Viking Pump TSM275 User Manual

I

NSTALLATION

A

ND

AINTENANCE

M

F

OR THE

, O

PERATION

ANUAL

M

Page 1

Johnson Pump (UK) Ltd.

A unit of IDEX Corporation

Highfield Industrial Estate, Edison Road

Eastbourne, East Sussex, BN23 6PT, England

Phone: Natl (01323) 509211 – Intl +44 1323 509211

Fax: Natl (01323) 507306 – Intl +44 1323 507306

E-Mail: Jinfo@Idexcorp.com

Issue C – Draft 20/06/03

Page 2

I

NSTALLATION

, O

PERATION AND MAINTENANCE MANUAL

F

OR THE ACCULOBE PUMP

1.0 Safety Information

1.1 Risk assessment relating to the use of Johnson Pump (UK) Ltd. Classic rotary

lobe pumps and pump units in potentially explosive atmospheres. ________________6

2.0 Introduction

2.1 General___________________________________________________________7

2.2 Johnson Pump (UK) Ltd Distributors _________________________________7

2.3 Receipt and Storage ________________________________________________ 7

2.4 Cleaning. _________________________________________________________7

2.5.2 Atex Identification Plate____________________ Error! Bookmark not defined.

2.5.3 Equipment Groups & Catergories ___________ Error! Bookmark not defined.

3.0 General

3.1 System Design and Installation.______________________________________11

3.2 Installations with CIP Systems ______________________________________13

3.3 Start Up Procedure. _______________________________________________14

3.4 Shutdown Procedure. ______________________________________________14

4.0 Product Seal Fitting and Removal ______________________________________15

_______________________________________________________ 7

____________________________________________________________ 4

_________________________________________________ 4

5.0 Seal Assembly.

5.1 Rotary Faces _____________________________________________________17

5.2 Single Mechanical Seal. ____________________________________________18

5.3 Single Flushed Mechanical Seal. _____________________________________20

6.13 Seal Arrangement (Exploded) _______________________________________22

7.0 Technical Data

7.1 Clearance Chart __________________________________________________23

7.2 Torque Settings ___________________________________________________24

7.3 Lubricants._______________________________________________________24

7.4 Tool List _________________________________________________________25

7.5 Pump Data _______________________________________________________25

7.8 Acculobe Installation Dimensions ____________________________________26

7.9 Trouble Shooting. _________________________________________________31

7.10 Service History. ___________________________________________________ 32

7.11 Notes____________________________________________________________33

____________________________________________________ 17

____________________________________________________ 23

Page 3

and/or protection of the pump or pump

1.0 Safety Information

INCORRECT INSTALLATION, OPERATION OR MAINTENANCE OF EQUIPMENT MAY

CAUSE SEVERE PERSONAL INJURY AND/OR EQUIPMENT DAMAGE AND MAY

THIS INFORMATION MUST BE READ FULLY BEFORE COMMENCING INSTALLATION,

OPERATION OR MAINTENANCE AND MUST BE KEPT WITH THE PUMP. SUITABLY

TRAINED OR QUALIFIED PERSONS MUST UNDERTAKE ALL INSTALLATION AND

Safety instructions given in this

manual non-compliance with which

would affect safety are identified by

the symbol

DO NOT OPERATE PUMP IF:

- THE FRONT COVER IS NOT INSTALLED CORRECTLY.

- ANY GUARDS ARE MISSING OR INCORRECTLY INSTALLED.

- THE SUCTION OR DISCHARGE PIPE WORK IS NOT CONNECTED.

DO NOT PLACE FINGERS ETC INTO THE PUMPING CHAMBER OR ITS

CONNECTION PORTS OR INTO ANY PART OF THE GEARBOX IF THERE IS

ANY POSSIBILITY OF THE PUMP SHAFTS BEING ROTATED. SEVERE INJURY

WILL OCCUR.

DO NOT exceed the rated pressure, speed, and temperature, or change the

system/duty parameters from those for which the pump was originally supplied,

without confirming its suitability for the new duty. Running of the pump outside of its

operation envelope can cause mechanical contact, excessive heat and can represent

a serious risk to health and safety.

Installation and operation of the pump must always comply with health and safety

regulations.

A device must be incorporated into the system or drive to prevent the pump

WARNING

exceeding its stated duty pressure. It must be suitable for both directions of pump

rotation where applicable. Do not allow pump to operate with a closed/blocked

discharge unless a pressure relief device is incorporated.

The mounting of the pump or pump unit should be solid and stable. Pump orientation

must be considered in relation to drainage requirements. Once mounted, shaft drive

elements must be checked for correct alignment. Rotate pump shaft by at least one

full revolution to ensure smoothness of operation. Incorrect alignment will produce

excessive loading and will create high temperatures and increased noise emissions.

The installation must allow safe routine maintenance and inspection (check for

leakage, monitor pressures, etc) and provide adequate ventilation necessary to

prevent overheating. It may also be necessary to earth the pump head to avoid the

build up of a potential charge difference that could cause a spark.

INVALIDATE THE WARRANTY.

MAINTENANCE ONLY.

Safety instructions, which shall be

considered for reasons of safe

operation of the pump or pump unit

unit itself, are marked:

DANGER

WARNING

Page 4

WARNING

WARNING

WARNING

WARNING

WARNING

Before operating the pump, ensure that it and all parts of the system to which it is

connected are clean and free from debris and that all valves in the suction and

discharge pipelines are fully opened. Ensure that all pipe work connecting to the

pump is fully supported and aligned with its relevant connections. Misalignment

and/or excess loads will cause severe pump damage. This could result in

unexpected mechanical contact in the pump head and has the potential to be a

source of ignition.

Ensure that pump rotation is correct for the desired direction of flow.

Do not install the pump into a system where it will run dry (i.e. without a supply of

pumped media) unless it is equipped with a flushed shaft seal arrangement complete

with a fully operational flushing system. Mechanical seals require a thin fluid film to

lubricate the seal faces. Dry running can cause excessive heat and seal failure.

Install pressure gauges/sensors next to the pump suction and discharge connections

to monitor pressures.

Caution must be taken when lifting the pump. Suitable lifting devices should be used

as appropriate. If pump is base plate mounted, the base plate must be used for all

lifting purposes, not any part of the pump. If slings are used for lifting, they must be

safely and securely attached. For weights of bare shaft pumps refer to pump

installation dimensions section.

DO NOT attempt any maintenance or disassembly of the pump or pump unit without

first ensuring that:

- The pump is fully isolated from the power source (electric, hydraulic,

pneumatic).

- The pumping chamber and any shaft seal support system, front cover barrier

support system, and rotorcase port barrier support system are de-pressurised

and purged.

- Any temperature control devices (jackets, heat-tracing, etc) are fully isolated,

that they are de-pressurised and purged, and components allowed to reach a

safe handling temperature.

DO NOT loosen or undo the front cover, any connections to the pump, shaft seal

housings, barrier support systems, temperature control devices, or other

components, until sure that such action will not allow the unsafe escape of any

pressurised media.

Avoid any contact with hot parts of pumps and/or drives, which may cause injury.

Certain operating conditions, temperature control devices (jackets, heat-tracing, etc),

bad installation, or poor maintenance can all promote high temperatures on pumps

and/or drives.

When cleaning, either manually or by CIP method, the operator must ensure that a

suitable procedure is used in accordance with the system requirements. For CIP

cleaning requirements, refer to section 3.3.2. The exterior of the pump should be

cleaned periodically.

Surface temperature of pump is also dependent on the temperature of

pumped medium.

Page 5

Frequency Of

User must ensure temperature limits.

Service

plan.

Pump liquid leakage. Build

suitable for application. Ensure cover

Pump liquid leakage. Build

up of explosive gas.

contact.

Leakage.

Build up of explosive gas.

sealing

Pump liquid leakage. Build

up of explosive gas.

must be suitable for application.

Mechanical contact.

Can cause excessive pressue, heat

Chapter 1.0

See Chapter 1.0.

Electrostatic charging

1.1 Risk assessment relating to the use of Johnson Pump (UK) Ltd.

Acculobe rotary lobe pumps and pump units in potentially explosive

atmospheres.

Note:- For a feature to be suitable for an application, The feature must be fit for its

designated purpose and also suitable for the environment where it is to be installed.

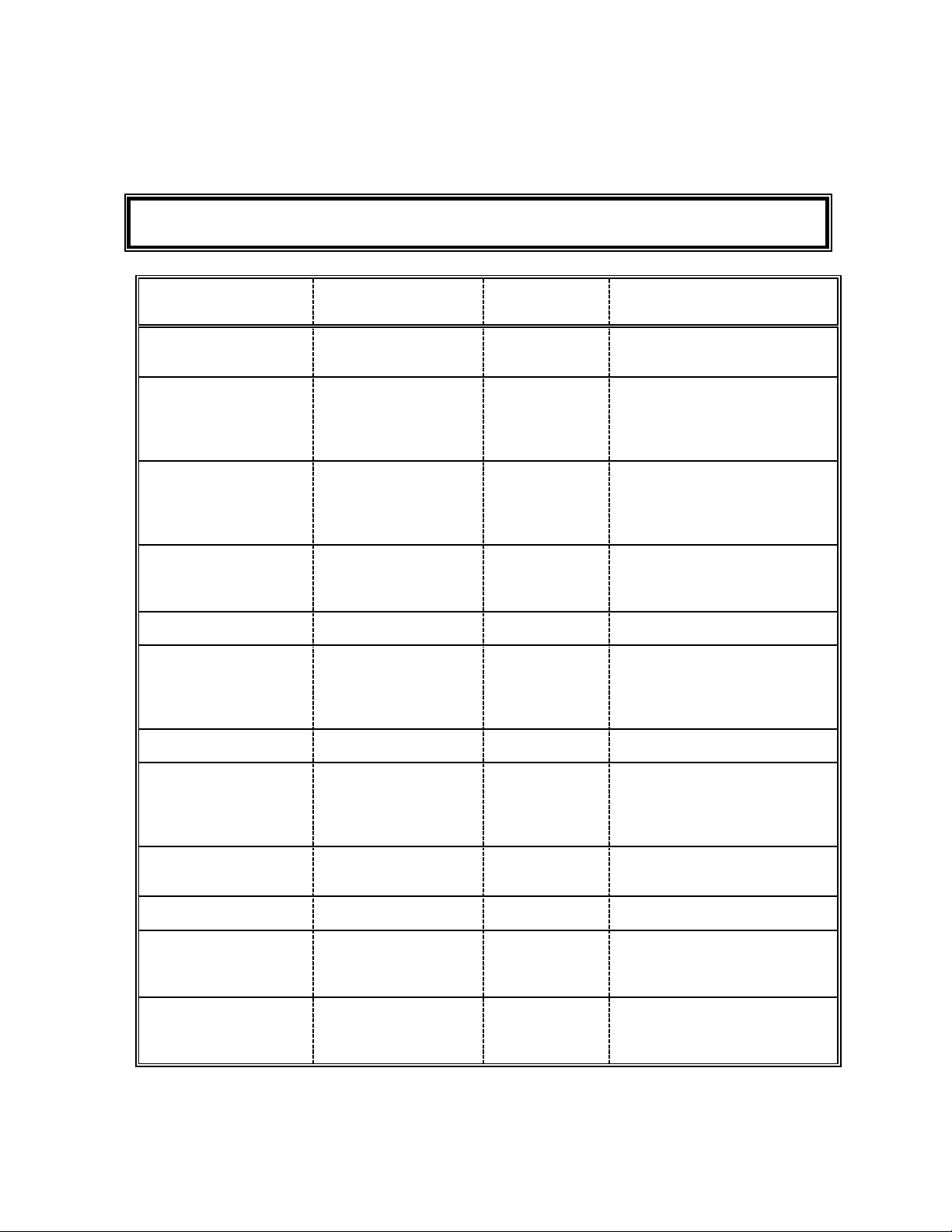

Source Of Hazards Potential Hazards

Unvented cavities Build up of explosive gas

Rotorcase / Rotors / Front

Cover

Pump external surfaces

Cover 'O' ring

Pump casing / cover

Shaft seals

Auxiliary system for shaft

Rotation direction test Excess temperature

Closed valve condition

Unintended mechanical

contact

excess temperature.

Electrostatic charging

up of explosive gas.

excess temperature.

Unintended mechanical

Excess Temperature.

Excess Pressure.

Hazards

Very Rare

Rare

Rare

Very Rare

Very Rare

Rare

Rare

Very Rare

Rare

Recommended Measures

Ensure that pump is totally filled.

Consider mounting ports vertically.

See Chapter 1.0

Ensure that operating pressures are

not exceeded. Ensure that suffcient

NPSH to prevent cavitation.

Chapter 1.0/3.1

Do not overfill gearboxes with

lubricant. Provide a ground contact

for pump.

Check selection of elastomers are

retaining nuts are tight. Service plan.

Stainless steel, Corrosion resistant.

Selection of seal system must be

Chapter1.0 / 4.0. Service plan.

Selection of auxiliary seal system

If flushed seals are installed ensure

assemblys. Only allow pump to run

See Chapter 1.0 /

suitable for application. See

that flush is applied to seal

for minimum period - just a few

and mechanical contact.

Service plan.

seconds.

See

See

Shaft Random induced current

Mechanical shaft coupling

(Torque Protection)

Mechanical shaft coupling

(standard)

Temperature from friction

Sparks from break up of

shear pins.

Break up of spider.

Unintended mechanical

contact.

Electrostatic charging

Page 6

Very Rare

Rare

Rare

Provide a ground contact for pump.

Coupling selection must suit

application.

Coupling selection must suit

application. Service plan. See

See Chapter 1.0.

Chapter 1.0.

2.0 Introduction

2.1 General

Acculobe rotary lobe pump is manufactured by Johnson Pump (UK) Ltd. a subsidiary

of Viking Pump Inc., Cedar Falls, USA, (a unit of the IDEX Corporation) herein after

referred to as ‘JPUK’.

This manual includes all the necessary information for the Acculobe pump and

should be read prior to commencing installation, operation or maintenance.

When asking for assistance please quote the pump model and serial number. This

information can be obtained from the pump nameplate, which is located on the top of

the pump gearbox body.

If it is proposed to modify the system or change the characteristics of the product to

be pumped from that for which the pump was originally selected, Johnson Pump

(UK) or their authorised distributor should be consulted.

2.2 Johnson Pump (UK) Ltd Distributors

Johnson Pump (UK) distributes their products internationally via a network of

authorised distributors. Throughout this manual where reference is made to Johnson

Pump (UK), any authorised distributor will also provide service and assistance.

Should you require any additional information regarding the Acculobe pump contact

Johnson Pump (UK) or their local authorised distributor.

2.3 Receipt and Storage

On receipt of the pump, immediately examine for any signs of visible damage. If any

damage is noted, contact Johnson Pump (UK) and clearly mark upon the carriers’

paperwork that the goods have been received in a damaged condition, with brief

description of damage.

If the pump is not required for immediate installation then it should be stored within a

suitable environment.

2.4 Cleaning.

The product seals are mounted directly behind the rotors and are designed

and positioned to minimize product entrapment and maximize the effects of

cleaning.

It is recommended that the exterior of the pump is cleaned periodically.

Page 7

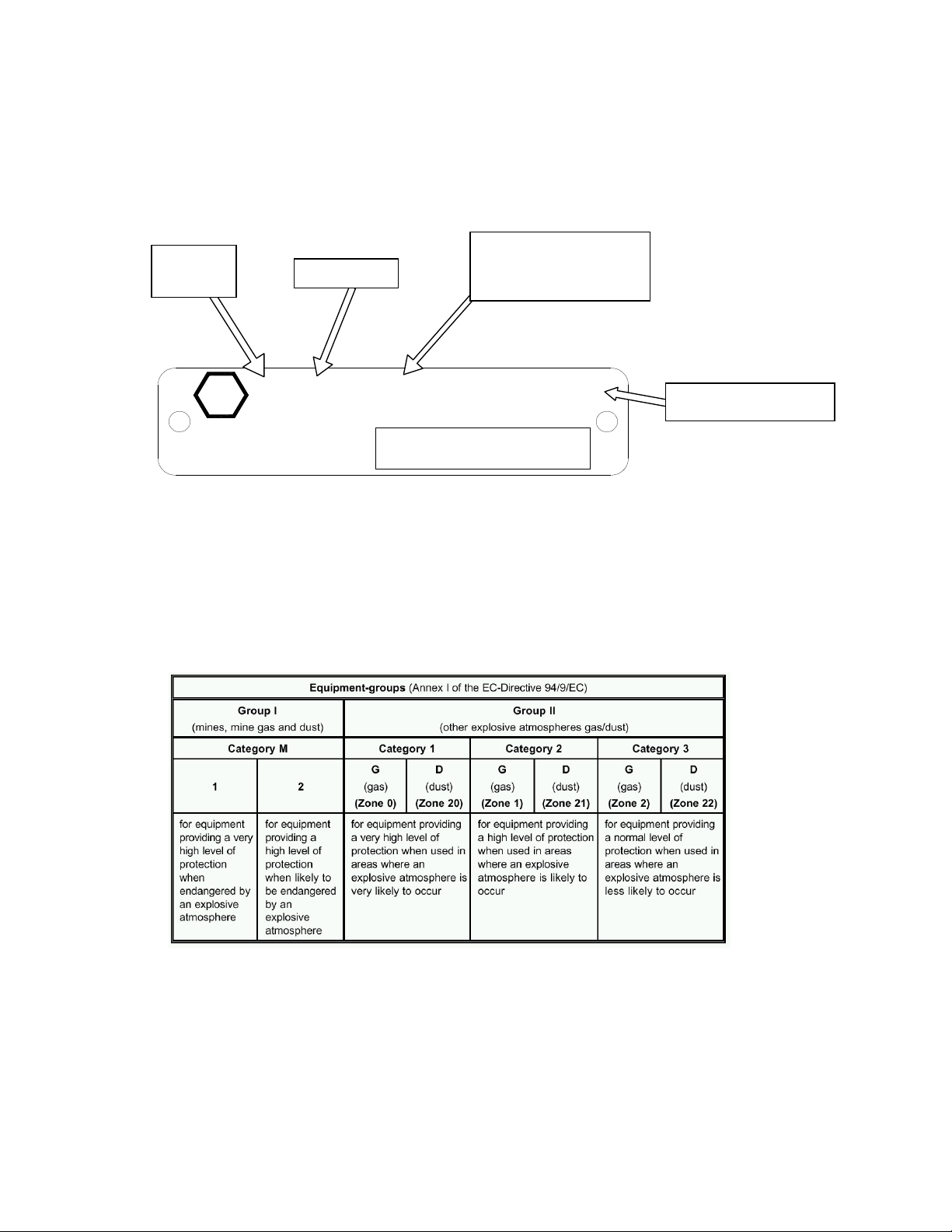

Group

Category 2

Unit is suitable for

Temperature Cl

ass.

2.5 Atex Information Plate

II.

ex

II - 2 - G/D

SERIAL NO:

2.5.1 Equipment Groups & Categories

TEMP - T3

environments

containing dust or gas

Page 8

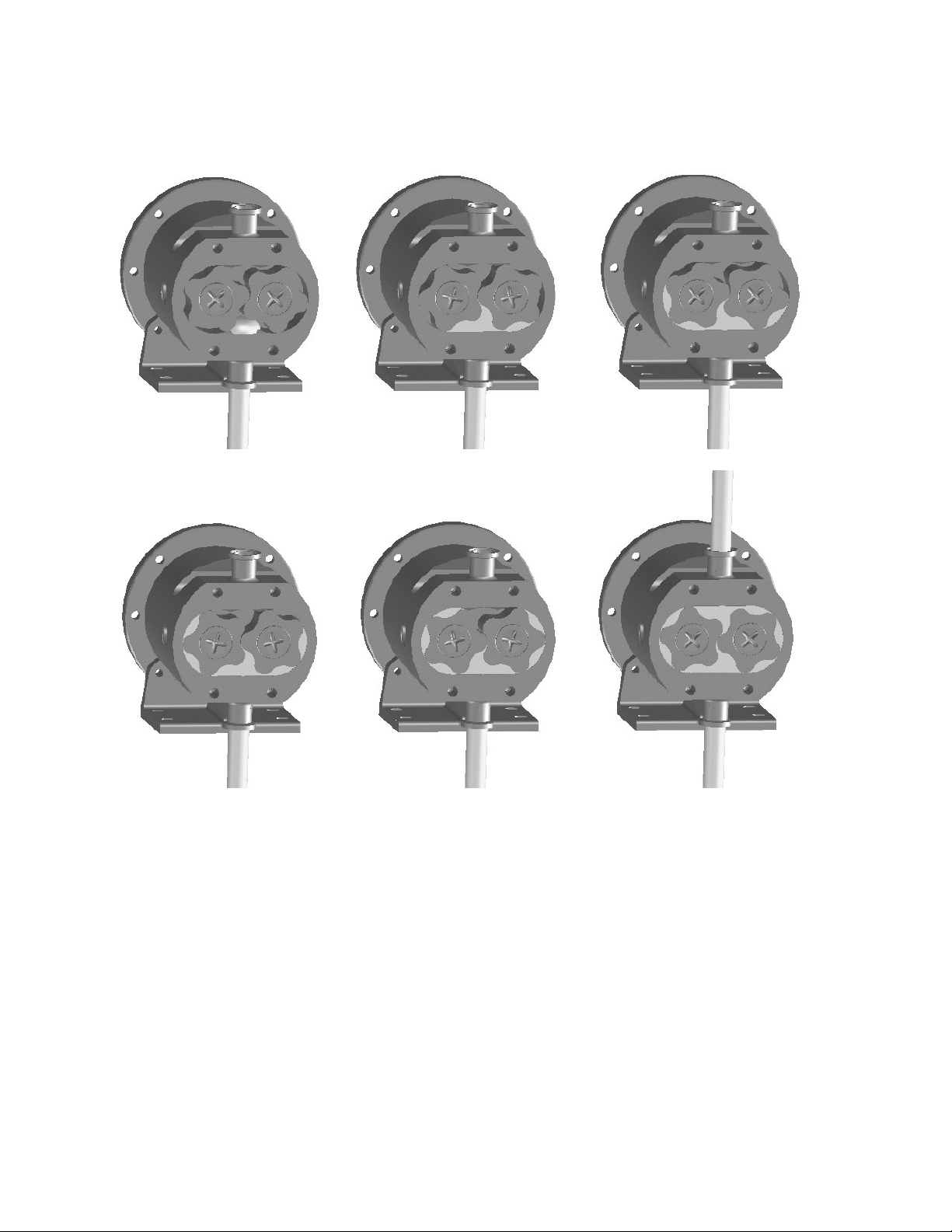

B A

3.0 General

D

The pumping action of the rotary lobe pump principle is generated by the contrarotation of two pumping elements (rotors) within a chamber (rotorcase). The rotors

are located on shafts, which in turn are held within the pump body. The shaft

assemblies comprise of the support bearings and the timing gears. The timing gears

transfer the drive from the driven shaft to the lay shaft, synchronising the rotors such

that they rotate without contact with each other.

As the rotors pass the suction port, (see ‘A’), the cavity generated increases creating

a pressure decrease, which induces the media to be pumped to flow into the

rotorcase (‘B’).

The pumped media is carried around the rotorcase by the rotors; (‘C’ and ‘D’) to the

discharge side of the pump (‘E’). Here the cavity decreases and the pumped medium

is discharged from the rotorcase (‘F’).

The maximum pressure and speed operating parameters are shown below. In

practice these may be limited due to the nature of the product to be pumped and/or

C

E

F

Page 9

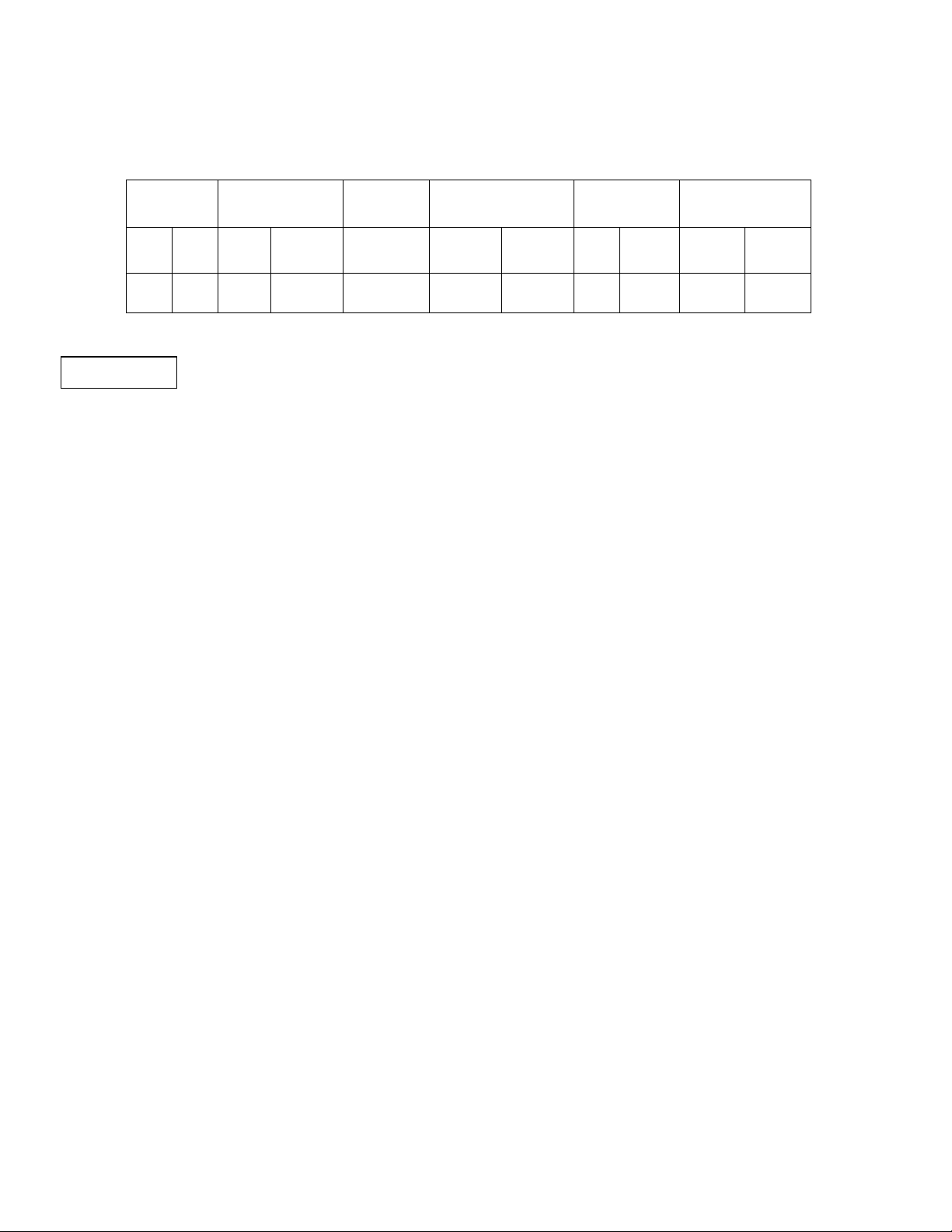

Pressure

Rating

design of the system in which the pump is to be installed. Consult Johnson Pump

(UK) Ltd or your local distributor for assistance.

Displacement

Maximum

Speed

Port Size

Maximum

Temperature

Maximum

Viscosity

bar psi L/rev

12 174 0.02 0.00528 1750 12 & 19 ½” & ¾” 150 300

WARNING

US gal /

rev

Rotor rpm mm inches

°C °F

cPs ssu

150,000 682,500

If the system or product characteristics are to be changed from the original

application for which the pump was selected, the factory or their authorized

distributor should be consulted to ensure the pump is suitable for the new

application.

The pump should not be subjected to sudden temperature changes to avoid the risk

of damage from sudden expansion/contraction of components. Care should be taken

when selecting pumps for handling liquids containing abrasive particles as these may

cause wear of pump head components. Contact the factory

or their authorized

distributor for advice or assistance.

Model Designation: AL05

Standard Construction:

• 316L St. Steel Wetted Parts (0.6 µM Surface Finish).

Multi-Lobe (5 Lobe) Rotors

•

• 1/8” Male BSP Flush Connections

¾” Tri-Clamp Connections

•

• Foot Mounted

FDA EPDM Elastomers

•

• Silicon Carbide Seal Faces

Sealed For Life Grease Lubrication

•

Should any additional information be required, contact the factory or their authorized

distributor quoting the pump model and serial number as stated on the nameplate

fastened to the exterior of the pump.

Should this be damaged or missing, the serial number is also stamped on the

gearbox endplate.

Page 10

Loading...

Loading...