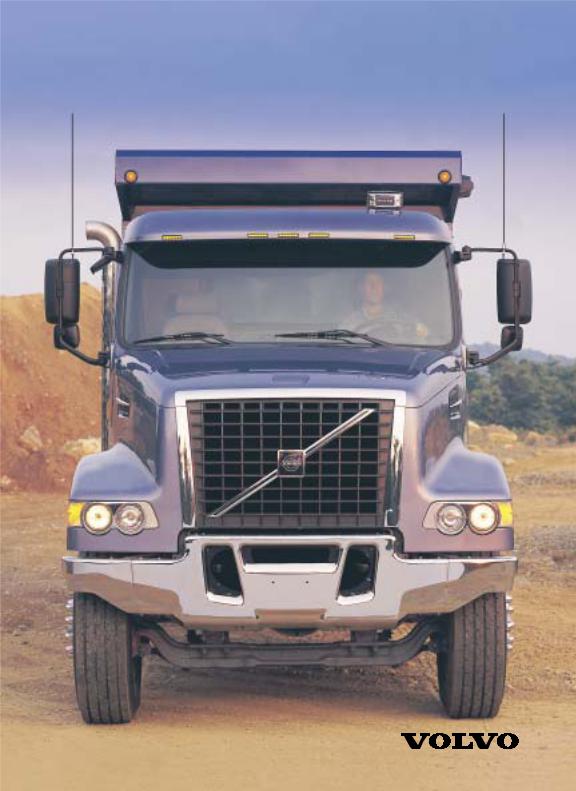

Volvo VHD User Manual

OPERATOR’S MANUAL VHD

New Roads.TM

Foreword

This manual contains information concerning the safe operation of your vehicle. It is extremely important that this information is read and understood before the vehicle is operated. This manual also contains a considerable amount of information concerning the vehicle, such as vehicle identification, Preventive Maintenance recommendations and a log for your service records. Please keep this in the vehicle at all times. Information from other component manufacturers is supplied in separate manuals in the Owner’s Package.

NOTE! It is important that this manual stays with the vehicle when it is sold. Important safety information must be passed on to the new customer. The service information contained in this manual gives the owner important information about maintaining the vehicle but is not intended as a substitute for the Preventive Maintenance Service Manual and must not be regarded as such.

The National Highway Traffic Safety Administration (NHTSA) and Volvo Trucks North America, Inc. should be informed immediately if you believe that the vehicle has a defect that could cause a crash, injury or death.

Contact NHTSA by calling the Auto Safety Hotline at 1 (800) 424– 9393 (or 366–0123 in the Washington, DC area) or by writing to: NHTSA, U.S. Department of Transportation, Washington, DC 20590.

Volvo Trucks North America, Inc.

Greensboro, NC USA

Order number: PV776-20 139484

© 2000 Volvo Trucks North America, Inc., Greensboro, NC USA

All rights reserved. No part of this publication may be reproduced, stored in retrieval system, or transmitted in any forms by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Volvo Trucks North America, Inc..

Contents

General Information ............................. |

|

1 |

Information For the Owner ................... |

|

1 |

General Safety Information .................. |

|

3 |

Modifications to Vehicle ....................... |

|

7 |

Exhaust and Noise Emissions ............... |

|

8 |

Vehicle Data ........................................ |

|

16 |

Vehicle Access ...................................... |

|

19 |

Cab Doors and Door Lock ................. |

|

19 |

Cab Entry and Exit ............................. |

|

21 |

Hood .................................................... |

|

26 |

Pre-Trip Inspection and Daily Mainte- |

||

nance ..................................................... |

|

28 |

General ................................................ |

|

28 |

Pre-Trip Inspection Quick List ........... |

|

29 |

Daily Maintenance .............................. |

|

41 |

Additional Safety Features ................. |

|

46 |

Safety Belts ......................................... |

|

46 |

SRS Airbag ......................................... |

|

55 |

Safety Equipment ................................ |

|

62 |

VORAD Collision Warning System |

... 63 |

|

Instruments and Controls ................... |

|

64 |

Dash Overview .................................... |

|

64 |

Instrument Cluster Overview .............. |

|

65 |

Telltale Overview ................................ |

|

66 |

Graphic Display Telltale Overview |

.... |

67 |

Left Instrument Section ...................... |

|

68 |

Main Instrument Section ..................... |

|

76 |

Right Instrument Section .................... |

|

83 |

Changing Telltale Bulbs In Cluster |

.... |

89 |

Steering Column Switches .................. |

|

91 |

Left Switch Cluster ............................. |

|

94 |

Driving Light Switches ....................... |

|

98 |

Right Switch Cluster ......................... |

|

100 |

Pneumatic Switch Cluster ................. |

|

104 |

Optional Switch Cluster .................... |

106 |

|

Miscellaneous Switches .................... |

|

107 |

Graphic Display ................................. |

|

108 |

Graphic Display Overview ............... |

|

108 |

Graphic Display Controls ................. |

|

109 |

Graphic Display Telltales .................. |

|

111 |

Information and Stop Messages ....... |

|

112 |

Information Telltale ........................... |

|

113 |

Stop Telltale ...................................... |

|

120 |

Acknowledge Information and Stop |

|

|

Messages ........................................... |

|

124 |

Main Menu: Set-Up Mode ............... |

|

126 |

Main Menu: System Diagnostic ....... |

|

131 |

Main Menu: Data Log Mode (Volvo |

|

|

Engine Only) ..................................... |

|

146 |

Main Menu: Password Input ............ |

|

152 |

Main Menu: Gauge ........................... |

|

153 |

Main Menu: Fuel Economy (option) |

157 |

|

Main Menu: Time/Distance .............. |

|

159 |

Main Menu: FAULTS? ..................... |

|

164 |

Heating and Air Conditioning ......... |

|

168 |

General .............................................. |

|

168 |

Climate Unit Main Control Panel |

.... 169 |

|

Cab Ventilation .................................. |

|

177 |

Cab Air Filter .................................... |

|

178 |

A/C Diagnostic Module .................... |

|

179 |

Seats ..................................................... |

|

180 |

General .............................................. |

|

180 |

National Standard Seat Adjustments |

181 |

|

Volvo Standard Seat Adjustments |

.... 182 |

|

National Stationary Seat ................... |

|

183 |

Cab Interior ....................................... |

|

184 |

Interior/Reading Lights ..................... |

|

184 |

Communication and Entertainment |

187 |

|

Antennas ............................................ |

|

187 |

Stereo/Radio ...................................... |

188 |

Communication Equipment .............. |

189 |

Fuel Economy Driving ...................... |

190 |

Fuel Economy ................................... |

190 |

Engine Start and Operation ............. |

197 |

Starting the Engine ........................... |

197 |

Cold Weather Start and Operation |

... 202 |

Engine Operation .............................. |

209 |

Cruise Control ................................... |

218 |

Fuel Tank(s) ...................................... |

220 |

Clutch and Transmission .................. |

222 |

Clutch ................................................ |

222 |

Brakes ................................................. |

223 |

Brakes ................................................ |

223 |

Electrical System ............................... |

244 |

Electrical System ............................... |

244 |

Power Steering ................................... |

256 |

General .............................................. |

|

256 |

Axles and Wheels ............................... |

|

258 |

Axles .................................................. |

|

258 |

Wheels ............................................... |

|

261 |

Fifth Wheel Instructions ................... |

|

264 |

Fifth Wheel General Information |

..... |

264 |

Fifth Wheel ....................................... |

|

265 |

Fifth Wheel Slider (option) .............. |

|

267 |

Unlocking the Fifth Wheel ............... |

|

268 |

Trailer Coupling Procedures ............. |

|

270 |

Trailer Uncoupling Procedures ......... |

|

275 |

Operating the Fifth Wheel Slider |

..... |

280 |

Emergency Information .................... |

|

282 |

Towing Procedure ............................. |

|

282 |

Service Information ........................... |

|

287 |

Service Assistance and Manuals ...... |

|

287 |

Index .................................................... |

|

289 |

Warning Label Information

IMPORTANT

Before driving this vehicle, be certain that you have read and that you fully understand each and every step of the driving and handling information in this Operator’s Manual. Be certain that you fully understand and follow all safety warnings. It is extremely important that this information is read and understood before the vehicle is operated.

IT IS IMPORTANT THAT THE FOLLOWING INFORMATION CONCERNING LABELS BE READ, UNDERSTOOD AND ALWAYS FOLLOWED.

The following types of labels are used throughout this manual:

NOTE! A note defines an operating procedure, practice, condition, etc., which is essential to proper operation of the vehicle.

CAUTION

CAUTION

A caution label directs the operator’s attention to unsafe practices where personal injury is not likely but property damage could occur. The caution label is in black type on a white background with a black border.

WARNING

WARNING

A warning label directs the operator’s attention to unsafe practices which could result in personal injury or severe damage to the vehicle. The warning label is in black type on a gray background with a black border.

A danger label directs the operator’s attention to unsafe practices which could result in serious personal injury or death. The caution label is in white type on a black background with a black border.

General Information 1

Information For the Owner

If there are questions on the maintenance and performance of your vehicle, please discuss them with your Volvo Truck dealer. Your authorized dealer is required to have trained mechanics, special tools and spare parts to fully service your vehicle. If necessary, your dealer will contact the manufacturer for any assistance.

In addition to this Operator’s Manual, there may be additional instruction/operator’s manuals supplied by component manufacturers. These manuals are placed in the Owner’s Package and placed in the cab. Be sure to read all the manuals thoroughly before operating the vehicle.

Also, various safety labels may be placed on components by the component manufacturer. Be sure to read and follow these labels to prevent damage to the vehicle, personal injury or even death.

Information in this manual refers to Volvo components and Volvo drivetrain. Information concerning non-Volvo engines and/or drivetrains can be obtained by contacting the respective manufacturer.

Establish a Preventive Maintenance Program with the help of your local Volvo Truck dealer. A Preventive Maintenance Program makes it possible to maximize the amount of time your vehicle is up and running, resulting in longer component life. This makes for a safer vehicle by reducing any mechanical failures due to poor maintenance practices.

Various truck warranty coverage plans, contingent on application and weight class, are available. Please contact an authorized Volvo Truck Dealer for complete details. Replacement warranty certificates for Volvo Trucks are available from Volvo dealers.

For trucks placed in service after August 1, 2000 and operating in the USA and Canada, Volvo dealers can print copies of the Standard Truck Warranty Certificate and the Premium (Purchased) Truck Coverage Certificate. Copies are available in either English or Canadian French at the dealer communication system (DCS) website. Look in the Service/Warranty folder.

NOTE! Federal law requires manufacturers to notify owners of its products in the event of a non-compliance to a Federal Motor Vehicle Safety Standard or if a safety related defect is discovered. If you are not the original owner of this vehicle, please notify us about the change in ownership at the address below or through an authorized Volvo Truck dealer. This is the only way we will be able to contact you if necessary.

Volvo Trucks North America, Inc.

Att: Vehicle Registration dept.

P. O. Box 26115

Greensboro, NC 27402–6115

United States of America

2 General Information

Do Not Remove this manual from the vehicle. It contains important operational and safety information that is needed by all drivers and owners of this vehicle.

This Operator’s Manual covers Volvo VHD-series vehicles manufactured by Volvo Trucks North America, Inc. with any of the following designations:

VHD42 VHD64 VHD84 VHD104

VHD124 VHD42T VHD64T VHD84T

T=tractor, F=forward position axle B=back position axle

Explanation: The first number after the model designation (4, 6, 8, 10 or 12) represents the total number of wheels (hubs) per vehicle. The last number (2 or 4) represents the number of wheels (hubs) that drive the vehicle.

This manual, together with manuals for specific components, for example, Volvo engine, Cummins engine, Eaton transmission, etc., contain important information for you to be able to operate this vehicle safely. They contain advice and instructions which will enable you to get the operating economy and performance that you expect from this quality vehicle.

All information, illustrations and specifications contained in this manual are based upon the latest product information available at the time of publication. If any questions arise concerning the current status of Federal or state laws, the appropriate Federal or state agency should be contacted.

Volvo Trucks North America, Inc. reserves the right to make changes at any time or to change specifications or design without notice and without incurring obligation.

W8002807

Back position axle

W0001920

Forward position axle

General Information 3

General Safety Information

Operating the Vehicle

Every vehicle, including heavy duty vehicles, has blind spots. The size of blind spots varies from driver to driver and from situation to situation. As a skilled, professional driver, you are in the best position to avoid accidents in turns, lane changes or other maneuvers. Volvo Trucks North America, Inc. provides standard equipment (such as cabs, windshields, window sizes and mirrors), preferred by most owners and drivers under most conditions and in most applications.

However, due to differences in the size of drivers, their seating positions, the way that they use and operate their vehicles, personal preferences and other factors, no combination of mirrors and other visibility enhancement devices will eliminate all blind spots in every situation.

The safe operation of this vehicle is up to you. Because of your special preferences, needs and circumstances, you may want to add extra mirrors and/or other visibility enhancement devices. If so, you should contact an authorized Volvo Truck dealer to obtain those parts which best fit your own personal needs and preferences.

WARNING

WARNING

All items within the cab must be secured before the vehicle is set in motion. This includes, but is not limited to, drinks, clothes, books, televisions, etc. In the event of a collision, loose items could fly around inside the cab. This could cause personal injury.

Never try to operate or work on this vehicle while under the influence of alcohol. Your reflexes can be affected by even a small amount of alcohol. Drinking and operating this vehicle can lead to an accident, causing serious personal injury or death.

4 General Information

Operating In Bobtail Mode

Tractors are equipped with a bobtail air brake proportioning valve which automatically redistributes the braking force between front and rear axles when not hooked up to a semitrailer (bobtail operation).

When operating in bobtail mode, the rear brake chambers receive reduced or proportional brake air pressure. When the tractor is towing a trailer, the rear brake chambers will receive full (normal) brake pressure.

NOTE! When operating bobtail, be certain that glad hands, trailer air hoses, electrical cable and connectors are properly stowed and secure. Do not allow them to rub or chafe on other components.

WARNING

WARNING

When operating bobtail, the brake system on the vehicle reduces the possibility of rear wheel brake lockup, except on full pedal application. When bobtailing, be certain that adequate pedal pressure is applied. There is no need to reduce pedal effort. Failure to do so may result in increased stopping distances.

General Information 5

Do Not Overload

This vehicle has been designed and assembled for a maximum gross vehicle weight rating (GVWR) and a maximum front and rear axle weights rating (FAWR and RAWR). The actual rating for this vehicle can be found on the label attached to the door frame on the driver’s side. If any of these three ratings is exceeded and overloading occurs, instability, poor handling, failure of parts and accelerated wear can occur.

Under no circumstances should the published GVWR, FAWR, and/or RAWR be exceeded. Failure to observe these precautions can lead to the loss of vehicle control, resulting in a crash causing serious personal injury or death.

W0001210

Do not exceed the load rating of the tires or the vehicle weight ratings. Overloading may result in tire failure causing loss of vehicle control, leading to an accident resulting in severe personal injury or death.

Operating

Before driving this vehicle, locate the instruments and controls, and become thoroughly familiar with their operation. After starting and when driving, always check to make sure that the instrument readings are normal.

6 General Information

Reporting Safety Defects

USA

The National Highway Traffic Safety Administration (NHTSA) and Volvo Trucks North America, Inc. should be informed immediately if you believe that the vehicle has a defect that could cause a crash, injury or death.

Contact NHTSA by calling the Auto Safety Hotline at 1 (800) 424–9393 (or 366–0123 in the Washington, DC area) or by writing to: NHTSA, U. S. Department of Transportation, Washington, DC 20590.

Canada

Refer consumer complaints to Volvo Trucks Canada, Inc. or to the Transport Canada - Department of Public Complaints, Recalls and Investigations.

Mexico

Volvo Trucks of Mexico, S.A. de C.V. should be informed immediately if you believe the vehicle has a defect that could cause a crash, injury or death. Contact Volvo Trucks de Mexico by calling or by writing to: Volvo Trucks de Mexico, S.A. de C.V., Prol. Paseo de la Reforma 600, 1er. Piso — 121, Col. Santa Fe Peña Blanca, C.P. 01210, México, D.F.

NOTE! For a listing of other contacts for information or help, see page 287.

1 (800) 424-9393

1 (905) 795-1555

01 (800) 90 94 900

General Information 7

Modifications to Vehicle

Chassis Frame

Frame side rails are heat treated. No welding is permitted because structural failure may result. Do not drill through either top or bottom flanges. A warning label is also attached to the frame for information.

Drilling is permitted in the frame web in accordance with a specified hole spacing pattern. Consult a Volvo Truck dealer to obtain approved hole spacing dimensions or refer to the Frame Rail and Cross Member Service Manual.

Frame rail and cross member nuts and bolts should be checked periodically and tightened to the specified torque if necessary.

Frame Alterations

Under no circumstances can the frame be cut and an extension piece added to increase the wheelbase. The only alteration allowed is wheel base shortening, where the only change in the frame rail is a new hole pattern drilled for the new location of the rear suspension.

Welding In Vehicle

Do not weld anywhere in or on the vehicle before disconnecting batteries, all electronic control units (ECU) and instrument cluster. See page 249 for more information. Do not use oxy/acetylene welding to repair cab panels. Refer to the service manuals for specific information.

W7001174

WARNING

WARNING

Do not weld on any part of the frame or drill holes in the top or bottom flanges. Serious structural damage could occur.

8 General Information

Exhaust and Noise Emissions

General

USA

The Federal Clean Air Act, Section 203 (a) (3), states the following concerning the removal of air pollution control devices or modification of a certified engine to a noncertified configuration:

“The following acts and the causing thereof are prohibited:

(3) For any person to remove or render inoperative any device or element of design installed on or in a motor vehicle or motor vehicle engine in compliance with regulations under this part prior to its sale and delivery to the ultimate purchaser, or for

any manufacturer or dealer knowingly to remove or render inoperative any such design after sale and delivery to the ultimate purchaser.”

Specifically, please note that no person may make such changes prior to the sale and delivery of the vehicle to the ultimate purchaser, and, in addition, no manufacturer or dealer may take such action after sale and delivery of the vehicle to the ultimate purchaser. The law provides a penalty of up to $10, 000 for each violation.

Canada

The same conditions that apply in the USA apply to Canada, with one exception. After the vehicle is sold to a retail customer, that is, the end user, the jurisdiction controlling the emission control devices becomes the province in which the vehicle is licensed. No changes should be made that render any or all of the devices inoperative.

Should the owner/operator wish to make any changes to the emission control devices, check with the provincial authority before making any such changes.

Mexico

The same conditions that apply in the USA apply to Mexico. Refer to the Mexican Federal Law for Emission Control which adheres to EPA regulations. No changes should be made that render any or all of the emissions control devices inoperative.

Should the owner/operator wish to make any changes to the emission control devices, check with the state authority before making any such changes.

General Information 9

California Emission Control Warranty Statement

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Volvo Trucks North America , Inc. (VTNA) are pleased to explain the emission control system warranty on your vehicle. In California, new motor vehicles must be designed, built and equipped to meet the State’s stringent anti-smog standards. Volvo Trucks North America, Inc. must warrant the emission control system on your vehicle for the periods of time listed listed below provided there has been no abuse, neglect or improper maintenance of your vehicle.

Your emission control system may include parts such as carburetor or fuel injection system and engine computer. Also included may be hoses, belts, connectors and other emissionrelated assemblies.

Where a warrantable condition exists, Volvo Trucks North America, Inc. will repair your vehicle at no cost to you including diagnosis, parts and labor.

MANUFACTURER’S WARRANTY COVERAGE

This warranty is applicable for a period of five years, 100 000 miles or 3 000 hours of operation, whichever first occurs. If an emission-related part of your vehicle is defective, the part will be repaired or replaced by Volvo Trucks North America, Inc.

This is your emission control system DEFECTS WARRANTY.

OWNER’S WARRANTY RESPONSIBILITIES

As the vehicle owner, you are responsible for the performance of the required maintenance listed in your owner’s manual. Volvo Trucks North America, Inc. recommends that you retain all receipts covering maintenance on your truck but Volvo Trucks North America, Inc. cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

You are responsible for presenting your vehicle to a Volvo Trucks North America, Inc. dealer as soon as a problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

As the vehicle owner, you should also be aware that Volvo Trucks North America, Inc. may deny you warranty coverage if your vehicle or a part has failed due to abuse, neglect, improper maintenance or unapproved modifications.

If you have any questions regarding your warranty rights and responsibilities, you should contact Volvo Trucks North America, Inc., Warranty Administration, (336) 393-2000 or the California Air Resources Board at 9480 Telstar Avenue, El Monte, CA 91731.

10 General Information

EMISSION CONTROL SYSTEM WARRANTY

Volvo Trucks North America, Inc. WARRANTS TO THE ORIGINAL OWNER, AND EACH SUBSEQUENT OWNER, OF A NEW TRUCK POWERED BY A VOLVO DIESEL ENGINE THAT THE EMISSION CONTROL SYSTEM OF YOUR TRUCK:

1Is designed, built and equipped so as to conform at the time of sale to all regulations of the U.S. Environmental Protection Agency and the California California Air Resources Board applicable at the time of the manufacture; and

2Is free from defects in material and workmanship which will cause the emission control components not to function as designed for a period of use of 5 years or 100 000 miles or 3 000 hours of engine operation, whichever comes first.

The 5 years/100 000 miles/3 000 hour warranty period shall begin on the date the vehicle is first delivered to the first retail purchaser or if the vehicle is placed in service as a demonstrator company vehicle prior to the sale at retail, on the date the vehicle is the first placed in service.

The emission control system of your new Volvo engine was designed, built and tested using genuine Volvo parts, and the engine is certified as being in conformity with Federal and California emission control regulations. Accordingly, it is recommended that any replacement parts used for maintenance, replacement or repair without invalidating this warranty; the cost of such services or or parts, however, will not be covered under the warranty except in an emergency situation. A part not being available or a repair not being completed within 30 days also constitutes an emergency.

Use of replacement parts which are not of equivalent quality may impair the effectiveness of emission control systems. If other than Volvo parts are used for maintenance, owner should obtain assurances that suck parts are warranted by their manufacturer to be equivalent to genuine Volvo parts. However, the use of other than Volvo replacement parts does not invalidate the warranty on other components, unless such parts cause damage to warranted parts.

Repairs and service covered by the warranty will be performed by an authorized Volvo Trucks North America, Inc. dealer at his place of business with no charge for parts or labor (including diagnosis) using Volvo parts for the emission control system, that requires replacement and is covered by the warranty and found defective. In case of an emergency, where an authorized Volvo Trucks North America, Inc. dealer is not available, repairs may be performed at any available service establishment or by the owner, using any equivalent replacement parts and Volvo Trucks North America, Inc. will reimburse the owner for such repairs (including diagnosis) not to exceed Volvo Trucks North America, Inc’s suggested retail retail price for the warranted parts and the labor rate appropriate for the geographical area and the tasks performed.

Replaced parts and paid invoices must be presented to a Volvo Trucks North America, Inc. dealer for reimbursement.

General Information 11

The emissions control parts covered by this Emission Control System Warranty are listed under "What Is Covered by the Emissions Warranty." You are responsible for the performance of all required maintenance on your new Volvo engine, including maintenance or repairs needed due to severe operating conditions. Volvo Trucks North America, Inc. will not deny a warranty claim solely because you have no record of maintenance. However, Volvo Trucks North America, Inc. may deny a warranty claim if your failure to perform required maintenance resulted in the failure of a warranted part. Receipts covering the performance of regular maintenance should be retained in the event questions arise concerning maintenance. The receipts should be transferred to each subsequent owner of the vehicle with the emission warranted engine.

CUSTOMER ASSISTANCE

Volvo Trucks North America, Inc. wishes to help to assure that the Emission Control System Warranty is properly administered. In the event that you do not receive the warranty service to which you believe you are entitled under the Emission Control System Warranty, you should contact Volvo Trucks North America, Inc. Warranty Administration, (336) 3932000. The address and telephone number of each Regional Office is in your vehicle owner’s manual. If you need additional assistance or information concerning the Emission Control System Warranty, contact: Volvo Trucks North America, Inc., Warranty Administration, (336) 393-2000.

WHAT IS NOT COVERED BY THE EMISSION WARRANTY

This warranty does not cover:

1Malfunctions in any part caused by any of the following: misuse, abuse, improper adjustments unless performed by a Volvo Trucks North America, Inc. dealer, modifications, alterations, tampering, disconnection, improper or inadequate maintenance, or use of fuels not recommended for the engine as described in the owner’s manual.

2Damage resulting from accident, acts of nature or other events beyond the control of Volvo Trucks North America, Inc.

3The replacement of expendable maintenance items such as filters, hoses, belts, oil, thermostat and coolant made in connection with scheduled maintenance services once these parts have been replaced. Any parts replaced under warranty before the first required replacement point are warranted for the remainder of the warranty period.

4Replacement items which are not genuine Volvo parts or not authorized by Volvo Trucks North America, Inc.

5Loss of time, inconvenience, loss of use of vehicle or engine, or commercial loss.

6Any vehicle on which the odometer or hourmeter has been disconnected or the mileage (or hours) has been altered so the actual usage cannot be readily be determined.

7Any vehicle registered and normally operated outside the United States.

12 General Information

WHAT IS COVERED BY THE EMISSION WARRANTY

The following is a list of the items that are considered a part of the Emission Control Systems and are covered by the Emission Warranty when installed as original equipment by Volvo Trucks North America, Inc. on vehicles which were built to conform to Environmental Protection Agency and California Air Resources Board regulations

IMPORTANT - This may not include expendable maintenance items. Emission related parts requiring scheduled maintenance are warranted until their first scheduled replacement point.

I.Fuel Injection System

II.Air Induction System

A.Intake Manifold

B.Turbocharge System

C.Charge Air Cooler (Intercooler) III. Exhaust Manifold

IV. Miscellaneous Items Used in Above Systems

A.Hose, clamps, fittings and tubing

B.Pulleys, belts and idlers

C.Vacuum, temperature, and time sensitive valves and switches

D.Mounting hardware, sealing gaskets and PVC (if applicable)

THIS CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT IN NO WAY REPLACES, MODIFIES, ALTERS OR SUPERSEDES THE TRUCK WARRANTY CERTIFICATE, ITS TERMS AND CONDITIONS, AND ITS

LIMITATIONS AND EXCLUSIONS.

BE CERTAIN YOU READ AND UNDERSTAND ALL WARRANTIES WHICH

ACCOMPANIED YOUR VEHICLE.

NOTE! Warranty coverage is subject to change without notice. Contact your Volvo Truck dealer for the current warranty statement.

General Information 13

Noise Emissions

Volvo Trucks North America, Inc. warrants to the first person who purchases this vehicle for purposes other than resale and to each subsequent purchaser, that this vehicle as manufactured by Volvo Trucks North America, Inc. was designed, built and equipped to conform, at the time it left the control of Volvo Trucks North America, Inc., with all applicable U.S. EPA Noise Control Regulations.

This warranty covers this vehicle as designed, built and equipped by Volvo Trucks North America, Inc., and is not limited to any particular part, component or system of the vehicle manufactured by Volvo Trucks North America, Inc. Defects in design, assembly or in any part, component or system of the vehicle as manufactured by Volvo Trucks North America, Inc., which, at the time it left the control of Volvo Trucks North America, Inc. caused noise emissions to exceed Federal standards, are covered by this warranty for the life of the vehicle.

14 General Information

Tampering with Noise Control System

Federal law prohibits the following acts or the causing thereof:

(1) The removal or rendering inoperative by any person, other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any new vehicle for the purpose of noise control prior to its sale or delivery to the ultimate purchaser or while it is in use;

or

(2) the use of the vehicle after such device or element of design has been removed or rendered inoperative by any person.

Among those acts presumed to constitute tampering are the acts listed below:

Air Intake System

Removing or rendering inoperative the air cleaner or intake piping.

Engine Cooling Fan

Removing or rendering inoperative the fan clutch.

Removing the fan shroud.

Engine

Removing or altering engine speed programming so as to allow engine speed to exceed manufacturer’s specifications.

Modifying the parameters of the Engine Electronic Control Unit.

General Information 15

Fuel System

Removing or altering engine speed programming so as to allow engine speed to exceed manufacturer’s specifications.

Inner Fender Shields and Cab Skirts

Removing shields or skirts.

Cutting away parts of shields, skirts or damaged or loose portions of shields or skirts.

16 General Information

Vehicle Data

Identification and Labels

It is extremely important that the correct vehicle model and serial number are given whenever replacement parts or service literature are ordered. Using these numbers, as well as giving the major component model and serial numbers, will prevent delay and errors in obtaining the correct material. Space is given on the rear inside cover of this manual for noting the main component model and serial numbers.

The full 17–digit Vehicle Identification Number (VIN) is shown on the Vehicle Identification label located in the door opening on the driver’s side (see next page). The 8–digit chassis number is stamped into the right-hand frame rail underside and the left-hand frame rail topside, 42 inches (1065 mm) back from the front edge of the frame rail. The use of this number is very helpful when ordering parts for

your vehicle.

W0001732

Vehicle Order

The Vehicle Order is a complete and detailed record of all data pertaining to the assembly of the vehicle. It should be filed in the Owner’s office where it will be readily available for reference. Any changes made to the vehicle must become a part of the Vehicle Order and must comply with all applicable Federal Motor Vehicle Safety Standards.

General Information 17

Identification and Certification Labels

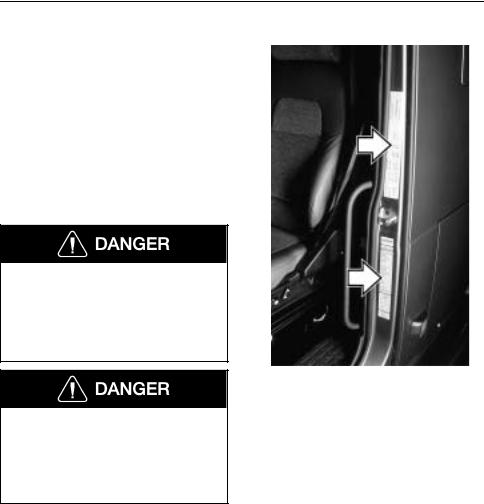

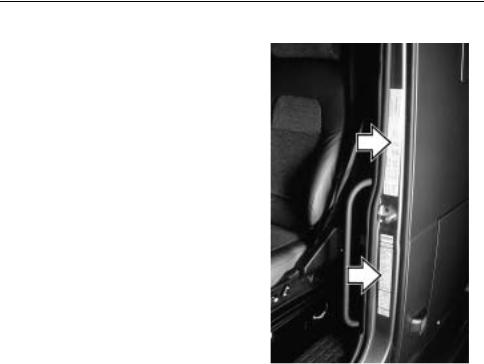

There are two labels that are located on the rear, lower face of the driver side door frame. These should be part of the vehicle at all times.

The VIN is shown on the Vehicle Identification label. The VIN includes the vehicle make, model series, weight class, engine model, where the vehicle was built and the vehicle serial number. This label also shows the truck model designation, major component model and serial number, cab model and serial number, cab and chassis paint colors, and color numbers.

On the upper part of the door frame is the Certification label showing the axle and load ratings for the vehicle as it was built. Do not exceed these ratings by overloading.

NOTE! To deter tampering with the original build information, the information on the label will be destroyed if label is

removed. If for any reason a label is dam- |

W0001210 |

|

|

aged, contact your Volvo Truck dealer for a |

|

replacement. |

|

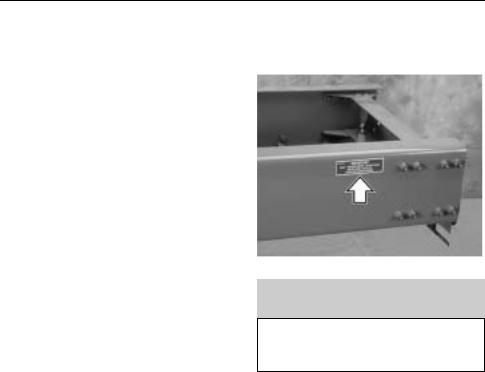

Noise Emission Control Label

A Noise Emission Control label is located in the rear of the door frame. It is the Owner’s responsibility to maintain the vehicle so that it conforms to EPA regulations.

Refer to page 14 for a listing on what constitutes tampering with the Noise Emissions Control.

18 General Information

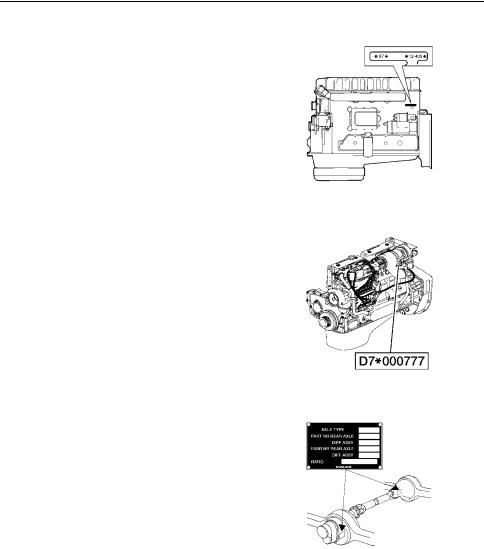

Components

The Volvo D12 engine serial number is located on the rear, left side of the cylinder block.

There is also a label on the engine electronic control unit that shows the engine serial number.

W0001529

The Volvo D7 engine serial number is located on the rear, left side of the cylinder block.

There is also a label on the rear valve cover that shows the engine serial number.

W2002707

The Volvo rear axle model and serial number is located on the right side of the transfer gear housing on the tandem front axle. It is located on the left side of the differential housing on the tandem rear axle and on the right side of the single axle.

W4000894

Vehicle Access 19

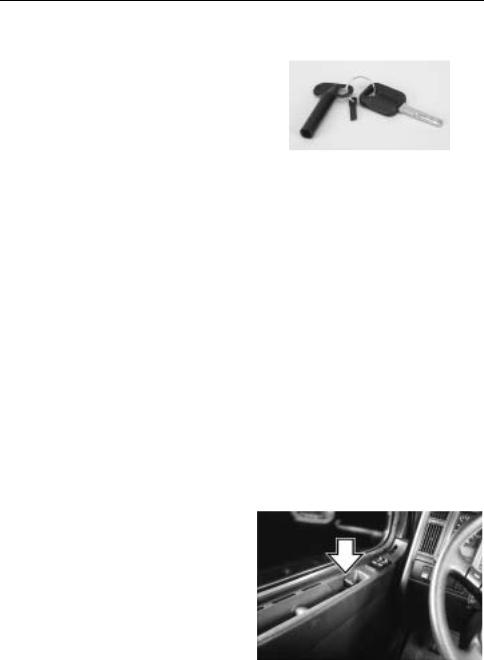

Cab Doors and Door Lock

The cab door is unlocked with the same key used for the ignition lock. Keys can be made to fit only one vehicle or all the vehicles in a fleet of Volvos. A tool for changing bulbs in the instrument cluster is included on the keychain.

The key fits in the door lock either way. Insert the key and turn it 1/4 turn counterclockwise to unlock or clockwise to lock the door.

NOTE! The vehicle is delivered with 2 identical keys. If more keys are needed, order them through your Volvo Truck authorized dealer. The keys are laser cut and require a special machine for copying, available through the dealer. Record the key code and keep it in a secure place. A new key can be made if the keys are lost.

The door locks are mechanically or electrically operated. The lock is activated by either the key from the outside or the door lock handle from the inside. With mechanical locks, only one door can be locked/unlocked at a time. With electrical locks, both doors will be locked/unlocked by operating either the key or the inner door lock handle on either side.

To lock either door from the inside, push the door lock handle forward. The handle will stay in place, indicating the door is locked. It can be unlocked without opening the door by moving the door lock handle to the middle position.

No door can be locked while it is still open. The door must be closed for the lock to work. In the event of a power failure the electrical lock system reverts back to a mechanically functioning system.

W0001231

Key code on tag of keychain

W8001462

20 Vehicle Access

The door has a position lock that enables the door to remain open in two different positions. An indented bar is holding the door at approximately 30 and in the fully open position at approximately 85 .

To close the door from the inside, place the hand in the handhold and pull the door in.

To lessen the chance of being thrown |

|

from the vehicle in case of an accident, |

|

always lock the door and wear the safety |

|

belt while driving. Failure to do so can |

|

cause serious personal injury or death if |

W8001854 |

involved in an accident. |

|

CAUTION

CAUTION

Do not shut the door by pushing on the door panel. Hard pushing may distort the metal in the door panel.

To close the door from the outside, place the hand flat against the door lock area and push the door shut.

W8001853

Vehicle Access 21

Cab Entry and Exit

General

To avoid personal injury due to a slip and/or fall, observe all the guidelines explained in this section marked Cab Entry and Exit.

Do not stand on the steps or any other part of the vehicle while it is in motion. The steps and the back of cab access deck plates are only for entering/exiting the vehicle and not for riding on. Failure to heed this warning can result in serious personal injury or death.

Steps are designed to be slip resistant and to provide a stable surface for entering or exiting the cab. However, accumulation of ice, dirt, lubricants, etc. on the steps can make entering or exiting hazardous. Always make sure the steps are free from slippery substances. Failure to follow this guideline may result in a fall that can cause serious personal injury or death.

WARNING

WARNING

Wearing shoes with soles that are dirty or wet increases the chance of slipping and falling. Be careful when entering the cab with dirty or wet soles.

WARNING

WARNING

Both the operator and passenger should exercise caution when entering or exiting the cab. Use the steps and grab handles to safely get in and out of the cab.

W8002808

22 Vehicle Access

General Entry Guidelines

To avoid personal injury due to a slip and/or fall, observe the following guidelines.

1Always have three limbs (one foot and two hands or two feet and one hand) in contact with the vehicle at all times when entering or exiting the cab or the area behind the cab.

2Be certain you have a firm handhold and/or stable foot position before transferring weight to that position. For example, do not start to put weight on a foot until you are certain your foot is properly on the step and will not slip when you transfer your weight.

3Do not climb on top of the frame, fuel tanks or storage boxes to make trailer hook-ups.

4If the vehicle is equipped with air fairings, do not use the side mounted fairing (wind deflector) brackets and braces as steps or grab handles.

5Be certain that the grab handles are clear of snow, mud, ice or other substances that could make them slippery before using them. Do not use steps or grab handles if they are slippery or damaged.

6Be certain that all grab handles, steps and related parts are in good working condition. Any defects should be reported and repaired before using the grab handles and steps.

7Do not step on the curved surface of the fuel tanks. They may be slippery from snow, mud, ice, water, spilled fuel or other slippery substances.

8If a step is mounted to the top of the battery box, be certain that the battery box cover is properly fastened before stepping.

9Do not jump from the cab or from the steps to the ground.

10Always face the cab when entering or exiting.

11Do not hold anything in your hands when entering or exiting the cab or the area behind the cab. Log books, cups, clipboards, jackets, luggage and the like can be placed on the cab floor or rear deck plate before entering or exiting.

12Be sure to disconnect the safety belt before exiting the cab.

13Be sure that the safety belt is fully retracted and out of the way prior to entering or exiting the cab.

14Do not put your foot on any surface that does not have slip resistant, selfcleaning material. If there is no step material, the surface may be slippery and you could fall.

15Before entering or exiting, be certain that the soles of your shoes/boots are free from grease, mud or any other substance which could make them slippery.

16Always put the foot flat on the top of the step. Do not place your foot on the side or edge of the step.

BE SURE TO FOLLOW ALL OF THESE INSTRUCTIONS BEFORE ENTERING OR EXITING THE CAB OR THE AREA BEHIND THE CAB.

Vehicle Access 23

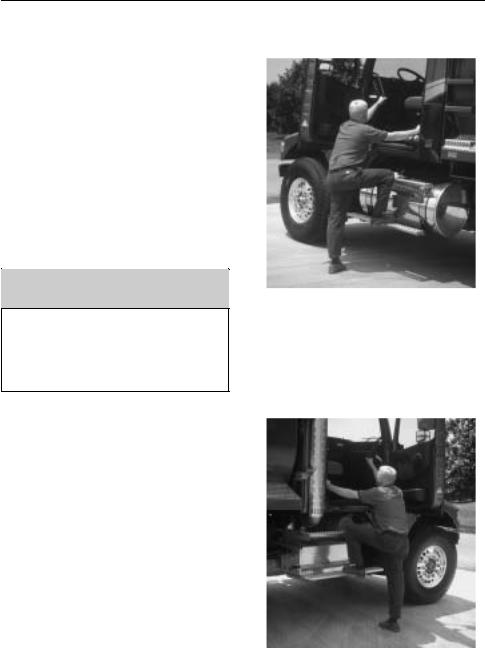

Driver Side Entry/Exit

Open the door. Place any hand-carried items on the cab floor. Grasp the right grab handle with your right hand and the left grab handle with your left hand. Put the right foot fully on the bottom step and pull yourself up to the opening.

Slide hands up on the handles, if necessary. Put the left foot on the top step and step up. Step into the cab with the right foot first.

To exit, reverse the process. Do not attempt to exit the cab while carrying any items in your hands.

WARNING

WARNING

On vehicles without side fairings, always make sure that the battery box cover is securely fastened before stepping up. Failure to fasten the cover may lead to personal injury.

Passenger Side Entry/Exit

Open the door. Place any hand-carried items on the cab floor. Grasp the left grab handle with your left hand and the right grab handle with your right hand. Put the left foot fully on the bottom step and pull yourself up to the opening.

Slide hands up on the handles, if necessary. Put the right foot on the top step and step up.

Step into the cab with the left foot first.

To exit, reverse the process. Do not attempt to exit the cab while carrying any items in your hands.

W0001911

W0001910

24 Vehicle Access

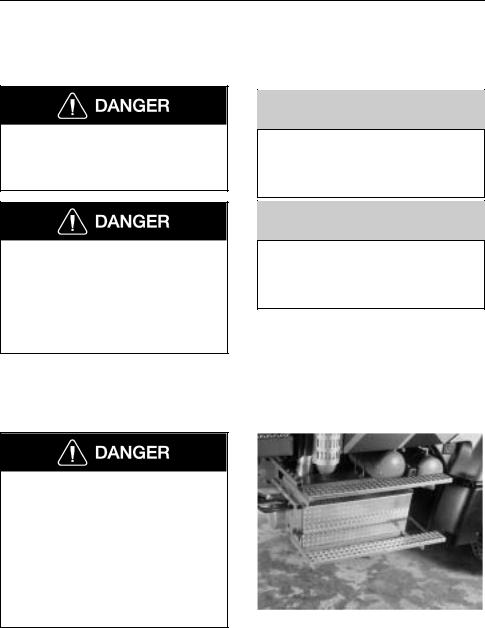

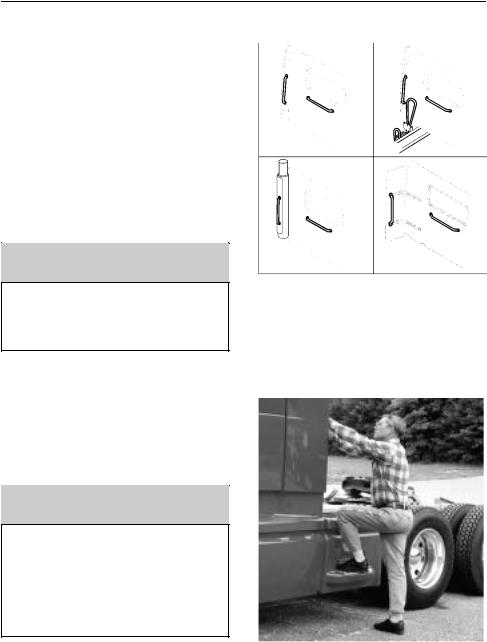

Behind the Cab Entry

When trailer air and electrical connections can not be coupled from the ground, Federal Regulations require commercial carriers to provide back-of-cab access steps, grab handles and plates.

Depending on what option is chosen, grab handles are available in many variations. In each case, make sure to always have three limbs (one foot and two hands or two feet and one hand) in contact with the vehicle at all times when entering or exiting the area behind the cab.

WARNING

WARNING

W8001363

Wearing shoes with soles that are dirty or wet increases the chance of slipping or falling. Be careful when entering the back-of-cab area with dirty or wet soles.

Grasp the grab handle to the left with both hands. Put the left foot onto the bottom step and pull yourself up. Put the right foot on the top step and step onto the deck plate with the left foot.

WARNING

WARNING

Always perform trailer hook-ups while standing on the ground. Do not climb on top of fuel tanks or frame rails to hook up or disconnect trailer air lines and electrical cord. Use only the metal, slip resistant steps provided to prevent a slip and fall injury.

W9000077

Loading...

Loading...