Viking Pump TSM344 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

COMPOSITE MAG DRIVE PUMPS

MODELS E02, E05, E12, E25, E75 AND E125

CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . 1

Special Information . . . . . . . . . . . . . . . . . . . 1

Safety Information. . . . . . . . . . . . . . . . . . . . 2

Maintenance . . . . . . . . . . . . . . . . . . . . . . 3

Exploded Views . . . . . . . . . . . . . . . . . . . . . 4

E02 . . . . . . . . . . . . . . . . . . . . . . . . . . 4

E05 . . . . . . . . . . . . . . . . . . . . . . . . . . 5

E12 . . . . . . . . . . . . . . . . . . . . . . . . . . 6

E25 . . . . . . . . . . . . . . . . . . . . . . . . . . 7

E75 and E125 . . . . . . . . . . . . . . . . . . . . 8

Disassembly/Assembly - E02 . . . . . . . . . . . . . . 9

Disassembly . . . . . . . . . . . . . . . . . . . . . 9

Inspection. . . . . . . . . . . . . . . . . . . . . . .10

Assembly . . . . . . . . . . . . . . . . . . . . . . .10

Disassembly/Assembly - E05 and E12 . . . . . . . . .12

Disassembly . . . . . . . . . . . . . . . . . . . . .12

Inspection. . . . . . . . . . . . . . . . . . . . . . .13

Assembly . . . . . . . . . . . . . . . . . . . . . . .13

Disassembly/Assembly - E25, E75 and E125 . . . . .15

Disassembly . . . . . . . . . . . . . . . . . . . . .15

Inspection. . . . . . . . . . . . . . . . . . . . . . .16

Assembly . . . . . . . . . . . . . . . . . . . . . . .16

Inspection and Wear Limits . . . . . . . . . . . . . . .18

Service and Replacement Limits . . . . . . . . . . . .18

Troubleshooting Chart . . . . . . . . . . . . . . . . .19

Bolt Torque Recommendations . . . . . . . . . . . . .20

ATEX Directive . . . . . . . . . . . . . . . . . . . . .21

Temperature Class and Max. Liquid Temperatures . . .21

Sample Tag . . . . . . . . . . . . . . . . . . . . . . .22

Normal Operation . . . . . . . . . . . . . . . . . . . .23

Expected Malfunction . . . . . . . . . . . . . . . . . .23

SECTION TSM 344

CMD SERIES

PAGE 1 Of 24

ISSUE f

ATTENTION !

To ensure safe handling and operating

situations, please thoroughly review

all of the warnings listed on the

following page.

FIGURE 1

MODEL E05 WITH MOTOR

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and cannot be used for ordering parts. Obtain

a parts list from the factory or a Viking representative. Always

give a complete name of the part, part number and material

with the model number and serial number of pump when

ordering repair parts. The unmounted pump or pump unit

model number and serial number are on the nameplate.

This manual deals only with CMD Series Composite Mag

Drive Pumps. Refer to Figures 1 through 47 for general

configuration and nomenclature used in this manual. Pump

specifications and recommendations are listed in Catalog

Section 344.

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

FIGURE 2

MODEL E25 WITH MOTOR

SPECIAL INFORMATION

ROTATION: Shaft rotation determines which port is suction

and which is discharge. Viewed from shaft end, with clockwise

rotation, the right port is suction and left port is discharge.

With counterclockwise rotation, the left port is suction and

right port is discharge.

SAFETY INFORMATION

INCORRECT INSTALLATION, OPERATION OR MAINTENANCE OF EQUIPMENT MAY CAUSE SEVERE

PERSONAL INJURY OR DEATH AND/OR EQUIPMENT DAMAGE AND MAY INVALIDATE THE WARRANTY.

This information must be read fully before beginning installation, operation or maintenance and must be

kept with the pump. All installation and maintenance must be undertaken by suitably trained or qualified

persons only.

Warning - Safety instructions which

shall be considered for reasons of safe

operation of the pump or pump unit and/

or protection of the pump or pump unit

itself are marked by this symbol.

Symbol

Legend :

Danger - Failure to follow the listed

precautionary measures identified by

this symbol may result in serious injury

!

or death.

WARNING

!

!

!

!

!

WARNING

!

!

DO NOT OPERATE PUMP IF:

– The front cover is not installed correctly.

– Any guards are missing or incorrectly installed.

– The suction or discharge piping is not connected.

DO NOT place fingers, etc. into the pumping chamber

or its connection ports or into any part of the drive train

if there is ANY possibility of the pump shafts being

rotated. Severe injury will occur.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those for which the pump was originally supplied,

without confirming its suitability for the new duty.

INSTALLATION AND OPERATION OF THE PUMP

MUST ALWAYS COMPLY WITH HEALTH AND

SAFETY REGULATIONS.

Rare earth magnets used in couplings have

extremely strong magnetic fields capable of

changing performance or damaging items such as:

Pacemakers, Metal Implants, Watches, Computers

& Disks, and Credit Cards

Completely assembled magnetic couplings will

not affect items listed above - only disassembled

components.

There are no known harmful effects of these

magnetic fields on the human body.

A device must be incorporated into the pump, system,

or drive to prevent the pump exceeding its stated duty

pressure. It must be suitable for both directions of

pump rotation where applicable. Do not allow pump

to operate with a closed/blocked discharge unless a

pressure relief device is incorporated. If an integral

relief valve is incorporated into the pump, do not allow

re-circulation through the relief valve for extended

periods.

The mounting of the pump or pump unit should be

solid and stable. Pump orientation must be considered

in relation to drainage requirements. Once mounted,

shaft drive elements must be checked for correct

alignment. Rotate pump shaft by at least one full

revolution to ensure smoothness of operation.

Incorrect alignment will produce excessive loadings

and will create high temperatures and increased noise

emissions. Do not use any drive arrangements which

cause sideloading of the drive shaft.

The installation must allow safe routine maintenance

and inspection (to check for leakage, monitor

pressures, etc) and provide adequate ventilation

necessary to prevent overheating.

WARNING

WARNING

WARNING

!

!

!

!

!

!

Before operating the pump, be sure that it and all

parts of the system to which it is connected are clean

and free from debris and that all valves in the suction

and discharge pipelines are fully opened. Ensure that

all piping connecting to the pump is fully supported

and correctly aligned with its relevant connections.

Misalignment and/or excess loads will cause severe

pump damage.

Be sure that pump rotation is correct for the desired

direction of flow.

DO NOT INSTALL THE PUMP INTO A SYSTEM

WHERE IT WILL RUN DRY (I.E. WITHOUT A

SUPPLY OF PUMPED MEDIA).

Pressure gauges/sensors are recommended, next

to the pump suction and discharge connections to

monitor pressures.

Caution must be taken when lifting the pump. Suitable

lifting devices should be used as appropriate. Lifting

eyes installed on the pump must only be used to lift

the pump, not pump with drive and/or baseplate. If

pump is baseplate mounted, the base plate must be

used for all lifting purposes. If slings are used for lifting,

they must be safely and securely attached. For weights

of bare shaft pumps refer to catalog.

DO NOT attempt any maintenance or disassembly of

the pump or pump unit without first ensuring that :

– The pump is fully isolated from the power source

(electric, hydraulic, pneumatic).

– The pumping chamber, relief valve and any

shaft seal support system are depressurized and

purged.

– Any temperature control devices (jackets, heat-

tracing, etc) are fully isolated, that they are

depressurized and purged, and components are

allowed to reach a safe handling temperature.

DO NOT attempt to dismantle a pressure relief valve

which has not had the spring pressure relieved or is

mounted on a pump that is operating. Serious personal

injury or death and/or pump damage may occur.

DO NOT loosen or undo the front cover, any

connections to the pump, shaft seal housings,

temperature control devices, or other components,

until sure that such action will not allow the unsafe

escape of any pressurized media.

Pumps and/or drives can produce sound power levels

exceeding 85 dB(A) under certain operating conditions.

When necessary, personal protection against noise

must be taken.

Avoid any contact with hot parts of pumps and/or

drives which may cause injury. Certain operating

conditions, temperature control devices (jackets, heattracing, etc.), bad installation, or poor maintenance

can all promote high temperatures on pumps and/or

drives.

SECTION TSM 344 ISSUE F PAGE 2 OF 24

SPECIAL INFORMATION (CONT’D)

PRESSURE RELIEF VALVES:

1. Viking pumps are positive displacement pumps and

must be provided with some sort of pressure protection.

This may be an inline pressure relief valve, a torquelimiting device, or a rupture disk, or other method.

NOTE: Pump can be operated in reverse direction for

short duration at low differential pressure to clean/flush

out lines.

2. If pump rotation is to be reversed during operation,

pressure protection must be provided on both sides

of the pump.

3. Pressure relief valves cannot be used to control pump

flow or regulate discharge pressure.

For additional information on pressure relief valves, refer

to Technical Service Manual TSM000 and Engineering

Service Bulletin ESB-31.

MAINTENANCE

Series CMD pumps are designed for long, trouble-free

service life under a wide variety of application conditions with

a minimum of maintenance. The following points will help

provide long service life.

Pumps that are mounted directly to the motor will need to be

removed from the mounting bracket to perform mechanical

seal maintenance or replacement.

CLEANING PUMP: Keep the pump as clean as possible.

This will facilitate inspection, adjustment, and repair work.

STORAGE: If pump is to be stored, or not used for six

months or more, the pump must be drained and a light coat

of light oil must be applied to all internal pump parts.

Apply grease to the pump shaft extension. Viking suggests

rotating pump shaft by hand one complete revolution every

30 days to circulate the oil. Tighten all pump assembly bolts

before putting the pump in service after being stored.

DANGER !

Before opening any Viking pump liquid

chamber (pumping chamber, reservoir,

relief valve adjusting cap fitting, etc.)

Be sure:

1. That any pressure in the chamber has

been completely vented through the

suction or discharge lines or other

appropriate openings or connections.

2. That the driving means (motor,

turbine, engine, etc.) has been

“locked out” or made non-operational

so that it cannot be started while

work is being done on pump.

3. That you know what liquid the

pump has been handling and the

precautions necessary to safely

handle the liquid. Obtain a material

safety data sheet (MSDS) for the

liquid to be sure these precautions

are understood.

Failure to follow above listed

precautionary measures may result in

serious injury or death.

CMD - E02 E L V F - X

Series:

Composite Mag Drive

* Export license required under U.S. Export

Administration ECCN 28350 and 28999.

Viton® is a registered trademark of DuPont Performance Elastomers.

Model:

E02

E05

E12 *

E25 *

E75 *

E125 *

Materials/Ports:

E = ETFE, FNPT

(E02, E05, E12

B = ETFE, ISO 7-1

(E02, E05, E12

F = ETFE, Flange

(E25, E75, E125

O-Rings:

V = Viton

)

)

)

Bearings:

L = Carbon Graphite

B = Graphite-Impregnated

Silicon-Carbide

E = EPDM

®

Mounting Arrangement:

F = NEMA 56C (E02, E05, E12, E25

O = NEMA 143TC-182C (E05, E12, E25, E75, E125

R = NEMA 182TC-184TC (E75, E125

H = IEC B34 63 (E02, E05, E12

K = IEC B34 80 (E02, E05, E12

P = IEC B14 100/112 (E25, E75, E125

Y = No Motor Mount Kit (E02, E05, E12, E25, E75, E125

SECTION TSM 344 ISSUE F PAGE 3 OF 24

Options:

A = Bearing Flush Ports

B = Combination of Options A and N

N = Without Drive Magnet

X = Complete Pump (No Options

)

)

)

)

)

)

)

)

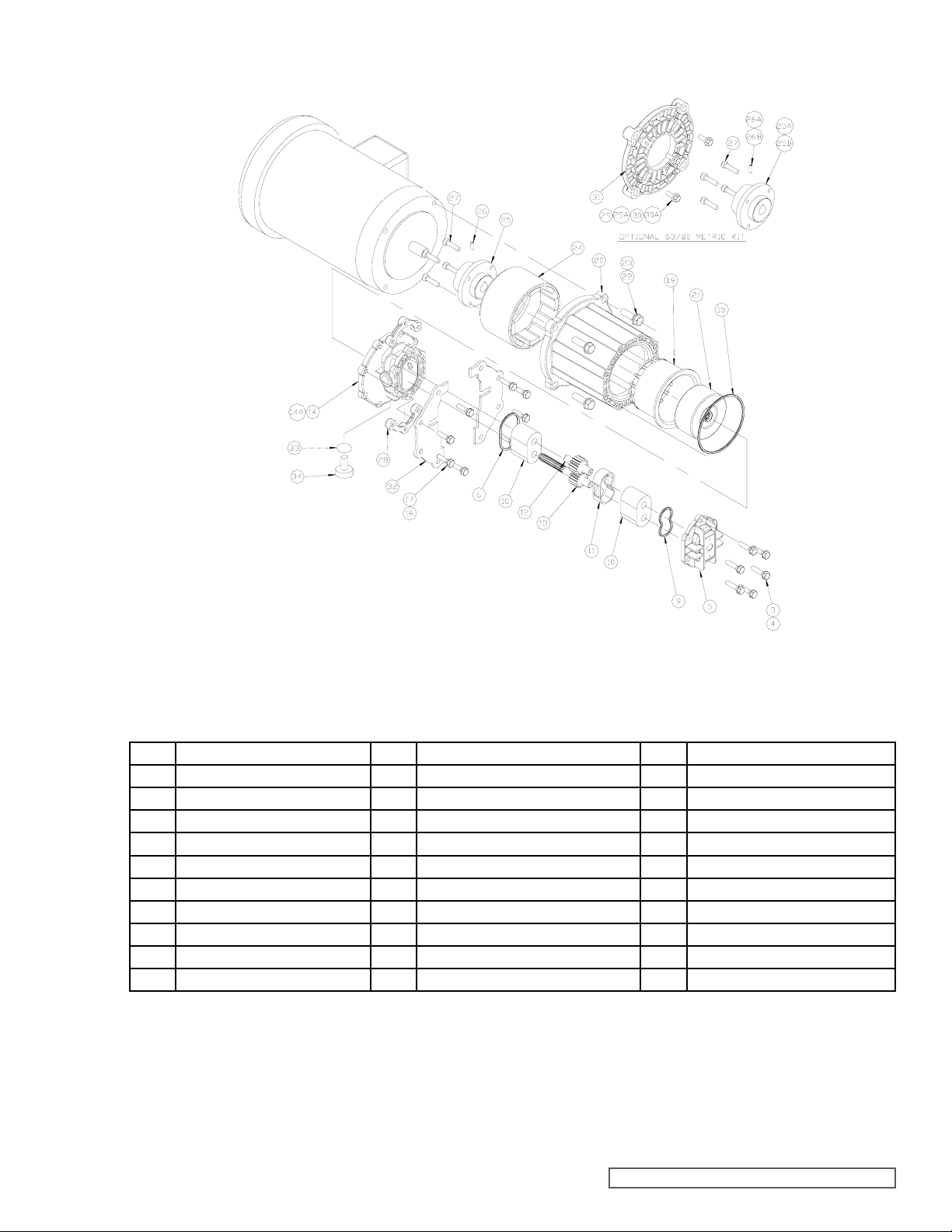

E02

EXPLODED VIEW OF E02 PUMP (TYPICAL)

Item Description Item Description Item Description

2 Drive Screw 13 Drive Gear Assembly * 23 Washer

3 Bolts 14 Center Housing 24 Drive Magnet

4 Washers 15 O-Ring, Containment Canister * 25 Coupling Hub

5 Front Cover 16 Bolts 26 Set Screw

6 O-Ring, Cover * 17 Washers 27 Screws

7 Bolts 18 Adapter, Canister 29 Bolts

9 O-Ring, Compression * 19 Containment Canister 30 Washer

10 Bearing * 20 Adapter, Spool 31 Adapter, Motor

11 Housing Liner * 21 Driven Magnet Assembly

12 Idler Gear Assembly * 22 Bolts

* Recommended spare parts.

SECTION TSM 344 ISSUE F PAGE 4 OF 24

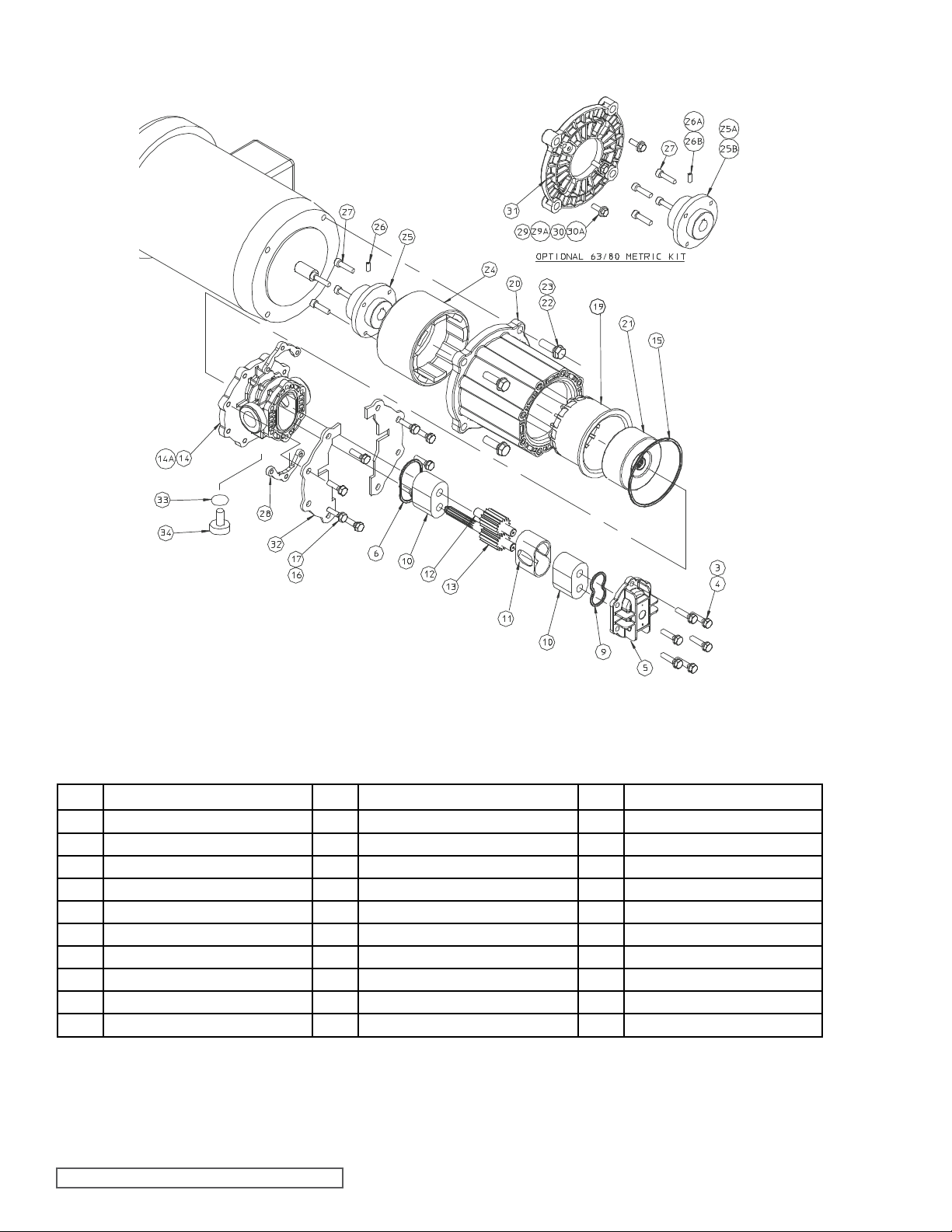

E05

EXPLODED VIEW OF E05 PUMP (TYPICAL)

Item Description Item Description Item Description

2 Drive Screw 14 Center Housing 25 Coupling Hub

3 Bolts 15 O-Ring, Containment Canister * 26 Set Screw

4 Washers 16 Bolts 27 Screws

5 Front Cover 17 Washers 28 Nut Plate

6 O-Ring, Cover * 19 Containment Canister 29 Bolts

9 O-Ring, Compression * 20 Adapter, Spool 30 Washer

10 Bearing * 21 Driven Magnet Assembly 31 Adapter, Motor

11 Housing Liner * 22 Bolts 32 Retaining Plate

12 Idler Gear Assembly * 23 Washer 33 O-Ring, Drain Plug *

13 Drive Gear Assembly * 24 Drive Magnet 34 Drain Plug

* Recommended spare parts.

SECTION TSM 344 ISSUE F PAGE 5 OF 24

E12

EXPLODED VIEW OF E12 PUMP (TYPICAL)

Item Description Item Description Item Description

2 Drive Screw 14 Center Housing 25 Coupling Hub

3 Bolts 15 O-Ring, Containment Canister * 26 Set Screw

4 Washers 16 Bolts 27 Screws

5 Front Cover 17 Washers 28 Nut Plate

6 O-Ring, Cover * 19 Containment Canister 29 Bolts

9 O-Ring, Compression * 20 Adapter, Spool 30 Washer

10 Bearing * 21 Driven Magnet Assembly 31 Adapter, Motor

11 Housing Liner * 22 Bolts 32 Retaining Plate

12 Idler Gear Assembly * 23 Washer 33 O-Ring, Drain Plug *

13 Drive Gear Assembly * 24 Drive Magnet 34 Drain Plug

* Recommended spare parts.

SECTION TSM 344 ISSUE F PAGE 6 OF 24

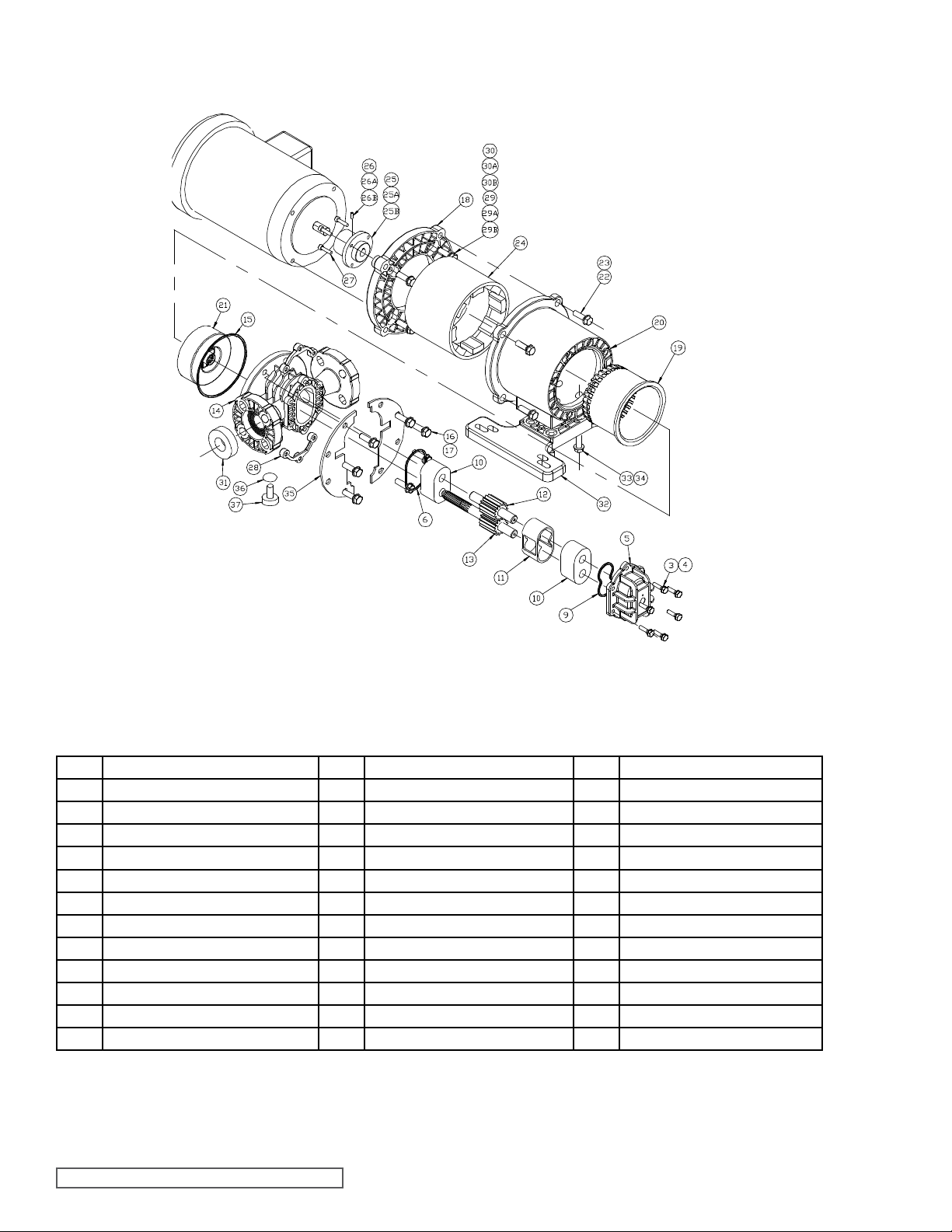

E25

EXPLODED VIEW OF E25 PUMP (TYPICAL)

Item Description Item Description Item Description

2 Drive Screw 16 Bolts 28 Nut Plates

3 Bolts 17 Washers 29 Bolts

4 Washers 18 Adapter, Motor 30 Washer

5 Front Cover 19 Containment Canister 31 Flange Gaskets

6 O-Ring, Cover * 20 Adapter, Spool 32 Mounting Base

9 O-Ring, Compression * 21 Driven Magnet Assembly 33 Bolt

10 Bearing * 22 Bolt 34 Washer

11 Housing Liner * 23 Washer 35 Retaining Plate

12 Idler Gear Assembly * 24 Drive Magnet 36 O-Ring, Drain Plug *

13 Drive Gear Assembly * 25 Coupling Hub 37 Drain Plug

14 Center Housing Flange 26 Set Screw

15 O-Ring, Containment Canister * 27 Screws

* Recommended spare parts.

SECTION TSM 344 ISSUE F PAGE 7 OF 24

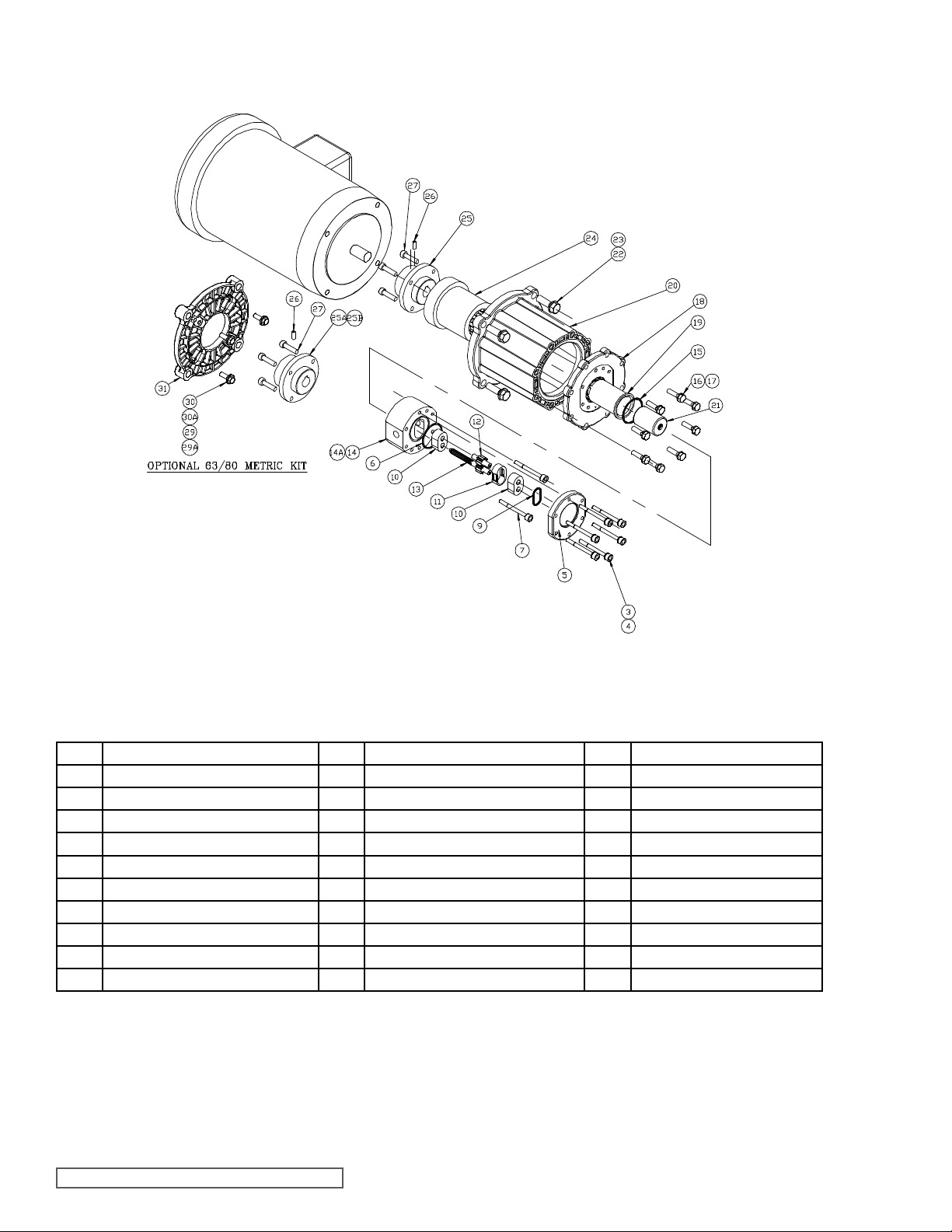

E75 AND E125

EXPLODED VIEW OF E75 AND E125 PUMPS (TYPICAL)

Item Description Item Description Item Description

2 Drive Screw 16 Bolts 28 Nut Plates

3 Bolts 17 Washers 29 Bolts

4 Washers 18 Adapter, Motor 30 Washer

5 Front Cover 19 Containment Canister 31 Flange Gaskets

6 O-Ring, Cover * 20 Adapter, Spool 32 Mounting Base

9 O-Ring, Compression * 21 Driven Magnet Assembly 33 Bolt

10 Bearing * 22 Bolt 34 Washer

11 Housing Liner * 23 Washer 35 Retaining Plate

12 Idler Gear Assembly * 24 Drive Magnet 36 O-Ring, Drain Plug *

13 Drive Gear Assembly * 25 Coupling Hub 37 Drain Plug

14 Center Housing Flange 26 Set Screw

15 O-Ring, Containment Canister * 27 Screws

* Recommended spare parts.

SECTION TSM 344 ISSUE F PAGE 8 OF 24