Vitek VT-3485 SERVICE MANUAL

VT-3485

CAUTION: Before servicing the chassis, read the "Important Service Safety Information"

section on page 2 of this manual.

RADIO CASSETTE RECORDER WITH CD/MP3 PLAYER

STNETNOC

IMPORTANT SERVICE SAFETY INFORMATION

SPECIFICATIONS

DISASSEMBLY INSTRUCTIONS

ALIGNMENT PROCEDURES

TROUBLESHOOTING GUIDE

BLOCK DIAGRAM

WIRING DIAGRAM

IC BLOCK DIAGRAM

PRINTED CIRCUIT BOARDS

SCHEMATIC DIAGRAMS

EXPLODED VIEW

EXPLODED PARTS LIST

REPLACEMENT PARTS LIST

2

3-6

7

8

9

10

11

12-15

16-22

23-26

27

28

29-40

IMPORTANT SERVICE SAFETY INFORMATION

1.

SAFETY PRECAUTIONS

Before returning a unit to the customer, always make a safety check of

the entire unit, including, but not limited to the following items:

a. Be sure that no built-in protective devices are defective and/or have

been defeated during servicing.

(1)

Protective shields are provided to protect both the technician and

the customer. Correctly replace all missing protective shields

including any removed for servicing convenience.

(2)

When reinstalling the chassis and/or other assemblies in the

cabinet, be sure t put back in place all protective devices, including,

but not limited to, nonmetallic control knobs, insulating fishpapers,

adjustment and compartment covers/shields and isolation resistor/

capacitor networks. Do not operate this unit or permit it to be

operated without all protective devices correctly installed and

functioning.

b.

Be sure that there are no cabinet openings through which an adult or

child might be able to insert their fingers and contact a hazardous

voltage. such openings include, but are not limited to, excessively wide

cabinet ventilation slots, and an improperly fitted and/or incorrectly

secured cabinet back cover.

c.

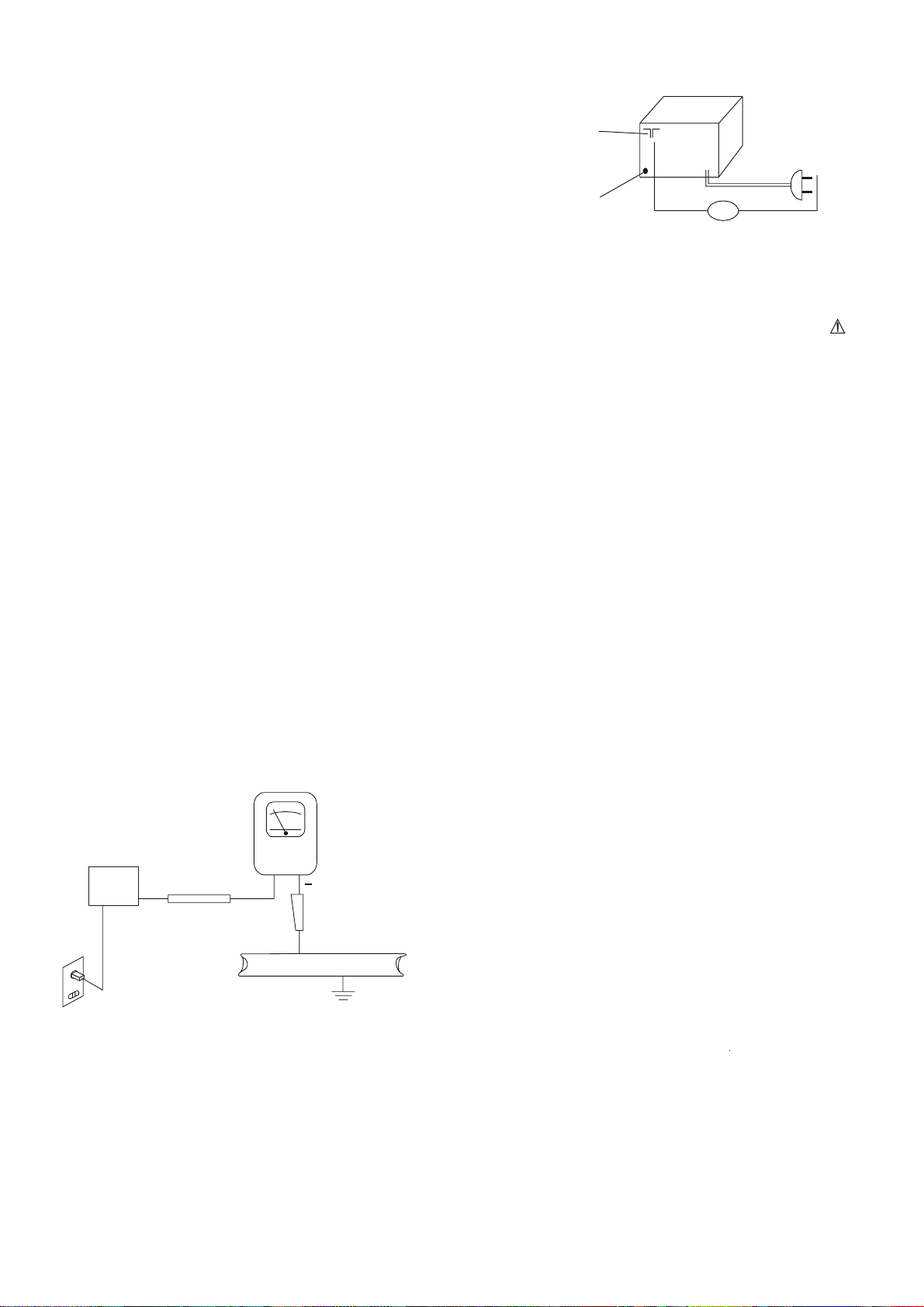

" Leakage Current Hot Check - With the unit completely reassembled,

plug the AC line cord directly into a (EU voltage)V AC outlet. (Do not

use an isolation transformer during this test.) Use a leakage current

tester or a metering system that complies with IEC60990 figure 4. With

the unit AC switch first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe, conduit, etc.),

especially any exposed metal parts that offer an electrical return path to

the chassis. Any current measured must not exceed the following

values:

. for a.c.: U1 = 35 V (peak) and U2 = 0,35 V (peak);

. for d.c.: U1 = 1,0 V.

NOTE: The limit values of U2 = 0,35 V (peak) for a.c. and U1 = 1,0 V for

d.c. correspond to the values 0,7 mA(peak) a.c. and 2,0 mA d.c.

The limit value U1 = 35 V (peak) for a.c. corresponds to the value 70

mA (peak) a.c. for frequencies greater than 100 kHz.

Reverse the unit power cord plug in the outlet and repeat test. ANY

MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HERENIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE

ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

"

(READING SHOULD

NOT BE ABOVE

0.5mA)

AC Leakage Test

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

d.

Insulation Resistance Test Cold Check

Unplug the power supply cord and connect a jumper wire between the

two prongs of the plug.

Turn on the power switch of the unit.

Measure the resistance with an ohmmeter between the jumpered AC

plug and each exposed metallic cabinet part on the unit, such as

screwheads, antenna, control shafts, handle brackets, etc. When the

exposed metallic part has a return path to the chassis, the reading

should be between 1 and 5.2 megohms. When there is no return path to

the chassis, the reading must be “infinite”. If it is not within the limits

specified, there is the possibility of a shock hazard, and the unit must be

repaired and rechecked before it is returned to the customer.

TEST ALL

EXPOSED METAL

SURFACES

+

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

ANTENNA

TERMINAL

EXPOSED

METAL

PART

2.

PRODUCT SAFETY NOTICE

OM

OHMMETER

Some electrical and mechanical parts have special safety related

characteristics which are often not evident from visual inspection, nor

can the protection they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage, etc. Parts that

have special safety characteristics are identified by a on

schematic and parts list. Use of a substitute replacement that does not

have the same safety characteristics as the recommended

replacement part might create shock, fire, and/or other hazards.

Product safety is under review continuously and new instructio ns are

issued whenever appropriate.

SERVICING PRECAUTIONS

3.

CAUTION”Before servicing the unit covered by this service manual

and its supplements read and follow the SAFETY PRECAUTIONS on

this page. NOTE”If unforeseen circumstances create a conflit

between the following servicing precautions and any of the safety

precautions, always follow the safety precautions. Rem ember: Safety

First.

General Servicing Precautions.

a. Always unplug the unit’s AC power cord from the AC power

source before:

(1) removing or reinstalling any component, circuit board, module, or

any other unit assembly.

(2) disconnecting or reconnecting any unit electrical plug or other

electrical connection.

(3) connecting a test substitute in parallel with an electrolytic

capacitor in the unit.

Caution: A wrong part substitution or incorrect polarity installation

of electrolytic capacitors may result in an explosion

hazard.

b. Do not defeat any plug/socket B+ voltage interlocks with which

the unit covered by this service manual might be equipped.

c. Do not apply AC power to this unit and/or any of its electrical

assemblies unless all solid-state device heat sinks are correctly

installed.

d. always connect a test unit instrument’s ground lead to the unit’s

chassis ground before connecting the test instrument’s positive

lead. Always remove the test instrument’s ground lead last.

LASER PRECAUTIONS

4.

WARNING!!

When servicing, (in case it is necessary to confirm Laser Beam

1.

Emission) be sure not to place your eyes any closer than 1 ft or

30cm from the surface of the Objective Lens on the Opticval

Pickup Block.

HANDLING THE LASER PICKUP

2.

Laser diodes are extremely susceptible to damage from static

electricity. Even if a static discharge does not ruin the diode, it can

shorten its life or cause it to work improperly. When replacing the

pickup, use a conductive mat on the floor and desk and wear a

wrist band connected to ground through a 1M ohm resistor to

protect the laser diode from static damage. If the lens should get

dusty, blow off the dust carefully from the object.

3.

There are no adjustable parts in the pickup assembly. If it is

defective, replace the whole pickup assembly.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS OR PERFORMANCE OF

PROCEDURES HEREIN MAY RESULT IN HAZARDOUS

RADIATION EXPOSURE.

DANGER:

IF INTERLOCK FAILS OR IS DEFEATED, THE LASER LIGHT IS

ABLE TO FUNCTION. THE LASER IS INVISIBLE, AVOID DIRECT

EXPOSURE TO BEAM.

2

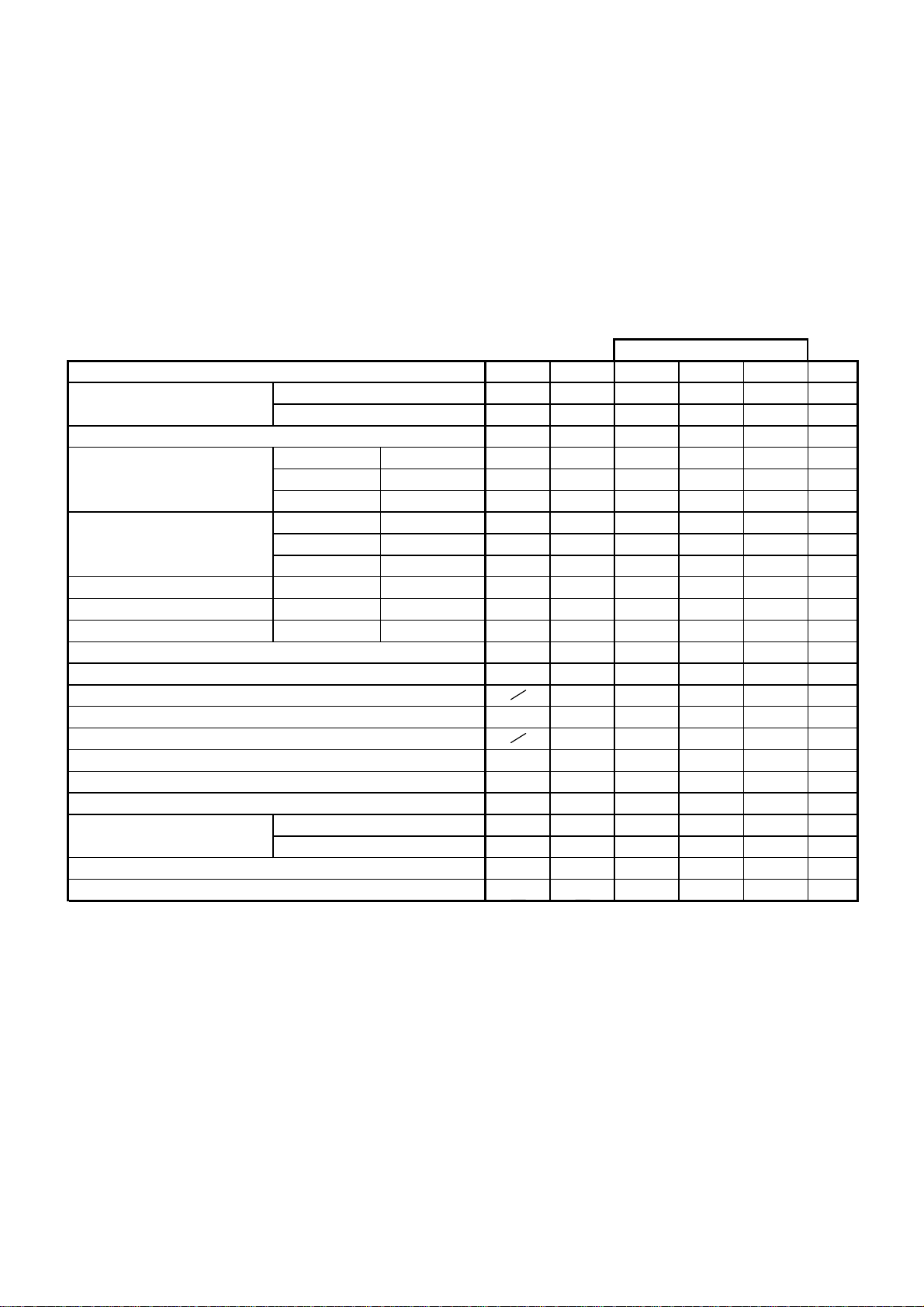

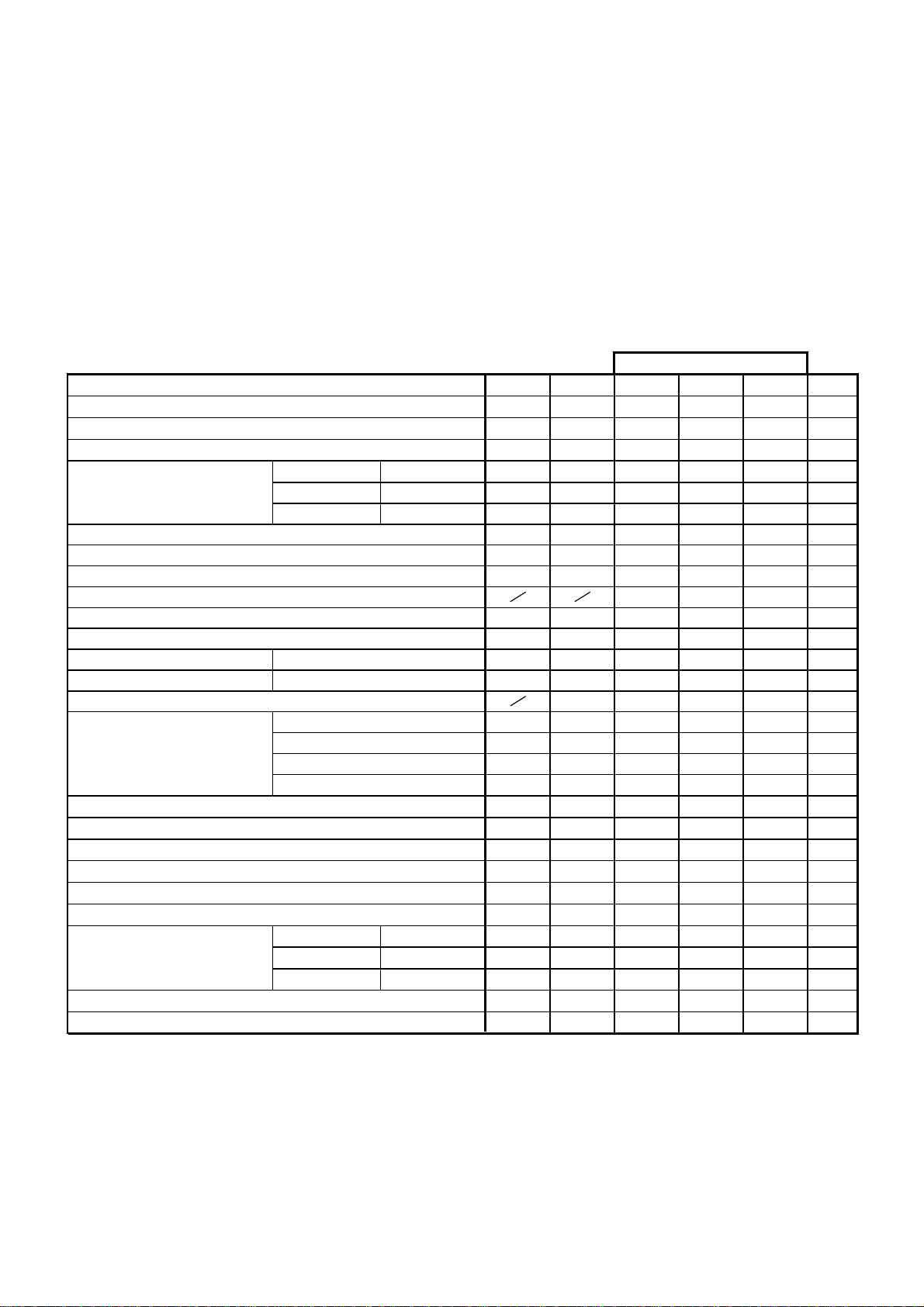

SPECIFICATIONS

GENERAL

POWER INPUT----------------------------------POWER CONSUMPTION---------------------

AM/FM TUNER SECTION

ANTENNA SYSTEM-----------------------------

TUNING RANGE----------------------------------

BAND SECTION:AM

AC 230V, 50Hz

AM: FERRITE BAR

FM: PIG TAIL

AM: 522~1620KHz

FM: 87.5~108MHz

LOW END

HIGH END

AUDIO SECTION

SPEAKER IMPEDANCE-----------------------

SAMPLE

6 ohms

smho23----------------ECNADEPMISENOHPDAEHsttaW02CA

TINU321timiLlamroNMETI

zHK4-/+025EGNAR.10

zHK0255-/+0171

zHK01713+054.F.I.20

M/Bd0548505zHK016

M/Bd948505zHK0001ytivtisneSXAM.30

M/Bd848505zHK0041)Bd6-(

M/Bd048626zHK016rofytivtisneS.40

M/Bd858626zHK0001N/SBd02M/Bd268626zHK0041

M/Bd066606zHK016ytivtisneSnacSOTUA.50

M/Bd454685zHK0001

M/Bd454685zHK0041

Bd450405zHK016tanoitcejeRF.I.60

Bd040252zHK0041tanoitcejeRegaml.70

%101<.F.Ix2zHK009m/Vm5tateewT.80

Bd0251-/+02-/+zHK0001tazHK01-/+.A.C.A.90

zHK2151-5m/Bd001zHK0001taBd6-htdiWdnaB.01

Bd470454m/Bd001zHK0001ta)Bd01-(C.G.A.11

%131tuptuO.FERtanoitrotsiD.21

W28.12m/Bd001%08.DOM@rewoPtuptuOXAM.31

zH05051001woLesnopseRycneuqerF.41

zHK5.32.23hgiHBd6-

Vm131muHemuloVNIM.51

Bd835203m/Bd001zHK0001@muHnoitaludoM.61

3

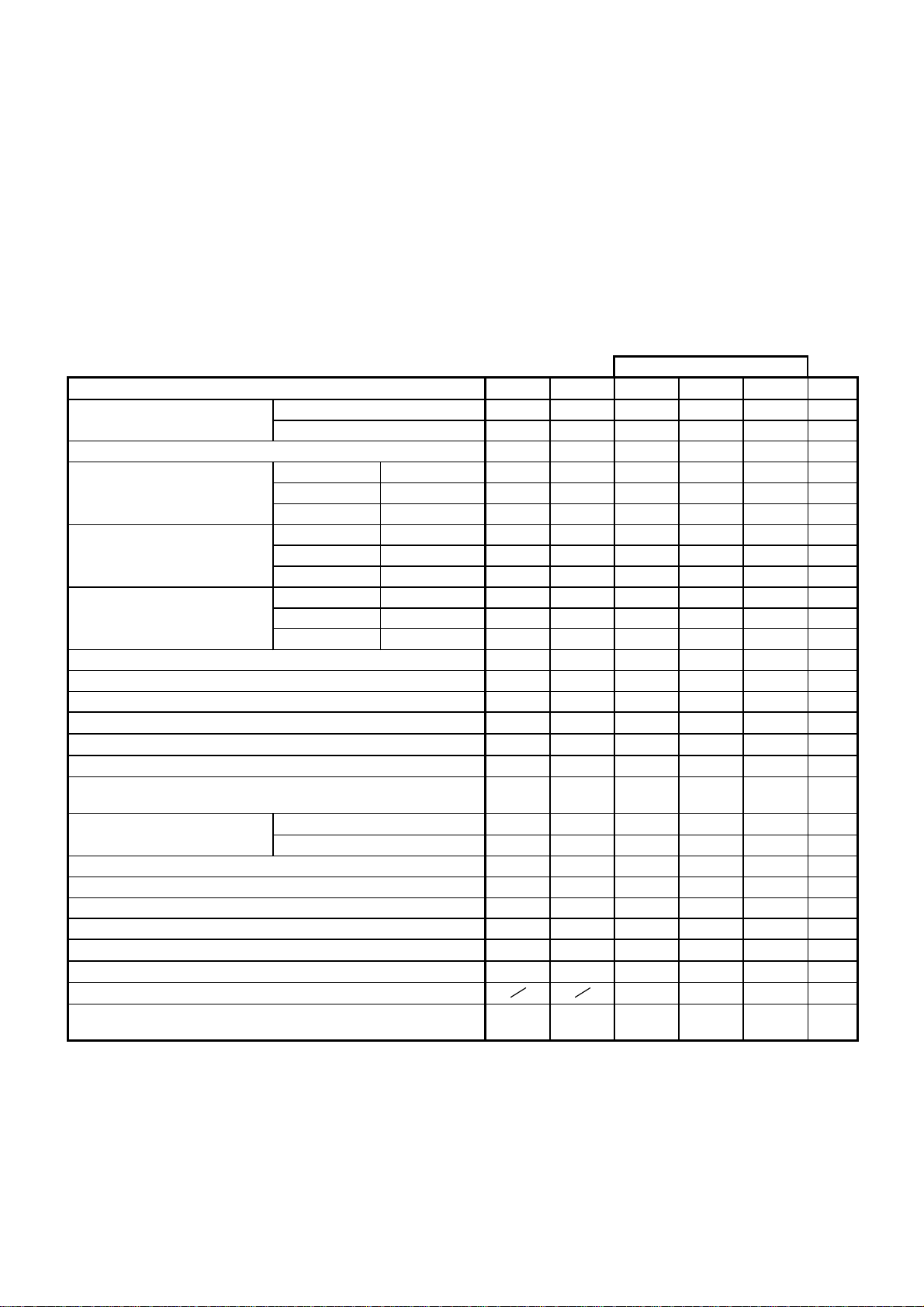

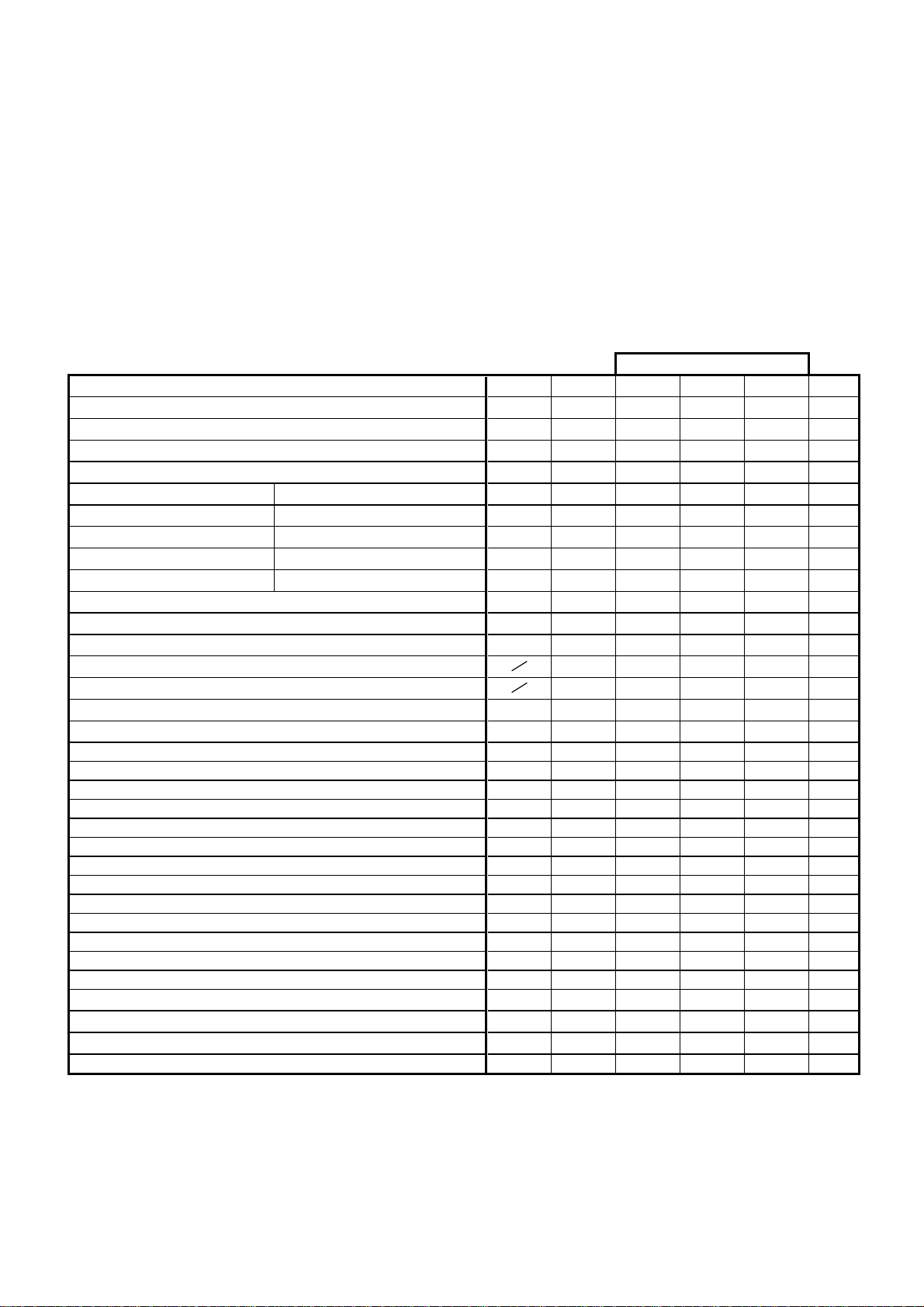

SPECIFICATIONS

GENERAL

POWER INPUT----------------------------------POWER CONSUMPTION---------------------

AC 230V, 50Hz

AUDIO SECTION

SPEAKER IMPEDANCE-----------------------

6 ohms

smho 23----------------ECNADEPMI SENOHPDAEHsttaW02CA

AM/FM TUNER SECTION

ANTENNA SYSTEM-----------------------------

TUNING RANGE----------------------------------

BAND SECTION:AM

AM: FERRITE BAR

FM: PIG TAIL

AM: 522~1620KHz

FM: 87.5~108MHz

SAMPLE

LOW END

HIGH END

12. Power at 75KHz DEV. 1mV

MAX Output Power

14. Modulation Hum @100dB Bd050454

15. MIN Volume Hum Vm131

MULTIPLEX

02. Separation at 98.1MHz with 19KHz Filter at 45K DEV.1mV Bd725282

04. S/N Ratio dB

05. Stereo Distortion at 98.1MHz

REF Output with 19KHz Filter at45KHz 1mV

TINU321timiLlamroNMETI

zHM5.781.0-/+5.78EGNAR.10

zHM8011.0-/+801

zHM7.011.0-/+7.01ycneuqerFetaidemretnl.20

Bd010261zHM1.09

Bd90261zHM1.89ytivtisneSXAM.30

Bd010261zHM1.601)Bd6-(

Bd316222zHM1.09rofytivtisneS.40

Bd316222zHM1.89N/SBd03Bd416222zHM1.601

Bd123372zHM1.09ytivitisneSnacSOTUA.50

Bd123372zHM1.89

Bd323372zHM1.601

Bd055405zHM09tanoitcejeR.F.I.60

Bd928142zHM601tanoitcejeRegamI.70

Bd70342Vm1zHM89taytivtisneSgnitimiLBd3-.80

Bd235203Vm1zHM89tanoisserppuS.M.A.90

Bd450464Vm1zHM89taoitaRN/S.01

%2.031tuptuOFERtanoitrotsiD.11

W28.12

ZH05051001woLesnopseRycneuqerF.31

zHK545hgiHBd6-

Bd415202zHM89taytivtisneSnoitacidnloeretS.10

Bd131ecnalaBlennahC.30

%5.253

4

SPECIFICATIONS

GENERAL

POWER INPUT----------------------------------POWER CONSUMPTION---------------------

AM/FM TUNER SECTION

ANTENNA SYSTEM-----------------------------

TUNING RANGE----------------------------------

BAND SECTION:TAPE

FM 40KHz DEV. 1MV REF Bd0FER

13. Audio Balance

14. Bass Boost at 100Hz

RECORDING / PLAYBACK ( DC BIAS )

AM 50% Modulation 0 Bd13-/+

TAPE -4dB

CD -10dB

AC 230V, 50Hz

AM: FERRITE BAR

FM: PIG TAIL

AM: 522~1620KHz

FM: 87.5~108MHz

AUDIO SECTION

SPEAKER IMPEDANCE-----------------------

SAMPLE

+3 Bd23-/+

-3 Bd3-3-/+

+6 Bd82-/+

6 ohms

smho 23----------------ECNADEPMI SENOHPDAEHsttaW02CA

TINU321timiLlamroNMETI

%1.053.0N111-TTMrettulF&woW.10

%5.131N811-TTMnoitrotsiDkcaByalP.20

zH0603%2-/3+0003N111-TTMdeepSepaT.30

Bd03-/+0zH521

Bd0FERFERzHK1esnopseRycneuqerFyalP.40

Bd06-/3+0zHK01

Bd535203121-TTM)retliFtuohtiW(klaTssorC.50

Bd440353B211-TTM)retliFtuohtiW(oitaRN/S.60

Bd538233141-TTMnoitarapS.70

%talF@QE/PBd0tceffElortnoC.loVXAM.80

W3.222NB211-TTMrewoPtuptuOXAM.90

Bd5.030N811-TTMecnereffiDlennahCR/L.01

Vm131emuloVNIMesioN&muH.11

Vm520453emuloVXAM

CES071<EPYT06-C).WER&.DWF(emiTgnidniW.21

%2016noitrotsiDR/P.10

Bd823282oitaResarEP/R.20

Bd733282oitaRN/SP/R.30

Bd5.030ecnalaBlennahCP/R.40

Bd1-6-/3+0zH521

Bd00FERzHK1esnopseRycneuqerFP/R.50

Bd8-6-/3+0zHK8

Bd33±3+Vm1zHK5.22MFlevelP/R.60

zHK065±zHK06ycneuqerFtnerrucsaiBCA.70

5

SPECIFICATIONS

GENERAL

POWER INPUT----------------------------------POWER CONSUMPTION---------------------

AC 230V, 50Hz

AM/FM TUNER SECTION

ANTENNA SYSTEM-----------------------------

TUNING RANGE----------------------------------

BAND SECTION:TAPE

05. Frequency Response: (TCD-781)

AM: FERRITE BAR

FM: PIG TAIL

AM: 522~1620KHz

FM: 87.5~108MHz

AUDIO SECTION

SPEAKER IMPEDANCE-----------------------

SAMPLE

1-2-/+1-zHK61

6.222rewoPtuptuOemuloVXAM.70

5

575657)A444-CBS(tnirpregniF.21

04107041)117-DCT(yticirtneccE.31

6 ohms

smho 23----------------ECNADEPMI SENOHPDAEHsttaW02CA

TINU321timiLlamroNMETIDC

Bd5.021ecnalaBlennahC.10

%1.021)187-DCT()Bd01-zHK1(noitrotsiD.20

Bd750525)287-DCT()Bd0zHK1(FPBo/wN/S.30

Bd440353)287-DCT()Bd0zHK1(noitarapSlennahC.40

Bd02-/+1-zH721

Bd0FERFERzHK1

dB

Bd1-2-/+2-zHK81

Vm131muHemuloVNIM.60

W

W3.28.12rewoPtuptuOnoitrotsiD%01DC.80

CES36<)287-DCT()KCARTTSRIF(emiTsseccA.90

CES21<)287-DCT()KCARTTSAL(

MU009006009)A444-CBS(noitpurretnl.01

MU008006008)A444-CBS(toDkcalB.11

UM

UM

MU00010080001)R237-DCT(noitaiveDlacitreV.41

6

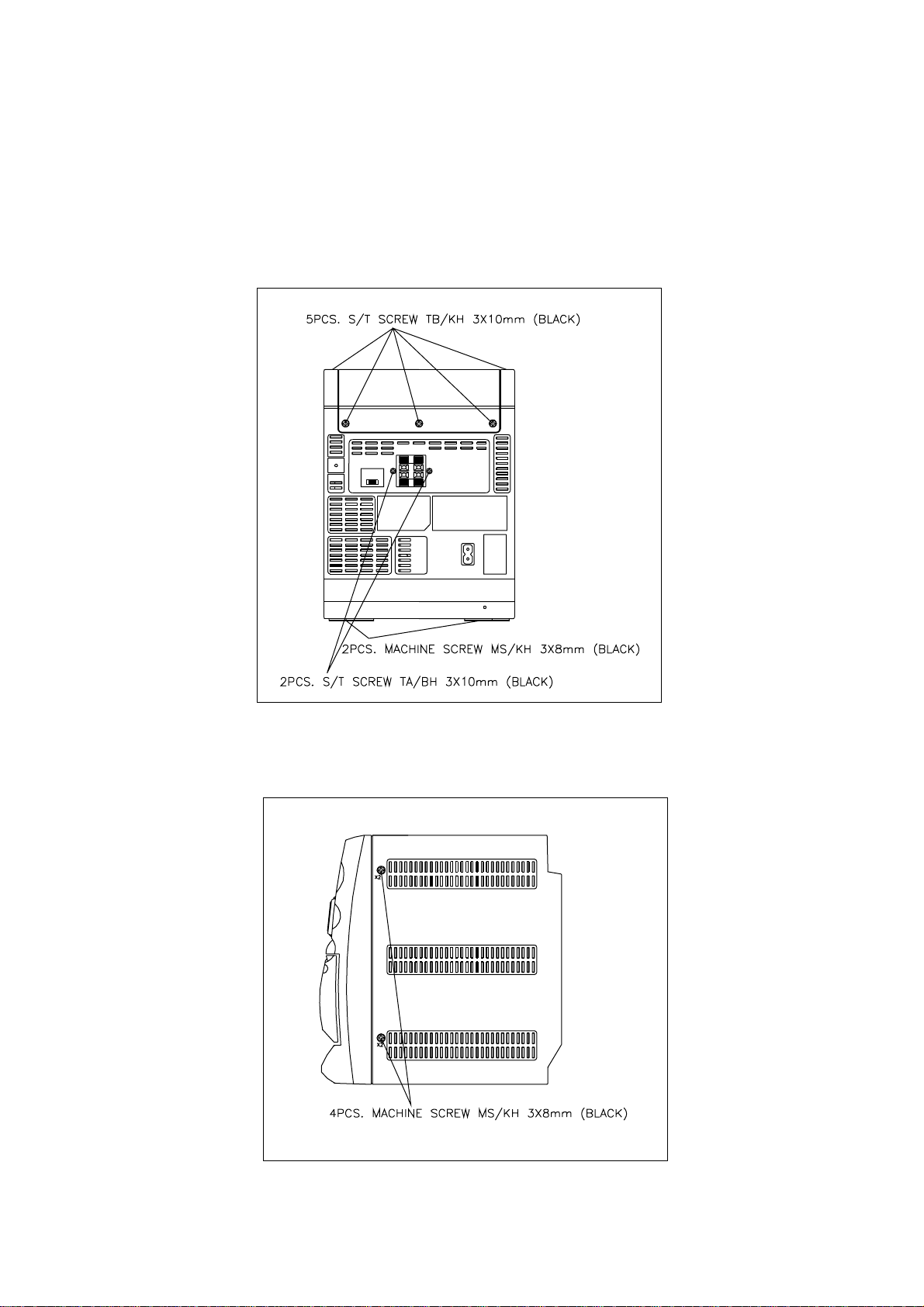

DISASSEMBLY INSTRUCTIONS

1) ROTATE THE UNIT TO EXPOSE THE BACK SIDE.

2) REMOVE THE 9 SCREWS AS SHOWN IN FIG.1.

3) ROTATE THE UNIT TO EXPOSE THE LEFT SIDE AND RIGHT SIDE.

4) REMOVE THE 4 SCREWS AS SHOWN IN FIG.2.

FIG1

FIG2

7

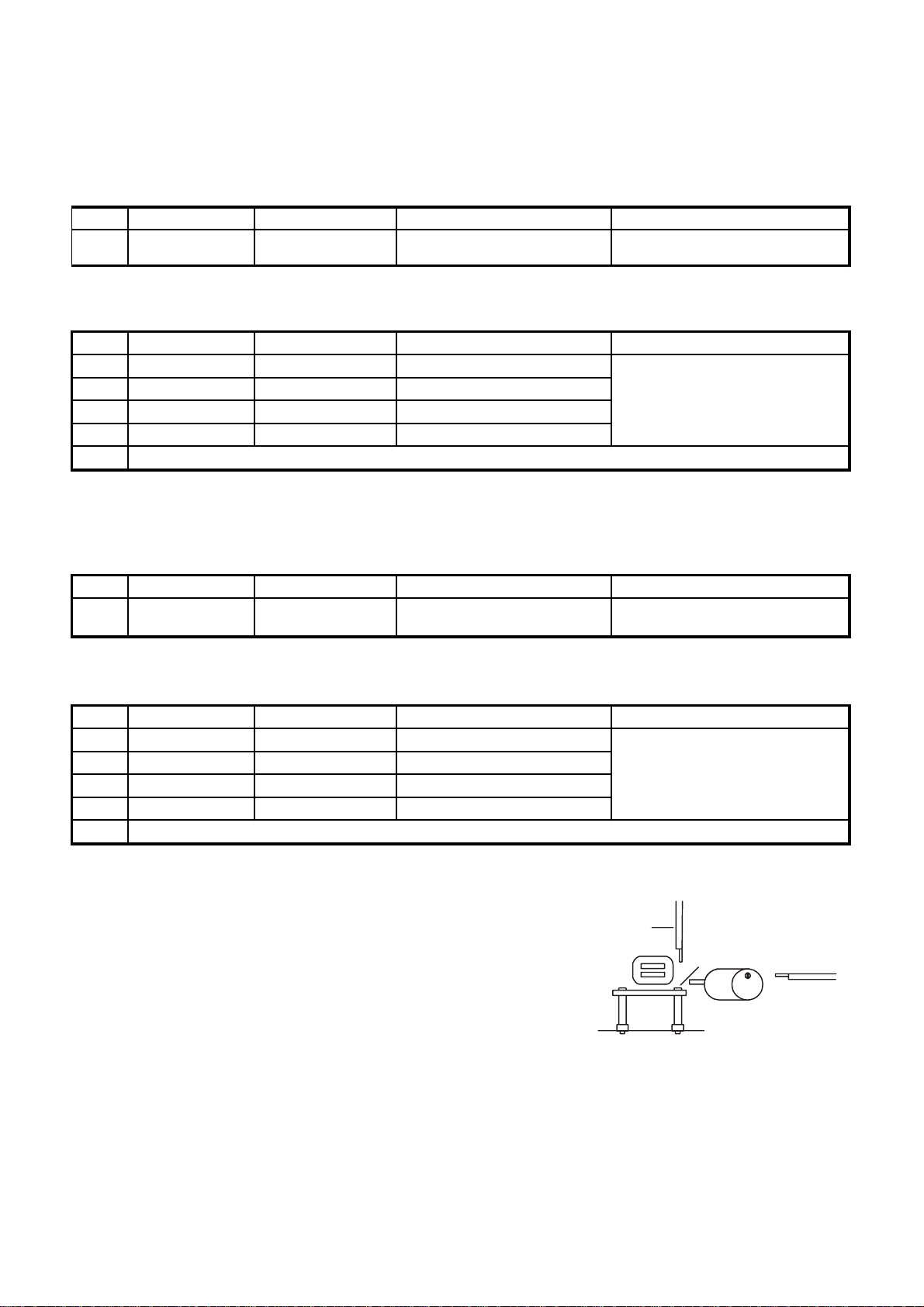

ALIGNMENT PROCEDURES

AM I.F. ALIGNMENT

1. Set the POWER BUTTON to POWER "ON".

2. Set the FUNCTION SELECTOR SWITCH to RAD IO & AM BAND.

3. Connect a SWEEPSCOPE OUTPUT to AM antenna terminal.

4. Connect a SWEEPSCOPE INPUT to pin13 or 14 of IC1 through a 1uf capacitor and ground.

1450KHz GANGOPEN CF2(AMIF)

AM R.F. ALIGNMENT

1. Connect an RF generator to a standard radiating loop.

2. Connect a SCOPE and VTVM across the speaker output.

1 520KHz GANG CLOSED T2 (AMOSCCOIL)

2 1710KHz GANG OPEN CT1 (AM OSC TRIM.) MAX IM UM

3 610KHz 600KHz AMCOIL(AM ANT COIL) OUTPUT

4 1400KHz 1400KHz CT3 (AMANTTRIM.)

5 REPEAT STEPS 3 AND 4 TO OBTAIN BEST TRACKING.

FM I.F. ALIGNMENT

1. Set the POWER SWITCH to POWER "ON" .

2. Set the FUNCTION SELECTOR to RADIO & FM BAND .

3. Connect a SWEEPSCOPE OUTPUT to pin21 of I C1 through a 20pF capacitor and ground.

4. Connect a SWEEPSCOPE INPUT to pin13 or 14 of IC1 through a 1uf capacitor and ground.

1

10.7MHz GAND OPEN CF3 (FM ORG)

& MAXIMUM OUTPUT

MAX.AMPLITUDE

BALANCED CURVE

ROF TSUJDATSUJDALAID TESLANGIS TESPETS

CENTER

ROF TSUJDATSUJDALAID TESLANGIS TESPETS

ROF TSUJDATSUJDALAID TESLANGIS TESPETS

FM R.F. ALIGNMENT

1. Connect an RF generator to the FM antenna terminal and ground.

2. Connect a SCOPE & VTVM across the speaker output.

1

2 108MHz GANG OPEN MAXIMUM

3 90.1MHz 90.1MHz L4 (FM RF COIL) OUTPUT

4 106.1MHz 106.1MHz CT2(FMRF TRIM)

5 REPEAT STEPS 3 AND 4 TO OBTAIN MAX ADJUST.

87.5MHz

GANG CLOSED

L3 (FM OSC COIL)

CASSETTE ALIGNMENT

1. Set the FUNCTION SELECTOR SWITCH TO TAPE.

2. Connect a Scope & VTVM across the speaker output.

3. Insert the 8KHz tape in to cassette deck and push play BUTTON.

4. ADJUST HEAD for speaker maximum output.

5. Motor speed adjustment for tape speed.

SCREWDRIVER

ADJUSTING

SCREW

CD ALIGNMENT

Auto alignment.

MOTOR

ROF TSUJDATSUJDALAID TESLANGIS TESPETS

SCREWDRIVER

8

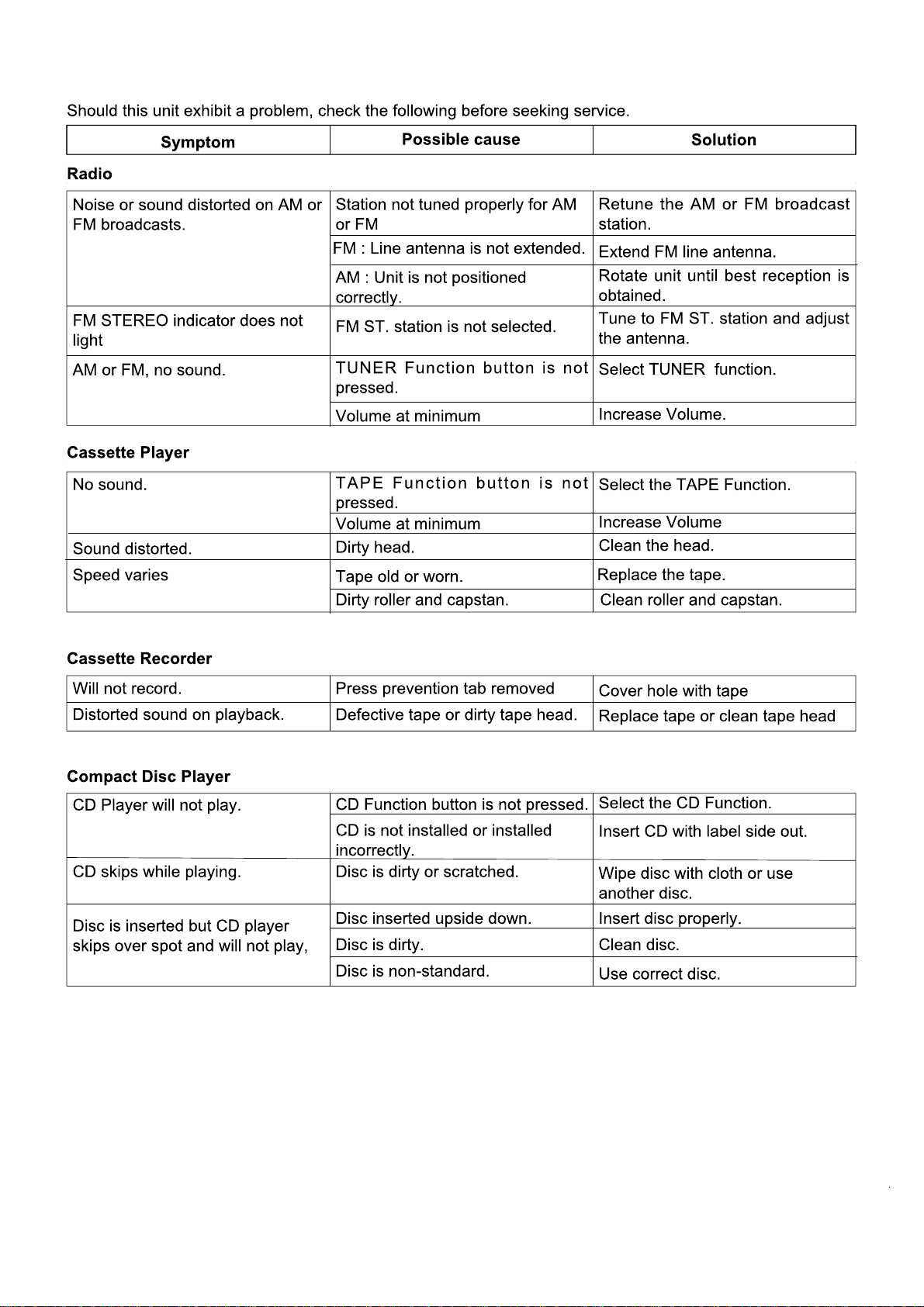

TROUBLESHOOTING GUIDE

9

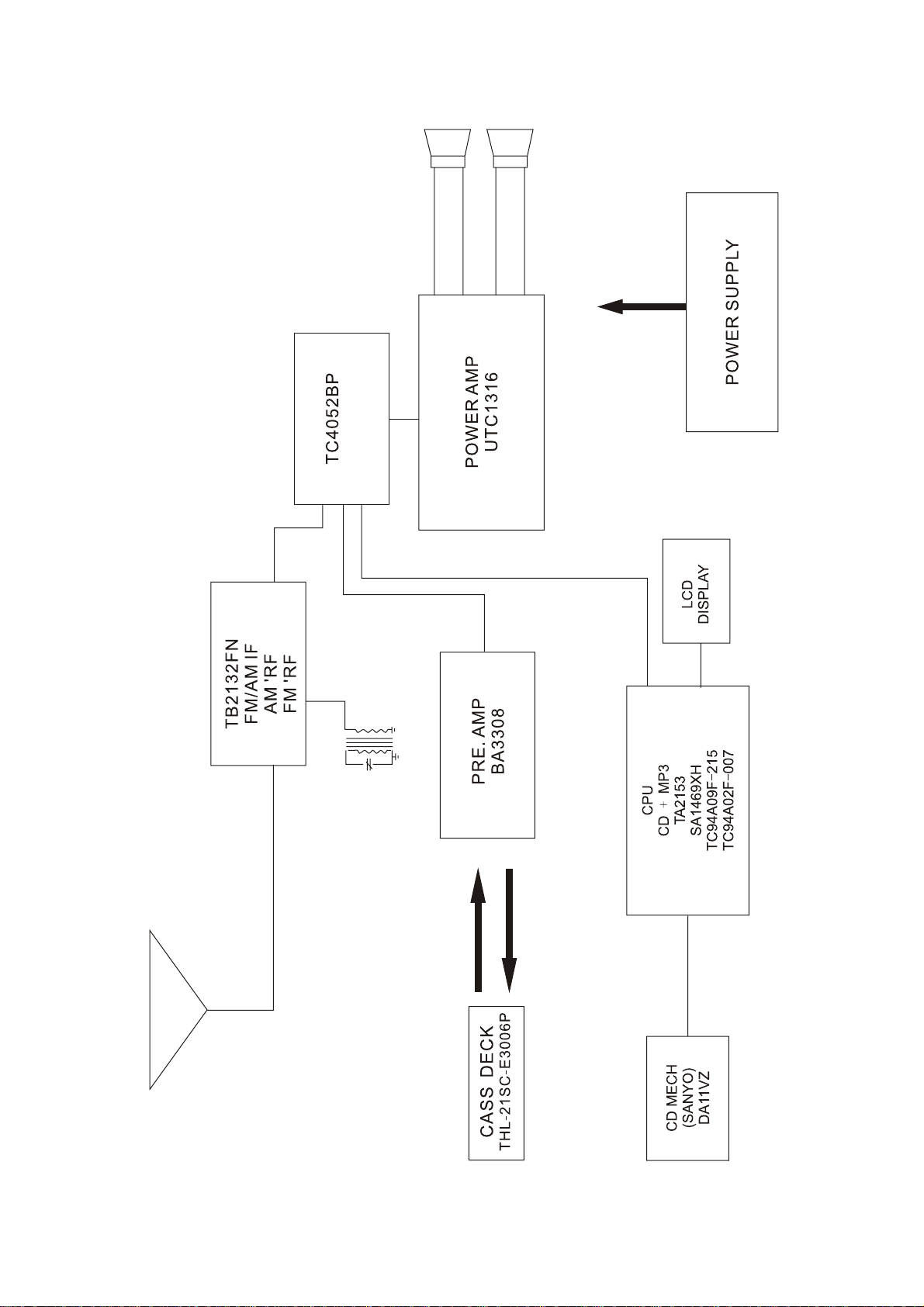

BLOCK DIAGRAM

10

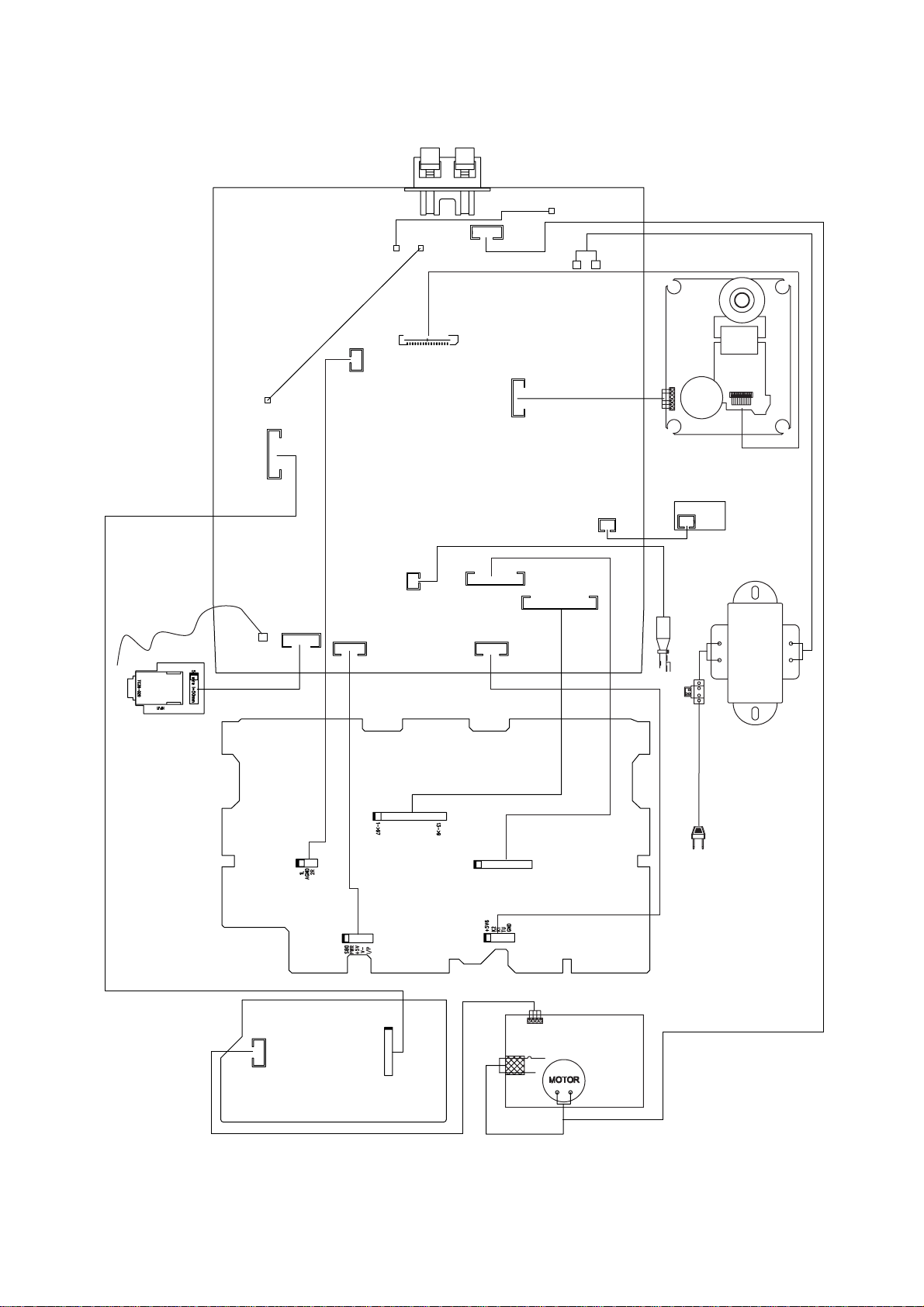

WIRING DIAGRAM

TO SPEAKER

SPKJ1

CN7

CN302

16P 1mm 180C

4P 2.5mm 180C

CN4

3P 2mm 180C

G3

G1

G2

AC1

AC2

CD DECK

CNP5

G4

CN5

8P 2mm 180C

FM-ANT

CN8

5P 2.5mm 180C

MAIN PCB BOARD

CN10

5P 2mm 180C

CN301

2P 2mm 180C

CN2

10P 2mm 180C

CN3

5P 2mm 180C

DISPLAY PCB BOARD

DISPLAY

CN303

6P 2mm 180C

CN1

13P 2mm 180C

CN304

2P 2mm 180C

CNP304

CD door switch

TRANSFORMER

CNP4

CNP4

RECODER PCB BOARD

CW3

CNP5

CW1

CW2

CASSETTE DECK

11

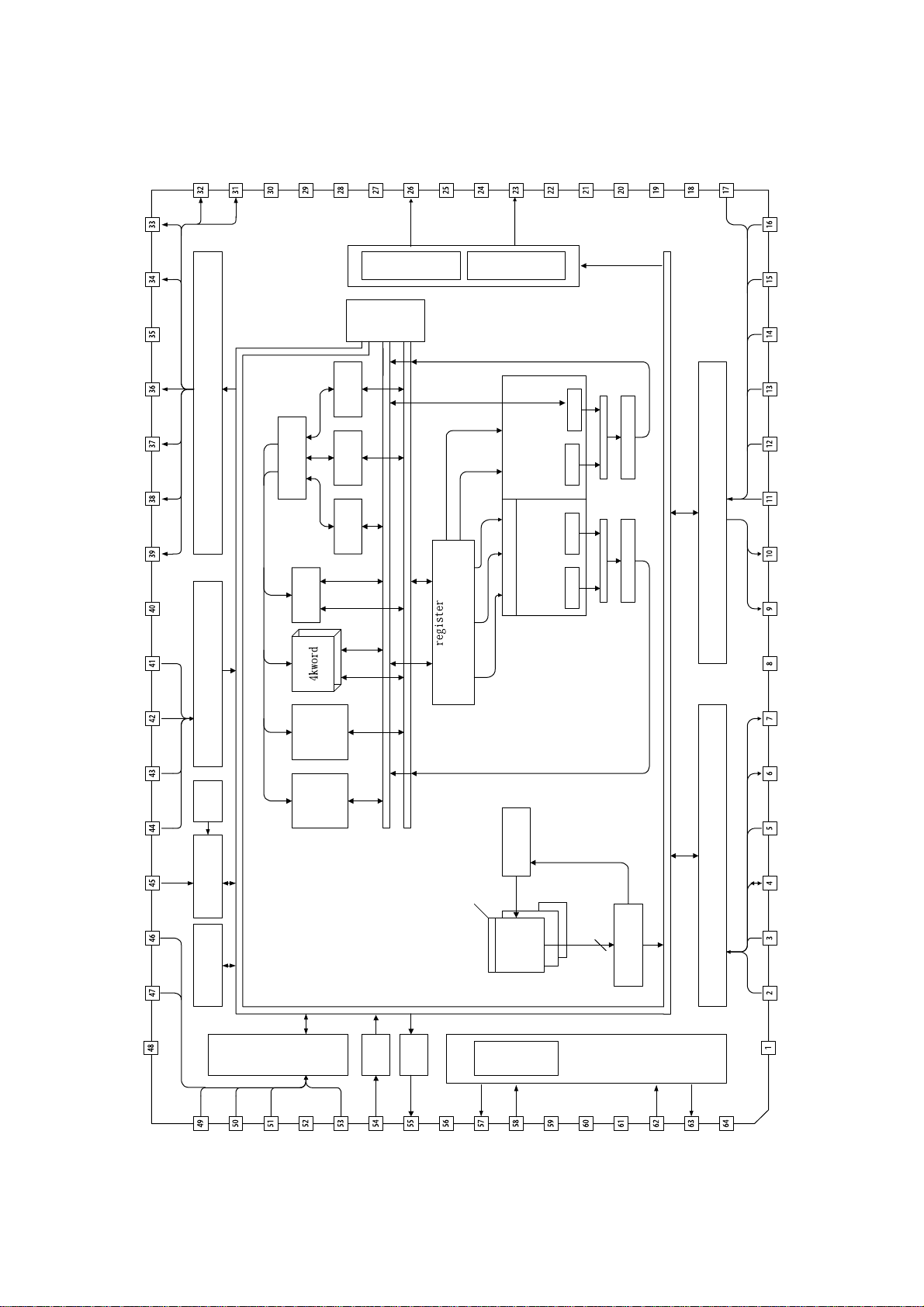

TC94A02F-007

IC BLOCK DIAGRAM

AD10

AD9

VDDT

AD8

AD7

AD6

REQ

VSS

AD11

General

Output Port

AD12

CKS

TESTP

2sets

Address Calc.

ERAM

2k word

VSSR

register

C-Pointer

register

Y-Pointer

register

X-Pointer

VRAR

Bus

DAC

Switch

VDAR

Ro

VDAL

DAC

VRAL

Lo

VSSL

VSS

STANDBY

VDD

/oE

/CE

AD5

LRCKiA

BCKiA

A3

SDi0

AD4

AD3

AX AY

ALU

A2

A1

round & limit

Audio I/F

MAC

MX MY MZ

A0

round & limit

SDo

AD13

AD14

/WR

AD16

AD15

VSS

io0

io1

Flag

Timer

Control

Interrupt

SRAM I/F

I-Bus

Input Port

General

*3

CROM

4k word

YRAM

4k word

XRAM

Prog.

X-Bus

Start

Y-Bus

DIT

X0 X1 X2

Y0 Y1 Y1

PRAM

256word

PROM

VCO

Control

Program

4k*2+2k

=10kword

40bit

Generator

Timing

Decoder

Instruction

Microcom. I/F

VDDT

AD2

/MiCK

MiDio

AD1

AD0

MiMD

/RESET

io2

io3

io4

VDD

io5

io6

io7

VSSP

12

PDo

VCoi

VDDP

CKO

VDDX

Xi

Xo

VSSX

Loading...

Loading...