Page 1

MEDUMAT Transport

Emergency ventilator

MEDUMAT Transport

with CO

MEDUMAT Transport

without CO

Description and Operating Instructions

measurement WM 28400

2

measurement WM 28300

2

Page 2

Contents

1. Overview . . . . . . . . . . . . . . . . . . . . . 4

2. Description . . . . . . . . . . . . . . . . . . .15

2.1 Intended use . . . . . . . . . . . . . . . . 15

2.2 Applications . . . . . . . . . . . . . . . . . 15

2.3 User qualification . . . . . . . . . . . . . 16

2.4 Function. . . . . . . . . . . . . . . . . . . . 16

3. Installation . . . . . . . . . . . . . . . . . . . 18

3.1 Connecting oxygen cylinder . . . . . 18

3.2 Hose system . . . . . . . . . . . . . . . . . 20

3.3 Accessories from other

manufacturers . . . . . . . . . . . . . . . 21

3.4 Permanent installation of the unit. 23

4. Safety information . . . . . . . . . . . . . 24

5. Operation . . . . . . . . . . . . . . . . . . . . 28

5.1 Controls . . . . . . . . . . . . . . . . . . . . 28

5.2 Switching the unit on/Self-test . . . 31

5.3 Navigating in menus. . . . . . . . . . . 33

5.4 Emergency modes . . . . . . . . . . . . 35

5.5 Selecting a ventilation mode. . . . . 36

5.6 Pressure-controlled ventilation

modes . . . . . . . . . . . . . . . . . . . . . 38

5.7 Volume-controlled ventilation

modes . . . . . . . . . . . . . . . . . . . . . 42

5.8 Other ventilation functions . . . . . . 46

5.9 Performing ventilation . . . . . . . . . 48

5.10 Monitoring ventilation . . . . . . . . . 49

5.11 Alarm signals . . . . . . . . . . . . . . . . 51

5.12 Ventilation with filters

(not supplied with the unit) . . . . . 52

5.13 Ending ventilation . . . . . . . . . . . . 52

5.14 Calculating the oxygen level/

operating time . . . . . . . . . . . . . . . 53

5.15 Alternative ventilation. . . . . . . . . . 55

5.16 Changing battery during use . . . . 55

5.17 Battery management . . . . . . . . . . 56

6. Configuring the unit . . . . . . . . . . . . 60

6.1 Automatic alarm limits . . . . . . . . . 60

6.2 Setting alarm limits. . . . . . . . . . . . 61

6.3 Setting the presentation of

ventilation values (only with units

with etCO

6.4 Setting advanced respiratory

parameters . . . . . . . . . . . . . . . . . 63

6.5 “Night colors“ display mode . . . . 66

6.6 Setting the display brightness

and the volume . . . . . . . . . . . . . . 67

6.7 Options . . . . . . . . . . . . . . . . . . . . 68

7. Hygienic preparation . . . . . . . . . . .70

7.1 MEDUMAT Transport . . . . . . . . . 70

7.2 Hose systems . . . . . . . . . . . . . . . . 70

7.3 Parts and accessories . . . . . . . . . . 71

7.4 Fittings . . . . . . . . . . . . . . . . . . . . 71

7.5 Cleaning, disinfection and

sterilization . . . . . . . . . . . . . . . . . 72

8. Function check . . . . . . . . . . . . . . . .74

8.1 Intervals. . . . . . . . . . . . . . . . . . . . 75

8.2 Checking the system for leaks . . . 75

8.3 Checking the patient valve

(only reusable hose system) . . . . . 77

8.4 Automatic function check . . . . . . 77

9. Troubleshooting . . . . . . . . . . . . . . .80

9.1 Troubleshooting . . . . . . . . . . . . . 80

9.2 Physiologic alarms . . . . . . . . . . . . 81

9.3 System alarms . . . . . . . . . . . . . . . 82

10. Maintenance . . . . . . . . . . . . . . . . . .85

10.1 MEDUMAT Transport . . . . . . . . . 85

10.2 Batteries . . . . . . . . . . . . . . . . . . . 86

10.3 Accessories . . . . . . . . . . . . . . . . . 86

10.4 Changing the suction filter . . . . . 87

10.5 Storage . . . . . . . . . . . . . . . . . . . . 88

10.6 Disposal. . . . . . . . . . . . . . . . . . . . 88

11. Product, accessories . . . . . . . . . . . .89

11.1 Standard scope of supply. . . . . . . 89

11.2 Accessories . . . . . . . . . . . . . . . . . 90

11.3 Replacement parts . . . . . . . . . . . . 93

12. Technical Data . . . . . . . . . . . . . . . .95

12.1 Specifications. . . . . . . . . . . . . . . . 95

12.2 Block diagram . . . . . . . . . . . . . . . 99

measurement) . . . . . . 62

2

2 Contents

Page 3

12.3 Separation distances . . . . . . . . . . . 99

12.4 O

consumption of the unit . . . . 100

2

12.5 Possible O2 concentration with

counterpressure . . . . . . . . . . . . . 100

12.6 Attainable tidal volume with

counterpressure . . . . . . . . . . . . . 101

13. Warranty . . . . . . . . . . . . . . . . . . . . 102

14. Declaration of Conformity . . . . . . 103

Contents 3

Page 4

1. Overview

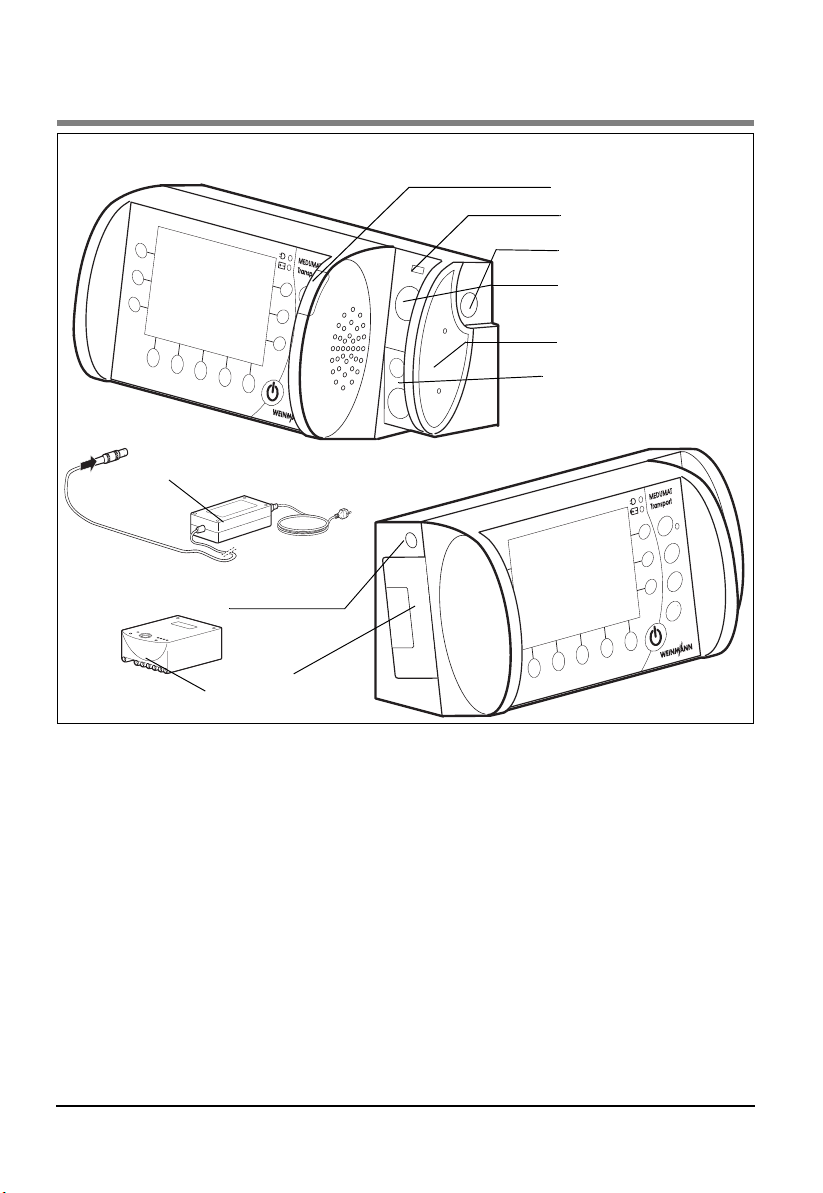

Connections on MEDUMAT Transport

9 External power supply unit

8 DC connection

1 Alarm display

2 USB interface

3 O

inlet

2

4 O2 inlet/outlet

5 Filter compartment

cover, air inlet

6 Ventilation connection

terminal

7 Rechargeable

battery

1 Alarm display

Glows to indicate alarms.

2 USB interface

Means of data transfer for servicing and

maintenance purposes.

3 O2 inlet

Connection point, e.g., for an oxygen cylinder.

4 O2 inlet/outlet

At this connection point, oxygen can be

extracted, e.g., using an inhalation device, or

an oxygen source can be connected.

5 Filter compartment cover, air inlet

Covers the filter and ensures it is securely

positioned.

4 Overview

6 Ventilation connection terminal

The tube system is connected here.

7 Rechargeable battery

Provides mobile power supply to the unit.

8 DC connection

For DC power supply via an external power supply

unit or via the electrical circuit of an ambulance or

rescue vehicle.

9 External power supply unit

Provides power supply to the unit via a 100V 240V grid.

Page 5

Controls of MEDUMAT Transport

11Function buttons for

emergency ventilation

10 Context-dependent control knobs

9 Navigation knob

1 Context-dependent

function button

2 Alarm mute button with

LED

3 Context-dependent

function button

4 Function button for

main menu

5 Context-dependent

function button

6 Function button for

100% O

2

7 Function button for

inspiratory O

concentration

8 On/Standby/Off

button

2

1, 3, 5 Context-dependent function button

These buttons are used to set various ventilation

parameters, depending on the ventilation mode

selected.

2 Alarm mute button with LED

With this button, acoustic alarms can be muted

briefly (for 2 minutes). If alarms are muted, the

LED lights up. Visual alarms are still displayed.

4 Function button for main menu

This button calls up the main menu.

6 Function button for 100% O

This button calls up the 100% O2 function to ventilate the patient briefly (2 minutes) with

100% O

(FiO2 = 1.0).

2

2

7 Function button for inspiratory O2

concentration

This button calls up the O2 concentration menu.

The required inspiratory O

respiratory gas can be set in this menu.

concentration in the

2

8 On/Standby/Off button

A short press switches the unit on and off. A long

press switches it off completely.

9 Navigation knob

For navigating in menus and confirming your settings on the unit. During ventilation, this knob is

to set the I:E ratio.

10 Context-dependent control knobs

For setting various parameters, depending on

which ventilation mode is active. Settings made

here must be confirmed with the Navigation

knob.

11 Function buttons for emergency

ventilation

These buttons start emergency ventilation. By

pressing the buttons, preset parameters for

infants, children or adults are activated.

Overview 5

Page 6

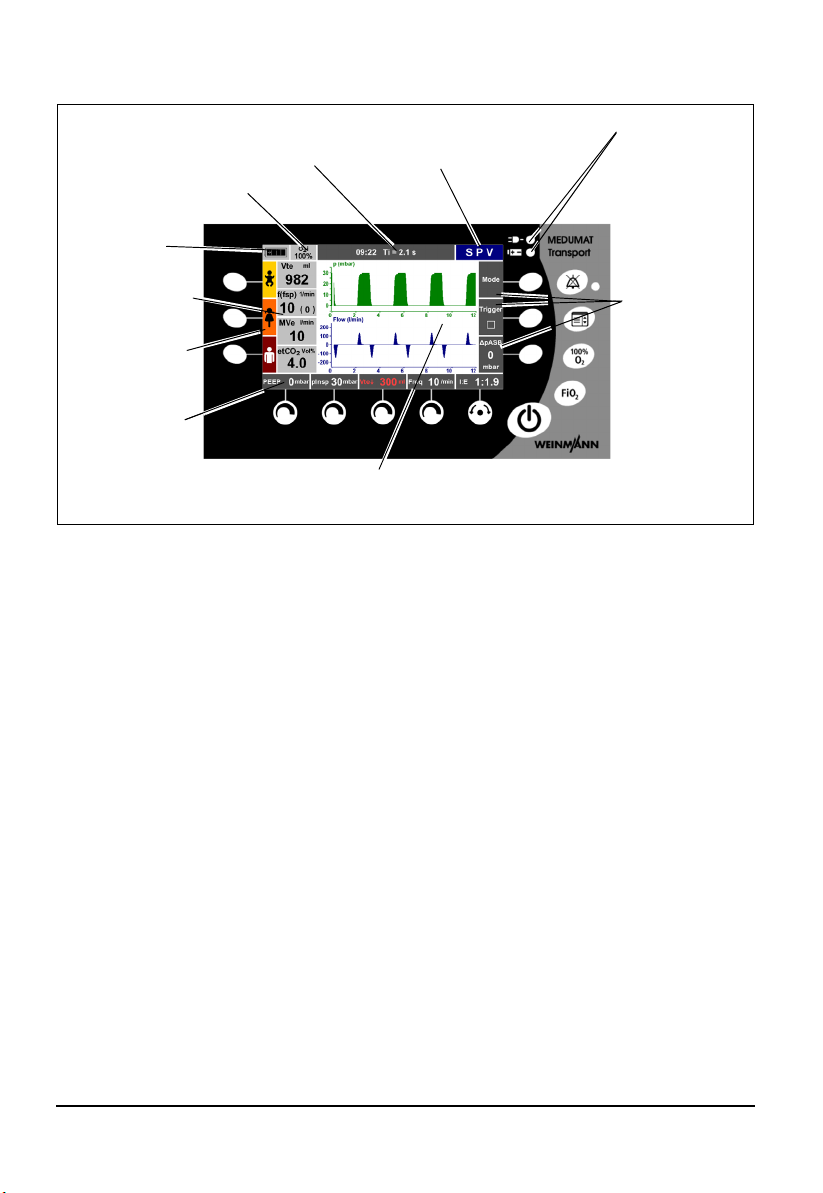

Display of MEDUMAT Transport

1 Battery/Line operation indicators

8 Indicator for inspiratory

O

concentration (FiO2)

2

7 Battery

charge

status

6 Numeric mea-

surement display

5 Function indica-

tor for contextdependent function buttons

4 Function indica-

tor for contextdependent control knobs

9 Info field

3 Ventilation progress display

1 Battery/Line operation indicators

Indicates whether the unit is being operated with

the external power supply unit (upper LED) or

with the internal battery (lower LED).

2 Function indicator for context-

dependent function buttons

The currently available function of the contextdependent function buttons is indicated here.

3 Ventilation progress display

Here, the ventilation progress is displayed in up to

three graphs (ventilation pressure, ventilation

flow, CO

tilator version. In the case of emergency

ventilation, a pressue gauge is displayed.

concentration), depending on the ven-

2

4 Function indicator for context-

dependent control knobs

The currently available function of the contextdependent control knobs is indicated here.

5 Function indicator for context-

dependent function buttons

The three directly selectable emergency ventilation modes (infant, child, adult) are indicated here.

6 Numeric measurement display

The current measurements are indicated

numerically here.

10Mode indicator

2 Function

indicator for

contextdependent

function

buttons

7 Battery charge status

The battery charge status is indicated here.

8 Indicator for inspiratory O2

concentration (FiO2)

The inspiratory O2 concentration (FiO2) is

indicated here.

9 Info field

Information (error messages, visual alarms) about

the state of the patient and the ventilator is displayed here. The time of day is also displayed in

this field.

10 Mode indicator

The ventilation mode set by the user is indicated

here.

6 Overview

Page 7

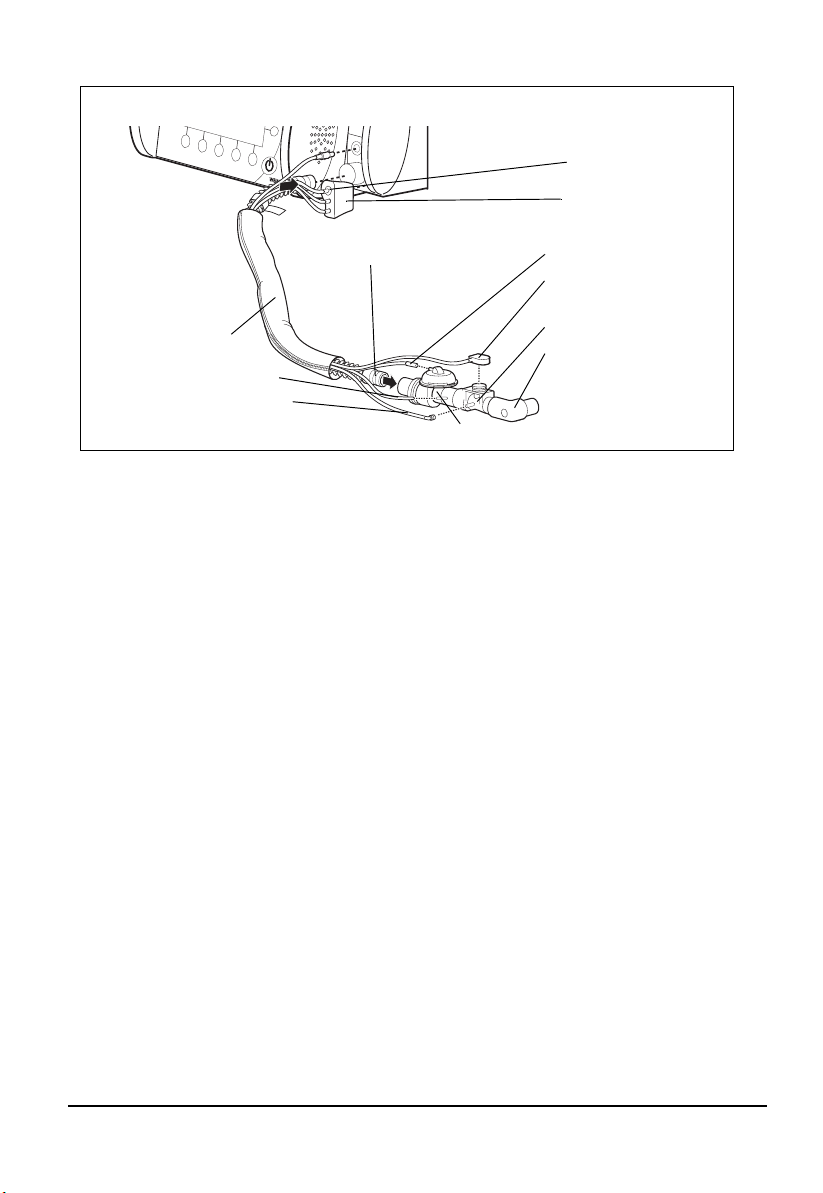

Hose system (reusable and disposable versions available)

2 Water filter for CO2

measurement

3 Connector

1 Ventilation hose

11Tube protec-

tion sleeve

10Pressure-

measurement tube

9 CO

removal tube

2

1 Ventilation hose

The respiratory gas flows through the respiration

tube to the patient valve.

2 Water filter for CO2 measurement

The water filter protects the measuring chamber

of the MEDUMAT Transport against moisture

from the patient's respiratory gas.

3 Connector

The measurement-tube system is connected to

MEDUMAT Transport by means of this connector.

4 PEEP control tube

With this tube, MEDUMAT Transport controls the

patient valve and the PEEP.

5 BiCheck flow sensor connection line

This electric lead transfers the measuring signals

from the BiCheck flow sensor to the MEDUMAT

Transport.

6 BiCheck flow sensor

This sensor supplies monitoring data on flow,

MV

, Vte and f.

e

4 PEEP control tube

5 BiCheck flow sensor

connection line

6 BiCheck flow sensor

7 Elbow

8 Patient valve

7 Elbow

The mask/tube is connected here. The elbow is removable, i.e., the mask/tube can also be connected to the BiCheck flow sensor itself,

depending on the position of the patient.

8 Patient valve

Switchover between inspiration and expiration

happens here.

9 CO2 removal tube

Test gas is removed via this tube if your unit is

equipped with the optional CO

facility.

measurement

2

10 Pressure- measurement tube

For patient-side measurement of ventilation

pressure.

11 Tube protection sleeve

Protects tubes and leads against soiling and

damage.

Note

Detailed information about the hose systems can be found in the “Patient Hose

System“ instruction manual WM 66696.

Overview 7

Page 8

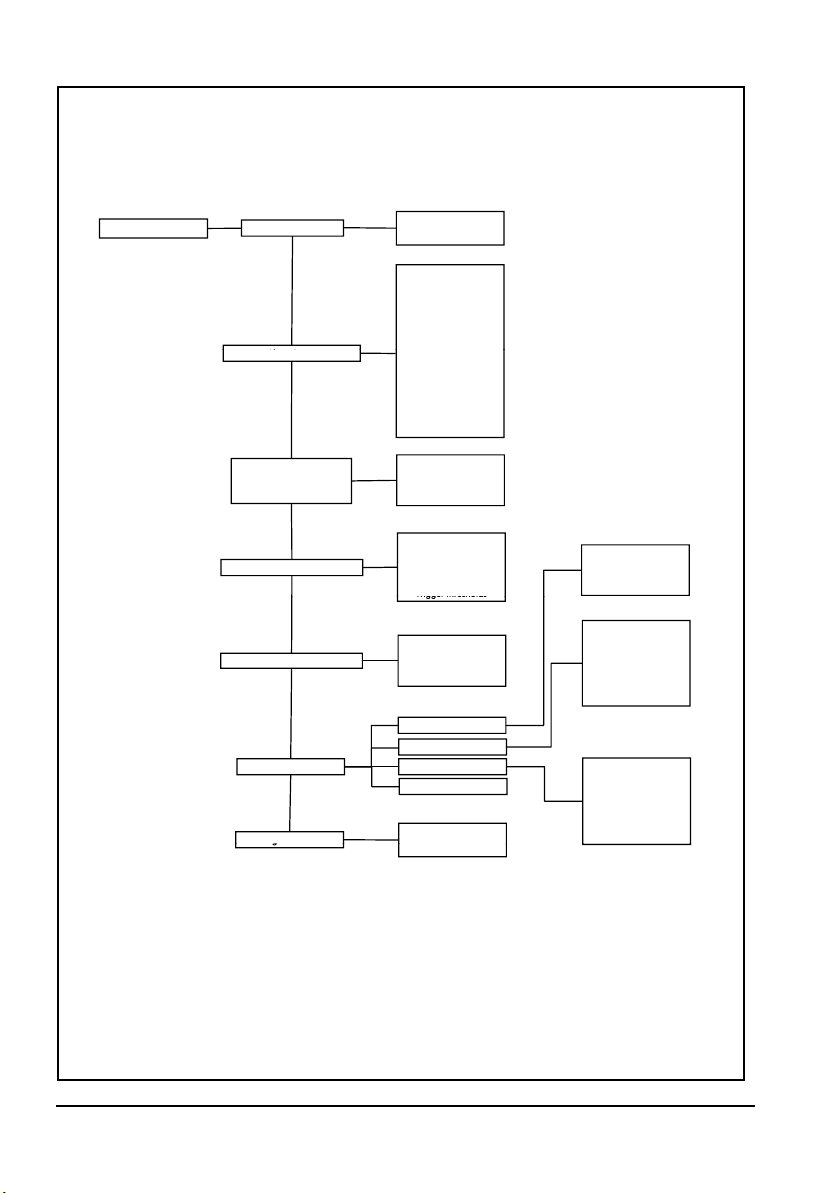

MEDUMAT Transport Main menu

no

Mai

n menu

Aut

omatic alarm limits

yes

Automatic alarm limits

Vte n

Vte p

MVe n

MVe p

Al

arm Limits

Curves

Pressure, flow

f n

Apnoea

etCO

2

n

etCO

2

p

CO

2

i n

(Only CO2measurement

option)

Pressure, CO

2

Pressure, flow, CO

2

Pressure ramp

Flow ramp

Flow progress

Tri

r thrhl

Advanced ventilation parameters

mmHg

Vol%

kPa

Audio/Video

Trigger thresholds

Brightness/Day

Brightness/Night

Volume

Year

Month

Day

Hour

Minute

Options

Night colours

activate

Deutsch

English

Español

Italiano

…

CO2configuration

Date, time

Language

Device data

g

deactivate

MEDUMAT Transport Main menu

8 Overview

Page 9

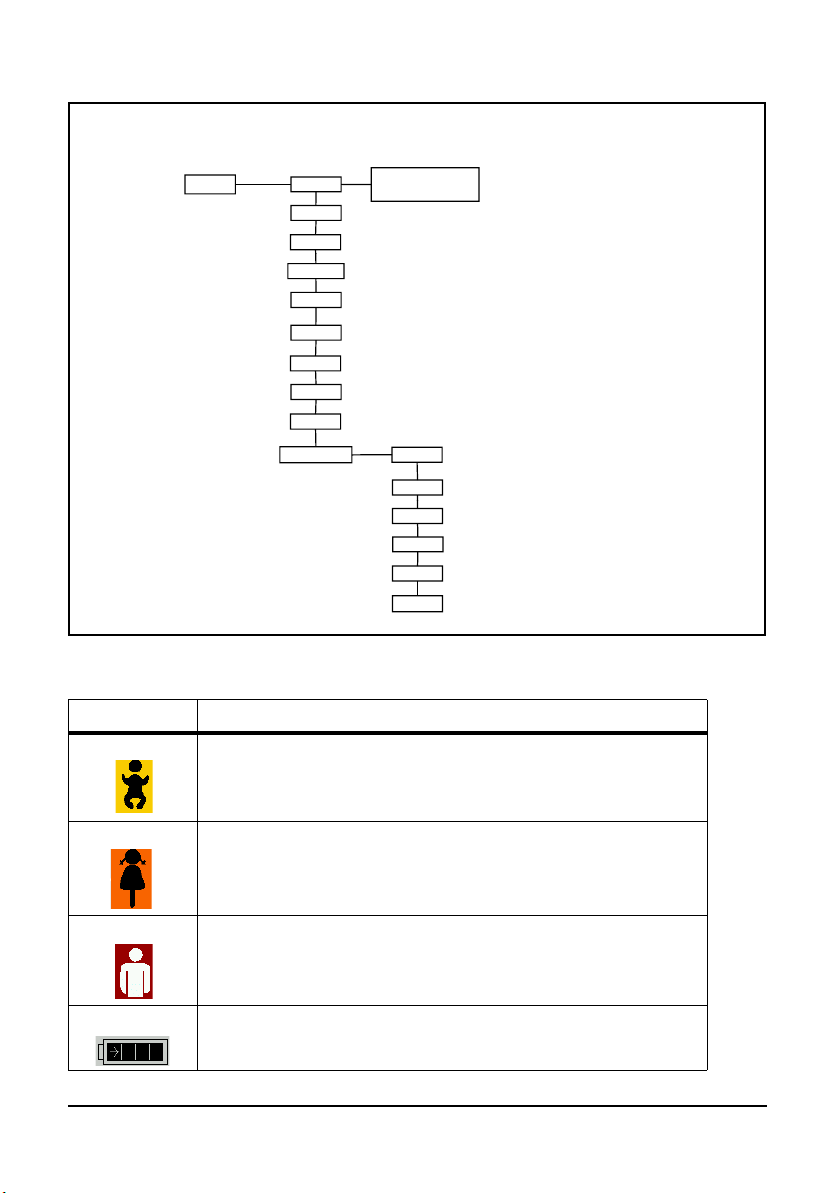

Mode menu

Mode

BILEVEL

NIV

PCV

activate

deactivate

IPPV

CPAP + ASB

SIMV

S-IPPV

20 l/min

25 l/min

SPV

Preoxygenation

SVV

15 l/min

5 l/min

10 l/min

Off

Symbols used on the display

Symbol Meaning

Emergency mode - Infant

Emergency mode - Child

Emergency mode - Adult

Battery status indicator

Overview 9

Page 10

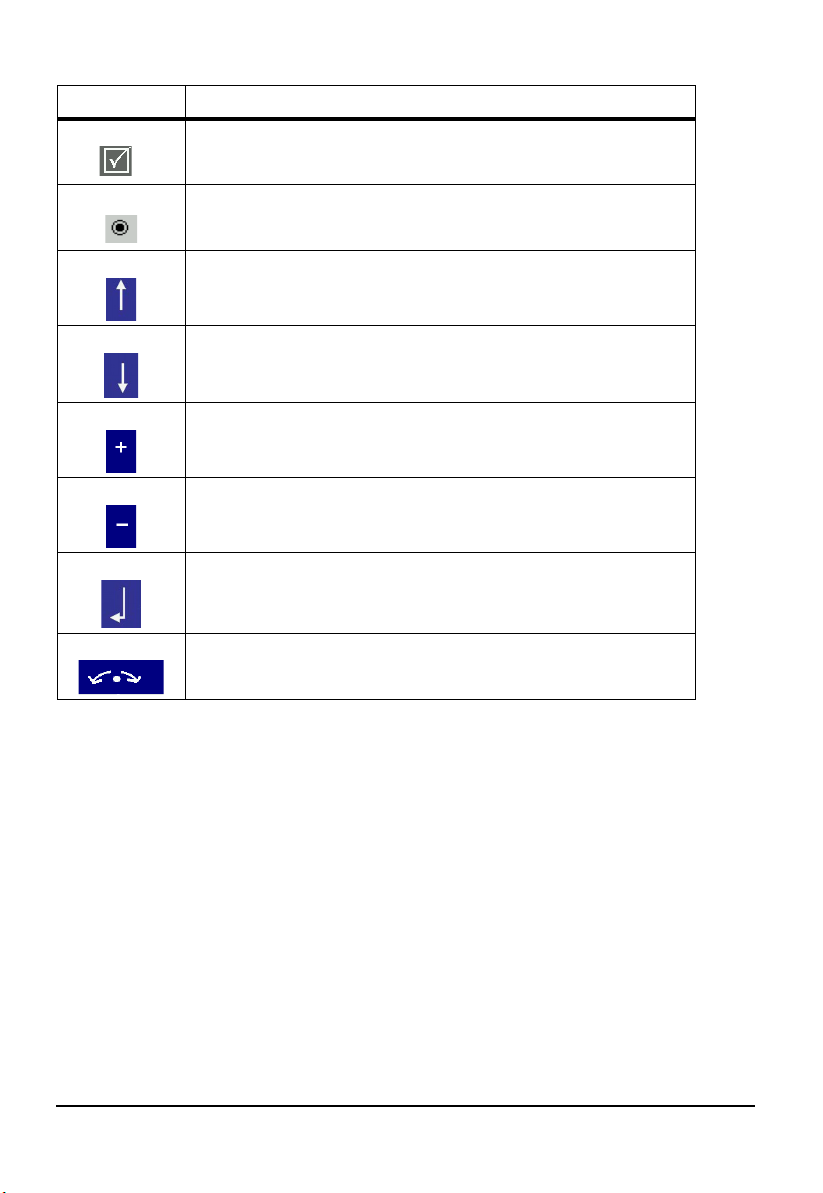

Symbol Meaning

Tick box: option activated

Radio button: function selected

Navigate upwards

Navigate downwards

Increase value

Decrease value

Confirm your selection

Navigation knob active

10 Overview

Page 11

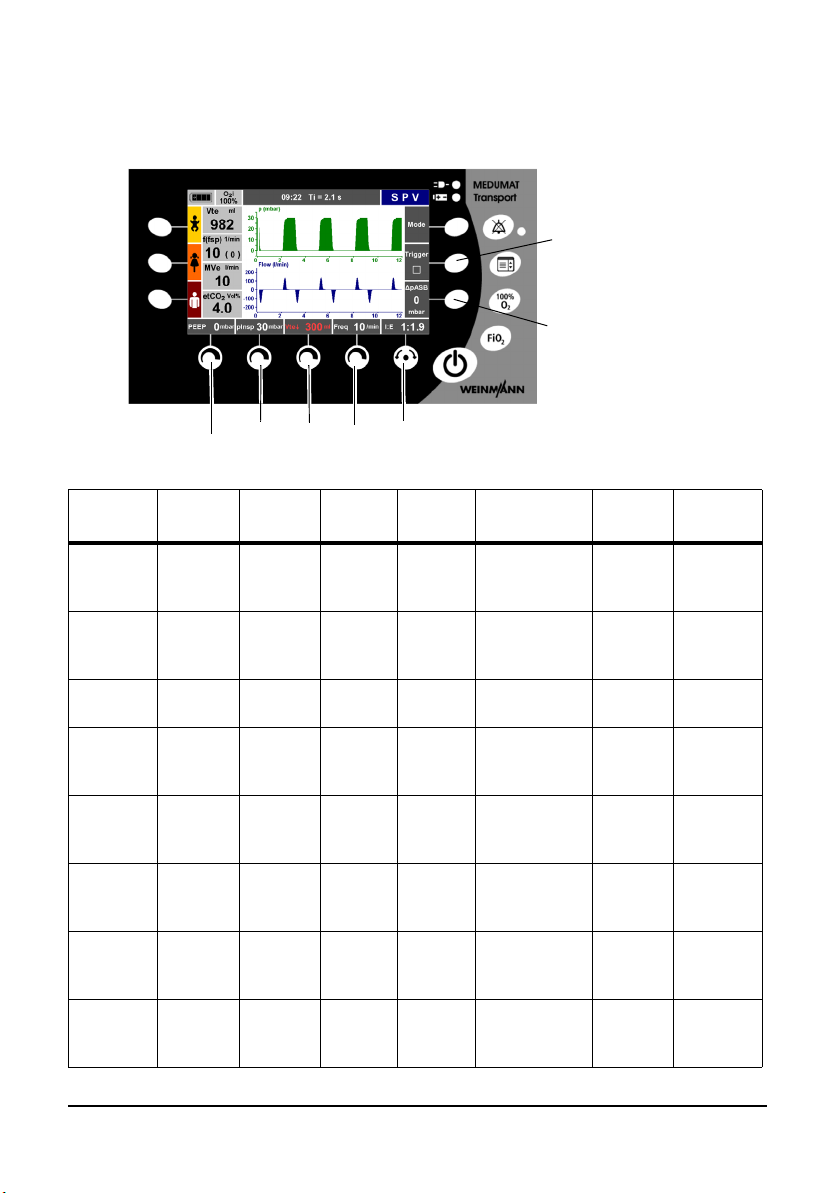

Function of the controls during ventilation

Depending on the ventilation mode selected, you can set the following ventilation

parameters using the controls:

7

6

1 2345

Ventilation

mode

SVV

SPV

CPAP + ASB

BILEVEL

PCV

IPPV

S-IPPV

SIMV

Control

knob

PEEP p

PEEP p

CPAP - V

PEEP p

PEEP p

PEEP p

PEEP p

PEEP p

Control

1

knob 2

max

insp

insp

insp

max

max

max

Control

knob 3

V

t

V

tmin

tmin

V

tmin

V

tmin

V

t

V

t

V

t

Control

knob 4

Freq.

Freq.

-

Freq.

Freq.

Freq.

Freq.

Freq.

Navigation knob 5Function

button 6

I:E and

Selection/

Confirmation

I:E and

Selection/

Confirmation

Only Selection/

Confirmation

I:E and

Selection/

Confirmation

I:E and

Selection/

Confirmation

I:E and

Selection/

Confirmation

I:E and

Selection/

Confirmation

I:E and

Selection/

Confirmation

Δ

pASB Trigger

Δ

pASB Trigger

Δ

pASB

Δ

pASB Trigger

--

--

--

--

Function

button 7

−

Overview 11

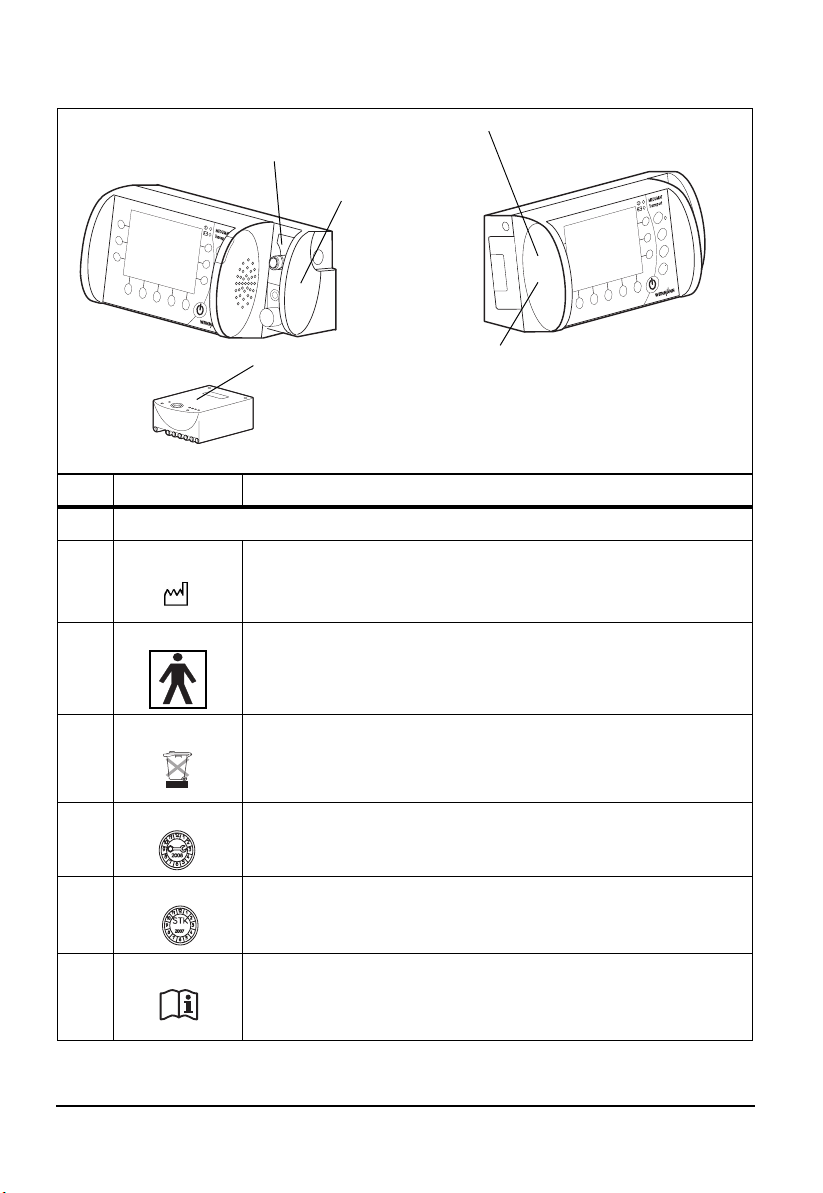

Page 12

Symbols used on the unit

MEDUMAT Transport

5 Cover of USB interface

1 MEDUMAT Transport type plate

4 Filter compart-

ment cover

Battery

1

1

1

2

2

1, 4, 5

3 Rechargeable

battery type plate

2 STK and service label

Symbol Meaning

MEDUMAT Transport type plate

Year manufactured

Type BF device

Do not dispose of the unit in the household waste

Service label: indicates when the next service is required.

STK label: (only in the Federal Republic of Germany) indicates

when the next safety check in accordance with §6 Medical Device

Operator Ordinance (MPBetreibV) is required.

Observe the information in the instruction manual.

12 Overview

Page 13

Symbol Meaning

Rechargeable battery type plate

3

Do not dispose of the unit in the household waste.

3

Do not subject the unit to hard knocks or shocks.

3

Do not open the unit using force.

3

Protect the unit against heat.

3

Protect the unit against moisture.

Labeling on the packaging

Symbol Meaning

MEDUMAT Transport:

SN

Serial number of the unit

3

RH % 0-95

Permissible storage temperature: -30°C to +70°C

Permissible humidity for storage: up to 95% relative humidity

Overview 13

Page 14

Safety information in this manual

The safety instructions in this instruction manual are marked as follows:

Warning!

Warns of risk of injury and possible damage to the unit.

Caution!

Warns of material damage and possibly incorrect therapy results.

Note:

Offers useful tips.

14 Overview

Page 15

2. Description

2.1 Intended use

The MEDUMAT Transport is an automatic oxygen emergency ventilator with additional

preoxygenation and monitoring functions (pressure, flow and CO

MEDUMAT Transport is used for controlled and assisted, as well as for invasive and noninvasive, ventilation of persons with a respiratory volume of 50 ml upwards.

MEDUMAT Transport must only be operated when installed permanently or on approved

portable systems.

2.2 Applications

MEDUMAT Transport can be used in the following cases:

Emergency

• for resuscitation at the place of the emergency

• for longer-tem use in continuing emergency situations

• for preoxygenation via a ventilation mask

).

2

Transport

• in ground, sea and air emergency medical service

• between hospital rooms and departments

• between a hospital and other locations (secondary transport)

Short-term ventilation in hospitals

• recovery room

• intensive care unit

• surgery preparation and follow-up

• emergency department

MEDUMAT Transport is also suitable for gentle ventilation of anesthetized patients (TIVA:

total intravenous anesthesia).

Description 15

Page 16

2.3 User qualification

MEDUMAT Transport must only be used by persons who can verify that they have the

following qualifications:

• A medical qualification and training in ventilation techniques.

• Training in the use of the MEDUMAT Transport by a person authorized

by WEINMANN.

Improper use may lead to serious physical injury.

2.4 Function

The unit

MEDUMAT Transport is used to treat apnea and to provide respiratory support. By means

of adjustable ventilation parameters, the unit ensures uniform ventilation tailored to the

patient.

Four pressure-controlled ventilation modes (SPV, CPAP + ASB, BIPAP, PCV) and four volume-controlled ventilation modes (SVV, IPPV, S-IPPV, SIMV) can be selected to provide optimum patient ventilation.

In CPAP + ASB mode, the unit enables assisted spontaneous breathing with continuous

positive airway pressure and respiration-controlled oxygen inhalation. In addition, the unit

permits O

The unit allows the oxygen concentration of the respiratory gas to be adjusted.

Depending on the version, the unit's large display can show up to three spirometric graphs

(pressure, flow and CO

For emergency situations, rapid selection of default types of ventilation is possible.

inhalation for preoxygenating the patient.

2

).

2

16 Description

Page 17

Patient Hose System

The ventilation gas is supplied to the patient via the Patient Hose System, comprising the

ventilation hose and all leads necessary for comprehensive ventilation and monitoring.

The Patient Hose System is designed to permit spontaneous respiraton even if the

MEDUMAT Transport malfunctions.

The Patient Hose System is available in two versions:

• Reusable hose system

• Disposable hose system

Description 17

Page 18

3. Installation

As a rule, MEDUMAT Transport only has to be installed for stationary use in rescue vehicles,

helicopters or aircraft. In this case, fastening sets can be supplied as accessories.

If MEDUMAT Transport is supplied complete on a portable system, the unit is ready for

operation and no further installation work is required. There are separate instruction

manuals for the portable systems.

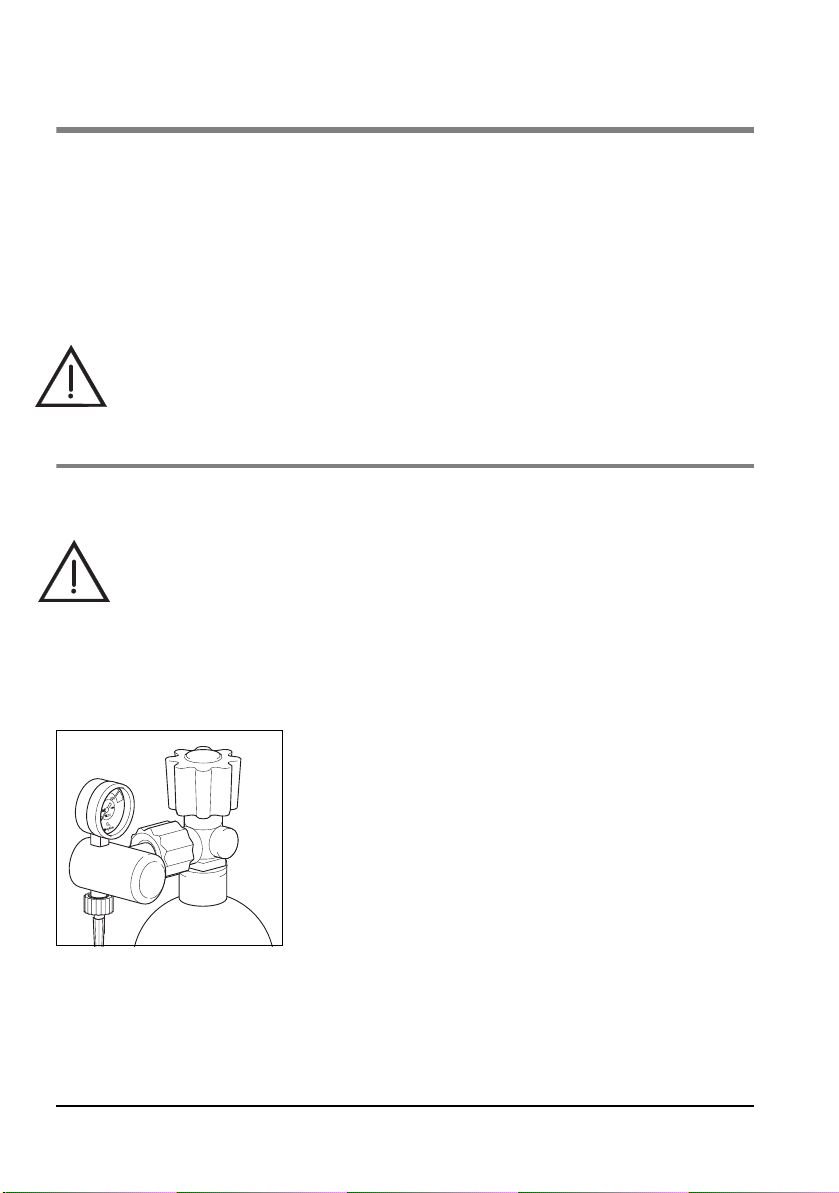

Warning!

After installation, you must perform a functional check (see “8. Function check” on

page 74) to ensure reliable operation.

3.1 Connecting oxygen cylinder

Warning!

• Risk of explosion! Wash your hands thoroughly before doing any work

on the oxygen supply. Hydrocarbon compounds (e.g. oil, grease,

cleaning alcohol, hand cream or adhesive plasters) can cause explosive

reactions if they come into contact with highly compressed oxygen.

• Never use wrenches or other tools to tighten or unscrew the union nuts.

Removing the empty cylinder

1. Close the valve on the oxygen cylinder.

Switch on MEDUMAT Transport at the On/Standby/Off

switch. This allows the remaining oxygen to escape and

the unit is pressure-free. Only when the contents gauge

on the pressure reducer indicates 0 bar, can the

screwed union be undone by hand.

2. Switch MEDUMAT Transport off again.

3. Undo the screwed union at the cylinder by hand.

18 Installation

Page 19

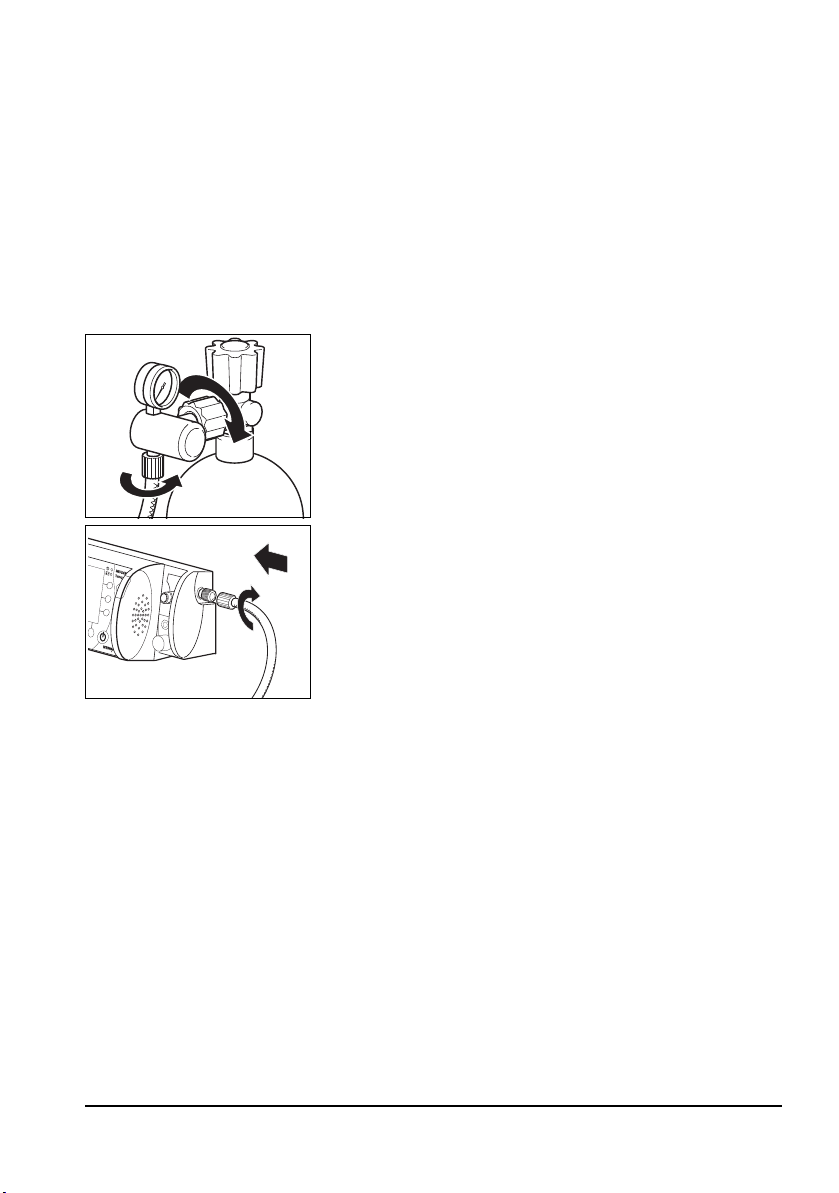

Connecting a new cylinder

1. Briefly open the valve of the new oxygen cylinder, then shut it again. This is to blow

away any particles of dust.

Caution!

• Make sure that the patient is not connected up to the MEDUMAT

Transport when you are establishing the gas supply. Otherwise, the

unit’s automatic self-test will lead to incorrect results.

• When doing this, hold the valve opening away from your body in such a

way that any flying particles cannot injure yourself or other people!

2. Screw the pressure reducer to the cylinder valve using

the knurled union nut. Tighten the union nut by hand.

3. Screw the pressure hose onto the outlet of the pressure

reducer (if not already connected) using the G 3/8

union nut.

4. Screw the other end of the pressure hose to the

compressed gas connection of the MEDUMAT

Transport (if not already connected).

Connecting a second oxygen source

Caution!

• Risk of insufficient oxygen supply

Two oxygen sources can be connected to this unit simultaneously. Make

sure that only one oxygen source is open at any given time and that there

is no gas reflux. Otherwise, one of the oxygen sources may empty itself

unnoticed. Sufficient oxygen supply to the patient can then no longer be

guaranteed when the unit is in use.

If desired or if foreseen in your establishment, you can connect a second oxygen source, e.g.,

an oxygen cylinder or a CGC to the O2 inlet/outlet (quick connector to the front of the unit).

Note:

If your unit is equipped with a DIN quick connector, no oxygen can be fed into the

unit with the associated DIN gas probe. With this combination it is only possible to

draw off oxygen.

Installation 19

Page 20

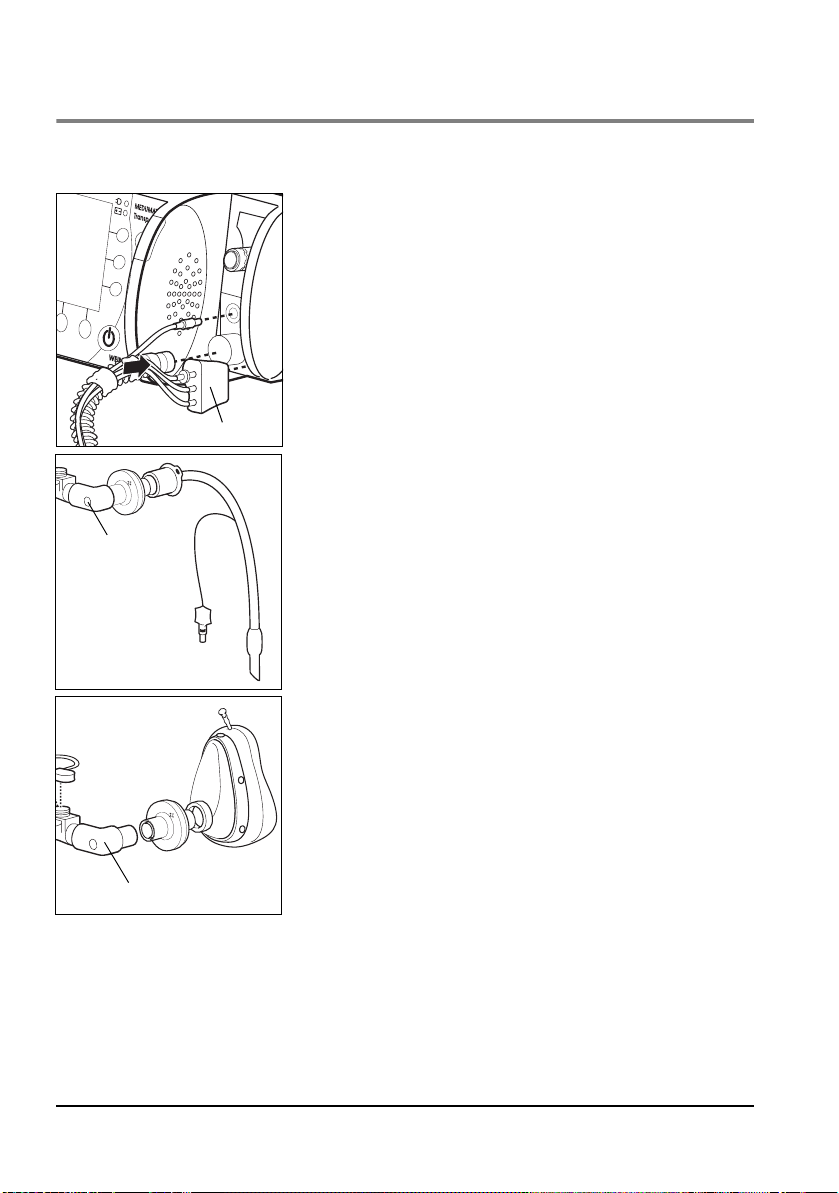

3.2 Hose system

A reusable hose system is supplied with the MEDUMAT Transport. Optionally, a disposable

hose system is also available. The procedure for connecting both systems is as follows:

1. Press the ventilation hose onto the corresponding

connection on the unit.

2. Attach the connector of the BiCheck flow sensor

connection line to the corresponding connection on the

unit.

3. Press the connector (contains PEEP control line, CO

removal tube, pressure-measurement tube) onto the

corresponding connection on the unit. Make sure that

the connected tubes are not kinked.

Connector

Elbow

Caution!

Only grip the ventilation hose by its ends. Otherwise the

hose may be damaged.

4. Connect the patient valve with BiCheck flow sensor to

the hose following intubation. If performing mask

ventilation, attach the ventilation mask to the patient

valve with the BiCheck flow sensor (identical to tube

connection).

2

Elbow

20 Installation

Note!

You can remove the elbow to reduce the dead space or

to adapt the hose routing to suit the patient's position.

Page 21

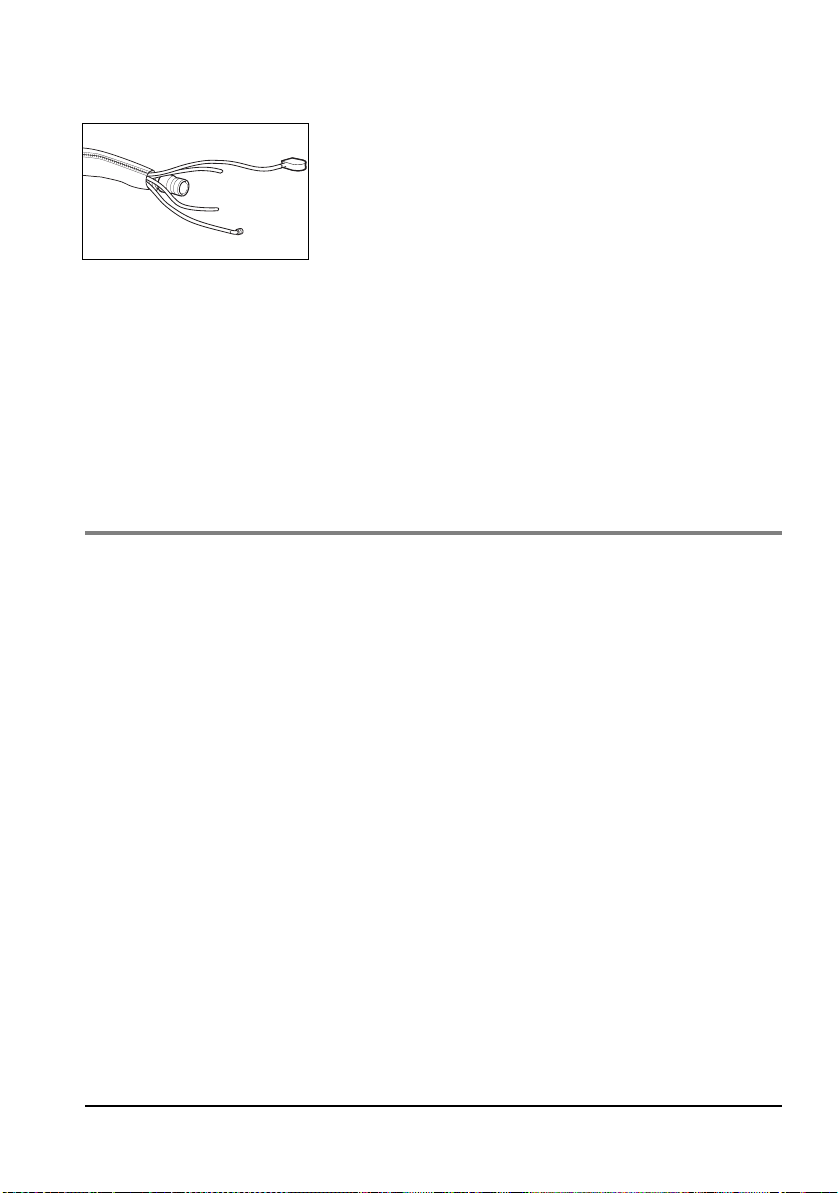

Tube protection sleeve

The tube protection sleeve is pulled over the ventilation

hose with connected BiCheck flow sensor. It prevents the

hose system from tangling on other items of equipment

and being damaged.

Water filter for CO2 removal tube

The water filter WM 97012 loses efficiency after approx. 8 hours of continuous operation,

depending on the temperature, humidity and any coarse particles, such as mucus.

Change the filter after eight hours at the latest.

The filter's decreasing efficiency is indicated by the alarm message “CO

display. This message is accompanied by a low-priority audible alarm

occlusion“ on the

2

3.3 Accessories from other manufacturers

Caution!

The unit's USB interface is intended exclusively for use by the manufacturer or an

authorized technician for servicing work. Do not connect equipment of any sort to

the USB, as this will interfere with operation of the unit, putting the patient at risk.

HME filter/bacterial filter/combined HME bacterial filter

If a filter is used, install it between the patient connection of the BiCheck flow sensor

(optionally with elbow) and the tube or mask. Follow the manufacturer's instructions.

Ventilation mask

Attach the ventilation mask to the BiCheck flow sensor. The mask used must have a

standard connection, as per ISO 5356-1.

Laryngeal mask

You can use a laryngeal mask instead of a ventilation mask. The tube used must have a

standard connection, as per ISO 5356-1.

Installation 21

Page 22

Endotracheal tube

Instead of attaching the BiCheck flow sensor to a ventilation mask, you can attach it to an

endotracheal tube. The tube used must have a standard connection, as per ISO 5356-1.

Tracheostomy tube

Instead of attaching the BiCheck flow sensor to a ventilation mask, you can attach it to a

tracheostomy tube. The tube used must have a standard connection, as per ISO 5356-1.

Supplying oxygen to external units

You can use the O2 inlet/outlet to connect the units, modules or inhalation devices to the

MEDUMAT Transport (quick connector on the front of the units).

When doing so, bear in mind that the outlet gas flow reduces the efficiency of the gas

supply (see 11.5 “Required gas supply” on page 95).

22 Installation

Page 23

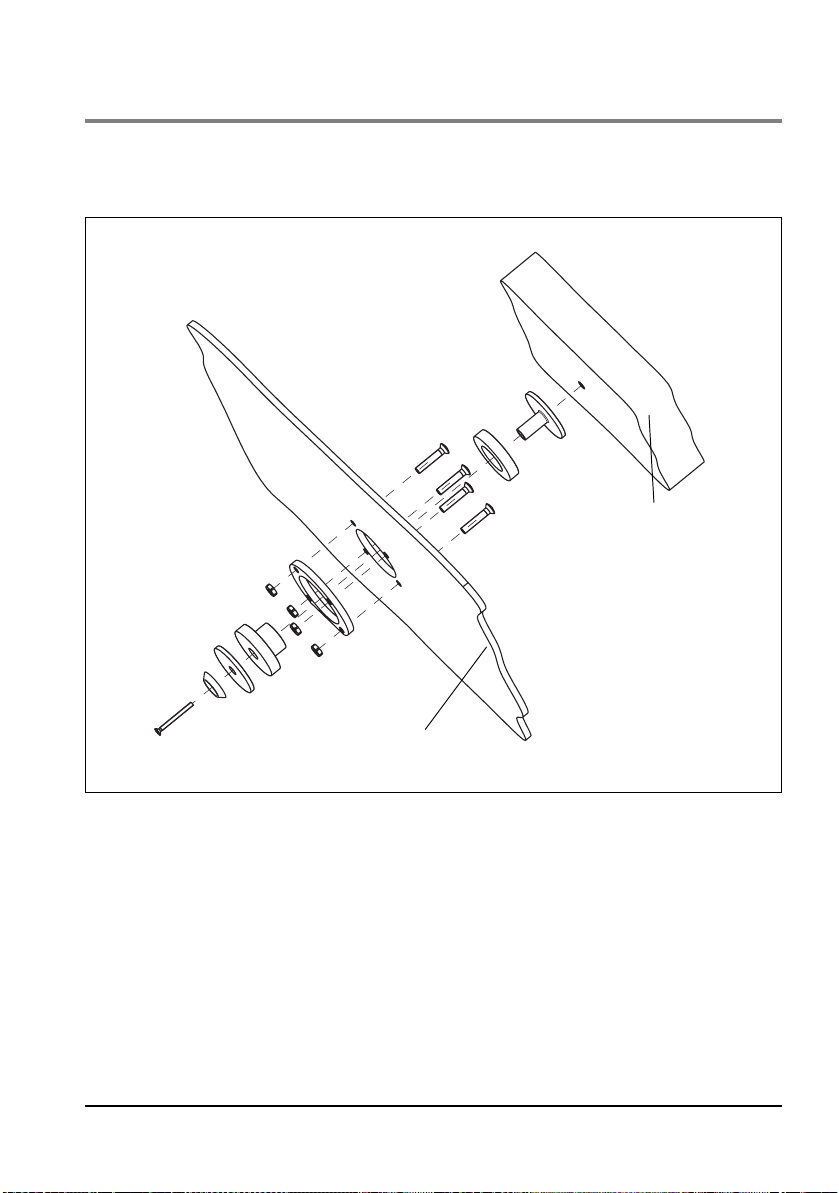

3.4 Permanent installation of the unit

If you wish to install the unit on a portable system or permanently install it in a vehicle or

aircraft, you require the fastening set WM 15730.

Back panel of

MEDUMAT Transport

Portable system

Installation 23

Page 24

4. Safety information

Read this instruction manual carefully. It is part of the unit and must be available at all

times.

For your own safety and that of your patients, and in accordance with the requirements of

Directive 93/42/EEC, please observe the following points:

General

• Always carry out a functional check before using the unit

(see “8. Function check” on page 74).

• Please observe the section “7. Hygienic preparation” on page 70 in

order to avoid infection or bacterial contamination.

Warning!

• Risk of injury. Only use MEDUMAT Transport if you are a qualified

medical professional and have received training in respiration

techniques. Improper use may lead to serious physical injury.

• Risk of injury. Never leave the patient or the ventilator unattended during

ventilation. Only then can you respond quickly if the patient's condition

deteriorates or in the event of an alarm or malfunction. Delayed response

on the part of medical personnel may lead to serious physical injury.

• Only use MEDUMAT Transport for the designated purpose

(see “2.1 Intended use” on page 15).

• MEDUMAT Transport is not suitable for hyperbaric use (pressure

chamber).

• The unit is not licensed for use in explosive atmospheres. The unit must

not be used in combination with flammable gases or anesthetics.

• The unit is not licensed for use in poisonous or contaminated

atmospheres.

• Only have modifications to the unit carried out by the manufacturer,

WEINMANN, or by a technician expressly authorized by WEINMANN.

Caution!

• Do not place a switched-on cellular phone or radio closer than 1 m from

the MEDUMAT Transport, as this could cause malfunctions.

• Remember that the respiratory resistance of the system as a whole may

increase beyond the level specified by the standard when an HME filter

24 Safety information

Page 25

(heat and moisture exchanger), a bacterial filter or a combined HME

bacterial filter is used.

• When operating the unit with the power supply unit, always connect the

unit to an easily accessible outlet so that it can be unplugged quickly in

the event of a malfunction.

• When operating the unit with the power supply unit, make sure that the

power cord cannot cause anyone to trip or cause any obstruction. If

necessary, do not use an external power supply, but operate the unit

with the battery instead.

• When operating the unit with the 12 V supply cord, always connect the

unit to an easily accessible vehicle electrical system receptacle so that it

can be unplugged quickly in the event of a malfunction.

• When operating the unit with the 12 V supply cord, make sure that the

cord cannot cause anyone to trip or cause any obstruction. If necessary,

do not use the vehicle electrical system, but operate the unit with the

battery instead.

• A spare unit must always be kept ready for use in case of failure.

• After using the unit in a dusty environment (e.g., a gravel plant), change

the suction filter, as described in the section “10.4 Changing the suction

filter” on page 87.

Safe handling of oxygen

Warning!

• Risk of explosion! In combination with combustible substances (grease,

oil, alcohol etc.), highly compressed oxygen may give rise to spontaneous

explosive reactions.

• Risk of fire! If only the O

side with a suitable cap. Otherwise, oxygen will escape from the O

on the side.

• Risk of poisoning! Highly concentrated oxygen can have a toxic effect on

the patient if administered for too long and depending on the age of the

patient. When ventilating with pure oxygen or an oxygen-air mixture,

make sure that oxygen is only administered for an appropriate period.

• Keep the units and all screwed unions absolutely free from oil and

grease.

• Be sure to wash your hands before working on the oxygen supply.

• Smoking and open flames are strictly prohibited in the vicinity of fittings

containing oxygen.

inlet/outlet is used, close the O2 inlet on the

2

inlet

2

Safety information 25

Page 26

Caution!

• When assembling the unit, and when changing cylinders, tighten all

screwed unions on the oxygen cylinder and pressure reducer by hand

only. Never use tools. Overtightening damages the threads and seals,

resulting in leaks.

• Secure the oxygen cylinders so that they cannot fall over. If a cylinder falls

on the pressure reducer or valve, these could break off, causing a violent

explosion.

• Risk of insufficient oxygen supply

Two oxygen sources can be connected to this unit simultaneously. Make

sure that only one oxygen source is open at any given time and that there

is no gas reflux. Otherwise, one of the oxygen sources may empty itself

unnoticed. Sufficient oxygen supply to the patient can then no longer be

guaranteed when the unit is in use.

• Always open the cylinder valve slowly to prevent pressure hammer on the

fittings.

• Do not empty oxygen cylinders completely, as this may allow moist

ambient air to enter and cause corrosion.

Ventilation/Handling

• Patient and emergency ventilator must be kept under continuous

observation during ventilation.

• Prolonged ventilation can lead to atrophy of the muscles (dependency of

the patient on ventilation).

• Prolonged ventilation may lead to the airway drying out. Ensure

adequate conditioning of the respiratory air.

• Only apply high ventilation pressures for short periods and only if

medically indicated. Permanently applied high ventilation pressures can

be injurious to the patient.

• Make sure that the patient valve is not covered or its function impaired,

e.g. by the patient's position.

26 Safety information

Page 27

Patient Hose System

Warning!

• Risk of injury. Only use the Patient Hose System if you are a qualified medical

professional and have received training in respiration techniques. Improper use

may lead to serious physical injury.

• The Patient Hose System must be subjected to a functional check and visual

inspection by the user before use. For this, refer to the instruction manual for the

Patient Hose System.

• When connecting the patient valve, check that the direction of flow of the

respiratory gas is correct. Make sure that the expiration opening of the patient

valve is not covered or prevented from functioning, e.g., by the patient's

position.

• Only use the Patient Hose System for the purpose described. For this, refer to

the instruction manual for the Patient Hose System.

• The Patient Hose System is not suitable for hyperbaric use (pressure chamber).

• Also refer to the instruction manual for the Patient Hose System.

Software

• Risks due to software errors have been minimized by means of extensive

qualification measures.

Accessories/Repairs/Replacement parts

Caution!

• Protect silicone/rubber parts against UV light and prolonged direct

exposure to sunlight to prevent them becoming brittle.

• We recommend that work such as inspections and repairs should be

carried out by the manufacturer, WEINMANN, or by a technician

expressly authorized by WEINMANN.

• If third-party items are used, functional failures may occur and fitness for

use may be restricted. Biocompatibility requirements may also not be

met. Please note that in such cases, any claim under warranty and liability

will be voided if neither the accessories nor genuine replacement parts

recommended in the instructions for use are used.

Safety information 27

Page 28

5. Operation

5.1 Controls

Display

The display contains the following information while the

unit is in use.

• Progress of the current ventilation

• Current measurements

• Ventilation parameters set/to be set

• Current assignment of the context-dependent

function buttons and control knobs

• Alarms and error messages

Function buttons with fixed assignment

The fixed-assignment function buttons enable you to carry

Function but-

tons with fixed

assignment

out the following actions directly:

• Mute acoustic alarms

• Call up the main menu

• Activate the “100% O

• Call up the “O

“ function

2

concentration“ menu

2

28 Operation

Page 29

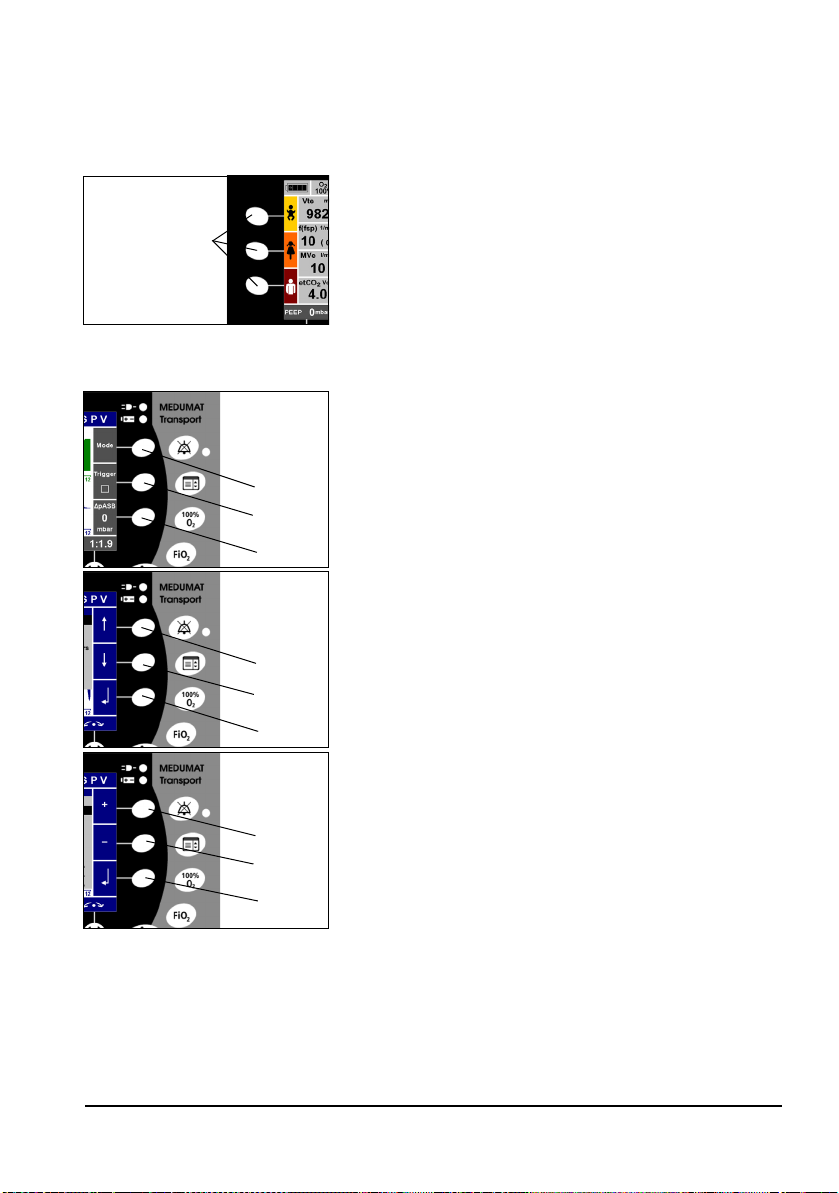

Context-dependent function buttons

On both sides of the display there are context-dependent

function buttons for calling up the following functions:

Left side of the display:

Function buttons

for emergency

ventilation

Context-

dependent

buttons

1

2

3

Context-

dependent

buttons

1

2

3

Context-

Context-

dependent

dependent

buttons

buttons

1

2

3

• Selecting emergency modes (available in every

ventilation mode):

– Infant (approx. 10 kg)

– Child (approx. 25 kg)

– Adult (approx. 75 kg)

Right side of the display:

• Calling up menus during ventilation:

–Button 1: Selecting a ventilation mode

–Button 2: Activating/deactivating triggers in SVV,

SPV, BILEVEL modes

–Button 3: Setting the pressure level of the ASB

function (ASB=Assisted Spontaneous Breathing in

SVV, SPV, BILEVEL and CPAP + ASB modes)

• Navigating in a menu:

–Button 1: Up

–Button 2: Down

–Button 3: Confirm your selection

Alternatively, these settings can also be made with the

navigation knob (Dual Navigation).

• Setting a parameter:

–Button 1: Increase value

–Button 2: Decrease value

–Button 3: Confirm your selection

Alternatively, these settings can also be made with the

navigation knob (Dual Navigation).

Operation 29

Page 30

Navigation knob

When a menu is open, you can navigate using the

navigation knob, as follows:

• Turn counterclockwise: to move the selection bar

upwards in the menu

• Turn clockwise: to move the selection bar

downwards in the menu

Navigation knob

• Press navigation knob to confirm your selection

When no menu is open, you can carry out the following

functions:

• Confirm setting parameters that have been set

with the context-dependent control knobs.

• Set and confirm the I:E ratio

Context-dependent control knobs

Depending on the ventilation mode selected, you can set

the following parameters using the control knobs:

• Control knob 1: PEEP, CPAP

• Control knob 2: p

1 2345

ventilation modes, this knob has no function

• Control knob 3: V

• Control knob 4: Respiratory rate (no function in

some modes)

• Navigation knob 5: I:E (no function in some modes)

If the ventilation parameters are changed using the control

knobs, the corresponding parameters and the

above the navigation button will flash for 5 seconds.

Changed parameters that are not confirmed within

5 seconds by the navigation button or the contextdependent button will not be applied.

(alarm limit), P

max

, Vte ↓ (alarm limit)

t

. In some

insp

30 Operation

Page 31

5.2 Switching the unit on/Self-test

1. Slowly open the valve on the oxygen cylinder. The contents gauge now indicates the cylinder pressure.

2. Calculate the remaining operating time (see 5.14 “Calculating the oxygen level/operating time”on page 53).

You should change the cylinder in good time, e.g.,

when the pressure falls below 50 bar, to ensure a sufficiently long operating time.

3. To switch on MEDUMAT Transport, press the On/

Standby/Off button. An automatic self-test runs.

During the self-test, the alarm LED lights up briefly. The

buzzer gives a series of five signals and then the

loudspeaker gives two acoustic signals.

On/Standby/Off button

If the self-test is not successful, the “Fault“ message

appears in the display. The unit cannot then be

operated.

Caution!

The automatic self-test is not a substitute for the

functional check. Before using the unit, always carry

out a functional check, as described in Section

“8. Function check” on page 74. That is the only way

to ensure that the unit is fully functional.

4. The “Start menu“ appears on the display. You now

have the following options:

– Press one of the emergency buttons (Infant, Child,

Adult). The unit immediately begins ventilation

with preset parameters.

– Do not make any selection: after 20 seconds the

“Start menu“ will disappear. The unit begins

ventilation in the mode that was last selected and

with the parameters last set.

Operation 31

Page 32

– Press the “Last patient“ button: The unit

immediately begins ventilation in the last mode

selected.

– Press the “New patient“ button: Then select the

“Adult“, “Infant“ or “Child“ setting. The “Mode“

menu appears. Select the appropriate ventilation

mode and confirm your selection. Use the control

knobs to set the parameters for ventilating the

patient. Then select “Start ventilation“ with the

context-dependent buttons if you are ready to start

ventilation, or select “Back“ if you wish to change

the settings.

– Select the “Functional check“ menu, and the unit

will begin the automatic functional check (see 8.4

“Automatic function check”on page 77).

5. When the self-test has finished and the ventilation

mode has been set, connect the patient.

6. During ventilation, make any necessary changes to the

ventilation values, as described later in this section.

32 Operation

Page 33

5.3 Navigating in menus

The vast majority of functions of the MEDUMAT Transport are accessed via menus.

MEDUMAT Transport offers two methods of navigating in these menus:

• using the navigation knob

• using the context-dependent function buttons on the right of the display.

Menus can be closed at any time by pressing the Menu button again. If no parameters are

changed, the menus close automatically after 20 seconds.

Parameter changes will not be implemented unless they are confirmed with the navigation

knob or context-dependent button .

Navigating with the navigation knob

1. Select a menu using the function buttons (here: Alarm

limits).

2. Select a menu item by turning the navigation knob

clockwise (the selection bar moves downwards) or

counterclockwise (the navigation bar moves upwards).

3. Confirm your selection by pressing the navigation

knob.

4. To leave a menu, select the menu item “Back“ using

the navigation knob, and confirm your selection by

pressing the navigation knob.

Proceed in the same way when making numeric

settings (here: Alarm limits):

Navigation knob

– Turn the navigation knob clockwise to raise the

value, and counterclockwise to lower it.

– Press the navigation knob to confirm the newly set

value.

5. To switch from a sub-menu direct to the ventilation

screen, press the function button for “Main menu“

again.

Operation 33

Page 34

Navigating with the context-dependent function buttons.

1. First, select a menu using the function buttons (here:

Main menu).

2. Select a menu item by pressing the function button

(the selection bar moves downwards) or the button

(the navigation bar moves upwards).

3. Confirm your selection by pressing the button.

4. To leave a menu, select the menu item “Back“ using

the or button, and confirm your selection by

pressing the button.

Proceed in the same way when making numeric settings

(here: Alarm limits):

– Press the button to raise the value and the

button to lower it.

– Press the button to confirm the newly set value.

5. To switch from a sub-menu direct to the ventilation

screen, press the function button for “Main menu“

again.

Other symbols used in the menus:

Radio button:

If a menu contains functions which have a so-called “radio

button“, only one function at a time can be selected in this

menu.

Tick box:

If a menu contains functions which have a so-called “tick

box“, these functions can be activated in addition to other

functions.

34 Operation

Page 35

5.4 Emergency modes

Three modes with preset ventilation parameters are available for emergency ventilation. You can select these at any

Context-

dependent

buttons

1

2

3

IPPV ventilation is started with preset parameters. These are optimized for the following

patient groups:

• Infant (approx. 10 kg body weight)

• Child (approx. 25 kg body weight)

• Adult (approx. 75 kg body weight)

Parameter Adult Child Infant

PEEP

p

max

I:E

Frequency

V

0 mbar 0 mbar 0 mbar

30 mbar 25 mbar 20 mbar

1:1.7 1:1.7 1:1.7

12/min 20/min 30/min

600 ml 200 ml 100 ml

t

time during ventilation by pressing the context-dependent

function buttons on the left of the display twice.

• Button 1: Infant

• Button 2: Child

• Button 3: Adult

All three emergency modes are based on the IPPV ventilation mode (see “IPPV”on page 43). This mode is activated

automatically when you call up an emergency mode from

another ventilation mode, e.g. SVV.

Operation 35

Page 36

5.5 Selecting a ventilation mode

MEDUMAT Transport offers the following ventilation modes. Details about the individual

modes are given on the pages indicated below.

Pressure-controlled ventilation modes

• SPV (see “SPV“ on page 38)

• CPAP + ASB (see “CPAP + ASB“ on page 39)

• BILEVEL (see “BILEVEL“ on page 40)

• PCV (see “PCV“ on page 41)

Volume-controlled ventilation modes

• SVV (see “SVV“ on page 42)

• IPPV (see “IPPV“ on page 43)

• S-IPPV (see “S-IPPV“ on page 44)

• SIMV (see “SIMV“ on page 45)

To select a ventilation mode, proceed as follows:

1. First, select the “Mode“ menu using the “Mode“

function button.

2. Select the ventilation mode you require using the navigation knob or the context-dependent function buttons on the right of the display. If necessary, you can

additionally activate the NIV function.

3. Confirm your selection by pressing the navigation knob

or the corresponding context-dependent function

button.

Note:

In combined ventilation modes, breaths can be triggered by the patient within a time

slot of 20% (depending on the rate) or 100% (S-IPPV mode) before the mandatory

breath is initiated.

36 Operation

Page 37

NIV

NIV: Non-Invasive Ventilation (mask ventilation)

This additional function can be activated in all the ventilation modes. The leakage alarm is

deactivated. The unit uses optimised trigger points for the NIV mode.

Caution

• If the NIV function is not activated during ventilation with leakages, the

unit can only be triggered by the patient by greatly increased respiratory

efforts. This may endanger the success of treatment.

• In certain circumstances, the required O

achieved during ventilation with leakages. This is for technical reasons

and is not a malfunction. When the NIV mode is activated, the alarm limit

is therefore automatically set to 20%.

concentration may not be

2

Preoxygenation

1. Call up the “Mode“ menu by pressing the corresponding function button.

2. Select the “Preoxygenation“ function in the “Mode“

menu, and confirm your selection.

3. Select the liter capacity you require using the navigation

knob, and confirm your selection.

The selected liter capacity is indicated in the blue Mode

field on the screen.

4. To end preoxygenation, select “Off“ and confirm your

selection. The “Preoxygenation“ menu is closed. The

“Mode“ menu is displayed.

Changing to a different ventilation mode

If you change from one ventilation mode to another, the unit will respond as follows:

• Ventilation parameters which are also available in the new ventilation

mode are retained unchanged.

• Ventilation parameters which are not available in the new ventilation

mode are saved, but have no influence on the current ventilation. The

saved values become available again as soon as the previous ventilation

mode is reactivated.

• When changing from volume-controlled ventilation to pressure-controlled ventilation, the inspiratory pressure is limited to 15 mbar.

Operation 37

Page 38

5.6 Pressure-controlled ventilation modes

SPV

SPV: Smart Pressure Ventilation

SPV mode is used for pressure-controlled ventilation with

fixed pressure levels.

This mode offers maximum flexibility: By selecting suitable

parameters, all other ventilation modes that are integrated

in MEDUMAT Transport can be implemented.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: P

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

• You can set the following parameters using the context-dependent

function buttons on the right of the display.

•Button 1: Select a different ventilation mode

•Button 2: Activate/deactivate trigger

•Button 3:

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

Δ pASB

insp

↓ (alarm limit)

te

at a breathing rate < 6/min.

i

38 Operation

Page 39

CPAP + ASB

CPAP: Continuous Positive Airway Pressure

ASB: Assisted Spontaneous Breathing

CPAP mode is used to increase the pressure level of

respiration in order to raise the functional residual capacity

(FRC).

ASB mode is used for pressure support of insufficient

spontaneous respiration. The patient is able to breathe

spontaneously without any restriction, but is supported in

his breathing effort by the MEDUMAT Transport.

The CPAP + ASB mode is used exclusively on patients with adequate spontaneous respiration.

You can set the following ventilation values using the

control knobs:

• Control knob 1: CPAP

• Control knob 2: No function

• Control knob 3: V

• Control knob 4: No function

• Navigation knob: No function

You can set the following parameters using the context-dependent function buttons on

the right of the display.

• Button 1: Select a different ventilation mode

• Button 2: No function

• Button 3:

Δ pASB

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

↓ (alarm limit)

te

Operation 39

Page 40

BILEVEL

BILEVEL: Positive airway pressure during inspiration and expiration

BILEVEL mode is used for pressure-controlled ventilation

combined with free spontaneous respiraton during the

entire breathing cycle and for adjustable pressure support

at PEEP level.

This mode is used on patients who have no spontaneous

respiration or on spontaneously breathing patients prior to

extubation. This mode can also be used for weaning by

gradually reducing the mandatory part of the total minute

volume (MV) and reduction of the support pressure (ASB).

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: P

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

You can set the following parameters using the context-dependent function buttons on

the right of the display.

•Button 1: Select a different ventilation mode

•Button 2: Activate/deactivate trigger

•Button 3:

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

Δ pASB

insp

↓ (alarm limit)

te

at a respiratory rate < 6/min.

i

40 Operation

Page 41

PCV

PCV: Pressure Controlled Ventilation

PCV mode is used for mandatory pressure-controlled

ventilation with fixed pressure levels.

This mode is used on patients who have no spontaneous

respiration.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: P

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

You can set the following parameters using the context-dependent function buttons on

the right of the display.

• Button 1: Select a different ventilation mode

• Button 2: No function

• Button 3: No function

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

insp

↓ (alarm limit)

te

at a respiratory rate < 6/min.

i

Operation 41

Page 42

5.7 Volume-controlled ventilation modes

Caution!

In the volume-controlled modes, the ventilation pressure is limited to p

limitation). An alarm is triggered when this pressure limit is reached. It is then no

longer guaranteed that the set tidal volume is actually released to the patient. In this

event, check the patient’s condition and, if necessary, reset the ventilation

parameters.

max

(pressure

SVV

SVV: Smart Volume Ventilation

SVV mode is used for volume-controlled ventilation with a

fixed tidal volume.

This mode offers maximum flexibility: By selecting suitable

parameters, all other volume-controlled ventilation modes

that are integrated in MEDUMAT Transport can be

implemented.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: p

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

You can set the following parameters using the context-dependent function buttons on

the right of the display.

•Button 1: Select a different ventilation mode

•Button 2: Activate/deactivate trigger

•Button 3:

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

Δ pASB

(pressure limitation)

max

t

at a respiratory rate < 6/min.

i

42 Operation

Page 43

IPPV

IPPV: Intermittent Positive Pressure Ventilation

IPPV mode is used for mandatory volume-controlled

ventilation with a fixed tidal volume.

This mode is used on patients who have no spontaneous

respiration.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: p

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

You can set the following parameters using the context-dependent function buttons on

the right of the display.

• Button 1: Select a different ventilation mode

• Button 2: No function

• Button 3: No function

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

(pressure limitation)

max

t

at a respiratory rate < 6/min.

i

Note

If you select a PEEP > 0 in this mode, the mode designation changes from IPPV to

CPPV (Constant Positive Pressure Ventilation).

Operation 43

Page 44

S-IPPV

S-IPPV: Synchronized Intermittent Positive Pressure Ventilation

Warning!

• Risk of hyperventilation! Continuously monitor the patient's measured

respiratory rate and measured minute volume in order to prevent

hyperventilation.

• Risk of air trapping! Continuously monitor the airway pressure in order

to prevent air trapping.

S-IPPV mode is used for volume-controlled ventilation with a variable mandatory minute

volume (MV). Throughout the entire expiration phase, a trigger is active which enables the

patient to initiate a new breath. The patient is thus able to increase the respiratory rate,

and therefore the minute volume MV, and to adapt them to his/her requirement.

This mode is used on patients who have inadequate spontaneous respiration.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: p

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E or T

You can set the following parameters using the context-dependent function buttons on

the right of the display.

•Button 1: Select a different ventilation mode

•Button 2: No function

•Button 3: No function

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

(pressure limitation)

max

t

at a respiratory rate < 6/min.

i

44 Operation

Page 45

SIMV

SIMV: Synchronized Intermittent Mandatory Ventilation

SIMV mode is used for volume-controlled ventilation with

a fixed mandatory minute volume (MV).

Between the mandatory mechanical breaths, the patient

can breathe spontaneously and so increase the minute

volume.

If there is spontaneous respiration, the mandatory

mechanical breath is synchronized with the patient's

breathing. The mandatory minute volume remains

unchanged.

This mode is used on patients with inadequate spontaneous respiration or for weaning patients by gradually reducing the mandatory part of the total minute volume.

You can set the following ventilation values using the control knobs:

• Control knob 1: PEEP

• Control knob 2: p

• Control knob 3: V

• Control knob 4: Respiratory rate

• Navigation knob: I:E

You can set the following parameters using the context-dependent function buttons on

the right of the display.

• Button 1: Select a different ventilation mode

• Button 2: No function

• Button 3: No function

You can find more setting options under the menu item “Advanced ventilation parameters“ in the “Main menu“ (see 6.4 “Setting advanced respiratory parameters”on page 63).

(pressure limitation)

max

t

Operation 45

Page 46

5.8 Other ventilation functions

The ventilation functions “O2 concentration“ and “100% O2“ are available for all the

ventilation modes. You can call up and set these functions at any time using the fixedassignment function buttons on the right of the display.

Warning!

Risk of poisoning! Highly concentrated oxygen can have a toxic effect on the patient

if administered for too long and depending on the patient's age. When ventilating

with pure oxygen or an oxygen-air mixture, make sure that oxygen is only administered for an appropriate period.

Setting the O2 concentration

To save oxygen, ventilation is normally carried out with an oxygen/air mixture. The administered oxygen concentration can be selected between 40% and 100%. The currently measured value is shown in the top info field on the display.

If you switch from oxygen/air mixture (40% O

minute volume changes within the preset tolerances (see 12. “Technical Data”on

page 95), at the most. To set the O

concentration, proceed as follows.

2

1. Call up the “O

button.

) to pure oxygen (100% O2), the respiratory

2

concentration“ menu using the FiO2

2

46 Operation

2. Select “O2 concentration“ in the menu and confirm

your selection.

3. Select the required O2 concentration using the

navigation knob or the function buttons.

4. Press the button or the navigation knob to confirm

your selection.

Page 47

100% O2 function

To raise the oxygen concentration to 100% (for a maximum of two minutes), you can use

the “100% O

“ function.

2

1. Press the “100% O2“ button to confirm the function.

The message “100% O2“ appears on the display.

2. Press the “100% O

Ventilation is continued with the originally set O

“ button again to end the function.

2

con-

2

centration. The function is ended automatically after

two minutes.

Operation 47

Page 48

5.9 Performing ventilation

Tube

As a rule, the patient is intubated before the tube is connected to the patient valve.

1. Set the desired ventilation mode and the associated ventilation parameters.

2. Attach the patient valve to the connector of the endotracheal tube.

3. During ventilation, check the respiratory parameters on the display. This will enable you

to determine whether ventilation is adequate.

Note

If your unit is equipped with the optional CO

position on the basis of the capnogram and correct it if necessary.

Ventilation mask

1. If necessary, use the elbow supplied with the hose sytem to ensure optimum routing of

the hose system, depending on the patient's position.

Caution

Using the elbow increases the dead space of the hose system. Take this into account

when setting the ventilation parameters. Otherwise the success of treatment may be

compromised.

2. Attach the mask to the hose system.

3. If necessary, introduce a Guedel oropharyngeal tube to keep the patient’s airways free.

4. Place the ventilation mask over the patient's mouth and nose.

5. Extend the patient's head and, at the same time, hold the mask tight against the

patient's face by means of the EC grip.

measurement, you can check the tube

2

48 Operation

Page 49

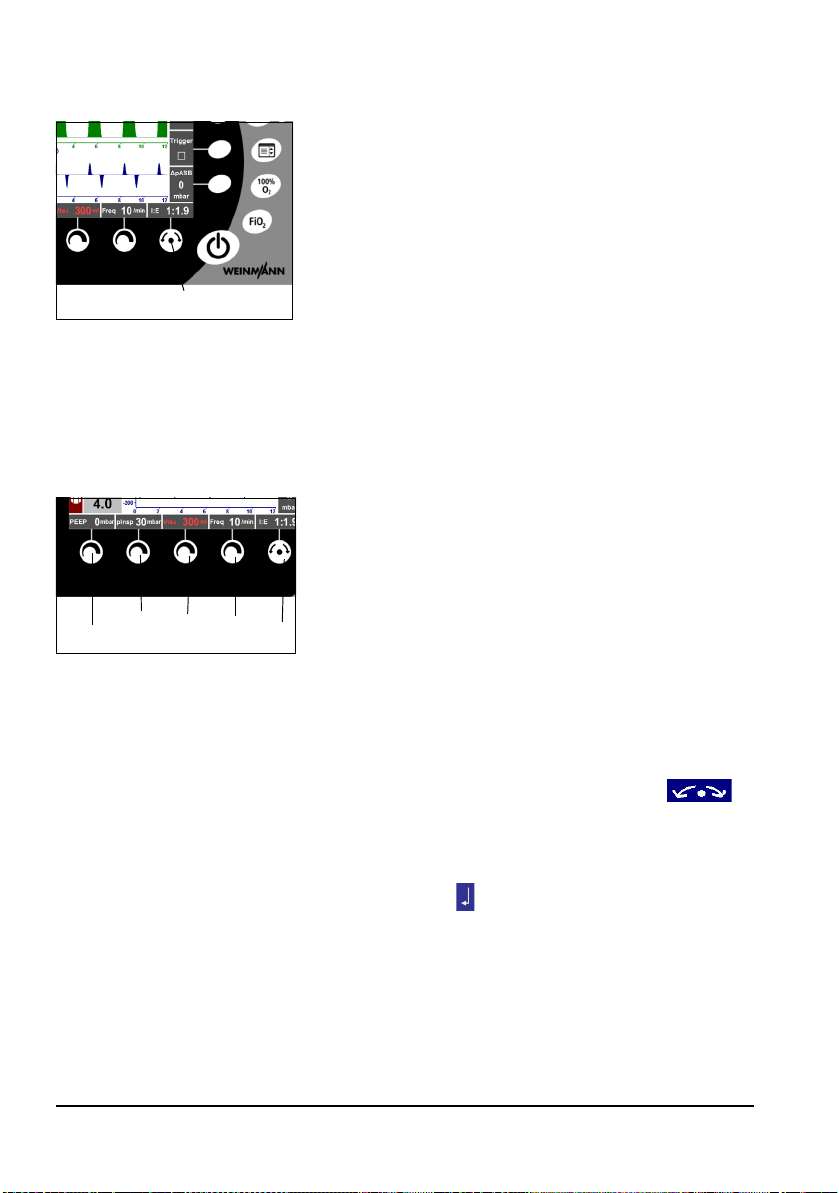

5.10 Monitoring ventilation

General

During ventilation, you must monitor the patient continuously. You can follow the progress

of ventilation on the display. You can select various display formats.

High airway resistances, e.g., due to obstructions of the airway or during external cardiac

massage, may change the respiratory minute volume, depending on the ventilation mode.

If lung compliance decreases, the unit responds as follows:

• With volume-controlled ventilation, the ventilation pressure rises until

the set pressure limit is reached, while the ventilation volume remains

constant. Then the applied volume drops.

• With pressure-contolled ventilation, the applied volume drops while the

pressure remains constant.

Example of ventilation progression before and after

decrease in compliance during volume-controlled

ventilation

Note

All the displayed measurements for flow, volume, or MV relate to ambient

temperture and ambient air pressure.

Operation 49

Page 50

Displayed measurements

During ventilation, the following parameters are shown on

the display as numbers:

Ventilation progress graphs

For the purpose of ventilation monitoring, the standard

unit displays the following parameters:

If you have a unit equipped with CO2 measurement, you

can display up to three graphs. The following presentaion

versions are possible:

–V

: expiratory tidal volume

te

– f(fsp): respiratory rate/number of spontaneous

breaths per minute

: expiratory minute volume

–MV

e

–etCO

–O

: end-tidal CO2 concentration (only with

2

units equipped with optional CO

i: inspiratory O2 concentration delivered by the

2

measurement)

2

unit

– Ventilation pressure, flow

– Ventilation pressure, flow

– Ventilation pressure, CO

– Ventilation pressure, flow, CO

2

2

50 Operation

Page 51

5.11 Alarm signals

Alarm priority

MEDUMAT Transport classifies alarms in the following priority levels:

• high priority

• medium priority

• low priority

If two or more alarms occur simultaneously, alarms with the currently highest priority are

displayed cyclically.

You can set limit values for alarms relating to respiratory physiology (see 6.2 “Setting alarm

limits”on page 61).

Display of alarms

MEDUMAT Transport displays alarms as follows:

• High priority

– LED flashes red

– Audible alarm “high priority“ every 8 seconds

– Alarm text appears in info field; info field flashes

Info field

red

• Medium priority

– LED off

– Audible alarm “medium priority“ every 15 seconds

– Alarm text appears in info field; info field flashes

yellow

• Low priority

– LED off

– Audible alarm “low priority“ every 30 seconds

– Alarm text appears in info field; info field has

turquoise background

Operation 51

Page 52

Muting the alarm

When an alarm occurs, you can mute the audible alarm

temporarily (120 seconds) by pressing the Alarm Mute

button. For these 120 seconds, a yellow LED is alight. Press

the button again to reactivate the acoustic alarm. The

visual alarm remains active.

As soon as a higher-priority alarm occurs, the acoustic

alarm is immediately reactivated.

Visual and acoustic alarms are automatically reset as soon

as the cause of the alarm has been rectified.

5.12 Ventilation with filters (not supplied with the unit)

For hygiene purposes, and to condition the air for breathing, you can equip the patient

valve with commercially available filters (HME, bacterial or combined HME/bacterial filters)

with standard 15/22 mm connections. This increases both the inspiration and expiration

resistance, so you should monitor the ventilation pressure and volume with special care.

Allowance must be made for the larger dead space, especially with children.

Always follow the filter manufacturer's operating instructions.

5.13 Ending ventilation

Caution!

Never empty the oxygen cylinder completely. Always ensure that there is a certain

residual pressure in the cylinder when you return it for filling, as this prevents moist

ambient air from entering and causing corrosion.

1. Check the remaining oxygen content on the contents gauge. If the contents gauge

indicates 50 bar or less, the cylinder must be refilled or a reserve cylinder obtained to

ensure that the unit remains ready for use.

2. Close the valve on the oxygen cylinder.

52 Operation

Page 53

3. Hold down the On/Standby/Off button for 2 seconds to

switch the unit to standby.

Note:

The unit still uses up electricity in standby mode. If the unit does not need to be used

for a long time or is not connected to the power supply, we recommend switching

it off. To do so, hold down the On/Standby/Off until the LED alarm goes out (approx.

10 seconds ).

5.14 Calculating the oxygen level/operating time

Caution!

When calculating the oxygen level in the cylinder, take into account the unit's

O

consumption (see 12.4 “O2 consumption of the unit”on page 100). Otherwise

2

you may miscalculate how long the cylinder will last, which may impair the success

of treatment.

Oxygen level in the cylinder

Oxygen volume = cylinder volume x cylinder pressure.

Cylinder volume x Cylinder pressure = Oxygen content

Example 1

Example 2

10 l x 200 bar = 2000 l

10 l x 100 bar = 1000 l

Available operating time for ventilation

Vt (tidal volume) x f (respiratory rate)= MV (minute volume)

Oxygen content (l)

Available operating time for ventilation (min)

------------------------------------------------------------- - -

Vt x f + O2 consumption

Example 1:

O

supply = 1000 l; Vt x f = 11 l/min; 100% O2, O2 consumption 0.3 l (see 12.4 “O2 con-

2

sumption of the unit”on page 100).

100

--------------------------------------------

×=

O2 concentration

Operation 53

Page 54

This gives: 3

Available operating time for ventilation (min)

1000 l

------------------------- -

11.3 l/min

100

--------------- -

× 88 min 1h 28 min===

100%

If MEDUMAT Transport is operated with an O2 concentration less than 100%, the operating

time will increase correspondingly.

54 Operation

Page 55

5.15 Alternative ventilation

In the event of the MEDUMAT Transport breaking down during ventilation, you have the

following alternatives:

Ventilation bag

1. Pull the patient valve off the tube or mask.

2. Attach the ventilation bag, e.g., COMBIBAG WM 11000 from WEINMANN and carry

out manual ventilation.

Ventilation aid

You can use the LIFEWAY WM 10580 from WEINMANN to perform mouth-mask

ventilation.

Oxygen failure

In exceptional situations, when there is no oxygen supply, the MEDUMAT Transport can

also be operated with sterile compressed air.

Note

During ventilation with sterile compressed air or concentrator oxygen, the unit gives

the “

O

↓“ alarm continuously.

2

5.16 Changing battery during use

The battery should be changed in good time when it starts to run low. Always keep a fully

charged battey ready for changeover.

Note

If you change the battery within the space of 30 seconds, the unit restarts

automatically. Settings made before changing battery are then retained.

Proceed as follows:

1. Have the fully charged battery ready to hand.

2. Pull the low battery out of the unit's battery compartment.

3. Insert the replacement battery into the compartment within 30 seconds.

4. Continue with ventilation.

Operation 55

Page 56

5.17 Battery management

MEDUMAT Transport has an internal power supply with a rechargeable battery.

Two battery versions are available:

• Battery pack Plus WM 28385 for internal and external charging; can be

recharged either in the unit or using an external charger WM 28390;

charge level can be checked on the battery.

• Battery pack WM 28384 for internal charging; can only be recharged in

the unit; charge level can be checked on the battery.

For recharging, an external DC power supply with 12 – 15 V (internal charging) or 15V

(external charging) is required. Only use the vehicle/aircraft electrical power supply. If

charging in an AC wall outlet, use the charger WM 28390.

MEDUMAT Transport can be operated from an external power supply when the battery is

empty. The battery is charged while the unit is in operation, but charging takes longer than

when the unit is off.

Caution!

• The unit must never be operated without the battery installed because any

voltage dips in the power supply cannot then be bridged, which would mean

that uninterrupted ventilation of the patient is not guaranteed.

• Battery-operated medical devices have a limited operating period.

MEDUMAT Transport can be operated for at least three hours without

an external power supply, provided that the battery is fully charged. You

should therefore ensure that the battery is always as fully charged as possible, or have a spare battery ready for use.

Battery charge level indicator (MEDUMAT Transport)

At the top left of the display you will find the symbol indicating the battery charge level. The indication is in five

stages. The picture opposite shows examples of a full, half-

empty

56 Operation

fullhalf-full

full and empty battery.

Page 57

Charge level indicaton on the battery itself

When the battery is removed from the unit, you can check

the charge level on the battery itself. The state of charge is

indicated by 4 green LEDs. Press the button on the battery

(see drawings opposite).

Charge level

indicator

Battery charge level

4 LEDs 100%

3 LEDs 75%

2 LEDs 50%

Charge

indicator

Button

Status LED

1 LED 25%

1 LED flashing less than 10 minutes charge left

The battery's state of charge is indicated by the status LED

Status LED Battery

LED glows green Battery fully charged

LED flashes green Battery is being charged

Accu-Pack Plus

MEDUMAT Transport

WM 28385

LED glows red Battery defective. Do not use.

Charging status indicator

The charging status is only indicated when the external power supply is connected, as only

then is it possible to charge the battery.

When MEDUMAT Transport is off, the charging status is shown by the charging indicator.

When MEDUMAT Transport is on, both the charging status and the battery's charge level

are indicated.

Key to charging status and charge level indicators:

Unit off Unit on

Battery charging

Battery full

Charging

indicator

flashes green flashes green

green green

Charging indicator Charge level indicator

(current charge status)

(full)

Operation 57

Page 58

Unit off Unit on

Problem during

charging

Battery is being

discharged

Battery missing or

defective

red red

off off

off red

Charging batteries

MEDUMAT Transport starts charging the battery

conditions are met:

• External power supply with at least 12 V DC

connected

• The battery is not full (<95% charge)

• Battery temperature not above 45°C or

below +5°C

Note

The battery WM 28385 has its own charging interface,

so it can also be charged outside the

Charging indicator

Transport. Only use the charger WM 28390.

If charging cannot be started, e.g., because the battery

temperature is outside the permitted range (+ 5°C 45°C), the charging indicator glows red. It only goes

out once all the conditions for starting charging are

met.

While the battery is being charged, the charging indicator

flashes green.

(current charge status)

(current charge status)

(current charge status)

automatically as soon as the following

MEDUMAT

Ending battery charging

MEDUMAT Transport automatically determines the optimum point at which to end charging by measuring and evaluating the charging curve and battery temperature. As soon as

charging has ended, the charging indicator glows steady green.

58 Operation

Page 59

Interrupting battery charging

Battery charging is continuously monitored by MEDUMAT Transport.

Problems which lead to charging being interrupted are:

• Battery temperature rises above 45°C, e.g., due to high ambient temperature,

or falls below +5°C

• Charging current is too high (>3 A) e.g., short-circuit

If one of these problems occurs, charging is automatically interrupted and the charging

indicator glows red.

Charging is also interrupted if there is no external power supply, e.g., because the unit,

mounted on a portable system, has been removed from the wall mounting. The charging

indicator does not light up in this case because this is not a fault, but a normal operating

state. As soon as the external power is restored, e.g., when the portable system is replaced

in the wall mounting, charging continues.

Operation 59

Page 60

6. Configuring the unit

In the main menu, you can optimize the unit's settings to

suit the particular service conditions. The main menu can

be called up at any time using the function button for

“Main menu”.

To navigate in the menu, you can use either the navigation

knob or the context-dependent function buttons on the

right of the display (see “5.1 Controls” on page 28).

6.1 Automatic alarm limits

General

When the “Automatic alarm limits“ function is active, the unit automatically sets limits for

the alarms relating to respiratory physiology. The determining factor for setting the limits

is the respiratory values (V

when the function is activated.

In the “Alarm limits“ menu (see “6.2 Setting alarm limits” on page 61), you can set the