Page 1

Instrument Description and Operating Instructions

OXYMAT2

Its own oxygen source

Page 2

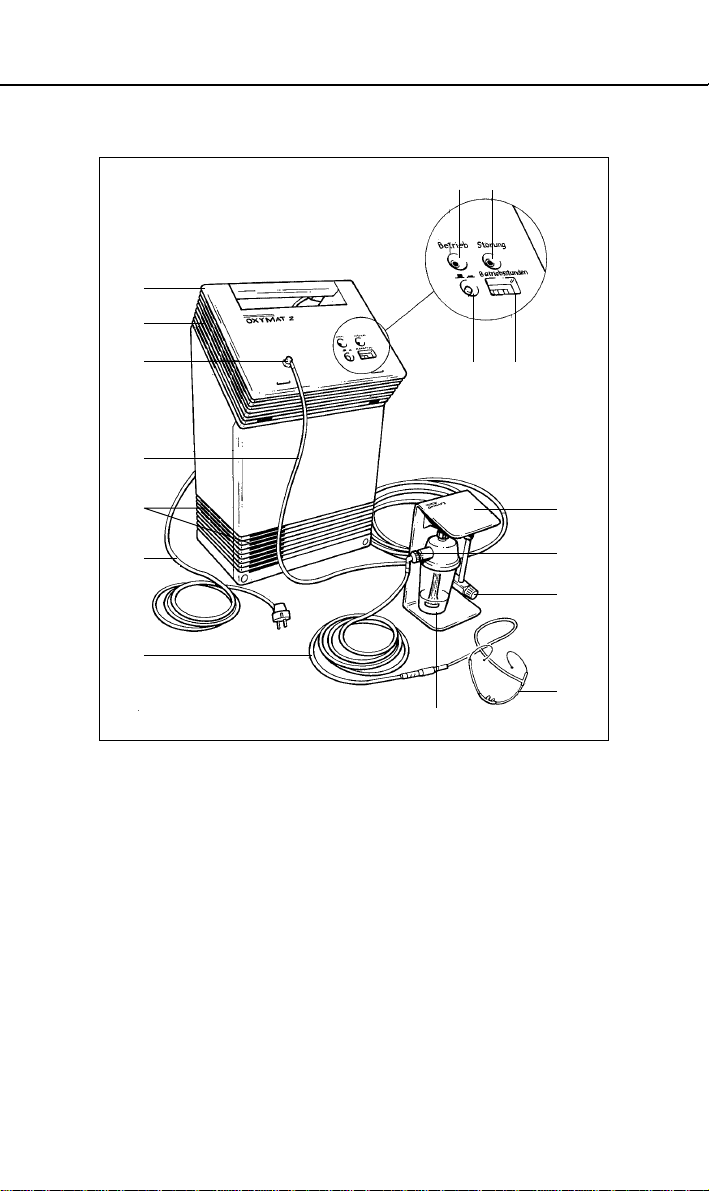

OXYMAT2

Fig. 1

1

15

5 6

2

8

15

7

13

3

11

Legends

1 OXYMAT2 oxygen concentrator

2 Oxygen outlet

3 Main switch

4 Running time meter

5 On indicator (green)

6 Fault indicator (red)

7 Mains lead

8 Connecting hose, 20m

9 Flow monitor

10 Oxygen dosage control knob

11 Bubbler humidifier

12 Angled hose connection

13 Extension hose for oxygen nasal cannula, 3m

14 Oxygen nasal cannula

15 Air intake slots

4

9

12

10

14

Page 3

Contents

1 Instrument Description 2

1.1 Purpose 2

1.2 Function 2

1.3 Circuit diagram OXYMAT

2 Technical Data 4

3 Extent of Supply 5

4 Accessories and Spare Parts 5

5 Use 5

5.1 Setting up the instrument 5

5.2 Putting into use 6

5.3 After use 6

6 Cleaning and Disinfection 7

7 Checking the Function 8

8 Maintenance 8

9 Safety Precautions 9

10 Guarantee 10

11 Trouble-Shooting 10

2 oxygen concentrator 3

Page

Page 4

1 Instrument Description

1.1 Purpose

The OXYMAT2 oxygen concentrator is used to increase the

percentage of the oxygen volume in the inspired air.

Oxygen therapy is a clear indication in cardiac circulation

disturbances and diseases of the respiratory organs. It is the

most common prophylactic or therapeutic measure in cases of

existing or impending hypoxia.

Where patients who require continuous administration of a

higher oxygen content in the inspired air are treated with the

OXYMAT

made for emergency supply from an oxygen cylinder in the

case of instrument failure (e.g. as a result of power failure).

1.2 Function

An electrically operated compressor sucks-in ambient air

through dust- and fine-mesh filters and forces the slightly

compressed air into containers fitted with molecular filters.

Molecular filters work on the principle of absorption of the

nitrogen present in the air.

The oxygen-enriched air flows from the containers into the

oxygen tank, from which it passes through a pressure

controller and bacterial filter to the oxygen outlet of the

OXYMAT

The rate of flow required can be set on the oxygen dosage

control knob and read-off on the top of the flowmeter cone (see

circuit diagram in Fig. 2).

2 oxygen concentrator, provision must always be

2 oxygen concentrator.

2

Page 5

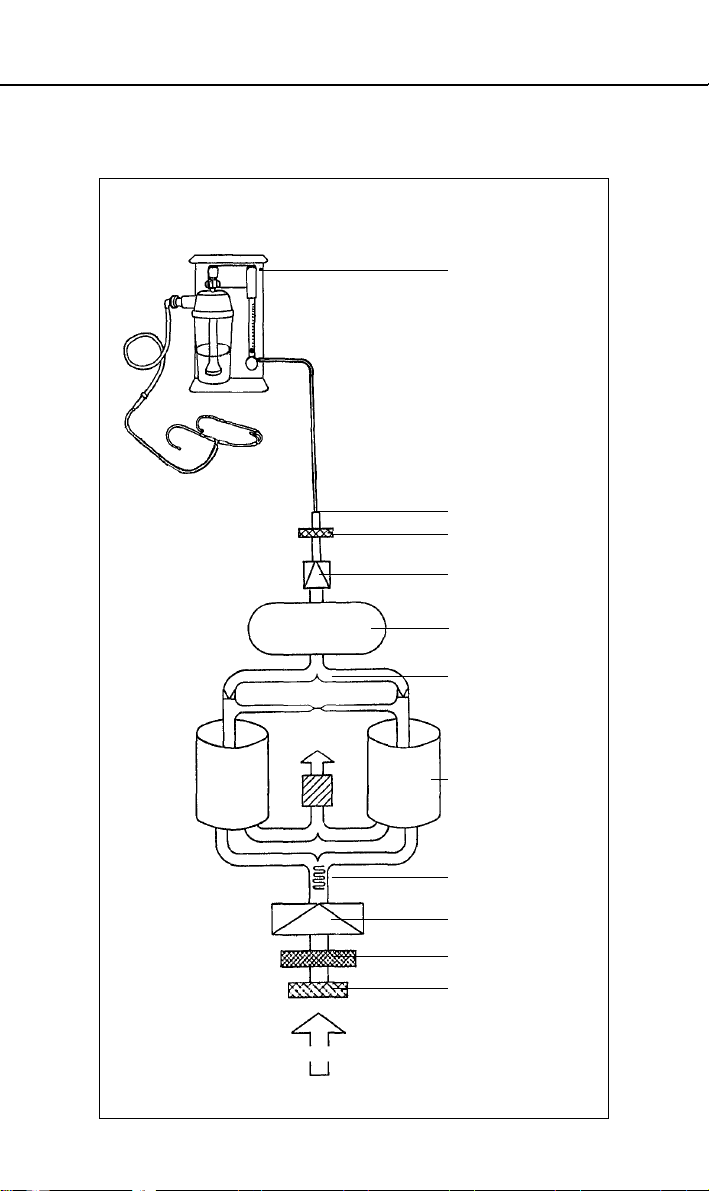

1.3 Circuit diagram

OXYMAT

2 oxygen concentrator

Fig. 2

Flow monitor with

oxygen nasal

cannula,

bubbler humidifier,

flowmeter

Oxygen outlet

Bacterial filter

Pressure controller

Oxygen tank

Nozzle

Exhaust air

Ambient air

III

Non-return valves

Molecular filters

I and II

Cooler

Compressor

Fine-dust filter

Dust filter

3

Page 6

2 Technical Data

G

e

p

r

ü

f

t

e

r

L

ä

r

m

s

c

h

u

t

z

G

e

r

ä

u

s

c

h

a

r

m

0197

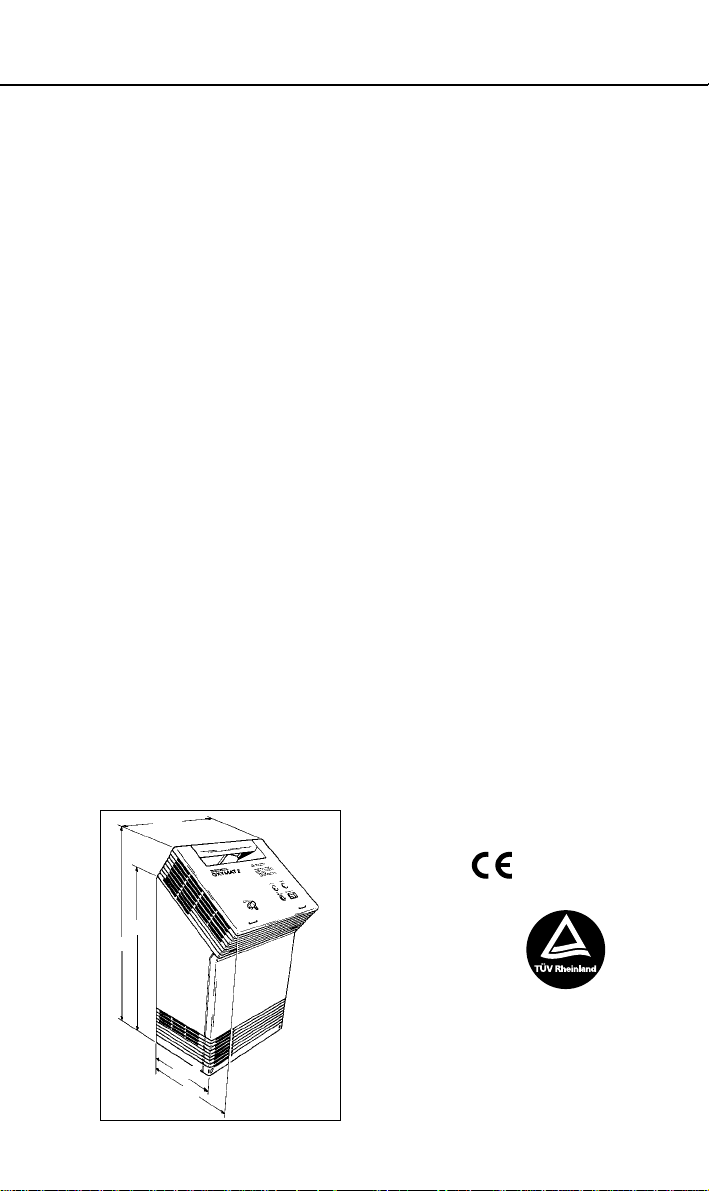

Classification acc. to

EU-Guideline 93/42/EEC: II a

Dimensions: see Dimension Drawing (Fig. 3),

Weight: app. 19.5 kg

Ambient temperature

for operation: +10°C to +40°C

for storage: –20°C to +70°C

Electrical connection: 230 V ~, 50Hz

Wattage and current

consumption: 250 W, 1.4 A

Fuse: T 1.6 AL 250V acc. IEC 127-2

Classification acc. to EN 60601-1

Type of

electr. shock protection: Class II

Level of

electr. shock protection: Type B

Noise level: 50 dB (A) acc. ISO 3743

delivery: 95 ± 2 vol.% O2 to 2 l/min flow

O

2

(values after 10 minutes 93 ± 2 vol.% O

operation, at +20°C and min. 70 vol.% O

50% relative humidity and

1013 mbar)

Flow pressure nasal cannula: 0,05 bar at 4 l/min flow

Flow check: 0,4 – 4 l/min,

Fault warning: visible and audible

Electro magnetic compatibility

(EMC)

Interference suppression: EN 55011 (VDE 0875 T.11)

Interference resistance: IEC 801 part 2 to part 5

Maintenance: every 5.000 running hours

345

Fig. 3

dimensions in mm

to 3 l/min flow

2

to 4 l/min flow

2

surface flowmeter ball

(Subject to changes in construction)

590

4

505

230

286

Page 7

3 Extent of Supply

OXYMAT2 oxygen concentrator, complete WM 12300

Components:

OXYMAT2 oxygen concentrator WM 12301

Flow monitor, complete WM 12250

Extension hose for oxygen nasal cannula, 3 m WM 5720

Oxygen nasal cannula, double outlet,

with ear clips and connecting hose WM 1929

Oxygen nasal cannula, single outlet,

with silicone seal and connecting hose WM 1960

Connecting hose, 20 m WM 12330

4 Accessories and Spare Parts

Bubbler humidifier with angled hose connection WM 1375

Angled hose connection WM 1305

Oxygen nasal cannula, double outlet,

with ear clips and connecting hose WM 1929

Oxygen nasal cannula, single outlet,

with silicone seal and connecting hose WM 1960

Connecting hose, 20 m WM 12330

Extension hose for oxygen nasal cannula, 3 m WM 5720

Oxygen flow monitor without humidifier WM 12255

Gasket (for wing nut) WM 1145/31

Gasket for bubbler humidifier WM 1145/93

Transport-caddy WM 12305

WEINMANN:HAMBURG supplies portable oxygen therapy units

(e.g. OXYTRON

supply outside the home.

2 Mobile) as accessories and for oxygen

5 Use

5.1 Setting up the instrument

The OXYMAT2 oxygen concentrator should be located in a

fixed, not humid and not disturbing position, e.g. in a corridor.

We recommend placing it on a smooth floor, not on a deep-pile

carpet or rug, which might block the air circulation. It must not

be placed too close to a wall (at least 15 cm away, see page 9

Fig. 9).

Fit the 20m connecting hose (do not confuse with the 3 m

extension hose) at the oxygen outlet of OXYMAT2 (see Fig. 4)

and at the flowmeter-inlet of the flow monitor as well (see Fig. 5).

5

Page 8

Fig. 4

Fig. 5

5.2 Putting into use

● If the instrument prior use has been located in

environmental conditions below +10°C, wait for warming of

at least +10°C room temperature.

● Check that the mains voltage agrees with that given on the

instrument (see rating plate, Fig. 6).

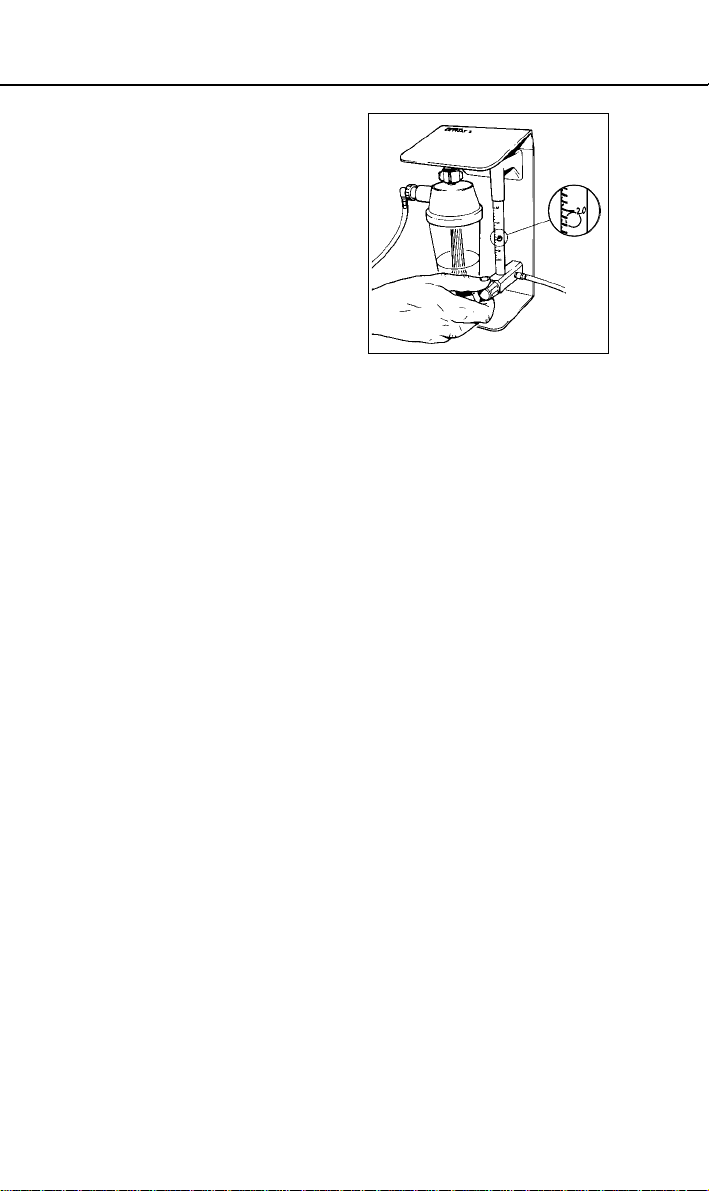

● Push the mains lead connector into the instrument (Fig. 6)

and the mains plug into the mains socket.

● Unscrew the bubbler humidifier from the flow monitor, fill up

to the mark with distilled water (Aqua Dest.) and screw on

again.

● Fit the 3-m extension hose (WM5720) to the oxygen

nasal cannula and to the angled socket of the bubbler

humidifier (Fig. 7), ensuring that the connections are tight.

Fig. 6

Rating plate

● Switch on the instrument (green "On" light comes on

permanently, red fault light comes on briefly and an

audible signal sounds.

● Set the flow required on the oxygen dosage control knob

(see Fig. 8).

6

Fig. 7

Page 9

● The instrument is now ready

for use and the oxygen

nasal cannula can be put on.

Fig. 8

Top of

cone

5.3 After use

Switch off the instrument by pressing the main switch. The flow

setting can be left as it is. If no further therapy is to be carried

out that day, empty the bubbler humidifier.

6 Cleaning and Disinfection

The oxygen nasal cannula should never be used by more than

one patient. The bubbler humidifier can be autoclaved and

sterilised at 134°C. We recommend cleaning the oxygen

goggles, hoses, etc. under running water after each use.

The instrument casing and mains lead are kept clean simply by

wiping with commercial disinfectants (observing their

Instructions of Use). Do not allow water or disinfectant to

penetrate into the air intake slots.

The spray humidifier, oxygen nasal cannula and hoses should

be changed before use on a new patient.

For health reasons, the bubbler humidifier should be cleaned

daily and the distilled water (Aqua dest.) regularly changed. In

home therapy, where the bubbler humidifier is used by only

one patient, it is sufficient to use a disinfectant, rinsing the

parts with distilled water after disinfection and drying them.

The air intake slots of the OXYMAT

should be freed from dust every week using a soft brush or the

flexible tube of a vacuum cleaner. Do not probe into the air

intake slots (Fig. 9) with hard objects.

2 oxygen concentrator

7

Page 10

7 Checking the Function

A function check must be carried out twice a year.

● Switch on the OXYMAT

Following:

– the green "On" light comes on

– the red fault light comes on briefly

– a short audible signal sounds.

● The red minute counter of the running time meter must

move round every 6 minutes.

● Check that the humidifier bottle cap and humidifier/flow

monitor connections are tight, retightening by hand if

necessary.

● Set a flow of 2 I/min. on the oxygen dosage control knob

(Fig. 8).

● To check that the dosage monitor is leak-tight, remove the

hose from the angled coupling of the bubbler humidifier

and seal-off the socket.

● The flow monitor system is tight if the flowmeter cone drops

down completely. Should a leak be present, change the

gaskets on the humidifier.

● Check the mains power failure alarm by removing the

mains plug. A continuous audible signal should sound.

● Switch the instrument off at the mains switch.

2 oxygen concentrator.

8 Maintenance

In addition to the function check, we recommend that the

OXYMAT2 oxygen concentrator is overhauled every 5,000

running hours (see running time meter). Once this is achieved

maintenance has to be carried out by specific shilled and

authorized personnel or return to the manufacturer

WEINMANN:HAMBURG.

For safety reasons, a check should be made every three

months to see whether the instrument has reached 5,000

running hours.

Do not despatch the hose systems and oxygen nasal cannula

with the instrument.

N.B.

Please store the original carton, since we recommend the

instrument should be packed in for transport.

8

Page 11

9 Safety Precautions

For your and your patient’s safety!

To conform with EU-Guidelines (93/42/EEC), we have to point

out the following:

● Observe the Operating lnstructions which is a component

of the instrument.

● Any use of or intervention with the instrument requires

accurate knowledge and observation of these Operating

Instructions. The instrument is intended only for the purpose

described.

● With exchange of accessories and spare parts recom-

mended in this operating instructions by using foreign items,

the function as well as the O

● The OXYMAT2 oxygen concentrator produces oxygen.

Items of clothing which come into contact with oxygenenriched air represent an increased fire risk! For this reason,

smoking, naked lights and fires are strictly prohibited in the

vicinity, even after therapy, until the high oxygen concentration in the clothing has dissipated .

● Check the mains voltage.

● Keep the instrument and the hoses free from grease and oil.

● Use the carrying handle to transport the instrument (Fig. 9).

● The left-hand side of the instrument with the air intake slots

(top and bottom)

must be at least 15

cm away from the

wall. The major part

the instrument must

not be located close

to a heat source

(Fig. 9).

● Air intake slots

weakly to clean.

● When red alarm light

and intermittent

sound comes up,

switch of the

instrument.

compatibility may be reduced.

2

Fig. 9

Carrying handle

9

Page 12

10 Guarantee

The instrument is guaranteed for one year from the date of

delivery for defects arising from material or manufacturing faults.

Defects covered by the Guarantee will be rectified under the

terms of our Guarantee Conditions. Plastic, glass and rubber

parts are not covered by the Guarantee. Transport to and from

our works for repair is at the cost of the customer.

WEINMANN:HAMBURG offers no guarantee when the user has

jeopardised the function of the instrument through nonobservation of these Operating Instructions, incorrect use or

handling or unauthorised interference with the instrument. In

such instances, responsibility passes to the user.

Important:

The guarantee is only valid when the purchase invoice is

produced.

11 Trouble-Shooting

Fault

No motor noise,

operating light

does not come

on, power failure

alarm sounds

(continuous

alarm).

Instrument

running, but intermitted audible

alarm and

flashing fault light.

After prolonged

use, instrument

emits audible

alarm, fault light

comes on, no

motor noise.

10

Cause

No mains power.

Faulty fuse.

Instrument overheated. Air intake

slots blocked or

covered.

Motor not

running.

Remedy

Check mains lead

connection. If necessary

check that socket has mains

power (e.g. plug in a lamp).

Remove mains lead plug

from socket and disconnect

mains lead from instrument!

Change fuse (T 1.6AL 250V

acc. IEC 127-2) by squeezing

together the two tongues of the

fuse cartridge, removing and

replacing the cartridge (Fig. 10).

Clean air intake slots.

Instrument too close to the

wall – provide minimum

distance of 15 cm. Allow

instrument to cool down.

Check that air intake slots are

not dirty and that instrument

is in correct distance from

wall. Allow instrument to cool

down, then restart. If alarm

sounds again after a short

time, instrument is faulty.

Notify manufacturer.

Page 13

Fault

No flow at

oxygen nasal

cannula. No

alarm given by

instrument.

Reduced flow.

Cause

Hose connection

interrrupted.

Hose kinked,

faulty gasket or

leaking screw

coupling.

Oxygen distributor

in humidifier

blocked.

Remedy

Check that there is a flow

indication on the flow

monitor. Check that all hose

connections and screw

couplings are tight and

change gaskets if necessary.

Clean oxygen distributor and

replace if necessary.

Should there are any faults be present which cannot be

rectified, contact the manufacturer or having the instrument

overhauled by the manufacturer. Do not continue to use the

instrument once the red fault light has come on.

WEINMANN:HAMBURG supplies various portable oxygen

therapy units suitable as emergency reserve for home use (e.g.

in case of power failure). For oxygen supply outside home,

WEINMANN:HAMBURG supplies the OXYTRON 2 Mobile,

which enables the patient to leave his home for fairly long

periods of time without having to interrupt oxygen therapy. Ask

your supplier or consultant for details.

Fig. 1 0

Spare fuse

Fuse holder

11

Page 14

Gottlieb Weinmann

Geräte für Medizin und Arbeitsschutz GmbH+Co.

P.O. Box 54 02 68 · D-22502 Hamburg

Phone 40/5 47 02- 0 · Telefax 40/54 70 24 61

Teletex 40 37 53 · Telex 17 40 37 53

WM 16091b – 05/95

Paper free of chlorine bleaching-agents

Loading...

Loading...