Viking Pump TSM420 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

HEAVY-DUTY REFRIGERATION AMMONIA PUMPS

CONTENTS

Installation, General Comments . . . . . . . . . . . . 1

Pump Installation . . . . . . . . . . . . . . . . . . . . 3

Preventative Maintenance . . . . . . . . . . . . . . . 4

Safe Practices. . . . . . . . . . . . . . . . . . . . . . 5

Venting the Pump . . . . . . . . . . . . . . . . . . . . 5

Disassembly . . . . . . . . . . . . . . . . . . . . . . 7

Assembly . . . . . . . . . . . . . . . . . . . . . . . .10

Thrust Bearing Adjustment . . . . . . . . . . . . . . .11

Installation of Carbon Graphite Bushings . . . . . . . .12

Pressure Relief Valve Instructions . . . . . . . . . . 12

Troubleshooting. . . . . . . . . . . . . . . . . . . . .15

Ammonia . . . . . . . . . . . . . . . . . . . . . . . .16

INTRODUCTION

The illustrations in this manual are for identification purposes

only and cannot be used for ordering parts. Obtain a parts

list from the factory or a Viking® representative. Due to the

nature of the pump and the close manufacturing tolerances,

certain replacement parts are only available in assemblies.

Always give complete name of part, part number or material

with model number and series number of pump when ordering

repair parts. The pump or pump unit model number and serial

number are on the nameplate.

In the Viking® model number system, the basic size letters

are combined with the series (4925) indicating either an

unmounted pump or mounted pump unit.

Model Chart Number

UNMOUNTED UNITS

MECH. SEAL

HL4925

K4925

KK4925

LQ4925

LL4925

This manual deals exclusively with Series 4925 Heavy Duty

Refrigeration Ammonia Pumps. Refer to Figures 1 thru 24

for general configuration and nomenclature used in this

manual. NOTE: DO NOT OPERATE SERIES 4925 PUMPS

AT SPEEDS HIGHER THAN THOSE STATED IN CATALOG

SECTION 420 (Series 4925 Heavy Duty Refrigeration

Ammonia Pumps).

NOTE: Single reservoir sight glass is standard. Images are

shown with optional reservoir fittings.

Units are designated by the

unmounted pump model numbers

followed by a letter(s) indicating

drive style.

P = Commercial Speed Reducer

SECTION TSM 420

PAGE 1 Of 18

SERIES 4925

SIZES HL

-

LL

ISSUE E

FIGURE 1

Series 4925 Unmounted Pump

INSTALLATION,

GENERAL COMMENTS

Consideration of the following points during design and

installation of the system will help insure successful operation

of the Viking Refrigeration Ammonia Pump.

1. SUBMERGENCE - Submergence is the head of liquid

ammonia above the centerline of the pump suction port.

A liquid head is necessary to keep the ammonia from

flashing as it goes into the pump. The minimum liquid

head or submergence for good pump operation is 4 feet;

this is assuming a large, short suction line.

2. SUCTION LINE - A large, short suction line is necessary

for good operation. A good suction line:

2.1. is a suction line that is at least one size larger than

the pump suction port connection,

2.2. is connected to the pump by an eccentric reducer

(with the offset or eccentric portion down) when suction

to the pump is horizontal,

2.3. is as short as practical for the installation,

2.4. has no strainer (sometimes a temporary strainer is

used during start up to keep weld beads, etc., from going

through the pump),

2.5. uses a long sweep elbow if any elbow is

unnecessary,

2.6. has a full flow shut off valve,

2.7. and is fully insulated to prevent head pickup.

3. INSULATION - Insulation on the suction line and on the

pump helps reduce the amount of heat pickup by the

heat pickup by the liquid ammonia.

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

SAFETY INFORMATION AND INSTRUCTIONS

IMPROPER INSTALLATION, OPERATION OR MAINTENANCE OF PUMP MAY CAUSE SERIOUS INJURY

OR DEATH AND/OR RESULT IN DAMAGE TO PUMP AND/OR OTHER EQUIPMENT. VIKING’S WARRANTY

DOES NOT COVER FAILURE DUE TO IMPROPER INSTALLATION, OPERATION OR MAINTENANCE.

THIS INFORMATION MUST BE FULLY READ BEFORE BEGINNING INSTALLATION, OPERATION OR

MAINTENANCE OF PUMP AND MUST BE KEPT WITH PUMP. PUMP MUST BE INSTALLED, OPERATED

AND MAINTAINED ONLY BY SUITABLY TRAINED AND QUALIFIED PERSONS.

THE FOLLOWING SAFETY INSTRUCTIONS MUST BE FOLLOWED AND ADHERED TO AT ALL TIMES.

Symbol

Legend :

!

!

!

!

!

WARNING

!

WARNING

Danger - Failure to follow the indicated

instruction may result in serious injury

!

or death.

BEFORE opening any liquid chamber (pumping

chamber, reservoir, relief valve adjusting cap fitting,

etc.) be sure that :

● Any pressure in the chamber has been completely

vented through the suction or discharge lines or

other appropriate openings or connections.

● The pump drive system means (motor, turbine,

engine, etc.) has been “locked out” or otherwise

been made non-operational so that it cannot be

started while work is being done on the pump.

● You know what material the pump has been

handling, have obtained a material safety data

sheet (MSDS) for the material, and understand

and follow all precautions appropriate for the safe

handling of the material.

BEFORE operating the pump, be sure all drive guards

are in place.

DO NOT operate pump if the suction or discharge

piping is not connected.

DO NOT place fingers into the pumping chamber or

its connection ports or into any part of the drive train

if there is any possibility of the pump shafts being

rotated.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those the pump was originally supplied, without

confirming its suitability for the new service.

BEFORE operating the pump, be sure that:

● It is clean and free from debris

● all valves in the suction and discharge pipelines

are fully opened.

● All piping connected to the pump is fully supported

and correctly aligned with the pump.

● Pump rotation is correct for the desired direction

of flow.

WARNING

WARNING

!

WARNING

!

!

!

WARNING

!

WARNING

Warning - In addition to possible serious

injury or death, failure to follow the

indicated instruction may cause damage

to pump and/or other equipment.

INSTALL pressure gauges/sensors next to the

pump suction and discharge connections to monitor

pressures.

USE extreme caution when lifting the pump. Suitable

lifting devices should be used when appropriate. Lifting

eyes installed on the pump must be used only to lift

the pump, not the pump with drive and/or base plate.

If the pump is mounted on a base plate, the base plate

must be used for all lifting purposes. If slings are used

for lifting, they must be safely and securely attached.

For weight of the pump alone (which does not include

the drive and/or base plate) refer to the Viking Pump

product catalog.

DO NOT attempt to dismantle a pressure relief valve

that has not had the spring pressure relieved or is

mounted on a pump that is operating.

AVOID contact with hot areas of the pump and/or

drive. Certain operating conditions, temperature

control devices (jackets, heat-tracing, etc.), improper

installation, improper operation, and improper

maintenance can all cause high temperatures on the

pump and/or drive.

THE PUMP must be provided with pressure protection.

This may be provided through a relief valve mounted

directly on the pump, an in-line pressure relief valve,

a torque limiting device, or a rupture disk. If pump

rotation may be reversed during operation, pressure

protection must be provided on both sides of pump.

Relief valve adjusting screw caps must always point

towards suction side of the pump. If pump rotation is

reversed, position of the relief valve must be changed.

Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure. For additional

information, refer to Viking Pump’s Technical Service

Manual TSM 000 and Engineering Service Bulletin

ESB-31.

THE PUMP must be installed in a matter that allows

safe access for routine maintenance and for inspection

during operation to check for leakage and monitor

pump operation.

SECTION TSM 420 ISSUE E PAGE 2 OF 18

4. PUMP SPEED - The slower the operating speed the

longer the longer the service life. This is particularly true

on refrigeration ammonia pumps where:

4.1. the liquid has virtually no lubrication value or film

strength to prevent surface to surface contact and,

4.2. the heat generated by friction can cause the ammonia

to vaporize, which in turn causes cavitation.

5. TESTING - All Viking Ammonia pumps are tested prior

to shipment, but it is good practice to pressure test the

pump along with the rest of the system before adding

the ammonia. Shipping, storage and installation all have

strange ways of producing detrimental effects on sound

equipment.

6. SYSTEM CLEANLINESS - Ammonia is a good

detergent, as such it has a tendency to remove all

the dirt, pipe scale, weld beads, and loose or foreign

material in the system. Unfortunately not all of this

material settles out in traps or can be caught in strainers;

and as a result, a considerable amount goes through the

pump, the abrasive solids going through the pump will

of course cause excessive wear during the start up of

a new system, thus the cleaner a new system is before

start up, the less wear and trouble with the pump.

7. STAND BY EQUIPMENT - Stand by equipment is always

good insurance when possible breakdown of any single

piece of equipment could be jeopardise the operation of

the entire system. Often on circulating, two pumps are

used, with operation of the pumps alternated by day or

week. Alternating operation of the pumps is not always

considered the best practice since both pumps may both

wear out at the same time. If operation of the pumps

is not alternated, the stand by pump should be run for

several hours at least once a month to make sure it is in

good operating condition. Sometimes on large systems

three pumps are used, two running continuously, with

the third for use as a standby and for peak loads.

PUMP INSTALLATION

One of the most important considerations on any circulation

Refrigeration Ammonia pump installation is proper design of

the pump inlet line. Refrigeration Ammonia, when stored in

a closed container, will exert a pressure within the container

equal to its saturated vapor pressure. The saturated pressure

of a liquid may be defined as the pressure at which both liquid

and vapor exist in equilibrium in the same container. The

vapor pressure has a different value for each temperature.

The saturated vapor pressure of water at 212ºF. (waters

boiling point) is 14.7 PSIA. In other words, when handling

Refrigeration Ammonia, we are handling a liquid, which is at its

boiling point. A slight reduction in the pressure being exerted

on the liquid will cause boiling and thus vapor formation.

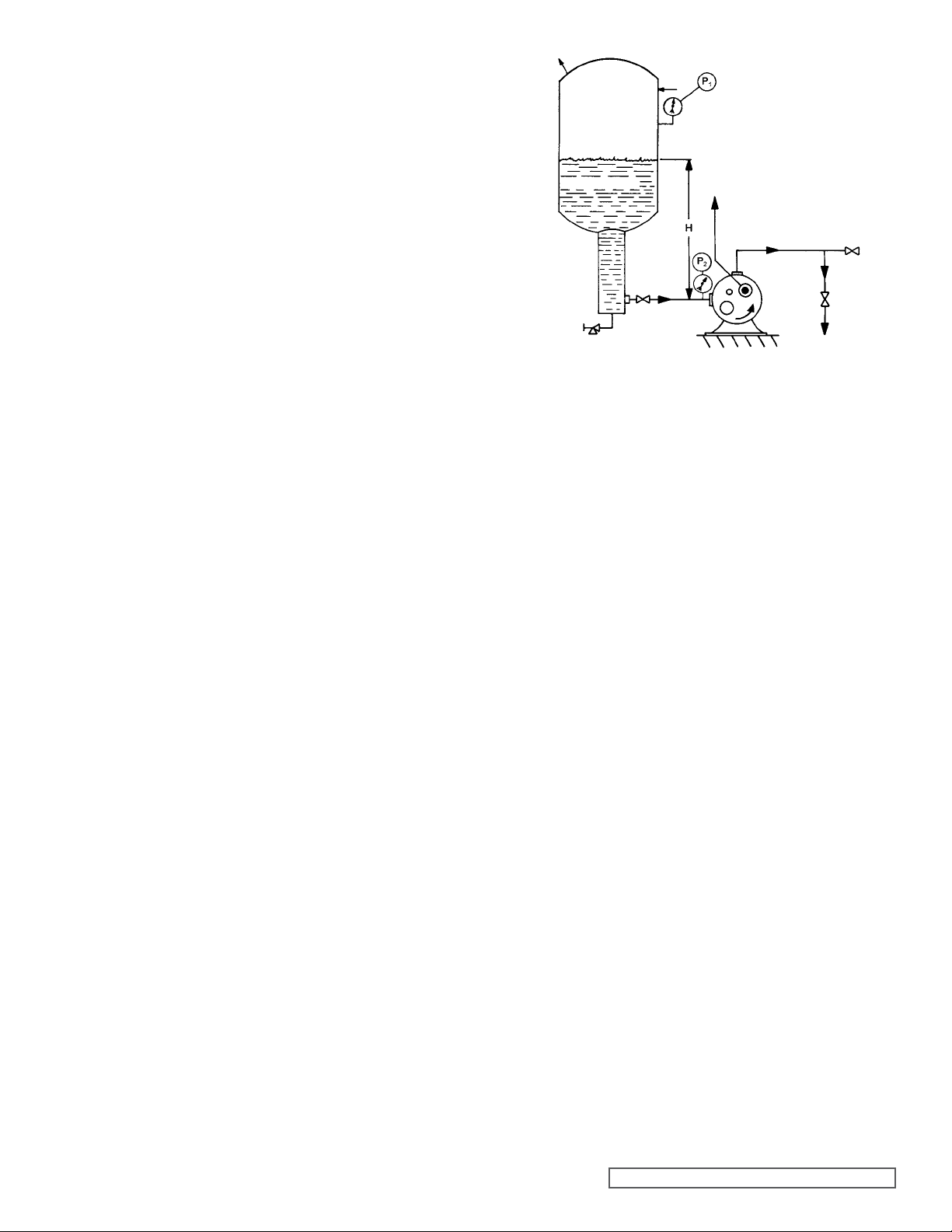

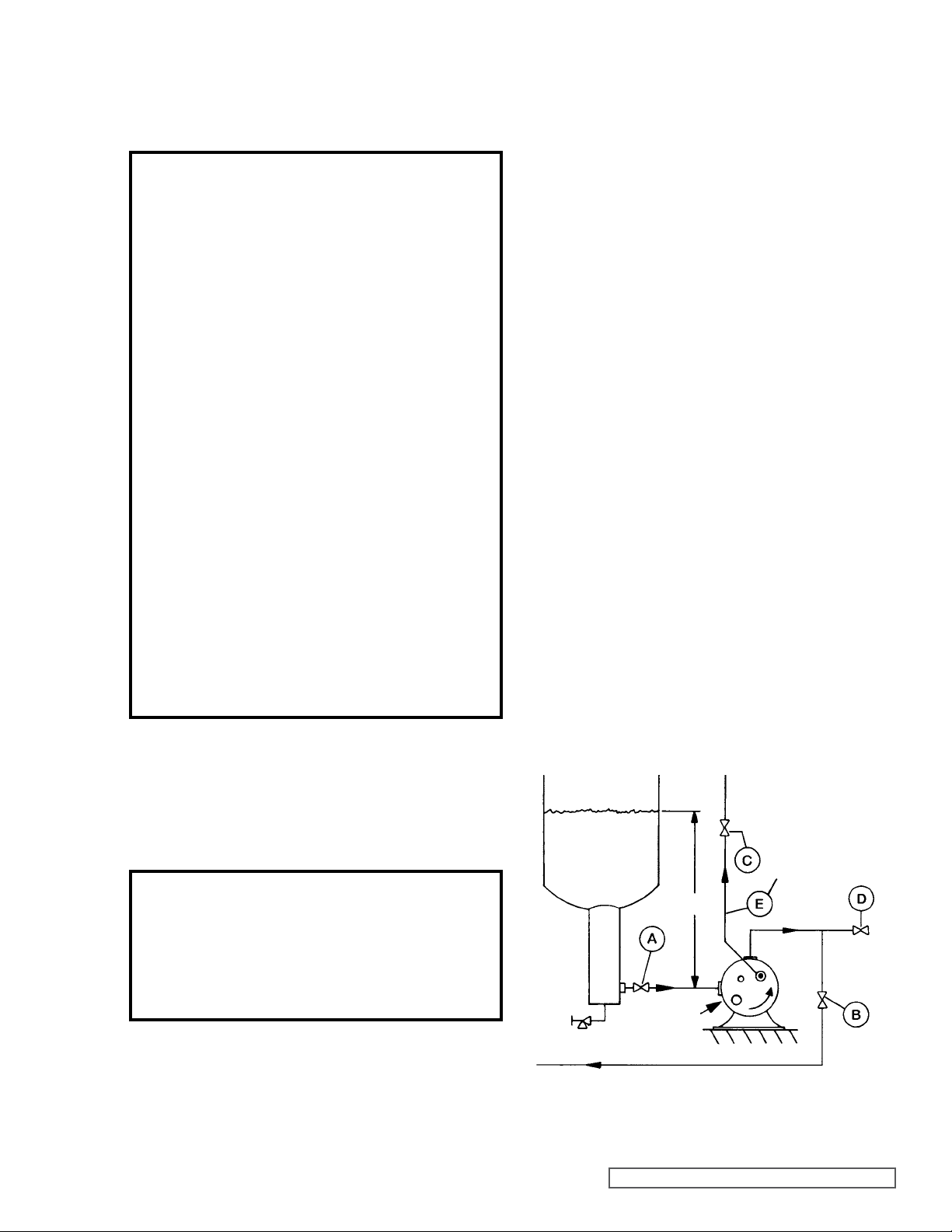

With this information in mind let us examine figure 2, which

illustrates one of the most important considerations when

installing a pump to handle Refrigeration Ammonia.

The pressure (P1) in the accumulator is equal to the

saturated vapor pressure of the ammonia. When the pump

is not running the pressure (P2) at the pump inlet is equal to

the tank pressure (P1) plus the static head (H). P2 = P1 + H

ACCUMULATOR

PUMP

FIGURE 2

As soon as the pump started and the liquid begins to flow, the

pressure at the pump (P2) will drop by an amount equal to

the pressure loss in the piping between the accumulator and

the pump. When liquid is flowing: P2 = P1 + H - (pressure

loss in the piping).

In order to have an installation in which the pump handles all

liquid and no vapor, the pressure drop in the piping must be

equal to or less than the static head (H) on the pump inlet. If the

piping loss is greater than the static head, the liquid ammonia

will start to boil or vaporize and the pump will be required to

take in a mixture of liquid and vapor. Since a given weight of

vapor takes up a much greater volume than the same weight

of liquid, handling both liquid and vapor will reduce the liquid

output from the pump. The vapor is compressed back to a

liquid on the discharge side of the pump causing it to be noisy

and to wear rapidly.

Values for pipe friction losses for calculating suction line

pressure drop can be found in refrigeration hand books.

Since Viking pumps are of the positive displacement type, be

sure that there is no obstruction in the discharge line and that

all valves are in operating position before starting the pump.

Factory assembled port will have right hand port suction and

top port discharge unless otherwise specified. Port location

is determined by looking at shaft end of pump. The pressure

relief valve on the pump provides over pressure protection.

Return-to-Tank pressure relief valves should be mounted on

the discharge side of the pump. Internal type pressure relief

valves should be mounted with the cap pointing towards the

suction side of pump. Also see formation under Relief Valve

Instructions page 12. The Viking pump mounted return-totank pressure relief valve (see Figure 16, PAGE 11 & Figure

17, page 12) is fitted with a pressure relief plug to keep a

valid off return line from building up excessive pressures.

SECTION TSM 420 ISSUE E PAGE 3 OF 18

DANGER !

Include provision for a pressure relief

device in any part of a pump and piping

system that can be valved off and, thus,

completely isolated. Cold liquid ammonia

when isolated will, as it warms up to

room temperature, expand and exert

tremendous pressures which may rupture

the pump or piping unless relieved.

See Viking Technical Service Manual TSM000 for additional

general installation information.

PREVENTATIVE MAINTENANCE

Series 4925 pumps are designed for long, trouble free

life under a wide variety of application conditions with a

minimum of maintenance, however the following should be

considered:

1. LUBRICATION - 1.1. Periodic external lubrication should

be applied slowly with a hand gun at all lubrication

fittings.

A good quality of general purpose grease is satisfactory

in the majority of cases, however, applications involving

very low temperatures may require other types of

lubricants. suggested frequency of lubrication is once

every 500 hours of operation. Do not over grease. Consult

the factory if you have specific lubrication questions.

1.2. Double Mechanical Seal Reservoir: After replacing

seal and/or before letting ammonia into new or rebuilt

pump, fill oil reservoir with one pint of light Refrigeration

Oil.

Before opening valves and allowing ammonia to fill the

pump be sure the hand valve on the reservoir, shown in

figure 8, is open.

Change the oil in your double seal pump reservoir after

first 200 hours of operation and then every 1000 hours

by the method mentioned below:

A. Stop pump and close hand valve on oil reservoir, see

figure 8.

B. Remove ½ inch NPT oil filler plug in top of reservoir

carefully and allow the small amount of ammonia trapped

in the reservoir to vent.

C. Open oil drain plug and allow old oil to drain.

D. Replace oil drain plug and fill reservoir with light

Refrigeration Oil to within 1½ inch of the top

(approximately 1 pint).

E. Replace ½ inch NPT oil filler plug in top of reservoir.

F. Open hand valve.

G. Wait one minute then star the pump and allow it to run

from two to three minutes before the liquid is introduced

onto the pump. This will allow the seat to seal itself

properly before the pressure is applied.

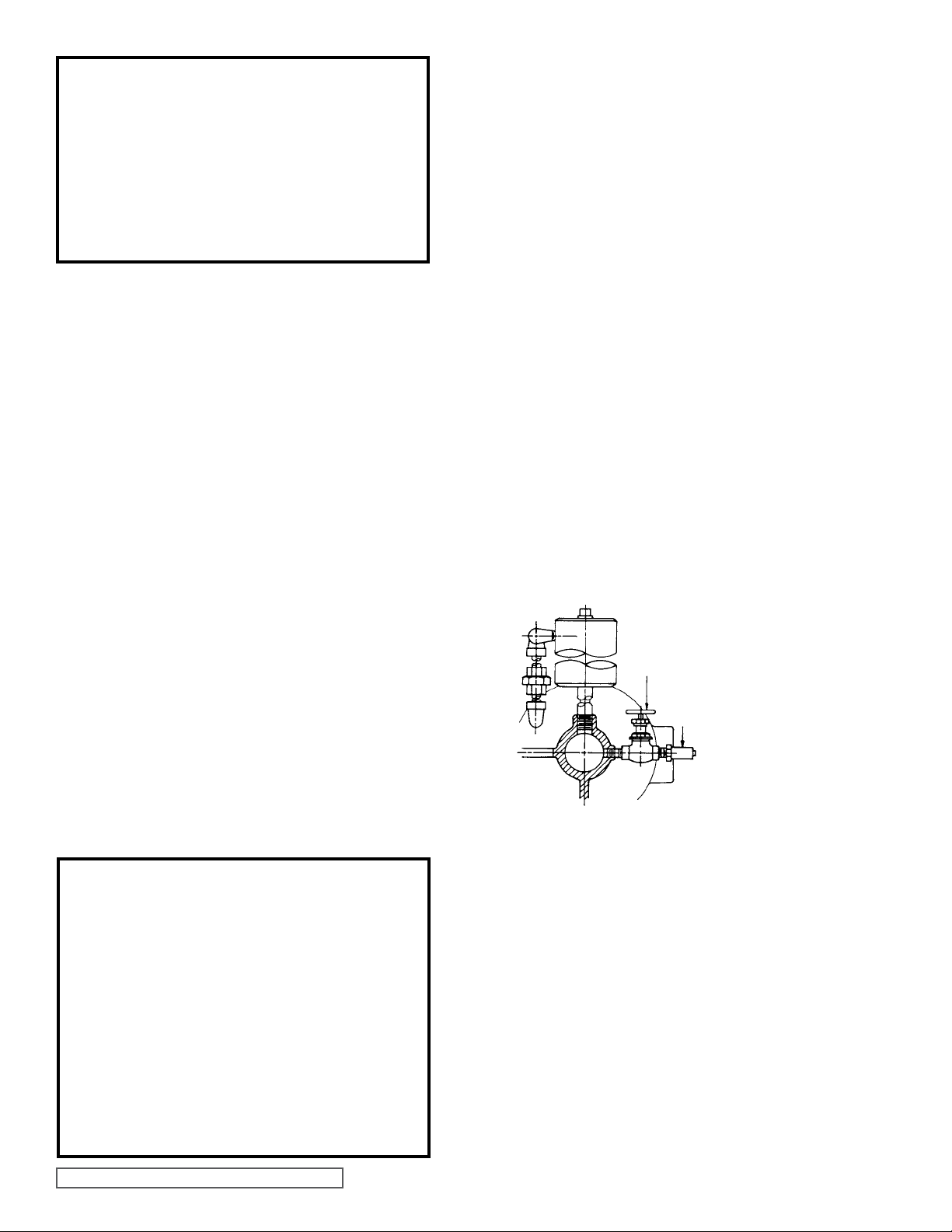

NOTE: If your pump has an automatic snap on filler valve

arranged similar to that shown in figure 3, it is not necessary

to stop the pump to add oil to the reservoir. Merely connect

lubrication pump to automatic filler valve. Open manual valve

and fill reservoir with light Refrigeration Oil to approximately

1½ inch from the top. Close manual valve and remove

lubrication pump from filler to valve. To change oil: proceed

as indicated in steps A thru G except vent pumping chamber

to atmosphere before changing oil.

2. END CLEARANCE ADJUSTMENT - After long term

operation it is sometimes possible to improve the

performance of pump, without major repair, through

adjustment of end clearance of the pump. Refer to

instruction under thrust bearing Adjustment, page

11, for information regarding this procedure.

MANUAL VALVE

FILLER VALVE

FIGURE 3

DANGER !

Be sure ammonia pressure in pump is

not above 5 PSIG when filling reservoir.

If pressure is higher, pumping chamber

should be bled down to reduce pressure

to 5 PSIG or below. (Before bleeding

pump, read SAFE PRACTICES page 4 and

VENTING THE PUMP page 4). Pressure

above 5 PSIG in the pump may cause inner

seal seat to be unseated or may force the

faces of the inner seal apart allowing any

dirt accumulated around the inner seat to

be forced between the faces. When the

pump is started the seal may leak.

SECTION TSM 420 ISSUE E PAGE 4 OF 18

3. CLEANING THE PUMP - It is good practice to keep the

pump as clean as possible. This will facilitate inspection,

adjustment and repair work to help prevent over looking

a covered grease fitting.

4. STORAGE - If the pump has to be stored or not used for

an appreciable length of time it should be drained and

a light coat of lubricating and preventive oil should be

applied to the internal parts. Lubricate all fittings.

MAINTENANCE

IMPORTANT: READ THE FOLLOWING BEFORE

REMOVING A PUMP FROM AN AMMONIA SYSTEM OR

BEFORE STARTING REPAIR WORK ON A PUMP.

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

etc.) Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

(See detailed procedure for venting

the pumps, pages 4, 5 and 6).

2. That the driving means (motor,

turbine, engine, etc.) has been

“locked out” or otherwise made nonoperational so that it cannot be

inadvertently started while work is

being done on the pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

AMMONIA (Anhydrous Ammonia, NH3)

Ammonia is a colorless gas or liquid, has a pungent odor, as

a gas is lighter than air, is easily liquefied by pressure alone

and is very soluble in water. It boils at -28º F.; vapor pressure

is 16 PSIG at 0º F., 45 PSIG at 30º F., 93 PSIG at 60º F., and

138 PSIG at 80º F.

A listing of safe practices and equipment are available from

many sources, including those listed below. A copy of such

a listing and safe practices and equipment should be made

available to everyone working where ammonia is used.

Safety Department. The Safety Department of any company

using ammonia should have information about the basic

safety practices and equipment to use when working with

ammonia. The supplier of the ammonia should always have

the same information.

ANSI - American National Standard Institute, Inc.

1430 Broadway

New York, New York 10018

Bulletin ANSI-K61.1

CGA - The Compressed Gas Association, Inc.

500 Fifth Avenue

New York, New York 10036

Pamphlet G-2 on Anhydrous Ammonia

IIAR - International Institute of Ammonia Refrigeration

1 Illinois Centre

111 East Wacker Drive

Chicago, Illinois 60601

The above references give specifics on safety practices and

equipment. In addition to those, some general precautions

include:

WORK CAREFULLY.

DO NOT HURRY.

LOOK AT ANY PRESSURE GAUGES TO DETERMINE

CONDITIONS IN THE SYSTEM.

HAVE PLENTY OF WATER AVAILABLE.

VENTING THE PUMP

1. Stop the pump (some maintenance people close the

inlet shutoff valve before stopping the pump; but, this is

not recommended practice).

2. Close the inlet (suction) side shutoff valve. A in figure 4.

3. Close the discharge side shutoff valve. B in figure 4.

ACCUMULATOR

SEE THE “ * ”

ON PAGE 6.

DANGER !

Exposure to ammonia causes intense

irritation to the surface tissue of the eyes,

nose, throat and lungs. Exposure to high

concentrations of ammonia may blind,

burn, strangle or kill.

SAFE PRACTICES

Basic safety practices and equipment should always be used

when working with ammonia. Only personnel familiar with

ammonia systems should work on these pumps.

4’

PUMP

FIGURE 4

Schematic of Piping and Valves For a Liquid Ammonia

Recirculating Pump in a Refrigeration System

SECTION TSM 420 ISSUE E PAGE 5 OF 18

4. Close all other shut off valves in lines connected to the

pump. Typical would be valve C in line E* in figure 4

from the pump mounted return-to-tank type relief valve

to the accumulator or the valve from an in line mounted

safety relief valve to the accumulator or the valve in a

pressurizing line 2 in figure 5, from the high pressure

side of the system to the pump double sea oil reservoir.

5. Allow ice on pump to melt. This process can be speeded

up by running cold water over the pump.

Start the venting process as soon as convenient after the

ice has been removed from the pump. This will prevent

venting the ammonia at the lower pressures of a cold

pump rather than at the high vapor pressures in a room

temperature pump.

For systems with vent (purge or bleed) valves (e.g. D

figure 4) go to step 6; for systems without a vent valve,

go to step 7.

6. A hose should be connected to any vent valve (e.g. D

in figure 4) in the blocked off portion of the system. The

open end of the horse should be placed under water in a

tank containing at least 10 times as much water as there

is ammonia in the blocked off portion of the system or the

end of the hose should be lead to a safe, well ventilated

area. After the hose has been attached to the open end

properly located, then open the vent valve. Check the

open end of the hose to make sure the ammonia is

venting. After ammonia has stopped venting, continue

with step 8.

②

⑤

⑥

If there is no line from the bracket to the reservoir, carefully

loosen the pipe plug (drain), 3 in figure 6 towards the

bottom of he bracket. This pipe plug is found only on the

“K”, “KK”, “LQ” and “LL” 4925 pumps. The small “HL”

4925 does not have one. When working on the “HL”

4925 that has no trouble fitting between the bracket and

double seal oil reservoir, carefully loosen the pipe plug,

4 in figure 6, in the suction port of the pump.

*This segment of line, (E in figure 4) between the return

to tank pressure relief valve and the shutoff valve, C,

should include a pressure relief valve vented to a safe

area.

8. Carefully loosen any unions or tubing fittings in any other

lines to the pump that have been blocked off by closing

the shutoff valves, so that venting from these segments

of the system can be accomplished. Typical of such lines

would be that from the pump mounted return-to-tank

relief valve to the accumulator, E* in figure 4, or a line, 2

in figure 5, from the high pressure side of the system to

the double seal oil reservoir.

ALWAYS LISTEN FOR THE “PSST” AT ANY POINT

LOOSENED TO PROVIDE VENTING.

9. Carefully loosen the fill plug. 5 in Figure 5, in the top of

the double seal oil reservoir.

10. After the ammonia has stopped venting turn the pump

shaft, 6 in figure 5, over for at least 10 complete

revolutions. This will make sure that there is no pocket of

accumulated ammonia that has not been exposed to a

venting point.

11. Carefully loosen the plugs, 4 in figure 6 and 7 in figure

5, in the suction and discharge ports of the pump. If

ammonia continues to vent, wait until the venting stops.

When venting from all the loosened connections stops,

then complete the loosening of the fittings and complete

the removal of the plugs.

⑦

①

FIGURE 5

Viking K4925

Refrigeration Ammonia Pump with Return-To-Tank

Pressure Relief Valve

7. If there are no vent valves in the blocked off piping, the

Viking Model 4925 ammonia pump should be vented by

carefully loosening the fitting (1 in figure 5) on the lower

end of the tubing that runs from the pump bracket to the

double seal oil reservoir.

THERE SHOULD BE A DISTINCT “PSST” SOUND

WHEN THE AMMONIA VAPOR LIQUID STARTS TO

VENT. LEAVE THE AREA UNTIL THE VENTING IS

COMPLETE.

If there is rigid pipe instead of tubing running from the

pump bracket to the double seal oil reservoir, the pipe

union should be loosened carefully until the “psst” is

heard.

SECTION TSM 420 ISSUE E PAGE 6 OF 18

④

③

FIGURE 6

Viking K4925

Refrigeration Ammonia Pump with Internal

Pressure Relief Valve

Loading...

Loading...