Viking Pump TSM270 User Manual

Electronic copies of the most current TSM issue can be found on the Viking Pump website at www.vikingpump.com

TECHNICAL SERVICE MANUAL

CONTENTS

Safety Information 1

Introduction 1

Special Information 4

Maintenance 4

Suggested Repair Tools 5

Disassembly 5

Cartridge Seal 6

Labyrinth Seal 7

Assembly 7

Thrust Bearing Adjustment 8

Installation of PEEK® Bushings 9

Warranty 12

INDUSTRIAL ROTARY LOBE PUMP

MODEL RL41507

FIGURE 1

MODEL RL41507

DANGER!

Incorrect installation, operation or maintenance of

equipment may cause severe personal injury or

death and/or equipment damage.

SECTION TSM 270

PAGE 1 Of 10

ISSUE f

TABLE OF ILLUSTRATIONS

RL41507 Pump Assembly 1

Exploded Pump Parts View 2

Pump Rotation 4

Head Removal 5

Timing Gear Removal 5

Use Of Bearing Puller 6

Bracket Removal 6

Fluidtec P/S®-II Cartridge Seal 6

Lobe Positioning 7

Bearing Housing Assembly 7

Timing Gear Positioning 7

INTRODUCTION

The illustrations used in this manual are for identification

purposes only and cannot be used for ordering parts. Obtain

a parts list from the factory or a Viking representative.

Always give a complete name of part, part number and

material with the model number and serial number of pump

when ordering repair parts. The unmounted pump or pump

unit model number and serial number are on the nameplate.

This manual deals only with Viking Rotary Lobe Pumps.

Specifications and recommendations are listed in Catalog

Section 270.

This information must be read fully before beginning

installation, operation or maintenance and must be

kept with the pump. It is suggested that suitably

trained or qualified persons perform all installation

and maintenance procedures.

DANGER !

Before opening any Viking pump liquid chamber

(pumping chamber, reservoir, etc.) be sure:

1. That any pressure in the chamber has been

completely vented through the suction or

discharge lines or other appropriate openings or

connections.

2. That the driving means (motor, turbine, engine, etc.)

has been “locked out” or made non-operational so

that it cannot be started while work is being done

on pump.

3. That you know what liquid the pump has been

handling and the precautions necessary to

safely handle the liquid. Obtain a material safety

data sheet (MSDS) for the liquid to be sure these

precautions are understood.

4. That the timing gearbox to cool before handling the

pump. The oil will become very hot during normal

operation. Allow the timing gearbox oil.

PEEK® is a trademark of Victrex PLC.

VIKING PUMP, INC. • A Unit of IDEX Corporation • Cedar Falls, IA 50613 USA

Failure to follow above listed precautionary measures may result in serious injury or death.

SECTION TSM 270 ISSUE F PAGE 2 OF 10

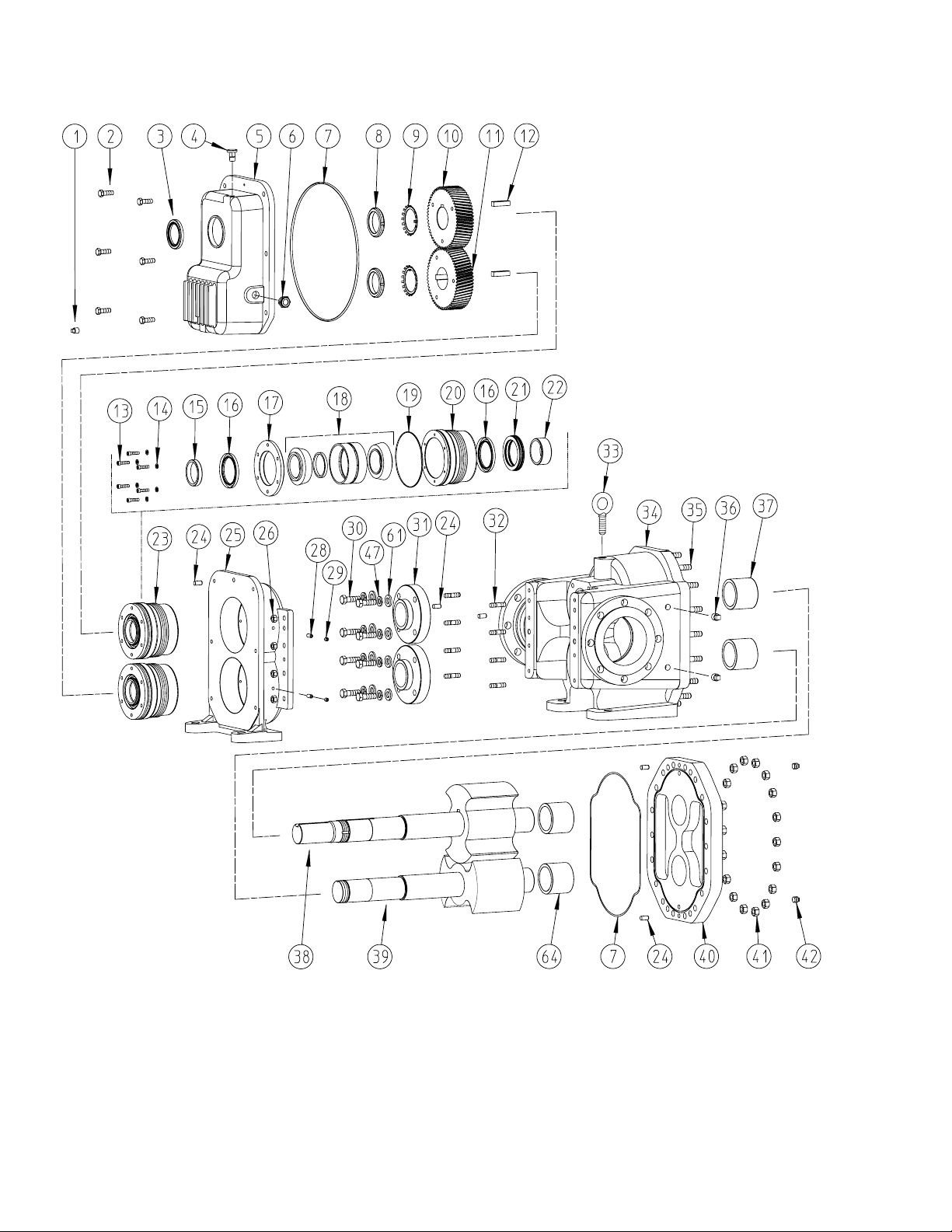

FIGURE 2 EXPLODED PARTS VIEW

TABLE 1 RL41507

ITEM DESCRIPTION ITEM DESCRIPTION

1 Magnetic Drain Plug for Gear Case 24 Dowel Pin, (5 Req’d)

2 Capscrew for Gear Cover 25 Bracket

3 Lipseal for Gear Box Cover 26 Nut 1/2” NC for Bracket, (8 Req’d)

4 Breather 28 Setscrews for Bearing Housing, (4 Req’d)

5 Gear Case Cover 29

6 Sight Glass 30 Capscrew for Seal, 5/8”, (8 Req’d)

7 Gear Case Cover or Head O-ring 31 Cartridge Lipseal, (2 Req’d)

8 Locknut TN-14, (2 Req’d) 32 1/2” Stud for Bracket, (8 Req’d)

9 Lockwasher TN-14, (2 Req’d) 33 Lifting Eye

10 Timing Gear for Driver Shaft 34 Casing/Bushing Assembly

11 Timing Gear for Driven Shaft 35 5/8” Stud for Head, (18 Req’d)

12 Key, Special 36 ½” Pipe Plugs, to Casing, (4 Req’d)

Capscrew for Bearing Housing Assembly, (12 Req’d - 6 for each

13

Bearing Housing Assembly)

Lockwasher for Bearing Housing Assembly, (12 Req’d - 6 for

14

each Bearing Housing Assembly)

Outer Bearing Spacer, (2 Req’d - 1 for each Bearing Housing

15

Assembly)

Lipseal for Bearing Housing, (4 Req’d - 2 for each Bearing

16

Housing Assembly)

Endcap for Bearing Housing, (2 Req’d - 1 for each Bearing

17

Housing Assembly)

Double Tapered Roller Bearing, (2 Req’d - 1 for each Bearing

18

Housing Assembly)

O-ring for Bearing Assembly, (2 Req’d - 1 for each Bearing

19

Housing Assembly)

Bearing Housing, (2 Req’d - 1 for each Bearing Housing

20

Assembly)

21 Labyrinth Seal, (2 Req’d - 1 for each Bearing Housing Assembly) 64 Bushings for Head, (2 Req’d)

Inner Bearing Spacer, (2 Req’d - 1 for each Bearing Housing

22

Assembly)

23 Bearing Housing Assembly, Includes Items 13-22, (2 Req’d)

illus.

illus.

Pipe Plug for Bearing Housing, 1/8”, (4

Req’d)

37 Casing Bushings (2 Req’d)

38 Lobe/Shaft Assembly, Driver

39 Lobe/Shaft Assembly, Driven

40 Head/Bushing Assembly

41 Nut, 5/8” for Head, (18 Req’d)

42 Pipe Plug, 1/4”, to Head (2 Req’d)

47 Lockwasher for Seals, (8 Req’d)

61 Washer for Seals, (8 Req’d)

not

Pipe Plug 1/8”, (2 Req’d), see page 2

not

Bearing Housing Spanner Wrench

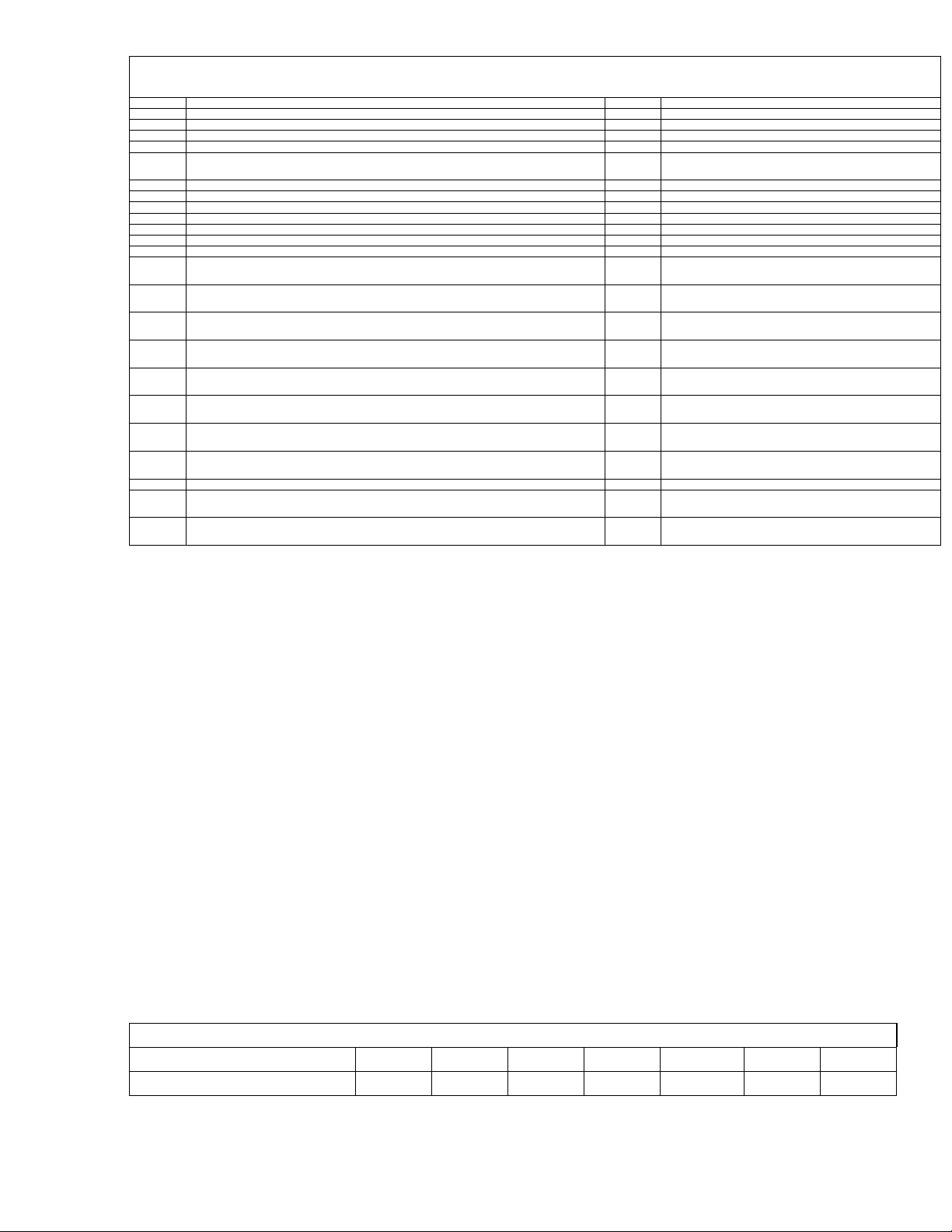

TABLE 2 Torque Specifications

Item Number 2 8 13 26 28 30 41

RECOMMENDED TORQUE (ft-lb) 75 600 18 75 8 (100 in-lb) 15 75

SECTION TSM 270 ISSUE F PAGE 3 OF 10

Loading...

Loading...