Viking Pump TSM343.1 User Manual

TECHNICAL SERVICE MANUAL

VI-CORR® MAG DRIVE® COMPOSITE PUMPS

SERIES RP- 805 & RP- 807

CONTENTS

with model number and series number of pump when

MODEL NUMBER CHART

UNMOUNTED

PUMPS

FIGURE 1

FIGURE 2

SECTION TSM 343.1

PAGE 1 OF 13

ISSUE C

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

INTRODUCTION 1

SPECIAL INFORMATION 2

INSTALLATION 2

DISASSEMBLY OF MD-A2, MD-A8, MD-B15

or MD-B40 COUPLINGS 4

GENERAL PUMP DISASSEMBLY 8

RP-805 SERIES PUMP DISASSEMBLY 8

RP-805 SERIES PUMP ASSEMBLY 8

RP-807 SERIES PUMP DISASSEMBLY 9

RP-807 SERIES PUMP ASSEMBLY 9

ASSEMBLY OF MD-A2, MD-A8, MD-B15 or

MD-B40 COUPLINGS 9

TROUBLESHOOTING 11

DO'S AND DON'S 12

INTRODUCTION

TECHNICAL SERVICE MANUAL

VI-CORR® MAG DRIVE® COMPOSITE PUMPS

SERIES RP-805 & RP-807

RP-80525

RP-80550

RP-80570

RP-80514

RP-80782

RP-80716

RP-80724

RP-80732

SECTION TSM 343.1

PAGE 1 OF 13

ISSUE E

Units are designated by the

unmounted pump model numbers

followed by a letter indicating drive

M = Motor Mounted (Close Coubled

B = Bearing Carrier Mounted

R = Viking Reducer Drive

P = Commercial Reducer Drive

(Example RP-80514-MD-A8B)

UNITS

style.

D = Direct Drive

C-Flange)

The illustrations in this manual are for identification purposes

only and cannot be used for ordering parts. Obtain a parts list

from the factory or a Viking

nature of the pump and the close manufacturing tolerances,

certain replacement parts are only available in assemblies.

Always give complete name of part, part number or material

ordering repair parts. The pump or pump unit model number

and serial number are on the nameplate.

In the Viking® model number system, the first number "8"

indicates a magnetic coupled design. The next two numbers

determine the pump series ad the last two numbers indicate

pump size.

® representative. Due to the

The RP-805 Series gear pumps mount to the MD-A2 or MDA8 coupling. The larger RP-807 Series gear pumps are

available with the MD-A2, MD-A8, MD-B15 or MD-B40

couplings.

This manual deals only with RP Series composite pumps.

Refer to figures 1 thru 20 for general configuration and

nomenclature used in this manual. Pump specifications and

recommendations are listed in Catalogue Section 343.

SERIES RP-805 PUMP

MOTOR CONNECTED TO

FOOTLESS BRACKET AND PUMP

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

SERIES RP-807 PUMP

BEARING CARRIER, FOOTED BRACKET

AND MOUNTED PUMP

SPECIAL INFORMATION

3. If a relief valve is not furnished on the pump, some means

If pump rotation is to be reversed during normal

Check alignment after mounting of units with a bearing

THAT ANY PRESSURE IN CHAMBER HAS

BEEN COMPLETELY VENTED THROUGH

APPROPRIATE OPENINGS OR

THAT THE DRIVING MEANS (MOTOR,

HAS BEEN HANDLING AND THE

NECESSARY TO SAFELY

SAFETY DATA SHEET (MSDS) FOR THE

FAILURE TO FOLLOW ABOVE LISTED

DANGER

HE PUMP IN THE OPPOSITE

DANGER

BEFORE OPENING ANY VIKING PUMP LIQUID

CHAMBER (PUMPING CHAMBER, RESERVOIR,

RELIEF VALVE ADJUSTING CAP FITTING ETC.)

BE SURE:

1.

SUCTION OR DISCHARGE LINES OR OTHER

CONNECTIONS.

2.

TURBINE, ENGINE, ETC.) HAS BEEN “LOCKED

OUT” OR MADE NON- OPERATIONAL SO THAT

IT CANNOT BE STARTED WHILE WORK IS

BEING DONE ON PUMP.

3. THAT YOU KNOW WHAT LIQUID THE PUMP

PRECAUTIONS

HANDLE THE LIQUID. OBTAIN A MATERIAL

LIQUID TO BE SURE THESE PRECAUTIONS

ARE UNDERSTOOD.

PRECAUTIONARY MEASURES MAY RESULT IN

SERIOUS INJURY OR DEATH.

of over pressure protection such as an in-line relief valve

should be provided.

4.

operation, pressure protection must be provided on both

sides of pump.

5. Relief valve adjusting screw cap must always point

towards suction side of pump.

6. Pressure relief valves cannot be used to control flow to

regulate pressure.

For additional information on pressure relief valves, refer to

Technical Service Manual TSM 000 and Engineering Service

Bulletin ESB-31.

INSTALLATION

General

The following items must be considered prior to pump

installation:

1. Location - locate the pump as close as possible to supply

of liquid being pumped. If possible locate pump below

liquid supply. Viking pumps are self-priming; but, the

better the suction conditions the better the pump will

perform.

2. Accessibility - pump must be accessible for inspection,

maintenance and repair.

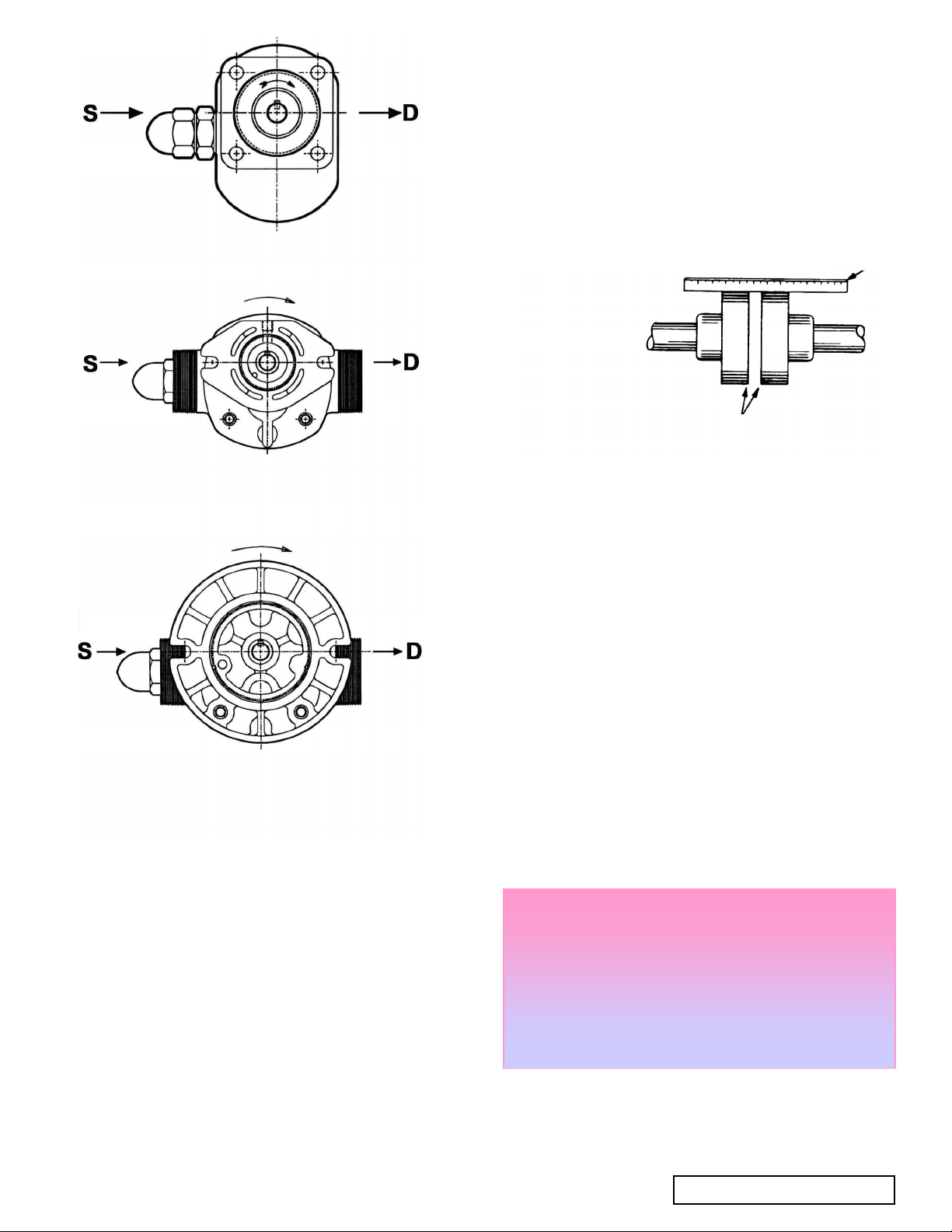

3. Suction/Discharge - SG Series pumps are designed for

clockwise rotation as standard (viewed from end of shaft).

Refer to Figure 3.

Mounting

Rotation:

Although shaft rotation determines which port is suction and

which is discharge, Viking magnetic drive composite pumps

are designed to run in a designated direction (indicated on

pump decal).

RUNNING T

DIRECTION TO THE DESIGNATED DIRECTION

MAY RESULT IN SERIOUS INJURY OR DEATH.

Pressure Relief Valves:

1. Relief valves are mounted on the head or casing of all

RP series composite pumps.

2. The RP series is a positive displacement pump and

requires some sort of over pressure protection. Without

over pressure protection, the following is likely to occur:

motor stalls, drive equipment fails, a pump part breaks

and the piping and/or equipment in the system bursts.

This may be an internal relief valve.

TSM 343.1 ISSUE D PAGE 2 OF 13

1. The pump mounting surface must be clean and flat.

2. Use SAE Grade 5 or better capscrews to mount pump.

3. The mounting capscrews for RP-05 & RP-07 pumps must

have a minimum of ½ inch thread engagement.

4. Mechanical Seal and Lip Seals RP Series pumps are

designed to be used with jaw type couplings that do not

induce axial thrust on the pump shaft. If an improper type

coupling is used, internal damage may result.

5. Do not strike or press inner magnet coupling half to install

on the pump shaft. Damage to pump or coupling may

result if coupling does not slide onto pump shaft, inspect

coupling bore, shaft and key for nicks or burrs and

remove if present.

6. Once pump has been mounted, place a small amount of

compatible liquid into suction port and turn by hand to

ensure pump turns freely.

Alignment

carrier.

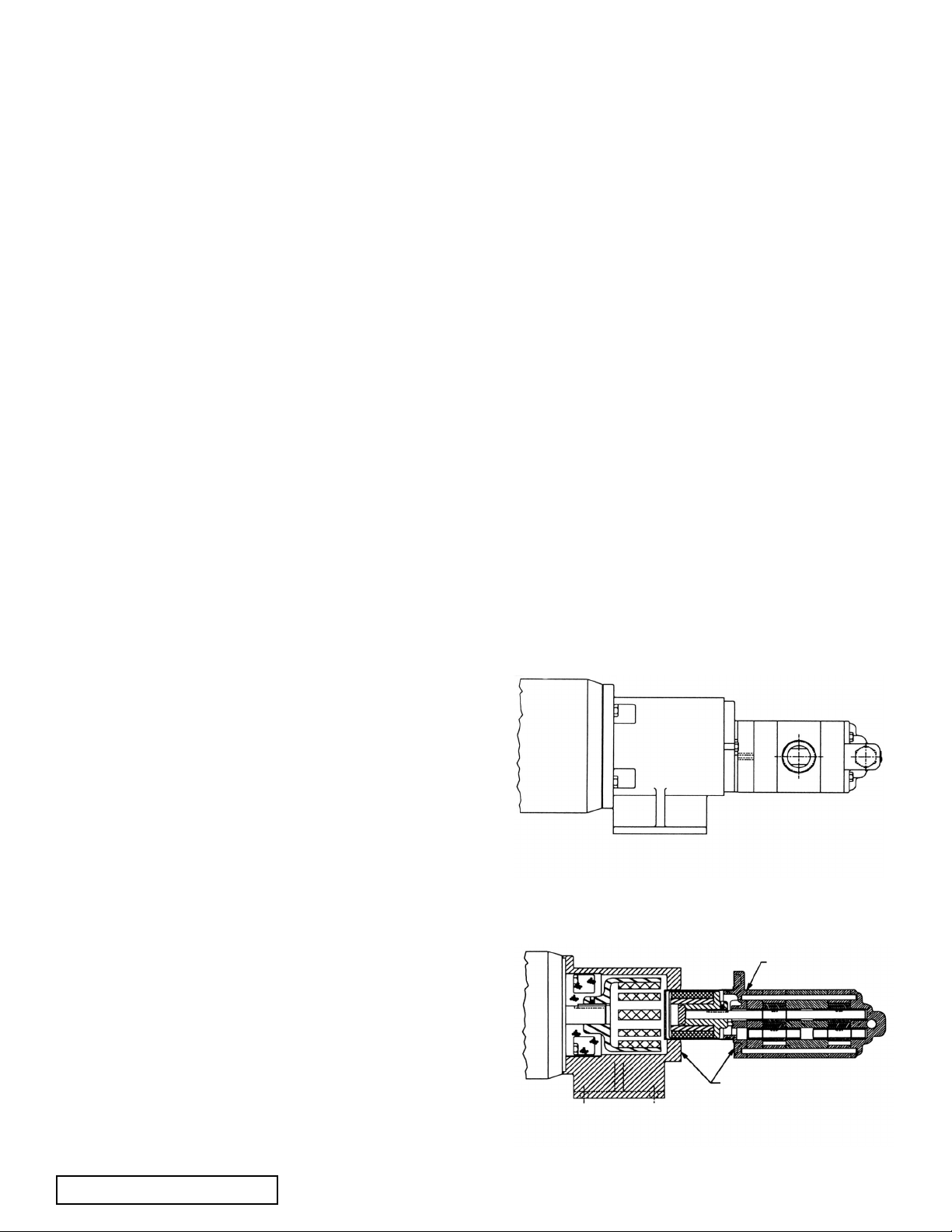

1. If unit has flexible coupling, remove any coupling guards

or covers and check alignment of coupling halves. A

straight edge (piece of key stalk will work) across coupling

must rest evenly on both rims at top, bottom and sides.

See Figure 4.

2. Make final check on alignment after piping is hooked up.

Replace the guards.

Piping/Hose

4. A strainer on the suction side of the pump should always

protect the pump without causing excessive pressure

areful not to over tighten fittings as this can cause

is needed for proper connection. Do not use Teflon tape.

Clockwise Rotation RP-805

CW ROTATION

(viewed from shaft end)

Clockwise Rotation RP-807 (MD-B)

CHECK WIDTH BETWEEN THESE SURFACES WITH

INSIDE CALIPERS TO BE CERTAIN THE FACES ARE

EQUAL DISTANCE APART AND PARALLEL.

be considered in any pumping system. The straining will

keep foreign matter from entering the pump. The strainer

mesh or perforation size should be as fine as possible to

drop. Use of a strainer is particularly important at start up

to help clean the system of weld beads, pipe scale and

other foreign objects.

5. A pressure relief valve is required in the discharge line.

See Pressure Relief Valves, SPECIAL INFORMATION,

page 2.

(viewed from shaft end)

Clockwise Rotation RP-807 (MD-A)

CW ROTATION

USE STRAIGHT EDGE. THESE SURFACES MUST BE PARALLEL

COUPLING

ALIGNMENT

FIGURE 4

6. Pump must not be used to support piping. Weight of pipe

must be carried by hangers, supports, stands, etc.

7. When fastening to the pump to impose any strain on

pump casing. "Springing" or "drawing" piping up to pump

will cause distortion; possible misalignment and probable

rapid wear of pump. Do not use pipe to correct errors in

piping layout or assembly.

8. All joints of piping system must be tight; liquid thread

sealant will help assure leak free threaded joints. Loose

joints result in liquid leaks or suction side leaks. Air leaks

make the pump noisy and reduce flow. CAUTION: Be

c

cracked joints. One full turn beyond hand tight is all that

(viewed from shaft end)

FIGURE 3

The cause of many pumping problems can be traced to

suction piping. It should always be as large in diameter and

as short in length as possible.

Before starting layout and installation of your piping system,

consider the following points:

1. Never use piping smaller than pump port connections.

Piping larger in diameter than the port connection is

sometimes is required to reduce suction losses.

2. Be sure the inside of pipe is clean before installing.

3. When approaching an obstacle in the suction line, go

around instead of over it. Going over obstacle creates an

air pocket. Where practical slope piping, slope piping so

no air or liquid pockets will be formed. Air pockets in

suction line make it hard for the pump to prime.

Reduced friction makes over tightening very easy and will

result in cracked ports.

9. Drive alignment must be checked after piping is hooked

up.

10. Provide a pressure relief device if any part of a pump and

piping system that can be valved off, thus completely

isolated. A rise in temperature will cause liquid to expand.

With no provision for pressure relief in the closed off

section, there is a chance that the pump or piping will

rupture.

BEFORE STARTING PUMP, BE SURE ALL DRIVE

Start Up:

EQUIPMENT GUARDS ARE ADEQUATE AND IN

DANGER

PLACE.

FAILURE TO PROPERLY MOUNT GUARDS MAY

RESULT IN SERIOUS INJURY OR DEATH.

Before pushing "start" button, check the following:

1. Vacuum and pressure gauges (liquid filled) are mounted

on or near the pump. Gauges are the quickest and most

accurate way of finding out what is happening in the

pump.

TSM 343.1 ISSUE D PAGE 3 OF 13

2. Check Pump alignment (See page 3).

Review steps just outlined. Consider what suction and

4. Arbor press

5. Torque wrench

DISASSEMBLY OF MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1.

Read all of the instructions before proceeding with

disassembly of the coupling and/or pump. Remove

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace -

especially the encapsulated O-rings. Follow instructions

in ASSEMBLY

for installation of a new Teflon®

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

bearing carrier. Loosen setscrews in outer magnet

assembly to pull assembly off shaft.

FIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE FINGERS

HERE AT ANY TIME

FIGURE 6

Typical Pump Removal from Coupling Bracket

4. Arbor press

disassembly of the coupling and/or pump. Remove

for installation of a new Teflon®

bearing carrier. Loosen setscrews in outer magnet

FIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE FINGERS

FIGURE 6

2. Check Pump alignment (See page 3).

3. Check piping to be sure there is no strain on the pump

casing.

4. Rotate the pump shaft by hand to be sure it turns freely.

55. Motor has been jogged and is running in the correct

direction. Refer to "General" on page 2.

6. Pressure relief valve is installed properly.

7. Suction piping is connected and tight, and valves are

open.

8. Make sure discharge piping is connected and tight,

valves are open and, and end of shaft is below liquid

level.

9. All guards are in place.

10. The above checklist is a general guideline to be used

prior to starting pump. Since Viking pump cannot foresee

every application for our product and possible system

design, final responsibility is with the user. The pump

must be utilized within the catalog specifications and the

pump system must be designed to provide safe working

conditions.

Push the "start" button. Pump should begin to deliver liquid

within 15 seconds!

If the pump does not deliver liquid, push the stop button. Do

not run the pump without liquid flow longer than 30

seconds because pump or coupling could be damaged

or ruined.

Review steps just outlined. Consider what suction and

discharge gauges indicate. If everything appears in order, put

more liquid in the pump suction port. See item 6 on page 3.

Push the start button. If nothing happens within 30 seconds,

stop the pump. The pump is not a compressor and will not

build up much air pressure. It may be necessary to vent the

discharge line until liquid begins to flow. Use a safe venting

procedure especially when handling hazardous liquids.

If the pump still does not deliver liquid, consider one or more

of the following:

1. Suction line air leaks; vacuum gauge reading should help

determine if this is the problem.

2. End of suction pipe not submerged deep enough in liquid.

3. Suction lift is too great or suction piping is too small.

4. Liquid is vaporizing in the suction line before it gets to the

pump.

5. Magnetic coupling is decoupling for some reason.

If after consideration of these points, the pump still does not

deliver liquid, review all points given under START UP and

read through the TROUBLESHOOTING guide and try again.

If pump still will not deliver liquid, contact your Viking Pump

supplier.

SUGGESTED REPAIR TOOLS: The following are required

to properly repair a RP Series Mag Drive pump. The tools are

in addition to standard mechanics tools such as open end

wrenches, pliers, screw drivers, etc. Most of the items can be

obtained from an industrial supply house.

1. Soft face hammer

2. Allen wrenches

4. Arbor press

5. Torque wrench

DISASSEMBLY OF MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1.

Read all of the instructions before proceeding with

disassembly of the coupling and/or pump. Remove

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace -

especially the encapsulated O-rings. Follow instructions

in ASSEMBLY

for installation of a new Teflon®

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

bearing carrier. Loosen setscrews in outer magnet

assembly to pull assembly off shaft.

FIGURE 5

RP-80732 - MD-B15 with motor

PLACE HANDS BACK HERE

CAUTION: DO NOT PLACE FINGERS

HERE AT ANY TIME

FIGURE 6

Typical Pump Removal from Coupling Bracket

3. Check piping to be sure there is no strain on the pump

casing.

4. Rotate the pump shaft by hand to be sure it turns freely.

55. Motor has been jogged and is running in the correct

direction. Refer to "General" on page 2.

6. Pressure relief valve is installed properly.

7. Suction piping is connected and tight, and valves are

open.

8. Make sure discharge piping is connected and tight,

valves are open and, and end of shaft is below liquid

level.

9. All guards are in place.

10. The above checklist is a general guideline to be used

prior to starting pump. Since Viking pump cannot foresee

every application for our product and possible system

design, final responsibility is with the user. The pump

must be utilized within the catalog specifications and the

pump system must be designed to provide safe working

conditions.

Push the "start" button. Pump should begin to deliver liquid

within 15 seconds!

If the pump does not deliver liquid, push the stop button. Do

not run the pump without liquid flow longer than 30

seconds because pump or coupling could be damaged

or ruined.

discharge gauges indicate. If everything appears in order, put

more liquid in the pump suction port. See item 6 on page 3.

Push the start button. If nothing happens within 30 seconds,

stop the pump. The pump is not a compressor and will not

build up much air pressure. It may be necessary to vent the

discharge line until liquid begins to flow. Use a safe venting

procedure especially when handling hazardous liquids.

If the pump still does not deliver liquid, consider one or more

of the following:

1. Suction line air leaks; vacuum gauge reading should help

determine if this is the problem.

2. End of suction pipe not submerged deep enough in liquid.

3. Suction lift is too great or suction piping is too small.

4. Liquid is vaporizing in the suction line before it gets to the

pump.

5. Magnetic coupling is decoupling for some reason.

If after consideration of these points, the pump still does not

deliver liquid, review all points given under START UP and

read through the TROUBLESHOOTING guide and try again.

If pump still will not deliver liquid, contact your Viking Pump

supplier.

SUGGESTED REPAIR TOOLS: The following are required

to properly repair a RP Series Mag Drive pump. The tools are

in addition to standard mechanics tools such as open end

wrenches, pliers, screw drivers, etc. Most of the items can be

obtained from an industrial supply house.

1. Soft face hammer

2. Allen wrenches

TSM 343.1 ISSUE D PAGE 4 OF 13

3. Internal snap ring pliers (for bearing carriers only) 2-810-

029-047-999 (Truarc No. 0500)

4. External snap ring pliers 2-810-029-375 (Truarc No. 0400)

5.

5. Torque wrench

6.

DISASSEMBLY OF MD-A2, MD-A8,

MD-B15, or MD-B40 COUPLINGS

1. Read all of the instructions before proceeding with

piping to ports and remove the mounting capscrews

securing pump to bracket. Support larger pumps with

overhead hoist if possible. Remove pump from coupling

bracket. See FIGURE 6 on page 4.

2. Canister will probably be full of liquid, use care while

removing from pump and pull straight off. Loosen both

setscrews and pull off inner magnet assembly. MD-A2

and MD-A8 couplings require removing the pipe plug in

pump bracket to gain access to the setscrews holding

the inner magnet.

Don't forget this is a very powerful magnet. Do not

remove O-ring on bracket unless you plan to replace especially the encapsulated O-rings. Follow instructions

in ASSEMBLY

encapsulated O-ring.

3. You should be able to visually inspect other magnets

from end of bracket. If removal is necessary, start by

removing (4) capscrews and separating from motor or

assembly to pull assembly off shaft.

Typical Pump Removal from Coupling Bracket

HERE AT ANY TIME

Loading...

Loading...