Viking Pump TSM430 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

JACKETED ASPHALT PUMPS

NOTE: The Technical Service Manual for the electrically heated pumps

is located in the Universal Seal manuals: TSM 630.1 (H-LL sizes),

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . 1

Special Information . . . . . . . . . . . . . . . . . . . 1

Safety Information. . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . 3

Disassembly . . . . . . . . . . . . . . . . . . . . . . 6

Assembly . . . . . . . . . . . . . . . . . . . . . . . . 7

Valve Instructions . . . . . . . . . . . . . . . . . . . . 8

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and should not be used for ordering parts.

Secure a parts list from the factory or a Viking representative.

Always give complete name of part, part number and material

with the model and serial number of the pump when ordering

repair parts.

UNMOUNTED PUMP UNITS

PACKED MECH. SEAL

HL34 HL434

KK34 KK434

LQ34 LQ434

Q34 Q434

M34 M434

N34 N434

This manual deals exclusively with series 34 and 434

Jacketed General Purpose Pumps. Refer to Figures 1

through 11 for general configuration and nomenclature used

in this manual.

Units are designated by the

unmounted pump model

numbers followed by a

letter indicating drive style.

V = V-belt

TSM 630.2 (LS-QS sizes) and TSM 630.3 (N-RS sizes)

SECTION TSM 430

PAGE 1 OF 9

SERIES 34 AND 434

ISSUE G

SIZES HL, KK, LQ, Q, M, N

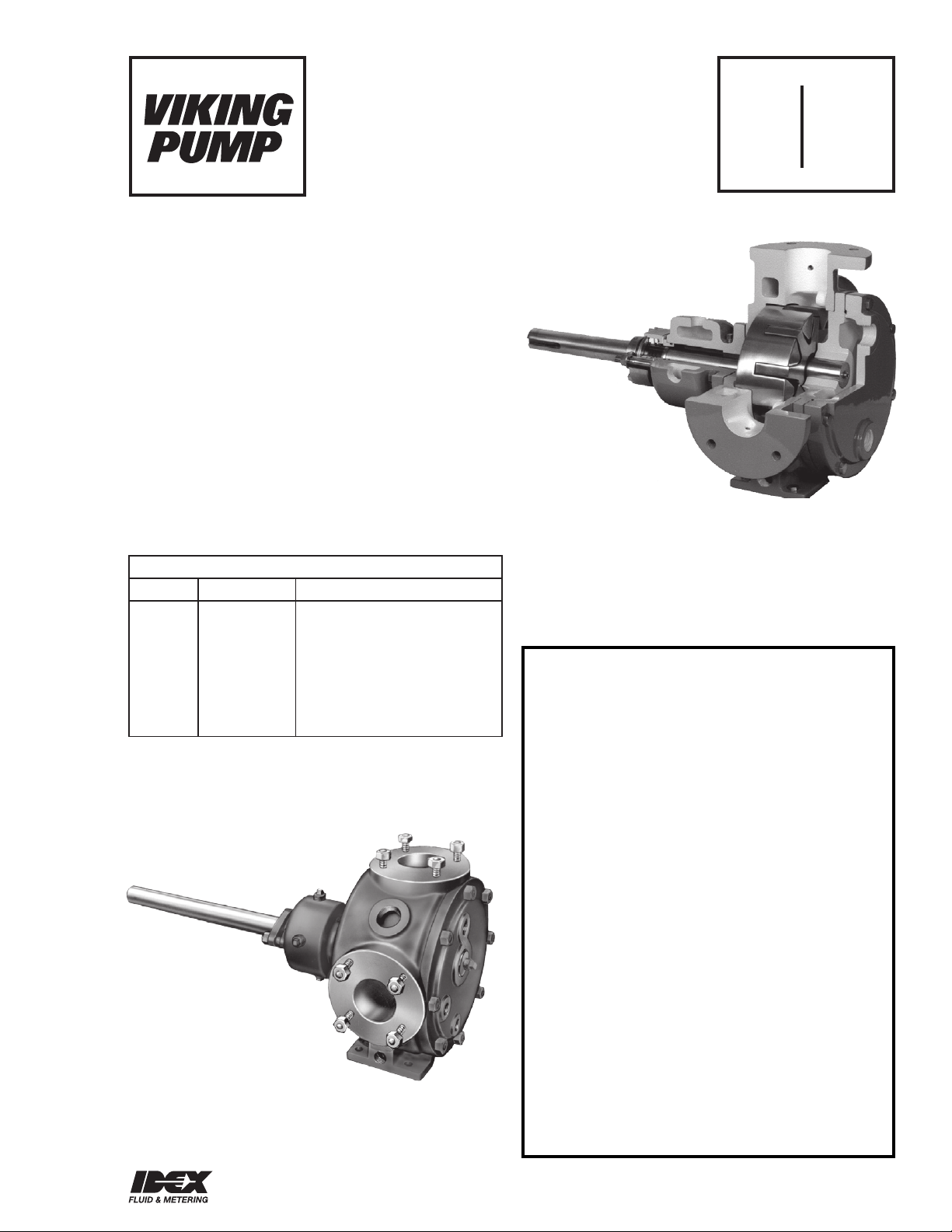

FIGURE 2

CUTAWAY VIEW OF SERIES 434

JACKETED PUMP

SPECIAL INFORMATION

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor, turbine,

engine, etc.) has been “locked out” or

made non-operational so that it cannot

be started while work is being done

on pump.

3. That you know what liquid the pump

has been handling and the precautions

necessary to safely handle the liquid.

Obtain a material safety data sheet

(MSDS) for the liquid to be sure these

precautions are understood.

FIGURE 1

ILLUSTRATION OF SERIES 34

JACKETED PUMP

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

Failure to follow above listed

precautionary measures may result in

serious injury or death.

SAFETY INFORMATION AND INSTRUCTIONS

IMPROPER INSTALLATION, OPERATION OR MAINTENANCE OF PUMP MAY CAUSE SERIOUS INJURY

OR DEATH AND/OR RESULT IN DAMAGE TO PUMP AND/OR OTHER EQUIPMENT. VIKING’S WARRANTY

DOES NOT COVER FAILURE DUE TO IMPROPER INSTALLATION, OPERATION OR MAINTENANCE.

THIS INFORMATION MUST BE FULLY READ BEFORE BEGINNING INSTALLATION, OPERATION OR

MAINTENANCE OF PUMP AND MUST BE KEPT WITH PUMP. PUMP MUST BE INSTALLED, OPERATED

AND MAINTAINED ONLY BY SUITABLY TRAINED AND QUALIFIED PERSONS.

THE FOLLOWING SAFETY INSTRUCTIONS MUST BE FOLLOWED AND ADHERED TO AT ALL TIMES.

Symbol

Legend :

!

!

!

!

!

WARNING

!

WARNING

Danger - Failure to follow the indicated

instruction may result in serious injury

!

or death.

BEFORE opening any liquid chamber (pumping

chamber, reservoir, relief valve adjusting cap fitting,

etc.) be sure that :

● Any pressure in the chamber has been completely

vented through the suction or discharge lines or

other appropriate openings or connections.

● The pump drive system means (motor, turbine,

engine, etc.) has been “locked out” or otherwise

been made non-operational so that it cannot be

started while work is being done on the pump.

● You know what material the pump has been

handling, have obtained a material safety data

sheet (MSDS) for the material, and understand

and follow all precautions appropriate for the safe

handling of the material.

BEFORE operating the pump, be sure all drive guards

are in place.

DO NOT operate pump if the suction or discharge

piping is not connected.

DO NOT place fingers into the pumping chamber or

its connection ports or into any part of the drive train

if there is any possibility of the pump shafts being

rotated.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those the pump was originally supplied, without

confirming its suitability for the new service.

BEFORE operating the pump, be sure that:

● It is clean and free from debris

● all valves in the suction and discharge pipelines

are fully opened.

● All piping connected to the pump is fully supported

and correctly aligned with the pump.

● Pump rotation is correct for the desired direction

of flow.

WARNING

WARNING

!

WARNING

!

!

!

WARNING

!

WARNING

Warning - In addition to possible serious

injury or death, failure to follow the

indicated instruction may cause damage

to pump and/or other equipment.

INSTALL pressure gauges/sensors next to the

pump suction and discharge connections to monitor

pressures.

USE extreme caution when lifting the pump. Suitable

lifting devices should be used when appropriate. Lifting

eyes installed on the pump must be used only to lift

the pump, not the pump with drive and/or base plate.

If the pump is mounted on a base plate, the base plate

must be used for all lifting purposes. If slings are used

for lifting, they must be safely and securely attached.

For weight of the pump alone (which does not include

the drive and/or base plate) refer to the Viking Pump

product catalog.

DO NOT attempt to dismantle a pressure relief valve

that has not had the spring pressure relieved or is

mounted on a pump that is operating.

AVOID contact with hot areas of the pump and/or

drive. Certain operating conditions, temperature

control devices (jackets, heat-tracing, etc.), improper

installation, improper operation, and improper

maintenance can all cause high temperatures on the

pump and/or drive.

THE PUMP must be provided with pressure protection.

This may be provided through a relief valve mounted

directly on the pump, an in-line pressure relief valve,

a torque limiting device, or a rupture disk. If pump

rotation may be reversed during operation, pressure

protection must be provided on both sides of pump.

Relief valve adjusting screw caps must always point

towards suction side of the pump. If pump rotation is

reversed, position of the relief valve must be changed.

Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure. For additional

information, refer to Viking Pump’s Technical Service

Manual TSM 000 and Engineering Service Bulletin

ESB-31.

THE PUMP must be installed in a matter that allows

safe access for routine maintenance and for inspection

during operation to check for leakage and monitor

pump operation.

SECTION TSM 430 ISSUE G PAGE 2 OF 9

ROTATION: Viking pumps operate equally well in a clockwise

or counter clockwise rotation. Shaft rotation determines

which port is suction and which is discharge. Port in area

where pumping elements (gear teeth) come out of mesh is

suction port.

PRESSURE RELIEF VALVES:

1. Viking pumps are positive placement pumps and must

be provided with some sort of pressure protection. This

may be a relief valve mounted directly on the pump, an

in-line pressure relief valve, a torque limiting device or a

rupture disk.

2. There are relief valve options available on these pumps.

Options may include a plain or a jacketed relief valve

depending on the pump size. Pumps equipped with a

jacketed head plate are generally not available with a

relief valve.

3. If pump rotation is to be reversed during operation,

pressure protection must be provided on both sides of

pump.

4. Relief valve adjusting screw cap must always point

towards suction side of pump. If pump rotation is

reversed, remove pressure relief valve and turn end for

end.

5. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

For additional information on pressure relief valves, Refer to

Technical Service Manual TSM000 and Engineering Service

Bulletin ESB-31.

MAINTENANCE

Series 34 and 434 jacketed pumps are designed for long,

trouble-free service life under a wide variety of application

conditions with a minimum of maintenance, however, the

following should be considered.

1. LUBRICATION: External lubrication must be applied

slowly with a handgun to all lubrication fittings every 500

hours of operation with multi-purpose grease, NLGI # 2.

Do not over-grease. Applications involving very high or

low temperatures will require other types of lubrication.

Refer to Engineering Service Bulletin ESB-515. Consult

factory with specific lubrication questions.

2. PACKING ADJUSTMENT: New packed pumps generally

require some initial packing adjustment to control leakage

as packing “runs-in”. Make initial packing adjustments

carefully and do not over-tighten the packing gland. After

initial adjustment occasional inspection will reveal the

need for packing gland adjustment and/or replacement

of the packing. See instructions in disassembly and

reassembly regarding re-packing the pump.

3. END CLEARANCE ADJUSTMENT: After long term

operation it is sometimes possible to improve the

performance of the pump, without major repair, through

adjustment of end clearance of the pump. Refer to

instructions under Step 3 of Assembly, page 7.

4. CLEANING PUMP: It is good practice to keep the pump

as clean as possible. This will facilitate inspection,

adjustment and repair work and help prevent omission

of lubrication to fittings covered or hidden with dirt.

5. STORAGE: If pump is to be stored, or not used for any

appreciable length of time it should be drained and a

light coat of lubricating and preservative oil should be

applied to the internal parts. Lubricate all fittings. Be

sure to drain all steam jacket chambers to prevent

freezing during cold weather. Tighten all assembly bolts

before the pump is put into service after being stored.

SUGGESTED REPAIR TOOLS: The following tools must be

available to properly repair Series 34 and 434 pumps. These

tools are in addition to standard mechanics’ tools such as

open end wrenches, pliers, screwdrivers etc. Most of the

items can be obtained from an industrial supply house.

1. Soft Headed Hammer

2. Packing hooks, flexible (packed pumps)

Large for 0.375 inch and up cross section packing

3. Arbor Press

4. Allen wrenches (for mechanical seals)

5. Feeler gage set (for mechanical seals)

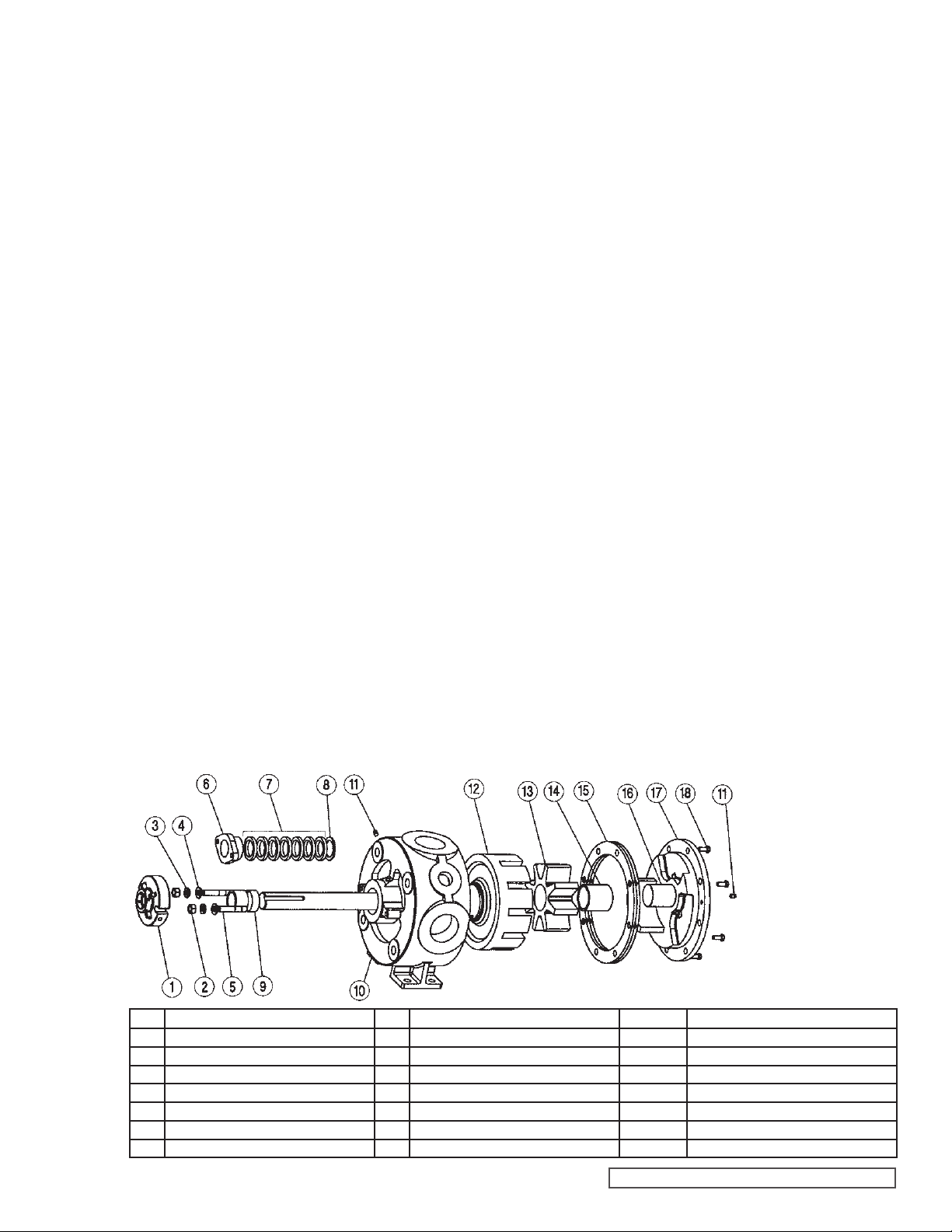

FIGURE 3

EXPLODED VIEW

SERIES 34 & 434 PUMPS (HL SIZE)

ITEM NAME OF PART ITEM NAME OF PART ITEM NAME OF PART

1 Mechanical Seal 8 Packing Retainer Washer 15 Head Gasket Set

2 Nut 9 Casing Bushing 16 Idler Pin

3 Lockwasher 10 Casing (Jacketed) 17 Head (Jacketed) and Idler Pin Assembly

4 Flat Washer 11 Pipe Plug 18 Capscrew

5 Stud 12 Rotor and Shaft Assembly Not Illus. Relief Valve

6 Packing Gland 13 Idler and Bushing Assembly Not Illus. Relief Valve Gasket

7 Packing 14 Idler Bushing Not Illus. Relief Valve Capscrews

SECTION TSM 430 ISSUE G PAGE 3 OF 9

Loading...

Loading...