Page 1

User Guide

OpenFlex™ F3100 and E3000

1ET2050

Version 1.0

October 2019

Page 2

User Guide Table of Contents

Table of Contents

Copyright................................................................................................................................................................................... iv

Points of Contact.......................................................................................................................................................................v

Chapter 1. Overview........................................................................................................................................................................ 1

OpenFlex™ F3100 and E3000.................................................................................................................................................. 2

Servicing Features.............................................................................................................................................................. 3

Composable Infrastructures...............................................................................................................................................3

NVMe-oF..............................................................................................................................................................................4

Supported SKUs................................................................................................................................................................. 4

List of Compatible Devices............................................................................................................................................... 4

System Architecture Overview................................................................................................................................................. 5

System High Speed Data Ingest Architecture.................................................................................................................5

System Thermal and Cooling............................................................................................................................................5

OpenFlex F3100 and E3000 Specification Summary.............................................................................................................. 7

Physical Design.........................................................................................................................................................................10

LEDs....................................................................................................................................................................................12

Cables................................................................................................................................................................................ 16

Restrictions and Limitations.....................................................................................................................................................16

Site Requirements.....................................................................................................................................................................17

Power Requirements......................................................................................................................................................... 17

Rack Requirements............................................................................................................................................................17

Thermal and Cooling Requirements............................................................................................................................... 18

Servicing Requirements....................................................................................................................................................18

Chapter 2. Components............................................................................................................................................................... 20

Chassis.......................................................................................................................................................................................21

Chassis Specifications.......................................................................................................................................................21

PSU............................................................................................................................................................................................ 22

PSU Specifications............................................................................................................................................................22

Fan Module...............................................................................................................................................................................23

Fan Module Specifications............................................................................................................................................... 23

BMC Module............................................................................................................................................................................. 24

BMC Module Specifications.............................................................................................................................................24

Rails........................................................................................................................................................................................... 25

Rails Specifications...........................................................................................................................................................25

i

Page 3

User Guide Table of Contents

OpenFlexF3100......................................................................................................................................................................... 26

OpenFlexF3100 Specifications.........................................................................................................................................26

OpenFlex E3000 Fabric Device Blank.................................................................................................................................... 27

OpenFlex E3000 Fabric Device Blank Specifications.................................................................................................... 27

List of Field/Customer Replaceable Units.............................................................................................................................28

Chapter 3. Management............................................................................................................................................................... 29

OCGUI.......................................................................................................................................................................................30

Login Page........................................................................................................................................................................30

Dashboard.........................................................................................................................................................................30

Storage Device Page....................................................................................................................................................... 35

Chassis Device Page........................................................................................................................................................ 42

Basic Operational Functions............................................................................................................................................ 49

Power Cycling................................................................................................................................................................... 74

Firmware Upgrade............................................................................................................................................................ 75

Part Replacement.....................................................................................................................................................................81

Fan Module Replacement................................................................................................................................................ 82

PSU Replacement.............................................................................................................................................................84

BMC Module Replacement.............................................................................................................................................. 88

OpenFlexF3100 Replacement...........................................................................................................................................91

Rails Replacement............................................................................................................................................................95

Chassis Replacement.......................................................................................................................................................113

Chapter 4. Safety......................................................................................................................................................................... 135

Electrostatic Discharge.......................................................................................................................................................... 136

Optimizing Location............................................................................................................................................................... 136

Power Connections................................................................................................................................................................ 136

Power Cords........................................................................................................................................................................... 136

Rackmountable Systems........................................................................................................................................................ 137

Restricted Access Location................................................................................................................................................... 137

Safety and Service..................................................................................................................................................................137

Safety Warnings and Cautions.............................................................................................................................................. 138

Chapter 5. Regulatory................................................................................................................................................................. 139

Europe (CE Declaration of Conformity)................................................................................................................................140

FCC Class A Notice............................................................................................................................................................... 140

ICES-003 Class A Notice—Avis NMB-003, Classe A........................................................................................................... 140

Japanese Compliance Statement, Class A ITE.................................................................................................................... 140

ii

Page 4

User Guide Table of Contents

KCC Notice (Republic of Korea Only), Class A ITE............................................................................................................. 140

Taiwan Warning Label Statement, Class A ITE.....................................................................................................................141

iii

Page 5

User Guide Copyright

Copyright

The following paragraph does not apply to the United Kingdom or any country where such provisions

are inconsistent with local law: Western Digital a Western Digital company PROVIDES THIS PUBLICATION

"AS IS" WITHOUT WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED

TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. Some

states do not allow disclaimer or express or implied warranties in certain transactions, therefore, this

statement may not apply to you.

This publication could include technical inaccuracies or typographical errors. Changes are periodically made

to the information herein; these changes will be incorporated in new editions of the publication. Western

Digital may make improvements or changes in any products or programs described in this publication at any

time.

It is possible that this publication may contain reference to, or information about, Western Digital products

(machines and programs), programming, or services that are not announced in your country. Such references

or information must not be construed to mean that Western Digital intends to announce such Western Digital

products, programming, or services in your country.

Technical information about this product is available by contacting your local Western Digital representative

or on the Internet at: support@wdc.com

Western Digital may have patents or pending patent applications covering subject matter in this document.

The furnishing of this document does not give you any license to these patents.

Long Live Data™ is a trademark of Western Digital, Inc. and its affiliates in the United States and/or other

countries.

Western Digital trademarks are authorized for use in countries and jurisdictions in which Western Digital

has the right to use, market and advertise the brands. Other product names are trademarks or registered

trademarks of their respective owners.

One MB is equal to one million bytes, one GB is equal to one billion bytes, one TB equals 1,000GB (one trillion

bytes) and one PB equals 1,000TB when referring to storage capacity. Usable capacity will vary from the raw

capacity due to object storage methodologies and other factors.

References in this publication to Western Digital products, programs or services do not imply that Western

Digital intends to make these available in all countries in which Western Digital operates.

Product information is provided for information purposes only and does not constitute a warranty.

Information is true as of the date of publication and is subject to change. Actual results may vary. This

publication is for general guidance only. Photographs may show design models.

Western Digital

5601 Great Oaks Parkway

San Jose, CA 95119

© 2019 Western Digital Corporation or its affiliates.

iv

Page 6

User Guide Points of Contact

Points of Contact

For further assistance with a Western Digital product, contact Platform Engineering technical support. Please

be prepared to provide the following information: part number (P/N), serial number (S/N), product name

and/or model number, and a brief description of the issue.

Email:

support@wdc.com

Website:

https://portal.wdc.com/Support/s/

v

Page 7

Western Digital

Overview

In This Chapter:

- OpenFlex™ F3100 and E3000.......................2

- System Architecture Overview.....................5

- OpenFlex F3100 and E3000 Specification

Summary........................................................... 7

- Physical Design............................................. 10

- Restrictions and Limitations........................ 16

- Site Requirements.........................................17

1

Page 8

User Guide

1.1 OpenFlex™ F3100 and E3000

The OpenFlex™ F3100 and E3000 is a 3U rack

mounted data storage enclosure built on the

OpenFlex platform. OpenFlex is Western Digital’s

architecture that supports Open Composable

Infrastructure (OCI). The OpenFlex F3100 and

E3000 are fabric devices that leverage this OCI

approach in the form of disagreggated data storage

using NVMe-over-Fabrics (NVMe-oF). NVMe-oF is

a networked storage protocol that allows storage

to be disaggregated from compute to make that

storage widely available to multiple applications

and servers. By enabling applications to share a

common pool of storage capacity, data can be easily

shared between applications, or needed capacity

can be allocated to an application regardless of location. Exploiting NVMe device-level performance,

NVMe-oF promises to deliver the lowest end-to-end latency from application to shared storage. NVMeoF enables composable infrastructures to deliver the data locality benefits of NVMe DAS (low latency, high

performance) while providing the agility and flexibility of sharing storage and compute.

The maximum data storage capacity is 614TB * when leveraging a full set of 10 F3100 fabric devices.

The enclosure runs on an input voltage of 200V - 240V and consumes ~1400W of power under typical

conditions. It requires a maximum of 1600W at full load.

1. Overview

1.1 OpenFlex™ F3100 and E3000

Composable Infrastructure

An emerging category of

datacenter infrastructure that

seeks to disaggregate compute,

storage, and networking fabric

resources into shared resource

pools that can be available

for on-demand allocation (i.e.,

“composable”). Composability

occurs at the software level,

disaggregation occurs at the

hardware level using NVMe™over-Fabric—will vastly improve

compute and storage utilization,

performance, and agility in the

data center.

• 614TB

• 12GBps NVMe-oF over QSFP28

• 68.5 kg / 151.1 lbs.

*

Cables

OpenFlex

OpenFlex is Western Digital’s

architecture that supports Open

Composable Infrastructure

through storage disaggregation

– both disk and flash natively

attached to a scalable fabric.

OpenFlex does not rule out

multiple fabrics, but whenever

possible, Ethernet will be used as

a unifying connect for both flash

and disk because of its broad

applicability and availability.

• 200V - 240V Input Voltages

• 3U Form Factor

• Hot-swappable PSUs and Fans

Open Composable API

Western Digital's new Open

Composable API is designed

for data center composability.

It builds upon existing industry

standards utilizing the best

features of those standards as

well as practices from proprietary

management protocols.

• Dual 1600W PSUs

• Operational Temperature: 5°C to

35°C

• Dynamic Provisioning Supported

* Max storage capacity depends on device version and device configuration.

2

Page 9

User Guide

1.1.1

1.1.2

Servicing Features

The OpenFlex F3100 and E3000 are equipped with several features that make servicing simpler and safer.

Every CRU component has been designed with toolless removal features.

The BMC Module, Fan Module, PSU, and F3100 devices are all hotswappable components. This document

provides full instructions on how these features operate in the Management (page 29) section.

Composable Infrastructures

An emerging category of datacenter infrastructure that seeks to disaggregate compute, storage, and

networking fabric resources into shared resource pools that can be available for on-demand allocation (i.e.,

“composable”). Composable occurs at the software level, disaggregation occurs at the hardware level.

Western Digital’s vision for Open Composable Infrastructures is based on four key pillars:

• Open

1. Overview

1.1 OpenFlex™ F3100 and E3000

◦ Open in both API and form factor

◦ Designed for robust interoperability of multi-vendor solutions

• Scalable

◦ Ability to compose solutions at the width of the network

◦ Enable self-organizing systems of composable elements that communicate horizontally

• Disaggregated

◦ Pools of resources available for any use case that is defined at run time

◦ Independent scaling of compute & storage elements to maximize efficiency & agility

Extensible

•

◦ Inclusive of both disk and flash

◦ Entire ecosystem of composable elements managed & orchestrated using a common API

framework

◦ Prepared for yet-to-come composable elements – e.g., memory, accelerators

1.1.2.1 Open Composable

The Western Digital Open Composable Infrastructure (OCI) uses a common API to manage and

coordinate with all fabric-attached storage including pools of flash and disk. The infrastructure also

supports the management of networking and compute resources. The API is used for all managed

elements to accelerate the ability to use disaggregated resources where components are no longer subcomponents, but core elements connected to the network.

1.1.2.2 Open Composable API (OCAPI)

Western Digital’s Open Composable API is a RESTful interface for OpenFlex that enables a Unified Fabric

Control Plane for Storage Fabric Devices. This allows for composing disaggregated storage resources—

with compute, networking, and memory—into virtual systems in the future. These virtual systems will be

dynamically provided to the right application at the right time, ensuring SLAs can be met automatically.

• Volume management (create / modify / delete namespaces, format media)

3

Page 10

User Guide

• Monitor hardware sensors (temperatures, voltages, fan speeds, hardware state)

• Configure hardware (update firmware, reboot individual components or systems, assert LEDs)

• Monitor performance (statistics, bandwidth, IOPS, latency)

• Capture inventory data (serial number, part number, etc.)

• Capture log information

• Configure policies (user access lists, authentication, LUN masking, HTTPS/TLS encryption/security

with certificate/key settings)

• Self-discovery of other locally-available resources configurable using the Open Composable API for

OpenFlex

1.1.2.3 OCGUI

The Open Composable Graphical User Interface (OCGUI) is the graphical representation of all of the data

shared up to the fabric by the OCAPI. This GUI is presented to the user by browsing to the IP address

of any device on the fabric. The GUI has a "command-center" design layout that presents all vital health,

utilization, and performance statistics related to devices on the network at a glance.

1.1.3

NVMe-oF

1. Overview

1.1 OpenFlex™ F3100 and E3000

1.1.4

Non-Volatile Memory Express over Fabric (NVMe-oF) is one of the primary enabling technologies for the

OpenFlex platform. NVMe-oF enables the high-speed, low-latency storage performance of NVMe over

a fabric switching network. OpenFlex products drive network communications across the fabric using

100Gb/s Ethernet protocol. This allows for a complex network of computing devices to all share the same

storage resources with very high performance.

Supported SKUs

The following table lists the versions of this Western Digital product that are supported by this document.

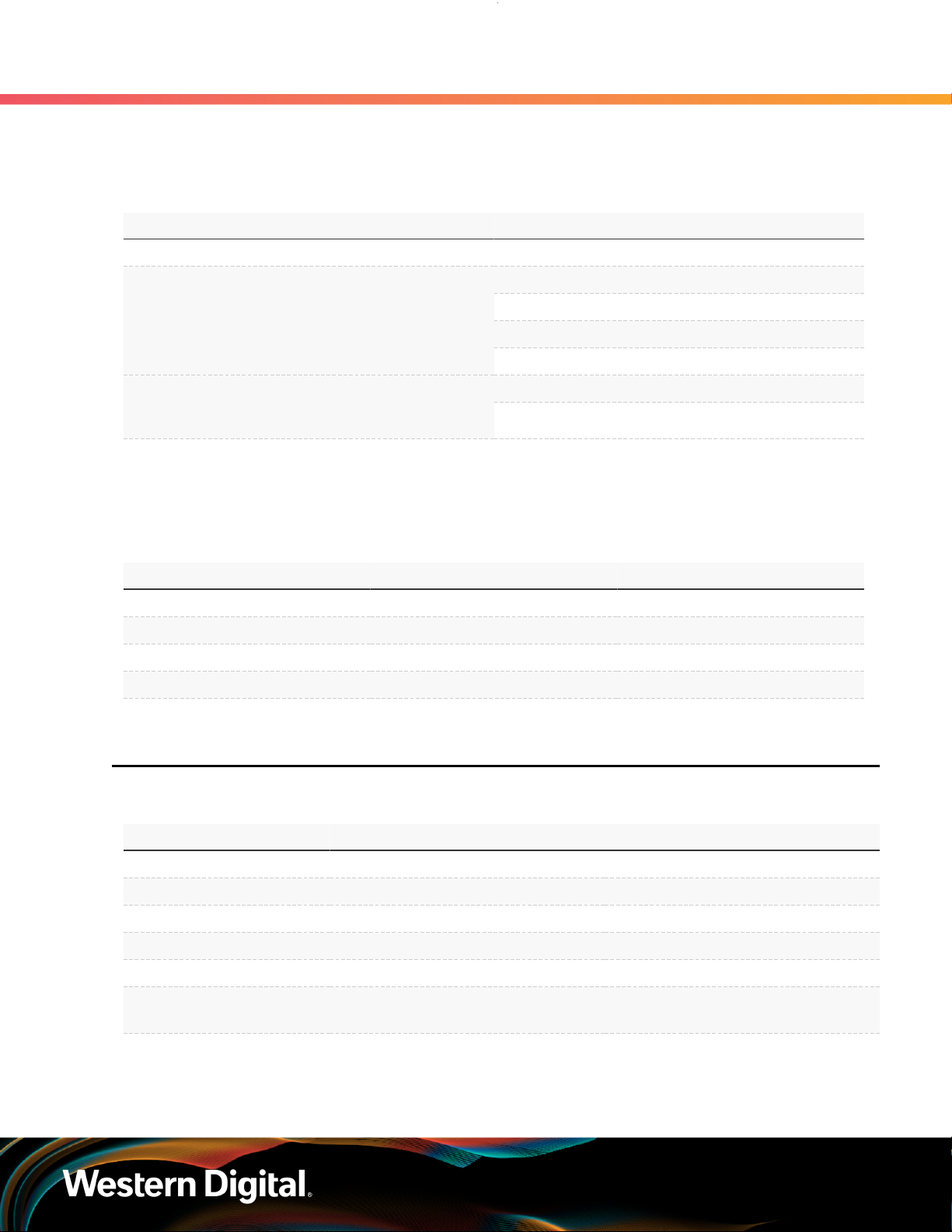

Table 1: List of Supported SKUs

Component Capacity SKU

OpenFlex E3000 Chassis 3U10 Enclosure N/A 1ES1778

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-2DW/D ISE 12.8TB 1EX2413

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-0.8DW/D ISE 15.36TB 1EX2416

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-2DW/D ISE 25.6TB 1EX2414

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-0.8DW/D ISE 30.72TB 1EX2417

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-2DW/D ISE 51.2TB 1EX2415

OpenFlex F3100 Fabric Device 2x50GbE nTAA PCIe RI-0.8DW/D ISE 61.44TB 1EX2418

1.1.5

List of Compatible Devices

4

Page 11

User Guide

Table 2: Devices

1. Overview

1.2 System Architecture Overview

Device Volume Bandwidth *Drive Writes Encryption

OpenFlex F3100 Fabric Device 12.8TB 12GB/s RI-2DW/D ISE 1EX2413

OpenFlex F3100 Fabric Device 15.36TB 12GB/s RI-0.8DW/D ISE 1EX2416

OpenFlex F3100 Fabric Device 25.6TB 12GB/s RI-2DW/D ISE 1EX2414

OpenFlex F3100 Fabric Device 30.72TB 12GB/s RI-0.8DW/D ISE 1EX2417

OpenFlex F3100 Fabric Device 51.2TB 12GB/s RI-2DW/D ISE 1EX2415

OpenFlex F3100 Fabric Device 61.44TB 12GB/s RI-0.8DW/D ISE 1EX2418

1.2 System Architecture Overview

1.2.1

System High Speed Data Ingest Architecture

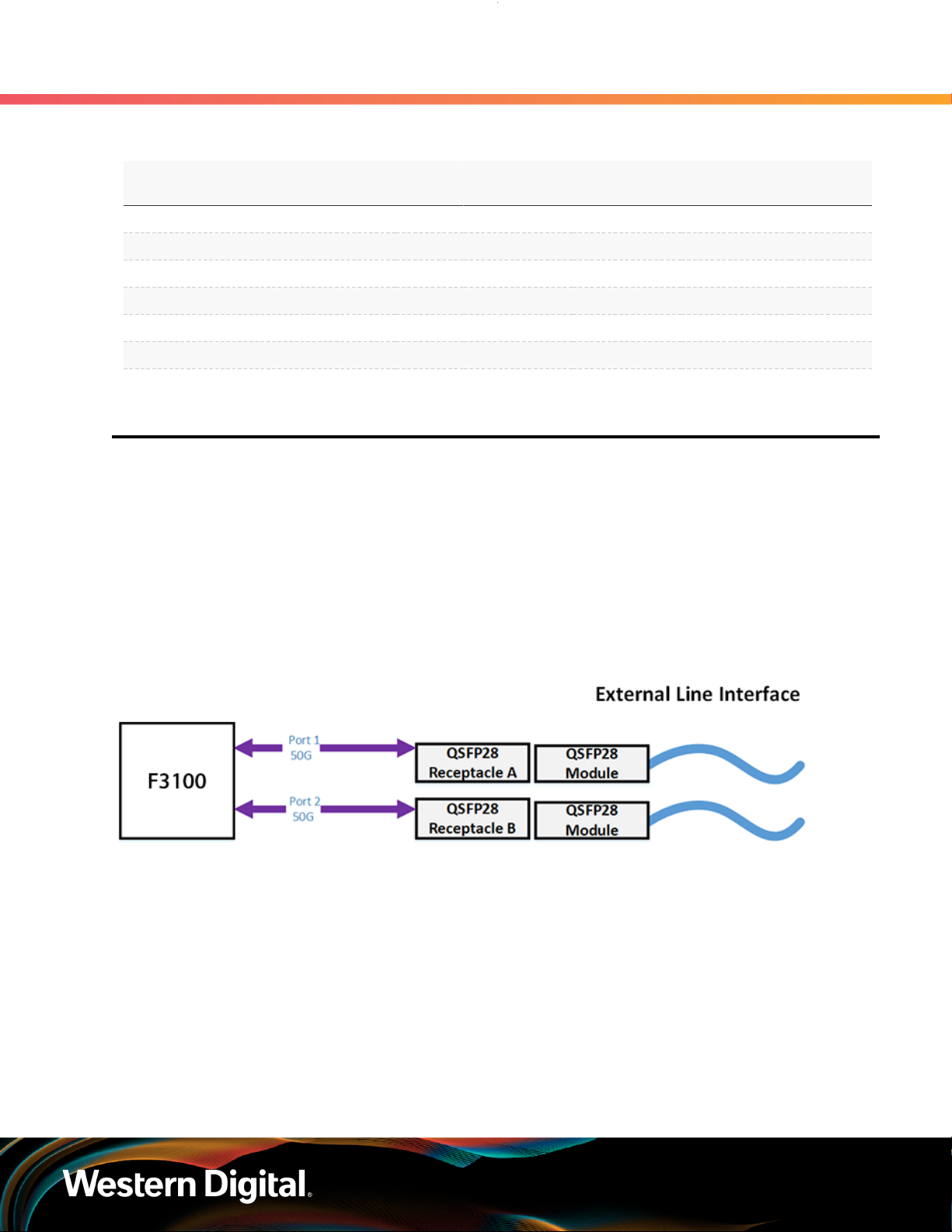

The system main data ingest architecture uses two separate 50G Ethernet connections each on a dual

QSFP28 connector on the rear I/O of the chassis. This completes the connection from the device that is

inserted into a chassis slot, through the backplane into the QSFP connectors. The architecture supports

the hot swap nature of the devices and do not require any sort of shut down or disconnection before

servicing. Each 100G Ethernet connection is split in half at the QSFP28 connectors resulting in 50G per

connector allowing for dual port functionality with the device.

Part

Number

1.2.2

Figure 2: System High Speed Data Ingest

System Thermal and Cooling

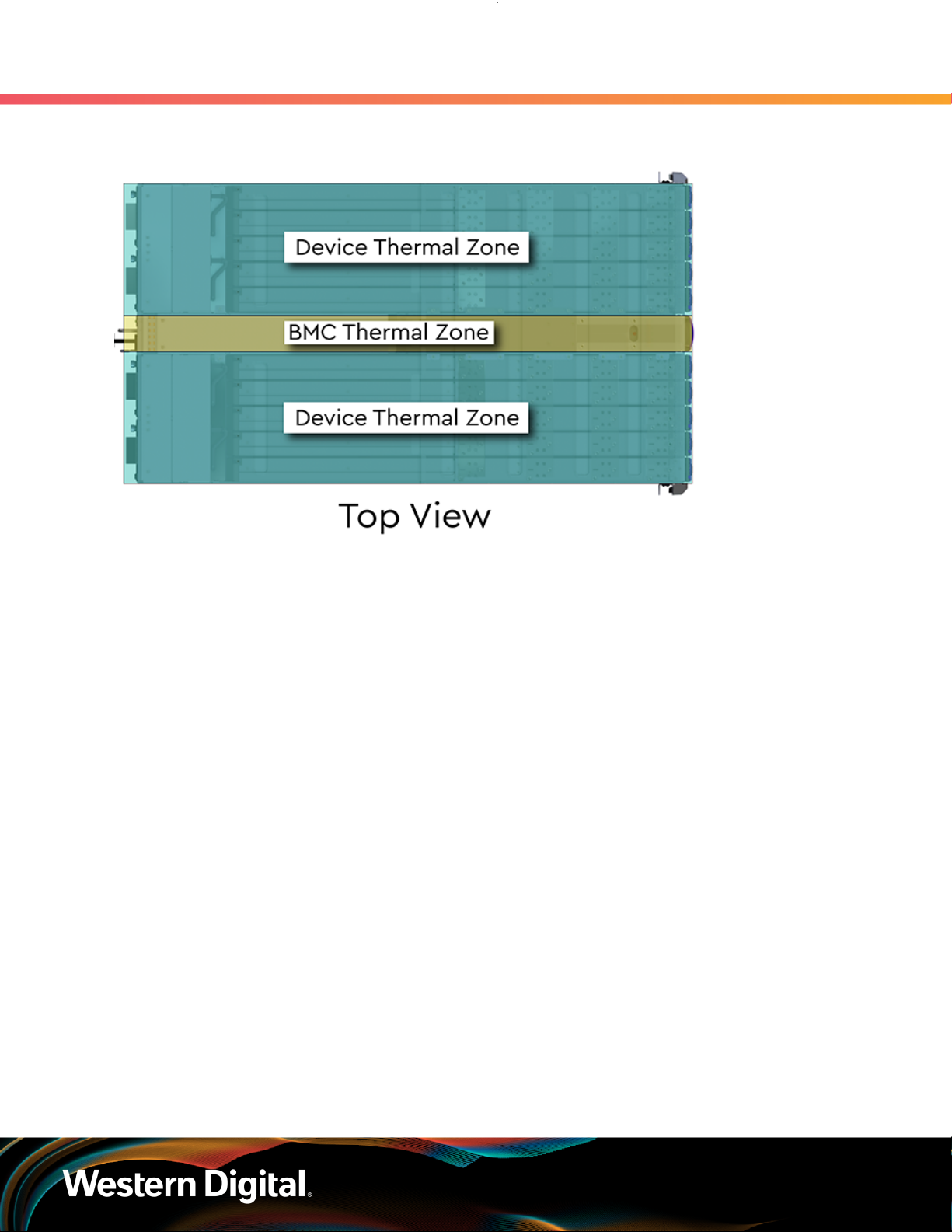

The following image displays the thermal zones as viewed from the top of the enclosure. When viewing

the enclosure from the front, the right device zone is on the right-hand side and the left device zone is

on the left-hand side. When viewing the enclosure from the rear, the order is reversed. Each of the two

thermal zones contains major components that are thermally maintained within their specific zone.

* Bandwidth obtained by sequential read

5

Page 12

User Guide

Figure 3: System Thermal Zones

1. Overview

1.2 System Architecture Overview

The E3000 uses a base algorithm, called a thermal algorithm, to control the overall thermal environment of

the system. The system is mechanically separated into two thermal zones to support efficient cooling of

the system components in order to achieve the intended performance of the system. The thermal zones

are split into device zones (the left and right side of the enclosure) and center zone when standing at the

front of the system. The device thermal zones contain up to ten devices or device blanks each that are

cooled by four fan modules that are located directly behind the devices. The four fan modules behind the

devices maintain the cooling for devices contained within the device slot installed into A through J. The

center thermal zone contains the BMC module that is cooled by the fans contained in the redundant PSUs

the are located directly behind the BMC module. The different thermal zones are designed to maintain

proper thermal cooling across the entire system. During servicing the system increases the speed of the

fan modules and PSU fans to maintain a balanced thermal load.

1.2.2.1 System Thermal Algorithm

The System Thermal Algorithm is designed to use temperature sensors and defined thresholds to

determine if the algorithm will select critical, increase, decrease, or no change as the device decision.

The System Thermal Algorithm uses the concept of priorities to ensure the proper function of the system.

As a result, any critical fault results in the system ramping the fans to maximum RPMs to protect the

hardware for the duration of the fault. The fault will remain in a critical state until the fault is fully resolved

and by bringing the temperature back within the specified defined thresholds.

The System Thermal Algorithm contains minimum and maximum thresholds related to the ambient

temperature of the system. The system is designed to maintain a maximum ambient temperature of 35°C.

Exceeding 35°C may result in damage to the hardware and potentially void the product warranty. These

thresholds allow for the best possible operating conditions. If the system goes outside of the minimum or

maximum threshold window, the BMC will adjust the fan speed to accommodate the issue and a fault will

be reported. The following table lists the Thermal Algorithm Thresholds along with the related fault levels

and threshold values.

6

Page 13

User Guide

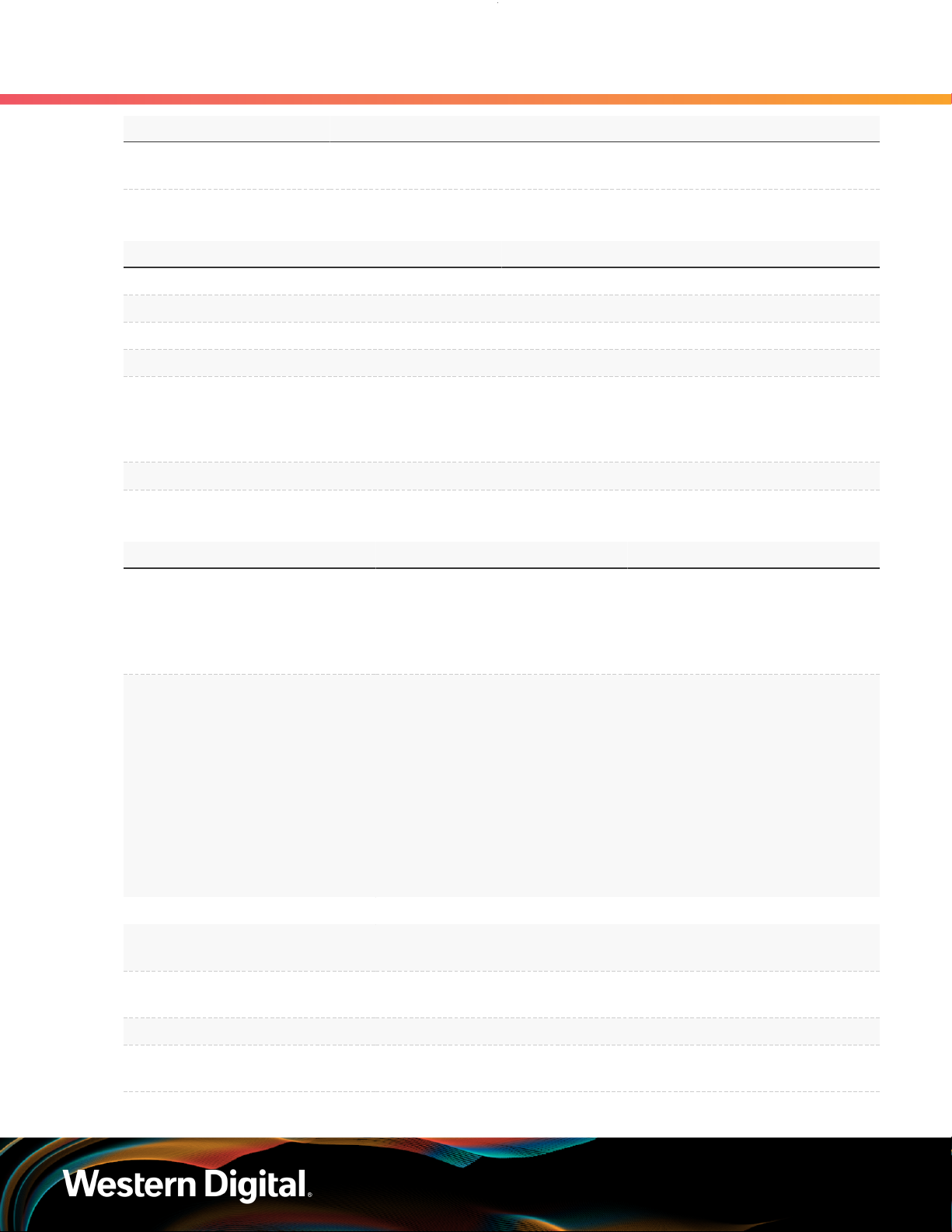

The following table lists the different severity of thermal algorithm critical faults that are reported to the

user.

Table 3: Thermal Algorithm Critical Faults

1. Overview

1.3 OpenFlex F3100 and E3000 Specification Summary

Component Critical Faults

Device Any sensor >= critical

BMC

The following table lists the device decision values that the system chooses from during operation. It

describes how the pulse width modulation (PWM) of the power that is being distributed to the cooling

fans reacts to different fault types.The fault will be reported based on the severity of the thermal issue.

Not installed FAN

Not installed PSU

Not installed Device or Blank

Not installed BMC

Any sensor >= criticalPSU

Any critical status on SMBus

Table 4: Thermal Algorithm Device Decision for Fan Control

Fault Sensor Value Fan Response

Critical Sensor >= Critical 100% PWM

Increase Sensor >= Max PWM + increase step

Decrease Sensor <= Min PWM - decrease step

No Change Min < Sensor < Max Hold PWM

1.3 OpenFlex F3100 and E3000 Specification Summary

Table 5: Environmental Specifications

Specification Non-Operational Operational

Temperature -30°C to 60°C 5°C to 35°C

Temperature Gradient 30°C per hour max 20°C per hour max

Temperature De-rating 1°C per 300m above 3000m 1°C per 175m above 950m

Relative Humidity 5-95% Non-Condensing 8-85% Non-Condensing

Relative Humidity Gradient 30% per hour maximum 30% per hour maximum

Altitude -300m to 12,000m / -984 ft. to

39,370 ft

-300m to 3048m / -984 ft. to 10,000

ft.

7

Page 14

User Guide

Cooling N/A 4 Fan Modules (N+1 Supported),

Table 6: Electrical Specifications

Max Power Consumption 1600W

Typical Power Consumption ~1400W

Input Voltage 200V - 240V

PSU Connector Type C16

Inrush Current Maximum (per PSU) AC line inrush current shall not exceed 40A peak,

PSU Efficiency 80 PLUS Platinum

1. Overview

1.3 OpenFlex F3100 and E3000 Specification Summary

Specification Non-Operational Operational

containing two fans per module

Specification Value

for up to one-quarter of the AC cycle after which,

the input current should be no more than the

specified maximum input current.

Table 7: Mechanical Specifications

Specification Non-Operational Operational

Shock 20G, 7ms half sine; 3 positive

and 3 negative pulses in each

axis Z and Y. X axis- 15G, 7ms half

sine, 3 positive and 3 negative

pulses

Vibration Linear Random: 0.50Grms;

5-500Hz; 10 minutes each axis in

X, Y, and Z

Linear Random: 0.54Grms;

1-200Hz; 60 minutes in Z axis.

Linear Random: 0.80Grms; 2 200Hz; 15 minutes in Z axis

Swept Sine: 0.50G, 0 - peak

swept sine; 5 - 500Hz; 1

complete sweep @ 1/2 octave

per minute

Weight 68.5 kg / 151.1 lbs.

Dimensions W: 447.2 mm x L: 828.04 mm x H: 130.9 mm / W: 17.6 in. x L: 32.6 in.

x H: 5.2 in.

5G, 11ms half sine; 3 positive and

3 negative pulses in each axisminimum 6 seconds between

shocks

Linear Random: 0.15 Grms 5-500

Hz 10 minutes each axis in X, Y

and Z

Swept Sine:0.17 G, 0 - peak,

5-500 Hz 0.5 octaves/min,

approx. 13 minutes each axis

System Installation Length 778 mm / 30.6 in. from the front rack chassis mounts to the rear of

the system

Required Rack Depth 1000 mm (39.4 in.) of usable rack space, frame to frame

Required Rack Width 450mm (17.72in.) with 465mm (18.31in.) ± 1.5mm nominal hole

spacing. See EIA-310 Rack Standard

8

Page 15

User Guide

Rack Units (U) 3U

Vertical Rack Rail Spacing 718 mm – 850 mm / 28.26 in. – 33.46 in.

Table 8: Performance Specifications

Number of Device Slots 10 Dual-port Fabric Device Bays

Data Transfer Rates 12GBps NVMe-oF

Max Raw Data Storage Capacity 614TB

Ethernet Ports 20 x 50Gbps QSFP28 ( 2 per Fabric Device)

Table 9: Performance Specifications by CRU P/N

1. Overview

1.3 OpenFlex F3100 and E3000 Specification Summary

Specification Non-Operational Operational

Specification Value

*

1 x 10/100/1G Ethernet

CRU P/N 1EX2413 1EX2416 1EX2414 1EX2417 1EX2415 1EX2418

Capacity/

Endurance

Random Read

(4KB, QD=1024)

Random Write

(4KB, QD=1024)

Random Mixed

70R/30W

(4KB, QD=1024)

Sequential Read

(128KB, QD=320)

Sequential Write

(128KB, QD=320)

Random Write

Latency

(4KB, QD=1, 99.99%)

Notes on Testing:

• Latency measured through a single Mellanox SN2700 switch

• K IOPs = IOPs x 1000

• Devices pre-conditioned with 2 full sequential fills

12.8TB

1-2DWPD

2199K

IOPs

1493K

IOPs

2199K

IOPs

11.8 GB/s 11.7 GB/s 11.7 GB/s 11.7 GB/s 11.7 11.7 GB/s

9.9 GB/s 9.9 GB/s 9.9 GB/s 9.4 GB/s 9.4 GB/s 9.9 GB/s

33.9 us 33.7 us 33.7 us 33.9 us 33.7 33.5 us

15.36TB

0.8DWPD

2111K

IOPs

1433K

IOPs

2137K

IOPs

25.6TB

2DWPD

2164K

IOPs

1431K

IOPs

2183K

IOPs

30.72TB

0.8DWPD

2160K

IOPs

1397K

IOPs

2188K

IOPs

51.2TB

0.8DWPD

2176K

IOPs

1464K

IOPs

2227K

IOPs

61.44TB

0.8DWPD

2191K

1

IOPs

1400K

1

IOPs

2251K

IOPs

* Max storage capacity depends on device version and device configuration.

9

Page 16

User Guide

Table 10: Acoustic Specifications

1. Overview

1.4 Physical Design

Quantities Declared

A-weighted sound power level1, L

WAd

{1 B = 10

Idle

Mode

8.5 8.5 9.6 9.6

Operating

Mode

Fan Fail

Mode

5

Max Fan

Mode

dB}

Average A-weighted emission sound pressure

level2, L

(dB) {bystander position3}

pAm

66.0 66.0 74.9 76.2

Statistical adder for verification4, K (dB) 2.5 2.5 2.5 2.5

Notes on Acoustic Testing Methodology and Environment:

1

Declared A-weighted sound power level for a single machine, calculated per section 4.4.2 of ISO

9296-1988 and measured per ISO 3744

2

Declared A-weighted sound pressure level for a single machine, calculated per section 4.4.4 of

ISO-9296-1988 and measured per ISO 3744

3

The front and rear of the UUT were selected for the bystander location, due to access typically from the

cool or hot isle in a data center. This does not meet the four bystander positions as specified in ECMA-74

2012, but the microphones were adjusted to the preferred location.

4

The statistical adder, K, accounts for random measurement error, and is equal to 2.5 dB, which is

appropriate for a 5% risk of rejection for SR = 1.5 dB per section 4.4.2 of ISO 9296-1988.

5

At steady state condition, system/PSU fans reached 100% pwm speeds during fan fail mode testing.

• Background noise: <7dBA

• Environmental test conditions: ~23° C, 57% RH, 101.3 kPa

• Tested configuration: 3U NVMeOF VBOF device with 10 devices installed.

1.4 Physical Design

The OpenFlex F3100 and E3000 physical design emphasizes easy access to hot-swappable components,

maximization of data storage capacity in the rack, and bold aesthetic design.

10

Page 17

User Guide

Figure 4: OpenFlex F3100 and E3000 Layout

1. Overview

1.4 Physical Design

The enclosure measures 447.2 mm/17.6 in. wide by 828.04 mm/32.6 in. long. It's height is 130.9 mm/5.2 in.

or 3U. The chassis installation length is 778 mm / 30.6 in. from the front rack chassis mounts to the rear of

the system.

Figure 5: OpenFlex F3100 and E3000 Dimensions

11

Page 18

User Guide

1.4.1

LEDs

Chassis LEDs

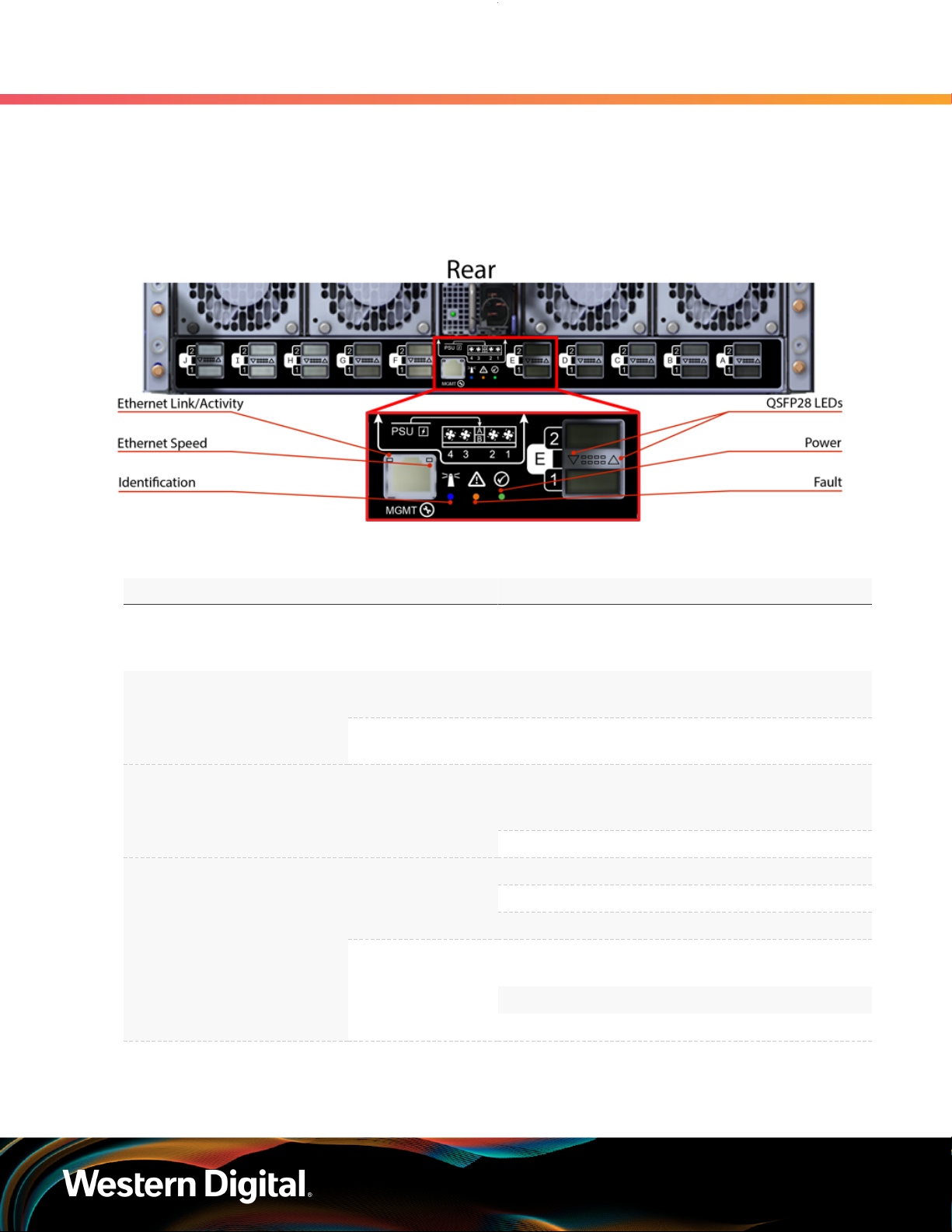

Figure 6: Chassis Rear IO LEDs

1. Overview

1.4 Physical Design

Table 11: Chassis Rear IO LED Flash Patterns

LED Name Color Behavior

Ethernet Link/Activity Green Off: No Connection

Solid: Connected

Blink: Activity

Ethernet Speed

Identification Blue

QSFP28 LED

Green Off: Operating at 10 Mbps

Solid: Operating at 100 Mbps

Amber Off: Operating at 10 Mbps

Solid: Operating at 1Gpbs

Blink @ 1 Hz: Blinks only when Identification has

been activated. Will blink when any component

is identified, e.g. Fans, PSUs, etc.

Off: Enclosure not being identified/located

Green

Amber

Solid: Link operating at maximum speed

Blink (3Hz): Link activity

Off: Default state

Solid: Link operating at a lower speed, 50G or

less

Blink (3Hz): Low speed link activity

Blink (1Hz): On/Off - Identify

12

Page 19

User Guide

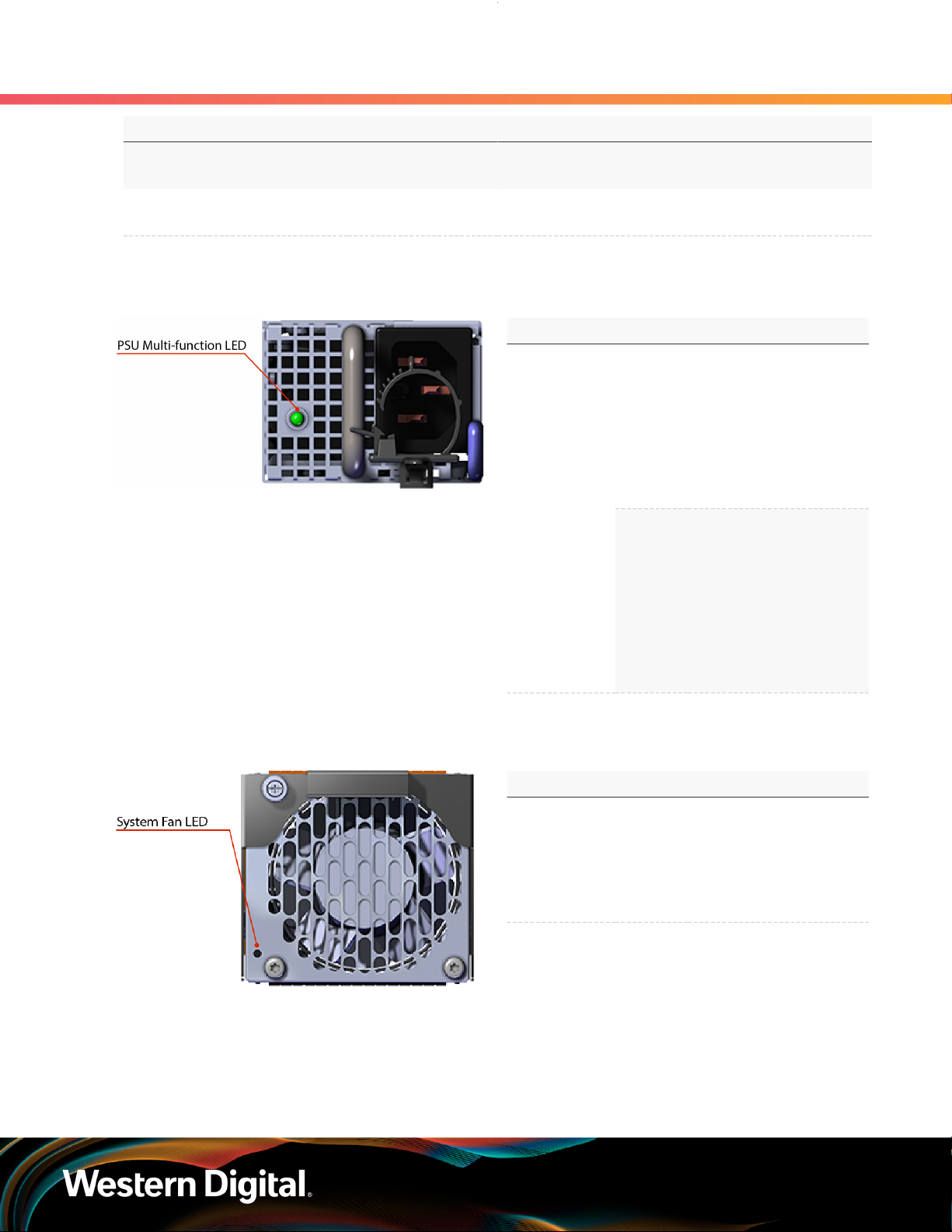

PSU LED

1. Overview

1.4 Physical Design

LED Name Color Behavior

Power Green Solid:Enclosure is powered on

Off:Enclosure is powered off

Fault Amber Blink @ 2 Hz: Enclosure has a fault

Off: Enclosure has no fault

Figure 7: PSU LED

Fan Module LED

Table 12: PSU LED Flash Patterns

LED Name Color Behavior

Multi-

function LED

Green Solid: PSU is on and

reporting no faults

Blinking @ 2Hz: PSU

in firmware update

mode

Off: PSU is

disconnected from

power

Amber Solid: PSU is

disconnected from

power or critical fault

causing a shutdown

failure

Blinking @ 0.5Hz: PSU

reporting warnings

Off: PSU is reporting

no faults

Figure 8: Fan Module LED

Table 13: Fan Module LED Flash Patterns

LED Name Color Behavior

LED Amber Blinking @ 2 Hz: Fan is

reporting a fault

Blinking @ 1 Hz: Fan is

being identified

Off: Fan is on and

reporting no faults

13

Page 20

User Guide

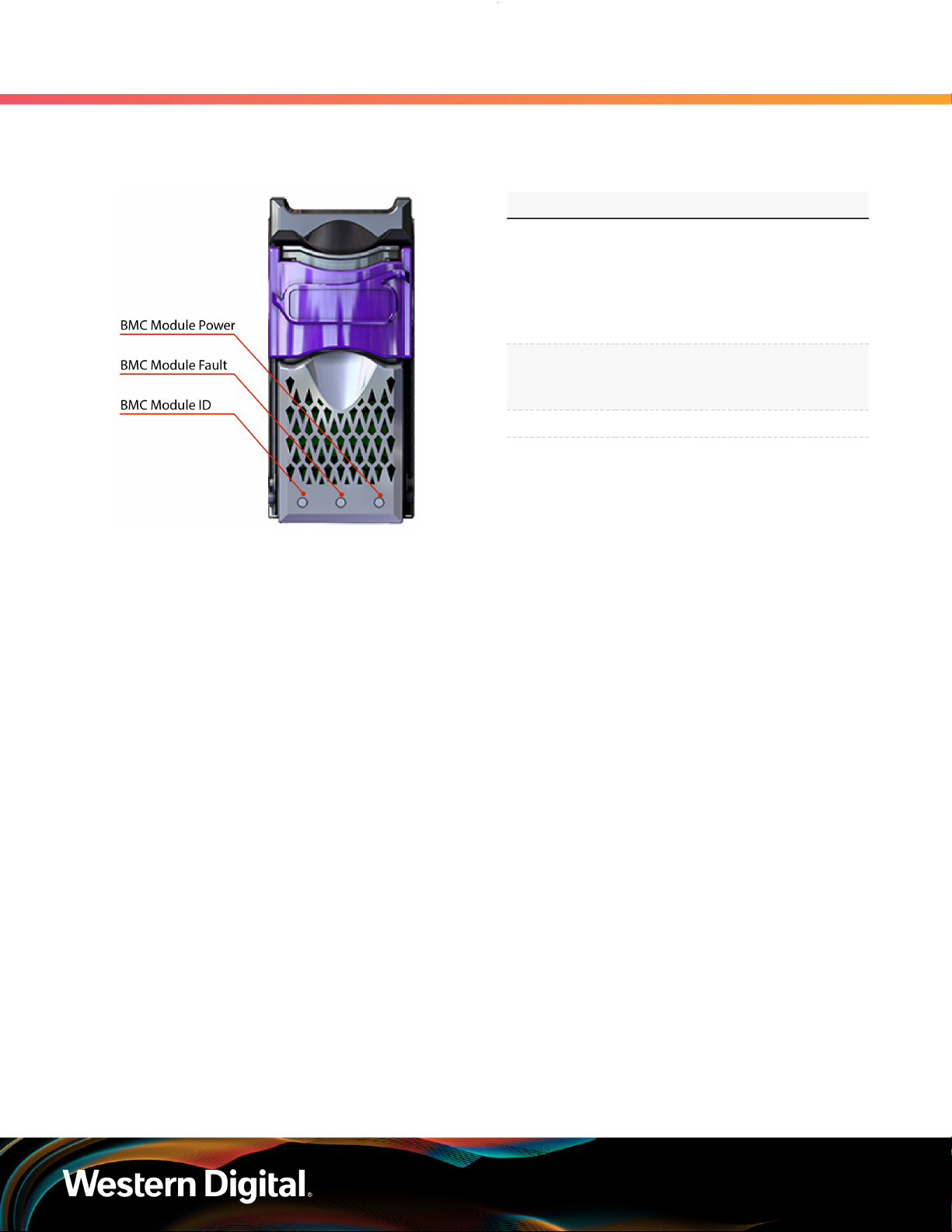

BMC Module LEDs

1. Overview

1.4 Physical Design

Figure 9: BMC Module LEDs

Table 14: BMC Module LED Flash Patterns

LED Name Color Behavior

Identification Blue Blink @ 1 Hz:

Blinks only when

Identification has been

activated. Will blink

when any component

is identified.

Fault Amber Blink @ 2 Hz:

Enclosure has a fault

Off: Default State

Power Green Solid: Powered On

14

Page 21

User Guide

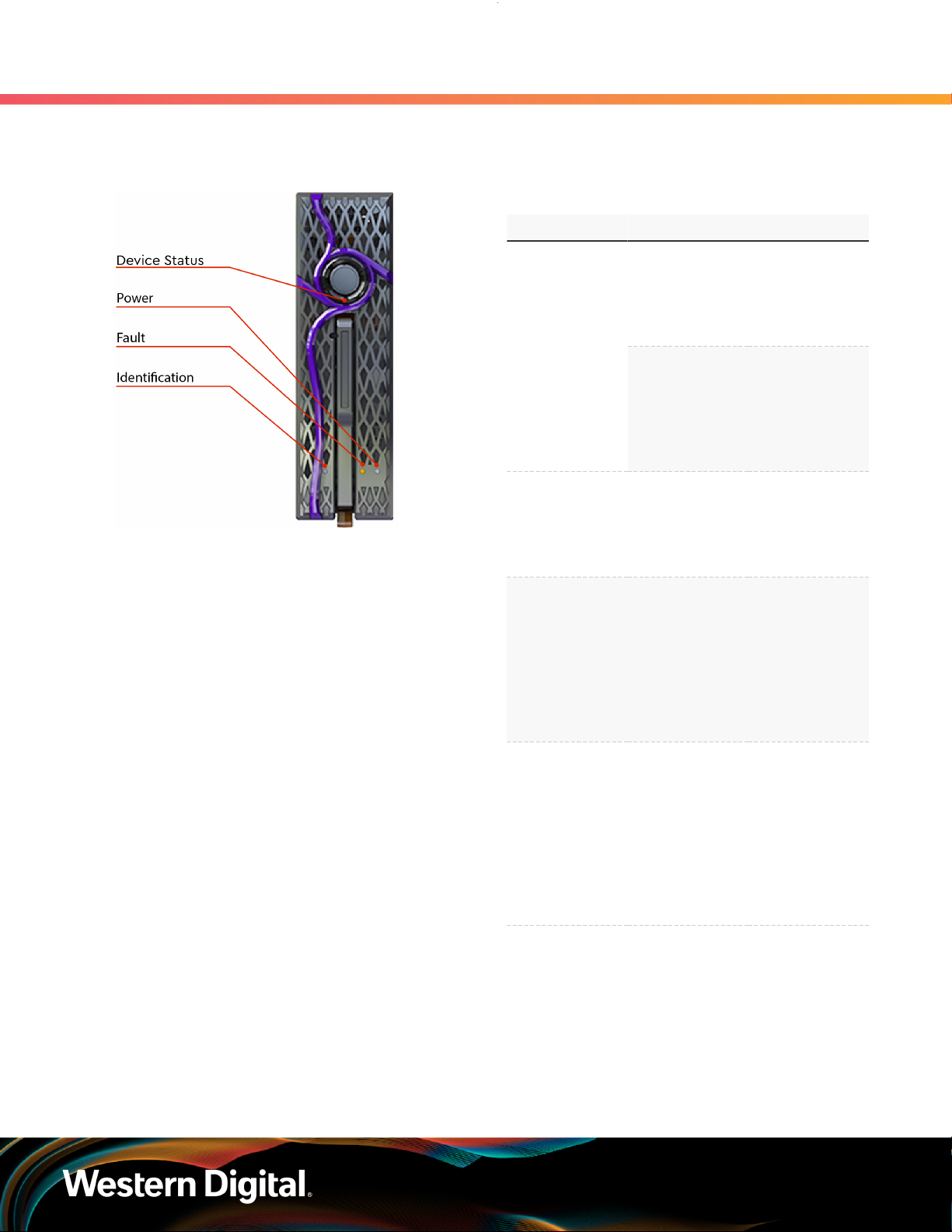

OpenFlex F3100 LEDs

1. Overview

1.4 Physical Design

Figure 10: OpenFlex F3100 LEDs

Table 15: OpenFlex F3100 LED Flash

Patterns

LED Name Color Behavior

Device Status

Power Green On: Device is

Fault Amber Blink @ 1 Hz:

White Solid: On and

Connected

Off: Not Ready

or Powered

down

Blue Blink @ 1 Hz:

OpenFlexF3100

is flushing the

cache

Off: Default

State

Powered On

Off: Device

is Powered

Down

Device has a

fault

Solid: Device

is Powered

Down

Off: Device has

no fault

Identification Blue Blink @ 1

Hz: Blinks

only when

Identification

has been

activated.

Off: Device

is not being

identified.

15

Page 22

User Guide

1.4.2

Cables

The following table displays the power cable supported by Western Digital:

Table 16: Approved Power Cables

1. Overview

1.5 Restrictions and Limitations

Type Part Number Length

IEC C14 to IEC C15 Heavy

Duty 15A Power Cable

The following table displays the Ethernet cables approved by Western Digital:

Note: These cables are approved, but not provided by Western Digital.

(Provided in Accessory Kit) 6 ft.

Table 17: Approved Ethernet Cables

Vendor Active/Passive Vendor Model Number

Mellanox

Amphenol

Passive MCP1600-C001

Passive MCP1600-C002

Passive MCP1600-C003

Active MFA1A00-C005

Passive NDARHG-0001

Passive NDARHG-0004

Passive NDARHF0002

Passive NDARHJ0003

Western Digital

Part Number

1.5 Restrictions and Limitations

The OpenFlex F3100 and E3000 have the following restrictions and limitations on functionality:

• All E3000 chassis must be full for proper airflow. This means that if there is only one device installed, the

rest of the device slots must be filled with device blanks.

• If the BMC Module is not installed in the E3000 chassis, F3100 devices cannot be added or slot

swapped.

• Only hot-swap a single component at a time. Never remove more than one at a time.

• VLAN tagging is not supported.

• RoCE v1 is not supported. F3100 will support RoCE v2 only.

16

Page 23

User Guide

• To power off an F3100, browse directly to the F3100. Power off cannot be done from the E3000. To

power back on the F3100, browse to the E3000.

• IPv4 networking only.

• Only one browser session allowed to an individual F3100 device.

• Enforced maximum limits on configuration

◦ 256 Volumes

◦ 256 Hosts

◦ 2048 Queue Pairs

◦ 128 Queue Pairs (1 Admin, 127 IO) per connection

◦ 64 max queue depth per IO Queue Pair

1.6 Site Requirements

1.6.1

Power Requirements

The E3000 is equipped with redundant PSU units. The PSUs are hot-swappable and are located at the rear

of the chassis. The following is a specification summary. Note that the system does not support lowline

voltage.

1. Overview

1.6 Site Requirements

1.6.2

Table 18: Power Specification

Specification Value

Power Output 1600W

Input Voltage 200V - 240V

80 PLUS Standard Platinum

Connector Type C16

Rack Requirements

The E3000 is designed to be installed into a rack that meets the EIA-310 standard with a minimum of 1000

mm (39.4 in.) of usable rack space, frame to frame. The vertical rack rails must be set between 718 mm

– 850 mm / 28.26 in. – 33.46 in. to support the enclosure. It requires 3U of rack space, and it should be

installed into the rack at the lowest possible U height to keep the load on the rack balanced.

Table 19: Required Rack Specifications

Parameter Requirement

Rack Depth 1000 mm (39.4 in.) of usable rack space, frame to

frame

Rack Width 450mm (17.72in.) with 465mm (18.31in.) ± 1.5mm

nominal hole spacing. See EIA-310 Rack Standard

Rack Units (U) 3U

Vertical Rack Rail Spacing 718 mm – 850 mm / 28.26 in. – 33.46 in.

17

Page 24

User Guide

Static Load Rating Rack meets ISTA 3E or 3B test requirements and

Dynamic Load Rating Rack meets ISTA 3E or 3B test requirements and

1.6.3

Thermal and Cooling Requirements

The thermal output of the OpenFlex F3100 and E3000 depends on the number of F3100s that are

populated in the E3000. Use the following table to determine how many BTUs of heat will exhaust from the

rear of the unit.

Table 20: BTU Exhaust per Component

1. Overview

1.6 Site Requirements

Parameter Requirement

regulations when mounted to the shipping pallet

regulations when mounted to the shipping pallet

Condition Typical BTU Output Max BTU Output

1.6.4

Single E3000 w/ BMC Module 768 BTU/hr = 225 W

(25C/77F, fans at 50%)

Single F3100 409 BTU/hr = 120 W

(25C/77F, Workload: Random

Read/Write, queue depth

32, 80% internal processors

dedicated to workload)

E3000 Fully Populated with

F3100s

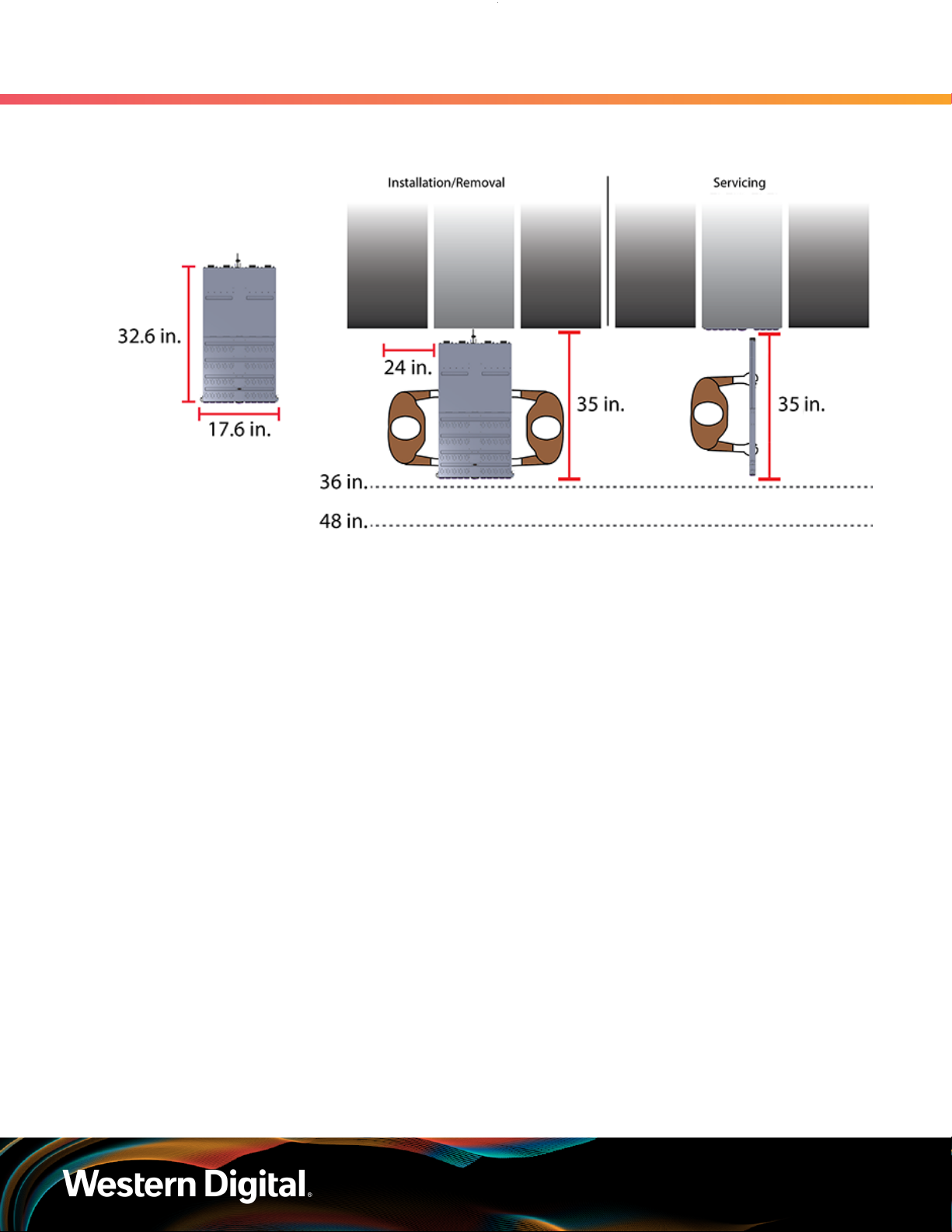

Servicing Requirements

Space Requirements

The installation of the OpenFlex F3100 and E3000 will require enough space in front of the rack for two

people to perform a safe installation. The recommended forward clearance is 889 mm / 35 in. from the

front of the rack and 609.6 mm / 24 in. on both sides of the enclosure. It is also recommended to make

considerations for any carts or lift equipment that might be used to perform the installation. * The servicing

of the enclosure requires one person and a minimum of 508 mm / 20 in. of space in front of the rack to

allow enough clearance to remove an F3100 from the enclosure. See the following diagram for details.

5244 BTU/hr = 1537 W

(25C/77F, fans at 50%)

1177 BTU/hr = 345 W

(35C/95F, fans at 100%)

546 BTU/hr = 160 W

(35C/95F, workload: Highest

throughput to drives – Seq

Write, queue depth 32, all

internal processors at 100%)

5884 BTU/hr = 1725 W

(35C/95F, fans at 100%)

* The weight of the enclosure during installation will vary, depending on the number of F3100 devices and blanks

contained in the E3000. In some situations, carts or lift equipment may be required.

18

Page 25

User Guide

Figure 11: Installation and Servicing Space

1. Overview

1.6 Site Requirements

19

Page 26

Western Digital

Components

In This Chapter:

- Chassis........................................................... 21

- PSU.................................................................22

- Fan Module....................................................23

- BMC Module..................................................24

- Rails................................................................25

- OpenFlex F3100............................................26

20

Page 27

User Guide

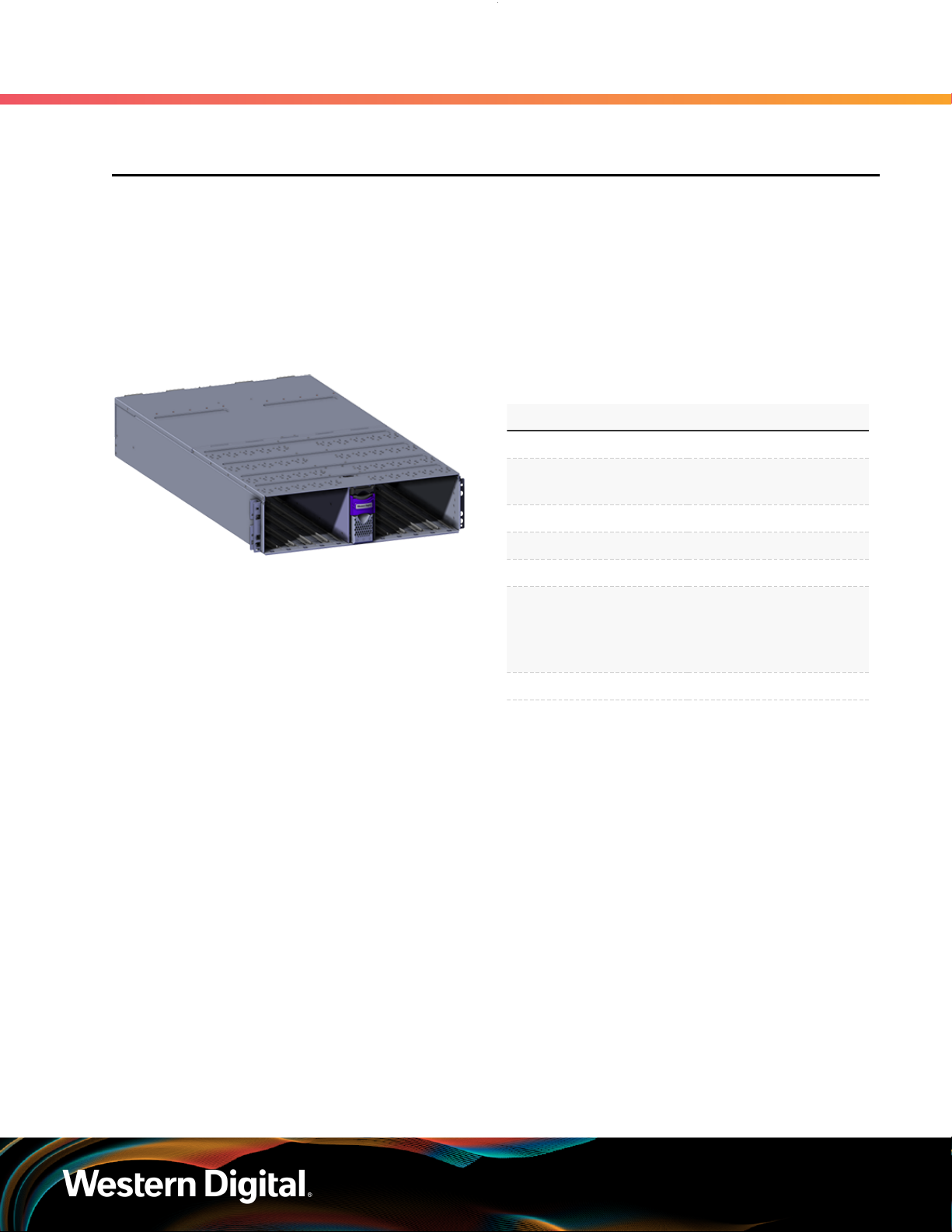

2.1 Chassis

The OpenFlex E3000 chassis is the primary housing that contains and connects all of the system

components that comprise the OpenFlex F3100 and E3000 . The chassis contains one BMC Module in the

front, and the rear contains two redundant PSUs and four Fan Modules that come preinstalled in the chassis.

The chassis also contains ten device slots that can be populated with approved OpenFlex™ components.

The E3000 is installed and secured onto shelf style rail mounts. The rear IO houses the primary connections

such as power and QSFP28 ports and the status LEDs for all of the components.

2.1.1

Chassis Specifications

2. Components

2.1 Chassis

Table 21: Chassis Specification Summary

Specification Value

Rack Units 3U

Number of Device

Slots

Number of BMC Slots 1

Part Number 1EX1919

Hot Swappable? No

Dimensions W: 447.2 mm x L:

Weight 38.2 lbs / 17.32 kg

10

828.04 mm x H: 130.9

mm / W: 17.6 in. x L:

32.6 in. x H: 5.2 in.

21

Page 28

User Guide

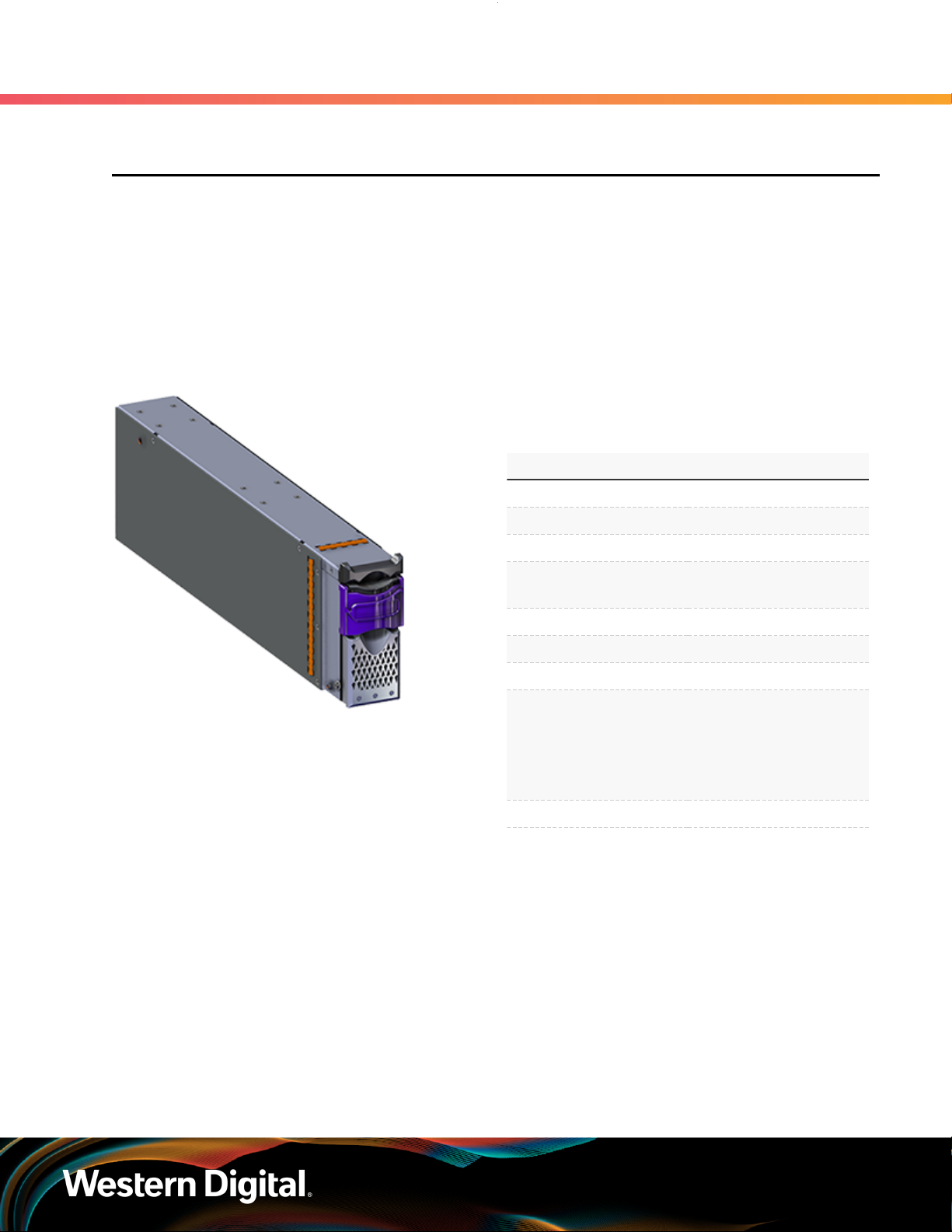

2.2 PSU

The OpenFlex E3000 chassis contains toolless redundant 1600W Power Supply Units (PSU). Each PSU

requires an input voltage of between 200V - 240V. The PSUs are certified 80 PLUS Platinum and use the C16

connector type. Due to the redundant nature of the PSUs, they may be serviced or replaced, one at a time,

while the enclosure is powered on.

2.2.1

PSU Specifications

2. Components

Table 22: PSU Specification Summary

Specification Value

Power Output 1600W

Input Voltage 200V - 240V

80 PLUS Standard Platinum

Connector Type C16

2.2 PSU

Internal Fan Speed Up to 25,000 RPM

Number per Enclosure 2

Part Number 1EX1916

Hot Swappable? Yes

Service Window 5 minutes

Dimensions

Weight 2.31 lbs. / 1.05 kg

W: 54.5 mm x L: 321.5

mm x H: 40.1 mm

W: 2.15 in. x L: 12.66 in.

x H: 1.58 in.

22

Page 29

User Guide

2.3 Fan Module

The OpenFlex E3000 contains four toolless Fan Modules to maintain the cooling across the entire system.

The Fan Modules are connected to the rear of the Chassis using a handle to seat the module in place

and captive screw to secure the Fan Module into the fan bay. Due to the redundant nature of the Fan

Modules, they may be serviced or replaced, one at a time, while the enclosure is powered on. The Fan

Modules will accelerate to maximum RPM while the BMC Module or devices are removed during servicing or

replacement.

2.3.1

Fan Module Specifications

2. Components

2.3 Fan Module

Table 23: Fan Module Specification

Summary

Specification Value

Rated Voltage 12V

Fan Speed 12000 RPM

Acoustics 76 dB measured at 1

meter from the fan inlet

Number per Enclosure 4 Fan Modules

containing two rotors

per module

Part Number 1EX1915

Hot Swappable? Yes

Service Window 5 minutes

Dimensions

Weight 1.76 lbs. / 0.8 kg

W: 92.74 mm x L: 127.2

mm x H: 85.2 mm

W: 3.65 in x L: 5.01 in x

H: 3.35 in

23

Page 30

User Guide

2.4 BMC Module

The OpenFlex E3000 contains a toolless BMC Module that is installed into the center slot at the front of the

Chassis. The BMC Module is accessed using a 1GBe Ethernet management RJ45 port on the rear IO of the

Chassis. The BMC Module enables out of band management (OOBM) using a RESTful interface (via HTTP

or HTTPS). OOBM controls the actions between devices and the BMC Module for powering down, setting

system configurations, and the cooling algorithm for the Fan Modules. The BMC Module may be serviced or

replaced while the enclosure is powered on as long as it is replaced within five minutes of removing it from

the slot. Replacing a BMC module will not effect data flow to devices.

2.4.1

BMC Module Specifications

2. Components

2.4 BMC Module

Table 24: BMC Module Specification

Summary

Specification Value

Input Current 2A Maximum

Input Power 25W

Rated Voltage 12V +/- 10%

Number per Enclosure 1 installed in the center

device slot

Part Number 1EX1917

Hot Swappable? Yes

Service window 5 minutes

Dimensions

Weight 3.26 lbs. / 1.48 kg

W: 55.6 mm x L: 459.12

mm x H: 126.94 mm

W: 2.19 in x L: 18.08 in x

H: 5 in

24

Page 31

User Guide

2.5 Rails

The E3000 is installed onto shelf style rails. The rail length can be adjusted between 850.31 mm / 33.47

in (max) and 693.69 mm / 27.31 in. (min) in order to fit into different vertical rack rail settings. Once the

enclosure is installed onto the rails, it may be secured to the rails using the provided M5 screws.

2.5.1

Rails Specifications

2. Components

Table 25: Rails Specification Summary

Specification Value

Length 693.69 mm / 27.31 in.

(min)

850.31 mm / 33.47 in

(max)

Part Number 1EX2198

2.5 Rails

Hot Swappable? No

Dimensions

Weight 5.08 kg / 11.2 lbs (both

W: 34.4 mm x L: 693.69

mm x H: 89.65 mm

W: 1.35 in. x L: 27.31 in.

x H: 3.53 in.

rails)

25

Page 32

User Guide

2.6 OpenFlex F3100

The F3100 is a fabric device that contains a maximum of 61.4TB of raw data storage capacity per device. The

device supports Open Composable Infrastructure (OCI) through storage disaggregation using NVMe-overFabrics (NVMe-oF). The front of the F3100 contains a button latch release system and status LEDs and the

rear contains the device connector.

2.6.1

OpenFlex F3100 Specifications

2. Components

2.6 OpenFlex F3100

Table 26: OpenFlex F3100 Specification

Summary

Specification Value

Max Raw Data Storage

Capacity per device

Data Ingest Capability 2x 50G Ethernet

Data Transfer Rates 12 GBps

Number per enclosure Up to 10

Part Numbers See the List of

Hot Swappable? Yes

Service Window 5 minutes

Dimensions W: 37.53 mm x L: 694.4

Weight 4.44 kg / 9.8 lbs

61.4 TB

(see System High

Speed Data Ingest

Architecture (page 5))

*

Compatible Devices

(page 4) to find the

specific part number

required.

mm x H: 124.11 mm

W: 1.48 in x L: 27.34 in

x H: 4.89 in

26

Page 33

User Guide

2.7 OpenFlex E3000 Fabric Device Blank

2.7 OpenFlex E3000 Fabric Device Blank

The OpenFlex E3000 chassis may contain up to 9 OpenFlex E3000 Fabric Device Blanks *. The chassis must

contain at least one device, and the remaining slots must be populated with either devices or device blanks

to avoid compromising the cooling of the enclosure. Each OpenFlex E3000 Fabric Device Blank may be

replaced with a device as the enclosure is scaled up. The OpenFlex E3000 Fabric Device Blank may be

serviced or replaced one at a time while the enclosure is powered on.

2.7.1

OpenFlex E3000 Fabric Device Blank Specifications

Table 27: OpenFlex E3000 Fabric Device

Blank Specification Summary

Specification Value

Number per enclosure Up to 9

Part Number 1EX1918

2. Components

Hot Swappable? Yes

Service Window 5 minutes

Dimensions W: 37.53 mm x L:

694.4 mm x H: 124.11

mm

W: 1.48 in x L: 27.34 in

x H: 4.89 in

Weight 4.12 lbs. / 1.87 kg

* The form factor of the fabric device blank is compatible with all F-Series devices.

27

Page 34

User Guide

2.8 List of Field/Customer Replaceable Units

2.8 List of Field/Customer Replaceable Units

The following table lists the replaceable components and their part numbers.

Table 28: List of Field/Customer Replaceable Components

Component Part Number

Chassis 1EX1919

PSU 1EX1916

Fan Module 1EX1915

BMC Module 1EX1917

Rails 1EX2198

Accessory Kit 1EX2199

OpenFlex E3000 Fabric Device Blank 1EX1918

OpenFlex F3100 Fabric Device See Supported SKUs (page 4)

2. Components

28

Page 35

Western Digital

Management

In This Chapter:

- OCGUI............................................................30

- Part Replacement......................................... 81

29

Page 36

User Guide

3.1 OCGUI

3.1.1

Login Page

3. Management

3.1 OCGUI

3.1.2

The login page displays two panels. The left panel provides username and password fields for logging

into the enclosure. The right panel lists basic information about the enclosure itself, including the type of

device, the OS version, and its status.

Note: For instructions on navigating to the login page, see Navigating to a Device Using the

OCGUI (page 49).

Dashboard

30

Page 37

User Guide

Figure 20: Dashboard

3. Management

3.1 OCGUI

The dashboard provides vital statistics on the health and performance of all of the devices on the fabric.

It is the first page that will load when one logs into any of the fabric-attached devices. The dashboard has

a list of all the devices on the fabric, and clicking through this section will link to the device page for that

device.

3.1.2.1 System Health View

Figure 21: System Health View

31

Page 38

User Guide

The system health view provides an overview of the health of the fabric network. All of the devices on

the fabric are queried when the page loads, and this view is updated. If there are fabric devices that

are flagging errors or faults, the system health view will respond accordingly. The following images

demonstrate the various states that the system health pie chart can present.

Figure 22: System Health View States

The following states correspond to the health status definitions presented by the devices through the

OCAPI:

• OK

• Critical Failure

• Not Available

• Not Installed

3. Management

3.1 OCGUI

3.1.2.2 System Performance View

32

Page 39

User Guide

Figure 23: System Performance View

The System Performance View provides general, bitwise system performance information that relates to

all devices on the fabric.

3. Management

3.1 OCGUI

3.1.2.3 System Utilization View

Figure 24: System Utilization View

The System Utilization View displays the overall level of storage that is being used on the fabric in TB.

3.1.2.4 Storage Health Modal

33

Page 40

User Guide

Figure 25: Storage Health Modal

The storage health modal provides an overview of the health of all of the storage devices that are present

on the fabric. The modal will provide seperate tables for fabric devices that are presenting diffierent

health states up to the OCGUI.

3. Management

3.1 OCGUI

3.1.2.5 Chassis Health Modal

Figure 26: Chassis Health Modal

The chassis health modal provides an overview of the health of all of the chassis devices that are present

on the fabric. This status comes from the BMC module installed in the chassis. The modal will provide

seperate tables for fabric devices that are presenting diffierent health states up to the OCGUI.

3.1.2.6 Device List

34

Page 41

User Guide

Figure 27: Device List

The device list provides summary details about all of the devices that are present on the fabric. Users

can also link to the device page for the OpenFlex device of their choosing for management purposes.

Vital information such as the version of firmware code that is loaded on each device, the type of device

that was discovered, and the UUID. This list will be updated with each refresh of the page as a query

command is sent across the fabric network to discover OpenFlex devices.

3. Management

3.1 OCGUI

3.1.3

Storage Device Page

Figure 28: Storage Device Page

35

Page 42

User Guide

The storage device page presents all of the vital information related to a specific storage resource.

3.1.3.1 Storage Device Health Panel

Figure 29: Storage Device Health Panel

3. Management

3.1 OCGUI

The Device Health Panel shows a visual summary of the general health of devices on the network.

3.1.3.2 Storage Device Utilization Panel

Figure 30: Storage Device Utilization Panel

36

Page 43

User Guide

The Device Utilization panel provides a visual summary of the amount of storage that is available or that

has been consumed on this device.

3.1.3.3 Storage Device Performance Panel

Figure 31: Storage Device Performance Panel

3. Management

3.1 OCGUI

The Device Performance panel provides a visual summary of the current IO performance of the device.

3.1.3.4 Device Information

37

Page 44

User Guide

Figure 32: Device Information Panel - Storage

3. Management

3.1 OCGUI

The Device Information panel provides information about the device itself, such as the ID and Serial

Number, as well as performance statistics related to this device.

3.1.3.5 Operating System (Device Firmware)

Figure 33: Operating System Info (Device Firmware)

The Device OS panel displays the firmware version. Use this panel to upgrade firmware.

3.1.3.6 Hosts

38

Page 45

User Guide

Figure 34: Hosts Configuration

The Hosts panel provides information on the Hosts that are available to be connected to storage and

allows configuration of those hosts on the fabric.

3.1.3.7 Location

Figure 35: Location Information

3. Management

3.1 OCGUI

The Location panel provides information regarding the physical location of the device.

3.1.3.8 Paths

39

Page 46

User Guide

Figure 36: Paths Configuration

The Paths panel lists all of the current paths that are available to the storage volumes. Paths connect

storage to hosts.

3.1.3.9 Pools

Figure 37: Pools Configuration

3. Management

3.1 OCGUI

The Pools panel shows all of the pools that are configured on this storage device. The number of pools

can be set to 1, 2, 4, or 8.

3.1.3.10 Ports

40

Page 47

User Guide

Figure 38: Ports Information (Network Settings)

3. Management

3.1 OCGUI

The Ports panel provides access to the networking settings for the ports that exist on the device.

3.1.3.11 Sensors

Figure 39: Sensors Information

The Sensors panel lists all of the sensors that are present on the device hardware and reports the status

readings that the sensors are taking.

3.1.3.12 Volumes

41

Page 48

User Guide

Figure 40: Volumes Configuration

The Volumes panel displays all of the volumes that have been configured on the device and allows for

volumes to be added, modified, or deleted.

3.1.3.13 Administration

3. Management

3.1 OCGUI

Figure 41: Administration

The Administration panel allows system administrators to perform important management functions to the

device.

3.1.3.14 Accounts

Figure 42: Account Information

3.1.4

The Accounts panel provides a list of all the accounts that can access this device.

Chassis Device Page

42

Page 49

User Guide

Figure 43: Chassis Device Page

3. Management

3.1 OCGUI

The chassis device page presents all of the vital information related to a specific chassis resource.

3.1.4.1 Chassis Device Health Panel

Figure 44: Device Health Panel

This Device Health Panel shows a visual summary of the general health of devices on the network.

3.1.4.2 Chassis Device Power Utilization

43

Page 50

User Guide

Figure 45: Chassis Device Power Utilization

The Power Utilization Panel gives a summary of the sensor data that is being reported by the power

supplies. Charts displays the current amps and volts being consumed by the system, as well as the

temperature.

3. Management

3.1 OCGUI

3.1.4.3 Chassis Device Performance

Figure 46: Chassis Device Cooling Performance

The cooling performance panel displays the current RPMs at which the onboard cooling fans are

operating.

3.1.4.4 Device Information

44

Page 51

User Guide

Figure 47: Chassis Device Information

3. Management

3.1 OCGUI

The Device Information panel provides information about the device itself, such as the ID and Serial

Number.

3.1.4.5 Operating System (Device Firmware)

Figure 48: Operating System (Device Firmware)

The Device OS panel displays the firmware version. Use this panel to upgrade firmware.

3.1.4.6 Fans

45

Page 52

User Guide

Figure 49: Chassis Fan Information

3. Management

3.1 OCGUI

The fans panel shows that status and health of all of the fans installed in the device.

3.1.4.7 Admin

Figure 50: Administration Panel

The Administration panel provides access to maintence and system administration functions.

3.1.4.8 Accounts

46

Page 53

User Guide

Figure 51: Account Configuration

The Accounts panel provides a list of all the accounts that can access this device.

3.1.4.9 Location

Figure 52: Location Information

3. Management

3.1 OCGUI

The Location panel provides information regarding the physical location of the device.

3.1.4.10 Ports

47

Page 54

User Guide

Figure 53: Chassis Ports Configuration

The Ports panel provides access to the networking settings for the ports that exist on the device.

3.1.4.11 PSUs

Figure 54: Chassis Power Supplies Information

3. Management

3.1 OCGUI

The Power Supplies panel provides health and status information of the power supplies installed in the

device.

3.1.4.12 Slots

48

Page 55

User Guide

Figure 55: Chassis Slots Information

3. Management

3.1 OCGUI

The Slots panel gives information on the devices that are installed in each slot.

3.1.5

3.1.5.1 Navigating to a Device Using the OCGUI

Basic Operational Functions

For the OpenFlex F3100 and E3000 , the basic operational functions are the tasks needed to begin the

initial operation of the system, e.g. check system health, create a user account, etc.

This task provides instructions for using the OCGUI to navigate to a device's dashboard through any

other fabric-connected device.

The BMC's MAC address is listed on a label affixed to the module's side. This MAC address can be used

to determine the IP addresses assigned via DHCP to the OpenFlex™ E3000 chassis and the F3100 storage

devices contained within it.

49

Page 56

User Guide

Figure 56: BMC Module MAC Address Label

Step 1 : Open a browser and enter the IP address for any fabric-connected device into the address

3. Management

3.1 OCGUI

bar.

The login page for the device appears.

Step 2 : Enter a valid username and password, and click the Login button.

The device's dashboard appears. In addition, the Devices banner provides access to all

other fabric-connected devices.

50

Page 57

User Guide

3. Management

3.1 OCGUI

Step 3 : Click the Devices banner to view a list of all connected devices:

Step 4 :

Step 5 : Click the Device Actions icon:

Step 6 : Click the Open in a new tab/window option to open the device page in a new window. This

Locate the new device in the list.

will keep the existing dashboard live in the current window.

The new device's dashboard appears.

3.1.5.2 Checking System Health Using the OCGUI

This task provides steps that should be followed to check the health of the system and system

components using the OCGUI.

This health check will cover the following:

51

Page 58

User Guide

• Device Information

• Device Logs

• PSUs

• Fans

• Ports

• Sensors

• Slots

Step 1 : Enter a valid username and password, and click the Login button:

3. Management

3.1 OCGUI

Note: The default username/password is admin/admin.

The system dashboard appears:

52

Page 59

User Guide

Step 2 : Click the Devices banner to view a list of all connected devices:

3. Management

3.1 OCGUI

Step 3 :

Step 4 : Click the Device Actions icon:

Step 5 : Click the Open in a new tab/window option to open the device page in a new window. This

Step 6 : Click the Device Information icon:

Step 7 :

Step 8 : Click the Device Logs button:

Locate the system that will be checked for health status in the list.

will keep the existing dashboard live in the current window.

The new device's dashboard appears.

After clicking device information, the status of device will appear at the bottom of the GUI.

Review the health information related to the devices.

Step 9 : Select one of the logs by clicking the radio button next to an option in the Device Log Viewer.

The log can be exported by clicking export at the bottom of the viewer.

53

Page 60

User Guide

Step 10 : Click the Power Supplies icon:

3. Management

3.1 OCGUI

Step 11 : After clicking power supplies, the status of power supplies will appear at the bottom of the

GUI. Review the health information related to each of the power supplies.

Step 12 : Click the Fans icon:

Step 13 :

Step 14 : Click the Ports icon:

Step 15 :

Step 16 : Click the Sensors icon:

After clicking fans, the status of fans will appear at the bottom of the GUI. Review the health

information related to each of the fans. If there is an issue reported on a fan, the physical LED

may be turned on by clicking the Locator LED next to the fan health column.

After clicking ports, the status of ports will appear at the bottom of the GUI. Review the health

information related to each of the ports.

54

Page 61

User Guide

Step 17 : After clicking sensors, the status of sensor will appear at the bottom of the GUI. Review the

Step 18 : Click the Slots icon:

3. Management

3.1 OCGUI

health information related to each of the sensors. Each of the sensors reports a current reading

related to temperature, volts, or amps.

Step 19 :

After clicking slots, the health status of the slot the will appear above the top right corner of

the device table.

3.1.5.3 Establishing a Location Using the OCGUI

Step 1 : Enter a valid username and password, and click the Login button:

Note: The default username/password is admin/admin.

The system dashboard appears:

55

Page 62

User Guide

3. Management

3.1 OCGUI

Step 2 : Click the Devices banner to view a list of all connected devices:

Step 3 : Click the Device Actions icon:

Step 4 : Click the Open in a new tab/window option to open the device page in a new window. This

will keep the existing dashboard live in the current window.

The new device's dashboard appears.

Step 5 : Click the Location icon:

56

Page 63

User Guide

Step 6 : After clicking location, the location information related to the device will appear at the bottom

3. Management

3.1 OCGUI

of the GUI. Each attribute can be assigned a value by clicking the pencil button and adding

text to the field and clicking the check mark to save the value. Complete all of the values that

apply.

3.1.5.4 Editing Port Information Using the OCGUI

This task provides instructions for editing the port information of a device using the OCGUI.

Step 1 : Navigate to the device's dashboard.

Step 2 : Click the Ports icon:

The device's port information appears:

57

Page 64

User Guide

3. Management

3.1 OCGUI

Step 3 : Click on the Pencil icon to edit the port information for a device on the list.

The first Update Port: management window appears.

58

Page 65

User Guide

3. Management

3.1 OCGUI

Step 4 : Edit the port information for the device and click the Next button.

The second Update Port: management window appears.

59

Page 66

User Guide

3. Management

3.1 OCGUI

Step 5 : Select the checkbox to confirm the edits.

60

Page 67

User Guide

3. Management

3.1 OCGUI

Step 6 : Click the Update button to save the updates.

3.1.5.5 Creating Accounts Using the OCGUI

This task provides instructions for creating a user account for a device using the OCGUI.

Step 1 : Navigate to the device's dashboard.

Step 2 : Click the Accounts icon:

The device's account information appears:

61

Page 68

User Guide

Step 3 : Click the Create Accounts button:

3. Management

3.1 OCGUI

The Create Accounts window appears:

62

Page 69

User Guide

Step 4 : Enter an ID in the User ID field and a password in both the Password and Confirmation fileds.

3. Management

3.1 OCGUI

Step 5 : Click the Create button to create the account.

Step 6 : Click Close to close the Create Accounts window.

The device's account information appears, showing the newly created account.

63

Page 70

User Guide

3.1.5.6 Creating a Secure HTTPS Connection Using the OCGUI

The OCGUI provides a feature for uploading a customer-generated SSL/TLS certificate and key, based on

the IP address and/or DNS name, to create a fully-secure HTTPS connection to a device.

Step 1 :

Step 2 : Click the Administration icon:

Navigate to the device's dashboard.

3. Management

3.1 OCGUI

The device's administration information appears:

Step 3 : Click the Certificate & Key Upload button:

The TLS Certificate & Key Pair window appears:

64

Page 71

User Guide

3. Management

3.1 OCGUI

Step 4 : Click the Select File button:

Step 5 : Navigate to the location of the appropriate PEM files for the Certificate File and Key File fields.

Note: The files are not validated. It is up to the user to ensure that the correct

file is chosen for the appropriate field. If the chosen files are not valid, the

OCGUI will reuse the defaults already on the system.

65

Page 72

User Guide

3. Management

3.1 OCGUI

Step 6 : Click the Next button:

The TLS Certificate & Key Pair confirmation window appears:

66

Page 73

User Guide

3. Management

3.1 OCGUI

Step 7 : Confirm that the correct files are listed for Certificate and Key. If so, select the Please Confirm

checkbox and click the Upload Certificate & Key button.

The TLS Certificate & Key Pair confirmation window closes, and the device's dashboard

appears.

Step 8 : Click the Device Info icon:

Step 9 : Click the Device Logs button:

Step 10 : Confirm that the chosen certificate file is one of the selectable options listed in the Device Log

Viewer window.

67

Page 74

User Guide

3. Management

3.1 OCGUI

3.1.5.7 Configuring a Host Using the OCGUI

This task provides instructions for configuring a host using the OCGUI.

Step 1 : Navigate to the device's dashboard (see Navigating to a Device Using the OCGUI (page

49)).

Step 2 : Click the Hosts icon:

The storage device's Hosts page appears:

68

Page 75

User Guide

Step 3 : Click the Create Hosts button:

3. Management

3.1 OCGUI

The Create Hosts dialog box appears:

Step 4 :

Step 5 : Click the Next button:

In the Host Name and Description fields, type a name and description for the host.

The Confirmation step of the Create Hosts dialog appears:

69

Page 76

User Guide

3. Management

3.1 OCGUI

Step 6 : Click the checkbox next to Please Confirm, and then click the Create button:

The newly created host will appear in the list on the device's Hosts page.

3.1.5.8 Configuring a Path Using the OCGUI

This task provides instructions for configuring a Path between a Host and Volume using the OCGUI.

Note: A Path is a dedicated line of communications between a Host and a Volume, which

cannot be established until both the Host and Volume have been created.

Note: The following instructions define how to create a Path to a Host through the device's

Volumes page. That same path may also be created from the other direction—to a Volume

through the device's Hosts page.

Step 1 :

Step 2 : Click the Volumes icon:

Navigate to the device's dashboard (see Navigating to a Device Using the OCGUI (page

49)).

70

Page 77

User Guide

3. Management

3.1 OCGUI

The storage device's Volumes page appears:

Step 3 : From the list of available volumes, identify the one that will used to create the path.

If that volume has been configured to allow any host, a dedicated path cannot be

established between it and a specific host. If this is the case, it will be indicated by the

following:

The Allow Any Host setting will be toggled to the ON (enabled) position:

•

• The path arrows beside the Pool ID will be grayed-out, and when the user hovers over

them, the tooltip will indicate that any host is allowed:

Step 4 : Disable the Allow Any Host setting for that volume by clicking the on/off toggle switch:

The path arrows beside the Pool ID will turn black, and when the user hovers over them,

the tooltip will indicate that path management is now available: