Volvo VHD, VH Service manual

Service Manual

Trucks

D

Group 28, 36, 43

Fault Code Guide

2007 Emissions

VN, VHD VERSION2, VT

PV776-20180137

Foreword

Descriptions and instructions in this handbook are based on design and

method studies up to and including 1.2007.

The products are under continual development. Values and repair

methods may therefore differ on vehicles and components manufactured

after this date.

This service information uses the following observation and warning levels:

Note! Indicates a situation, use or circumstance that should

be emphasized.

Important! Indicates a situation, where a special service hint or

technique

Caution! Indicates a situation that, unless avoided, can lead to

physical damage to the product.

Warning! Indicates a dangerous situation that, unless avoided, can

led to personal injury.

Danger! Indicates a dangerous situation that, unless avoided, can

lead to serious personal injury or death.

is used.

D

Order number: PV776-20180137

© 2007 Volvo Trucks North America, Inc., Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced, stored in

retrieval system, or transmitted in any forms by any means, electronic,

mechanical, photocopying, recording or otherwise, without the prior written

permission of Volvo Trucks North America, Inc.

USA25976.ihval

Group 28 Design and Function

Group 28

Design and Function

D

Engine Control System

The “Premium Tech Tool” (PTT) is the preferred tool for

performing diagnostic work. Contact your local dealer

for more information.

System Overview

Five electronic control modules are used; the Engine

Management System (EMS) Module, Instrument Cluster

Module (ICM), Vehicle Electronic Control Unit (VECU),

Transmission Electronic Control Unit (TECU) and

the Gear Selector Electronic Control Unit (GSECU).

Together, these modules operate and communicate

through the J1939 high speed serial data line to control

a variety of engine and vehicle cab functions. The

Engine Management System (EMS) Module controls

fuel timing and delivery, fan operation, engine protection

functions, engine brakeoperation, the EGR valve, and the

turbocharger nozzle. The Vehicle Electronic Control Unit

(VECU) controls cruise control functions, accessory relay

controls and idle shutdown functions. The Instrument

Cluster Module (ICM) primarily displays operational

parameters and communicates these to the other ECU’s.

All have the capability to communicate over the J1587

normal speed data lines primarily for programming,

diagnostics and data reporting.

In addition to their control functions, the modules

have on-board diagnostic capabilities. The on-board

diagnostics are designed to detect faults or abnormal

conditions that are not within normal operating

parameters. When the system detects a fault or abnormal

condition, the fault will be logged in one or both of the

modules’ memory, the vehicle operator will be advised

that a fault has occurred by illumination a malfunction

indicator lamp and a message in the driver information

display, if equipped. The module may initiate the engine

shutdown procedure if the system determines that the

fault could damage the engine.

In some situations when a fault is detected, the system

will enter the "limp home" mode. The limp home mode

allows continued vehicle operation but the system may

substitute a sensor or signal value that may result in

poor performance. In some instances, the system will

continue to function but engine power may be limited to

protect the engine and vehicle. Fault codes logged in the

system memory can later be read, to aid in diagnosing

the faults, with a diagnostic computer or through the

instrument cluster display,if equipped. When diagnosing

an intermittent code or condition, it may be necessary

to use a diagnostic computer connected to the Serial

Communication Port.

Additional data and diagnostic tests are available

when a diagnostic computer is connected to the Serial

Communication Port.

For diagnostic software, contact your local dealer.

The Vehicle Electronic Control Unit (VECU) is mounted

on a panel below the top dash access panel in the center

of the dash on conventional models. The VECU is a

microprocessor based controller programmed to perform

several functions, these include:

Driver controls

•

Vehicle and engine speed controls

•

Starter control

•

Cab power

•

Idle controls

•

Broadcasting data on the serial data lines

•

Trip data logging

•

Diagnostic fault logging and password processing

•

The VECU performs these functions by monitoring the

signals from sensors and switches, and data received

over the serial data lines from the other ECU’s. The

VECU directly monitors the Throttle Position (TP) Sensor

and Vehicle Speed Sensor (VSS).

The VECU also monitors the position or state of a number

of switches to perform its control and diagnostic functions.

They are:

A/C Pressure Switch

•

Air Suspension Height Control Switch

•

Differential Lock Switch

•

Engine Brake Switches

•

Ignition Key Switch

•

PTO Switches (if equipped)

•

Service and Park Brake Switches

•

Speed Control Switches (Set/Decel, Resume/Accel)

•

5th Wheel Slide Switch

•

1

Group 28 Design and Function

The EMS is a microprocessor based controller

programmed to perform fuel injection quantity and timing

control, diagnostic fault logging, and to broadcast data to

other modules. The fuel quantity and injection timing to

each cylinder is precisely controlled to obtain optimal fuel

economy and reduced exhaust emissions in all driving

situations.

The EMS controls the operation of the Electronic Unit

Injectors (EUIs), engine brake solenoid, EGR valve,

turbocharger nozzle position, and cooling fan clutch

based on input information it receives over the serial data

lines and from the following sensors:

Ambient Air Temperature Sensor

•

Ambient Pressure sensor

•

Boost Air Pressure (BAP) Sensor

•

Camshaft Position (Engine Position) Sensor

•

Cooling Fan Speed (CFS) Sensor

•

Crankshaft Position (Engine Speed) Sensor

•

Differential Pressure DPF Sensor

•

EGR Differential Pressure Sensor

•

EGR Temperature Sensor

•

Engine Coolant Level (ECL) Sensor

•

Engine Coolant Temperature (ECT) Sensor

•

Engine Oil Pressure (EOP) Sensor

•

Engine Oil Level (EOL) Sensor

•

Engine Oil Temperature (EOT) Sensor

D

•

Exhaust Temperature Sensor (DPF Sensors)

•

Fuel Pressure Sensor

•

Intake Air Temperature And Humidity (IATH) Sensor

•

Intake Manifold (Boost) Temperature Sensor

•

Throttle Position (TP) Sensor

•

Turbo Speed Sensor

•

Variable Geometry Turbocharger (VGT) Position

•

Sensor

The Vehicle Electronic Control Unit (VECU) and Engine

Management System (EMS) Module are dependent on

each other to perform their specific control functions. In

addition to switch and sensor data the broadcast of data

between modules also includes various calculations and

conclusions each module has developed, based on the

input information it has received.

2

Group 28 Design and Function

Sensors

Ambient Air Temperature Sensor

The Ambient Air TemperatureSensor is used to detect the

outside air temperature. The sensor modifies a voltage

signal from the ECM. The modified signal returns to the

ECM as the ambient air temperature. The sensor uses a

thermistor that is sensitive to the change in temperature.

The electrical resistance of the thermistor decreases as

temperature increases.

The Ambient Air Temperature Sensor is located in the

front of the vehicle.

D

Ambient (Atmospheric) Pressure Sensor

The Ambient (Atmospheric) Pressure Sensor contains a

pressure sensitive diaphragm and an electrical amplifier.

Mechanical pressure applied to the diaphragm causes

the diaphragm to deflect and the amplifier to produce an

electrical signal proportional to the deflection.

The Ambient (Atmospheric) Pressure Sensor is built into

the Engine Management System (EMS) Module.

Camshaft Position Sensor

The Camshaft Position (Engine Position) Sensor is

located in the rear face of the timing gear cover at the

rear of the engine, near the bottom of the valve cover. It

uses magnetic induction to generate a pulsed electrical

signal. It senses the passage of seven (7) timing bumps

on the edge of the camshaft dampener. Six of the holes

correspond to the phasing of the electronic unit injectors,

while the seventh hole indicates the top dead center

position.

Cooling Fan Speed (CFS) Sensor

On engines with an electronically controlled viscous fan

drive, the electronic fan drive contains a Hall effect speed

sensor. When the engine is running, a series of vanes in

the fan drive housing rotates past a magnet in the fan

drive solenoid generating a pulsed voltage signal. The

Engine Management System (EMS) Module monitors

the status if the air conditioning system and signals from

the Engine Coolant Temperature (ECT) Sensor, the

Engine Oil Temperature (EOT) Sensor, and the Engine

Speed/Timing (RPM/TDC) Sensor and calculates the

optimal cooling fan speed.

The Cooling Fan Speed Sensor is located in the fan drive

on the front of the engine.

3

Group 28 Design and Function

Crankshaft Position (Engine Speed) Sensor

The Crankshaft Position (Engine Speed) Sensor uses

magnetic induction to generate a pulsed electrical signal.

Notches are machined into the edge of the flywheel.

When one of the notches passes close to the sensor,

electric pulses result.

The Crankshaft Position (Engine Speed) Sensor also

indicates when the crankshaft is at the top dead center

position.

D

Differential Pressure DP Sensor

The differential pressure sensor is used for flow

measurement of the Diesel Particulate Filter (DPF). This

sensor has two pressure ports and senses the difference

in pressure between the two ports. Measurement of the

pressure before and after the DPF is used to calculate

diesel filter regeneration.

The Differential Pressure DPF Sensor is located on the

side of the Diesel Particulate Filter (DPF).

EGR Differential Pressure Sensor

The EGR differential pressure sensor is used for flow

measurement of the Exhaust Gas Recirculation (EGR)

valve. This sensor has two pressure ports and senses

the difference in pressure between the two ports.

Measurement of the pressure before and after the EGR

valve is used to calculate EGR flow.

The EGR Differential Pressure Sensor is located on the

left or right side of the engine.

EGR Temperature Sensor

The EGR temperature sensor detects exhaust gas

temperature for EGR system. The sensor modifies a

voltage signal from the control unit. The modified signal

returns to the control unit as the exhaust temperature

of the EGR system to confirm EGR operation. The

sensor uses a thermistor that is sensitive to the change

in temperature.

The EGR Temperature Sensor is located near the EGR

valve.

Engine Coolant Level (ECL) Sensor

The Engine Coolant Level (ECL) Sensor is a switch. If

engine coolant level falls below a calibrated point the

contacts open and the driver will be notified of the low

coolant level.

The Engine Coolant Level (ECL) Sensor is located in the

cooling system reservoir tank.

4

Group 28 Design and Function

Engine Coolant Temperature (ECT) Sensor

The Engine Coolant Temperature Sensor is located at

the front of the engine. The sensor will indicate a high

coolant temperature caused by problems like radiator

blockage, thermostat failure, heavy load, or high ambient

temperatures. This sensor is also used for cold start

enhancement and for fan clutch engagement.

D

Engine Oil Pressure (EOP) Sensor

The Engine Oil Pressure Sensor contains a pressure

sensitive diaphragm and a electrical amplifier. Mechanical

pressure applied to the diaphragm causes the diaphragm

to deflect and the amplifier to produce an electrical signal

proportional to the deflection.

The Engine Oil Pressure Sensor is located on the oil filter

assembly. The sensor monitors engine oil pressure to

warn of lubrication system failure.

Engine Oil Level (EOL) Sensor

The Engine Oil Level Sensor is located in the oil pan.

Engine Oil Temperature (EOT) Sensor

The Engine Oil Temperature Sensor is a thermistor

whose resistance varies inversely to temperature. The

sensor has a negative temperature coefficient, which

means the sensor resistance will decrease as the engine

oil temperature increases.

The Engine Oil Temperature Sensor is located in the oil

pan.

Exhaust Temperature Sensor (DPF Sensors)

The exhaust gas temperature sensor detects exhaust

gas temperature for DPF protection as well as DPF

regeneration control. The sensor modifies a voltage

signal from the control unit. The modified signal returns to

the control unit as the exhaust temperature at that specific

location of the exhaust. The sensor uses a thermistor that

is sensitive to the change in temperature.

The Exhaust Temperature Sensors are located in the

DPF assembly.

Fuel Pressure Sensor

The fuel pressure sensor contains a diaphragm that

senses fuel pressure. A pressure change causes the

diaphragm to flex, inducing a stress or strain in the

diaphragm. The resistor values in the sensor change in

proportion to the stress applied to the diaphragm and

produces an electrical output.

The Fuel Pressure Sensor is located on top of the fuel

filter housing.

5

Group 28 Design and Function

Intake Air Temperature and Humidity (IATH) Sensor

The Intake Air Temperature and Humidity (IATH)

Sensor contains a thermistor and a capacitive sensor.

The resistance of the thermistor varies inversely to

temperature. The output of the capacitive sensor

increases as the humidity of the surrounding air increases.

By monitoring the signals from both portions of the

sensor, the Engine Management System (EMS) Module

calculates the temperature and humidity of the air passing

through the air filter housing.

The Intake Air Temperature and Humidity (IATH) Sensor

is located in the air intake tube just downstream from the

air filter canister.

D

Intake Manifold (Boost) Temperature Sensor

The Intake Manifold (Boost) Temperature Sensor is

a thermistor whose resistance varies inversely to

temperature. The sensor has a negative temperature

coefficient, which means the sensor resistance will

decrease as the inlet air temperature increases.

The Intake Manifold (Boost) Temperature Sensor is

located in the intake manifold.

Intake Manifold Pressure Sensor

The Intake Manifold Pressure Sensor contains a

pressure sensitive diaphragm and an electrical amplifier.

Mechanical pressure applied to the diaphragm causes

the diaphragm to deflect and the amplifier to produce an

electrical signal proportional to the deflection.

The Intake Manifold Pressure Sensor is located on the air

inlet pipe before the intake manifold.

Throttle Position (TP) Sensor

The Throttle Position Sensor is a potentiometer that

is mechanically linked to the accelerator pedal. A

potentiometer is a variable resistor whose resistance

will change as the pedal is pressed. As the resistance

changes, the signal voltage of the sensor changes

indicating the accelerator pedal position.

The Throttle Position Sensor is located above the

accelerator pedal. The sensor is designed to improve the

driver’s control by reducing sensitivity to chassis motion.

This sensor provides the driver’s fuel request input to the

VECU.

Turbo Speed Sensor

The Turbo Speed Sensor informs the EMS of the turbo

shaft speed. The sensor does not read from the vanes,

but reads from the shaft. The Engine Management

System (EMS) Module uses this signal in conjunction with

the VGT position sensor signal to control the speed of the

turbocharger and therefore optimize the intake manifold

pressure.

The Turbo Speed Sensor is mounted in the center of the

turbocharger.

6

Group 28 Design and Function

Variable Geometry Turbocharger Smart Remote Actuator (VGT SRA)

The Variable Geometry Turbocharger Smart Remote

Actuator (VGT SRA) takes the position commands from

the EMS, moves the nozzle of the turbocharger to the

desired position, and performs all of the diagnostics and

self checks on the actuator.

D

7

Group 28 Design and Function

MID 130 Transmission Control Unit

The “Premium Tech Tool” (PTT) is the preferred tool for

performing diagnostic work. Contact your local dealer

for more information.

D

System Overview

The I-Shift transmission is a technologically advanced

automated mechanical transmission, designed

specifically to work in conjunction with Volvo’s new family

of heavy-duty diesel engines. In order to work as a total

package, the I-Shift is programmed with each engines’

efficiency map and is offered with different software

options to fulfill each operators needs.

All variants of the Volvo I-Shift have 12 forward speeds

and up to 4 reverse speeds depending on programming.

It is a single countershaft transmission built up with a

splitter section, a main section with three forward and one

reversegear, and a range gear section. It is an automated

mechanical transmission and uses synchronizers in its

splitter and range gears but not in the main section. The

main section utilizes a countershaft brake to mesh gears

and equalize shaft speeds as needed. A single disc

automated clutch system is utilized. The I-Shift is a "two

pedal" transmission and does not require a clutch pedal.

The I-Shift uses compressed air and electrical solenoids

to perform shift functions, clutch control and countershaft

brake functions. All of these functions are timed and

controlled by the Transmission Electronic Control Unit

(TECU). A dedicated air tank is needed on the vehicle to

supply air for these components. The air is plumbed to

the transmission via a supply line and is distributed to the

other components internally. The air control solenoids are

housed in the Transmission Control Housing and in the

Clutch Control Valve Assembly.

All Volvo Truck models will be available with this

transmission including the VT, VN Series & VHD

vocational trucks. Four I-Shift models will be offered

to support the power ranges of the engines as well as

offering different gear arrangements:

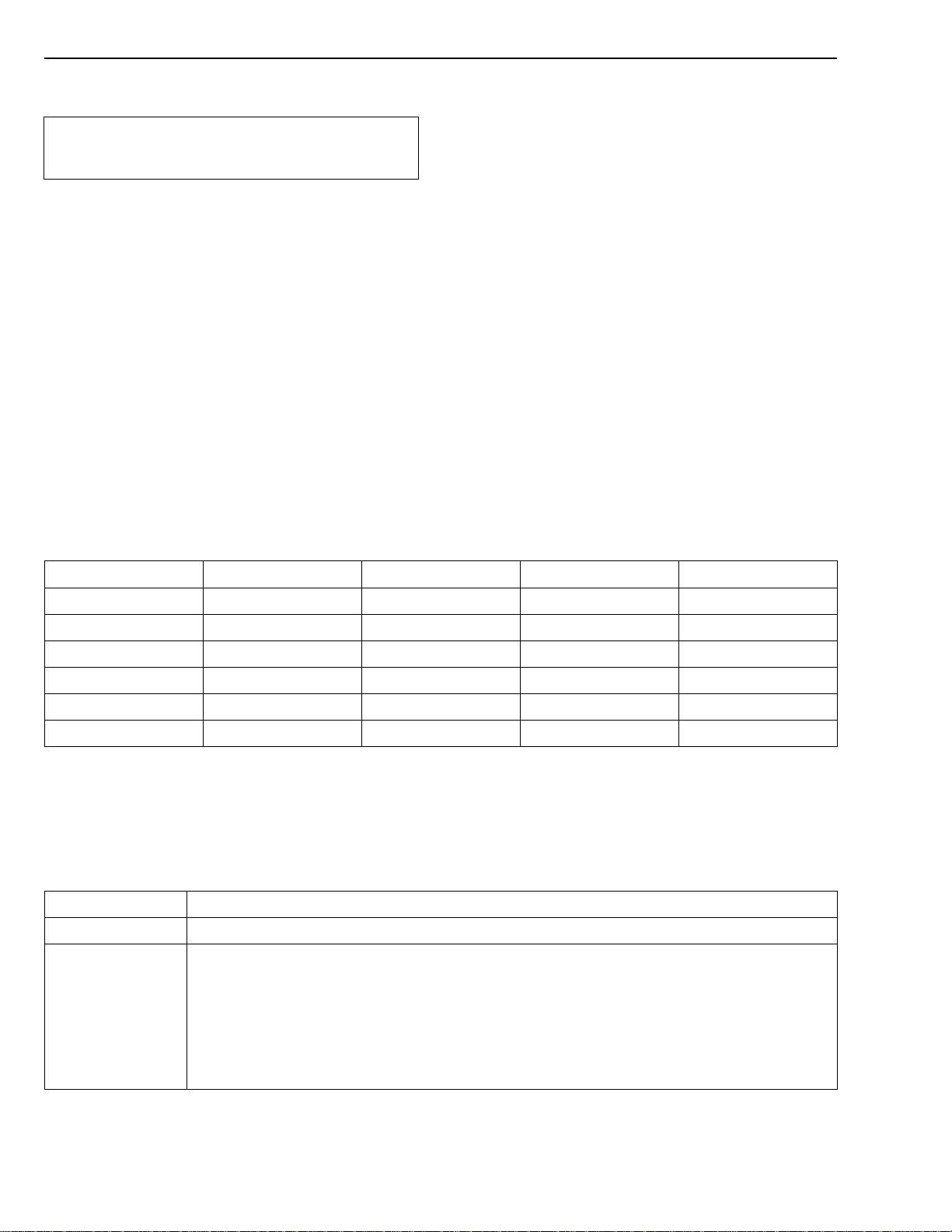

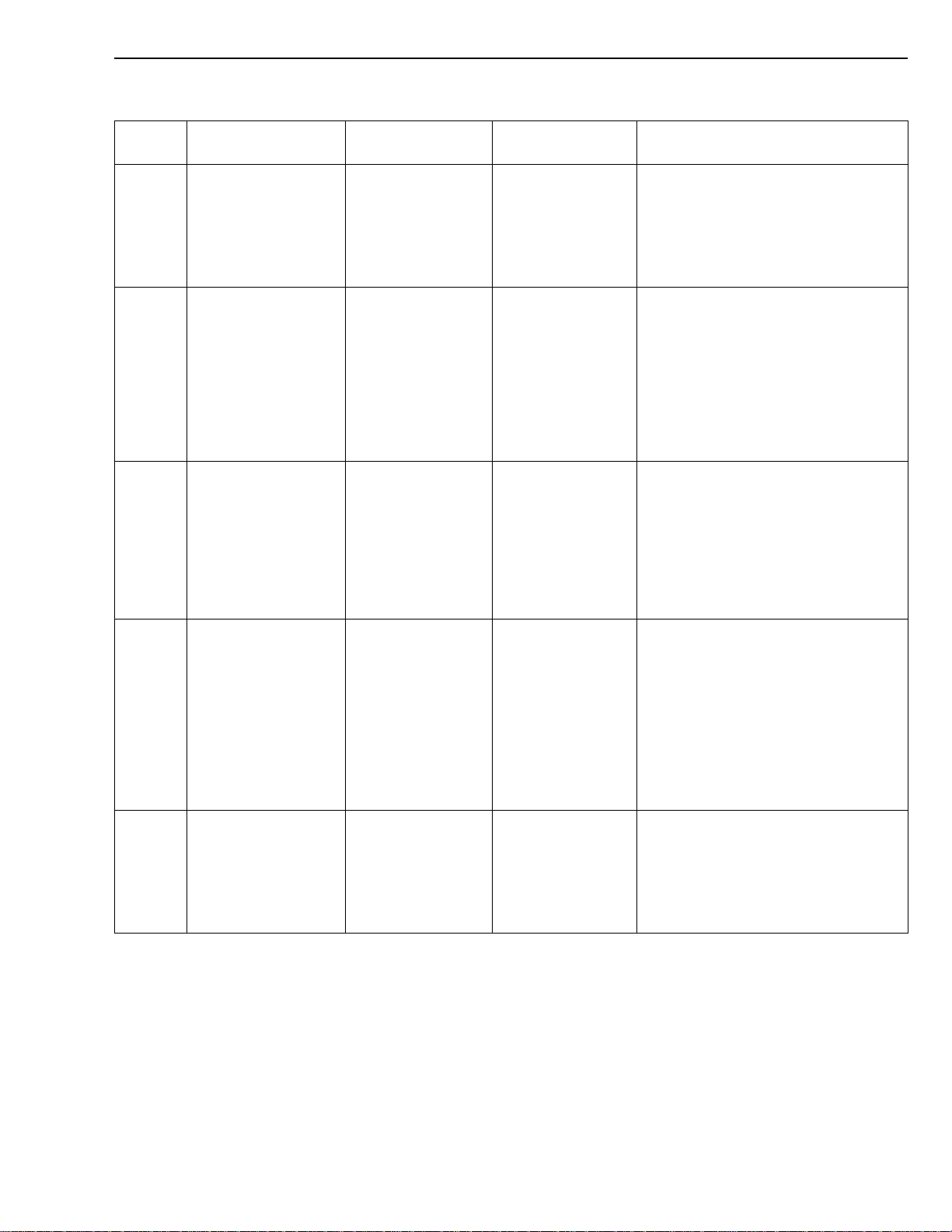

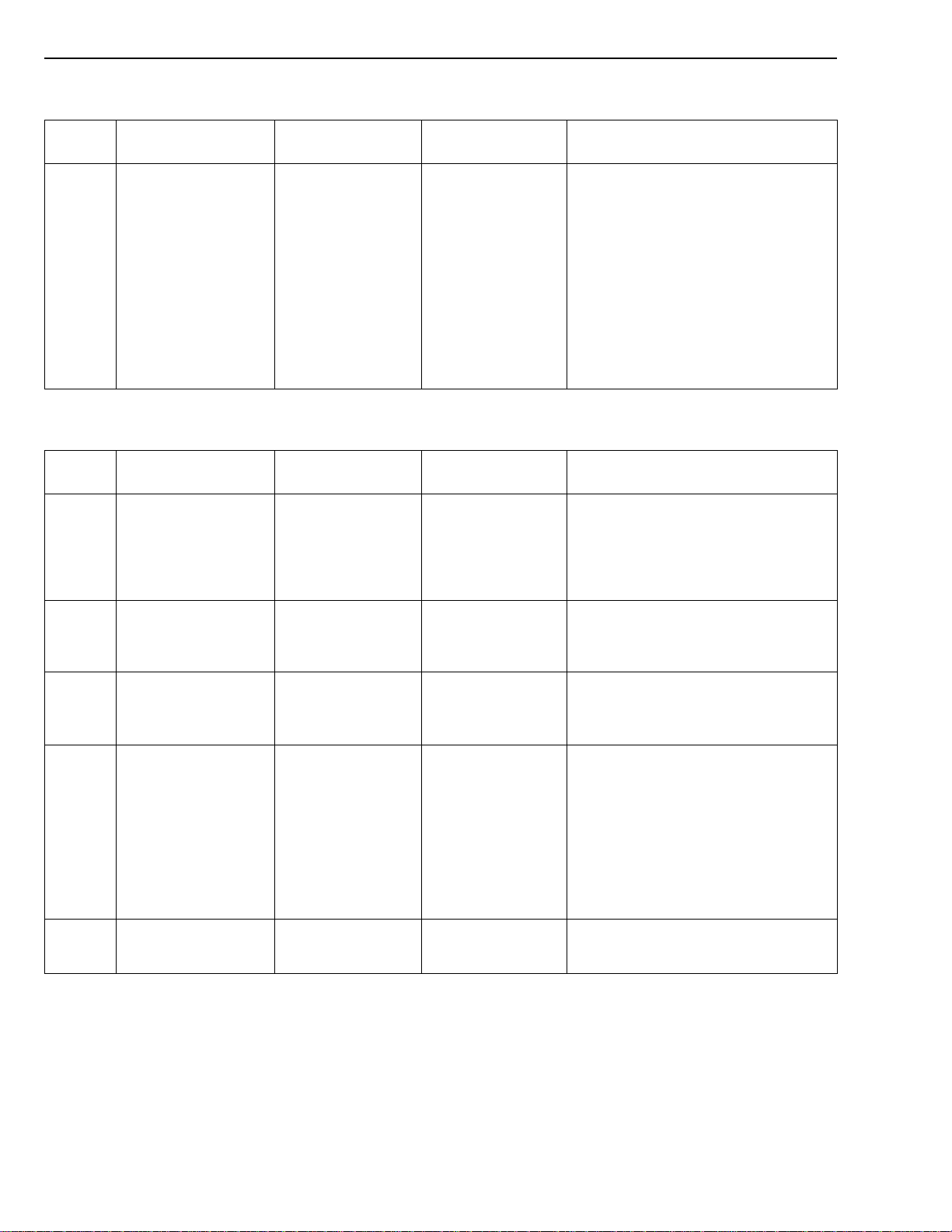

AT2512C ATO2512C AT2812C ATO3112C

Operation Two Pedal Two Pedal Two Pedal Two Pedal

Forward Speeds

Engines Available

Overall Ratio

Top Ratio Direct 1.00:1 Overdrive 0.78:1 Direct 1.00:1 Overdrive 0.78:1

Weight lbs (kg)

12 12 12 12

D11/D13 D11/D13 D16 D16

14.94:1 15.04:1 14.94:1 15.04:1

597 (275) 597 (275) 610 (281) 610 (281)

Transmission Identification

Each transmission has two identification tags. One is

found on the top of the clutch housing and the other is

found on the back of the range housing. The transmission

version can be readily identified by the following

nomenclature table.

Make Volvo

Type AT2512C, ATO2512C, AT2812C and ATO3112C

Description A — Automatic

T — Transmission

O — Overdrive

25 — Torque Capacity 2500 Nm (1850 lb/ft)

28 — Torque Capacity 2800 Nm (2050 lb/ft)

31 — Torque Capacity 3100 Nm (2300 lb/ft)

12 — Number of forward gears

C — Design Level

8

Group 28 Design and Function

Sensors

Clutch Position Sensor

The Clutch Position Sensor is located on the side of the

clutch cylinder assembly (inside bell housing).

Main Shaft Speed Sensor(s)

The speed sensors are located on the control housing

and measure the speed of the main shaft and the speed

of the countershaft.

The main shaft speed sensor is a electronic sensor with a

hall element. Using a hall element makes it possible to

measure the rotation speed and rotation direction of the

shaft.

The countershaft speed sensor is an inductive sensor.

Knowing the speed of the countershaft makes it possible

to calculate the precise speed of every gear in the

transmission.

The speed sensor(s) are located in the transmission on

the lower portion of the control housing.

D

Output Shaft Speed Sensor

The Output Shaft Speed Sensor is located on the side of

the rear transmission housing.

Range Cylinder Position Sensor

There are four position sensors in the transmission

control housing. These sensors measure the position of

the specific air cylinder within the control housing. The

sensors are inductive and the inductive characteristics

change depending on the position of the metal pin that

follows the movements of the air cylinders.

The Range Cylinder Position Sensor is located in the

transmission on the lower portion of the control housing.

Split Cylinder Position Sensor

The Split Cylinder Position Sensor is located in the

transmission on the lower portion of the control housing.

1st/Reverse Cylinder Position Sensor

The 1st/Reverse Cylinder Position Sensor is located in the

transmission on the lower portion of the control housing.

2nd/3rd Gear Cylinder Position Sensor

The 2nd/3rd Gear Cylinder Position Sensor is located

in the transmission on the lower portion of the control

housing.

9

Group 28 Design and Function

Transmission Electronic Control Unit

The TECU communicates with the Gear Selector ECU

and other ECUs in the vehicle through the J1939 and

J1587 data buses. The functionality of the TECU can be

different depending on the type of software packages

that are installed. The TECU contains the following

components:

SAE J11708/1587 CAN

•

SAE J1939 CAN

•

Powertrain CAN

•

11 Powerdrivers

•

Inclination Sensor

•

Temperature Sensor

•

9 Controlling Solenoid Valves

•

The Transmission Electronic Control Unit located on the

upper portion of the control housing.

D

Lubrication System

The transmission is lubricated through a combination of

pressure from an oil pump and splashing. The oil is led

into the main shaft to lubricate and cool the range gears,

the input shaft and main shaft bearings. The countershaft

brake and output shaft bearings, are also lubricated. The

lubrication system has two overflow valves. One valve

ensures that the transmission is lubricated if the filter gets

blocked while the other prevents excessive pressure in

the system, e.g. during cold start. The valves are made

up of a compression spring and a valve peg.

10

Group 28 Design and Function

MID 223 Gear Selector Control Unit

The “Premium Tech Tool” (PTT) is the preferred tool for

performing diagnostic work. Contact your local dealer

for more information.

D

System Overview

The gear selector is attached to the drivers seat and can

be folded away to aid in entering the cabin. There are two

available selector configurations, a basic and a premium.

The selector in the vehicle is dependant on which program

package level the vehicle is built with. Both selectors

have gear positions of R (Reverse), N (Neutral), D (Drive),

and M (Manual). With the selector in the drive position

the transmission will shift as an automatic, performing

gear selections and shifting without driver input. When in

the manual position, the driver either selects the gears

using the gear selector button (premium selector) or will

lock the gear that the transmission is presently operating

in and hold that gear until the selector is placed in the

drive position again (basic selector). With the basic

selector, if the manual position is engaged at a stop the

vehicle will start in first and hold that gear. The basic

selector isn’t equipped with a gear selector button or a

economy/performance dive mode button. In situations

where the I-Shift is unintentionally left in gear with the

parking brake applied, the TECU will automatically go to

neutral when the key switch is turned off. This is done

to avoid the transmission getting stuck in gear due to

drive line "torque up". There is a gear selector electronic

control unit (GSECU) that is located in the center of the

dash. The GSECU receives signals from the selector and

interprets these signals into communication information

that is transmitted to the TECU.

Selector Folding

The gear selector is capable of folding forward to aid in

cab entry and is also used to identify which software level

that is programmed in the Transmission Electronic Control

Unit (TECU). With the selector in the neutral position

Limp Home Mode

Note: Limp Home Mode should only be used to get a

vehicle to a safe or secure location. It is not meant for

driving any distance.

At times when a sensor failure or certain internal

transmission damage has occurred, "Limp Home Mode"

can be activated. Press the ”L” button on the gear selector

and move the gear lever to the D position to active "Limp

Home Mode". When activated, L is displayed as the

Sensors

Gear Selector Electronic Control Unit

The gear selector communicates with the Gear Selector

Electronic Control Unit using 8 wires. These wires are

used to decode a switch matrix inside the GSECU.

Inside the gear selector lever there are a number of

switches. Some of the switches are normal and some are

hall-effect switches.

(N) press in the fold button and the lever can be folded

forward. The display will then show the program package

level in place of the driving mode. This is found just to the

right of the present gear within the display.

driving mode in the DID. In "Limp Home Mode", only

forward gears 1, 3 and 5 are available for vehicles with

the premium selector and only first gear for vehicles with

the basic selector. No matter which selector the vehicle

has, reverse gear 1 is available also. The vehicle must be

stationary to shift gears. The "Limp Home Mode", will be

deactivated when the ignition is turned off. This mode is

only meant to get a vehicle to a safe or secure location.

The Gear Selector Electronic Control Unit is located in the

center of the dash just rear of the VECU.

11

D

12

Group 28 Troubleshooting

Troubleshooting

Engine ECU, Fault Tracing

The “Premium Tech Tool” (PTT) is the preferred tool for

performing diagnostic work. Contact your local dealer

for more information.

The control units on the information link communicate

according to the SAE J1587 standard. The standard

has been extended with Volvo’s own supplement

(PPID, PSID). The fault codes set by the control units

contain information that is described by the following

abbreviations.

MID Message Identification Description:

Identification of a control unit.

PID Parameter Identification Description:

Identification of a parameter (value).

PPID Proprietary Parameter Identification

Description Volvo:

Unique identification of a parameter

(value).

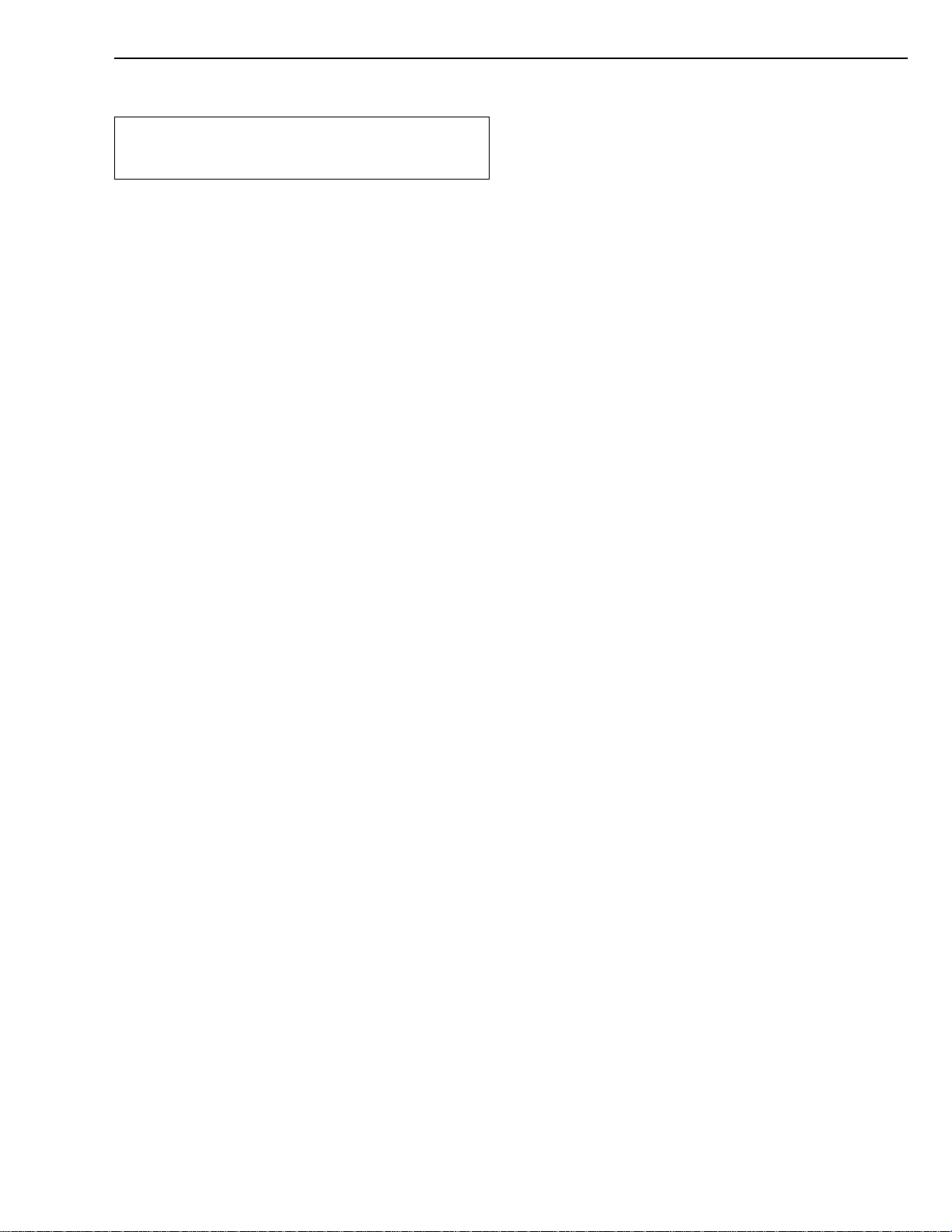

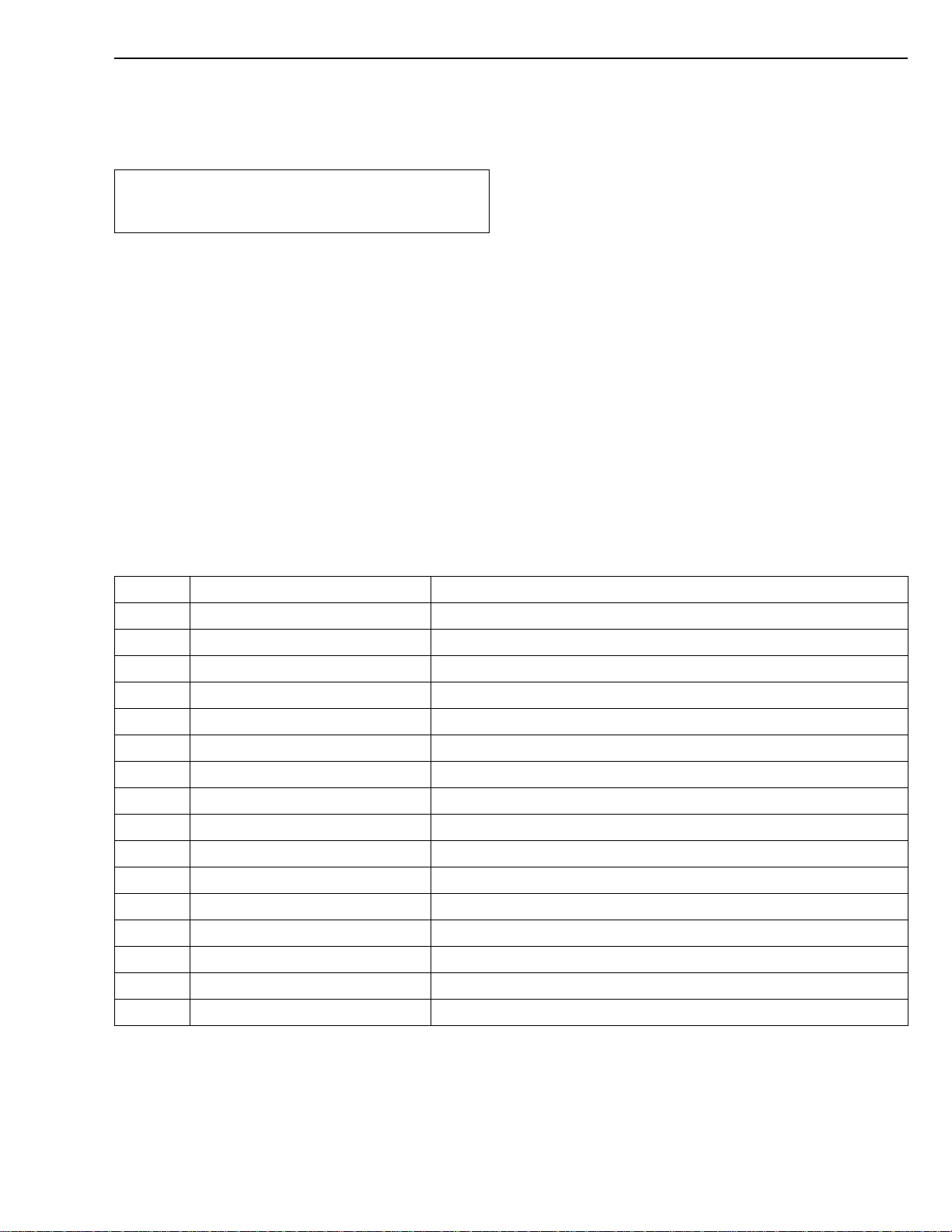

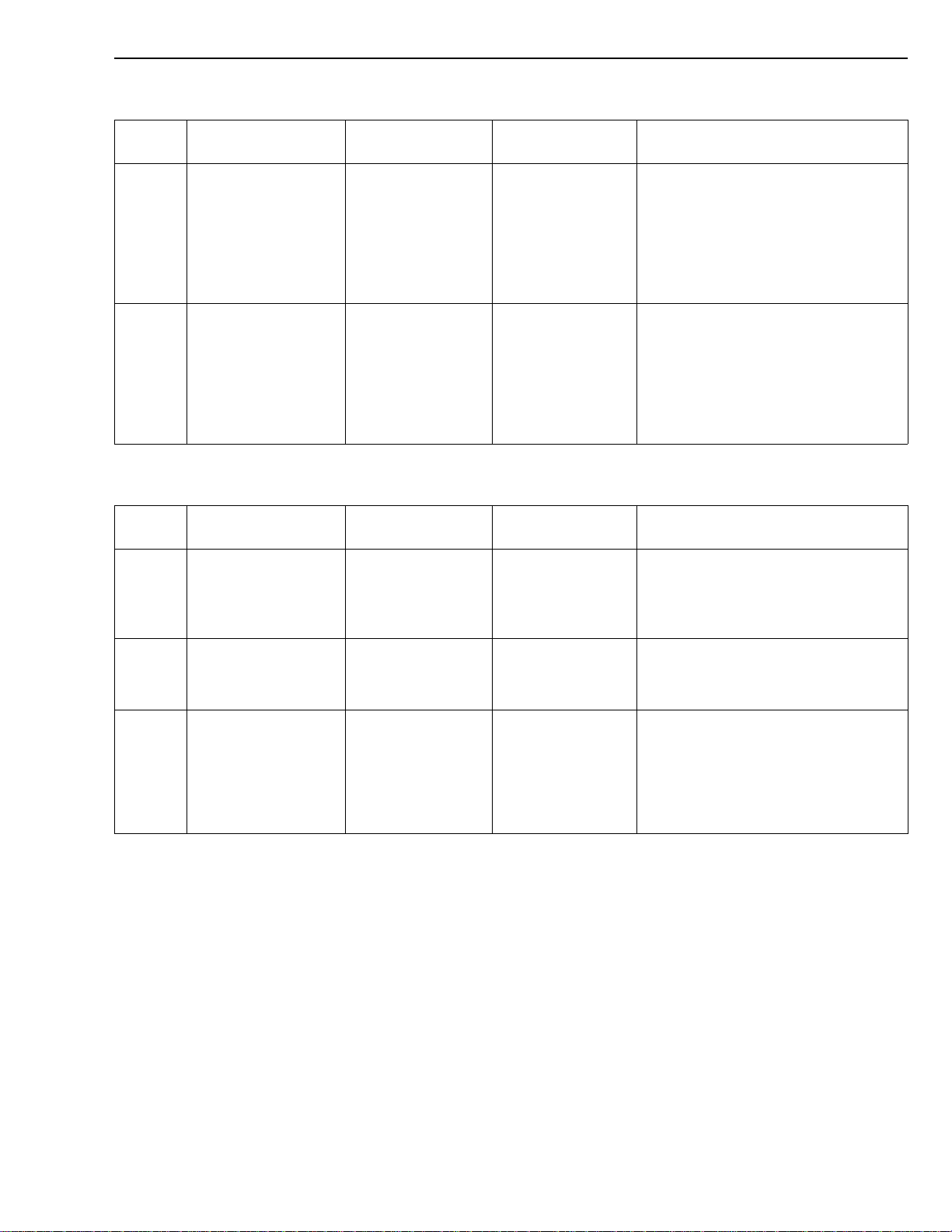

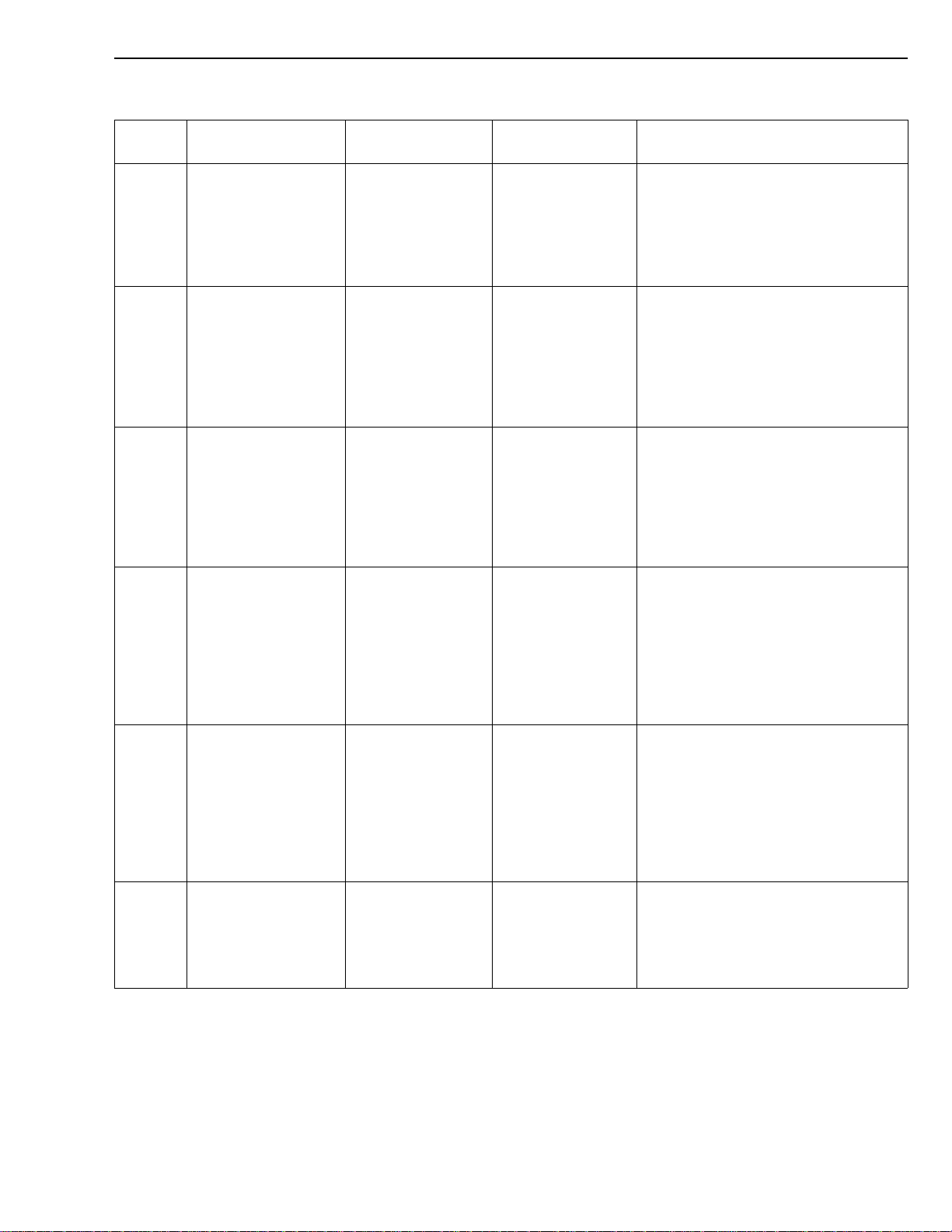

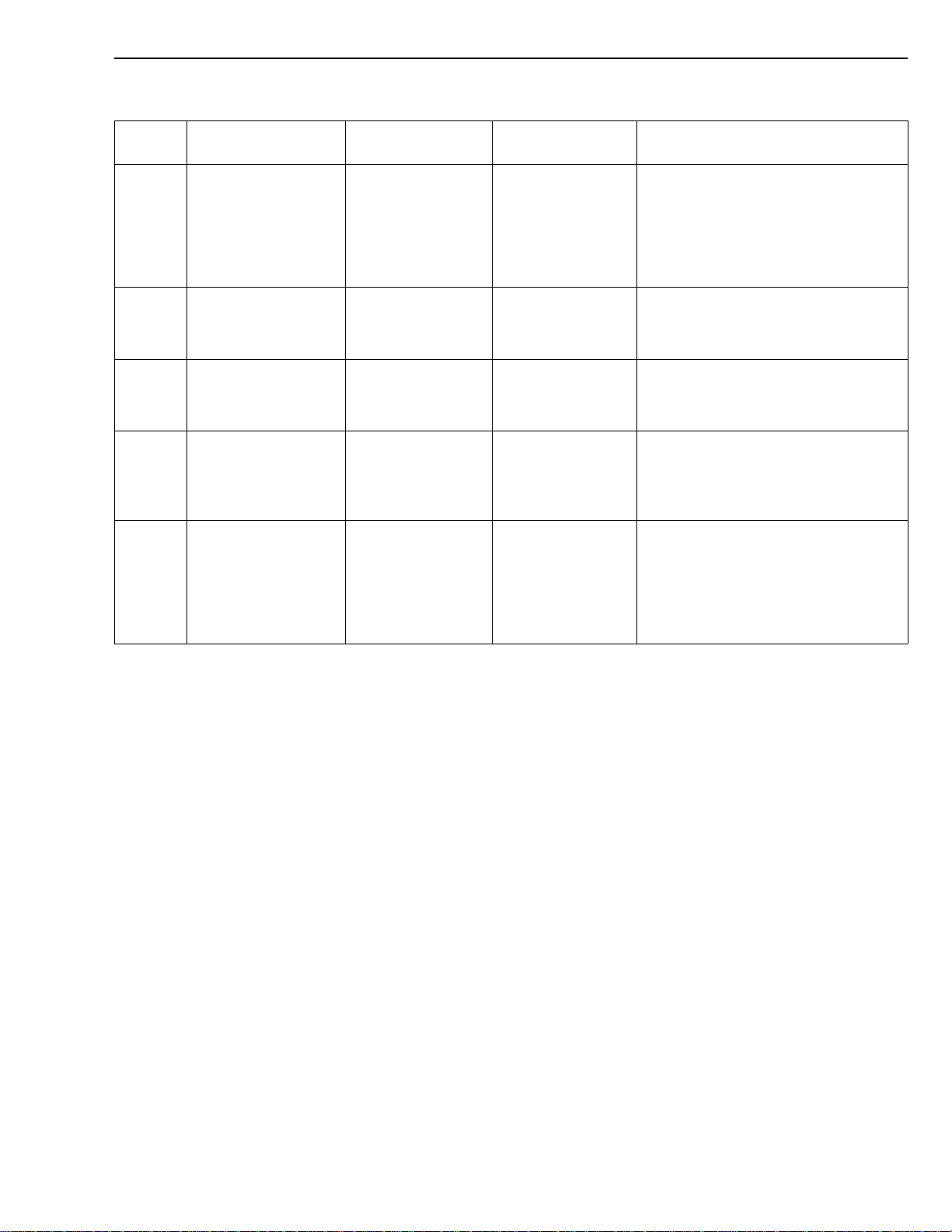

FMI Table

FMI Display Text

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Value to high Data valid, but above the normal working range

Value too low Data valid, but below the normal working range

Incorrect data Intermittent or incorrect data

Electrical fault Abnormally high voltage or short circuit to higher voltage

Electrical fault Abnormally low voltage or short circuit to lower voltage

Electrical fault Abnormally low current or open circuit

Electrical fault Abnormally high current or short circuit to ground

Mechanical fault Incorrect response from a mechanical system

Mechanical or electrical fault Abnormal frequency

Communication fault Abnormal update rate

Mechanical or electrical fault Abnormally strong vibrations

Unknown fault Non-identifiable fault

Component fault Faulty unit or component

Incorrect calibration Calibration values outside limits

Unknown fault Special instructions

Unknown fault Reserved for future use

SAE Text

D

SID Subsystem Identification Description:

Identification of a component.

PSID Proprietary Subsystem Identification

Description Volvo:

Unique identification of a component.

FMI Failure Mode Identifier:

Identification of fault types.

Note: When performing diagnostic test on intermittent

faults, gently wiggle the wires and connectors to help find

the intermittent faults.

13

Group 28 Troubleshooting

Engine ECU, Fault Tracing

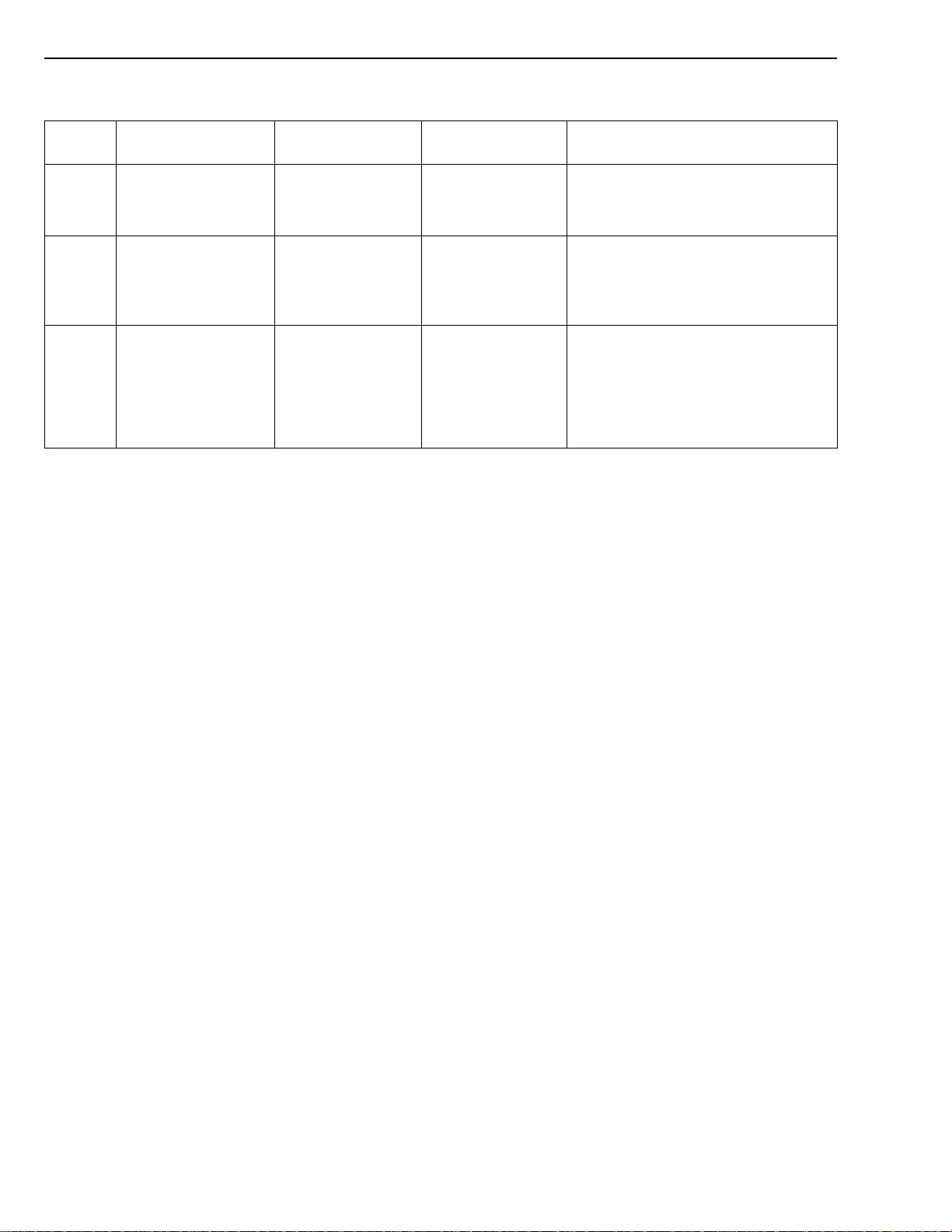

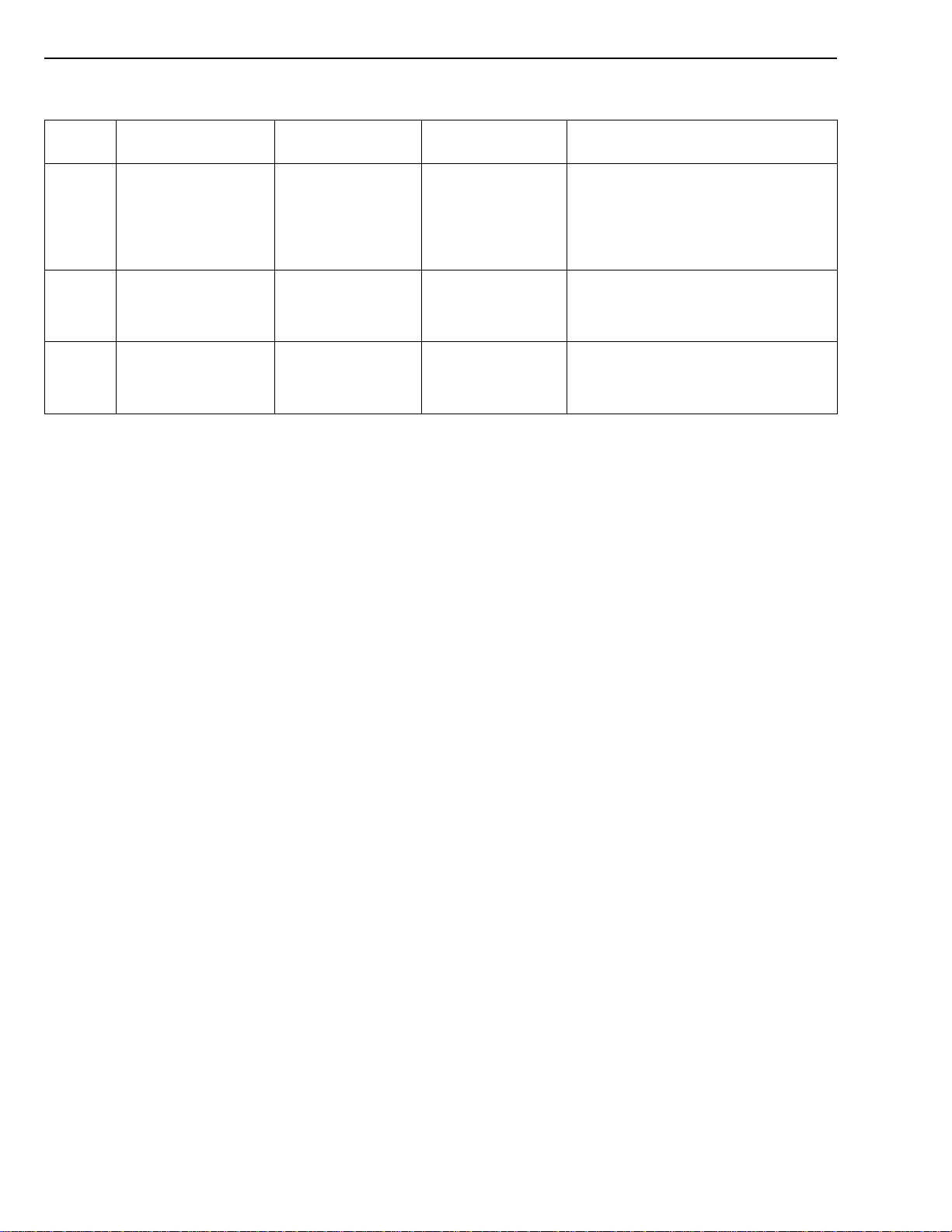

PID

“MID 128 PID 26 Fan Speed Percent” page 16

“MID 128 PID 45 Preheater Relay” page 16

“MID 128 PID 81 Particulate Filter” page 17

“MID 128 PID 84 Vehicle Speed” page 17

“MID 128 PID 85 Cruise Control Status” page 17

“MID 128 PID 91 Accelerator Pedal Position” page 18

“MID 128 PID 94 Fuel Delivery Pressure” page 18

“MID 128 PID 97 Water in Fuel Indicator” page 19

“MID 128 PID 98 Engine Oil Level” page 19

“MID 128 PID 100 Engine Oil Pressure” page 20

“MID 128 PID 102 Intake Manifold Pressure” page 21

“MID 128 PID 103 Turbo Speed” page 22

“MID 128 PID 105 Intake Manifold Temperature” page 23

“MID 128 PID 108 Atmospheric Pressure” page 24

“MID 128 PID 110 Coolant Temperature” page 25

“MID 128 PID 111 Coolant Level” page 26

“MID 128 PID 153 Crankcase Pressure” page 27

“MID 128 PID 171 Ambient Temperature” page 28

D

“MID 128 PID 173 Exhaust Temperature” page 28

“MID 128 PID 175 Engine Oil Temperature” page 29

“MID 128 PID 354 Relative Humidity” page 30

“MID 128 PID 411 EGR Exhaust Back Pressure” page 31

“MID 128 PID 412 EGR Temperature” page 32

PPID

“MID 128 PPID 35 EGR Mass Flow” page 33

“MID 128 PPID 89 Variable Geometry Turbocharger Smart Remote Actuator Temperature” page 33

“MID 128 PPID 122 Engine Compression Brake” page 34

“MID 128 PPID 270 NOx Sensor” page 35

“MID 128 PPID 326 Soot Level” page 36

“MID 128 PPID 272 Air Pressure Compensation” page 36

“MID 128 PPID 328 Aftertreatment Injection Shutoff Valve” page 37

“MID 128 PPID 329 Aftertreatment Fuel Injector” page 37

“MID 128 PPID 330 DRV” page 38

“MID 128 PPID 337 Ash Level” page 39

“MID 128 PPID 387 Temperature Sensor, Catalytic Converter” page 39

“MID 128 PPID 436 Exhaust Gas Temperature Sensor 3” page 40

“MID 128 PPID 437 Aftertreatment Injector Fuel Pressure Sensor” page 41

14

Group 28 Troubleshooting

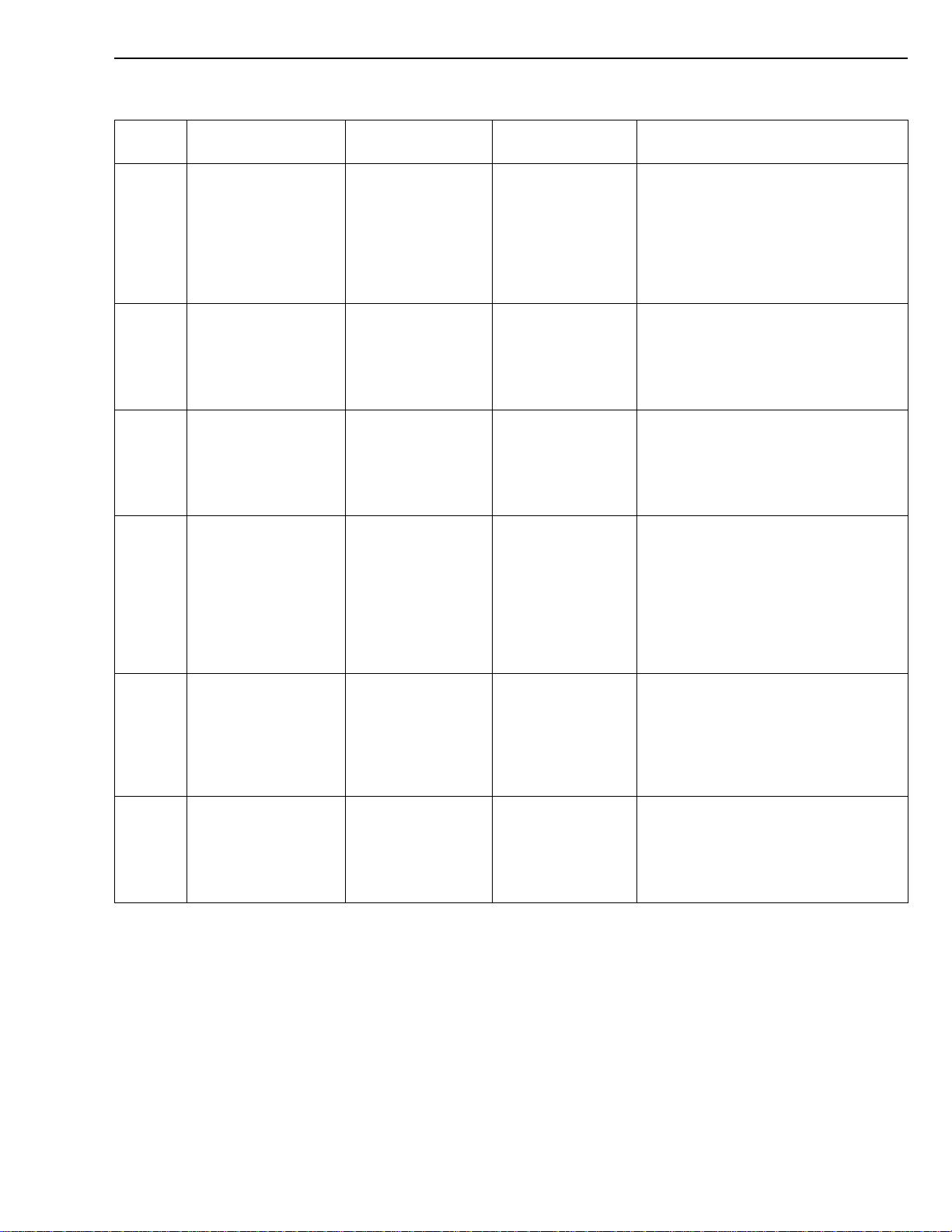

PSID

“MID 128 PSID 47 Particulate Trap Regeneration” page 42

“MID 128 PSID 98 Boost Air System” page 42

“MID 128 PSID 108 Aftertreatment Injection System” page 43

“MID 128 PSID 109 Engine Coolant Temperature Sensor” page 44

SID

“MID 128 SID 1/2/3/4/5/6 Unit Injector” page 45

“MID 128 SID 18 Drain Valve, Water Separator” page 46

“MID 128 SID 21 Engine Position Timing Sensor” page 47

“MID 128 SID 22 Engine Speed Sensor” page 48

“MID 128 SID 27 Variable Geometry Turbocharger” page 49

“MID 128 SID 33 Fan Control” page 50

“MID 128 SID 70 Preheater Element 1” page 50

“MID 128 SID 71 Preheater Element 2” page 51

“MID 128 SID 146 EGR Valve 1” page 51

“MID 128 SID 211 5 Volt DC Supply” page 52

“MID 128 SID 230 Idle Validation Switch 1” page 52

“MID 128 SID 232 5 Volt DC Supply to Sensor” page 53

D

15

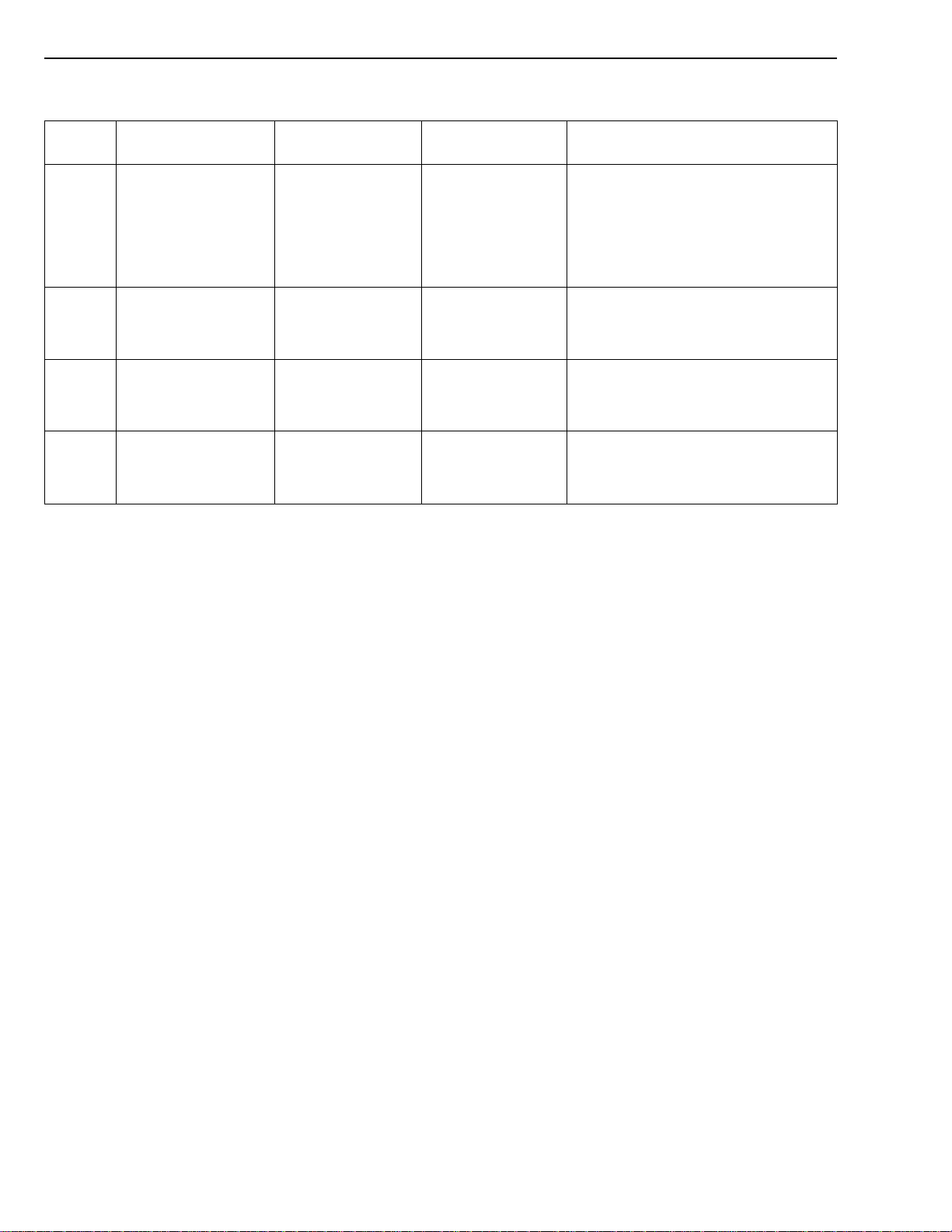

Group 28 Troubleshooting

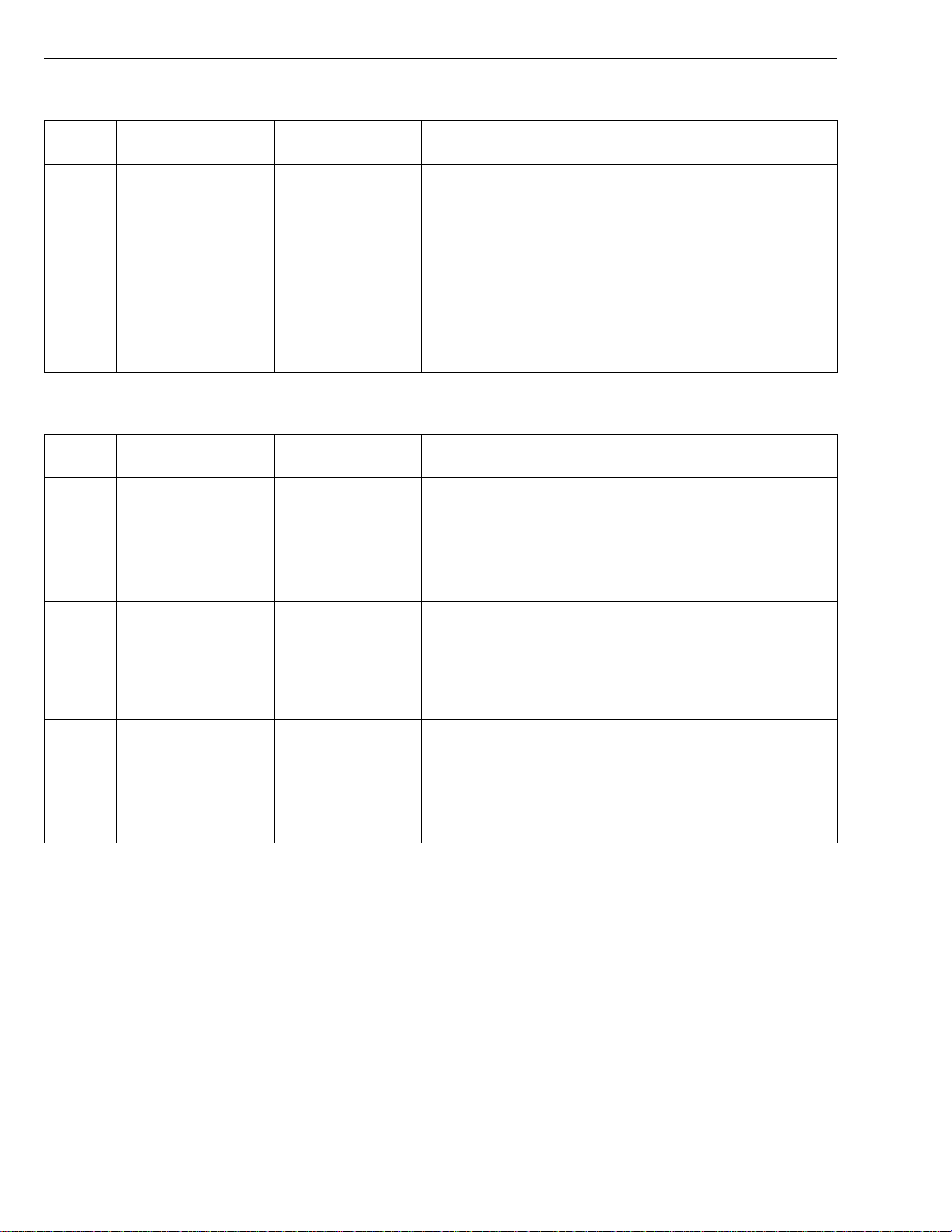

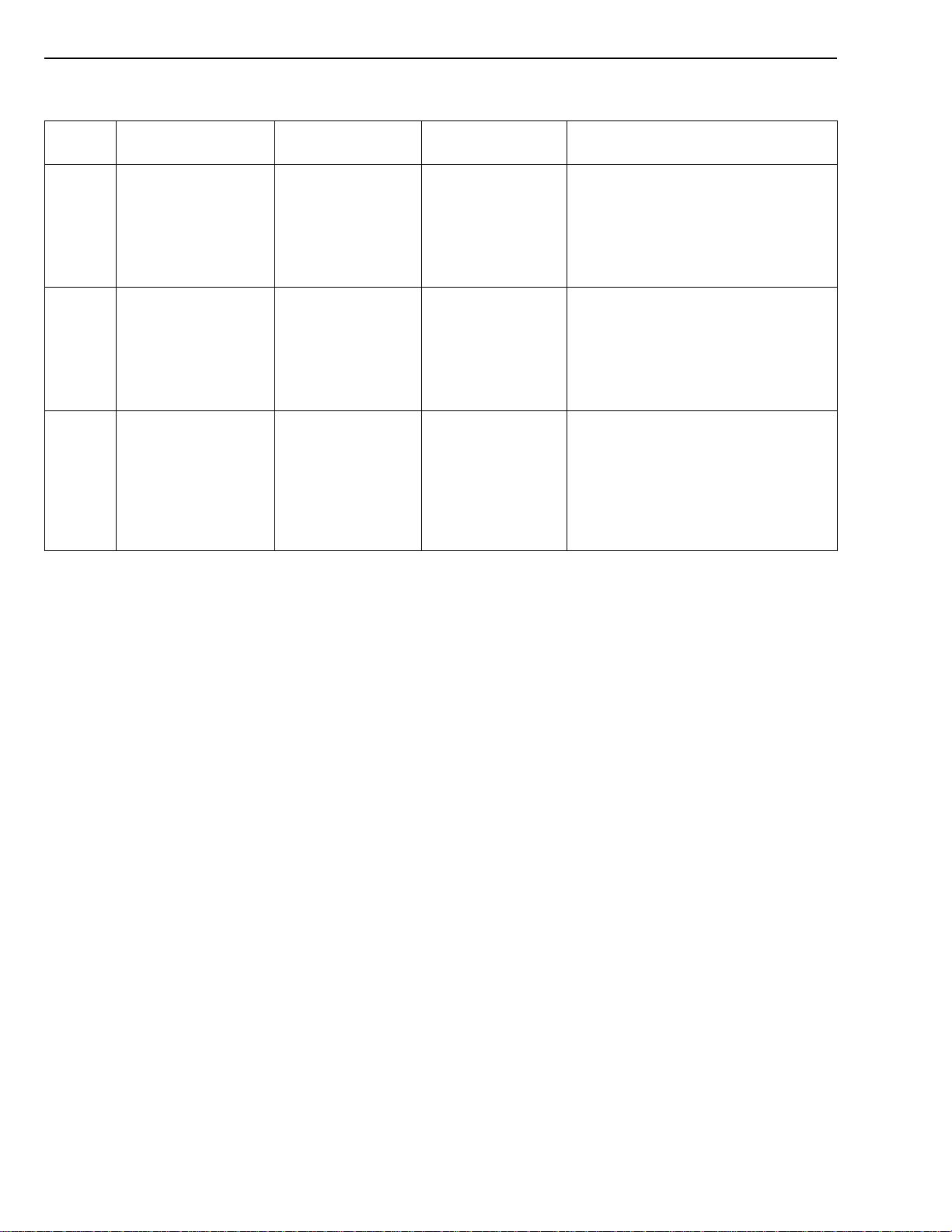

MID 128 PID 26 Fan Speed Percent

Type of

fault:

FMI 3

FMI Description:

Voltage above

•

normal or shorted

to high

Fault Condition:

Missing signal

•

from Fan Speed

Sensor

Short Circuit +,

•

Measuring line

Short Circuit -,

•

Measuring line

Open Circuit,

•

Measuring line

Open Circuit,

•

Ground line

MID 128 PID 45 Preheater Relay

Type of

fault:

FMI 3

FMI Description:

Voltage above

•

normal or shorted

to high

Fault Condition:

Short Circuit +,

•

Measuring line

Possible

Symptoms:

D

Higher fuel

•

consumption

Will work as

•

on/off fan,

100%fan speed

if cooling is

needed

Possible

Symptoms:

Preheat relay not

•

activated

White smoke for

•

cold start

Start problems in

•

cold climate

Possible Cause:

Cooling Fan Speed (CFS) sensor

•

failure

Faulty Cooling Fan Speed (CFS)

•

sensor harness

Possible Cause:

Preheat relay solenoid shorted

•

FMI 4

FMI 5

Voltage below

•

normal or shorted

low

Current below

•

normal or open

circuit

Short Circuit -,

•

Measuring line

Open Circuit

•

Induction air is

•

hot

Preheat relay

•

is impossible to

turn off

Preheat relay not

•

activated

White smoke for

•

cold start

Start problems in

•

cold climate

Faulty harness

•

Faulty Preheat relay

•

Faulty harness

•

16

Group 28 Troubleshooting

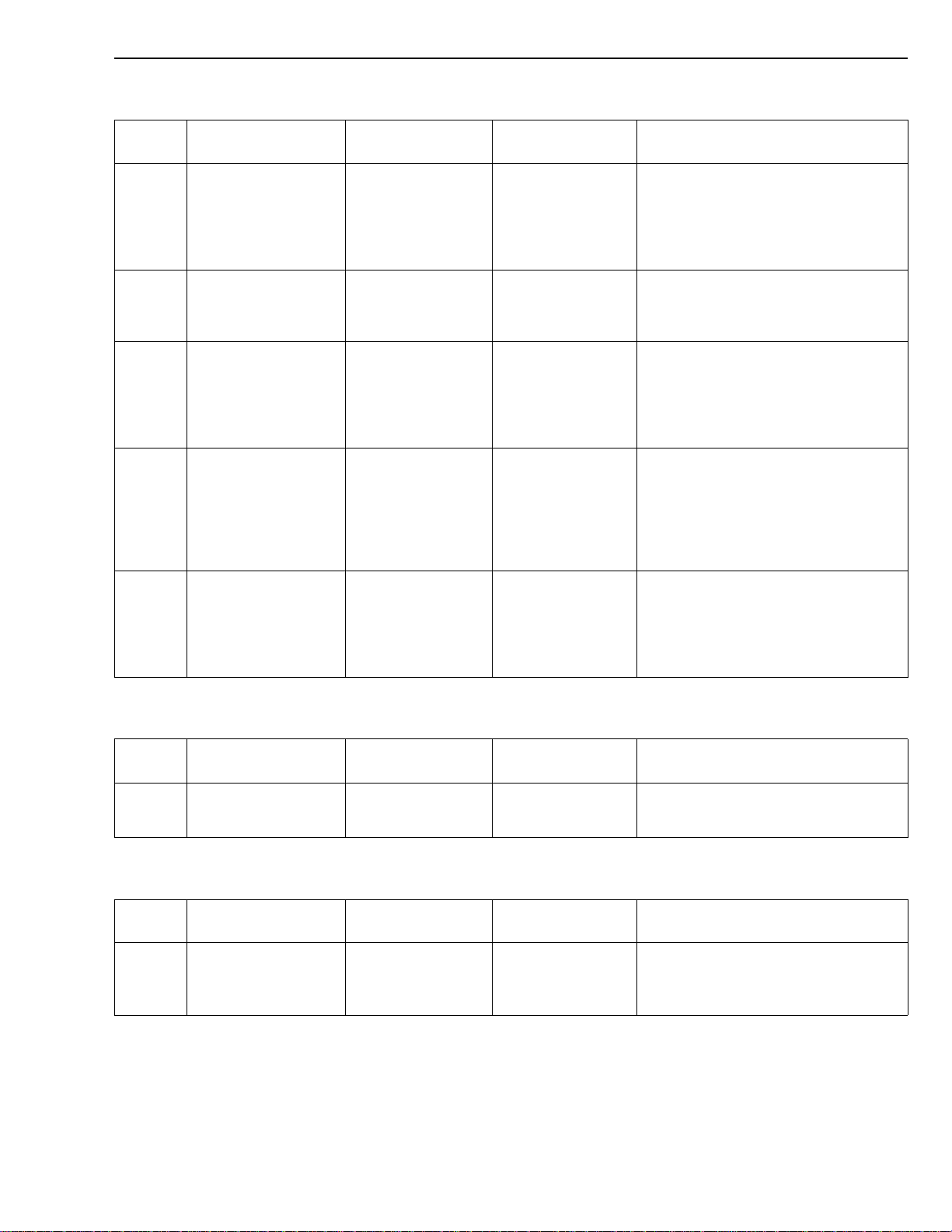

MID 128 PID 81 Particulate Filter

Type of

fault:

FMI 0

FMI 2

FMI 3

FMI 5

FMI Description:

Data valid but

•

above normal

operational

range-most severe

level

Data erratic,

•

intermittent or

incorrect

Voltage above

•

normal or shorted

high

Current below

•

normal or open

Fault Condition:

Moderately high

•

pressure

Sensor is not

•

rational

Short to battery

•

on the metering

side

Open in the

•

ground line

Open in 5 volt

•

supply line

Short to ground

•

in metering line

Open in metering

•

line

Possible

Symptoms:

D

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Malfunction

•

indicator lamp

illuminated

Malfunction

•

indicator lamp

illuminated

Malfunction

•

indicator lamp

illuminated

Possible Cause:

Particulate Trap Pressure (PTP)

•

Sensor failure

Particulate Trap Pressure (PTP)

•

Sensor failure

Particulate Trap Pressure (PTP)

•

Sensor failure

Faulty Particulate Trap Pressure

•

(PTP) Sensor connector

Faulty harness

•

Particulate Trap Pressure (PTP)

•

Sensor failure

Faulty harness

•

FMI 12

Bad intelligent

•

device or

component

Particulate Trap

•

Pressure (PTP)

Sensor signal

high or low but

still within range

Engine derate

•

MID 128 PID 84 Vehicle Speed

Type of

fault:

FMI 9

FMI Description:

Abnormal update

•

rate

Fault Condition:

Missing signal

•

from VECU

Possible

Symptoms:

Engine derate

•

MID 128 PID 85 Cruise Control Status

Type of

fault:

FMI 9

FMI Description:

Abnormal update

•

rate

Fault Condition:

Missing (Cruise

•

Control) signal

from VECU

Possible

Symptoms:

Cruise Control

•

does not work

Diesel Particulate Filter (DPF) is

•

damaged, filled with soot or missing

Possible Cause:

J1708 vehicle speed message does

•

not exist, (VECU error)

Possible Cause:

No clutch info to EMS (J1939)

•

17

Group 28 Troubleshooting

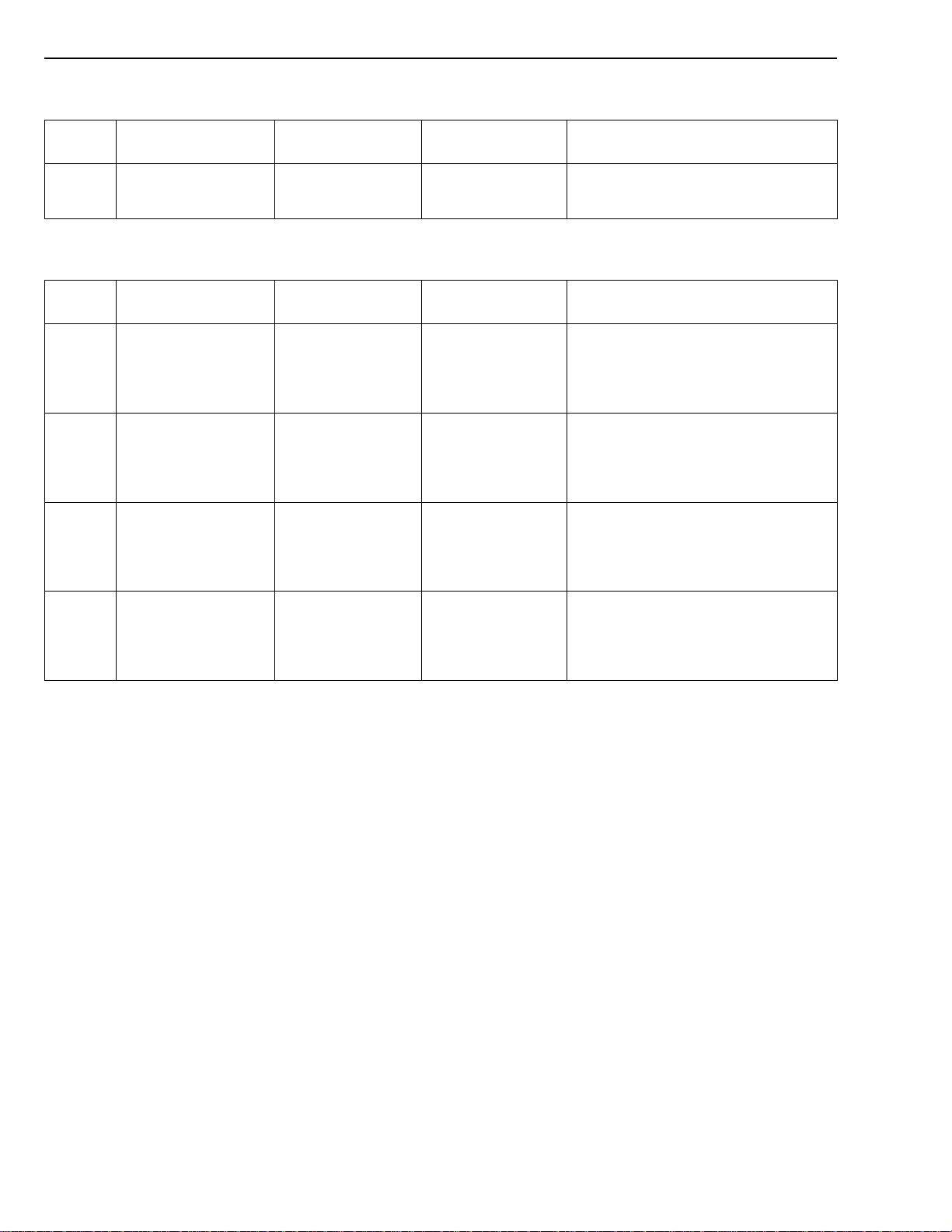

MID 128 PID 91 Accelerator Pedal Position

Type of

fault:

FMI 9

FMI Description:

Abnormal update

•

rate

Fault Condition:

Missing signal

•

from VECU

Possible

Symptoms:

D

N/A

•

MID 128 PID 94 Fuel Delivery Pressure

Type of

fault:

FMI 1

FMI 3

FMI 5

FMI Description:

Pressure critically

•

low

Voltage high/open

•

Current low/open

•

Fault Condition:

EMS module

•

detects a low fuel

pressure reading

Low Fuel

•

Pressure (FP)

Sensor signal

line voltage

Low Fuel

•

Pressure (FP)

Sensor signal

line voltage

Possible

Symptoms:

Rough idle

•

Uneven running

•

Engine derate

•

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Possible Cause:

J1708 pedal information not

•

available

Possible Cause:

A clogged fuel filter

•

Fuel leaking from a fuel line or fitting

•

Poor fuel pump pressure

•

Low fuel level

•

Damaged contacts in harness

•

Faulty Fuel Pressure (FP) sensor

•

Open circuit.

•

Damaged contacts in harness

•

Faulty Fuel Pressure (FP) sensor

•

FMI 7

Current low/open

•

Drop in fuel

•

pressure

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Clogged fuel filter

•

Leaking fuel line or fitting

•

Poor fuel pump response

•

18

Group 28 Troubleshooting

MID 128 PID 97 Water in Fuel Indicator

Type of

fault:

FMI 3

FMI 4

FMI Description:

Voltage high/open

•

Voltage low

•

Fault Condition:

N/A

•

N/A

•

D

MID 128 PID 98 Engine Oil Level

Type of

fault:

FMI 1

FMI Description:

Data valid but

•

below normal

operational range

Fault Condition:

Moderately

•

below range

Critically below

•

range

Possible

Symptoms:

Undetected

•

water in fuel

supply

Uneven running

•

Malfunction

•

indicator lamp

illuminated

Undetected

•

water in fuel

supply

Uneven running

•

Malfunction

•

indicator lamp

illuminated

Possible

Symptoms:

N/A

•

Possible Cause:

Open circuit

•

Short to ground

•

Open circuit

•

Faulty sensor

•

Possible Cause:

Low oil level Leakage

•

Critically low oil level Leakage

•

FMI 4

FMI 5

Voltage below

•

normal or shorted

low

Current below

•

normal or open

circuit

Short Circuit -

•

Positive side

Short Circuit +,

•

Positive side

Open Circuit +,

•

Positive side

Open Circuit-

•

Negative side

Oil level can not

•

be measured

Oil level can not

•

be measured

Engine Oil Level (EOL) sensor

•

failure

Faulty harness

•

Engine Oil Level (EOL) sensor

•

failure

Faulty harness

•

19

Group 28 Troubleshooting

MID 128 PID 100 Engine Oil Pressure

Type of

fault:

FMI 1

FMI 3

FMI 5

FMI Description:

Data valid but

•

below normal

operational range

Voltage below

•

normal or shorted

low

Current below

•

normal or open

circuit

Fault Condition:

Critically below

•

range

Short Circuit +,

•

Measuring line

Open Circuit,

•

Ground line

Open Circuit +,

•

5V Supply line

Short Circuit -,

•

Measuring line

Open Circuit,

•

Measuring line

Possible

Symptoms:

D

Engine derate

•

Low pressure

•

Oil pressure

•

shows 0 in the

cluster, engine is

running

Oil pressure

•

shows 0 in the

cluster, engine is

running

Possible Cause:

Oil leakage

•

Broken oil pump

•

Clogged oil system

•

Engine Oil Pressure (EOP) sensor

•

failure

Faulty harness

•

Engine Oil Pressure (EOP) sensor

•

failure

Faulty harness

•

20

Group 28 Troubleshooting

MID 128 PID 102 Intake Manifold Pressure

Type of

fault:

FMI 0

FMI 1

FMI 2

FMI 3

FMI Description:

Data valid but

•

above normal

operational range

Data valid but

•

below normal

operational range

Data erratic,

•

intermittent or

incorrect

Voltage above

•

normal or shorted

to high source

Fault Condition:

Intake Manifold

•

Pressure Sensor

output is high

Intake Manifold

•

Pressure is

indicating an

unphysical value

Intake Manifold

•

Pressure Sensor

is indicating an

unphysical value

Intake Manifold

•

Pressure Sensor

output is too high

or too low

A short to battery

•

in the metering

circuit

An open in

•

the ground

circuit of the

Intake Manifold

Pressure Sensor

Possible

Symptoms:

D

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Possible Cause:

Variable Geometry Turbo (VGT)

•

actuator stuck

Faulty Intake Manifold Pressure

•

Sensor harness

Intake Manifold Pressure Sensor

•

failure

Intermittent fault in the Intake

•

Manifold Pressure Sensor harness

Faulty Boost Air Pressure connector

•

Intake Manifold Pressure Sensor

•

failure

Intermittent fault in the Intake

•

Manifold Pressure Sensor harness

Faulty Boost Air Pressure connector

•

Intake Manifold Pressure Sensor

•

failure

Intermittent fault in the Intake

•

Manifold Pressure Sensor harness

Faulty Boost Air Pressure connector

•

Intake Manifold Pressure Sensor

•

failure

FMI 5

FMI 11

Current below

•

normal or open

circuit

Root cause not

•

known (Data

Incorrect)

A short to ground

•

in the harness

An open in the 5

•

volt supply circuit

An open in the

•

metering circuit

Intake Manifold

•

Pressure Sensor

output is too high

or low

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Intermittent fault in the Intake

•

Manifold Pressure Sensor harness

Faulty Boost Air Pressure connector

•

Intake Manifold Pressure Sensor

•

failure

Faulty Intake Manifold Pressure

•

Sensor harness

Inlet air leakage

•

Intake Manifold Pressure Sensor

•

failure

21

Group 28 Troubleshooting

MID 128 PID 103 Turbo Speed

Type of

fault:

FMI 0

FMI 1

FMI 9

FMI Description:

Data valid but

•

above normal

operational range

Data valid but

•

below normal

operational range

Abnormal update

•

rate (missing

sensor signal)

Fault Condition:

Turbocharger

•

speed is at least

25% greater than

the target wheel

speed for the

measured boost

Turbocharger

•

speed is at least

25% less than

the target wheel

speed for the

measured boost

A faultisloggedif

•

the Turbo Speed

Sensor signal is

lost

Possible

Symptoms:

D

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Possible Cause:

Miss detection

•

Faulty Turbo Speed Sensor harness

•

Faulty Turbo Speed Sensor

•

connector

Turbo Speed Sensor failure

•

Miss detection

•

Faulty Turbo Speed Sensor harness

•

Faulty Turbo Speed Sensor

•

connector

Turbo Speed Sensor failure

•

Communication fault in the metering

•

line of the Turbo Speed Sensor

circuit

Short to ground in the metering line

•

of the Turbo Speed Sensor circuit

An open in the metering line of the

•

Turbo Speed Sensor circuit

22

Group 28 Troubleshooting

MID 128 PID 105 Intake Manifold Temperature

Type of

fault:

FMI 0

FMI 1

FMI 2

FMI 4

FMI Description:

Data valid but

•

above normal

operational range

Data valid but

•

below normal

operational range

Data erratic,

•

intermittent or

incorrect

Voltage below

•

normal or shorted

low

Fault Condition:

The Intake

•

Manifold

Temperature

Sensor is

indicating an

unphysical value

The Boost

•

Temperature

Sensor is

indicating an

unphysical value

The Intake

•

Manifold

Temperature

Sensor output is

too high or too

low

N/A

•

Possible

Symptoms:

D

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Minor engine

•

derate

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Difficult to start

•

in cold climates

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Possible Cause:

Faulty Intake Manifold Temperature

•

Sensor or Engine Management

System (EMS) Module connector

Temperature Sensor harness

•

Malfunction Intake Manifold

•

Temperature Sensor

Faulty Intake Manifold Temperature

•

Sensor or Engine Management

System (EMS) Module connector

Break in the Intake Manifold

•

Temperature Sensor harness

Malfunction Intake Manifold

•

Temperature Sensor

Faulty Intake Manifold Temperature

•

Sensor or Engine Management

System (EMS) Module connector

Break in the Intake Manifold

•

Temperature Sensor harness

Malfunction Intake Manifold

•

Temperature Sensor

Short circuit

•

Intermittent fault in the Intake

•

Manifold Temperature Sensor

harness

Faulty Intake Manifold Temperature

•

Sensor connector

Intake Manifold Temperature Sensor

•

failure

FMI 5

FMI 10

Current below

•

normal or open

circuit

Abnormal rate of

•

change

A short to battery

•

An open in the 5

•

volt supply circuit

The Boost

•

Temperature

Senor output

is showing a

constant value

Difficult to start

•

in cold climates

Engine derate

•

Malfunction

•

indicator lamp

illuminated

Engine derate

•

Malfunction

•

indicator lamp

illuminated

A short circuit in the metering circuit

•

Intermittent fault in the Intake

•

Manifold Temperature Sensor

harness

Faulty Intake Manifold Temperature

•

Sensor connector

Intake Manifold Temperature Sensor

•

failure

Faulty Intake Manifold Temperature

•

Sensor harness

Intake Manifold Temperature Sensor

•

failure

23

Group 28 Troubleshooting

MID 128 PID 108 Atmospheric Pressure

Type of

fault:

FMI 2

FMI 3

FMI 4

FMI Description:

Data erratic,

•

intermittent or

incorrect

Voltage above

•

normal or shorted

to high source

Voltage below

•

normal or shorted

to low source

Fault Condition:

Atmospheric

•

Pressure Sensor

output is too

high or too low

(abnormal value)

Short to battery

•

on the metering

side

A short to ground

•

on the metering

side

Possible

Symptoms:

D

Minor engine

•

derate

N/A

•

N/A

•

Possible Cause:

FaultyAtmosphericPressureSensor

•

Faulty Engine Management System

•

(EMS) Module

Internal fault in the Engine

•

Management System (EMS) Module

FaultyAtmosphericPressureSensor

•

Internal fault in the Engine

•

Management System (EMS) Module

FaultyAtmosphericPressureSensor

•

24

Group 28 Troubleshooting

MID 128 PID 110 Coolant Temperature

Type of

fault:

FMI 0

FMI 2

FMI 4

FMI Description:

Data valid but

•

above normal

operational range

Data erratic,

•

intermittent or

incorrect

Voltage below

•

normal or shorted

low

Fault Condition:

The Engine

•

Coolant

Temperature

(ECT) Sensor

is indicating an

unphysical value

The Engine

•

Coolant

Temperature

(ECT) Sensor

output is too high

or too low

N/A

•

Possible

Symptoms:

D

Malfunction

•

indicator lamp

illuminated

May affect

•

driveability in

extreme cases

Malfunction

•

indicator lamp

illuminated

Difficult to start

•

in cold climates

Idle run

•

regulation is

deteriorated

Malfunction

•

indicator lamp

illuminated

Possible Cause:

Extreme driving condition

•

Faulty coolant thermostat

•

Malfunctioning fan

•

Blocked radiator

•

Faulty Engine Coolant Temperature

•

(ECT) Sensor or Engine

Management System (EMS)

Module connector

Break in Engine Coolant

•

Temperature (ECT) Sensor

harness

Malfunctioning Engine Coolant

•

Temperature (ECT) Sensor

Internal fault in the Engine Coolant

•

Temperature (ECT) Sensor harness

Faulty Engine Coolant Temperature

•

(ECT) Sensor connector

Faulty Engine Coolant Temperature

•

(ECT) Sensor

FMI 5

FMI 10

Current below

•

normal or open

circuit

Abnormal rate of

•

change

N/A

•

The Engine

•

Coolant

Temperature

(ECT) Sensor

output is showing

a constant value

Difficult to start

•

in cold climates

Idle run

•

regulation is

deteriorated

Malfunction

•

indicator lamp

illuminated

May affect

•

vehicle

driveability

An open in the Engine Coolant

•

Temperature (ECT) Sensor circuit

An open in the Engine Coolant

•

Temperature (ECT) Sensor

Intermittent fault in the Engine

•

Coolant Temperature (ECT) Sensor

Faulty Engine Coolant Temperature

•

(ECT) Sensor connector

Faulty Engine Coolant Temperature

•

(ECT) Sensor

Faulty Engine Coolant Temperature

•

(ECT) Sensor harness

Engine Coolant Temperature (ECT)

•

Sensor failure

25

Group 28 Troubleshooting

MID 128 PID 111 Coolant Level

Type of

fault:

FMI 1

FMI 3

FMI 4

FMI 5

FMI Description:

Data valid but

•

below normal

operational range

Voltage above

•

normal or shorted

to high source

Voltage below

•

normal or shorted

low

Current below

•

normal or open

circuit

Fault Condition:

Moderately

•

below range

Critically below

•

range

Short Circuit -,

•

Measuring line

Short Circuit +

•

Measuring line

Short Circuit -,

•

Measuring line

Open Circuit

•

Possible

Symptoms:

D

Engine derate

•

Coolant level can

•

not be detected

Coolant level can

•

not be detected

Coolant level can

•

not be detected

Possible Cause:

Coolant level below range

•

Faulty harness

•

Engine shutdown

•

Faulty harness

•

Faulty harness

•

Faulty harness

•

26

Group 28 Troubleshooting

MID 128 PID 153 Crankcase Pressure

Type of

fault:

FMI 0

FMI 1

FMI 2

FMI 3

FMI 5

FMI Description:

Data valid but

•

above normal

operational range

Data valid but

•

below normal

operational range

Data erratic,

•

intermittent or

incorrect

Voltage above

•

normal or shorted

to high source

Current below

•

normal or open

circuit

Fault Condition:

Out of range,

•

max voltage,

illegal

Critically Above

•

Range

Out of range, min

•

voltage, illegal

Plausibility

•

Short Circuit +,

•

Measuring line

Open Circuit,

•

Ground line

Open Circuit +,

•

5V Supply Line

Short Circuit -,

•

Measuring line

Open Circuit,

•

Measuring line

Possible

Symptoms:

D

Forced idle

•

Engine shut

•

down

N/A

•

N/A

•

N/A

•

N/A

•

Possible Cause:

The non-filtered pressure difference

•

(between crankcase pressure and

ambient air pressure) is/was above

limit. (The fault code will remain

during the entire driving cycle

(unless reset)

Crankcase Pressure Sensor out of

•

range

The crankcase pressure is showing

•

either too high or too low value

(abnormal value)

Crankcase Pressure Sensor failure

•

Faulty harness

•

Crankcase Pressure Sensor failure

•

Faulty harness

•

27

Group 28 Troubleshooting

MID 128 PID 171 Ambient Temperature

Type of

fault:

FMI 9

FMI Description:

Abnormal Update

•

Rate

Fault Condition:

This fault will

•

become active

when the Engine

Management

System (EMS)

Module detects

that the Ambient

Air Temperature

message from

the Instrument

Cluster Module

does not exist.

Possible

Symptoms:

D

Malfunction

•

indicator lamp

illuminated

MID 128 PID 173 Exhaust Temperature

Type of

fault:

FMI 0

FMI Description:

Data valid but

•

above normal

operational range

— most severe

level

Fault Condition:

Exhaust Gas

•

Temperature is

too high

Possible

Symptoms:

Engine derate

•

Poor driveability

•

Possible Cause:

Faulty Ambient Air Temperature

•

Sensor harness

Possible Cause:

Faulty Exhaust Gas Temperature

•

(EGT) system

Faulty harness or connector

•

FMI 2

FMI 4

FMI 5

FMI 10

Data erratic,

•

intermittent or

incorrect

Voltage below

•

normal or shorted

low

Current below

•

normal or open

circuit

Abnormal rate of

•

change

Sensor is not

•

rational

Short to ground

•

on the metering

side of the circuit

Short to battery

•

on the metering

side of the circuit

Open in the

•

metering side of

the circuit

Open in the

•

ground side of

the circuit

Sensor is stuck

•

Poor driveability

•

Poor driveability

•

Poor driveability

•

Poor driveability

•

Harness connected to incorrect

•

sensor

Sensor failure

•

Sensor failure

•

Faulty harness

•

Faulty harness

•

Sensor failure

•

Sensor failure

•

28

Loading...

Loading...