Viking Pump TSM285 User Manual

TECHNICAL SERVICE MANUAL

SECTION TSM 285

CLASSIC+ SERIES ROTARY LOBE PUMPS

MODELS CP10, CP20, CP30, CP40 & CP50

CONTENTS

1.0 Safety Information........................................................................ 2

Risk Assessment Relating to the Use of Viking Pump

1.1

Classic+ Rotary Lobe Pumps and Pump Units in

Potentially Explosive Atmospheres ..............................................

Introduction. .................................................................................3

2.0

2.1 General. .......................................................................................3

2.2 Viking Pump Distributors. ............................................................3

2.3 Receipts and Storage. ................................................................. 3

2.4 Cleaning....................................................................................... 3

2.5 Pump Model Designation............................................................. 4

2.5.1 AtexIdenticationPlate ...............................................................4

2.5.2 Equipment Groups & Categories .................................................4

2.6 Pump Model and Serial Number. ................................................. 4

Standard Pump Component Terms .............................................5

2.7

General. .......................................................................................5

3.0

3.1 Classic+ Pumping Principal. ........................................................5

3.2 Classic+ Range Operating Parameters. ......................................5

3.3 System Design............................................................................. 6

3.3.1 System Design and Installation. .................................................. 6

3.3.2 Installations with In-Line Cleaning Systems. ............................... 7

3.4 Start Up Procedure. .....................................................................8

3.5 Shutdown Procedure. .................................................................. 8

3.6 Routine Maintenance. .................................................................. 8

3.7 Heating and Cooling Jackets .......................................................8

3.8 Integral Pressure Relief Valves ..................................................10

3.8.1 Setting and Operating Spring Loaded Valves ............................ 10

3.8.2 Setting and Operating Air Loaded Integral

Pressure Relief Valves ...............................................................

Classic+ Disassembly and Assembly. .......................................12

4.0

4.1 CP10, CP20 & CP30 Pump - Disassembly and Assembly. .......12

4.1.1 CP10, CP20 & CP30 Head and Rotor Removal ........................ 12

4.1.2 CP10, CP20 & CP30 Casing Removal ...................................... 13

4.1.2.1 CP10, CP20 & CP30 Casing Removal - Single

Un-ushedMechanicalSealsandSingleO-RingSeals ............

4.1.2.2 CP10, CP20 & CP30 Casing Removal - Single Flushed

or Double Flushed Mechanical Seals. .......................................

4.1.3 CP10, CP20 & CP30 Gearbox Disassembly .............................14

4.1.4 CP10, CP20 & CP30 Gearbox Assembly .................................. 15

4.1.5 CP10, CP20 & CP30 Casing, Rotor and

Head Assembly ..........................................................................

4.2 CP40 Pumps - Disassembly and Assembly...............................17

4.2.1 CP40 Head and Rotor Removal ................................................17

4.2.2 CP40 Casing Removal .............................................................. 17

4.2.2.1 CP40CasingRemoval-SingleUn-ushedMechanical

Seals and O-Ring Seals ............................................................

4.2.2.2 CP40 Casing Removal - Single Flushed or Double

Flushed Mechanical Seals. ........................................................

4.2.3 CP40 Gearbox Disassembly...................................................... 18

4.2.4 CP40 Gearbox Assembly........................................................... 19

4.2.5 CP40 Casing, Rotor and Head Assembly .................................. 20

4.3 CP50 Pumps - Disassembly and Assembly...............................21

4.3.1 CP50 Head and Rotor Removal ................................................21

4.3.2 CP50 Casing Removal .............................................................. 21

4.3.2.1 CP50CasingRemoval-SingleUn-ushedMechanical

Seals and O-Ring Seals ............................................................

4.3.2.2 CP50 Casing Removal - Single Flushed and Double

Flushed Mechanical Seals .........................................................

4.3.3 CP50 Gearbox Disassembly...................................................... 22

4.3.4 CP50 Gearbox Assembly........................................................... 23

4.3.5 CP50 Casing, Rotor and Head Assembly .................................. 24

Classic+ Mechanical Seal Removal & Replacement. ................ 25

5.0

5.1 General Procedures for Installing Mechanical Seals. ................ 25

10

13

14

16

17

18

21

21

PAGE 1 OF 36

ISSUE A

5.2 CP10, CP20, CP30 & CP40 Mechanical Seals ......................... 25

5.2.1 CP10, CP20, CP30 & CP40

Single Mechanical Seal Removal ..............................................

5.2.2 CP10, CP20, CP30 & CP40

3

Single Mechanical Seal Replacement .......................................

5.2.3 CP10, CP20, CP30 & CP40

Single Flushed Mechanical Seal Removal ................................

5.2.4 CP10, CP20, CP30 & CP40

Single Flushed Mechanical Seal Replacement .........................

5.2.5 CP10 Double Flushed Mechanical Seal Removal ..................... 26

5.2.6 CP10 Double Flushed Mechanical Seal Replacement .............. 27

5.2.7 CP20, CP30 & CP40

Double Flushed Mechanical Seal Removal ...............................

5.2.8 CP20, CP30 & CP40

Double Flushed Mechanical Seal Replacement ........................

5.3 CP50 Mechanical Seals............................................................. 28

5.3.1 CP50 Single Mechanical Seal Removal ....................................28

5.3.2 CP50 Single Mechanical Seal Replacement .............................28

5.3.3 CP50 Single Flushed Mechanical Seal Removal ...................... 28

5.3.4 CP50 Single Flushed Mechanical Seal Replacement ............... 28

5.3.5 CP50 Double Flushed Mechanical Seal Removal ..................... 29

5.3.6 CP50 Double Flushed Mechanical Seal Replacement .............. 29

Classic+ Single O-Ring Seals .................................................... 29

6.0

6.1 General Procedures for Fitting Single O-Ring Seals ................. 29

6.2 O-Ring Seals for CP10, CP20, CP30 & CP40 Pumps............... 29

6.2.1 CP10, CP20, CP30 & CP40 O-Ring Seal

Assembly and Removal .............................................................

6.3 O-Ring Seal for CP50 Pump...................................................... 30

6.3.1 CP50 O-Ring Seal Assembly and Removal............................... 30

Flushed Product Seals Auxiliary Services ................................. 30

7.0

7.1 Single Mechanical Seal (for Low-Pressure Quench or Flush) ... 30

7.2 Double Mechanical Seal (for High Pressure Flush) ................... 30

Specications............................................................................. 31

8.0

Clearance Chart......................................................................... 31

8.1

Fasteners and Torque Settings .................................................. 32

8.2

Lubricants .................................................................................. 33

8.3

Troubleshooting ......................................................................... 33

8.4

8.5 MaterialSpecications ...............................................................

Foundation Dimensions and Weights ........................................ 34

8.6

Typical Noise Emission Data - CP10, CP20 & CP30 Pumps .... 35

8.7

Typical Noise Emission Data - CP40 & CP50 Pumps ............... 35

8.8

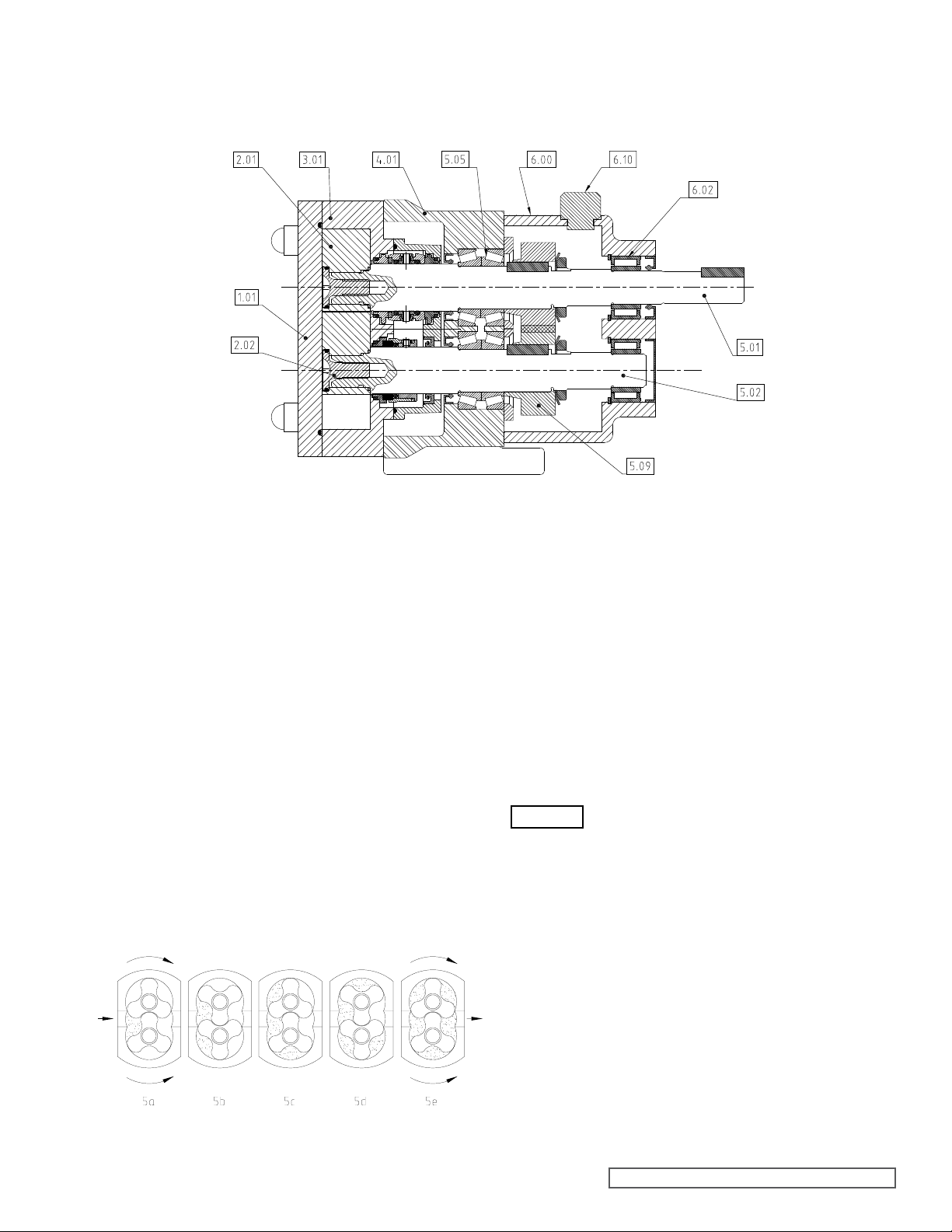

Classic+ Series CP20 Pump

25

25

26

26

27

27

29

33

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

1.0 SAFETY INFORMATION

INCORRECT INSTALLATION, OPERATION OR MAINTENANCE OF EQUIPMENT MAY CAUSE SEVERE

PERSONAL INJURY OR DEATH AND/OR EQUIPMENT DAMAGE AND MAY INVALIDATE THE WARRANTY.

This information must be read fully before beginning installation, operation or maintenance and must be

kept with the pump. All installation and maintenance must be undertaken by suitably trained or qualified

persons only.

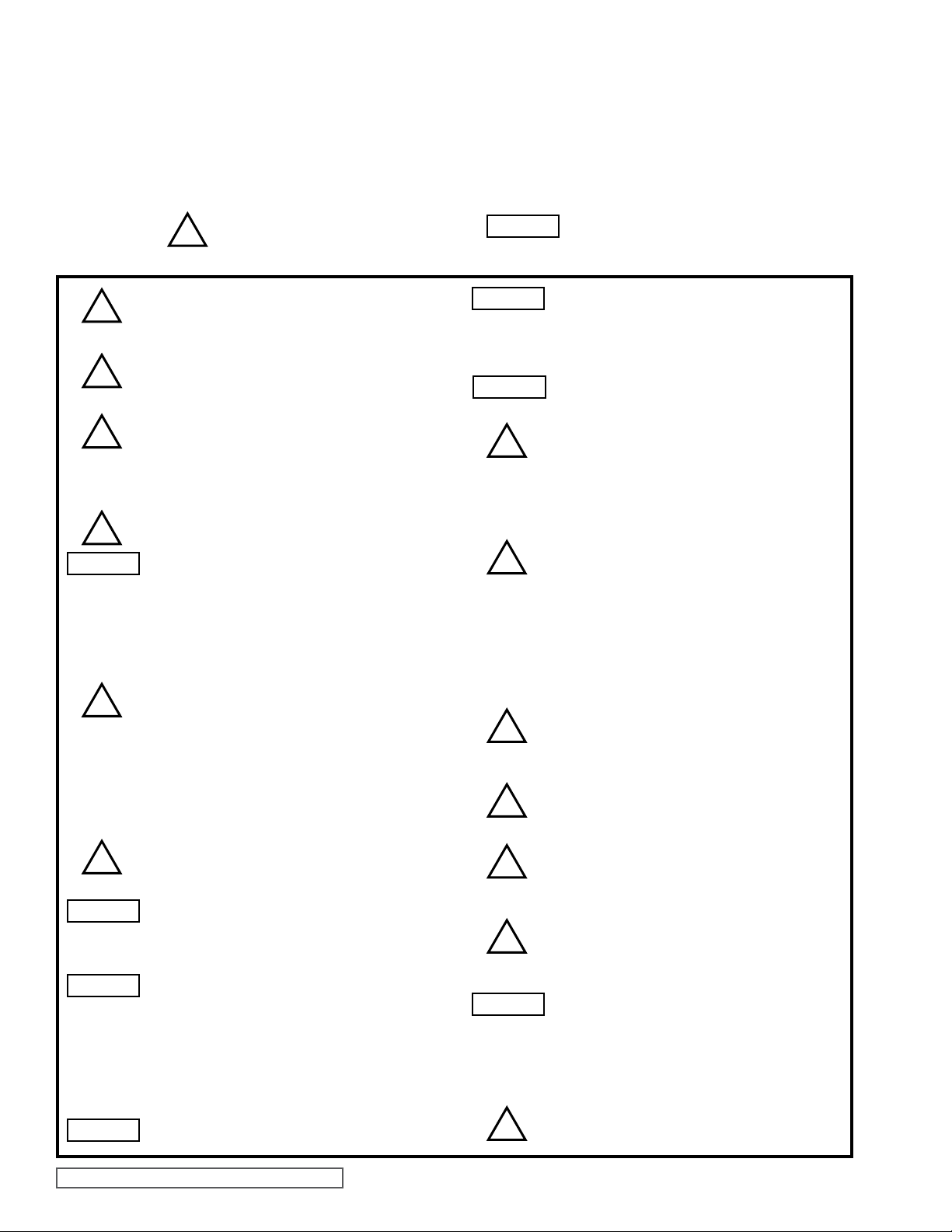

Symbol

Legend :

Danger - Failure to follow the listed

precautionary measures identified by

this symbol may result in serious injury

!

or death.

WARNING

Warning - Safety instructions which

shall be considered for reasons of safe

operation of the pump or pump unit and/

or protection of the pump or pump unit

itself are marked by this symbol.

!

!

!

!

WARNING

!

!

WARNING

WARNING

WARNING

DO NOT OPERATE PUMP IF:

- The head is not installed correctly.

- Any guards are missing or incorrectly installed.

- The suction or discharge piping is not connected.

DO NOTplace ngers,etc. intothepumping chamber

or its connection ports or into any part of the gearbox if

there is ANY possibility of the pump shafts being rotated.

Severe injury will occur.

DO NOT exceed the pumps rated pressure, speed, and

temperature, or change the system/duty parameters

from those for which the pump was originally supplied,

withoutconrmingitssuitabilityforthenewduty.Running

the pump outside of its operation envelope can cause

mechanical contact, excessive heat and can represent a

serious risk to health and safety.

Installation and operation of the pump must always

comply with health and safety regulations.

A device must be incorporated into the pump, system,

or drive to prevent the pump exceeding its stated duty

pressure. It must be suitable for both directions of pump

rotation where applicable. Do not allow pump to operate

with a closed/blocked discharge unless a pressure

relief device is incorporated. If an integral relief valve is

incorporated into the pump, do not allow re-circulation

through the relief valve for extended periods (refer to

section 3.8).

The mounting of the pump or pump unit should be solid

and stable. Pump orientation must be considered in

relation to drainage/cavity ventilation requirements.

Once mounted, shaft drive elements must be checked for

correct alignment. Rotate pump shaft by at least one full

revolution to ensure smoothness of operation. Incorrect

alignment will produce excessive loading and will create

high temperatures and increased noise emissions. It

may also be necessary to earth the pump head to avoid

the build up of a potential charge difference that could

cause a spark.

The installation must allow safe routine maintenance and

inspection (to replenish lubricants, check for leakage,

monitor pressures, etc) and provide adequate ventilation

necessary to prevent overheating.

Fill all gearboxes with the recommended grades and

quantities of lubricant (refer to section 3.4 and 8.3).

Beware ofover/underlling the gearbox as this could

cause the pump to overheat and mechanical damage

to occur.

Before operating the pump, be sure that it and all parts

of the system to which it is connected are clean and

free from debris and that all valves in the suction and

discharge pipelines are fully opened. Ensure that all

piping connecting to the pump is fully supported and

correctly aligned with its relevant connections. Misalignment and/or excess loads will cause severe pump

damage. This could result in unexpected mechanical

contact in the pump head and has the potential to be an

ignition source.

Be sure that pump rotation is correct for the desired

directionofow(refer to section 3.4).

WARNING

WARNING

!

!

!

!

!

!

WARNING

!

DO NOT install the pump into a system where it will run

dry (i.e. without a supply of pumped media) unless it is

equippedwithaushedshaftsealarrangementcomplete

withafullyoperationalushingsystem.Mechanicalseals

requirea thin uid lmtolubricate thesealfaces. Dry

running can cause excessive heat and seal failure.

Pressure gauges/sensors are recommended, next to

the pump suction and discharge connections to monitor

pressures.

Caution must be taken when lifting the pump. Suitable

lifting devices should be used as appropriate. Lifting eyes

installed on the pump must only be used to lift the pump,

not pump with drive and/or base plate. If pump is base

plate mounted, the base plate must be used for all lifting

purposes. If slings are used for lifting, they must be safely

and securely attached. For weights of bare shaft pumps,

refer to section 8.6.

DO NOT attempt any maintenance or disassembly of the

pump or pump unitwithoutrstensuringthat:

- The pump is fully isolated from the power source

(electric, hydraulic, pneumatic).

- The pumping chamber, pneumatic relief valve and

any shaft seal support system are depressurized and

purged.

- Any temperature control devices (jackets,

etc.) are fully isolated, that they are depressurized and

purged, and components are allowed to reach a safe

handling temperature.

DO NOT attempt to dismantle a pressure relief valve,

which has not had the spring pressure relieved, is still

connected to a pressurized gas/air supply or is mounted

on a pump that is operating. Serious personal injury or

death and/or pump damage may occur.

DO NOT loosen or undo the head, any connections to the

pump, shaft seal housings, temperature control devices,

or other components, until sure that such action will not

allow the unsafe escape of any pressurized media.

Pumps and/or drives can produce sound power levels

exceeding 85dB (A) under certain operating conditions.

When necessary, personal protection against noise must

be taken. Typical noise emission data can be found in

sections 8.7 and 8.8.

Avoid any contact with hot parts of pumps and/or drives

that may cause injury. Certain operating conditions,

temperature control devices (jackets, heat-tracing, etc.),

bad installation, or poor maintenance can all promote

high temperatures on pumps and/or drives.

When cleaning, either manually or by an in-line cleaning

method, the operator must ensure that a suitable

procedure is used in accordance with the system

requirements. During a in-line cleaning cycle, a pump

differential pressure of between 2 and 3 bar (30 and 45

psi) is recommended to ensure suitable velocities are

reached within the pump head. The exterior of the pump

should be cleaned periodically.

Surface temperature of pump is also dependent on the

temperature of pumped medium.

heat-tracing,

SECTION TSM 285 ISSUE A PAGE 2 OF 36

1.1 RISK ASSESSMENT RELATING

TO THE USE OF VIKING PUMP

CLASSIC+ ROTARY LOBE

PUMPS AND PUMP UNITS IN

POTENTIALLY EXPLOSIVE

ATMOSPHERES

NOTE

For a feature to be suitable for an application, the

feature must be t for its designated purpose and also

suitable for the environment where it is to be installed.

Source

of Hazards

Unvented

Cavities

Casing /

Rotors /

Head

Pump

External

Surfaces

Cover

O-Ring

Pump

Casing / Cover

Shaft Seals

Auxiliary

System for

Shaft

Sealing

Rotation

Direction

Test

Closed

Valve

Condition

Shaft

Mechanical

Shaft

Coupling

(Torque

Protection)

Mechanical

Shaft

Coupling

(Standard)

Potential

Hazards

Build up of explosive gas

Unintended mechanical

contact

Excess temperature.

Electrostatic charging

Pump liquid leakage.

Build up of explosive gas

Pump liquid leakage.

Build up of explosive gas

Excessive temperature.

Unintended mechanical

contact. Leakage.

up of explosive gas

Pump liquid leakage.

Build up of explosive gas

Excess Temperature

Excess Temperature.

Excess Pressure.

Mechanical Contact

Random induced current

Temperature from

friction. Sparks from

break up of shear pins.

Electrostatic charging

Break up of spider.

Unintended

mechanical contact.

Electrostatic charging

Build

Frequency

of Hazards

Very Rare

Rare

Rare

Very Rare

Very Rare

Rare

Rare

Very Rare

Rare

Very Rare

Rare

Rare

Recommended

Measures

Ensure that pump is totally

lled. Consider mounting

ports vertically.

See Chapter 1.0

Ensure that operating

pressures are not

exceeded. Ensure that

sufcient NPSH to prevent

cavitation. See Chapter

1.0 / 3.3.1 Service Plan

User must ensure

temperature limits. Do not

overll gearboxes with

lubricant. Provide a ground

contact for pump. See

Chapter 1.0 / Service plan

Check selection of

elastomers are suitable for

application. Ensure cover

retaining nuts are tight.

Service plan

Stainless Steel.

Corrosion Resistant

Selection of seal system

must be suitable for

application. See Chapter

5.0. Service plan. Seals

must never run dry

Selection of auxiliary seal

system must be suitable

for application. Seals must

never run dry

If ushed seals are

installed, ensure that

ush is applied to seal

assemblies. Only allow

pump to run for minimum

period - just a few seconds

Can cause excessive

pressure, heat and

mechanical contact.

See Chapter 1.0

Provide a ground contact

for pump. See Chapter 1.0

Coupling selection must

suit application.

See Chapter 1.0

Coupling selection must

suit application. Service

plan. See Chapter 1.0

2.0 INTRODUCTION

2.1 GENERAL

Classic+ rotary lobe pumps are manufactured by Johnson

Pump (UK) Ltd. a subsidiary of Viking Pump Inc., Cedar Falls,

USA, (a unit of the IDEX Corporation).

This manual includes all the necessary information for the

Classic+ and should be read prior to beginning installation,

operation, or maintenance.

Should you require any additional information regarding

the Classic+ contact Viking Pump or their local authorized

distributor, refer to section 2.2.

When asking for assistance please provide the pump model

and serial number. This information can be obtained from the

pump nameplate which is located on the side of the pump

gearbox cover, refer to section 2.6.

Should the nameplate be unreadable or missing, the serial

number is also stamped on either side of the casing refer to

section 2.6.

If the system or product characteristics are to be changed from

the original application for which the pump was selected, Viking

Pump or their authorized distributor should be consulted to

ensure the pump is suitable for the new application.

2.2 VIKING PUMP DISTRIBUTORS

Viking Pump distributes its products internationally via a network

of authorized distributors. Throughout this manual where

reference is made to Viking Pump, service and assistance will

also be provided by any Viking Pump authorized distributor for

Classic+.

2.3 RECEIPTS AND STORAGE

Upon receipt of the pump, immediately examine it for any signs

of visible damage. If any damage is noted, contact Viking

Pump or your Viking Pump distributor and clearly mark upon

the carriers’ paperwork that the goods have been received in a

damaged condition, with a brief description of damage.

If the pump is not required for immediate installation then it

should be stored in a clean, dry environment. It is recommended

that storage temperature should be between –10° and 40°C

(14°F and 105°F).

Further to the above, if the pump is not intended for installation

or use within 18 months or more then refer to Viking Pump,

or the Viking Pump authorized distributor for storage

recommendations.

2.4 CLEANING

The Classic+ pump series is suitable for both manual cleaning

and in-line cleaning, refer to section 3.3.2.

It is recommended that the exterior of the pump be cleaned

periodically with a non-aggressive, non-abrasive cleaning

solution.

SECTION TSM 285 ISSUE A PAGE 3 OF 36

2.5 PUMP MODEL DESIGNATION

The designations of pump models in the Classic+ range are

asfollows:

CP10S CP20S CP30S CP40S

CP50S

CP10M CP20L CP30L CP40L CP50L

CP10L

This information, together with the pump serial number, should

be provided when requesting additional information on the

pump or when ordering spare parts. The pump serial number

is stamped on the pump nameplate and the casing, (refer to

section 2.6, Figures 2 and 3).

For the maximum operating pressures, temperatures and

speeds refer to section 3.2, Figure 6.

CP 30 / 0069 / 12

2.6 PUMP MODEL AND SERIAL

NUMBER

Should you require any information regarding your Classic+

rotary lobe pump contact Viking Pump or your Viking Pump

distributor, providing the pump model and serial number as

statedonthepumpnameplate,seeFigure2,whichisxedto

the pump gearbox cover.

Should this be damaged or missing, the pump serial number

is also stamped on opposite corners of the casing, (see

Figure 3).

Pump

Range

Model

Size

Displacement

(Ltrs/Rev)

Max Pressure

(Bar)

Figure 1

CP Designated Models Only

2.5.1 ATEX IDENTIFICATION PLATE

Unit is suitable

for environments

Temperature

Class

Group II Category 2

containing dust

or gas

2.5.2 EQUIPMENT GROUPS

& CATEGORIES

Equipment-groups (Annex I of the EC-Directive 94/9/EC)

Group I

(mines, mine gas & dust)

Category M Category 1 Category 2 Category 3

1 2

for equipment

providing a

very high level

of protection

when

endangered by

an explosive

atmosphere

for equipment

providing a

high level of

protection when

likely to

be endangered

by an explosive

atmosphere

(gas)

(Zone 0)

for equipment providing

a very high level of

protection when used

in areas where an

explosive atmosphere

is very likely to occur

(other explosive atmospheres gas/dust)

G

D

(dust)

(Zone 20)

Group II

G

(gas)

(Zone 1)

for equipment providing

a high level of

protection when used

in areas where an

explosive atmosphere

is likely to occur

D

(dust)

(Zone 21)

G

(gas)

(Zone 2)

for equipment providing

a normal level of

protection when used

in areas where an

explosive atmosphere

is less likely to occur

(dust)

(Zone 22)

VIKING P UMP, INC.

A Unit of IDE X Corporati on

CEDAR FAL LS, IOWA USA

Phone:( 319)266-17 41

Fax:(31 9)273-815 7

Figure 2

Nameplate

12345/A/67

Figure 3

Serial Number Position on Casing

D

SECTION TSM 285 ISSUE A PAGE 4 OF 36

2.7 STANDARD PUMP

ROTORS

FRONT COVER

ROTOR

RETAINER

ROTORCASE

BEARING

HOUSING

FRONT

BEARINGS

GEARBOX

COVER

BREATHER

/FILLER CAP

REAR

BEARINGS

DRIVE

SHAFT

DRIVEN

SHAFT

TIMING

GEARS

COMPONENT TERMS

Figure 4

Pump Component Terms

3.0 GENERAL

3.1 CLASSIC+ PUMPING PRINCIPAL

The pumping action of the rotary lobe pump principle is

generated by the contra rotation of two pumping elements

(rotors) within a chamber (casing) - see Figure 5. The rotors are

located on shafts, which in turn are mounted within an external

gearbox and supported by the bearings; the timing gears are

also located on the shafts. The timing gears transfer the energy

from the drive shaft to the driven shaft, synchronizing the rotors

such that they rotate without contact with each other.

As the rotors pass the suction port, see Figure 5a, the cavity

generated increases creating a pressure decrease, which

inducesthepumpedmediumtoowintothecasing.

The pumped medium is carried around the casing by the rotors;

see Figure 5b and 5c, to the discharge side of the pump, Figure

5d. Here the cavity decreases and the pumped medium is

discharged from the casing, Figure 5e.

For pump component terms, see Figure 4.

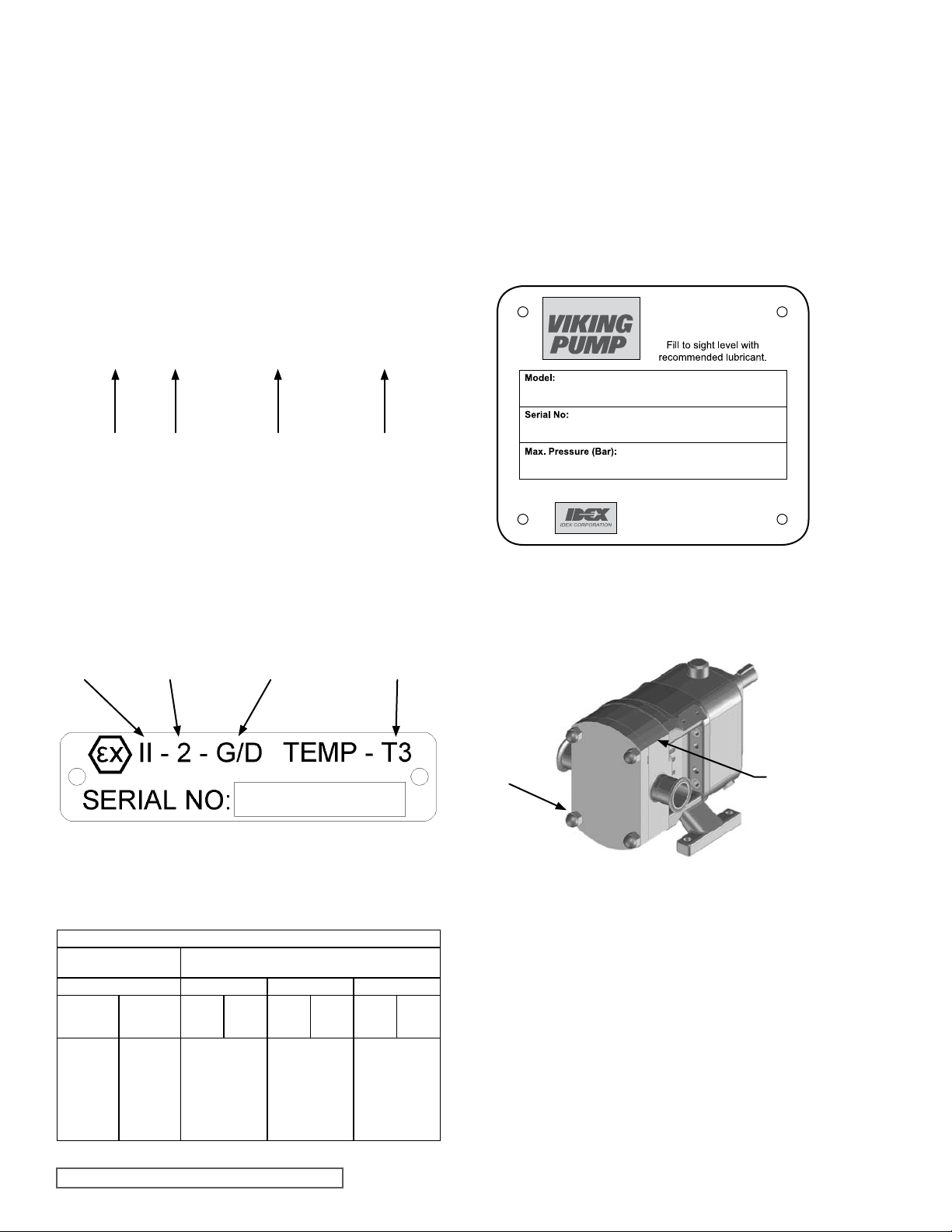

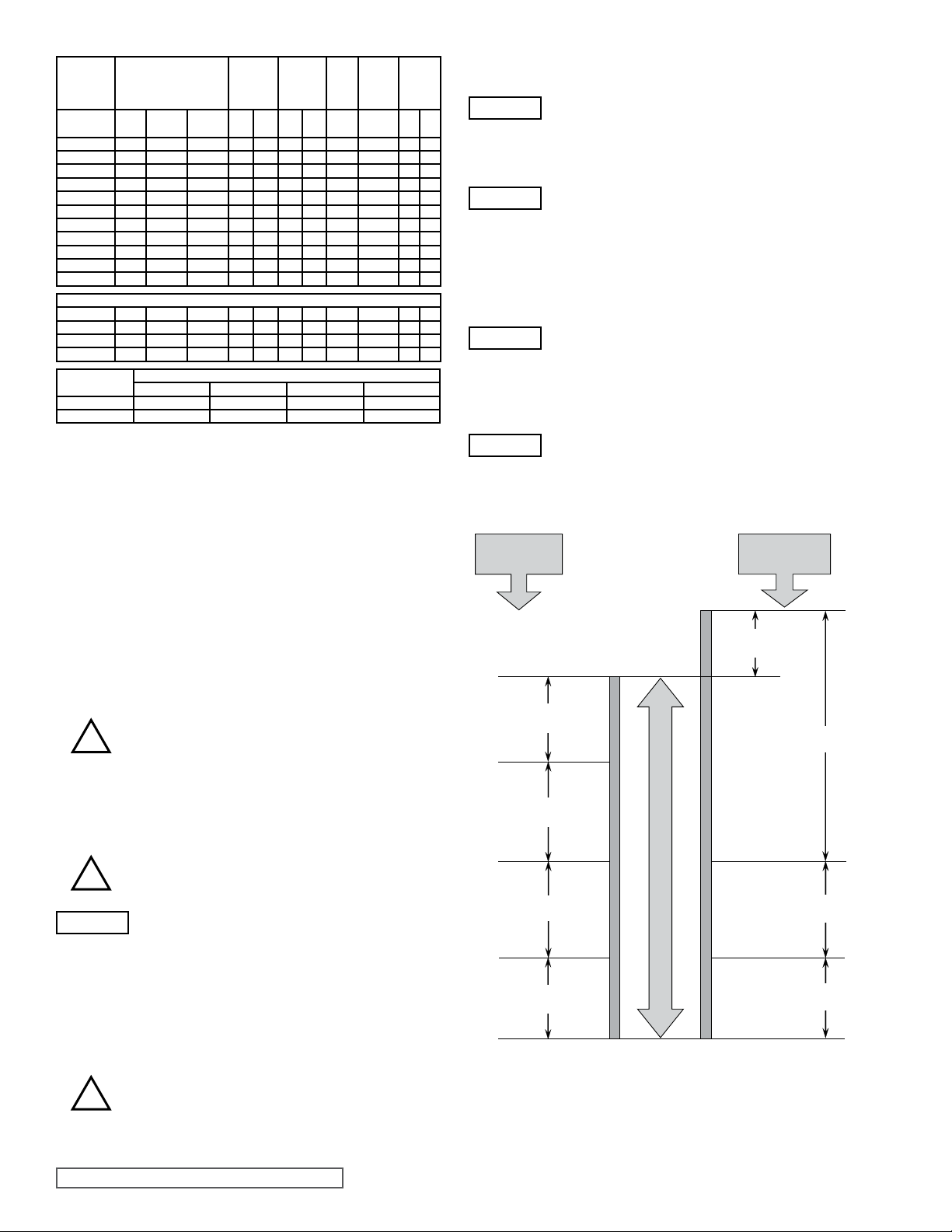

3.2 CLASSIC+ RANGE OPERATING

PARAMETERS

The maximum pressure and speed operating parameters are

given in Figure 6. In practice these may be limited due to the

nature of the product to be pumped and/or design of the system

in which the pump is to be installed. Consult Viking Pump or

your Viking Pump distributor for assistance.

The operating temperature limit of the pump is determined

by the rotor clearance. For the CP10, CP20, CP30 and CP40

series pumps there are three rotor clearance bands (class A,

B and C), and two (class B and D) for the CP50 series pumps.

WARNING

The pump should not be subjected to sudden temperature

changes to avoid the risk of damage from sudden expansion/

contraction of components. Care should be taken when

selecting pumps for handling liquids containing abrasive

particles as these may cause wear of pump head components.

For advice or assistance contact Viking Pump or your Viking

Pump distributor.

If the system or product characteristics are to

be changed from the original application for

which the pump was selected, Viking Pump or

their authorized distributor should be consulted

to ensure the pump is suitable for the new

application.

Figure 5

Rotary Lobe Pumping Principle

SECTION TSM 285 ISSUE A PAGE 5 OF 36

Pump Range Theoretical Displacement

10.0 Meters (32.8 Feet) Water Column

Suction Lift

Or Vacuum

Atmospheric

Pressure

Suction

Head

NPSH

Available

Suction Line

Friction Loss

Vapour

Pressure

NPSH

Available

Suction Line

Friction Loss

Vapour

Pressure

For Suction Lift

Or Vacuum

Conditions.

For Conditions

With Positive

Suction Head.

Atmospheric

Vacuum

Imp.gal

ltr/rev

CP10S 0.046 1.01 1.22 25 1 12 175 1400 1000 8.5 120

CP10M 0.083 1.83 2.19 38 1.5 8 120 1400 1000 5.5 75

CP10L 0.111 2.44 2.93 38 1.5 5 70 1400 1000 3.5 50

CP20S 0.202 4.44 5.34 38 1.5 12 175 1000 750 8.5 120

CP20L 0.313 6.89 8.27 50 2 7 100 1000 750 5.0 70

CP30S 0.694 15.27 18.34 50 2 12 175 750 550 8.5 120

CP30L 1.125 24.75 29.72 76 3 7 100 750 550 5.0 70

CP40S 1.800 39.60 47.56 76 3 12 175 700 520 8.5 120

CP40L 2.500 55.00 66.05 101 4 7 100 700 520 5.0 70

CP50S 3.514 77.31 92.84 101 4 12 175 650 420 8.5 120

CP50L 5.250 115.50 64.20 152 6 8 115 600 420 5.5 75

CP20/CP30 High Efciency Operating Parameters.

CP20S 0.202 4.44 5.34 38 1.5 7 100 1000 750 5.0 70

CP20L 0.313 6.89 8.27 50 2 4 55 1000 750 3.0 40

CP30S 0.694 15.27 18.34 50 2 7 100 750 520 5.0 70

CP30L 1.125 24.75 29.72 76 3 4 55 750 520 3.0 40

Classic+ Series

CP10, 20, 30, 40 70 100 150 N/A

CP50 N/A 100 N/A 180

/100 rev

Class A Class B Class C Class D

Nominal

Connection

Size

US gal

mm in. bar psi

/100 rev

Operating Temperature Limit (°C)

Max

Differential

Pressure

Max.

Speed

rev/

min

Max

Speed @

Max Diff.

Pressure

rev/min bar psi

Figure 6

Operating Parameters

3.3 SYSTEM DESIGN

Max Diff.

Pressure

@ Max

Speed

WARNING

WARNING

WARNING

WARNING

- Incorporation of a torque-limiting device in the

drive system.

It is recommended that all piping and associated

equipment from the tank to the discharge point

is thoroughly cleaned before installation of the

pump to avoid the possibility of debris entering

the pump and causing damage.

Pressure gauges should be installed adjacent to

the pump suction and discharge connections such

that system pressures can be monitored. These

gauges will provide a clear indication of changes

in operating conditions and where a relief valve

is incorporated in the system, will be necessary

for setting and checking the functioning of the

valve.

It is imperative that the suction condition at the

pump inlet meets the Net Positive Suction Head

required (NPSHr) by the pump. Failure to observe

this could cause cavitation, resulting in noisy

operation,reductioninowrateandmechanical

damage to the pump and associated equipment.

The Net Positive Suction Head available

(NPSHa) from the system must always exceed

the Net Positive Suction Head required (NPSHr)

by the pump.

3.3.1 SYSTEM DESIGN AND

INSTALLATION

When incorporating any pump into a system it is considered

good practice to minimize piping runs and the number of pipe

ttings (tees, unions, bends etc.) and restrictions. Particular

care should be taken in designing the suction line, which

should be as short and straight as possible with a minimum of

pipettingstominimiserestrictingproductowto the pump.

The following should be considered at the design stage of any

system.

Be sure ample room is provided around the pump

!

!

WARNING

Valves should be provided adjacent to the pump suction and

discharge connections to allow the pump to be isolated from

the system for routine inspection and maintenance.

!

SECTION TSM 285 ISSUE A PAGE 6 OF 36

toallowfor:

- Access to the pump and drive for routine

inspection and maintenance, i.e. to remove

pump head and rotors.

- Ventilation of the drive to prevent over

heating.

The exterior of the pump unit may exceed 68°C

(154°F); Appropriate measures must be taken to

warn or protect operators.

The pump must not be used to support piping.

All piping to and from the pump unit must be

independently supported. Failure to observe

this may distort the pump head components

or assembly and cause serious consequential

damage to the pump.

Rotary lobe pumps are of the positive displacement

type and therefore an overload protection device

mustbeprovided.Thiscantaketheformof:

- An in-line pressure relief system, i.e. external

to the pump.

Figure 7

NPSH

Observing the following general guidelines should ensure the

best possible suction condition is created.

- Suction piping is at least the same diameter

connections.

- The length of suction piping is kept to the

minimum.

- The minimum number of bends, tees and

restrictions are used.

- Calculations to determine system NPSHa are

the worst condition see below.

Should advice on pump or system NPSH characteristics be

required contact the factory or their authorized distributor.

When installing a pump complete with base plate, motor and

drive,thefollowingguidelinesmustbeobserved:

a) The preferred drive arrangement for any

is in-line direct coupled. If an alternative is required please

contact Viking Pump or your Viking Pump distributor.

b) Flexible couplings must always be

!

!

!

!

f) When using electric motor drives, ensure

supply is compatible with the drive and controls and that the

method of wiring is correct for the type of starting required

by the motor i.e. Direct On Line, or other similar method.

Ensure all components are correctly grounded.

incorporated and correctly aligned within

the limits recommended by the coupling

manufacturer. To check coupling alignment

rotate the shaft by at least one full revolution

and ensure that the shaft rotates smoothly.

Couplings of a non-flexible design must never

be used.

c) Couplings must always be enclosed in a

suitable guard to prevent contact with rotating

parts, which could result in personal injury.

Guards should be of suitable material, (see d)

and of sufciently rigid design to prevent

contact with rotating parts under normal

operating conditions.

d) Whenthepumpisinstalledinaammableor

explosive environment, or is used for handling

ammable or explosive materials, special

consideration must be given. Not only to the

safety aspects of the drive unit enclosure

but also to the materials used for both the

coupling and the guard to eliminate the risk of

explosion.

e) Base plates must be secured to a at level

surface such that distortion and misalignment

are avoided. Once base plates are fastened

in position the drive alignment must be rechecked, (see b).

as the pump

absolute

pipework

carried out for

rotary lobe pump

that the electrical

When installing a pump complete with base plate, motor and

drive,thefollowingguidelinesmustbeobserved:

a) The preferred drive arrangement for any

is in-line direct coupled. If an alternative is required please

contact Viking Pump or your Viking Pump distributor.

b) Flexible couplings must always be

!

!

!

!

f) When using electric motor drives, ensure

supply is compatible with the drive and controls and that the

method of wiring is correct for the type of starting required

by the motor i.e. Direct On Line, or other similar method.

Ensure all components are correctly grounded.

incorporated and correctly aligned within

the limits recommended by the coupling

manufacturer. To check coupling alignment

rotate the shaft by at least one full revolution

and ensure that the shaft rotates smoothly.

Couplings of a non-flexible design must never

be used.

c) Couplings must always be enclosed in a

suitable guard to prevent contact with rotating

parts, which could result in personal injury.

Guards should be of suitable material, (see d)

and of sufciently rigid design to prevent

contact with rotating parts under normal

operating conditions.

d) Whenthepumpisinstalledinaammableor

explosive environment, or is used for handling

ammable or explosive materials, special

consideration must be given. Not only to the

safety aspects of the drive unit enclosure

but also to the materials used for both the

coupling and the guard to eliminate the risk of

explosion.

e) Base plates must be secured to a at level

surface such that distortion and misalignment

are avoided. Once base plates are fastened

in position the drive alignment must be rechecked, (see b).

rotary lobe pump

that the electrical

3.3.2 Installations with

CIP SYSTEMS

The Classic+ pump range is designed to be effectively cleaned

by the CIP procedures recommended for in place cleaning of

process plant. It is recommended that a differential pressure

of 2 to 3 Bar (30 to 45 psi) be developed across the pump

headduringcleaninginordertodevelopthenecessaryuid

velocities required for thorough cleaning.

SECTION TSM 285 ISSUE A PAGE 7 OF 36

3.4 Start Up Procedure

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

WARNING

- Before beginning operation, it is considered

to momentarily start/stop the pump to check the direction of

rotation and ensure that the pump is free of obstructions.

Once this has been carried out, begin operation keeping a

visual check on suction and discharge pressure gauges and

monitor the pump temperature and absorbed power where

possible.

- Check that all piping and associated equipment

are clean and free from debris and that all pipe

connections are secure and leak free.

- For pumps tted with ushed product seals

check all auxiliary services are in place

and connected and provide sufcient ow

and pressure for ushing purposes, refer to

section 7.0.

- Ensure lubrication is provided for both pump

and drive. The Classic+ is shipped without oil

as standard and should be lled to the level

of the oil sight glass - refer to section 8.3 for

pump oil capacities and grades.

- If an external relief valve is incorporated in the

system, check that it is set correctly. For start up

purposes, it is considered good practice to set

the relief valve lower than the system design

pressure. On completion of start up, the relief

valve should be reset to the required setting

for the application. The required setting should

never exceed the lower of either the pumps

maximum pressure rating or the system design

pressure. For setting integral relief valves refer

to sections 3.8.1 and 3.8.2.

- Be sure both suction and discharge valves are

fully opened and that pipe work is free from

all obstructions. The Classic+ is a positive

displacement type pump and should therefore

never be operated against a closed valve as this

would result in pressure overload, resulting in

damage to the pump and possibly the system.

- Make sure that the drive shaft rotation is correct

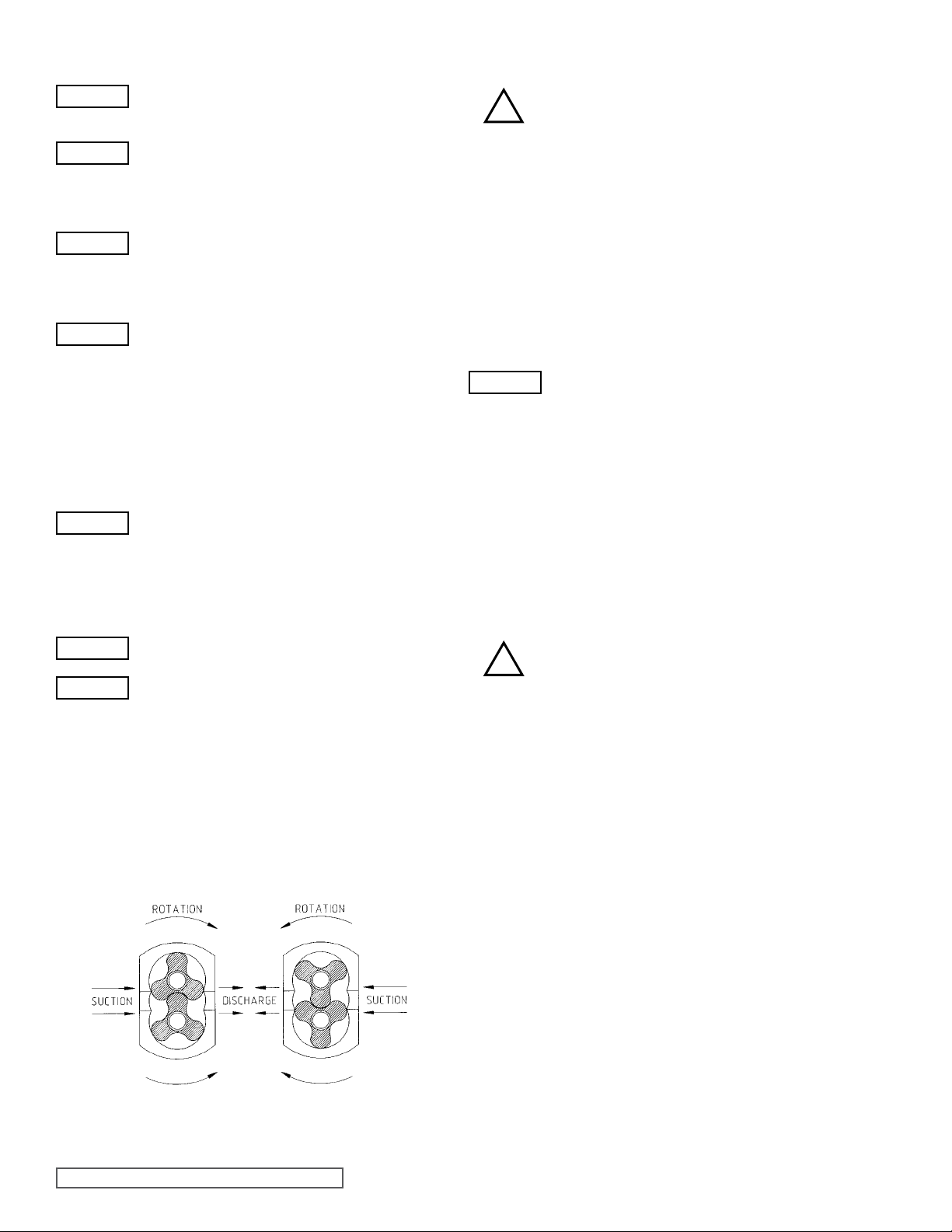

forthedirectionofowrequired.SeeFigure8.

- Be sure product is available in the suction

vessel before starting the pump. This is very

important for pumps tted with un-ushed

product seals, as these sealing arrangements

must never be allowed to run dry.

good practice

3.5 SHUTDOWN PROCEDURE

When shutting the pump down, stop pump, close

!

both the suction and discharge valves and ensure

thatthenecessarysafetyprecautionsaretaken:

- The prime mover power source has been

isolated.

- If installed, pneumatically operated integral

relief valve has been depressurized.

- Flushed product seal auxiliary services have

been isolated and depressurized.

- Pump head and piping have been drained and

purged.

- Before undertaking any work on the pump refer

to sections 4, 5, 6 and 7.

3.6 ROUTINE MAINTENANCE

WARNING

- Change the oil every 12 months or 3000

whichever is the sooner.

- For lubricant capacities and grades refer to

- Check oil levels regularly.

operating hours,

section 8.3.

3.7 HEATING AND COOLING

JACKETS

SeeFigure9andFigure10.

The Classic+ can be supplied with a jacketed head and casing

for circulation of a heating/cooling media.

The jacketed head and casing ports are strategically positioned

such that the required thermal effect acts on the pumping

chamber.

The pressure rating of the Classic+ series jacketed

!

Heating/cooling of the pump head is used to maintain, rather

than increase/decrease the temperature of the pumped media

and should be used as part of a complete system where suction

and discharge lines and vessels are also heated/cooled.

Where heating/cooling devices are employed, the heating/

cooling media should be circulated 15-20 minutes prior to pump

start-up and should be allowed to continue for a similar period

of time after the pump has been shut down. Where an in-line

cleaning cycle is employed as part of the process, then the

heating/cooling media should continue to be circulated during

the cleaning cycle.

head and casing is 3 Bar (50 psi) and this should

not be exceeded without consulting Viking Pump

or your local Viking Pump distributor.

Figure 8

Rotation Against Suction and Discharge

SECTION TSM 285 ISSUE A PAGE 8 OF 36

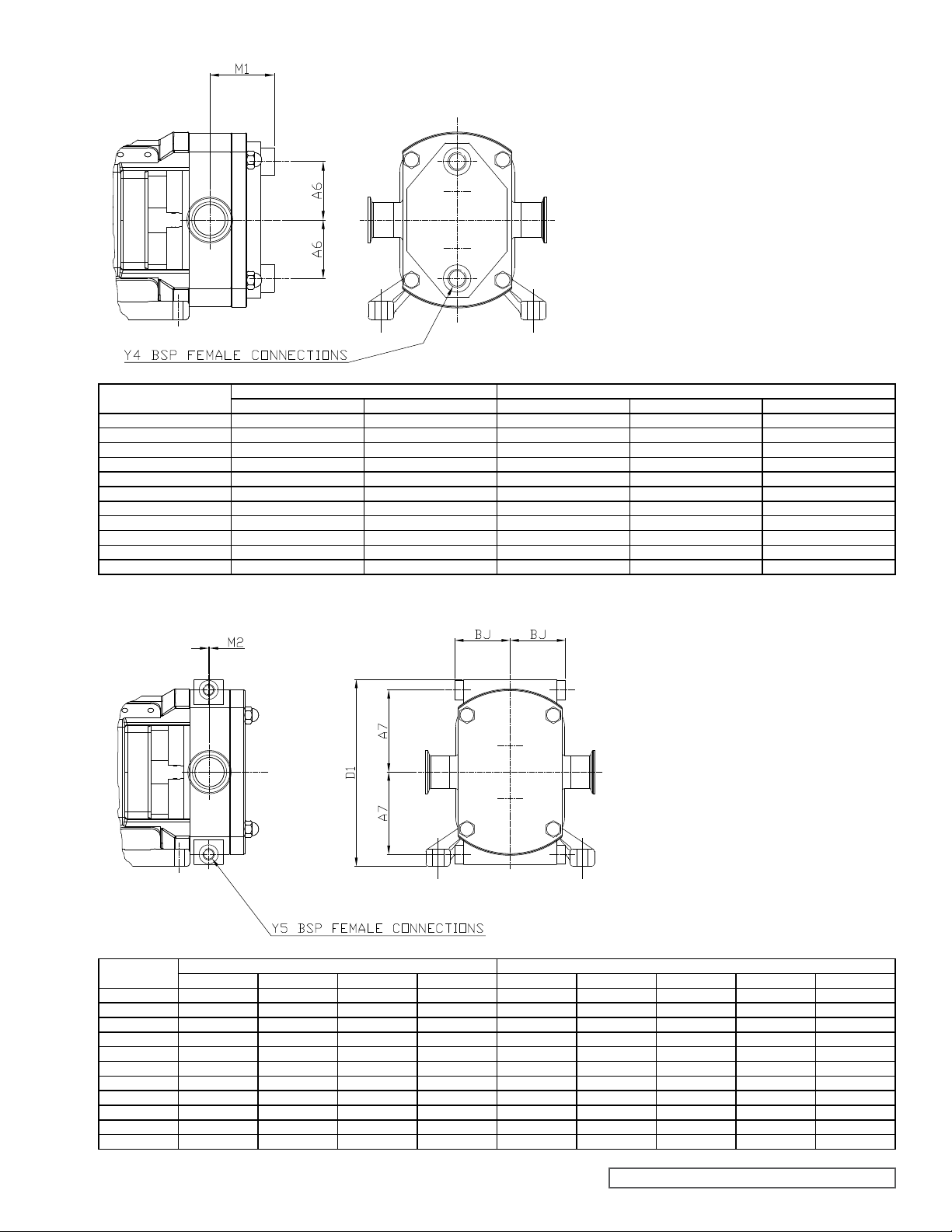

Figure 9

Dimensions of Jacketed Head

for Heating/Cooling

Model

CP10/0005/12 50.0 52.0 1.97 2.05 ¼”

CP10/0008/08 50.0 61.0 1.97 2.40 ¼”

CP10/0011/05 50.0 61.0 1.97 2.40 ¼”

CP20/0020/12 64.0 71.0 2.52 2.80 ½”

CP20/0031/07 64.0 81.0 2.52 3.19 ½”

CP30/0069/12 92.5 81.0 3.64 3.19 ½”

CP30/0113/07 92.5 96.0 3.64 3.78 ½”

CP40/0180/12 130.0 108.0 5.12 4.25 ½”

CP40/0250/07 130.0 123.0 5.12 4.84 ½”

CP50/0351/12 175.0 115.0 6.89 4.53 ½”

CP50/0525/08 175.0 138.0 6.89 5.43 ½”

A6 M1 A6 M1 Y4

Millimeters Inches

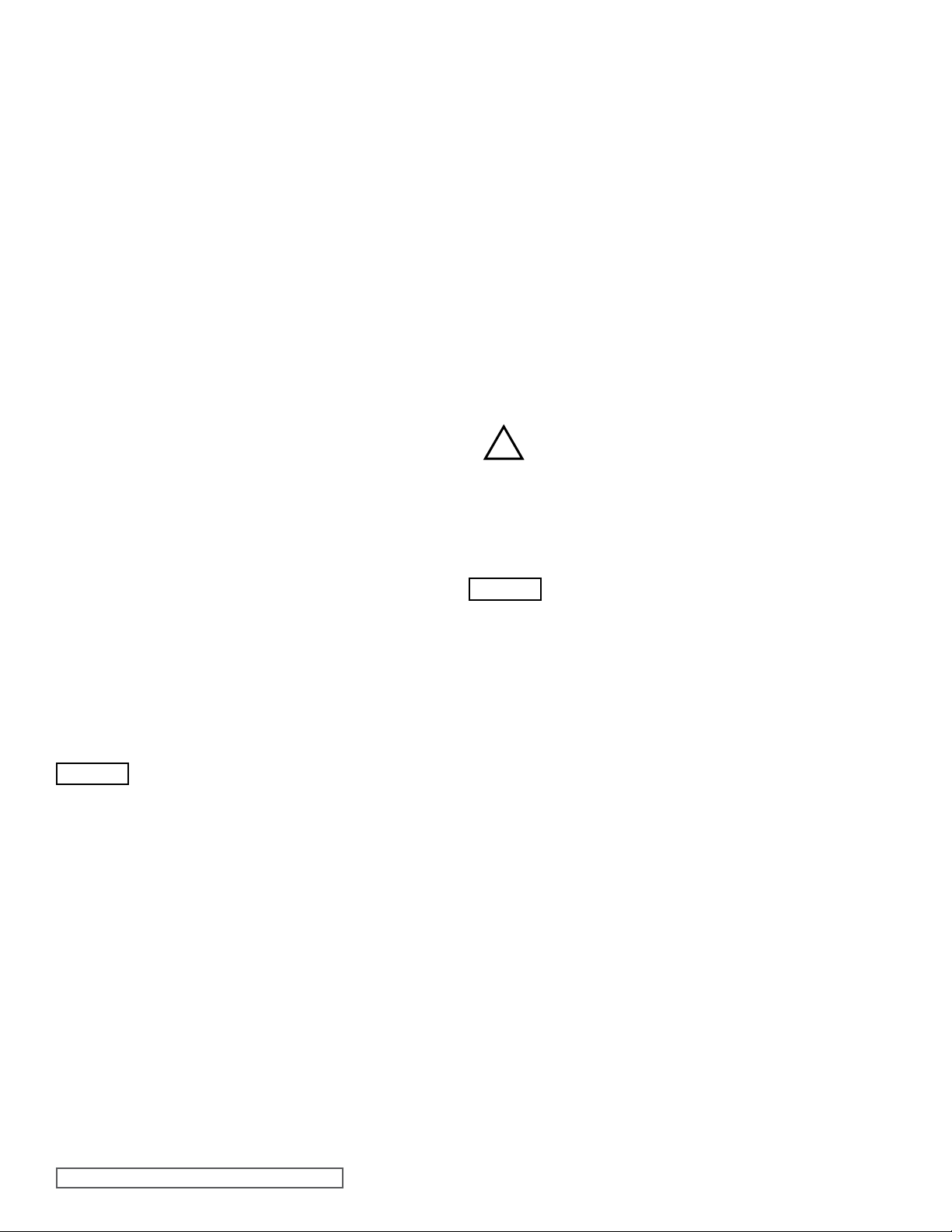

Figure 10

Dimensions of Jacketed Casing

for Heating/Cooling

Model

CP10/0005/12 70.0 56.0 156.0 3.0 2.76 2.20 6.14 0.12 ¼

CP10/0008/08 70.0 56.0 156.0 2.0 2.76 2.20 6.14 0.08 ¼

CP10/0011/05 70.0 56.0 156.0 7.5 2.76 2.20 6.14 0.30 ¼

CP20/0020/12 80.0 64.0 216.0 0.0 3.15 2.52 8.50 0.00 ¼

CP20/0031/07 80.0 64.0 216.0 1.0 3.15 2.52 8.50 0.04 ¼

CP30/0069/12 118.0 93.0 280.0 1.0 4.65 3.66 11.02 0.04 ½

CP30/0113/07 118.0 93.0 280.0 3.5 4.65 3.66 11.02 0.14 ½

CP40/0180/12 156.0 125.0 352.0 2.5 6.14 4.92 13.86 0.10 ½

CP40/0250/07 156.0 125.0 352.0 3.5 6.14 4.92 13.86 0.14 ½

CP50/0351/12 191.0 155.0 430.0 8.0 7.52 6.10 16.93 0.31 ½

CP50/0525/08 191.0 155.0 430.0 10.0 7.52 6.10 16.93 0.39 ½

A7 BJ D1 M2 A7 B J D1 M2 Y5

Millimeters Inches

SECTION TSM 285 ISSUE A PAGE9 OF 36

3.8 INTEGRAL PRESSURE RELIEF

VALVES

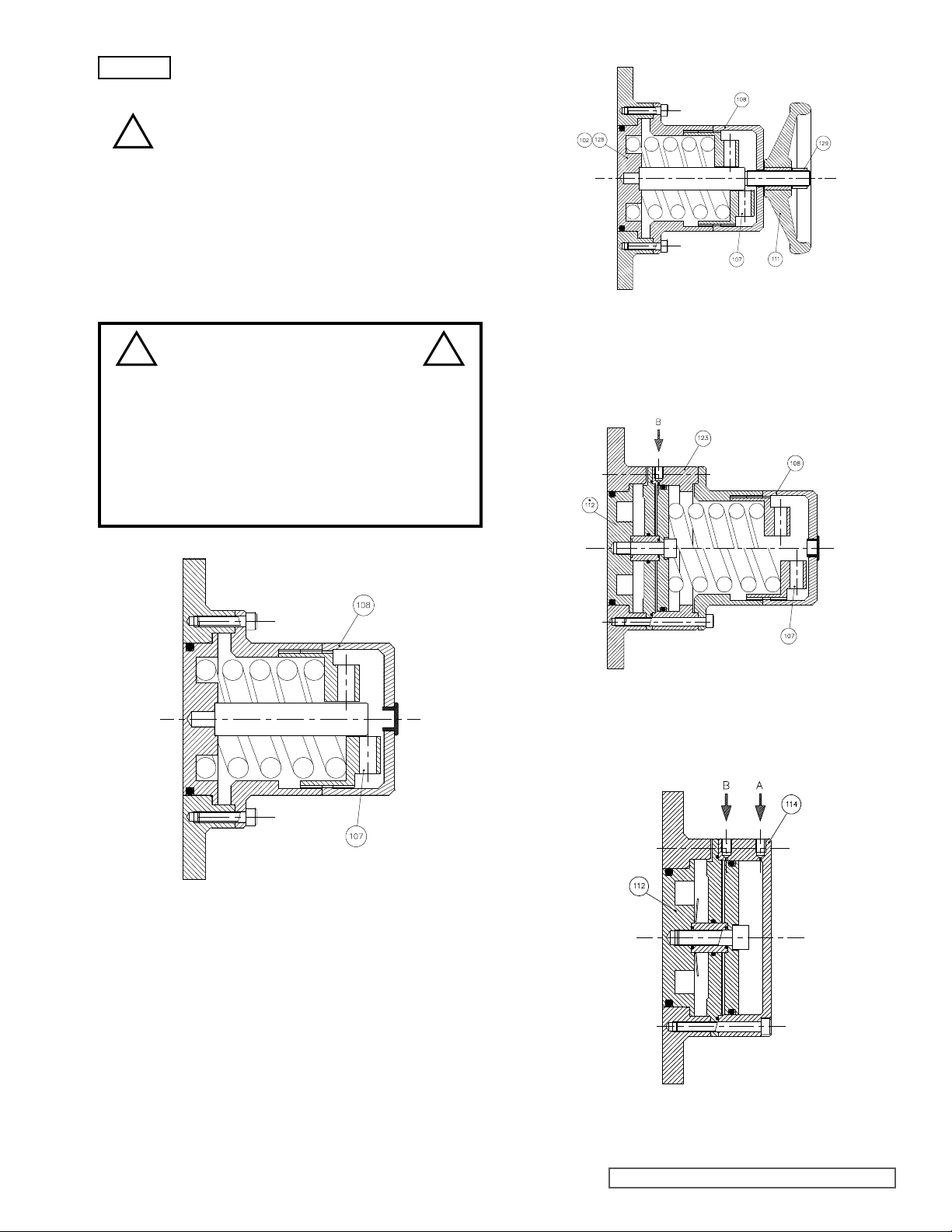

See Figures 11, 12, 13 and 14.

The Classic+ models CP10, CP20, CP30 and CP40 can be

supplied with integral pressure relief valves. For the CP10,

CP20 and CP30 both spring and air loaded versions are

available. The function of the valves can be further enhanced

with the option of manual or airlift override, offering particular

benetswhere CIPorSIPproceduresareemployed.Valves

incorporating this option can be opened to regulate the ow

of the cleaning media through the pump chamber, thereby

avoiding the need for manual cleaning or external bypass.

Where the pump is mounted onto a portable base plate,

complete with motor and drive to be used as a mobile set, an

integral pressure relief valve should be installed.

TheClassic+integralpressurereliefvalvesavailableinclude:

Spring Loaded - see Figure 11.

- Valve can be set to the required pressure relief setting.

Spring Loaded with Manual Lift - see Figure 12.

- Valve can be set to the required pressure relief setting.

Manual lift override can be used to open valve without

disturbing pressure relief setting.

Spring Loaded with Air Lift - see Figure 13.

- Valve can be set to the required pressure relief setting. Air

override, which operates on an air supply of up to 7 Bar (102

psi) depending on pressure relief setting, can be used to

open valve without disturbing pressure relief setting.

Air Loaded with Air Lift - see Figure 14.

- Valve, which operates on an air supply of up to 7 Bar

psi) regulated for required setting, can be set to the required

pressure relief setting. Airlift override, which operates on an

air supply of up to 7 Bar (102 psi) depending on pressure

relief setting, can be used to open valve without disturbing

pressure relief setting.

Air actuated relief valves can be operated remotely and interfaced with other elements of the system or process control.

WARNING

Ifthepumponwhichthevalveisttedistobeinstalledwithin

either a pressurised system or one incorporating a vessel under

vacuum then the application of the valve should be referred to

Viking Pump.

Integral pressure relief valves are normally used

to protect the pump from the effects of increases

in system pressure caused, for example, by a

restricted or closed discharge line. In response

to a pressure increase, the valve opens and

internally circulates the pumped media within the

pump chamber. When the valve opens, because

the volume of liquid circulating is relatively small,

the temperature of the liquid in the pump chamber

may rise if the pump continues to operate for

an extended period. In severe cases, this may

result in temperatures in excess of the pumps

operating limits, or vaporisation of the liquid, both

of which should be avoided. For these reasons

when the valve is activated the cause of the

system pressure increase should be eliminated

as continuous operation of the pump with the

valve open is not recommended and may cause

severe damage to the pump.

lift

(102

The selection, setting and application of integral relief valves is

inuencedbytheviscosityandnatureofthepumpedmedia,the

pumps operating speed and the required pressure relief setting

and mode of operation. For these reasons and to cover the

diverse range of products, the conditions under which they are

pumped and application demands, it is not practical to factoryset integral relief. Valves and the setting of the valves should

be carried out on site, under the proposed duty conditions for

which the pump and valve were selected.

For setting and operating Classic+ integral relief valves refer

to sections 3.8.1 and 3.8.2. Before beginning the relief valve

setting procedure the pump should be installed, refer to section

3.3.1, paragraph (vi), with a pressure gauge in the discharge

line adjacent to the pump discharge port.

3.8.1 SETTING AND OPERATING

SPRING LOADED VALVES

See Figures 11, 12 and 13.

- Remove cover (108). For integral relief valve with manual lift,

seeFigure12;rstremovenut(129)andhandwheel(111).

- Unscrew nut (107) using pry bar in holes

!

- Start pump. - refer to section 3.4.

- Screw in nut (107) using pry bar in holes provided until the

required pressure relief setting is reached.

WARNING

- Reinstall cover (108). For integral relief valve with manual

lift,seeFigure12;reinstallhandwheel(111)andnut(129).

- The relief valve is now set.

For Integral Relief Valve with Manual Lift - see Figure 12.

- To operate the manual lift, turn the hand wheel (111)

which will lift the valve head (102/128). To resume normal

relief valve operation, turn the hand wheel (111) counterclockwise.

For Integral Relief Valve with Air Lift - see Figure 13.

- To actuate the airlift, connect an air supply not exceeding

7 Bar (102 psi) to the cylinder (123), connection ‘B’, which

will lift the valve head (112). To resume normal relief valve

operation, exhaust the cylinder (123).

provided to relieve spring compression. For

integral relief valve with airlift, see Figure 13,

the air cylinder must be exhausted prior to

unscrewing the nut (107).

Note: Care should be taken not to exceed the

lower of either the pump’s maximum pressure

rating or the system design pressure.

clockwise,

3.8.2 SETTING AND OPERATING

AIR LOADED INTEGRAL

PRESSURE RELIEF VALVES

See Figure 14.

- Connect an air supply, not exceeding 7 Bar (102 psi), via

a regulating valve to the relief valve connection ‘A’ in the

cylinder (114). Do not turn on the air supply.

- Start the pump, refer to section 3.4.

- Using the regulating valve, gradually increase the air

pressure until required pressure relief setting is reached. The

air pressure must not exceed 7 Bar (102 psi).

- The relief valve is now set.

SECTION TSM 285 ISSUE A PAGE 10 OF 36

WARNING

!

! !

Note: Care should be taken not to exceed the

lower of either the pump’s maximum pressure

rating or the system design pressure.

- To use the air lift system, the regulated air

supply must be routed through a change-over

valve in order to transfer air from the relief valve

load air chamber, connection ‘A’, to the lift air

chamber, connection ‘B’, while depressurizing

the load chamber and vice versa. The changeover valve will actuate the air lift which will lift

when the air supply is diverted to connection

‘B’, and will close, restoring normal relief valve

operation, when the air supply is diverted back

to connection ‘A’.

DANGER !

Under no circumstances should any

attempt be made to dismantle a pressure

relief valve which has not had the spring

pressure relieved, is still connected to a

pressurized air supply, or is mounted on a

pump that is operating. Serious personal

injury or pump damage may occur.

Figure 12

Spring Loaded Integral Pressure Relief Valve

with Manual Lift

CP10, CP20 and CP30

Figure 11

Spring Loaded Integral Pressure Relief Valve

CP10, CP20, CP30, CP40

Figure 13

Spring Loaded Integral Pressure Relief Valve with Air Lift

CP10, CP20 and CP30

Figure 14

Air Loaded Integral Pressure Relief Valve with Air Lift

CP10, CP20, CP30 and CP40

SECTION TSM 285 ISSUE A PAGE 11 OF 36

Loading...

Loading...