Viking Pump TSM270.2 User Manual

TECHNICAL SERVICE MANUAL

HIGH PRESSURE MODELS RL0167, 40167, 0257, 40257

CONTENTS

Introduction 1

Safety Information 1

Exploded Parts View 2

Torque Specifications 3

Special Information 4

Maintenance 4

Suggested Repair Tools 4

Mechanical Seal Information 5

Disassembly 6

Bearing Housing Information 7

Assembly 8

Installation of PEEK Bushings 9

Warranty

12

INDUSTRIAL ROTARY LOBE PUMP

FIGURE 1

RL40257 HIGH PRESSURE DESIGN

DANGER!

Incorrect installation, operation or maintenance of

equipment may cause severe personal injury or

death and/or equipment damage.

SECTION TSM

PAGE

ISSUE

270.2

1

B

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and cannot be used for ordering parts. Obtain

a parts list from the factory or a Viking representative.

Always give a complete name of part, part number and

material with the model number and serial number of pump

when ordering repair parts. The unmounted pump or pump

unit model number and serial number are on the nameplate.

This manual deals only with Viking Rotary Lobe Pumps.

Specifications and recommendations are listed in Catalog

Section 270.

UNMOUNTED PUMP AND UNIT MODEL NUMBERS

UNMOUNTED PUMP UNITS

PACKED MECHANICAL SEAL

RL0167

RL0257

RL40167

RL40257

Units are designated by the

un-mounted pump model

numbers followed by a letter

indicating the drive style.

R = Viking Speed Reducer

P = Commercial Speed

Reducer

This information must be read fully before beginning installation, operation or maintenance and

must be kept with the pump. It is suggested that

suitably trained or qualified persons perform all

installation and maintenance procedures.

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, etc.) be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine,

etc.) has been “locked out” or made nonoperational so that it cannot be started while work

is being done on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to safely

handle the liquid. Obtain a material safety data

sheet (MSDS) for the liquid to be sure these

precautions are understood.

4. That the timing gearbox to cool before handling

the pump. The oil will become very hot during

normal operation. Allow the timing gearbox oil.

®

*PEEK

is a trademark of Victrex PLC

Failure to follow above listed precautionary measures may result in serious injury or death.

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

SECTION TSM 270.2 ISSUE A PAGE 3 OF 12

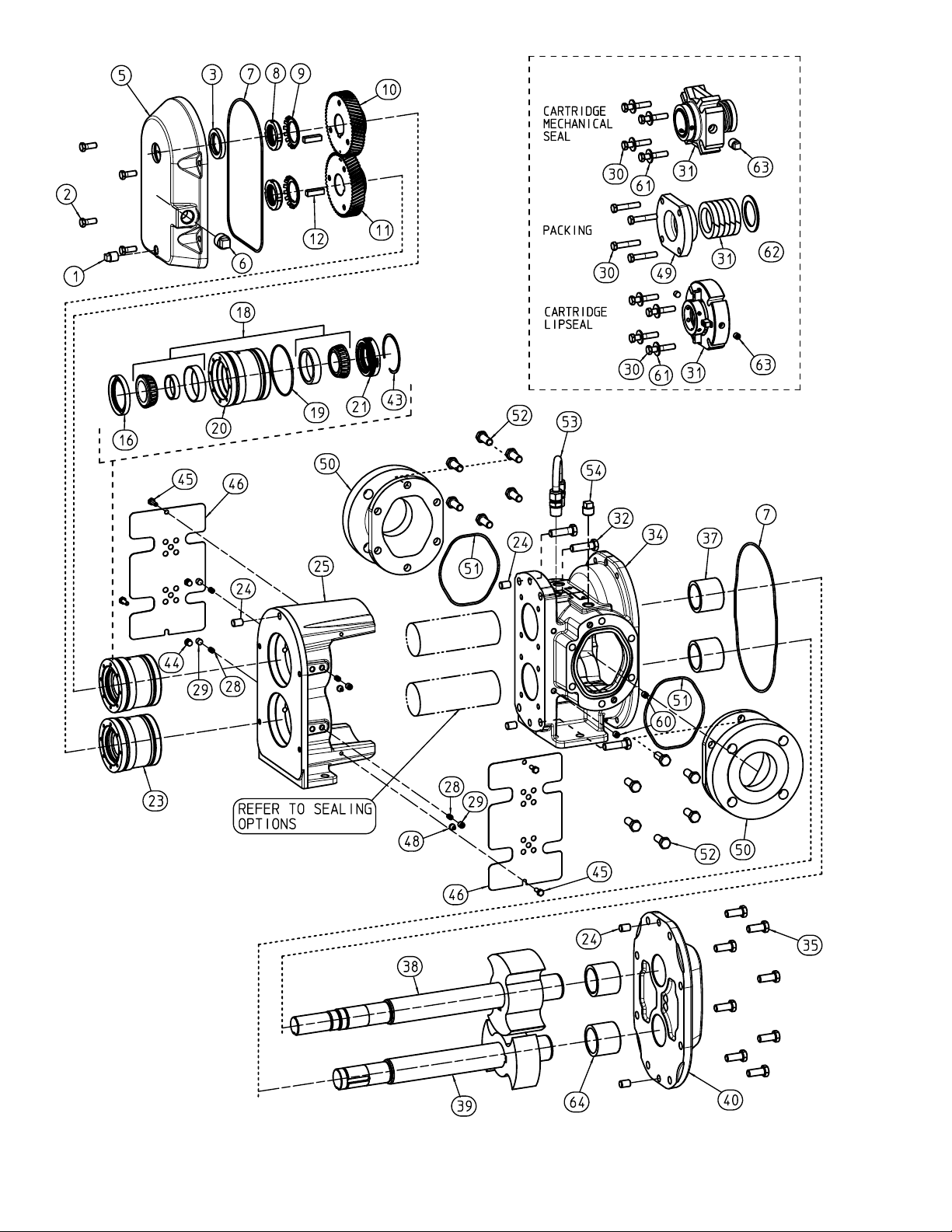

SEALING OPTIONS

SECTION TSM 270.2 ISSUE A PAGE 2 OF 12

FIGURE 2 EXPLODED PARTS VIEW

TABLE 1 – High Pressure Option

ITEM DESCRIPTION ITEM DESCRIPTION

1 Plug for Gear Case, 3/8” Square Head 32 Capscrew for Bracket, 1/2” NC x 1.75 L (4 Req’d)

Capscrew for Gear Case Cover 3/8” NC x 1.00 Long

2

(4 Req’d)

34 Casing/Bushing Assembly

3 Lipseal for Gear Case Cover 35 Capscrews for Head, 1/2” NC x 1.25 Long (8 Req’d)

5 Gear Case Cover 37 Bushings for Casing (2 Req’d)

6 Pipe Plug for Fill Hole, 3/4” NPT 38 Lobe/Shaft Assembly, Driver

7 O-Ring for Head and Gear Case Cover (2 Req’d) 39 Lobe/Shaft Assembly, Driven

8 Locknut W-08 (2 Req’d) 40 Head/Bushing Assembly

9 Lockwasher TW-108 (2 Req’d) 43

Retaining Ring for Bearing Housing Assembly

(2 Req’d - 1 for each Bearing Housing Assembly)

10 Timing Gear for Driver Shaft 44 Pressure Relief Fitting for Bearing Housing (2 Req’d)

11 Timing Gear for Driven Shaft 45

Capscrews for Bearing Housing Cover Plate

(4 Req’d)

12 Key for Timing Gears, 3/8” x 1.38” Long (2 Req’d) 46 Cover Plate for Bearing Housing Bracket (2 Req’d)

Lip Seal for Bearing Housing (2 Req’d - 1 for each

16

Bearing Housing Assembly)

Tapered Roller Bearing Set (2 Req’d - 1 for each

18

Bearing Housing Assembly)

O-Ring for Bearing Set (2 Req’d - 1 for each Bearing

19

Housing Assembly)

Bearing Housing (2 Req’d - 1 for each Bearing

20

Housing Assembly)

Labyrinth Seal (2 Req’d - 1 for each Bearing Housing

21

Assembly)

Bearing Housing Assembly, Items 16, 18-21, 43

23

(2 Req’d)

Grease Fitting for Bearing Housing, 1/8 NPT (2

48

Req’d)

49 Packing Gland (2 Req’d)

50 Bolt-on Port (2 Req’d)

51 O-ring for Bolt-on Ports (2 Req’d)

Capscrews for Bolt-on Ports, 1/2” NC x 1.25” Long

52

(12 Req’d)

53 Circulation Line Assembly

24 Dowel Pin, 0.5” Dia. X 0.75” Long (4 Req’d) 54 Pipe Plug 1/2” NPT square head

25 Bracket 60 Pipe Plug 1/8” NPT Allen Head, to Seal Chamber

28 Set Screw for Bearing Housing (4 Req’d) 61 Washer for Seals or Packing Gland (8 Req’d)

Pipe Plug for Bearing Housing, 1/8 NPT, Allen Head

29

(4 Req’d)

62 Packing Washer (2 Req’d)

30 Capscrews for Seals, or Packing Gland (8 Req’d) 63 Pipe Plug for Seal Gland

31 Sealing Option (2 Seals or 10 Packing Rings Req’d) 64 Bushings for Head (2 Req’d)

TABLE 2 Torque Specifications

Item Number 2 8 30 32 35 52

RECOMMENDED TORQUE (ft-lb) 31-34 200 20-22 75-82 43-47 43-57

SECTION TSM 270.2 ISSUE A PAGE 3 OF 12

SECTION TSM 270.2 ISSUE A PAGE 5 OF 12

SPECIAL INFORMATION

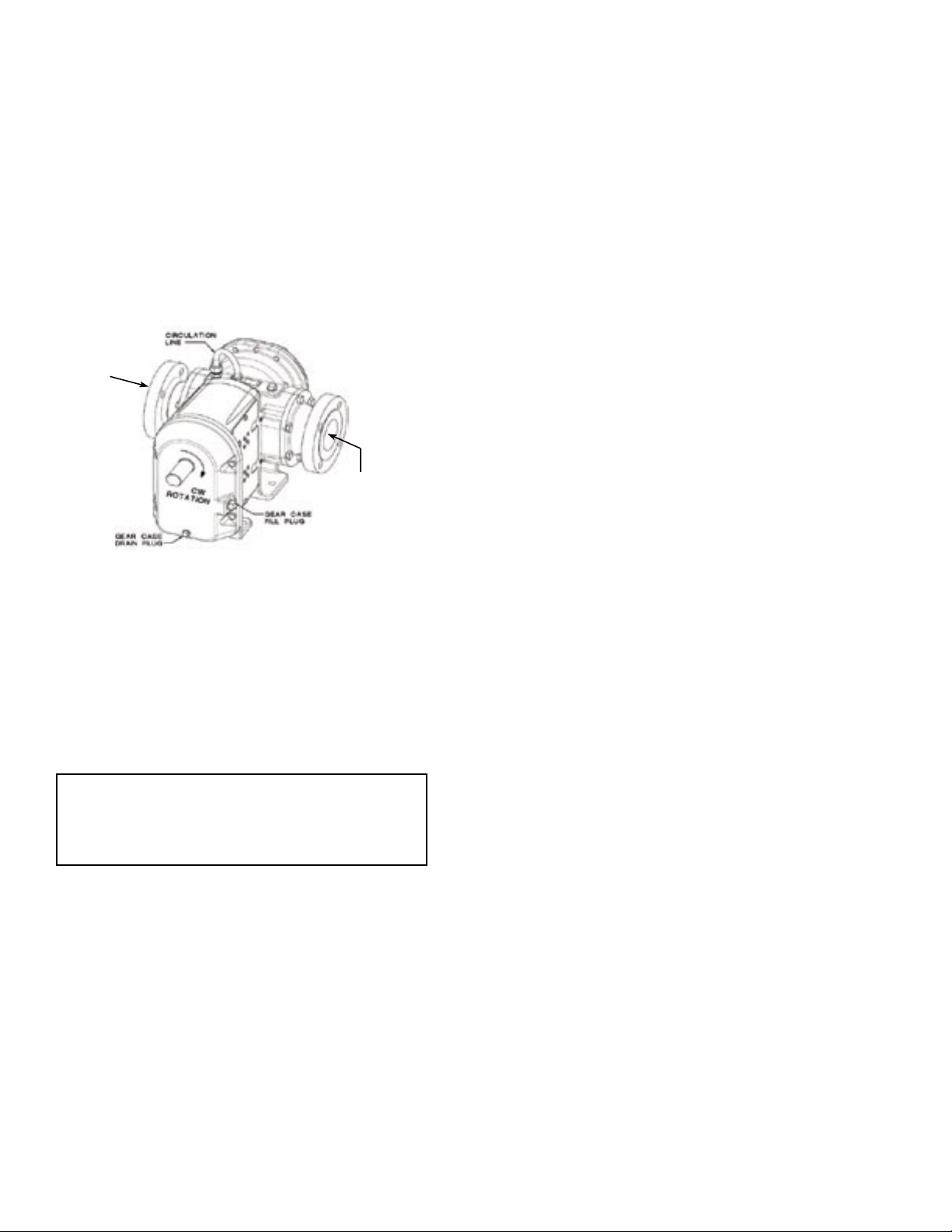

ROTATION

Viking Industrial Rotary Lobe pumps may be operated in

either a clockwise or counterclockwise rotation (clockwise

rotation is standard). Rotation is determined by viewing the

pump from the shaft end as shown in Figure 3. The circulation line provided vents the seal chamber to the inlet port.

When reversing the rotation on the pump, the seal chamber

will experience an increase in pressure, which may affect

seal performance. Refer to seal manufacture’s specications

or contact the factory for recommended pressure limits.

If rotation is reversed, this line should be switched to the opposite port.

INLET FOR

CLOCKWISE

ROTATION

(STD)

INLET FOR

COUNTER

CLOCKWISE

ROTATION

TAPERED ROLLER BEARINGS

External lubrication must be applied slowly with a manual

grease gun to both lubrication fittings every 500 hours of

operation with multi-purpose grease, NLGI # 2. Do not overgrease. Applications involving very high or low temperatures

will require other types of lubrication. Refer to ESB 515.

Consult the factory with specific lubrication questions.

Pumps supplied from the factory are packed with heavyduty grease. Upon disassembling the bearing housing, the

bearings should be cleaned and repacked with heavy-duty

multi-purpose grease.

BUSHINGS

The bushings used in this pump are lubricated with the

product and do not require any external source of lubrication

during operation.

PACKING ADJUSTMENT

New packed pumps require initial packing adjustment

to control leakage as the packing “runs in”. Make initial

adjustments carefully and do not over-tighten the packing

gland. After initial adjustment, inspection will reveal the need

for packing gland adjustment or packing replacement. Refer

to instructions under “Packing Replacement, Installation”,

page 6, regarding repacking pump.

FIGURE 3

PRESSURE RELIEF VALVES

Viking Industrial Rotary Lobe pumps are positive

displacement pumps and must be provided with some sort

of pressure protection. An inline pressure relief valve, a

torque limiting device or a rupture disk must be provided in

the pumping system.

MAINTENANCE

LUBRICATION:

CAUTION:

Pumps are supplied without gear case oil. Be sure

to add the proper amount and type of lubricant before operating the pump. Do not overfill!

GEAR CASE - Use a grade of gear lube oil with EP (Extreme

Pressure) additive for the ambient temperature range.

EP150 0 - 32° F

EP220 32 – 85° F

EP320 above 85° F

Refer to Figure 3. Remove the pipe plug from the fill hole

and add 15 oz. of the specified lubricant. Fill to the bottom

of the fill plug hole.

After 100 hours of operation, drain and refill with new

lubricant.

Check the oil level regularly and add lubricant as necessary.

Drain and refill with new lubricant every 12 months or 3000

hours of operation, whichever comes first.

SECTION TSM 270.2 ISSUE A PAGE 4 OF 12

CLEANING THE PUMP

Keep the pump as clean as possible to facilitate inspection

and repair work.

STORAGE

If a new pump is to be stored or not used for six months or

more, add 5 oz. of non-detergent SAE 30 weight oil in the

timing gear box. Viking suggests rotating the pump shaft

by hand one complete revolution every 30 days to circulate

the oil.

SUGGESTED REPAIR TOOLS

The following tools must be available to properly repair

Viking Industrial Rotary Lobe pumps. These tools are in

addition to standard mechanics’ tools such as open end

wrenches, pliers, screw drivers, etc. Most items can be

obtained from an industrial supply house.

1. Soft headed hammer

2. Allen wrenches

3. Depth micrometer (0-1” Range)

4. Bearing Locknut Spanner Wrench (Adjustable

Face, Pin Style - 3/16 Dia Pin)

5. Adjustable Hook Spanner Wrench, for 1-1/4” to 3”

diameter.

6. Jackscrews - 3/8 UNC by 3” length capscrew

threaded the entire length (3 Required)

7. Brass bar or wood block

8. Arbor Press

Loading...

Loading...