Page 1

0102

II 2D 2mJ

P_01660

Manual powder spray gun

PEM-X1

Version 03/2014

Translation of the Original

Operating Manual

Page 2

Page 3

3

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Table of Contents

1 ABOUT THIS MANUAL 6

1.1 Preface 6

1.2 Warnings, Notices, and Symbols in this Operating Manual 6

1.3 Languages 7

1.4 Abbreviations 7

2 CORRECT USE 8

2.1 Device Type 8

2.2 Type of Use 8

2.3 Use in Potentially Explosive Areas 8

2.4 Safety Parameters 9

2.5 Processible Working Materials 9

2.6 Reasonably Foreseeable Misuse 10

2.7 Residual Risks 10

3 IDENTIFICATION 11

3.1 Explosion Protection Identi cation 11

3.2 Permissible Device Combinations 11

4 GENERAL SAFETY INSTRUCTIONS 12

4.1 Safety Instructions for the Operator 12

4.1.1 Electrical Devices and Equipment 12

4.1.2 Sta Quali cations 12

4.1.3 Safe Work Environment 12

4.2 Safety Instructions for Sta 13

4.2.1 Safe Handling of WAGNER Powder Spray Devices 13

4.2.2 Grounding the Device 13

4.2.3 Product Hoses 13

4.2.4 Cleaning 14

4.2.5 Handling Powder Lacquers 14

4.3 Information About Safe Discharges 15

4.4 Protective and Monitoring Equipment 16

5 DESCRIPTION 17

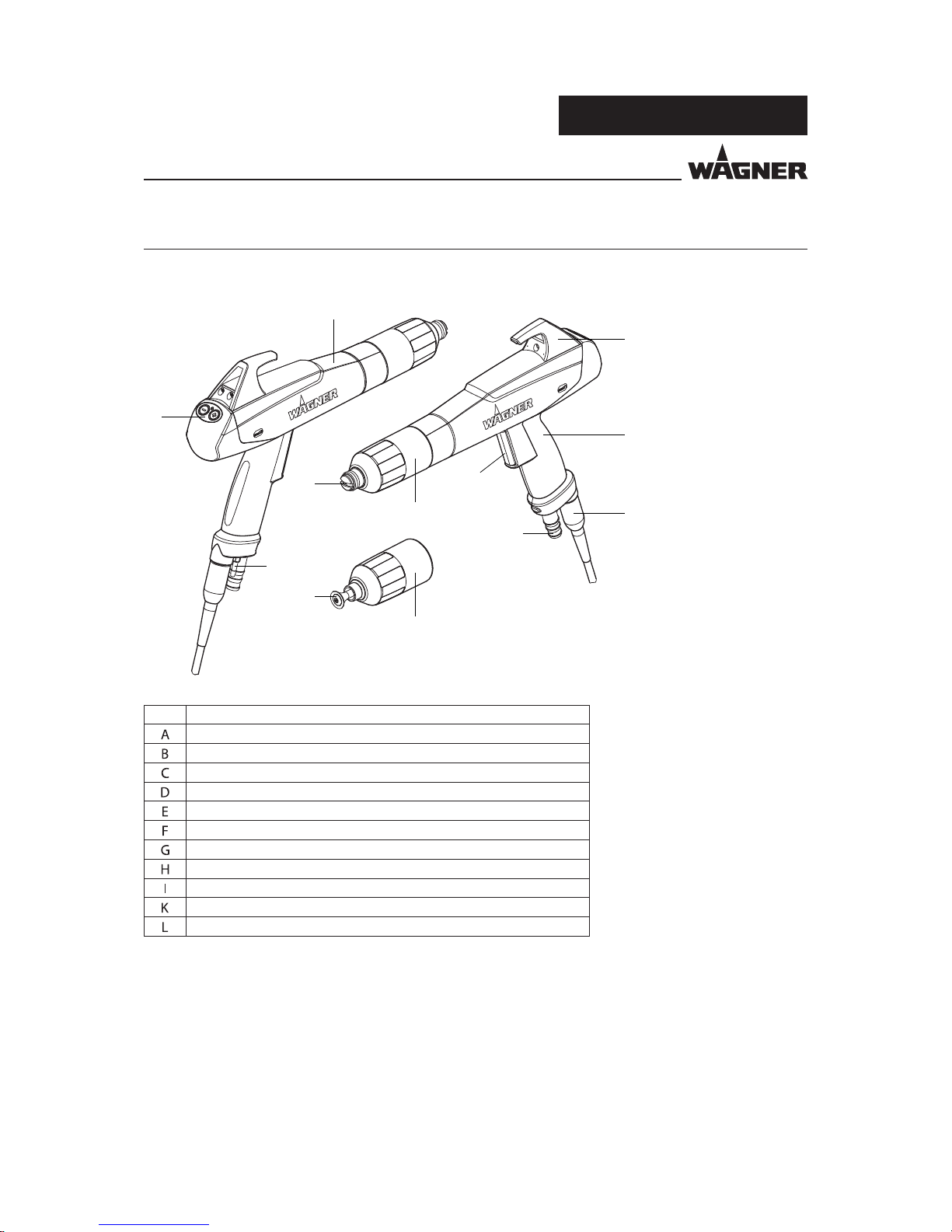

5.1 Spray Gun Design 17

5.2 Functioning of the Spray Gun 17

5.3 Technical Data 18

5.3.1 Dimensions 19

5.4 Permitted Accessories 20

5.5 Scope of Delivery 20

6 ASSEMBLY AND COMMISSIONING 21

6.1 Training Assembly/Commissioning Sta 21

6.2 Storage Conditions 21

6.3 Installation Conditions 21

6.4 Preparing the Spray Gun 22

6.4.1 Selection of the Suitable Nozzle System 22

6.5 Connecting the Spray Gun 24

6.6 Grounding 26

6.6.1 Grounding the Powder Coating System 27

Page 4

4

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Table of Contents

7 OPERATION 28

7.1 Training the Operating Sta 28

7.2 Safety Instructions 28

7.3 Optimizing the Powder Cloud for Your Coating 29

7.3.1 Recommended Settings for Total Air Volume 29

7.4 Switching O the Spray Gun 30

7.5 Adjustment of Powder Quantity 31

7.6 "Double Click" Program (High Dynamic Remote) 32

7.7 Reproducible Setting of the Nozzle Position 33

8 CLEANING AND MAINTENANCE 34

8.1 Cleaning 34

8.1.1 Cleaning Sta 34

8.1.2 Safety Instructions 34

8.1.3 Cleaning Procedures 35

8.2 Maintenance 36

8.2.1 Maintenance Sta 36

8.2.2 Safety Instructions 36

8.2.3 Maintenance Procedures 37

8.2.4 Replacing the Spray Gun 38

8.3 Removing the Fan spray nozzle 39

8.4 Fitting the Fan spray nozzle 40

8.5 Removing the Round spray nozzle 41

8.6 Fitting the Round spray nozzle 42

8.7 Replacing the Protective Wedge 43

8.8 Changing from Fan spray nozzle to Round spray nozzle 45

8.9 Assembly of the CoronaStar 47

8.10 Replacing the Suspension Hook 48

9 INSPECTIONS IN ACCORDANCE WITH DIN EN 500502: 2014 49

9.1 Overview of Inspections 50

10 DISASSEMBLY AND DISPOSAL 51

10.1 Disassembly 51

10.2 Disposal 51

11 TROUBLESHOOTING AND RECTIFICATION 52

12 ACCESSORIES 54

12.1 Fan spray nozzle 54

12.2 De ector Cone 54

12.3 Electrode Holder 54

12.4 Hose Take-up 55

12.5 CoronaStar Retro t Set 55

12.6 Wedge Tool 55

12.7 Nozzle Extension, X1 VL 150/300/500 56

12.8 Nozzle Extension, X1 VL 750 56

12.9 Powder Hose 57

12.10 Gun Connection Cable 57

12.11 Wall Mount 57

12.12 Recipe Sticker 58

12.13 Powder Measuring Adapter 59

Page 5

5

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Table of Contents

13 SPARE PARTS 60

13.1 How Can Spare Parts Be Ordered? 60

13.2 PEM-X1 Corona Manual Gun With a Fan spray nozzle 61

13.3 PEM-X1 Corona Manual Gun With a Round spray nozzle 62

13.4 Electrode Holder, X1 R 63

14 DECLARATION OF WARRANTY AND CONFORMITY 64

14.1 Important Notes Regarding Product Liability 64

14.2 Warranty Claim 64

14.3 Declaration of Conformity 65

14.4 EC Type Examination Certi cate 66

14.5 FM Approval 67

Page 6

6

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

1 ABOUT THIS MANUAL

The operating manual contains information about safely operating, maintaining, cleaning

and repairing the device.

The operating manual is part of the device and must be available to operating and service

sta .

Operating and service sta should be instructed according to the safety instructions.

The device may only be operated in compliance with this operating manual.

This equipment can be dangerous if it is not operated according to the instructions in this

operating manual.

Electrostatic manual coating systems may only be operated by quali ed personnel.

1.1 PREFACE

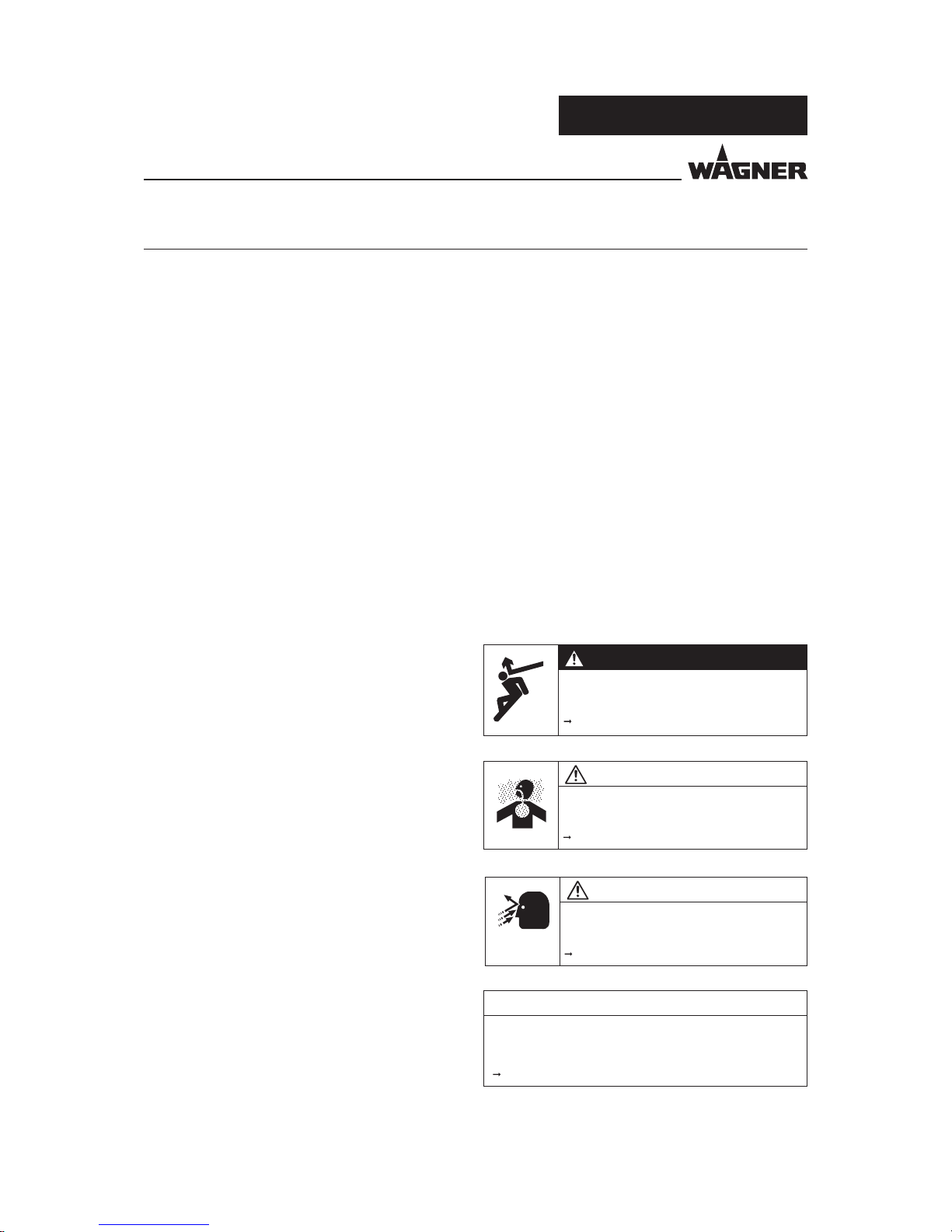

1.2 WARNINGS, NOTICES, AND SYMBOLS IN THIS OPERATING MANUAL

Warning instructions in this operating manual highlight particular dangers to users and to

the device and state measures for avoiding the hazard. These warning instructions fall into

the following categories:

Danger - immediate risk of danger.

Non-observance will result in death or serious injury.

Warning - possible imminent danger.

Non-observance may result in death or serious injury.

Caution - a possibly hazardous situation. Nonobservance may result in minor injury.

Note - provides information about particular characteristics and how to proceed.

Notice - a possibly hazardous situation.

Non-observance may result in damage to property.

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

DANGER

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

WARNING

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions.

The signal word indicates the hazard level.

The measures for preventing the danger and its consequences.

CAUTION

This notice warns you of a hazard!

Possible consequences of not observing the warning instructions. The signal word

indicates the hazard level.

The measures for preventing the danger and its consequences.

NOTICE

Page 7

7

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

1.3 LANGUAGES

The operating manual is available in the following languages:

German 2326019 English 2326020

French 2326021 Italian 2326022

Spanish 2326023 Russian 2333344

Chinese 2333345 Dutch 2337552

Swedish 2345951 Hungarian 2341080

Portuguese 2345347 Danish 2348202

Finnish 2348203 Norwegian 2348238

1.4 ABBREVIATIONS

Number of pieces

Position

Marking in the spare parts lists

Order No. Order number

Spare part

Page 8

8

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

2 CORRECT USE

2.1 DEVICE TYPE

Powder spray guns for manual coating of grounded work pieces

2.2 TYPE OF USE

The PEM-X1 manual powder spray gun is designed for the electrostatic coating of work

pieces with organic powders. Any other form of use is considered non-intended use.

Wagner disclaims liability for any damage resulting from non-intended use.

Electrostatic manual coating systems may only be used in spray areas equipped in

accordance with EN 12981 or under equivalent ventilation conditions.

2.3 USE IN POTENTIALLY EXPLOSIVE AREAS

In explosion hazard areas, only use approved explosion-proof electrical devices.

This type A-P electrostatic powder spray gun is suitable for processing industrial powder

paints for coating electrically conductive objects and can be used in potentially explosive

areas (zone 22). (See Chapter 3.1 Explosion Protection Identi cation).

Page 9

9

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

2.4 SAFETY PARAMETERS

WAGNER accepts no liability for any damage arising from non-intended use.

Electrostatic manual coating systems may only be operated in an undamaged condition.

Damaged devices must be decommissioned immediately and repaired immediately.

Use the device only to work with the products recommended by WAGNER.

Operate only the device as a whole.

Do not deactivate safety xtures.

Spare parts and accessories may have safety-relevant properties.

Use only WAGNER original spare parts and accessories.

The manual powder spray gun may only be operated under the following conditions if:

the operating sta have previously been trained on the basis of this operating manual,

the safety regulations listed in this operating manual are observed,

the operating, maintenance and repair information in this operating manual is observed,

and the statutory requirements and accident prevention regulations standards in the

country of use are observed.

2.5 PROCESSIBLE WORKING MATERIALS

Types of powder which can be charged electrostatically

Metallic powder

Page 10

10

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

2.6 REASONABLY FORESEEABLE MISUSE

2.7 RESIDUAL RISKS

Residual risks are risks which cannot be excluded even in the event of correct use.

If necessary, warning and prohibition signs at the relevant points of risk indicate residual

risks.

The following is prohibited:

coating work pieces which are not grounded,

unauthorized conversions and modi cations to the spray gun,

processing liquid or similar coating products,

using defective components, spare parts, or accessories other than those described in

Chapter 12 of this operating manual.

The forms of misuse listed below may result in physical injury or property damage:

Use of damp powder lacquer

Incorrectly set values for powder discharge

Incorrectly set electrostatic values

Use of defective components and accessories

Use for foodstu s

Use in the pharmaceutical sector

Use with non-authorized control units

Residual risk Source Consequences Speci c measures Lifecycle phase

Skin contact with

powder lacquers

and cleaning agents

Handling powder

lacquers and

cleaning agents

Skin irritation,

allergies

Wear protective

clothing,

Operation,

observe safety data

sheets

maintenance,

disassembly

Powder lacquer

in air outside the

de ned working

area

Lacquering outside

the de ned working

area

Inhalation of

substances

hazardous to health

Observe working

and operating

instructions

Operation,

maintenance

Page 11

11

PEM-X1

0102

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

3 IDENTIFICATION

3.1 EXPLOSION PROTECTION IDENTIFICATION

The EC type examination certi cate PTB 12 ATEX 5002 can be found in Chapter 14.4.

3.2 PERMISSIBLE DEVICE COMBINATIONS

Gun type: PEM-X1

Manufacturer: J. Wagner AG

CH - 9450 Altstätten

II 2 D 2mJ 85 °C

CE: European Communities

0102: Number of noti ed body which issues the recognition of quality

assurance in production

Ex: Symbol for explosion protection

II: Device class II

2: Category 2

D: Ex-atmosphere dust

2mJ: Maximum ignition energy 2 mJ

85 °C: Maximum surface temperature

Incorrect use!

Risk of injury and damage to the device.

Only connect original Wagner devices to the PEM-X1 powder

spray gun.

WARNING

The PEM-X1 powder spray gun may only be connected to the control devices listed below:

EPG-Sprint X with the corresponding PI-F1/HiCoat ED-F powder injector

EPG-Sprint with the corresponding PI-F1/HiCoat ED-F powder injector*

EPG S2 with the corresponding PI-F1/HiCoat ED-F powder injector*

* The remote control function of the PEM-X1 spray gun is not available when using these

control units.

Permissible device combinations for the USA and Canada, see Chapter 14.5 "FM Approval".

Page 12

12

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

4 GENERAL SAFETY INSTRUCTIONS

4.1 SAFETY INSTRUCTIONS FOR THE OPERATOR

4.1.1 ELECTRICAL DEVICES AND EQUIPMENT

4.1.2 STAFF QUALIFICATIONS

4.1.3 SAFE WORK ENVIRONMENT

Keep this operating manual at hand near the device at all times.

Always follow local regulations concerning occupational safety and accident

prevention.

To be provided in accordance with the local safety requirements with regard to the

operating mode and ambient in uences.

May only be maintained by skilled electricians.

Must be operated in accordance with the safety regulations and electrotechnical

regulations.

Must be repaired immediately in the event of problems.

Must be decommissioned if they pose a hazard.

Must be de-energized before work is commenced on active parts.

Secure the device against being switched back on without authorization. Inform sta

about planned work.

Observe electrical safety regulations.

The oor in the working area must be electrostatically conductive (measurements

according to EN 1081 and EN 61340-4-1).

The footwear worn by the operators must comply with the requirements of

EN ISO 20344. The measured insulation resistance must not exceed 100 MΩ (megaohms).

The protective clothing, including gloves, must comply with the requirements of

EN ISO 1149-5. The measured insulation resistance must not exceed 100 MΩ

(megaohms).

The powder release must be electrically interlocked with the powder spray system's

exhaust air equipment.

Excess coating product (overspray) must be collected up safely.

Ensure that there are no ignition sources such as naked ames, sparks, glowing wires,

or hot surfaces in the vicinity. Do not smoke.

Maintain su cient quantities of suitable re extinguishers and ensure that they are

serviceable.

The operating company must ensure that an average concentration of powder lacquer

in the air does not exceed 50% of the lower explosion limit (LEL = max. permitted

concentration of powder to air). If no reliable LEL value is available, the average

concentration must not exceed 10 g/m³.

Ensure that the device is operated, maintained and repaired only by trained persons.

Page 13

13

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

4.2.1 SAFE HANDLING OF WAGNER POWDER SPRAY DEVICES

4.2.2 GROUNDING THE DEVICE

4.2.3 PRODUCT HOSES

4.2 SAFETY INSTRUCTIONS FOR STAFF

Only use an original Wagner powder hose.

Always follow the information in this manual, particularly the general safety instructions

and the warning instructions.

Always follow local regulations concerning occupational safety and accident

prevention.

Under no circumstances may people with pacemakers enter the area where the

high-voltage eld between the spray gun and the work piece to be coated builds up!

Do not point spray guns at people.

Before all work on the device, in the event of work interruptions and functional faults:

- Switch o the energy/compressed air supply.

- Secure the spray gun against actuation.

- Relieve pressure on spray gun and device.

- In case of functional faults: Identify and correct the problem, proceed as described in

the "Fault Recti cation" chapter.

The electrostatic charge may, in certain cases, give rise to electrostatic charges on the

device. This may result in the formation of sparks or ames when discharging.

Ensure that the device is grounded before each coating process.

All the system's conductive elements, such as oors, walls, ceilings, protective

grating, transport equipment, work pieces, powder tanks, automatic moving devices

or construction parts etc. in the spray area, with the exception of parts which carry

high-voltage during operation, must be connected to the grounding system.

Parts of the booth must be grounded in accordance with EN 12981.

Ensure that all persons inside the working area are grounded, e.g., by wearing

electrostatically conductive shoes.

The functionality of grounding cables must be checked regularly (see EN 60204).

Page 14

14

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

4.2.5 HANDLING POWDER LACQUERS

4.2.4 CLEANING

Before starting cleaning or any other manual work, the high-voltage in the spray area

must be shut down and locked to prevent it from being switched back on.

Lock the compressed air supply and decompress the device.

Secure the device against being switched back on without authorization.

Use only electrically conducting and grounded tanks for cleaning uids.

Preference should be given to non- ammable cleaning uids.

Flammable cleaning liquids may only be used if, after switching o the high-voltage,

all high-voltage conducting parts are discharged to a discharge energy of less than

0.24mJ before they can be accessed.

Most ammable solvents have an ignition energy of around 0.24 mJ or 60 nC.

The cleaning agent's ash point must be at least 15 K above the ambient temperature.

Only mobile industrial vacuum cleaners of design 1 (see EN 60335-2) may be used to

remove dust deposits.

When preparing or processing the powder and cleaning the device, take note of the

processing regulations, laid down by the manufacturer of the powder lacquers, being

used.

Take note of the manufacturer’s instructions and the relevant environmental protection

regulations when disposing of powder lacquers.

Take the prescribed safety measures, in particular the wearing of safety glasses and

safety clothing as well as the use of protective hand cream.

Use a mask or breathing apparatus if necessary.

To ensure su cient protection of health and the environment, only operate the device

in a powder booth or on a spray wall with activated ventilation (exhaust air).

Page 15

15

PEM-X1

P_01698

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

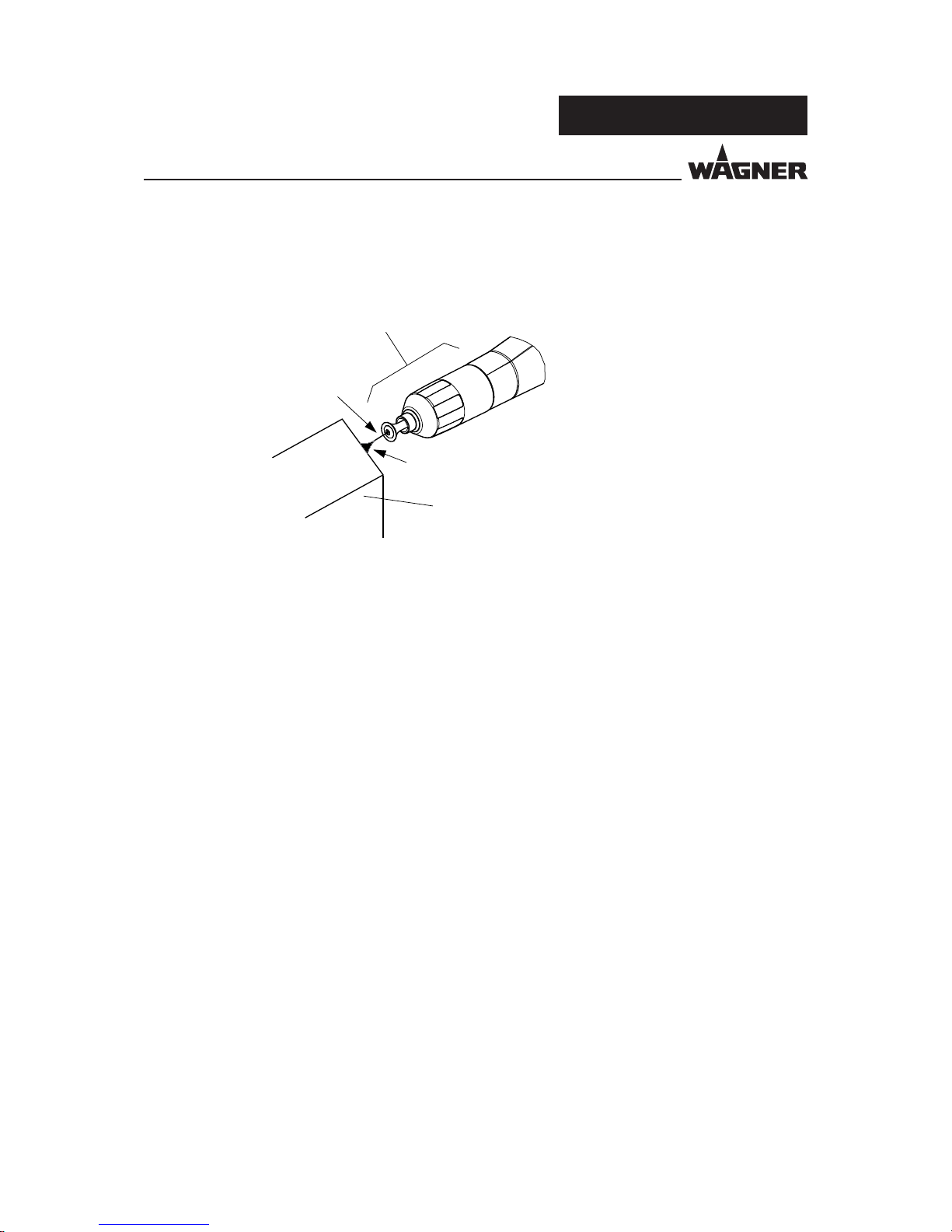

4.3 INFORMATION ABOUT SAFE DISCHARGES

With the high-voltage switched on, a luminous or corona discharge occurs at the electrode

tip; this can only be seen in the dark. This physical e ect can be seen when the electrode

is brought near the grounded work piece. This luminous discharge does not involve any

ignition energy and has no e ect on system handling. When the electrode approaches the

work piece, the control unit automatically reduces the high-voltage to a safe value. If you

touch plastic parts of the spray gun with your nger, harmless discharges may occur due to

the high-voltage eld around the spray gun (so-called brush discharges). However, these

do not contain any ignition energy.

Work piece

Luminous discharge

Nozzle

Electrode

Page 16

16

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

4.4 PROTECTIVE AND MONITORING EQUIPMENT

To prevent electrostatic ashover, the union nut for securing the nozzles is designed in a

certain geometric shape.

This shape, together with the shape of the fan spray nozzle or de ector cone sleeve,

prevents the nozzles from coming loose unintentionally (see Chapters 8.3, 8.5, 8.8).

To ensure safety, only use genuine Wagner spare parts!

Incorrect use!

Risk of injury and damage to the device.

Protective and monitoring equipment must not be removed,

modi ed or rendered unusable.

Regularly check for perfect functioning.

If defects are detected on protective and monitoring equipment,

the system must not be operated until these defects are

remedied.

WARNING

Page 17

17

PEM-X1

A

B

C

K

I

F

P_01663

E

D

G

F

L

H

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

5 DESCRIPTION

5.1 SPRAY GUN DESIGN

Designation

Suspension hook

Handle

Electrical connection cable

Powder hose connection

Trigger lever

Union nut

Round spray nozzle

Atomizing air connection

Fan spray nozzle

Buttons to adjust the powder quantity

Spray gun body

5.2 FUNCTIONING OF THE SPRAY GUN

High-voltage is activated in the manual gun when the trigger is actuated!

The powder supply and air supply to the gun are activated at the same time.

The control unit must be switched o in order to lock the spray gun.

To prevent electrostatic ashover, the union nut for securing the nozzles is designed with

a labyrinth.

Page 18

18

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

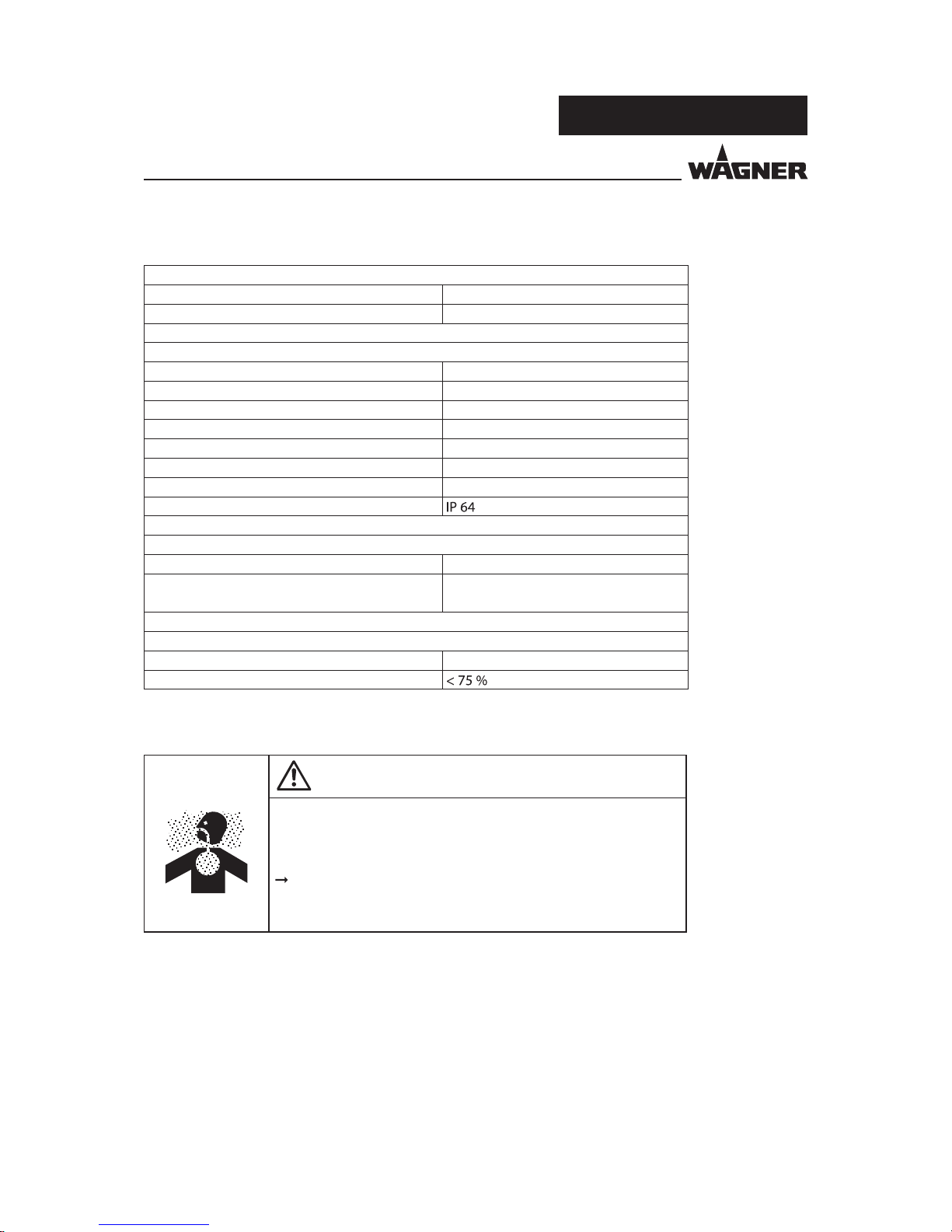

Dimensions:

Length/width/height see Chapter 5.3.1

Weight 490 g; 1.08 lbs

Electrical:

Input voltage maximum 22 Vpp

Input current maximum 0.9 A

Frequency 19 - 30 kHz

Output voltage maximum 100 kV DC

Maximum Corona current 120 μA

Polarity negative

Construction type in accordance with EN 50050-2

Protection class

Pneumatic:

Input air pressure (atomizing air volume) maximum 3 bar; 0.3 MPa, 43.51 psi

Powder output quantity maximum 450 g/min;

maximum 0.99 lbs/min

Ambient conditions:

Operating temperature range 5 - 45 °C; 41 - 113 °F

Relative humidity

5.3 TECHNICAL DATA

Ambient conditions:

If low-melting powders are used, the ambient temperature may have to be lower than

30 °C; 86 °F.

Volume measures:

for volumes speci ed in Nm³ (standard cubic meters). One cubic meter of a gas at 0 °C and

1.013 bar is called norm cubic meter.

Outgoing air containing oil!

Risk of poisoning if inhaled.

Insu cient paint application quality.

Provide compressed air free from oil and water

(Quality Standard 3.5.2 according to ISO 8573.1)

3.5.2 = 5 μm / +7 °C; 44.6 °F / 0.1 mg/m³.

WARNING

Page 19

19

PEM-X1

A

P_01662

B

C

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

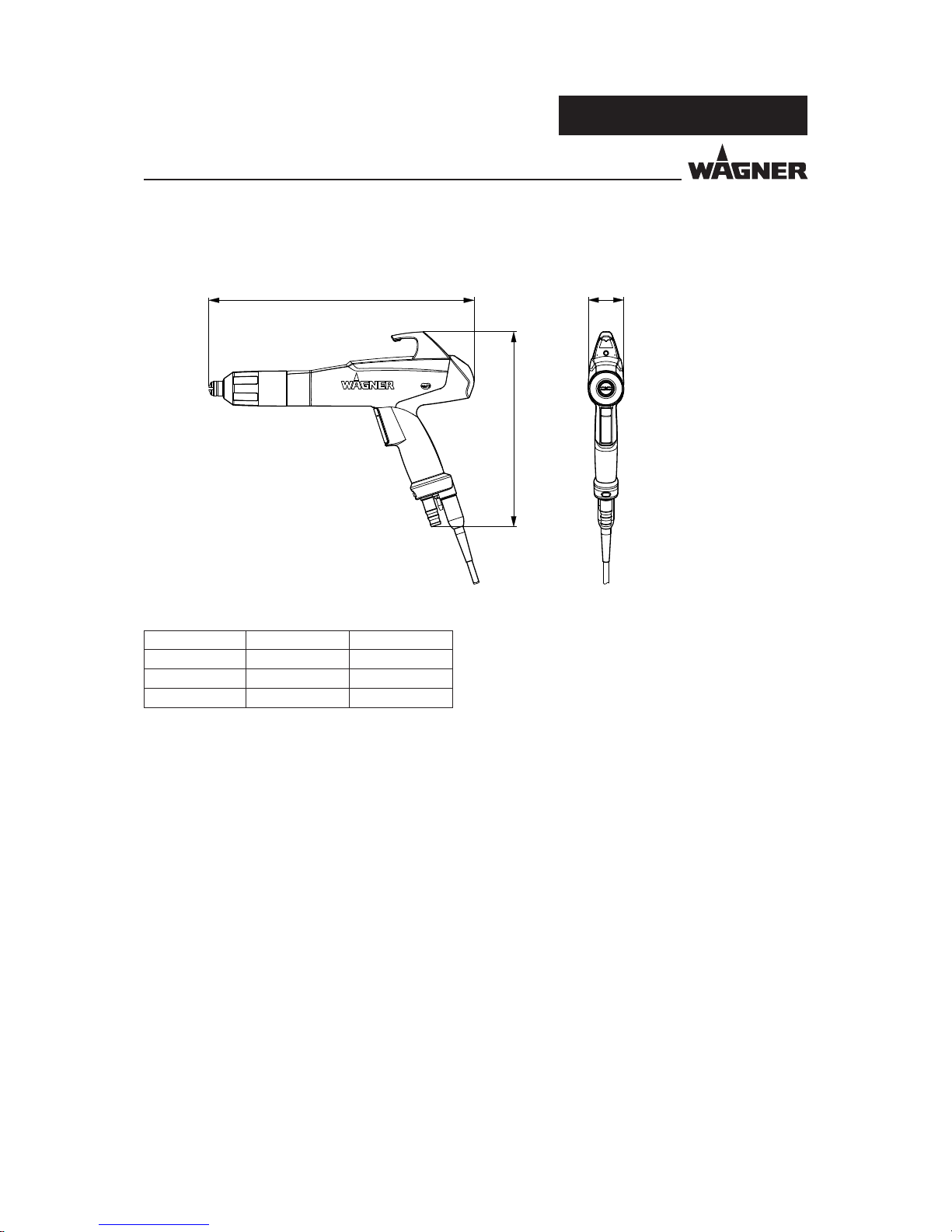

5.3.1 DIMENSIONS

Measurement mm inch

A* 335/349 13.19/13.74

B 248 9.76

C 45 1.77

* with fan spray nozzle/with de ector cone

Page 20

20

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Stk Order No. Designation

1 2322587 PEM-X1 manual gun with a fan spray nozzle

2335844 PEM-X1 manual gun with a round spray nozzle

1

Nozzle set

The standard equipment includes:

1 2326024 Declaration of conformity

1 2326019 Operating manual, German

1 see Chapter 1.3 Operating manual in local language

5.5 SCOPE OF DELIVERY

5.4 PERMITTED ACCESSORIES

Only the accessories listed in the "Accessories" chapter of this operating manual may be

connected to the PEM-X1 powder spray gun.

The accessories listed in the "Accessories" chapter were included in the EC type examination

and are approved for use with the gun.

Page 21

21

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

6 ASSEMBLY AND COMMISSIONING

6.1 TRAINING ASSEMBLY/COMMISSIONING STAFF

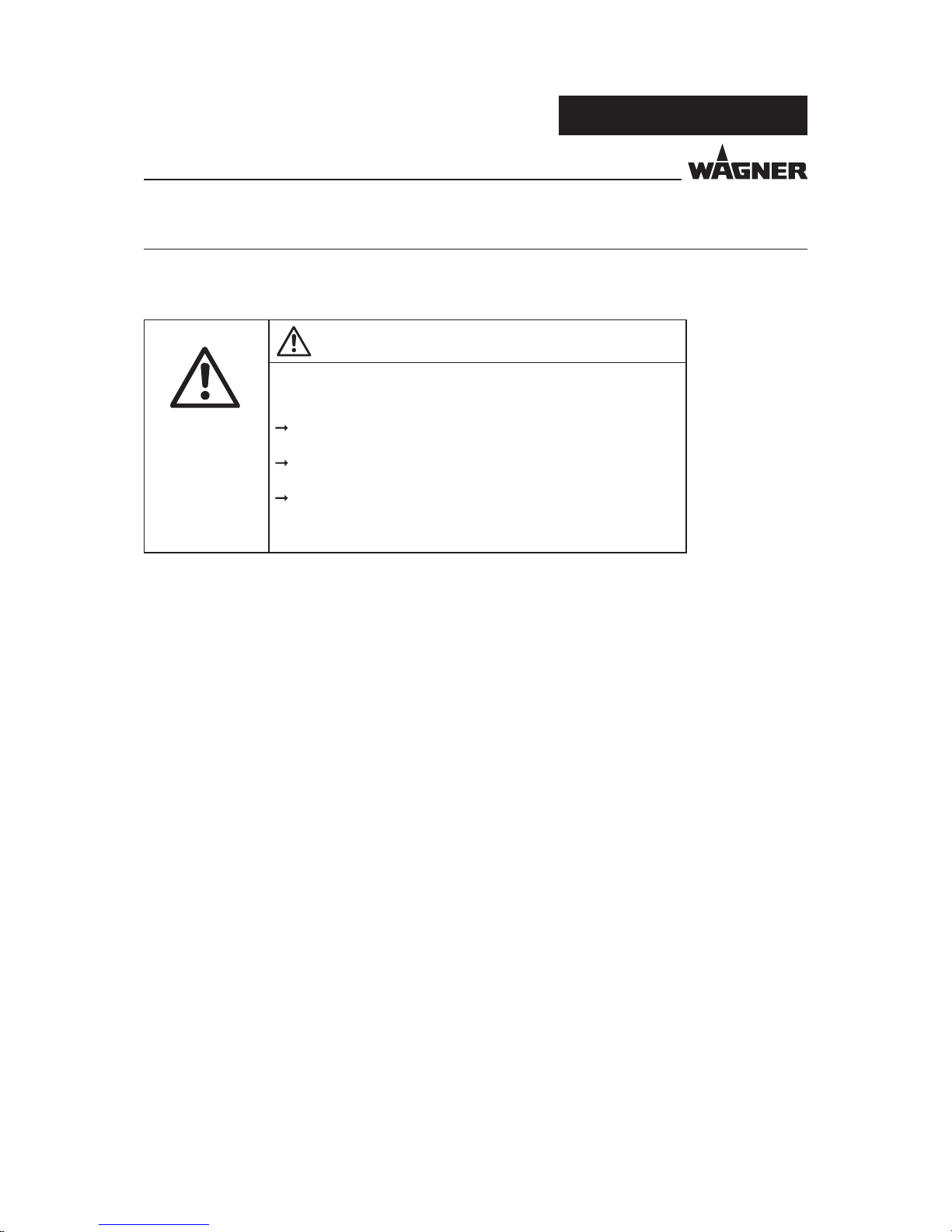

Incorrect installation/operation!

Risk of injury and damage to the device.

The commissioning sta must have the technical skills to safely

undertake commissioning.

The commissioning sta must be familiar with the provisions of

European standard DIN EN 50050-2.

When commissioning and for all work, read and follow the

operating manual and safety regulations for the additionally

required system components.

WARNING

6.2 STORAGE CONDITIONS

Until the point of assembly, the powder spray gun must be stored in a dry location, free

from vibrations and with a minimum of dust. The powder spray gun must be stored in

closed rooms.

The air temperature at the storage location must be between 5 - 45 °C; 41 - 113 °F.

The relative air humidity at the storage location must not exceed 75%.

6.3 INSTALLATION CONDITIONS

The air temperature at the assembly site must be between 5 - 45 °C; 41 - 113 °F.

Depending on the powder lacquer used, the maximum permissible ambient temperature

for reliable operation can be signi cantly below +40 °C; 104 °F.

The relative air humidity at the assembly location must not exceed 75%.

Page 22

22

PEM-X1

P_01664

P_01664

P_01665

P_02209

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

6.4 PREPARING THE SPRAY GUN

6.4.1 SELECTION OF THE SUITABLE NOZZLE SYSTEM

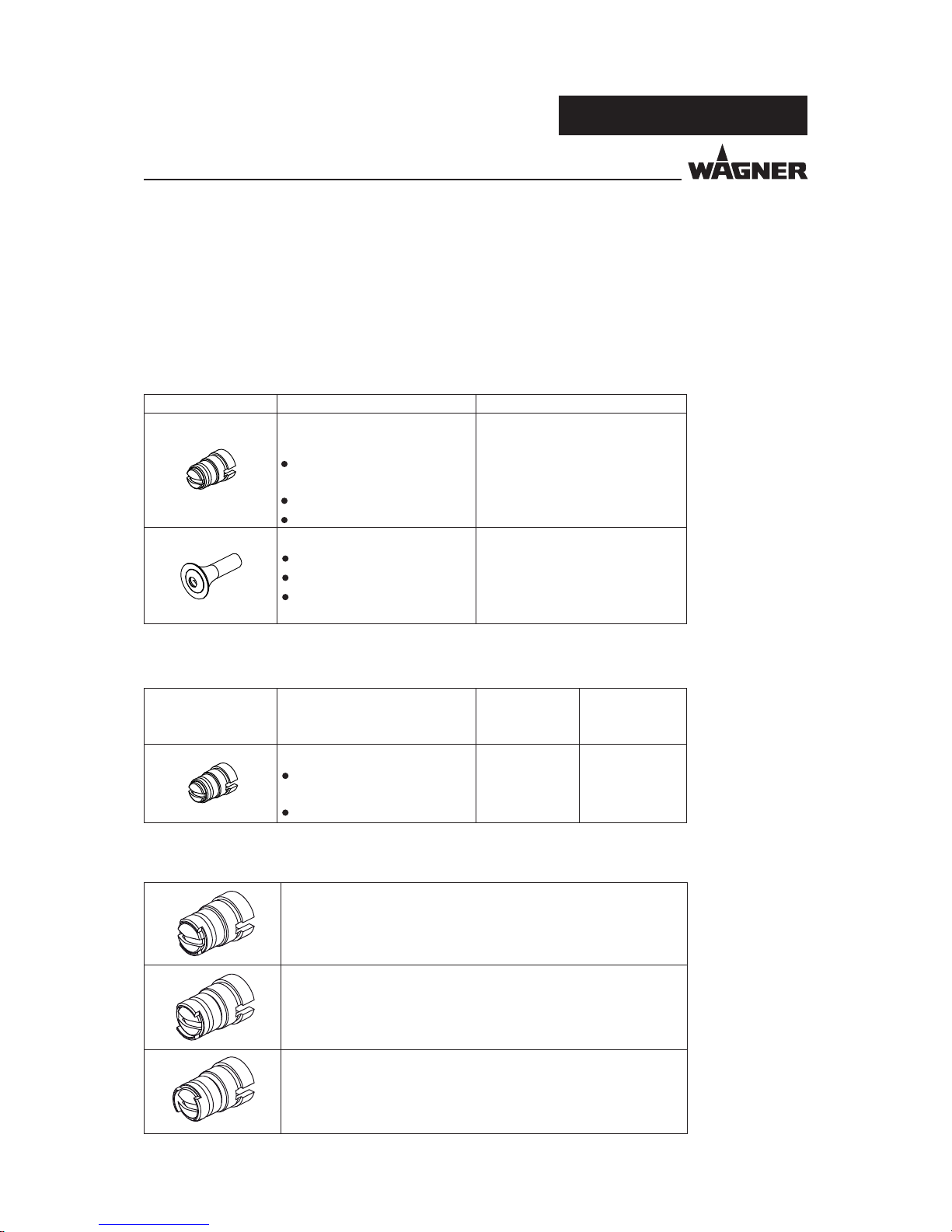

Nozzle Application Distance to

work piece

Powder output

(mm) (g/min)

Universal

120 ... 300 50 ... 300

Deep and complex part

geometries

Extensive work pieces

The spray width can be adjusted by the sliding ring.

Rear sliding ring

Wide cloud

Cloud opening angle approx. 80°

Front sliding ring, front

Narrow cloud

Cloud opening angle approx. 60°

Front sliding ring, front, turned by 90°

Extra narrow cloud

Cloud opening angle approx. 40°

Nozzle Application overview Powder cloud

Fan spray nozzle Complex part geometries Widely spread at powder cloud

Flat work pieces

(reduced picture frame)

Pro les

Undercuts

De ector cone Round powder cloud:

Wire goods Size of the powder cloud is

dependent on the de ector plate

diameter

Grid designs

Small components

The process of changing from the fan spray nozzle to the de ector cone is described in

Chapter 8.8 "Changing from Fan spray nozzle to Round spray nozzle".

You will nd the article numbers of the di erent nozzles in Chapter 12 "Accessories".

Page 23

23

PEM-X1

P_01665

P_01666

P_01667

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

De ector cone Application Distance to work piece

(mm)

R18

100 ... 300

18 mm

Smaller at parts

R25

100 ... 300

25 mm

Medium sized at parts

R34

100 ... 300

34 mm

Large at parts

Output quantity [g/min]

Overall air

Feed air [%] 4.00 Nm³/h 5.00 Nm³/h 6.00 Nm³/h

50 140 170 210

60 200 240 260

70 250 270 300

80 300 320 350

90 330 360 380

100 370 400 420

The values have been determined by means of an PI-F1 injector and a powder hose

11mm,

length 5m.

These values have to be considered as reference values and depend on the characteristics

of the powder and the status of the transport relevant pieces (e.g., injector).

Page 24

24

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Procedure:

1. Switch o the high-voltage generation on the control unit.

2. Before connecting the spray gun, check that all components (such as the nozzle system

and union nut) are correctly tted.

3. Connect electrical cable of spray gun to control unit.

4. Connect the powder feed hose to the spray gun and to the powder injector.

5. Connect the atomizing air hose to the spray gun and to the control unit.

6.5 CONNECTING THE SPRAY GUN

Unintentional putting into operation!

Risk of injury.

Before any work on the device, in the event of work interruptions

and malfunctions:

Switch o the energy/compressed air supply.

Relieve spray gun and device pressure.

Secure the spray gun against actuation.

In the event of malfunctions, remedy the fault as described in

the "Troubleshooting" chapter.

WARNING

Page 25

25

PEM-X1

P_01668

I

O

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

to the electrical connection on the control unit

Powder feed from the powder injector

Atomizing air from control unit

Powder spray gun

Control unit

Powder injector

red

blue

transparent

Page 26

26

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

6.6 GROUNDING

No Grounding!

Risk of explosion and risk of electric shock.

Electrostatic control units and the associated spray equipment

may only be connected to mains supplies with a protective

conductor connection (PE conductor)!

DANGER

Heavy powder mist if grounding is insu cient!

Danger of poisoning.

Insu cient paint application quality.

Ground all device components.

Ground the work pieces to be coated.

WARNING

For safety reasons, the control unit must be properly grounded. The ground connection

to the energy supply (socket) takes the form of the mains connection cable's protective

conductor, while that to the work piece / system is via the knurled screw on the rear of the

control unit. Both connections are absolutely essential. If installed correctly as described

above, the spray gun is grounded via the gun cable between the control unit and spray

gun.

Good grounding of the work piece is also necessary for optimum powder coating.

A poorly grounded work piece causes:

dangerous electric charging of the work piece,

very poor wrap-around,

uneven coating,

back spraying to the spray gun, i.e. contamination.

Prerequisites for perfect grounding and coating are:

Clean work piece suspension.

Grounding of spray booth, conveyor system and suspension on the building side in

accordance with the operating manuals or the manufacturer's information.

Grounding of all conductive parts within the working area.

The grounding resistance of the work piece may not exceed 1 MΩ (megohm).

(Resistance to ground measured at 500 V or 1,000 V).

Page 27

27

PEM-X1

P_01120

1

2

3

6

7

5

4

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

6.6.1 GROUNDING THE POWDER COATING SYSTEM

The footwear worn by the operators must comply with the requirements of EN ISO 20344.

The measured insulation resistance must not exceed 100 MΩ (megohms).

The protective clothing, including gloves, must comply with the requirements of

ENISO 1149-5. The measured insulation resistance must not exceed 100 MΩ (megohms).

Sparks between conveyor, conveyor hooks (hangers) and work piece can occur

if electric contact points between conveyor, conveyor hooks (hangers) and work

piece are not su ciently cleaned and therefore the work pieces are not su ciently

grounded!

These sparks can cause heavy radio frequency interference (EMC).

1 Only use mains cables with grounding strand!

2 Connect grounding cable with booth and signal ground!

3 Connect grounding cable to an uncoated metal part of the booth!

4 All paint must be removed from hook and other hanger parts!

5 Wear electrostatically conductive gloves!

6 Wear electrostatically conductive footwear!

7 The oor must be electrostatically conductive!

Page 28

28

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

7 OPERATION

7.1 TRAINING THE OPERATING STAFF

7.2 SAFETY INSTRUCTIONS

Incorrect operation!

Risk of injury and damage to the device.

The operating sta must be quali ed to operate the entire system.

Before work commences, the operating sta must receive

appropriate system training.

The operating sta must be familiar with the provisions of

European standard DIN EN 50050-2.

WARNING

Incorrect operation!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 29

29

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Procedure:

1. Switch on the high-voltage generation and the powder feed.

Note:

To minimize wear on the wearing parts, the total air volume should be below 5 Nm³/h!

The atomizing air should be adjusted for the:

fan spray nozzle to 0.1 Nm³/h,

round spray nozzle to > 0.2 Nm³/h

2. Adjust the powder quantity and the powder speed on a test piece.

7.3 OPTIMIZING THE POWDER CLOUD FOR YOUR COATING

7.3.1 RECOMMENDED SETTINGS FOR TOTAL AIR VOLUME

Hose diameter

Hose length 9 mm 10 mm 11 mm 12 mm

4 - 8 m 2.0 - 2.5 m³/h 3.0 - 3.5 m³/h 4.0 - 4.5 m³/h

8 - 12 m 2.5 - 3.0 m³/h 3.5 - 4.0 m³/h 4.5 - 5.0 m³/h

12 - 16 m 3.0 - 3.5 m³/h 4.0 - 4.5 m³/h 5.0 - 5.5 m³/h

Page 30

30

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

7.4 SWITCHING OFF THE SPRAY GUN

By releasing the trigger the powder feed is stopped and the high-voltage switched o .

To safely switch o the spray gun, e.g., for maintenance work, the control unit must be

switched o .

Page 31

31

PEM-X1

P_01669

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

7.5 ADJUSTMENT OF POWDER QUANTITY

LED display green

Reduce powder quantity

Increase powder quantity

LED display Operation mode

Flashing Normal operation of gun

Constant blinking Activated program has been changed using the "+" or

"-" button.

By selecting another program the modi ed values of

the powder quantity are not taken over, however, the

current values of the other program are taken over

and the blinking changes to ashing.

By saving these settings the current values of the

powder feed are taken over in the current program.

The blinking changes back to ashing.

By activating the "Double Click" function the blinking

is switched o as well, the preset program values are

then active again.

Permanent lighting Trigger has been actuated with "Double Click", i.e., the

"Double Click" program is activated.

Note:

This function can only be activated in combination with the EPG-Sprint X control unit.

By pressing the buttons "+/-" the preset program values of the feed air (powder quantity)

can be changed in the desired direction.

In this case the total air remains unchanged, the feed and dosing air is readjust accordingly.

Page 32

32

PEM-X1

2x

P_01701

2x

2x

kV

80

60

40

20

100

Tri Cor

5

4

3

2

1

120

80

40

20

10

μA

2x

2x

kV

80

60

40

20

100

Tri Cor

5

4

3

2

1

120

80

40

20

10

μA

2x

2x

kV

80

60

40

20

100

Tri Cor

5

4

3

2

1

120

80

40

20

10

μA

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

7.6 "DOUBLE CLICK" PROGRAM HIGH DYNAMIC REMOTE

This function is used to change quickly to another program during a coating operation.

The operator can access a previously set program by double-clicking on the trigger lever

on the spray gun, for example to recoat parts using di erent parameters (high-voltage,

current limitation, air volumes etc.).

To access the function, press the trigger lever on the spray gun twice in quick succession

and hold down. Upon releasing the trigger, the original program will be returned to.

Page 33

33

PEM-X1

P_01671

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

7.7 REPRODUCIBLE SETTING OF THE NOZZLE POSITION

An adjustment tool is provided for the fan spray nozzle.

It permits turning the fan spray nozzle without

damaging the electrodes and without removing the

union nut.

The union nut only has to be slackened.

Page 34

34

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8 CLEANING AND MAINTENANCE

Cleaning work should be undertaken regularly and carefully by quali ed and trained sta .

The sta must be familiar with the DIN EN 50050-2 provisions. They should be informed of

speci c hazards during their training.

The following hazards may arise during cleaning work:

Health hazard from inhaling powder lacquer

Use of unsuitable cleaning tools and aids

8.1 CLEANING

8.1.2 SAFETY INSTRUCTIONS

8.1.1 CLEANING STAFF

Explosive powder/air mixes!

Danger to life and damage to the device.

Before starting cleaning or other manual work, the high-voltage

must be shut down and locked to prevent it from being switched

back on!

The spray gun must be separated from the high-voltage supply

and compressed air supply before any cleaning work is started!

Use only electrically conductive tanks for cleaning liquids!

Ground the tank!

Preference should be given to non- ammable cleaning uids.

Flammable cleaning liquids may only be used if, after switching

o the high-voltage, all high-voltage conducting parts are

discharged to a discharge energy of less than 0.24 mJ before

they can be accessed.

Most ammable solvents have an ignition energy of around

0.24 mJ or 60 nC.

The cleaning agent's ash point must be at least 15 K above the

ambient temperature.

Only mobile industrial vacuum cleaners of design 1 (see EN 60335-2)

may be used to remove dust deposits.

DANGER

Page 35

35

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

The cleaning intervals should be adapted by the operator depending on the level of use

and if necessary the level of soiling.

If in doubt, we recommend contacting J. Wagner AG's specialist personnel.

The valid health and safety speci cations and the safety instructions provided in Chapter 4

must be adhered to for all cleaning work.

8.1.3 CLEANING PROCEDURES

Incorrect maintenance!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not exceed

100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 36

36

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.2 MAINTENANCE

Maintenance work should be undertaken regularly and carefully by quali ed and trained

sta . They should be informed of speci c hazards during their training.

The following hazards may arise during maintenance work:

Health hazard from inhaling powder lacquer

Use of unsuitable tools and aids

Once the maintenance work is complete, the device must be checked by a quali ed person

to ensure a reliable condition.

8.2.1 MAINTENANCE STAFF

8.2.2 SAFETY INSTRUCTIONS

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve spray gun and device pressure.

- Secure the spray gun against actuation.

Observe the operating manual and service manuals at all times

when carrying out work.

DANGER

Incorrect maintenance/repair!

Danger to life and damage to the device.

Repair or replacement of devices or parts of devices are only

allowed to be performed outside the hazard area by quali ed

personnel.

Before starting maintenance or other manual work, the high-

voltage must be shut down and locked to prevent it from being

switched back on!

The spray gun must be separated from the high-voltage supply

and compressed air supply before any maintenance work is

started!

DANGER

Page 37

37

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

The maintenance intervals should be adapted by the operator depending on the level of

use and if necessary the level of soiling.

If in doubt, we recommend contacting J. Wagner AG's specialist personnel.

The valid health and safety speci cations and safety instructions provided in Chapter 4

must be adhered to for all maintenance work.

Maintenance work Point in time

per shift weekly

Blow out gun and check for sintering

Check gun settings

Check gun discharge pressure

Blow out powder hoses

Check grounding

Check compressed air quality

Check gun voltage

Check powder hoses for bends and sintering

8.2.3 MAINTENANCE PROCEDURES

Incorrect maintenance!

Risk of injury and damage to the device.

If contact with powder products or cleaning agents causes skin

irritation, appropriate precautionary measures must be taken,

e.g., wearing protective clothing.

The footwear worn by operating sta must comply with

EN ISO 20344. The measured insulation resistance must not

exceed 100 megohms.

The protective clothing, including gloves, must comply with

EN ISO 1149-5. The measured insulation resistance must not

exceed 100 megohms.

WARNING

Page 38

38

PEM-X1

5

4

3

2

1

P_01672

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.2.4 REPLACING THE SPRAY GUN

Before replacing the spray gun, any powder residue must be thoroughly removed.

The wearing parts in the spray gun, marked in the spare parts list with "

", must be regularly

checked and, if necessary replaced.

Procedure:

1. Switch o control unit.

2. Disconnect electrical cable 1 from control unit 2.

3. Disconnect powder feed hose 3 and atomizing air hose 4 from spray gun 5.

4. Connect powder feed hose 3 and atomizing air hose 4 to the new spray gun 5.

5. Connect electrical cable 1 to control unit 2.

6. Switch on the control unit.

7. The spray gun is ready for use again.

Page 39

39

PEM-X1

1.

2.

P_01673

3.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.3 REMOVING THE FAN SPRAY NOZZLE

3. The parts can be separated by gently pressing the sliding

ring on the fan spray nozzle.

4. Remove powder residues from the parts removed and from

the spray gun.

Note:

Never place the spray gun or parts of the spray gun in cleaning

agent.

As a rule the protective wedge needs to be checked for wear and

replaced if necessary.

Procedure:

1. Unscrew union nut from gun housing.

2. Take union nut with nozzle system o gun body.

The nozzle system remains inserted in the union nut.

Note:

If the nozzle system doesn't remain inserted in the union nut, the

nozzle system and union nut must be replaced.

Page 40

40

PEM-X1

2.

4.

3.

P_01674

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.4 FITTING THE FAN SPRAY NOZZLE

4. Screw union nut onto gun housing until fan spray nozzle

can no longer be turned by hand.

Procedure:

Note:

1. Before inserting the electrode holder, the spring contact

of the gun body and contact surface of the electrode

holder should be checked. The spring contact must be

clean and smooth-running, the gun body must also be

clean and free of powder deposits.

2. Insert electrode holder into gun housing.

3. Attach fan spray nozzle to electrode holder and attach

union nut.

Page 41

41

PEM-X1

1.

3.

P_01677

2.

4.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.5 REMOVING THE ROUND SPRAY NOZZLE

Procedure:

1. Pull o de ector cone.

2. Unscrew union nut from gun housing.

3. Take union nut with nozzle system o gun

body. The nozzle system remains inserted in

the union nut.

Note:

If the nozzle system doesn't remain inserted in the

union nut, the nozzle system and union nut must

be replaced.

4. Press nozzle system out of union nut by gently

pressing on de ector cone sleeve.

5. Remove powder residues from the parts

removed and from the spray gun.

Note:

Never place the spray gun or parts of the spray gun

in cleaning agent.

As a rule the protective wedge needs to be checked

for wear and replaced if necessary.

Page 42

42

PEM-X1

2.

P_01678

3.

4.

5.

6.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.6 FITTING THE ROUND SPRAY NOZZLE

Procedure:

Note:

1. Before inserting the electrode holder, the spring

contact of the gun body and contact surface of

the electrode holder should be checked.

The spring contact must be clean and smoothrunning, the gun body must also be clean and

free of powder deposits.

2. Attach de ector cone sleeve onto electrode holder.

3. Insert electrode holder into gun housing.

4. Slide union nut onto gun housing.

5. Screw union nut onto gun housing (hand-tight).

6. Slide de ector cone over de ector cone sleeve.

Page 43

43

PEM-X1

P_01675

2.

1.

3.

2

3

1

E

A

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.7 REPLACING THE PROTECTIVE WEDGE

1 Wedge tool

2 Electrode holder (shown with a cut-away

view to improve comprehension)

3 Protective wedge (when positioned)

Procedure:

1. Guide wedge tool 1 into electrode holder2

up to stop.

3. Press protective wedge 3 sideways out of

wedge tool 1 manually (without tool).

Note:

A wedge tool is available to prevent the protective wedge from being damaged when

dismantling and inserting.

The wedge tool has a removal side (E) and an attachment side (A). Use the right side for the

corresponding procedure!

You will nd the necessary wearing parts and spare parts in Chapter 13 "Spare Parts" of this

operating manual.

2. Pull protective wedge 3 out of electrode

holder 2 using wedge tool 1.

Page 44

44

PEM-X1

Y

X

P_01676

3.

1.

2.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Procedure:

1. Guide protective wedge 2 into wedge tool 1.

2. Insert both parts into opening on electrode

holder up to stop.

If it is not possible to push the wedge tool in

as far as the X mark, rotate the wedge tool a

little until it can be pushed up to the mark.

The mark X must be ush with the Y end of the

electrode holder.

3. The protective wedge is now correctly

assembled and the wedge tool can be pulled

out of the electrode holder.

4. The protective wedge remains inserted in the

electrode holder.

Prior to re- tting, check whether the contact

points on electrode holder 3 and in gun

housing 5 have been thoroughly cleaned so

that the electrode tip is electrically connected

to the high-voltage generator.

5. Mount fan or round spray nozzle with the

corresponding electrode holder.

Note:

The same wedge tool is used to insert the protective wedge.

Page 45

45

PEM-X1

1.

4.

2.

3.

P_01679

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

The standard Corona spray gun is delivered with a fan spray nozzle. The nozzle can be

changed easily, as described below.

The X1 R electrode holder is necessary to perform the change.

8.8 CHANGING FROM FAN SPRAY NOZZLE TO ROUND SPRAY NOZZLE

Procedure:

1. Unscrew union nut from gun housing.

2. Take union nut with nozzle system o gun body. The nozzle

system remains inserted in the union nut.

Note:

If the nozzle system doesn't remain inserted in the union nut, the

nozzle system and union nut must be replaced.

3. The parts can be separated by gently pressing the sliding

ring on the fan spray nozzle.

4. Attach de ector cone sleeve onto X1 R electrode holder.

Electrode tip!

Risk of injury.

Take care when tting the X1 R electrode holder.

CAUTION

Page 46

46

PEM-X1

P_01690

8.

7.

9.

6.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Procedure:

5. Before inserting the electrode holder, the spring contact of

the gun body and contact surface of the electrode holder

should be checked. The spring contact must be clean and

smooth-running, the gun body must also be clean and free

of powder deposits.

6. Insert electrode holder into gun housing.

7. Slide union nut onto gun housing.

8. Screw union nut onto gun housing (hand-tight).

9. Slide de ector cone over de ector cone sleeve.

Page 47

47

PEM-X1

1

2

B

±90°

P_01703

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.9 ASSEMBLY OF THE CORONASTAR

The CoronaStar is a retro t set for the spray gun, which helps to achieve a better surface

quality (e.g., reduction of "orange peel").

Procedure:

1. Guide plug-in contact 1 of CoronaStar into drilled

hole B on hook.

2. Attach clip 2 of CoronaStar to housing.

Flexible positioning in a range of ± 90° is possible.

Danger from electric current!

Risk of injury and damage to the device.

The conversion to the CoronaStar may only be carried out by

trained personnel.

Prior to assembling the CoronaStar, the high-voltage and

powder feed must be switched o and secured against being

inadvertently switched on.

WARNING

Page 48

48

PEM-X1

P_01717

1.

2.

3.

4.

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

8.10 REPLACING THE SUSPENSION HOOK

Procedure:

1. Loosen retaining bolts on rear of hook and unscrew.

2. Slide hook in direction indicated by arrow and

remove from gun housing.

3. Fit new hook on receiver and slide in direction

indicated by arrow.

4. Fit retaining bolts and tighten.

Page 49

49

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

9 INSPECTIONS IN ACCORDANCE WITH DIN EN 500502: 2014

If the system is used for electrostatic coating with ammable coating powders, testing

should be undertaken in accordance with DIN EN 50050-2: 2014 as per Table 1.

Page 50

50

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

9.1 OVERVIEW OF INSPECTIONS

Section Type of inspection Requirements Inspection by Type of inspection Inspection

interval

1 Resistance to ground of work

piece's locating point

The resistance to ground of

every work piece's locating point

must not exceed 1 megohm

(measurement voltage must be

1000 V). The design of the work

piece receiver must ensure that the

adapters remain grounded during

coating.

CP ME/CI

Measure resistance to ground

(work piece receiver - ground

potential)

max. 1 megohm @ 1,000 V.

weekly

2 Interlock between technical

ventilation and high-voltage,

compressed air and coating product

supply

The technical ventilation should

be interlocked such that the

powder feed and high-voltage

cannot be switched on, while the

technical ventilation is not working

e ectively.

CP FI

Test whether the system is safely

stopped and the product supply,

supply air and high-voltage

are switched o when the

ventilation is shut down.

annually

3 Checking the electrostatic manual

coating system for damage

Electrostatic manual coating

systems may only be operated in an

undamaged condition. Damaged

devices must be decommissioned

immediately and repaired

immediately.

CP FI

Inspect and test

(e.g., by measurement) whether

all parts carrying high-voltage

do not result in discharge which

puts people at risk.

weekly

Legend:

MA = Manufacturer

EM = Employer

CP = Capable person

FSE = Fire safety engineer

ELC = Electrician

TP = Trained person

FI = Function inspection

ME = Measurement

SI = Standard inspection

VI = Visual inspection

CI = Continuous inspection

TI = Technical inspection

Page 51

51

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Do not dispose of used electrical equipment with household

refuse!

In accordance with European Directive 2002/96/EC on the disposal

of used electrical equipment and its implementation in national

law, this product may not be disposed of with the household refuse,

but must be recycled in an environmentally correct manner.

Wagner or one of our dealers will take back your used Wagner waste

electrical or electronic equipment and will dispose of it for you in

an environmentally friendly way. Please contact one of our service

points, one of our representatives or us directly to arrange this.

NOTICE

10.2 DISPOSAL

10 DISASSEMBLY AND DISPOSAL

10.1 DISASSEMBLY

Procedure:

1. Switching o the system.

2. Lock the compressed air supply and decompress system.

3. Disconnect the gun connection cable from control unit.

4. Disconnect the powder feed hose to the spray gun and to the powder injector.

5. Disconnect the atomizing air hose to the spray gun and to the control unit.

WARNING

Incorrect disassembly!

Risk of injury and damage to the device.

Before starting disassembly:

- Switch o the energy/compressed air supply.

- Ensure that all system components are grounded.

- Secure system against being switched back on without

authorization.

Observe the operating manuals for any work.

Page 52

52

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

11 TROUBLESHOOTING AND RECTIFICATION

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Relieve spray gun and device pressure.

- Secure the spray gun against actuation.

Observe the operating manual and service manuals at all times

when carrying out work.

DANGER

Incorrect maintenance/repair!

Danger to life and damage to the device.

Wagner devices, protective systems and safety, monitoring and

control equipment may only be maintained/repaired as de ned

in Directive 94/9/EC (ATEX) by trained Wagner service personnel

or capable persons in accordance with TRBS 1203! Note national

regulations!

Repair or replacement of devices or parts of devices may only be

performed outside the hazard area!

DANGER

Page 53

53

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Fault Cause Remedy

No electrostatic (e.g., no wrap

around or no powder adhesion)

Fault in the high-voltage

generator

Contact a Wagner service center

Electrical cable from spray gun

to control unit faulty

Contact a Wagner service center

Cascade in spray gun faulty Contact a Wagner service center

Poor powder wrap around

Back-spray

Insu cient or no grounding See Chapter 6.6 "Grounding"

Powder outlet uneven or

inadequate

Contamination Blow through parts carrying

powder

Powder sintering Clean parts carrying powder

Feed device contaminated See operating manuals for the

related devices connected

Feed air / dosing air ratio incorrect Adjust at control module resp.

control unit

Wear on powder injector nozzle Replace worn parts on powder

injector ¹)

Spray pattern is uneven Parts of nozzle system worn Replace worn parts

Cracks in the gun housing

Improper handling of the

powder spray gun

Gun housing must be replaced

Contact a Wagner service center

1.) You will nd the wear parts and spare parts in the powder injector operating manual.

Page 54

54

PEM-X1

P_01664

P_01665

P_01666

P_01667

P_01691

P_01692

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12 ACCESSORIES

12.1 FAN SPRAY NOZZLE

Order No. Designation

Fan spray nozzle, X1, complete

12.2 DEFLECTOR CONE

Order No. Designation

De ector cone, D18, complete

De ector cone, D25, complete

De ector cone, D34, complete

12.3 ELECTRODE HOLDER

Order No. Designation

Electrode holder, X1 F ET

Electrode holder, X1 R ET

Page 55

55

PEM-X1

P_01693

P_01694

P_01695

1

P_01696

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12.4 HOSE TAKEUP

Order No. Designation

Hose take-up, D10-D12, complete

Hose take-up, D8-D10, complete

12.5 CORONASTAR RETROFIT SET

Pos Order No. Designation

CoronaStar, PEM-X1, complete

CoronaStar electrode, PEM-X1 ET

12.6 WEDGE TOOL

Pos K Stk Order No. Designation

Wedge tool, X1 + 20 wedges

available as accessory, not included in the purchased parts package

20x

Page 56

56

PEM-X1

P_01697

P_02163

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12.7 NOZZLE EXTENSION, X1 VL 150/300/500

Pos K Stk Order No. Designation

Nozzle extension, X1 VL 150 (150 mm; 5.91 inches)

Nozzle extension, X1 VL 300 (300 mm; 11.81 inches)

1 2323338 Nozzle extension, X1 VL 500 (500 mm; 19.68 inches)

1 2324147 Fan spray nozzle, X1 VL ET

Round spray nozzle, X1 VL ET

available as accessory, not included in the purchased parts package

12.8 NOZZLE EXTENSION, X1 VL 750

Pos K Stk Order No. Designation

2330497 Nozzle extension, X1 VL 750 (750 mm; 29.53 inches)

1 2324147 Fan spray nozzle, X1 VL ET

2324148 Round spray nozzle, X1 VL ET

available as accessory, not included in the purchased parts package

Page 57

57

PEM-X1

P_01861

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12.9 POWDER HOSE

Order No. Designation

Powder hose 9 mm

Powder hose 10 mm

Powder hose 11 mm

Powder hose 12 mm

12.10 GUN CONNECTION CABLE

Order No. Designation

2334275 Manual gun cable, PEM-X1 6m ET

2334568 Manual gun cable, PEM-X1 15m ET

Note:

The replacement of the gun cable may only be performed by Wagner service personnel!

12.11 WALL MOUNT

Order No. Designation

Wall mount with bracket

Page 58

58

PEM-X1

2x

2x

Tribo Corona

m /h

3.0

0.5

0.3

0.1

1.5

3

Tri

Ø

12

10

11

9

8

m /h

2.0

3

5.5

4.5

3.5

2.5

0 %

100 %

10

20

30

40

50

60

70

80

90

[μA] [Nm³/h] [%][kV]

[Nm³/h]

0.1

> 0.2

@

90 80 4.0 70

50 20 3.6 57

70 40 3.6 50

P5

P6

P7

P8

P9

P10

name 80 100 4.5 80

______________________________

www

✆

www.wagner-group.com/industry

______________________________

2x

82 20 3.6 45

P_01829

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12.12 RECIPE STICKER

Order No. Designation

2331223 Recipe sticker

Page 59

59

PEM-X1

P_01716

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

12.13 POWDER MEASURING ADAPTER

Order No. Designation

Powder measuring adapter with X1 bag, complete

for measuring powder quantities for the PEM-X1 spray gun

The powder measuring adapter is slid onto the nozzle.

Risk of explosion due to electrostatic charging!

Danger to life and damage to the device.

Only use powder measuring adapter when high-voltage is

switched o !

DANGER

Page 60

60

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

13 SPARE PARTS

13.1 HOW CAN SPARE PARTS BE ORDERED?

To ensure proper spare parts delivery, the following information is necessary:

Order number, designation, and quantity

The quantity need not be the same as the number given in the quantity column "Stk" on

the lists. This number merely indicates how many of the respective parts are used in each

component.

The following information is also required to ensure smooth processing of your order:

Identi cation in spare parts lists

Explanation of column "K" (labeling) in the following spare parts lists.

- Billing address

- Delivery address

- Name of the person to be contacted in the event of any queries

- Type of delivery (normal mail, express delivery, air freight, courier etc.)

= Wearing parts

Note: These parts are not covered by warranty terms

= Not part of the standard equipment but available as a special accessory.

Incorrect maintenance/repair!

Risk of injury and damage to the device.

Have repairs and part replacements carried out only by specially

trained sta or a WAGNER service center.

Before all work on the device and in the event of work

interruptions:

- Switch o the energy/compressed air supply.

- Ensure that all system components are grounded.

- Secure the device against being switched back on without

authorization.

Observe the operating manual and service manuals at all times

when carrying out work.

WARNING

Page 61

61

PEM-X1

1

3

4

5

6

7

10

P_01699

2

8

9

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

13.2 PEMX1 CORONA MANUAL GUN WITH A FAN SPRAY NOZZLE

PEM-X1 manual gun

Pos K Stk Order No. Designation

PEM-X1 Corona manual gun

Hose take-up, D10-12, complete

O-ring

Union nut, X1

Fan spray nozzle, X1, complete

Electrode holder, X1 F ET

Replacement protective wedge, X1

Gun hook, X1 ET

Screw

Wedge tool, X1

11 1 2313993 Hose, transparent 6 mm

Wearing parts

Not part of the standard equipment but available as a special accessory

Only available as a set

Page 62

62

PEM-X1

1

3

4

6

9

P_01661

2

7

8

5

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

13.3 PEMX1 CORONA MANUAL GUN WITH A ROUND SPRAY NOZZLE

PEM-X1 manual gun

Pos K Stk Order No. Designation

2335844 PEM-X1 Corona manual gun

2322761 Hose take-up, D10-12, complete

9971364 O-ring

2320464 Union nut, X1

Electrode holder, X1 R, with nozzle

6 1 Replacement protective wedge, X1

7

Gun hook, X1 ET

82 Screw

91 Wedge tool, X1

10 1 2313993 Hose, transparent 6 mm

Wearing parts

Not part of the standard equipment but available as a special accessory

Only available as a set

Page 63

63

PEM-X1

4

3

5

6

7

P_01700

2

1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Electrode holder, X1 R, with nozzles

Pos K Stk Order No. Designation

Electrode holder, X1 R, with nozzle

Electrode holder, X1 R ET

Replacement protective wedge, X1

De ector cone sleeve, X1

De ector cone, D18, complete

De ector cone, D25, complete

De ector cone, D34, complete

Wearing parts

Not part of the standard equipment but available as a special accessory

Only available as a set

13.4 ELECTRODE HOLDER, X1 R

Page 64

64

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

14 DECLARATION OF WARRANTY AND CONFORMITY

14.1 IMPORTANT NOTES REGARDING PRODUCT LIABILITY

14.2 WARRANTY CLAIM

As a result of an EC regulation e ective from January 1, 1990, the manufacturer shall only

be liable for his product if all parts originate from him or are approved by him, and if the

devices are properly mounted, operated and maintained.

The manufacturer will not be held liable or will only be held partially liable if third-party

accessories or spare parts have been used.

With genuine WAGNER accessories and spare parts, you have the guarantee that all safety

regulations are complied with.

Full warranty is provided for this device:

We will at our discretion repair or replace free of charge all parts which within 24 months

in single-shift, 12 months in 2-shift or 6 months in 3-shift operation from date of receipt by

the purchaser are found to be wholly or substantially unusable due to causes prior to the

sale, in particular faulty design, defective materials or poor workmanship.

The type of warranty provided is such that the device or individual components of the

device are either replaced or repaired as we see t. The resulting costs, in particular

shipping charges, road tolls, labor and material costs will be borne by us except where

these costs are increased due to the subsequent shipment of the device to a location other

than the address of the purchaser.

We do not provide warranty for damage that has been caused or contributed to for the

following reasons:

Unsuitable or improper use, faulty assembly or commissioning by the purchaser or a

third party, normal wear, negligent handling, defective maintenance, unsuitable coating

products, substitute products and the in uence of chemical, electrochemical or electrical

agents, except when the damage is attributable to us.

Components that have not been manufactured by WAGNER are subject to the original

warranty of the manufacturer.

Replacement of a component does not extend the period of warranty of the device.

The device should be inspected immediately upon receipt. To avoid losing the warranty,

we or the supplier company are to be informed in writing about obvious faults within 14

days upon receipt of the device.

We reserve the right to have the warranty compliance met by a contracting company.

The services provided by this warranty are dependent on evidence being provided in the

form of an invoice or delivery note. If the examination discovers that no warranty claim

exists, the costs of repairs are charged to the purchaser.

It is clearly stipulated that this warranty claim does not represent any constraint on statutory

regulations or regulations agreed to contractually in our general terms and conditions.

J. Wagner AG

Page 65

65

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

14.3 DECLARATION OF CONFORMITY

PEM-X1 manual gun 2326024

Herewith we declare that the supplied version of

- PEM-X1 manual gun, order no. 2322587, 2335844

complies with the following provisions applying to it:

- 94/9/EC (ATEX Directive)

- 2006/42/EC (Machine Directive)

- 2004/108/EC (EMV Directive)

- 2002/95/EC (RoHs Directive)

- 2002/96/EC (WEEE Directive)

Applied standards, in particular:

Applied national technical standards and speci cations, in particular:

- BGI 764

Identi cation:

0102 II 2D 2mJ

PTB 12 ATEX 5002

EN 50050-2: 2012

CE Certi cate of Conformity

The CE certi cate of conformity is enclosed with this product. If needed, further copies

can be ordered through your WAGNER dealer by specifying the product name and serial

number.

Order number:

Page 66

66

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

14.4 EC TYPE EXAMINATION CERTIFICATE

Page 67

67

PEM-X1

Specialconditionsofuse:

ThesourceelectricalconnectionfortheControlUnitsaretobeconnectedinanunclassified

(ordinary)locationonly.

P_00309

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

14.5 FM APPROVAL

The PEM-X1 powder spray gun is approved in the USA and Canada using con guration

drawing no. 2309729.

Page 68

68

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Page 69

69

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Page 70

70

PEM-X1

OPERATING MANUAL

VERSION 03/2014 ORDER NUMBER DOC 2326020

Page 71

Page 72

C

E

R

T

I

F

I

E

D

Order No. 2326020

Edition 03/2014

Germany

Phone

Fax

E-mail

Switzerland

Phone

Fax

More contact addresses on the internet at:

Company/Locations/WAGNER worldwide

Subject to changes without notice

Document No. 11130849

Version B

Loading...

Loading...