Page 1

Servicing and

repair instructions

OXYMAT 3

Oxygen Concentrator

from Appliance No. 8000

Page 2

Contents

Introduction

1.

Overview

2.

Functional description

3.

Servicing

3.1

3.2

3.3

4.

Hygienic Preparation

4.1

4.2

5.

Functional check

5.1

5.2

5.3

6.

Troubleshooting

6.1

6.2

6.3

6.4

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

General

Implementation

Disposal

No change of patient

Change of patient or reuse

General

Intervals

Implementation

5.3.1

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.3.9

5.3.10

5.3.11

5.3.12

5.3.13

5.3.14

Visual and acoustic signals

from

6.1.1

6.1.2

6.1.3

Remedies

O2 concentration outside

tolerance range . . . . . . . . . . . . . . . . .

System pressure fault

. . . . . . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . 10

Checking the housing

Checking the coarse dust filter

Checking the power cord

Checking the fuse

Checking the main switch and

LED displays

Checking the dosage monitor for

leaks

Checking the flowmeter for leaks

Checking the operating hours

meter

Checking the O2 concentration

Checking the mains failure alarm

Checking the indirect

cator (yellow LED) with appliance

closed

Checking the indirect status

indicator (yellow LED) with the

appliance

System pressure test

Checking the O2 system for leaks

OXYMAT 3 . . . . . . . . . . . . . . . .

Alarms

Signal patterns

Deactivating the signal functions

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . 8

. . . . . . . . . . . . . . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . 9

. . . . . . . . . . 9

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . 10

status indi

open

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . 27

10

-

19

19

27

3

4

5

8

9

7.

Repair information and repair instructions

7.1

General

7.2

Replacing the castors

7.3

Opening the appliance

7.4

Closing the

7.5

Replacing the compressor

(up to appliance no. 13350) . . . . . . . .

7.6

Replacing the compressor

(from appliance no. 13351 to 14999) .

7.7

Replacing the compressor

(from appliance no. 15000) . . . . . . . .

7.8

Replacing the operating hours meter

7.9

Replacing the circuit board

7.10

Replacing the fan

7.11

Replace adsorption containers

(Mac valves) . . . . . . . . . . . . . . . . . . .

7.12

Replace adsorption container

(plastic magnetic valve block) . . . . . . . .

7.13

Replace adsorption containers

(aluminum magnetic valve block) . . . . . .

7.14

Replace cover

7.15

Replacing the pressure reducer

7.16

Replacing the frame

(up to appliance no. 19999) . . . . . . . .

7.17

Replacing the frame

(from appliance no. 20000) . . . . . . . .

7.18

Replacing magnetic valves with valve block

(up to appliance no. 34999) . . . . . . . .

7.19

Replace magnetic valve block

8.

Spare parts

8.1 List of spare parts . . . . . . . . . . . . . . . 69

8.2 Maintenance set. . . . . . . . . . . . . . . . 72

9. Tools, testing equipment, disinfectants . . . . . 73

9.1 General tools and test equipment. . . . . 73

9.2 Special tools and test equipment . . . . . 73

9.3 Disinfectants . . . . . . . . . . . . . . . . . . 74

10. Technical Data. . . . . . . . . . . . . . . . . . . . . . . 75

10.1 Arrangement of the PCBs . . . . . . . . . . 76

11. Technical Changes . . . . . . . . . . . . . . . . . . . . 77

12. Repair and inspection log . . . . . . . . . . . . . . 78

13. Test report. . . . . . . . . . . . . . . . . . . . . . . . . . 79

. . . . . . . . . . . . . . . . . . . . . 28

. . . . . . . . . . . . . 28

. . . . . . . . . . . 29

appliance

. . . . . . . . . . . . . . . . . 53

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . 30

. . . . . . . . . 40

. . . . . . . . . . . . . . . 42

. .

28

30

33

36

. . . 39

43

46

49

. . . . . . 54

57

59

60

. . . . . . . 66

69

© Copyright Weinmann GmbH & Co. KG.

The content and presentation are copyright protected and may only be used by authorised Weinmann Service Partners in the

course of their service operations. The content must not be reproduced or passed on to third parties. The complete documents

must be returned on termination of the cooperation with Weinmann.

2

Page 3

Introduction

For decades, Weinmann has developed, manufactured and distributed equipment for oxygen therapy, inhalation therapy, sleep apnea therapy and

emergency medicine.

In 1982, Weinmann introduced the first oxygen

concentrator to the market.

Long-term oxygen therapy with an oxygen concentrator now has a firm place in the treatment of

chronic obstructive diseases of the respiratory

tracts. Many studies have proven that long-term

oxygen therapy can bring about a tangible improvement in life expectancy and quality of life.

The OXYMAT 3 oxygen concentrator from Weinmann is part of this therapy concept.

The aim of these service and repair instructions is

to familiarise you, as a knowledgeable expert, with

the OXYMAT 3 with regard to function, technology, servicing and repairs. In conjunction with the

training you have already received from Weinmann, you are now a "trained, qualified expert"

and are able to instruct your clients correctly, rectify

faults yourself, and carry out the functional checks

described in the instructions, as well as conduct

any repairs which may be necessary, as outlined

in these service and repair instructions.

In the event of a guarantee claim, OXYMAT 3 should

be returned to Weinmann.

In order to enable us to process any guarantee or

goodwill claims, please return the consumer's

proof of purchase (invoice) together with the appliance.

Repair and maintenance work must be carried out

only by Weinmann or by knowledgeable expert

staff.

You are responsible for any repairs performed by

yourself and for guaranteeing them!

Only original Weinmann spare parts should be used

for repair purposes.

Please remember:

Your customer trusts you and relies on your expertise, just as you rely on Weinmann.

Note:

The following information can be found in the description and operating instructions for OXYMAT 3:

• Safety instructions

• Installation

• Operation

• Hygienic preparation

• Warranty

3

Page 4

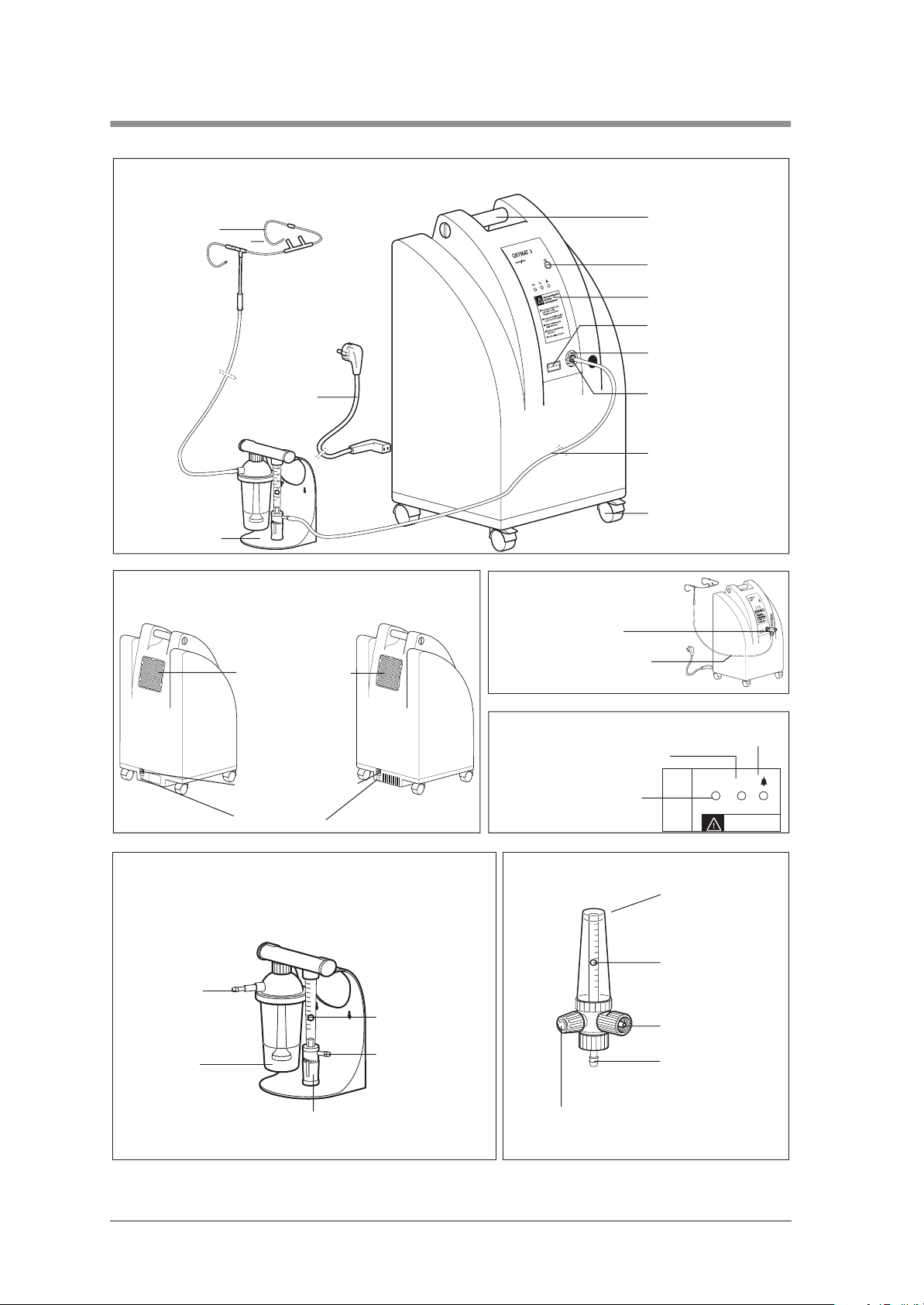

1. Overview

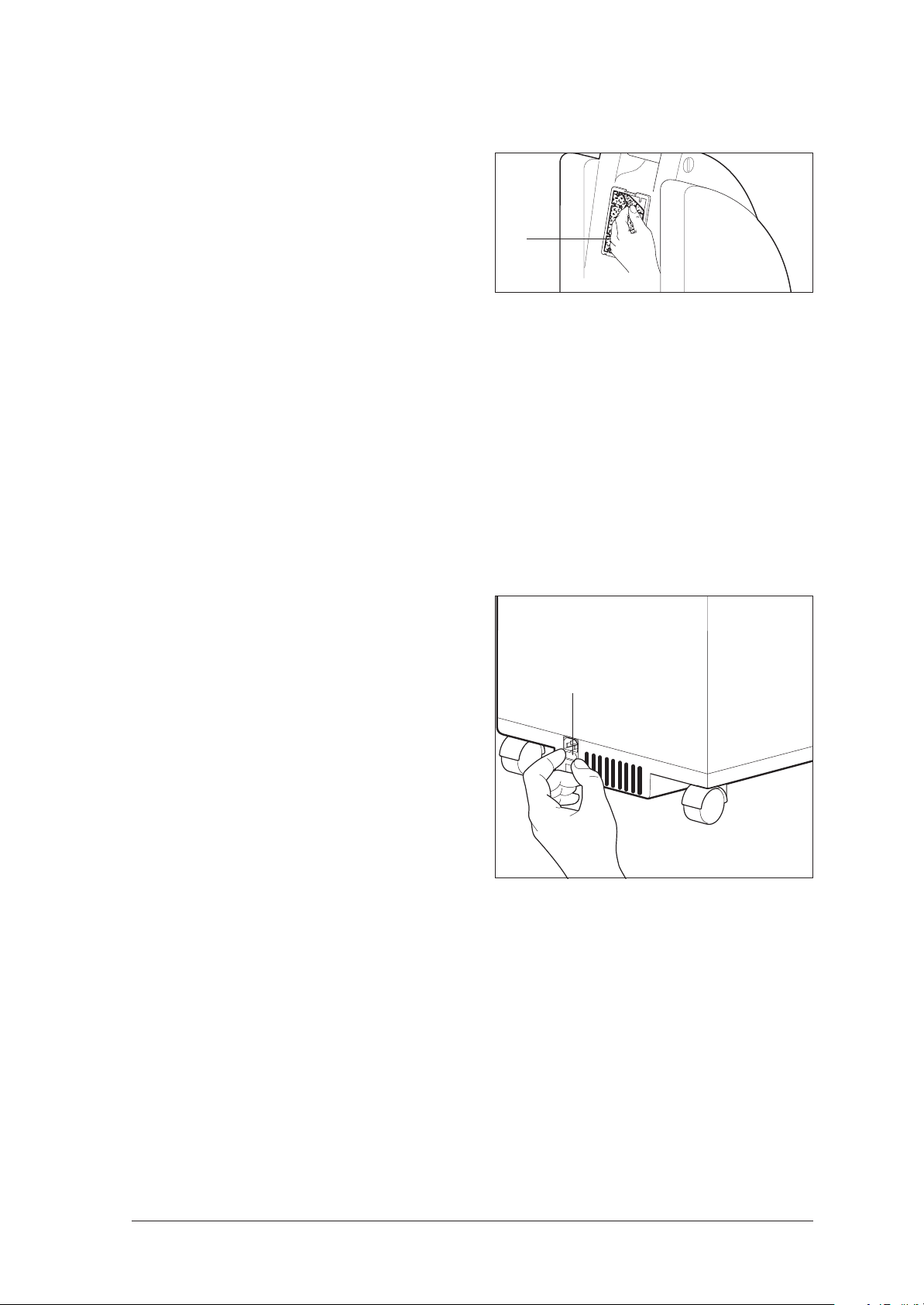

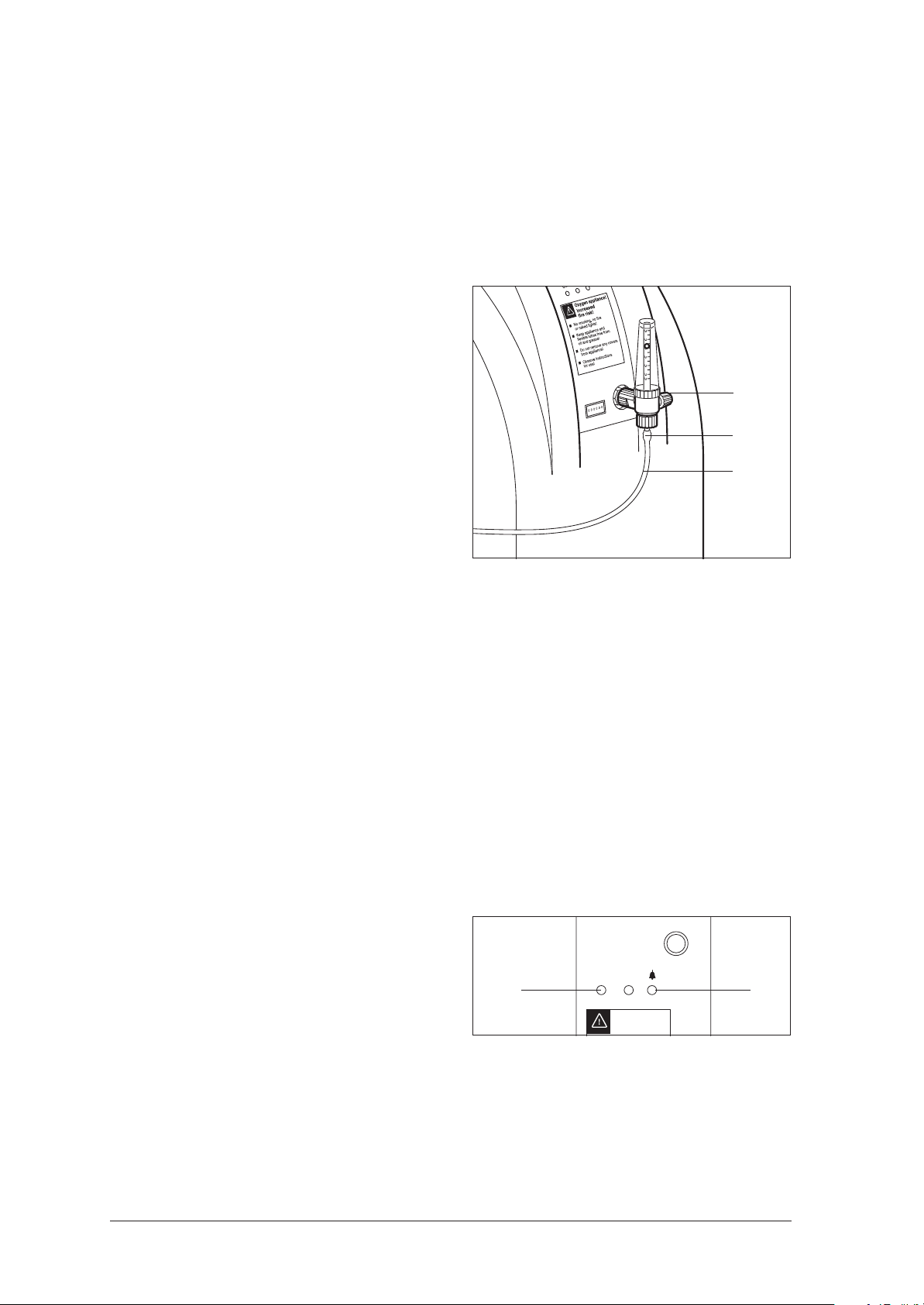

Front

(with dosage monitor)

12 Nasal cannula

11 Connecting tube

(3 m) for nasal

cannula

1 Handle for lifting or

moving

2 On/Off knob

3 Warning notices

4 Operating hours meter

5 Oxygen outlet

10 Power cord

Dosage monitor

9

Back

up to appliance no. 19999 from appliance no. 20000

13 Coarse dust filter

14 Power cord socket

15 Fuse holder

Front

(with Flowmeter)

16 Flowmeter

17 Connecting tube

(10 m)

Indicators

19 Oxygen concentration status

indicator (yellow)

20 Power indicator (green)

6 Connecting nipple

with union nut (fitted)

7 Connecting tube

(20 m)

8 Castors with brake

18 Fault indicator (red)

O

O/I

2

Oxygen appliance!

Increased

Dosage monitor

26 Connection,

3 m hose to

nasal cannula

25 Humidifier

glass of

bubble

humidifier

4 Overview

21 Dosage unit (flowmeter)

0

,

5

0

,

4

0

,

3

0

,

2

0

,

1

5

,

0

24 Flow control knob

22 Ball, indicates

flow

23 Connection, long

tube to

OXYMAT 3 (20 m)

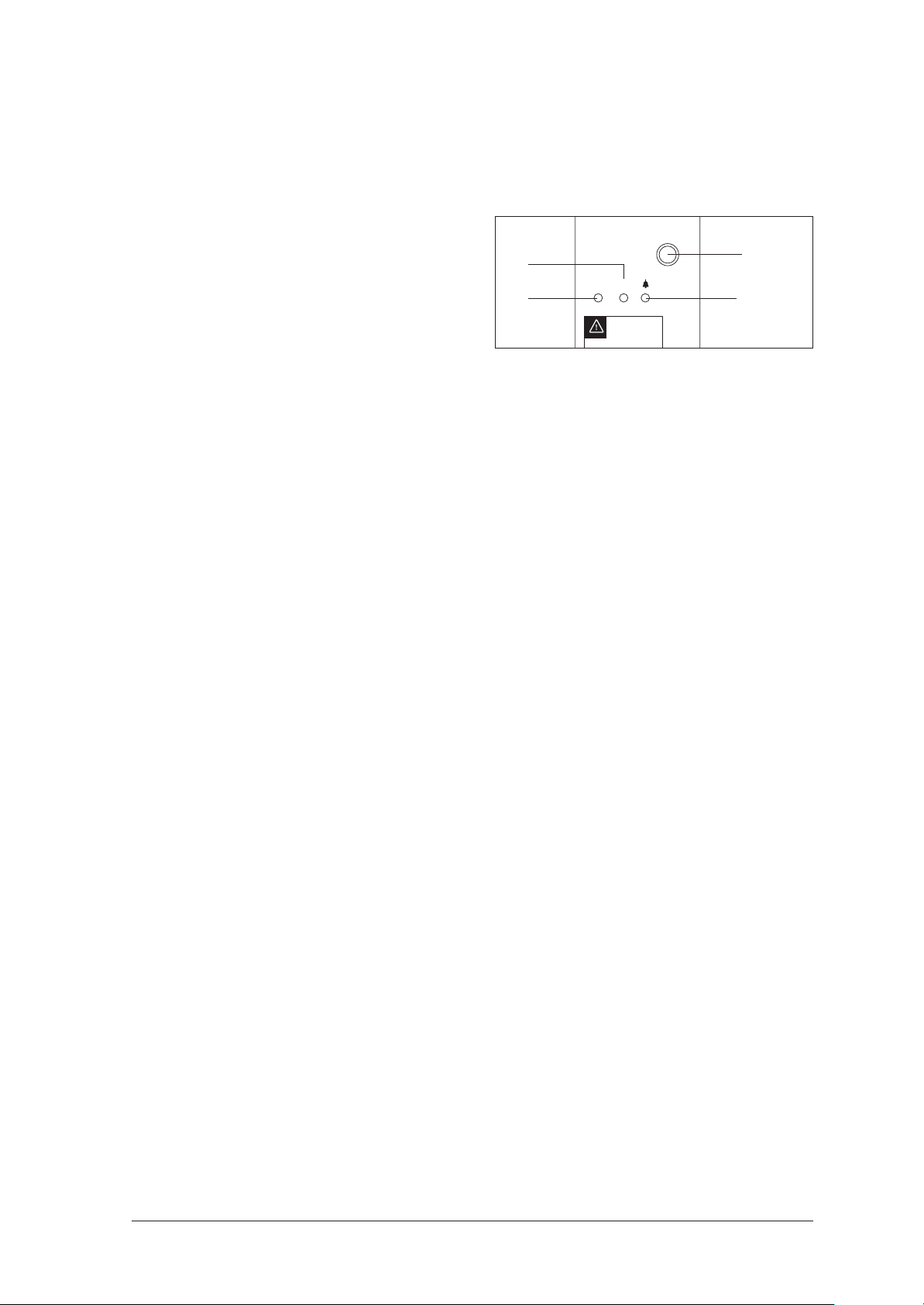

Flowmeter

16 Flowmeter

22 Ball, indicates

flow

28 Connection,

OXYMAT 3

29 Connection for

tubes

(3 m or 10 m)

27 Flow control knob

Page 5

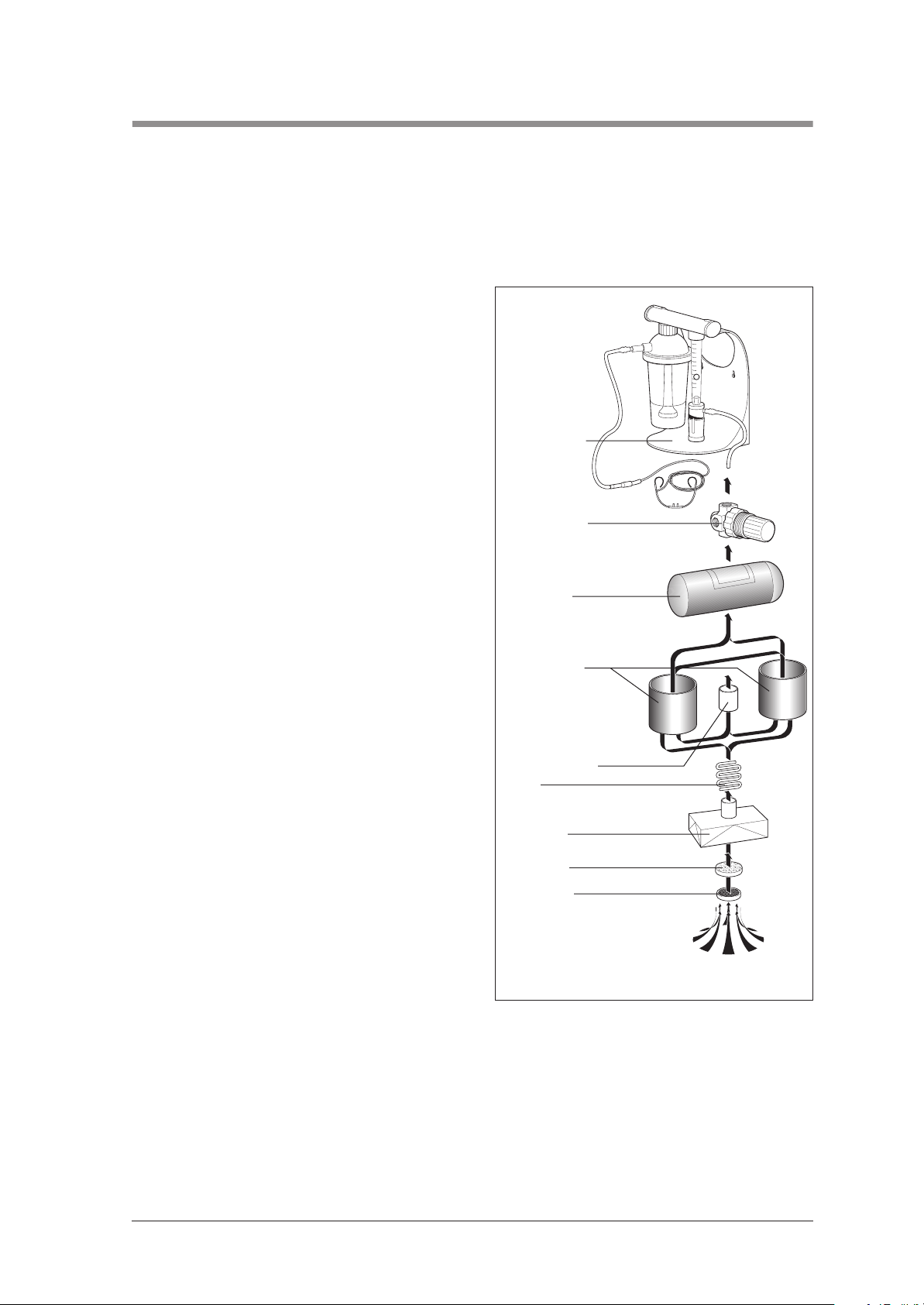

2. Functional description

OXYMAT 3 is a time-controlled appliance, i.e. the changeover time remains constant; only the pressure is

monitored.

Layout

The appliance essentially consists of three components:

• the compressor,

• the O2 system,

• the electronic/pneumatic control.

During operation, the compressor draws in ambient air via a coarse dust filter and a suction filter,

and passes the compressed air (approx. 1.7 bar

overpressure) into containers with molecular sieves

where the actual oxygen enrichment takes place.

The functional principle of molecular sieves is

based on their property of absorbing the nitrogen

contained in the air. The oxygen contained in the

air is then collected in the oxygen tank (further details can be found in the chapter “ The O2 enrichment process” on page 6).

The outlet pressure is regulated by a pressurereducer set to 0.6 bar.

The required quantity (flow) of oxygen is set on the

oxygen dosage control knob 24. Where a flowmeter is used, the flow is controlled via the flow

control knob 27. The flow is read at the top edge

of the flowmeter ball 22.

Every time it is switched on, the appliance control

system performs an internal self-test of the entire O2

system. This test takes about a minute. If the test detects an error in the O2 system that results in a drop

in the oxygen concentration, it activates the yellow

status indicator 19.

After the self-test, OXYMAT 3 switches to normal

operation. During normal operation the sequence

control constantly monitors the electrical and pneumatic circuits of the oxygen system.

Dosage monitor

Pressure-reducer

Oxygen tank

Container with

molecular sieve

Noise suppressor

Cooler

Compressor

Suction filter

Coarse dust

filter

5,0

4,0

3,0

2,0

1,0

0,5

Ambient air

In order to allow the process to run continuously, the containers operate alternately, i.e. before one container

is saturated with nitrogen, the system switches to the second container, which then continues with oxygen

enrichment. During this period, the first container is regenerated by a brief reduction in pressure, and at the

same time is flushed by a partial flow of enriched oxygen. This procedure is implemented cyclically at 7second intervals, thereby ensuring continuous oxygen enrichment of the inspiratory air.

Functional description 5

Page 6

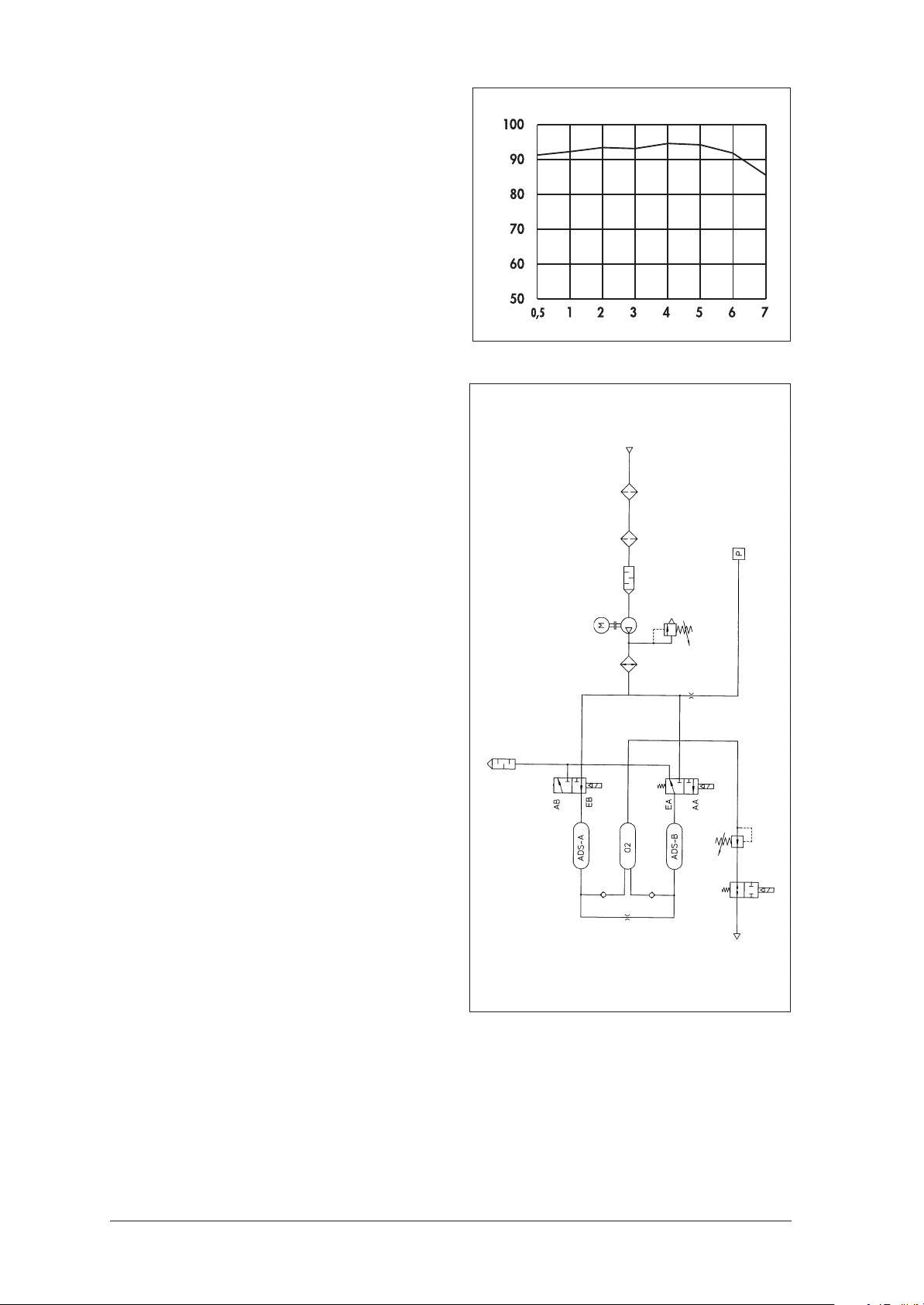

The level of oxygen concentration depends on the

set flow and is available within a few minutes.

The waste air is expelled to the rear via a noise

suppressor on the underside of the appliance.

The electronic control with microprocessor consists

of one circuit board. It is housed separately from

the oxygen system on the front panel.

The O2 enrichment process

The compressor draws the ambient air into the

housing via a coarse dust filter. Part of this air is

used to cool the compressor assembly. The other

part enters the compressor via the suction filter,

where it is compressed. A cooler reduces the temperature of the air. The compessed and cooled air

is then passed to the O2 system to enrich the oxygen.

Oxygen concentration

Flow [ l/min ]

Ambient air

The adsorption containers (ADS containers) are

alternately filled with compressed air in fixed

cycles, then regenerated by expanding the

compressed air and flushing with oxygen.

At the end of each enrichment, a pressure of

around 1.7 bar will have built up in the currently

active container.

After 7 seconds, the magnetic valves are alternately triggered by the electronic control and

switch between the two ADS containers.

Of the valves in the two ADS containers, one is

open and the other closed during operation.

Once the changeover time has been reached,

pressure compensation is implemented between

the two ADS containers. During pressure compensation, both valves are open for approximately

1 second.

The actual process of oxygen enrichment takes

place in the ADS containers. A molecular sieve

adsorbs the nitrogen from the air, thereby increasing the proportion of oxygen by volume.

As soon as the pressure in the ADS container has

risen sufficiently, air enriched with oxygen flows

into the oxygen tank at the other end of this container via the non-return valve.

Noise suppressor

Magnetic valves

Non-return valves

Suction filter

Compressor

Cooler

ADS container

Oxygen tank

Coarse dust filter

ADS container

Flushing nozzle

Throttle

Shutoff valve

outlet

2

O

Pressure sensor

Pressure reducer

6 Functional description

Page 7

Part of the oxygen flows via the flushing nozzle into

the other ADS container for flushing.

During the oxygen enrichment process, the area

where adsorption of the nitrogen occurs will shift

from the beginning of the ADS container towards

the end. Before reaching the end of the container,

the pressure between the two ADS containers is

compensated via the pressure compensating

valve. Parallel to this, the pressure escapes via the

noise suppressor and the other ADS container is

opened. The same procedure then takes place

there.

Via pressure compensation, the remaining oxygen

passes to the other ADS container, compression

energy is saved, and blow-off noise is reduced.

The nitrogen adsorbed in the first ADS container is

desorbed as a result of the pressure drop when the

valve is opened and is expelled via the noise

suppressor.

Displays and alarms

In order to attain adequate desorption of the molecular sieve, part of the oxygen extracted in one

ADS container is continuously passed to the other

ADS container via the flushing nozzle.

The oxygen stored in the oxygen tank at an overpressure of up to 1.7 bar is reduced to 0.6 bar via

the pressure-reducer.

The pressure sensor monitors this system pressure.

If the pressure falls below 0.5 bar or rises above

2.5 bar, the system activates visual and acoustic

alerts.

At an overpressure of around 0.6 bar, the oxygen

flows towards the outlet of the appliance.

The prescribed flow is set on the dosage monitor

or on the flowmeter. It then flows to the patient via

the nasal cannula.

• If a leak that is likely to cause a drop in the oxy-

gen concentration occurs after the internal self-

test, this situation is indicated immediately by a

visual warning signal (yellow lamp).

• If the compressor output falls off, a visual alarm

signal is displayed (red lamp flashes) and an

acoustic warning (intermittent tone) sounds.

Further information on displays and alarms can be found in Chapter “6.1 Visual and acoustic signals from

OXYMAT 3” on page 19“.

• The green lamp indicates that the system is operational.

• In the event of a power failure, an intermittent

warning signal will sound and the red lamp

will flash. The green lamp is not illuminated.

Functional description 7

Page 8

3. Servicing

3.1 General

• Important!

Enter the operating hours of OXYMAT 3 and the

oxygen concentration in your service record

(see page 78).

• The number of operating hours can be read

from the operating hours meter 4 on the front of

the device.

• As a precautionary measure, we recommend

that the OXYMAT 3 be serviced once a year

or every 5,000 operating hours.

• After each servicing, a functional check should

be carried out (see "5. Functional check" on

page 10).

Note: Dark discoloration of the intake filter 30 does

not mean that its flow characteristics are impaired,

provided its operating hours do not exceed

5,000 h; an exception applies if the device is operated in a very dusty environment.

3.2 Implementation

Servicing the OXYMAT 3 involves changing the coarse dust filter and the suction filter and performing a final

check (see "5. Functional check" on page 10).

The filters are located on the back of the appliance.

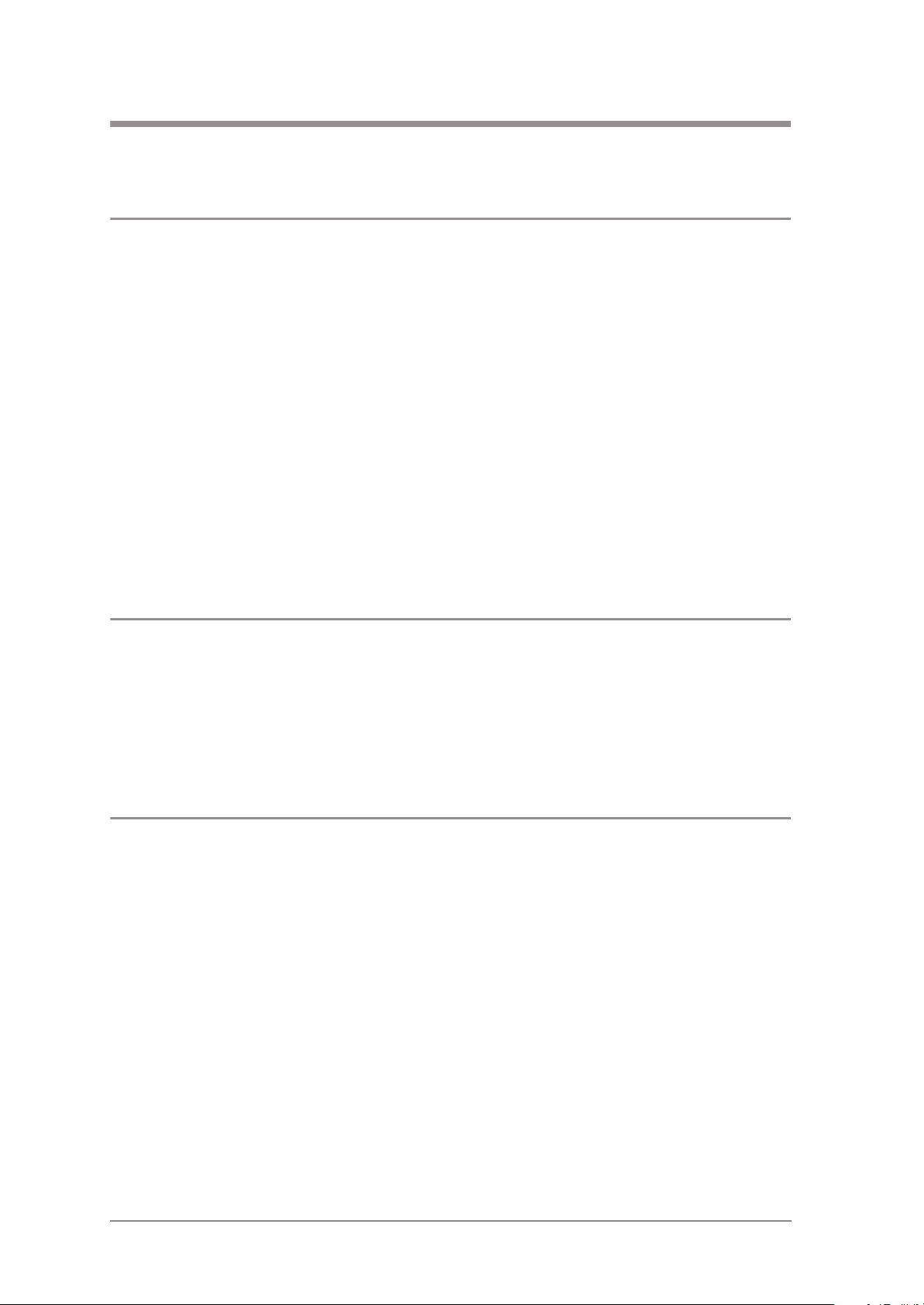

1. Detach the coarse dust filter 13 from the

service flap 38.

13

2. Release the lock on the service flap 38 and

remove the latter from the appliance.

When removing the suction filter, please proceed

with caution, since the connector and tube may be

torn off if the suction filter is handled carelessly.

3. You will find a black clip in the recess to the

left of the suction filter. Use your fingers or an

object to press against this clip to prevent it

from being pulled out as well.

4. Pull the suction filter 30 off the connector 71

without twisting. The suction filter must not be

twisted, as the connector could become

detached from the tube.

5. Connect the new filter 30 to the connector.

6. Clean the service flap 38 and insert it.

7. Clip a new coarse dust filter 13 into the service

flap 38.

38

71

30

8 Servicing

Page 9

3.3 Disposal

Do not dispose of the unit with domestic waste. For proper disposal of the device and its components, please contact a certified waste disposal site for electronic goods. Ask your Environmental

Officer or local council for the address. Appliance packaging (cardboard and inserts) may be disposed of in the paper recycling bin.

4. Hygienic Preparation

4.1 No change of patient

Proceed as described in the operating instructions

for the OXYMAT 3.

4.2 Change of patient or reuse

• Dispose of extension tubes and nasal cannulas, and replace with new parts.

• Dispose of coarse dust filter and suction filter,

and replace with new parts.

• For the bubble humidifier, please observe the

separate operating instructions.

• Wipe housing and power cord with TERRALIN

disinfectant.

• Clean inside of housing with vacuum cleaner,

clean any particularly dirty parts with household cleaner (to open and close the appliance, see sections 7.3 and 7.4 on page 29

and page 30).

Hygienic Preparation 9

Page 10

5. Functional check

5.1 General

• Should you discover any faults or deviations

from the set values during your functional

check, OXYMAT 3 must not be used again until the faults have been rectified.

• The possible causes underlying the fault and

how to rectify them are outlined in Chapter “6.

Troubleshooting” on page 19.

Please use the following equipment to carry out the functional check:

• Oxygen measuring device,

• Filled oxygen cylinder with adjustable pressure reducer (e.g. HIT,WM 33100),

• Respiratory tubes WM 5726 and WM 5772.

• For environmental reasons a capacitor backup unit has been installed instead of a battery

to serve the power failure alarm function.

As soon as OXYMAT 3 is operational, the capacitor is recharged. Charging takes approximately 5 minutes.

If the device has been out of service for some

time, an alarm cannot be triggered until the device has been operational for at least 5 minutes.

5.2 Intervals

A final check must be performed on the appliance:

• after every service;

• after every repair.

5.3 Implementation

5.3.1 Checking the housing

Check the housing to determine its general

condition.

• Dirt can be wiped off with a damp cloth. The

all-purpose cleaner WM 14937 is also very

suitable.

• If you want to use a disinfectant, we recommend TERRALIN.

10 Functional check

• If the housing is defective, replace it (see "7.3

Opening the appliance" on page 29) and

„7.4 Closing the appliance“ auf Seite 30.

• If the frame is defective, please replace it (see

"7.16 Replacing the frame (up to appliance

no. 19999)" on page 57).

Page 11

5.3.2 Checking the coarse dust filter

Check the coarse dust filter 13 to determine its general condition:

1. Unclip the coarse dust filter from the back of

OXYMAT 3.

2. If the filter is dirty, clean it. As a general rule,

the filter should be freed from dust once a

week (either by tapping or vacuuming).

3. If the filter is defective, replace it.

13

5.3.3 Checking the power cord

1. Check the power cord 10.

Make sure that

– the insulation is undamaged,

– the cable is undamaged,

– none of the contacts are wobbly.

2. If any of these requirements are not satisfied,

replace the power cord 10.

5.3.4 Checking the fuse

The fuse holder 15 can be found on the rear of the appliance beneath the power socket 14.

1. Pull the power cord 10 from the socket and

from the device.

2. Press the side tabs on the fuse holder 15 together and pull out the fuse holder.

3. Check that the correct fuses are installed.

There should always be two fuses installed:

A mains fuse and a spare fuse.

The fuses 39 should carry the following label:

DIN EN 60127-T 2.5 A H 250 V.

4. If necessary, replace the defective or missing

fuses.

5. Push the fuse holder 15 into the housing until it

locks home.

15

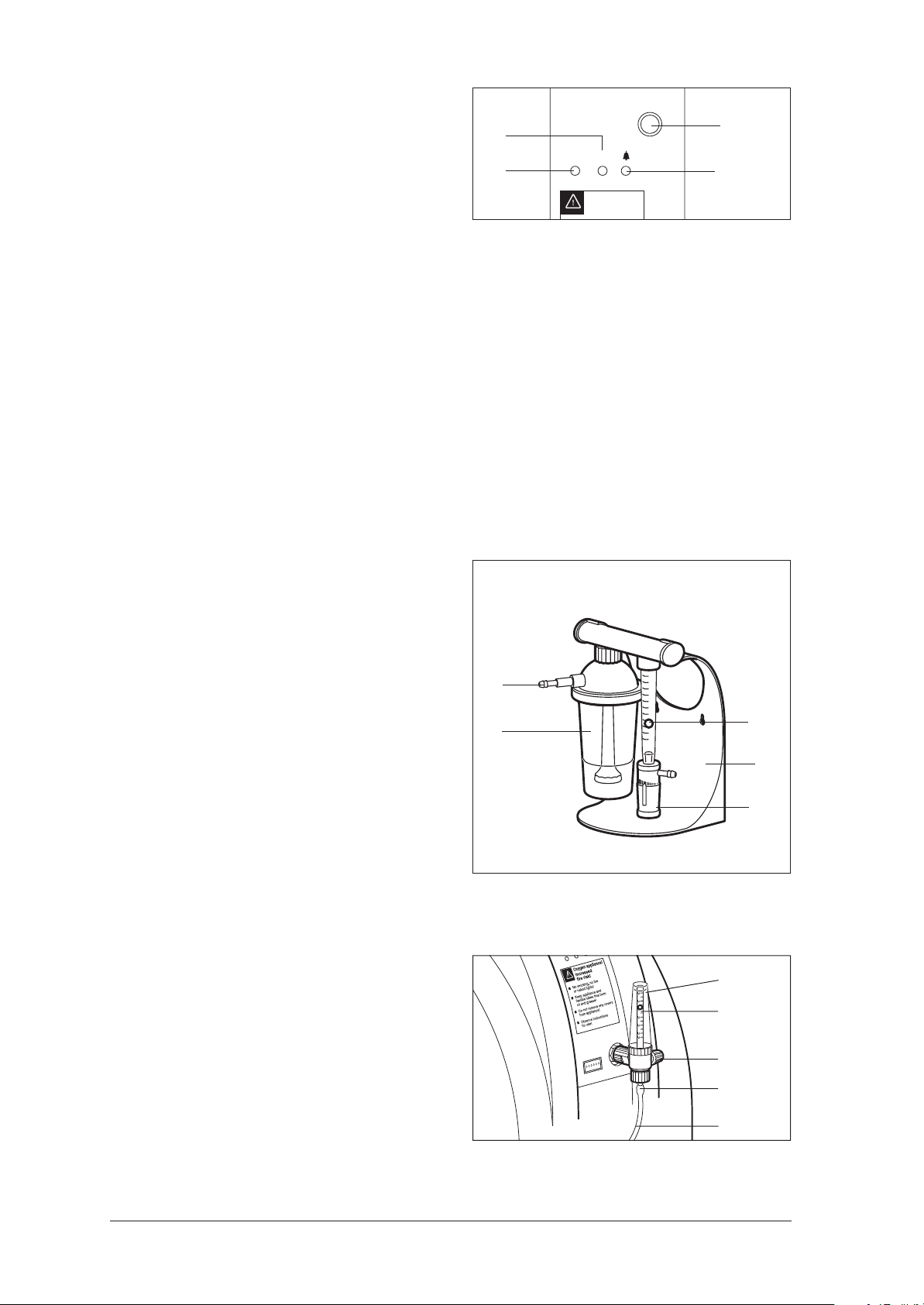

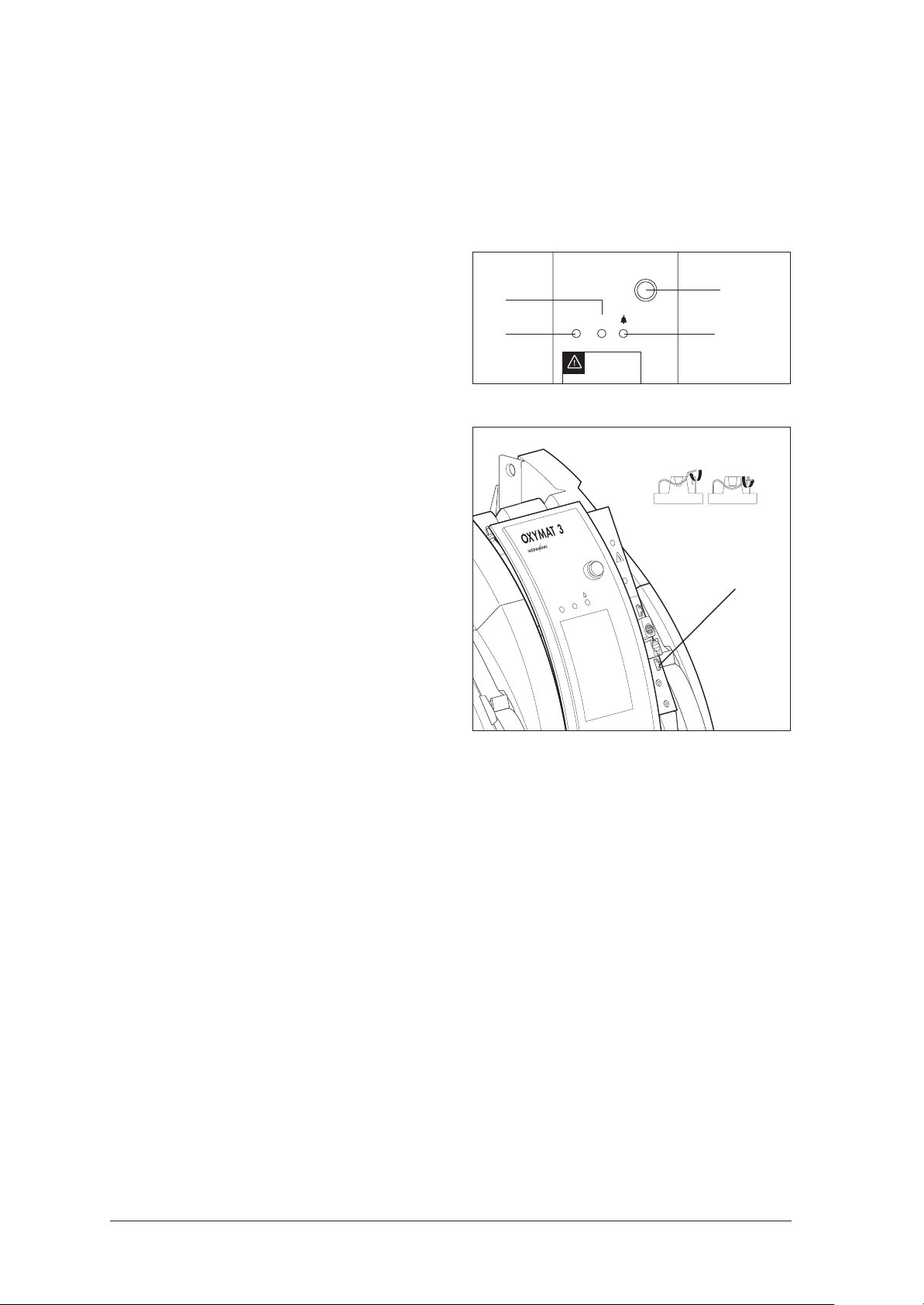

5.3.5 Checking the main switch and LED displays

1. Connect the power cord 10 to OXYMAT 3

and to a wall socket.

2. Connect the dosage monitor or the flowmeter

to the oxygen outlet 5.

Functional check 11

Page 12

3. Switch on the OXYMAT 3 at the On/Off

knob 2. The following LED displays will appear:

– The power indicator (green LED) 20 lights

up.

– The fault indicator (red LED) 18 and status

indicator (yellow LED) 19 light up briefly.

Important

The program then makes an internal check for

leaks:

– Pressure is built up within 20 seconds. The

green operating indicator 20 flashes light/

dark.

– Then the compressor is switched off and the

existing pressure is monitored for about 20

seconds. If there is a fault and the pressure

drops, the yellow status indicator 19 lights

up.

– Finally the system is vented so that the com-

pressor can start up again without any

back-pressure.

5.3.6 Checking the dosage monitor for leaks

19

20

O/I

Oxygen appliance!

Increased

fire risk!

O/ I

2

O

2

18

1. Check the screw connections between the humidifier glass/cap and humidifier/dosage

monitor to verify that they are firmly seated. If

necessary, re-tighten the connections by hand.

2. Set a flow of 4 l/min on the flow control

knob 24 for oxygen dosage.

3. To check the dosage monitor 9 for leaks,

– bend the 3 m tube 11

– or pull the 3 m tube 11 from the connection

of the bubble humidifier 25 and hold the

connection 26 closed.

If the ball 22 sinks all the way to the bottom,

there are no leaks in the dosage monitor system.

4. In the event of leaks, change the sealing rings

on the humidifer.

5.3.7 Checking the flowmeter for leaks

1. Set a flow of 4 l/min on the knob 27.

2. To check the flowmeter 16 for leaks:

– Bend the connection tube 17

– or pull the tube 17 from the connection of

the flowmeter and hold the connection 29

closed.

If the ball 22 sinks all the way to the bottom,

there are no leaks in the flowmeter.

3. In the event of leaks, change the sealing rings

on the flowmeter.

26

25

0

,

5

0

,

4

0

,

3

0

,

2

0

,

1

5

,

0

22

9

24

16

22

27

29

17

12 Functional check

Page 13

5.3.8 Checking the operating hours meter

Check that the red minute counter on the operating

hours meter 4 is incremented every 6 minutes.

5.3.9 Checking the O2 concentration

Leave the OXYMAT 3 to run for at least 10 minutes

before starting the measurement.

Before you check the oxygen concentration on the

OXYMAT 3, you must first calibrate the oxygen

measuring device (e.g. OXYcontrol WM 13550).

For this purpose, you will need the respiratory tube

WM 5726 and an oxygen cylinder with an adjustable pressure reducer (e.g. WM 33100).

Caution !

Please observe the instructions for handling oxygen!

Important!

Before calibrating the oxygen sensor for the first

time, the sensor must be stored in ambient air for

at least 15 minutes (refer to instructions for use of

the sensor).

Observe instructions

for use!

4

000000

How to calibrate the oxygen sensor:

1. Connect the oxygen measuring device to the

pressure reducer of the oxygen cylinder using

the respiratory tube WM 5726.

2. Slowly open the cylinder valve. One revolution

is sufficient!

3. Set a flow of 4 l/min at the pressure reducer.

4. Leave the oxygen measuring device (e.g.

OXYcontrol) flowing for approximately 2 minutes,

until the displayed oxygen level remains steady.

5. Set a value of "100" using the calibration

knob.

6. Close the cylinder valve again.

The oxygen measuring device is now calibrated

and you can check the oxygen concentration on

OXYMAT 3.

Please remember that OXYMAT 3 must have already

been operational for at least 10 minutes.

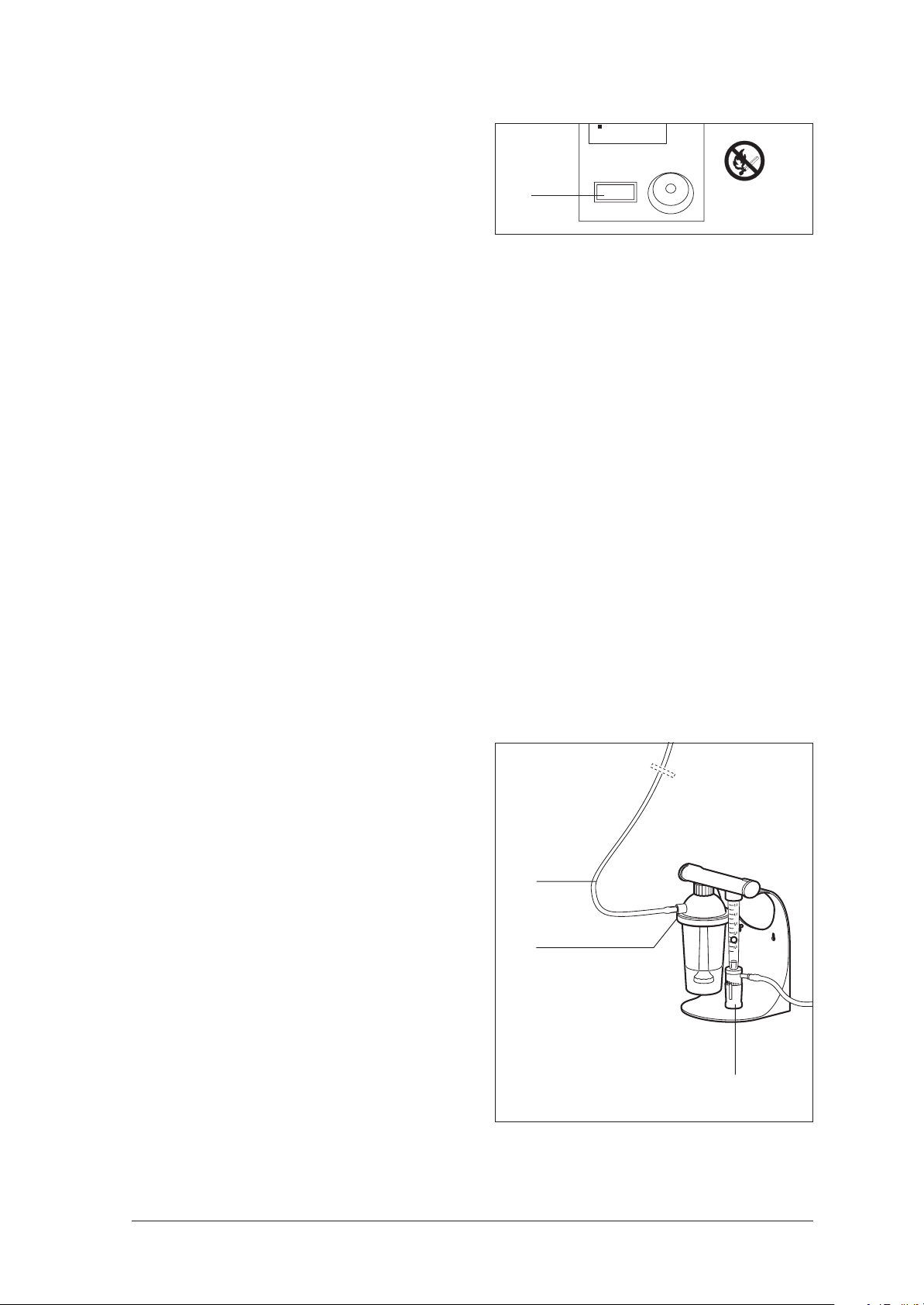

When operating with a dosage monitor:

Important!

It is vital that you empty the humidifier glass 25 of the

bubble humidifier; otherwise, the oxygen sensor of

the oxygen measuring device will be damaged.

7. Connect the oxygen measuring device:

– To do so, remove connecting tube 11 from

connection 26 of the dosage monitor and

use breathing tube WM 5772 to make a

connection between connection 26 and the

oxygen measuring device;

or

– Unscrew the bubble humidifer (sterile water

system) from the dosage monitor and attach

the connecting tube to the OXYcontrol at

this point with the union nut.

8. Using the flow control knob 24, set a flow of

4 l/min.

11

26

24

Functional check 13

Page 14

9. After waiting for a short while, read the oxygen concentration from the oxygen measuring

device.

It should be between 90 and 95 % by volume.

10. Re-connect the connecting tube 11.

11. If the O2 concentration is outside the tolerance

range, proceed as described in “6.3 O2 concentration outside tolerance range” on

page 27.

When operating with a flowmeter:

7. Connect the oxygen measuring device:

– To do this, remove connecting tube 17 from

connection 29 of the flowmeter and use

breathing tube WM 5772 to make a connection between connection 29 and the

oxygen measuring device;

or

– Unscrew the union nut from the flowmeter

and attach the connecting tube to the

OXYcontrol at this point with the union nut.

8. Using the flow control knob 27 set a flow of

4 l/min.

9. After waiting for a short while, read the oxygen concentration from the oxygen measuring

device.

27

29

17

It should be between 90 and 95 % by volume.

10. Re-connect the connecting tube 17.

11. If the O2 concentration is outside the tolerance

range, proceed as described in “6.3 O2 concentration outside tolerance range” on

page 27.

5.3.10 Checking the mains failure alarm

Note:

As power is supplied to the alarm function via a capacitor, the OXYMAT 3 should first be operated for 5 minutes

to allow the capacitor to charge.

1. Pull the power cord from the socket or from the

device.

2. Check whether the following displays and

alarms occur:

– Acoustic: The device emits a continuous

tone.

– Optical: The red fault indicator 18 lights up;

the green power indicator 20 is off.

3. Re-make the connection to the mains.

Now:

– The acoustic alarm should be silenced.

– The red fault indicator 18 should go out.

O

20 18

O/I

Oxygen appliance!

Increased

fire risk!

– The green power indicator 20 should be

on.

– The appliance should start up.

O/ I

2

14 Functional check

4. Switch off the appliance at the On/Off knob 2.

Page 15

5.3.11 Checking the indirect status indicator (yellow LED) with appliance closed

The purpose of this check is to establish whether the status indicator that warns if a leak that is likely to cause

a drop in the oxygen concentration is working properly. This is done by an internal program that creates an

artificial leak which results in the alarm being triggered.

1. Switch on the OXYMAT 3 at the On/Off

switch 2.

An internal leak test will run for about 1 minute.

19

The green operating indicator 20 flashes while

this is in progress.

20

2. With the appliance running, set a flow of

4 l/min at the top of the ball.

To start the test program, proceed as follows:

3. Remove power cord 10 from the wall socket or

the appliance.

4. Wait for the acoustic power failure alarm to

sound (two groups of five tones – – – – –).

5. Switch off the OXYMAT 3 at the On/Off

switch 2. Do not connect the power cord

again.

6. Switch OXYMAT 3 on again at On/Off

switch 2.

11. Check that the yellow status indicator 19 is on

while this is happening.

If the status indicator does not light up, either:

– you have not set the flow to exactly 4 l/min

or

– the status indicator is faulty.

12. Switch off the OXYMAT 3 at the On/Off

switch 2, then switch it on again.

The test program is now deactivated and the

OXYMAT 3 is in normal operating mode.

7. Wait for the acoustic power failure alarm to

sound again (two groups of five tones

– – – – –).

8. Switch off the OXYMAT 3 at the On/Off

switch 2.

The yellow status indicator 19 must now light

up. If it does not, repeat the procedure.

9. Connect the power cord again.

10. Switch on the OXYMAT 3 at the On/Off

switch 2.

The following LED indicators appear:

– green operating indicator 20 lights up

– red fault indicator 18 lights up briefly

– yellow status indicator 19 lights up briefly.

O/I

Oxygen appliance!

Increased

fire risk!

O/ I

2

O

2

18

The program then runs an internal leak check

routine:

– pressure is built up within 20 s. The green

operating indicator 20 flashes.

– the pressure is checked for about 20 s with

the compressor switched off.

An artificial leak is created in the OXYMAT 3, and

this results in the oxygen concentration falling below 82 %.

Functional check 15

Page 16

5.3.12 Checking the indirect status indicator (yellow LED) with the appliance open

Note:

Not necessary as part of a normal functional check or service.

The purpose of this check is to establish whether the status indicator that warns if a leak that is likely to cause

a drop in the oxygen concentration is working properly. This is done by an internal program that creates an

artificial leak which results in the alarm being triggered. If the appliance is open (e.g. for repair work) you

can start this test program with switch S5 on the printed circuit board.

1. Switch on the OXYMAT 3 at the On/Off

switch 2.

An internal leak test will run for about 1 minute.

19

The green operating indicator 20 flashes while

this is in progress.

20

2. With the appliance running, set a flow of

4 l/min at the top of the ball.

To start the test program, proceed as follows:

3. Switch off the OXYMAT 3 at the On/Off

switch 2.

4. Open coding switch S5 on the printed circuit

board.

5. Switch on the OXYMAT 3 at the On/Off

switch 2.

The following LED indicators appear:

– green operating indicator 20 lights up

– red fault indicator 18 lights up briefly

O

O/I

– yellow status indicator 19 lights up briefly.

The program then runs an internal leak check

routine:

– pressure is built up within 20 s. The green

operating indicator 20 flashes.

– the pressure is checked for about 20 s with

the compressor switched off.

O/I

Oxygen appliance!

Increased

fire risk!

O/I

2

O/ I

2

O

2

18

S5

An artificial leak is created in the OXYMAT 3, and

this results in the oxygen concentration falling below 82 %.

6. Check that the yellow status indicator 19 is on

while this is happening.

If the status indicator does not light up, either:

– you have not set the flow to exactly 4 l/min

or

– the status indicator is faulty.

7. Switch off the OXYMAT 3 at the On/Off

switch 2.

8. Close coding switch S5 on the printed circuit

board.

The test program is now deactivated and the

OXYMAT 3 is in normal operating mode.

9. Close the appliance (see "7.4 Closing the

appliance" on page 30).

16 Functional check

Page 17

5.3.13 System pressure test

General

The system pressure should only be tested if there is a fault in the appliance.

Fitting the test pressure gauge

1. Connect the test pressure gauge inlet directly

to the oxygen outlet 5.

If your pressure gauge also has an outlet, close

it (e.g. with your thumb).

2. Open the appliance housing (see "7.3 Opening the appliance" on page 29).

3. Open the strap system 42 without pulling the

strap out of its buckle.

4. Carefully remove foam section 44.

5. To prevent the ADS containers from slipping

out, lay the strap system 42 over the remaining

foam sections and gently tighten it.

44

I

/

O

2

O

/I

O

O

2

0000

0

0

5

To make fitting easier, the test pressure gauge is

not fitted directly to the inlet of the O2 tank, but

before the 6 mm diameter tube 56 which leads

directly to the O2 tank.

6. At the T-connector 74, push back the sleeve of

the elbow connector and remove the tube 56.

7. Push the tube of the test pressure gauge firmly

into the elbow connector.

8. Push the tube 56 into the free inlet of the test

pressure gauge.

Pressure test

Oxygen outlet

1. Plug the power cord 10 into the appliance and

insert the mains plug in a wall socket.

2. Switch the OXYMAT 3 on.

3. After 10 minutes, attach the pressure gauge to

the oxygen outlet 5.

4. Read off the pressure.

The reading must be in the range

0.6 bar ± 0.1 bar (at sea level).

5. Rectify any discrepancies you find (see "6.2

Remedies" on page 22).

42

56

74

6. Switch the appliance off, then remove the

mains plug from the wall socket and the power

cord from the appliance.

7. Remove the pressure gauge.

8. Perform a functional check (see "5. Functional

check" on page 10).

Functional check 17

Page 18

O2 tank inlet

9. Attach the dosage unit 21 or the flowmeter 16.

10. Plug the power cord 10 into the appliance and

insert the mains plug in a wall socket.

11. Switch the OXYMAT 3 on.

Caution!

Risk of injury or death!

Beware of live or moving components.

12. Set the flow to 4 l/min.

13. After 10 minutes, read off the pressure on the

pressure gauge.

The reading must be in the following range:

At the O2 tank inlet:

min. 1.2 + 0.3/- 0.2 bar to

max. 1.65 bar + 0.3/- 0.2 bar

at 4 l/min (at sea level).

Rectify any discrepancies you find(siehe „6.2

Remedies“ auf Seite 22).

5.3.14 Checking the O2 system for leaks

14. Switch the appliance off, then remove the

mains plug from the wall socket and the power

cord from the appliance.

15. Remove the dosage unit 21 or flowmeter 16

from the appliance.

16. Remove the pressure gauge.

17. Attach the tube 56.

18. Slacken the strap system.

19. Carefully insert the foam section 44 and tighten the straps again.

20. Close the appliance (see "7.4 Closing the

appliance" on page 30).

21. Perform a functional check (see "5. Functional

check" on page 10).

General

A check for leaks should only be made if there is a

problem with the appliance.

Method

Soap all connections between the compressor exit,

the pressure equalization system (tubes, exit) and

the shutoff valve after the pressure reducer.

18 Functional check

Page 19

6. Troubleshooting

6.1 Visual and acoustic signals from OXYMAT 3

6.1.1 Alarms

The following appliance states trigger an alarm:

1. Power failure

2. Overheating

3. Memory error

4. Under-pressure

5. Over-pressure

6. Implausible pressure measurement

7. Leak in O2 system

1. Power failure

The energy for a power failure alarm is supplied by

a capacitor back-up unit. If the capacitor back-up

unit is fully discharged, the power failure alarm is

not available for the first minute after switching on

the OXYMAT 3 until the back-up unit has charged

up again.

2. Overheating

A temperature sensor is mounted on the printed circuit board. If the temperature rises above 60 °C

(± 2.5 °C), an alarm is given and at the same time

the compressor is switched off. The compressor remains switched off as long as the temperature

alarm is activated. The cause may for example be

a malfunction of the fan.

3. Memory error

Every time the appliance is switched on, the

EEPROM is first read out. Among other things, this

contains the operating cycles for the valves and the

calibration data for the temperature sensor. A plausibility check is performed on the data read out.

If a memory error occurs:

– default values (basic settings) are read from

the program memory and used to start the

control program;

– the memory error alarm is activated;

– after every alarm cycle a fresh attempt is

made to read the EEPROM;

– after a successful read attempt the alarm is

terminated.

4. Under-pressure

This alarm is activated if the pressure sensor at the

inlet to the O2 system measures a pressure lower

than the required operating pressure.

5. Over-pressure

This alarm is activated if the pressure sensor at the

inlet to the O2 system measures a pressure higher

than the required operating pressure.

6. Implausible pressure measurement

Since the OXYMAT 3 has a time control, there

must be a defined pressure pattern over time. This

pressure pattern is measured by the pressure

sensor and analyzed by the appliance software. If

necessary an alarm is activated.

7. Leak in O2 system

Every time the appliance is switched on, the control system runs a leak test on the entire O2 system.

If a leak is found, the yellow status indicator 19 is

switched on, as sooner or later this leak in the O2

system may result in the oxygen concentration at

the outlet falling below 82 %.

During the leak test the green power indicator 20

flashes.After the leak test the OXYMAT 3 switches to

normal operating mode.

If the leak test is not successfully completed within

one minute, the control system stops the test cycle

and switches on the yellow status indicator 19 to

indicate an operating fault. The cause of the leak

must now be identified.

No further test for leaks is performed during normal

operation.

Troubleshooting 19

Page 20

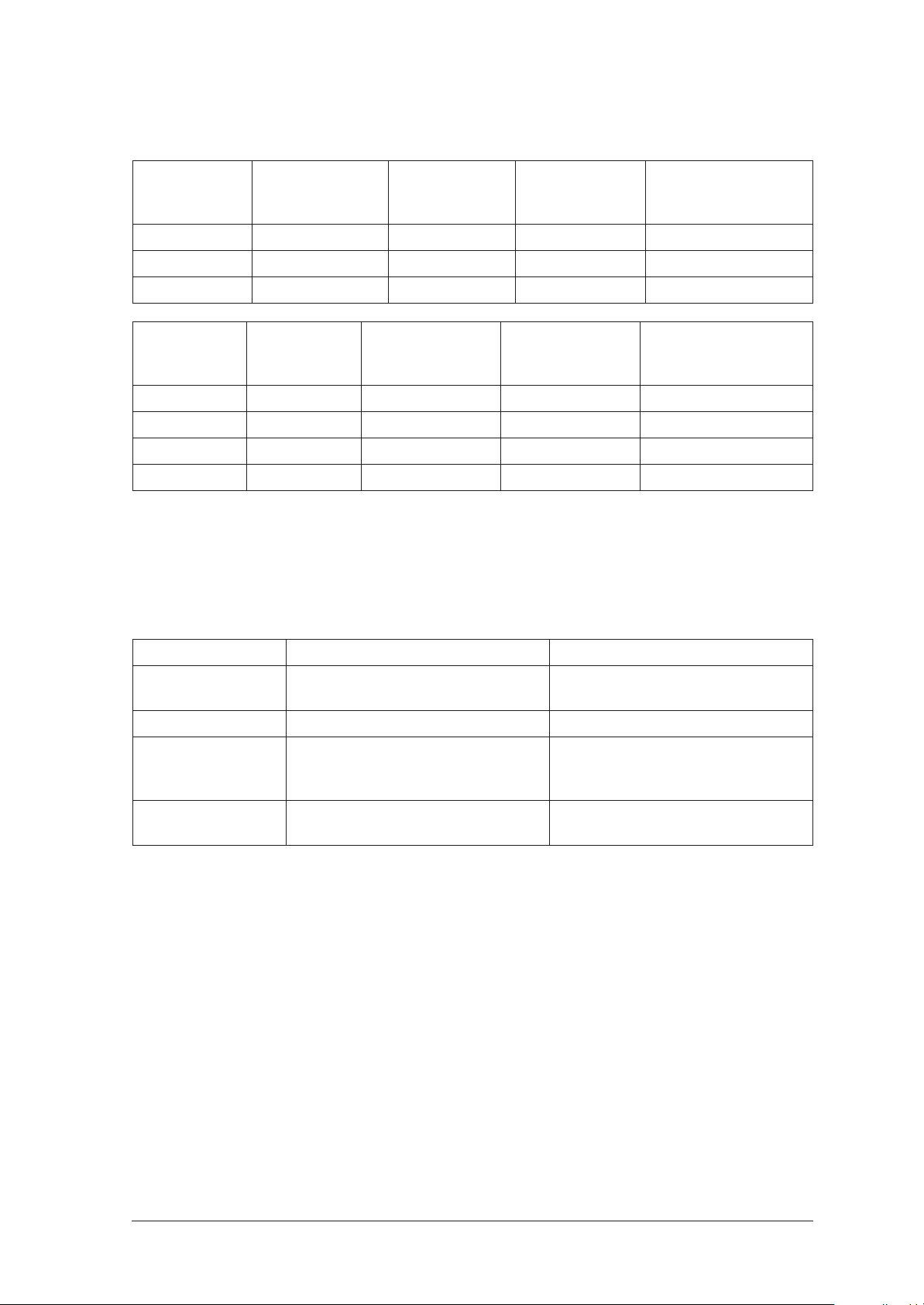

6.1.2 Signal patterns

The alarm signal patterns are in accordance with EN 475 (see Table of Signal Patterns). To make it possible

to distinguish the alarm sources, this standard assigns specific signal patterns to individual error situations

(see Table of Error Situations).

Since it is possible that two or more errors may occur at the same time, the alarms are weighted by the

software and the appropriate alarm pattern is output. For example: if under-pressure and overheating occur

simultaneously, the alarm pattern for overheating is output (see Table of Alarm Situations).

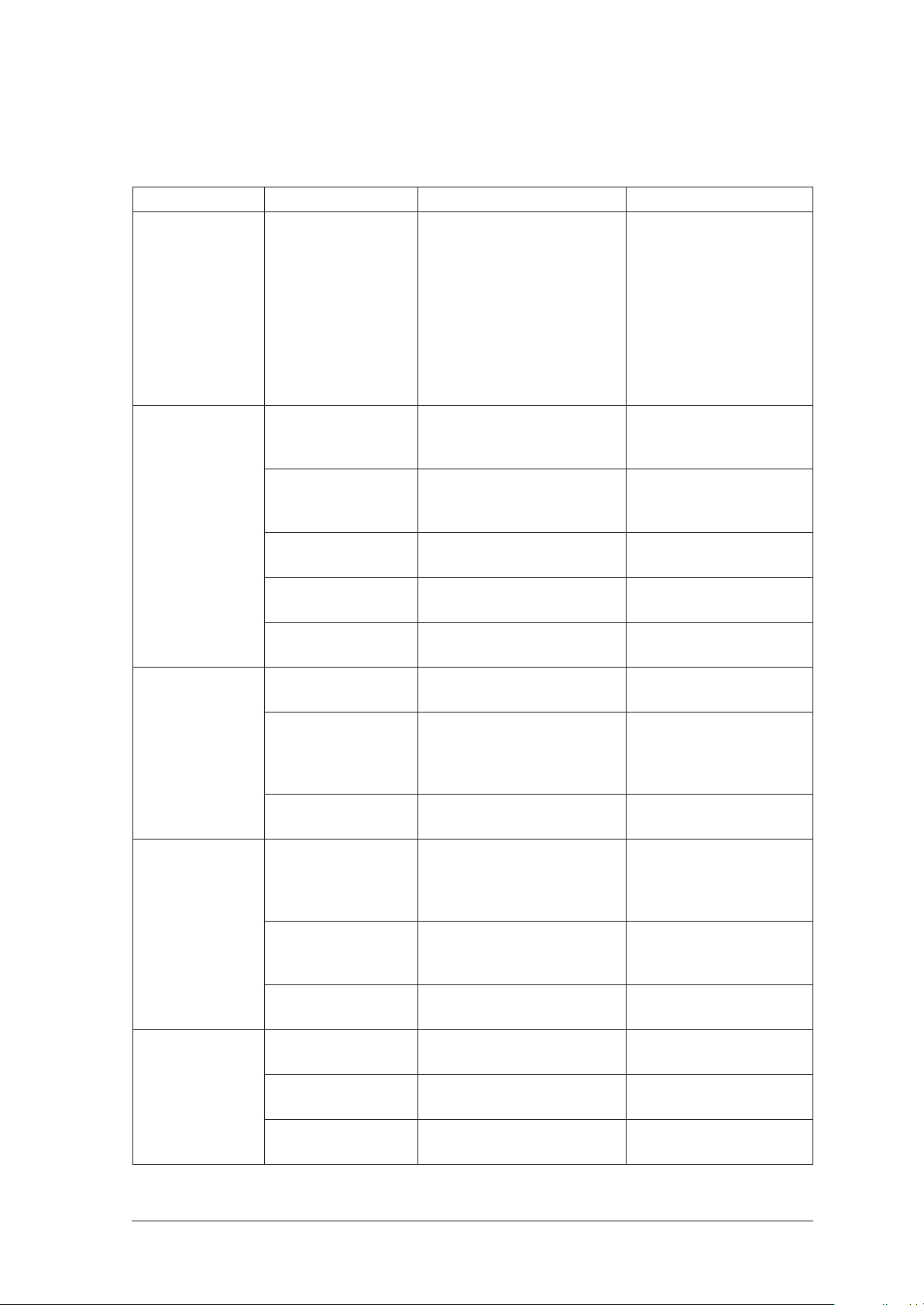

Table of Alarm Situations:

Appliance Status

Power failure

Overheating

Implausible

pressure reading

Memory error

Under-pressure

Over-pressure

O2 status

Release after

x minutes

1 minute after

cold start

Immediately after

switching on

1 minute after

end of leak test

Immediately after

switching on

1 minute after

end of leak test

1 minute after

end of leak test

Test immediately

after switching on

Pattern of alarm

signal indicators

Buzzer: A

Red LED: A

Yellow LED: off

Green LED: off

Buzzer: A

Red LED: A

Yellow LED: off

Green LED: on

Buzzer: A

Red LED: C

Yellow LED: off

Green LED: on

Buzzer: B

Red LED: B

Yellow LED: off

Green LED: on

Buzzer: C

Red LED: C

Yellow LED: off

Green LED: on

Buzzer: C

Red LED: D

Yellow LED: off

Green LED: on

Buzzer: off

Red LED: off

Yellow LED: on

Green LED: on

Classification of

Weighting

1 High priority

1 High priority

2 High priority

3 High priority

4 High priority

5 High priority

Is indicated

independently by

the yellow LED

signal patterns

under EN 475

Low priority

Note:

The green power indicator 20 is not an alarm signal indicator. Its status is only given here for completeness’

sake.

20 Troubleshooting

Page 21

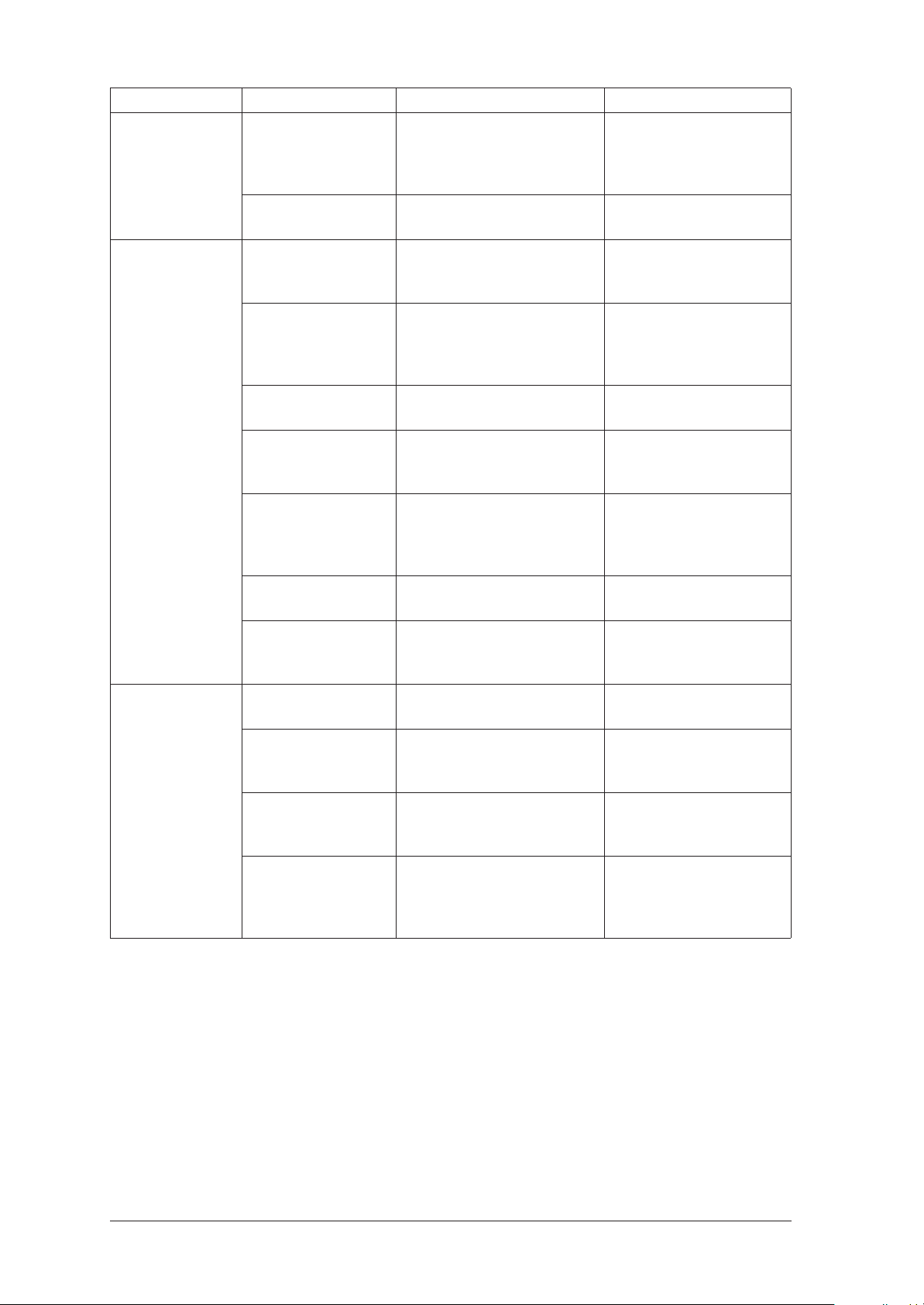

The signal patterns for the buzzer consist of 2 identical pulse sequences, repeated every 10 seconds. Each

pulse sequence consists of 5 individual pulses (see Table of Signal Patterns).

Table of Signal Patterns:

Buzzer pattern

for one pulse

sequence

Pulse duration / ms

(= buzzer on)

Pulse interval/ ms

(= buzzer off)

Pulse interval

between 3rd and

4th pulse / ms

Graphic representation

A 150 100 500 — — — — —

B 150 10 320 — — — — —

C 150 0 300 ——— ——

Flashing pattern

for

red LED

Flashing

frequency / Hz

On time / ms Off time / ms Graphic representation

A 1.43 200 500 — —

B 1.43 400 300 —— ——

C 2.5 80 320 – –

D 2.5 240 160 — —

6.1.3 Deactivating the signal functions

The signal functions can be deactivated by means of the switches S2, S3, S4 and S5 on the printed circuit

board. To see where the switches are located on the PCB, consult the illustrations in Section “10.1 Arrangement of the PCBs” on page 76.

Coding switch Open Closed

S2

S3

Power supply for power failure alarm

deactivated.

Buzzer deactivated. Buzzer activated.

Alarm suppression during warming-up

S4

phase deactivated

(i.e. alarm function activated).

S5

Tip:

Activates program for checking status

indicator

Power supply for power failure alarm

activated.

Alarm suppression during warming-up

phase activated

(i.e. alarm function deactivated).

Normal operation

For fault-finding purposes it can be useful to open coding switch S4. This enables the alarms immediately on

completion of the leak test.

Troubleshooting 21

Page 22

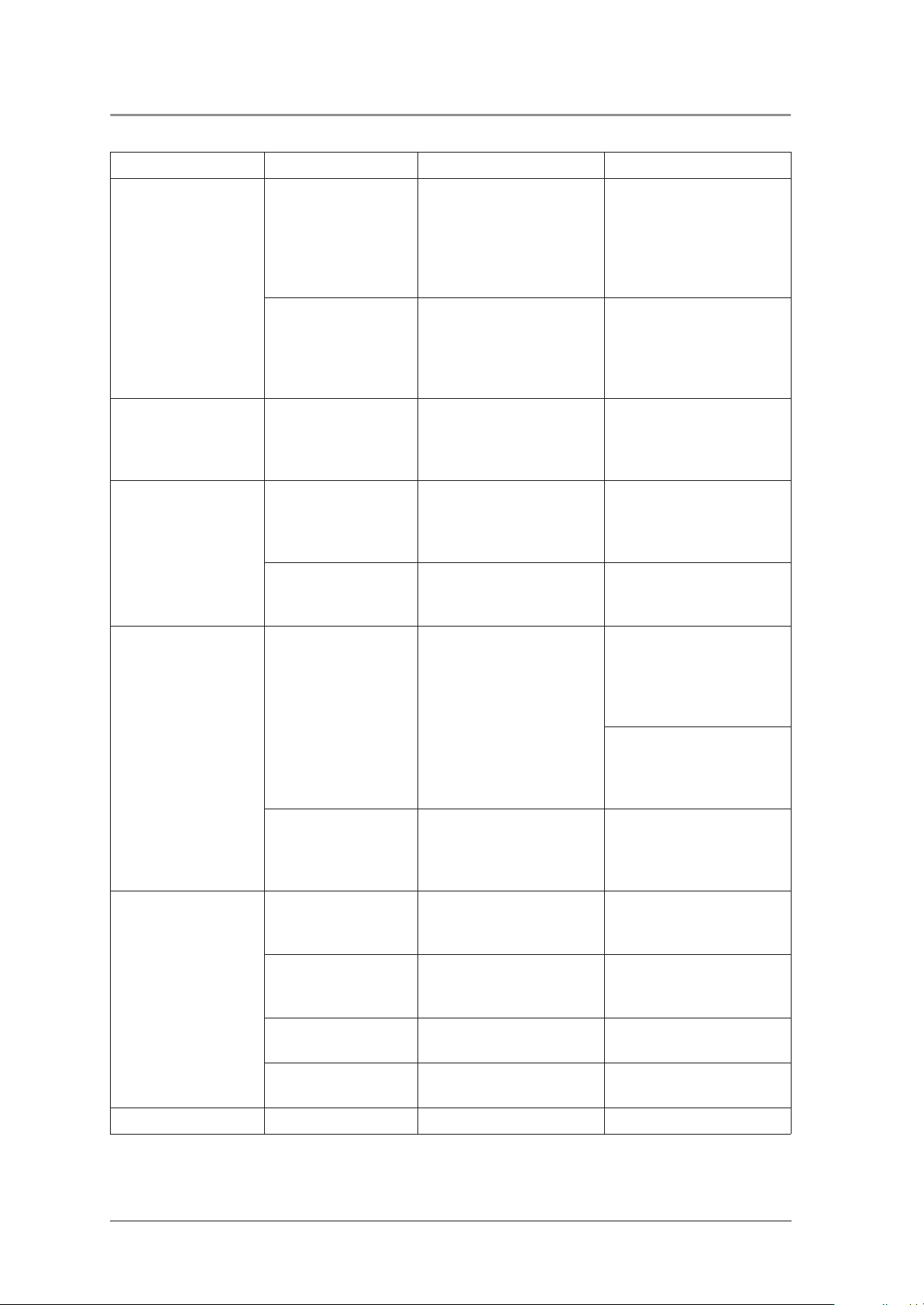

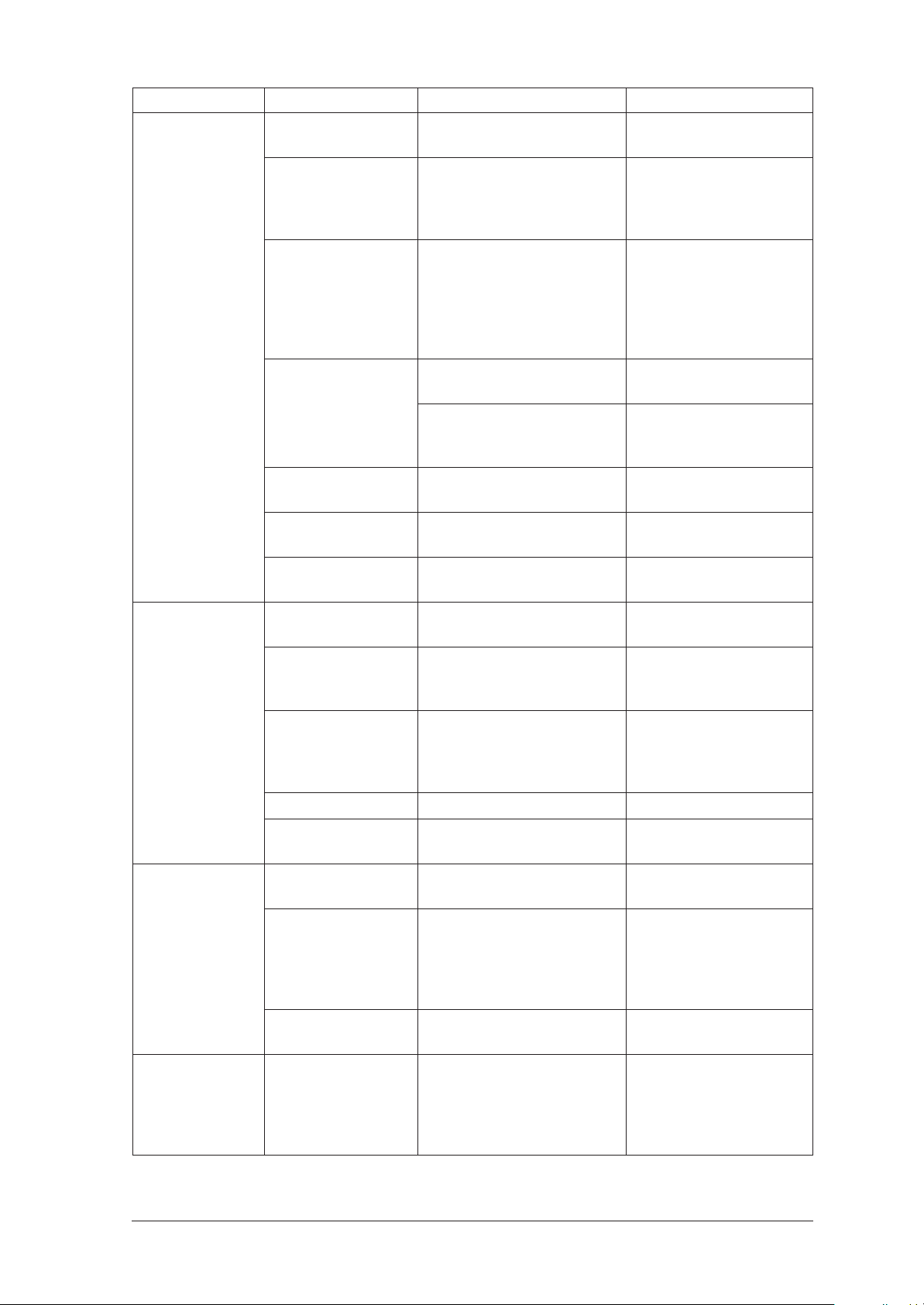

6.2 Remedies

Fault Cause Localisation Remedy

No motor noises,

power indicator does

not light up, mains

failure alarm sounds.

No power.

Faulty fuse.

Check mains lead for

secure connection.

If applicable, check

whether power is available

at the mains (e.g. with a

lamp).

Replace fuse 39 (see "5.3.4

Checking the fuse" on

page 11).

A spare fuse can be found

in the fuse box.

Power indicator fails to

illuminate, no acoustic

alarm.

No flow at nasal

cannula, although

there is flow at the

appliance outlet. In

such cases, the

appliance does not

emit an alarm.

After running for a

long period,

appliance emits

intermittent acoustic

warnings and red fault

indicator flashes;

no flow.

After running for a

long period,

appliance emits

intermittent acoustic

warnings and red fault

indicator flashes.

Power cord damaged. Replace power cord.

Capacitor for mains

failure alarm is

completely

discharged.

Tube connections

interrupted.

Oxygen distributor in

bubble humidifier

blocked.

Motor compressor not

rotating.

Crank mechanism stiff,

motor circuit-breaker of

compressor is

activated.

Appliance too hot,

coarse dust filter

blocked.

Leak at compressor

outlet port elbow

connector

Suction filter blocked.

Overtemperature of

60 °C ± 2.5 °C.

Disconnect tube from inlet of

dosage monitor; check

whether flow is escaping

from the tube.

Loosen union nut of bubble

humidifier; the ball should

then rise.

Leave the appliance to run

for 5 minutes.

Seal all connection and

sealing points from the

appliance outlet to the inlet

of the dosage monitor.

Clean or replace the

oxygen distributor.

Capacitor incorrectly

connected or not connected

at all. Connect the

capacitor correctly

(7.5, page 30).

Check the voltage supply at

the motor. Motor defective:

Replace the compressor

(7.5, page 30).

Compressor defective:

Replace compressor

(7.5, page 30).

Clean or replace coarse

dust filter.

(3.2, page 8).

Replace parts (7.5,

page 30)

Replace suction filter.

(3.2, page 8).

Check fan

(7.10, page 42).

22 Troubleshooting

Page 23

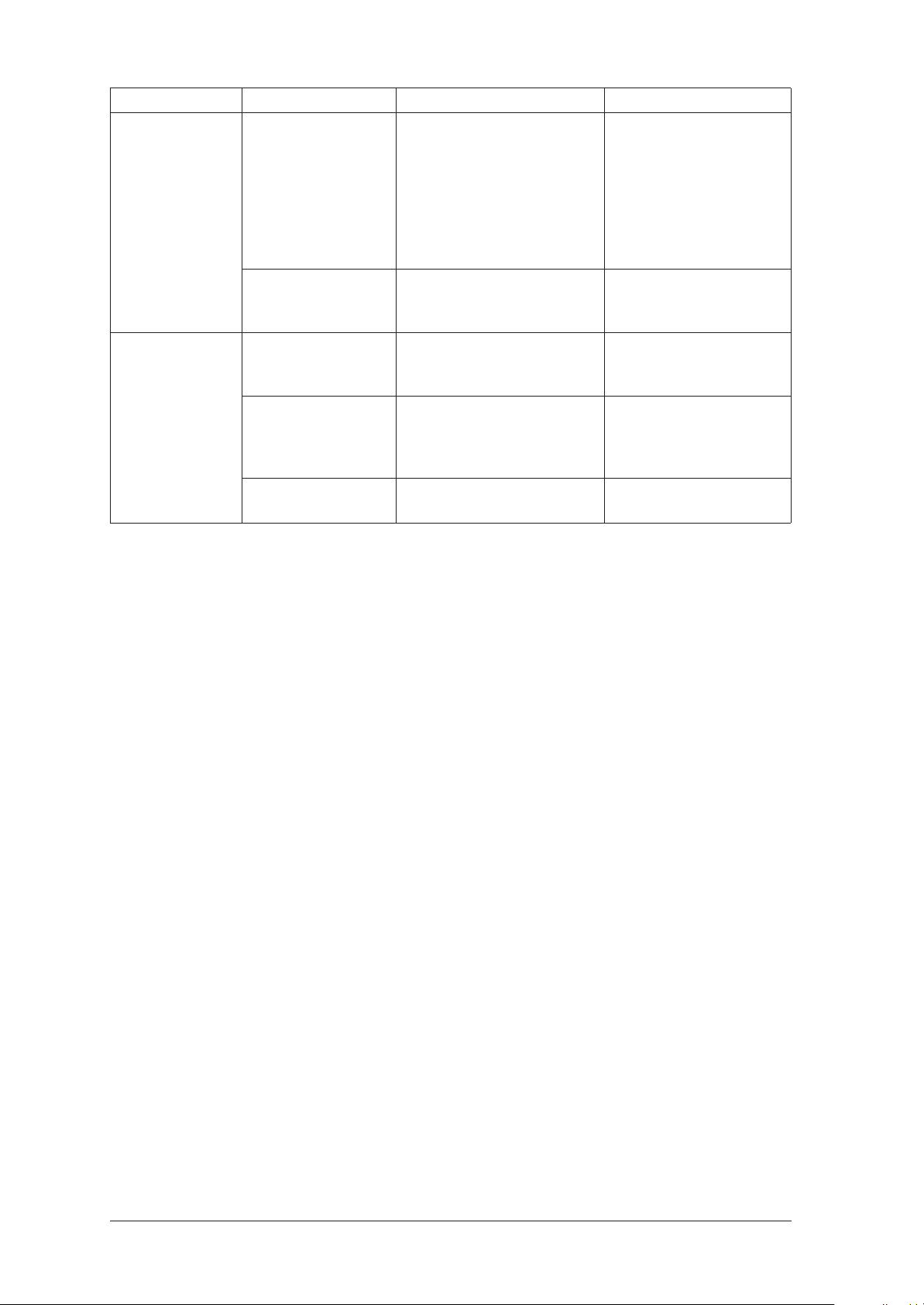

The following faults are based on a defective circuit. They occur with the compressor and fan running.

Caution !

Always pull out the mains plug before working on electrical components.

Remember that all coding switches on the circuit board must be closed during normal operation.

Fault Cause Localisation Remedy

After switching on, first of all

After running for a

long period,

appliance emits

intermittent acoustic

warnings and red

fault indicator

flashes.

Memory failure.

the EEPROM is read. In the

event of a memory failure,

an alarm is issued and it is

then re-read. If this readout

attempt is successful, the

fault will be cleared. If not,

the circuit board should be

replaced.

(7.9, page 40).

Blow-off noises on

compressor

(overpressure valve

activated).

Connectors X10 and/

or X11 have worked

loose.

Inadequate voltage

supply to magnetic

valves.

No voltage supply to

magnetic valves.

Fuse F1 tripped.

Green LED is illuminated and

an acoustic pressure alarm

sounds.

See above.

See above.

Green LED not illuminated,

mains failure alarm.

Re-make the connection

(7.9, page 40).

Ensure that the mains

voltage is at least 207 V.

Replace fuse F2

(7.9, page 40).

Replace fuse F1

(7.9, page 40).

Overpressure

alarm

(acoustic alarm,

red LED 18 flashing

2.5 times per

second).

No overpressure

alarm, even though

overpressure exists.

Underpressure

alarm

(acoustic alarm,

red LED 18 flashes

briefly 2.5 times

per second).

Thermal release in

transformer tripped.

Overpressure exists.

Valves of O2 system

jamming

Circuit board

defective.

Warm-up phase not

yet complete.

Pressure measurement

tube faulty.

Circuit board

defective.

Underpressure exists.

Circuit board

defective.

Pressure measurement

tube has come loose.

Green LED not illuminated,

mains failure alarm.

Check pneumatic system for

blockages.

Perform a system pressure test

(5.3.13, page 17)

Each time the device is

switched on, the overpressure

alarm is blocked for one

minute.

Visual check on tube for:

properly seated connection;

not blocked.

Check pneumatic system for

leaks.

Perform a system pressure test

(5.3.13, page 17)

Visual check for proper seating

of pressure measurement tube.

Replace the circuit board

(7.9, page 40).

Rectify blockage

(7.9, page 40).

(see " Blow-off noises on

compressor (overpressure

valve activated)." on

page 23)

Replace the circuit board

(7.9, page 40).

Wait for one minute.

Replace pressure measurement tube if necessary.

Replace the circuit board

(7.9, page 40).

Remedy the leak.

Replace circuit board

Establish trouble-free

pneumatic connection.

Troubleshooting 23

Page 24

Fault Cause Localisation Remedy

Each time the appliance is

No underpressure

alarm.

Warm-up phase not

yet complete.

Circuit board

defective.

Miniature fuse in nonheating appliance

connector has tripped.

switched on, the overpressure

alarm is blocked for one

minute.

Compressor and fan not

running and green LED is

extinguished.

Wait for one minute.

Replace the circuit board

(7.9, page 40).

Check fuse 39 and replace

if necessary (5.3.4,

page 11).

Internal connection has

worked loose at nonheating appliance

See above.

Check connection and remake if necessary.

connector.

Mains failure alarm

Connector X1 has

worked loose.

Cable harness

defective.

Fuse F1 has tripped.

See above.

See above.

Compressor and fan not

running and green LED is

extinguished.

Check connection and remake if necessary.

Replace the cable harness

(item no. 86 in the spare

parts list).

Check fuse F1 and replace

if necessary

(7.9, page 40)

(10.1, page 76).

Device fails to emit

correct mains

failure alarm.

Thermal release in transformer has tripped.

Circuit board

defective.

Coding switch S3 is

open.

Coding switch S2 is

open.

Voltage supply for

mains failure alarm

discharged.

Mains failure alarm is

shorter than 1 minute.

See above.

Green LED illuminated,

compressor and fan running.

Valves are switching.

Green LED is extinguished.

Buzzer off. Red LED is flashing.

Green LED is extinguished.

Buzzer off. Red LED is

extinguished.

See above.

Operate the appliance for 30

minutes. If the alarm duration is

then shorter than 1 minute, the

circuit board is defective.

Replace the circuit board

(7.9, page 40).

Replace the circuit board

(7.9, page 40).

Close coding switch S3

(7.9, page 40).

Close coding switch S2

(7.9, page 40).

Operate the device for one

minute to recharge the

voltage supply.

Replace the circuit board

(7.9, page 40).

24 Troubleshooting

Page 25

Fault Cause Localisation Remedy

Leak in O2 system

Switch S5 for checking

status indicator was not

closed again (5.3.12,

page 16)

Examine pneumatic system for

leaks.

Switch off OXYMAT 3.

Close switch S5.

Switch on OXYMAT 3.

Eliminate leaks.

Close switch S5.

During a power failure

O2 alarm

alarm the OXYMAT 3

was switched off and on

twice, thereby starting a

status indicator check

(5.3.11, page 15)

Check plug-in connection X13.

Connect OXYMAT 3 to

mains.

Then switch OXYMAT 3 off

and on again.

Ensure trouble-free plug-in

connection.

No voltage at shutoff

valve.

Check fuse F3.

Change fuse F3

(7.9, page 40),

(10.1, page 76).

Shutoff valve 83 faulty.

Pressure measurement

tube 63 blocked.

Flow starts immediately after

switching on.

Self-test is stopped after 60 s

without stopping compressor.

Change shutoff valve 83.

Re-route tube 63, replace if

necessary.

No O2 alarm,

even though

concentration is

< 82 % by

volume.

Compressor not

running

Temperature alarm,

fan not running.

Pressure sensor B1

faulty.

Leak occurred since

last switching on.

Pressure sensor faulty.

Compressor overpressure

valves activate after 30 s.

Switch OXYMAT 3 off then on

again to initiate self-test.

Check indirect status indicator

(5.3.11, page 15) (5.3.12,

page 16).

Change board

(7.9, page 40).

Eliminate leak.

If yellow LED does not light

up, change board

(7.9, page 40).

OXYMAT 3 was operated for long time at

relative humidity in

Weigh ADS container

(7.11, 7.12 and 7.13).

Change ADS container

(7.11, 7.12 and 7.13).

excess of 75 %.

Fuse F3 defective. Green LED is on. Replace fuse F3.

Suction filter blocked.

Plug-in connection X2

faulty.

Check plug-in connection

Clean or replace suction

filter (3.2, page 8).

Replace wiring harness if

necessary.

Allow OXYMAT 3 to cool

Overheating alarm.

Appliance control system

switches off compressor if

overheating alarm given.

down. After the end of the

overheating alarm the control system switches the

OXYMAT 3 on again.

Board faulty.

Change board

(7.9, page 40).

Check connection at fan. If

Fan failure.

No draught can be felt at the

coarse dust filter, compressor is

running.

necessary, replace cable

harness (item no. 86 in

spare parts list) or fan

(7.10, page 42).

Troubleshooting 25

Page 26

Fault Cause Localisation Remedy

Comply with maximum

Temperature alarm

although fan is

running.

Appliance was

operated at an

ambient temperature

of > 41 °C, or was

switched off briefly

and back on.

Accumulated heat warmed the

temperature sensor after

switching off.

ambient temperature of

40 °C. After operating for

a short time, the

accumulated heat is

eliminated by the fan and

the temperature alarm must

stop.

Ambient temperature is

< 40 °C, fan and compressor

working correctly.

Visual inspection to verify

correct seating of the

connector.

Install a replacement meter as a

test. If it moves forward by

00000.1 after 6 minutes, the

old meter was defective.

If the above measures have

failed to solve the problem.

Replace the circuit board

(7.9, page 40).

Re-make the connection

(7.9, page 40).

Replace the operating hours

meter

(7.8, page 39).

Replace the circuit board

(7.9, page 40).

Operating hours

meter no longer

counting.

Circuit board

defective.

Connector at X9 has

worked loose.

Meter is defective.

Circuit board

defective.

26 Troubleshooting

Page 27

6.3 O2 concentration outside tolerance range

If the check described in “5.3.9 Checking the O2

concentration” on page 13 indicates an oxygen

concentration of less than 91% at a flow of 4 l/min

after 15 minutes operating time, proceed as

follows:

1. Check the system pressures as described in

“5.3.13 System pressure test” on page 17.

2. If the test described in “5.3.13 System pressure test” reveals that the pressures are outside

the tolerance range, proceed as described in

“6.4 System pressure fault” .

If the system pressures are within the tolerance

range, continue with test step “5.3.14 Checking the O2 system for leaks”. If this check reveals leaks or faulty valves, repair them.

– Then check the O2 concentration again as

described in “5.3.9 Checking the O2 concentration”.

– If the new check on O2 concentration still re-

sults in unsatisfactory values, perform another system pressure test as described in

5.3.13. Then change the adsorption containers as described in section 7.11.

3. If the check on the oxygen system in accordance with 5.3.14 reveals that there are no

leaks or faulty valves, continue as described in

“7.11 Replace adsorption containers (Mac

valves)”.

4. Perform a functional check (see "5. Functional

check" on page 10).

6.4 System pressure fault

Note:

The pressure values listed below refer to sea level. If the measurements are conducted at different altitudes, corresponding correction factors must be taken into account.

Pressure measurement Setpoint Fault Cause/remedy

Pressure too high

Pressure measurement at

oxygen outlet 5

Pressure measurement at

O2 tank

(or at outlet of O2 system)

* Water uptake by the ADS container increases the flow resistance of the molecular sieve. As a result,

pressure equalization during the flushing phase is disturbed and the pressure increases.

Pressure

0.6 bar ± 0.1 bar

Measurement at 4 l/

min Pressure range:

– Min. 1.2 bar

+ 0.3 /– 0.2 bar

– Max. 1.65 bar

+ 0.3 /– 0.2 bar

Pressure too low

Pressure too high

Pressure too low

Pressure-reducer defective,

replace (7.15, page 54)

Leak at the connection points

between the pressure-reducer

and the oxygen outlet 5.

Repair leak.

Pressure-reducer defective,

replace (7.15, page 54)

ADS container has absorbed

water.*

Replace the ADS container

(7.11, 7.12 and 7.13)

Leak at the connection points

between the suction filter and

the O2 tank.

Remedy the leak.

Troubleshooting 27

Page 28

7. Repair information and repair instructions

7.1 General

Repairs to OXYMAT 3 must always be carried out at an ESD workplace!

• Please follow the safety instructions on page 4 of

the operating instructions for OXYMAT 3.

• Caution!

Do not use liquids or foaming agents to check for

leaks in the region of the solenoid valve 54, as

moisture could penetrate into the solenoid valve,

thereby causing corrosion which could prevent it

functioning properly.

• Any handling of the appliance requires a

precise knowledge of and compliance with

the operating instructions and the service and

repair instructions.

• Please carry out only the repairs described in

these service and repair instructions. This is the

only way to guarantee perfect functioning of

OXYMAT 3.

• Please ensure that your hands and workplace

are clean when carrying out repairs.

• Conduct a functional check after every repair

job (see "5. Functional check" on page 10).

• When you replace components or individual

parts, please use only genuine Weinmann

parts.

• When ordering a frame 57 or 58 , please also

quote the model, year of construction and

appliance number.

• Many parts have to be screwed in using a

torque wrench. To ensure that the quoted

torque is maintained, check regularly that

your torque wrench adheres to the torque

(monitor testing equipment).

• Note:

The item numbers quoted in the following text

match the item numbers in the parts list on

page 69 and the overview on page 4.

7.2 Replacing the castors

1. Position the appliance with the housing lying

on its back.

2. Pull off the defective castors and replace them

with new ones.

28 Repair information and repair instructions

Page 29

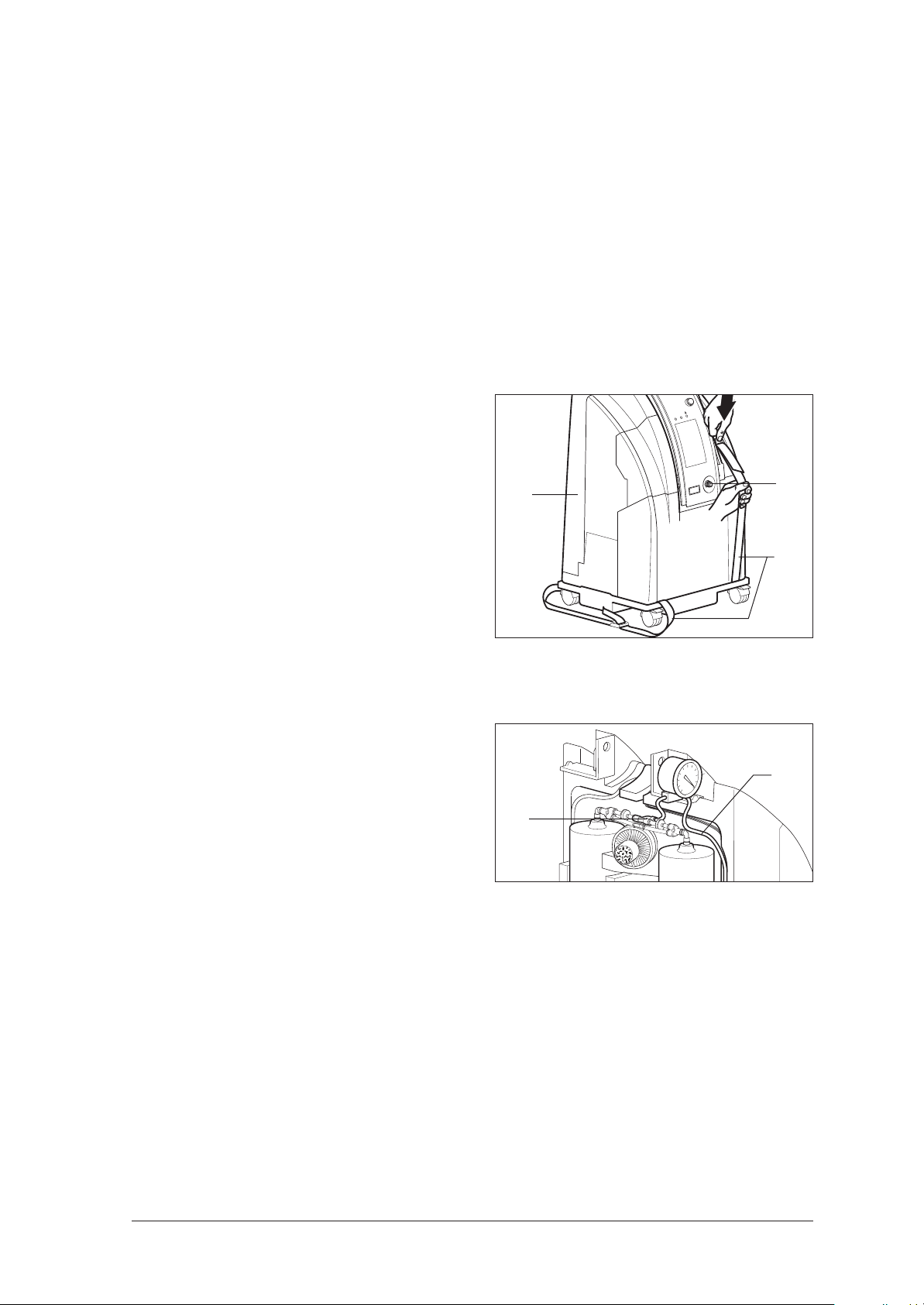

7.3 Opening the appliance

Tools required:

• Spanner set WM 14249,

• Allen key 6 mm.

Caution !

If the appliance is standing on a table, lock the castors.

1. Disconnect the plug from the socket and pull

the power cord 10 from the appliance.

3. Remove the stoppers 32:

– Using the disk on the spanner set, rotate the

stopper 32 through 90° to the left.

– Lever it out downwards .

4. Unscrew the two screws 33 and remove them

together with the spring washer 34 .

To make it easier to remove the screws, set the

spanner in the hexagon and pull out the screw.

5. Remove the handle 1 upwards, or leave it

lying in the appliance.

6. Pull off the housing 35 upwards.

2. Remove the connecting nipple with union nut 6

or the flowmeter 16 from the oxygen outlet 5.

321

34

33

O/I

35

O/I

2

O

O/I

O

2

0

00

0

00

Note:

If the housing cannot be pulled off, it may be caught

on the service flap. In such cases, release the lock at

the service flap 38, and remove the flap from the

appliance.

38

Repair information and repair instructions 29

Page 30

7.4 Closing the appliance

Tools required:

• Spanner set WM 14249,

• Allen key 6 mm.

Caution !

If the appliance is standing on a table, please lock the castors.

1. Carefully slide the housing 35 over the foam

sections.

2. Position the housing 35 on the frame in such a

way that the enclosure wall engages with the

groove all the way round.

3. Insert the handle 1 and secure it with the

screws 33 (not forgetting the spring washers 34).

4. Insert the two stoppers 32.

5. Using the disk on the spanner set, rotate the

stoppers 32 through 90° to the right.

6. Secure the connecting nipple 6 or the

flowmeter 16 at the oxygen outlet 5.

34

33

32

1

O/I

7.5 Replacing the compressor (up to appliance no. 13350)

Tools required:

• Spanner set WM 14249,

• Allen key 6 mm.

1. Open the housing (see "7.3 Opening the

appliance" on page 29).

I

/

2. Loosen the straps 42, without pulling the strap

out of the fastener, and place them next to the

appliance.

3. Remove the front plate 46:

– Tilt the front plate forwards and

– pull it out upwards.

O

2

O

/I

O

O

2

0000

0

0

42

30 Repair information and repair instructions

46

Page 31

The illustration opposite shows the installation

position of the compressor with its electrical and

pneumatic connections.

4. Disconnect the electrical connection.

5. Pull off the tubes 51 and 70 :

– Take the appropriate spanner from the

spanner set and position it between the

coupling 69 and the inlet/outlet of the

compressor.

– Now pull off the tube.

6. To remove the defective compressor, always

take hold of it at the cylinder head.

Caution !

The cylinder head may still be hot!

Tilt the defective compressor 48 forwards and

lift it out.

7. Pull the capacitor 49 out of the foam

section 43.

50 67

70

69

51

O

2

000000

cylinder head

48

60

43

49

Before fitting the new compressor, check the

condition of the vibration dampers 60.

They must be soft, elastic and must not be deformed.

If the vibration dampers are hard and inelastic, they

must be changed.

Then install the new compressor 48:

8. If the capacitor is faulty, disconnect both

spade connectors from the capacitor 49.

9. Connect the spade connectors of the

compressor to the capacitor.

Caution !

Do not short-circuit the capacitor!

The connectors must be on the left and right of the

central bar (see illustration).

Repair information and repair instructions 31

Page 32

10. Place the two tubes 51 and 70 sideways

across the frame.

11. Then insert the compressor:

– Grasp the compressor in such a way that

you are able to read the letters on the

cylinder head the right way round.

– Insert the front screws of the compressor into

the vibration damper 60.

– Tilt the compressor into the appliance.

Make sure that the compressor is securely and

safely positioned.

12. Slide the capacitor 49 into the opening of the

foam section 43 and lay the cables neatly into

the groove.

000000

O

2

70

60

43

49

51

13. Connect tube 70 to the inlet and tube 51 to the

outlet of the compressor.

14. Attach the connector of the compressor to the

power supply socket and lay the cables neatly

into the groove.

15. Check that the compressor is positioned in the

appliance the right way round, i.e. with the

inlet pointing to the right:

– Connect the power cord 10 to the

appliance and to a socket.

– Switch on the appliance.

– Feel from which side of the compressor air

is being drawn in. This side is the inlet. It

must be on the right.

16. Check that all cables are laid correctly in the

groove.

00000

0

70

51

– Switch off the appliance and pull the power

cord 10 from the socket and from the

appliance.

– If the inlet of the compressor is on the left-

hand side, re-install the compressor.

17. Place the lower edge of the front plate 46 into

the frame and tilt it against the foam section 45.

18. Place the straps 42 over the foam sections and

tighten them.

32 Repair information and repair instructions

45

46

Page 33

19. Before assembling the housing, subject the

compressor to a test run:

– Connect the power cord 10 to the

appliance and to a socket.

20. Close the appliance (see "7.4 Closing the

appliance" on page 30).

21. Perform a functional check (see "5. Functional

check" on page 10).

– Switch on the appliance.

If no rattling or slipping is audible, the

compressor is correctly installed.

– Switch off the appliance and pull the power

cord 10 from the socket and from the

appliance.

7.6 Replacing the compressor (from appliance no. 13351 to 14999)

Tools required:

• Spanner set WM 14249,

• Allen key 6 mm,

• Water-pump pliers.

1. Open the housing (see "7.3 Opening the

appliance" on page 29).

I

/

2. Loosen the straps 42, without pulling the strap

out of the fastener, and place them next to the

appliance.

O

2

O

/I

O

O

2

0000

0

0

42

3. Remove the front plate 46:

– Tilt the front plate forwards and

– pull it out upwards.

The illustration opposite shows the installation

position of the compressor with its electrical and

pneumatic connections.

46

50 67

Repair information and repair instructions 33

Page 34

4. Disconnect the electrical connection.

000

5. Pull off the tubes 51 and 70 :

– Loosen clip 89 on tube 51 with the water-

pump pliers.

– Now pull off the tube.

6. To remove the defective compressor, always

take hold of it at the cylinder head.

Caution !

The cylinder head may still be hot!

Tilt the defective compressor 48 forwards and

lift it out.

7. Pull the capacitor 49 out of the foam

section 43.

Before fitting the new compressor, check the

condition of the vibration dampers 60.

They must be soft, elastic and must not be deformed.

If the vibration dampers are hard and inelastic, they

must be changed.

0

00

70

89

51

O

2

000000

cylinder head

48

60

43

49

Then install the new compressor 48:

8. If the capacitor is faulty, disconnect both

spade connectors from the capacitor 49.

9. Connect the spade connectors of the

compressor to the capacitor.

Caution !

Do not short-circuit the capacitor!

The connectors must be on the left and right of the

central bar (see illustration).

10. Place the two tubes 51 and 70 sideways

across the frame.

11. Then insert the compressor:

– Grasp the compressor in such a way that

you are able to read the letters on the

cylinder head the right way round.

– Insert the front screws of the compressor into

the vibration damper 60.

– Tilt the compressor into the appliance.

Make sure that the compressor is securely and

safely positioned.

12. Slide the capacitor 49 into the opening of the

foam section 43 and lay the cables neatly into

the groove.

000000

O

2

70

60

43

49

51

34 Repair information and repair instructions

Page 35

13. Push clip 89 onto tube 51. Then connect tube

70 to the compressor inlet and tube 51 to the

compressor outlet. Now attach tube 51 to the

compressor outlet with the aid of clip 89 and

the water-pump pliers.

14. Attach the connector of the compressor to the

power supply socket and lay the cables neatly

into the groove.

15. Check that the compressor is positioned in the

appliance the right way round, i.e. with the

inlet pointing to the right:

– Connect the power cord 10 to the

appliance and to a socket.

– Switch on the appliance.

– Feel from which side of the compressor air

is being drawn in. This side is the inlet. It

must be on the right.

– Switch off the appliance and pull the power

cord 10 from the socket and from the

appliance.

– If the inlet of the compressor is on the left-

hand side, re-install the compressor.

000000

70

89

51

16. Check that all cables are laid correctly in the

groove.

17. Place the lower edge of the front plate 46 into

the frame and tilt it against the foam section 45.

18. Place the straps 42 over the foam sections and

tighten them.

19. Before assembling the housing, subject the

compressor to a test run:

– Connect the power cord 10 to the

appliance and to a socket.

– Switch on the appliance.

If no rattling or slipping is audible, the

compressor is correctly installed.

– Switch off the appliance and pull the power

cord 10 from the socket and from the

appliance.

20. Close the appliance (see "7.4 Closing the

appliance" on page 30).

21. Perform a functional check (see "5. Functional

check" on page 10).

45

46

Repair information and repair instructions 35

Page 36

7.7 Replacing the compressor (from appliance no. 15000)

Tools required:

• Spanner set WM 14249,

• Allen key 6 mm.

• Hexagon socket wrench 8 mm,

• Water-pump pliers.

1. Open the housing (see "7.3 Opening the

appliance" on page 29).

2. Detach the compressor:

– Place the appliance on its back;

– Detach the compressor by using the socket

wrench to remove the 4 hexagonal nuts 92

with washer 90 and spring washer 91 from

the underside of the chassis.

– Then stand the appliance upright again.

3. Loosen the straps 42, without pulling the strap

out of the fastener, and place them next to the

appliance.

90

91

92

I

/

O

2

O

/I

O

O

2

0000

0

0

42

4. Remove the front plate 46:

– Tilt the front plate forwards and

– pull it out upwards.

The illustration opposite shows the installation

position of the compressor with its electrical and

pneumatic connections.

46

50 67

36 Repair information and repair instructions

Page 37

5. Disconnect the electrical connection.

6. Pull off the tubes 51 and 70 :

– Loosen clip 89 on tube 51 with the water-

pump pliers.

– Now pull off the tube.

7. To remove the defective compressor, always

take hold of it at the cylinder head.

Caution !

The cylinder head may still be hot!

Tilt the defective compressor 48 forwards and

lift it out.

8. Pull the capacitor 49 out of the foam

section 43.

Before fitting the new compressor, check the

condition of the vibration dampers 60.

They must be soft, elastic and must not be deformed.

If the vibration dampers are hard and inelastic, they

must be changed.

000000

O

2

70

89

51

cylinder head

48

60

43

49

Then install the new compressor 48:

9. If the capacitor is faulty, disconnect both

spade connectors from the capacitor 49.

10. Connect the spade connectors of the

compressor to the capacitor.

Caution !

Do not short-circuit the capacitor!

The connectors must be on the left and right of the

central bar (see illustration).

11. Place the two tubes 51 and 70 sideways

across the frame.

12. Then insert the compressor:

– Grasp the compressor in such a way that

you are able to read the letters on the

cylinder head the right way round.

– Insert the bolts of the vibration dampers 60

in the holes provided in the chassis.

– Tilt the compressor into the appliance,

making sure that the bolts of the rear

vibration dampers are also inserted in the

holes.

Make sure that the compressor is securely and

safely positioned.

13. Slide the capacitor 49 into the opening of the

foam section 43 and lay the cables neatly into

the groove.

000000

O

2

70

60

43

49

51

Repair information and repair instructions 37

Page 38

14. Push clip 89 onto tube 51. Then connect tube

70 to the compressor inlet and tube 51 to the

compressor outlet. Now attach tube 51 to the