Page 1

SERVICE GUIDE

For

WARN PULLZALL 24Vdc

P/N 885005 & 885006

REPAIR / REPLACEMENT INSTRUCTIONS

TROUBLE SHOOTING GUIDE

987606A1.doc Page 1 of 46

Page 2

Always

refer to the

wiring diagram

for all wiring schematics and specific details on how

WARNING

This guide identifies potential hazards and has important safety messages that help you

and others avoid personal injury or death. WARNING and CAUTION are signal words

that identify the level of hazard. These signal words mean:

WARNING signals a hazard that may cause serious injury or death, if you do not

follow recommendations. CAUTION signals a hazard that may cause minor to

moderate injury, if you do not follow recommendations.

This guide uses NOTICE to call attention to important mechanical information, and

Note: to emphasize general information worthy of special attention.

Notice

This guide has been provided for use by WARN Authorized Service Centers. Any

other use is prohibited.

Caution

Moving parts entanglement hazard

Failure to observe these instructions could lead to minor or moderate injury

Always take time to read fully and understand the instructions.

Never operate this product if you are under 16 years of age.

Never operate this product under the influence of drugs, alcohol or medications.

Read instructions thoroughly

Notice

Equipment damage

to wire this WARN product.

Read instructions thoroughly.

987606A1.doc Page 2 of 46

Page 3

CONTENTS

1. GENERAL DESCRIPTION 4

2. DISASSEMBLY AND ASSEMBLY

2.1. Suggested Tools 6

2.2. Battery 7

2.3. Housing 11

2.4. Motor 16

2.5. Wire Rope Assembly 18

2.6. Safety Hook 25

2.7. Tail Hook 29

2.8. Gear Sets 33

2.9. Drum Assembly 33

2.10. Wiring Diagrams 34

2.11. Torque Specifications 42

3. PULLZALL TROUBLE SHOOTING 43

4. SERVICE PART LIST 45

987606A1.doc Page 3 of 46

Page 4

1. GENERAL DESCRIPTION

The PullzAll is a powerful, lightweight, easy-to-use handheld electric tool with the ability to

lift or pull up to 1,000 lbs. A strong Motor and Variable Speed Control allow you to move

heavy items into place smoothly and precisely. These features equate to saving both time and

money.

The PullzAll helps in getting the job done easier, faster and with less manual labor than a

come-a-long or chain fall, making you more productive. The PullzAll is for the tradesperson,

farmer/rancher, or anyone that needs to lift or pull up to 1,000 lbs. This makes PullzAll ideal

for construction, pipe fitting, iron work, equipment and plant maintenance, farm and ranch use,

auto shops, garages, machine shops, home improvement, hunting, camping and more.

Cordless PullzAll 24VDC Specifications:

1. Part number 885005 (Domestic US), 885006 (International).

2. Light weight and portable.

3. Powerful 24 Volt rechargeable NiMH Battery pack (with charger and spare Battery)

4. 1,000 lbs. lifting/pulling capacity.

5. 15' of 7/32" diameter Wire Rope.

6. Variable Speed Control for precision load placement.

7. Convenient forward/reverse Switch.

8. Electronic Load Limiter with LED Indicator for operator feedback.

987606A1.doc Page 4 of 46

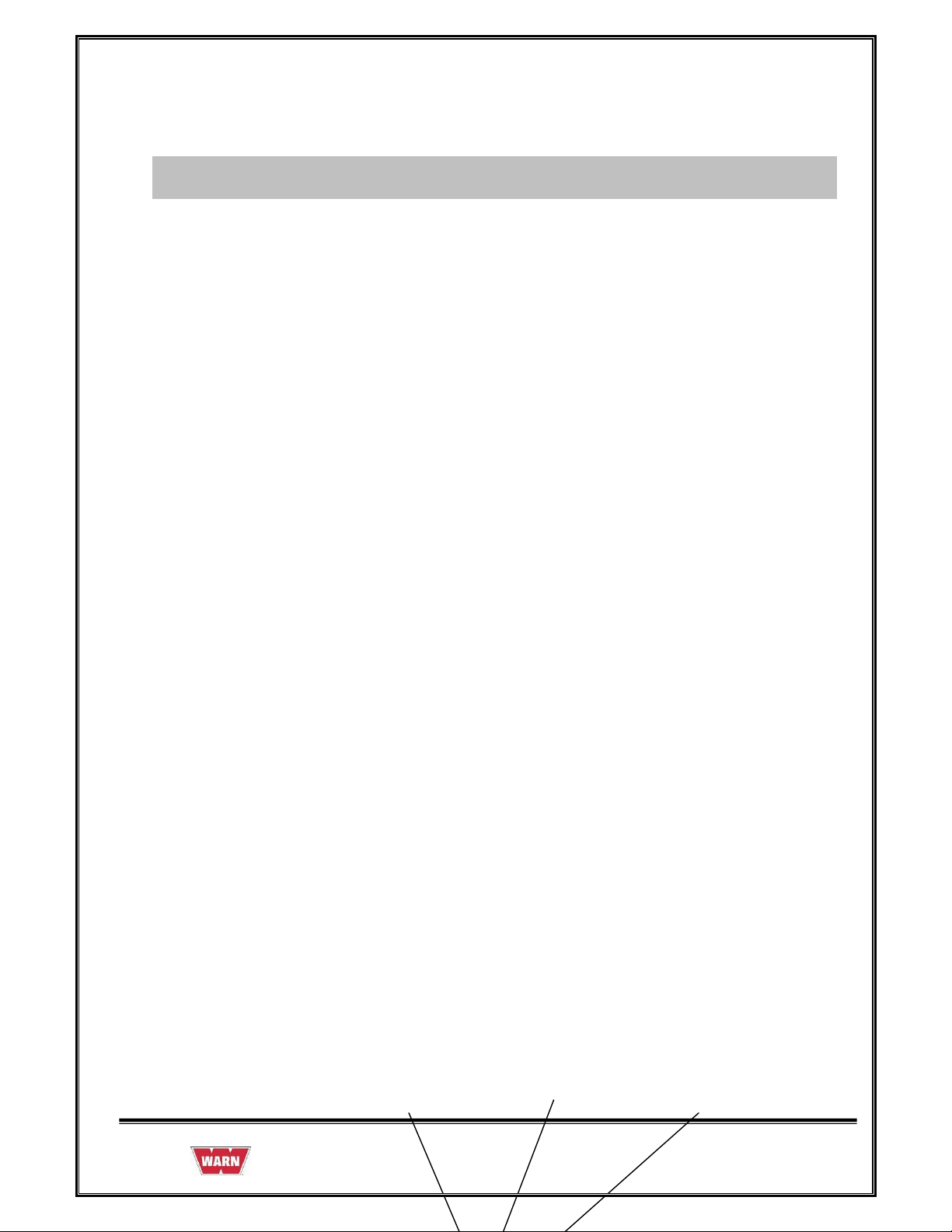

Page 5

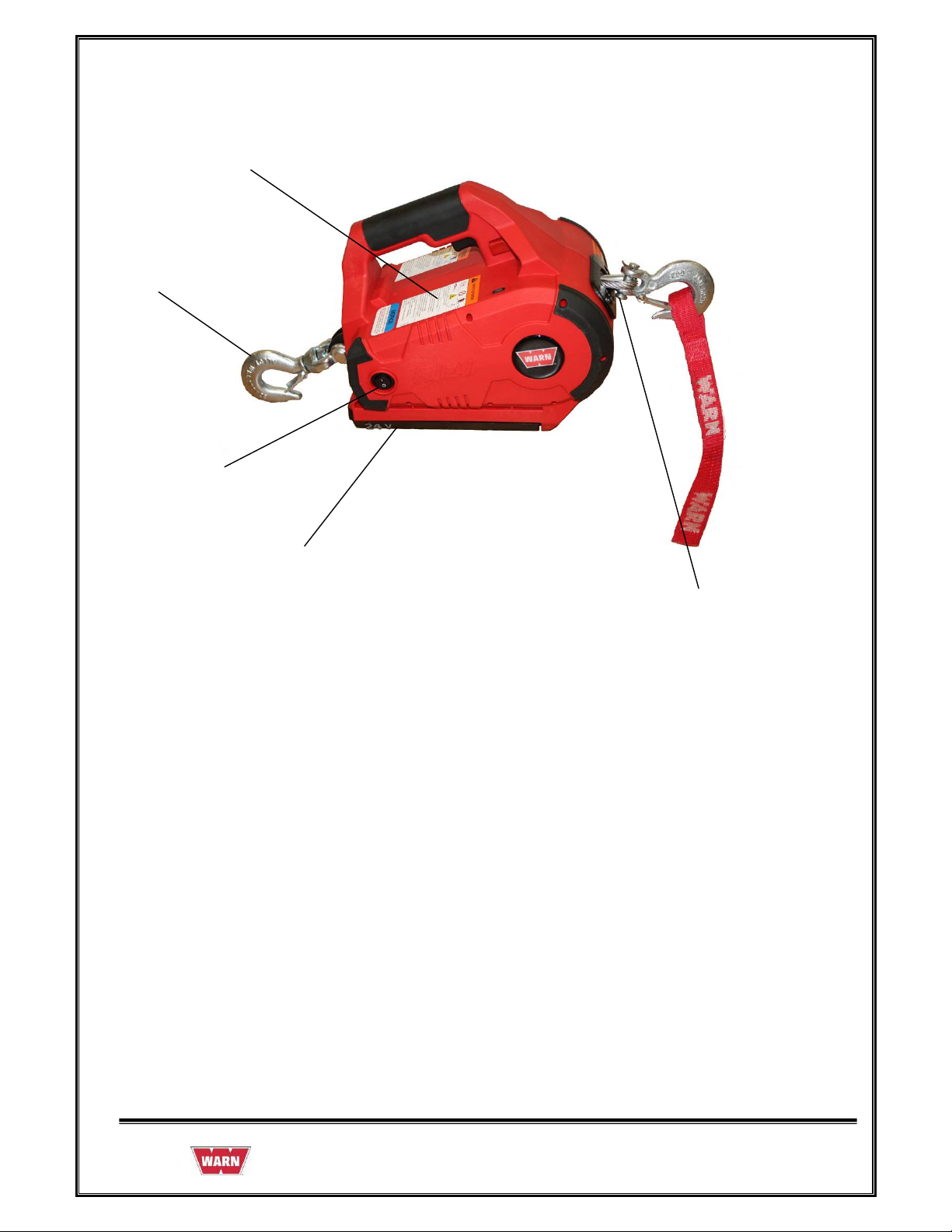

1,000lbs lifting/pulling

Integrated

Swiveling

Anchor

Hook

On/Off Switch

Variable Speed Trigger Switch

Convenient Forward /

Reverse Switch

Electronic Load

Limiter with LED

Indicator for

Operator Feedback

Powerful 24volt Recharge NiMH Battery Pack

15’ of Ø7/32” Wire Rope

987606A1.doc Page 5 of 46

Page 6

2.1 SUGGESTED TOOLS

1. Hammer

2. Snap ring plier

3. Allen key set

4. Screw driver

5. Cutting plier

6. Pin remover (Punch)

7. Insulation tape

8. Gloves

987606A1.doc Page 6 of 46

Page 7

2.2 BATTERY

2.2.1 REMOVAL OF BATTERY

Removing the Battery Pack

• Verify the power switch is in the OFF position.

• Push down the release button back of the Battery and slide the Battery away from the

PullzAll body.

• Remove the Battery when not in use. Permanent damage may occur if the unit is

allowed to self-discharge in ON position

987606A1.doc Page 7 of 46

Page 8

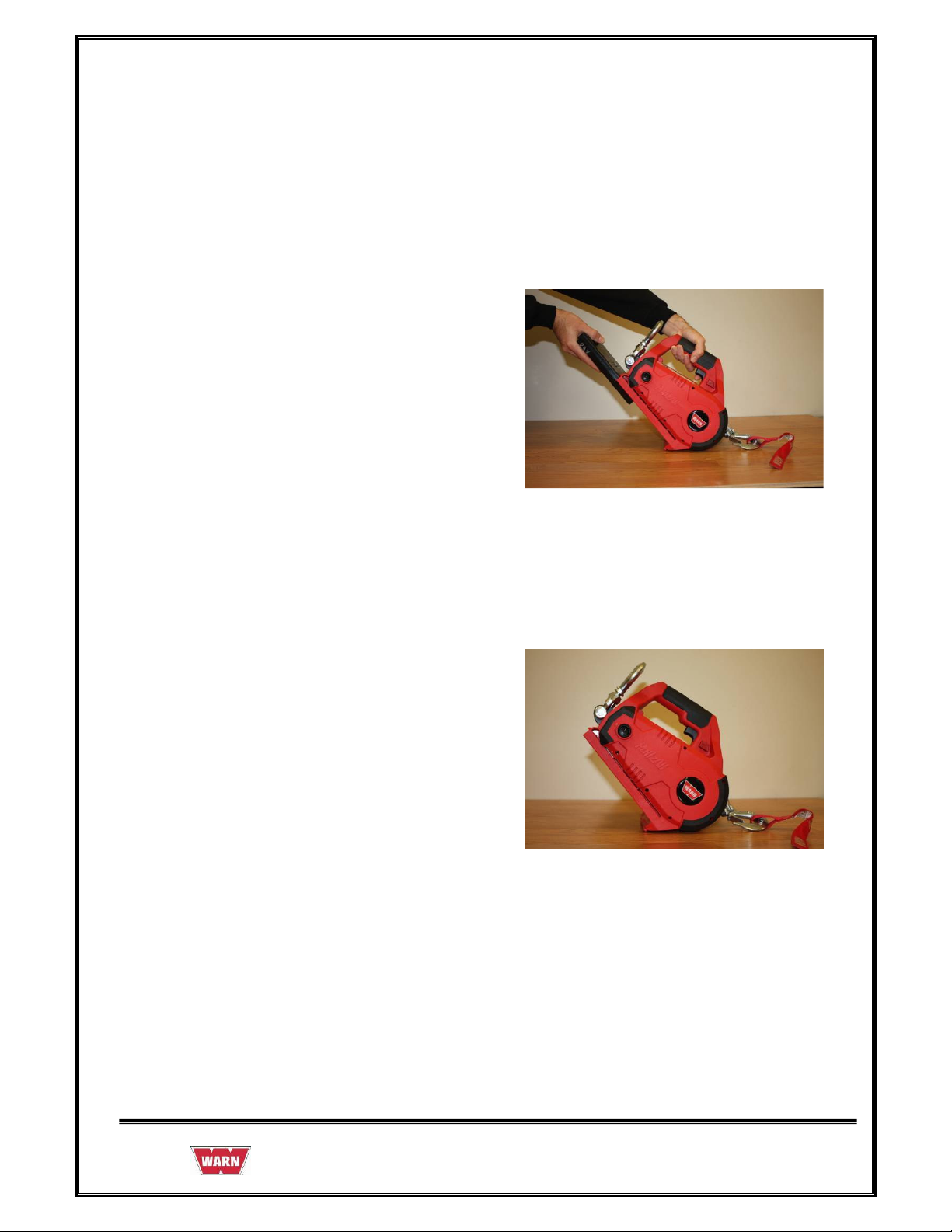

1. Hold the PullzAll in the position shown in

figure, push down the release button at back

of the Battery and slide the Battery away

from the PullzAll body and pull Battery as

shown direction

2. Slide away complete Battery from the

PullzAll body

987606A1.doc Page 8 of 46

Page 9

2.2.2 ASSEMBLY OF BATTERY

1. Hold the PullzAll in the position as shown in

figure. Slide the Battery pack into the body as

shown direction

2. Slide Battery pack completely into the

PullzAll body; make sure that the latch is

fully engaged.

The PullzAll Battery uses NiMH technology. Generally, they can be disposed of in a municipal

waste stream. However, check your local ordinances for disposal or recycling regulations.

987606A1.doc Page 9 of 46

Page 10

2.2.3 INSPECTION OF BATTERY

• Inspect the Battery is not cracked or damaged.

• Inspect whether the release button in hold position or not.

Safety Rules & Guidelines:

• Battery tools are always in an operative condition. Be aware of the possible hazards.

Always remove the Battery when the PullzAllTM is not in use.

• Battery leakage may occur under extreme usage or temperature conditions. If liquid

comes in contact with skin, wash quickly with soap and water, then with lemon juice or

vinegar. If liquid gets into your eyes, flush them with water for a minimum of 10

minutes and seek medical attention.

• Do not run the PullzAll

Battery Care:

When Batteries are not in tool, keep them away from the metal objects. For

example: To protect the terminals from shorting. DONOT place

Batteries in a toolbox or pocket with nails, screws, keys, etc. Fire or injury may result.

DO NOT PUT BATTERY INTO FIRE OR EXPOSURE TO HIGH HEAT. They

may explode.

Battery Disposal:

WARNING

Do not attempt to disassemble the Battery or remove any component projecting from

TM

while carrying it at your side.

the Battery terminals. Fire or injury may result. Prior to disposal protect exposed

terminal with heavy insulating tape to prevent shorting.

987606A1.doc Page 10 of 46

Page 11

2.3 HOUSING

Before opening the Housing follow the below instructions:

Power Switch:

Always turn Power switch off. Permanent battery damage may occur if the unit is allowed to

self discharge in the ON position.

Removing the Battery Pack:

• Verify the power Switch is in the OFF position.

Push down the release Button back of the Battery and slide the Battery away from the PullzAll

body as shown.

987606A1.doc Page 11 of 46

Page 12

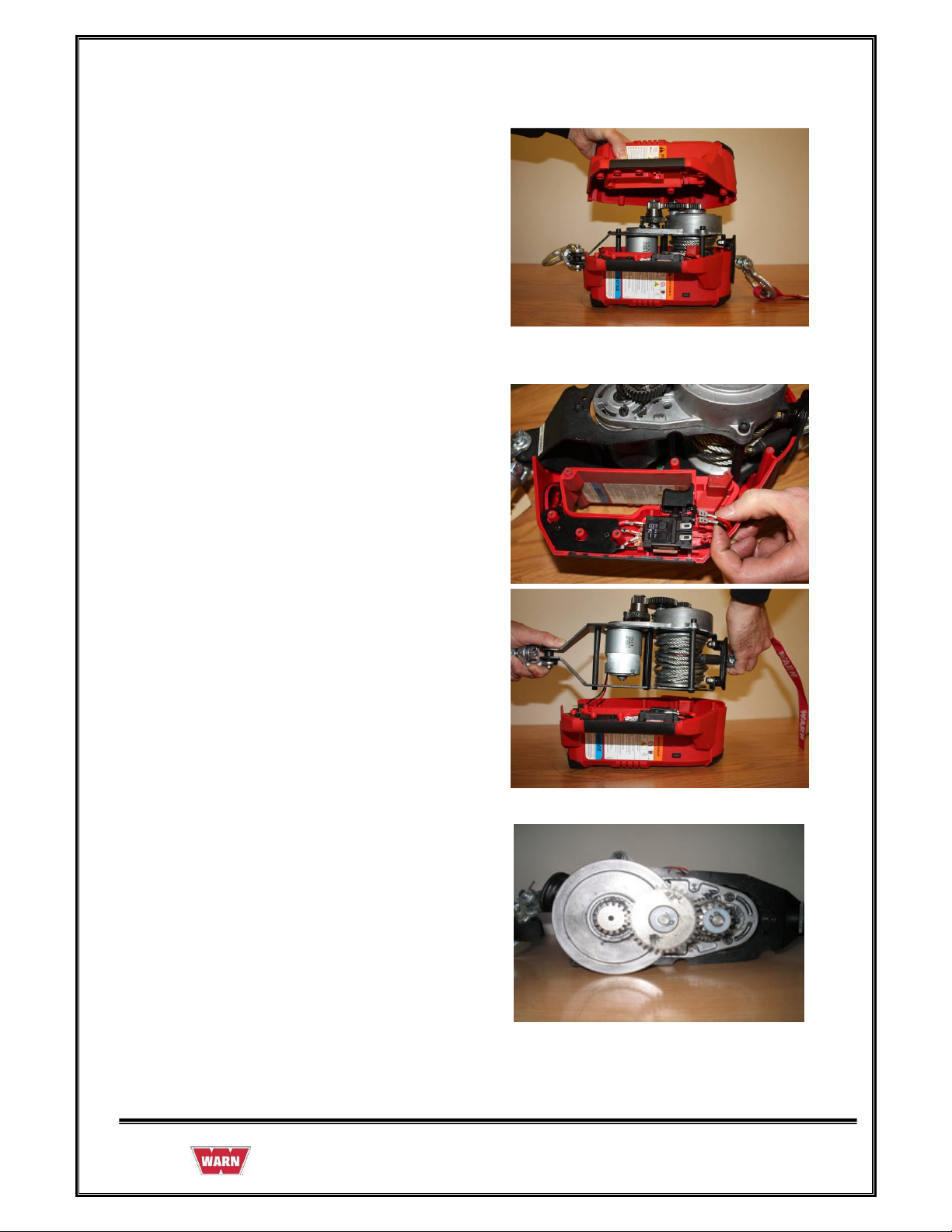

2.3.1 REMOVAL OF HOUSING

1. Remove 6 screws (#6 x .75) from Handle

2. Remove 6 screws (#8 X 1.25) from the

main body of the Housing.

3. Keep the assemblies on the work bench

facing the cover in the direction shown in

the figure.

987606A1.doc Page 12 of 46

Page 13

4. Remove the Plastic Housing (left hand)

from the assembly as shown in the figure.

5. Remove wiring connections of the Motor

assembly from Trigger Switch (red and

black wires) as shown in figure.

6. Remove the Main Chassis from the

Plastic Housing.

7. Keep the Main Chassis on the work

bench.

987606A1.doc Page 13 of 46

Page 14

2.3.2 ASSEMBLY OF HOUSING

1. Keep the right hand Housing on the work

bench

2. Install the Chassis assembly into the right

hand Housing as shown, verify the right

hand frame Bracket is fully seated into

the right Housing before installing the

left hand Housing.

3.Install wiring connections of the Motor

assembly from Trigger Switch (red and black

wires) per wiring diagram (Red to M+ or

M1, Black to M- or M2).

4. Install the Plastic Housing left hand

from the assembly as shown in the figure.

987606A1.doc Page 14 of 46

Page 15

5. Keep the assembly on the work bench

facing the cover in the direction shown in

the figure.

6. Install 6 screws (#8 X 1.25) from the

main body of the Housing.

7. Install 6 screws (#6 x .75) in Handle.

Note: When replacing the Housings with a Housing Service kit, be sure to affix ALL

appropriate labels from the service kit onto the new housings, using the housings

being replaced as a guide for placement of your new labels. Your service kit will

include extra labels for other languages and markets that can be discarded after you

select the ones needed for your product.

987606A1.doc Page 15 of 46

Page 16

2.4 MOTOR

2.4.1 REMOVAL OF MOTOR

Before removing the Motor follow the below instructions:

1. Remove the Motor Assembly from the

End Housing by removing the 2 screws

(M5 x .8 x 12), Qty 2 from the casting

securing the Motor using a 4mm Allen

Wrench.

2. Tap the motor with dead blow hammer to

remove the Motor Assembly remove

from the Chassis assembly.

3. After removal of the Motor assembly

from the Chassis, keep the Motor

assembly on the work bench.

987606A1.doc Page 16 of 46

Page 17

2.4.2 ASSEMBLY OF MOTOR

8. Install the Motor assembly in to the

Chassis assembly.

9. Tighten the two CapScrews to secure

Motor assembly in position.

10. Install Motor leads to top terminals of

Switch per wiring diagram (Red to M+ or

M1, Black to M- or M2).

987606A1.doc Page 17 of 46

Page 18

2.4.3 INSPECTION OF MOTOR

• Visual inspection.

• Ensure that Motor has been properly placed inside the End Housing and the screw had

been properly tightened

2.5 WIRE ROPE ASSEMBLY

2.5.1 REMOVAL OF WIRE ROPE

Note:

Prior to disassembly:

1. Spool out all Wire Rope.

2. Use of gloves is recommended while handling frayed or damaged Wire Rope.

3. Unplug unit / remove Battery before disassembly.

Tasks:

Disassemble the Wire Rope.

1. Push the Wire in the direction of the

arrow mark as shown in the figure.

987606A1.doc Page 18 of 46

Page 19

2. Using a punch or drift and hammer, tap

the end of the Wire Rope to push the loop

back through the Drum.

3. Use the pin remover (punch) to remove

the Wire Rope from the Drum.

4. Remove the Stop Button from Drum

by using snap ring plier as shown in the

figure

987606A1.doc Page 19 of 46

Page 20

5. Straighten the bent Rope and pull the

Rope out of Drum hole in the shown

direction.

6. Remove the hawse fairlead from the

Bracket of the Chassis.

7. Remove and discard the Tension Plate (if

equipped).

987606A1.doc Page 20 of 46

Page 21

2.5.2 ASSEMBLY OF WIRE ROPE

1. Assemble the Hawse Fairlead to the

Bracket of the Chassis.

2. Tighten the CapScrews with Allen key

and opened end wrench.

3. Keep the insulation tape to the edge of the

Wire Rope.

987606A1.doc Page 21 of 46

Page 22

4. Insert the Wire Rope into the Drum

through the Hawse Fairlead.

5. Pull the wire from the other end of the

Drum hole.

6. Bend the Wire Rope and insert in to the

same hole in the direction shown in the

figure.

7. Pull the Wire Rope from the hole as

shown in the figure.

987606A1.doc Page 22 of 46

Page 23

8. Support one edge of the Wire and pull the

other Wire as shown in the figure.

9. Verify Wire Rope stop button is inserted

into the loop as shown before pulling the

Wire Rope tight.

10. Hit wire rope loop with a hammer, so that

the Wire Rope will be pushed in to the

rope retention hole.

987606A1.doc Page 23 of 46

Page 24

11. Check the Wire Rope so that it enters

completely into the Drum hole.

12. Check from the other side of the Drum

whether the Wire Rope is perfectly

assembled to the Drum.

2.5.3 INSPECTION OF WIRE ROPE

• Inspect the Wire Rope for signs of wear or damage. Worn and damaged parts must be

replaced.

• See the Rope for damage for kinks, cuts, knots, mashed or frayed portions and broken

strands.

• Keep the Rope free from contaminants. Use a clean towel to remove the dirt and debris.

• Use of light oil on the Wire Rope can prevent corrosion.

987606A1.doc Page 24 of 46

Page 25

2.6 SAFETY HOOK

2.6.1 REMOVAL OF SAFETY HOOK

To remove Safety Hook, follow the Instructions:

987606A1.doc Page 25 of 46

Page 26

1. First straighten the bent end of the Cotter

Pin by using pliers, and then pull away the

Cotter Pin by holding head of the Pin with

the help of pliers from the Pin.

2. Remove the Pin from the Safety Hook and

Wire Rope.

987606A1.doc Page 26 of 46

Page 27

3. Remove the Safety Hook from Wire Rope.

2.6.2 ASSEMBLY OF SAFETY HOOK

To reassemble Safety Hook follow the Instructions:

1. Place the Safety Hook and align the

mounting holes with the loop of the Wire

Rope

2. Insert the Pin through Safety Hook and

Wire Rope loop.

987606A1.doc Page 27 of 46

Page 28

3. Insert the Cotter Pin inside the hole of the

Pin and bend the ends of the Cotter Pin

with the help of pliers.

2.6.3 INSPECTION OF SAFETY HOOK

• Inspect the Hook for signs of wear and damage.

• Hook damage examples: cracks, twisted components, excessive opening, seat wear,

loose or damaged safety latch or corrosion.

987606A1.doc Page 28 of 46

Page 29

2.7 TAIL HOOK

Original Tailhook Assy

2nd Generation Tailhook Assy

Service Part Tailhook Assy

987606A1.doc Page 29 of 46

Page 30

2.7.1 REMOVAL OF TAIL HOOK

To remove Tail Hook, follow the instructions below:

1. First straighten the bent end of the Cotter

Pin, and then pull out.

2. Remove the Pin from the Hook assembly.

3. Remove the Tail Hook from Chassis

assembly.

987606A1.doc Page 30 of 46

Page 31

4. Remove Spacer Bracket from Chassis

assembly while loosening the capscrew.

2.7.2 ASSEMBLY OF TAIL HOOK

To reassemble Tail Hook follow the instructions:

1. Place Spacer Bracket in Chassis

assembly with capscrew and then apply

the torque.

987606A1.doc Page 31 of 46

Page 32

2. Take the Tail Hook and align the

mounting holes with the Spacer Bracket

holes and Chassis assembly.

3. Insert the Pin through the Hook

assembly.

4. Insert the Cotter Pin inside the hole of the

Pin and bend the ends of the Cotter Pin

with the help of pliers.

987606A1.doc Page 32 of 46

Page 33

2.7.3 INSPECTION OF TAIL HOOK

• Inspect the Hook for signs of wear and damage.

• Hook damage examples: cracks, twisted components, excessive opening, seat wear,

loose or damaged safety latch or corrosion.

987606A1.doc Page 33 of 46

Page 34

2.8 GEARSETS

• If the gearsets are worn or damaged, the entire PullzAll must be replaced, no

replacement parts are available.

2.9 DRUM

• If the drum is worn or damaged, the entire PullzAll must be replaced, no replacement

parts are available.

987606A1.doc Page 34 of 46

Page 35

2.10 WIRING DIAGRAM

WIRING DIAGRAM - 75824

987606A1.doc Page 35 of 46

Page 36

2.10.1 WIRING DETAILS

• Route Red Lead Wire from J3 Terminal on Circuit Board through Wire guides

up into handle to Trigger Switch.

• Route Red Lead Wire (soldered to Male Terminal Support) from J2 Terminal

on Circuit Board through Wire guides up to where the male Terminal support

is mounted.

• Route Black Lead Wire from J4 Terminal on Circuit Board through Wire

guides up to Trigger Switch.

• Route the black lead attached to male terminal support to Rocker Switch.

• Route black lead attached to Black J4 lead at Trigger down through guides

and attach to Rocker Switch.

• Route Motor wires to top of Trigger Switch. Red lead to M+ terminal, black

lead to M - terminal.

• Use tie strap to secure Motor Wires to the right hand frame.

• Secure the Trigger Switch with switch Retainer and a screw. Secure the Wires

in the handle using wire retainer and screws.

• See Wiring diagram 75824 for installation Wiring schematic

987606A1.doc Page 36 of 46

Page 37

Switch Pin-out Table

Manufacturer name is embossed on switch.

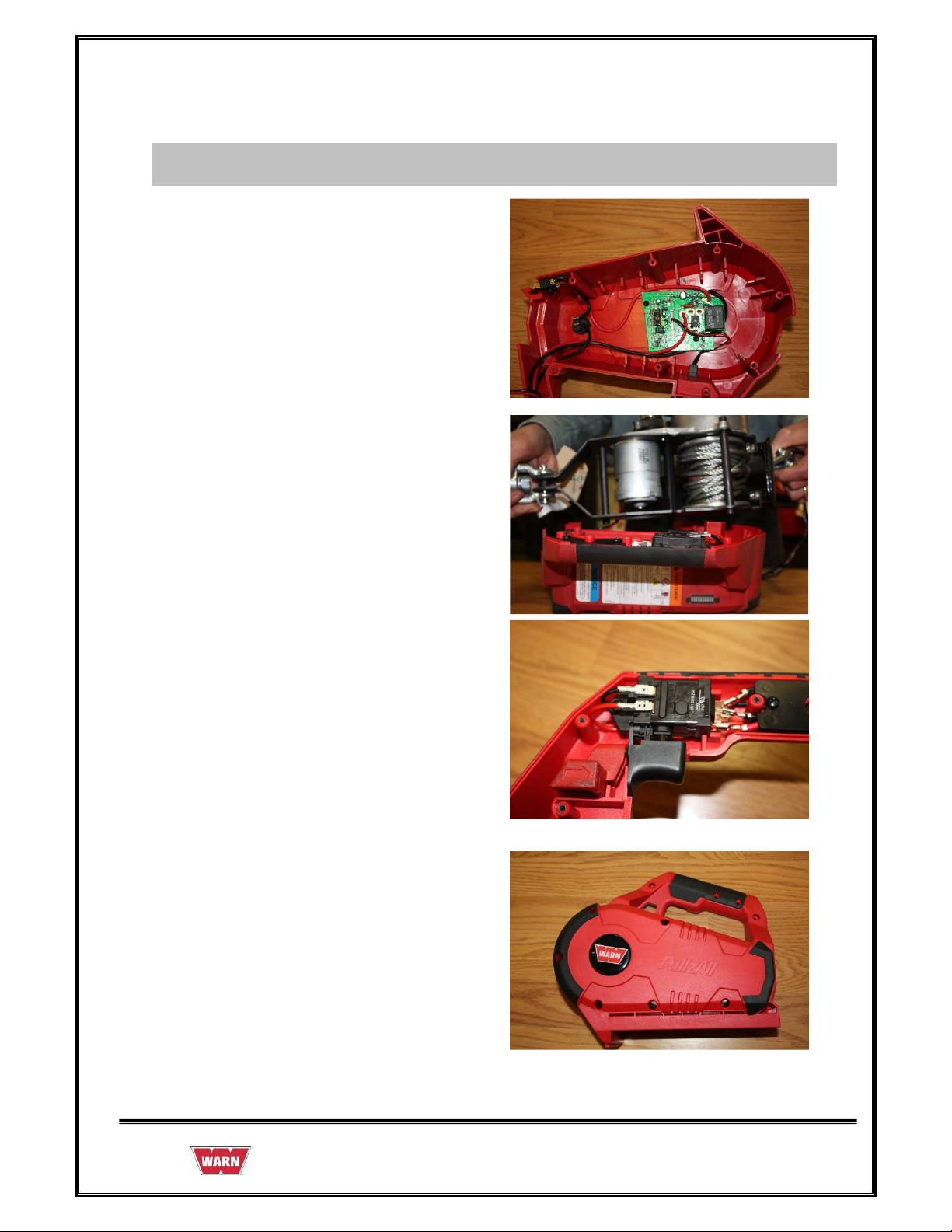

2.10.2 REMOVAL OF WIRING

1. Remove the leads from Battery Terminals if

required.

Trigger Switch:

2. Remove the Wires from Trigger Switch.

987606A1.doc Page 37 of 46

Page 38

3. Remove the leads from Rocker Switch if

required.

4. Take out Load limiter Board Assy from right

Plastic Cover after unscrewing all the screws.

5. Remove the 3 leads from out Load limiter

Board Assy if required.

987606A1.doc Page 38 of 46

Page 39

2.10.3 ASSEMBLY OF WIRING

1. Install Load limiter Board Assy to right

Plastic Cover.

2. Install the two screws at Load limiter

Board Assy with the help screw driver

right Plastic Cover.

987606A1.doc Page 39 of 46

Page 40

Electronic Load Limiter

3. Push the Plastic Retainers out that secure

the LED display

4. Install Battery Terminal into Right Hand

Housing using Screws (6 x 0.50), Qty 2.

987606A1.doc Page 40 of 46

Page 41

5. Route Red Lead Wire (soldered to Male

Terminal Support) from J2 Terminal on

Circuit Board through wire guides up to

rear of Housing to where the Male

Terminal support is mounted.

Trigger Switch

6. Route Red Lead Wire from load limiter

circuit board J3 and black wire from load

limiter J4 through wire guides up in to

handle to Trigger Switch (Red to B+,

Black to B-) Black wire is connected to

black wire from rocker switch.

987606A1.doc Page 41 of 46

Page 42

7. Install leads to Rocker Switch

2.10.4 INSPECTION OF WIRING

VISUAL INSPECTION

• While disconnecting the connectors, never pull the Wiring Harnesses. Unlock the

connector first and then pull them apart by holding Connectors themselves.

• While connecting Connectors, also hold Connectors and put them together until they lock

securely (a click is heard).

• While Installing the Wiring Harness, fix it with clamps so that no slack is left.

• While using a tester for checking continuity or measuring voltage, be sure to insert the

tester probe from the Wire harness side.

987606A1.doc Page 42 of 46

Page 43

2.11 TORQUE SPECIFICATIONS

987606A1.doc Page 43 of 46

Page 44

3. PULLZALL TROUBLE SHOOTING

PROBLEM POSSIBLE CAUSE CORRECTIVE ACTION

1.1 PullzAll does not

power in or pulls

slowly.

Check the speed mode

Battery is not fully charged.

Loose connection on Battery

or Motor Terminals.

selected

Charge Battery

Be sure all connections are tight

and clean. Do not let bottom nut

or stud turn while tightening.

Change mode as required.

Battery voltage too low due

to Battery deterioration.

Worn Trigger Switch

Worn Brushes/Motor.

Poor Wiring Connections.

Check for loaded condition

whether overloaded.

1.2 Noise

Rope is interfacing with Tie

Rod or other part of PullzAll.

Motor is hot.

Abnormally worn Bushing.

Worn or Broken Gearset.

Motor malfunctioning.

Replace Battery.

Repair or Replace Switch.

Replace Motor

Check Wiring connections.

Use the unit within the

permissible load limits.

Rewind Rope on Drum so that it is

level and not rubbing on other

parts of PullzAll.

Allow PullzAll Motor to cool for

at least 10 minutes between short

pulls. Increase cooling time for

heavy loads or long pulls.

Replace PullzAll.

Replace PullzAll

Replace Motor.

987606A1.doc Page 44 of 46

Page 45

1.3 Motor running but

not pulling

1.4 Motor does not run. Check Battery Condition

Damaged Geartrain

visually (any short circuit )

Check Battery condition

Faulty Trigger Switch

Defective Motor

1.6 Electrical sparks

appear around

Motor.

1.7 Wire harness

insulation has melted

Loose connection of Wires to

Motor Terminals.

Switch held in power in

position while PullzAll is

stalled.

Poor installation caused Wire

insulation to be rubbed off or

cut, causing direct short.

Replace PullzAll

Check Wiring condition

Repair or replace it with new

Repair or replace Switch

Replace Motor

Replace Motor Assembly.

Replace Wire harness or PullzAll

Motor Assembly.

Replace Wire harness.

1.8 PullzAll makes

squeaking / high

pitch noise.

1.9 Full speed only, no

variable speed control

1.10 Malfunctioning

1.11 Rapid discharge of

Battery

Drum Bushing not lubricated. Grease Drum Bushings.

Ensure trigger is only

partially depressed

Not operating correctly.

Replace Variable Speed Trigger

switch

Cease operation. Diagnose,

Repair or Replace.

Check for Power Switch Left

on during storage.

Check for Terminals

corrosion

Defects in charging system

such as faulty Regulator,

Always turn unit off when not in

use.

Clean and service

Check charging system

987606A1.doc Page 45 of 46

Page 46

loose Terminals, etc...

Damaged Wiring.

Check Electrical Circuits

4. SERVICE PART LIST

Description Part Number

1. Service Part -Motor Assembly 24vdc 77916

(Includes Motor & Screws)

2. Service Part - Variable Speed Trigger, 24vdc 77913

3. Service Part - Load Limiter Assembly, 24vdc 86355

(Includes LED Bezel, Screws and LED Retention Pins)

4. Service Part - Wire Rope Assembly, PullzAll 76065

(Includes Fairlead)

5. Service Part - Rapid Charger-120v 77922

6. Service Part - Rapid Charger-230v 77923

7. Service Part - Tail Hook Assembly 77930

8. Service Part - Front Hook Assembly 78052

987606A1.doc Page 46 of 46

Loading...

Loading...