Page 1

http://www.wagner-group.com

Operating Manual

Tribo Cup Gun

DANGER

High Voltage!

Turn power off

before servicing!

Read rules for safe

operation and

instructions

carefully!

CAUTION

pemtg3_0000

0351967

PEM-TG3

C

E

R

T

I

F

I

E

D

D

I

N

I

S

O

9

0

0

1

04/2006 0351717

Page 2

Introduction

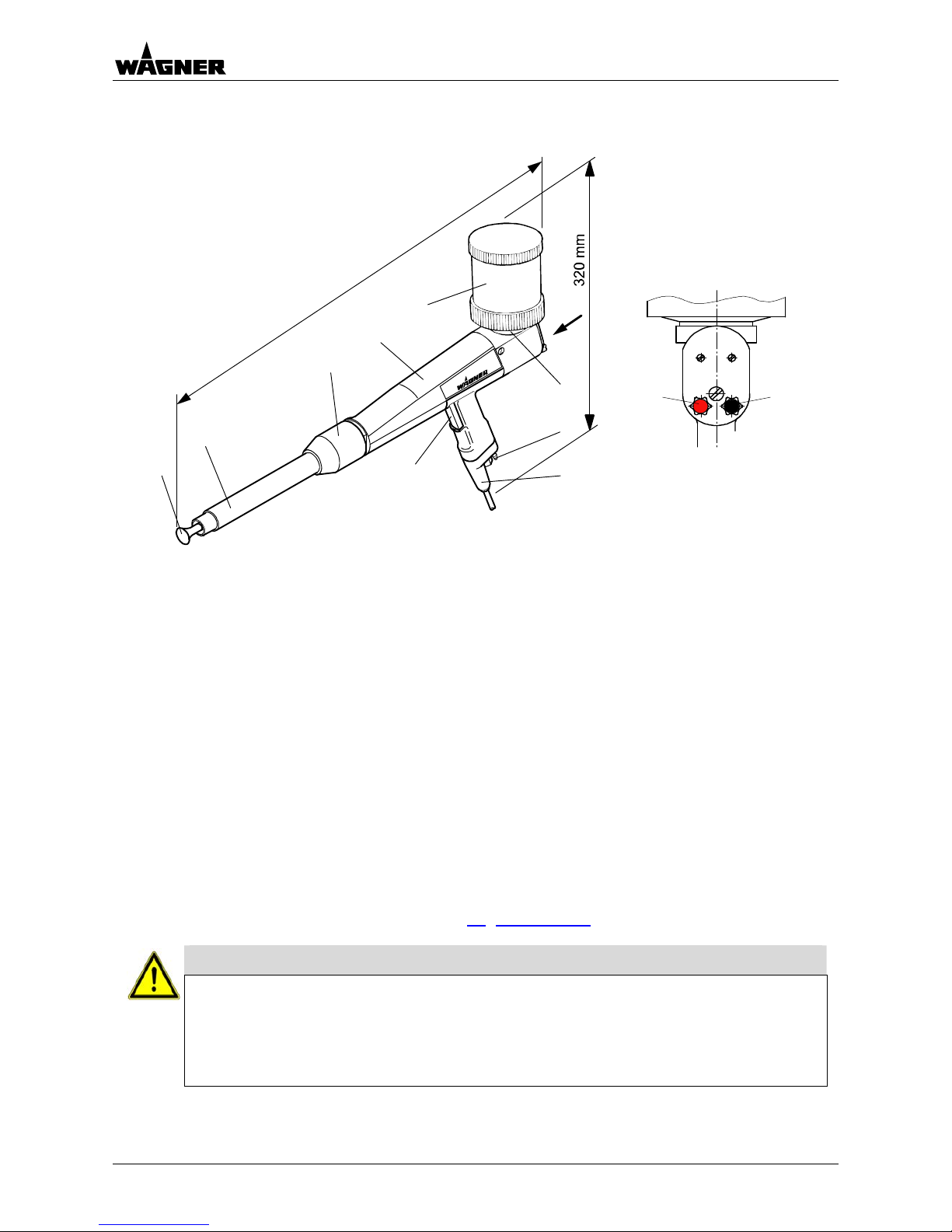

Tribo Cup Gun PEM-TG3 Article No. 0351036

00_Pemtg3_Aufbau.doc

570

m

m

X

A

B

F

G

J

E

C

D

H

Pemtg3_0001a

X

K L

Pemtg3_0001b

A Deflector cone

B Nozzle body

C Outer nut

D Spray gun body

E Trigger

F Air supply (input air)

G Electrical connection

H Powder container with fluidization

J Adapter with integrated powder injector

K Setting knob red for setting the feed air

L Setting knob black for setting the Tribo air

The Tribo cup gun PEM-TG3 is used for processing all coating powders suitable for friction

charging.

The Tribo cup gun is mainly suitable for laboratory tests, sample coating and/or low volume

production.

By actuating the trigger the compressed air supplies to the gun is turned on. This compressed

air is required for Tribo, feed, dosing and fluid air applications.

This cup gun can be operated with the control unit EPG 2008.

The cup gun is equipped with a powder container with a capacity of 500 cm

3

. You can also

mounted different powder containers on the cup gun.

You will find the article numbers in chapter 10

"Accessories".

Caution

The operator must ensure that the spray gun PEM-TG3 s only connected to Wagner

devices!

High room temperatures and, in particular, laying hoses in areas exposed to sunlight in

factory buildings must be avoided!

To secure the spray guns, the control unit must be switched off!

2 0351717 - PEM-TG3 04/2006

Page 3

Introduction

Table of contents Page

1. Safety regulations.......................................................................................................5

1.1 Safety hints....................................................................................................................5

1.2 EU Declaration of conformity.........................................................................................8

2. Preparing the spray gun.............................................................................................9

2.1 Selection of the suitable equipment ..............................................................................9

2.2 Mounting the powder container...................................................................................10

2.3 Connecting the spray gun ...........................................................................................10

2.4 Grounding....................................................................................................................11

3. Working with the spray guns...................................................................................12

3.1 Starting up the spray gun and adjusting Tribo air........................................................12

3.2 Switching off the spray gun.........................................................................................12

3.3 Performing a color change..........................................................................................13

4. Maintenance and cleaning........................................................................................15

4.1 Replacing the spray gun..............................................................................................15

4.2 Cleaning the spray gun and replacing the wear parts.................................................17

4.3 Check the standard settings........................................................................................18

4.4 Disposal.......................................................................................................................19

5. Rectification of malfunctions...................................................................................20

6. Technical data ...........................................................................................................21

7. Applicable safety regulations ..................................................................................22

8. Warranty.....................................................................................................................23

9. Scope of delivery and spare parts lists...................................................................24

9.1 How to order spare parts.............................................................................................24

9.2 Scope of delivery and spare parts list PEM-TG3 ........................................................25

10. Accessories...............................................................................................................27

10.1 Powder container ........................................................................................................27

10.2 Special accessory .......................................................................................................28

04/2006 0351717 - PEM-TG3 3

Page 4

Introduction

00_..doc

This manual contains information and hints for the service, repair and maintenance of the

equipment. The user must obey all the rules of operation found in this manual; failure to do so

will render the warranty invalid.

Wagner powder systems are designed to meet the most stringent safety requirements. They

can be operated in compliance with generally applicable safety codes and applicable national

safety regulations.

Please pay particular attention to the parts marked by the following symbols. Follow the

instructions exactly, in the interests of both your own safety and the correct functioning of the

unit.

Warning

This symbol draws attention to the fact that if the operating instructions, working

instructions, prescribed working sequences etc. are not followed exactly, this can

lead to injury or even fatal accidents.

Caution

This symbol indicates that failure to follow the operating instructions, working

instructions, prescribed working sequences etc. exactly can lead to material damage.

Hint

This symbol draws your attention to useful additional information and tips. Failure to

observe these instructions can cause malfunctions.

4 0351717 - PEM-TG3 04/2006

Page 5

Safety regulations

1. Safety regulations

1.1 Safety hints

010101_ .doc

Warning

This equipment can be dangerous if it is not operated in accordance with this

operating manual!

There might be additional regulations to be observed, put into effect by

governmental, state or other official agencies or local security (fire)

departments

!

Warning

Under no circumstance may persons with a cardiac pacemaker come close

to the area between the tip of the spray gun and the work piece to be

coated!

The following rules must be observed in order to ensure a safe and efficient use of the

equipment:

• The user has to observe particularly the safety

guidelines of the VdS, the local professional and

security institutions.

• Trained and qualified personnel may only operate the electrostatic coating equipment.

• The spray gun may only be operated in powder

coating booths or on powder coating stands that

are equipped with a ventilation system.

• The user has to make sure, that the average

powder/air concentration does not exceed 50%

of the LEL (maximum allowed concentration of

powder in air). If a reliable LEL value is not

available, the average powder/air concentration

may not exceed 10 g/m³.

• Over sprayed powder must be reliably collected.

• Adhere to the instructions given by the manufac-

turers and to the prevalent local laws on the

environment when disposing of waste coating

powder.

• The main power connection for operation of the

Wagner powder equipment must be electrically

interlocked with the exhaust system of the

powder coating booth.

• In the event of faults or defects, repair work is to

be performed at the user's discretion.

• The user must conduct periodic checks of the

powder spray equipment (at least every year)

with regard to explosion-protection.

• Repairs may only be carried out by trained technicians and may never be carried out in an

explosion hazardous area. Protective measures

against explosions must still be installed.

• The work area must have an electrostatically

conductive floor (measured in accordance with

EN 1081).

• All conductive parts in the work area must be

electrostatically grounded (work area = 1 m

around every spray location or opening in the

booth).

• All persons inside the work area must wear

electrostatically conductive footwear.

• Spray guns should be operated with bare hands!

If gloves are used they must be made of conductive material.

• Guideline 94/9/EG: The device is suited for the

applications it was designed for, even in

explosion-hazard areas.

Also refer to chapter 7

"Applicable safety regulations".

04/2006 0351717 - PEM-TG3 5

Page 6

Safety regulations

010102_ .doc

• Wear suitable work clothing

• Use breathing protection or a vizard for work

which produces powder and when

developing solvent steams:

Avoid health dangers by inhalation and skin

contacts of solvent steams and lacquer aerosols; Cornea injuries by splashes in the eye.

• Check the equipment for damage

Before operating the system, check if slightly

damaged parts still function correctly. Check

whether the moving parts operate properly,

whether they jam and whether parts are

damaged.

Damaged parts should be repaired or

replaced by a Wagner customer service.

Warning

For your own safety, use only accessories and equipment listed in the

operating manual. The use of individual parts other than those

recommended in the operating manual may create a hazard to personal safety.

Use only original Wagner replacement parts!

Alteration or repair of Wagner original spare parts may cause fatal

accidents or explosions in the coating system!

6 0351717 - PEM-TG3 04/2006

Page 7

Safety regulations

HAZARD PREVENTION

Electrostatic arcing may cause an explosion or fire.

Mixtures of powder and air can explode or ignite

causing property damage and/or severe injury.

• Operator must be grounded. Grounding straps must be used

when wearing rubber soled shoes.

• Operator must remove all metallic objects from his or her

person, which are not grounded.

• The object being sprayed must be grounded.

• All metallic objects within the spray area must be grounded

(including spray booth, part hangers, fire extinguishers, etc.)

• Grounded conductive floor must be provided in spray area.

• Turn off the Power Pack and unplug from outlet before flushing

out the gun, cleaning or replacing parts on the gun such as

changing tips.

Explosion or fire. Mixtures of powder and air can

explode or ignite causing property damage and/or

severe injury.

• Exhaust and fresh air introduction must be provided to keep the

air within the spray area free of accumulation of flammable

atmosphere.

• Smoking must not be allowed in spray area.

• Fire extinguishing equipment must be present and in working

order.

• Electrostatic arcing must be prevented.

(See Electrostatic arcing)

• When cleaning the system, use only materials recommended

by the coatings manufacturer. Be sure Power Pack is turned off

and unplugged.

• Avoid all ignition sources such as static electricity sparks, open

flames such as pilot lights, hot objects such as cigarettes and

sparks from connecting and disconnecting power cords and

working light switches.

• To prevent hazardous concentrations of flammable

atmospheres, spray only in a properly ventilated spray booth.

• Never operate spray gun unless ventilation fans are operating

properly.

• Check and follow all National, State and Local codes regarding

air exhaust velocity requirements.

• Ventilation must be maintained during the cleaning operation.

Toxic Substances: Some materials may be harmful if

swallowed or come in contact with the skin.

• Follow the requirements of the Material Safety Data Sheet

supplied by the coatings manufacturer.

• Exhaust and fresh air introduction must be provided within the

spray area to keep the air free of high powder accumulations.

• Wear a mask or respirator. Read all instructions for the mask to

insure that it will provide the necessary protection against the

inhalation of powder.

General

• Read all instructions and safety precautions before operating.

• Comply with all appropriate local, state and national codes

governing ventilation, fire prevention, and operation of

Electrostatic equipment usage.

• The United States Government Safety Standards have been

adopted under the Occupational Safety and Health Act. These

standards, particularly the General Standards, Part 1910 and

the Construction Standard, Part 1926, should be consulted.

• NFPA Standard No. 33 is to be followed when setting up your

spray area. Contact the National Fire Protection Association,

Batterymarch Park, Quincy, Massachusetts, 02269 for more

information.

• Check with insurance company for additional requirements.

• Use only identical replacement parts.

• Personnel must be given training in accordance with the

requirements of NFPA Standard No. 33 chapter 18.

• It is the duty of all personnel responsible for the spray

equipment operation and maintenance to read and understand

all safety information furnished with this equipment.

04/2006 0351717 - PEM-TG3 7

Page 8

Safety regulations

1.2 EU Declaration of conformity

0103_ .doc

Wagner hereby declares that the unit described in these operating instructions has been

designed and manufactured according to the provisions of EU Directives 98/37/EC,

94/9/EC, 73/23 EEC and 89/336 EEC.

The following European standards were applied:

EN 12100-1/-2 EN 50281-1-1/-1-2 EN 61000-6-1

EN 61000-6-2 EN 61000-6-3 EN 60204-1

EN 50053-2 EN 50050 EN 50177

The following German standards and/or Guidelines were applied:

BGI 764

The product includes an EU declaration of conformity. This can be ordered again if

necessary from your WAGNER dealer by giving details of the product and serial number

involved.

The EU declaration of conformity has the number 0351967.

8 0351717 - PEM-TG3 04/2006

Page 9

Preparing the spray gun

04/2006 0351717 - PEM-TG3 9

2. Preparing the spray gun

2.1 Selection of the suitable equipment

0201_Duesenauswahl_tribo.doc

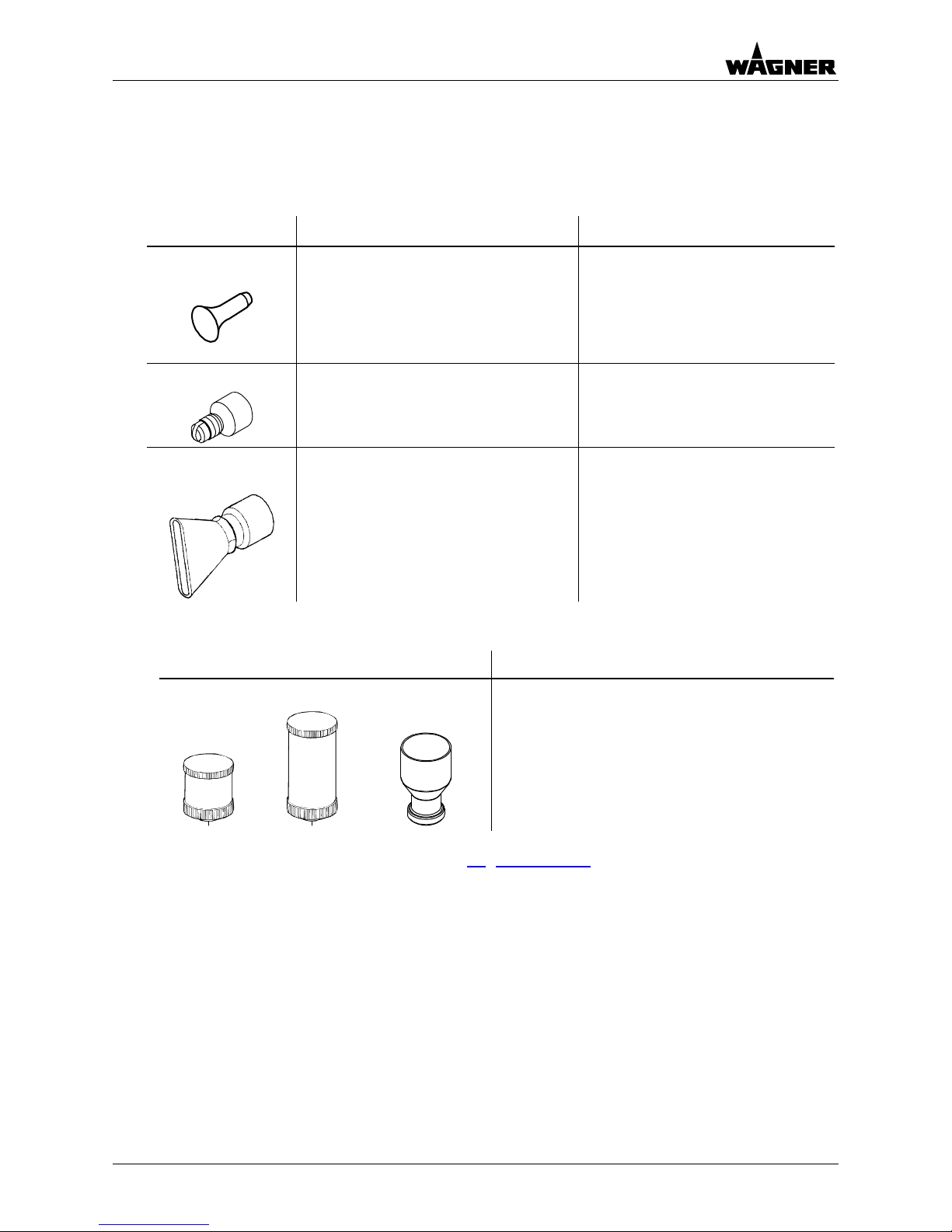

Nozzle Overview Application Spray pattern

Deflector cone

• Wire goods

• Grid designs

Oval powder cloud:

Size is dependent on the deflector

cone diameter.

For powder quantities from:

50 ... 300 g/min

Fan spray nozzle

Difficult workpieces:

•

Undercuts

• Profiles

Widely spread flat powder cloud.

For powder quantities:

from 50 ... 150 g/min

Wide fan spray

nozzle

Difficult workpieces:

• Undercuts

• Profiles

Widely spread flat powder cloud.

For powder quantities:

from 100 ... 250 g/min

Powder container Comments

500 cm3 900 cm3 220 cm

3

Select the powder container size dependently

of the powder volume required for coating.

You will find the article numbers in chapter 10

"Accessories".

Page 10

Preparing the spray gun

10 0351717 - PEM-TG3 04/2006

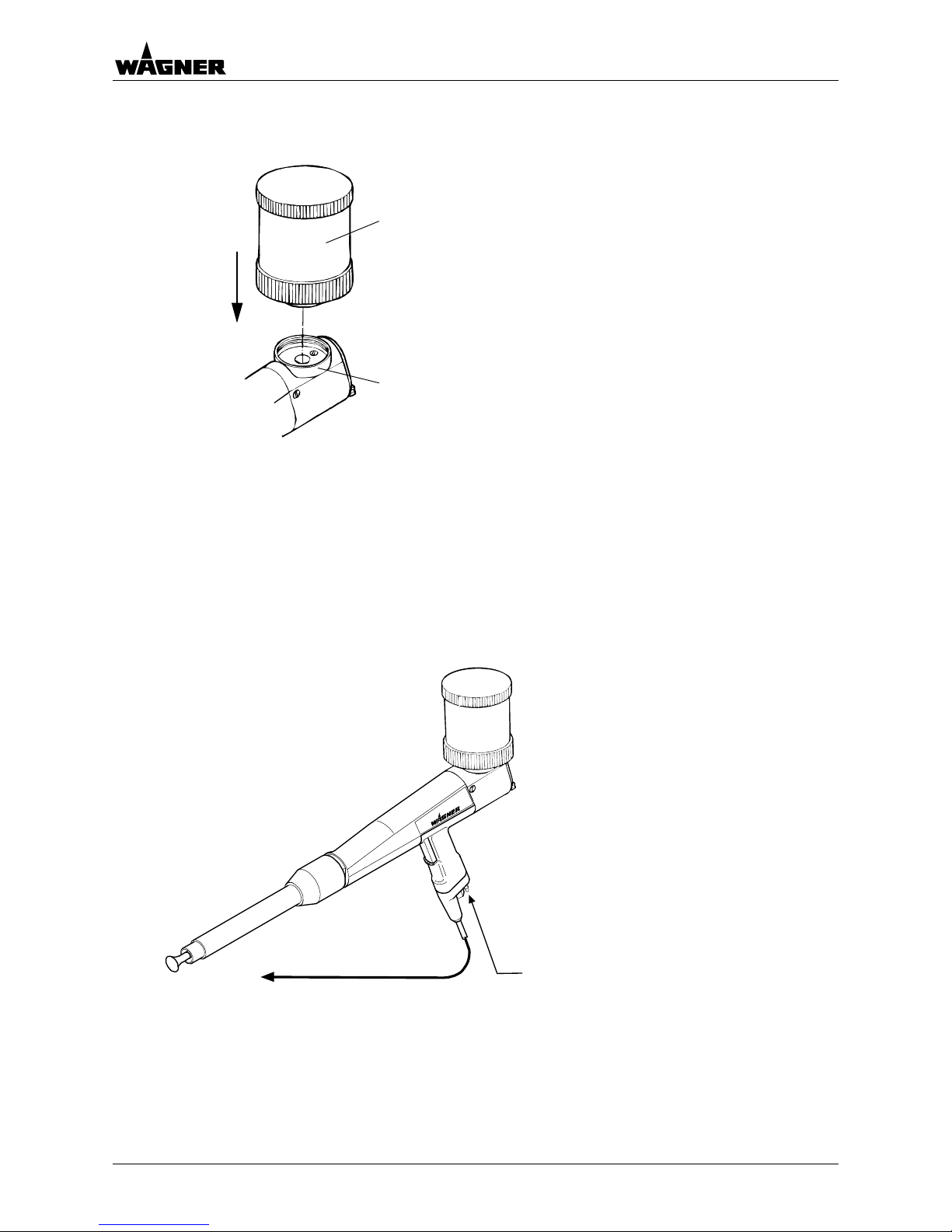

2.2 M ounting the powder container

H

J

pemcg4_0002a

The cup gun is delivered in two dismantled parts:

• spray gun and

• powder container (500 cm

3

)

Screw the powder container H onto the adapter J,

turning the powder container simultaneously right up to

the limit, thus ensuring that it is securely closed.

2.3 Connecting the spray gun

Pemtg3_0003

• Connect the spray gun to the

control unit

A with the electrical

cable.

• Connect the black hose (external

∅ 6x2) for the air supply to the spray

gun.

Air supply

B from the control unit

to the electrical connection

A at the control unit

Page 11

Preparing the spray gun

04/2006 0351717 - PEM-TG3 11

Rückwand EPG 2008

the spray gun is connected to

the EPG 2008, then the reduction

piece (6/8) must be placed at the

other end of the hose and connected

to the Y-plug connection

B.

• The Y-plug connection (8-8) is

connected with the two blue hoses

(external ∅ 8x1.5)

C to the feed and

dosage air connection of the

EPG 2008.

• The air vent has to be blocked with

the stopper

D.

The required parts are listed in section

"Special accessory

• When

".

2.4 Grounding

For safety reasons, the spray gun must be properly grounded. This occurs through the

electrical cable.

0203_ .doc

Good grounding of the workpiece is also necessary for optimum powder coating.

A poorly grounded workpiece causes:

• dangerous electric charging of the workpiece

• back-spray onto spray gun and user

• uneven coating

• very bad wrap around

Warning

Sparks between workpiece and conveyor hooks (hangers) can occur if hooks or

other hanger parts are not completely cleaned!

These sparks can cause heavy radio frequency interference.

Page 12

Working with the spray gun

12 0351717 - PEM-TG3 04/2006

3. Working with the spray guns

3.1 tarting up the spray gun and adjusting Tribo air

S

Caution

The powder cup may only be filled up to 75%, as fluidization swells the volume of the

powder.

K L

Pemtg3_0001b

• Open the powder cup and fill it up to max. 75% of the volume

with pow

• Switch o

quantity

• Shut off the feed air with the red setting knob K.

• Actuate the trigger and keep it actuated.

• Check whether sufficient fluid air is present. Correct the fluid air

if required as

described in chapter 4.3

der, but do not close the cup yet.

n the control unit and with knob 22 adjust the overall air

to approximately 3 Nm

3

/h.

.

• Close the powder cup.

• Set the feed air for the desired powder output quantity wit h the

red setting knob K.

• Correct the Tribo air with the black setting knob L if required.

Hint

• The amount of fluid air depends on the characteristics of the powder.

• Avoid a build up of powder dust (too much fluid air) in the powder cup!

3.2 Switching off the spray gun

Hint

At every work interruption, blow through the spray gun and the powder feed

components and remove any residual powder. These measures help in preventing the

build-up of powder deposits and powder su ed on

rges when the spray gun it turn

again.

Page 13

Working with the spray gun

04/2006 0351717 - PEM-TG3 13

X

H

J

pemcg4_0002b

X

K L

Pemtg3_0001b

• Release the spray gun trigger.

• The powder feed is deactivated.

• Remove the powder cup H from the

adapter J.

• With the black setting knob L open

the Tribo air all the way and with

the red setting knob K open the

ir quantity to the

maximum with knob 22.

• Hold the spray gun in the coating

booth, actuate the spray gun

trigger and remove any residual

powder inside the spray gun.

• Now the control unit can be

switched off.

. erforming a color change

Duri hange all parts carrying powder must be thoroughly cleaned of powder

resid lowing only the procedure for the powder spray gun is described.

feed air all the way.

• Set the overall a

3 3 P

ng a color c

ue. In the fol

Hint

Use a separate cup for each color if you want to shorten the cleaning time of the powder

cup.

• Release the spray gun trigger.

• The powder feed is deactivated.

Page 14

Working with the spray gun

14 0351717 - PEM-TG3 04/2006

J

5

6

3

H

2

4

1

Pemtg3_0005a

K L

Pemtg3_0001b

• Unsc

adap

rew the powder cup H from the

ter J.

• With the black setting knob L open the

Tribo air all the way and with the red

• Set the overall air quantity to the

maximum with knob 22.

• Hold the spray gun in the coating

booth, actuate the spray gun trigger

and remove any residual powder

inside the spray gun.

• Switch the control unit off and secure

it against being unintentionally

switched on again.

ousing 5.

body 3 off the

setting knob K open the feed air all the

way.

• Pull the deflector cone 1 off the

charging body 4.

• Unscrew the outer nut 2 from the

spray gun h

• Carefully pull the nozzle

powder tube 6.

• Carefully pull the charging body 4 out

of the powder tube 6.

Caution

When pulling , ensure that the charging body is not

damaged!

out and inserting the parts

• Remove powder residue from the parts removed, from the spray gun and the powder

container.

• Mount the cleaned or a new powder container.

• Carefully push the charging body 4 into the powder tube 6.

• Push the nozzle body 3 over the powder tube 6 and tighten using the outer nut 2.

• Slide the deflector cone 1 back over the charging body 4.

Activate the spray guns in accordance with chapter:

" g up the spray gun and adjusting Tribo air

•

Startin

".

Page 15

Maintenance and cleaning

04/2006 0351717 - PEM-TG3 15

4. Maintenance and cleaning

WARNING

CAUTION

WH

THE

FAI

RES N EXPLOSION/FIRE.

Turn power pack to the "OFF" position and unplug from

power source before starting to clean.

• Exhaust and fresh air introduction must be maintained

during the clean up operation.

• Keep cleaning materials in approved safety containers.

• All personnel and cleaning equipment, including

container used in cleaning operation, must be

grounded.

• DO NOT turn on the POWER PACK until the cleaning

operation has been completed, all cleaning materials

have been removed from spray area, and spray area is

free of any mixtures of powder and air produced by the

cleaning operation.

• If defects in the equipment are found, DO NOT use until

repairs are completed.

• Be sure the Power Pack is turned off and unplugged

from the power source.

NOTE

• The powder passages of the spray gun should be

cleaned while cleaning the powder hose and

powder pump, following instructions, provided with

the powder pump (injector).

(See powder injector operating manual)

• Clean the spray tip by removing from spray gun,

flushing with air and replacing on spray gun.

EN CLEANING THE ELECTROSTATIC SYSTEM,

SE SAFETY PROCEDURES MUST BE FOLLOWED.

LURE TO FOLLOW THESE PROCEDURES MAY

ULT IN A

• Clean equipment immediately after use.

• NEVER IMMERSE SPRAY GUN OR PARTS OF IT IN

ANY FLUID AT ANY TIME.

•

4.1 Replacing the spray gun

0401_ .doc

Before you commence the replacement of the spray gun any powder residue must be

removed thoroughly.

Caution

Repair or replacement of the spray gun or parts of the spray gun are only allowed to be

performed outside the hazard area and in a suitable place by specialist personnel!

The wearing parts in the spray gun, marked in the spare parts list with *, must be regularly

checked and, if necessary replaced.

Page 16

Maintenance and cleaning

16 0351717 - PEM-TG3 04/2006

0401_Pemtg3_Ausbauen.doc

H

J

D

G

M

F

Pemtg3_0004

• Switch the control unit and/or the powder

feed off.

• Unscrew the powder container H from

the adapter J.

• Remove the air supply (input air) F from

the spray gun D.

• Remove the electrical cable H from the

control unit K.

Page 17

Maintenance and cleaning

04/2006 0351717 - PEM-TG3 17

4.2 ing the wear parts

Cleaning the spray gun and replac

Caution

Never place the spray gun or parts of the spray gun in cleaning agent!

When pulling out and inserting the wear parts, ensure that the charging body is not

damaged!

5

6

4

3

2

1

Pemtg3_0005b

• Pull the deflector cone 1 off the

charging body 4.

• Unscrew the outer nut 2 from the spray

gun housing 5.

• Carefully pull the nozzle body 3 off the

powder tube 6.

• Carefully pull the charging body 4 out

of the powder tube 6.

• Check the removed parts for wear.

The entire charging body can be

replaced with a new one.

It is also possible to dismantle the charging body and merely replace the parts affected by

wear.

12

13

7

8

9

11

10

Pemtg3_0006

• Carefully Unscrew the tip 8 from the

threaded rod 7 and dismantle the

charging body.

• Unscrew the air nozzle 12 from the

deflector cone rod 13 if worn and

replace it with a new one.

• Complete clean residual powder from

all parts.

• Replace worn parts with new ones.

• Reassemble the charging body.

• Carefully push the charging body into

the gun and reassemble the gun.

Page 18

Maintenance and cleaning

18 0351717 - PEM-TG3 04/2006

4.3 heck the standard settings

The spray gun has been set at the factory to provide the optimum spray cloud with standard

powders:

Input air pressure: max. 43.5 psi (3 bar)

Powder output quantity: max. 200 g/min

Type of powder: Standard powders with grain size distribution of

35 ... 40% < 32 μm

• Check the input air pressure and readjust it

• Check the fluid base of the powder container fo with a new one if

required.

C

if required.

r damage and replace

K L

N M

Pemtg3_0001c

K Feed air adjustment 1)

L Tr

M Dosage air

N Flu

1) Rotate coun

ibo air adjustment 1)

adjustment 1)

id air adjustment 1)

ter-clockwise to increase the values.

Caution

Never turn the spindles M and N all the way in (danger of damaging the parts!).

By adjusting the dosage air M and/or the Tribo

reset if required.

air L the powder cloud can be readjusted or

Hint

Normally, the dosage air M and the atomizing air N do not have to be adjusted.

Page 19

Maintenance and cleaning

04/2006 0351717 - PEM-TG3 19

4.4 Disp

04_Entsorgung.doc

osal

waste

waste electrical

plementation in accordance with

f together with household

environmentally friendly way!

Only for EU countries

Do not dispose of electric tools together with household

material!

In observance of the European Directive 2002/96/EC on

and electronic equipment and im

national law, this product is not to be disposed o

waste material but must be recycled in an

Wagner or one of our dealers will take back your used Wagner waste electrical or electronic

equipment and will dispose of it for you in an environmentally friendly way. Please ask your

local Wagner service center or dealer for details or contact us direct.

Page 20

Rectification of malfunctions

20 0351717 - PEM-TG3 04/2006

5. Rectification of malfunctions

Malfunction Cause Rectification

- Fault in the monitoring

- Electrical cable from s

to c

device

pray gun

- Contact Wagner Service

ontrol unit faulty

N

wder use

ear

ble powder

- Replace worn parts

o Tribo current

display on PEM-TG3

- Unfit po d - Use suita

- W

Poor wrap around

Back spray

- Inadequate or no ground - See chapter 2.4

Pulveraustritt un-

oder

ir su p

- Soiling in the powder

- Blockages in the gun

- Feed air / dosage air ratio

- Wear

supply

properly

- Empty the powder container

and blow through powder air

channels

- Dismantle spray gun and clean

the parts in accordance with

chapter 3.3

gleichmäßig

nicht ausreichend.

- Bad compressed a

- Powder container is

p ly - Check compressed air

not sitting - Tighten powder container

tightly

incorrect

- Redetermine the feed air- /

with chapter 4.3

dosage air ratio in accordance

- Replace worn parts

Spray pattern is

une

- Nozzle system wear

- Replace nozzle system in

ven accordance with chapter 4.2

Fluidizat

quate or has failed

ion inade-

tainer is not sitting

tightly

- Soiling or blockage of fluidized

bed

- Wear

- Readjust the fluid air with the

spindle N in accordance with

- Fluid air too low

- Powder con

chapter 4.3

- Retighten the powder container

- Clean fluidized bed connection

and fluidization disc

- Change worn out parts

(e.g. fluidization disc)

No powder output

- The powder container is empty

- The spray gun is clogged

- Refill with powder

- Blow through the spray gun

Page 21

Technische Daten

04/2006 0351717 - PEM-TG3 21

6. echnical data

Weight: 990 g

Electrical:

Design: as per EN 50177 and EN 50050

Protection class: IP 54

Pneumatic:

Input air pressure: max. 29 psi (2 bar - standard setting)

Powder output quantity:

Required compressed air quality:

T

max. 200 g/min at 43.5 psi (3 bar)

06_ .doc

Quality class

Compressed air quality according to ISO 8573.1

5

Max. residual water:

(pressure dew point in °F at 100 psi

/ °C at 700 kPa)

+44.6 °F / +7 °C

2

Max. oil contents: 0.1 mg oil/m3 / 0.1 oz/ft3

3

Max. concentration: 5 mg/m3 / 5 oz/ft3

3

Max. particle size:

5 μm / 5 microns

Ambient conditions:

low temperature powders are used, the ambient temperature may have to be lower than

6 °F (30 °C).

If

8

Volume measures:

For volumes, specified in Nm3 (standard cubic meters). One cubic meter of a gas at

32 °F (0 °C) and 1.013 bar is called norm cubic meter.

1 Nm

3

/h = 35.3 ft3/h; 1 bar = 14.504 psi

Page 22

Applicable safety regulations

22 0351717 - PEM-TG3 04/2006

7. Applicable safety regulations

07_ .doc

EN

N 5

-2

Electrical equipment for use in areas with flammable dust

(Beuth-Verlag,

Berlin)

EN 61000-6-1 Electro-magnetic compatibility (EMC)

Generic standard resistance to interference

(Beuth-Verlag,

Berlin)

EN 61000-6-2 Electro-magnetic compatibil

Basic Standards – Interference

EN 61000-6-3 Electro-magnetic compatibil

Generic standard interference emi

EN 60204-1 VDE guidelines for the elec

BGI 764 Safety regulations for electr

equipment's (Operating condition

BGR 132

(ZH1/200)

Safety regulations governing preve

electrical charging

EN 12981 Safety requirements for coating equi

organic powder

h-Verlag,

Berlin)

EN 50050 Electrostatic manual powder coating equipment

(Beuth-Verlag,

Berlin)

systems

Instructions for fire fighting in electric equipment and nearby

(Beuth-Verlag,

Berlin)

VdS 2093 and

VdS 2325

Safety regulations governing CO

VDE 0134 Instructions for first aid in case of accid

(Beuth-Verlag,

12100-1/-2 Machine Safety

(Beuth-Verlag,

Berlin)

0281-1-1/ E

-1

ity (EMC)

resistance within industry

(Beuth-Verlag,

Berlin)

ity (EMC)

ssions

(Beuth-Verlag,

Berlin)

trical equipment of machines

(Beuth-Verlag,

Berlin)

ostatic powder coating in coating

s)

(C. HeymannsVerlag, Cologne)

ntion of combustion during

(C. HeymannsVerlag, Cologne)

pment in spray booths for

(Beut

EN 50053-2 Regulations for selecting, installing and operating electrostatic

powder coating systems, electrostatic manual powder coating

(Beuth-Verlag,

Berlin)

VDE 0132

2

fire extinguishers

(VdS Box 10 20 24

50460 Cologne)

ent

Berlin)

Page 23

Warranty

04/2006 0351717 - PEM-TG3 23

8. Warranty

08_ .doc

What is arranty? covered by this w

Faulty o ced acco ral delivery conditions.

Within t rrant period, Wag tive

parts without charge if such parts are returned with transportation charges prepaid to the

earest authorized service center. If Wagner is unable to repair this product so as to conform

to this Limited Warranty after a reasonable number of attempts, Wagner will provide, at our

fund of the purchase price of this

sole and exclusive

r defective parts are repla rding to our gene

he applicable wa ner will repair or replace, at our option, defec

n

option, either a replacement for this product or a full re

product.

These remedies are the

remedies available for breach of express and

plied warranties.

What is not covered by this warranty?

im

This warranty does not cover any of the following damages or defects:

1. Damages or defects caused by use or installation of repair or replacement parts or

accessories not manufactured by Wagner,

2. Damages or defects caused nyone other than a Wagner

authorized service center, or

3. Damages or defects caused abuse, misuse,

negligence, accident, normal wea tampering in a manner which

impairs normal operation.

Limitation of remedies:

by repair performed by a

by or related to abrasion, corrosion,

r, faulty installation or

IN NO CASE SHALL WAGNER BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR

CONSEQUENTIAL DAMAGES OR LOSS, INCLUDING TRANSPORTATION COSTS,

WHETHER SUCH DAMAGES ARE BASED UPON A BREACH OF EXPRESS OR IMPLI ED

WARRANTIES, BREACH OF CONTRACT, NEGLIGENCE, STRICT TORT, OR ANY OTHER

EGAL THEORY.

Disclaimer of implied warranties:

L

TH ESS

R S OF

ERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

E FOREGOING WARRANTIES ARE IN LIEU OF ALL OTHER WARRANTI ES, EXPR

IMPLIED, INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIEO

M

No ability to transfer:

This warranty is extended to the original purchaser only and is not transferable.

Your rights under state law:

So clusion of

cid t apply to

ou. This warranty gives you specific legal rights; you may also be entitled to other rights,

which vary from state to state.

me states do not allow limitations on how long an implied warranty lasts or the ex

ental or consequential damages, so the above limitation and exclusion may noin

y

Page 24

Scope of delivery and spare parts lists

24 0351717 - PEM-TG3 04/2006

9. Scope of delivery and spare parts lists

9.1 ow to order spare parts

c

Faulty and unserviceable parts are replaced in a

tions of Delivery.

In order to be able tion is necessary:

- Invoici

- Delivery address

H

0901_ .do

ccordance with our General Terms and Condi-

to guarantee safe and smooth spare parts delivery, the following informa

ng address

- Name of contact persons for check back

- Type of delivery

- Quantity ordered, article number and designation

Page 25

Scope of delivery and spare parts lists

04/2006 0351717 - PEM-TG3 25

9.2 Scope of delivery and spare parts list PEM-TG3

0351036

6

4

5

7

2

1

03

tic

51036_et

Item Ar le No. Description

- - 0351036 Spray gun PEM-TG3

1 0259) 474 *

Deflector cone (∅22

1 025947

lector cone (∅28) **

5 *

Def

2 0260928 * Fan spray nozzle

4 3050701 Powder container 500 cm3

5 0351 ET 654 Tribo outer nut

6 0351581 Nozzle body

7 0260629 * e) Charging body (complet

-- 9982079

Hose (black) external ∅ 6x1:

e Y-piece of the EPG 2008

c

gun:

ter

Pneumatic line from th

to the compressed air onnection on the spray

• also refer to chap "Special accessory"

-- 9998 eduction 8/6:

to connect the pneumatic

Y-piece on the EPG 2008:

e "

137 R

line to the

• also refer to chapt r "Special accessory

Wearing part ** Special accessory

*

Page 26

Scope of delivery and spare parts lists

26 0351717 - PEM-TG3 04/2006

Item Art. No. Designation

- - 0260629 Charging body

lete) (comp

6 0260472 * Tip

7 0260473 Threaded bar

8 0260474 * Ring

9 0260471 * Charging tube

10 0260476 * Support ring

11 0260470 * Rod

12 0260463 * Central air supply

13 0260469 * Deflector cone rod

14 0260632 * Air nozzle (complete)

0260629

14

13

12

11

7

9

10

8

6

0260629_et

* Wearing part

Page 27

Accessories

04/2006 0351717 - PEM-TG3 27

10. Accessories

10.1 owder container

30507

P

01

Item Art. No. Designation

- - 3050701 Powder container 500 cm3

- - 3053662 Powder container 900 cm3

1 3050737 * Container lid

2 3050748 * O-ring 80x2

3 3050735 Cup tube 500 cm3

3 3050736 Cup tube 900 cm3

4 3050734 Cover

5 3050739 Nut

6 3050738 * Fluidization disc

7 3050733 Cup socket **

7/1 3050742 * O-ring 39x2

7/2 9971137 * O-ring 20x2

1

2

7/2

7

7/1

6

5

4

3

3050701_et

** Only available as a set

02411

nation

* Wearing part

17

Item Art. No. Desig

- - 0241117 Powder container 220 cm

3

1 3050742 * O-ring 39x2

2 9971137 * O-ring 20x2

2

1

0241117_e

t

* Wearing part

Page 28

Accessories

28 0351717 - PEM-TG3 04/2006

10.2 Special accessory

The following parts are not included in the scope of delivery of the cup gun and have

to be

ordered separately.

These parts are necessary to connect the spray gun to the EPG 2008.

3159464 Y- plug connection (8-8)

9982062

Blue hose (external ∅ 8x1.25)

Page 29

Notes

04/2006 0351717 - PEM-TG3 29

Page 30

Notes

30 0351717 - PEM-TG3 04/2006

Page 31

ADDRESSES

Germany Sw rland

J. WAGNER GmbH J. W N

Otto-Lilienthal-Str. 18 Postfach 109

D-88677 Markdorf Industrie

CH-9450

Phone +49(0)7544/505-0 Pho /75

Fax +49(0)7544/505-200 Fax +41 5

Austria Ne la

itze

AG ER AG

strasse 22

Altstätten

ne +41(0)71

(0)71/7

72211

72222

ther nds

J. WAGNER GmbH W r de B.V.

Otto-Lilienthal-Str. 18 Pr we

Postfach 1120 NL-3543 T

D- 88677 Markdorf

Phone: ++49/ (0)7544 / 5050 Ph /24

Fax: ++49/ (0)7544 / 505200 Fa /24

Belgium Denmark

agne

oost

Systemen Ne

tering 105 C

rland

AC UTRECH

one

x

+31(0)30

+31(0)30

10688

10765

Estee Industries WAGNER Powder Systems Scvandinavia

Leenbeekstraat 9 Juupajokivej 8

B-9770 Kruishoutem DK-8850 Bjerringbro

Phone +32(0)9/3885410 Phone +45 7023 2052

Fax +32(0)9/3885440 Fax +45 8668 2052

Sweden

WAGNER Powder Systems Scandinavia AB

Hedenstorpsvägen 4

Sverige - 55593 Jönköping

Phone +46(0)36/341590

Fax +46(0)36/368580

Great Britain USA

WAGNER Spraytech (UK) Ltd. WAGNER Systems Inc.

Unit 3 Haslemere Way 175 Della Court

Tramway Industrial Estate Carol Stream, IL 60188

UK-Banbury, Oxon OX 16 8TY

Phone +44-1295-265353 Phone +1(0)630/7848900

Fax +44-1295-269861 Fax +1(0)630/7848970

Page 32

ADDRESSES

WAGNER- HOSOKAWA Micron Ltd.

No. 9, 1-Chome

Shodal Tajka, Hirakata-Shi

673-1132

Phone +81(0)728/566751

Fax +81(0)728/573722

China

Japan

Osaka

WAGNER SPRAYTECH SHANGHAI CO T

4

th

Flr, No. 395 Jiangchangxi Road

Shibei Industrial Zone

Shanghai, 200436

Phone +86(0)2166521858

Fax +86(0)2166529819

France

LD .

J. Wagner France SARL

B.P. 75, 5, Avenue du 1er Mai

F-91122 Palaiseau-Cédex

Phone +33(0)825/011111

Fax +33(0)1/69817257

Italy Spain

WAGNER Itep S.p.A. WAGNER Spraytech Iberia S.A.

Via Santa Vecchia, 109 P.O.Boc, 132, Crtra. N-340, Km. 1245,4

I-22049 Valmadrera - LC E-08750 Molins de Rei (Barcelona)

+39/0341/212211 one /6800028

Fax +39/0341/210200 x

Phone Ph +34(0)93

Fa +34(0)93/6800555

Loading...

Loading...