P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

Workshop Manual

Amarok 2011 ➤ , Caddy 2004 ➤ ,

Caddy 2011 ➤ ,

Caddy Kasten/Kombi 1996 ➤ ,

Caddy Pickup 1997 ➤ ,

Caravelle 2010 ➤ , Crafter 2006 ➤ ,

LT 1997 ➤ , Multivan 2010 ➤ ,

Transporter 1991 ➤ ,

Transporter 1996 ➤ ,

Transporter 2004 ➤ ,

Transporter 2010 ➤ , Zugkopf 2010 ➤

Wheels and Tyres Guide

Edition 11.2012

Service Department. Technical Information

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re pa ir G ro up

44 - Wheels, tyres, vehicle geometry

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2012 Volkswagen AG, Wolfsburg K0056560120

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

Contents

44 - Wheels, tyres, vehicle geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 General notes on wheels and tyres (commercial vehicles) . . . . . . . . . . . . . . . . . . . . . . . . 1

2 Legislative and technical conditions for converting wheel and tyre combinations . . . . . . . . 3

2.1 Legislative conditions for converting wheel and tyre combinations . . . . . . . . . . . . . . . . . . 3

2.2 Technical conditions for converting wheel and tyre combinations . . . . . . . . . . . . . . . . . . . . 3

2.3 Additional wheel housing extensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4 “Series 80” tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3 Documents and codes/designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 New vehicle registration documents since 01.10.2005 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.2 COC document (EEC Certificate of Conformity) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Official type designations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.1 Official type approval, sales or trade designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

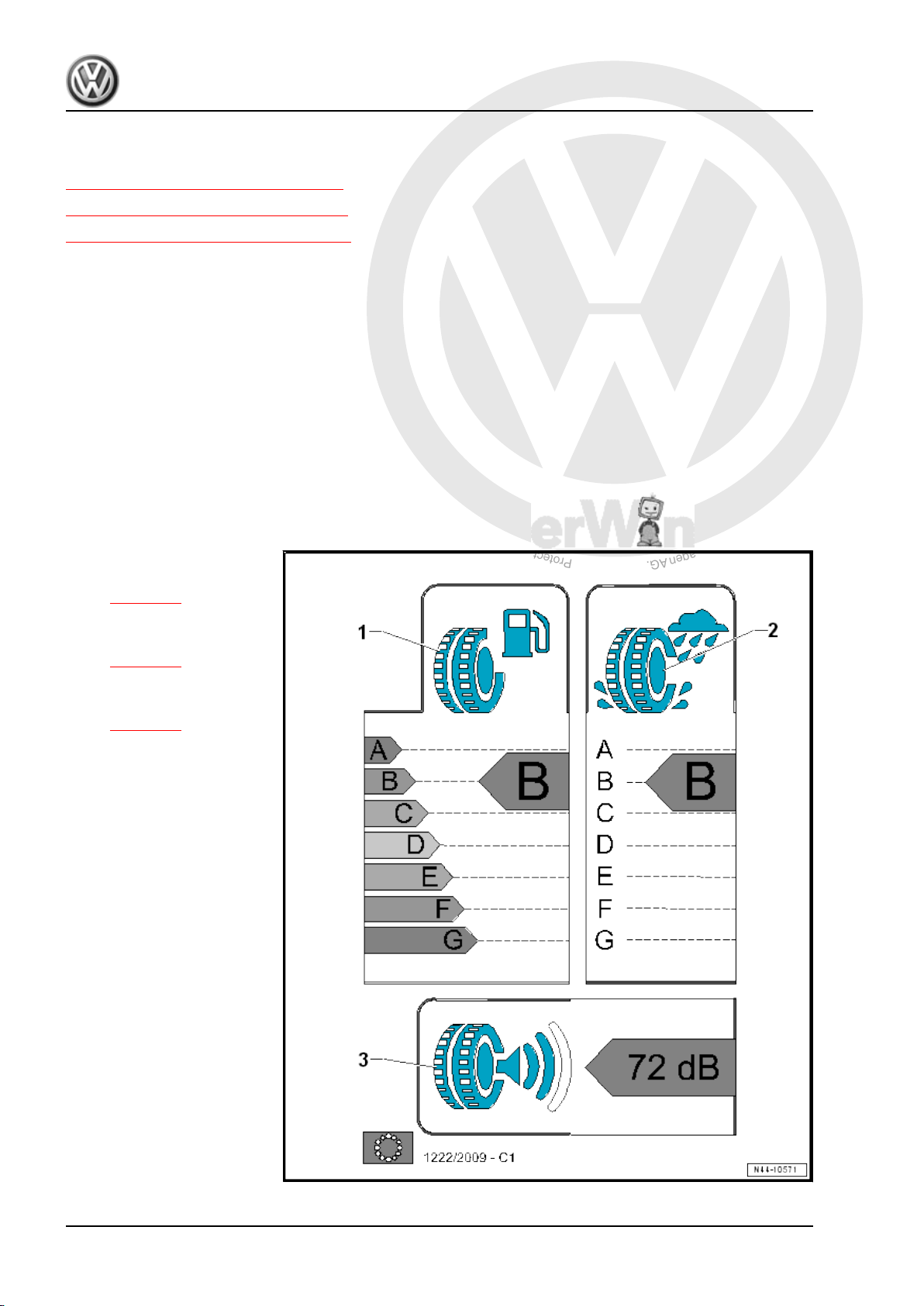

5 EU tyre label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.1 EU tyre label, summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

5.2 EU tyre label, objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

5.3 EU tyre label, categories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

6 Facts about wheels and tyres (commercial vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.1 Useful information regarding tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

6.2 Tyre wear/ mileage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.3 Tyre noise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4 Rough running caused by wheels/tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.5 Vehicle pulls to one side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.6 Tyre damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.7 Useful information about rims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.8 Fitting and removing wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.9 Breakdown set for VW Vehicles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7 Wheel and tyre combinations, Amarok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.1 Vehicles without wheel house extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7.2 Wheel allocation for vehicles without wheel house extension . . . . . . . . . . . . . . . . . . . . . . 65

7.3 Vehicles with wheel house extension . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

7.4 Wheel allocation for vehicles with wheel house extension . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8 Wheel and tyre combinations, Caddy model year 1996 to model year 2002 . . . . . . . . . . . . 72

8.1 Appendix for parts certificate, Caddy Kombi, type 9KV and Caddy panel van, type 9KVF,

model year 1996 to model year 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.2 Wheel allocation for Caddy Kombi type 9 KV and Caddy panel van type 9KVF, model year

1996 to model year 2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9 Wheel and tyre combinations, Caddy pickup, model year 1997 to model year 2002 . . . . . . 76

9.1 Appendix for parts certificate, Caddy pickup, type 9U, model year 1997 to model year

2002 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

9.2 Wheel allocation Caddy pickup, type 9U, model year 1997 to model year 2002 . . . . . . . . 77

10 Wheel and tyre combinations, Caddy, from model year 2004 to 2011 (model code 2K) . . 78

10.1 Appendix for certificate statement, Caddy panel van, sales type 2KA, model year 2004 to

model year 2008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

10.2 Appendix for certificate statement, Caddy panel van, sales type 2KA, from model year 2009

to model year 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

10.3 Wheel allocation for Caddy panel van, sales type 2KA, from model year 2004 to model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10.4 Appendix for parts certificate, Caddy Maxi panel van, sales type 2KH, from model year 2008

to model year 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

10.5 Wheel allocation for Caddy Maxi panel van, sales type 2KH, from model year 2008 to model

year 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

10.6 Appendix for parts certificate, Caddy Kombi, sales type 2KB, model year 2004 to model year

2008 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Contents i

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

10.7 Appendix for parts certificate, Caddy Kombi, sales type 2KB, from model year 2009 to model

year 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

10.8 Wheel allocation for Caddy Kombi, sales type 2KB, from model year 2004 to model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10.9 Appendix for parts certificate, Caddy Maxi Kombi, sales type 2KJ, from model year 2008 to

model year 2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.10 Wheel allocation for Caddy Maxi Kombi, sales type 2KJ, from model year 2008 to model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

11 Wheel and tyre combinations, Caddy, from model year 2011 . . . . . . . . . . . . . . . . . . . . . . 95

11.1 Appendix for certificate statement for Caddy panel van, sales type 2CA from model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.2 Wheel allocation Caddy panel van, sales type 2CA from model year 2011 . . . . . . . . . . . . 96

11.3 Appendix for certificate statement for Caddy Kombi, sales type 2CB from model year 2011

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.4 Wheel allocation for Caddy Kombi, sales type 2CB from model year 2011 . . . . . . . . . . . . 100

11.5 Appendix for certificate statement for Caddy Maxi panel van, sales type 2CH from model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

11.6 Wheel allocation for Caddy Maxi panel van, sales type 2CH from model year 2011 . . . . . . 104

11.7 Appendix for certificate statement for Caddy Maxi Kombi, sales type 2CJ from model year

2011 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

11.8 Wheel allocation for Caddy Maxi Kombi, sales type 2CJ from model year 2011 . . . . . . . . 109

12 Wheel and tyre combinations, Transporter model year 1991 to model year 1995 . . . . . . . . 112

12.1 Appendix for parts certificate, Transporter, Transporter Syncro, type 70X0 A to D and 70X1

A to D, model year 1991 to model year 1995 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

12.2 Wheel allocation Transporter, Transporter Syncro, type 70X0 A to D and 70X1 A to D model

year 1991 to model year 1995 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

13 Wheel and tyre combinations, Transporter from January 1996 to model year 2003 . . . . . . 117

13.1 Appendix for parts certificate, Transporter, Transporter Syncro, type 70X02 A to D and 70X12

A to D, from January 1996 to model year 2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

13.2 Transporter, Transporter Syncro from January 1996 to model year 2003 (passenger

vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

13.3 Wheel allocation Transporter, Transporter Syncro from January 1996 to model year 2003

(passenger vehicles) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

13.4 Transporter, Transporter Syncro, 111 kW TDI model year 2000 . . . . . . . . . . . . . . . . . . . . 121

13.5 Wheel allocation Transporter, Transporter Syncro, 111 kW TDI model year 2000 . . . . . . 122

13.6 Transporter, Transporter Syncro 111 kW TDI and V6 150 kW from model year 2001 to model

year 2003 as well as 65 kW, 75 kW and 85 kW from model year 2002 to model year 2003

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

13.7 Wheel allocation Transporter, Transporter Syncro 111 kW TDI and V6 150 kW from model

year 2001 to model year 2003 as well as 65 kW, 75 kW and 85 kW from model year 2002 to

model year 2003 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

14 Wheel and tyre combinations, Transporter from model year 2004 to model year 2009 . . . . 126

14.1 Appendix for parts certificate Transporter, sales type 7HM Multivan model year 2004 to model

year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

14.2 Wheel allocation for Transporter, sales type 7HM Multivan model year 2004 to model year

2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

14.3 Appendix for parts certificate Transporter, sales type 7HM Multivan model year 2008 to model

year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

14.4 Wheel allocation for Transporter, sales type 7HM Multivan model year 2008 to model year

2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

14.5 Appendix for parts certificate Transporter, sales type 7HC California model year 2004 to

model year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

14.6 Wheel allocation for Transporter, sales type 7HC California model year 2004 to model year

2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

14.7 Appendix for parts certificate Transporter, sales type 7HC California model year 2008 to

model year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

14.8 Wheel allocation for Transporter, sales type 7HC California model year 2008 to model year

2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

14.9 Appendix for parts certificate Transporter, sales type 7HF, Multivan Beach model year 2004

to model year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

ii Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

14.10 Wheel allocation for Transporter, sales type 7HF; Multivan Beach model year 2004 to model

year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

14.11 Appendix for parts certificate, Transporter, sales type 7HF; Multivan Beach, Multivan

Startline, California Beach model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . . . 150

14.12 Wheel allocation for Transporter, sales type 7HF; Multivan Beach, Multivan Startline,

California Beach model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

14.13 Appendix for parts certificate, Transporter Kombi; Transporter Shuttle; Caravelle, sales type

7HB and 7HJ model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

14.14 Wheel allocation for Transporter Kombi; Transporter Shuttle; Caravelle, sales type 7HB and

7HJ model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

14.15 Appendix for parts certificate, Transporter Kombi; Transporter Shuttle; Caravelle, sales type

14.16 Wheel allocation for Transporter Kombi; Transporter Shuttle; Caravelle, sales type 7HB and

14.17 Appendix for parts certificate, Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum

14.18 Wheel allocation for Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum permitted

14.19 Appendix for parts certificate, Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum

14.20 Wheel allocation for Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum permitted

14.21 Appendix for parts certificate, Transporter panel van, sales type 7HA and 7HH with a

14.22 Wheel allocation for Transporter panel van, sales type 7HA and 7HH with a maximum

14.23 Appendix for parts certificate, Transporter panel van, sales type 7HA and 7HH with a

14.24 Wheel allocation for Transporter panel van, sales type 7HA and 7HH with a maximum

14.25 Appendix for parts certificate, Transporter panel van, sales type 7HA and 7HH with a

7HB and 7HJ model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

7HJ model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

permitted weight to 3000 kg, model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . 164

weight to 3000 kg, model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . . . . . . . . . 166

permitted weight to 3000 kg, model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . 168

weight to 3000 kg, model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . . . . . . . . . 170

maximum permitted weight to 3000 kg, model year 2004 to model year 2007 . . . . . . . . . . 173

permitted weight to 3000 kg, model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . 174

maximum permitted weight to 3000 kg, model year 2008 to model year 2009 . . . . . . . . . . 177

permitted weight to 3000 kg, model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . 178

maximum permitted weight of 3200 kg, model year 2004 to model year 2007 . . . . . . . . . . 182

14.26 Wheel allocation for Transporter panel van, sales type 7HA and 7HH with a maximum

permitted weight of 3200 kg, model year 2004 to model year 2007 . . . . . . . . . . . . . . . . . . 183

14.27 Appendix for parts certificate, Transporter panel van, sales type 7HA and 7HH with a

maximum permitted weight of 3200 kg, model year 2008 to model year 2009 . . . . . . . . . . 184

14.28 Wheel allocation for Transporter panel van, sales type 7HA and 7HH with a maximum

permitted weight of 3200 kg, model year 2008 to model year 2009 . . . . . . . . . . . . . . . . . . 186

15 Wheel and tyre combinations, Transporter, from model year 2010 . . . . . . . . . . . . . . . . . . 188

15.1 Appendix for certificate statement, Transporter with a maximum permitted weight to 3080

kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

15.2 Wheel allocation for Transporter with a maximum permitted weight to 3080 kg . . . . . . . . 191

15.3 Appendix for certificate statement, Transporter with a maximum permitted weight to 3080

kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

15.4 Wheel allocation for Transporter with a maximum permitted weight to 3080 kg . . . . . . . . 199

15.5 Appendix for certificate statement, Transporter with a maximum permitted weight to 3080

kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

15.6 Wheel allocation for Transporter with a maximum permitted weight to 3080 kg . . . . . . . . 208

15.7 Appendix for certificate statement, Transporter with a maximum permitted weight above 3080

kg . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

15.8 Wheel allocation for Transporter with a maximum permitted weight above 3080 kg . . . . . . 216

16 Wheel and tyre combinations, LT, model year 1997 to model year 2006 . . . . . . . . . . . . . . 219

16.1 Appendix for parts certificate, LT, type 2DM model year 1997 to model year 2006 . . . . . . 219

16.2 Wheel allocation for LT type 2DM, model year 1997 to model year 2006 . . . . . . . . . . . . . . 221

17 Wheel and tyre combinations, Crafter, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 223

17.1 Appendix for certificate statements, Crafter 30 Kombi, sales type 2EB, 2EE with a maximum

permitted weight to 3190 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

17.2 Wheel allocation, Crafter 30 Kombi, sales type 2EB, 2EE with a maximum permitted weight

to 3190 kg from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

17.3 Appendix for certificate statements, Crafter 35 Kombi, sales type 2EB, 2EE, 2EK with a

maximum permitted weight to 3500 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 226

Contents iii

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

17.4 Wheel allocation for Crafter 35 Kombi, sales type 2EB, 2EE, 2EK with a maximum permitted

weight to 3500 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

17.5 Appendix for certificate statements Crafter 30 panel van, sales type 2EA, 2ED with a

maximum permitted weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 229

17.6 Wheel allocation for Crafter 30 panel van, sales type 2EA, 2ED with a maximum permitted

weight to 3025 kg from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

17.7 Appendix for certificate statement Crafter 35 panel van, sales type 2EA, 2ED, 2EH, 2EX with

a maximum permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . 231

17.8 Wheel allocation for Crafter 35 panel van, sales type 2EA, 2ED, 2EH, 2EX with a maximum

permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

17.9 Appendix for certificate statement Crafter 50 panel van, sales type 2ED, 2EH, 2EX with a

maximum permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 234

17.10 Wheel allocation for Crafter 50 panel van, sales type 2ED, 2EH, 2EX with a maximum

permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 236

17.11 Appendix for certificate statement for Crafter 30 chassis, dropside, sales type 2FF with a

maximum permitted weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 238

17.12 Wheel allocation for Crafter 30 chassis, dropside, sales type 2FF with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

17.13 Appendix for certificate statements for Crafter 35 chassis, dropside, sales type 2FC, 2FF,

2FG, 2FL, 2FM, 2FZ with a maximum permitted weight to 3880 kg, from model year 2006

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241

17.14 Wheel allocation for Crafter 35 chassis, dropside, sales type 2FC, 2FF, 2FG, 2FL, 2FM, 2FZ

with a maximum permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . 242

17.15 Appendix for certificate statements for Crafter 50 chassis, dropside, sales type 2FF, 2FG,

2FL, 2FM with a maximum permitted weight to 5000 kg, from model year 2006 . . . . . . . . 244

17.16 Wheel allocation for Crafter 50 chassis, dropside, sales type 2FF, 2FG, 2FL, 2FM with a

maximum permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 246

18 Recommended summer tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

18.1 Summer tyres, Amarok . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

18.2 Summer tyres for Caddy, model year 1996 to model year 2002 . . . . . . . . . . . . . . . . . . . . 249

18.3 Summer tyres for Caddy Pick Up, model year 1997 to model year 2002 . . . . . . . . . . . . . . 250

18.4 Summer tyres for Caddy panel van, sales type 2KA from model year 2004 . . . . . . . . . . . . 250

18.5 Summer tyres Caddy Maxi panel van, sales type 2KH from model year 2008 . . . . . . . . . . 250

18.6 Summer tyres for Caddy Kombi, sales type 2KB from model year 2004 . . . . . . . . . . . . . . 251

18.7 Summer tyres Caddy Maxi Kombi, sales type 2KJ from model year 2008 . . . . . . . . . . . . 251

18.8 Summer tyres Caddy panel van, sales type 2CA from model year 2011 . . . . . . . . . . . . . . 252

18.9 Summer tyres Caddy Maxi panel van, sales type 2CH from model year 2011 . . . . . . . . . . 252

18.10 Summer tyres for Caddy Kombi, sales type 2CB, from model year 2011 . . . . . . . . . . . . . . 253

18.11 Summer tyres for Caddy Maxi Kombi, sales type 2CH , from model year 2011 . . . . . . . . 253

18.12 Summer tyres for Transporter, model year 1991 to model year 1995 . . . . . . . . . . . . . . . . 254

18.13 Summer tyres for Transporter from January 1996 to model year 2003 . . . . . . . . . . . . . . . . 254

18.14 Summer tyres for Transporter, sales type 7HM Multivan from model year 2004 . . . . . . . . 255

18.15 Summer tyres for Transporter, sales type 7HC California from model year 2004 . . . . . . . . 255

18.16 Summer tyres for Transporter, sales type 7HF; Multivan Beach, Multivan Startline from model

year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

18.17 Summer tyres for Transporter Kombi, Transporter Shuttle, Caravelle, sales type 7HB and

7HJ, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

18.18 Summer tyres for Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum permitted

weight to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

18.19 Summer tyres for Transporter panel van, sales type 7HA and 7HH with a maximum permitted

weight to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

18.20 Summer tyres for Transporter panel van, sales type 7HA and 7HH with a maximum permitted

weight 3200 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

18.21 Summer tyres for Transporter with a maximum permitted weight 3080 kg, from model year

2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 258

18.22 Summer tyres for Transporter with a maximum permitted weight above 3080 kg, from model

year 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

18.23 Summer tyres for LT, model year 1997 to model year 2005 . . . . . . . . . . . . . . . . . . . . . . . . 259

18.24 Summer tyres for Crafter 30 Kombi, sales type 2EB, 2EE with a maximum permitted weight

to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

iv Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

18.25 Summer tyres for Crafter 35 Kombi, sales type 2EB, 2EE, 2EK with a maximum permitted

weight to 3500 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

18.26 Summer tyres for Crafter 30 panel van, sales type 2EA, 2ED with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

18.27 Summer tyres for Crafter 35 panel van, sales type 2EA, 2ED, 2EH, 2EX with a maximum

permitted weight to 3880 kg from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

18.28 Summer tyres for Crafter 50 panel van, sales type 2ED, 2EH, 2EX with a maximum permitted

weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

18.29 Summer tyres for Crafter 30 chassis, dropside, sales type 2FF with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

18.30 Summer tyres for Crafter 35 chassis, dropside, sales type 2FC, 2FF, 2FG, 2FL, 2FM, 2FZ

with a maximum permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . 261

18.31 Summer tyres for Crafter 50 chassis, dropside, sales type 2FF, 2FG, 2FL, 2FM with a

19 Recommended all-season tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

19.1 All-season tyres for Caddy, model year 1996 to model year 2002 . . . . . . . . . . . . . . . . . . . . 263

19.2 All-season tyres for Caddy panel van, sales type 2KA, from model year 2004 . . . . . . . . . . 263

19.3 All-season tyres Caddy Maxi panel van, sales type 2KH, from model year 2008 . . . . . . . . 263

19.4 All-season tyres for Caddy Kombi, sales type 2KB, from model year 2004 . . . . . . . . . . . . 264

19.5 All-season tyres Caddy Maxi Kombi, sales type 2KJ, from model year 2008 . . . . . . . . . . 264

19.6 All-season tyres for Caddy panel van, sales type 2CA, from model year 2011 . . . . . . . . . . 264

19.7 All-season tyres for Caddy Maxi panel van, sales type 2CH, from model year 2011 . . . . . . 264

19.8 All-season tyres for Caddy Kombi, sales type 2CB, from model year 2011 . . . . . . . . . . . . 265

19.9 All-season tyres for Caddy Maxi Kombi, sales type 2CJ, from model year 2011 . . . . . . . . 265

19.10 All-season tyres for Transporter, model year 1991 to model year 1995 . . . . . . . . . . . . . . 265

19.11 All-season tyres for Transporter from January 1996 to model year 2003 . . . . . . . . . . . . . . 265

19.12 All-season tyres for Transporter, sales type 7HM Multivan, from model year 2004 . . . . . . 266

19.13 All-season tyres for Transporter, sales type 7HC California, from model year 2004 . . . . . . 266

19.14 All-season tyres for Transporter, sales type 7HF; Multivan Beach, Multivan Startline, from

19.15 All-season tyres for Transporter Kombi; Transporter Shuttle; Caravelle, sales type 7HB and

19.16 All-season tyres for Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum permitted

19.17 All-season tyres for Transporter panel van, sales type 7HA and 7HH with a maximum

maximum permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 262

model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 266

7HJ, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

weight to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

permitted weight to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

19.18 All-season tyres for Transporter panel van, sales type 7HA and 7HH with a maximum

permitted weight of 3200 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

19.19 All-season tyres for Transporter with a maximum permitted weight to 3080 kg from model

year 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

19.20 All-season tyres for Transporter with a maximum permitted weight above 3080 kg, from model

year 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

19.21 All-season tyres for LT, model year 1997 to model year 2006 . . . . . . . . . . . . . . . . . . . . . . 269

19.22 All-season tyres for Crafter 30 Kombi, sales type 2EB, 2EE with a maximum permitted weight

to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

19.23 All-season tyres for Crafter 35 Kombi, sales type 2EB, 2EE, 2EK with a maximum permitted

weight to 3500 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

19.24 All-season tyres for Crafter 30 panel van, sales type 2EA, 2ED with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

19.25 All-season tyres for Crafter 35 panel van, sales type 2EA, 2ED, 2EH, 2EX with a maximum

permitted weight to 3880 kg from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

19.26 All-season tyres for Crafter 50 panel van, sales type 2ED, 2EH, 2EX with a maximum

permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

19.27 All-season tyres for Crafter 30 chassis, dropside, sales type 2FF with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

19.28 All-season tyres for Crafter 35 chassis, dropside, sales type 2FC, 2FF, 2FG, 2FL, 2FM, 2FZ

with a maximum permitted weight to 3880 kg from model year 2006 . . . . . . . . . . . . . . . . 270

19.29 All-season tyres for Crafter 50 chassis, dropside, sales type 2FF, 2FG, 2FL, 2FM with a

maximum permitted weight to 5000 kg from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 271

20 Recommended winter tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Contents v

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

20.1 Amarok winter tyres . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

20.2 Winter tyres for Caddy panel van, sales type 2KA from model year 2004 . . . . . . . . . . . . . . 272

20.3 Winter tyres for Caddy Maxi panel van, sales type 2KH from model year 2008 . . . . . . . . 272

20.4 Winter tyres for Caddy Kombi, sales type 2KB from model year 2004 . . . . . . . . . . . . . . . . 273

20.5 Winter tyres for Caddy Maxi Kombi, sales type 2KJ from model year 2008 . . . . . . . . . . . . 273

20.6 Winter tyres for Caddy panel van, sales type 2CA from model year 2011 . . . . . . . . . . . . . . 273

20.7 Winter tyres for Caddy Maxi panel van, sales type 2CH from model year 2011 . . . . . . . . 274

20.8 Winter tyres for Caddy Kombi, sales type 2CB from model year 2011 . . . . . . . . . . . . . . . . 274

20.9 Winter tyres for Caddy Maxi Kombi, sales type 2CJ from model year 2011 . . . . . . . . . . . . 274

20.10 Winter tyres for Transporter, model year 1991 to model year 1995 . . . . . . . . . . . . . . . . . . 275

20.11 Winter tyres for Transporter from January 1996 to model year 2003 . . . . . . . . . . . . . . . . . . 275

20.12 Winter tyres for Transporter, sales type 7HM Multivan from model year 2004 . . . . . . . . . . 275

20.13 Winter tyres for Transporter, sales type 7HC California from model year 2004 . . . . . . . . . . 275

20.14 Winter tyres for Transporter, sales type 7HF; Multivan Beach, Multivan Startline from model

year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

20.15 Winter tyres for Transporter Kombi, Transporter Shuttle, Caravelle, sales type 7HB and 7HJ

from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

20.16 Winter tyres for Transporter, sales type 7JD; 7JE; 7JL; 7JZ with a maximum permitted weight

to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

20.17 Winter tyres for Transporter panel van, sales type 7HA and 7HH with a maximum permitted

weight to 3000 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

20.18 Winter tyres for Transporter panel van, sales type 7HA and 7HH with a maximum permitted

weight of 3200 kg, from model year 2004 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

20.19 Winter tyres for Transporter with a maximum permitted weight of 3080 kg, from model year

2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

20.20 Winter tyres for Transporter with a maximum permitted weight above 3080 kg, from model

year 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

20.21 Winter tyres for LT, model year 1997 to model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . 278

20.22 Winter tyres for Crafter 30 Kombi, sales type 2EB, 2EE with a maximum permitted weight to

3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

20.23 Winter tyres for Crafter 35 Kombi, sales type 2EB, 2EE, 2EK with a maximum permitted

weight to 3500 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

20.24 Winter tyres for Crafter 30 panel van, sales type 2EA, 2ED with a maximum permitted weight

to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

20.25 Winter tyres for Crafter 35 panel van, sales type 2EA, 2ED, 2EH, 2EX with a maximum

permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

20.26 Winter tyres for Crafter 50 panel van, sales type 2ED, 2EH, 2EX with a maximum permitted

weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

20.27 Winter tyres for Crafter 30 chassis, dropside, sales type 2FF with a maximum permitted

weight to 3025 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

20.28 Winter tyres for Crafter 35 chassis, dropside, sales type 2FC, 2FF, 2FG, 2FL, 2FM, 2FZ with

a maximum permitted weight to 3880 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . 280

20.29 Winter tyres for Crafter 50 chassis, drop-side, sales type 2FF, 2FG, 2FL, 2FM with a

maximum permitted weight to 5000 kg, from model year 2006 . . . . . . . . . . . . . . . . . . . . . . 280

vi Contents

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

44 – Wheels, tyres, vehicle geometry

1 General notes on wheels and tyres

(commercial vehicles)

(VRL005145; Edition 11.2012)

This information is intended to help you form an opinion as precise

and accurate as possible in cases of tyre damage and other com‐

plaints.

In this chapter you will learn more about tyres and wheels/rims.

Tyres are high-tech products that are especially adapted to the

requirements of modern vehicles.

As with all highly developed technical products, tyres require

proper care, maintenance and service. This is essential to ensure

safety, performance and comfort for the entire service life of the

tyre.

Tyres are constantly being further developed. Quality tyres are

the result of modern design methods and production processes,

as well as continuous quality checks. All tyres that are recom‐

mended by VW have been tested by the technical development

department and have been designed specifically for each model

in collaboration with the tyre manufacturers.

We therefore recommend fitting only the recommended tyre

makes when renewing tyres.

Vehicle safety is the top priority. With regard to the various oper‐

ating conditions such as

• differing speed ranges,

• winter and summer use and

• wet and dry roads,

the optimal compromise for vehicle safety must be found.

Every tyre is subjected to a wide range of different driving condi‐

tions over its entire service life. It is therefore important that the

basic requirements for ensuring optimal tyre performance are

met.

Proper adjustment of the axle geometry during wheel alignment

is an important prerequisite for ensuring the maximum service life

of the tyre. The wheel alignment must always be within the speci‐

fied tolerance range.

Information for wheel alignment ⇒ Running gear, axles, steering;

Rep. gr. 44 .

Note

Tyre damage and related problems can have various causes. It

is, therefore, very important that you determine whether the prob‐

lem has been caused by the tyre or by other components.

Normal wear and tear on a tyre will alter its characteristics. Rolling

noises or rough running can be the result of such wear. These are

simply the symptoms of normal wear and tear and do not consti‐

tute damage in the sense of the tyre being defective. You can take

measures to eliminate the symptoms at least to some degree.

However, in some cases it may not be possible to eliminate tyre

noise completely.

1. General notes on wheels and tyres (commercial vehicles) 1

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

Special models

Special models are only partly represented in the tables in ap‐

pendix 2 or appendix for parts certificate. Modification of these

vehicles depends on the engine capacity of the basic model.

2 Rep. gr.44 - Wheels, tyres, vehicle geometry

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

2 Legislative and technical conditions

for converting wheel and tyre combi‐

nations

2.1 Legislative conditions for converting wheel and tyre combinations

The manufacturer is issued with a general operating permit (GTA

in accordance with § 20 StVZO (German road traffic and licensing

regulations) and EU operating permit) for the overall vehicle with

all parts for specific conversions.

Conversions of wheels and tyres can only be carried out under

certain conditions. When doing this, the following points must be

observed:

♦ If the size of wheel and tyre, with an indication of the load index

and the speed symbol, is included in the vehicle GTA and EU

operating permit/type approval ⇒ page 6 , this wheel and

tyre combination can be fitted on the vehicle without any prob‐

lem.

It is not necessary for the wheel and tyre combination specified

in the registration certificate part I (certificate of registration) to be

fitted. All combinations approved in the vehicle GTA or EU oper‐

ating permit/type approval ⇒ page 6 may be fitted to the

vehicle.

♦ There is no general type approval according to § 22 StVZO for

the modifications recommended by Volkswagen AG (see at‐

tachment or Appendix 2 to Parts Certificate).

♦ Unless the wheels and/or tyres are included in the relevant

vehicle GTA or EU operating permit/type approval, the vehicle

will no longer meet the requirements of the road traffic regu‐

lations if converted.

These versions are based on the conditions valid in the European

Union and no guarantee can be provided for their completeness.

In some cases there are different legislative requirements outside

the European Union.

The table included in the attachment or Appendix 2 to Parts Cer‐

tificate shows the Volkswagen AG recommended and TÜV

NORD Mobilität GmbH Co. KG tested wheel and tyre combina‐

tions on VW vehicles and also the conditions to be observed for

fitting. The use of genuine disc-type wheels on a vehicle to which

they have not been allocated is not permissible.

The list of possible conversions deals with combinations that meet

the requirements of Volkswagen AG with regards to road handling

and road safety. They are the result of practical trials and are

therefore recommended by Volkswagen AG.

Refer also to the new vehicle registration documents that were

issued from 01.10.2005 ⇒ page 5 .

2.2 Technical conditions for converting wheel and tyre combinations

• The wheel and tyre combinations and conversions listed in the

tables of the individual vehicles refer exclusively to Volkswa‐

gen genuine wheels.

• Approval of wheel and tyre combinations or a change to

wheels from the accessories trade is not possible with the

parts certificate attached here.

2. Legislative and technical conditions for converting wheel and tyre combinations 3

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

• Tubeless radial tyres may only be fitted to rims with a safety

hump feature on the shoulder.

• If the wheel and tyre combinations listed are used, the asso‐

ciated tyre inflation pressures must be adhered to. The tyre

inflation pressure for summer tyres can be found on the sticker

on the inside of the tank flap or in the tables of the individual

vehicles.

• Sufficient clearance to the wheels and tyres at parts of the

wheel housing, suspension and braking system is assured if

the notes and specifications established in the parts certificate

are observed in all operating conditions.

• Unless otherwise stated, snow chains may be fitted only to the

drive wheels.

• The same sized wheels and tyres must be used at the front

and rear of the vehicle. On vehicles with all-wheel drive, tyres

must be of the same manufacturer and have the same tread

profile.

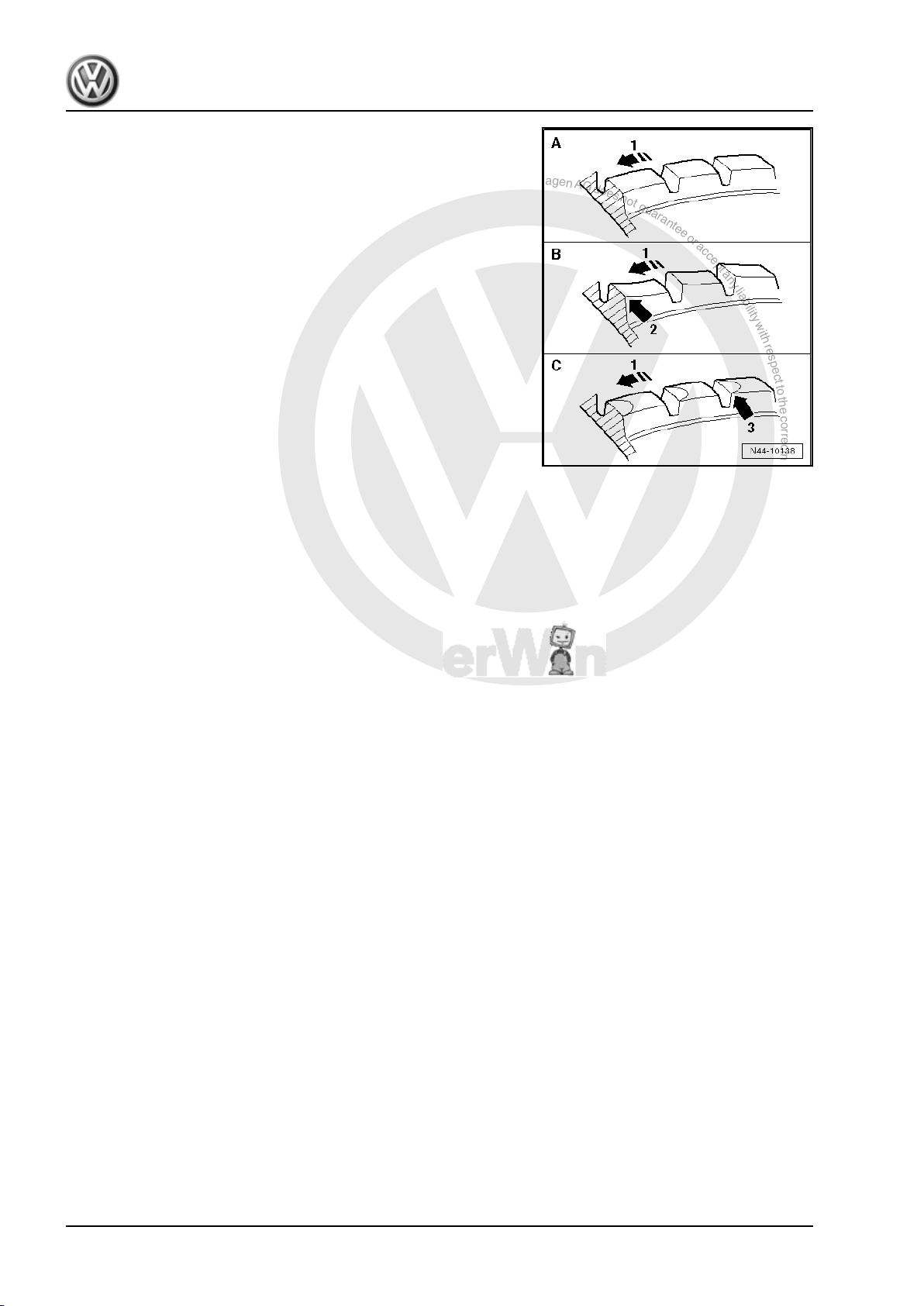

2.3 Additional wheel housing extensions

For technical reasons, some vehicles require wheel housing ex‐

tensions on the wing or bumper -arrows- when using certain

wheel and tyre combinations.

Please check if there is a requirement to fit the extensions.

The information is located in the overview table for the respective

vehicle.

2.4 “Series 80” tyres

Tyres of the “80” series (e.g. 145/80 R 13 74 S) will replace the

“82” series (e.g. 145/82 R 13 74 S). Legislation stipulates that “82”

series tyres may be replaced by “80” series tyres without having

been entered in the vehicle documents.

The condition for this is that the “80” series tyres have the same

width are of the same type – cross-ply or radial belted – and have

the same or higher load index.

If only “80” series tyres are entered in the vehicle documents, “82”

series tyres may only be used if an entry has been made in the

vehicle documents.

4 Rep. gr.44 - Wheels, tyres, vehicle geometry

P

r

o

t

e

c

t

e

d

b

y

c

o

p

y

r

i

g

h

t

.

C

o

p

y

i

n

g

f

o

r

p

r

i

v

a

t

e

o

r

c

o

m

m

e

r

c

i

a

l

p

u

r

p

o

s

e

s

,

i

n

p

a

r

t

o

r

i

n

w

h

o

l

e

,

i

s

n

o

t

p

e

r

m

i

t

t

e

d

u

n

l

e

s

s

a

u

t

h

o

r

i

s

e

d

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

V

o

l

k

s

w

a

g

e

n

A

G

d

o

e

s

n

o

t

g

u

a

r

a

n

t

e

e

o

r

a

c

c

e

p

t

a

n

y

l

i

a

b

i

l

i

t

y

w

i

t

h

r

e

s

p

e

c

t

t

o

t

h

e

c

o

r

r

e

c

t

n

e

s

s

o

f

i

n

f

o

r

m

a

t

i

o

n

i

n

t

h

i

s

d

o

c

u

m

e

n

t

.

C

o

p

y

r

i

g

h

t

b

y

V

o

l

k

s

w

a

g

e

n

A

G

.

Amarok 2011 ➤ , Caddy 2004 ➤ , Caddy 2011 ➤ , Caddy Kasten/Kombi 1996 ➤ ...

Wheels and Tyres Guide - Edition 11.2012

3 Documents and codes/designations

3.1 New vehicle registration documents since 01.10.2005

The implementation of EU Directive 1999/37/EU "Registration

Documents for Vehicles" in national law and legal requirements

for data protection have necessitated the introduction of new, fal‐

sification-proof registration documents.

Since 01.10.2005, only the new documents are issued by the

registration authorities in the event of new registrations, change

of ownership, registration of technical modifications and all other

matters.

The new registration documents are comprised of:

♦ Registration certificate part I, which replaces the certificate of

registration and

♦ Registration certificate part II, which replaces the vehicle log

book.

Registration certificate part I (certificate of registration)

♦ Contains all vehicle technical data which must be available to

register a vehicle in Europe; however, only one wheel and tyre

combination approved as standard is specified

♦ Contains the EU-wide, standardised, alphanumerical codes

assigned to the technical data, so that the German registration

certificate can be converted without problems into the regis‐

tration document prescribed in other EU states for registration

there

♦ Contains a field for documenting temporary or final immobili‐

sation of the vehicle, and is therefore no longer withdrawn in

the event of temporary or final immobilisation.

Registration certificate part II (vehicle log book)

♦ Contains the note that the holder of the registration certificate

is not identified as the owner

♦ Contains only the current and, if applicable, the previous ve‐

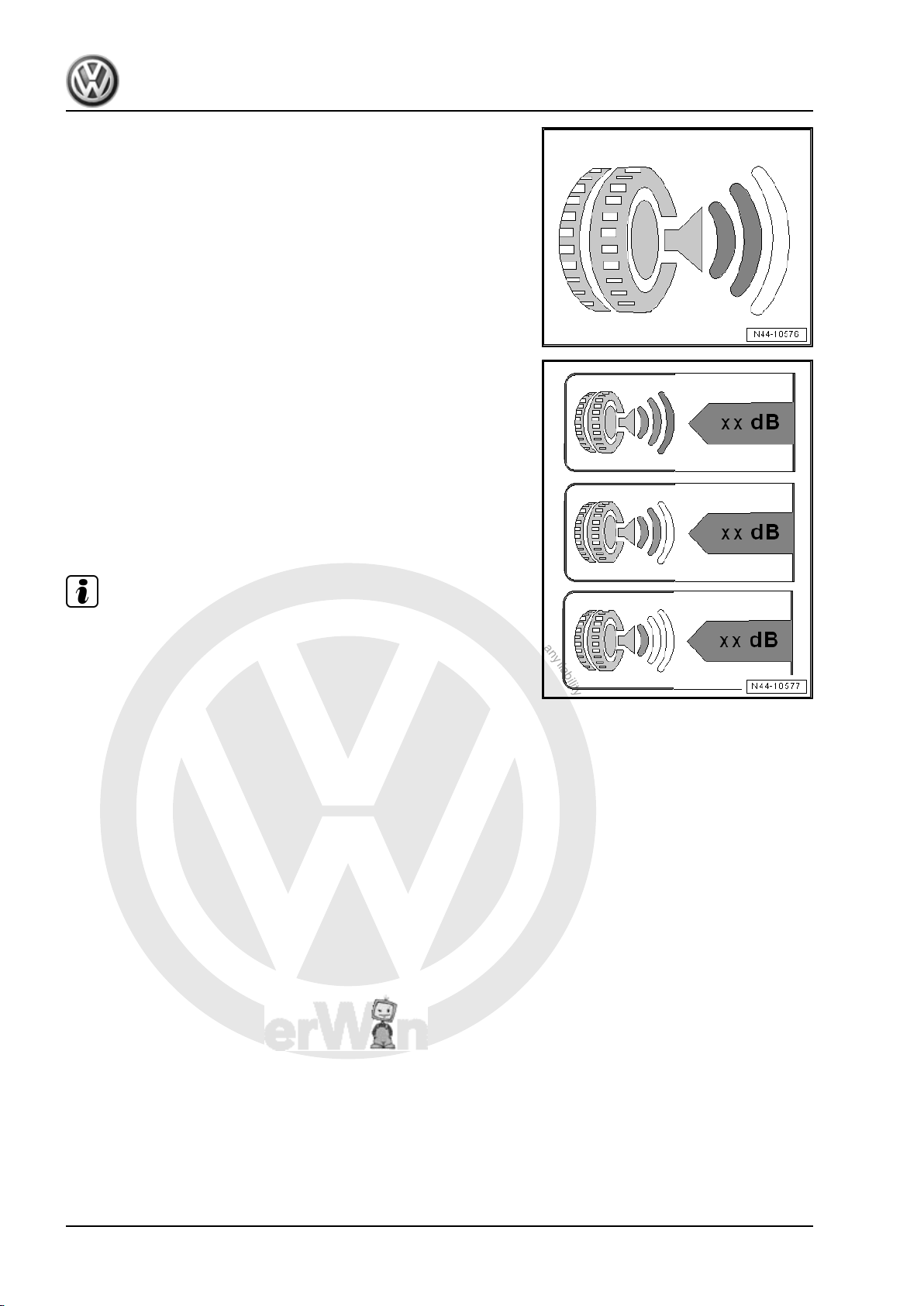

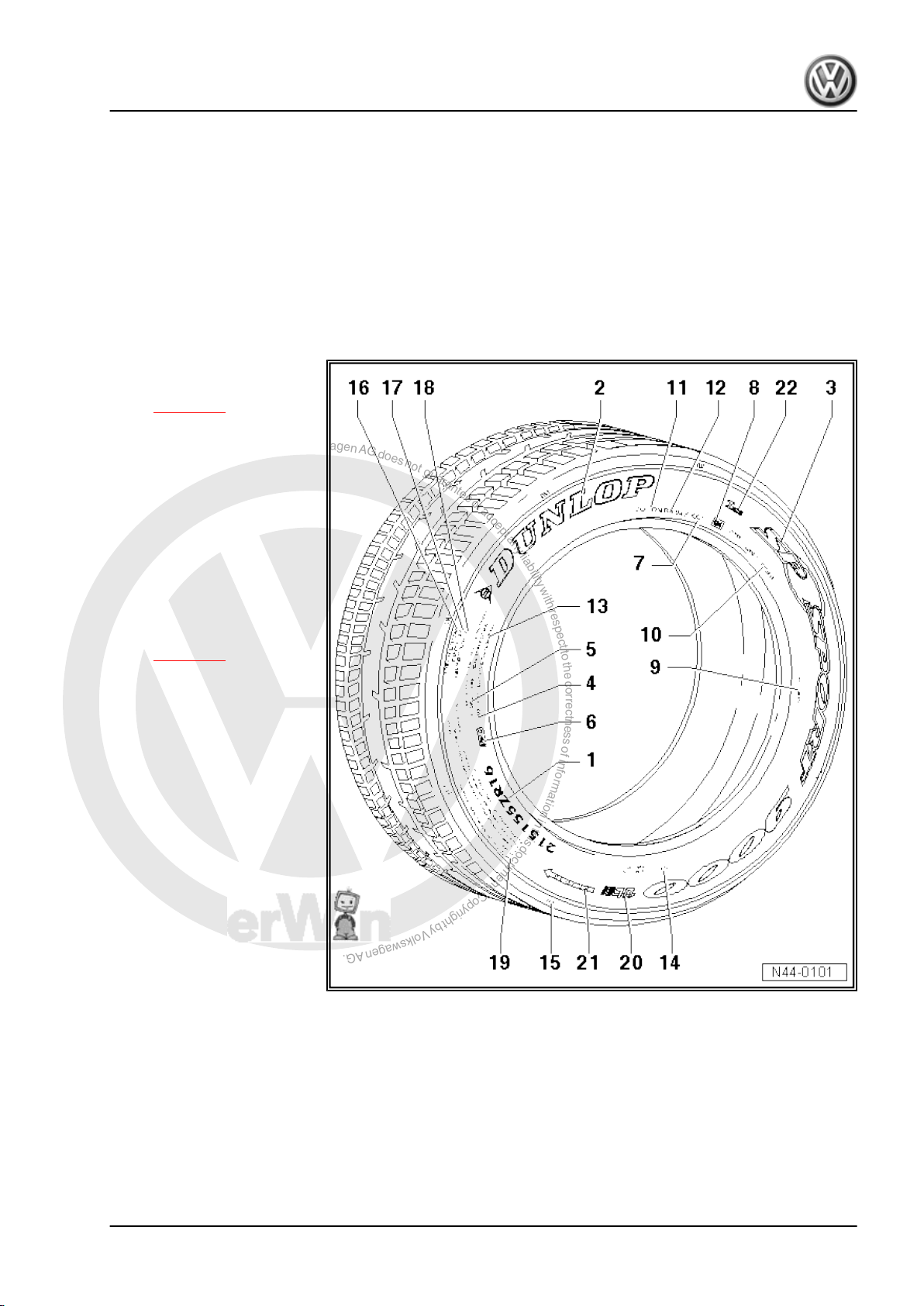

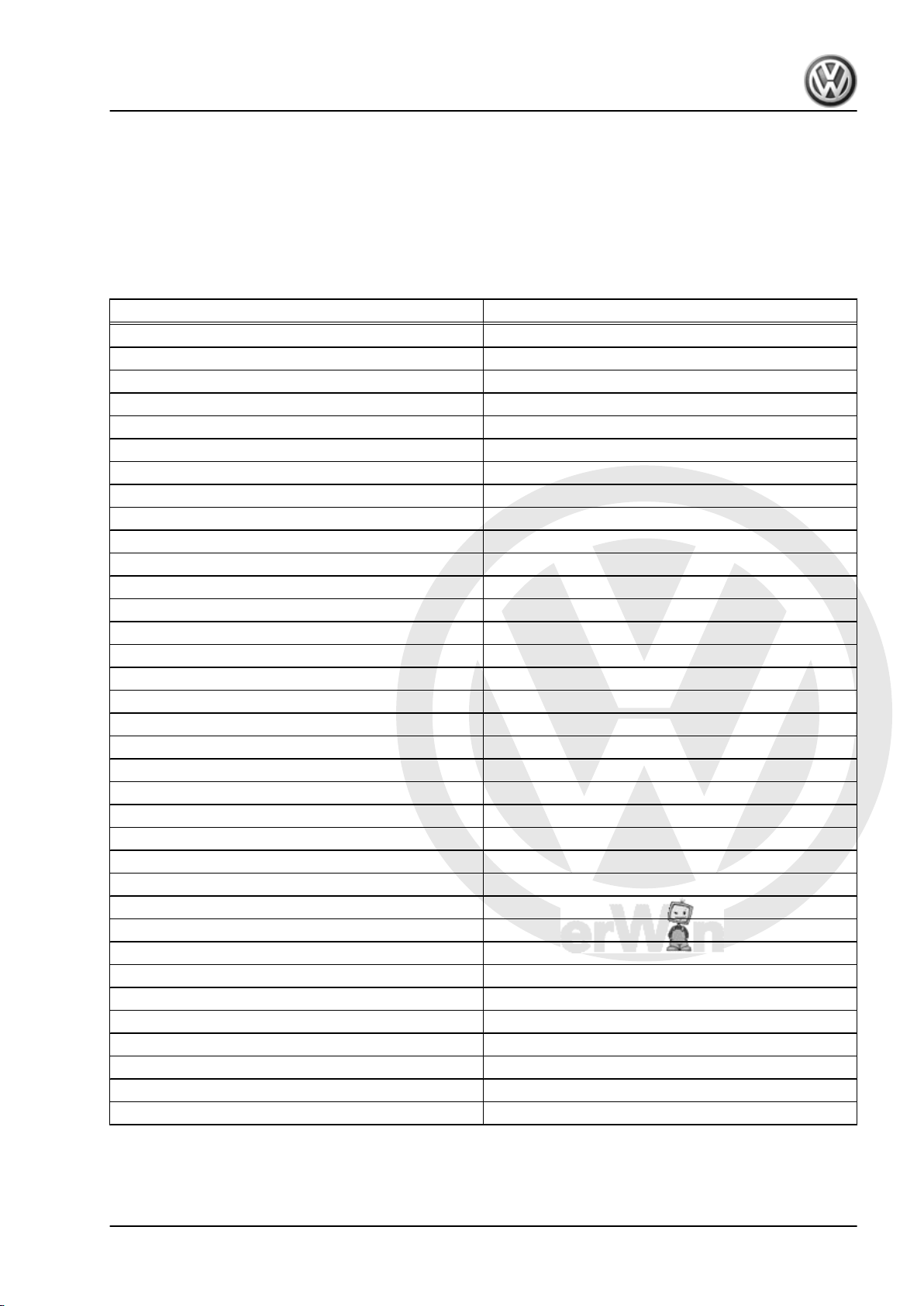

hicle keeper; the actual number of former keepers is shown