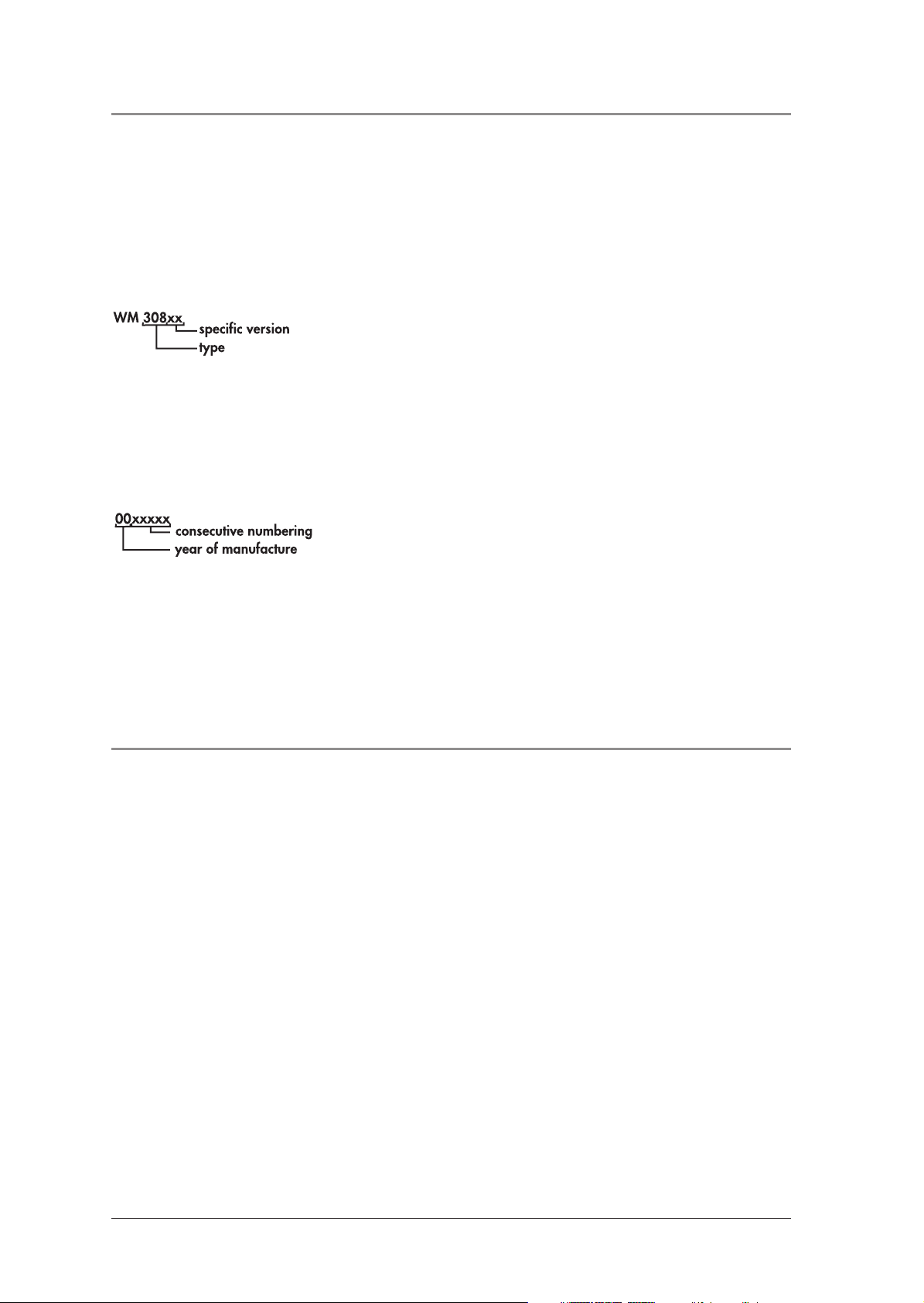

1. Overview

1 Contents gage

2 Connector

(oxygen bottle)

3 Rating plate

4 Body

22 Cover

Oxygen outlet

(to consumer)

6 Index head

Fixed pressure reducer FIX

WM 30050; 30100; 30200;

30300; 30350

2 Connector (oxygen

bottle)

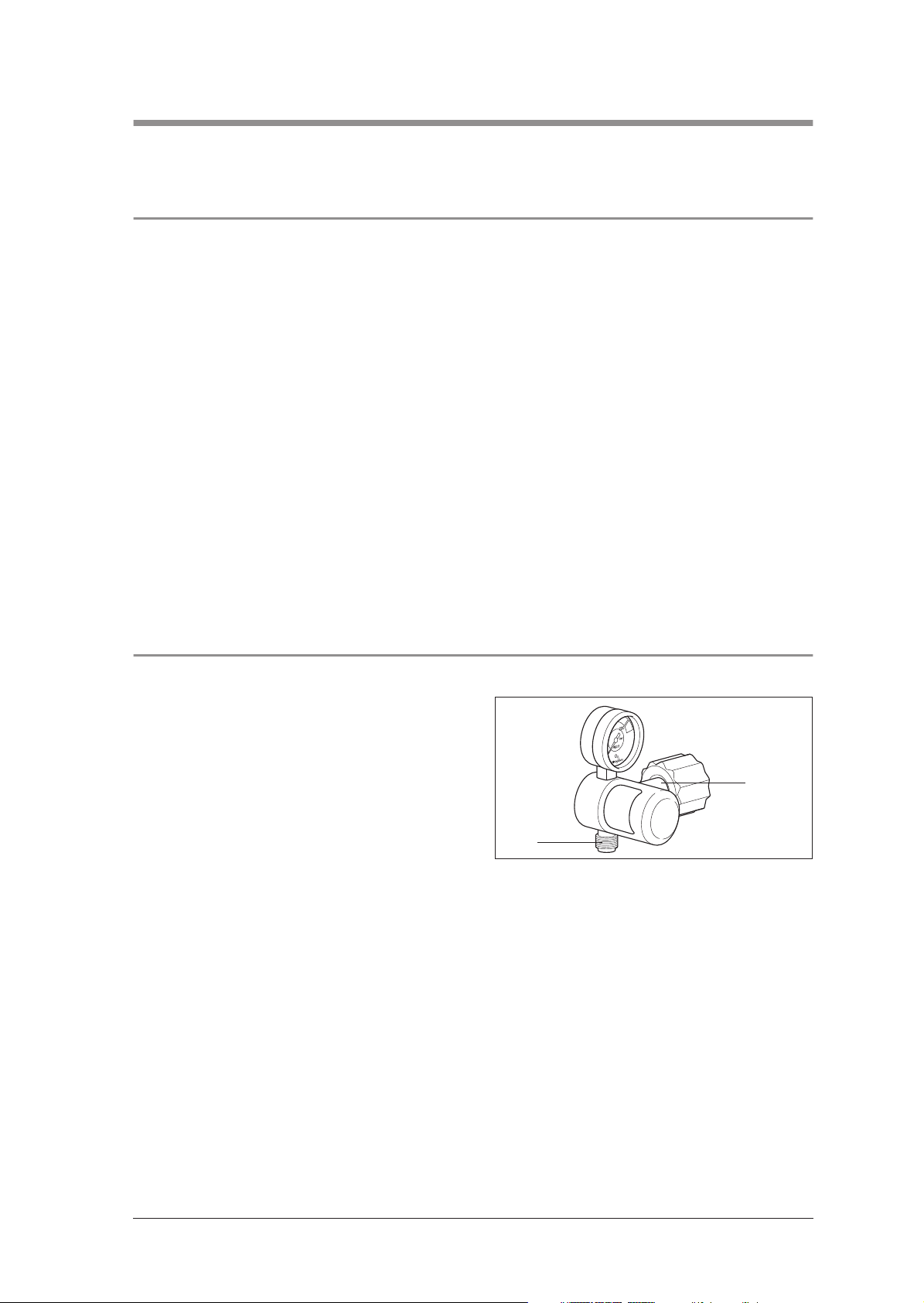

Multistep pressure reducer Fast II High Flow

WM 31899

8 Flow gage

Indexed pressure reducer FAST

WM 30600; 30800; 30850

1 Contents gage

6 Index head

Oxygen outlet

(to consumer)

1 Contents gage

15 Connection nut

2 Connector (oxygen

bottle)

4 Body

22 Cover

Oxygen outlet

(to consumer)

9 Adjuster knob

Variable pressure reducer FINE

WM 30500; 30700; 30750

4

Overview

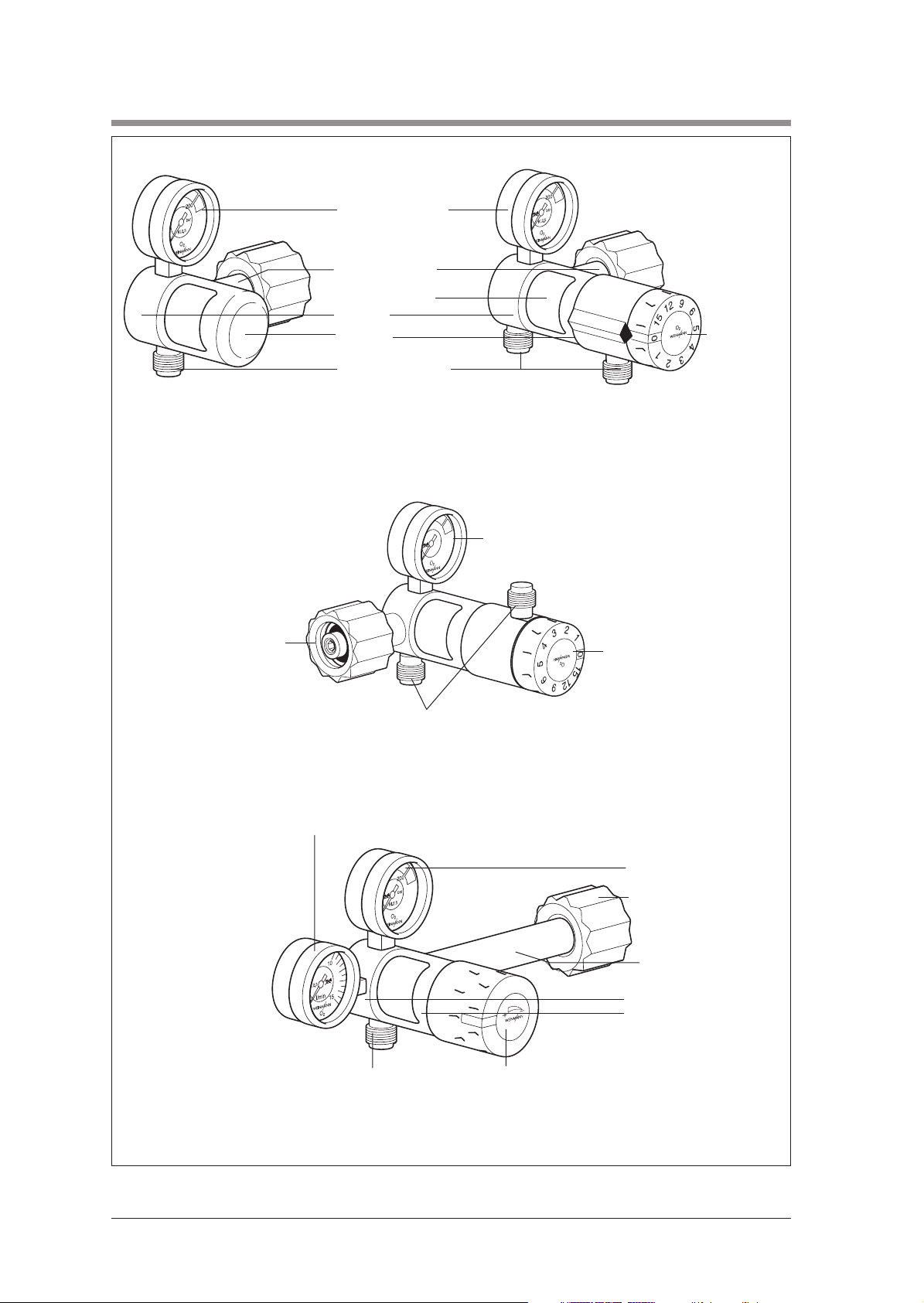

Page 5

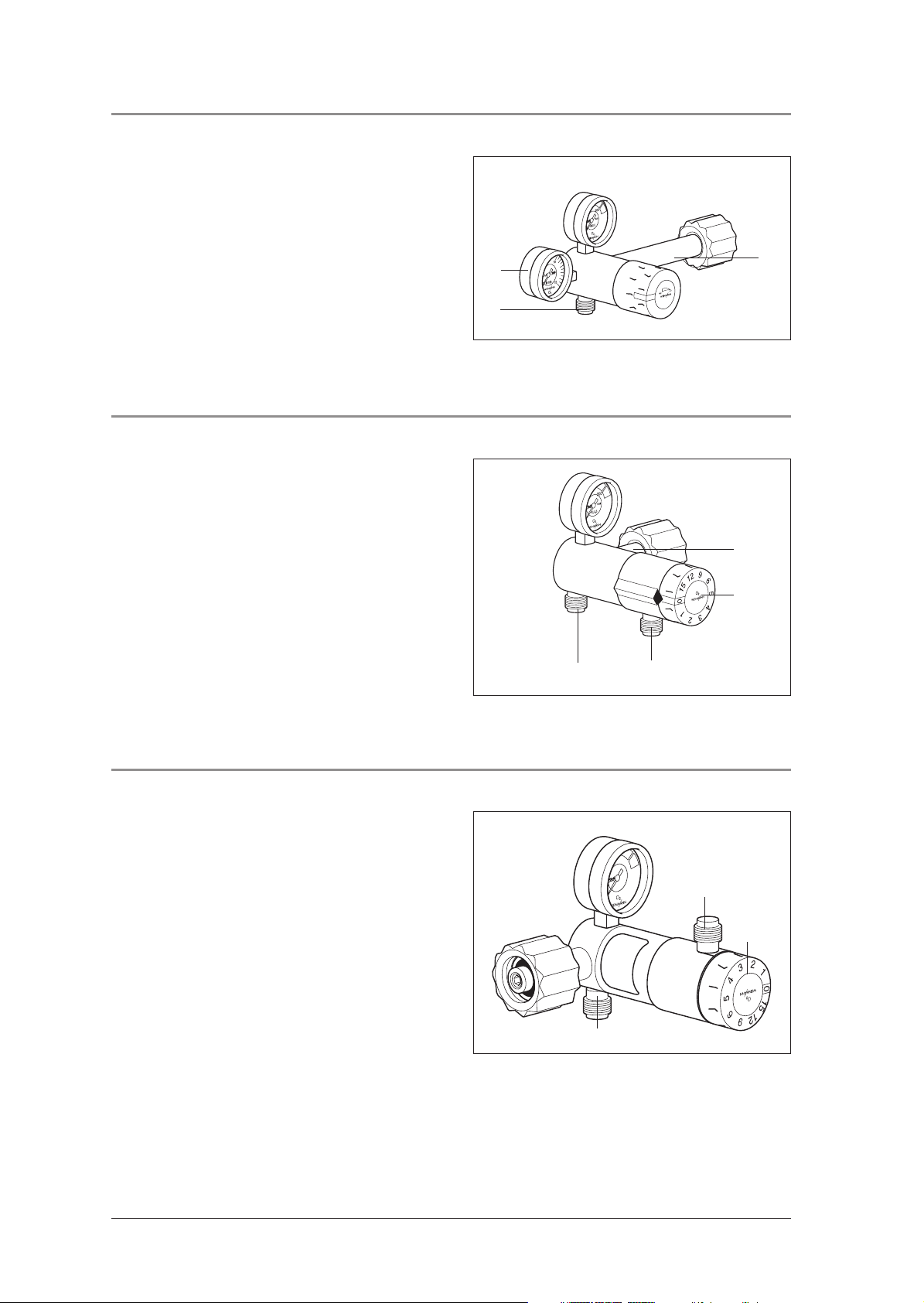

1 Contents gage

15 Connection nut

2 Connector (oxygen

bottle)

4 Body

22 Cover

52 Body stage 2

Oxygen outlet

(to consumer)

Two-stage pressure reducer

OXYTRON WM 30150

2 Connector

22 Cover

3 Rating plate

6 Index head

13 Service plate

20 Plate for changing

filter screw

14 Sealing ring

Oxygen outlet

(to consumer)

Indexed flowmeter

OXYWAY Click WM 31030

12 Filter screw

10 Appliance number

11 Safety valve

Rear view of pressure reducer

Overview

5

Page 6

1.1 Explanation of Numbers

Type: 30800

The type row indicates the basic design of the

pressure reducer, e.g. “30800” for indexed

pressure reducers (Fast I).

Order number:

In the order number the first three numbers are a

short indication of the type, and the last two digits

indicate the specific version (e.g. the connection

variants).

Appliance number:

The first two digits of the appliance number show

the year of manufacture. The next five digits are the

consecutive appliance serial number within each

type. The appliance number is stamped on the

back of the pressure reducer.

1.2 Information about conformity with standards

Up to serial number 0849999, OXYWAY

pressure reducers meet standard EN 738-1.

From serial number 0850000, OXYWAY

pressure reducers meet standard EN ISO 105241:2006.

In the course of adapting the products to standard

EN ISO 10524-1:2006, it was not possible to

design all components to be downward-compatible. Parts which are not downward-compatible are

available for both device statuses separately and

are marked accordingly in the replacement parts

lists (see “8. Replacement Parts” on page 64) of

these instructions.

• Fit replacement parts which are not downward-compatible only

pressure reducer serial numbers quoted.

• Do not convert pressure reducers up to

SN 0849999 “to suit the new standard”.

in accordance

with the

Caution!

Malfunction as a result of unclear device status.

If replacement parts which are not downward-compatible are used in the wrong pressure reducers,

connected devices will malfunction.

6

Overview

Page 7

2. Function

2.1 General

During operation, the oxygen coming from the

oxygen bottle passes through the bottle valve and

the connector 2 into the body 4 of the pressure

reducer. You can read off the bottle pressure (delivery pressure) at the contents gage 1.

WEINMANN piston pressure reducers are of

modular design. This makes it possible to keep the

number of replacement parts to a minimum.

A filter screw with integrated sinter filter (see explanation on right) traps any impurities. A further sinter

filter absorbs pressure surges in the oxygen flow.

The filter screw 12 is located at the entrance to the

connector 2. The second sinter filter is fitted between

the connector 2 and the body 4.

In the reduction stage the bottle pressure is reduced

to the required nominal outlet pressure, depending

on type. The principle used, with crater drill hole

and spring-loaded piston, ensures especially constant pressure in spite of variations in flow.

All pressure reducers are protected against excess

pressure by a safety valve 11.

Explanations:

Sinter filter: Small spherical bronze particles are

pressed together under heat, creating a filter with a

particularly fine pore structure (50 - 75 µm).

Flow: Outlet volume; expressed in liters per minute.

2.2 Fixed pressure reducer FIX

(WM 30050; 30100; 30200; 30300; 30350)

A fixed orifice in oxygen outlet 7 creates a constant

flow.

The pressure reducers in this series differ in the

length and position of the connector 2 and the

oxygen outlet 7.

2

7

Function

7

Page 8

2.3 Variable pressure reducer FINE (WM 30500; 30700; 30750)

The piston is acted upon by a second spring which

can be adjusted via a spindle system and thereby

creates different outlet pressures. In conjunction

with the fixed orifice in the oxygen outlet 7 you can

therefore make continuously variable adjustments

to the flow. You can read off the flow setting at the

flow gage 8.

8

2

The pressure reducers in this series differ in the

length and position of the connector 2.

7

2.4 Indexed pressure reducer FAST (WM 30600; 30800; 30850)

As in the fixed pressure reducers, this creates a

constant operating pressure (outlet pressure).

The index head 6 contains an orifice disc with

various orifice diameters which are aligned by an

index (click-in) system with the oxygen outlet 35.

This enables you to set various flow rates.

The pressure reducers in this series differ in the

length and position of the connector 2. A pressure

reducer of type WM 30850 has two oxygen

outlets.

7

35

2

6

2.5 Multistep pressure reducer Fast II High Flow (WM 31899)

As in the Fast multistep pressure reducers, there is an

orifice disk with a variety of orifice diameters in adjuster 6 which is brought into line with oxygen outlet 35

by means of a locating system.

35

In addition to the flow outlet, there is a pressure outlet

for medical devices with an oxygen requirement in excess of 90 l/min. The pressure outlet and the flow outlet may not be in operation simultaneously.

7

6

8

Function

Page 9

2.6 Two-stage pressure reducer OXYTRON (WM 30150)

The two-stage pressure reducer has a first stage in

the form of a fixed pressure reducer WM 30100,

and a second reduction stage 52 to permit optimal

adjustment of pressure and flow to suit the

OXYTRON oxygen device.

In the second stage the pressure of 4.5 bar from

the first stage is similarly reduced by a system of

crater drill hole and spring-loaded pistion to

1.6 bar.

A fixed orifice in the oxygen outlet 7 generates a

constant flow of 12 l/min.

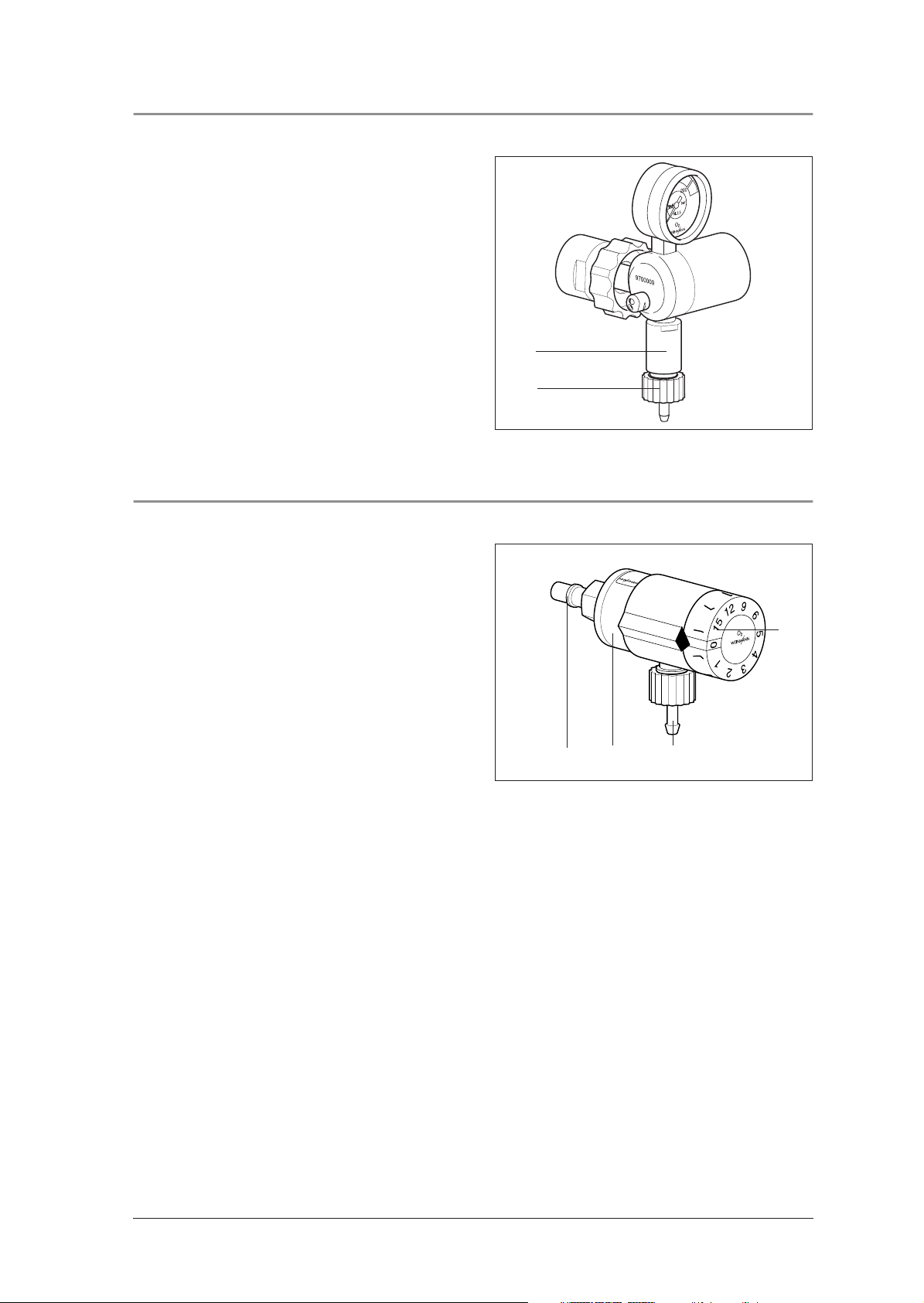

2.7 Indexed flowmeter OXYWAY Click

During operation, the oxygen supplied by the central

gas system at a pressure of 4.5 bar passes through the

inlet connector 2 into the body 22 of the OXYWAY

Click.

The dial head 6 contains an orifice disk with orifices of different diameters which are lined up with

the oxygen outlet 35 by means of a click dial system. You can set the following flow rates: 1, 2, 3,

4, 5, 6, 9, 12, 15 l/min..

52

7

2 35

6

22

Function

9

Page 10

2.8 Oxygen outlets pressure reducer OXYWAY

Oxyway pressure reducers are available with different oxygen outlets: the pressure outlet and the

flow outlet are different (see also “10. Technical

Data” on page 79).

Flow outlets are intended for the direct supply of

the patient, e.g. via nasal cannula, mask or

Flow outlet

(Fix I, Lateral outlet Fix I)

9/16 UNF thread

Pressure and flow outlet

(Fast II)

(Fine I up to III)

9/16 UNF thread

Pressure and flow outlet

(Fast II High Flow)

intermediate humidifier. Flow outlets have a 9/16

UNF thread.

Pressure outlets are intended to supply ventilators

such as the Medumat, modules or distributor bars.

Pressure outlets have a G 3/8" thread.

Flow outlet

Flow outlet

(Fast I and III)

9/16 UNF thread

Pressure outlet

(Fix III, Fix III left)

G 3/8"

thread

9/16 UNF

thread

Flow outlet

(Oxytron)

18 x 11 thread

G 3/8"

thread

G 3/8" thread

9/16 UNF

thread

Flow outlet

(Oxyway Click)

9/16 UNF thread

10

Function

Page 11

3. Final Check

3.1 General

Test conditions:

• Ambient temperature: 15 °C

• Ambient pressure: 1013 hPa

• Connection to oxygen supply. For flow tests, a

constant pressure* of 100 bar or 200 bar is

required.

* 100 bar up to SN 0849999

200 bar from SN 0850000

All the tolerances listed in these instructions (see

“10. Technical Data” on page 79) relate to these

conditions. Note that if different ambient conditions prevail, deviating measuring results may be

obtained.

For the check you will need:

• shutoff valve (max. 6 bar) after oxygen outlet

• test pressure gage 0 - 10 bar

• test pressure gage 0 - 2.5 bar

and three flow meters:

• 0 - 50 ml/min

• 0 - 20 l/min

• 0 - 220 l/min.

If the final check reveals faults, the device must not

be used until the defect has been rectified. For possible causes of the defect and how to remedy

them, see Chapter “5. Troubleshooting” on

page 18.

A complete check of the OXYWAY Fix, Fast and

Fine pressure reducer includes:

• Visual inspection for mechanical damage,

• “3.3.1 Testing system for leaks” on page 12,

• “3.3.2 Testing safety valve for leaks” on

page 13,

• “3.3.3 Checking “0” position of contents

gage” on page 13,

• “3.3.4 Checking “0” position of flow gage on

pressure reducer FINE” on page 13

• “3.3.5 Checking for leaks with valve closed

on pressure reducer FINE” on page 14,

• “3.3.6 Checking adjustable flow rate on pressure reducer FINE” on page 14,

• “3.3.7 Checking adjustable flow rate on pressure reducer FAST” on page 14.

• “3.3.8 Checking constant flow rate in pressure reducers FIX, FAST and

FAST II high Flow” on page 15

• “3.3.9 Checking static outlet pressure p4 for

all pressure reducers” on page 15.

A complete check of the OXYWAY Click flowmeter includes:

• “3.4 Checking the adjustable output (flow)

on the OXYWAY Click” on page 15.

We recommend that you always keep in stock:

• Replacement seal set WM 1148,

• Filter screw WM 30905.

3.2 Intervals

After any servicing or repair work

• Perform a final check.

Final Check

11

Page 12

3.3 Performing check

3.3.1 Testing system for leaks

1. Close system after pressure reducer, e.g. by

closing a valve after the pressure reducer.

2. Check that all screwed joints and hoses are

firmly seated. If necessary tighten joints by

hand.

3. Slowly open valve of oxygen bottle. Contents

gage 1 of pressure reducer now shows bottle

pressure, e.g. 200 bar.

4. To detect leaks, wet screwed connections with

a soap-and-water solution. Use Lanosan

for this purpose.

Warning!

Risk of explosion from soap penetration.

Leaks can cause soap to penetrate the system

and combine with the oxygen to form an explosive mixture.

• Open the O2 valve before wetting parts of the

system with a soap-and-water solution. The

system is then pressurized. No soap can penetrate the system.

• Remove the soap-and-water solution without

leaving any residues after the test is complete.

5. Close bottle valve again.

6. Observe needle of contents gage 1 for about

1 minute. If needle stays in same position, the

system is gas-tight. If the needle falls steadily,

there is a leak.

®

med

1

Eliminating leaks

We recommend that you keep a stock of replacement seals for the connections.

1. Prepare solution of soapy water, using perfume-free soap.

2. Wet all screwed joints with solution. If bubbles

form, this indicates a leak.

3. Release pressure in system:

– Close oxygen bottle valve.

– Open valve after pressure reducer until

contents gage 1 reads “0”.

12 Final Check

4. Replace faulty seal responsible for leak (see

“6.2 Replacing sealing ring in connector” on

page 20).

Important!

Screwed joints of oxygen line must only be hand

tightened.

5. Check for leaks again.

6. If leak cannot be eliminated, unit must be

repaired.

Page 13

3.3.2 Testing safety valve for leaks

1. Test must be performed at maximum flow. In

the Fine and Fast series this is set accordingly.

2. Slowly open oxygen bottle valve.

3. Test with finger whether oxygen is escaping

from safety valve 11.

If oxygen is escaping, have pressure reducer

repaired by manufacturer (WEINMANN).

Alternatively, you can also wet the safety valve

with soap-and-water solution to find leaks. Use

Lanosan® med.

Warning!

Risk of explosion from soap penetration.

Leaks can cause soap to penetrate the system

and combine with the oxygen to form an explosive mixture.

• Open the O2 valve before wetting parts of the

system with a soap-and-water solution. The

system is then pressurized. No soap can

penetrate the system.

• Remove the soap-and-water solution without

leaving any residues after the test is complete.

11

3.3.3 Checking “0” position of contents gage

1. Slowly open oxygen bottle valve.

Contents gage

1 now shows bottle pressure.

2. To release pressure in system:

– Close oxygen bottle valve

– Switch on connected appliance

– Open shutoff valve after oxygen outlet.

3. Needle of contents gage

“0”. Wait until needle stops moving. Now

switch appliance off.

4. Check whether needle points exactly to “0”.

If not, fit replacement contents gage (see “6.5

Replacing gage” on page 27).

3.3.4 Checking “0” position of flow gage on pressure reducer FINE

1. Slowly open oxygen bottle valve.

2. Set flow rate (e.g. 7 l/min) at adjuster knob

You can read the set value at the flow gage 8.

3. To release pressure in system:

– Close oxygen bottle valve

– Open shutoff valve after oxygen outlet

– Switch on connected appliance.

4. Needle of flow gage 8 now falls toward “0”.

Wait until needle stops moving. Now switch

appliance off.

9.

1

8

1 now falls toward

9

5. Check whether needle points exactly to “0”.

If not, fit replacement gage (see “6.5 Replacing gage” on page 27).

Final Check 13

Page 14

3.3.5 Checking for leaks with valve closed on pressure reducer FINE

You need a flow meter with a range of 0 – 50 ml/min.

Perform measurement at an inlet pressure of 200 bar.

1. Slowly open oxygen bottle valve.

Contents gage 1 now shows bottle pressure.

2. Check whether flow gage 8 shows a flow rate

of “0”.

If not, use adjuster knob 9 to set flow rate to

“0”.

3. Connect flow meter (0 - 50 ml/min) to oxygen

outlet 7.

4. Wait until flow meter shows constant reading.

5. Read off value.

If value is greater than 30 ml/min, fit replacement piston (see “6.7 Replacing piston in pressure reducer FINE (WM 30500, 30700,

30750)” on page 30).

3.3.6 Checking adjustable flow rate on pressure reducer FINE

You need a flow meter with a range of 0 – 20 l/min.

Perform measurement at an inlet pressure of 100 bar ± 10 bar.

1. Slowly open oxygen bottle valve.

Contents gage 1 now shows bottle pressure.

2. Turn adjuster knob 9 to the left as far as it will

go, until flow gage 8 shows a flow rate of “0”.

3. Connect flow meter to oxygen outlet 7.

4. Set any desired flow rate at adjuster knob 9.

Note: Checking the flow of the second oxygen outlet is described in a later section (3.3.8, page 15).

5. Check on flow meter whether actual value

agrees with set value.

Note tolerances of pressure reducer:

1 to 5 l/min: ± 0.5 liters,

6 to 15 l/min: ± 10 %.

6. If any value does not agree, have pressure reducer repaired by manufacturer

(WEINMANN).

3.3.7 Checking adjustable flow rate on pressure reducer FAST

You need a flow meter with a range of 0 – 20 l/min.

Perform measurement at an inlet pressure of 100 bar ± 10 bar.

1. Slowly open oxygen bottle valve.

Contents gage 1 now shows bottle pressure.

2. Set flow of “0” at index head 6.

3. Connect flow meter to oxygen outlet 7.

4. Set any desired flow rate at index head 6.

Note: Checking the flow of the second oxygen outlet is described in a later section (3.3.8, page 15).

5. Check on flow meter whether actual value

agrees with set value.

Note tolerances of pressure reducer:

1 to 5 l/min: ± 0.5 liters,

6 to 15 l/min: ± 10 %.

6. If any value does not agree, have pressure

reducer repaired by manufacturer

(WEINMANN).

14 Final Check

Page 15

3.3.8 Checking constant flow rate in pressure reducers FIX, FAST and

FAST II high Flow

You need a flow meter as follows:

• For WM 30050, 30100, 30150: flow meter 0 – 20 l/min

• For WM 30200, 30300, 30350, 30850, 31899: flow meter 0 – 220 l/min.

1. Connect flow meter to oxygen outlet.

2. Close

– on pressure reducers WM 30850 and

WM 31899: oxygen outlet for adjustable

flow,

– on pressure reducer WM 30200: second

oxygen outlet (on the side).

3. Slowly open oxygen bottle valve.

– Contents gage 1 now shows bottle pressure

– Flow meter shows flow rate.

4. Check flow rate reading against set value.

Pressure reducers must maintain the following

flow rates:

WM 30050, 30100: 4 l/min ± 0.5 l/min

WM 30150: 12 l/min ± 1.2 l/min

WM (30200), 30300,

30350: 120 l/min ± 15 l/min

WM 30850: 90 l/min ± 10 l/min

WM 31899: min. 160 l/min

5. In the event of discrepancies, have pressure reducer repaired by manufacturer

(WEINMANN).

6. There is a second oxygen outlet on pressure

reducer WM 30200. This is a free pressure

outlet.

3.3.9 Checking static outlet pressure p4 for all pressure reducers

1. Connect appropriate test gage to oxygen

outlet 7.

2. Check closing pressures p4 (see “10. Technical Data” on page 79). They are valid for a

delivery pressure of p

* = 100 bar or

1

200 bar and must be reached within 1 minute

at most. After this they must not show any further increase.

* 100 bar up to SN 0849999

200 bar from SN 0850000

3.4 Checking the adjustable output (flow) on the OXYWAY Click

You need a flow meter with a range of 0 – 20 l/min.

Perform the measurement at an inlet pressure of 4.5 bar ±0.2 bar.

1. Set the flow "0" at index head 6.

2. Plug the flowmeter into a suitable compressed

gas supply (e.g. a central gas supply system).

3. Connect the flow meter to the oxygen outlet.

4. Set any flow value at index head 6.

5. Check on the flow meter whether the set value

corresponds to the actual value.

Please observe the tolerances of the flowmeter in

the process.

Rising test:

1 to 5 l/min: ±0.5 liter,

6 to 15 l/min: ±10 %.

Falling test:

6 ±10 % and 0/min: ±0.15 l/min

Final Check 15

Page 16

4. Servicing

4.1 General

We recommend that all maintenance work, such

as inspections and repairs, be carried out by the

manufacturer (WEINMANN) or by expert technical personnel trained by WEINMANN.

When carrying our repairs, be sure to observe the

directions in these Service and Repair Instructions.

4.2 Intervals and scope for OXYWAY and OXYTRON pressure

reducers

In cases of dirt accumulation, or at least every 2 years:

1. Fit replacement filter screw 12 (see “6.3 Re-

placing filter screw” on page 21).

Every 4 years

1. Fit replacement filter screw 12 (see “6.3 Re-

placing filter screw” on page 21);

2. Completely replace piston 16.

– For pressure reducers WM 30050,

30100, 30200, 30300 and 30350:

see Section 6.6, page 28,

– For pressure reducers WM 30500,

30700, 30300 and 30750:

see Section 6.7, page 30,

– For pressure reducers WM 30600;

30800, 30850:

see Section 6.8, page 33;

2. Perform a functional check (see “6. Functional

Check“ on page 12 of the Operating Instructions”).

– For pressure reducers WM 31899;

30800, 30850:

see Section 6.9, page 36;

3. Fit replacement sinter filter 19 (see “6.12 Replacing Connector and Sinter Filter” on

page 50);

4. Fit replacement sealing ring 14 (see “6.2 Replacing sealing ring in connector” on

page 20)

5. Perform a final check (see “3. Final Check” on

page 11). If you find any faults, rectify them.

6. Replace service plate 13 with a new one with

the new data from “8. Replacement Parts” on

page 64.

4.3 Intervals and scope for OXYWAY Click flowmeter

Check metering accuracy by having a check measurement performed every 4 years.

We recommend that repair work be performed

only by the manufacturer, WEINMANN, or by

trained qualified experts expressly authorized by

WEINMANN.

16 Servicing

Page 17

4.4 Storage

If the pressure reducer is to remain unused for long periods, we recommend the following procedure:

1. Clean pressure reducer (see “Hygienic

preparation” in the Operating Instructions).

2. Store pressure reducer in a dry place.

4.5 Disposal

Do not dispose of the unit with domestic

waste. To dispose of the unit properly,

please contact a licensed, certified

electronic scrap disposal merchant. This

address is available from your Environment Officer or from your local authority.

Important:

Be sure to observe the servicing intervals for stored appliances as well. Otherwise the appliance is no longer

fit for use on removal from storage.

Servicing 17

Page 18

5. Troubleshooting

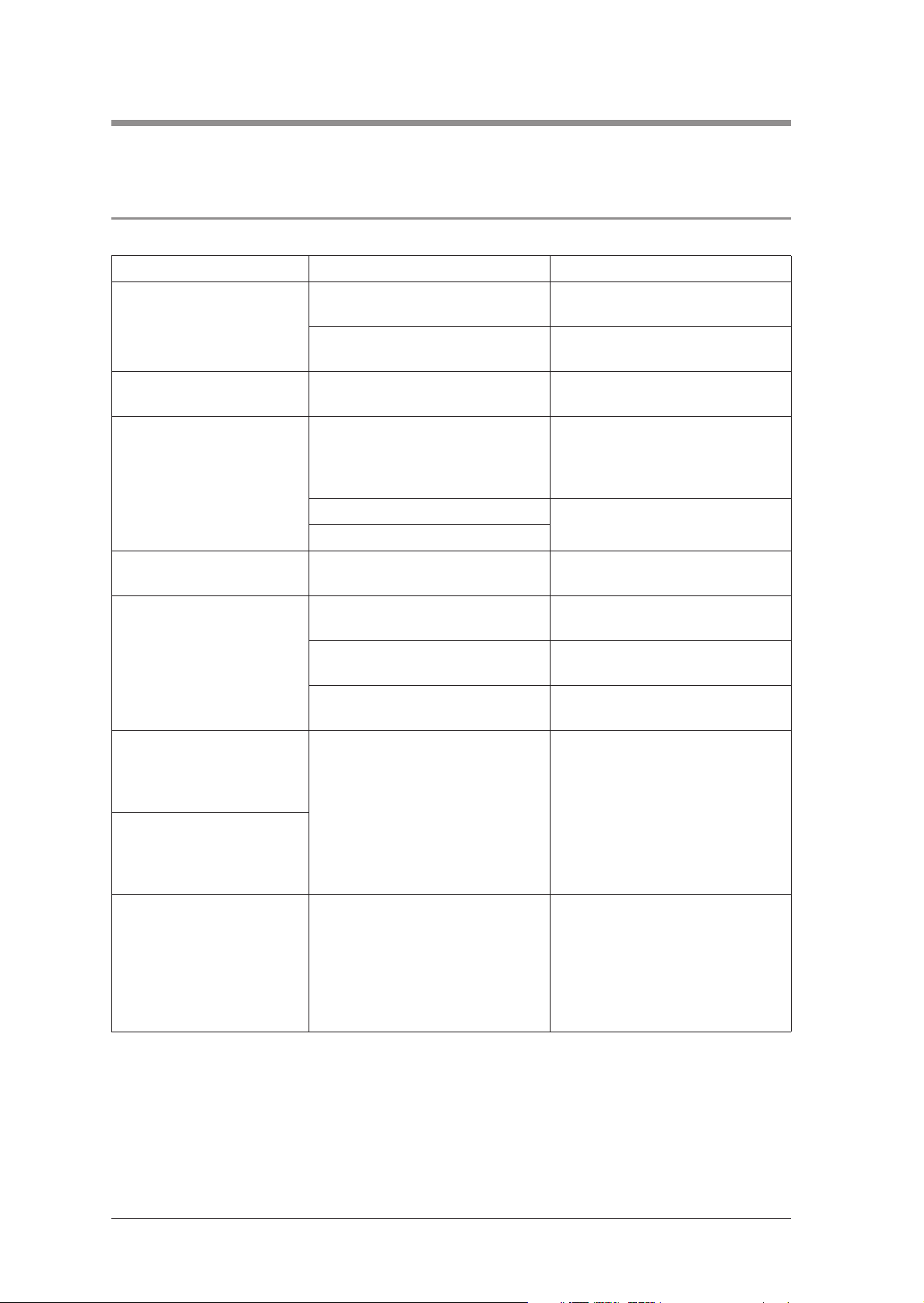

5.1 Pressure reducer OXYWAY and OXYTRON

Fault Cause Remedy

Replace sealing ring

(Section 6.2, page 20).

Replace connector

(Section 6.12, page 50).

Replace sealing ring

(Section 6.2, page 20).

Replace piston

(Section 6.6, page 28 or

Section 6.7, page 30 or

Section 6.8, page 33).

Have pressure reducer repaired by

manufacturer (WEINMANN).

Replace pressure gage

(Section 6.5, page 27).

Replace oxygen outlet

(Section 6.4, page 21)

Replace index disc (Section 6.9,

page 36)

Replace index disc (Section 6.9,

page 36)

Leak at connector

(bottle connection).

Leak at oxygen outlet

(appliance connection).

Leak at relief valve.

Pressure gage does not read

“0” at zero pressure.

Outlet flow rate too low.

Damaged sealing ring.

Damaged seat for connector sealing

ring.

Damaged sealing ring.

Unacceptable pressure rise in

pressure reducer (delayed rise

effect).

Relief valve not gas-tight.

Crater in body faulty.

Pressure gage faulty.

Oxygen outlet faulty.

Index disk faulty.

Index disk incorrectly adjusted.

Outlet flow rate of OXYTRON

WM 30150 outside

tolerance of

12 l/min ± 1.2 l/min

Outlet pressure of OXYTRON

WM 30150 outside

tolerance of

1.5 bar ± 0.08 bar

Variable pressure reducer:

leak at oxygen outlet 7

> 30 ml/min

(with valve closed and

200 bar bottle pressure).

Second stage faulty

Unacceptable pressure rise in

pressure reducer.

Replace complete piston

(Section 6.16, page 56)

Replace piston

(Section 6.6, page 28 or

Section 6.7, page 30 or

Section 6.8, page 33)

or

have pressure reducer repaired by

manufacturer (WEINMANN).

18 Troubleshooting

Page 19

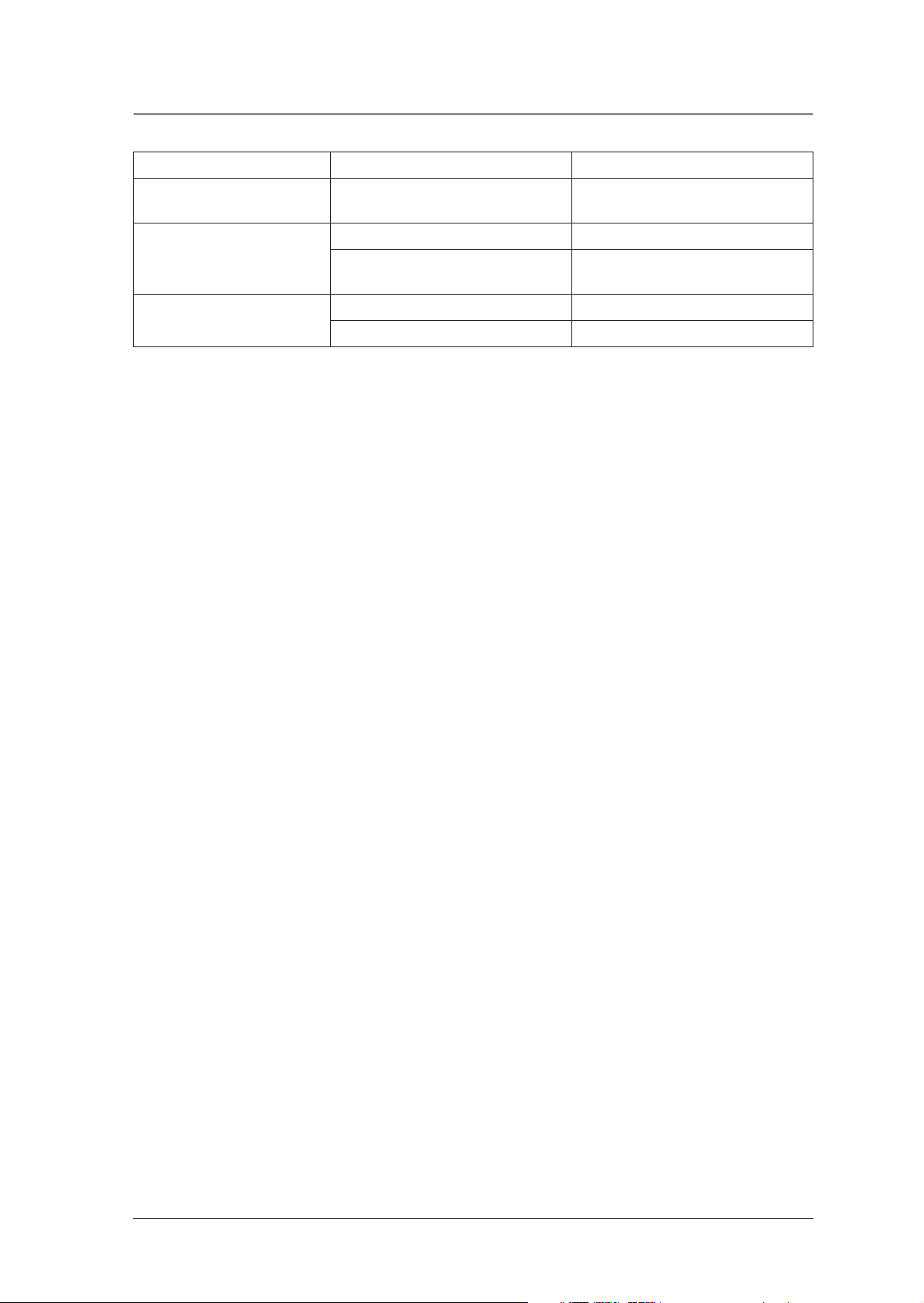

5.2 Flowmeter OXYWAY Click

Fault Cause Remedy

Unusually high oxygen

consumption

Inadequate O2 supply during

inhalation

Flowmeter not working

Leak in system Find and eliminate leak

Leak in system Find and eliminate leak

Defect or internal soiling in

flowmeter

Flowmeter defective Have flowmeter repaired

Oxygen source defective or empty Check oxygen source

Have flowmeter repaired

Troubleshooting 19

Page 20

6. Repair Information and Repair Instructions for

pressure reducer OXYWAY and OXYTRON

6.1 General

• Observe the safety information on page 4 of the

Operating Instructions for OXYWAY.

• Caution: Risk of explosion!

To prevent explosion risks, make sure your

hands, tools and workplace are absolutely

free from oil and grease during the repair

work.

For this reason you should always wash your

hands before starting work.

• Any operations on the appliance presuppose

detailed knowledge and observance of the

Operating Instructions and the Service and

Repair Instructions.

• You should only carry out repairs described in

these Service and Repair Instructions. Otherwise proper functioning of OXYWAY cannot

be guaranteed.

• Be sure to perform a final check after every

• If you replace components or individual parts,

• If there is a fault in the body or the relief valve,

• Certain parts must be screwed up using a

• Note:

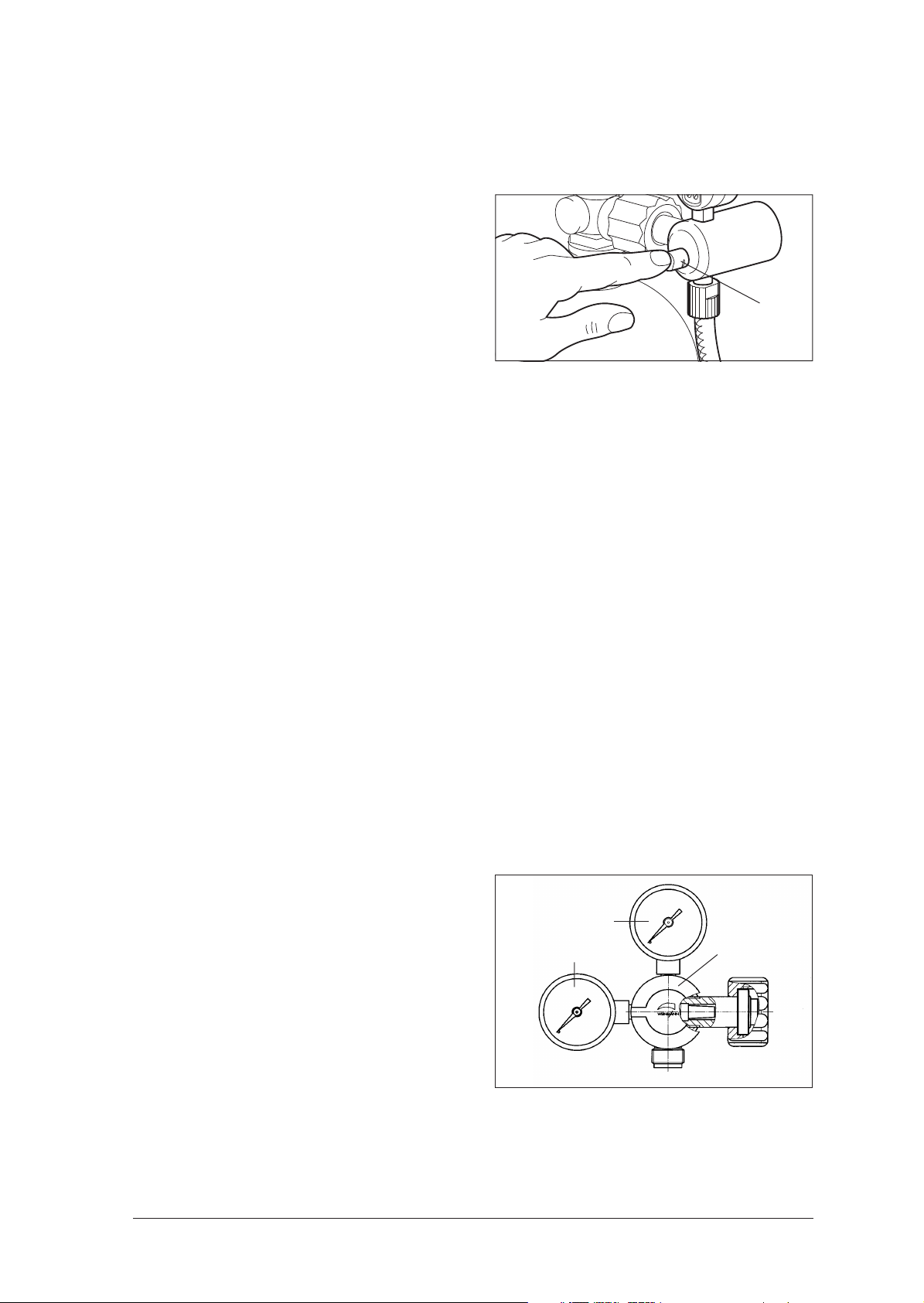

6.2 Replacing sealing ring in connector

repair (see “3. Final Check” on page 11).

always use genuine WEINMANN parts only.

have OXYWAY repaired by the manufacturer

(WEINMANN).

torque wrench. To ensure compliance with the

specified torque, check your torque wrench

regularly for torque compliance (control of inspection, measuring and test equipment).

The item numbers in the following text are the

same as the item numbers in the Replacement

Parts List on page 64 and the overview on

page 4.

Tools required:

• From tool set WM 15366:

– Watchmaker’s screwdriver WM 3004130041 (cleaned with methylated spirit).

1. Using a cleaned screwdriver, ease sealing

ring 14 carefully out of its groove.

Be careful not to damage the groove in any way.

2. If necessary, clean the groove with a dry cloth

or a cloth moistened with clean water.

3. Carefully press a new sealing ring into the

groove. Do not use any tools for this.

4. Perform a final check (see “3. Final Check” on

page 11).

14

20 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 21

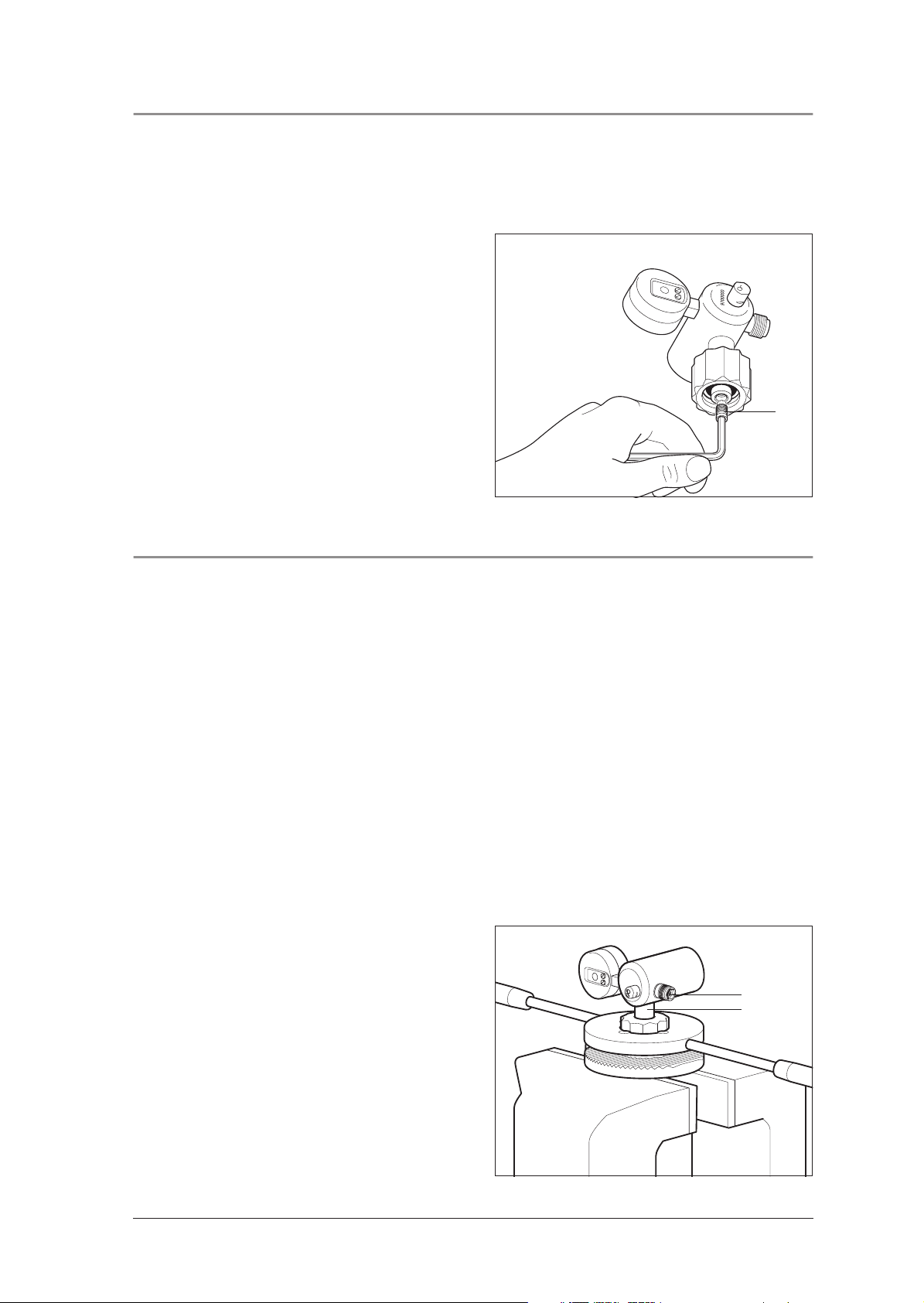

6.3 Replacing filter screw

Tools required:

• From tool set WM 15366:

– Allen wrench 4 mm WM 30042 (cleaned with methylated spirit).

1. If necessary, clean out the hexagonal socket of

the filter screw 12 with a small screwdriver.

2. Loosen the filter screw

12, but do not unscrew

it completely yet.

3. So that no dirt can fall into the pressure reducer,

hold it with the connector pointing down. In this

position, remove the filter screw

12.

4. Screw a new filter screw 12 into the connector

stub and tighten.

5. Perform a final check. Enter the change of filter

screw with date in the service record.

6.4 Replacing oxygen outlet

12

6.4.1 Replacing G 3/8 pressure outlet

Tools and material required:

• From tool set WM 15366:

– Counter tool with clamping handle WM 30035,

– Screwdriver bit 9 mm WM 30039 (cleaned with methylated spirit);

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit);

• Vise;

• Sealing ring

• Loctite 245 WM 14920 (never use other Loctite products).

• Torque wrench 25 Nm ± 1 Nm,

Note:

The oxygen outlet must always be replaced as a complete unit, because the flow rate cannot be guaranteed if

individual parts are replaced.

1. Clamp pressure reducer firmly in counter tool.

To do this, perform the following steps:

– Using a cleaned screwdriver, carefully ease

sealing ring 14 out of groove in connector.

Be careful not to damage the groove at all.

– Clamp bottom part of counter tool firmly in

a vise.

– Place the top part of the counter tool on the

bottom part of the counter tool.

– Screw the connection nut onto the bottom

part of the counter tool.

– Tighten the connection nut using the top part

of the counter tool.

14 (WM 1145);

7

2

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 21

Page 22

2. Using cleaned screwdriver bit, unscrew defective oxygen outlet 7 by turning to left.

3. Fit new oxygen outlet 7:

– Remove any adhesive residues from screw

threads. Use a brass wire brush for the external thread and if necessary a tap G 1/

8 for the internal thread.

Caution:

When cleaning threads, no dirt must enter

body of pressure reducer.

– Take a new oxygen outlet .

Caution:

The oxygen outlet must be clean and free

from oil and grease.

– Apply a little Loctite 245 to screw thread

with the exception of the first two turns.

The first two turns must be kept free of Loctite

to ensure that no Loctite enters the body of the

pressure reducer.

– Screw oxygen outlet 7 by hand into pres-

sure reducer.

– Tighten oxygen outlet 7 with 9 mm screw-

driver bit and a torque wrench

(25 Nm ± 1 Nm).

7

2

7

4. Release pressure reducer from counter tool.

5. If necessary, clean groove in connector

2 with

dry cloth or cloth moistened with clean water.

6. Now press

new sealing ring 14 carefully into

groove. Do not use any tools.

7. Perform a final check

(see “3. Final Check” on page 11).

6.4.2 Replacing UNF 9/16 flow outlet

Tools required:

• UNF 9/16 counter tool, consisting of:

– counter tool WM 14224

– locknut WM 14223

• special wrench SW 20/22, WM 22391

• counter tool WM 30035 (clamping handle not required)

• torque wrench with SW 22 open-end wrench insert.

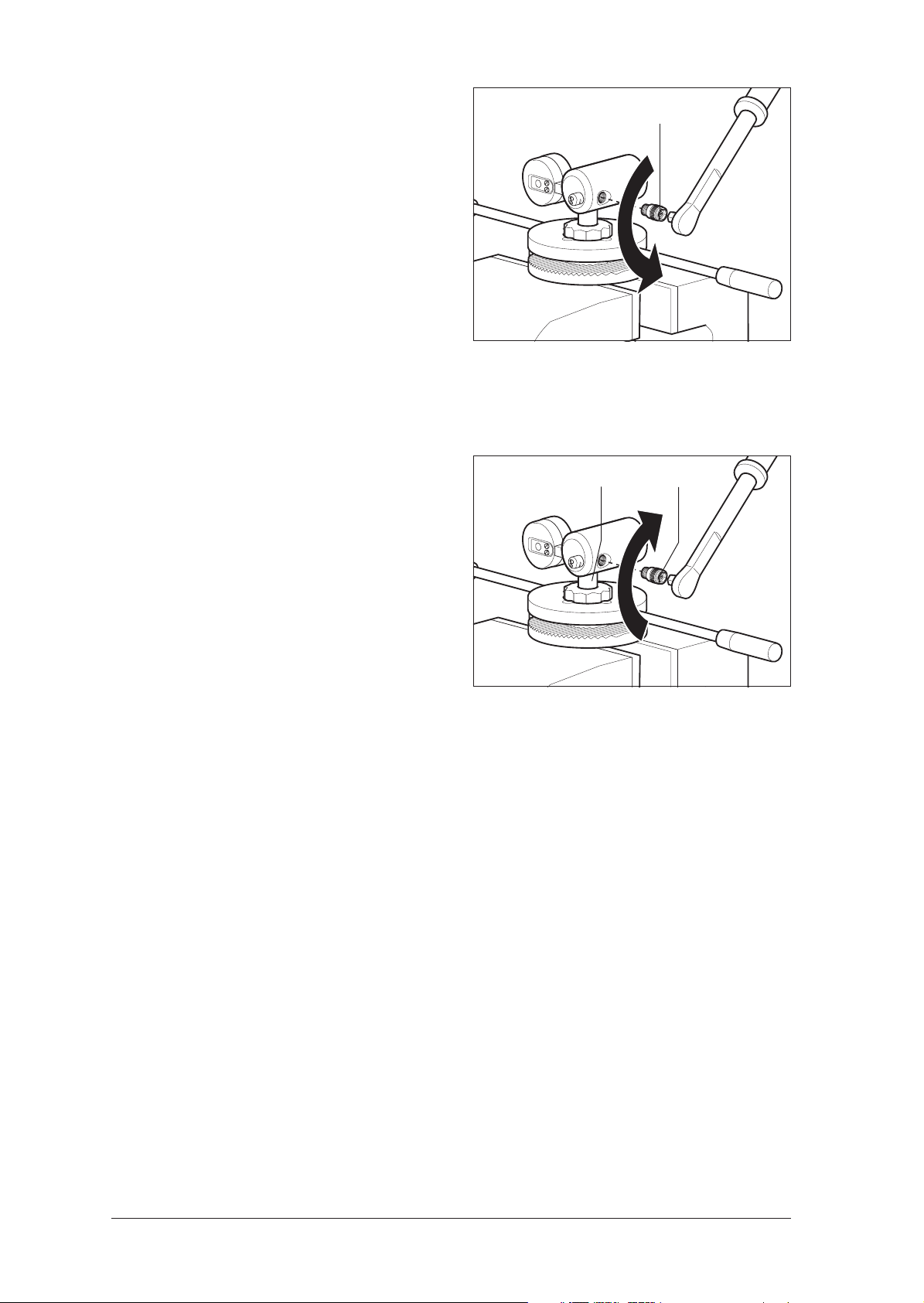

Remove defective flow outlet

1. Screw locknut WM 14223 onto counter tool

WM 14224.

22 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 23

2. Screw the UNF counter tool completely onto

the flow outlet of the pressure reducer.

3. Clamp the pressure reducer in a vise so that

only counter tool WM 14224 is actually in the

vise.

4. To clamp the defective flow outlet firmly in the

counter tool, turn locknut WM 14223 clockwise with a 22 mm open-end wrench.

5. To release the pressure reducer from the flow

outlet, turn the pressure reducer anticlockwise

by hand.

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 23

Page 24

6. Take the pressure reducer off the flow outlet.

7. To release the defective flow outlet in the

counter tool, turn locknut WM 14223 anticlockwise with the 22 mm open-end wrench.

8. Unscrew the defective flow outlet from the locknut.

Assembling new flow outlet

Caution:

When cleaning threads, no dirt must enter body

of pressure reducer.

1. Take a new oxygen outlet.

Caution:

The oxygen outlet

from oil and grease.

35 must be clean and free

2. Screw the new flow outlet fully into the counter

tool.

3. Wet about 2 threads of the new flow outlet

with Loctite 245 (WM 14920).

The first two turns must be kept free of Loctite to

ensure that no Loctite enters the body of the pressure reducer.

4. Clamp the counter tool in a vise so that only

counter tool WM 14224 is actually in the

vise.

5. To clamp the new flow outlet firmly in the

counter tool, turn the counter tool clockwise

with the 22 mm open-end wrench.

35

24 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 25

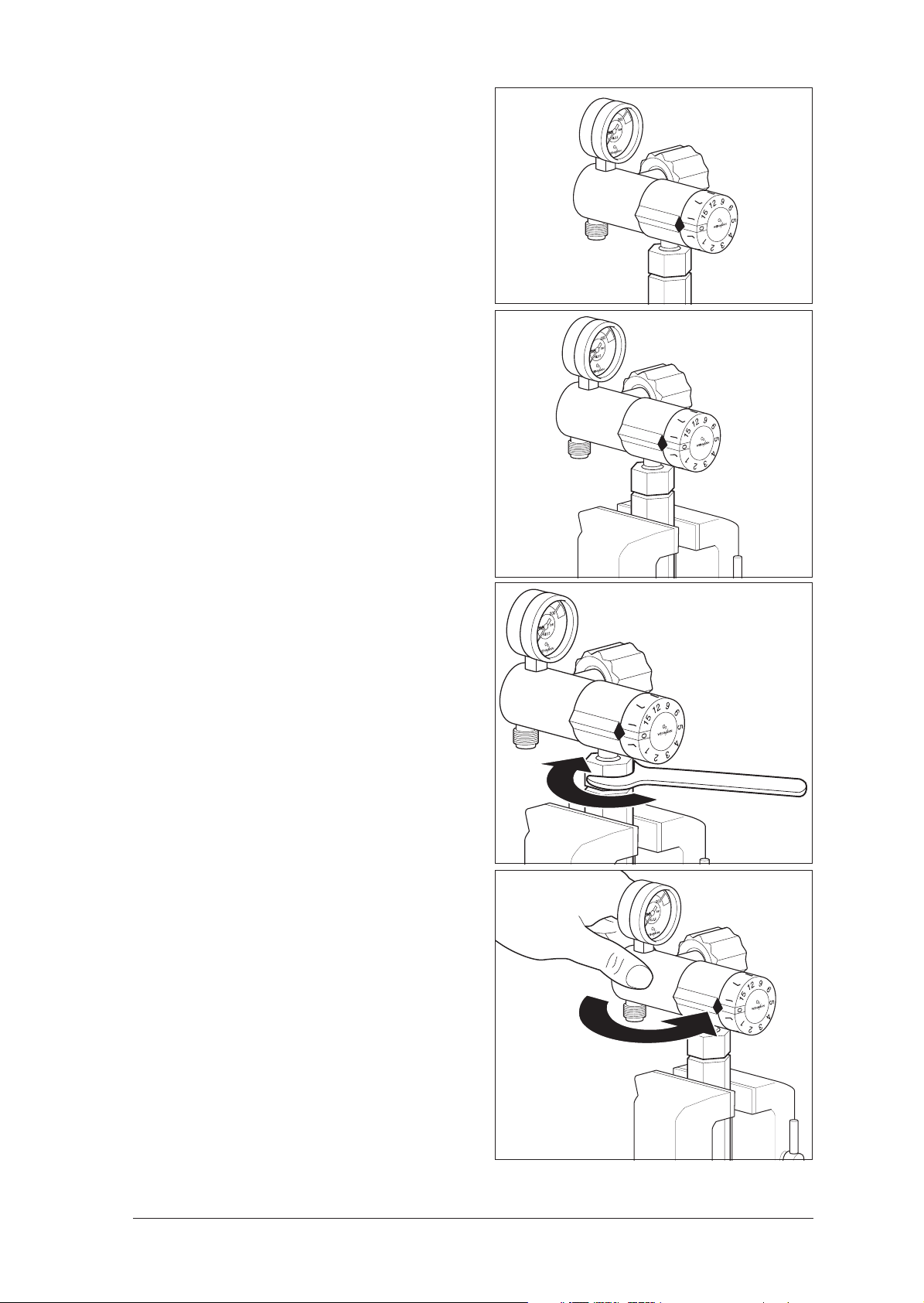

6. Screw the pressure reducer onto the new flow

outlet hand-tight.

7. Take the pressure reducer with the counter tool

screwed onto it out of the vise.

8. Clamp counter tool WM 30035 in the vise.

9. Screw the pressure reducer and oxygen inlet

hand-tight to clamped counter tool WM

30035.

10. Put a torque wrench with open-end wrench insert SW 22 on counter tool WM 14224.

11. Tighten counter tool WM 14224 and thus the

new flow outlet on the pressure reducer

(torque: 25 Nm ±1 Nm).

12. Release the pressure reducer from counter tool

WM 30035.

13. Take counter tool WM 30035 out of the vise.

14. Clamp the pressure reducer in the vise so that

only counter tool WM 14224 is actually in the

vise.

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 25

Page 26

15. To release locknut WM 14223 from the flow

outlet, turn it anticlockwise with the 22 mm

open-end wrench.

16. Unscrew the pressure reducer and flow outlet

from locknut WM 14223.

17. Take the counter tool out of the vise.

18. Perform a final check

(see “3. Final Check” on page 11).

26 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 27

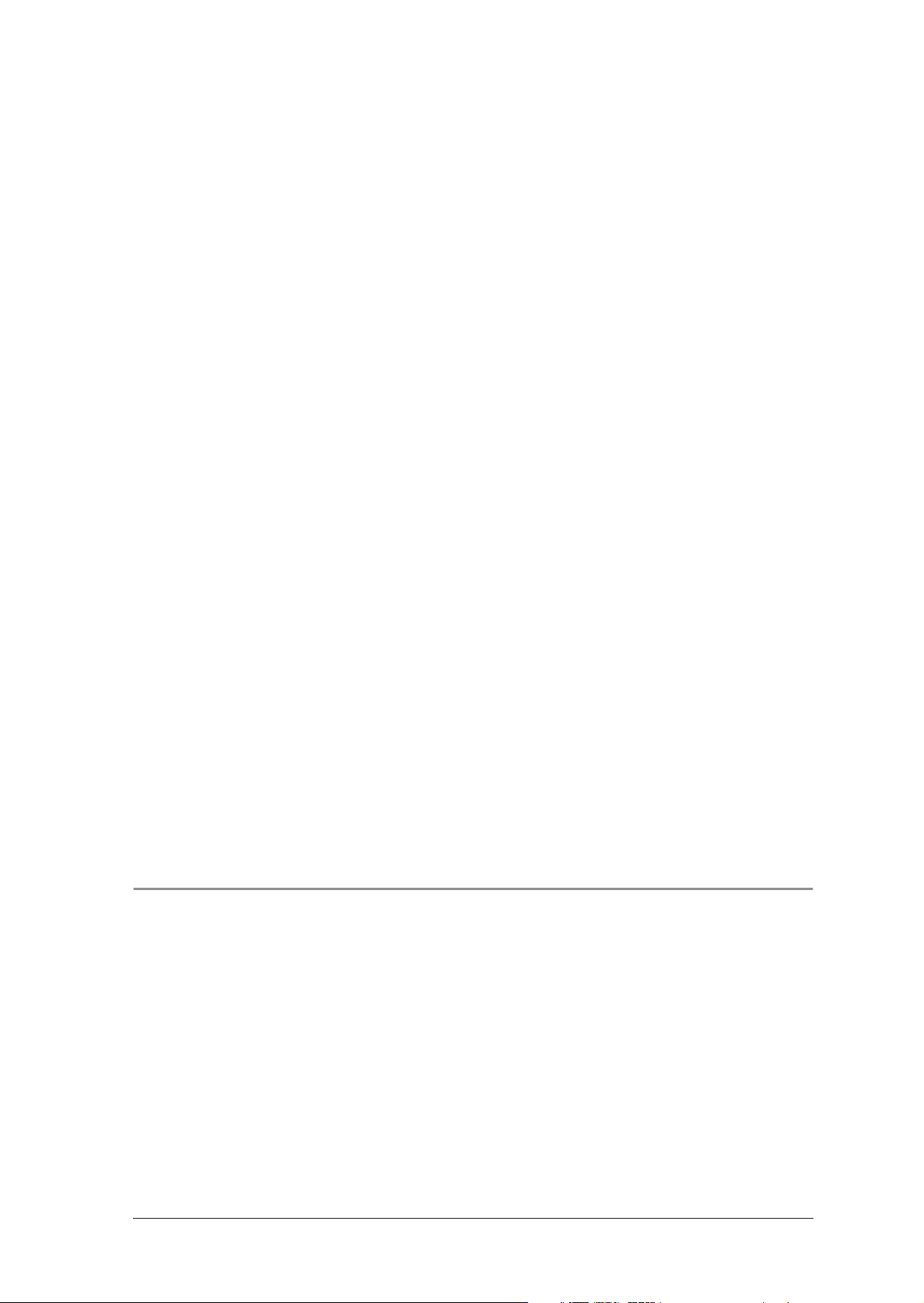

6.5 Replacing gage

Tools and material required:

• From tool set WM 15366:

– Counter tool with clamping handle WM 30035,

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit);

• Vise;

• Sealing ring 14 (WM 1145);

• Packing washer 0.5 mm 17 (WM 1145/35);

• Packing washer 0.8 mm

• Torque wrench 23 Nm – 1 Nm,

• Torque wrench 28 Nm + 2 Nm,

• Open-end wrench SW 12 or SW 14;

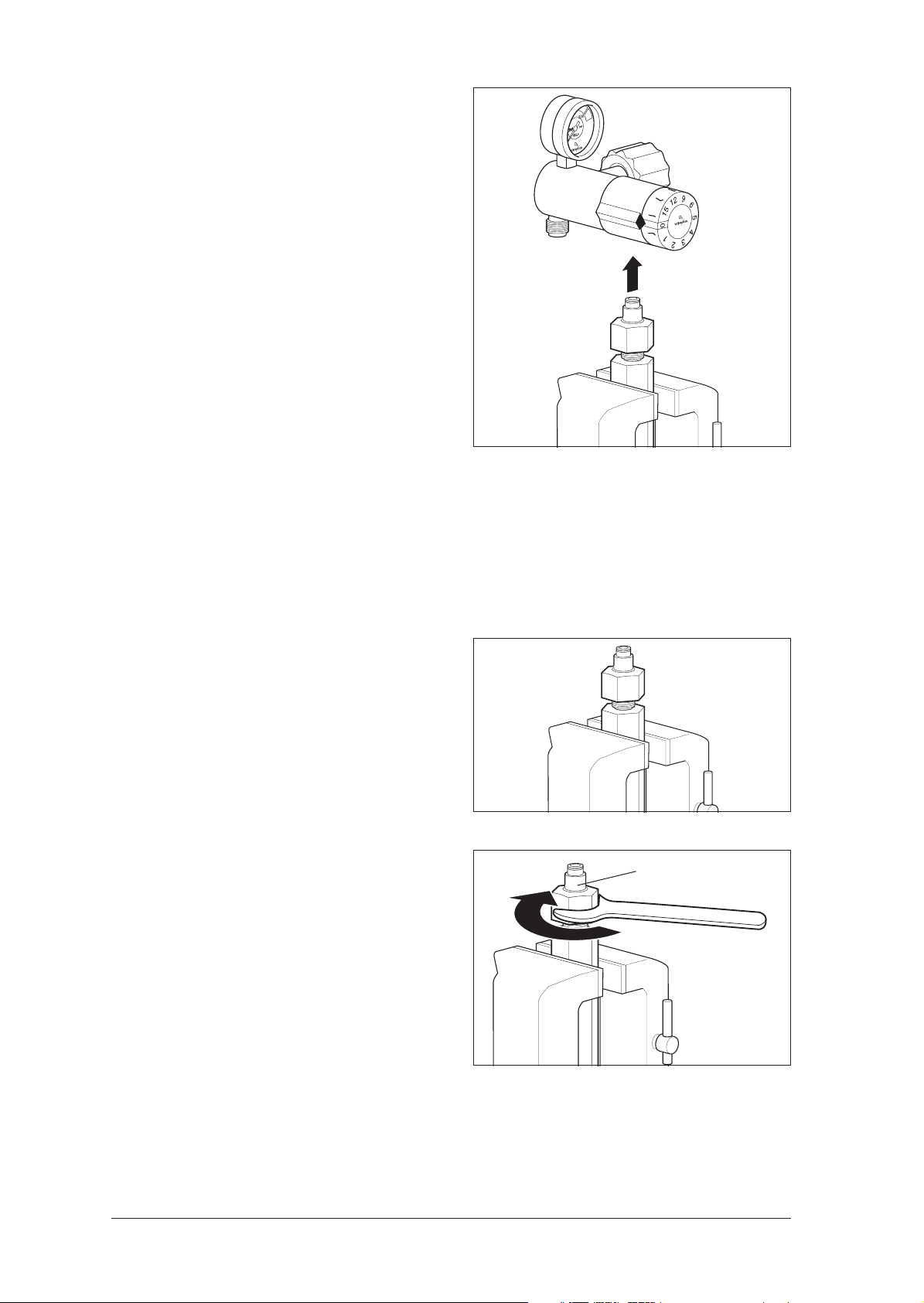

1. Clamp pressure reducer firmly in counter tool.

To do this, perform the following steps:

– Using a

cleaned screwdriver, carefully ease

sealing ring 14 out of groove in connector.

Be careful not to damage the groove at all.

– Clamp bottom part of counter tool firmly in

a vise.

– Place the top part of the counter tool on the

bottom part of the counter tool.

– Screw the connection nut onto the bottom

part of the counter tool.

– Tighten the connection nut using the top part

of the counter tool.

18 (WM 1145/36).

2

2. Loosen defective gage 1 or 8 with an openend wrench, then unscrew it by hand.

3. Carefully remove two packing washers 17 and

18 from threaded hole.

Take care not to damage sealing surface in body

of pressure reducer.

Ensure when taking out the packing washers

that no particles of dirt get into the bore of the

inside of the pressure reducer housing.

To guarantee the function of the pressure reducer, we recommend checking the inside of

the pressure reducer housing for any contamination before the final check. To do so, proceed in accordance with the relevant section

“Replacing piston on pressure reducer” (without changing the piston).

If you cannot remove the packing washers, do

not insert an additional packing washer

, but

send the pressure reducer to WEINMANN for

repair.

1 or 81718

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 27

Page 28

4. Of the two new packing washers, first insert

only the thicker 0.8 mm packing washer 18 in

the threaded hole.

5. Place open-end wrench insert in torque

wrench (23 Nm – 1 Nm).

6. Screw gage into pressure reducer by hand, then

tighten firmly with torque wrench.

7. Check position of gage. If not correct,

– unscrew gage again,

– insert second packing washer 17 (0.5 or

0.8 mm) in threaded hole and

– tighten gage with torque wrench

(23 Nm – 1 Nm).

8. If position of gage in relation to body is still not

correct, turn gage to correct position using a

maximum torque of 28 Nm + 2 Nm.

9. Release pressure reducer from counter tool.

10. If necessary, clean groove in connector 2 with

dry cloth or cloth moistened with clean water.

17 (Do not use unless position of fitted gage is

incorrect. See step 7.)

11. Carefully press new sealing ring 14 into

groove. Do not use any tools.

12. Perform final check

(see “3. Final Check” on page 11).

6.6 Replacing piston in pressure reducer FIX

(WM 30050, 30100, 30200, 30300, 30350)

Tools and material required:

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device WM 30037,

– Counter crown WM 30038,

• Vise;

• Oxygen lubricant WM 14934.

• Torque wrench 8 Nm + 2 Nm,

• Open-end wrench insert SW 12;

1. Gently clamp cover clamping device in a vise.

2. Insert pressure reducer in cover clamping de-

vice.

3. Now clamp cover clamping device firmly in

the vise. This presses the two halves of the

clamping device together and holds the

pressure reducer in position.

4. Place counter crown over body. “A” on

counter crown must point toward connector 2.

5. Now turn body to left to loosen it, but do not

remove it yet

.

2

Counter crown

28 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 29

6. Undo vise and remove pressure reducer.

7. Now carefully remove cover by hand.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

8. Remove spring 21.

9. Remove any adjustment washers inserted by

the factory. Be sure to note their positions.

10. Remove faulty piston 16 from cover.

11. Blow out body and cover with oxygen.

Caution!

Make sure the oxygen you use for blowing out is

directed away from you in order to prevent any

accumulation of oxygen in your clothing.

When reassembling as described below, make

sure that all parts are clean and free from oil and

grease

.

21 16Washer

Body Cover

12. Apply a little oxygen lubricant to O-rings of

new piston 16, then carefully insert piston in

cover.

Important!

Take care not to damage O-rings.

13. Place body 4 in cover fitting device.

14. If adjustment washers were fitted, place them

in body. Be sure to place them in the correct

positions.

15. Insert spring 21 in body.

16. Carefully place cover on spring.

17. Now use cover fitting device to press cover

down onto body.

18. Maintaining compression, screw cover onto

body by hand (two to three turns are sufficient).

19. Remove pressure reducer from cover fitting

device.

O-rings

16

Cover

Cover

21

4

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 29

Page 30

20. Tighten cover by hand.

21. Clamp pressure reducer in cover clamping

device.

22. Place counter crown over body 4. “A” on

counter crown must point toward connector 2.

23. Screw body firmly onto cover with a torque

wrench (8 Nm + 2 Nm).

24. Undo vise and remove pressure reducer.

25. Perform final check

(see “3. Final Check” on page 11).

2

6.7 Replacing piston in pressure reducer FINE

(WM 30500, 30700, 30750)

Tools and material required:

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device WM 30037,

– Counter crown WM 30038,

• Socket wrench 8 mm;

• Vise;

• Torque wrench 8 Nm + 2 Nm,

• Open-end wrench insert SW 12;

• Flat-bladed knife;

• Oxygen lubricant WM 14934.

Counter crown

1. Turn adjuster knob 9 to left until it meets the

stop.

2. Now remove cap 30 from adjuster knob by

sliding knife blade under cap and levering

cap off.

3. Hold adjuster knob tightly and unscrew nut 32

with a socket wrench.

4. Pull adjuster knob 9 off pressure reducer.

Take care not to lose driving plate 31 on inside of

adjuster knob.

309

32931

30 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 31

5. Gently clamp cover clamping device in a vise.

6. Insert pressure reducer in cover clamping device.

7. Now clamp cover clamping device firmly in

vise. This presses the two halves of the cover

clamping device together and holds the pressure reducer in position.

8. Place counter crown over body. “A” on

counter crown must face toward connector 2.

9. Turn body to left to loosen it, but do not unscrew

completely yet

.

10. Undo vise and remove pressure reducer.

11. Carefully unscrew cover by hand.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

12. Remove any adjustment washers inserted by

the factory. Be sure to note their positions.

13. Pull faulty piston 16 out of cover.

14. Remove small spring from piston.

15. Blow out body and cover with oxygen.

Caution!

Make sure the oxygen you use for blowing out is

directed away from you in order to prevent any

accumulation of oxygen in your clothing.

Counter crown

2

21 16WasherBody

Small spring

Cover

When reassembling as described below, make

sure that all parts are clean and free from oil and

grease

.

16. Put the small spring in the piston.

17. Push the piston carefully into the cover.

Important!

Take care not to damage the O-rings.

18. Place body 4 in cover fitting device.

19. If adjustment washers were fitted, place them

in body taking care to ensure correct

positions.

20. Insert spring 21 in body.

21. Carefully place cover on spring.

Small spring16Cover

O-rings

Washer

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 31

Page 32

22. Use cover fitting device to press cover down

onto body.

23. Maintaining compression, screw cover by

hand onto body (two to three turns is sufficient).

24. Remove pressure reducer from cover fitting

device.

25. Tighten cover by hand.

26. Clamp pressure reducer in cover clamping

device.

27. Place counter crown over body 4. “A” on

counter crown must face connector 2.

28. Screw body firmly to cover using a torque

wrench (8 Nm + 2 Nm).

29. Undo vise and remove pressure reducer.

Cover

21

4

Counter crown

2

30. Push driver plate

31 onto square part of

spindle 28.

31. Now push adjuster knob onto spindle

9 so that

driver plate 31 engages in recess in adjuster

knob.

32. Screw adjuster knob on firmly with new nut 32.

33. Push cap 30 onto adjuster knob.

34. Perform final check

(see “3. Final Check” on page 11).

32931

30

28

32 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 33

6.8 Replacing piston in pressure reducer FAST

(WM 30600, 30800, 30850)

Tools and material required:

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device WM 30037,

– Counter crown WM 30038,

– Screwdriver 3 mm WM 30043.;

– Screwdriver bit 9 mm WM 30039 (cleaned with methylated spirit),

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit),

• Vise;

• Torque wrench 8 Nm + 2 Nm,

• Open-end wrench insert SW 12;

• Flat-bladed knife;

• Oxygen lubricant WM 14934;

• plus for repairing pressure reducer WM 30850:

– Counter tool with clamping handle WM 30035 from tool set WM 15366,

• Torque wrench 25 Nm ± 1 Nm,

• Thread tap G 1/8,

• Brass wire brush,

• Sealing ring 14 (WM 1145);

• Loctite 245 WM 14920 (Never use a different Loctite product).

1. Turn index head 6 to position “0”.

2. Remove cap 51 from index head by sliding

knife blade under cap and levering off.

3. Hold index head tightly and unscrew the two

countersunk screws 52.

Take care not to change position of index head.

Otherwise you cannot be sure that the actual

flow values after reassembly will agree with

those shown on the index head.

4. Lever off loose part of index head 6.

5. Pull long part 50 of index head off body.

rear

oxygen

outlet

front

oxygen outlet

index head

front

oxygen

outlet

516

52650

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 33

Page 34

6. Gently clamp cover clamping device in a vise.

7. Slide the pressure reducer into the cover

clamping device so that the front oxygen outlet

fits into the opening of the cover clamping

device.

Please note!

Slide the pressure reducer into the cover clamping device until you clamp on to the cover only.

8. Now clamp cover clamping device firmly in

vise. This presses two halves of clamping

device together and holds pressure reducer in

position.

9. Place counter crown over body. “A” on

counter crown must face connector 2.

10. Now turn body to left to loosen it, but do not

completely unscrew it yet

.

11. Undo vise and remove pressure reducer.

12. Carefully unscrew cover by hand.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

13. Remove spring 21 and any adjustment washers from body. Be sure to note their positions.

14. Pull faulty piston 16 out of cover.

15. Blow out body and cover with oxygen.

Counter crown

2

21 16

Cover

Body

Caution!

When blowing out with oxygen, take care that

the oxygen is directed away from you to prevent

any accumulation of oxygen in your clothing.

Cover assembly should not be loosened (dismantled) any farther, as this would cause changes in

the relevant flow rates and the alignment of the

two oxygen outlets in relation to each other.

When reassembling as described below, make

sure all parts are clean and free from oil and grease.

16. Carefully insert piston in cover.

Important!

Take care not to damage O-rings.

O-rings

16

Cover

Index heac

Cover

Front

oxygen outlet

index head

34 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 35

17. Place body in cover fitting device.

18. If adjustment washers were fitted, place them

in body taking care to ensure correct positions.

19. Insert spring 21 in cover.

20. Carefully place cover onto body.

21. Use cover fitting device to press cover down

onto body.

22. Maintaining pressure, screw cover onto body

by hand (two to three turns are sufficient).

23. Remove pressure reducer from cover fitting

device.

24. Screw on cover hand tight.

25. Clamp pressure reducer in cover clamping

device.

26. Place counter crown over body. “A” on

counter crown must face connector 2.

27. Screw body firmly to cover using a torque

wrench (8 Nm + 2 Nm).

Caution!

The two oxygen outlets must be aligned.

Washer

Cover

21

4

Counter

crown

2

28. Undo vise and remove pressure reducer.

29. Push long part 50 of index head onto body.

30. Place index head 6 on pressure reducer.

Take care to fit it in correct position. Triangular

marker on long part of index head must then

point to “0”.

31. Screw on index head with two countersunk

screws 52.

32. Push cap 51 onto index head.

33. Perform final check

(see “3. Final Check” on page 11).

Front

oxygen outlet

Cover

Index head

52

51650

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 35

Page 36

6.9 Replacing piston in pressure reducer Fast II High Flow

(WM 31899)

Tools and material required:

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device WM 30037,

– Counter crown WM 30038,

– Screwdriver 3 mm WM 30043.;

– Screwdriver bit 9 mm WM 30039 (cleaned with methylated spirit),

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit),

• Vise;

• Torque wrench 8 Nm + 2 Nm,

• Open-end wrench insert SW 12;

• Flat-bladed knife;

• Oxygen lubricant WM 14934;

• plus for repairing pressure reducer WM 31899:

– Counter tool with clamping handle WM 30035 from tool set WM 15366,

• Torque wrench 25 Nm ± 1 Nm,

• Thread tap G 1/8,

• Brass wire brush,

• Sealing ring 14 (WM 1145);

• Loctite 245 WM 14920 (Never use a different Loctite product).

1. Turn index head 6 to position “0”.

2. Remove cap 51 from index head by sliding

knife blade under cap and levering off.

3. Hold index head tightly and unscrew the two

countersunk screws 52.

Take care not to change position of index head.

Otherwise you cannot be sure that the actual

flow values after reassembly will agree with

those shown on the index head.

4. Lever off loose part of index head 6.

5. Pull long part 50 of index head off body.

rear

oxygen

outlet

front

oxygen outlet

index head

front

oxygen

outlet

516

52650

36 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 37

6. Gently clamp cover clamping device in a vise.

7. Slide the pressure reducer into the cover

clamping device so that the front oxygen outlet

fits into the opening of the cover clamping device.

Please note!

Slide the pressure reducer into the cover clamping device until you clamp on to the cover only.

8. Now clamp cover clamping device firmly in

vise. This presses two halves of clamping

device together and holds pressure reducer in

position.

9. Place counter crown over body. “A” on

counter crown must face connector 2.

10. Now turn body to left to loosen it, but do not

completely unscrew it yet

.

11. Undo vise and remove pressure reducer.

12. Carefully unscrew cover by hand.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

13. Remove spring 21 and any adjustment washers from body. Be sure to note their positions.

14. Pull faulty piston 16 out of cover.

15. Blow out body and cover with oxygen.

Caution!

When blowing out with oxygen, take care that

the oxygen is directed away from you to prevent

any accumulation of oxygen in your clothing.

Caution!

Cover assembly should not be loosened (dismantled) any farther, as this would cause changes in

the relevant flow rates and the alignment of the

two oxygen outlets in relation to each other.

2

Body

Counter crown

21 16

Cover

When reassembling as described below, make

sure all parts are

clean and free from oil and grease.

16. Carefully insert piston in cover.

Important!

Take care not to damage O-rings.

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 37

O-rings

16

Cover

Index heac

Cover

Front

oxygen outlet

index head

Page 38

17. Place body in cover fitting device.

18. If adjustment washers were fitted, place them

in body taking care to ensure correct positions.

19. Insert spring 21 in body.

20. Carefully place cover on spring.

21. Use cover fitting device to press cover down

onto body.

22. Maintaining pressure, screw cover onto body

by hand (two to three turns are sufficient).

23. Remove pressure reducer from cover fitting

device.

24. Screw on cover hand tight.

25. Clamp pressure reducer in cover clamping

device.

26. Place counter crown over body. “A” on

counter crown must face connector 2.

27. Screw body firmly to cover using a torque

wrench (8 Nm + 2 Nm).

Washer

Cover

21

4

Counter

crown

2

28. Undo vise and remove pressure reducer.

29. Push long part 50 of index head onto body.

30. Place index head 6 on pressure reducer.

Take care to fit it in correct position. Triangular

marker on long part of index head must then

point to “0”.

31. Screw on index head with two countersunk

screws 52.

32. Push cap 51 onto index head.

33. Perform final check

(see “3. Final Check” on page 11).

front

oxygen outlet

index headcap

52650

38 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 39

6.10 Replacing index head / cover

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device, WM 30037,

– Counter crown WM 30038,

– Special pliers for WM 30046,

– Counter tool:

UNF (from WM 14223 and WM 14224),

G 3/8 WM 22827 (from 15348 or WM 15349),

– Fitting aid,

– Allen (internal hexagon) key, 2 mm,

– Screwdriver 3 mm WM 30043;

– Screwdriver bit 9 mm WM 30039 (cleaned with methylated spirit),

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit),

• Vise;

• Torque wrench 8 Nm + 2 Nm;

• Open-end wrench insert SW 12;

• Flat-bladed knife;

• Oxygen lubricant WM 14934;

• plus for repairing pressure reducer WM 30850:

– Counter tool with clamping handle WM 30035 from tool set WM 15366,

• Torque wrench 25 Nm ± 1 Nm,

• Thread tap G 1/8,

• Brass wire brush,

• Sealing ring 14 (WM 1145);

• Loctite 245 WM 14920 (Never use a different Loctite product).

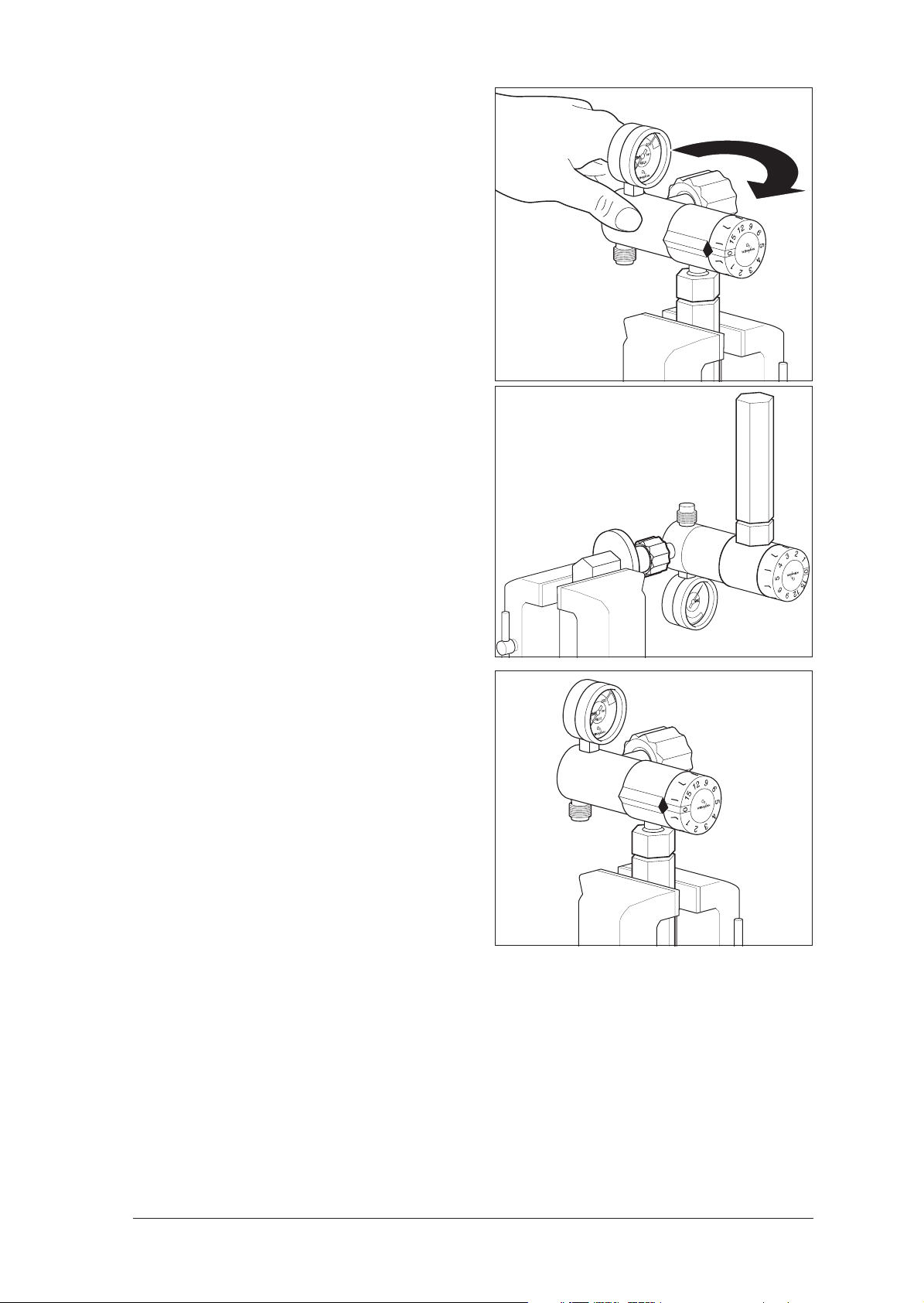

6.10.1 Dismantling adjuster knob

1. Set index head 6 to “0”.

2. Remove cap 51 from index head by sliding

knife blade under cap and levering off.

Rear

oxygen

outlet

Front

oxygen

outlet

516

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 39

Page 40

3. Hold index head firmly and unscrew the two

countersunk screws 52.

Take care not to change position of index head.

Otherwise you cannot be sure that the actual

flow values after reassembly will agree with

those shown on the index head.

Front

oxygen outlet

4. Lift off loose part of index head 6.

5. Pull long part 50 of index head off body.

6.10.2 Removing cover with index head from body

1. Gently clamp cover clamping device in a vise.

2. Insert pressure reducer in cover clamping

device so that front oxygen outlet fits into

opening in cover clamping device.

Caution!

Push pressure reducer into cover clamping device

only just far enough to clamp the cover itself.

3. Now clamp cover clamping device firmly in

vise. This presses the two halves of the cover

clamping device together and holds the

pressure reducer in position.

4. Place counter crown over body. “A” on

counter crown must face towards connector 2.

5. Turn body to left to loosen it, but do not unscrew

completely yet

.

6. Open vise and remove pressure reducer.

7. Carefully unscrew cover from index head.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

8. Remove spring 21 and any adjustment

washers from body. Be sure to note their

positions.

A

2

Index head

21 16

52650

Counter crown

Front oxygen

outlet

Body

40 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Cover

22

Page 41

6.10.3 Removing index head from cover

Caution!

Under the index disk are balls and springs which

are under compression. Perform the following

steps carefully, otherwise the springs and balls

could fly out at you.

1. Loosen grub screw 45 of index disk 43.

2. Carefully remove index disc 43, slide ring 44,

springs 42 and balls 41 from index head.

3. Push the locator for the orifice disk completely

out of the index head.

4. Clamp the cover about 20 mm down in the

cover clamping device.

5. Screw the special counter tool onto the oxygen

outlet and use the special pliers to remove the

union nut of the index head from the cover.

45

44

42

37

Cover

clamping

device

WM 30047

Special pliers

WM 30046

45

43

41

22

43

22

Counter tool

6.10.4 Assembling index head and cover

1. Take a new index head or cover, as

necessary.

2. Screw cover hand tight onto body.

3. Clamp pressure reducer in cover clamping

device.

4. Place counter crown over body. “A” on

counter crown must face towards connector.

5. Screw body onto cover using a torque wrench

(8 Nm +2 Nm).

22

A

Counter

crown

2

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 41

Page 42

6.10.5 Aligning oxygen outlet

1. Screw the empty index head onto the bottom

part of the housing.

2. Schrauben Sie die Anschlussmutter auf das

Konterwerkzeug.

3. Befestigen Sie das Konterwerkzeug an dem

Sauerstoffausgang.

4. Use the rubber-jawed pliers to slacken the

screwed connection on the index head.

5. Now use the special counter tool to turn the oxygen outlet into its final position. It should now

no longer be possible to turn the index head.

6. Both oxygen outlets are in line.

7. Release the special counter tools.

8. Unscrew the connection nut from the counter

tool.

9. Clamp the pressure reducer in the cover

clamping device.

10. Clamp the counter crown over the housing.

The A on the counter crown must point towards

the connection bolt.

11. Now release the housing by turning it

anticlockwise.

Counter tool

A

2

Special pliers

WM 30046

37

22

Counter

crown

6.10.6 Inserting orifice disk and fitting index disk

1. Place orifice holder 38 complete with orifice

disk 39 and slide disk 40 onto fitting aid and

push cover with index head onto it as far as

possible.

2. Remove pre-assembled cover from fitting aid.

40

39

38

42 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Cover

clamping

device

Page 43

3. Align hole on inside of cover with hole in notch

pin.

4. Put the preassembled housing back on the

fitting aid. There must be no change in the

position of orifice holder in relation to cover.

hole on inside

of cover

hole in orifice disk

hole in notch pin

of orifice holder

5. Place slide disc 44 over projecting spindle of

orifice holder.

6. Insert springs 42 in corresponding holes and

place balls 41 on springs 42.

7. Place index disk 43 on balls 41 so that thread

of fixing screw is opposite oxygen outlet 35.

8. Use fitting aid to press index disk onto index

head. Secure index head with fixing screw.

9. Take assembled unit from fitting aid and check

position of holes in cover and notch pin.

44

45

37

36

43

41

42

35

22

40

39

38

6.10.7 Fitting index head with cover on body

1. Blow out body and cover with oxygen.

Caution!

When blowing out with oxygen, take care that

the oxygen is directed away from you to prevent

any accumulation of oxygen in your clothing.

When reassembling as described below, make

absolutely sure that all parts are clean and free from

oil and grease

2. Push the piston carefully into the cover.

Important

Take care not to damage O-rings.

3. Place body in cover fitting device.

4. If any adjustment washers were present, place

them in the body. Take care to fit in correct

position.

5. Insert spring

.

21 into cover.

O-rings

16

Cover

Index head

Cover

Front oxygen

outlet

Index head

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 43

Page 44

6. Carefully place cover onto body.

7. Now use cover fitting device to press cover

down onto body.

8. Maintaining the pressure, screw cover onto

body by hand (two to three turns is sufficient).

9. Remove pressure reducer from cover fitting

device.

10. Screw cover on firmly by hand.

11. Clamp pressure reducer in cover clamping

device.

12. Place counter crown over body. “A” on

counter crown must face towards connector 2.

13. Screw body onto cover using a torque wrench

(8 Nm + 2 Nm).

Caution!

The two oxygen outlets must be aligned.

14. Undo vise and remove pressure reducer.

Cover

21

4

Counter crown

2

6.10.8 Fitting adjuster knob

1. Push long part 50 of index head onto body.

2. Place index head

Take care to fit in correct position. Triangular

marker on long part of index head must then

point to “0”.

3. Screw on index head with two countersunk

screws 52.

4. Push cap

51 onto index head.

5. Perform final check.

(see “3. Final Check” on page 11).

6 on pressure reducer.

Front

oxygen outlet

Cover

Index head

52

51650

44 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

Page 45

6.11 Replacing index head/cover on Fast II High Flow pressure

reducer

• From tool set WM 15366:

– Cover clamping device WM 30036,

– Cover fitting device, WM 30037,

– Counter crown WM 30038,

– Special pliers for WM 30046,

– Counter tool UNF (from WM 14223 and WM 14224),

– Fitting aid,

– Allen (internal hexagon) key, 2 mm,

– Screwdriver 3 mm WM 30043;

– Screwdriver bit 9 mm WM 30039 (cleaned with methylated spirit),

– Watchmaker’s screwdriver WM 30041 (cleaned with methylated spirit),

• Vise;

• Torque wrench 8 Nm + 2 Nm;

• Open-end wrench insert SW 12;

• Flat-bladed knife;

• Oxygen lubricant WM 14934;

• plus for repairing pressure reducer WM 30850:

– Counter tool with clamping handle WM 30035 from tool set WM 15366,

• Torque wrench 25 Nm ± 1 Nm,

• Thread tap G 1/8,

• Brass wire brush,

• Sealing ring 14 (WM 1145);

• Loctite 245 WM 14920 (Never use a different Loctite product).

6.11.1 Dismantling adjuster knob

1. Set index head 6 to “0”.

2. Remove cap 51 from index head by sliding

knife blade under cap and levering off.

rear

oxygen

outlet

front

oxygen

outlet

516

Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON 45

Page 46

3. Hold index head firmly and unscrew the two

countersunk screws 52.

Take care not to change position of index head.

Otherwise you cannot be sure that the actual

flow values after reassembly will agree with

those shown on the index head.

front

oxygen outlet

4. Lift off loose part of index head 6.

5. Pull long part 50 of index head off body.

6.11.2 Removing cover with index head from body

1. Gently clamp cover clamping device in a vise.

2. Insert pressure reducer in cover clamping

device so that front oxygen outlet fits into

opening in cover clamping device.

Caution!

Push pressure reducer into cover clamping device

only just far enough to clamp the cover itself.

3. Now clamp cover clamping device firmly in

vise. This presses the two halves of the cover

clamping device together and holds the

pressure reducer in position.

4. Place counter crown over body 22. “A” on

counter crown must face towards connector 2.

5. Turn body 22 to left to loosen it, but do not

unscrew completely yet

.

6. Undo vise and remove pressure reducer.

7. Carefully unscrew cover from index head.

Caution!

The piston spring is under strong compression.

Cover and spring could fly out at you.

8. Remove spring 21 and any adjustment

washers from body. Be sure to note their

positions.

A

2

Body

52650

index headcap

Counter crown

22

21 16

Cover

6.11.3 Removing index head from cover

Caution!

Under the index disk are balls and springs which

are under compression. Perform the following

steps carefully, otherwise the springs and balls

could fly out at you.

46 Repair Information and Repair Instructions for pressure reducer OXYWAY and OXYTRON

45

44

42

37

43

41

22

Page 47

1. Loosen grub screw 45 of index disk 43.

2. Carefully remove index disc 43, slide ring 44,

springs 42 and balls 41 from index head.

3. Push orifice disk holder completely out of index

head.

4. Clamp cover about 20 mm deep in cover

clamping device.

Cover

clamping

device

WM 30047

45

43

22

5. Screw counter tool onto oxygen outlet and use

special pliers to remove union nut of index

Special pliers

WM 30046

head from cover.

6.11.4 Assembling and aligning index head and cover

1. Take a new index head or cover, as

necessary.

2. Screw cover hand tight onto body.

3. Clamp pressure reducer in cover clamping

device.

4. Place counter crown over body. “A” on

counter crown must face towards connector.

5. Screw body onto cover using a torque wrench

(8 Nm +2 Nm).

Special pliers

WM 30046

Counter tool UNF

37

22

Counter tool UNF

37

22

6. Place index head on cover so that oxygen

outlet is about 45 degrees before its end

position. Tighten union nut of index head by

hand.

7. Screw union nut of index head against cover

until you meet appreciable resistance.

8. Screw counter tool onto oxygen outlet.

9. Now use counter tool to turn oxygen outlet to

its end position. It should no longer be