Page 1

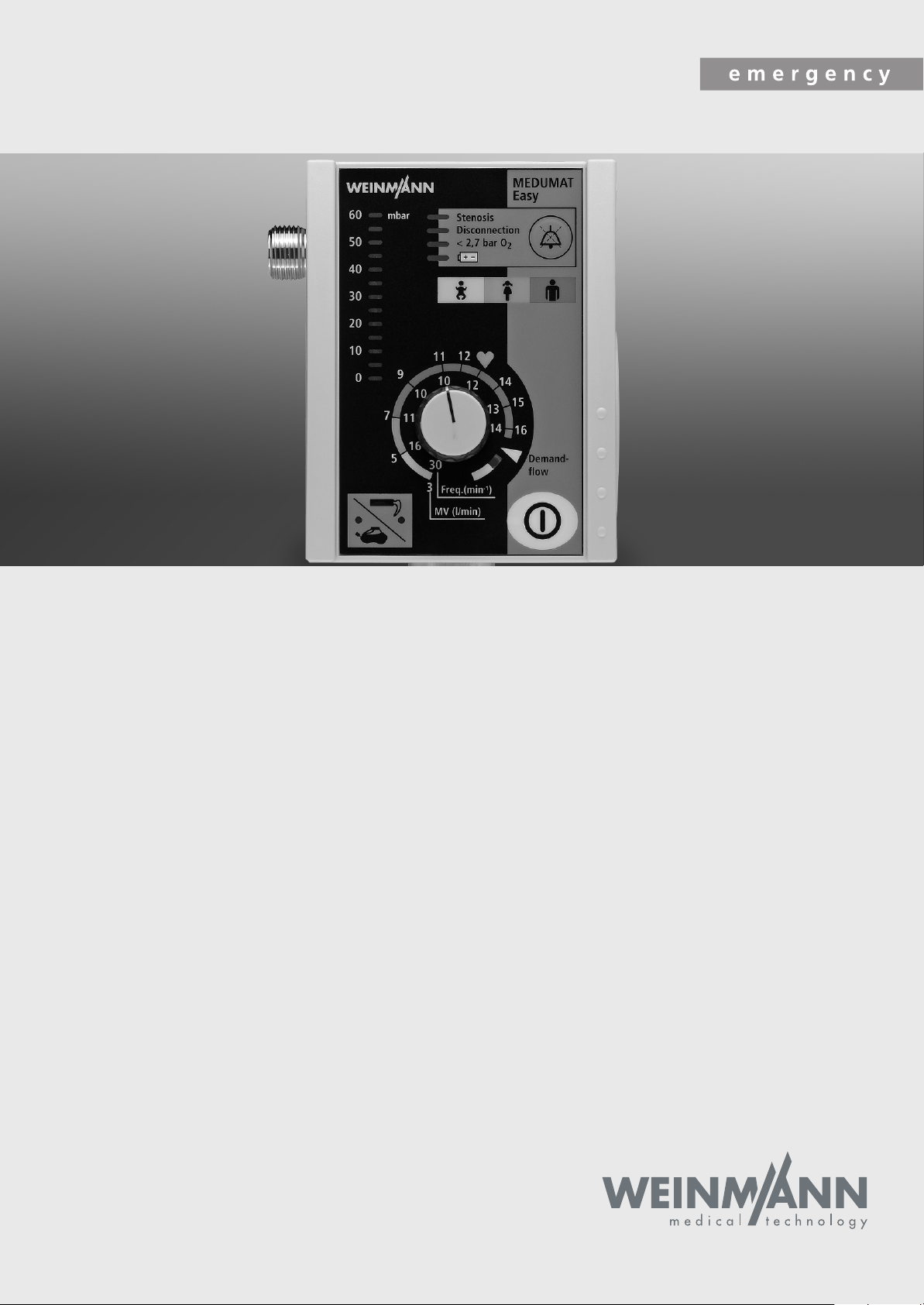

MEDUMAT Easy

Ventilator

Servicing and repair instructions

WM 28000

Page 2

Contents

Introduction

1.

Overview

1.1

2.

Description

2.1

2.2

2.3

2.4

2.5

3.

Final check

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

3.11

3.12

3.13

3.14

3.15

3.16

3.17

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Special symbols on the ventilator

. . . . . . . . . . . . . . . . . . . . . . . . . .

Uses

. . . . . . . . . . . . . . . . . . . . . . . . .

Ventilation function

Demandflow function

Patient valve

Audio response

. . . . . . . . . . . . . . . . . . . . . . . . . .

Testing equipment required

Preparing for final check

Entering the device data

Testing for leaks and pressure reading

Self-test when device is switched on

Functional check on controls

(button check)

Functional test and alarms

Battery power

Test pressure sensors

Functional check on frequency setting

Functional check

at 4.5 bar input pressure and

10 mbar back pressure

Checking O2 concentration

Functional check on pressure limit

Functional check on relief valve

without patient valve

Checking the type plate data

Check on external condition

Documentation

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

breath volume

. . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . .

. . . . . . . . .

. . . . . . . .

. . . .

. . . . . . .

. . . . . . . .

. .

. . . .

. .

10

10

11

12

12

13

13

13

13

14

14

3

4

5

6

6

6

7

7

7

8

8

8

8

9

9

9

4.

Servicing

4.1

4.2

4.3

5.

Troubleshooting

6.

Repair information and instructions

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

6.12

6.13

7.

Spare parts

7.1

7.2

8.

Tools and Test Equipment

8.1

8.2

8.3 Testing equipment. . . . . . . . . . . . . . . 39

9. Technical data . . . . . . . . . . . . . . . . . . . . . . . 40

9.1 Pneumatic / electronic systems . . . . . . 41

10. Technical Changes . . . . . . . . . . . . . . . . . . . 42

11. Repair and service records . . . . . . . . . . . . . . 43

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Intervals and scope

Batteries

Storage

General

Changing the filter in the pressurised

gas connection

Opening the device

Closing the device

Replacing button cell

Changing the speaker

Changing the board

Replacing the pneumatic block

Replacing the 3/2-way magnetic valve 29

Calibrating the potentiometer

(after changing pneumatic block

including potentiometer)

Changing upper part of housing

Changing the fascia film

Changing lower part of housing

Spare parts list

Service sets

General tools

Special tools

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . .

. . . . . . . . . . .

. . . . .

. . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

15

15

16

16

17

20

20

20

21

22

24

25

26

27

30

31

32

33

35

35

37

38

38

38

© Copyright WEINMANN GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised WEINMANN Service Partners in

the course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with WEINMANN.

2

Page 3

Introduction

For decades WEINMANN has been developing,

manufacturing and marketing devices for emergency medical care, oxygen therapy and inhalation

therapy.

In 1972 WEINMANN put the first MEDUMAT

emergency respirator on the market.

MEDUMAT emergency respirators are automatic

respirators. They are used for controlled respiration

in emergency medical care, e.g. in cases of acute

respiratory disorders, and also secondary obstructions.

The new generation of devices, developed specifically to meet users’ requirements and put on the

market in 1997, offers users and patients increased security. An intelligent alarm system monitors the patient’s breathing and informs the user

about any problems that occur. These devices thus

offer even greater security and reliability during

respiration.

The aim of these servicing and repair instructions is

to familiarise you, as an expert in the field, with the

function, technology, servicing and repair of the

MEDUMAT respirator. Thanks to training which you

have already received from WEINMANN, you now

count as “trained expert personnel” and can therefore give your customers appropriate instructions,

remedy problems on your own and perform the

functional checks prescribed in the operating instructions and any repairs required in accordance with

these Service and Repair Instructions.

In the event of a warranty claim, send the MEDUMAT

to WEINMANN.

To enable us to process ex gratia requests or warranty claims, please enclose the customer’s proof

of purchase (invoice) with the device.

Repairs or servicing work may be performed only

by WEINMANN or by trained specialist staff.

You are responsible for repairs carried out yourself

and for their warranty!

Use only original WEINMANN spares for repairs.

Please bear in mind:

Your customer trusts you and relies on your expert

capability, just as you rely on WEINMANN.

Note:

For the following information, please consult the Operating Instructions for MEDUMAT:

• Safety Information

• Fitting accessories

• Operating MEDUMAT emergency respirators

• Hygienic preparation

• Functional check

Introduction 3

Page 4

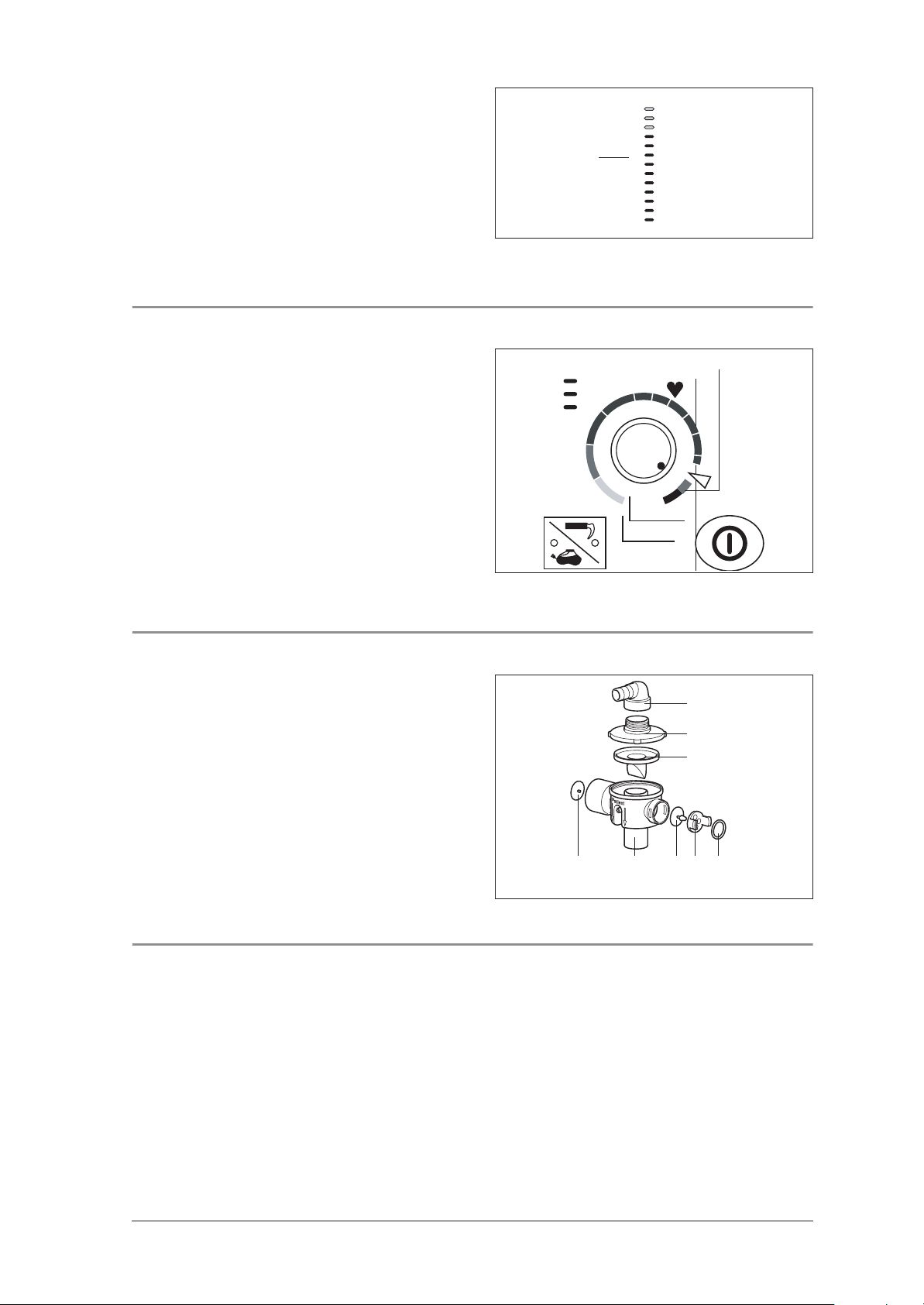

1. Overview

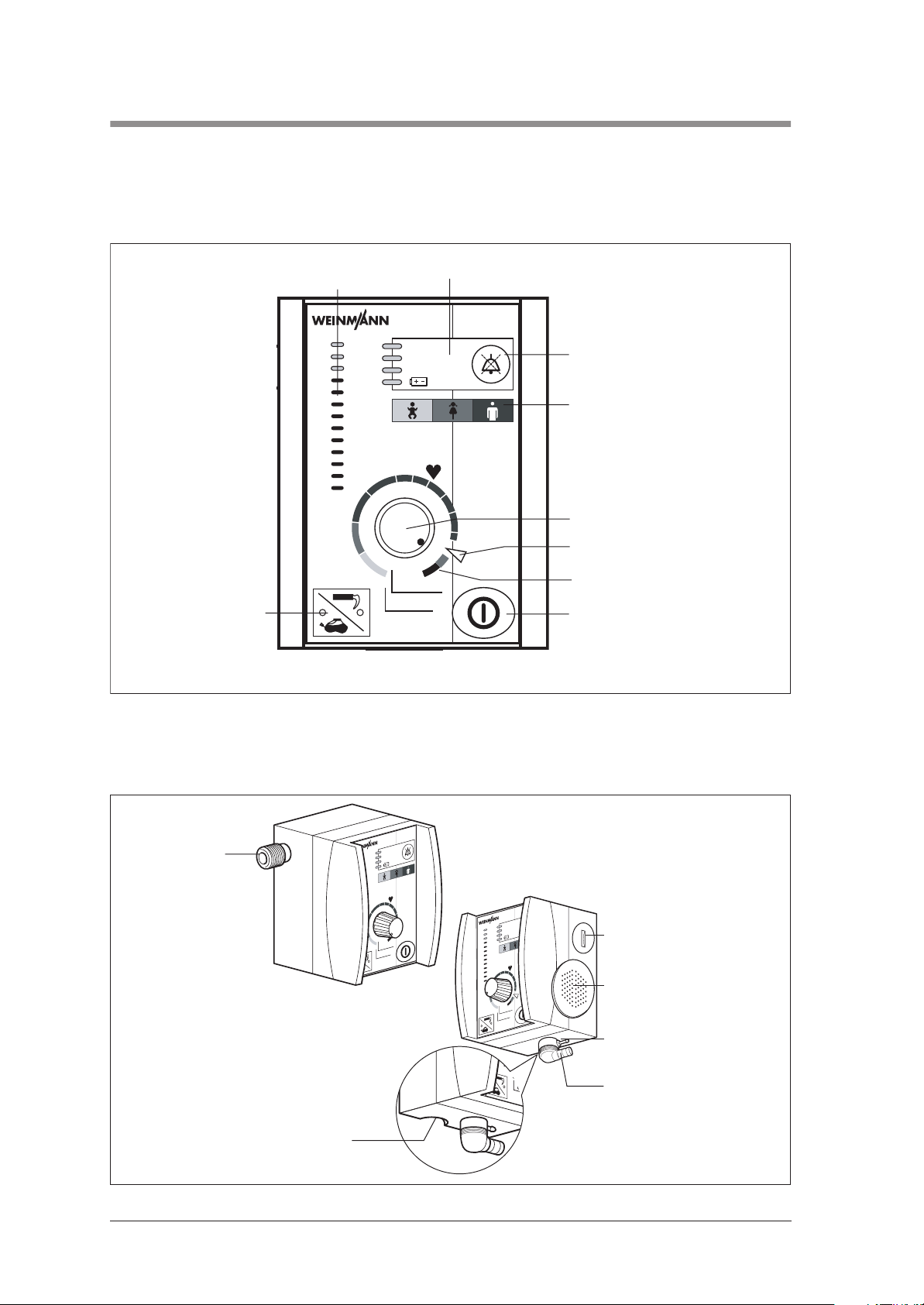

Control panel MEDUMAT Easy

1 Mask/tube ventilation

switch with indicator

LEDs

2 Respiratory pressure

indicator (bar graph)

60

mbar

50

40

30

20

10

0

11

9

10

7

11

16

5

30

3

MV (l/min)

Stenosis

Disconnection

< 2,7 bar O

12

10

12

Freq.(min

3 Alarm panel

MEDUMAT

Easy

2

14

15

13

14

16

Demandflow

-1

)

4 Alarm confirmation

5 Colour code

6 Adjuster knob, ventilation parameters

7 Index position

8 LED Demandflow

9 ON/OFF switch

Connections MEDUMAT Easy

r

a

b

10 Pressurized gas

connection

15 Relief outlet valve

m

60

50

40

30

20

11

10

10

9

0

10

11

7

16

30

5

eq.(

r

F

3

l/min

(

V

M

T

A

M

U

D

E

M

sy

a

E

is

s

o

n

e

t

S

n

io

t

c

e

n

n

o

c

s

i

D

O

2

r

a

b

,7

2

<

12

14

12

15

13

16

14

-

d

n

a

m

e

D

w

lo

f

-1

)

in

m

)

60

50

40

30

20

10

0

T

A

M

U

D

E

M

sy

a

E

is

s

o

n

e

t

S

n

io

t

c

e

n

n

r

a

o

c

is

mb

D

O

2

r

a

b

7

,

2

<

12

1

1

4

1

12

10

9

15

3

10

1

6

1

14

1

1

7

-

d

n

a

m

e

D

w

o

l

16

f

30

5

1

-

)

n

i

m

(

.

eq

Fr

3

)

n

i

m

/

l

(

V

M

11 Battery compartment

12 Speaker

13 Pressure gauge hose

connection

14 Ventilation hose connection

4 Overview

Page 5

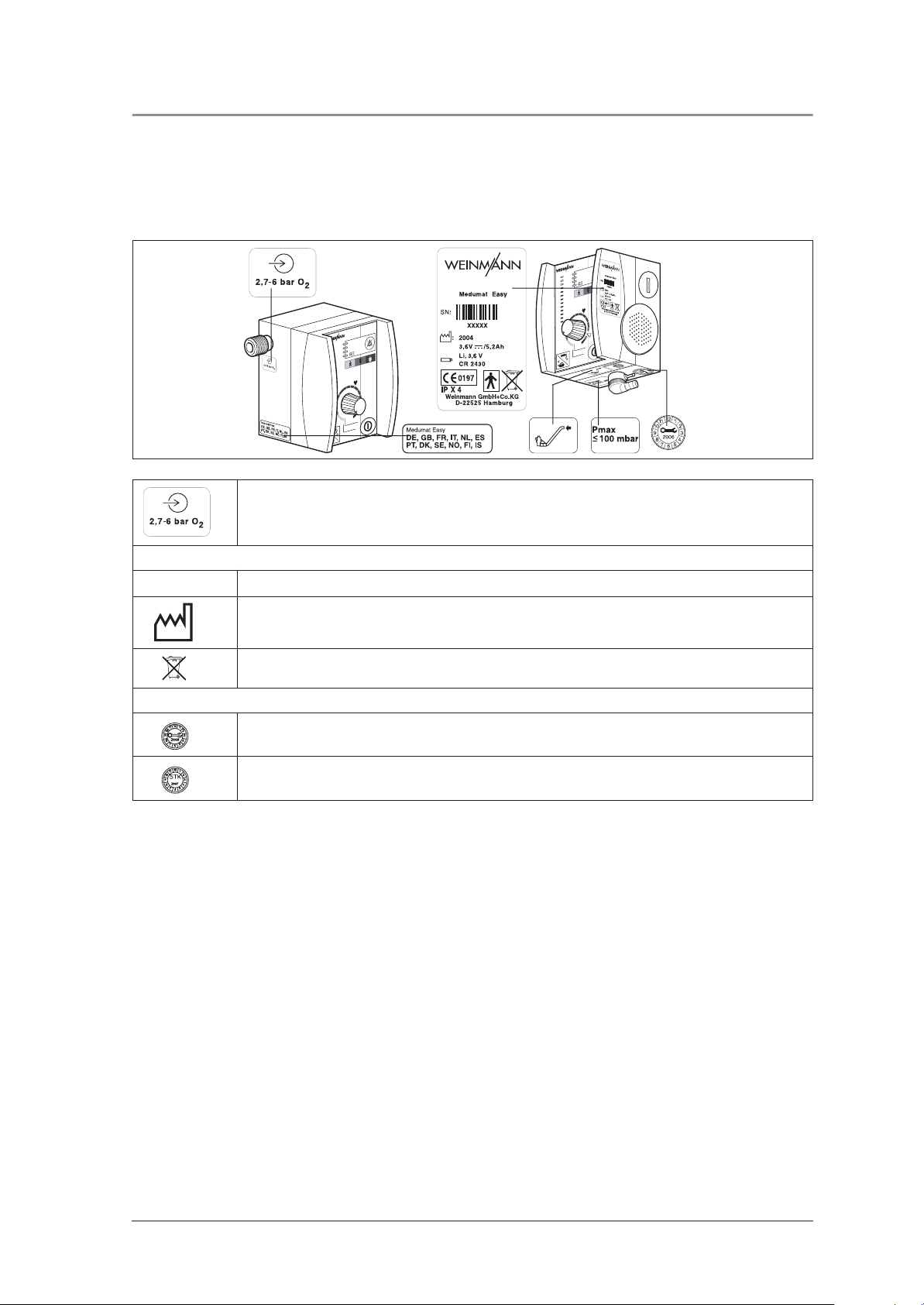

1.1 Special symbols on the ventilator

Symbols on MEDUMAT Easy

Typ :

T

A

M

EDU

M

y

as

E

s

i

s

o

n

e

t

S

n

o

i

t

c

e

n

n

r

o

c

ba

s

i

m

D

O

2

r

a

60

b

7

,

2

<

50

40

30

20

12

11

10

14

12

10

9

15

0

10

13

16

14

11

7

-

d

n

a

m

e

D

w

o

l

16

f

30

5

1

-

)

n

i

m

(

.

q

e

r

F

3

)

n

i

m

/

l

(

V

M

Inlet 2,7 - 6 bar O2.

T

A

UM

ED

M

Easy

e

t

u

a

h

n

o

i

s

s

e

r

e

s

P

s

a

b

n

Ty

o

p

i

s

:

s

e

r

P

mbar

O

2

r

0

a

6

b

,7

2

<

0

5

0

4

0

3

0

2

2

1

1

1

0

4

1

1

2

1

0

1

9

5

1

0

0

3

1

1

6

1

4

1

1

1

7

6

1

30

5

3

SN

MEDUMAT Easy device information plate

Serial number of device

Year of manufacture

Do not dispose of device in domestic waste.

Safety check and servicing label

Servicing label: indicates when the next service is due.

Safety check label: (in Germany only) marks when the next safety check as per §6 of the German

law relating to users of medical devices is required.

Overview 5

Page 6

2. Description

2.1 Uses

MEDUMAT Easy is an automatic oxygen respiration device (short-term ventilator) with additional inhalation

facility.

You can use MEDUMAT Easy:

• to revive patients at the site of the emergency;

• for longer periods in more protracted

emergencies, e.g. fires;

• for short-term O2 inhalation using a respiration

mask.

You can use MEDUMAT Easy while transporting

patients:

• between the various rooms and departments

of a hospital;

• between the hospital and other premises;

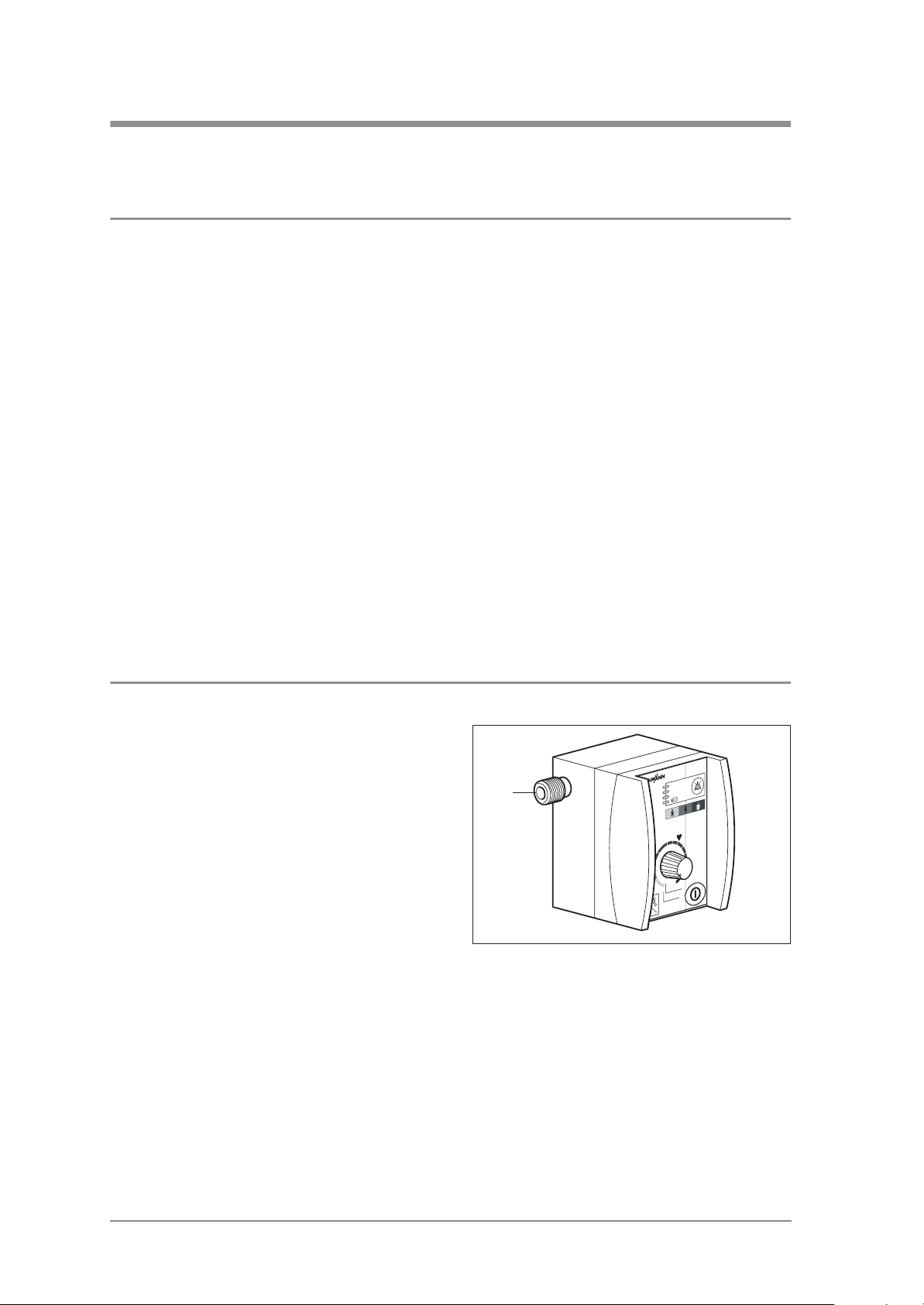

2.2 Ventilation function

MEDUMAT Easy operates within a pressure range

of 2.7 to 6 bar and at a flow rate of not less than

70 l/min O2. It has a built-in power supply.

It uses high-pressure, medicinal-grade oxygen. An

external pressure reducer brings this down to the

required operating pressure. The oxygen supply is

fed in at input valve 10.

The ventilation settings are continuously variable.

These settings (frequency and volume per minute

are coupled) and the inspiration/expiration ratio

of 1:1.67 are regulated by internal electronic

control mechanisms.

• in emergencies;

• when transport over considerable distances is

planned.

MEDUMAT Easy:

• is designed to provide controlled ventilation to

persons of 10 kg body weight or more;

• is used to treat respiratory arrest;

• can be preset to parameters that ensure evenly

balanced ventilation, provided that the

selected maximum ventilation pressure P

max

is

not exceeded;

• permits breathing-controlled oxygen inhalation

in Demand mode.

MEDUMAT

Easy

Stenosis

r

a

b

m

Disconnection

2

60

10

< 2,7 bar O

50

40

30

20

12

11

10

14

12

10

9

15

0

10

13

16

14

11

7

Demand-

w

16

flo

30

5

-1

)

q.(min

Fre

3

MV (l/min)

The gas for inspiration flows along the hose and

through the patient valve and either the mask or

tube into the patient’s airways. The patient valve is

fitted with a lip membrane that enables expired

gas to be conducted away through the expiration

tube.

6 Description

Page 7

You can check the course of ventilation on the

10

respiration pressure indicator 2.

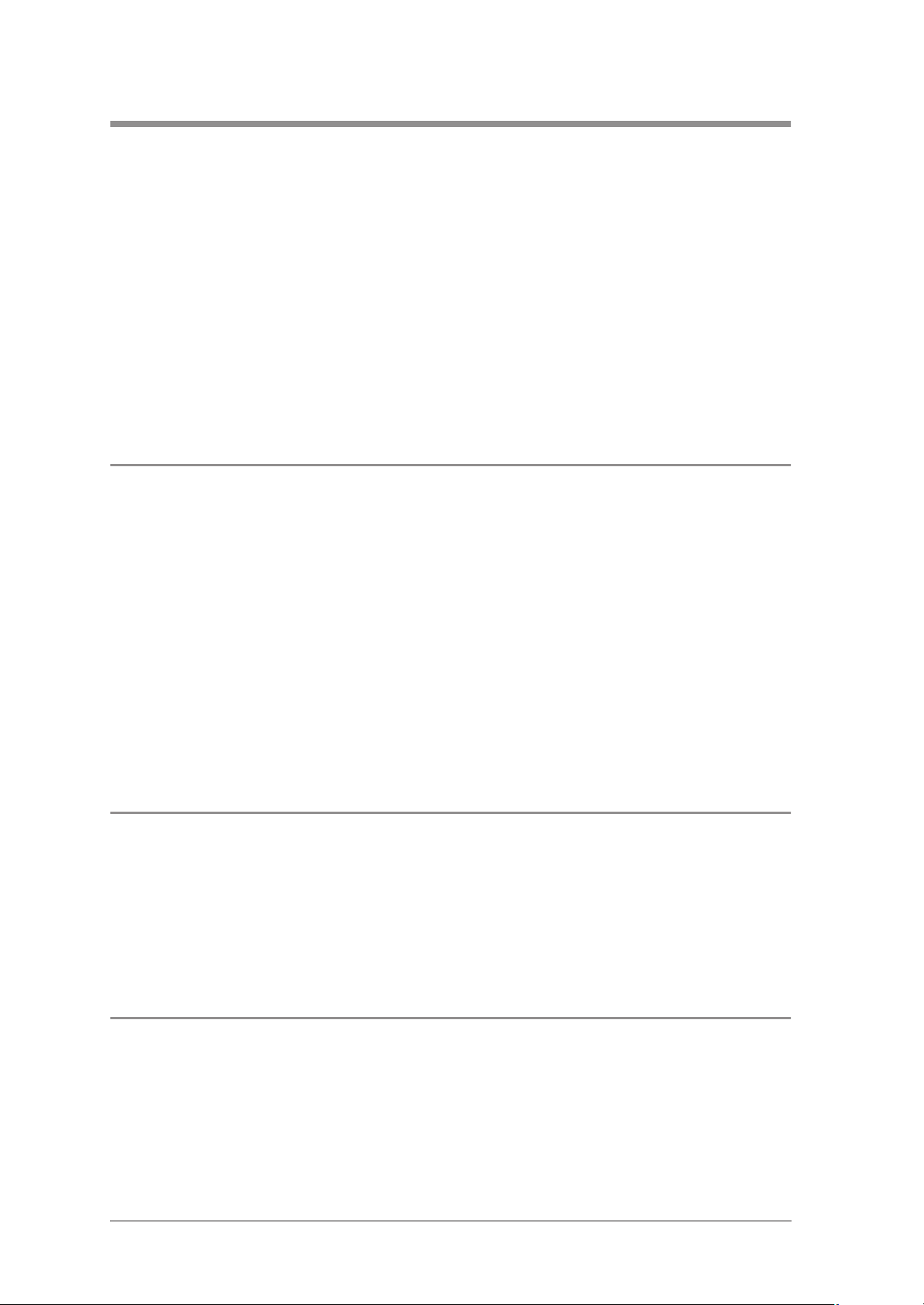

2.3 Demandflow function

mbar

60

50

2

40

30

20

10

9

0

The Demandflow setting switches the

MEDUMAT Easy to breathing-controlled O2

inhalation. Such inhalation must be carried out

with the respiration mask. A small inspiration

(trigger) pulse causes oxygen to continue flowing

until slight overpressure interrupts the flow.

Expiration then takes place via the patient valve as

in ventilation.

2.4 Patient valve

The gas for inspiration is channelled into the

patient’s airways through the patient valve.

The valve is designed to enable spontaneous

breathing in the event of failure of the

MEDUMAT Easy.

0

Demandflow setting

12

11

9

10

10

7

11

16

5

30

3

Freq.(min

MV (l/min)

12

14

15

13

14

16

Demandflow

-1

)

38

37

39

40 34 35 36 41

2.5 Audio response

The device has an audio response facility that can

be switched on for user guidance, especially for

users who have little practice.

If audio guidance is not wanted, it can be

switched off by pressing a combination of keys

(see “4.10 Audio response for user guidance” in

the operating instructions).

Description 7

Page 8

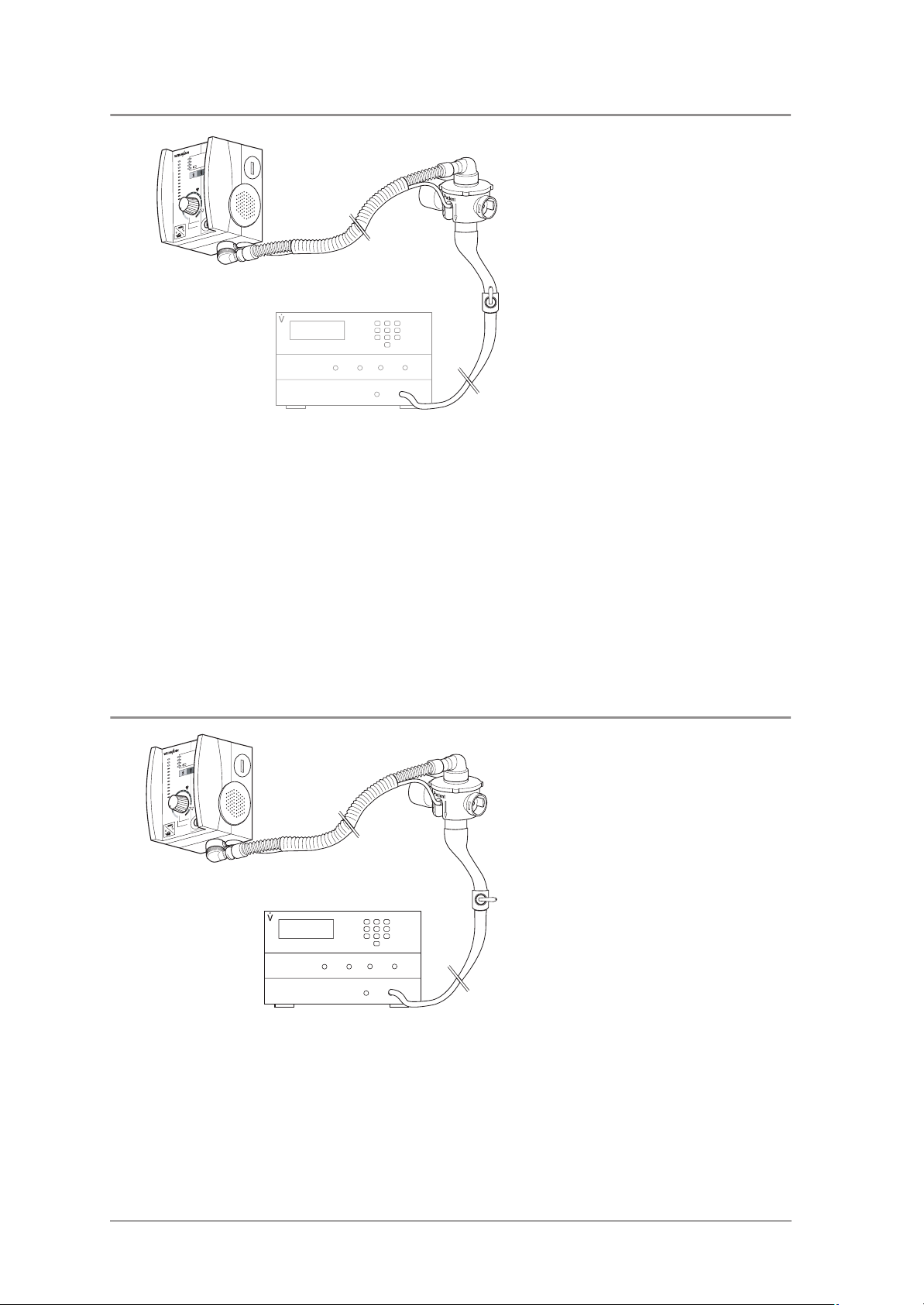

3. Final check

After every repair and every service, the device

must be subjected to the following final check in

accordance with Test Instructions WM 28001

and the test record.

Note:

For the final check on the MEDUMAT Easy you

must connect the ventilation hose and the patient

valve to the device.

MEDUMAT Easy must not be used if the final

check reveals defects or deviations from the

specified parameters.

We recommend that you always hold reserve

stocks of the following items:

• replacement washers for the connections;

• lip membrane for the patient valve.

• membrane for spontaneous breathing tube;

• membrane for exhalation tube;

• O-ring 1145/118.

3.1 Testing equipment required

• Volume flow meter, Type RT 200 (Timeter), Type EKU VIP – ventilator, PF 300 Imtmedical or comparable

test device

• Adjustable orifice, e.g. ball valve, internal diameter ≥ 10 mm

• Test set for functional checks WM 15323

• Oxygen concentration meter, 0 – 100% ± 1%,

e.g. Type Oxycontrol WM 13550

• Set, hose with syringe WM 15359

• Pressure gauge 0 - 6.3 bar, class 1.6

• Pressure gauge 0 -100 mbar, class 1.6

• Set, supply test Medumat / Modules WM 15440

3.2 Preparing for final check

1. Connect MEDUMAT Easy to the 4.5 - 6 bar pressure supply.

2. Connect ventilation hose and pressure measurement tube to MEDUMAT Easy.

3. Device setting: Freq. = 30 min-1, MV = 3 l/min.

4. Language setting “English”.

3.3 Entering the device data

• Enter the device number and the tester number in the test record.

8 Final check

Page 9

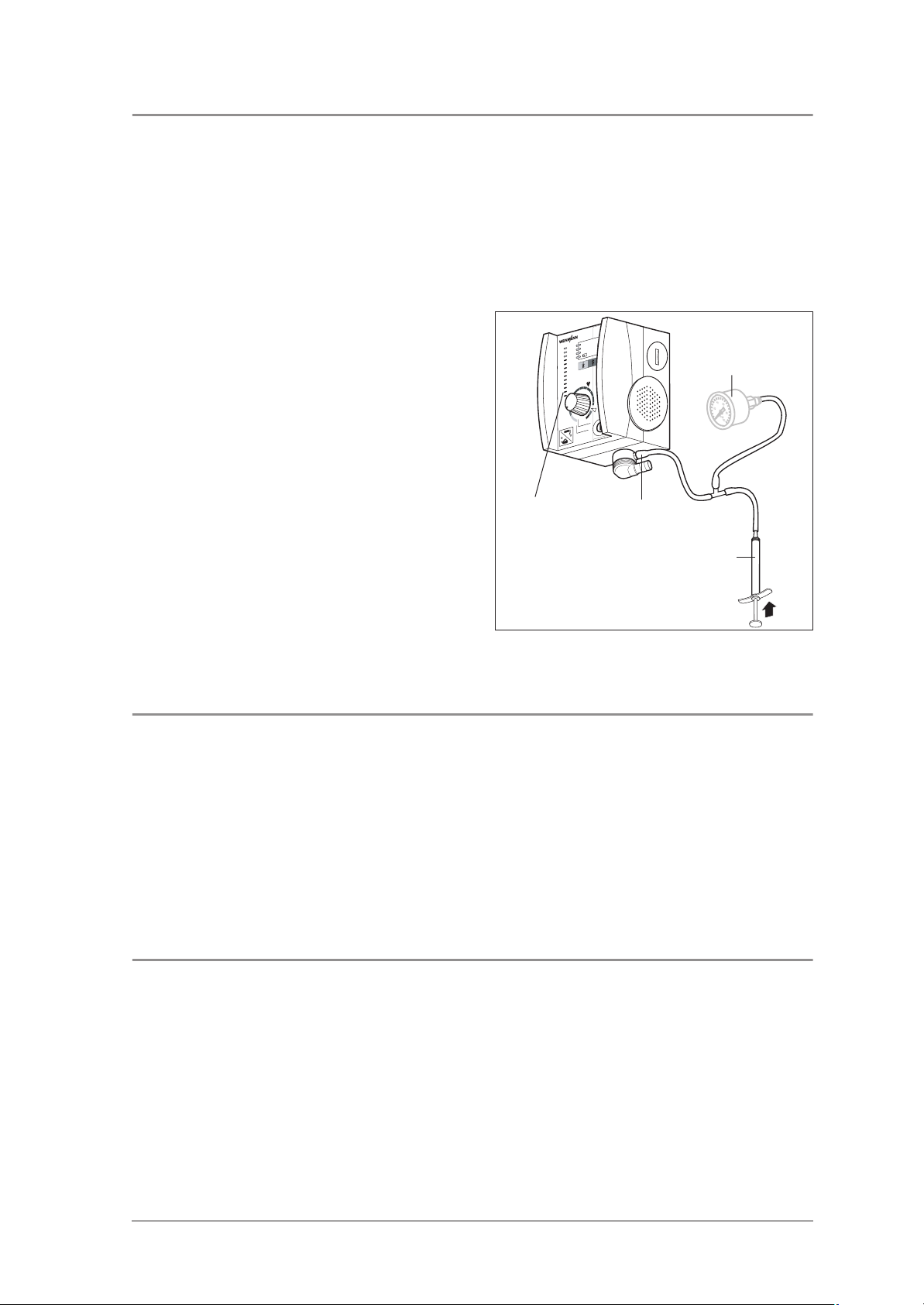

3.4 Testing for leaks and pressure reading

3.4.1 Checking input side for leaks

• With the device switched off, apply 6 bar pressure to input side and and shut off output pressure.

Requirement: The pressure drop must be less than 0.2 bar/min.

3.4.2 Checking pressure measurement zone for leaks

• Apply 55 mbar ± 2 mbar to MEDUMAT

pressure measurement zone.

Requirement: The pressure drop must be

≤ 2 mbar/min.

Respiration

T

A

M

U

D

E

M

sy

Ea

s

i

s

o

n

e

t

n

S

o

i

t

c

e

n

n

o

c

r

s

a

i

b

D

m

2

0

6

< 2,7 bar O

0

5

0

4

30

0

2

2

1

1

1

0

4

1

1

2

1

0

1

9

15

0

0

3

1

1

6

1

4

1

1

1

7

16

30

5

3

Test pressure

gauge

13

pressure indicator

Syringe

3.5 Self-test when device is switched on

If audio response is enabled, you will hear the sentence “Open oxygen cylinder” before the self-test starts.

1. Apply 4.5 bar to the input.

2. Switch on MEDUMAT Easy at button 9.

Requirement: The self-test starts, the ventilation mode LEDs light up once each one after the other, the alarm

LEDs flash, the pressure indicator LEDs are run through 3 times, a signal tone sounds and an audio

response sentence is spoken.

3.6 Functional check on controls (button check)

1. Open the pressure supply.

2. Switch on the device.

3. Switch from mask ventilation to tube ventilation.

4. Press the alarm acknowledgement button.

Final check 9

Page 10

3.7 Functional test and alarms

3.7.1 Test Stenosis alarm

• Switch to tube ventilation ( ) and close patient valve outlet.

• Operate device at Freq. setting = 30 min-1 and MV = 3 l/min.

Requirement: The Stenosis alarm must be triggered after two ventilation cycles. If audio response is

enabled, the ventilator announces “Check airways and minute volume”.

3.7.2 Checking alarm confirmation

• Immediately after the first alarm tone sounds, press Alarm confirmation button 4.

Requirement: The alarm tone must be suppressed immediately.

3.7.3 Test Disconnection alarm

• Open patient valve outlet.

Requirement: The Disconnection alarm must be triggered after two ventilation cycles. If audio response

is enabled, the ventilator announces “Check ventilation system and settings”.

3.7.4 Test Pressure alarm

• Shut off pressurised gas connection of MEDUMAT (2.7 - 6.0 bar).

Requirement: The Pressure alarm must be triggered. If audio response is enabled, the ventilator

announces “Check pressure hose system and gas supply”.

3.7.5 Checking Demand mode LED

• Open the pressure supply.

Requirement: Demand mode LED must come on (flickering).

3.7.6 Check voice output

3.8 Battery power

3.8.1 3.0 V battery (on board)

Since the 3.0 V lithium cell is difficult to access, its

charge status can be checked both via the

interface and in a relevant menu.

To do so, hold down the alarm confirmation button

while switching the device on. The device is then

in battery check mode for 3 seconds, before

switching to normal operating mode.

During this 3-second period the “Power supply”

alarm in the alarm panel lights up and the voltage

measured for the lithium cell is shown on the

pressure bar graph.

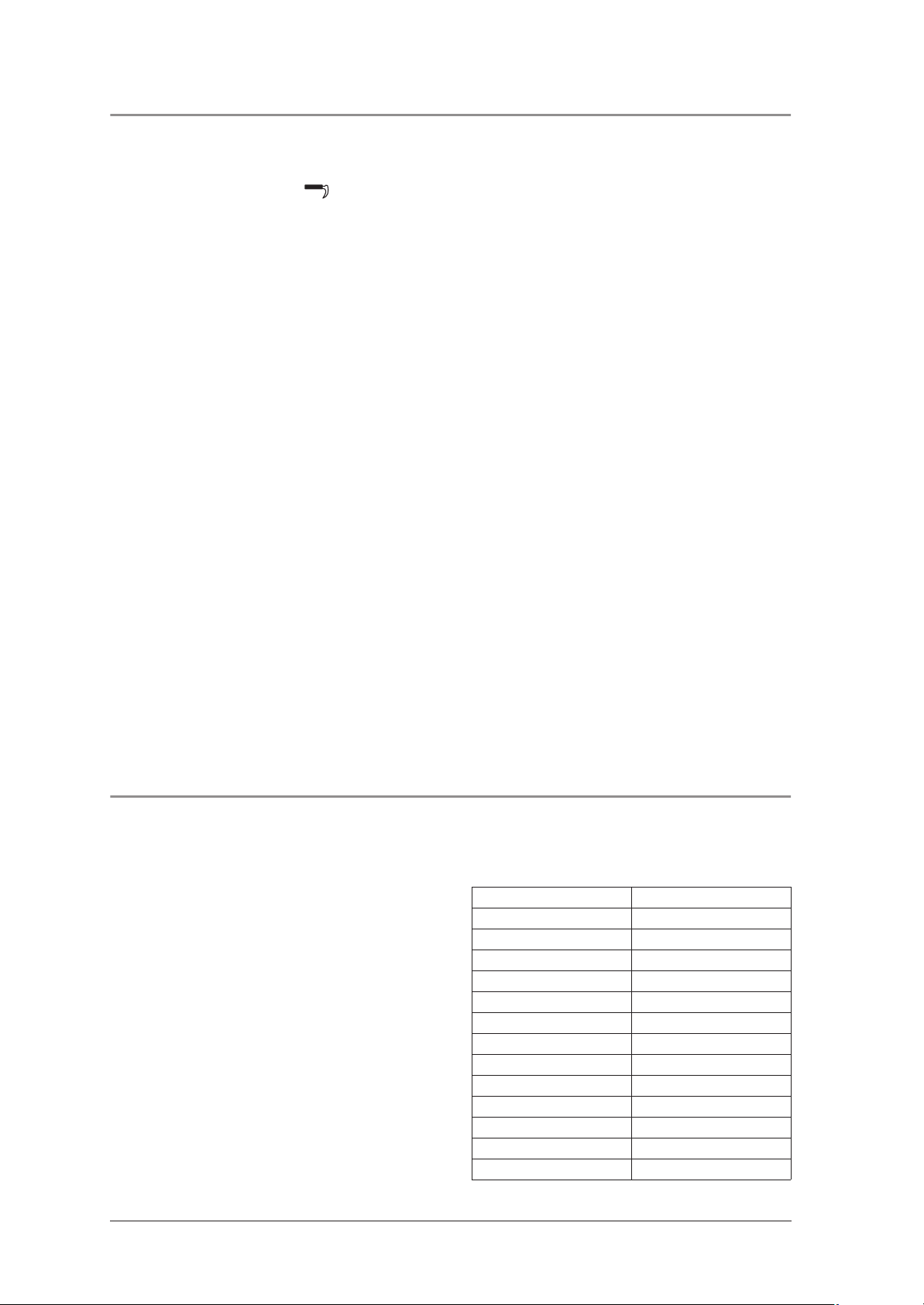

The adjacent table shows how the voltage

readings correspond to the bar graph values.

Bar graph value (mbar) Battery voltage (V)

60 3.21

55 3.19

50 3.17

45 3.15

40 3.13

35 3.11

30 3.09

25 3.07

20 3.05

15 3.03

10 3.01

5 2.99

0 2.97

10 Final check

Page 11

Requirement: Voltage measured for 3.0 V battery is in the range 3.0 to 3.2 V; the alarm for this cell is

triggered at 2.7 V.

3.8.2 3.6 V battery (battery compartment)

Remove the 3.6 V battery from the battery compartment and measure the voltage with a digital multimeter.

Requirement: Voltage measured for 3.6 V battery is in the range 3.4 to 3.7 V.

3.9 Test pressure sensors

3.9.1 Input pressure sensor

• Shut off pressurised gas connection of MEDUMAT (2.7 - 6.0 bar).

Requirement: The Pressure alarm must be triggered. If audio response is enabled, the ventilator

announces “Check pressure hose system and gas supply”.

3.9.2 Ventilation pressure sensor

• Connect ventilation hose to test bag.

• Run device with settings: Freq. = 10 min-1 and MV = 11 l/min.

• Switch device to mask ventilation.

Requirement: The pressure limit must respond at 20 ± 5 mbar.

• Switch device to tube ventilation.

Requirement: The pressure limit must respond at 45 ± 5 mbar.

3.9.3 Demand flow sensor

1. Supply device with pressure.

2. Switch on MEDUMAT Easy at button 9.

3. Connect ventilation tube and patient valve to test bag.

4. Set MEDUMAT Easy to demand flow mode.

5. Green LED in demand mode button illuminates.

6. Squeeze the test bag.

Requirement: Releasing the test bag triggers a short ventilation.

Final check 11

Page 12

3.10 Functional check on frequency setting

T

A

M

U

D

E

M

y

s

a

E

Stenosis

tion

c

r

a

b

Disconne

m

O

2

r

60

,7 ba

2

<

50

40

30

20

12

11

10

14

12

0

1

9

5

1

0

0

3

1

1

6

1

14

11

7

16

0

3

5

3

Patient valve with

hose system

Volume flow meter

Orifice 10 mbar

open

• Connect ventilation hose to 10 mbar orifice and to volume flow meter.

• Run device with settings: Freq. = 14 min-1 and MV = 16 l/min.

Requirement: The frequency must be 14 ± 2 min

-1

.

• Run device with settings: Freq. = 10 min-1 and MV = 11 l/min.

Requirement: The frequency must be 10 ± 2 min

-1

.

• Run device with settings: Freq. = 30 min-1 and MV = 3 l/min.

Requirement: The frequency must be 30 ± 2 min

-1

.

3.11 Functional check breath volume at 4.5 bar input pressure and 10 mbar back pressure

T

A

M

U

D

E

M

y

s

a

E

is

s

o

n

te

n

S

io

t

c

e

n

n

o

c

is

bar

D

m

O

2

r

0

a

6

b

7

,

2

<

0

5

0

4

0

3

0

2

2

1

1

1

0

4

1

1

2

1

0

1

9

5

1

0

0

3

1

1

6

1

4

1

1

1

7

6

1

0

3

5

3

Patient valve with

hose system

Volume flow meter

Orifice at 10 mbar

setting

• Run device with settings: Freq. = 14 min-1 and MV = 16 l/min.

Requirement: Breath volume must be 1140 ± 170 ml.

• Run device with settings: Freq. = 10 min-1 and MV = 11 l/min.

Requirement: Breath volume must be 1100 ± 170 ml.

• Run device with settings: Freq. = 30 min-1 and MV = 3 l/min.

Requirement: Breath volume must be 100 ± 20 ml.

12 Final check

Page 13

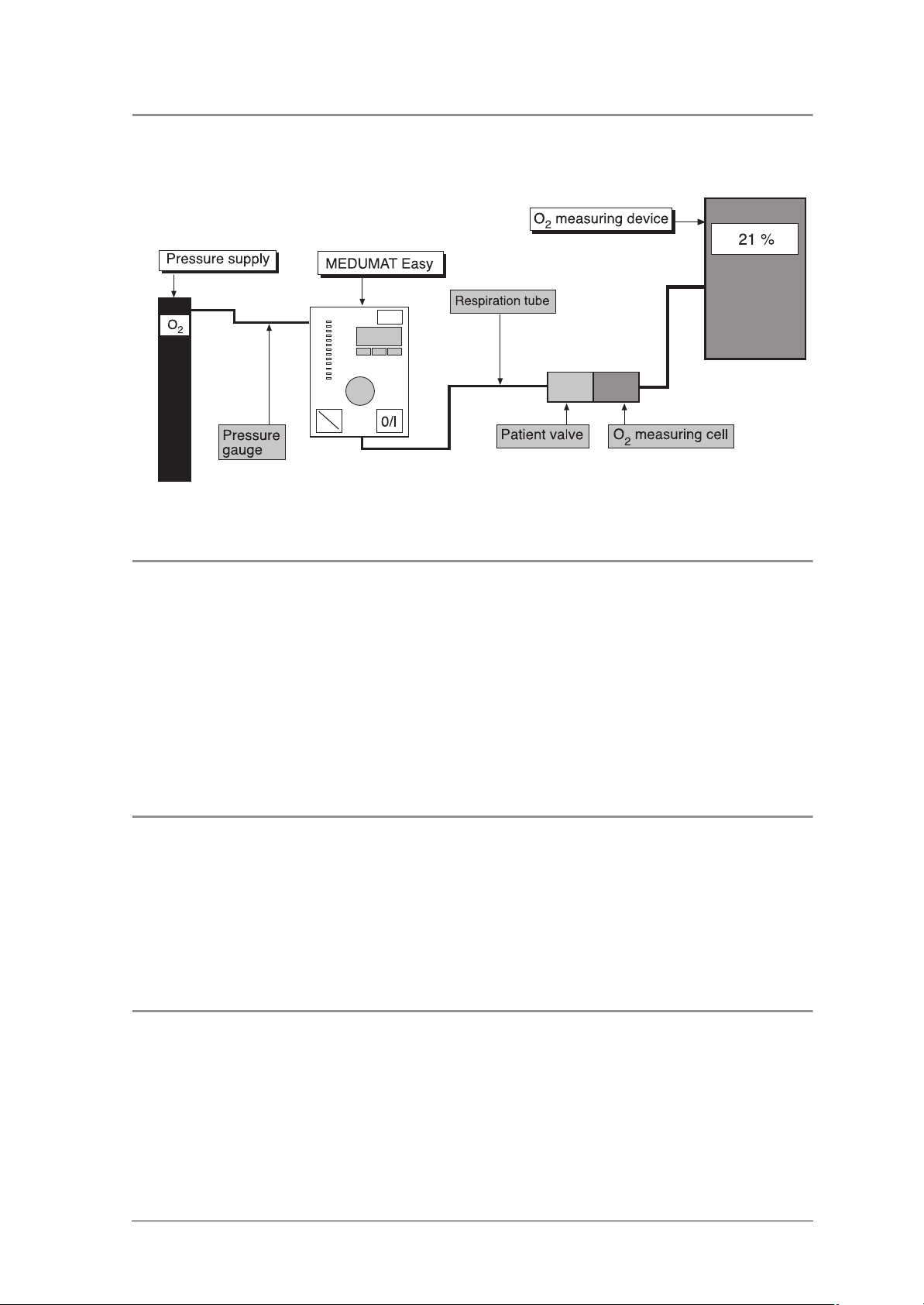

3.12 Checking O2 concentration

• Run device with settings: Freq. = 10 min-1, MV = 11 l/min and 100% O2.

Requirement: The O

concentration must be > 98%.

2

3.13 Functional check on pressure limit

• Connect ventilation hose to test bag.

• Run device with settings: Freq. = 10 min-1 and MV = 11 l/min.

• Switch device to mask ventilation.

Requirement: The pressure limit must respond at 20 ± 5 mbar.

• Switch device to tube ventilation.

Requirement: The pressure limit must respond at 45 ± 5 mbar.

3.14 Functional check on relief valve without patient valve

• Run device with settings: Freq. = 11min-1 and MV = 7 l/min.

• Switch ventilation hose to test bag.

Requirement: The test bag is fully inflated during the inspiration stroke. The ventilator is then heard to

release pressure.

3.15 Checking the type plate data

• Check type plate data against drawing.

Requirement: The type plate data must be correctly entered in accordance with the drawing.

Final check 13

Page 14

3.16 Check on external condition

• Check external condition.

Requirements: The outside of the device is not scratched and there are no flaws.

The connection thread is undamaged and screws easily.

The adjuster knob is secured by self-locking against inadvertent changes.

Elbow outlet turns easily.

3.17 Documentation

• Document items 3.3 to 3.16, and also test date and tester number, in the test record.

14 Final check

Page 15

4. Servicing

Note:

Remember to perform a final check after every repair.

We recommend that maintenance work such as inspections and repairs be performed only by the

manufacturer, i.e WEINMANN, or by qualified technicians expressly authorized by WEINMANN.

4.1 Intervals and scope

Every 2 years:

Every 2 years the device (incl. patient valve and hose system) must undergo servicing and be subjected to a

safety check as specified below.

You can also have servicing and the safety check performed by WEINMANN.

Be sure to check the following items:

• Check equipment for completeness;

• Visual check:

– Mechanical damage

– Labelling of controls

– Damage to all external hoses;

• Renew parts subject to wear / parts requiring

compulsory replacement (see “7.2 Service

sets” on page 37);

• Check system components: carrying platforms,

oxygen fittings, secretion suction system, hose

connections etc.;

• Check test bag;

• Final check in accordance with Test Instructions/

Test Record STK WM 28001 (see “3. Final check”

on page 8 and see “11. Repair and service

records” on page 43).

Every 4 years:

• Servicing of the fittings in the oxygen supply system (e.g. pressure reducer) either by the manufacturer or

by a specialist expressly authorized by the manufacturer.

Every 10 years:

• Repeat testing of conventional steel or aluminium oxygen cylinders by the responsible testing

organisation. The repeat testing date is stamped on the shoulder of the cylinder.

Servicing 15

Page 16

4.2 Batteries

MEDUMAT Easy is equipped with two batteries.

The main battery 18 must always be changed. The

button cell 17 (CR2430) only has to be replaced

every 4 years.

The button cell 17 supplies auxiliary power to the

electronic system if the main battery 18 fails. This

makes it possible to set off an alarm even if the

main battery suddenly fails. The device then

switches to exhalation.

In principle, the battery capacity is designed so

that under normal conditions of use, it will not need

changing in the 2 years between services. The

main battery 18 is to be renewed during the 2yearly service, the button cell 17 only every 4

years.

17

60

MEDUMAT

m

b

a

r

Easy

S

te

n

os

50

is

D

isco

n

n

ec

t

io

n

<

2

,7

ba

40

r

O

2

30

20

10

11

12

0

9

10

10

12

14

7

11

15

13

14

16

16

5

30

D

em

an

d

-

3

flow

Freq

.(

m

-

1

in

)

M

V

(

l/m

i

n

)

42

18

When changing batteries, special precautions

must be taken to protect the electronic circuits (see

“6.5 Replacing button cell” on page 24).

17: Button cell for back-up power

18: Lithium battery 3.6 V for main power

supply MEDUMAT Easy

When changing the main battery 18, you must

change the O-ring 42 on the battery compartment

cover as well.

4.3 Storage

If you do not intend to use MEDUMAT Easy for a long period, we recommend the following storage

precautions:

1. Clean and disinfect the device (see “5.

Hygienic Preparation” in the operating

instructions).

2. Store MEDUMAT Easy in a dry place.

Important

Remember that devices still require servicing at the

specified intervals even when in storage, otherwise

they are not allowed to be used when removed

from storage.

16 Servicing

Page 17

5. Troubleshooting

Fault Cause Remedy

A battery is exhausted

Fuse defective Change board (6.7, page 26)

MEDUMAT Easy does not

start up when switched on

MEDUMAT Easy will not

switch off

MEDUMAT Easy is

functioning, but without any

displays

MV too high

MV not correct

Ribbon cable X100 of fascia film is

faulty or not connected

On/Off button 9 defective Change fascia film (6.12, page 32)

Board defective Change board (6.7, page 26)

Magnetic valve defective

Operating error

On/Off button 9 defective Change fascia film (6.12, page 32)

Pressure gauge hose on

MEDUMAT Easy or on patient valve

has slipped off

Kink in pressure gauge hose

Pressure gauge hose within device is

kinked or has slipped off

Measured without 10 mbar back

pressure

Measuring device not calibrated Calibrate measuring device

Input pressure > 6 bar

Patient valve not in order

Potentiometer wrongly adjusted

Adjuster knob out of adjustment

Pneumatic block leaking

Change main battery 18 (4.2,

page 16), check button cell 17

(3.8.1, page 10) and replace if

necessary (4.2, page 16)

Check plug-in connection and cable

(6.7, page 26)

If necessary, replace upper part of

housing (6.11, page 31)

Change magnetic valve (6.9,

page 29)

Keep On/Off button 9 pressed for

at least 2 seconds

Check pressure gauge hose

Set to 10 mbar back pressure

Reduce system setting to less than

6 bar

Check membranes and O-ring,

replace if necessary (Chapter 6.7 of

operating instructions)

Readjust potentiometer (6.10,

page 30)

Readjust adjuster knob (6.10,

page 30)

Replace pneumatic block (6.8,

page 27)

Troubleshooting 17

Page 18

Fault Cause Remedy

+–

Incorrect setting selected on device

Make correct setting (Chapter 6.5 of

operating instructions)

Check membranes and O-ring,

Patient valve not in order

replace if necessary (Chapter 6.7 of

operating instructions)

Pressure limit (P

max

) not in

Patient valve or test bag not correctly

connected

MV not in order See fault “MV not in order”

Check hose connections and test

bag

order

Hose connections in device not in

order

Check hoses, replace if necessary

(6.8, page 27)

Pressure sensor on board is faulty Change board (6.7, page 26)

Adjuster knob for ventilation

defective

Pressure measurement connection

blocked

Replace adjuster knob (6.3,

page 21 and 6.4, page 22)

Replace (6.8, page 27)

LED’s do not light up Change board (6.7, page 26)

Alarms (visual + acoustic) not

in order

Incorrect indication (Stenosis/

Disconnection)

Check settings, check hose

connection to patient valve (Chapter

6.7 of operating instructions)

No (visual + acoustic) alarm Board defective Change board (6.7, page 26)

Alarm confirmation pressed? Wait for between 30 – 120 s

No acoustic alarm

Speaker defective Replace speaker (6.6, page 25)

Pressure sensor defective Change board (6.7, page 26)

Alarm < 2.7 bar although

pressure present

Hose connections in device not in

order

Check hoses, replace if necessary

(6.8, page 27)

Change main battery 18 (4.2,

alarm. Battery failing

page 16), check button cell 17

(3.8.1, page 10) and replace if

necessary (4.2, page 16)

Pressure inlet leaking

Hose system in device is

leaking

Pressure sensor on board is

leaking

Angled connector in device is loose

or defective

Check (6.8, page 27)

Check hoses, replace if necessary

(6.8, page 27)

Change board (6.7, page 26)

Mask/tube switch 1 defective Change fascia film (6.12, page 32)

Pneumatic block leaking

Potentiometer wrongly adjusted

Replace pneumatic block (6.8,

page 27)

Adjust potentiometer (6.10,

page 30)

Frequencies not in order

Replace pneumatic block (6.8,

page 27)

Test bag is not filled

sufficiently during functional

check, Disconnection alarm

Potentiometer defective

Ventilation parameters incorrectly set Correct ventilation parameters

Patient valve not working properly Check lip membrane

Pressure measurement tube not fitted Fit pressure measurement tube

18 Troubleshooting

Page 19

Fault Cause Remedy

No Stenosis alarm when

patient valve closed during

functional check (see

“Checking the breath volume”

in the operating instructions)

Patient valve not working properly Check lip membrane

Troubleshooting 19

Page 20

6. Repair information and instructions

6.1 General

Always perform repairs to MEDUMAT Easy at an ESD-protected workplace.

• Observe the safety information in the Operating

Instructions for MEDUMAT Easy.

• All operations on this device require detailed

knowledge and observation of the Operating

Instructions and the Service and Repair

Instructions.

• Do not carry out any repairs that are not

described in these Service and Repair

Instructions. This is the only way to guarantee

trouble-free functioning of MEDUMAT Easy.

• Make sure that your hands and workplace are

clean during the repair work.

• Be sure to carry out a final check after every

repair (see “3. Final check” on page 8).

• If you replace components or individual parts,

use only genuine WEINMANN parts.

• When ordering the lower part of the

housing 24, please specify device type, year

of manufacture and device number.

• Note:

The item numbers quoted in the following text

are identical to the item numbers in the spare

parts list on Page 35 and the overview on

Page 4.

6.2 Changing the filter in the pressurised gas connection

Tools and equipment required

• Flat-head screwdriver

• Tweezers.

1. Unscrew the slot-head screw from the

pressurised gas connection 10.

2. Use tweezers to remove filter set 57.

3. Carefully insert a new filter set 57 in the

pressurised gas connection.

4. Screw the slot-head screw firmly into the

pressurised gas connection.

57

20 Repair information and instructions

Page 21

6.3 Opening the device

12

11

Tools and equipment required

• ESD-protected workplace,

• Phillips screwdriver, size 1,

• Tubular hexagon box spanner 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the battery compartment with a coin

and remove the battery.

60

M

E

D

U

M

m

b

A

a

r

T

E

a

s

y

S

te

no

50

s

is

D

is

c

o

n

n

e

c

tio

n

<

2

,7

b

40

a

r

O

2

30

20

10

11

12

0

9

10

10

12

14

7

11

15

13

14

16

16

5

30

D

e

m

a

n

d

-

3

flo

F

r

w

e

q

.(

m

1

in

)

M

V

(

l/m

in

)

2. Lift off the lid 32.

3. Hold the adjuster knob 33 still with the special

tool and loosen the nut with a tubular hexagon

socket spanner (10 mm).

Do not unscrew the nut completely – only loosen

it. Otherwise the knob will split into its separate

parts.

4. Pull off the adjuster knob 33.

5. Place the device on a non-slip surface and

unscrew the 4 screws 43 from the rear of the

device.

6. Place the device on its side and carefully pull

the two parts of the housing apart until the

locating pin of the adjuster knob is pulled

completely out of the upper part of the

housing 20.

7. Remove the speaker 12 from the lower part of

the housing 24 and disconnect it.

10

0

7

5

14

12

10

9

15

10

13

16

14

11

16

Demand-

flow

30

-1

)

q.(min

Fre

3

33

32

MV (l/min)

43

24

43

60

M

E

D

U

M

m

b

A

a

r

T

E

a

s

y

Stenosis

50

Disconnection

< 2,7 bar O

40

2

30

20

10

11

12

0

9

10

10

12

14

7

11

15

13

14

16

16

5

30

Demand-

3

flow

Freq.(

min

1

)

MV (

l/m

in)

24

12

20

Repair information and instructions 21

Page 22

8. Disconnect the plug of wiring harness 51 from

the board.

Note:

This is best done with flat-nose pliers. Be very

careful not to damage the board with the

pliers.

9. Unscrew the blue sensor tube 53 from the

pneumatic block.

Note:

Do NOT pull sensor tube 53 off the pressure

sensor on the board, as this will damage the

sensor.

10. Pull the ends of the Y-shaped sensor tube 54 off

the sensors on the board.

11. Flap the two parts of the housing apart and

place them with the outside downwards.

12. Unscrew screw 47 with the serrated washer 48

from the earth connection to the pneumatic

block.

13. Unscrew the two screws 46 with the spring

washers 45 and remove the battery contacts

from the battery compartment.

The two halves of the housing are now

separated.

Earth connection

53 5154 47

46

45

48

6.4 Closing the device

Tools and equipment required

• ESD-protected workplace,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Tubular hexagon box spanner 10 mm,

• Special tool WM 22829 from special tool set WM 15349,

• Allen key SW 2.5.

1. Place the two parts of the housing side by side

with the outside facing downwards.

2. Place the battery contacts in the battery

compartment and screw them in place with the

two screws 46 and the spring washers 45.

46

45

22 Repair information and instructions

Page 23

3. Push the ends of the Y-shaped sensor tube 54

12

11

onto the sensors on the board.

4. Screw the blue sensor tube 53 onto the

pneumatic block.

5. Connect the plug of wiring harness 51 to the

board.

6. Attach the earth connection to the pneumatic

block using screw 47 and serrated washer 48.

Earth connection

7. Connect up the speaker 12 and insert it in the

recess in the lower part of the housing 24. The

centering lug of the speaker must be located in

the corresponding groove in the lower part of

the housing.

8. Push the adjuster knob locating pin through the

hole in the board and put the two halves

together.

9. Insert the battery in the battery compartment

and close the lid with a coin. Make sure the

battery is correctly connected.

10. Now screw up the lower part of the housing

with the 4 screws 43 using a torque of

50 ±5 Ncm.

53 5154 47

60

M

E

D

U

M

m

b

A

a

r

T

E

a

s

y

Stenosis

50

Disconnection

< 2,7 bar O

40

2

30

20

10

11

12

0

9

10

10

12

14

7

11

15

13

14

16

16

5

30

Demand-

3

flow

Freq.(

min

1

)

MV (

l/m

in)

48

24

Centering

lug

1220

60

M

E

D

U

M

m

b

A

a

r

T

E

a

s

y

S

te

n

o

50

s

is

D

is

c

o

n

n

e

c

tio

n

<

2

,7

b

40

a

r

O

2

30

20

10

11

12

0

9

10

10

12

14

7

11

15

13

14

16

16

5

30

D

e

m

a

n

d

-

3

flo

F

r

w

e

q

.(m

1

in

)

M

V

(

l/m

in

)

11. Secure the adjuster knob 33:

– Push the adjuster knob onto the spindle as

far as it will go, then pull it out a fraction.

– Hold the knob firm with the special tool and

screw it tight with a torque of

200 ±10 Ncm.

43

24

43

10

0

7

5

14

12

10

9

15

10

13

16

14

11

16

30

Fre

3

q.(min

and-

Dem

flow

-1

)

33

32

MV (l/min)

Repair information and instructions 23

Page 24

12. Check the alignment of the adjuster knob.

When the knob is turned fully to the left, the

white line must point to MV: 3 l/min.

If it does not, slacken the nut and realign the

adjuster knob.

13. Place the cap 32 on the adjuster knob 33.

14. Perform the final check (see “3. Final check” on

page 8).

6.5 Replacing button cell

Tools and equipment required

• ESD-protected workplace,

• Phillips screwdriver, size 1,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Release the ribbon cable from its clamp X100:

To do so, lift up the top part of the clamp. Then

you can pull out the cable.

3. Unscrew the two screws 49 and remove the

board 21 from the upper part of the housing.

4. To remove the button cell 17, use a match or

similar to ease it slightly out of the holder and

pull the button cell out sideways with the other

hand.

Caution!

Do not use sharp or pointed objects for this

purpose, as this could damage the board.

5. Insert a new button cell 17.

Make sure it is installed the right way round.

X100

Push here

49

21

49

17

24 Repair information and instructions

Page 25

6. Insert the board 21 in the upper part of the

housing.

Make sure that the ribbon cable is not under the

board or jammed between it and the housing.

49

21

7. Attach the board 21 with the two screws 49.

8. Place the ribbon cable in the clamp X100 on

the board and then press down the top part of

the clamp.

X100

49

9. Close the device (see “6.4 Closing the

device” on page 22). Use a new main

battery 18.

10. Perform a final check (see “3. Final check” on

page 8).

Please remember that old batteries must not be disposed of in household waste. Always take old batteries

to a local collection point.

6.6 Changing the speaker

Tools and equipment required

• ESD-protected workplace,

• Phillips screwdriver, size 1,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349.

1. Open the device (see „6.3 Opening the

device“ on page 21, steps 1. to 6.).

2. Remove the speaker 12 from the lower part of

the housing 24 and disconnect the speaker

cable plugs. Put the old speaker on one side.

3. Take the new speaker 12 and connect the

speaker cable plugs.

4. Insert the speaker 12 in the recess in the lower

60

50

40

30

20

10

0

part of the housing 24. The centering lug of the

speaker must be located in the corresponding

groove in the lower part of the housing.

5. Close the device (see „6.4 Closing the

device“ on page 22, steps 8. to 13.).

6. Perform the final check (see “3. Final check” on

page 8).

M

E

D

U

M

m

b

A

a

r

T

E

a

s

y

Stenosis

Disconnection

< 2,7 bar O

2

24

11

12

9

10

10

12

14

7

11

15

13

14

16

16

5

30

Demand-

3

flow

Freq.(

min

1

)

MV (

l/m

in)

Centering

lug

1220

Repair information and instructions 25

Page 26

6.7 Changing the board

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 1,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Release the ribbon cable from its clamp X100:

To do so, lift up the top part of the clamp. Then

you can pull out the cable.

3. Unscrew the two screws 49 and remove the

board 21 from the upper part of the housing.

4. Place the new board 21 on the spacers.

Make sure that the ribbon cable is not under the

board or jammed between it and the housing.

X100

49

21

49

5. Attach the board 21 with the two screws 49.

6. Place the ribbon cable in the clamp X100 on

the board and then press down the top part of

the clamp.

7. The screw of the blue sensor tube 53 is secured

with a nut for transport. Remove the nut before

screwing the tube to the pneumatic block

8. Close the device (see “6.4 Closing the

device” on page 22).

9. Perform a final check (see “3. Final check” on

page 8).

49

21

53

X100

49

26 Repair information and instructions

Page 27

6.8 Replacing the pneumatic block

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 2,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Press the catch and unplug the magnetic valve

control cable.

3. Unplug the potentiometer cable.

Potentiometer

cable

4. Remove the clip 27 from the pneumatic

block 22.

5. Pull the elbow connector 26 off the pneumatic

block 22.

6. Turn the lower part of the housing over, hold it

and the pneumatic block tight and unscrew

both screws 44 together with the spring

washers 45.

7. Turn the lower part of the housing over again.

8. Press the catch towards the elbow connector

and pull the pneumatic block 22 off the

tube 56.

When you remove the pneumatic block from

the lower part of the housing, the O-ring 28

will fall out of the connection. Make sure that

the O-ring 31 does not fall out of the relief

outlet valve.

56

Catch

22

Magnetic valve

control cable

22

27

26

45

44

28 31

Repair information and instructions 27

Page 28

9. When inserting the new or replacement

pneumatic block 22, insert the tube 56 in the

elbow connector. Make sure that the cables

are routed below the pneumatic block to the

right-hand side.

10. Turn the lower part of the housing over, hold it

and the pneumatic block tight and screw up

both screws 44 with their spring washers 45.

56

45

44

22

Cable

11. Lubricate the O-rings of the elbow connector

26 with a little O

lubricant (WM 14298).

2

Make sure that the compensating hole remains

free.

12. Insert the O-ring 28 in the groove in the outlet

from the pneumatic block.

13. Insert the elbow connector 26 in the pneumatic

block 22.

14. Insert the clip 27 in the pneumatic block 22.

15. Plug in the potentiometer cable.

16. Plug in the magnetic valve control cable.

17. Close the device (see “6.4 Closing the

device” on page 22).

18. Perform a final check (see “3. Final check” on

page 8).

22

27

28

26

26

Compensating

hole

Potentiometer

cable

Magnetic valve

control cable

28 Repair information and instructions

Page 29

6.9 Replacing the 3/2-way magnetic valve

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 2,

• Phillips screwdriver, size 0,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Remove the pneumatic block (see “6.8

Replacing the pneumatic block” on page 27).

3. Place the pneumatic block on the side with the

type plate.

4. Unscrew the two securing screws and remove

the 3/2-way magnetic valve 23.

5. Insert the new 3/2-way magnetic valve 23 in

the correct position.

Make sure that the seal for the 3/2-way magnetic

valve is seated in the correct position.

6. Fasten the 3/2-way magnetic valve with the

screws supplied with it.

7. Reinstall the pneumatic block (see “6.8

Replacing the pneumatic block” on page 27).

8. Close the device (see “6.4 Closing the

device” on page 22).

9. Perform a final check (see “3. Final check” on

page 8).

23

Repair information and instructions 29

Page 30

6.10 Calibrating the potentiometer (after changing pneumatic block including potentiometer)

When the pneumatic block including potentiometer is changed, the potentiometer must be recalibrated for

the board.

1. Make sure the device is switched off.

2. Press the On/Off switch 9 and immediately

hold down the alarm confirmation button 4

and the mask/tube ventilation switch 1. Then

release the button. After a brief interval, the 30

mbar LED on the bar graph indicator lights up.

3. To set the first calibration value, turn the

adjuster knob 6 fully to the left to the value

MV 3, Freq. 30.

4. Press the mask/tube switch 1. The device now

makes a plausibility check.

– If the value is not correct, all alarm LEDs light

up until the correct value is present at the

adjuster knob 6 and has been confirmed

with the mask/tube ventilation switch 1. Or

you can cancel the potentiometer

calibration process by pressing the On/Off

switch 9.

– If the value is correct, this is indicated by the

0 mbar LED on the bar graph lighting up.

You can now set the next value.

5. Turn the adjuster knob 6 fully to the right to the

white Demandflow zone.

6. Press the mask/tube switch 1. The device

accepts this value The LED on the bar graph

lights up, and you can move on to setting the

next value.

7. Turn the adjuster knob 6 back beyond the

index point 7 to the ventilation mode zone,

then to the right again until it reaches the index

point (zone MV 16, Freq. 14 ).

8. Press the mask/tube switch 1 again. The

calibration values are stored and the device

exits the calibration mode.

Note:

60

mbar

50

40

30

20

10

0

1 9

11

9

10

7

11

16

5

30

3

MV (l/min)

Stenosis

Disconnection

< 2,7 bar O

12

10

Freq.(min

MEDUMAT

Easy

2

14

12

15

13

14

16

Demandflow

-1

)

4

6

7

Until the last step the calibration mode can be

cancelled at any time by pressing the On/Off

switch 9, without storing the new values. If an

invalid value is detected during calibration (all

alarm LEDs light up), no value is stored either.

30 Repair information and instructions

Page 31

6.11 Changing upper part of housing

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 2,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Remove the board (see „6.7 Changing the

board“ on page 26, steps 2. and 3.).

3. Remove the grommet 52 from the upper part of

the housing 20.

You have now removed all the parts. You can start

reassembling.

4. Insert the grommet 52 in the new upper part of

the housing 20.

5. Refit the board (see „6.7 Changing the board“

on page 26, steps 4. to 6.).

6. Close the device (see “6.4 Closing the

device” on page 22).

7. Perform a final check (see “3. Final check” on

page 8).

20

52

Repair information and instructions 31

Page 32

6.12 Changing the fascia film

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 2,

• Tubular hexagon box spanner 8 mm,

• Tubular hexagon box spanner 10 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special tool WM 22829 from special tool set WM 15349,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Remove the board (see „6.7 Changing the

board“ on page 26, steps 2. and 3.).

3. Remove the grommet 52 from the upper part of

the housing 20.

4. From inside the housing, insert the tubular box

spanner through the hole for the grommet 52

and press the fascia film 19 outwards until you

can grasp it on one side. Then completely

remove the fascia film from the upper part of

the housing.

5. Use 70% isopropanol to remove all traces of

adhesive from the upper part of the housing.

Then wait until the isopropanol has completely

evaporated from the housing surface.

You have now removed all the parts. You can start

reassembling.

6. Stick the new fascia film 19 to the upper part

of the housing:

– First position the fascia film on the upper

part of the housing on the side where the

ribbon cable is attached.

– Run the ribbon cable through the slit in the

upper part of the housing.

– Then affix the entire fascia film, taking care

to avoid bubbles.

19

20

19

20

52

6

0

5

0

4

0

3

0

2

0

1

0

0

MEDUMAT

Easy

m

b

a

r

S

t

e

n

o

s

is

D

is

c

o

n

n

e

c

t

io

n

<

2

,7

b

a

r

O

2

1

1

1

2

9

1

0

1

1

2

4

1

0

7

1

5

1

1

1

3

1

4

1

6

1

6

5

3

0

D

e

m

a

n

d

-

flow

3

F

re

q

.(m

-1

i

n

)

M

V

(l/min

)

Ribbon

cable

32 Repair information and instructions

Page 33

7. Refit the grommet 52 in the upper part of the

housing 20.

8. Refit the board (see „6.7 Changing the board“

on page 26, steps 4. to 6.).

9. Close the device (see “6.4 Closing the

device” on page 22).

20

52

10. Perform a final check (see “3. Final check” on

page 8).

6.13 Changing lower part of housing

Tools and equipment required:

• ESD-protected workplace,

• Phillips screwdriver, size 2,

• Open-ended spanner, 13 mm,

• Open-ended spanner, 22 mm,

• Torque spanner 50 ±5 Ncm,

• Torque spanner 200 ±10 Ncm,

• Special counter tool G 3/8 (WM 22827) and special spanner 17 mm (WM 22828) from special tool

set WM 15349,

• Vice with jaw protectors,

• Flat-nose pliers.

1. Open the device (see “6.3 Opening the

device” on page 21).

2. Remove the pneumatic block (see „6.8

Replacing the pneumatic block“ on page 27,

steps 2. to 8.).

3. Undo the screws 50 and remove the wiring

harness 51.

4. Use a pointed object to push the blanking plug

59 of the interface connection out of the lower

part of the housing 24 from inside.

5. Remove the O-ring 31 from the lower part of

the housing 24.

50

51

24

59

24

31

Repair information and instructions 33

Page 34

6. Screw the special counter tool onto the

pressurised gas connection 10.

7. Clamp the special counter tool in a vice.

10

8. Use a 22-mm open-ended spanner to screw

the nut of the special counter tool firmly again

the pressurised gas connection.

9. Screw the elbow connector 25 off with a

13-mm open-ended spanner.

10. Use the 17-mm special spanner to slacken the

nut 30 and unscrew it completely.

11. Lift out the plate 29.

12. Remove the lower part of the housing 24.

13. Take the new lower part 24 and place it on the

pressurised gas connection 10.

14. Slide the plate 29 on the inside of the housing

onto the connection.

15. Tighten the 17-mm nut 30 on the inside of the

connection.

16. Fasten the elbow connector 25 to the

connection.

17. Use the 22-mm open-ended spanner to undo

the nut of the special counter tool.

18. Open the vice.

29

30

10

24

25

19. Screw the special counter tool off the

pressurised gas connection 10.

20. Using screws 50, screw the interface cable of

the wiring harness 51 into the new lower part

of the housing 24.

21. Push the blanking plug 59 into the interface

connection from outside.

22. Refit the O-ring 31 in the lower part of the

housing 24.

23. Reinstall the pneumatic block (see „6.8

Replacing the pneumatic block“ on page 27,

steps 9. to 16.).

24. Close the device (see “6.4 Closing the

device” on page 22).

25. Perform the final check (see “3. Final check” on

page 8).

50

51

31

59

24

34 Repair information and instructions

Page 35

7. Spare parts

7.1 Spare parts list

Note:

The item numbers in the following table are identical to the numbers in the text of these Service and Repair

Instructions and in the Operating Instructions.

Item No. Description Order No.

10 Pressurised gas connection (threaded), preassembled WM 22685

12

16 Ventilation hose WM 22647

17

18

19 Fascia film WM 28009

20

Speaker

– Seal

– Button cell CR 2430

– Battery 3.6 volt

Upper part of housing with film up to device no. 2279*

comprising:

– Upper part of housing with film

– Label for languages

– Label for patient connection

Upper part of housing with film from device no. 2280*

comprising:

– Upper part of housing with film

– Rating plate

– Label for patient connection

WM 28077

WM 28066

WM 22652

WM 28045

WM 28078

WM 28078

21 PCB, MEDUMAT Easy, exchange WM 28079

22 Pneumatic block, complete, new WM 28025

23 3/2-way magnetic valve WM 28035

Lower part of housing up to device no. 2279*

comprising:

– Lower part of housing

– Rating plate

– Label for O2 input

– Label for excess pressure valve

24

25 Elbow connector 4/6 WM 22552

26

– Label for battery position

Lower part of housing from device no. 2280*

comprising:

– Lower part of housing

– Label for O2 input

– Label for languages

– Label for excess pressure valve

– Label for battery position

Elbow connector ventilation hose, complete

– Hose connection for patient valve

WM 28137

WM 28137

WM 28057

WM 3213

Spare parts 35

Page 36

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

Clip for elbow connector

O-ring, elbow connector

Torque plate

Nut for pressure connection

O-ring, pressure relief valve

Cap

Short knob

Patient valve, comprising:

–

bottom part of control unit for spontaneous breathing

–

Membrane for Spontaneous breathing tube

–

insert for spontaneous breathing tube

–

top part of control unit

–

tube connection for patient valve

–

Lip membrane

–

Disc membrane Exhalation tube

–

O-ring 15-1,5

O-ring for battery compartment lid

Fillister head screw 30 x 40 mm for housing

Fillister head screw M3 x 16mm for pneumatic block

Spring washer for fastening pneumatic block and battery

contacts

Fillister head screw KB 35 x 8 for battery contacts

Cheese-head screw M3 x 6 for earth connection

Serrated washer for earth connection

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

WM

1145/118

WM

WM

WM

WM

WM

WM

WM

28052

1145/141

22509

22586

1145/3

22941

4891

3280

3281

3284

3282

3181

3213

3211

3212

1145/145

58347

53033

50350

58350

50594

51850

49 Fillister head screw KB 30 x 6 for board WM 23159

50

Fillister head screw KB 25 x 6 for interface cable, lower part of

housing

WM 58320

51 Cable harness WM 28088

52 Grommet WM 4112

53 Sensor tube, length 65 mm WM 22966

Set, tubes MEDUMAT,

WM 15058

comprising:

54

55

56

– 3x tube, silicone, length 52 mm

– Y-connector

– Oxygen inlet tube, length 40 mm

WM 28097

WM 28053

WM 28095

Set, filter,

57

comprising:

– Filter

WM 15284

– Sealing washer 3.5 x 6 x 0.5

Service label

58

– for servicing in 2 years' time

– for servicing in 4 years' time

– for servicing in 6 years' time

WM 75340

WM 75341

WM 75339

59 Blanking plug for interface connection, lower part of housing WM 1504

Operating instructions GB, ES, PT WM 16862

*

When placing an order, please make sure to include type, unit serial no. and year built.

36

Spare parts

Page 37

7.2 Service sets

Overview

Years 2 4 6 8 10 12 14 16

Service set

Service set 2, 6, 10 and 14 years

Set, WM 15463

comprising:

WM 15463 WM 15462 WM 15463 WM 15464 WM 15463 WM 15465 WM 15463 WM 15464

• Battery

• Lip membrane

• Membrane for test connector

• Membrane for spontaneous breathing tube

• Membrane for exhalation tube

• Sealing washer 3.5 x 6 x 0.5

• Filter

• O–ring 15 x 1.5

Service set 4 years

Set, WM 15462

comprising:

• Set WM 15463 • Button cell

Service 8 and 16 years

Set, WM 15464

comprising:

• Set WM 15463

• Button cell

• Seal for speaker

• Set, tubes

• Pneumatic block

• 2x O–ring 11 x 1.5 for elbow outlet

Service 12 years

Set, WM 15465

comprising:

• Set WM 15463

• Printed circuit board (PCB) MEDUMAT Easy

• O-ring 26 x 2 for battery compartment lid

Spare parts 37

Page 38

8. Tools and Test Equipment

This section lists all the tools and test equipment mentioned in these Service and Repair Instructions.

The specific tools and test equipment required in each case are listed in the individual chapter.

You can obtain special tools from WEINMANN.

8.1 General tools

• Flat-head screwdriver, size 0.5 x 3 x 100;

• Phillips screwdriver, size 0;

• Phillips screwdriver, size 1;

• Phillips screwdriver, size 2;

• Open-ended spanner, 13 mm,

for elbow connector at O2 inlet;

• Open-ended spanner, 22 mm,

for special counter tool;

• Vice with jaw protectors,

countering threaded connection;

• Tubular hexagon box spanner 10 mm,

for adjuster knob;

• Tubular hexagon box spanner 8 mm,

for fascia film;

• Tweezers,

for filter set;

• Diagonal cutter;

• Flat-nose pliers;

• Allen key, 2.5 mm.

• Torque spanner 50 ±5 Ncm;

• Torque spanner 200 ±10 Ncm.

8.2 Special tools

The following tools can be obtained from WEINMANN:

• Special tool set, comprising: WM 15349

– Special counter tool G 3/8, WM 22827

for countering threaded connection

at O2 inlet

– Special spanner, 17 mm, WM 22828

for counter nut at O2 inlet;

– Special tool, WM 22829

for holding securing adjuster knob.

– Set, hose with syringe WM 15359

– Special pliers WM 22928

38 Tools and Test Equipment

Page 39

8.3 Testing equipment

• Oxygen concentration meter, type Oxycontrol WM 13550

• Volume flow meter

Type RT 200 (Timeter)

obtainable from:

Allied Healthcare Products Inc.

1720 Sublette Avenue

St. Louis, Missouri, MO 63110

USA

Tel.: 001-800-444-3954

Fax: 001-314-771-5183

or

Type EKU VIP ventilator tester

obtainable from:

EKU Elektronik GmbH

Feldstrasse 9a

D-56291 Leiningen

Germany

Tel.: 00 49 6746-1018

Fax: 00 49 6746-8484

www.eku-elektronik.de

or

Type Flow Analyser PF-300

obtainable from:

SI-special instruments GmbH

Strelgasse 2

D-86720 Nördlingen

Germany

Tel.: 00 49 90 81/2 20 61 or 2 20 62

Fax: 00 49 90 81/2 20 63

www.specialinstruments.com

• www.eku-elektronik.deTest set for final check

WM 15323

• Set, supply test

Medumat/Modules WM 15440

• Set, test set respiration and pressure reducer

flow WM 15443

• Pressure gauge 0 to 6.3 bar, class 1.6;

• Pressure gauge 0 – 100 mbar, class 1.6

Type WIKA

obtainable from:

Alexander Wiegand GmbH & Co.

Alexander-Wiegand-Strasse 30

D-63911 Klingenberg am Main

Germany

Tel.: 00 49 9372/1320

• Digital multimeter

• Hazet torque wrench

obtainable from:

Hommel

Heidelberger Str. 52

D-68519 Viernheim

Germany

Tel.: 00 49 6204/738-0

Fax: 00 49 6204/739-222

Tools and Test Equipment 39

Page 40

40

9. Technical data

MEDUMAT Easy

Product category

according to

II b

93/42/EEC

Dimensions

L x W x H

Weight incl.

accessories

100 x 145 x 90

incl. connections

approx. 0.6 kg

Operation:

– Temperature range

– Humidity

– Air pressure

-18°C to +60°C

max. 95 %

70 kPa to 110 kPa

Storage -40°C to +70°C

Electromagnetic

compatibility acc. to

EN60601-1-2 and

EN 794-3:

(the test parameters and

threshold values are

obtainable from the

manufacturer on request)

– Radio interference

suppression

EN 55011

– Radio interference

resistance

Control

EN 61000-4-2 to 3

Timing pulse,

volume constant

Gas input Medicinal oxygen

Operating pressure 2.7 to 6.0 bar

Minimum gas volume

required

Insp-exp. ratio

Ventilation frequency

Minute volume (MV)

MV tolerances:

– Room temp. (20 °C)

70 l/min O

2

1:1.67

Continuously variable

from 10 to 30 min

continuously adjustable

from 3 to 16 l/min

for 3 l/min =±20%

for >3 l/min = ±15%

– -18°C to +60°C

for 3 l/min =±35%

for >3 l/min = ±20%

Max. ventilation

pressure

concentration

O

2

Pressurized gas

connection

20 or 45 mbar

100% O

2

External thread G 3/8

MEDUMAT Easy

Patient valve

– Expiration tube

Power supply

30 mm socket

ISO 5356-1

Maintenance-free lithium

battery 3.6 V; 5.2 Ah,

Life expectancy

Max. storage period

Auxiliary power for

> 2 years

10 years after delivery

Button cell CR 2430

alarm system

Max. storage period

10 years after delivery

Fuse F1 T 500 L 250 V

Ventilation hose

Degree of protection

against water

Standards complied

with

Spiral silicone

NW 10

IP X4

EN 794-3;

EN 60601-1

EN 1789

Alarm sound pressure 60 dB (A)

Accuracy of ventilation

pressure measurement

±5% of upper range

value

Resistance,

patient valve (under

EN 794-3):

– Inspiration

– Expiration

– Spontaneous

<6 mbar at 60 l/min

<6 mbar at 60 l/min

<1.5 mbar at 30 l/min

breathing

Elasticity of breathing

-1

system

Patient valve dead

space

Components with

critical flow direction

Components

containing latex

Subject to technical change without notice.

Negligible

12.8 ml

Patient valve

None

Ventilation hose

connection

Patient valve

– Inspiration tube

Technical data

External diameter

13 mm

15 mm socket

22 mm plug

ISO 5356-1

Page 41

9.1 Pneumatic / electronic systems

The input pressure at p is max. 6bar. This is dynamically reduced by V1 to 2.5 bar. This is the input pressure

at V2, V3 and V4.

Inspiration

An electrical impulse to V2 opens V3 and closes V4. Oxygen flows through the ventilation hose to the patient

valve. If the ventilation pressure in the patient valve reaches >100 mbar, the relief valve V5 will open.

Expiration

A fresh electrical impulse closes V2. The relief valve V4 opens and vents the ventilation hose. The patient

breathes out through the patient valve.

Demandflow

An inspiration impulse (trigger) at V2 opens valves V3 and V4.

Electronic system

The microprocessor-controlled electronic system sets the ventilation parameters and monitors ventilation, and

also O2 supply and power supply. If necessary, a visual and acoustic alarm is given. The ventilator has an

audio response facility that can be switched on for user guidance.

Patient valve

During inspiration the respiratory gas flows to the patient.

During expiration the expiration pressure switches the valve so

that the patient can breathe out.

Technical data 41

Page 42

10. Technical Changes

Technical Changes From Device No. Date

New position of device information plates 2280 27.04.07

42 Technical Changes

Page 43

11. Repair and service records

Date Signature

Service performed in accordance

with MEDUMAT service

instructions

Company

_____________ __________________

Measures / Comments

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

Company

Date Signature

_____________ __________________

22525 Hamburg

Device master data Service and repair work carried out in accordance with service instructions

Manufacturer: WEINMANN GmbH +

Co.

Device type: MEDUMAT Easy

Order No.: ________________________

Date of manufacture: ________________