Page 1

Watson-Marlow qdos

User Manual

m-qdos-en-02 1

Page 2

Contents

1 Declaration of conformity 5

2 Warranty 6

2.1 Conditions 6

2.2 Exceptions 7

3 When you unpack your pump 8

3.1 Packaging disposal 8

3.2 Inspection 8

3.3 Components supplied 8

3.4 Optional accessories 9

3.5 Storage 9

4 Information for returning pumps 10

5 Safety notes 11

6 Pump specifications 13

6.1 Pump specifications 15

6.2 Standards (ACmains power supply) 16

6.3 Standards (12-24V DC power supply) 17

6.4 Dimensions 18

6.5 Weights 19

7 Good pump installation practice 20

7.1 General recommendations 20

7.2 Do's and do not's 21

7.3 Pressure capability 21

7.4 Dry running 21

8 Connecting to a power supply 22

8.1 AC mains power supply 22

8.2 DC power supply option 23

9 Start-up check list 24

10 Automatic control wiring - Universal, Universal+ and Remote models

without relay modules 25

10.1 Input pin assignments at the pump 26

10.2 Optional input lead 26

10.3 Output pin assignments at the pump 27

10.4 Optional output lead 29

11 Automatic control wiring - 24V relay module and 110V relay module

(Universal and Universal+ only) 30

11.1 Module: cover removal and refitting 30

11.2 Wiring up the terminal connectors 31

11.3 24Vrelay module pcb connectors 34

m-qdos-en-02 2

Page 3

11.4 110V relay module pcb connectors 37

12 PROFIBUS control wiring 40

12.1 PROFIBUS installation 40

12.2 Pin assignments at the pump 41

13 Switching on (Manual, PROFIBUS, Universal and Universal+) 42

13.1 Switching on the pump for the first time (Manual, PROFIBUS, Universal and

Universal+ only) 42

13.2 Switching the pump on in subsequent power cycles (Manual, PROFIBUS,

Universal and Universal+ only) 44

14 Switching on (Remote) 45

15 Pump operation 46

15.1 Pump operation (Remote pump) 46

15.2 Pump operation (Manual, PROFIBUS, Universal and Universal+ only) 46

16 Manual mode (Manual, PROFIBUS, Universal and Universal+ only) 49

17 PROFIBUS mode(PROFIBUS only) 52

17.1 Assigning the PROFIBUS station address at the pump 53

17.2 PROFIBUS communication errors 55

17.3 PROFIBUS GSD file 56

17.4 User Parameter Data 58

17.5 PROFIBUS data exchange 59

17.6 Device-related diagnostic data 62

17.7 Channel-related diagnostic data 62

18 Flow calibration mode (Manual, PROFIBUS, Universal and Universal+ only) 64

19 Analog 4-20mA mode (Universal and Universal+ only) 67

19.1 Calibrate the pump for 4-20mA control (Universal+ only) 72

20 Contact Mode (All Universal and Universal+ models except 110V relay

versions) 77

20.1 Contact settings 77

20.2 Contact operating mode (All Universal and Univ ersal+ models except 110V

relay versions) 79

20.3 Fluid recovery mode (Manual, PROFIBUS, Universal and Universal+ only) 80

20.4 Remote fluid recovery (Universal and Universal+ models without relay

modules) 82

21 Main menu (Manual, PROFIBUS, Universal and Universal+ only) 84

21.1 Fluid level monitor (Manual, PROFIBUS, Universal and Universal+ only) 85

21.2 Security settings (Manual, PROFIBUS, Universal and Universal+ only) 89

21.3 General settings (Manual, PROFIBUS, Universal and Universal+ only) 92

21.4 MODE menu (Manual, PROFIBUS, Universal and Universal+ only) 97

21.5 Control settings (Manual, PROFIBUS, Universal and Universal+ only) 98

21.6 Help (Manual, PROFIBUS, Universal and Universal+ only ) 105

m-qdos-en-02 3

Page 4

22 Status LEDs (Remote only) 106

23 Troubleshooting 107

23.1 Leak detection 107

23.2 Error codes 108

23.3 Error Indication (Remote only) 109

24 Technical support 110

25 Drive maintenance 111

26 Pumphead Replacement (qdos 30) 112

26.1 Connecting interface tubing 115

27 Pumphead Replacement (qdos 20, 60 and 120) 117

27.1 Connecting interface tubing 120

28 Ordering information 123

28.1 Pump part numbers 123

28.2 Spares and accessories 124

29 Performance data 127

29.1 Pumping conditions 127

29.2 Pressure capability 127

29.3 Dry running 127

29.4 Pumphead life 127

29.5 DC power supply option - input characteristics 127

29.6 Performance curves 128

30 Trademarks 129

31 Publication history 130

m-qdos-en-02 4

Page 5

1 Declaration of conformity

This pump is ETL listed: ETL control number 3050250. Cert to CAN/CSA std C22.2

No 61010-1. Conforms to UL std 61010A-1.

See "Pump specifications" on page13.

m-qdos-en-02 5

Page 6

2 Warranty

Watson-Marlow Limited (“Watson-Marlow”) warrants this product to be free from defects in

materials and workmanship for three years from the date of shipment, under normal use

and service.

Watson- Marlow’s sole responsibility and the customer’s exclusive remedy for any claim

arising out of the purchase of any product from Watson- Marlow is, at Watson Marlow’s

option: repair, replacement or credit, where applicable.

Unless otherwise agreed in writing, the foregoing warranty is limited to the country in

which the product is sold.

No employee, agent or representative of Watson-Marlow has the authority to bind WatsonMarlow to any warranty other than the foregoing unless in writing and signed by a director

of Watson-Marlow. Watson-Marlow makes no warranty of the fitness of its products for a

particular purpose.

In no event:

i. shall the cost of the customer’s exclusive remedy exceed the purchase price of the

product;

ii. shall Watson-Marlow be liable for any special, indirect, incidental, consequential,

or exemplary damages, however arising, even if Watson-Marlow has been advised

of the possibility of such damages.

Watson-Marlow shall not be liable for any loss, damage, or expense directly or indirectly

related to or arising out of the use of its products, including damage or injury caused to

other products, machinery, buildings, or property. Watson-Marlow shall not be liable for

consequential damages, including, without limitation, lost profits, loss of time,

inconvenience, loss of product being pumped, and loss of production.

This warranty does not obligate Watson-Marlow to bear any costs of removal, installation,

transportation, or other charges which may arise in connection with a warranty claim.

Watson-Marlow shall not be responsible for shipping damage of returned items.

2.1 Conditions

l Products must be returned by pre-arrangement to Watson-Marlow, or a Watson-Marlow

approved service centre.

l All repairs or modifications must have been made by Watson- Marlow Limited, or a

Watson-Marlow approved service centre or with the express permission in writing of

Watson-Marlow, signed by a manager or director of Watson-Marlow.

l Any remote control or system connections must be made in accordance to Watson-

Marlow recommendations.

l All PROFIBUS systems must be installed or certified by a PROFIBUS approved installation

engineer.

m-qdos-en-02 6

Page 7

2.2 Exceptions

l Consumable items including tubing and pumping elements are excluded.

l Pumphead rollers are excluded.

l Repairs or service necessitated by normal wear and tear or by lack of reasonable and

proper maintenance are excluded.

l Products which, in the judgement of Watson-Marlow, have been abused, misused, or

subjected to malicious or accidental damage or neglect are excluded.

l Failure caused by electrical surge is excluded.

l Failure caused by incorrect or sub-standard system wiring is ex cluded.

l Damage by chemical attack is excluded.

l Ancillaries such as leak detectors are excluded.

l Failure caused by UV light or direct sunlight.

l All ReNu pumpheads are excluded.

l Any attempt to disassemble a Watson- Marlow product will invalidate the product

warranty.

Watson-Marlow reserves the right to amend these terms and conditions at any time.

m-qdos-en-02 7

Page 8

3 When you unpack your pump

Unpack all parts carefully, retaining the packaging until you are sure all components are

present and in good order. Check against the components supplied list, below.

3.1 Packaging disposal

Dispose of packaging materials safely, and in accordance with regulations in your area. The

outer carton is made of corrugated cardboard and can be recycled.

3.2 Inspection

Check that all components are present. Inspect components for damage in transit. If

anything is missing or damaged, contact your distributor immediately.

3.3 Components supplied

Qdos 20, 60 and 120:

m-qdos-en-02 8

Page 9

Qdos 30:

Note: The appearance of the pump drive unit may vary from the that shown depending on

the pump model. The hydraulic connector pack shown is an optional accessory.

The following components are supplied with all qdos pumps:

l Pump drive unit

l ReNu pumphead

l User connection collars

l The designated power cable (attached to the pump drive unit)

l CD-ROM containing these operating instructions

l Quick start manual

l Product safety information booklet

3.4 Optional accessories

Spares and accessories are available such as:

l Additional ReNu pumphead

l HMI protective cover (not compatible with remote models)

l Interface tubing

l Input and output (I/O) leads

ll Hydraulic connector packs

For a full list of accessories see "Spares and accessories" on page124.

3.5 Storage

This product has an extended shelf life. However, care should be taken after storage to

ensure that all parts function correctly. Please observe the storage recommendations and

use-by dates which apply to ReNu pumpheads and tubing you may wish to bring into

service after storage.

m-qdos-en-02 9

Page 10

4 Information for returning pumps

In compliance with the UK Health and Safety at Work Act and the Control of Substances

Hazardous to Health Regulations, you are required to declare the substances which have

been in contact with product (s) you return to Watson- Marlow or its subsidiaries or

distributors. Failure to do so will cause delays. Please ensure that you fax us this form and

receive an RGA (Returned Goods Authorisation) before you despatch the product (s). A copy

of this form must be attached to the outside of the packaging containing the product(s).

Please complete a separate decontamination declaration for each product. A copy of the

appropriate decontamination declaration can be downloaded from the Watson- Marlow

website at: www.wmftg.com/decon.

You are responsible for cleaning and decontaminating the product(s) before return.

m-qdos-en-02 10

Page 11

5 Safety notes

In the interests of safety, this pump and pumphead should only be used by competent,

suitably trained personnel after they have read and understood this manual, and

considered any hazard involved. If the pump is used in a manner not specified by WatsonMarlow Limited, the protection provided by the pump may be impaired.

Any person who is involved in the installation or maintenance of this equipment should be

fully competent to carry out the work. In the UK this person should also be familiar with the

Health and Safety at Work Act 1974.

This symbol, used on the pump and in this manual, means: Caution,

refer to accompanying documents.

This symbol, used on the pump and in this manual, means: Do not

allow fingers to contact moving parts.

This symbol, used on the pump and in this manual, means: Caution,

hot surface.

Fundamental work with regard to lifting, transportation, installation,

starting-up, maintenance and repair should be performed by qualified

personnel only. The unit must be isolated from mains power while

work is being carried out. The motor must be secured against

accidental start-up.

There is a non-replaceable fuse on the switch-mode power supply

board. In some countries, the mains power plug contains a

replaceable fuse. There are no user-serviceable fuses or parts inside

this pump.

This pump must be used only for its intended purpose.

The pump must be accessible at all times to facilitate operation and maintenance. Access

points must not be obstructed or blocked. Do not fit any devices to the drive unit other

than those tested and approved by Watson- Marlow. Doing so could lead to injury to

persons or damage to property for which no liability can be accepted.

If hazardous fluids are to be pumped, safety procedures specific to the particular fluid and

application must be put in place to protect against injury to persons.

This product does not comply with the ATEX directive and must not be

used in explosive atmospheres.

m-qdos-en-02 11

Page 12

If pumping flammable liquids, a full risk assessment should be

completed prior to use.

The exterior surfaces of the pump may get hot during operation. Do

not take hold of the pump while it is running. Allow the pump to cool

after use before handling. The drive unit must not be run without a

pumphead fitted. The pumphead should not be run dry for extended

periods of time. The pump should not be used to pump fluids where

the temperature of the fluid can reach temperatures of more than

70°C.

Ensure the chemicals to be pumped are compatible with the

pumphead, lubricant, tubing, pipework and fittings to be used with

the pump. Please refer to the chemical compatibility guide which can

be found at: www.wmpg.com/chemical If you need to use the pump

with any other chemical please contact Watson-Marlow to confirm

compatibility

Operation of the pump after failure of the consumable peristaltic tube may result in a flow

of chemicals to the inside of the pumphead. Some aggressive chemicals are not compatible

with the pumphead materials. These aggressive chemicals will react to the matierials

internal to the pumphead and may cause leaks.

In the worst case, chemicals could leak out from the pumphead and attack the drive shaft

and lip seal, damaging the seal integrity. Damage to the seal could cause aggressive

chemicals to enter the pump housing and react wth the components internal to the pump

housing. The reaction may produce explosive gases inside the pump housing.

Danger of damage to pump and possible risk of explosion if dosing

liquid has entered the pump housing.

To prevent dosing liquid entering the pump housing follow the

recommended actions below.

In the event of tube failure the pump should be isolated from both

electrical and hydraulic supplies prior to pumphead replacement (See

"Pumphead Replacement (qdos 30)" on page112 or "Pumphead

Replacement (qdos 20, 60 and 120)" on page117.)

To prevent damage to the pump and pumphead due to failure of the consumable peristaltic

tube:

• change the pumphead shortly after failure

• install a non return valve in the discharge line close to the pump when pumping

against a positive pressure. This will prevent a constant stream of chemical flowing

back into the pumphead after failure

• consider using an electrical interlock to isolate the power to the pump, this can be

controlled by the pump alarm signal when a leak is detected by the pump

• do not disable the pump leak detection system

• change the pumphead prior to failure when pumping very aggressive chemicals that

are not compatible with the pumphead materials. There are volume and hours

counters in the product to provide indication of consumable life.

m-qdos-en-02 12

Page 13

6 Pump specifications

qdos 20, 60 and 120:

ReNu pumphead

(left hand mounted)

Pumphead locking

latch

Outlet

Inlet

Mounting plate

HMI

(not Remote)

Drive unit

qdos 20, 60 and 120 with relay module:

ReNu pumphead

(left hand mounted)

Pumphead locking

latch

Outlet

Inlet

Mounting plate

110v or 24v relay

module

HMI

(not Remote)

Drive unit

m-qdos-en-02 13

Page 14

qdos 30:

ReNu pumphead

(left hand mounted)

Pumphead retaining

clamps

Outlet

Inlet

Power

Mounting plate

HMI

(not Remote)

Drive unit

qdos 30 with 110v or 24v relay module:

pumphead retaining

clamps

ReNu pumphead

(left hand mounted)

Outlet

Inlet

Power

Mounting plate

110V or 24V relay

module

HMI

(not Remote)

Drive unit

m-qdos-en-02 14

Page 15

A nameplate is fixed to the rear of the pump. It contains manufacturer and contact details,

product reference number, serial number and model details.

0M0.223L.GLU Iss 1

qdos Manual 30l/hr 7bar

190gpd 100psi Sant PFPE

Serial Number

Manufacturer details

Product reference

Model

Serial number

6.1 Pump specifications

Flow Range (flow control)

Manual, PROFIBUS, Universal and

Universal+:

qdos120:0.1-2000 ml/min (20000:1)

qdos60:0.1-1000 ml/min (10000:1)

qdos30:0.1-500 ml/min (5000:1)

qdos20:0.1-333 ml/min (3330:1)

Remote:

qdos120:1.25-2000 ml/min (1600:1)

qdos60:0.6-1000 ml/min (1600:1)

qdos30:0.3-500 ml/min (1600:1)

qdos20:0.2-333 ml/min (1600:1)

AC Supply voltage/frequency ~100-240V 50/60Hz

m-qdos-en-02 15

Page 16

AC Power consumption 190VA

DC Supply voltage/frequency

(12/24VDC power option)

12-24V DC

DC Power consumption (12/24VDC

power option)

150W

Installation category (overvoltage

category)

II

±10% of nominal voltage. Maximum

voltage fluctuation

An electrical mains supply is required

along with cable connections to the best

practice of noise immunity

Enclosure rating

IP66 to BS EN 60529

NEMA 4X to NEMA 250*

Operating temperature range 4°C to 45°C, 41°F to 113°F

Storage temperature range -20°C to 70°C, -4°F to 158°F

Maximum altitude 2,000m, 6,560ft

Humidity (non-condensing)

80% up to 31°C, 88°F, decreasing linearly

to 50% at 40°C, 104°F

Pollution degree 2

Noise <70dB(A) at 1m

*Requires the fitting of the HMI protective cover.

6.2 Standards (ACmains power supply)

EC Harmonised

standards

Safety requirements for electrical equipment for measurement,

control and laboratory use: BS EN 61010- 1 incorporating A2

Category 2, Pollution degree 2

Degrees of protection provided by enclosures (IP code): BS EN

60529 amendments 1 and 2

EN61326-1:2006 Electrical Equipment for measurement control

and laboratory use EMC requirements Part 1

m-qdos-en-02 16

Page 17

Other Standards

UL 61010A-1, UL/CSA 61010-1

CAN/CSA-C22.2 No 61010-1

IEC 61010-1

Radiated emissions FCC 47CFR, Part 15

NEMA 4X to NEMA 250

NSF61 for pumphead

6.3 Standards (12-24V DC power supply)

EC Harmonised

standards

Safety requirements for electrical equipment for measurement,

control and laboratory use: BS EN 61010- 1 incorporating A2

Category 2, Pollution degree 2

Degrees of protection provided by enclosures (IP code): BS EN

60529 amendments 1 and 2

EN61326-1:2006 Electrical Equipment for measurement control

and laboratory use EMC requirements Part 1

Other Standards

UL 61010A-1, UL/CSA 61010-1

CAN/CSA-C22.2 No 61010-1

IEC 61010-1

Radiated/conducted emissions FCC 47CFR, Part 15

NEMA 4X to NEMA 250

NSF61 for pumphead

m-qdos-en-02 17

Page 18

6.4 Dimensions

A

B

C

D

F

G

H

I

E*

Dimension qdos20 qdos30 qdos60 qdos120

A 234mm (9.2”) 234mm (9.2”) 234mm (9.2”) 234mm (9.2”)

B 214mm (8.4”) 214mm (8.4”) 214mm (8.4”) 214mm (8.4”)

C 118mm (4.6”)

82.5mm

(3.2”)

118mm (4.6”) 118mm (4.6”)

D

266mm

(10.5”)

233mm (9.2”)

266mm

(10.5”)

266mm (10.5”)

E*—Optional relay modules (H or

R)

43mm (1.7”) 43mm (1.7”) 43mm (1.7”) 43mm (1.7”)

F 173mm (6.8”) 173mm (6.8”) 173mm (6.8”) 173mm (6.8”)

G 40mm (1.6”) 40mm (1.6”) 40mm (1.6”) 40mm (1.6”)

H 140mm (5.5”) 140mm (5.5”) 140mm (5.5”) 140mm (5.5”)

I 10mm (0.4”) 10mm (0.4”) 10mm (0.4”) 10mm (0.4”)

m-qdos-en-02 18

Page 19

6.5 Weights

qdos20, 60 and 120:

Model

Drive Drive with pumphead

kg lb kg lb

Manual 4.6 10lb 2oz 5.7 12lb 9oz

Remote 4.5 9lb 15oz 5.6 12lb 6oz

Universal 4.6 10lb 2oz 5.7 12lb 9oz

Universal+ 4.6 10lb 2oz 5.7 12lb 9oz

PROFIBUS 4.6 10lb 2oz 5.7 12lb 9oz

Universal 24V relay 4.8 10lb 9oz 5.9 13lb 0oz

Universal+ 24V relay 4.8 10lb 9oz 5.9 13lb 0oz

Universal 110V relay 4.8 10lb 9oz 5.9 13lb 0oz

Universal+ 110V relay 4.8 10lb 9oz 5.9 13lb 0oz

qdos30:

Model

Drive Drive with pumphead

kg lb kg lb

Manual 4.1 9lb 5.05 11lb 2oz

Remote 4.0 8lb 13oz 4.95 10lb 15oz

Universal 4.1 9lb 5.05 11lb 2oz

Universal+ 4.1 9lb 5.05 11lb 2oz

PROFIBUS 4.1 9lb 5.05 11lb 2oz

Universal 24V relay 4.3 9lb 8oz 5.25 11lb 9oz

Universal+ 24V relay 4.3 9lb 8oz 5.25 11lb 9oz

Universal 110V relay 4.3 9lb 8oz 5.25 11lb 9oz

Universal+ 110V relay 4.3 9lb 8oz 5.25 11lb 9oz

m-qdos-en-02 19

Page 20

7 Good pump installation practice

7.1 General recommendations

Always consult an expert before installing a metering pump in a

specialised system. Metering pumps should be maintained by

qualified persons.

The pump must be bolted to a flat, horizontal, rigid surface, free from excessive vibration,

to ensure correct lubrication of the gearbox and correct pumphead operation. Allow a free

flow of air around the pump to ensure that heat can be dissipated. Ensure that the ambient

temperature around the pump does not exceed 45°C (113°F).

The STOP key on pumps supplied with a keypad will alway s stop the pump. However, it is

recommended that a suitable local emergency stop device is fitted into the mains supply to

the pump.

Do not stack pumps.

This pump is self-priming and self-sealing against backflow. No valves are required in inlet

or discharge lines, except as described below. Valves in the process flow must be opened

before the pump operates.

Users must fit a non-return valve between the pump and the

discharge pipework to avoid the sudden release of pressurised fluid

in the event of a pumphead failure. This shall be fitted immediately

after the discharge of the pump.

qdos is a positive displacement pump; therefore, it is recommended

best practice that customers incorporate discharge pressure relief in

their piping system. Failure to fit a pressure release valve in the

discharge pipework will result in excessive build up of pressure

should the discharge become blocked. This may present a safety risk,

may cause damage to the system pipework or lead to premature

failure of the pump head. The pressure relief valve shall be rated at no

more than 10 bar. It shall always be rated at below the users system

maximum operating pressure. It shall be installed so as to provide

easy access for maintenance, inspection and repair. It shall not be

capable of being adjusted without the use of a tool. The discharge

opening must be located and directed so that the release material is

not directed towards any person and will not deposit on parts that

could cause a hazard. There must not be a shut-off valve between the

overpressure safety device and the pump.

Do not block the drain port of the ReNu pumphead.

Ensure the chemicals to be pumped are compatible with the

pumphead and the pipework and fittings to be used with the pump.

Please refer to the chemical compatibility guide which can be found at:

www.wmftg.com/chemical. If you need to use the pump with any

other chemical please contact Watson-Marlow to confirm compatibility.

m-qdos-en-02 20

Page 21

7.2 Do's and do not's

Do not build a pump into a tight location without adequate airflow around the pump.

Do keep delivery and suction tubes as short and direct as possible - though ideally not

shorter than one metre - and follow the straightest route. Use bends of large radius: at

least four times the tubing diameter. Ensure that connecting pipework and fittings are

suitably rated to handle the predicted pipeline pressure. Avoid pipe reducers and lengths of

smaller bore tubing than the pumphead section, particularly in pipelines on the suction

side. Any valves in the pipeline must not restrict the flow. Any valves in the flow line must

be open when the pump is running.

Do use suction and delivery pipes with the largest diameter bore tube that will fit with

your process, especially when pumping viscous product. Care should be taken when

pumping solids in suspension as large bore tubes will reduce the fluid velocity, this may

lead to solids dropping out of suspension.

Do site the pump at or just below the level of the fluid to be pumped if possible. This will

ensure flooded suction and maximum pumping efficiency.

Do run at slow speed when pumping viscous fluids. Flooded suction will enhance pumping

performance, particularly for materials of a viscous nature.

Do recalibrate after changing pumphead, fluid, or any connecting pipework. It is also

recommended that the pump is recalibrated periodically to maintain accuracy.

Do ensure your PROFIBUS pump is installed in accordance with PROFIBUS installation

guidelines.

Do not pump any chemical not compatible with the pumphead.

Do not tilt the drive with a pumphead fitted, even if it is not running.

Do not strap the control and mains cable together.

Do avoid tight bends in the PROFIBUS signal cable.

7.3 Pressure capability

qdos120 can be operated continuously at discharge pressures of up to 4 bar (60psi)

qdos20, qdos30 and qdos60 can be operated continuously at discharge pressures of up to 7

bar (100psi).

qdos30 can be operated at discharge pressures of up to 10 bar (145 psi), however flowrate

and pumphead life will be affected.

7.4 Dry running

qdos will continue to operate when there is gas present in the suction line and will

maintain prime in these conditions. The pump can be run dry, however flow rate and

pumphead life will be affected.

m-qdos-en-02 21

Page 22

8 Connecting to a power supply

8.1 AC mains power supply

This pump is fitted with a switch mode power supply and will operate from any mains

voltage in the range ~100-240V AC, 50/60Hz supplies.

Make suitable connection to an earthed, single-phase mains electricity supply.

We recommend using commercially available supply voltage surge

suppression where electrical noise may be present.

Power cable: The pump is supplied fitted with a cable gland and approximately 2.8m

(9.2ft) of power cable. The cable is not user-detachable and the entry gland at the front of

the pump should not be disassembled.

Each pump is supplied with a power cable. The connector at the pump end of the cable is

IP66 rated. The mains plug at the opposite end of the cable is NOT IP66 rated.

Ensure that all power supply cables are adequately rated for the

equipment.

The pump must be positioned so that the disconnection device (the

mains plug), is easily accessible when the equipment is in use.

When PAT testing this unit ensure that the earth bond test terminal is

used. Do not use the motor shaft as this could result in motor bearing

damage and reduce long term reliability.

Earth bond test terminal position

m-qdos-en-02 22

Page 23

8.2 DC power supply option

The range of DC sources is intended to include:

• Automotive— either mobile, such as trailer mounted, or static, such as a vehicle

battery or auxiliary output

• Conventional DCsupplies derived from AC mains, such as 12V or 24V supplies

powering PLCs

• Solar panels with any type of back-up battery within the input range

• Other renewable energy generators such as wind/hydro turbines with any type of

back up battery within the input range

Power cable: The pump is supplied fitted with a cable gland and approximately 2.0m

(6.6ft) of power cable and an IP31 splash proof blade fuse holder and 20A blade fuse. The

cable is not user-detachable and the entry gland at the front of the pump should not be

disassembled.

Notes

It is highly recommended that an isolating switch is provided between the power source

and the pump. The cable is fitted with M8 ring terminals to fit common isolators.

The 20A blade fuse is a safety device and should not be removed or the value changed.

The fuse holder is splashproof (IP31) but NOTwaterproof (IP66). Connection to the DC

source should be provided with appropriate IP protection.

Large start up currents may be required, especially at low voltages, see "Performance

data" on page127 for correct selection of power source.

We DO NOT recommend increasing the cable length when used in 12V systems due to

extra voltage loss in the cable. Increasing cable length will also invalidate the pumps EMC

compliance and require the user to perform their own system level EMC compliance check.

m-qdos-en-02 23

Page 24

9 Start-up check list

l Fit the pumphead to the drive. (See "Pumphead Replacement (qdos 30)" on page112 or

"Pumphead Replacement (qdos 20, 60 and 120)" on page117)

l Ensure the pumphead ports are securely fitted to the interface tubing.

l Ensure proper connection has been made to a suitable power supply.

l Ensure that the general recommendations are followed (see "General

recommendations" on page20).

m-qdos-en-02 24

Page 25

10 Automatic control wiring - Universal, Universal+ and

Remote models without relay modules

Interfacing the pump with other devices is by means of two IP66 rated five pole M12

connectors mounted on the front of the pump. M12 connectors with flying lead cables can

be purchased as an accessory from Watson- Marlow. The function of each of the leads is

labelled.

Input

Connection

Output

Connection

Input

connection

Output

connection

It is the user’s responsibility to ensure the safe and reliable operation of the pump under

remote and automatic control.

Never apply mains power to the five pole M12 connectors. Apply the

correct signals to the pins, as shown below. Limit signals to the

maximum values shown. Do not apply voltage across other terminals.

Permanent damage may result.

All input and output terminals are separated from mains circuits by

reinforced insulation. These terminals must only be connected to

external circuits that are also separated from mains voltages by

reinforced insulation as a minimum requirement.

m-qdos-en-02 25

Page 26

10.1 Input pin assignments at the pump

Pin 1

Pin 2

Pin 2

Pin 4

Pin 5

Pin 3

Pin

No.

Function Specification Referenced to

Input lead

colour

1 Run/stop Min. 5V, max.30V

Connect 5-24V DC supply to stop

(referenced to pin 4).

Alternatively, connect pin 5 of the

output connector to this pin via

normally open switch.

Brown

2

External

Contact

Reserved

Min. 5V, max .30V

Pulse 5-24V

40ms minimum pulse length

(referenced to pin 4).

Alternatively, connect pin 5 of the

output to this pin via normally

open switch.

White

3 4-20mA

250Ω input impedance

40mA max. current

250Ω load resistance 40mA

max.current

Referenced to GND Blue

4 GND Ground (0V) Black

5

Remote fluid

recovery

Min. 5V, max. 30V

Connect 5-24V DC supply to

reverse the pump in analog mode

Grey

10.2 Optional input lead

Input lead length: 3m (10ft)

Blue

insert

Brown

White

Blue

Black

Grey

m-qdos-en-02 26

Page 27

Remote stop

Depending on the polarity set in the control settings menu, applying a 5V to 24V signal to

pin 1 will STOP the pump in all operating modes. In manual and analogue mode, the pump

will start when the signal is removed. The user can reconfigure this input in the control

settings menu so that the pump will run when the signal is applied and stop when there is

no signal to pin 1.

The MAX key will work in manual mode regardless of the remote STOP input. This enables

priming without having to change pump settings or disconnect the input cable.

External contact—Universal and Universal+ models only

Digital pulse input min. 5V, min. pulse duration 40ms maximum duration 1000ms. This

input is used to trigger a user defined dose size. Refer to the contact mode section.

Speed: analog input

The speed of this pump can be controlled remotely by a current analog signal within the

range 4-20mA.

The analog signal must be applied to pin three of the M12 input connector. The pump will

provide an increasing speed for a rising control signal.

The Universal+ model can be calibrated by the user to control the speed proportionally or

inversely proportional to the input mA signal.

4-20mA circuit impedance: 250Ω.

Do not invert the polarity of the terminals. If the polarity is inverted

the motor will not run.

Remote fluid recovery

The user can reverse the pump remotely by supplying a signal to pin five.

10.3 Output pin assignments at the pump

Pin 1

Pin 2

Pin 4

Pin 5

Pin 3

Pin

No.

Function Specification

Output

lead

colour

1

Run status

output

Open collector output uncommitted Brown

2

Alarm

output

Open collector output uncommitted White

m-qdos-en-02 27

Page 28

Pin

No.

Function Specification

Output

lead

colour

3 Analog out 4-20mA into 250Ω ( referenced to pin 4) Blue

4 GND Black

5 Supply

Pin 5 supply voltage is 5V with impedance of 2.2k, this can be

connected via a NO switch to input pin 1 or 2 to power the inputs.

Grey

Example wiring for a "pull up resistor"

Diagram depicts either Alarm or Run Stop output.

+24VDC

INPUT

COMMON

PLC

2K2 Typical

1K2 Minimum

qdos

Example wiring for an external relay, the N/O or N/C contacts could be used for any device

Diagram depicts either Alarm or Run Status output.

qdos

+24VDC

Common

PLC

2K2 Typical

1K2 Minimum

1A 100V

The resistor or relay needs to be sized correctly to ensure no damage

to the pump transistors. Damage incurred due to incorrect sizing or

installation will not be covered by warranty.

These solutions require external 24V power. If connecting to a PLC 24V is usually available.

Alarm Output (Output 1)

Alarm conditions are generated by system errors or leak detection.

Run Status Output (Output 2)

This output changes state when the motor starts/stops.

Speed: analog output—Universal+ and Remote models only

A current analog signal within the range 4-20mA into 250Ω impedance is available between

pin three and pin four of the output connector. The current is fixed and directly proportional

to the pumphead rotation speed. 4mA = zero speed; 20mA = maximum speed.

m-qdos-en-02 28

Page 29

On the Universal+ version there is also an option to match the scale of the 4-20mA input if

this has been reconfigured by the user. This option is available in the Control settings

menu.

Note: If the mA output is to be used for reading from a multimeter, a 250Ω resistor is

required in series.

10.4 Optional output lead

Output lead length: 3m (10ft)

Yellow

insert

Brown

White

Blue

Black

Grey

m-qdos-en-02 29

Page 30

11 Automatic control wiring - 24V relay module and

110V relay module (Universal and Universal+ only)

The pump can be connected with other devices by means of the screw-terminal connectors

within the relay module situated on the side of the pump. The relay module must be

removed from the pump housing to allow suitable cables to be connected to the terminal

connectors via the watertight cable glands on the module. The pump can be supplied with

either a 24V or 110V relay module. Please confirm whether your relay module is 24V or

110V before wiring the module.

11.1 Module: cover removal and refitting

The pump can be connected with other devices by means of the screw-terminal connectors

within the relay module situated on the side of the pump. The relay module must be

removed from the pump housing to allow suitable cables to be connected to the terminal

connectors via the watertight cable glands on the module.

Removing the relay module cover

The module cover is secured to the side of the drive unit by four M3x10 Pozidriv pan head

stainless steel screws.

Remove the four screws from the module cover, leaving the

top left screw until last. It is possible that the sealing strip

may cause the module to adhere to the drive housing. If so a

gentle tap will free it. Do not use a tool to force it off.

The sealing strip should be retained within its channel on the

side panel of the drive housing. It ensures ingress protection

between the drive housing and the module cover. Check the

integrity of the sealing strip. If it is damaged it must be

replaced.

m-qdos-en-02 30

Page 31

Refitting the relay module cover

Ensure the sealing strip is undamaged and positioned within

its channel on the side of the drive housing. Hold the module

cover in place, taking care not to disturb the sealing strip.

Starting with the top left screw, tighten the four retaining

screws to 2.5Nm.

Ensure that the relay module cover is correctly secured at all times by

all four screws. Failure to do so may compromise the IP66 (NEMA 4X)

protection.

11.2 Wiring up the terminal connectors

It is the user’s responsibility to ensure the pump’s safe and reliable operation under

remote and automatic control.

Cable entry to the module is via two watertight cable glands on the module cover. These

may be fitted in place of the sealing plugs which are fitted to the side of the module cover

when the pump is shipped.

The number of glands needed depends on the number of connection cables required and

the convenience of the installer. As standard, two ½” cable glands are provided with the

pump.

Recommended control cable conductors for the terminal blocks: metric = 0.14sq mm -

2.5sq mm solid and 0.14sq mm - 1.5sq mm stranded. USA = 26AWG - 14AWG solid and

26AWG - 16AWG stranded. Cable: circular. Max/min outside diameter to ensure a seal when

passed through the standard gland: 9.5mm-12mm. The cable section must be circular to

ensure a seal.

For EMC protection, shielded control cable should be used. The shielding should be

terminated to either of the provided spade connections.

Cables should have a minimum temperature rating of 85°C.

Note: For 24V modules, screened, circular control cable up to 12 core must be used. For

110V modules, screened, circular control cable up to 25 core must be used. The cable

screen must be earthed at both ends of the cable.

Suitable cables for general-purpose use: 300V with extra premium grade PVC jacket with

good flame and moisture resistance.

Suitable cables for industrial use: 300V extra- rugged polyurethane grade jacket with

resistance to oils, fuels, solvents and water.

m-qdos-en-02 31

Page 32

For convenience of wiring more than 8 conductors per cable may be awkward to handle.

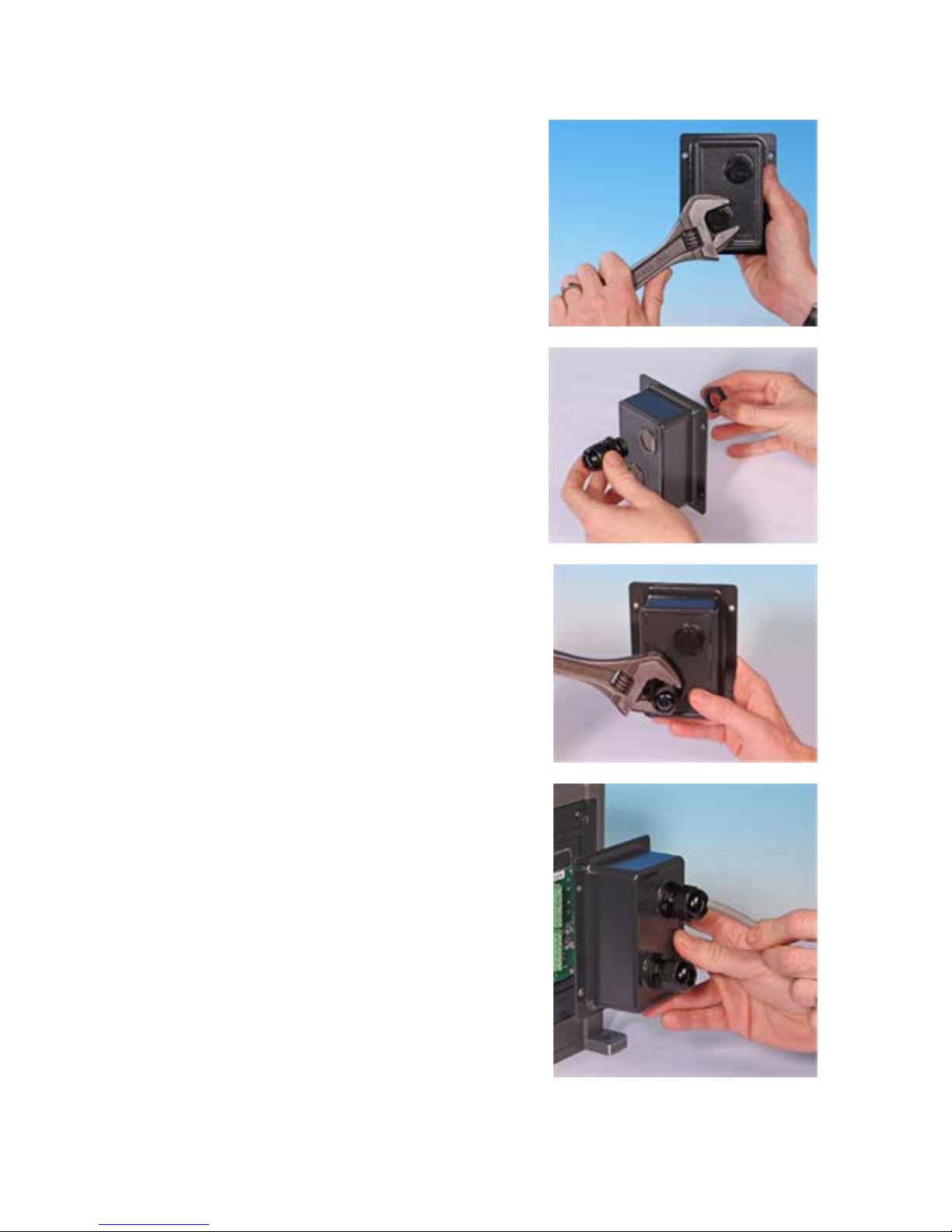

1. Use a suitable 21mm spanner to unscrew the

sealing plugs.

2. Screw in the supplied ½” NPT cable glands

complete with new sealing washers in place

of the plug, ensuring that the retaining nut is

properly seated.

3. Tighten the gland to 2.5Nm using a suitable

21mm spanner, to ensure a seal. If a different

gland is used, it must be watertight to IP66.

3. Loosen the gland cap (do not remove it) and

pass the cable in through the gland. When it

has passed through the gland, continue to

push the cable through.

4. Pull through sufficient cable to reach the

connectors required, leaving a little slack.

5. Strip the outer sheath as necessary and

remove 5mm of insulation from the

conductors. No tinning or ferrule is required.

Note:If very stiff or large-diameter cable is

used, it may be convenient to strip the outer

sheath before passing the cable’s conductors

through the gland. However, to ensure a

watertight seal, the cable must have an

undamaged sheath within the gland when it is

tightened.

m-qdos-en-02 32

Page 33

6. Prepare the cable screen(s) by twisting a

suitable length. The twisted length(s) shall

ideally be sleeved to prevent shorting.

7. Secure the end of the cable screen to the

Faston receptacles on the spade connectors

provided.

8. Push the bared conductor into the square hole

in the connector. When the conductor is fully

inserted, tighten the retaining screw to secure

it in place.

Ensure that multi strand

wires are terminated with a

crimp, suitable for the wire

diameter. Failure to do so

may result in electric shock.

9. When all conductors are in position replace

the module cover.

10. Using a 21mm spanner tighten the gland cap

to 2.5Nm to ensure a watertight seal.

Alternatively, tighten the gland by hand until

it is finger-tight and use a spanner to tighten

it further by one-half a turn.

Ensure that unused

openings on the module are

sealed using the blanking

plugs provided. Failure to do

so will result in loss of

ingress protection.

m-qdos-en-02 33

Page 34

11.3 24Vrelay module pcb connectors

As you look at the module the pcb will appear in the same orientation as shown in the

diagram below.

J1 J2 J3 J4 J5

4-20mA 4-20mA Stop/ RLY2 RLY1

O/P GND I/P GND +24V Contact N/O C N/C N/O C N/C

J6 J7

1 1 1 1 12 2 2 3 3

Never apply mains power to the 4-20mA input, 4-20mA

output,+24VDC or stop contact terminals. Apply the correct signals to

the terminals shown below. Limit signals to the maximum values

shown. Do not apply voltage across other terminals. Permanent

damage, not covered by warranty, may result. The maximum load on

the relay contacts of this pump is 110VAC 5A or 30VDC 5A.

Alarm output (J5)

Connect the output device to the C (common) terminal

of the relay connector and either the N/C (normally

closed) or N/O (normally open) terminal as required.

This relay coil is energised when the pump has an alarm

condition.

Note: Alarm conditions are generated by system errors.

This alarm will not be operated for analogue signal

errors.

The default for Relay 1 is Alarm, on universal+ models

this output (1) can be configured in the control settings

menu.

RLY1

N/C 3

J5

C

N/O

2

1

m-qdos-en-02 34

Page 35

Run status output (J4)

Connect the output device to the C (common) terminal

of the relay connector and either the N/C (normally

closed) or N/O (normally open) terminal as required.

This relay coil is energised when the pump is running.

The default for Relay 2 is run status, on universal+

models this output (2) can be configured in the control

settings menu.

RLY 2

N/C

3

J4

C

N/O

2

1

Configurable remote stop or contact

input - J3

If Analog 4-20mA mode is selected then

terminal J3 will be configured as a remote stop

automatically.

If Contact mode is selected then the input J3

will be configured as a contact input

automatically.

Rem Stop

Stop/contact 2

J3

J2

+24V

GND

1

2

Remote Stop

Connect a remote switch between the Stop/Contact terminal and the +24V terminal of

the Run/Stop I/P connector (J3). Alternatively a 24V logic input may be applied to the

Stop/Contact terminal, ground to the GND terminal of the adjacent 4-20mA I/P connector

(J2).

The sense of the remote stop input can be configured in software using the control settings

menu.

Remote stop is operational in manual and analog mode.

Contact

To operate the pump in contact mode the remote stop input should be set to "High".

Speed: analog input (J2)

The analog process signal must be applied to the I/P

terminal of the Analog connector (J2). Ground to the

GND connector of the same terminal. In Analog mode

the pump set speed will be proportional or inversely

proportional to the analog input.

4-20mA circuit impedance: 250Ω.

Max current 40mA

Note: inverting the signal response is set up in

software. Do not invert the polarity of the terminals.

Analog

GND 2

J2

I/P 1

See also "Analog 4-20mA mode (Universal and Universal+ only)" on page67 and "Calibrate

the pump for 4-20mA control (Universal+ only)" on page72.

m-qdos-en-02 35

Page 36

Speed: analogue output (J1) (Universal+ only)

A current analogue signal within the range 4-20mA is

available between the O/P (output) terminal and the

GND terminal. The current is fixed and directly

proportional to the pump speed. 20mA = maximum

speed, 4mA = zero speed.

There is also an option to match the scale of the 420mA input if this has been reconfigured by the user.

This option is available in the C ontrol settings menu.

Note: If the mA output is to be used for reading from a

multimeter (set on mA), a 250Ω resistor is required in

series.

4-20mA

GND 2

J1

O/P 1

Earth shielding terminals

4.8mm spade terminals are supplied for earth shielding of

cables. The input cable and output cable earths can be

connected to either terminal.

Keep 4-20mA and low voltage signals separate from mains power. Use

separate glanded input cables.

m-qdos-en-02 36

Page 37

11.4 110V relay module pcb connectors

As you look at the module the pcb will appear in the same orientation as shown in the

diagram below.

J1 J2 J3 J4 J5

4-20mA 4-20mA Run Stop RLY2 RLY1

O/P GND I/P GND AC1 AC2 N/O C N/C N/O C N/C

1 1 1 1 12 2 2

J6 J7

3 3

Apply the correct signals to the terminals shown below. Limit signals

to the maximum values shown. Do not apply voltage across other

terminals. Permanent damage, not covered by warranty, may result.

The maximum load on the relay contacts of this pump is 115VAC; max

current 5A. Voltages do not require transformer isolation. The relays

are specified to switch 115VAC mains powered loads. These relay

outputs are not suitable for 24VDC logic signals.

Alarm output (J5)

Connect the output device to the C (common) terminal

of the relay connector and either the N/C (normally

closed) or N/O (normally open) terminal as required.

This relay coil is energised when the pump has an alarm

condition.

Note: Alarm conditions are generated by system errors.

This alarm will not be operated for analogue signal

errors.

The default for Relay 1 is Alarm, on universal+ models

this output (1) can be configured in the control settings

menu.

RLY1

N/C 3

J5

C

N/O

2

1

m-qdos-en-02 37

Page 38

Run status output (J4)

Connect the output device to the C (common) terminal

of the relay connector and either the N/C (normally

closed) or N/O (normally open) terminal as required.

This relay coil is energised when the pump is running.

The default for Relay 2 is run status, on universal+

models this output (2) can be configured in the control

settings menu.

RLY 2

N/C

3

J4

C

N/O

2

1

Remote stop input (J3)

Apply a signal of 85VAC to 130VAC across terminals AC1

and AC2 to stop the pump. Polarity is not important.

The pump will not run while this signal is applied. In

manual and analog mode, the pump will start when the

signal is removed.

Rem Stop

AC1 2

J3

AC2 1

Speed: analog input (J2)

The analog process signal must be applied to the I/P

terminal of the Analog connector (J2). Ground to the

GND connector of the same terminal. In Analog mode

the pump set speed will be proportional or inversely

proportional to the analog input.

4-20mA circuit impedance: 250Ω.

Max current 40mA

Note: inverting the signal response is set up in

software. Do not invert the polarity of the terminals.

Analog

GND 2

J2

I/P 1

Speed: analogue output (J1) (Universal+ only)

A current analogue signal within the range 4-20mA is

available between the O/P (output) terminal and the

GND terminal. The current is fixed and directly

proportional to the pump speed. 20mA = maximum

speed, 4mA = zero speed.

There is also an option to match the scale of the 420mA input if this has been reconfigured by the user.

This option is available in the C ontrol settings menu.

Note: If the mA output is to be used for reading from a

multimeter (set on mA), a 250Ω resistor is required in

series.

4-20mA

GND 2

J1

O/P 1

m-qdos-en-02 38

Page 39

Earth shielding terminals

4.8mm spade terminals are supplied for earth shielding of cables.

The input cable and output cable earths can be connected to

either terminal.

4-20mA and low voltage signals separate

from mains power. Use separate glanded

input cables

m-qdos-en-02 39

Page 40

12 PROFIBUS control wiring

Interfacing the pump with the PROFIBUS network is by means of an M12 connector mounted

on a flying lead on the front of the pump.

It is the user’s responsibility to ensure the safe and reliable operation of the pump under

PROFIBUS control.

Note: The transmission speed is limited to a maximum of 1.5Mbit/s.

12.1 PROFIBUS installation

All dev ices in the bus system must be connected in a line. An IP66 rated T adaptor should

be used to connect the pump to the PROFIBUS line. A maximum of 32 stations (to include

master, slaves and repeaters) are possible and both the beginning and the end of the cable

must be terminated with a terminating resistor.

The M12 socket provided for PROFIBUS installation is IP66 rated. To maintain an IP66 rated

system, the PROFIBUS cable, T adaptors and terminating resistors used must be fitted with

IP66 rated M12 industrial connectors.

Note: To prevent low- frequency ground loops, screening which is earthed at one end

should be used. To counter magnetic HF pick-up, shielding earthed at both ends as well as

twisted conductors should be used, this will have no effect against electrical HF pick -up.

The permissible overall length of the bus cabling will vary according to the required bit

rate. If a longer cable or higher bit rate are required repeaters should be used. The

maximum bit rates achievable are shown in the table below.

Bit rate (Kbit/s) Max. length of type A bus cable (m)

1500 200

500 400

187.5 1000

93.75 1200

19.2 1200

9.6 1200

Note: Total stub length should not exceed 6.6m.

m-qdos-en-02 40

Page 41

12.2 Pin assignments at the pump

Pin 4

Pin 3

Pin 5

Pin 1

Pin 2

Pin No. Signal Function

1 VP +5V supply for terminating resistors

2 RxD/TxD-N Data line minus (A-line)

3 DGND Data ground

4 RxD/TxD-P Data line plus (B-line)

5 Shield Ground connection

Note: If the pump is the last bus device connected to the PROFIBUS cable it must be

terminated using terminating resistor (PROFIBUS standard EN 50170). To maintain ingress

protection the resistor must be IP66 rated.

m-qdos-en-02 41

Page 42

13 Switching on (Manual, PROFIBUS, Universal and

Universal+)

13.1 Switching on the pump for the first time (Manual,

PROFIBUS, Universal and Universal+ only)

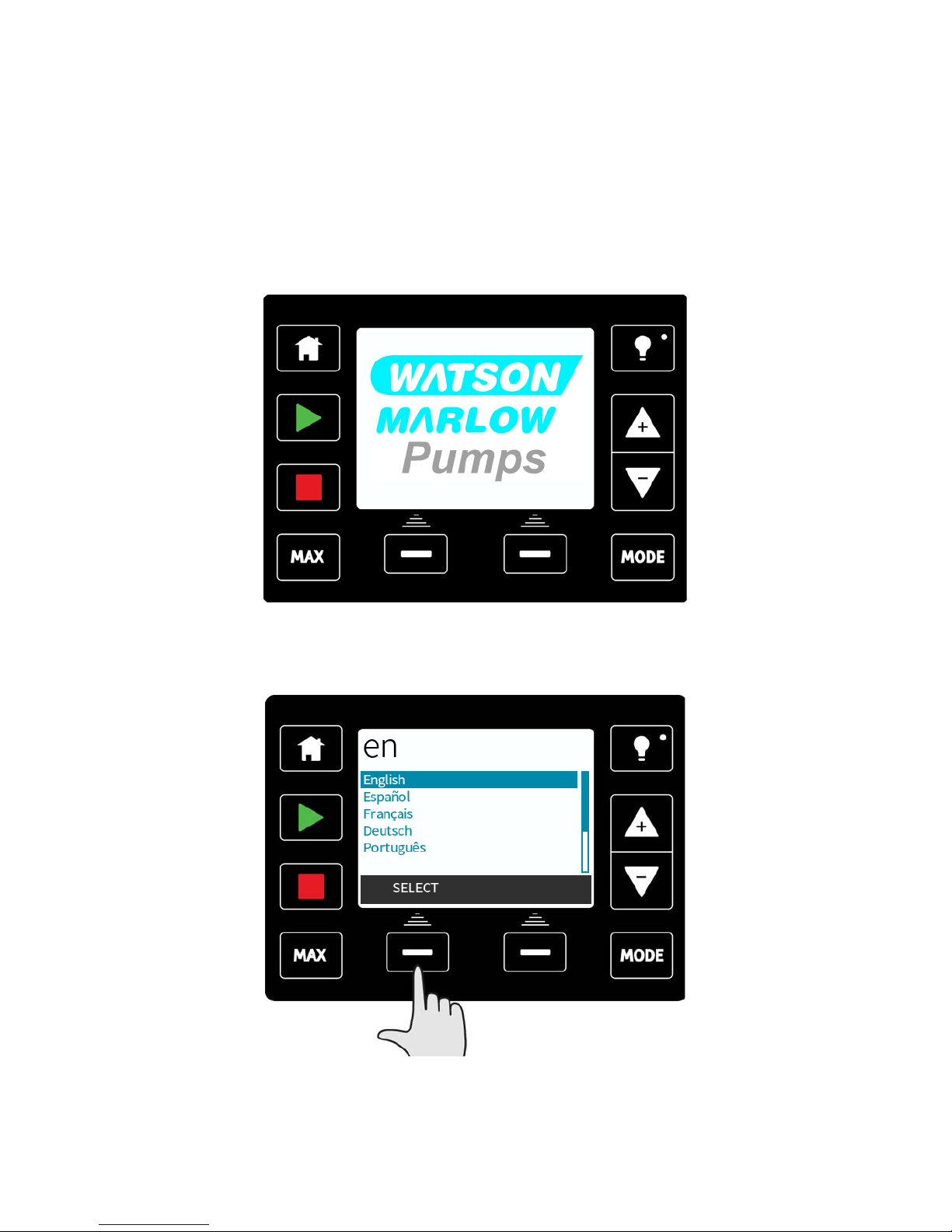

Power-up the pump.

The pump displays the start- up screen with the Watson- Marlow Pumps logo for three

seconds.

Selecting your chosen display language

Use the +/- keys to move the selection bar to your required language. Press SELECT to

choose.

Your selected language will now be displayed on screen, choose CONFIRM to continue. All

displayed text will now appear in your chosen language.

m-qdos-en-02 42

Page 43

Choose REJECT to return to the language choice screen.

The pump is preset with operational parameters as shown in the table below:

First-time start-up defaults

Flow rate

qdos120:960ml/min

qdos60:480ml/min

qdos30:240ml/min

qdos20:120ml/min

Pump status Stopped

Calibration

qdos120:16 ml/rev

qdos60:6.67ml/rev

qdos30:8 ml/rev

qdos20:4 ml/rev

Flow unit ml/min

Backlight 30 minutes Pump tag WATSON-MARLOW

Auto restart Off

This then proceeds to the home screen.

m-qdos-en-02 43

Page 44

The pump is now ready to operate according to the defaults listed above.

Note: The display background colour changes according to running state as follows:

l White background indicates pump stopped

l Blue background indicates pump running

l Red background indicates error or alarm

All operating parameters may be changed by means of key-presses (see "Pump operation"

on page46).

13.2 Switching the pump on in subsequent power cycles

(Manual, PROFIBUS, Universal and Universal+ only)

Subsequent power-up sequences will jump from the start-up screen to the home screen.

l The pump runs a power- on test to confirm proper functioning of the memory and

hardware. If a fault is found, an error code is displayed (see "Error codes" on page108).

l The pump displays the start-up screen with the Watson-Marlow Pumps logo for three

seconds followed by the home screen.

l Start-up defaults are those in place when the pump was switched off last.

Check that the pump is set to operate as you require it.

The pump is now ready to operate.

All operating parameters may be changed by means of key-presses (see "Pump operation"

on page46).

Power interruption

This pump has an auto restart feature which, when active, will restore the pump to the

operating state it was in when power was lost. See "Main menu (Manual, PROFIBUS,

Universal and Universal+ only) " on page84.

Stop / start power cycles

Do not power up/power down for more than 20 starts per hour, whether manually or by

means of the auto restart facility. We recommend remote control where a high frequency of

power cycles is required.

m-qdos-en-02 44

Page 45

14 Switching on (Remote)

When power is supplied to the pump, all the LED icons will illuminate for three seconds.

After this period the pump will operate in accordance with the inputs received.

m-qdos-en-02 45

Page 46

15 Pump operation

Note: Sections "Keypad functions (Manual, PROFIBUS, Universal and Universal+ only)"

below up to and including "Help (Manual, PROFIBUS, Universal and Universal+ only)" on

page105 apply to Manual, PROFIBUS, Universal and Universal+ only. It is only possible to

control the Remote pump via the input and output, (I/O) provided.

15.1 Pump operation (Remote pump)

The remote pump will operate proportionally to the analog signal provided. The default

figures are 4.1mA = 0 rpm, 19.8mA = 125 rpm.

To stop the pump remotely apply a signal, minimum 5V, maximum 24V, to input pin 1. To

run the pump in reverse, apply a signal, minimum 5V, maximum 24V to input pin 5.

15.2 Pump operation (Manual, PROFIBUS, Universal and

Universal+ only)

Keypad functions (Manual, PROFIBUS, Universal and Universal+ only)

Backlight

Change value /

move selection

bar

Mode

Priming

Stop

Start

Home

Colour TFT display

Left hand

function

Right hand

function

HOME

When the HOME key is pressed it will return the user to the last known operating mode. If

modifying pump settings when the HOME key is pressed, it will disregard any setting

changes and return you to the last known operating mode.

START

This key will start the pump at the displayed set speed when in manual mode or flow

calibration. This key will deliver a contact dose volume when in CONTACT mode. It has no

effect in the other remote modes.

STOP

This key will stop the pump when pressed at any time.

m-qdos-en-02 46

Page 47

MAX

This key can be used to prime the pump when in manual mode. When pressed the pump

will operate at maximum flow rate.

FUNCTION KEYS

When pressed will perform the function displayed on the screen directly above the relevant

function key.

After 30 minutes of no keypad activity, the HMI display will dim to 50% brightness.

To restore full power to the display and reset the timer, press the BACKLIGHT key.

+/- KEYS

These keys are used to change programmable values within the pump. For example, flow

rate. These keys are also used to move the selection bar up and down in the menus.

MODE

To change modes or mode settings, press the MODE key. The MODE key can be pressed at

any time to enter the mode menu. If modifying pump settings when the MODE key is

pressed, it will disregard any setting changes and return you to the MODE menu.

SCREEN SAVER

The display refreshes every 60 seconds. When this occurs you may notice a brief flash.

Screen Icons (Manual, PROFIBUS, Universal and Universal+ only)

Under certain conditions, various icons will appear in the screen display area:

The pump displays a RED stop icon when it is in a manually stopped condition.

In this state the pump will not start unless the START key is pressed.

The pump displays a RED PAUSE icon when it is receiving a remote stop input

whilst in a standby condition. The pump is placed in a standby condition by

pressing the START key in manual mode, or by selecting Analogue mode.

In this state the pump will respond to a change in state of the start/stop input,

and may start automatically when a control signal is received.

When the pump is running it displays a turning icon to indicate a pumping state.

Fundamental work with regard to lifting, transportation, installation,

starting-up, maintenance and repair should be performed by qualified

personnel only. The unit must be isolated from mains power while

work is being carried out. The motor must be secured against

accidental start-up.

m-qdos-en-02 47

Page 48

Switching between modes (Manual, PROFIBUS, Universal and Universal+ only)

Note: Remote model does not feature selectable modes.

Using +/- keys will scroll through the available modes. The available modes are:

l Manual (default)

l Flow calibration

l Analog 4–20mA (Universal and Universal+ only)

l Contact mode (Univ ersal+ only)

l PROFIBUS (PROFIBUS only)

l Fluid recovery

l CANCEL

Use SELECT to choose mode. Use the right hand function key to alter mode settings.

m-qdos-en-02 48

Page 49

16 Manual mode (Manual, PROFIBUS, Universal and

Universal+ only)

All settings and functions of the pump in manual mode are set and controlled by means of

key-presses. Immediately after the start-up display sequence (detailed in: "Switching the

pump on in subsequent power cycles (Manual, PROFIBUS, Universal and Univ ersal+ only)"

on page44 ), the manual mode home screen will be displayed unless auto restart is

enabled.

If enabled, the pump will return to the last known operating state when the power was

lost. When the pump is running it displays an animated clockwise arrow. In normal

operation, the direction of flow is into the bottom port of the pumphead and out of the top

port.

If an exclamation mark (! ) is displayed, it indicates that Auto restart is on (see 18.3

General settings on page 57). If a padlock icon shows, it indicates that the keypad lock is

on.

START

Starts the pump at the current flow displayed, and the display background changes to blue.

If the pump is running pressing this has no effect.

m-qdos-en-02 49

Page 50

STOP

Stops the pump. The display background changes to white. If the pump is not running

pressing this has no effect.

INCREASING AND DECREASING FLOWRATE

Using the +/- keys will increase or decrease the flowrate.

Decreasing flowrate:

l A single key press will decrease flowrate by the least significant digit of the chosen

flowrate unit.

l Repeat key presses as required to achieve the desired flowrate.

l Hold down the key for flowrate scrolling.

m-qdos-en-02 50

Page 51

Increasing flow rate:

l A single key press will increase flowrate by the least significant digit of the chosen

flowrate unit.

l Repeat key -presses as required to achieve the desired flowrate.

l Hold down the key for flowrate scrolling.

Max 100% function (Manual mode only)

l Press and hold the MAX key to run at maximum flow.

l Release the key to stop the pump.

l The volume dispensed and time elapsed are displayed whilst the MAX key is pressed

and held. The MAX function will work when the key is pressed in manual mode

regardless of the status of the START/STOP input.

m-qdos-en-02 51

Page 52

17 PROFIBUS mode(PROFIBUS only)

In this operating mode PROFIBUS control can be enabled or disabled. The qdos PROFIBUS

pump is designed so that the station address can only be set from the pump. The user can

set the station address within this mode.

Select MODE

Using the +/- keys scroll to PROFIBUS and press SELECT

If PROFIBUS is not enabled, the screen below will prompt you to CONFIRM that you would

like to enable PROFIBUS.

On the PROFIBUS home screen the white P icon indicates that there is data exchange.

m-qdos-en-02 52

Page 53

Pressing the INFO function key will display further information.

17.1 Assigning the PROFIBUS station address at the pump

The station address can only be set from PROFIBUS settings. The station address cannot be

automatically assigned by the master.

Select MODE

Using the +/- keys scroll to PROFIBUS and press SETTINGS

m-qdos-en-02 53

Page 54

Using the +/- k eys alter the station address, in the range from 1 to 125. (126 is the default

station address).

Press FINISH to set the station address, or NEXT to enable/disable PROFIBUS

communication.

Use the +/- key s to enable or disable PROFIBUS communication and press FINISH.

m-qdos-en-02 54

Page 55

17.2 PROFIBUS communication errors

In PROFIBUS mode, the screen below is displayed, the P indicates data exchange is

happening.

This screen will only be displayed after successful implementation of Master Slave

communications, which always follow the sequence described below.

Power ON Reset

Power ON / reset of Master or Slave

Download of parameters into the eld device (selected

during conguration by the user)

Download of I/O conguration into the eld device

(selected during conguration by the user)

Cyclic data exchange (I/O data) and eld device reports

diagnostic

Parameterisation

I/O conguration

Data exchange

If data exchange is lost at any time, the following screen will be displayed. The first red dot

corresponds to the stage at which the error occurred and subsequent stages will indicate a

red dot because the communication sequence halted before this point.

m-qdos-en-02 55

Page 56

The screen will state running or stopped, depending on how the user has set up the failsafe function within the PROFIBUS GSD file (see "PROFIBUS GSD file" below ). The MODE

button gives access to the PROFIBUS settings and the station address. When the menus are

accessed, the pump is still in PROFIBUS bus mode but with no communications.

After five minutes of inactivity the pump will revert back to the home screen and discard

any unsaved changes, if there are still no communications then the BUS ERROR screen will

be displayed.

17.3 PROFIBUS GSD file

The qdos PROFIBUS pump can be integrated into a PROFIBUS DP V0 network using a

General Station Data (GSD) file. The file identifies the pump and contains key data

including its communication settings, the commands it can receive and the diagnostic

information it can pass to the PROFIBUS master on interrogation.

The GSD file— file name WAMA0E7D.GSD—can bedownloaded from the Watson- Marlow

website and installed; or typed into a PROFIBUS master directly from this manual using a

GSD editor program.

Note: The data- flow to and from the pump may need to be byte- reversed, due to

differences of handling the data between suppliers of master devices.

The GSD file, filename: WAMA0E7D.GSD

;

;*************************************************************************

***********

;*

=======================================================

========================= *

;* *

;* Watson-Marlow Bredel Pumps *

;* Bickland Water Road *

;* Falmouth *

;* Cornwall *

;* TR11 4RU *

;* Tel.: +44(1326)370370 *

;* FAX.: +44(1326)376009 *

m-qdos-en-02 56

Page 57

;* *

;*

=======================================================

========================= *

;* Filename: WAMA0E7D.GSD *

;* GSD file version 3 from 2013-09-24 *

;* -------------------------------------------------------------------------------- *

;* *

;*************************************************************************

***********

#Profibus_DP

GSD_Revision = 3

Vendor_Name = “Watson Marlow”

Model_Name = “Qdos Profibus Pump”

Revision = “Version 3.00”

Ident_Number = 0x0E7D

Protocol_Ident = 0

Station_Type = 0

FMS_supp = 0

Hardware_Release = “V1.00”

Software_Release = “V1.00”

Redundancy = 0

Repeater_Ctrl_Sig = 0

24V_Pins = 0

9.6_supp = 1

19.2_supp = 1

45.45_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6=60

MaxTsdr_19.2=60

MaxTsdr_45.45=60

MaxTsdr_93.75=60

MaxTsdr_187.5=60

MaxTsdr_500=100

m-qdos-en-02 57

Page 58

MaxTsdr_1.5M=150

MaxTsdr_3M=250

MaxTsdr_6M=450

MaxTsdr_12M=800

Slave_Family = 0

Implementation_Type = “VPC3+S”

Info_Text=”PROFICHIP: PROFIBUS DPV0 - slave, Watson Marlow Qdos”

Bitmap_Device = “WAMA_1N”

Freeze_Mode_supp=1

Sync_Mode_supp=1

Fail_Safe=1

Auto_Baud_supp=1

Set_Slave_Add_supp=0

Min_Slave_Intervall=6

Modular_Station=0

Max_Diag_Data_Len=34

Max_User_Prm_Data_Len = 9

Ext_User_Prm_Data_Const(0)= 0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00,0x00

Module=”WM Pump, 3/14 word out/in” 0x62,0x5D

1

EndModule

17.4 User Parameter Data

The user parameter data is set by entering values into the ‘Ext_User_Prm_Data_ Const(0)’

line of the GSD file. This is indicated below and the relevant bytes are listed in the table.

No further changes should be made to the GSD file and Watson- Marlow accepts no

responsibility for pump failures arising from changes to the GSD file.

Byte1Byte2Byte3Byte4Byte5Byte6Byte7Byte8Byte

9

8 bit Byte 1 Pre Assigned

8 bit Byte 2 Reserved

8 bit Byte 3 Min Speed (High byte of 16-bit unsigned)

8 bit Byte 4 Min Speed (Low byte of 16-bit unsigned)

8 bit Byte 5 Max Speed (High byte of 16-bit unsigned)

8 bit Byte 6 Max Speed (Low byte of 16-bit unsigned)

m-qdos-en-02 58

Page 59

8 bit Byte 7 Fail Safe

8 bit Byte 8 Fail Safe Speed (Low byte of 16-bit unsigned)

8 bit Byte 9 Fail Safe Speed (High byte of 16-bit unsigned)

Set Min/Max Speeds

The Min/Max Speed parameters are used to set the minimum and max imum speed from the

PROFIBUS interface. The values are only used if the matching bit in the Control Word is

enabled and they are not zero. The values are 16 bit unsigned in 1/10th of RPM of the head

speed.

If the user requests the pump to operate at a lower speed than the defined minimum speed

from the user parameter data (bytes 3, 4) then the pump will operate at the defined

minimum speed.

If a max imum speed has been configured in the user parameter data, then the pump will be

limited to this maximum speed even when the master requests a higher rpm.

Fail Safe

The fail-safe user parameter is used to set the correct course of action to take in the event

of a PROFIBUS communications failure. The fail-safe byte is configured as shown in the

following table. If no bits are set or an invalid bit pattern is set the default fail safe

behaviour shall be to stop the pump.

Hex Description

0x00 The pump will stop

0x01 Continue driving using the last demanded speed

0x02 Continue driving using the fail safe speed

0x03 - 0x07 R eserved

Fail Safe Speed

The fail-safe speed parameter is used to set the speed at which the pump should be driven

if a PROFIBUS communications error occurs and if the fail-safe user parameter is set to

0x02.

17.5 PROFIBUS data exchange

The data in this section is provided as reference material for a PROFIBUS network operator.

Operating this pump under PROFIBUS control is beyond the scope of this instruction

manual. Consult your PROFIBUS network literature for further information.

Default address 126

PROFIBUS Ident 0x0E7D

GSD File: WAMA0E7D.GSD

Config: 0x62, 0x5D (3 words out, 14 words in)

User parameter bytes: 6

Cyclic Data Write (from Master to pump)

Cyclic Data Write (from Master to pump)

16 bit Byte 1 (low) , 2 (high) Control Word

16 bit Byte 3 (low) , 4 (high) Pumphead Speed Setpoint (unsigned)

m-qdos-en-02 59

Page 60

Cyclic Data Write (from Master to pump)

16 bit Byte 5 (low) , 6 (high) Set Flow Calibration in μl per revolution

Control Word

Bit Descrip tion

0 Motor running (1= Running)

1 Direction ( 0= CW, 1= CCW)

2 Motor revolution counter reset (1=R eset count)

3 Reserved

4 Enable User Parameter Min/Max Speeds (1= Enabled)

5 Enable Fieldbus master to set Flow Calibration (1= Enabled)

6 Ignore leak detection sensor

7 Fluid Level Reset

8-15 Reserved

Pumphead Speed Setpoint

The speed setpoint is a 16-bit unsigned integer value that represents the speed of the

pump head in 1/10th of RPM. For example 1205 represents 120.5 RPM.

Set Flow Calibration

This parameter is used to set the flow calibration value from the fieldbus interface. The

value is a 16 bit unsigned integer representing μl per revolution of the pumphead. Note

that this value is only used if bit 5 of the Control Word is enabled.

Ignore Leak Detection Sensor

If bit 6 of the control word is enabled, the following run screen will be displayed.

m-qdos-en-02 60

Page 61

If a leak is detected the leak detect screen (16.1 Leak detection on page 54) will not be

displayed. Bit 10 of the status word will be activated to indicate that a leak has occurred

and the pump will continue to run until the Master indicates what action should be taken.

Cyclic Data Read (from pump to Master)

Cyclic data read (from p ump to Master)

16 bit Byte 1, 2 Status Word

16 bit Byte 3, 4 Pumphead Measured Speed (unsigned)

16 bit Byte 5, 6 Hours Run

16 bit Byte 10,9 No of full motor revolutions

16 bit Bytes 8,7 Reserved

32 bit Byte 13, 14, 15, 16 Fluid Level

32 bit Byte 17, 18, 19, 20 Unassigned

32 bit Byte 21, 22, 23, 24 Unassigned

32 bit Byte 25, 26, 27, 28 Unassigned

Status Word

Bit Description

0 Motor running (1= Running)

1 Global Error Flag (1= Error)

2 Fieldbus C ontrol (1= Enabled)

3 Reserved

4 Over current error

5 Under voltage error

6 Over voltage error

7 Over temperature error

8 Motor stalled

9 Tacho fault

10 Leak detected

11 Low Setpoint- Out of range

12 High Setpoint- Out of range

13 Fluid level alert

14 Reserved

15 Reserved

m-qdos-en-02 61

Page 62

Pumphead Speed

The pumphead speed is a 16-bit unsigned integer value that represents the speed of the

pump head in 1/10th of RPM. For example 1205 represents 120.5 RPM.

Hours Run

The hours run parameter is a 16 bit unsigned integer and will represent whole hours of

runtime.

No of full motor revolutions

This counts down from FF for each complete motor revolution. Reset this counter to FF by

using bit 2 of the control word. The motor relates to the motor inside the pump before the

gearbox ratio. The number of pumphead revolutions can be obtained by dividing the

number of motor revolutions by the gearbox ratio of 29.55.

BYTE HEX TO DECIMAL

10 9 10 9

A FF FF 65536

B FF C4 65476

MOTOR FULL

REVOLUTIONS

A Minus B 59

A = Start of Dose

B = End of Dose

PUMPHEAD REVOLUTIONS

MOTOR REVS GEARBOX RATIO

59 29.55

Divide

1.996 RPM

Read Flow Calibration

The value is a 16 bit unsigned integer representing μl per revolution.

17.6 Device-related diagnostic data

8 bit Byte 1 Header Byte

16 bit Byte 2, 3 Reserved

16 bit Byte 4, 5 Reserved

16 bit Byte 6, 7 Min Speed (unsigned)

16 bit Byte 8, 9 Max Speed (unsigned)

32 bit Byte 10, 11, 12, 13 Software Version Main CPU

32 bit Byte 14, 15, 16, 17 Software Version HMI CPU

32 bit Byte 18, 19, 20, 21 Software Version Flash

32 bit Byte 22, 23, 24, 25 Software version PROFIBUS CPU

17.7 Channel-related diagnostic data

Channel-related diagnostic blocks are always three bytes long in the following format:

m-qdos-en-02 62

Page 63

Byte 26 Header

Byte 27 Channel type

Byte 28 Channel-related error code

Channel-related diagnostic data Byte 3

Global error =0xA9 (General error)

Over current =0xA1 (Short circuit)

Under voltage =0xA2 (Under voltage)

Over voltage =0xA3 (Over voltage) =0xA3 (Over voltage)

Motor stall =0xA4 (Overload)

Over temp =0xA5 (Over temp) =0xA5 (Over temp)

Tacho fault =0xB1 (Device related 0x11)

Leak detected =0xB2 (Device related 0x12)

Fluid lev el alert =0xB3 (Device related 0x15)

Reserved =0xA6 (Reserved)

Setpoint out of range- high =0xA7 (Upper limit exceeded)

Setpoint out of range- low =0xA8 (Lower limit exceeded)

m-qdos-en-02 63

Page 64