Page 1

INSTRUCTION MANUAL

Model

75

Arbitrary

Waveform Generator

0

1986

Wavetek

This document contains information

proprietary to

Wavetek and is provided solely for instrument

operation and maintenance. The information in this

document may not be duplicated in any manner without the prior approval in writing from Wavetek.

WAVETEIQ

WAVETEK SAN DIEGO, INC.

9045

Balboa Ave.. San Diego, CA

92123

P.

0.

Box

85265.

San Diego. CA

921 38

Tel

61 912792200

TWX

91 013352007

Manual Revision

2/89

Manual Part Number:

1300-00-0366

Scans

by

ArtekMedia

O

2006

Page 2

Scans

BY

Artek

Media

Artek

Media

1042

Plummer

Cir.SW

Rochester,

MN

55902

www

.artekmedia

.co

m

"High

resolution

scans

of

obsolete

technical

manuals"

if

your

looking

foraquality

scanned

technical

manual

in

PDF

format please

visit

our

WEB

site

at

www

.artekmedia

.co

m

or

drop

us

an

email

at

manuals

@

artekme

dia

.co

m

and

we

will

be

happy

to

email

you

a

current

list

of the

manuals

we

have

available

.

If

you

don't

see

the

manualyou

need

on

the

list

drop

us

a

line

anyway

we

may

stillbeable

to

point

you

to

other

sources.If

you

have an

existing

manual

you

would

like

scanned

please

write

for

details,

This

can

often

be

done

very

reasonablyinconsideration

for

adding

your

manual

to

our

library

.

Typically

the

scans

in

our

manuals

are

done

as

follows

;

1)

Typed

text

pages

are

typically

scanned

in

black

and

white

at

300

dpi

.

2)

Photo

pages

are

typically

scanned

in

gray

scale

mode

at

600

dpi

3)

Schematic

diagram

pages

are

typically

scanned

in

black

and

white

at

600

dpi

unless

the

original

manual

had

colored

high

lighting

(asisthe

case

for

some

70's

vintage

Tektronix

manuals)

.

if

you

purchased

this

manual

from

us

(typically

through

our

Ebay

name

of

ArtekMedia)

thank

you

very

much

.Ifyou

received

this

from

a

well-meaning

"friend"

for

free

we

would

appreciate

your

treating

this

much

like

you

would

"share

ware".By

that

we

mean

a

donation

of at

least

$5-10

per

manual

is

appreciated

in

recognition

of

the time

(a

manualcan

take as

much

as40hours

to

reproduce,

book,

link

etc

.),

energy

and

qualityofeffort

that

went

into

preserving

this

manual

.

Donations

via

PayPal

goto:

manmanuals@artekmedia

.co

m

or

can

be

mailedtous

the

address

above

.

Dave&Lynn

Henderson

Artek

Media

Page 3

CONTENTS

SECTION

1

GENERAL DESCRIPTION

1.1 MODEL 75

.................................................

1-1

........................................

1.2 WAVEFORM EDITING 1-1

.......................................

1.2.1 Standard Waveforms 1-1

......................................

1.2.2 Rubber Band Editing 1-1

............................

1.2.3 Digital Amplitude and Digital Offset 1-1

1.2.4 Point Edit

................................................

1-1

......................................

1.3 STANDARD FEATURES 1-1

........................

1.3.1 81 92 x 4095 Point Waveform Resolution 1-1

................................

1.3.2 Crystal Controlled Frequency 1-1

..........................................

1.3.3 Operating Modes 1-1

..................................

1.3.4 Internal Waveform Counter 1-1

1.3.5 Hold Function

.............................................

1-1

...........................................

1.3.6 Return Function 1-2

.........................................

1.3.7 Stored Waveforms 1-2

...............................

1.3.8 Non-Volatile Instrument Set-Up 1-2

...........................................

1.3.9 Series Operation 1-2

.........................................

1.3.1 0 Parallel Operation 1-2

...................................

1.3.1 1 Communications Options 1-2

...........................................

1.4 SPECIFICATIONS 1-2

.......................................

1.4.1 Standard Waveforms 1-2

..........................................

1.4.2 Operational Mode 1-2

.......................................

1.4.3 Waveform Resolution 1-2

..............................................

1.4.4 Sample Rate 1-2

............................................

1.4.5 Output Signals 1-3

......................................

1.4.6 Output Characteristics 1-3

...................................................

1.4.7 Inputs 1-3

1.4.8 Trigger Sources

...........................................

1-3

..............................

1.4.9 Communication Ports (Optional) 1-4

................................................

1.4.10 General 1-4

1.4.11 Options

.................................................

1-4

SECTION

2

INITIAL PREPARATION

....................................

2.1 UNPACKING INSPECTION 2-1

..................................

2.2 ELECTRICAL INSTALLATION 2-1

.........................................

2.2.1 Power Connection 2-1

...................................

2.2.2 Verifying the Line Voltage 2-1

..................................

2.2.3 Fuse and Voltage Selection 2-2

.......................................

2.2.4 Signal Connections 2-3

......................................

2.2.5 Interface Connections 2-3

.............................................

2.2.6 GPlB Address 2-4

......................

2.2.7

RS-232

Baud Rate and DTElDCE Selection 2-4

..............................

2.2.8 Connecting the RS-232 Interface 2-5

..............................

2.3 INITIAL CHECKOUT PROCEDURE 2-7

Scans

by

Artekhledia

O

2006

Page 4

CONTENTS (Continued)

SECTION

3

OPERATION

...

......

3.1 INTRODUCTION

.........

...........

3-1

....

3.2 CONTROLS, CONNECTORS. AND INDICATORS

..........

3-1

.................................

3.3 OPERATION

......

3-7

.......

3.4 INITIAL SETUP

......

................... 3-7

................................

3.5 EDITING WAVEFORMS 3-7

...........................

3.6 THUMBTACKS AND CURSOR 3-8

...........................

3.7 RUBBER BAND EDITING 3-8

3.8 INSERTING STANDARD WAVEFORMS

................ 3-8

3.9 DIGITAL AMPLITUDE

...............................

.

.

3-8

......

.........

3.1 0 NORMALIZING

......

. 3-8

.....

3.11 DIGITAL OFFSET

.............................

3-8

........................................

3.1 2 POINT EDITING 3-8

.............................

3.1 3 START AND STOP ADDRESSES 3-11

............................

3.1 4 WAVEFORM PARAMETERS 3-11

............

3.1 4.1 Waveform Frequency, Period, and Sample Freq 3-11

3.1 4.2 External Reference

................................

3-12

3.1 4.3 Waveform Amplitude

..........................

...

3-12

............................

3.1 4.4 Waveform Offset

...

3-12

................................

3.1 5 OPERATIONAL MODES 3-12

3.1 5.1 Continuous Mode

...............................

. .

3-12

......................................

3.1 5.2 Triggered Mode 3-12

3.15.3 Gated Mode

.............................

........ 3-12

.........................................

3.1 5.4 Toggled Mode 3-12

.....

3.15.5 Burst Mode

.......................

. .

3-1 3

....

3.16 SETTING AND CLEARING BREAK POINTS

...........

3-13

.............................

3.1 7 SYNC ADDRESS AND PHASE 3-13

......

3.1 8 STORllVG AND RECALLING WAVEFORMS

.......

3-13

3.19 CHAINED OPERATION

...............................

3-13

................................

3.20 WAVEFORM COUNTER 3-13

..................................

3.21 WAVEFORM HOLD 3-13

....................................

3.22 RETURN TO START 3-13

................................

3.23 LOW BATTERY INDICATOR 3-14

3.24 SERIES OPERATION

...............................

. 3-14

3.25 PARALLEL OPERATION

....................

...

3-14

.....................

3.26 GPlB CONTROLS (Option 001 Only) 3-15

...........................

3.26.1 GPlB Address DIP Switches 3-15

.........................................

3.26.2 Setup Menu Key 3-15

.........................................

3.26.3 BLIFFR Soft Key 3-15

........................................

3.26.4 ADRS Soft Key 3-15

.....................................

3.26.5 LOCAL Soft Key 3-15

.........................................

3.26.6 Control Knob 3-15

.................

3.27 GENERAL PLIRPOSE INTERFACE BUS (GPIB) 3-16

.................................

3.27.1 Bus Line Definitions 3-17

...................................

3.27.2 Handshake Sequence 3-18

..........................................

3.27.3 Commands 3-18

........................................

3.27.4 Listen Address 3-18

............................................

3.27.5 Talk Address 3-18

....................

.....

...

3.27.6 Secondary Address

..

..

3-18

....................................

3.27.7 Universal Commands 3-18

Scans

by

ArtekMedia

O

2006

Page 5

CONTENTS (Continued)

3.27.8 Addressed Commands

..................................

3-19

3.27.9 Data Transfer

.......................................

3-19

3.28 MODEL 75

GPlB PROGRAMMIIVG

.......................

3-19

3.28.1 General Programming Information

..................

3-19

3.28.2 Characters

.....................................

. . 3-19

3.28.3 Action and Parameter Commands

...............

...

3-20

3.28.4 Action Commands

.....................

.......

3-20

.....

3.28.5 Programming Parameters

......................

3-20

3.28.6 Sending Waveforms to the Model 75

.......

...........

3-20

3.28.7 High Speed Binary Waveform Transfer

.........

3-21

...

3.28.8 Reading Waveforms From the Model 75

...

3-21

..............................

3.28.9 Programming Reference Guide 3-21

...........

3.29 ERRORS - GPlB REPORTING

...........

3-26

............................................

3.29.1 Class 1 Errors 3-26

.........................................

3.29.2 Class 2 Errors 3-27

......................................

3.29.3 Class 3 Errors 3-27

3.30 RS-2326 CONTROLS

.....

. .

.

.

3-27

....

3.30.1 Setup Menu Key 3-27

3.30.2 BUFFR Soft Key

. . .

. 3-28

....................................

3.30.3 LOCAL Soft Key 3-28

...

3.30.4 HAND Soft Key

.

. . .

3-28

..................................

3.30.5 Control Knob 3-28

.........................................

3.30.6 Baud Rate Switch 3-28

...

......

3.31 GENERAL RS-2326 INFORMATION

.....

3-28

......

3.31.1 Characters

......

...

.

. 3-29

.........

3.31.2 RS-2326 Terminators ..... 3-29

............................

3.31.3 Action and Parameter Commands 3-30

.....

3.31.4 Action Commands

. .

.......

.

. 3-30

...

....

3.31.5 Programming Parameters

...........

3-30

.........................

3.31.6 Sending Waveforms to the Model 75 3-31

3.31.7 Reading Waveforms from the Model 75

.....................

3-31

3.31.8 Programming Reference Guide

...........................

3-31

...

3.32 ERRORS - RS-232-C

REPORTING

....................

3-31

3.32.1 Class 1 Errors

........................................

3-31

....

3.32.2 Class 2 Errors

....

3-32

3.32.3 Class 3 Errors

. .....

.....................

3-32

SECTION

4

CIRCUIT DESCRIPTION

4 1 INTRODUCTION 4-1

4 2 DETAILED CIRCUIT DESCRIPTION 4-1

4 2 1

S~gnal Path 4-1

4 2 2

T~m~ng And Tr~gger~ng 4-9

4 2 3 Instrument Control 4-1 2

4 2 4

Commun~cat~on Optlons 4-1 8

4 2 5 Power Supply 4-1 9

Scans

by

ArtekMedia

O

2006

Page 6

CONTENTS (Continued)

SECTION

5

CALIBRATION

SCOPE

................................

5-1

...........

..........................

FACTORY REPAIR

....

..... 5-1

REQUIRED TEST EQUIPMENT

... .................. 5-1

CALIBRATION

.

.

......

........

..............

5-1

AMPLITUDE

..................... ...........

5-3

OFFSET

....................................

......

5-4

FREQUENCY

..................................

....

5-5

OUTPUT WAVEFORM

RISE AND FALL TIME

.................

5-6

................

SUM IN

........................

5-7

SECTION

6

TROUBLESHOOTING

6.1 FACTORY REPAIR

................................... 6-1

6.2 BEFORE YOU START

..................................

6-1

6.2.1 Isolating a Problem

......................................

6-1

6.2.2 Troubleshooting Dynamic Digital Circuits

....................

6-3

6.3 TROUBLESHOOTING GUIDES

............................... 6-3

6.3.1 Power Supply

...........................................

6-3

6.3.2 Microprocessor and Main Memory

.........................

6-16

6.4 TROUBLESHOOTING

l NDlVlDUAL COMPONENTS

.................

6-20

6.4.1 Transistor

..........................................

3-20

6.4.2 Diode

............................................

6-20

6.4.3 Operational Amplifier

...............................

6-23

6.4.4 Field Effect Transistor (FET)

..............................

6-20

................................

6.4.5 Capacitor

....

6-20

6.4.6 Logic Levels

........................................

6-20

SECTION

7

PARTS LIST AND SCHEMATICS

7.1 DRAWINGS

.......................................

7-1

.............................................

7.2 ERRATA 7-1

7.3 ORDERING PARTS

.................................

7-1

APPENDIX

APPENDIX A AMERICAN STANDARD CODE FOR INFORMATION INTERCHANGE

(ASCII)

.................................................. A-1

APPENDIX B MODEL 75 QUICK REFERENCE GUIDE

.............................

B-1

Scans

by

ArtekMedia

O

2006

Page 7

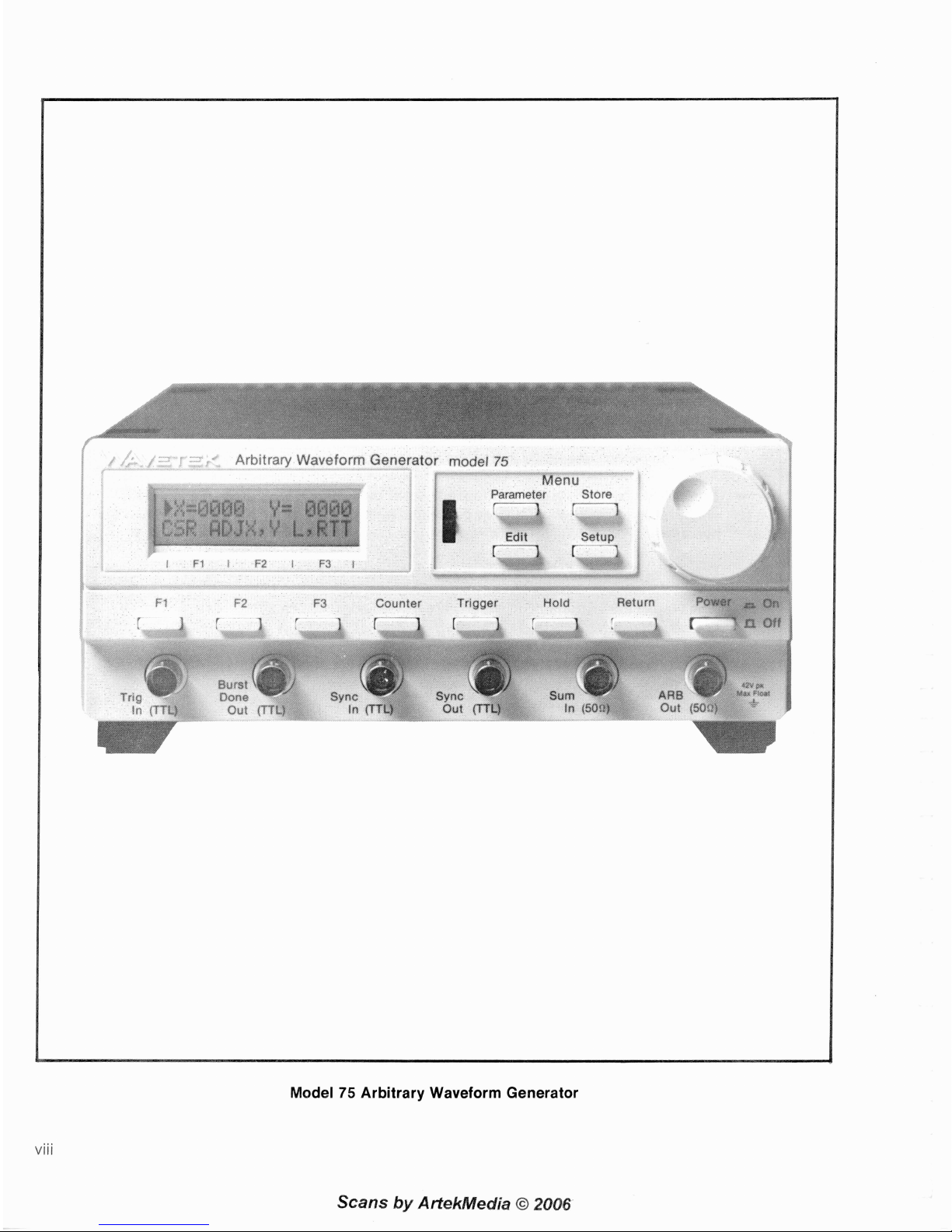

viii

Model

75

Arbitrary Waveform Generator

Scans

by

ArtekMedia

O

2006

Page 8

GENERAL DESCRIPTION

1.1 MODEL 75

The Model 75 is a versatile, yet easy to use arbitrary

waveform generator. It contains advanced waveform

editing features that allow the user to easily create and

edit complex waveforms.

1.2 WAVEFORM EDITING

The editing featuresare based on a pair of points called

"thumbtacks". These thumbtacks are placed at each

end of the portion of the waveform to be edited, then the

appropriate editing feature is invoked. The thumbtacks

will appear as bright dots on an oscilloscope using Z-axis

modulation.

1.2.1 Standard Waveforms

Standard waveforms are inserted between the thumbtacks. Astandard waveform can be the entire waveform

or only part of it. The standard waveforms are sine,

cosine, inverse sine, haversine (inverse cosine), triangle,

square, ramp up, ramp down, and dc. These standard

waveforms can then be edited using the other editing

features if desired.

1.2.2 Rubber Band Editing

Rubber band editing is analogous tostretching a rubber

band between two thumbtacks. A cursor is placed

between the thumbtacks which can be moved in either

theXor they direction.The waveform is then stretched

from each thumbtack to the cursor in real time.

1.2.3 Digital Amplitude and Digital Offset

The sectionof the waveform that is between the thumbtacks can beadjusted in amplitude and offset in real time

without affecting the rest of the waveform.

1.2.4 Point Edit

Individual points of the waveform can also be adjusted

in real time.

1.3 STANDARD FEATURES

1.3.1 81 92 x 4095 Point Waveform Resolution

The waveforms have a vertical resolution of 4095 points

and a horizontal resolution adjustable from 2 to 8192

points. The waveform memory is broken up into four

blocks of 2048 horizontal points. This can be used as one

waveform of up to 8192 points or as four different

waveforms (one active and three stored) of up to 2048

points each.

1.3.2 Crystal Controlled Frequency

The waveform clock (sample frequency) is crystal con-

trolled and adjustable from 20

mHz to 2 MHz (500 ns to

50s), allowing a waveform periodof 1 ps to 11 3.8 hours.

The frequency is adjustable as either waveform frequency, waveform period, or sample frequency. An

external

TTL

level clock of up to 2 MHz can also be used

as the waveform clock (sample freq).

1.3.3 Operating Modes

The Model 75 can operate in continuous, triggered,

gated, toggled, or burst modes. All modes except continuous are initiated (triggered) by either a front panel

pushbutton or an external signal. In these modes the

waveform stops at break points which can be inserted

anywhere in the waveform (by default one breakpoint will

be at the start address), then waits for another trigger.

In burst mode, a predetermined number of waveforms

(from

1

to 1,048,575) is generated before stopping.

1.3.4 Internal Waveform Counter

In gated, toggled, and burst modes an internal counter

can be used to display the number of complete

waveforms since the last trigger. This is particularly

useful for monitoring a burst of waveforms or counting

the number of waveforms for fatigue testing.

1.3.5 Hold Function

A front panel pushbutton or external signal will cause

the waveform to stop at the current output level and

remain there until the hold is released.

Scans

by

ArtekMedia

O

2006

Page 9

1.3.6 Return Function

A front panel pushbutton or external signal will cause

the output to ramp back to the start value. The rate of

this ramp is adjustable from

0 (instant return tostart) to

100 ms per vertical point.

1.3.7 Stored Waveforms

Three additional waveforms may be stored (with their

parameter settings) in waveform memory. These may

later be recalled into, or exchanged with the active

waveform. This feature is only available with horizontal

resolutions of 2048 points or less.

1.3.8 Nonvolatile Instrument Setup

The complete instrument setup is stored in battery

backed up memory so that it will not have to be reset

after the power has been turned off.

1.3.9 Series Operation

Several Model 75's can be connected in series, each one

producing a burst of waveforms, with their outputs

summed together (using the "sum in" connector). This

can be used to produce long waveforms or unusual

sequences such as 50 "normal" waveforms and then

1 "abnormal" waveform.

1.3.1 0 Parallel Operation

Several Model 75's can be connected in parallel to create

phase coherent arbitrary waveforms. The phase relationship is completely adjustable with a resolution equal to

the horizontal resolution of the waveform. This feature

is useful in three axis mechanical testing and multi-phase

power applications.

1.3.1 1 Communications Options

Either an IEEE-488or RS232Ccommunication interface

is available to transfer waveform data and control the

Model 75 from a computer.

1.4 SPECIFICATIONS

1.4.1 Standard Waveforms

DC, square, triangle, up-ramp, down-ramp, sine, cosine,

inverse sine, and haversine waveforms are provided.

Each of these waveforms can be stored into the

waveform memory between thumbtacks automatically,

and then edited with the waveform editing functions if

desired.

1.4.2 Operational Modes

Continuous

Output runs repetitively from the programmed start

address to the programmed stop address.

Triggered

Output quiescent until triggered by external signal or

front panel pushbutton, then runs until another break

point is encountered. Break points can be inserted

anywhere in the waveform with the default break point

at the beginning of the waveform.

Gated

Same as triggered mode except that the output is continuous for the duration of the gate signal and until the

first break point encountered after the gate signal ends.

Burst

Same as in the triggered mode except that a program-

mable number of waveforms is counted before the

waveforms stop. The maximum burst is 1,048,575

waveforms.

Toggled

The output is quiescent until triggered. It then runs continuously until another trigger stops the waveform at the

next break point.

1.4.3 Waveform Resolution

Normal Waveform

2048 points horizontal

x

4095 points vertical.

Chained Waveform

81 92 points horizontal

x

4095 points vertical. Stored

waveforms are not available with chained operation.

1.4.4 Sample Rate

Range

0.02 Hz to 2.0 MHz (50

s to 500 ns)

Waveform Period and Frequency

The actual waveform period is the number of horizontal

points (from start to stop address) times the sample time.

This can range from 1 microsecond for a square wave

to 11 3.8 hours for a waveform using all 81 92 points.

Frequency Resolution

4 digits

Frequency Accuracy

+

0.01 5

'10

Repeatability (24 Hr)

+

25 ppm

Temperature Coefficient

<5 ppml°C

Scans

by

Artekhledia

O

2006

Page 10

1.4.5

Output Signals Z-Axis Out

Amplitude

This signal is a pulse, adjustable in amplitude from 2 to

14 volts, that is used to modulate the Z-axis of an

Range:

+

0.005 to 5 Vp into 509 (0.01 to 10 VP-P into

oscilloscope when using the waveform editingfeatures.

509). + 0.01 to 1 OVp into an open circuit (0.02 to 20Vp-p

The logic polarity is also selectable.

into an open circuit).

Resolution: 3 digits.

Accuracy:

+

1.8% of setting and + 2.5 mVfor amplitude

1.4.7

Inputs

+

offset 20.5V.

k

1.8% of setting and ? 0.25 mV for 0.5V > amplitude

sum

In (509)

+

offset 250 mV.

The signal at this input is added to the arbitrary waveform

+

1.8% of setting and + 25 pV for 50 mV > amplitude

to produce an output (at waveform out)of the sum of the

+

offset.

two. A peak input of

+

5V w~ll produce an output equal

Repeatability (24 Hr):

k

0.1

O/O

of setting.

to the amplitude setting. Input is fuse protected.

Tem~erature Coefficient: 61 50 ppml°C of setting.

Accuracy is

4% (2% if internal fuse is shorted).

Offset

Trig In (TTL)

lm~edance is 100 KR. Sianal is used to control the

Range:

+

5~ to - 5V into 50R

(-

10V to + 1 OV into an

ge"erator in the trigger, gaie, toggle, and burst modes.

open circuit). Absolute amplitude

PIUS

offset may not

Slope polarity is selectable,

exceed + 5V into 50R

(+

10V into an open circuit).

Svnc In

(TTL)

Resolution: 3 digits.

lkpedanbe is 100 KR. A high input causes the waveform

Accuracy:

2% of setting and + 15 mV for amplitude

+

to restart at the start address. Primarily used for syn-

offset

20.5V.

chronizing several arbitrary waveform generators in

2% of setting and k 1.5 mVfor 0.5V>amplitude + off-

parallel operation.

set 250

mV.

Ref In (TTL)

2% of setting and + 0.1 5 mV for 50 mV > amplitude

+

Impedance is 100 KR. This signal input is used for the

offset.

sample clock when the external ref is selected.

Repeatability (24 Hr):

+

5 mV and + 0.1

O/O

of setting.

Temperature Coefficient:

6(+

1 mV + 150 ppm)l°C of

setting.

1.4.6

Outputs

ARB Out

(50R)

Source of primary waveform output.

Maximum

amplitude is

+

5 Vp into 50R. Output is fuse protected.

Sync Out

(TTL)

Will drive up to 10 LSTTL loads.This is a pulse 1 sample

time wide that is usually used to sync an oscilloscope

or another ARB generator. Pulse position is adjustable

to any point in the waveform.

Burst Done Out (TTL)

Will drive up to 10 LSTrL loads. ATTL low indicates that

the waveform is running. TTL high indicates that the

instrument is waiting for a trigger in triggered, gated,

toggle, or burst modes. Used primarily to start another

ARB generator in series operation.

Ref Out (TTL)

Will drive up to 10 LSTTL loads. This pulse train at the

sample frequency is used primarily as a reference

source for other ARB generators in series operation or

in parallel operation.

Hold In

Impedance is 100 KR. ATTL low or switch closure at this

input causes the generator to stop at the current output

level and remain there until released by a TTL high or

switch opening.

Return In

Impedance is 100 KR.

ATTLlowor switch closureat this

input causes the output level to ramp back to the start

value.

'The ramp rate is front panel selectable from 0 to

100 ms per point.

1.4.8

Trigger Sources

Manual

Use the Trigger pushbutton switch on front panel to

operate internal trigger circuitry. The slope polarity can

be set via the display menus.

External

Use the communication

ports(GPIB or RS-232C)or the

Trig In connector on front panel. Trig In connector frequency input can be up to 1 MHz. The slope polaritycan

be set via the display menus.

Scans

by

ArtekMedia O 2006

Page 11

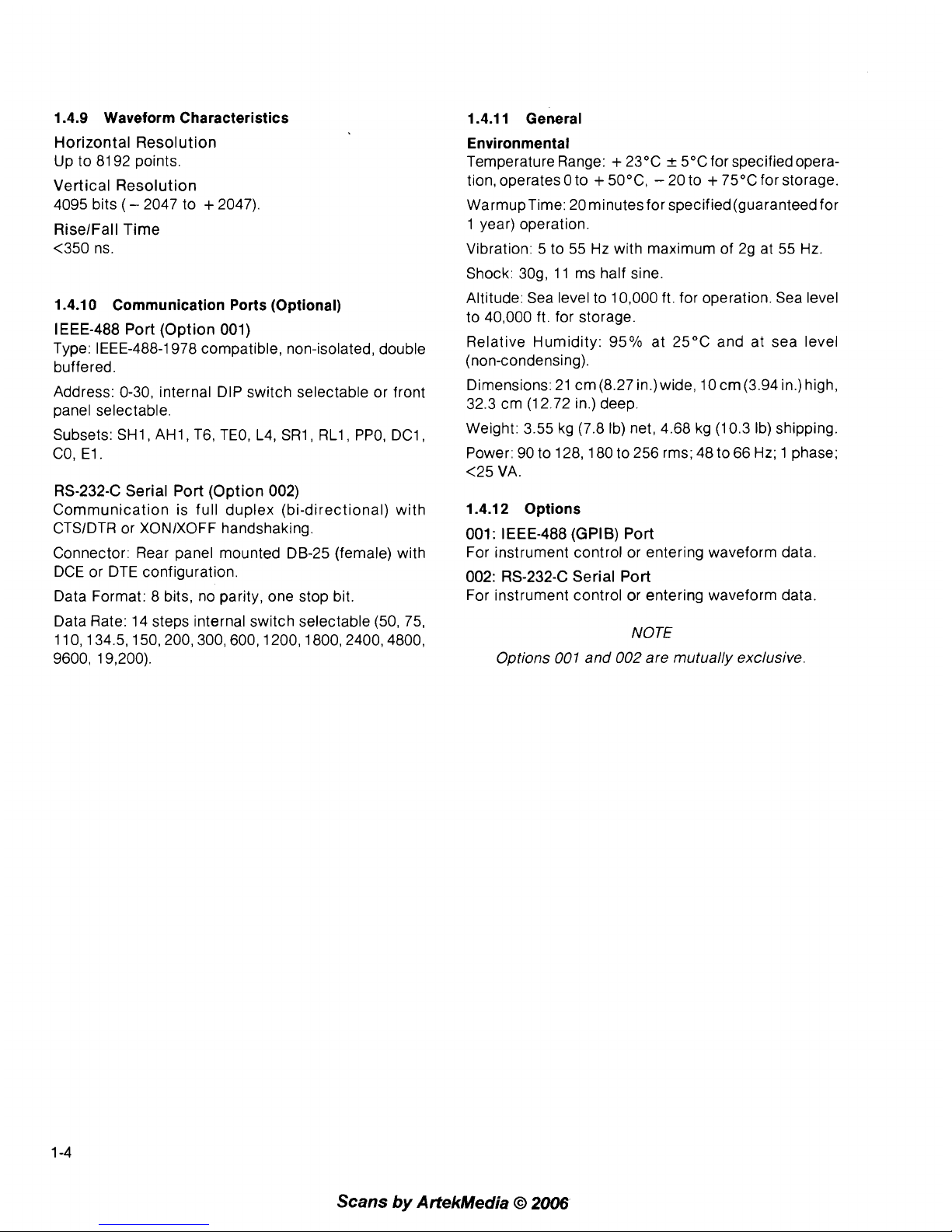

1.4.9 Waveform Characteristics

Horizontal Resolution

Up to 81 92 points.

Vertical Resolution

4095 bits

(

-

2047 to + 2047).

RiselFall Time

<350 ns.

1.4.10 Communication Ports (Optional)

IEEE-488 Port (Option 001)

Type:

IEEE-488-1978 compatible, non-isolated, double

buffered.

Address: 0-30, internal DIP switch selectable or front

panel selectable.

Subsets:

SHl, AHl, T6, TEO, L4, SRl, RLI, PPO, DCl,

CO. El.

RS-232-C Serial Port (Option 002)

Communication is full duplex

(bi-directional) with

CTSIDTR or XONIXOFF handshaking.

Connector: Rear panel mounted DB-25 (female) with

DCE or DTE configuration.

Data Format: 8 bits, no parity, one stop bit

Data Rate: 14 steps internal switch selectable (50, 75,

1

10,134.5,150,200,300,600,1200,1800,2400,4800,

9600, 19,200).

1.4.1 1 General

Environmental

Temperature Range: + 23°C + 5°C for specified operation, operates

0 to + 50°C, - 20 to + 75°C for storage.

WarmupTime: 20 minutes for specified(guaranteed for

1 year) operation.

Vibration: 5 to 55 Hz with maximum of

29 at 55 Hz.

Shock:

309, 11 ms half sine.

Altitude: Sea level to 10,000 ft. for operation. Sea level

to 40,000 ft. for storage.

Relative Humidity:

95% at 25°C and at sea level

(non-condensing).

Dimensions: 21 cm (8.27 in.) wide,

10 cm (3.94 in.) high,

32.3 cm (1 2.72 in.) deep.

Weight: 3.55 kg (7.8 Ib) net, 4.68 kg (1 0.3 Ib) shipping.

Power: 90 to 128,180 to 256 rms; 48 to 66 Hz; 1 phase;

<25 VA.

1.4.1 2 Options

001: IEEE-488 (GPIB) Port

For instrument control or entering waveform data.

002:

RS-232-C Serial Port

For instrument control or entering waveform data.

NOTE

Options

001

and

002

are mutually exclusive.

Scans

by

ArtekMedia

O

2006

Page 12

INITIAL PREPARATION

2.1 UNPACKING INSPECTION

After carefully unpacking the instrument, visually inspect

all external parts for possibledamage toconnectors, surface areas, etc. If damage is discovered, filea claim with

the carrier who transported the unit. The shipping container and packing material should be saved in case

reshipment is required.

2.2 ELECTRICAL INSTALLATION

2.2.1 Power Connection

WARNING

To preclude injury

ordeath due toshock, the

third wire earth ground must be continuous

to the facility power outlet. Before connect-

ing to the facility power outlet, examine

extension cords, autotransformers, etc.,

between the instrument and the facility power

outlet for acontinuous earth ground

path.The

earth ground path can be identified at the plug

on the instrument power cord; of three terminals, the earth ground terminal is the nonmatching shape, usually cylindrical.

CAUTION

To prevent damage to the instrument, check

for proper match of line and instrument

voltage and proper fuse type and rating.

Line Voltage

Refer to table 2-1 to determine the proper selection of

the line voltage connector. Unless otherwise specified

at the time of purchase, this instrument was shipped from

the factory with the power transformer connected for

operation on a

1 1

5

Vac line supply and with a 318 amp

fuse. If the unit is shipped for

11

5

Vac operation, there

will be no markings or tags on the unit. If the unit is

shipped for 220

Vac operation, there will be a 220 Vac

tag on the rear panel of the unit and a 3/16 amp fuse

installed.

2.2.2 Verifying the Line Voltage

To verify the line voltage (or change the fuse), the

operator must first remove the top and bottom covers.

Remove the top and bottom using the following steps and

figure 2-1.

1. Remove two (2) screws holding top and bottom

covers to rear panel.

2. Slide both covers (together as a unit) to the rear and

remove from the chassis assembly.

Figure 2-1. Top and Bottom Cover Removal

After the covers have been removed, the line voltage can

be checked by viewing the voltage label through the

inspection hole as shown in figure 2-2.

INSPECTION SLOT

GUARD PLATE

'

REAR PANEL

Figure 2-2. Line Voltage Inspection Hole

Scans

by

ArtekMedia

O

2006

Page 13

2.2.3 Fuse and Voltage Selection

If

the line voltage is not correct according to table 2-1,

perform the following steps and refer to figure 2-3 for

steps 1 and 2, and figure 2-4 for steps 3 thru 6

tochange

the line voltage and fuse.

1. Remove the two screws holding guard plate to the

rear panel.

2. Remove the guard plate from the rear panel.

GUARD

PLATE

SCREWS

/

VOLTAGE

SELECTOR

CONNECTOR

F

U

AC

PRIMARY

-

VOLTAGE

SELECTOR

Figure 2-3. Guard Plate Removal

Figure 2-4. Fuse and Voltage Selection

3. Remove the voltage selector connector from the ac

primary board. Rotate the connector until the correct voltage selector indicator is on top.

4. Reinstall the voltage selector connector.

5. Remove the fuse and install new fuse as called out

in table

2-1.

Connector Voltage

Position Range

90

to 128 Vac 318 amp

Table 2-1. VoltagelFuse Selection

220V

WARNING

Because lethal voltages are exposed, do

not apply ac power to the unit until the

guard plate is attached to the unit.

Reassembly

Refer to figure 2-5 for step 1 and figure 2-6 for steps 2

thru 5.

1. Insert the guard plate over the ac primary board and

voltage selector connector and align with screw

holes in the rear panel. Secure with two screws.

180

to

256 Vac

BOARD

311 6 amp

Figure 2-5. Rear Chassis Assembly

Scans

by

ArtekMedia

63

2006

Page 14

Figure

2-6.

Top and Bottom Cover Installation

2. Turn the instrument upside down, position the

bottom cover over the guard shield and rear panel.

Slide the bottom cover forward approximately two

(2) inches while engaging the

topcover shield slides

(see figure 2-6, detail A) and the outside slide rails

(see figure 2-6, detail B).

3.

Turn the instrument right side up. Install the topcover

using the same procedure as in step

2.

4. Align the rear of both the topand bottom cover with

each each other so that the cover interlocks are

properly mated. Once mated, hold the covers firmly

together and slide the chassis assembly into top and

bottom covers.

CAUTION

When sliding on the bottom cover, avoid

moving the ribbon cables located

nearthe

power transformer.

5. Secure covers to unit using two screws as shown

in figure 2-1

.

2.2.4

Signal Connections

Use RG58U 509 coaxial cables equipped with BNC connectors to distribute signals when connecting this instrument to associated equipment.

NOTE

Signal ground may be floated up to

_t

42V

with respect to chassisground. Bea ware that

all signal grounds are common and must all

be floated together.

2.2.5

Interface Connections

The GPlB (Option 001) 110 rear panel connector is an

Amphenol 57-10240 or equivalent and connects to a

GPlB bus cable connector (available from Wavetek in

1 and 2 meter lengths).

NOTE

The terms

"GP1B"and "IEEE-488"are used

synonymously in this manual.

Scans

by

Artekhledia

O

2006

Page 15

2.2.6 GPlB Address

For Option 001 instruments on the General Purpose

Interface Bus (GPIB), ensure that the instrument GPlB

address is correct. The GPlB default address can be

changed by resetting the internal DIP switch (for access,

remove the top cover, see paragraphs 2.2.2 and 2.2.3)

or changed temporarily by pressing the front panel ADRS

soft key and rotating the Control knob when the GPlB

address is displayed.

The switch sections are labeled from 1 thru 5 and their

OPEN position noted (OPEN

=

Binary "0" in table 2-2).

To verify the address, press ADRS soft key on the front

panel.

Table 2-2. GPlB Address Code

Device / Listen I Talk

1

1

2

3

4 5

Listen

1

Talk

2.2.7 The RS-2324 Connectors

The RS-232C 110 rear panel pin connections and signal

names are given in table

2-3. The panel connector is a

DB-25 female connector (see figure 2-7) and will connect to a standard

RS-232C cable (interface type

E).

The data format is an 8-bit, no parity, one stop bit. The

baud rate is selectable from those listed in table 2-5 using

dip switch

S1 (figure 2-8).

Table 2-3. RS-232-C Data InlOut

40

4

1

42

(Remaining Pins Not Connected)

43

'Transmit Data

'Receive Data

3~equest to Send

4~lear to Send

'Data Set Ready

'Receive Line Signal Detect

7~ata Terminal Ready

Pin

2

3

4

5

6

7

8

20

-

/

RS-232-C Connector

Name

TXD'

RXD~

RTS3

CTS~

DSR5

SIG GRD

RLSD'

DTR~

Direction (DCE

Configuration)

IN

OUT

N IC

OUT

OUT

-

OUT

IN

Z-AXIS

out

I60011

1

Ref Ref

Hold

In

Out

In

In

ITTLI ITTL) lTTLl ITTLI

Direction (DTE

Configuration)

OUT

IN

OUT

IN

IN

-

IN

OUT

nnnnnnnnn

Figure 2-7. RS-232-C Connector Pinouts

NOTE:

Address

31

is

not allowed

Scans

by

ArtekMedia

O

2006

Page 16

The following is a description of pin functions. Actual

installation is covered in paragraph 2.2.8.

In the DCE configuration, pins 2 and 3 are data input and

output respectively and must be used. Pin 5 may be used

to indicate that the Model 75 is ready to receive data.

Pin 20 tells the Model 75 that the connected device is

ready to receive data, but may be connected to pin 6 of

the Model 75 if the other device is always ready. Pin 7

is signal ground and must be used. Pins 6 and 8 will be

positive (asserted) when the Model 75 is on.

In the DTE configuration, pins 2 and 3 are data output

and input respectively and must be used. Pin 4 will be

positive whenever the Model 75 is On. Pin 5 tells the

Model 75 that the connected device is ready to receive

data.

If

the other device is always ready, pins 4 and 5

of the Model 75 may be connected together. Pins 6 and

8 are properly terminated inputs but have no function.

Pin

20

will be positive when the Model 75 is ready to

receive data. Pin 7 is signal ground and must be used.

1. Determine if the other device is a DCE device or a

DTE device. If this is not explicitly spelled out you

will need to look at the pin out for its connector. If

pin 2 is the data output, the device is a DTE (most

computers). If pin 3 is the data output, the device

is a DCE (most modems). Configure the Model 75

as the opposite type of device by connecting the

internal optioncable to theappropriate

header(see

figure 2-8).

In most cases a straight through cable can be used

to connect the Model 75 with the other device. The

Model 75 only requires the connection of pins 2, 3,

5,7, and 20 but the other device may require more.

Examples of typical cable assemblies are shown in

figure

2-9. However, there are many interpretations

of the

RS-232Cstandard and either of the following

procedures (a or b) should be used to ensure that

the control and handshake signals are properly

connected.

The handshaking method is front panel selectable as

a. If the Model 75 is configured as a DCE then;

CTSIDTR (hardware) or XONIXOFF (see paragraph 3-32

for more information).

(1) Pin 7 (signal ground) is always connected

straight through.

2.2.8 Connecting the RS-232-C Interface

Before connecting the Model 75 using the RS-232C

interface, the correct configuration (DCE or DTE) must

be selected and the internal ribbon cable connected to

either the DCE or DTE location (see figure 2-8) on the

RS-232-C option board. To determine which configuration is correct, you will need the manual for the device

to which you are connecting the Model 75. The following assumes that the other device has a DB-25,

RS-232-C connector.

DCE

HEADER

Figure 2-8. Baud Rate Switch and DTElDCE

Connections

(2) Pins 2 and 3 are connected straight through

if

DCEIDTE configuration is correct.

(3) Pin 5 of the Model 75 will need to be con-

nected to an input of the other device that

will enable and disable the character

transmission from that device. If the other

device does not support this, XONIXOFF

handshaking will be required and pin 5 can

be left disconnected.

(4) Pin 20 of the Model 75 should be connected

to an output pin on the other device that

indicates when it is ready to accept data.

If the other device does not have such a pin

but is not always ready, it can send

XOFFs

and XONs to indicate readiness. When

using this method, or if the other device is

always ready

toaccept data, this pin can be

connected to an always positive pin on the

other

deviceor topin 60r 8on the Model 75.

(5) Pins 6 and 8 are always positive when the

power is on and can be connected to any

pins on the other device that require being

held positive.

b. If the Model 75 is configured as a DTE then;

(1) Pin 7 (signal ground) is always connected

straight through.

(2) Pins 2 and 3 are connected straight through

if

DCEIDTE configuration is correct.

Scans

by

ArtekMedia

O

2006

Page 17

(3) Pin 20 of the Model 75 will need to be con-

nected to an input of the other device that

will enable (positive) and disable (negative)

the character transmission from that

device. If the other device does not support

this,

XONIXOFF handshaking will be

required and pin

20 can be left dis-

connected.

(4)

Pin 5 of the Model 75 should be connected

to an output pin on the other device that

indicates whether or not it is ready to accept

data. If the other devicedoes not have such

a pin but is not always ready, it can send

XOFFs and XONs to indicate readiness.

When using this method, or if the other

device is always ready to accept data, this

IBM-PC

APPLE

II

WITH SUPER SERIAL CARD

IBM-PC IN COMMUNICATIONS MODE

MODEL 75 MODEL 75

(DCE) APPLE II

DB-25

FEMALE

DB-25 DB-25

MALE MALE

DB-25

MALE

WAVETEK MODEL

6000

APPLE MACINTOSH

6000

MODEL 75 MODEL 75

(DCE) MACINTOSH (DTE)

D 6-25

MALE

D 6-25 DE-9

MALE MALE

Figure

2-9.

Typical Examples

of

Serial Cables

DB-25

MALE

2-6

Scans

by

Artekhledia

O

2006

Page 18

pin can be connected to an always positive

pin on the other device or to pin 4 on the

Model 75.

(5) Pin 4 is always positive when the power is

on and can be connected to any pin on the

other device that requires being held

positive.

(6) Pins 6and 8are properly terminated inputs

but have no function.

NOTE

Anypins not mentioned in the previous list are

not connected in the Model

75and therefore

can be connected to anything if the connections are already present in the cable.

3. The handshaking method is front panel selectable

as

CTSIDTR (hardware) or XONIXOFF (see para-

graph 3.31 for more information).

4. Set the baud

rateon the Model 75 to the highest rate

that is available on both the Model 75 and the other

device by setting the dip switches (figure 2-8)

according to table

2-4.

5. Configure the other device for the same baud rate

as in step 4, 1 stop bit, 8 data bits, and no parity.

Table 2-4. RS-232-C DIP Switch Settings

Baud Rate

SW1-4 SW1-3 SW1-2 SW1-1

Closed

Open

Open

Closed

Open

Open

Closed

Open

Closed

Open

Open

Closed

Open

Closed

Open

Open

Closed

Closed

Open

Closed

Closed

Closed

Open

Open

Closed

Open

1

Open I Closed

Closed

1

(3;:;

I

Closed

Open Open

Closed

Closed

Closed

Open

Closed

Closed

Open

*This is the factory set position

NOTE

1.

SW1-5 should always be OPEN

2.

Factory connector configuration is DCE

Closed

Closed

Closed

Open

Open

Open

Open

Open

Open

Closed

Closed

2.3 INITIAL CHECKOUT PROCEDURE

The Model 75 ARB waveform generator

will

supply a

variety of waveforms at the ARB Out connector that can

be modified at will using the front panel controls. In order

toverify the operation of the controls and the functions1

modeslvalues that they control, the generator must first

be set up to produce an output and then the effect of the

controls on the output and the display indications noted.

While this procedure verifies functional operation of this

instrument, it does not verify the

calibration.Thevalues

shown are typical values and should only be used as a

guide. Required tools and test equipment are shown in

table

2-5.

Closed

Open

Open

Open

Table 2-5. Test Equipment and Tools

Instrument Comments

Oscilloscope

*

50R Feedthrough

BNC Tee

BNC Coax Cable

Signal Source*

Frequency

Counter

Dual channel. 20 MHz rnin bandwidth with external trigger and Zaxis capability.

2% accuracy, 2W

1 male to 2 female

RG58U, Q 3 ft. length (4 each)

1 MHz capability with square

wave (1 0 Vp-p into

50R) and TTL

output.

Capable of both frequency and

period measurements.

*Check the oscilloscope manual to determine the

maximum allowable Z-axis input voltage. Do not

exceed that voltage.

*A second Model 75 can be used as the signal source.

For the TTL signal requirements, use the Ref Out

connector on the rear panel and use the SAMPL

soft key to set the frequency. For the 1 kHz, 10 Vp-p

signal, use the STOP soft key to set the stop address

to 1999, use the FREQ soft key to set the frequency,

and use the FUNC and EXEC soft keys to select a

square wave. See section 3 for more detail.

To verify the overall operation of the Model 75 ARB

waveform generator, follow the procedure in table

2-6.

Refer to the referenced figures and tables for appropriate

test equipment connections and settings. Refer to figure

3-1 and paragraph 3.2 for control and connector

locations.

Scans

by

ArtekMedia

O

2006'

Page 19

Table

2-6.

Checkout Procedure

Step

1

ControllSwitch

Power

PositionlOperation

Press On

ObservationlComments

Display indicates "WAVETEK MODEL 75".

I I

Adjust the LCD viewing control for best contrast.

--

-

-

This step verifies the "Reset" functions of the Model 75.

Press three times

Press once

Press once

2

Display indicates "RESET Ver

x.xx".

Display indicates "RESET Ver x.xx

X".

Setup

F2 (Reset)

F3 (Exec)

This step verifies the "Z-Axis" functions of the Model 75.

Setup

F2 (ZLOGIC)

Control knob

Control knob

F1 (ZLEVL)

Control knob

Control knob

Press once

Press once

Rotate until display

indicates "ZLOGIC

POS".

Rotate until display

indicates "ZLOGIC

NEG".

Press once

Rotate CW until

display indicates

"ZLEVEL

14V".

Rotate CCW to step

display through the

selectable settings.

Connect the Model 75 as shown in figure 2-10. Set

equipment controls as indicated in table

2-7.

Display indicates "ZLOGIC NEG" or "ZLOGIC POS".

Oscilloscope will indicate a dc level of

0

Vdc + 1V

with positive-going pulses.

Oscilloscope will indicate a dc level of

2,

4,

6,

8, 10,

12, or 14 Vdc with negative-going pulses.

Oscilloscope will indicate a dc level of

+

14V

+_

1V

with negative-going pulses.

Oscilloscope will indicate the selected voltage

+_

1V

with negative-going pulses. Leave Setting at "ZLEVEL

2V".

This step sets the "Z-Axis Out" voltage level and polarity.

Control knob Rotate CW or CCW

to set acceptable

contrast between

trace and thumb-

tacks. Adjust oscilloscope intensity if

required.

Connect the Model 75 as shown in figure 2-1 1. Set

equipment controls as indicated in table

2-8.

If thumbtack intensity is too bright at + 2V, terminate

the Z-axis cable with a 50Q load. If the thumbtacks are

dimmed instead of intensified, set ZLOGIC to POS.

Scans

by

ArtekMedia

O

2006

Page 20

Table 2-6. Checkout Procedure (Continued)

This step verifies the "Waveform Memory'' functions of the Model 75.

Store

F2 (CHAIN)

Control knob

ObservationlComments

F3 (EXEC)

Edit

F1 (FUNC)

Control knob

PositionlOperation Step

F3 (EXEC)

ControllSwitch

Edit

F1 (START)

Control knob

Control knob

F2 (STOP)

Control knob

Control knob

Store

F2 (CHAIN)

Control knob

F3 (EXEC)

Edit

F1 (FUNC)

F3 (EXEC)

Press two times

Press once

Rotate until display

indicates "CHAIN

8K".

Press once

Press two times

Press once

Rotate until display

indicates "FUNC

SINE"

Press once

Press two times

Press once

Rotate CW

Rotate CCW

Press once

Rotate CCW

Rotate CW

Press two times

Press once

Rotate until display

indicates "CHAIN

2K".

Press once

Press two times

Press once

Press once

Reset the oscilloscope horizontal sweep to 1

msIDIV.

Oscilloscope will indicate slightly more than one cycle

of the sine wave at approximately 10 Vp-p.

Display will indicate

">ST = 0000 SP = 8191

".

Oscilloscope waveform start point will move from left

to right until waveform disappears. Display will now

indicate

">ST = 81 91 SP = 81 91

".

Oscilloscope waveform start point will move from right

to left until waveform is complete. Display will now

indicate

">ST = 0000 SP = 81 91

".

Display will indicate "ST = 0000 >SP = 81 91.

Oscilloscope waveform stop point will move from right

to left until the waveform disappears. The display will

now indicate "ST

=

0000 >SP = 0000".

Oscilloscope waveform stop point will move from left

to right until the waveform is complete. The display

will

now indicate "ST = 0000 >SP = 81 91

".

Display indicates "CHAIN 8K"

Display indicates "FUNC SINE".

Set the oscilloscope sweep to

.5

mslDIV.

Display will indicate "FUNC SINE X". Oscilloscope

will display less than 3 cycles of a sine wave of approximately 10 Vp-p.

Scans

by

ArtekMedia

O

2006

Page 21

Table

2-6.

Checkout Procedure (Continued)

This step verifies the "Amplitude Control" functions of the Model

75.

Step

This step verifies the "Offset" functions of the Model

75.

ControllSwitch

Display will indicate "AMPL 5.000 Vp".

Oscilloscope amplitude decreases smoothly to

minimum of approximately

10 mVp-p. Display will now

indicate "AMPL 5.00

mVp".

6

This step verifies the "Frequency" functions of the Model

75.

PositionlOperation

7

ObservationlComments

Parameter

F1 (AMPL)

Control knob

Press two times

Press once

Rotate CCW

F2 (OFFSET)

Control knob

Control knob

Control knob

F1 (AMPL)

Control knob

F3 (SAMPL)

Connect a coax cable from the Ref Out connector on

the Model 75 rear panel to the frequency counter input.

Set frequency counter to frequency mode.

Press once

Control knob

Display will indicate "SAMPL 1.0000 MHz'' and counter

will indicate approximately 1 MHz.

Press once

Rotate CW

Rotate CCW

Rotate CW until

display indicates

"OFFSET 0.0

mV".

Press once

Rotate CW until

display indicates

"AMPL 5.000 Vp".

Rotate CCW until

display indicates

"SAMPL 500.0

KHz".

Counter will indicate approximately 500 kHz.

Display will indicate "OFFSET 0.0

mV".

Reset oscilloscope vertical gain to 2VIDIV.

Oscilloscope will increase smoothly to approximately

5.1 OV. The display will now indicate

"OFFSET5.1 OV".

Oscilloscope level decreases smoothly to

approxi-

mately - 5.10V. Display will now indicate "OFFSET

-

5.10V".

Resolution near zero is much greater so that the level

will change slower as zero is approached and passed.

Scans

by

Artekhledia

O

2006

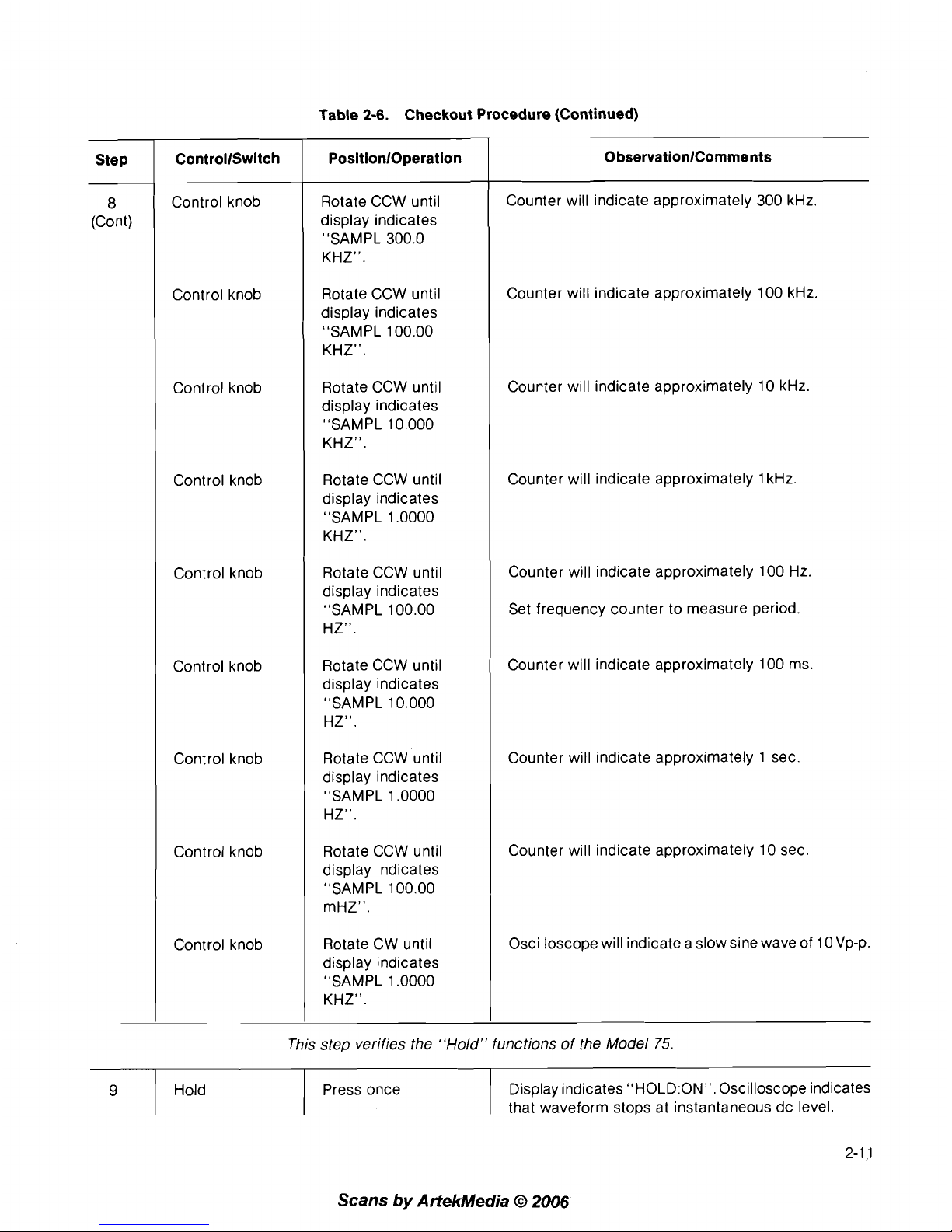

Page 22

Table

2-6.

Checkout Procedure (Continued)

This step verifies the "Hold" functions of the Model

75.

-

9

1

Hold

ObservationlComments

Counter will indicate approximately 300 kHz.

Counter will indicate approximately 100 kHz.

Counter will indicate approximately 10 kHz.

Counter will indicate approximately 1 kHz.

Counter will indicate approximately 100 Hz.

Set frequency counter to measure period.

Counter will indicate approximately 100 ms.

Counter will indicate approximately 1

sec.

Counter will indicate approximately 10 sec.

Oscilloscope will indicate a slow sine wave of

10Vp-p.

Press once

PositionlOperation

Rotate CCW until

display indicates

"SAMPL 300.0

KHz".

Rotate CCW until

display indicates

"SAMPL 1 00.00

KHZ".

Rotate CCW until

display indicates

"SAMPL 10.000

KHz".

Rotate CCW until

display indicates

"SAMPL 1.0000

KHz".

Rotate CCW until

display indicates

"SAMPL 100.00

HZ".

Rotate CCW until

display indicates

"SAMPL 10.000

HZ".

Rotate CCW until

display indicates

"SAMPL 1.0000

HZ".

Rotate CCW until

display indicates

"SAMPL 100.00

mHZ".

Rotate CW until

display indicates

"SAMPL 1.0000

KHz".

Step

8

(Cont)

Display indicates

"H0LD:ON". Oscilloscope indicates

that waveform stops at instantaneous dc level.

ControllSwitch

Control knob

Control knob

Control knob

Control knob

Control knob

Control knob

Control knob

Control knob

Control knob

Scans

by

ArtekMedia

O

2006

Page 23

Table

2-6.

Checkout Procedure (Continued)

9

(Cont)

Hold

Step

Press once

ControllSwitch

PositionlOperation

Apply a 7TL low or

switch closure input

connector.

ObservationlComments

Remove the 7TL low

or switch closure

from the rear panel

connector.

Oscilloscope waveform starts again.

Connect a coax cable from the

7TL source output to

the Hold In connector on the Model

75

rear panel.

Oscilloscope indicates that waveform stops at

instantaneous dc level.

Oscilloscope indicates that waveform starts again.

Return

Hold

This step verifies the "Return" functions of the Model

75.

Press once

Press once

Apply a

7TL low or

switch closure input

to the rear panel

connector.

Oscilloscope indicates that waveform stops at instantaneous dc level and moves slowly to approximately

0

Vdc. Display indicates "H0LD:ON

Y

=

0000".

OsciIloscope waveform starts again. Display indicates

"HOLD:OFFM.

Connect a coax cable from the TrL source output to

the Return In connector on the Model

75

rear panel.

Oscilloscope indicates that waveform stops at instantaneous dc level and moves slowly to approximately

0

Vdc. Display indicates "H0LD:ON

Y

=

0000".

Remove the 7TL low or switch closure input from the

rear panel connector.

I

Hold press once Oscilloscope indicates that waveform starts again.

This step verifies the "Mode" functions of the Model

75.

I

Parameter

F1

(MODE)

Control knob

Trigger

Press two times

Press once

Rotate CW until dis-

play indicates

"MODE

TRIGGERED".

Press once

Oscilloscope trace level approximately

0

Vdc. Set

oscilloscope sweep to

.5

seclDIV.

Oscilloscope waveform runs for one cycle, then stops

at

0

Vdc.

Scans

by

ArtekMedia

O

2006

Page 24

Table

2-6.

Checkout Procedure (Continued)

This step verifies the "Burst Done Out" signal of the Model 75.

0

bservationlComments

Oscilloscope waveform runs continuously.

Oscilloscope waveform stops at

0 Vdc.

Oscilloscope waveform runs continuously.

Oscilloscope waveform stops at

0 Vdc.

Oscilloscope waveform runs for 3 cycles, then stops

at

0 Vdc.

Display will indicate "COLINTER

=

3".

This step verifies the "Trig In" functions of the Model 75.

PositionlOperation

Rotate CW until

display indicates

"MODE GATED".

Press and hold

Release

Rotate CW until

display indicates

"MODE TOGGLED".

Press once

Press once

Press once

Rotate CCW until

display indicates

"BURST CT

3".

Press once

Rotate CW until

display indicates

"MODE BURST".

Press once

Press once

Step

11

(Cont)

12

Connect the Model 75 as shown in figure 2-12. Set

equipment controls as indicated in table

2-9.

ControllSwitch

Control knob

Trigger

Trigger

Control knob

Trigger

Trigger

F3 (BLIRST)

Control knob

F1 (MODE)

Control knob

Trigger

Counter

Scans

by

Artekhledia

O

2006

Trigger Press Once

Connect a cable from Burst Done Out connector to

oscilloscope CH 2 vertical input. Reset oscilloscope

vertical input to CHOPPED with

CHI and CH2 both

"On" and at

2VIDIV.

Oscilloscope Burst Done Out signal goes to OVdc while

waveform is running and then returns to

+

5V when

waveform stops.

Page 25

Table

2-6.

Checkout Procedure (Continued)

This step verifies the "Trigger Slope" function of the Model

75.

7

Parameter

1

press two times

Step

13

(Cont)

PositionlOperation

Press once

Rotate CW until

display indicates

"MODE

TRIGGERED".

Press once

Press once

Rotate CW until

display indicates

"FREQ

900.00

HZ".

ControllSwitch

F1 (MODE)

Control knob

Parameter

F1 (FREQ)

Control knob

1

Control knob

)

Rotate CW until

ObservationlComments

Oscilloscope displays one cycle of sine wave whose

start is coincident with rising edge of the trigger signal.

I

F2(TRSLP)

Oscilloscope displays one cycle of sine wave whose

Press once

This step verifies the "Sync In" functions of the Model

75

display indicates

"TRIG SLOPE NEG".

start is coincident with falling edge of the trigger signal.

Scans

by

ArtekMedia O 2006

Move the cable from the Trig In connector to the Sync

In connector.

Oscilloscope waveform runs continuously when the

Sync In signal is low. Waveform goes to

0

Vdc when

Sync In is high.

15

This step verifies the "Ref In" functions of the Model

75.

F1 (MODE)

Control knob

16

Press once

Rotate CCW until

display indicates

"MODE

CONTINUOUS".

Press two times

Parameter

Connect the Model

75

as shown in figure 2-13. Set

equipment controls as indicated in table 2-1

0.

Page 26

Table 2-6. Checkout Procedure (Continued)

F3 (REF)

Control knob

TTL

Signal

source

ObservationlComments

Press once

Rotate CW until

PositionlOperation

Step

display indicates

"REF EXTERNAL".

ControllSwitch

Vary the frequency

up and down.

Oscilloscope waveform frequency varies with the

TTL frequency.

Control knob

Edit

F1 (FLINC)

Control knob

This step verifies the "Sum In" functions of the Model

75.

Rotate CW until

display indicates

"REF INTERNAL"

Press two times

Press once

Rotate CW until

display indicates

"FUIVC DC".

1

F3 (EXEC)

I

Press once

Connect the Model

75

as shown in figure 2-14. Set

equipment controls as indicated in table 2-1 1.

Oscilloscope

(CHI) waveform is the same frequency

and approximately the same amplitude as the

(CH2)

waveform.

Z-AXIS

OUT

I

MODEL

75

I

OSCILLOSCOPE

Figure 2-10. Equipment Interconnection #1

Table 2-7. Test Equipment Control Setup#l

Oscilloscope

CHI Vert Input

5

VIDIV

Horiz Sweep

.5

mslDlV

Trigger Source

CHI

Trigger Mode Auto

Remaining Controls As Required

Scans

by

ArtekMedia

O

2006

Page 27

Figure 2-1 1.

Equipment lnterconnection

#2

Table 2-8. Test Equipment Control Setup #2 Table 2-9. Equipment Control Setup #3

Oscilloscope

CHI Vert Input 2 VlDlV

Horiz Sweep

.5

mslDlV

Trigger Source

Ext

(

-

10 if available)

Trigger Mode

Auto

Trigger Slope

Positive

Trigger Coupling

AC

Remaining Controls As Required

TTL SIGNAL SOURCE MODEL

75

OSCILLOSCOPE

50Q

00000000

..@ @ @ @

@

0

TRIG

ARB

IN

OUT

TTL Signal Source

Frequency 200 Hz

Function

TTL

Figure 2-12. Equipment lnterconnection #3

Oscilloscope

CHI Vert Input

2

VIDIV

CH2 Vert Input

2

VIDIV

Vert Mode Alt

Horiz Sweep

.5

ms1DIV

Trigger Source CH2

Trigger Mode Auto

Trigger Slope Positive

Trigger Coupling AC

Remaining Controls As Required

2-1

6

Scans

by

ArtekMedia

O

2006

Page 28

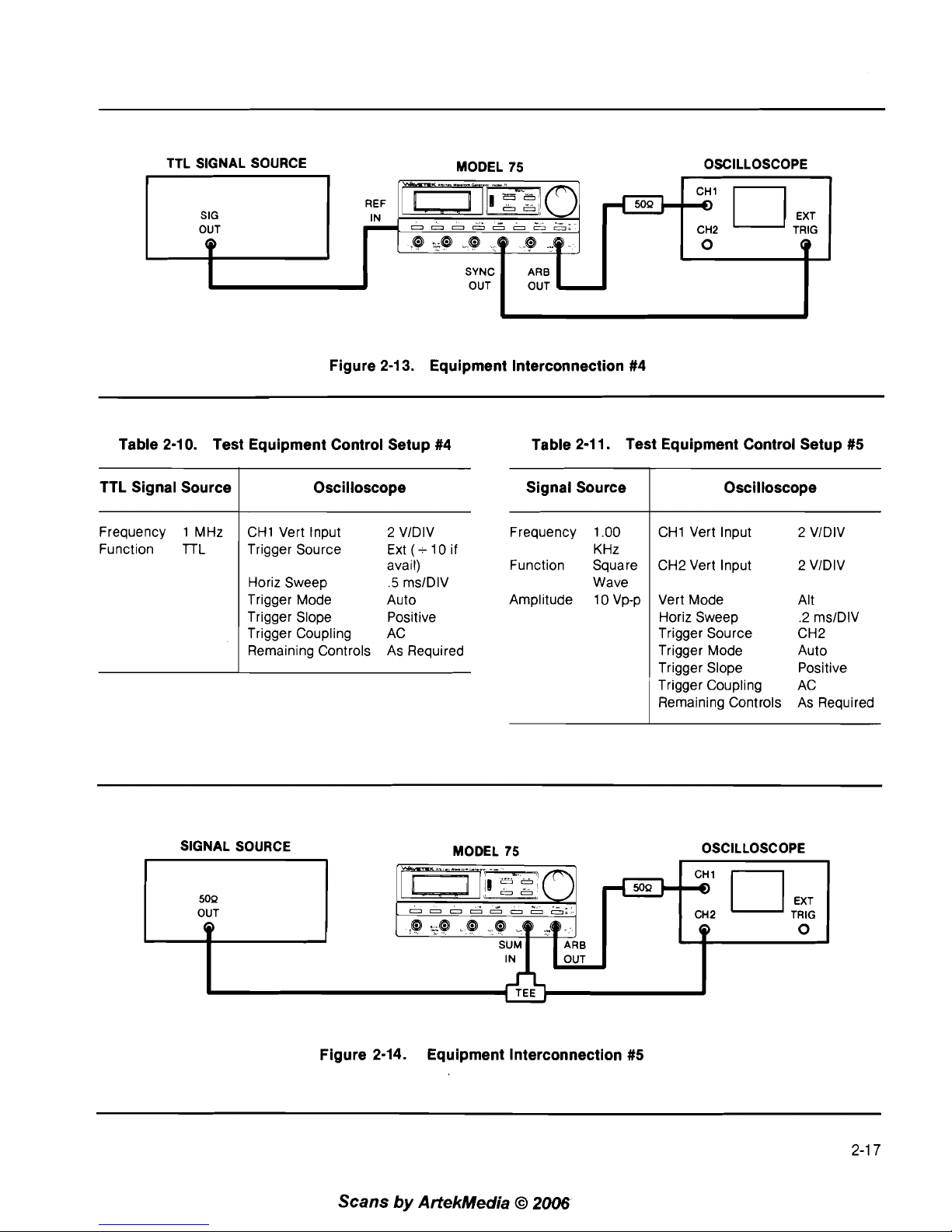

Figure 2-1

3.

Equipment lnterconnection #4

TTL SIGNAL SOURCE

MODEL 75 OSCILLOSCOPE

SIG

OUT

Q

Table 2-10. Test Equipment Control Setup #4 Table 2-1 1. Test Equipment Control Setup #5

Frequency 1 .OO

KHz

Function Square

Wave

Amplitude 1 0 Vp-p

REF

IN

-

TTL Signal Source

Frequency 1 MHz

Function

lTL

Signal Source

CHI Vert Input 2 VIDIV

SYNC

OUT

Oscilloscope

CHI Vert Input 2 VIDIV

Trigger Source Ext (-10 if

avail)

Horiz Sweep

.5

ms1DIV

Trigger Mode

Auto

Trigger Slope

Positive

Trigger Coupling AC

Remaining Controls As Required

Oscilloscope

CH2 Vert Input 2 VIDIV

'rn-mo'

0

0

.

-

-

...

.

OOOOOOOO0

@

L@

@

69

@

..q

ARB

OUT

Vert Mode Alt

Horiz Sweep

.2 ms1DIV

Trigger Source CH2

Trigger Mode Auto

Trigger Slope Positive

Trigger Coupling AC

Remaining Controls As Required

50Q

cl

CH2

,;

-

0

Q

SIGNAL SOURCE MODEL 75 OSCILLOSCOPE

CH2

0

SUM

ARB

IN

OUT

Figure 2-14. Equipment lnterconnection #5

Scans

by

ArtekMedia

O

2006

Page 29

r

WAMTCK:

1

San

Dleao

CA USA

-

I

MODEL

75

I

BEFOREOPENING UNPLUGPOWEO

CORD DANGEROUS

VOLTAGES

INSIDE SEE MANUAL FOO SAFETY

IY9TFtllCTIOII

Z

AXIS

out

IEEE-488

(600nI

Ref Ref

Hold

Return

In

Out

In In

(TTL)

(TTLI (TTL)

(TTL)

Figure

3-1.

Controls, Connectors, and Indicators

Scans

by

ArtekMedia

O

2006

Page 30

3.1 INTRODUC'I'ION

This section describes the operation of the Model 75.

Paragraph 3.2 describes the controls and connectors

of the instrument. The following paragraphs describe

how to use the various features and modes of the Model

75.

3.2 CONTROLS, CONNECTORS, AND INDICATORS

The front panel controls are organized into four menu

selection keys, three soft keys, three real time keys, the

Counter key, and the Control knob. To change any instrument setting, the appropriate menu key is pressed

repeatedly until thedesiredsoft key labelappears in the

bottom line of the display (see Appendix B for menu

organization). Pressing the associated soft key will cause

the top line of the display to indicate the setting to be

changed. Rotating the Control knob will change the

setting. When the setting being changed has the

possibility of irreversibly changing a waveform, an

execute label (EXEC) will appear for the F3 soft key and

must be pressed before the change takes place. The

Trigger, Hold, and Return keys control the waveform in

real time and are not directly associated with the Control knob. The Counter key causes the display to indicate

a waveform count as will be discussed below. The front

panel controls and connectors are shown in figure 3-1

and keyed (bold numbers) to the following descriptions.

W-TEK

Arbitrar, Waveform Generator

FFtEl;!

F;ER

;!;RplFL

1 Liquid Crystal Display

(See figure 3-2). The lower

row of this display will provide labels for the soft keys

that are located directly below the display. Each time

one of the menu keys is pressed the labels will be

updated to match the menu selection (see Appendix B). The upper row of the display will respond to

the soft keys and control knob by indicating the

setting or parameter value corresponding to the last

soft key that was pressed.

2

LCD Viewing Control.

This control allows the user

to adjust the intensity of the display to match the

viewing angle of the instrument.

3 Edit Key.

Each time the edit key is pressed the lower

line of the display will change to indicate three different waveform editing options. There are a total

of five different sets of three editing options. Any of

these can be invoked by pressing the soft key

[Fl

(21), F2 (1

9),

or F3 (1 7)] below the corresponding

label on the display.

NOTE

Refer to appendix B for a summary of soft key

options.

'

WAVETEK

Arbitrary Waveform Generator

L

FREQ SELECTED FROM PARAMETER MENU

ADJX

SELECTED FROM EDIT MENU

Figure 3-2. Typical Display Indications

3-1

Scans

by

ArtekMedia

O

2006

Page 31

Pressing the Edit key the first time enables the rubber

band editing features as follows:

The label for the

F1 soft key will read "CSR" (Cur-

sor). Pressing

F1 allows the cursor in the

waveform to be moved by rotating the control

knob. The top line of the display will indicate the

X-position of the cursor and the Y-value at that

position. If Z-axis modulation is used on an

oscilloscope, the cursor will be intensified. This

does not affect the output waveform.

The label for the F2 soft key will read

"ADJX,Ym

(Adjust X or Y). Pressing F2 once allows a vertex

(at the cursor position) of a waveform to be moved

horizontally (X) by rotating the control knob. Pressing the F2 key twice allows vertical (Y) movement.

The top line of the display will indicate the X and

Y position of the

vertex(cursor) and also(with an

annunciator) the adjustment axis (X or Y) currently

enabled

The label for the F3 soft key will read

"L,R'TT1' (Left

or Right Thumbtack). Pressing F3 once allows the

horizontal position of the left thumbtack to be

changed by rotating the control knob. Pressing

the F3 key twice allows the horizontal position of

the right thumbtack to be changed. The position

of both thumbtacks will be indicated on the top

line of the display along with an annunciator

indicating the thumbtack whose adjustment is

currentlyenabled. If Z-axis modulation is used on

an oscilloscope, the thumbtacks will be

intensified.

Pressing the Edit key the second time enables the

standard waveform features as follows:

The label for the

F1 soft key will read "FUNC"

(Function). Pressing

F1 allows standard waveforms to be inserted between thecurrent thumbtacks (as set by

L,RTT). The desired standard

waveform is selected by rotating the control knob

and is inserted when the EXEC soft key is pressed

as discussed below.

The label for the F2 soft key will read "ERASE"

Pressing this key followed by the EXEC soft key

will erase the entire active waveform by chang-

ing all Y-values to

0.

The label for the F3 soft key will read "EXEC".

(Execute). Pressing F3 causes the action selected

by the FUNC or ERASE keys to be executed. An

"Xu will be be displayed in the top right hand

corner of the display after EXEC has been

pressed.

Pressing the Edit keya third time enables thedigital

amplitude and offset features as follows:

The label for the

F1 soft key will read "DAMPL"

(Digital Amplitude). Pressing

F1 allows adjust-

ment, by rotating the control knob, of the amplitude of the portion of the waveform between the

thumbtacks without affecting the rest of the

waveform. To accomplish this, the Model 75

digitally scales the Y-values of the waveform

points between the thumbtacks. The top line of

the display will indicate the amplitude of the portion being adjusted as a percentage of full scale.

The digital amplitude can be adjusted to a

negative relative amplitude in order to invert a portion of the waveform.

The label for the F2 soft key will read "DOFF"

(Digital Offset). Pressing F2 allows a portion of the

waveform between the thumbtacks to be offset

vertically, by rotating the control knob, without

affecting the rest of the waveform. The Model 75

accomplishes this by adding (or subtracting) a

fixedvalue to all of the points between the thumbtacks.

The range of digital offset adjustment is

limited by the fact that the Y-value of any point

cannot be outside the range of

+

2047, so the

Model 75 will not allow this range to be exceeded.

The top line of the display will indicate the offset,

in points, relative to the original position, of the

portion being adjusted.

The label for the

F3soft keywill read "L,R'TT" (Left

or Right Thumbtack). Pressing

F3once allows the

horizontal position of the left thumbtack to be

changed by rotating the control knob. Pressing

F3 twice allows the horizontal position of the right

thumbtack to be changed. The position of both

thumbtacks will be indicated on the top line of the

display along with an annunciator indicating the

thumbtack whose adjustment is currently

enabled. Moving the thumbtacks has

noeffect on

theoutput waveform. If Z-axis modulation is used

on an oscilloscope, the thumbtacks will be

intensified.

Pressing the Edit key a fourth time enables

startlstop

address control and the waveform normalization

function as follows:

The label for the

F1 soft key will read "START"

(Start Address). Pressing

F1 allows setting, by

rotating the control knob, of the address of the

first waveform memory location to be part of the

active waveform. The top line of the display will

indicate both the current start and stopaddresses

along with an annunciator indicating that START

has been pressed.

The label for the F2 soft key will read "STOP"

(Stop Address). Pressing F2 allows setting, by

rotating the control knob, of the address of the

last waveform memory location to be part of the

Scans

by

ArtekMedia

O

2006

Page 32

active waveform. The top line of the display will

indicate both the current start and stop addresses

along with an annunciator indicating that START

has been pressed.

The label for the F3 soft key will read "NORML"