Page 1

8 Cleanup - Flushing the unit

9 Cleanup - Cleaning the spray gun

10 Reassembly / Maintenance

11 Troubleshooting

36 Parts List

40 Limited Warranty

Owner’s Manual

Read this manual for complete instructions

0712 • Form No. 0529826C

Patent pending

Contents

2 Important Safety Information

3 Controls and Functions

4 Assembly

5 Material Preparation

6 Spraying

Français - page 13 / Español - página 25

Questions? Product Registration

Call Wagner Technical Service at:

1-800-328-8251

Monday - Friday

8:00 am to 4:30 pm CST

In order to register your product today, visit:

www.wagnerspraytech.com/registration

We value your opinion. To complete your

review, please visit:

www.wagnerspraytech.com/reviews

Page 2

SafetySafety

Important Safety

Information

Read all safety information before

operating the equipment. Save these

instructions

Indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

a) To reduce the risks of re or explosion, electrical shock and

the injury to persons, read and understand all instructions

included in this manual. Be familiar with the controls and

proper usage of the equipment.

Grounding Instructions

This product must be grounded. In the event of an electrical short circuit,

grounding reduces the risk of electric shock by providing an escape wire

for the electric current. This product is equipped with a cord having a

grounding wire with an appropriate grounding plug. The plug must

be plugged into an outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

WARNING - Improper installation of the grounding plug

can result in a risk of electric shock.

If repair or replacement of the cord or plug is necessary, do

not connect the green grounding wire to either at blade

terminal. The wire with insulation having a green outer surface with or

without yellow stripes is the grounding wire and must be connected to

the grounding pin.

Check with a qualied electrician or serviceman if the grounding

instructions are not completely understood, or if you are in doubt as

to whether the product is properly grounded. Do not modify the plug

provided. If the plug will not t the outlet, have the proper outlet

installed by a qualied electrician.

This product is for use on a nominal 120 volt circuit and has a grounding

plug that looks like the plug illustrated below. Make sure that the

product is connected to an outlet having the same conguration as the

plug. No adapter should be used with this product.

Grounded Outlet

Grounding Pin

Cover for grounded outlet box

b) WARNING - To reduce the risk of re or

explosion:

1. Do not spray ammable or combustible

materials near an open ame, pilot lights

or sources of ignition such as hot objects, cigarettes, motors,

electrical equipment and electrical appliances. Avoid creating

sparks from connecting and disconnecting power cords.

2. For use with only water-based or mineral spirit-type materials

with a minimum ash point of 21ºC (70º F) — Do not spray

or clean with liquids having a ash point of less than 21ºC

(70º F). Flash point is the temperature at which a uid can

produce enough vapor to ignite.

3. Verify that all containers and collection systems are grounded

to prevent static discharge.

4. Connect to a grounded outlet and use grounded extension

cords (electric models only). Do not use a 3 to 2 adapter.

5. Do not use a paint or solvent containing halogenated

hydrocarbons. Such as chlorine, bleach mildewcide,

methylene chloride and trichloroethane. They are not

compatible with aluminum. Contact the coating supplier

about compatibility of material with aluminum.

6. Keep spray area well ventilated. Keep a good supply of fresh

air moving through the area to keep the air within the spray

area free from accumulation of ammable vapors. Keep

pump assembly in well ventilated area. Do not spray pump

assembly.

7. Do not smoke in the spray area.

8. Do not operate light switches, engines, or similar spark

producing products in the spray area.

9. Keep area clean and free of paint or solvent containers, rags,

and other ammable materials.

10. Know the contents of the paint and solvents being sprayed.

Read all Material Safety Data Sheets (MSDS) and container

labels provided with the paints and solvents. Follow the paint

and solvent manufacture’s safety instructions.

11. Fire extinguisher equipment shall be present and working.

c) WARNING - To reduce the risk of injury:

1. Always wear appropriate gloves, eye protection, clothing

and a respirator or mask when painting. Hazardous vapors

– Paints, solvents, insecticides, and other materials can be

harmful if inhaled or come in contact with body. Vapors can

cause severe nausea, fainting or poisoning.

2. Do not operate or spray near children. Keep children away

from equipment at all times.

3. Do not overreach or stand on an unstable support. Keep

eective footing and balance at all times.

4. Stay alert and watch what you are doing.

5. Do not operate the unit when fatigued or under the inuence

of drugs or alcohol.

6. Never aim spray gun at any part of the body.

7. Follow all appropriate local, state, and national codes

governing ventilation, re prevention, and operation.

8. The United States Government Safety Standards have

been adopted under the Occupational Safety and Health

Act (OSHA). These standards, particularly part 1910 of

the General Standards and part 1926 of the Construction

Standards should be consulted.

9. Use only manufacturer authorized parts. User assumes all

risks and liabilities when using parts that do not meet the

minimum specications and safety devices of the turbine

manufacturer.

10. Power cord must be connected to a grounded circuit.

11. All hoses, swivels, guns and accessories must be rated at or

above 10 PSI.

12. Do not spray outdoors on windy days.

13. Hose may become hot and cause skin burn.

14. Use only Wagner HVLP hose.

d) WARNING - To reduce the risk of electric shock:

1. Always remove turbine before cleaning.

2. Power cord must be connected to a grounded

circuit.

3. Never submerge electrical parts.

4. Never expose the equipment to rain. Store indoors.

5. Keep electrical cord plug and spray gun trigger free from

paint and other liquids. Never hold the cord at plug

connections to support the cord. Failure to observe may

result in an electrical shock.

Important Electrical Information

Use only a 3-wire extension cord that has a 3-blade grounding plug

and a 3-slot receptacle that will accept the plug on the product.

Make sure your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to carry the

current your product will draw. An undersized cord will cause a

drop in line voltage resulting in loss of power and overheating. A

14 gauge or 12 gauge cord is recommended. If an extension cord is

to be used outdoors, it must be marked with the sux W-A after the

cord type designation. For example, a designation of SJTW-A would

indicate that the cord would be appropriate for outdoor use.

Wagner Spray Tech accessory extension cords recommended:

P/N 0090241 20 foot extension cord

P/N 0090242 35 foot extension cord

IMPORTANT:

Household use only.

English

2

Page 3

English

3

Controls and

Functions

Start

ON/OFF switch:

The ON/OFF switch turns power

to the turbine on and o. The

ON/OFF switch is located on top

of the carrying handle of the

turbine.

Material ow adjustment:

The material ow adjustment

controls the amount of spray

material that is sprayed from the

spray gun.

Air pressure control dial:

The air pressure control dial

adjusts the level of air pressure

produced by the turbine.

Adjustment ring:

The adjustment ring determines

the width of the spray pattern

(white gun only).

Review the information on this page to familiarize

yourself with the controls and functions of your

unit.

Notice:

+

-

Air hose

White Spray Gun

Turbine

Yellow Spray Gun

Spray gun

handle

Air pressure

control dial

Turbine

handle

ON / OFF switch

Material ow

adjustment

Trigger

Trigger

Air cap

Adjustment ring

Material ow

adjustment

Material

container

Air cap

Material

container

Filter housing

(both sides)

Spray gun holder

Viscosity

cup

Page 4

English

4

Assembly

Start

1. Align the arrow on the spray gun

with the “unlock” symbol on the

spray gun handle.

4. Insert the air hose tightly into the

connection into the turbine. The

connections can be positioned as

desired.

2. Insert and twist the spray gun

into the handle toward the “lock”

symbol on the spray gun handle.

The tab below the trigger will

lock the two pieces into place.

5. Align the suction tube -

If you are going to be spraying in

a downward direction, the angled

end of the suction tube should be

pointing toward the front of the

gun.

3. Insert the air hose tightly into

the connection on the spray

handle. The connection can be

positioned as desired.

6. If you are going to be spraying in

an upward direction, the angled

end of the suction tube should be

pointing toward the rear of the

gun.

Your unit includes two spray guns. See below to

determine the correct spray gun for your spraying

project.

Yellow spray gun -

designed for spraying

thinner materials, such

as oil-based stains and

thinned paints. The

yellow spray gun leaves a

smooth nish.

White spray gun -

designed for spraying

thicker materials, such as

latex paints and stains.

Spraying with this gun will

leave a slightly coarser

nish that is between

a roller and ne-nish

sprayer.

Note: These two spray guns have dierent spray

pattern / width controls. Make sure to familiarize

yourself with the controls on each spray gun

head. See the “Spraying” section, page 6-7.

Notice:

1

4

2

5

3

6

Page 5

English

5

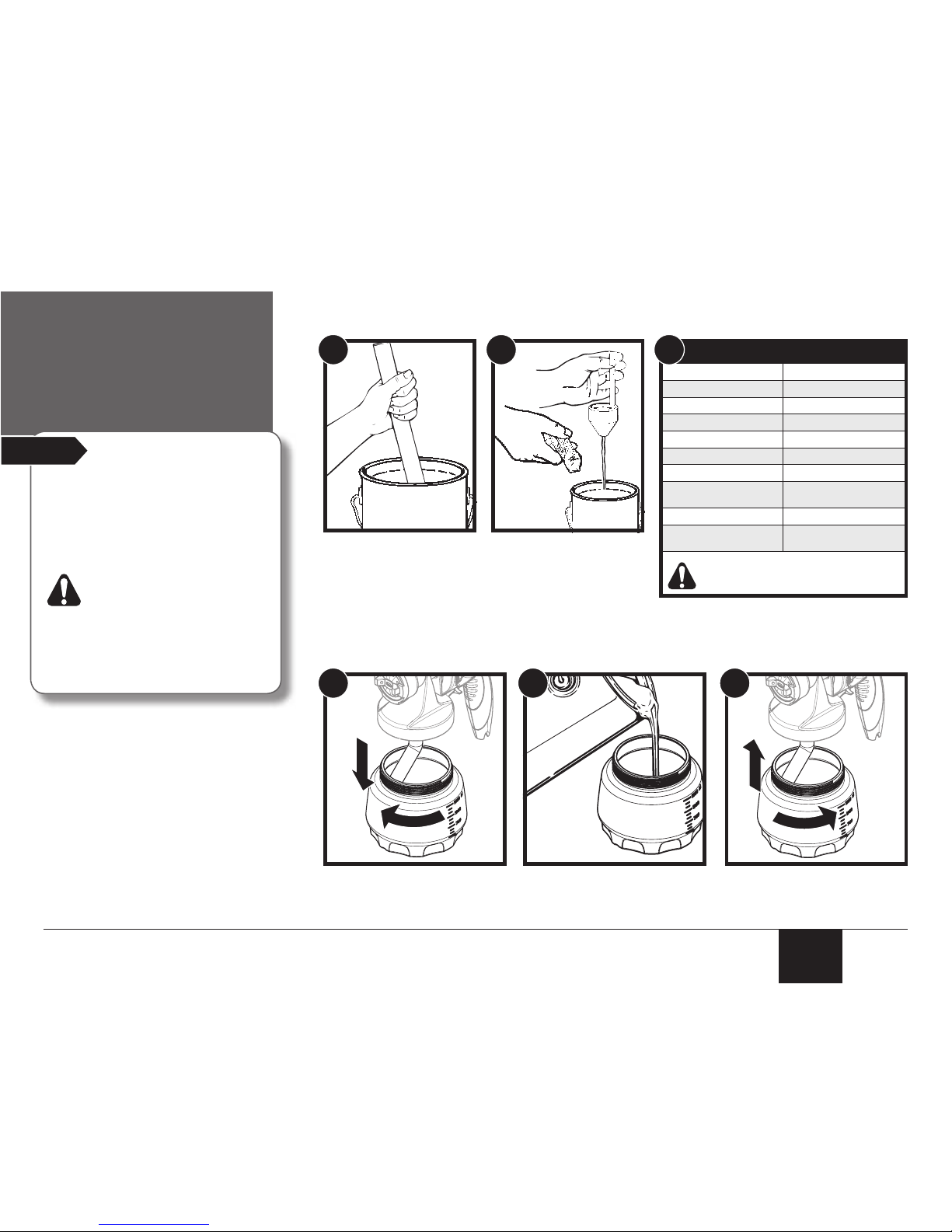

Material

Preparation

Start

Before spraying, the material being used may

need to be thinned with the proper solvent

as specied by the material manufacturer.

Never exceed the thinning advice given by the

coating manufacturer.

Note: Make sure to consider which spray gun you

are using when determining whether or not to

thin the material. See “Notice”, previous page.

Do not thin with materials that have

a ashpoint below 70°F (21°C). The

material ashpoint should be shown

on the material container.

Note: Material to be sprayed should always be

strained to remove any impurities in the paint

which may enter and clog the system. Impurities

in the paint will give poor performance and a

poor finish.

Thinning the material:

1. Stir the spraying material

thoroughly.

4. Unscrew the cup from the spray

gun.

5. After the material has been

properly thinned and strained,

ll the container to the top of the

neck.

6. Carefully screw the cup back

onto the spray gun.

2. Dip the viscosity test

cup completely into the

spraying material.

3. Hold the test cup up and measure the time in

seconds until the liquid empties out. This time is

referred to as Runout Time.

1

4 5 6

2

Thinning Chart

Material Runout Time (seconds)

Oil enamel 25-40

Oil based primer 30-45

Oil stain No thinning required

Clear sealer No thinning required

Polyurethane No thinning required

Varnish 20-50

Lacquer / lacquer sanding

sealer

25-35

Automotive nishes 20-40

Latex paint Follow manufacturer’s

recommendations

3

Material flash point must be 70°F (21°C)

or higher.

Page 6

English

6

Spraying

Start

Notice:

Spray performance will depend upon a number of factors:

material thickness, spray pattern selected, material volume,

and air pressure. With any type of air-assisted spraying,

desired spray results will be achieved through some trial and

error while adjusting some or all of these variables.

Review these pages to learn about the spray controls and how

they can be used to acheive the desired spray results.

Controls

Air Pressure Control Dial

The air pressure control dial adjusts the level of air pressure

produced by the turbine. The air pressure control dial is factoryset at maximum out of the box.

• A high air pressure level will result in a smoother nish.

• Lowering the air pressure will result in larger drops of

material being sprayed from the gun, and will create a

slightly rougher nish.

+

-

Tip: The thicker the material you are spraying, the higher the

turbine pressure you will need.

Tip: For ne-nish work with thinner materials, you may want

to decrease the air pressure. Spraying a thinner material at high

air pressure will result in more overspray. Overspray is sprayed

material that does not stick to the spray surface and bounces

back.

Material Flow Adjustment

The material ow adjustment controls the amount of spray

material that is sprayed from the spray gun.

• For thicker materials, it is recommended that you

start with the highest material ow setting and then

gradually decrease the ow to suit your particular

spraying needs.

• For thinner materials, it is recommended that you start

with a low material ow setting, and then gradually

increase the ow to suit your particular spraying

needs.

• The higher the ow setting, the quicker you will have

to work in order to avoid drips and sags in your spray

pattern.

Set the material volume by turning the knob on the trigger

of the spray gun.

Tip: Spraying with the knob set too high will result in a

spray pattern that runs and sags (too much material).

Tip: Spraying with the regulator set too low will result in a

spray pattern that does not cover (not enough material).

Adjust Spray Width - white gun only

The adjustment ring on the white spray gun determines the

width of the spray pattern.

Adjustment ring

Wide

pattern

For coating large surfaces

Use higher air pressure

Use higher material volume

Narrow

(round)

pattern

For coating smaller areas,

corners and edges

Use lower air pressure

Use lower material volume

Adjust Spray Shape - both guns

The spray pattern shape is adjusted by turning the

ears of the air cap to either the vertical, horizontal, or

diagonal positions. The positions of the air cap and the

corresponding spray pattern shapes are illustrated below.

Test each pattern and use whichever pattern is suitable for

your application.

NEVER trigger the gun while adjusting the

ears on the air cap. NEVER point the spray gun

at any part of the body.

Round pattern*

Horizontal pattern

Vertical pattern

Air cap ears

Yellow Gun

White Gun

Air cap ears

*Note: The air cap can be set diagonally on the yellow spray

gun only. To achieve a round pattern with the white spray

gun, see “Adjusting the Spray Width”, previous column.

=

=

Horizontal

pattern

Use ‘up and down’ spraying

motion

=

=

=

Vertical

pattern

Use ‘side to side’ spraying

motion

=

Round

pattern

Use ‘up and down’ or ‘side to

side’ spraying motion

Use lower air pressure /

material volume

For coating smaller areas,

corners and edges

Page 7

English

7

Proper Spraying Technique

STOP

The room you are spraying must be properly

masked in order to prevent overspray from

covering woodwork, oors or furnishings. Make

sure you have properly masked the room per the

instructions on the enclosed “Taping Guide”.

If spraying with an air-assisted spray system is new or unfamiliar

to you, it is advisable to practice on a piece of scrap wood or

cardboard before beginning on your intended workpiece.

Surface Preparation

All objects to be sprayed should be thoroughly cleaned before

spraying material on them. Areas not to be sprayed may, in

certain cases, need to be masked or covered.

Spray Area Preparation

The spray area must be clean and free of dust in order to avoid

blowing dust onto your freshly sprayed surface.

How to Spray Properly

STOP

It is important to keep your arm moving

whenever the gun is being triggered. If you

pause or linger in one spot too long, too much

material will be sprayed to the surface.

• Position the spray gun perpendicular to and six (6) or more

inches from the spray surface, depending upon the spray

pattern size desired.

• Spray parallel to the surface with smooth passes at a

consistent speed as illustrated below. Doing this will help

avoid irregularities in the nish (i. e. runs and sags).

• Always apply a thin coat of material on the rst pass and

allow to dry before applying a second, slightly heavier coat.

6 -12 inches

Correct

Even coat throughout

Keep stroke smooth and at an even speed

• When spraying larger surfaces, overlap each spray pass by

at least 50% This will ensure full coverage.

• When spraying, always trigger the spray gun after

spray pass has begun and release trigger before

stopping the pass. Always keep the gun pointed

squarely at the spray surface and overlap passes

slightly to obtain the most consistent and professional

nish possible.

Incorrect

Do not ex wrist while spraying.

Light coat Heavy coat Light coat

When you quit spraying for any length of time, turn the

turbine OFF and place the spray gun into the spray gun

holder on the turbine.

Pattern Examples

Use the images and guidelines below in order to assist you

in achieving the desired spray pattern for your project.

These are meant to be general starting points - you may

have to slightly modify certain controls on the system in

order to get the exact performance you need.

Low volume and pressure - round pattern

Generally, low volume and pressure is needed for spraying

smaller surface areas, such as corners, lattice, or spindles.

• If you feel the material is going on too thin, increase

the material volume.

• If you feel the material is going on too thick, decrease

the material volume even further or move the spray

gun further away from the surface.

High volume and pressure - vertical/horizontal

pattern

Generally, high volume and pressure is needed for spraying

large surface areas, such as a wall.

• The spray nozzle will determine the movement

direction of the spray gun.

• With the yellow spray gun, the pattern can be made

narrower by moving closer to the spray surface, and

wider by moving farther away.

Note: If after following the guidelines on these two pages

you are still not getting the spray performance you need,

refer to the ‘Troubleshooting’ section on page 11.

Besides adjusting the controls, other factors that should be

considered when spraying:

• Distance from the spray object - if you are too far

from the spraying surface, the material will go on too

thin, and vice versa.

• Material thickness - if the spray pattern runs and/or is

too splotchy, the material may need to be thinned.

• Spray gun movement - moving the gun too quickly

will cause the spray pattern to be too thin and excess

overspray. Moving the gun too slowly will cause the

spray pattern to be too coarse or thick.

=

=

=

=

=

=

OR

Page 8

English

8

Cleanup -

Flushing the unit

Start

Before you begin:

When cleaning, use the appropriate cleaning

solution (warm, soapy water for latex materials;

mineral spirits for oil-based materials)

IMPORTANT: Never clean nozzle or air holes in

the spray gun with sharp metal objects. Do not

use solvents or lubricants containing silicone.

Special cleanup instructions for use

with flammable solvents (must have

a flashpoint above 70ºF (21ºC):

• Alwaysushspraygunoutside.

• Areamustbefreeofammablevapors.

• Cleaningareamustbewell-ventilated.

• Donotsubmergeturbine!

1. Turn the turbine OFF. Loosen the

material container by 1/2 turn,

but do not remove it. This will

relieve any pressure left over in

the system.

Trigger the spray gun so that the

material inside the spray gun

ows back into the container.

4. Attach the cup to the gun and

plug in the sprayer.

2. Unscrew the container and

remove.

Empty any remaining material

back into the material container.

5. Turn the turbine ON.

Spray the cleaning solution into a

safe area.

While spraying, gently shake the

spray gun. This slight agitation

will help break up smaller

particles of spray material.

3. Pour a small amount of the

appropriate cleaning solution

into the cup.

6. Turn the turbine OFF. Loosen the

material container by 1/2 turn,

but do not remove it. This will

relieve any pressure left over in

the system.

Trigger the spray gun so that the

material inside the spray gun

ows back into the container.

Move on to “Cleanup - Cleaning the

spray gun components”, next page.

4

2

5

3

6

1/2

1/2

1

PULL

Empty waste

container

Page 9

English

9

Cleanup -

Cleaning the

spray gun

Start

Before you begin:

When cleaning, use the appropriate cleaning

solution (warm, soapy water for latex materials;

mineral spirits for oil-based materials)

IMPORTANT: Never clean nozzle or air holes in

the spray gun with sharp metal objects. Do not

use solvents or lubricants containing silicone.

Special cleanup instructions for use

with flammable solvents (must have

a flashpoint above 70ºF (21ºC):

• Alwaysushspraygunoutside.

• Areamustbefreeofammablevapors.

• Cleaningareamustbewell-ventilated.

• Donotsubmergeturbine!

1. Remove the air hose from the

rear of the spray gun handle.

Wipe the exterior of the cup and

gun until clean.

4. Remove the adjustment ring (a)

carefully from the connecting nut

(b). Loosen the connecting nut.

2. Unscrew the nut and remove the

air cap and nozzle.

5. Remove the parts as shown.

Clean all parts with a cleaning

brush and the appropriate

cleaning solution.

To reassemble, see the

instructions on the next page.

3. Remove the parts as shown.

Clean all parts with a cleaning

brush and the appropriate

cleaning solution.

Reassemble when clean* (see

“Cup Seal”, left).

6. Push the tab below the trigger,

twist and separate the spray gun

from the handle.

Clean the rear of the spray gun

(c) with the appropriate cleaning

solution. Use a thin layer of

petroleum jelly to lubricate the

O-ring (d).

* Cup seal

It is important that the cup seal inside the spray

gun be re-installed properly. Make sure the cup

side of the seal (the side with the groove) is facing

out towards the front of the spray gun.

Groove

(a)

(b)

1

4

2

5

(c)

(d)

3

6

Yellow Gun

White Gun

Page 10

English

10

Maintenance

Start

Important:

You should inspect the air lter in the turbine to

see if it is excessively dirty. If it is dirty, follow

these steps to replace it.

IMPORTANT: Never operate your unit without

the air lters. Dirt could be sucked in and

interfere with the function of the unit.

4. Press the tabs on each side of the turbine

to remove the lter covers.

5. Remove the dirty lters from the turbine

and replace with new ones. The smooth

side of the air lter must be placed toward

the turbine.

Secure the covers back onto the turbine.

1. Install the cup seal with the

groove (slot) facing toward the

nozzle*.

Insert the nozzle, keeping an eye

on the grooves (a).

2. Put the air screen (b) in the air cap

(c). Put both on the nozzle (d) and

secure with the connecting nut

(e).

3. Snap the adjustment ring (f) into

the connecting nut, enabling the

loop on the peg to be positioned

in the air cap.

Reassemble the spray gun.

* Cup seal

It is important that the cup seal inside the spray

gun be re-installed properly. Make sure the cup

side of the seal (the side with the groove) is facing

out towards the front of the spray gun.

Groove

4 5

(a)

1

(b)

(d)

(c)

(e)

2

(f)

3

Page 11

English

11

Troubleshooting

Any attempt to open the motor housing or repair any electrical parts within the

unit by anyone other than an authorized repair technician could cause serious

injury and will void the warranty.

This unit contains no servicable electrical parts. Do

not attempt to service yourself. Store indoors with

the cord wrapped around the turbine handle.

Problem A: Little or no material ow

Cause Solution

1. Nozzle clogged. Clean.

2. Suction tube clogged. Clean.

3.

Material volume setting turned too low (-).

Increase volume setting (+).

4. Suction tube loose. Insert.

5. No pressure build up in container. Tighten container.

6. Air lter clogged. Change.

Problem B: Material leaking

Cause Solution

1. Nozzle loose. Tighten.

2. Nozzle worn. Replace.

3. Nozzle seal worn. Replace.

4. Material build-up on air cap and nozzle Clean.

Problem C: Spray pattern too thick, runs and sags

Cause Solution

1. Viscosity of material too high. Thin.

2. Material volume too large. Decrease volume setting (-).

3. Material volume setting too high (+). Decrease volume setting (-).

4. Pressure setting too low. Increase pressure setting (+).

5. Nozzle clogged. Clean.

6. Air lter clogged. Change.

7. Too little pressure build-up in container. Tighten container.

Problem D: Spray jet pulsates

Cause Solution

1. Material in container running out. Rell.

2. Air lter clogged. Change.

Problem E: Pattern runs or sags

Cause Solution

1. Applying too much material.

Adjust material ow or increase

movement of spray gun.

Problem F: Too much overspray

Cause Solution

1. Gun too far from spray object. Reduce distance.

2. Too much material applied. Decrease volume setting (-).

3. Pressure setting too high. Decrease pressure setting.

Problem G: Pattern is very light and splotchy

Cause Solution

1. Moving the spray gun too fast.

Adjust material ow or

decrease movement of spray

gun.

Have you tried the recommendations above and are still having

problems? In the United States, to speak to a customer service

representative, call our Technical Service at 1-800-328-8251 Monday

through Friday between 8:00 AM and 4:30 PM Central time.

Page 12

English Français Español

36

1

14

2

3

4

5

15

16

17

18

6

8

7

11

12

19

20

13

21

Parts List • Liste de pièces • Lista de piezas

Spray Guns • Pistolets • Pistolas

Replacement parts available by calling

customer service

On peut obtenir des pièces de rechange

en appelant le Service à la clientèle.

Los repuestos están disponibles

llamanado al servicio a clientes.

1-800-328-8251

9

10

Page 13

EnglishFrançais

Español

37

Item

Article

Articulo

Part No.

Nº de piéce

Pieza No.

English

Description

Français

Description

Español

Descripción

Quantity

Quantite

Cantidad

1 2322547 White spray gun assembly (includes items 1-10) Ensemble de pistolet blanc (inclut des pièces 1 à 10) Ensamblaje de pistola blanco (incluye los articulos 1-10) 1

2 0417465 Nozzle seal Joint d’étanchéité de embout Sello de boquilla 1

3 2317424 Nozzle Embout Boquilla 1

4 2320187 Air screen Filtre à air Filtro de aire 1

5 2322541 Air cap Chapeau d’air Tapa de aire 1

6 2322537 Connecting nut Écrou d’assemblage Tuerca de conexión 2

7 2322542 Adjustment ring Anneau de tarage Anillo de ajuste 1

8 2322543 Lever Levier Palanca 1

9 0417356 Tube Tube Tube 1

10 2301587 Valve seal Joint de clapet Junta de la válvula 1

11 0417474 Seal Joint Sello 1

12 0417473 Suction tube Tube d’aspiration Tubo de succión 1

13 2303366 Material container Réservoir de liquide Recipiente 1

14 0417229 Yellow spray gun assembly (includes items 14-18) Ensemble de pistolet jaune (inclut des pièces 14 à 18) Ensamblaje de pistola amarillo (incluye los articulos 14-18) 1

15 0414353 Nozzle seal Joint d’étanchéité de embout Sello de boquilla 1

16 0417349 Nozzle Embout Boquilla 1

17 0414368 Air cap Chapeau d’air Tapa de aire 1

18 0414351 Connecting nut Écrou d’assemblage Tuerca de conexión 1

19 0417341 Container seal Joint d’étanchéité de réservoir Sello de recipiente 1

20 0414363 Suction tube Tube d’aspiration Tubo de succión 1

21 0414313 Material container (600 ml) Réservoir de liquide (600 ml) Recipiente (600 ml) 1

Page 14

English Français Español

38

Parts List • Liste de pièces • Lista de piezas

4

5

1

3

2

Replacement parts available by calling

customer service

On peut obtenir des pièces de rechange

en appelant le Service à la clientèle.

Los repuestos están disponibles

llamanado al servicio a clientes.

1-800-328-8251

Page 15

EnglishFrançais

Español

39

Item

Article

Articulo

Part No.

Nº de piéce

Pieza No.

English

Description

Français

Description

Español

Descripción

Quantity

Quantite

Cantidad

1 ------- Turbine (includes item 2) Turbine (inclut de pièce 2) Turbina (incluye le articulo 2) 1

2 2307279 Filter Filtre Filtro 2

3 0414219 Air hose Tuyau d’air Manguera de aire 1

4 2303300 Turbine handle Poignée de pistolet Asa de pistola 1

5 0413306 Viscosity cup Godet de viscosimètre Cubeta de viscosidad 1

Replacement parts available by calling customer service (1-800328-8251)

On peut obtenir des pièces de rechange en appelant le Service à

la clientèle (1 800-328-8251)

Los repuestos están disponibles llamanado al servicio a clientes

(1-800-328-8251)

Page 16

English Français Español

40

Limited warranty

HVLP paint spray equipment

This product, manufactured by Wagner Spray Tech Corporation

(Wagner), is warranted against defects in material and work-manship

for one year following date of purchase if operated in accordance

with Wagner’s printed recommendations and instructions. This

warranty does not cover damage resulting from improper use,

accidents, user’s negligence or normal wear. This warranty does not

cover any defects or damages caused by service or repair performed

by anyone other than a Wagner Authorized Service Center.

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE IS LIMITED TO one year FOLLOWING DATE OF

PURCHASE. WAGNER SHALL NOT IN ANY EVENT BE LIABLE FOR ANY

INCIDENTAL OR CONSEQUENTIAL DAMAGES OF ANY KIND, WHETHER

FOR BREACH OF THIS WARRANTY OR ANY OTHER REASON. THIS

WARRANTY DOES NOT APPLY TO ACCESSORIES.

THIS PRODUCT IS DESIGNED FOR HOME USAGE ONLY. IF USED FOR

COMMERCIAL OR RENTAL PURPOSES, THIS WARRANTY APPLIES ONLY

FOR 30 DAYS FROM DATE OF PURCHASE.

If any product is defective in material and/or workmanship during

the applicable warranty period, return it with proof of purchase,

transportation prepaid to any Wagner Authorized Service Center.

(Service Center listing is enclosed with this product.) Wagner’s

Authorized Service Center will either repair or replace the product (at

Wagner’s option) and return it to you, postage prepaid.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN

IMPLIED WARRANTY LASTS OR THE EXCLUSION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND

EXCLUSION MAY NOT APPLY TO YOU. THIS WARRANTY GIVES YOU

SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO HAVE OTHER RIGHTS

WHICH VARY FROM STATE TO STATE.

Garantie limitée

Pulvérisateur de peinture HVLP

Cet article fabriqué par Wagner Spray Tech Corporation (Wagner)

est garanti contre tout défaut de fabrication et de matériaux pour

une période d’un an suivant la date d’achat, à condition qu’il soit

utilisé conformément aux recommandations et aux instructions

écrites de Wagner. La garantie ne couvre pas les dommages résultant

d’un mauvais emploi, d’un accident, d’une négligence de la part de

l’utilisateur ou de l’usure normale de l’article. Elle ne couvre pas non

plus les défauts ou les dommages découlant de services d’entretien

ou de réparations assurées par tout autre établissement qu’un centre

de service après-vente agrée de Wagner.

TOUTE GARANTIE TACITE RELATIVE AUX QUALITÉS MARCHANDES

OU À L’UTILISATION DE CE PRODUIT DANS UN BUT PARTICULIER

N’EST VALABLE QUE POUR UNE PÉRIODE D’UN AN À COMPTER DE

LA DATE D’ACHAT. WAGNER NE SAURAIT ÊTRE TENU RESPONSABLE

DES DOMMAGES FORTUITS OU INDIRECTS QUELS QU’ILS SOIENT,

QUE CE SOIT POUR INOBSERVATION DE LA PRÉSENTE GARANTIE

OU POUR TOUTE AUTRE RAISON. LA GARANTIE NE COUVRE PAS LES

ACCESSOIRES.

CET ARTICLE A ÉTÉ CONÇU EXCLUSIVEMENT EN VUE D’UN USAGE

DOMESTIQUE. LA GARANTIE NE SERA VALABLE QUE POUR 30 JOURS

À COMPTER DE LA DATE D’ACHAT DE L’ARTICLE EST UTILISÉ À DES

FINS COMMERCIALES OU DE LOCATION.

Tout article comportant des défauts de fabrication ou de matériaux

au cours de la période de garantie applicable peut être retourné

en port payé à un centre de service après-vente agrée de Wagner,

accompagné de la preuve d’achat (une liste des centres de service

après-vente accompagne cet article). Le centre de service aprèsvente agrée de Wagner vous renverra l’article en port payé, après

l’avoir réparé ou remplacé (ce choix étant à la discrétion de Wagner).

COMME LES LIMITES DE TEMPS RELATIVES À UNE GARANTIE TACITE

OU À L’EXCLUSION DES DOMMAGES DE NATURE FORTUITE OU

INDIRECTE N’ONT PAS NÉCESSAIREMENT COURS DANS TOUTES LES

PROVINCES, IL SE PEUT QUE LESDITES LIMITES OU EXCLUSIONS NE

VOUS CONCERNENT PAS. CERTAINS DROITS PARTICULIERS VOUS

SONT DÉVOLUS EN VERTU DE LA PRÉSENTE GARANTIE ET PEUVENT

S’ACCOMPAGNER D’AUTRES DROITS EN FONCTION DE LA PROVINCE

OÙ VOUS RÉSIDEZ.

Garantía limitada

Equipo de atomización de pintura HVLP

Este producto, fabricado por la Wagner Spray Tech Corporation

(Wagner), está garantizado contra defectos de materiales y de

mano de obra por un año a partir de la fecha de compra siempre y

cuando se utilice de acuerdo con las recomendaciones e intrucciones

impresas de Wagner. Esta garantía no cubre daños ocasionados por

el uso incorrecto, accidentes, negligencia por parte del usario o el

desgaste normal. Esta garantía no cubre cualquier defecto o daño

ocasionado por el servicio o las reparaciones llevadas a cabo fuera de

un Centro de Servicio Wagner Autorizado.

CUALQUIER GARANTÍA IMPLÍCITA RFERENTE AL POTENCIAL

COMERCIAL O ADAPTABILIDAD pARA UN USO PARTICULAR SE

LIMITA A UN AÑO A PARTIR DE LA FECHA DE COMPRA. WAGNER EN

NINGÚN CASO SERÁ RESPONSABLE DE CUALQUIER DAÑO DIRECTO

O INDIRECTO DE CUALQUIER TIPO, YA SEA POR VIOLACIÓN DE ESTA

GARANTÍA O CUALQUIER OTRA RAZÓN. ESTA GARANTÍA NO SE

APLICA A LOS ACCESORIOS.

ESTE PRODUCTO ESTÁ DISEÑADO PARA SER UTILIZADO EN

EL HOGAR ÚNICAMENTE. SI SE UTILIZA PARA PROPÓSITOS

COMERCIALES O DE ALQUILER, ESTÁ GARANTÍA ES VÁLIDA

ÚNICAMENTE DURANTE 30 DÍAS A PARTIR DE LA FECHA DE COMPRA.

Si cualquier producto está defectuoso con respecto a los materiales

o mano de obra, regréselo porte pagado junto con el recibo de

compra a cualquier Centro de Servicio Wagner Autorizado (la lista

de Centros de Servicio se adjunta con este producto). El Centro de

Servicio Wagner Autorizado reparará o reemplazará el producto (a la

discreción de Wagner) y se lo regresará porte pagado.

ALGUNOS ESTADOS, DEPARTAMENTOS O PROVINCIAS NO PERMITEN

LIMITACIONES EN CUANTO AL PERÍODO DE VALIDEZ DE UNA

GARANTÍA IMPLÍCITA NI LA EXCLUSIÓN DE DAÑOS DIRECTOS O

INDIRECTOS. POR LA TANTO, LA LIMITACIÓN Y LA EXCLUSIÓN

ANTERIOR PUEDEN NO APLICARSE A USTED.

ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS Y

USTED TAMBIÉN PUEDE TENER OTROS DERECHOS QUE VARÍAN DE

UNA LOCALIDAD A OTRA.

Loading...

Loading...